Ricoh af180 Service Manual

STINGER-C1

(Machine Code: A250)

SERVICE MANUAL

Subject to change

Ricoh Technical Service

May 17th, 1999

I

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. If the “Start” key is pressed before the copier completes the warm-up period

(the “Start” key starts blinking red and green alternatively), keep hands away

from the mechanical and the electrical components as the copier starts

making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Always replace the ozone filters with the specified ones at the specified

intervals.

2. Toner is non-toxic, but if you get it in your eyes by accident, it may cause

temporary eye discomfort. Try to remove with eye drops or flush with water

as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The danger of explosion exists if batteries on the FCU and JBIG are

incorrectly replaced. Replace only with the same or an equivalent type

recommended by the manufacturer. Discard used batteries in accordance

with the manufacturer’s instructions.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate AIO cartridge. Toner dust may ignite suddenly when

exposed to and open flame.

2. Dispose of used AIO cartridge in accordance with local regulations. (This is

non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in or der to dispos e of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

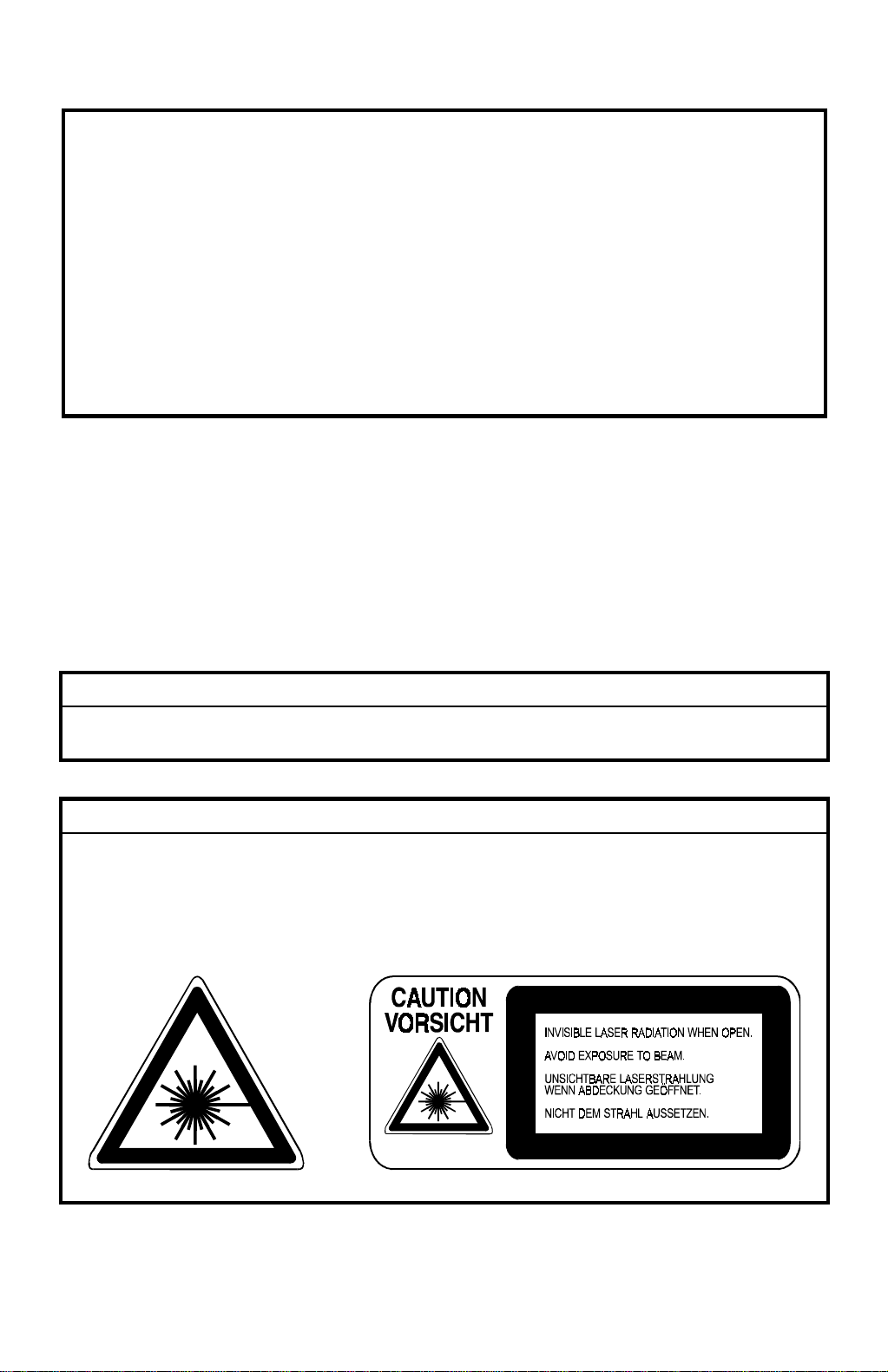

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

WARNING

I

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

WARNING FOR LASER UNIT

I

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can

seriously damage your eyes.

CAUTION MARKING:

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMAT ION........................................1-1

1.1 SPECIFICATIONS.................................................................................... 1-1

1.2 MACHINE CONFIGURATION.................................................................. 1-5

1.3 PAPER PATH........................................................................................... 1-6

1.4 MECHANICAL COMPONENT LAYOUT................................................... 1-7

1.5 ELECTRICAL COMPONENT DESCRIPTIONS........................................ 1-8

1.5.1 COPIER ENGINE ............................................................................ 1-8

1.6 DRIVE LAYOUT ..................................................................................... 1-11

1.7 COPY PROCESS................................................................................... 1-12

1.7.1 OVERVIEW ................................................................................... 1-12

1.8 BOARD STRUCTURE............................................................................ 1-14

1.8.1 OVERVIEW ................................................................................... 1-14

1.8.2 DESCRIPTION .............................................................................. 1-15

2. DETAILED SECTION DESCRIPTIONS.......................................2-1

2.1 SCANNING............................................................................................... 2-1

2.1.1 OVERVIEW ..................................................................................... 2-1

2.1.2 SCANNER DRIVE ........................................................................... 2-2

2.1.3 ORIGINAL SIZE DETECTION IN PLATEN MODE.......................... 2-3

2.2 IMAGE PROCESSING .............................................................................2-5

2.2.1 OVERVIEW ..................................................................................... 2-5

2.2.2 SBU (SENSOR BOARD UNIT)........................................................ 2-7

2.2.3 AUTO IMAGE DENSITY (ADS)....................................................... 2-8

2.2.4 IMAGE PROCESSING UNIT (IPU).................................................. 2-9

2.2.5 MEMORY CONTROLLER AND EXTENDED MEMORY

BOARD (EMB)............................................................................... 2-20

2.2.6 VIDEO CONTROL UNIT (VCU)..................................................... 2-21

2.2.7 IMAGE PROCESSING SUMMARY............................................... 2-23

2.3 LASER EXPOSURE............................................................................... 2-33

2.3.1 OVERVIEW ................................................................................... 2-33

2.3.2 OPTICAL PATH............................................................................. 2-34

2.3.3 AUTO POWER CONTROL (APC) ................................................. 2-35

2.3.4 LD SAFETY SWITCH.................................................................... 2-36

2.4 ALL-IN-ONE CARTRIDGE (AIO CARTRIDGE)...................................... 2-37

2.4.1 OVERVIEW ................................................................................... 2-37

2.4.2 DRIVE............................................................................................ 2-38

2.4.3 DRUM CHARGE............................................................................ 2-39

2.4.4 DEVELOPMENT............................................................................ 2-40

2.4.5 DRUM CLEANING......................................................................... 2-43

2.5 IMAGE TRANSFER AND PAPER SEPARATION.................................. 2-44

2.5.1 OVERVIEW ................................................................................... 2-44

2.5.2 TRANSFER CURRENT SETTINGS.............................................. 2-45

2.5.3 TRANSFER ROLLER CLEANING................................................. 2-46

2.6 PAPER FEED.........................................................................................2-47

i

2.6.1 OVERVIEW ................................................................................... 2-47

2.6.2 BUILT-IN TRAY............................................................................. 2-48

2.6.3 BY-PASS TRAY............................................................................. 2-51

2.6.4 PAPER REGISTRATION............................................................... 2-53

2.6.5 MISFEED DETECTION................................................................. 2-54

2.7 IMAGE FUSING...................................................................................... 2-57

2.7.1 OVERVIEW ................................................................................... 2-57

2.7.2 FUSING UNIT DRIVE.................................................................... 2-58

2.7.3 PRESSURE ROLLER/PAPER EXIT.............................................. 2-59

2.7.4 FUSING UNIT DRIVE RELEASE................................................... 2-59

2.7.5 FUSING TEMPERATURE CONTROL........................................... 2-60

2.7.6 OVERHEAT PROTECTION........................................................... 2-63

2.7.7 ENERGY SAVER MODE............................................................... 2-63

3. INSTALLA T ION...........................................................................3-1

3.1 INSTALLATION REQUIREMENTS .......................................................... 3-1

3.1.1 ENVIRONMENT ..............................................................................3-1

3.1.2 MACHINE LEVEL............................................................................ 3-2

3.1.3 MINIMUM SPACE REQUIREMENTS.............................................. 3-3

3.1.4 POWER REQUIREMENTS.............................................................. 3-4

3.2 COPIER INSTALLATION.......................................................................... 3-5

3.2.1 ACCESSORY CHECK..................................................................... 3-5

3.2.2 COPIER INSTALLATION PROCEDURE......................................... 3-6

3.3 ADF INSTALLATION.............................................................................. 3-10

3.3.1 ACCESSORY CHECK................................................................... 3-10

3.3.2 ADF INSTALLATION PROCEDURE ............................................. 3-11

3.4 PAPER TRAY UNIT (1 TRAY) INSTALLATION ..................................... 3-14

3.4.1 ACCESSORY CHECK................................................................... 3-14

3.4.2 PAPER TRAY UNIT INSTALLATION PROCEDURE..................... 3-15

3.5 PAPER TRAY UNIT (2 TRAYS) INSTALLATION................................... 3-18

3.5.1 ACCESSORY CHECK................................................................... 3-18

3.5.2 PAPER TRAY UNIT INSTALLATION PROCEDURE..................... 3-19

3.6 1-BIN SORTER INSTALLATION............................................................ 3-23

3.6.1 ACCESSORY CHECK................................................................... 3-23

3.6.2 1-BIN SORTER INSTALLATION PROCEDURE............................ 3-24

3.7 PLATEN COVER INSTALLATION.......................................................... 3-29

3.7.1 ACCESSORY CHECK................................................................... 3-29

3.7.2 PLATEN COVER INSTALLATION PROCEDURE......................... 3-29

3.8 EXTENDED MEMORY BOARD INSTALLATION................................... 3-30

3.8.1 ACCESSORY CHECK................................................................... 3-30

3.8.2 EXTENDED MEMORY BOARD INSTALLATION

PROCEDURE................................................................................ 3-31

3.9 DRUM HEATER INSTALLATION (OPTION).......................................... 3-32

3.10 OPTICS ANTI-CONDENSATION HEATER INSTALLATION

(OPTION).............................................................................................. 3-33

3.11 TRAY HEATER INSTALLATION.......................................................... 3-34

ii

4. SERVICE TABLES......................................................................4-1

4.1 GENERAL CAUTION................................................................................ 4-1

4.1.1 AIO CARTRIDGE (ALL-IN-ONE CARTRIDGE)............................... 4-1

4.1.2 TRANSFER ROLLER UNIT............................................................. 4-1

4.1.3 SCANNER UNIT..............................................................................4-1

4.1.4 LASER UNIT.................................................................................... 4-2

4.1.5 FUSING UNIT.................................................................................. 4-2

4.1.6 PAPER FEED.................................................................................. 4-2

4.1.7 OTHERS.......................................................................................... 4-2

4.2 SERVICE PROGRAM MODE................................................................... 4-3

4.2.1 SERVICE PROGRAM MODE OPERATION.................................... 4-3

4.1.2 SERVICE PROGRAM MODE TABLES........................................... 4-4

4.1.3 TEST PATTERN PRINTING (SP5-902)......................................... 4-38

4.1.4 INPUT CHECK (SP5-803)............................................................. 4-39

4.1.5 OUTPUT CHECK (SP5-804)......................................................... 4-44

4.1.6 COPY JAM HISTORY DISPLAY (SP7-903) .................................. 4-46

4.1.7 ORIGINAL JAM HISTORY DISPLAY (SP7-905)........................... 4-47

4.1.8 SYSTEM PARAMETER AND DATA LISTS (SP5-992).................. 4-48

4.1.9 MEMORY ALL CLEAR (SP5-801)................................................. 4-49

4.1.10 PROGRAM UPLOAD/DOWNLOAD............................................. 4-50

4.1.11 NVRAM DATA DOWNLOAD....................................................... 4-53

4.1.12 APS AND PLATEN/DF COVER SENSOR OUTPUT DISPLAY

(SP4-301) .................................................................................... 4-55

4.1.13 DF APS SENSOR OUTPUT DISPLAY (SP6-901)....................... 4-56

4.1.14 DISPLAY LANGUAGE (SP5-808)................................................ 4-57

4.1.15 SERIAL NUMBER INPUT (SP5-811)........................................... 4-57

4.3 USER TOOLS......................................................................................... 4-58

4.1.1 HOW TO ENTER AND EXIT USER TOOLS..................................4-58

4.1.2 USER TOOLS TABLE ................................................................... 4-58

4.4 LEDS...................................................................................................... 4-60

4.5 SPECIAL TOOLS AND LUBRICANTS ................................................... 4-60

4.5.1 SPECIAL TOOLS........................................................................... 4-60

4.5.2 LUBRICANTS................................................................................ 4-60

5. PREVENTIVE MAINTENANCE SCHEDULE...............................5-1

5.1 PM TABLE................................................................................................ 5-1

5.2 HOW TO CLEAR THE MAINTENANCE COUNTER................................ 5-2

6. REPLACEMENT AND ADJUSTMENT ........................................ 6-1

6.1 EXTERIOR REMOVAL............................................................................. 6-1

6.1.1 REAR COVER................................................................................. 6-1

6.1.2 COPY TRAY.................................................................................... 6-1

6.1.3 LEFT COVER.................................................................................. 6-1

6.1.4 FRONT COVER............................................................................... 6-2

6.1.5 UPPER RIGHT COVER................................................................... 6-3

6.1.6 LOWER RIGHT COVER.................................................................. 6-3

6.1.7 RIGHT SMALL COVER................................................................... 6-3

6.1.8 OPERATION PANEL....................................................................... 6-4

iii

6.2 SCANNER................................................................................................ 6-5

6.2.1 EXPOSURE GLASS REMOVAL...................................................... 6-5

6.2.2 LENS BLOCK REMOVAL................................................................ 6-7

6.2.3 EXPOSURE LAMP REPLACEMENT.............................................. 6-8

6.2.4 1ST SCANNER ALIGNMENT ADJUSTMENT................................. 6-9

6.2.5 2ND SCANNER POSITION ADJUSTMENT.................................. 6-10

6.3 LASER UNIT........................................................................................... 6-11

6.3.1 CAUTION DECAL LOCATIONS.................................................... 6-11

6.3.2 LASER UNIT/TONER SHIELD GLASS REMOVAL....................... 6-12

6.3.3 LD UNIT/LASER SYNCHRONIZATION DETECTOR

REMOVAL ..................................................................................... 6-13

6.3.4 EXIT TRAY PAPER SENSOR REMOVAL..................................... 6-13

6.3.5 POLYGONAL MIRROR MOTOR REMOVAL................................. 6-14

6.3.6 LASER UNIT ALIGNMENT ADJUSTMENT................................... 6-15

6.4 IMAGE TRANSFER................................................................................ 6-16

6.4.1 TRANSFER ROLLER REMOVAL.................................................. 6-16

6.5 FUSING.................................................................................................. 6-17

6.5.1 FUSING UNIT REMOVAL ............................................................. 6-17

6.5.2 HOT ROLLER, FUSING LAMP AND THERMOFUSE

REPLACEMENT............................................................................ 6-18

6.5.3 PRESSURE ROLLER REPLACEMENT........................................ 6-20

6.5.4 FUSING THERMISTOR REPLACEMENT..................................... 6-21

6.5.5 HOT ROLLER STRIPPER PAWL REPLACEMENT...................... 6-22

6.6 PAPER FEED.........................................................................................6-23

6.6.1 PAPER FEED ROLLER REPLACEMENT..................................... 6-23

6.6.2 FRICTION PAD REPLACEMENT.................................................. 6-24

6.6.3 STANDARD TRAY PAPER FEED CLUTCH REPLACEMENT...... 6-25

6.6.4 VERTICAL TRANSPORT ROLLER/SENSOR/

CLUTCH REPLACEMENT ............................................................ 6-26

6.6.5 BY-PASS FEED ROLLER REPLACEMENT.................................. 6-27

6.6.6 BY-PASS FEED FRICTION PAD REPLACEMENT....................... 6-28

6.6.7 BY-PASS FEED SENSOR REPLACEMENT................................. 6-29

6.6.8 BY-PASS TRAY REMOVAL ..........................................................6-30

6.6.9 BY-PASS FEED PAPER WIDTH SENSOR REMOVAL ................ 6-31

6.6.10 REGISTRATION ROLLER REMOVAL........................................ 6-32

6.6.11 REGISTRATION SENSOR REPLACEMENT.............................. 6-33

6.6.12 TONER END SENSOR REPLACEMENT.................................... 6-34

6.7 OTHERS................................................................................................. 6-35

6.7.1 MAIN MOTOR/GEAR BOX REPLACEMENT................................ 6-35

6.7.2 IOB (INPUT OUTPUT BOARD) REPLACEMENT ......................... 6-36

6.7.3 BICU (BASE-ENGINE IMAGE CONTROL UNIT)

REPLACEMENT............................................................................ 6-37

6.7.4 POWER SUPPLY UNIT AND B/C/T POWER PACK

REPLACEMENT............................................................................ 6-38

6.8 STANDARD WHITE DENSITY ADJUSTMENT...................................... 6-39

6.9 COPY ADJUSTMENT PRINTING/SCANNING....................................... 6-40

6.9.1 PRINTING...................................................................................... 6-40

6.9.2 SCANNING.................................................................................... 6-42

6.9.3 ADF IMAGE ADJUSTMENT.......................................................... 6-44

iv

7. TROUBLESHOOTING.................................................................7-1

7.1 SERVICE CALL CONDITIONS................................................................. 7-1

7.1.1 SUMMARY....................................................................................... 7-1

7.1.2 SC CODE DESCRIPTIONS............................................................. 7-2

7.2 BLOWN FUSE TABLE............................................................................ 7-10

7.3 ELECTRICAL COMPONENT DEFECTS................................................ 7-10

7.3.1 SWITCHES.................................................................................... 7-10

7.3.2 SENSORS..................................................................................... 7-11

OPTIONS

DOCUMENT FEEDER (A859)

1. OVERALL INFORMATION.................................................... A859-1

1.1 SPECIFICATIONS..............................................................................A859-1

1.2 MECHANICAL COMPONENT LAYOUT.............................................A859-2

1.3 ELECTRICAL COMPONENT LAYOUT..............................................A859-3

1.4 ELECTRICAL COMPONENT DESCRIPTION....................................A859-4

1.5 DRIVE LAYOUT .................................................................................A859-5

2. DETAILED SECTION DESCRIPTIONS.................................A859-6

2.1 ORIGINAL SIZE DETECTION............................................................A859-6

1.2 PICK-UP AND SEPARATION.............................................................A859-8

1.3 ORIGINAL TRANSPORT AND EXIT MECHANISM ...........................A859-9

1.4 STAMP .............................................................................................A859-10

1.5 TIMING CHARTS .............................................................................A859-11

1.5.1 A4 SIDEWAYS.........................................................................A859-11

1.5.2 A4 SIDEWAYS, STAMP MODE...............................................A859-12

1.6 JAM DETECTION.............................................................................A859-13

1.7 OVERALL ELECTRICAL CIRCUIT...................................................A859-14

3. REPLACEMENT AND ADJUSTMENT................................A859-15

3.1 FEED UNIT REMOVAL....................................................................A859-15

3.2 SEPARATION ROLLER REPLACEMENT........................................A859-15

3.3 PICK-UP ROLLER REPLACEMENT................................................ A859-16

3.4 FEED BELT REPLACEMENT..........................................................A859-16

3.5 ORIGINAL SET SENSOR REPLACEMENT.....................................A859-17

3.6 ORIGINAL WIDTH/LENGTH/TRAILING EDGE SENSOR

REPLACEMENT...............................................................................A859-18

3.7 ORIGINAL EXIT TRAY/FRONT COVER/REAR COVER

REMOVAL........................................................................................A859-19

3.8 FEED COVER OPEN SENSOR/DF OPEN SENSOR

REPLACEMENT...............................................................................A859-19

3.9 FEED CLUTCH/PICK-UP SOL/TRANSPORT MOTOR

REPLACEMENT...............................................................................A859-20

3.10 DF FEED COVER REMOVAL........................................................A859-21

3.11 REGISTRATION SENSOR REPLACEMENT.................................A859-21

3.12 STAMP SOLENOID REPLACEMENT............................................A859-22

v

PAPER TRAY UNIT (A860)

1. OVERALL MACHINE INFORMAT ION..................................A860-1

1.1 SPECIFICATIONS..............................................................................A860-1

1.2 MECHANICAL COMPONENT LAYOUT.............................................A860-2

1.3 ELECTRICAL COMPONENT LAYOUT..............................................A860-3

1.4 ELECTRICAL COMPONENT DESCRIPTION....................................A860-4

1.5 DRIVE LAYOUT .................................................................................A860-5

2. DETAILED DESCRIPTIONS .................................................A860-6

2.1 PAPER FEED AND SEPARATION MECHANISM..............................A860-6

2.2 PAPER LIFT MECHANISM................................................................A860-7

2.3 PAPER END DETECTION.................................................................A860-9

2.4 PAPER HEIGHT DETECTION.........................................................A860-10

1.5 PAPER SIZE DETECTION...............................................................A860-12

1.6 SIDE AND END FENCES.................................................................A860-13

3. REPLACEMENT AND ADJUSTMENT................................A860-14

3.1 FEED ROLLER REPLACEMENT.....................................................A860-14

3.2 TRAY MAIN BOARD REPLACEMENT.............................................A860-15

3.3 TRAY MOTOR REPLACEMENT......................................................A860-15

3.4 RELAY CLUTCH REPLACEMENT...................................................A860-16

3.5 UPPER PAPER FEED CLUTCH REPLACEMENT ..........................A860-17

3.6 LOWER PAPER FEED CLUTCH REPLACEMENT..........................A860-18

3.7 LIFT MOTOR REPLACEMENT........................................................A860-19

3.8 PAPER END SENSOR REPLACEMENT.........................................A860-20

3.9 VERTICAL TRANSPORT SENSOR REPLACEMENT ..................... A860-20

3.10 PAPER SIZE SWITCH REPLACEMENT........................................A860-21

PAPER TRAY UNIT (A861)

1. OVERALL MACHINE INFORMAT ION..................................A861-1

1.1 SPECIFICATIONS..............................................................................A861-1

1.2 MECHANICAL COMPONENT LAYOUT.............................................A861-2

1.3 ELECTRICAL COMPONENT LAYOUT..............................................A861-3

1.4 ELECTRICAL COMPONENT DESCRIPTION....................................A861-4

1.5 DRIVE LAYOUT .................................................................................A861-5

2. DETAILED DESCRIPTIONS .................................................A861-6

2.1 PAPER FEED AND SEPARATION ....................................................A861-6

2.2 PAPER LIFT MECHANISM................................................................A861-7

2.3 PAPER END DETECTION .................................................................A861-9

2.4 PAPER HEIGHT DETECTION.........................................................A861-10

2.5 PAPER SIZE DETECTION...............................................................A861-12

2.6 SIDE AND END FENCES.................................................................A861-13

vi

3. REPLACEMENT AND ADJUSTMENT................................A861-14

3.1 FEED ROLLER REPLACEMENT.....................................................A861-14

3.2 TRAY MAIN BOARD REPLACEMENT.............................................A861-15

3.3 TRAY MOTOR REPLACEMENT......................................................A861-15

3.4 TRAY MOTOR REPLACEMENT......................................................A861-16

3.5 LIFT MOTOR REPLACEMENT........................................................A861-17

3.6 PAPER END SENSOR REPLACEMENT.........................................A861-18

3.7 PAPER SIZE SWITCH REPLACEMENT..........................................A861-18

1-BIN SORTER (A869)

1. OVERALL INFORMATION.................................................... A869-1

1.1 SPECIFICATIONS..............................................................................A869-1

1.2 MECHANICAL COMPONENT LAYOUT.............................................A869-2

1.3 ELECTRICAL COMPONENT LAYOUT..............................................A869-3

1.4 ELECTRICAL COMPONENT DESCRIPTION....................................A869-4

2. DETAILED SECTION DESCRIPTIONS.................................A869-5

2.1 BASIC OPERATION...........................................................................A869-5

3. REPLACEMENT AND ADJUSTMENT..................................A869-6

3.1.1 TOP COVER REMOVAL...........................................................A869-6

3.1.2 TRAY OPEN SWITCH REPLACEMENT...................................A869-6

3.1.3 PAPER SENSOR AND EXIT SENSOR REPLACEMENT.........A869-6

vii

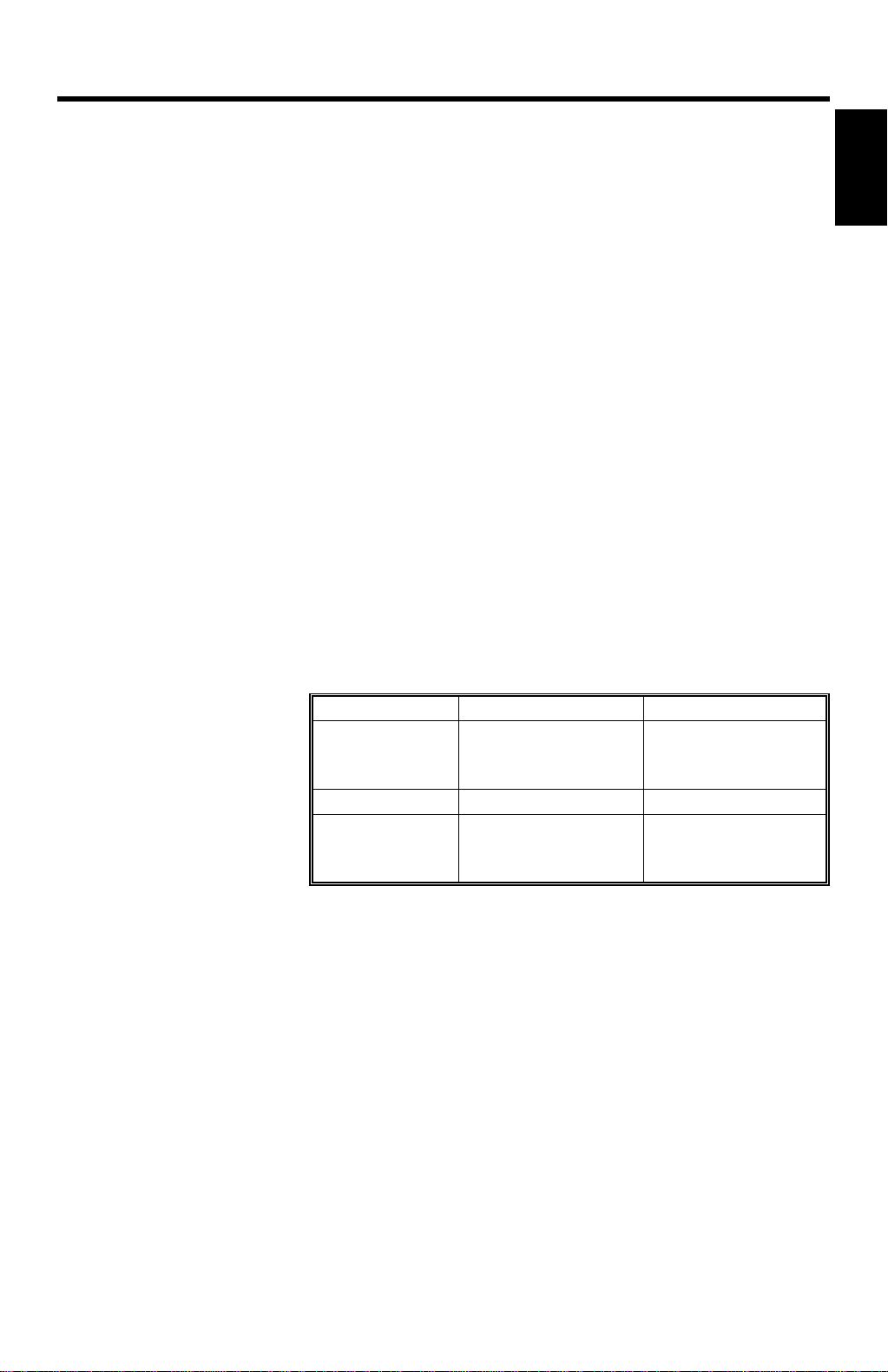

17 May, 1999 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum A3/11" x 17"

Copy Paper Size: Maximum

A3/11" x 17"

Minimum

A5/8

B6 lengthwise/5

Custom sizes in the by-pass tray:

Width: 90 ~ 305 mm (3.5" ~ 12.0")

Length: 148 ~ 1,260 mm (5.8" ~ 49.6")

Copy Paper Weight: Paper Tray:

60 ~ 90 g/m2, 16 ~ 24 lb

By-pass:

60 ~ 162 g/m2, 16 ~ 43 lb

Reproduction Ratios: 3 Enlargement and 3 Reduction

1/2

" x 5

" sideways (Paper tray)

1/2

1/2

" x 8

" (By-pass)

1/2

Overall

Information

A4/A3 Version LT/DLT Version

200%

Enlargement

Full Size 100% 100%

Reduction

141%

122%

93%

71%

50%

Zoom: 50% to 200% in 1% steps

Power Source: 120 V, 60 Hz:

More than 10 A (for North America)

220 ~ 240 V, 50/60 Hz

More than 6 A (for Europe/Asia)

110 V, 50/60 Hz

More than 11 A (for Taiwan)

155%

129%

121%

93%

78%

65%

1-1

SPECIFICATIONS 17 May, 1999

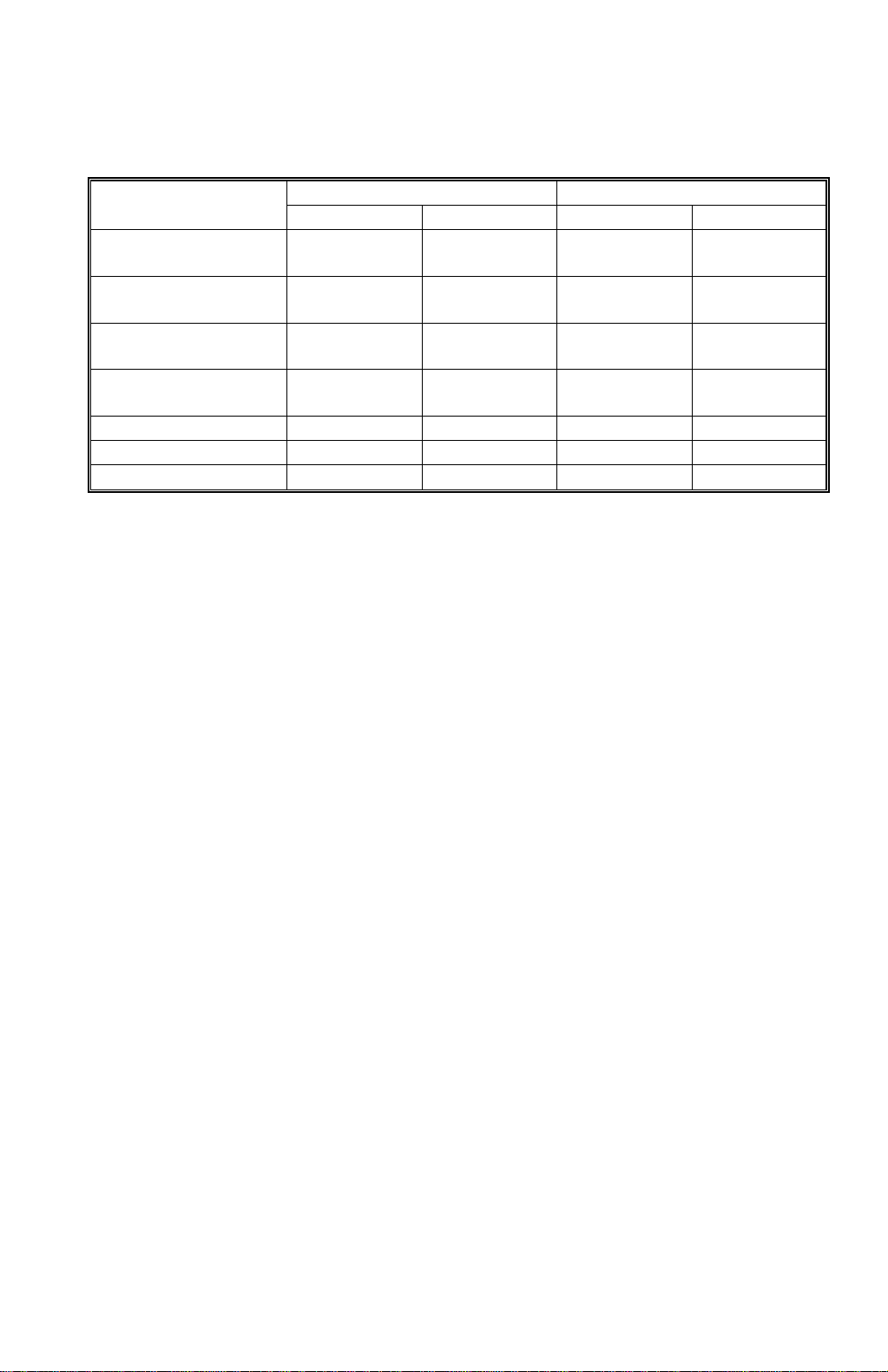

Power Consumption:

Mainframe Only Full System

120 V 220 ~ 240 V 120 V 220 ~ 240 V

Maximum Less than

1.1 kW

Copying Approx.

450 W

Warm-up

Stand-by Approx.

Energy Saver Level 1 Approx. 60 W Approx. 60 W Approx. 60 W Approx. 60 W

Energy Saver Level 2 Approx. 30 W Approx. 30 W Approx. 30 W Approx. 30 W

Auto Shut off 0 W 0 W 0 W 0 W

Approx.

860 W

110 W

Less than

1.1 kW

Approx.

450 W

Approx.

760 W

Approx.

110 W

Less than

1.2 kW

Approx.

460 W

Approx.

870 W

Approx.

130 W

Less than

1.3 kW

Approx.

460 W

Approx.

770 W

Approx.

130 W

NOTE:

1) Full system: Mainframe + ADF + 1-bin Sorter + Paper Tray Unit

2) Without the optional heaters, fax unit, and pri nter contr ol ler

Noise Emission (Sound Power Level):

Stand-by (Mainframe only): US/Asia Model: 42 dB(A)

Europe Model: 30 dB(A)

Operating (Mainframe only): US/Asia Model: 60 dB(A)

Europe Model: 66 dB(A)

Operating (Full System): 66 dB(A)

Off Mode: 30 dB(A)

NOTE:

1) The above measurements were made in accordance with ISO 7779.

2) Full System: Mainframe + ADF + 1-bin Sorter + Paper Tray Unit

Dimensions (W x D x H): 550 x 575 x 460 mm (21.7" x 22.7" x 18.2")

NOTE:

Measurement Conditions

1) With by-pass feed table closed

2) Without the ADF

Weight: Less than 35 kg (78 lb)

Not including ADF, Platen Cover, and AIO

1-2

17 May, 1999 SPECIFICATIONS

Copying Speed in Multicopy mode (copies/minute):

A4 sideways/

11" x 8

Non-memory copy mode 15 10 11

Memory copy mode 18 10 12

NOTE:

Measurement Conditions

1/2

"

A3/11" x 17" B4/8

" x 14"

1/2

1) Not APS mode

2) A4/LT copying

3) Full size

Warm-up Time: Less than 30 seconds (20°C, 68°F): 115 V machine

Less than 40 seconds (20°C, 68°F): 230 V machine

First Copy Time: Less than 6.5 seconds

NOTE:

Measurement Conditions

1) When polygonal mirror motor is spinning.

2) Not APS mode

3) A4/LT copying

4) Full size

Copy Number Input: Ten-key pad, 1 to 99 (count up or count down)

Manual Image Density: 7 steps

Overall

Information

Automatic Reset: 60 seconds is the standard setting; it can be changed

with a User Tool.

Automatic Shut Off: 15 minutes is the standard setting; it can be changed

with a User Tool.

Copy Paper Capacity: Paper Tray:

250 sheets

Optional Paper Tray Unit:

500 sheets x 1, or 500 sheets x 2

By-pass Tray:

100 sheets (A4, B5, A5, B6, 8

1/2

10 sheets (A3, B4, 11" x 17", 8

" x 11", 5

" x 13")

1/2

1/2

" x 8

1/2

")

1 sheets (non-standard sizes)

NOTE:

Copy weight: 80g/m2 (20 lb).

Toner Replenishment: All-in-one toner cassette cartridge (750 g/cartridge)

Toner Yield: 12 k copies (A4 sideways, 6% full black, 1 to 1 copying,

ADS mode)

1-3

SPECIFICATIONS 17 May, 1999

Optional Equipment:

·

Platen cover

·

Auto document feeder

·

Paper tray unit (1 tray)

·

Paper tray unit (2 trays)

·

1-bin sorter

·

Tray heater

·

Optics anti-condensation heater

·

Drum heater

·

Copier feature expander (48 MB memory)

Copy Capacity: Copy Tray: 250 sheets (without 1-bin sorter),

125 sheets (with 1-bin sorter)

1-bin Sorter: 125 sheets

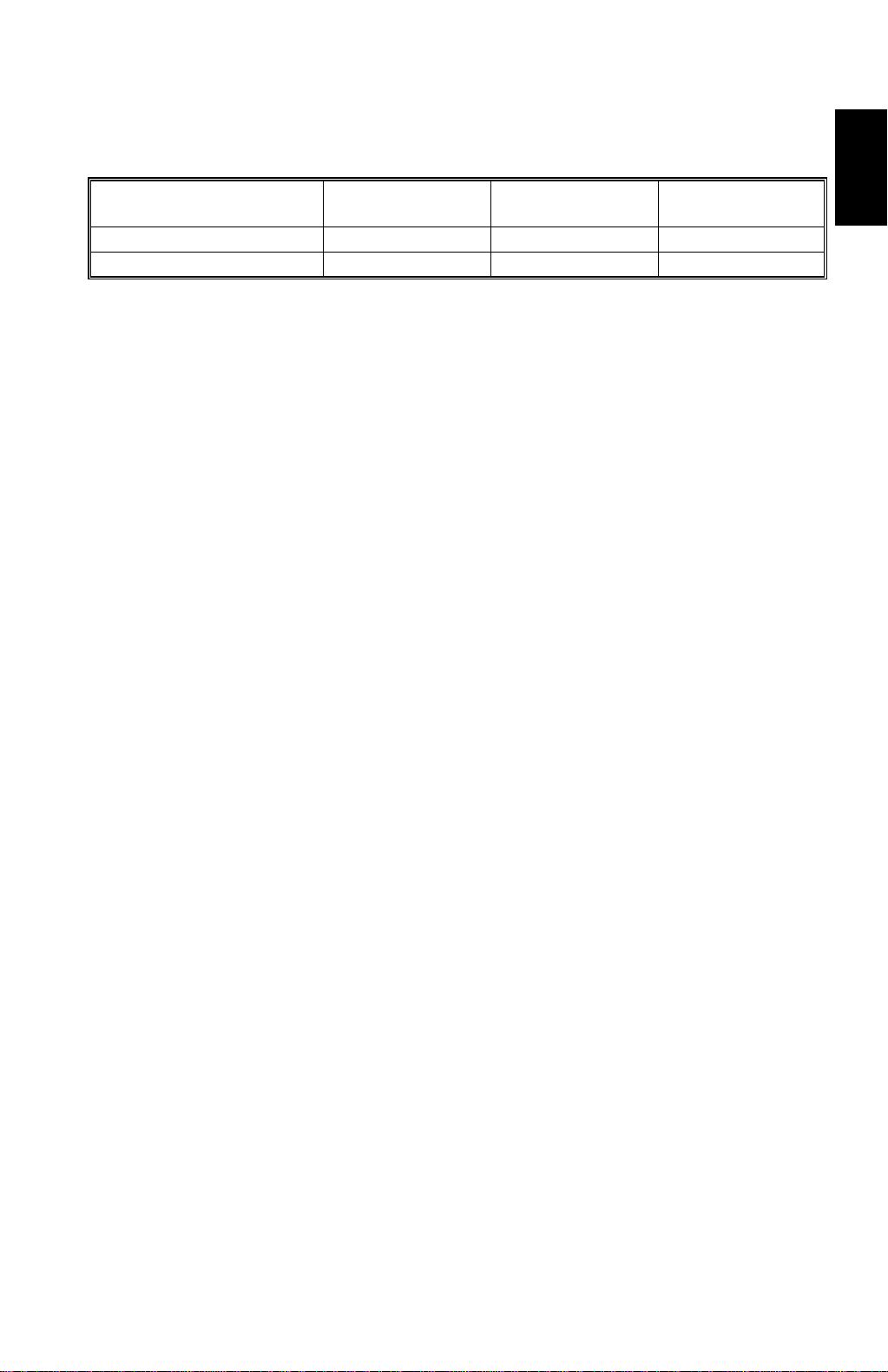

Memory Capacity:

Standard (16 MB) Optional (+48 MB)

Sort, Rotate Sort

Number of pages

A4, 8

B4, 8

A3, 11" x 17"

A4 ITU-T#4 12% 35 sheets 99 sheets

" x 11"

1/2

1/2

" x 14"

❍❍

❍❍

❍❍

A4 6% 80 sheets 99 sheets

NOTE:

The paper sizes that can be used with Rotate Sort are A4/8

and B5 only.

: Available

❍

" x 11"

1/2

1-4

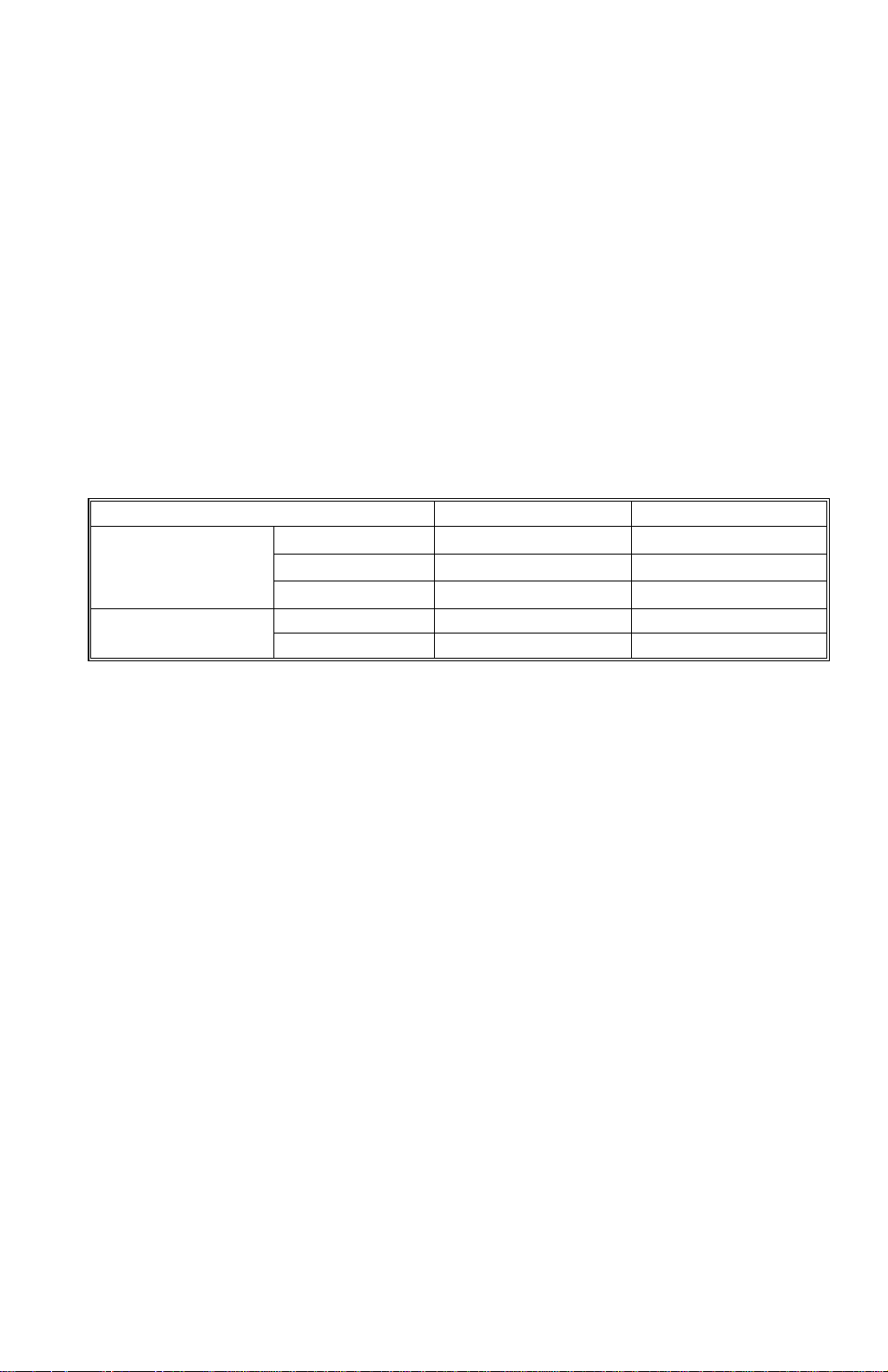

17 May, 1999 MACHINE CONFIGURATION

1.2 MACHINE CONFIGURATION

A

B

C

D

Overall

Information

A250V501.WMF

Version Item Machine Code No.

Copier

Fax

Printer

Copier A250 D

ADF (Optional) A859 C

Platen Cover (Optional) A893

Paper Tray Unit - 1 tray (Optional) A861

Paper Tray Unit - 2 trays (Optional) A860 E

1-bin Sorter (Optional) A869 B

Memory 48 MB (Optional) A887

Fax Controller (Optional) A891

Telephone (Optional) H160 A

ISDN (Optional) A890

PC Fax Expander (Optional) A894

Fax Function Expander (Optional) A892

Printer Controller (Optional) B305

PS Option (Optional) B308

HDD (Optional) G690

NIB (Optional) B307

Memory 32 or 64 MB (Optional) G688

E

1-5

PAPER PATH 17 May, 1999

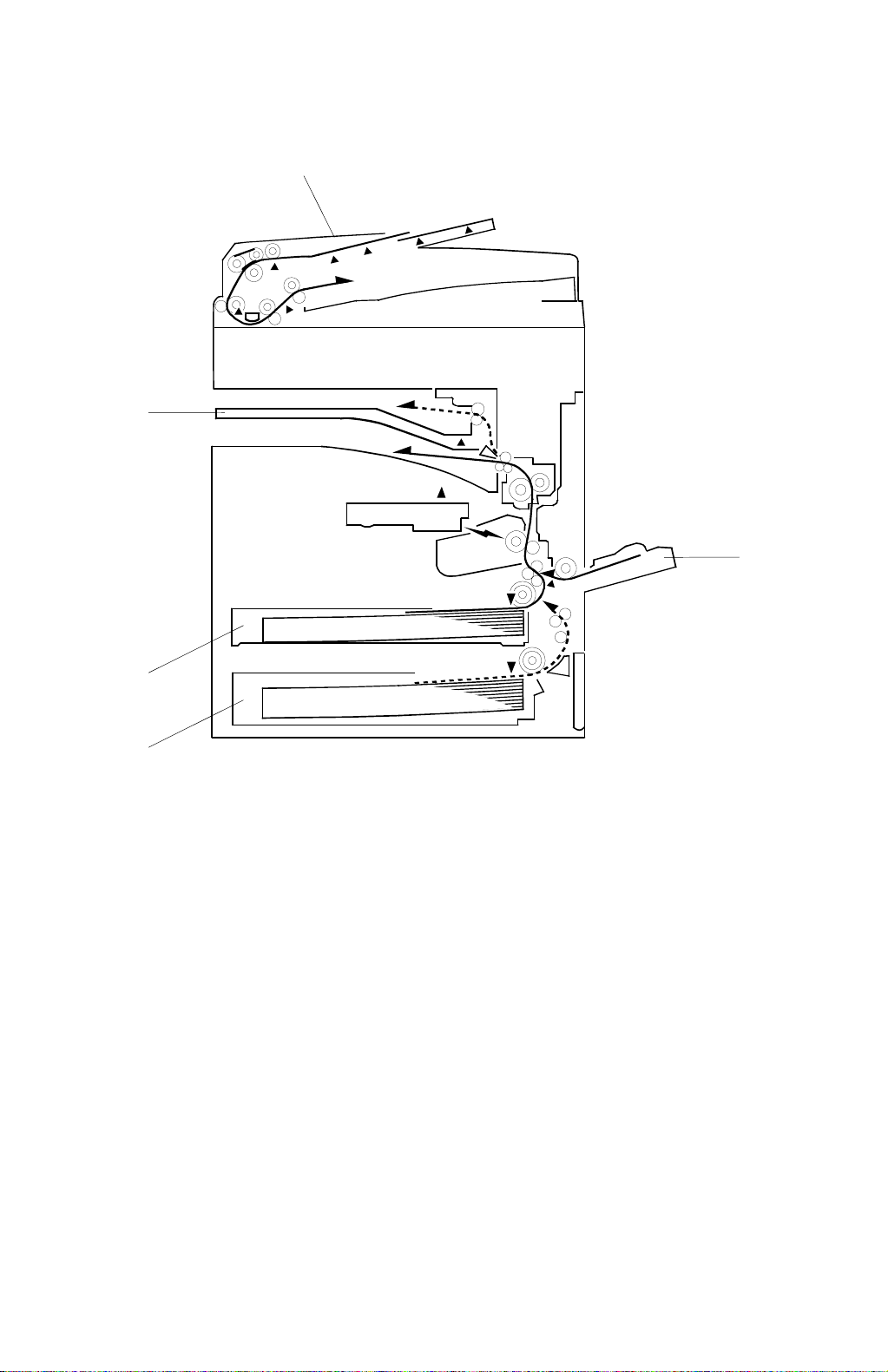

1.3 PAPER PATH

1

5

2

4

3

1. Optional ADF

2. By-pass feed tray

3. Optional paper tray (1 tray)

4. Paper tray

5. Optional 1-bin sorter

A250V000.WMF

1-6

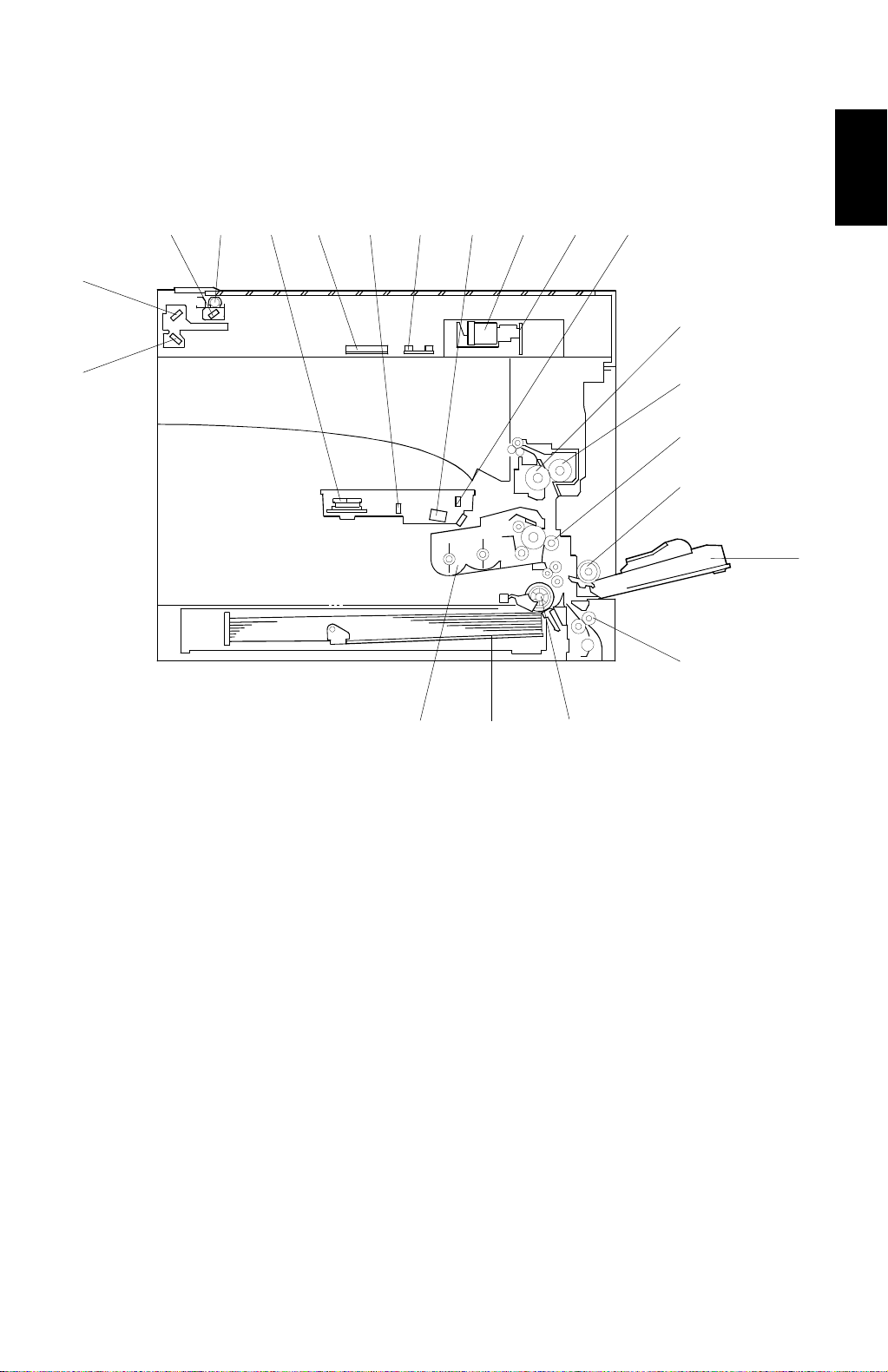

17 May, 1999 MECHANICAL COMPONENT LAYOUT

1.4 MECHANICAL COMPONENT LAYOUT

1 2 3 4 5 6 7 8 9 10

21

11

Overall

Information

20

1. 1st mirror (scanner)

2. Exposure lamp

3. Polygonal mirror motor

4. Original width sensor

5. 1st mirror (laser unit)

6. Original length sensor

7. Barrel toroidal lens (BTL)

8. Lens

9. SBU board

10. F-theta mirror

11. Hot roller

12

13

14

15

16

19 18 17

A250V561.WMF

12. Pressure roller

13. Transfer roller

14. By-pass feed roller

15. By-pass table

16. Vertical transport roller

17. Paper feed roller

18. Bottom plate

19. All-in-one cartridge (AIO cartridge)

20. 3rd mirror

21. 2nd mirror

1-7

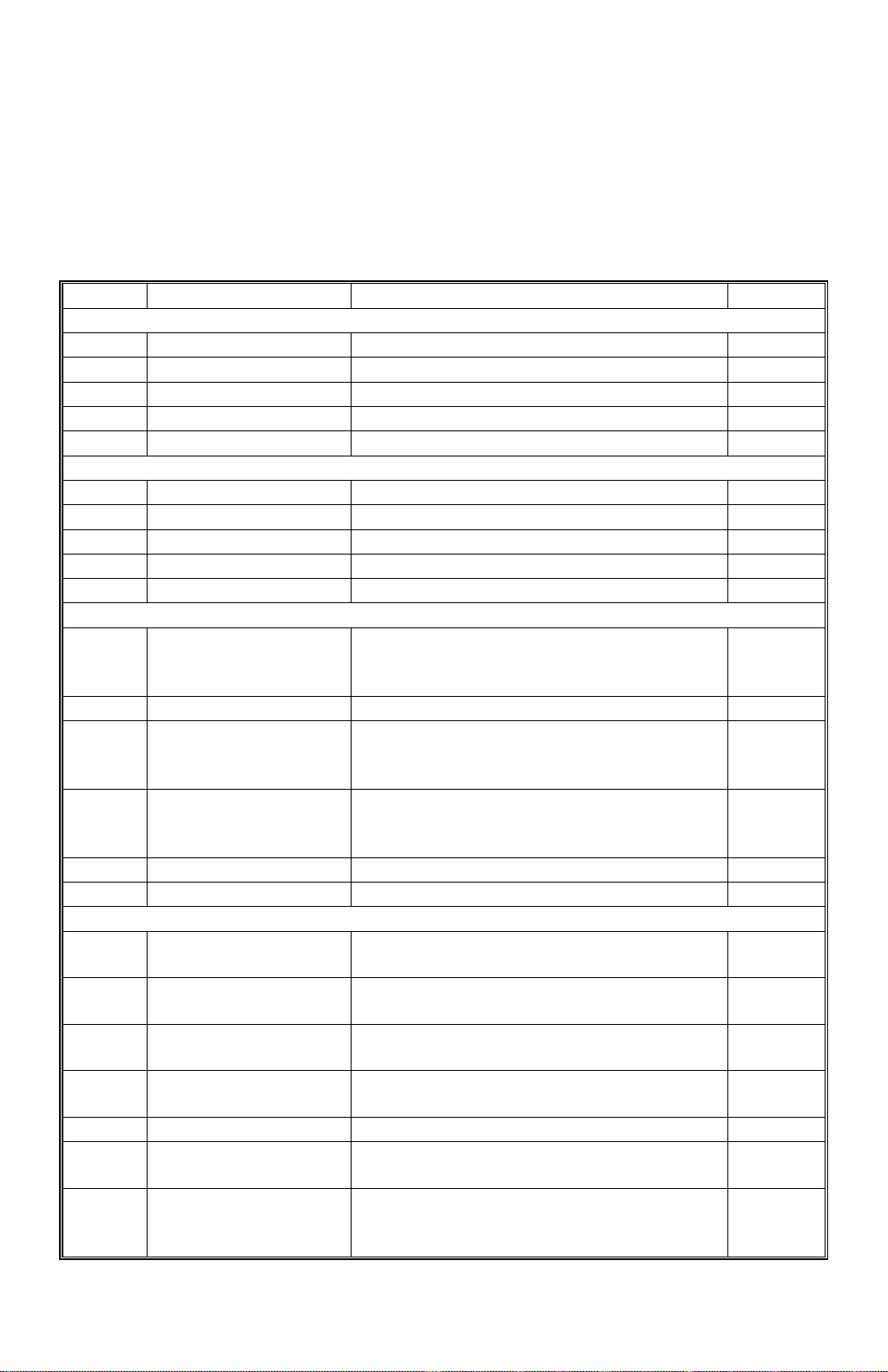

ELECTRICAL COMPONENT DESCRIPTIONS 17 May, 1999

1.5 ELECTRICAL COMPONENT DESCRIPTIONS

Refer to the electrical component layout on the reverse side of the point-to-point

diagram for the location of the components, using the symbols and index numbers.

1.5.1 COPIER ENGINE

Symbol Name Function Index No.

Motors

M1 Scanner Drives the 1st and 2nd scanners. 4

M2 Polygonal Mirror Turns the polygonal mirror. 28

M3 Main Drives the main unit components. 12

M4 Exhaust Fan Removes heat from around the fusing unit. 46

Magnetic Clutches

MC1 Paper Feed Starts paper feed from the tray. 14

MC2 By-pass Feed Starts paper feed from the by-pass table. 15

MC3 Vertical Transport Drives the vertical transport rollers. 18

MC4 Registration Drives the registration rollers. 13

Switches

Main Provides power to the machine. If this is

SW1

SW2 Right Door Switch 1 Cuts the +5 V LD dc power line. 30

Right Door Switch 2

SW3

Vertical Transport

SW4

SW5 Paper Size Detects paper size. 24

Sensors

S1

S2

S3

S4

S5 Toner Near-End Detects toner near-end. 21

S6

S7

Cover Switch

Scanner HP

Original Width Detects original width. This is one of the

Original Length 1 Detects original length. This is one of the

Original Length 2

Paper End Informs the CPU when the tray runs out of

Paper Near-End Informs the CPU when the paper in the

off, there is no power supplied to the

machine.

Detects if the front door is open or not, and

cuts the +24 V dc power line for the main

motor and power pack.

Detects if the front door is open or not, and

cuts the +24 V dc power line for the vertical

transport clutch.

Informs the CPU when the 1st and 2nd

scanners are at home position.

APS (Auto Paper Select) sensors.

APS (Auto Paper Select) sensors.

Detects original length. This is one of the

APS (Auto Paper Select) sensors.

paper.

tray is almost finished. The printer

controller uses this sensor.

40

31

25

3

37

6

6

23

19

1-8

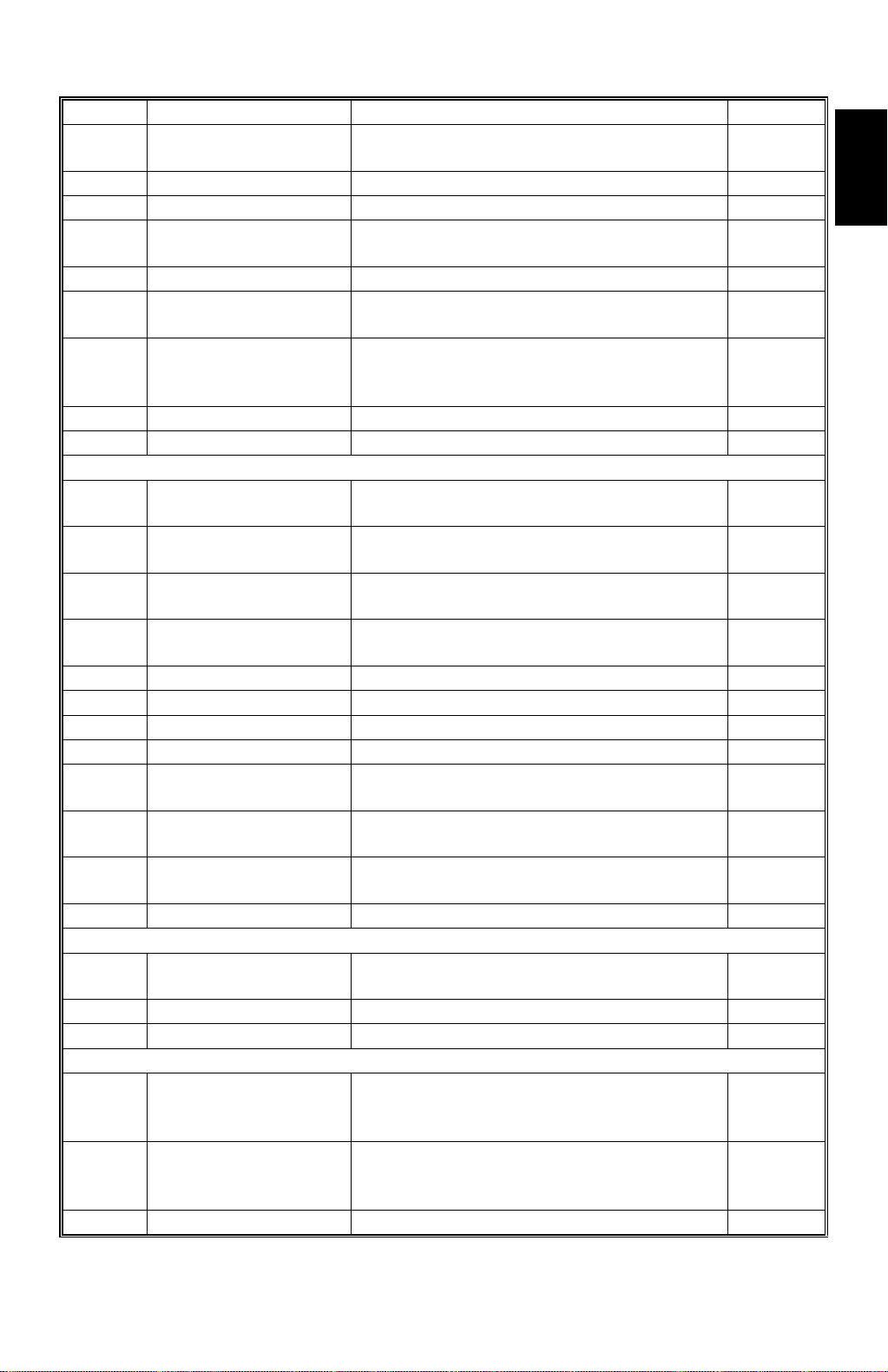

17 May, 1999 ELECTRICAL COMPONENT DESCRIPTIONS

Symbol Name Function Index No.

S8

By-pass Tray Paper

Informs the CPU that there is paper in the

by-pass feed table.

16

S9 By-pass Paper Size Detects the paper size in the by-pass tray. 20

S10 Vertical Transport Detects misfeeds. 22

S11

Registration

Detects misfeeds and controls registration

clutch off-on timing.

17

S12 Fusing Exit Detects misfeeds. 35

S13

Exit Tray Paper Detects if there is paper on the exit tray or

not.

27

Platen Cover Informs the CPU that the platen cover is in

S14

the up or down position (related to the

5

APS/ARE functions).

S15 AIO Set Informs the CPU that an AIO is installed. 33

PCBs

PCB1

PCB2

PCB3

PCB4

BICU

PSU Provides dc power to the system and ac

IOB Controls the fusing lamp and the

SBU

Controls all base engine functions both

directly and through other control boards.

power to the fusing lamp and heaters.

mechanical parts of the machine.

Contains the CCD, and outputs a video

signal to the BICU board.

44

39

45

8

PCB5 Lamp Stabilizer Stabilizes the power to the exposure lamp. 7

PCB6 LD Unit Cont rols the laser diode. 26

PCB7 Operation Panel Controls the operation panel. 36

PCB8 Memory (Option) Expands memory capacity. —

PCB9

PCB10

PCB11

Printer Controller

(Option)

FCU (Option) Controls all fax communications and fax

NCU (Option) Switches the analog line between the fax

Receives print data from a PC.

features, in cooperation with the BICU.

unit and the external telephone.

42

43

47

Overall

Information

Lamps

L1

Exposure Lamp Applies hig h int ensity light t o the original

for exposure.

L2 Fusing Lamp Heats the hot roller. 10

Heaters

H1

Anti-condensation

(Option)

Turns on when the main switch is off to

prevent moisture from forming on the

optics.

Drum (Option) Turns on when the main switch is off to

H2

prevent moisture from forming around the

drum.

1-9

2

1

—

ELECTRICAL COMPONENT DESCRIPTIONS 17 May, 1999

Symbol Name Function Index No.

Others

TF1

Fusing Thermofuse

Opens the fusing lamp circuit if the fusing

unit overheats.

9

TH1 Fusing Thermistor Detects the temperature of the hot roller. 11

PP1

LSD 1

CO1

CO2

C/B/T Power Pack

Laser Synchronization

Detector

Total Counter Keeps track of the total number of prints

Key Counter (Option)

Provides high voltage for the charge,

development and transfer rollers.

Detects the laser beam at the start of the

main scan.

made.

Used for control of authorized use. If this

feature is enabled for coping, coping will be

38

29

48

—

impossible until it is installed.

LED1 Exit Tray Indicates if there is paper on the exit tray. 32

LED2

1-bin Sorter Indicates if there is paper on the 1-bin

sorter. 1-bin sorter is option.

34

SP1 Speaker T urns on during fax communication. 41

1-10

17 May, 1999 DRIVE LAYOUT

1.6 DRIVE LAYOUT

5

1

2

3

4

Overall

Information

1. By-pass feed clutch

2. Vertical transport clutch

3. Registration clutch

4. Paper feed clutch

5. Main motor

A250V109.WMF

1-11

COPY PROCESS 17 May, 1999

1.7 COPY PROCESS

1.7.1 OVERVIEW

6

1

OPC

–600 V

5

2

–100 V

4

3

–400 V

A250V507.WMF

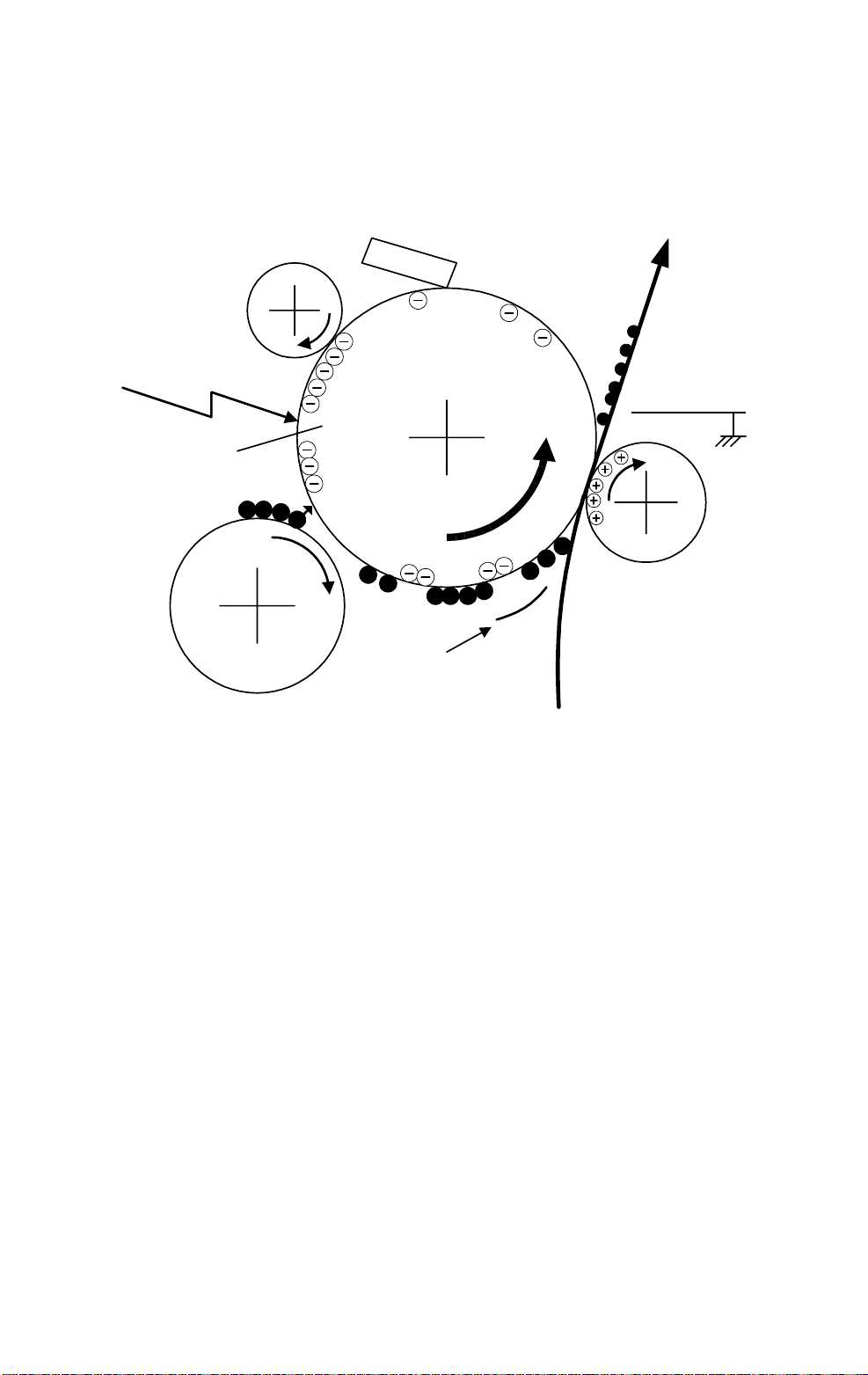

1. DRUM CHARGE

In the dark, the charge roller gives a negative charge of –600 volts to the

organic photo-conductive (OPC) drum. The charge remains on the surface of

the drum because the OPC layer has a high electrical resistance in the dark.

2. LASER EXPOSURE

The processed data scanned from the original is retrieved from the memory

and transferred to the drum by a laser beam, which forms an electrical latent

image on the drum surface. The amount of charge remaining as a latent image

on the drum (about –100 volts) depends on the laser beam intensity, which is

controlled by the BICU board.

3. DEVELOPMENT

The development roller charges the toner with a negative bias of –400 volts.

Toner particles jump across to the drum and electrostatically attach to the

areas of the drum surface where the laser reduced the negative charge on the

drum.

1-12

17 May, 1999 COPY PROCESS

4. IMAGE TRANSFER

Paper is fed to the area between the drum surface and the transfer roller at the

proper time for aligning the copy paper and the developed image on the drum

surface. Then, the transfer roller applies a high positive charge to the reverse

side of the paper. This positive charge pulls the toner particles from the drum

surface onto the paper. At the same time, the paper is electrostatically attracted

to the transfer roller.

5. PAPER SEPARATION

Paper separates from the drum as a result of the electrostatic attraction

between the paper and the transfer roller. The discharge plate helps separate

the paper from the drum.

6. CLEANING

The cleaning blade removes any toner remaining on the drum surface after the

image transfers to the paper.

7. QUENCHING

There is no quenching lamp. The power supply board applies 1.6 kVp-p (1.05

mA) 1 kHz AC to the charge roller. This current removes any remaining voltage

on the drum surface.

Overall

Information

1-13

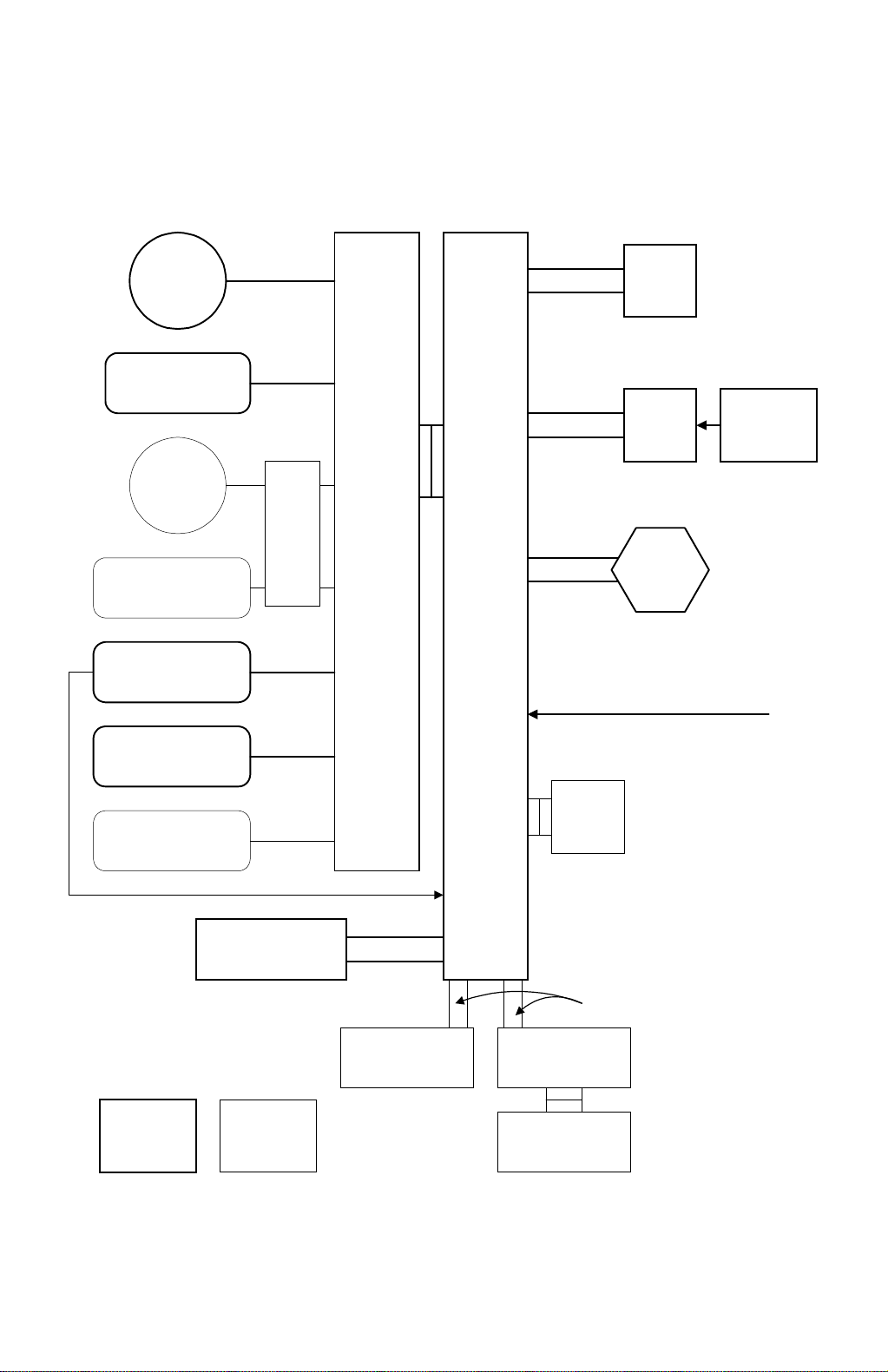

BOARD STRUCTURE 17 May, 1999

1.8 BOARD STRUCTURE

1.8.1 OVERVIEW

Scanner

Motor

Scanner Sensors

DF

Motor

DF Sensors,

Solenoids

Laser Printer

Sensors, Solenoids,

Motors, Clutches

PSU

DF

Drive

PCB

IOB

BICU

Flat Cable

Harness

Harness

Laser Synchronization

Signal = Fibre Optic Cable

SBU

LDD

Circuit

Board

Polygon

Mirror

Motor

Photo

Diode

Peripheral Sensors,

Motors, Solenoids,

Clutches

Operation Panel

Standard Option

EMB

Harness

Flat Cable

Fax Controller Mother Board

Printer Controller

A250V504.WMF

1-14

17 May, 1999 BOARD STRUCTURE

1.8.2 DESCRIPTION

1. BICU (Base Engine and Image Control Unit)

The main board controls the following functions:

·

Engine sequence

·

Scanner, laser printer engine

·

Timing control for peripherals

·

Image processing, video control

·

Operation control

·

Various application boards (fax, printer)

·

Machine control, system control

2. IOB (I/O Board)

The IOB handles the following functions:

·

Drive control for the sensors, motors, and solenoids of the printer and

scanner

·

High voltage control board control

·

Serial interfaces with peripherals

·

Fusing control

3. SBU (Sensor Board Unit)

Overall

Information

The SBU deals with the analog signals from the CCD and converts them into digital

signals.

4. EMB (Extended Memory Board) (Option)

The EMB stores the image data. An extra 48 MB of memory can be added. This

increases the number of pages that can be stored.

1-15

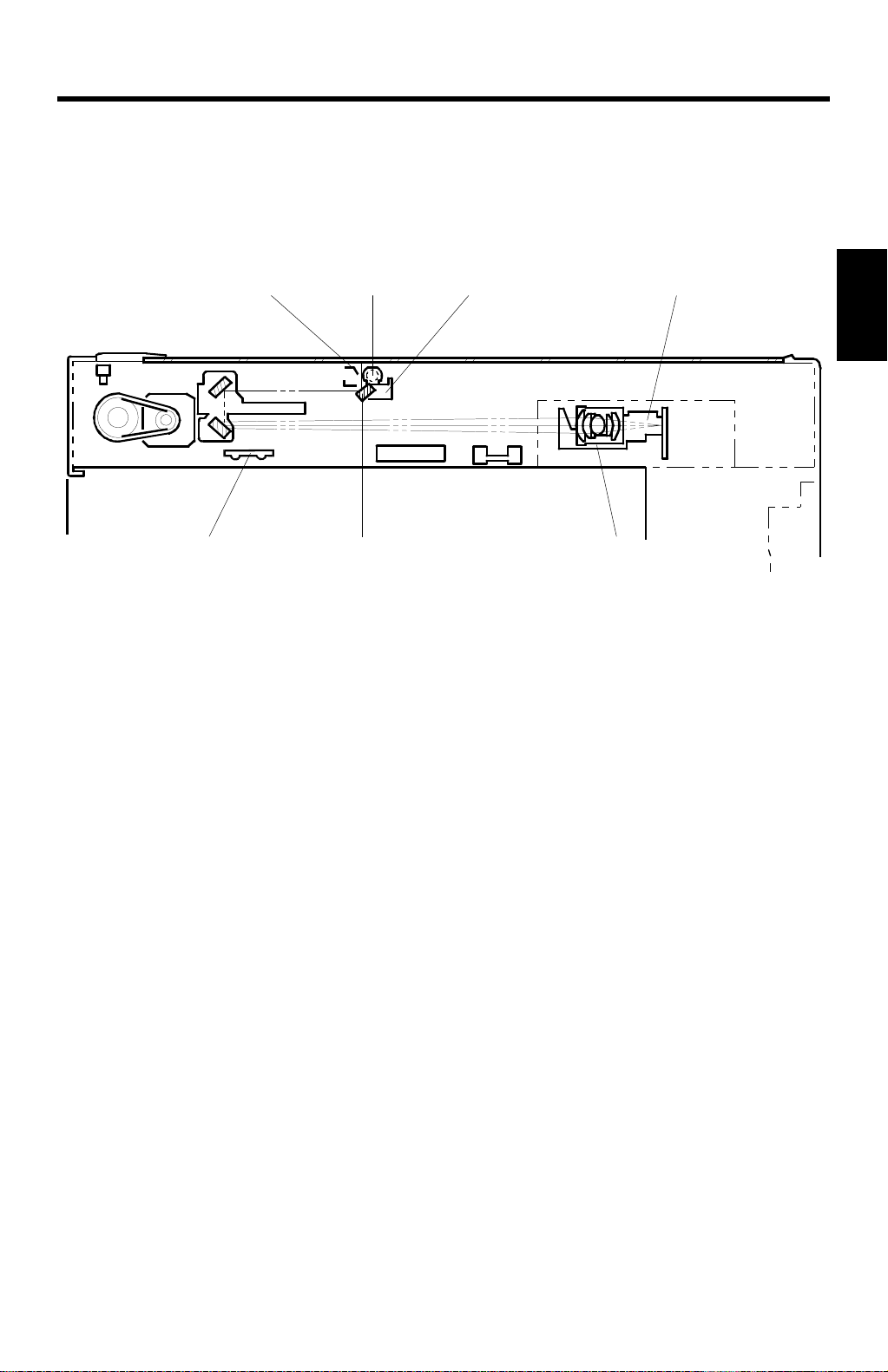

17 May, 1999 SCANNING

2. DETAILED SECTION DESCRIPTIONS

2.1 SCANNING

2.1.1 OVERVIEW

[E] [A] [D] [C]

[G] [F] [B]

Detailed

Descriptions

A250D003.WMF

An exposure lamp [A], a xenon lamp in this model, illuminates the original. The 1st,

2nd, 3rd mirrors, and lens [B] reflect the image onto the CCD (charge coupled

device) [C]. The SBU (Sensor Board Unit) consists of the CCD and the lens.

The 1st scanner [D] consists of the exposure lamp, a reflector [E], and the 1st

mirror [F].

The exposure lamp is energized by a DC supply to avoid uneven light intensity as

the 1st scanner moves in the sub-scan direction. The entire exposure lamp surface

is frosted to ensure even exposure in the main scan direction.

The light reflected by the reflector is of almost equal intensity to the light from the

exposure lamp, to reduce shadows on pasted originals.

An optics anti-condensation heater [G] is available as an option. It can be installed

on the left side of the scanner unit. It turns on whenever the power cord is plugged

in and the machine is in off condition.

2-1

SCANNING 17 May, 1999

2.1.2 SCANNER DRIVE

[A]

[E]

[D]

[C]

[B]

[D]

A250D001.WMF

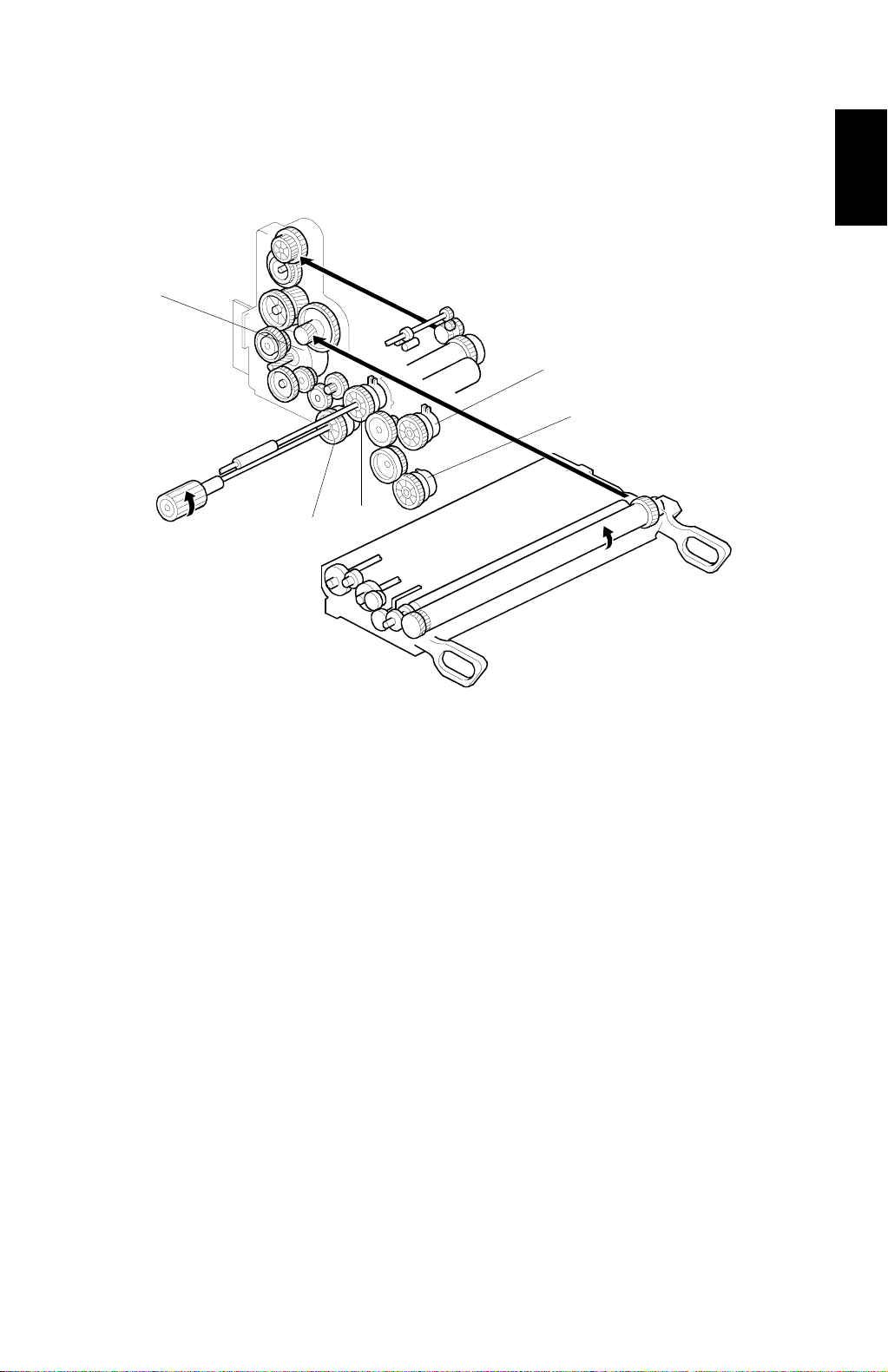

The scanner drive motor [A] (a stepper motor) drives the 1st and 2nd scanners [B,

C] through the timing belts [D], scanner drive pulley [E], and the Accuride rail at the

rear.

Book Mode

The main CPU controls and operates the scanner drive motor. In full size mode,

the 1st scanner speed is 92 mm/s during scanning. The 2nd scanner speed is half

that of the 1st scanner.

In reduction or enlargement mode, the scanning speed depends on the

magnification ratio (M: 0.5 to 2.00). The returning speed is always the same,

whether in full size or magnification mode.

Changing the scanner drive motor speed changes the magnification in the subscan direction. Use SP mode (SP4-101) to adjust this.

In the main scan direction, magnification is done by image processing on the BICU

(Base Engine Image Control Unit) board. Adjust magnification in the main scan

direction with SP4-008.

ADF Mode

The scanners remain in their home position (the scanner H.P sensor detects the

1st scanner) to scan the original. The ADF motor feeds the original through the

ADF.

In reduction/enlargement mode, changing the ADF motor speed adjusts the image

length in the sub-scan direction (adjust with SP6-007). The BICU board adjusts the

magnification in the main scan direction, in the same way as in book mode (adjust

with SP4-008).

2-2

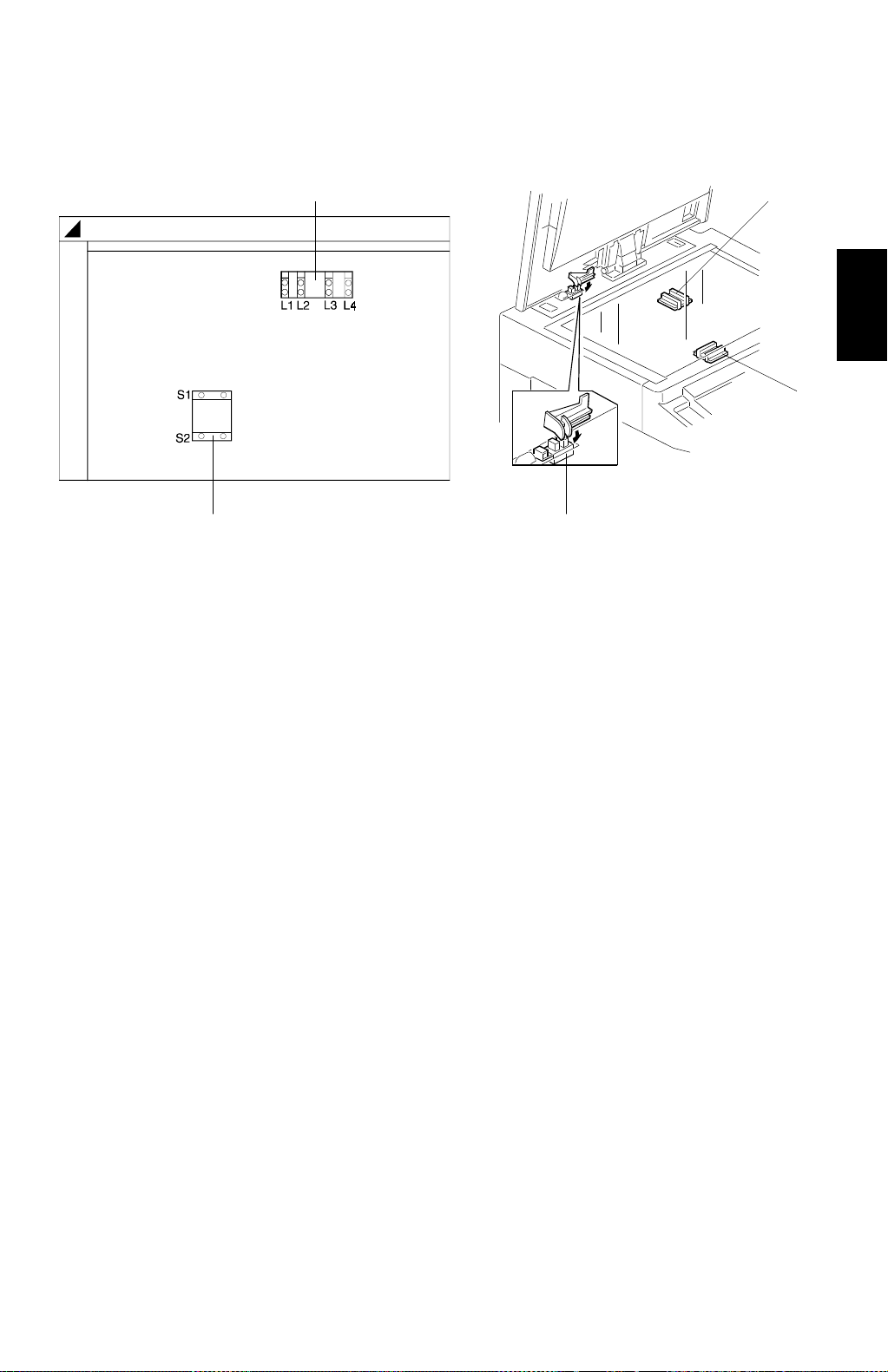

17 May, 1999 SCANNING

2.1.3 ORIGINAL SIZE DETECTION IN PLATEN MODE

[B]

[B]

[A]

A250D526.WMF

[A]

[C]

A250D002.WMF

In the optics cavity, there are four reflective sensors in the 115 V machines, and six

reflective sensors in the 230 V machines. These are the original width sensors [A]

and the original length sensors [B], and they detect the length and width of the

original. They are also known as the APS (Auto Paper Selection) sensors.

Detailed

Descriptions

While the main switch is on, these sensors are active and the original size data is

always sent to the CPU. However, the CPU checks the data only when the platen

cover is opened.

The main CPU takes the original size data when the platen cover sensor [C]

activates. This is when the platen is about 15 cm above the exposure glass. At this

time, only the sensor(s) located underneath the original receive the reflected light

and switch on. The other sensor(s) remain off. The main CPU can recognize the

original size from the on/off signals from the APS sensors.

If the copy is made with the platen fully open, the main CPU decides the original

size from the sensor outputs when the Start key is pressed.

2-3

SCANNING 17 May, 1999

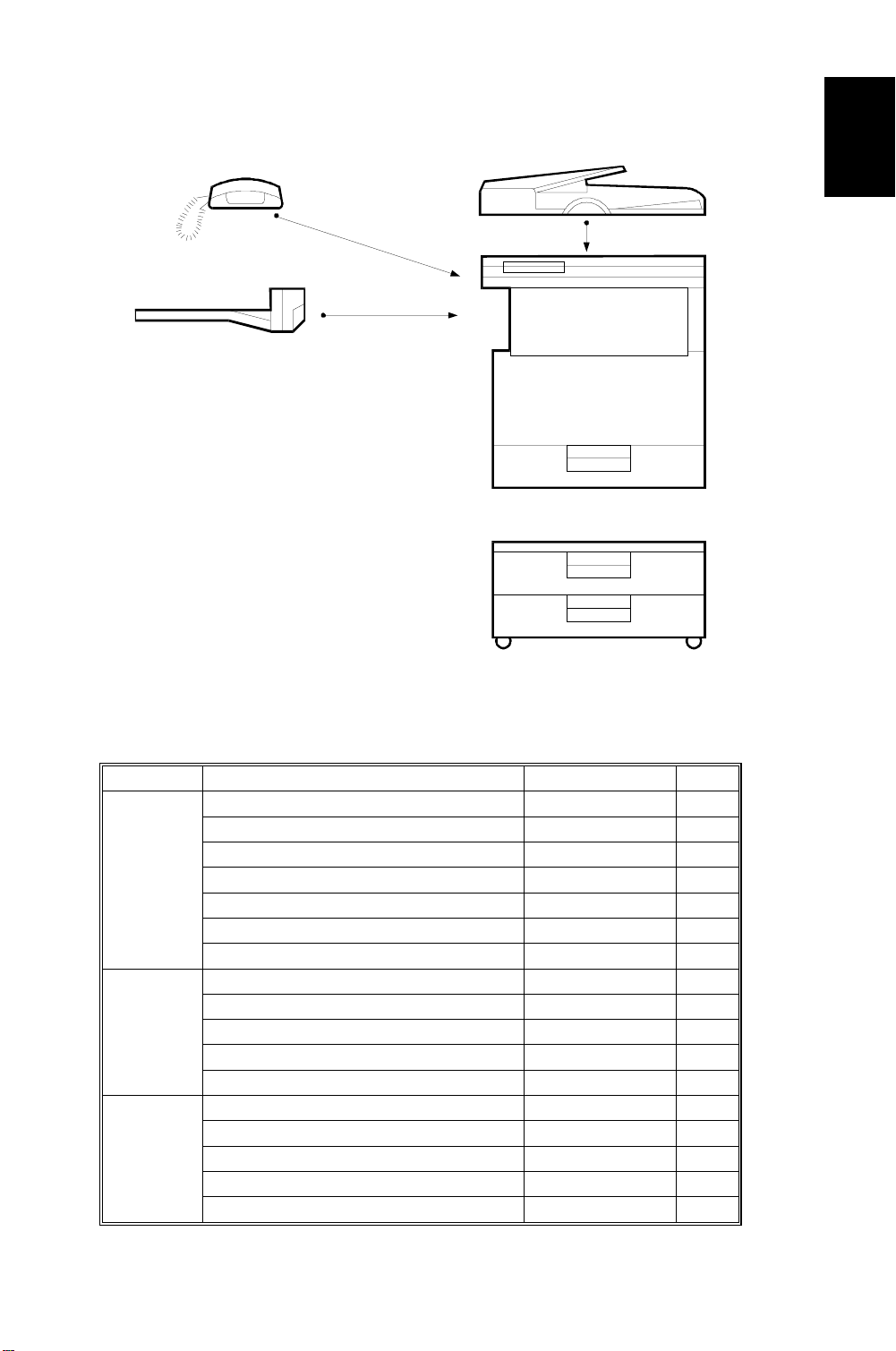

Original Size Length Sensors Width Sensors

A4/A3 ver sion LT/DLT version L1 L2 L3 L4 S1 S2

A3 11" x 17"

B4 10" x 14"

F4 8

A4-L 8

B5-L —

A4-S 11" x 8

B5-S —

1/2

" x 14" (8" x 13")

1/2

" x 11"

1/2

"

mmmmmm

mmmmm7

mmm7 77

mm7777

m77777

7777mm

7777m7

m

: ON 7: OFF

NOTE:

The length sensors L1 and L2 are used only for 230 V machines.

For other combinations, the operation panel will display “CANNOT DETECT ORIG.

SIZE”.

The above table shows the sensor output for each original size. This original size

detection method eliminates the necessity for pre-scanning and increases the

machine's productivity.

However, if the by-pass feed table is used, note that the machine assumes that the

copy paper is lengthwise. For example, if A4 sideways paper is placed on the bypass tray, the machine assumes it is A3 paper and scans a full A3 area,

disregarding the original size sensors. However, for each page, the data signal to

the laser diode is stopped to match the copy paper length detected by the

registration sensor. This means that copy time for the first page may be slower

(because of the longer time required for scanning), but it will be normal for the rest

of the job.

2-4

17 May, 1999 IMAGE PROCESSING

g

g

g

2.2 IMAGE PROCESSING

2.2.1 OVERVIEW

Circuit

Data from SBU

IPU

Detailed

Descriptions

Auto Shadin

Scanner Gamma

Correction

Magnification

Filterin

ID Gamma

Correction

Application

(Fax or

Printer Unit)

Gradation Processin

Video Data Control

FCI

Printer Gamma

Correction

LD Controller

EMB

LD Unit

VCU

A250D500.WMF

The CCD generates an analog video signal. The SBU (Sensor Board Unit)

converts the analog signal to an 8-bit digital signal, then it sends the digital signal

to the BICU (Base-engine and Image Control Unit) board.

The BICU board is divided into two image processing blocks; the IPU (Image

Processing Unit), and memory.

·

IPU: Auto shading, filtering, magnification, gamma (g) correction, and

gradation processing

Finally, the BICU board sends the video data to the LD unit at the correct time.

LD unit is divided into two blocks, VCU (Video Control Unit) and LD controller.

·

VCU:

FCI (Fine Character Image) – Smoothing, Printer gamma (g)

correction

·

LD controller:

LD print timing control

2-5

Loading...

Loading...