Page 1

MODEL MT

(Machine Code: B064/B065)

SERVICE MANUAL

Subject to change

Ricoh Technical Service

April 26, 2002

Page 2

!

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off

or open while the main switch is turned on, keep hands away from electrified

or mechanically driven components.

5. If the Start key is pressed before the copier completes the warm-up period

(the Start key starts blinking red and green alternatively), keep hands away

from the mechanical and the electrical components as the copier starts

making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your eyes

by accident, it may cause temporary eye discomfort. Try to remove with eye

drops or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course on

those models.

2. The NVRAM on the system control board has a lithium battery which can

explode if replaced incorrectly. Replace the NVRAM only with an identical

one. The manufacturer recommends replacing the entire NVRAM. Do not

recharge or burn this battery. Used NVRAM must be handled in accordance

with local regulations.

Page 3

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in or der to dispose of them later, do not

put more than 100 batteries per sealed box. Storing larger numbers or not

sealing them apart may lead to chemical reactions and heat build-up.

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

!

WARNING

WARNING: Turn off the main switch before atte mpting any of the

procedures in the Laser Unit section. Laser beams can

seriously damage your eyes.

CAUTION MARKING:

Page 4

What This Manual Contains

This preliminary manual describes the installation procedures for the B064/B065

Copier and its peripheral devices:

Main unit

• B064/065 Copier with ADF, Tandem Tray

Peripherals

• B473 LCT. (Attached to the right side of the machine). Provides an additional

feed station of 4,000 sheets.

• B474 LG/B4 Feeder Kit (Attached to B473 LCT). Converts the LCT to a feed

station for legal or B4 size paper.)

• B475 A3/DLT Feeder Kit (Installed in Tandem Tray). Converts the top tray to a

feed station for A3 paper.

• B468/B469 3000-Sheet Finishers (Attached to B064/B065). Both finishers

provide punch, staple, and shift capability. The B468 provides saddle-stitching

with staples, the B469 does not provide saddle-stitching.

• B470 Cover Interposer Tray (Attached to B468/B469). Mounted on top of the

B468/B469 finisher, provides a feed station for inserting cover sheets.

• B471 9-Bin Mailbox (Attached to B468/B469). Mounted on top of the B468/B469

provides 9 output trays, each assigned to a different user.

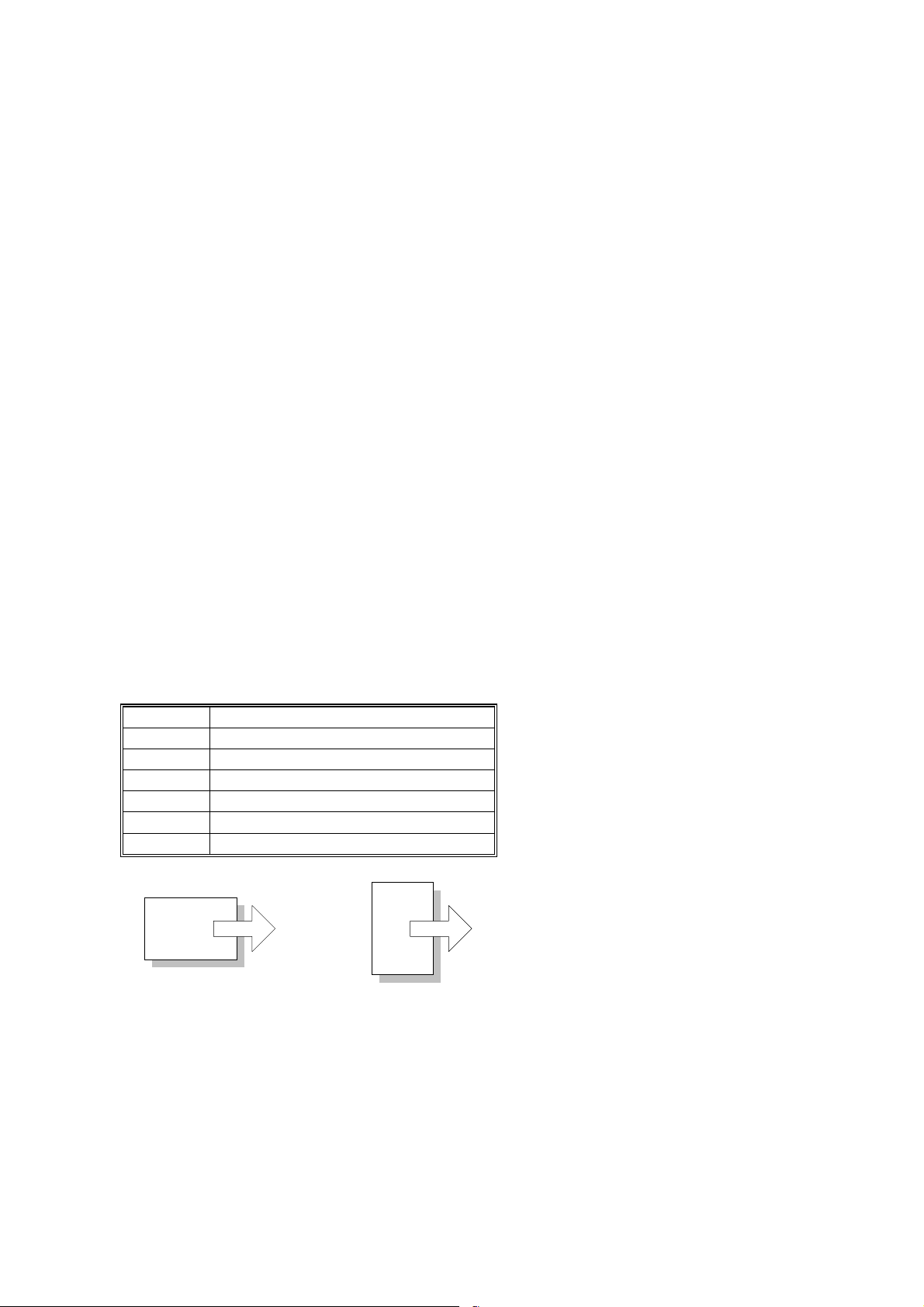

Conventions in this Manual

This manual uses several symbols.

Symbol What it means

☛

!

"

#

$

%

Refer to section number

See Core Tech Manual for detail s

Screw

Connector

E-ring

Clip ring

Long Edge Feed (LEF)Short Edge Feed (SEF)

Page 5

TABLE OF CONTENTS

1. INSTALLA TION .......................................................................... 1-1

1.1 INSTALLATION REQUIREMENTS...........................................................1-1

1.1.1 OPERATING ENVIRONMENT.........................................................1-1

1.1.2 MACHINE LEVEL.............................................................................1-2

1.1.3 MINIMUM SPACE REQUIREMENTS...............................................1-3

1.1.4 DIMENSIONS...................................................................................1-3

1.1.5 POWER REQUIREMENTS..............................................................1-4

1.2 MAIN MACHINE (B064/B065)...................................................................1-5

1.2.1 ACCESSORY CHECK......................................................................1-5

1.2.2 INSTALLATION PROCEDURE........................................................1-6

Removing Tapes and Retainers ...........................................................1-6

Connecting the ADF..............................................................................1-8

Removing and Filling the Development Unit.........................................1-9

Re-installing the Development Unit.....................................................1-11

Initializing the Drum Settings.............................................................. 1-12

Tandem Tray ......................................................................................1-13

Machine Level.....................................................................................1-15

Date/Time Setting...............................................................................1-15

SP Codes............................................................................................1-15

1.3 A3/DLT FEEDER KIT (B475)...................................................................1-16

1.3.1 ACCESSORY CHECK....................................................................1-16

1.3.2 INSTALLATION PROCEDURE......................................................1-17

1.4 LCT (B473)..............................................................................................1-19

1.4.1 ACCESSORY CHECK....................................................................1-19

1.4.2 INSTALLATION PROCEDURE......................................................1-20

Removing Tape ..................................................................................1-20

Preparing the Main Machine...............................................................1-21

Installing the LCT................................................................................1-21

1.5 LG/B4 FEEDER KIT (B474)....................................................................1-23

1.5.1 ACCESSORY CHECK....................................................................1-23

1.5.2 INSTALLATION PROCEDURE......................................................1-24

1.6 3000-SHEET FINISHERS (B468/B469)..................................................1-27

1.6.1 ACCESSORY CHECK....................................................................1-27

1.6.2 INSTALLATION PROCEDURE......................................................1-28

Removing Tapes and Retainers .........................................................1-28

B468/B469 Installation........................................................................1-29

Selecting the Staple Supply Name ..................................................... 1-31

Enabling Booklet Binding....................................................................1-31

1.7 PUNCH UNIT (B377)...............................................................................1-32

1.7.1 ACCESSORY CHECK....................................................................1-32

1.7.2 INSTALLATION PROCEDURE......................................................1-33

1.8 COVER INTERPOSER TRAY (B470).....................................................1-35

1.8.1 ACCESSORY CHECK....................................................................1-35

1.8.2 INSTALLATION PROCEDURE......................................................1-36

Removing Tapes and Retainers .........................................................1-36

i

Page 6

1.9 9-BIN MAILBOX (B471)...........................................................................1-39

1.9.1 ACCESSORY CHECK....................................................................1-39

1.9.2 INSTALLATION PROCEDURE......................................................1-40

Removing Tapes and Retainers .........................................................1-40

Installation...........................................................................................1-40

1.10 PRINTER/SCANNER KIT (G338), PRINTER KIT (G339).....................1-42

1.10.1 ACCESSORY CHECK..................................................................1-42

1.10.2 INSTALLATION PROCEDURE....................................................1-43

Inserting DIMMs..................................................................................1-43

Installation Procedure.........................................................................1-44

1.11 PS3 (B525-08).......................................................................................1-46

1.11.1 INSTALLATION PROCEDURE....................................................1-46

1.12 USB 2.0 (B525-01)................................................................................1-47

1.12.1 ACCESSORY CHECK..................................................................1-47

1.12.2 INSTALLATION PROCEDURE....................................................1-48

1.12.3 USB SP SETTINGS......................................................................1-49

1.13 IEEE1394 (G561) FIREWIRE INTERFACE ..........................................1-50

1.13.1 ACCESSORY CHECK..................................................................1-50

1.13.2 INSTALLATION PROCEDURE....................................................1-51

1.13.3 UP MODE SETTINGS FOR IEEE 1394 .......................................1-52

1.13.4 SP MODE SETTINGS FOR IEEE 1394........................................1-53

1.14 802.11B WIRELESS LAN (G628)..........................................................1-54

1.14.1 ACCESSORY CHECK..................................................................1-54

1.14.2 INSTALLATION PROCEDURE....................................................1-55

1.14.3 UP MODE SETTINGS FOR WIRELESS LAN..............................1-56

1.14.4 SP MODE SETTINGS FOR 802.11B WIRELESS LAN................1-58

2. PREVENTIVE MAINTENANCE................................................... 2-1

2.1 PM TABLES ..............................................................................................2-1

2.1.1 MAIN MACHINE...............................................................................2-1

2.1.2 ADF ..................................................................................................2-4

2.1.3 OPTIONAL PERIPHERAL DEVICES...............................................2-5

LCT (Large Capacity Tray) B473..........................................................2-5

Cover Interposer Tray B470..................................................................2-5

3000-Sheet Finisher with 50-sheet stapler and Saddle-Stitching

B468B469.............................................................................................2-5

2.2 RELATED SP CODES ..............................................................................2-5

3. REPLACEMENT AND ADJUSTMENT........................................ 3-1

3.1 GENERAL CAUTIONS..............................................................................3-1

3.1.1 DRUM...............................................................................................3-1

3.1.2 DRUM UNIT .....................................................................................3-1

3.1.3 TRANSFER BELT UNIT...................................................................3-2

3.1.4 SCANNER UNIT...............................................................................3-2

3.1.5 LASER UNIT ....................................................................................3-2

3.1.6 CHARGE CORONA..........................................................................3-3

3.1.7 DEVELOPMENT ..............................................................................3-3

3.1.8 CLEANING.......................................................................................3-4

3.1.9 FUSING UNIT...................................................................................3-4

ii

Page 7

3.1.10 PAPER FEED.................................................................................3-4

3.1.11 USED TONER................................................................................3-4

3.2 SPECIAL TOOLS AND LUBRICANTS................................................3-5

3.2.1 SPECIAL TOOLS.............................................................................3-5

3.2.2 LUBRICANTS...................................................................................3-5

3.3 OPERATION PANEL AND EXTERNAL COVERS....................................3-6

3.3.1 OPERATION PANEL........................................................................3-6

3.3.2 FRONT DOOR .................................................................................3-6

3.3.3 RIGHT COVERS..............................................................................3-7

3.3.4 LEFT COVERS.................................................................................3-8

3.3.5 REAR COVERS ...............................................................................3-9

3.4 SCANNER...............................................................................................3-10

3.4.1 ADF AND TOP COVERS ...............................................................3-10

ADF.....................................................................................................3-10

Top Covers.........................................................................................3-11

3.4.2 EXPOSURE GLASS.......................................................................3-12

3.4.3 SCANNER ORIGINAL SIZE SENSORS.........................................3-13

3.4.4 LENS BLOCK.................................................................................3-14

3.4.5 EXPOSURE LAMP.........................................................................3-15

3.4.6 LAMP REGULATOR.......................................................................3-16

3.4.7 SCANNER MOTOR DRIVE BOARD (SDRB).................................3-17

3.4.8 SCANNER MOTOR........................................................................3-18

3.4.9 SCANNER HP SENSOR................................................................3-19

3.4.10 SCANNER WIRE REPLACEMENT..............................................3-20

Preparation for Removal.....................................................................3-20

Wire Removal: Back...........................................................................3-21

Wire Removal: Front...........................................................................3-22

Attaching the New Wire ......................................................................3-23

3.4.11 SCANNER HEATER.....................................................................3-25

3.5 LASER UNIT...........................................................................................3-26

3.5.1 CAUTION DECALS........................................................................3-26

3.5.2 LD UNIT AND POLYGON MOTOR................................................3-27

3.5.3 LASER SYNCHRONIZATION DETECTOR REPLACEMENT........3-29

3.5.4 LASER UNIT ALIGNMENT.............................................................3-30

3.6 DRUM UNIT ............................................................................................3-32

3.6.1 DEVELOPMENT UNIT REMOVAL.................................................3-32

Removal..............................................................................................3-32

Re-installation.....................................................................................3-33

Replacement with a used Development Unit......................................3-33

3.6.2 CHARGE CORONA UNIT..............................................................3-34

3.6.3 CHARGE CORONA WIRE AND GRID...........................................3-35

3.6.4 CHARGE CORONA WIRE CLEANING PADS...............................3-36

3.6.5 OPC DRUM REMOVAL..................................................................3-37

3.6.6 QUENCHING LAMP.......................................................................3-38

3.6.7 DRUM POTENTIAL SENSOR........................................................3-38

3.6.8 CLEANING FILTER........................................................................3-39

3.6.9 CLEANING BLADE.........................................................................3-39

3.6.10 CLEANING BRUSH......................................................................3-40

3.6.11 PICK-OFF PAWLS.......................................................................3-41

iii

Page 8

3.6.12 ID SENSOR..................................................................................3-41

3.6.13 DRUM MOTOR.............................................................................3-42

3.6.14 TONER COLLECTION BOTTLE..................................................3-43

3.6.15 TONER SEPARATION UNIT........................................................3-43

3.6.16 OZONE FILTERS.........................................................................3-44

3.6.17 OPTICS DUST FILTER................................................................3-44

3.6.18 INTERNAL DUST FILTER ............................................................3-44

3.7 DEVELOPMENT UNIT............................................................................3-45

3.7.1 DEVELOPER REPLACEMENT......................................................3-45

3.7.2 DEVELOPMENT FILTER............................................................... 3-47

3.7.3 ENTRANCE SEAL AND SIDE SEALS ...........................................3-48

3.7.4 TD SENSOR...................................................................................3-49

3.7.5 TONER END SENSOR ..................................................................3-49

3.7.6 TONER SUPPLY MOTOR..............................................................3-50

3.7.7 DEVELOPMENT MOTOR..............................................................3-51

3.8 TRANSFER BELT UNIT..........................................................................3-52

3.8.1 TRANSFER BELT UNIT.................................................................3-52

3.8.2 TRANSFER BELT ..........................................................................3-53

3.8.3 TRANSFER ROLLER CLEANING BLADE.....................................3-55

3.8.4 DISCHARGE PLATE......................................................................3-56

3.8.5 TRANSFER POWER PACK...........................................................3-57

3.9 FUSING UNIT..........................................................................................3-58

3.9.1 FUSING UNIT.................................................................................3-58

3.9.2 FUSING UNIT THERMISTORS AND THERMOSTATS.................3-59

3.9.3 WEB CLEANING ROLLER.............................................................3-60

Web Unit Disassembly........................................................................3-60

Web Unit Assembly.............................................................................3-61

3.9.4 WEB MOTOR AND WEB END SENSOR.......................................3-62

3.9.5 PRESSURE ROLLER CLEANING UNIT........................................3-63

3.9.6 FUSING LAMPS, HOT ROLLER, AND PRESSURE ROLLER.......3-64

Important Notes about Fusing Unit Assembly.....................................3-67

3.9.7 PRESSURE ROLLER.....................................................................3-68

3.9.8 STRIPPER PAWLS........................................................................3-69

3.9.9 NIP BAND WIDTH ADJUSTMENT.................................................3-70

3.9.10 FUSING UNIT EXIT SENSOR......................................................3-71

3.9.11 FUSING/EXIT MOTOR.................................................................3-72

3.9.12 FUSING EXIT AND EXIT UNIT ENTRANCE SENSORS.............3-73

3.10 DUPLEX UNIT.......................................................................................3-74

3.10.1 DUPLEX UNIT REMOVAL ...........................................................3-74

3.10.2 DUPLEX UNIT SIDE-TO-SIDE ADJUSTMENT............................3-75

3.10.3 JOGGER FENCE ADJUSTMENT................................................3-75

3.10.4 DUPLEX MOTORS.......................................................................3-76

Duplex Inverter Motor.........................................................................3-76

Duplex Jogger and Transport Motors..................................................3-77

3.10.5 DUPLEX TRANSPORT CLUTCH/JOGGER HP SENSOR...........3-78

3.10.6 DUPLEX ENTRANCE SENSOR ..................................................3-79

3.10.7 DUPLEX TRANSPORT SENSOR 3.............................................3-80

3.10.8 INVERTER EXIT SENSOR, TRANSPORT SENSORS 1 & 2.......3-81

3.10.9 DUPLEX JOGGER BELT ADJUSTMENT.................................... 3-82

iv

Page 9

3.11 PAPER FEED........................................................................................3-83

3.11.1 PAPER TRAY REMOVAL............................................................3-83

Tandem Tray Removal.......................................................................3-83

3.11.2 REAR FENCE RETURN SENSOR REPLACEMENT...................3-85

3.11.3 REAR FENCE HP SENSOR REPLACEMENT.............................3-86

3.11.4 TANDEM RIGHT TRAY PAPER SENSOR REPLACEMENT.......3-87

3.11.5 BOTTOM PLATE LIFT WIRE REPLACEMENT ...........................3-88

3.11.6 TANDEM LCT PAPER SIZE CHANGE........................................3-90

3.11.7 PICK-UP, FEED, SEPARATION ROLLER REPLACEMENT .......3-93

3.11.8 FEED UNIT...................................................................................3-94

3.11.9 SEPARATION ROLLER PRESSURE ADJUSTMENT..................3-96

3.11.10 RELAY SENSOR........................................................................3-97

3.11.11 BY-PASS PAPER SIZE DETECTION BOARD...........................3-98

3.11.12 BY-PASS TRAY ROLLERS........................................................3-99

3.11.13 BY-PASS SEPARATION ROLLER PRESSURE

ADJUSTMENT .........................................................................3-100

3.11.14 REGISTRATION SENSOR.......................................................3-101

3.11.15 REGISTRATION AND BY-PASS UNIT REMOVAL..................3-102

3.12 PCBS AND HDD .................................................................................3-104

3.12.1 BCU BOARD (BASE ENGINE CONTROL UNIT).......................3-104

3.12.2 CONTROLLER BOARD .............................................................3-105

3.12.3 IPU BOARD (IMAGE PROCESSING UNIT)...............................3-106

3.12.4 DEVELOPMENT POWER PACK ...............................................3-106

3.12.5 PSU, PFC BOARDS...................................................................3-107

3.12.6 HDD ............................................................................................3-107

3.12.7 NVRAM.......................................................................................3-108

3.13 ADF.....................................................................................................3-109

3.13.1 ADF COVERS............................................................................3-109

3.13.2 FEED UNIT.................................................................................3-110

3.13.3 FEED BELT AND PICK-UP ROLLER.........................................3-111

3.13.4 SEPARATION ROLLER.............................................................3-112

3.13.5 REGISTRATION SENSOR.........................................................3-113

3.13.6 ADF CONTROL BOARD............................................................3-114

3.13.7 ORIGINAL WIDTH, INTERVAL, AND SKEW CORRECTION

SENSORS..................................................................................3-115

3.13.8 ORIGINAL LENGTH SENSORS ................................................3-116

3.13.9 DF POSITION AND APS SENSOR............................................3-117

3.13.10 OTHER ADF SENSORS ..........................................................3-118

3.13.11 BOTTOM PLATE LIFT MOTOR ...............................................3-119

3.13.12 FEED MOTOR..........................................................................3-120

3.13.13 EXIT MOTOR AND TRANSPORT MOTOR .............................3-121

3.13.14 PICK-UP ROLLER MOTOR AND HP SENSOR.......................3-122

3.13.15 CIS POWER SUPPLY BOARD AND CIS UNIT .......................3-123

3.13.16 ADF EXIT SENSOR.................................................................3-124

3.14 COPY IMAGE ADJUSTMENTS: PRINTING/SCANNING ...................3-125

3.14.1 PRINTING ..................................................................................3-125

Registration - Leading Edge/Side-to-Side.........................................3-125

Blank Margin.....................................................................................3-126

Registration Buckle Adjustment........................................................3-126

v

Page 10

3.14.2 SCANNING.................................................................................3-127

Registration: Platen Mode.................................................................3-127

Magnification.....................................................................................3-127

3.14.3 ADF SCANNING ADJUSTMENTS.............................................3-128

Vertical Black Lines ..........................................................................3-128

DIP Switch Settings (ADF Main Board).............................................3-128

ADF Skew Correction.......................................................................3-129

3.15 TOUCH SCREEN CALIBRATION.......................................................3-130

4. TROUBLESHOOTING ................................................................ 4-1

4.1 PROGRAM DOWNLOAD..........................................................................4-1

4.1.1 OVERVIEW......................................................................................4-1

4.1.2 RECOVERY METHODS...................................................................4-1

4.1.3 IMPORTANT SP CODES.................................................................4-2

4.1.4 DOWNLOAD ERROR CODES.........................................................4-3

4.2 CONTROLLER BOARD SELF-DIAGNOSTIC TEST.................................4-5

4.3 JAM DETECTION......................................................................................4-6

4.3.1 SENSOR LOCATIONS.....................................................................4-6

4.3.2 TIMING CHARTS.............................................................................4-7

Feed, Transport, Feed Out: Face-up ....................................................4-7

Transport, Inverter, Feed Out: Face-down............................................4-8

Duplex Transport..................................................................................4-9

4.4 SERVICE CALL CONDITIONS...............................................................4-10

4.4.1 SUMMARY.....................................................................................4-10

4.4.2 SC CODE DESCRIPTIONS ...........................................................4-11

Scanning System................................................................................4-11

Image Development System (1) .........................................................4-14

Image Development System (2) .........................................................4-19

Feed, Transport, Duplexing, and Fusing Systems..............................4-20

Data Communication..........................................................................4-23

Peripherals.......................................................................................... 4-25

Overall System ...................................................................................4-28

Miscellaneous.....................................................................................4-31

4.4.3 ADDITIONAL SC CODES PRINTED IN SMC REPORT ................4-33

4.5 BLOWN FUSE CONDITIONS.................................................................4-35

4.6 COMMON PROBLEMS...........................................................................4-35

5. SERVICE TABLES...................................................................... 5-1

5.1 SERVICE PROGRAM MODE....................................................................5-1

5.1.1 SERVICE PROGRAM MODE OPERATION.....................................5-1

To Enter and Exit the SP Mode ............................................................5-1

To Switch to the Copy Window for Test Printing...................................5-1

Using the SP Mode...............................................................................5-2

SP Mode Button Summary...................................................................5-3

5.2 RESETS....................................................................................................5-4

5.2.1 MEMORY ALL CLEAR: SP5801 ......................................................5-4

5.2.2 SOFTWARE RESET........................................................................5-5

5.3 TEST PATTERN PRINTING......................................................................5-6

5.3.1 IPU FRONT/BACK TEST PATTERNS: SP2902 001,002.................5-6

vi

Page 11

Test Pattern Table................................................................................5-7

5.3.2 PRINTING TEST PATTERN: SP2902 003.......................................5-8

5.3.3 IPU PRINTING TEST PATTERN: SP2902 004................................5-9

5.4 SOFTWARE UPDATE.............................................................................5-10

5.4.1 OVERVIEW....................................................................................5-10

5.4.2 SOFTWARE UPDATE PROCEDURE............................................5-11

GW Controller/BCU Update................................................................5-11

Forced Update....................................................................................5-12

Stamp Data Update............................................................................5-12

Operation Panel Software Update......................................................5-13

Printer Update.....................................................................................5-13

Scanner Update..................................................................................5-14

NIB Update.........................................................................................5-14

NetFile Firmware Update....................................................................5-14

NVRAM Firmware Update..................................................................5-15

5.5 USER TOOLS.........................................................................................5-16

5.5.1 OVERVIEW....................................................................................5-16

5.5.2 SYSTEM SETTINGS......................................................................5-17

5.5.3 COPIER/DOCUMENT SERVER FEATURES ................................5-18

5.5.4 PRINTER........................................................................................ 5-20

5.5.5 SCANNER......................................................................................5-21

5.5.6 INQUIRY.........................................................................................5-21

5.5.7 COUNTER......................................................................................5-21

5.6 SERVICE PROGRAM MODE TABLES...................................................5-22

5.6.1 COPIER SERVICE TABLE.............................................................5-22

SP1-xxx Feed.....................................................................................5-22

SP2-xxx Drum.....................................................................................5-26

SP3xxx Processing.............................................................................5-40

SP4-xxx Scanner................................................................................5-42

SP5-xxx Mode ....................................................................................5-52

SP6-xxx Peripherals...........................................................................5-68

SP7-xxx Data Logs.............................................................................5-71

5.6.2 PRINTER SERVICE TABLE...........................................................5-78

5.6.3 SCANNER SERVICE TABLE.........................................................5-79

5.7 INPUT/OUTPUT CHECK ........................................................................5-86

5.7.1 INPUT CHECK: SP5803.................................................................5-86

5.7.2 OUTPUT CHECK: SP5804.............................................................5-91

5.7.3 ADF INPUT CHECK: SP6007 ........................................................5-92

5.7.4 ADF OUTPUT CHECK: SP6008 ....................................................5-93

6. DETAILED DESCRIPTIONS....................................................... 6-1

6.1 OVERVIEW...............................................................................................6-1

6.1.1 PAPER PATH (WITH COVER INTERPOSER TRAY)......................6-3

6.1.2 PAPER PATH (WITH 9-BIN MAILBOX) ...........................................6-4

6.1.3 DRIVE LAYOUT...............................................................................6-5

6.2 BOARD STRUCTURE...............................................................................6-6

6.2.1 BLOCK DIAGRAM............................................................................6-6

6.2.2 COMPONENT DESCRIPTIONS ......................................................6-7

BCU (Base Engine Control Unit)...........................................................6-7

vii

Page 12

Controller Board....................................................................................6-7

MB (Mother Board)...............................................................................6-7

IPU (Image Processing Unit)................................................................6-7

SBU (Sensor Board Unit)......................................................................6-8

PFC (Paper Feed Control)....................................................................6-8

SDRB (Scanner Driver Board)..............................................................6-8

VIB (Video Interface Board)..................................................................6-8

DRB (Drive Board)................................................................................6-8

CNB (Connection Board)......................................................................6-8

HDD (Hard Disk Drive)..........................................................................6-9

6.3 COPY PROCESS OVERVIEW ...............................................................6-10

6.4 ADF.........................................................................................................6-12

6.4.1 OVERVIEW....................................................................................6-12

6.4.2 ADF DRIVE LAYOUT..................................................................... 6-13

6.4.3 PICK-UP ROLLER LIFT .................................................................6-14

6.4.4 BOTTOM PLATE LIFT....................................................................6-15

6.4.5 ORIGINAL SEPARATION..............................................................6-16

6.4.6 ORIGINAL TRANSPORT............................................................... 6-17

6.4.7 ORIGINAL SKEW CORRECTION.................................................. 6-18

6.4.8 ORIGINAL SIZE DETECTION........................................................6-20

6.4.9 ADF SCANNING.............................................................................6-23

6.4.10 JAM DETECTION.........................................................................6-24

6.5 SCANNING..............................................................................................6-25

6.5.1 OVERVIEW....................................................................................6-25

6.5.2 SCANNER DRIVE..........................................................................6-26

6.5.3 ORIGINAL SIZE DETECTION........................................................6-27

Sensors...............................................................................................6-27

Detection Timing.................................................................................6-28

6.5.4 SCANNING MAGNIFICATION.......................................................6-29

Book Mode..........................................................................................6-29

6.5.5 AUTO IMAGE DENSITY (ADS)......................................................6-30

Xenon Lamp ! CCD ADS..................................................................6-30

CIS ADS .............................................................................................6-30

6.6 IMAGE PROCESSING............................................................................6-31

6.6.1 OVERVIEW....................................................................................6-31

6.6.2 IMAGE PROCESSING FLOW........................................................6-32

6.6.3 IMAGE PROCESSING MODES.....................................................6-33

6.6.4 IMAGE QUALITY SP ADJUSTMENTS...........................................6-34

6.6.5 RELATION BETWEEN THE SP AND UP SETTINGS ....................6-40

6.6.6 IMAGE PROCESSING TROUBLESHOOTING ..............................6-42

6.7 LASER EXPOSURE................................................................................6-45

6.7.1 OVERVIEW....................................................................................6-45

OPTICAL PATH..................................................................................6-46

6.7.3 FOUR-BEAM EXPOSURE.............................................................6-47

6.7.4 COOLING FAN...............................................................................6-48

6.7.5 LD SAFETY SWITCHES................................................................6-49

6.8 DRUM UNIT ............................................................................................6-50

6.8.1 OVERVIEW....................................................................................6-50

6.8.2 OPC DRUM....................................................................................6-51

viii

Page 13

6.8.3 DRUM DRIVE.................................................................................6-51

6.8.4 DRUM CHARGE.............................................................................6-51

6.8.5 CHARGE CORONA WIRE CLEANING..........................................6-52

6.8.6 DRUM PICK-OFF MECHANISM.................................................... 6-53

6.8.7 DRUM CLEANING..........................................................................6-54

6.8.8 DRUM VENTILATION AND OZONE FILTER.................................6-55

6.8.9 TONER RECYCLING.....................................................................6-56

6.8.10 WASTE TONER COLLECTION ...................................................6-57

Mechanism .........................................................................................6-57

Error Detection....................................................................................6-57

6.8.11 PROCESS CONTROL..................................................................6-58

What Happens at Power On...............................................................6-58

Drum Potential Sensor Calibration......................................................6-59

Development Bias, Bias Grid, and LD Adjustment..............................6-60

ID Sensor Calibration (Vsg)................................................................6-62

TD Sensor Calibration (Vref)...............................................................6-62

6.9 DEVELOPMENT AND TONER SUPPLY................................................6-63

6.9.1 OVERVIEW....................................................................................6-63

Development Unit...............................................................................6-63

Toner Supply ......................................................................................6-64

6.9.2 DEVELOPMENT UNIT...................................................................6-65

6.9.3 DEVELOPER/TONER MIXING (AGITATION)................................6-66

6.9.4 DEVELOPMENT BIAS...................................................................6-67

6.9.5 TONER SUPPLY............................................................................6-68

6.9.6 DEVELOPMENT UNIT DRIVE AND VENTILATION......................6-69

6.9.7 TONER END SENSOR ..................................................................6-70

6.9.8 SHUTTER MECHANISM................................................................6-70

6.9.9 TONER BOTTLE SUPPLY AND VENTILATION............................6-71

6.9.10 TONER SUPPLY CONTROL .......................................................6-72

Sensor Control Mode..........................................................................6-72

Pixel Count Toner Supply Mode.........................................................6-73

TD Sensor Initialization.......................................................................6-74

Determining Vref.................................................................................6-74

Toner Supply without ID Sensor and TD Sensors.............................. 6-75

Abnormal TD Sensor Output...............................................................6-75

Abnormal ID Sensor Output................................................................6-75

Toner End Detection...........................................................................6-76

Toner End Recovery...........................................................................6-76

6.10 IMAGE TRANSFER AND PAPER SEPARATION.................................6-77

6.10.1 OVERVIEW..................................................................................6-77

6.10.2 TRANSFER BELT LIFT................................................................6-78

Mechanism .........................................................................................6-78

Timing.................................................................................................6-79

6.10.3 TRANSFER BELT CHARGE........................................................6-80

6.10.4 TRANSFER CURRENT SETTINGS.............................................6-81

6.10.5 TRANSFER CURRENT CIRCUIT................................................6-82

6.10.6 TRANSFER BELT DRIVE AND PAPER TRANSPORT................6-83

6.10.7 TRANSFER BELT CLEANING.....................................................6-84

6.10.8 ANTI-CONDENSATION HEATER................................................6-85

ix

Page 14

6.11 PAPER FEED........................................................................................6-86

6.11.1 OVERVIEW..................................................................................6-86

Tray Capacities...................................................................................6-87

Built-in Feed Stations..........................................................................6-87

By-pass Feed......................................................................................6-87

Paper Registration..............................................................................6-87

Jam Removal......................................................................................6-87

6.11.2 DRIVE...........................................................................................6-88

6.11.3 TRAY AND PAPER LIFT MECHANISM – TRAY 2,3....................6-89

Bottom Plate Lift .................................................................................6-89

Lift Sensor...........................................................................................6-90

6.11.4 PAPER FEED AND SEPARATION MECHANISM........................6-91

Paper Feed and Separation: No Paper Present .................................6-91

Paper Feed and Separation................................................................6-92

Separation Roller Release Mechanism...............................................6-93

6.11.5 PAPER NEAR-END AND PAPER END – TRAYS 2 AND 3.........6-94

6.11.6 PAPER SIZE DETECTION...........................................................6-95

Tandem Tray (Tray 1).........................................................................6-95

Universal Paper Cassettes (Tray 2, 3)................................................6-95

6.11.7 ANTI-CONDENSATION HEATERS..............................................6-96

6.11.8 TANDEM TRAY – TRAY 1...........................................................6-97

Overview............................................................................................. 6-97

Connecting the Left and Right Sides of the Tray................................6-98

Paper Lift/Remaining Paper Detection................................................6-99

Fence Drive ......................................................................................6-101

Rear Fence Drive..............................................................................6-102

Tray Side-to-side Positioning............................................................6-103

6.11.9 TRAY POSITIONING MECHANISM – TRAYS 1 TO 3...............6-104

6.11.10 BY-PASS TRAY........................................................................6-105

By-pass Feed and Separation ..........................................................6-105

By-pass Tray Paper End Detection...................................................6-106

By-pass Paper Size Detection..........................................................6-107

6.11.11 PAPER REGISTRATION..........................................................6-108

Overview........................................................................................... 6-108

Paper Registration Drive...................................................................6-109

Jam Removal at Paper Registration.................................................6-110

6.12 IMAGE FUSING AND PAPER EXIT....................................................6-111

6.12.1 OVERVIEW................................................................................6-111

6.12.2 FUSING MECHANISM...............................................................6-112

6.12.3 PRESSURE ROLLER.................................................................6-113

6.12.4 HOT ROLLER CLEANING .........................................................6-114

Overview........................................................................................... 6-114

Web Drive.........................................................................................6-115

Web Near-end ..................................................................................6-115

Web End...........................................................................................6-115

6.12.5 FUSING UNIT ENTRANCE GUIDE............................................6-116

6.12.6 FUSING UNIT DRIVE.................................................................6-117

6.12.7 CPM DOWN MODE....................................................................6-118

6.12.8 FUSING TEMPERATURE CONTROL........................................6-118

x

Page 15

6.12.9 EXIT............................................................................................6-120

6.12.10 EXIT JUNCTION GATE............................................................6-121

6.13 DUPLEX UNIT.....................................................................................6-122

6.13.1 OVERVIEW................................................................................6-122

6.13.2 DUPLEX DRIVE.........................................................................6-123

6.13.3 INVERTER OPERATION...........................................................6-124

Inverter Feed-in and Jogging............................................................6-124

Inverter Feed-out..............................................................................6-125

6.13.4 DUPLEX TRAY FEED................................................................6-126

6.13.5 DUPLEX INTERLEAVE FEED ...................................................6-127

6.14 ENERGY SAVER MODES..................................................................6-129

6.14.1 OVERVIEW................................................................................6-129

6.14.1 ENERGY SAVER MODE............................................................6-130

Entering the energy saver mode.......................................................6-130

What happens in energy saver mode...............................................6-130

Return to stand-by mode..................................................................6-130

6.14.2 LOW POWER MODE.................................................................6-131

Entering the low power mode ...........................................................6-131

What happens in low power mode....................................................6-131

Return to stand-by mode..................................................................6-131

6.14.3 AUTO OFF MODE......................................................................6-132

Entering auto off mode......................................................................6-132

What happens in auto off mode........................................................6-132

Returning to stand-by mode..............................................................6-132

Disabling auto off mode....................................................................6-132

6.14.4 NIGHT MODE.............................................................................6-133

Entering night stand-by and night modes..........................................6-133

What happens in night stand-by and night modes............................6-133

Returning to stand-by mode..............................................................6-133

xi

Page 16

PERIPHERALS

A3/DLT FEEDER KIT (B475)

1. REPLACEMENT AND ADJUSTMENT..................................B475-1

1.1 BOTTOM PLATE LIFT WIRE REPLACEMENT................................. B475-1

1.1.1 REMOVING THE LIFT WIRE.................................................... B475-1

1.1.2 INSTALLING THE LIFT WIRE................................................... B475-2

2. DETAILS...............................................................................B475-3

LCT (B473)

1. REPLACEMENT AND ADJUSTMENT..................................B473-1

1.1 EXTERNAL COVERS ........................................................................ B473-1

1.2 PICK-UP/FEED/SEPARATION ROLLERS......................................... B473-2

1.3 PICK-UP SOLENOID......................................................................... B473-3

1.4 PAPER END SENSOR, UPPER COVER SWITCHES....................... B473-4

1.5 TRAY MOTOR.................................................................................... B473-5

1.6 PAPER STACK SENSOR.................................................................. B473-5

1.7 PAPER SIZE ADJUSTMENT............................................................. B473-6

2. DETAILS...............................................................................B473-7

2.1 OVERVIEW........................................................................................ B473-7

2.1.1 LCT MAIN COMPONENTS....................................................... B473-7

2.1.2 LCT DRIVE LAYOUT................................................................. B473-9

2.2 PAPER FEED AND SEPARATION.................................................. B473-10

2.2.1 STARTING PAPER FEED....................................................... B473-10

2.2.2 FEED AND SEPARATION...................................................... B473-11

2.3 PAPER LIFT..................................................................................... B473-12

2.4 PAPER HEIGHT DETECTION......................................................... B473-14

2.5 PAPER END DETECTION............................................................... B473-15

3000-SHEET FINISHERS (B468/B469)

1. REPLACEMENT AND ADJUSTMENT..................................B468-1

1.1 EXTERNAL COVERS ........................................................................ B468-1

1.2 POSITIONING ROLLER..................................................................... B468-2

1.3 INNER COVER...................................................................................B468-2

1.4 BRUSH ROLLER................................................................................ B468-3

1.5 LOWER TRAY PAPER HEIGHT SENSORS 1, 2............................... B468-4

1.6 PROOF TRAY EXIT AND FULL SENSORS ...................................... B468-5

1.7 EXIT SENSOR ................................................................................... B468-6

1.8 FINISHER, STAPLER ENTRANCE SENSORS................................. B468-7

1.9 SADDLE-STITCH STAPLER REPLACEMENT.................................. B468-8

xii

Page 17

1.10 PUNCH POSITION ADJUSTMENT................................................ B468-10

1.11 JAM DETECTION........................................................................... B468-11

1.12 DIP SW 100 (MAIN BOARD).......................................................... B468-12

2. DETAILS.............................................................................B468-13

2.1 OVERVIEW...................................................................................... B468-13

2.2 DRIVE LAYOUT............................................................................... B468-14

2.3 TRAY/STAPLER JUNCTION GATES.............................................. B468-16

2.4 PRE-STACKING............................................................................... B468-17

2.5 VERTICAL LIFT MECHANISM......................................................... B468-18

2.5.1 OVERVIEW............................................................................. B468-18

2.5.2 UPPER TRAY.......................................................................... B468-19

Just After the Power is Switched on ............................................ B468-19

Height Adjustment During Feed-Out............................................ B468-19

Upper Tray Full............................................................................ B468-19

2.5.3 LOWER TRAY......................................................................... B468-20

Just After the Power is Switched on ............................................ B468-20

Positioning the Lower Tray for Feed-out...................................... B468-20

Lower Tray Height Adjustment During Feed-out .......................... B468-20

Lower Tray Full............................................................................ B468-21

2.6 SHIFT MECHANISM........................................................................ B468-22

2.7 PAPER POSITIONING..................................................................... B468-23

2.8 STAPLER......................................................................................... B468-24

2.8.1 STAPLING MECHANISM........................................................ B468-24

2.8.2 STAPLER MOVEMENT........................................................... B468-25

Horizontal Stapler Movement.......................................................B468-25

Rotational Stapler Movement....................................................... B468-26

2.8.3 FEED OUT .............................................................................. B468-27

2.9 BOOKLET FINISHING ..................................................................... B468-28

2.9.1 OVERVIEW............................................................................. B468-28

2.9.2 BOOKLET STAPLING AND FOLDING....................................B468-28

2.9.3 INITIAL FOLDING....................................................................B468-29

2.9.4 FINAL FOLDING AND FEED-OUT.......................................... B468-30

PUNCH UNIT (B377)

1. REPLACEMENT AND ADJUSTMENT..................................B377-1

1.1 PUNCH POSITION ADJUSTMENT.................................................... B377-1

2. DETAILS...............................................................................B377-2

2.1.1 PUNCH DRIVE MECHANISM................................................... B377-2

2.1.2 PUNCH WASTE COLLECTION................................................ B377-4

COVER INTERPOSER TRAY (B470)

1. REPLACEMENT AND ADJUSTMENT..................................B470-1

1.1 EXTERNAL COVERS ........................................................................ B470-1

xiii

Page 18

1.2 FEED UNIT AND PICK-UP ROLLER................................................. B470-2

1.3 FEED BELT........................................................................................ B470-3

1.4 GUIDE PLATE ADJUSTMENT........................................................... B470-4

1.5 MAIN BOARD..................................................................................... B470-5

1.6 MOTOR REPLACEMENT.................................................................. B470-6

1.6.1 VERTICAL TRANSPORT MOTOR............................................ B470-6

1.6.2 BOTTOM PLATE LIFT MOTOR ................................................ B470-6

1.6.3 FEED MOTOR, TRANSPORT MOTOR .................................... B470-7

2. DETAILS...............................................................................B470-8

2.1 OVERVIEW........................................................................................ B470-8

2.1.1 MAIN LAYOUT.......................................................................... B470-8

2.1.2 DRIVE LAYOUT........................................................................ B470-9

2.1.3 PAPER SIZE DETECTION...................................................... B470-10

2.1.4 PAPER PATH.......................................................................... B470-13

2.2 PAPER FEED................................................................................... B470-14

Power On..................................................................................... B470-14

Paper Separation and Feed......................................................... B470-14

Bottom Tray Lift ........................................................................... B470-14

Paper Near-end........................................................................... B470-14

Paper End.................................................................................... B470-14

9-BIN MAILBOX (B471)

1. REPLACEMENT AND ADJUSTMENT..................................B471-1

1.1 COVERS AND TRAYS....................................................................... B471-1

1.2 SENSORS.......................................................................................... B471-2

1.3 MAIN MOTOR AND CONTROL BOARD ........................................... B471-3

2. DETAILS...............................................................................B471-4

2.1 OVERVIEW........................................................................................ B471-4

2.1.1 MAIN COMPONENT LAYOUT.................................................. B471-4

2.1.2 DRIVE LAYOUT........................................................................ B471-5

2.1.3 PAPER PATH............................................................................ B471-6

2.2 BASIC OPERATION........................................................................... B471-7

2.2.1 PAPER PATH............................................................................ B471-7

2.3 OVERFLOW DETECTION................................................................. B471-8

2.3.1 OVERVIEW............................................................................... B471-8

2.3.2 DETECTION TIMING................................................................ B471-9

2.4 PAPER MISFEED DETECTION TIMING......................................... B471-10

2.4.1 A4 SIDEWAYS (LEF) ! 1ST BIN TRAY................................. B471-10

2.4.2 A4 SIDEWAYS (LEF) ! 2ND ~ 9TH BIN TRAY..................... B471-10

PRINTER/SCANNER KIT (G338), PRINTER UNIT (G339)

1. DETAILS...............................................................................G338-1

1.1 MACHINE LAYOUT............................................................................G338-1

xiv

Page 19

1.2 CONTROLLER BOARD.....................................................................G338-2

1.2.1 CONTROLLER BOARD LAYOUT.............................................G338-2

1.2.2 CONTROLLER BOARD DIP SWITCHES..................................G338-4

1.2.3 LED INDICATORS.....................................................................G338-4

1.3 ETHERNET BOARD ..........................................................................G338-5

1.3.1 ETHERNET BOARD LAYOUT ..................................................G338-5

1.3.2 ETHERNET BOARD OPERATION............................................G338-6

1.4 IEEE1394 BOARD (FIREWIRE).........................................................G338-7

1.4.1 OVERVIEW...............................................................................G338-7

1.5 USB....................................................................................................G338-9

1.5.1 SPECIFICATIONS.....................................................................G338-9

1.5.2 USB 1.1/2.0...............................................................................G338-9

1.5.3 USB CONNECTORS...............................................................G338-10

1.5.4 PIN ASSIGNMENT..................................................................G338-10

1.5.5 REMARKS ABOUT USB.........................................................G338-11

Related SP Mode.........................................................................G338-11

1.6 IEEE802.11B (WIRELESS LAN)......................................................G338-12

1.6.1 SPECIFICATIONS...................................................................G338-12

1.6.2 BLOCK DIAGRAM...................................................................G338-13

1.6.3 TRANSMISSION MODES.......................................................G338-14

Ad Hoc Mode...............................................................................G338-14

Infrastructure Mode......................................................................G338-14

1.6.4 SECURITY FEATURES..........................................................G338-15

Using the SSID in Ad hoc mode ..................................................G338-15

1.6.5 WIRELESS LAN TROUBLESHOOTING NOTES....................G338-16

Communication Status.................................................................G338-16

Channel Settings .........................................................................G338-16

Troubleshooting Procedure..........................................................G338-17

2. SPECIFICAT ION S...............................................................G338-18

2.1 SCANNER........................................................................................G338-18

2.2 PRINTER..........................................................................................G338-19

2.3 CONTROLLER BOARD CONFIGURATION....................................G338-20

2.4 SOFTWARE ACCESSORIES..........................................................G338-21

2.4.1 PRINTER.................................................................................G338-21

Printer Drivers..............................................................................G338-21

Printer Utility Software .................................................................G338-21

2.5 PAPER SIZES SUPPORTED BY THE PRINTER............................G338-22

2.6 USB SPECIFICATIONS.............................................................G338-23

2.7 IEEE 802.11B SPECIFICATIONS ..............................................G338-23

xv

Page 20

SPECIFICATIONS

SPECIFICATIONS.....................................................................SPEC-1

1. GENERAL SPECIFICATIONS.............................................................SPEC-1

1.1 COPIER .......................................................................................SPEC-1

1.2 ADF .............................................................................................SPEC-2

1.3 POWER CONSUMPTION...........................................................SPEC-3

2. MACHINE CONFIGURATION.............................................................SPEC-4

3. OPTIONAL EQUIPMENT....................................................................SPEC-5

3.1 A3/DLT KIT B475 ........................................................................SPEC-5

3.2 LCT (LARGE CAPACITY TRAY) B473........................................SPEC-5

3.3 3000-SHEET FINISHER WITH SADDLE-STITCH AND

50-SHEET STAPLER B468.........................................................SPEC-5

3.3.1 UPPER TRAY.....................................................................SPEC-5

3.3.2 LOWER TRAY....................................................................SPEC-6

3.3.3 PROOF TRAY.....................................................................SPEC-6

3.3.4 STAPLE SPECIFICATIONS...............................................SPEC-6

3.3.5 LOWER TRAY....................................................................SPEC-6

3.4 3000-SHEET FINISHER WITH 50-SHEET STAPLER B468.......SPEC-7

3.4.1 LOWER TRAY....................................................................SPEC-7

3.4.2 PROOF TRAY.....................................................................SPEC-7

3.4.3 STAPLE SPECIFICATIONS...............................................SPEC-7

3.4.4 LOWER TRAY....................................................................SPEC-7

3.5 PUNCH UNIT FOR B468/B469...................................................SPEC-8

3.6 COVER INTERPOSER TRAY B470............................................SPEC-8

3.7 9-BIN MAILBOX B471.................................................................SPEC-9

xvi

Page 21

26 April, 2002 INSTALLATION REQUIREMENTS

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS

1.1.1 OPERATING ENVIRONMENT

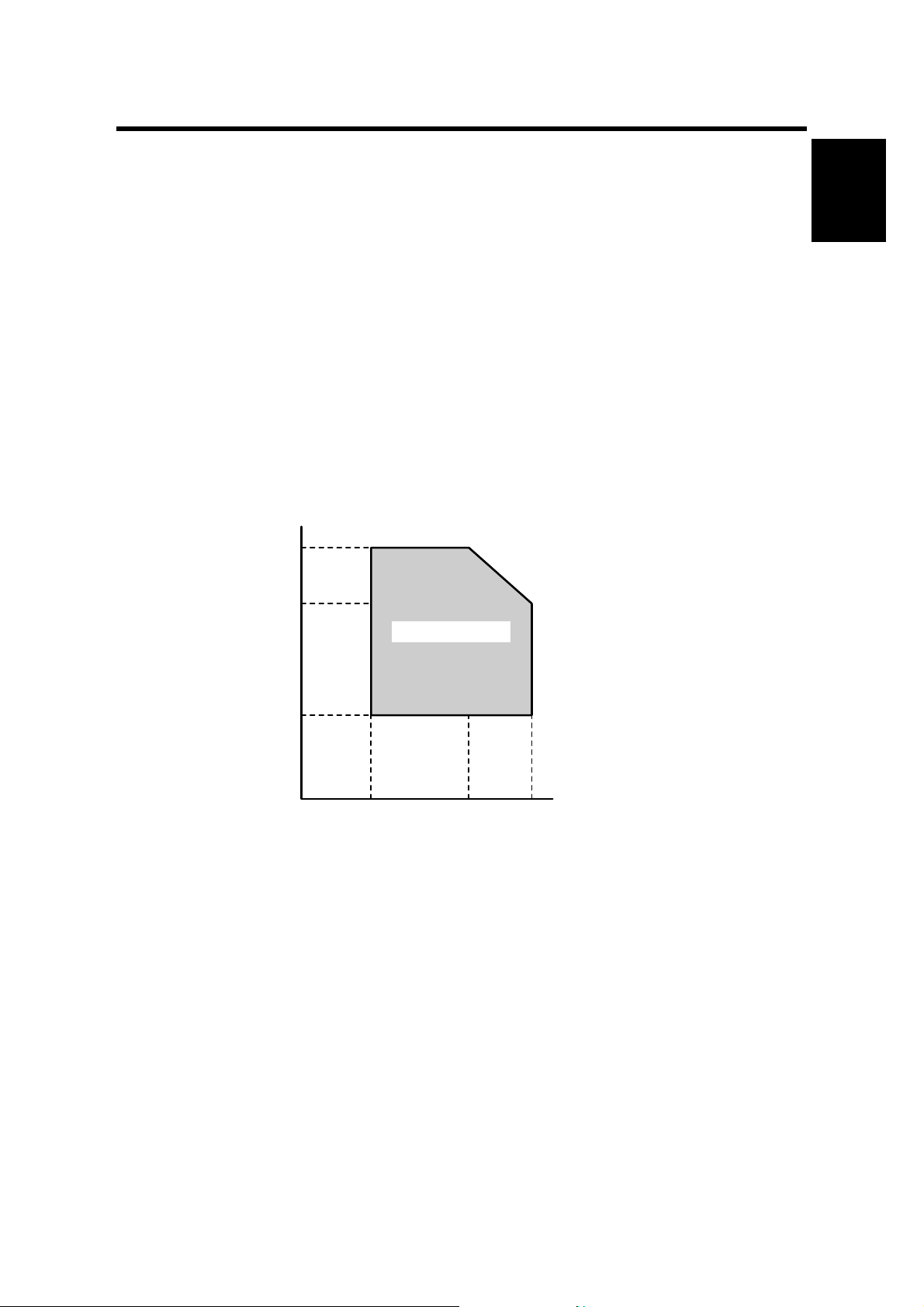

1. Temperature Range:

2. Humidity Range:

3. Ambient Illumination: Less than 1,500 lux (do not expose to direct sunlight or

4. Ventilation: Room air should turn over at least 3 times per hour

5. Ambient Dust: Less than 0.10 mg/m

Humidity

80%

54%

Recommended: 15°C to 25°C (59°F to 77°F)

Possible: 10°C to 32°C (50°F to 90°F)

15% to 80% RH (27°C 80%, 32°C 54%)

strong light.)

3

Operation range

Installation

15%

10°C

(50°F)

27°C

(80.6°F)

32°C

(89.6°F)

Temperature

B039I502.WMF

6. If the place of installation is air-conditioned or heated, do not place the machine

where it will be:

1) Subjected to sudden temperature changes

2) Directly exposed to cool air from an air-conditioner

3) Directly exposed to heat from a heater

1-1

Page 22

INSTALLATION REQUIREMENTS 26 April, 2002

7. Do not place the machine where it will be expos ed to corrosive gases.

8. Do not install the machine at any location over 2,000 m (6,500 feet) above sea

level.

9. Place the copier on a strong and level base with the front and back of the

machine within ±5 mm (0.2") of level.

10. Do not place the machine where it may be subjected to strong vibrations.

11. Do not connect the machine to a power source shared with another electrical

appliance.

12. The machine can generate a an electromagnetic field which could interfere with

radio or television reception.

1.1.2 MACHINE LEVEL

1. Front to back:

2. Right to left:

The machine legs may be screwed up or down in order to level the machine. Set a

carpenter’s level on the exposure glass.

Within ±5 mm (0.2") of level

Within ±5 mm (0.2") of level

1-2

Page 23

26 April, 2002 INSTALLATION REQUIREMENTS

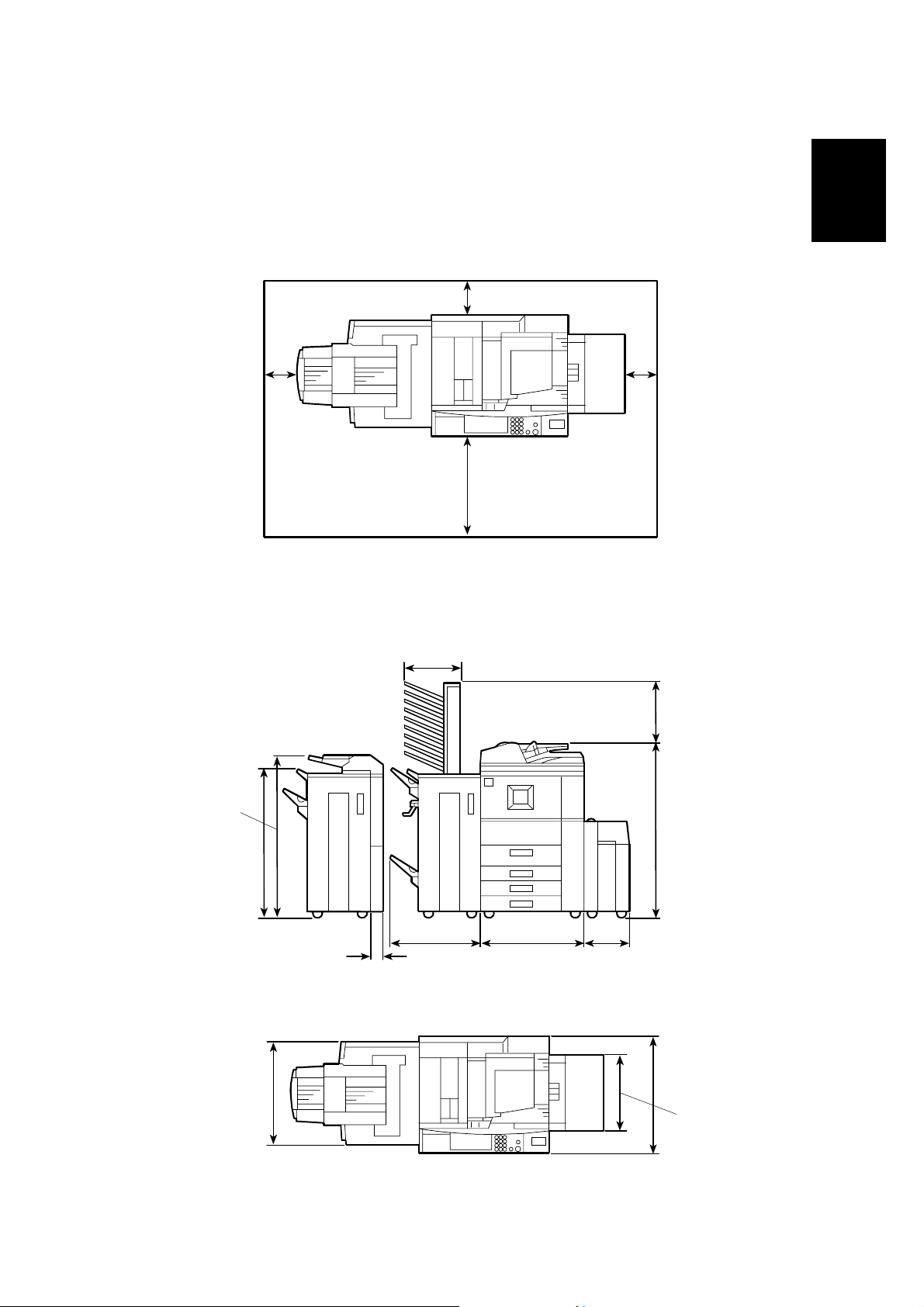

1.1.3 MINIMUM SPACE REQUIREMENTS

Place the copier near the power source, providing minimum clearance as shown

below. The same amount of clearance is necessary when optional peripheral

devices are installed.

50 mm (2") Back

Installation

100 mm (4") Left

1.1.4 DIMENSIONS

1,198 mm (43.2")

700 mm (27.6") Front

480 mm (18.9")

40 mm (1.6") Right

B064I001.WMF

425 mm (16.7")

1,165 mm (45.9")

1,014 mm (39.9")

620 mm (24.4")

90 mm (3.5")

690 mm (27.2")734 mm (28.9")

314 mm (12.4")

B064I003.WMF

750 mm (29.5")

458 mm (18")

B064I002.WMF

1-3

Page 24

INSTALLATION REQUIREMENTS 26 April, 2002

1.1.5 POWER REQUIREMENTS

!

CAUTION

1. Make sure that the wall outlet is near the main machine and easily

accessible. Make sure the plug is firmly inserted in the outlet.

2. Avoid multi-wiring.

3. Be sure to ground the machine.

4. Never set anything on the power cord.

North America 120 V, 60 Hz: More th an 12 AInput voltage level

Europe/Asia 220 V ~ 240 V, 50 Hz/60 Hz: more than 8 A

Permissible voltage fluctuation

!

CAUTION

Never turn off the main power switch when the power LED is lit or flashing.

To avoid damaging the hard disk or memory, press the operation power

switch to switch the power off, wait for the power LED to go off, and then

switch the main power switch off.

±10%

The Main Power LED (!) lights or flashes at the following times:

• While the platen cover or ADF is open

• While the main machine is communicating with the network server

• While the machine is accessing the hard disk or memory when reading or

writing data.

There are two power switches on the machine:

• Main Power Switch.

Located on the front left corner of the mac hine a nd cov er ed by a plastic cover.

This switch should always remain on unless the machine is being serviced.

• Operation Power Switch.

Located on the right side of the operation panel. This is the switch normally used

by the customer to power the machine on and off.

1-4

Page 25

26 April, 2002 MAIN MACHINE (B064/B065)

1.2 MAIN MACHINE (B064/B065)

1.2.1 ACCESSORY CHECK

Check the quantity and condition of the accessories in the box against the following

list:

Description Q’ty

1. Model Name Decal................................................................ 1

2. Operation Instructions............................................................ 2

3. NECR with Envelope............................................................. 1

4. Operation Panel Brand Decal................................................ 1

5. Paper Size Decal................................................................... 1

6. Decal – Face Up.................................................................... 1

7. Leveling Shoes...................................................................... 2

8. Operation Instruction Holder.................................................. 1

9. Decal – Cleaning ................................................................... 1

Installation

1-5

Page 26

MAIN MACHINE (B064/B065) 26 April, 2002

1.2.2 INSTALLATION PROCEDURE

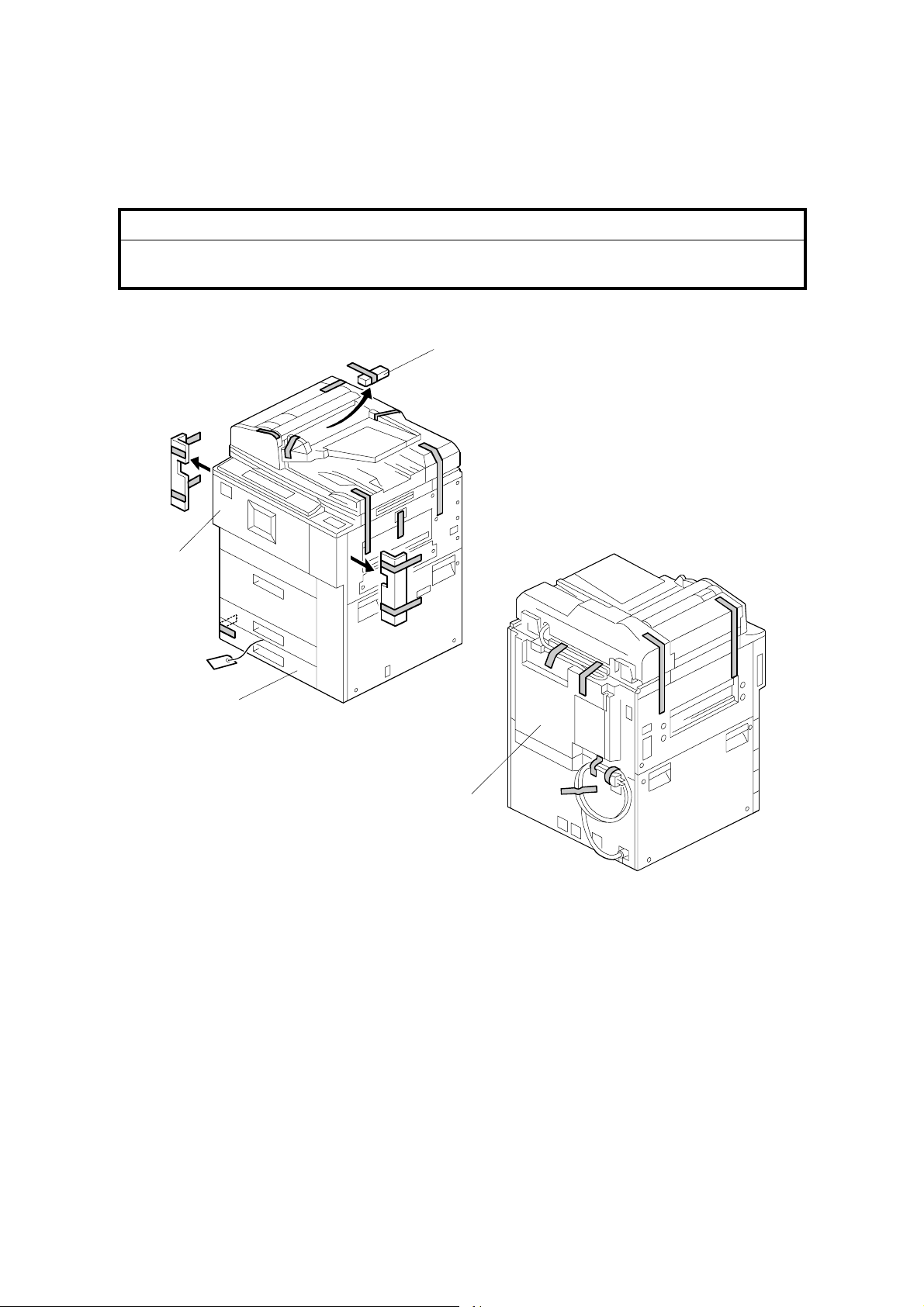

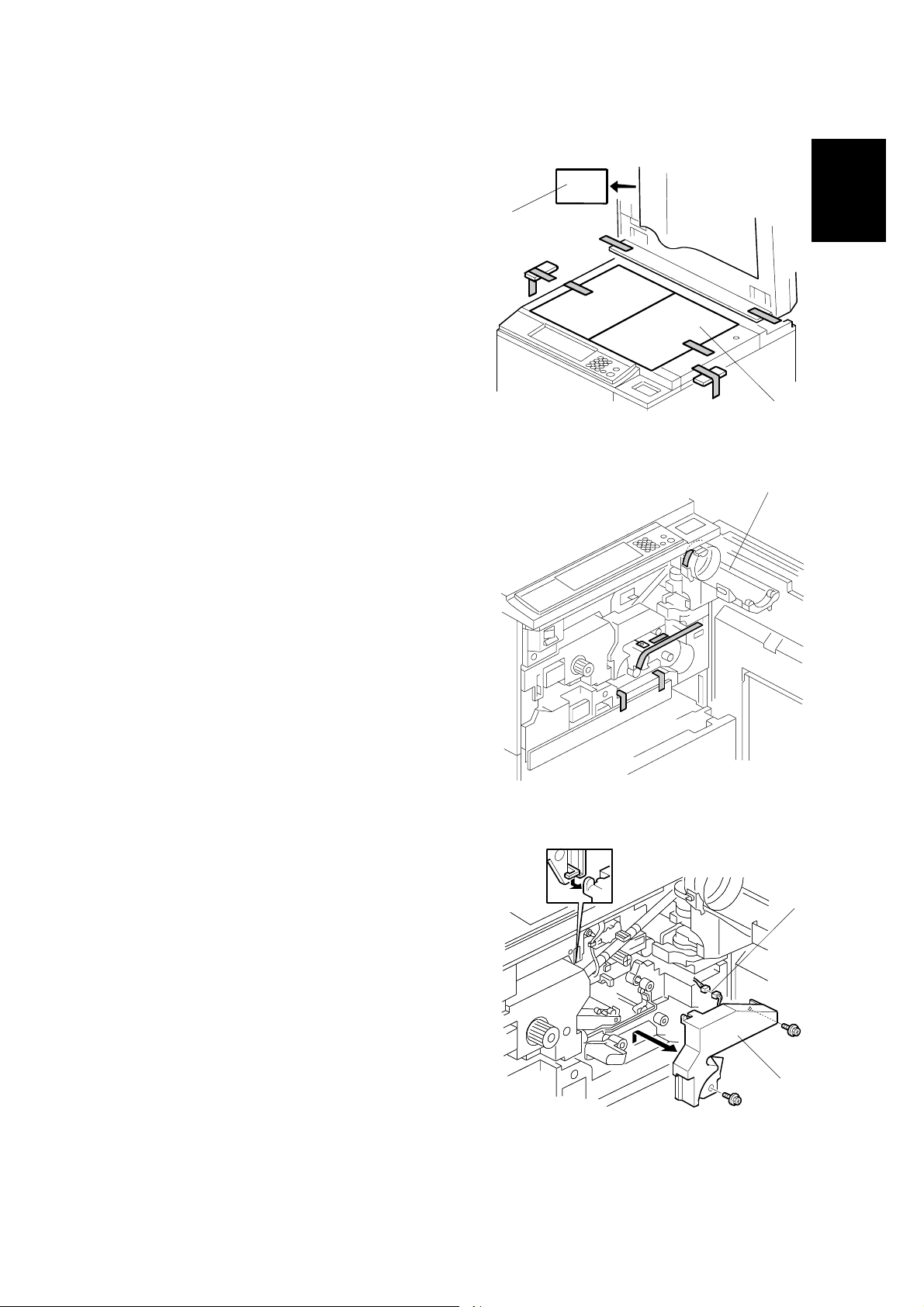

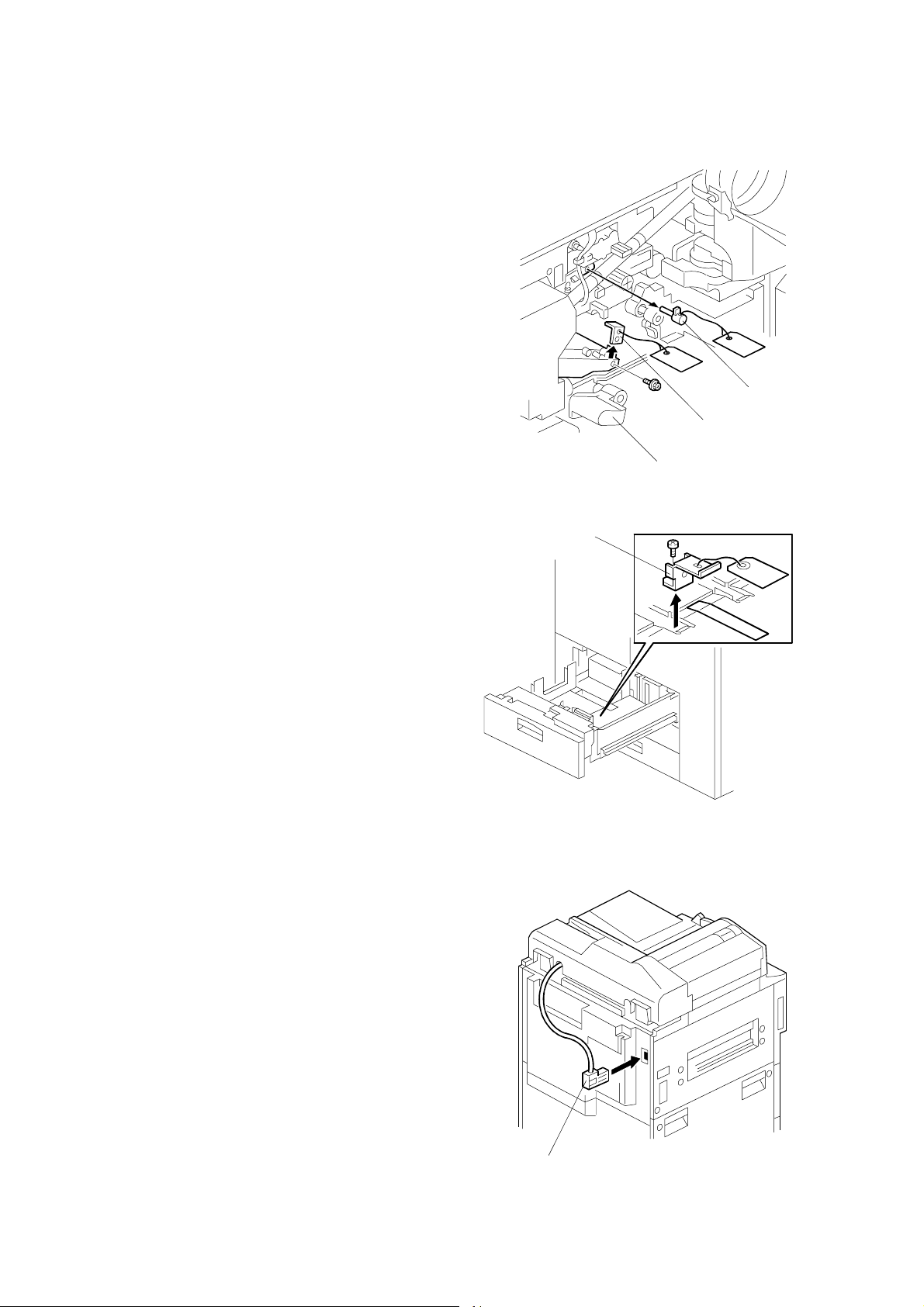

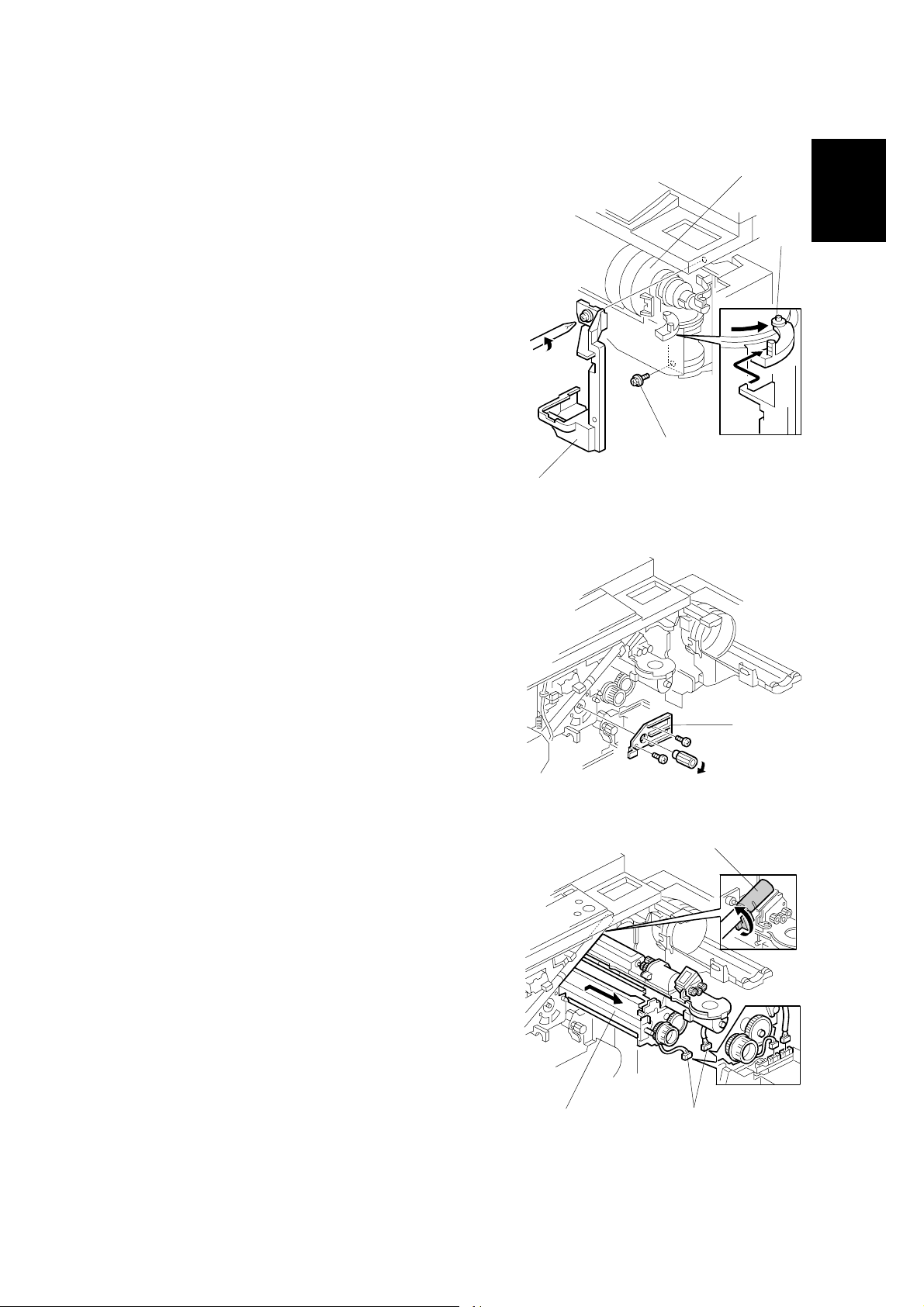

Removing Tapes and Retainers

!

CAUTION

To avoid serious injury, do not connect the power plug to the machine until

you are instructed to do so.

[C]

[A]

[B]

B064I403.WMF

[D]

1. Unpack the machine and remove all the wrapping.

2. Remove all filament tape from the front [A] of the machine.

B064I404.WMF

3. Open the lower tray [B] and remove the operating instructions holder and foot

risers.

4. Open the ADF feed cover and remove the tape and retainer [C].

5. Remove the tape from the back [D] of the machine.

NOTE: Save the filament tape and shipping retainers to prepare the machine

for shipping in the future.

1-6

Page 27

26 April, 2002 MAIN MACHINE (B064/B065)

6. Raise the ADF and remove all the