Page 1

Model A-C2

PRINTER/SCANNER CONTROLLERS

(Machine Code: B361, B362)

SERVICE MANUAL

January 19th, 2001

Subject to change

Page 2

Trademarks

Microsoft®, Windows®, and MS-DOS® are registered trademarks of Microsoft

Corporation in the United States and /or other countries.

PostScript® is a registered trademark of Adobe Systems, Incorporated.

PCL® is a registered trademark of Hewlett-Packard Company.

Ethernet® is a registered trademark of Xerox Corporation.

Other product names used herein are for identification purposes only and may be

trademarks of their respective companies. We disclaim any and all rights involved

with those marks.

Page 3

TABLE OF CONTENTS

1 INSTALLATION ........................................................................... 1-1

1.1 INSTALLATION REQUIREMENTS...........................................................1-1

1.2 PRINTER INSTALLATION........................................................................1-1

1.3 POSTSCRIPT UNIT (G577)......................................................................1-7

1.4 MEMORY (G578/G579) ............................................................................1-8

1.5 NIB (G574)................................................................................................1-9

1.6 IEEE1394 INTERFACE (G590)...............................................................1-10

1.7 CHECKING THE CONNECTIONS..........................................................1-11

2 TROUBLESHOOTING ................................................................. 2-1

2.1 CONTROLLER ERRORS..........................................................................2-1

2.2 LEDS AND TEST POINTS........................................................................2-1

3 SERVICE TABLES....................................................................... 3-1

3.1 SERVICE PROGRAM MODE....................................................................3-1

3.1.1 ENABLING AND DISABLING SERVICE PROGRAM MODE...........3-1

3.2 PRINTER SERVICE MODE......................................................................3-2

3.2.1 SERVICE MODE TABLE..................................................................3-2

3.2.2 SP MODES RELATED TO PRINTER CONTROLLER.....................3-2

3.3 SCANNER SERVICE MODE.....................................................................3-3

3.3.1 SCANNER PROGRAM MODE TABLE.............................................3-3

3.4 FIRMWARE UPDATE PROCEDURE......................................................3-11

3.5 POWER-ON SELF TEST........................................................................3-11

3.6 SELF DIAGNOSTIC TEST......................................................................3-11

3.7 USER PROGRAM MODE.......................................................................3-12

3.7.1 PRINTER USER PROGRAM MODE..............................................3-12

3.7.2 SCANNER USER PROGRAM MODE............................................3-13

4 DETAILED SECTION DESCRIPTIONS ....................................... 4-1

4.1 OVERVIEW...............................................................................................4-1

4.2 CONTROLLER FUNCTIONS....................................................................4-2

4.2.1 SAMPLE PRINT...............................................................................4-2

4.2.2 LOCKED PRINT...............................................................................4-2

4.2.3 PAPER SOURCE SELECTION........................................................4-3

4.2.4 AUTO CONTINUE............................................................................4-4

4.2.5 PAPER OUTPUT TRAY...................................................................4-5

4.2.6 DUPLEX PRINTING......................................................................... 4-5

4.2.7 STAPLING ........................................................................................4-6

4.2.8 PUNCHING ......................................................................................4-6

4.3 SCANNER FUNCTIONS...........................................................................4-7

4.3.1 IMAGE PROCESSING FOR SCANNER MODE ..............................4-7

4.4 NIB ............................................................................................................4-8

4.4.1 BLOCK DIAGRAM............................................................................4-8

4.4.2 LED INDICATORS............................................................................4-8

4.5 IEEE1394 INTERFACE.............................................................................4-9

i

Page 4

4.5.1 SPECIFICATIONS............................................................................4-9

4.5.2 IEEE1394 .........................................................................................4-9

4.5.3 BLOCK DIAGRAM..........................................................................4-10

4.5.4 PIN ASSIGNMENT.........................................................................4-10

4.5.5 REMARKS ABOUT THIS INTERFACE KIT....................................4-11

4.5.6 TROUBLESHOOTING NOTES......................................................4-11

SPECIFICATIONS.....................................................................SPEC-1

1 GENERAL SPECIFICATIONS..............................................................SPEC-1

1.1 PRINTER.....................................................................................SPEC-1

1.2 SCANNER...................................................................................SPEC-3

2 SOFTWARE ACCESSORIES..............................................................SPEC-4

2.1 PRINTER.....................................................................................SPEC-4

2.2 SCANNER...................................................................................SPEC-5

3 MEACHINE CONFIGURATION............................................................SPEC-6

3.1 SYSTEM COMPONENTS...........................................................SPEC-6

ii

Page 5

19 January, 2001 INSTALLATION REQUIREMENTS

1. INSTALLATION

1.1 INSTALLATION REQUIREMENTS

Please refer to section 1 of the main unit service manual.

1.2 PRINTER INSTALLATION

Accessory Check

Check the accessories in the box against the following list:

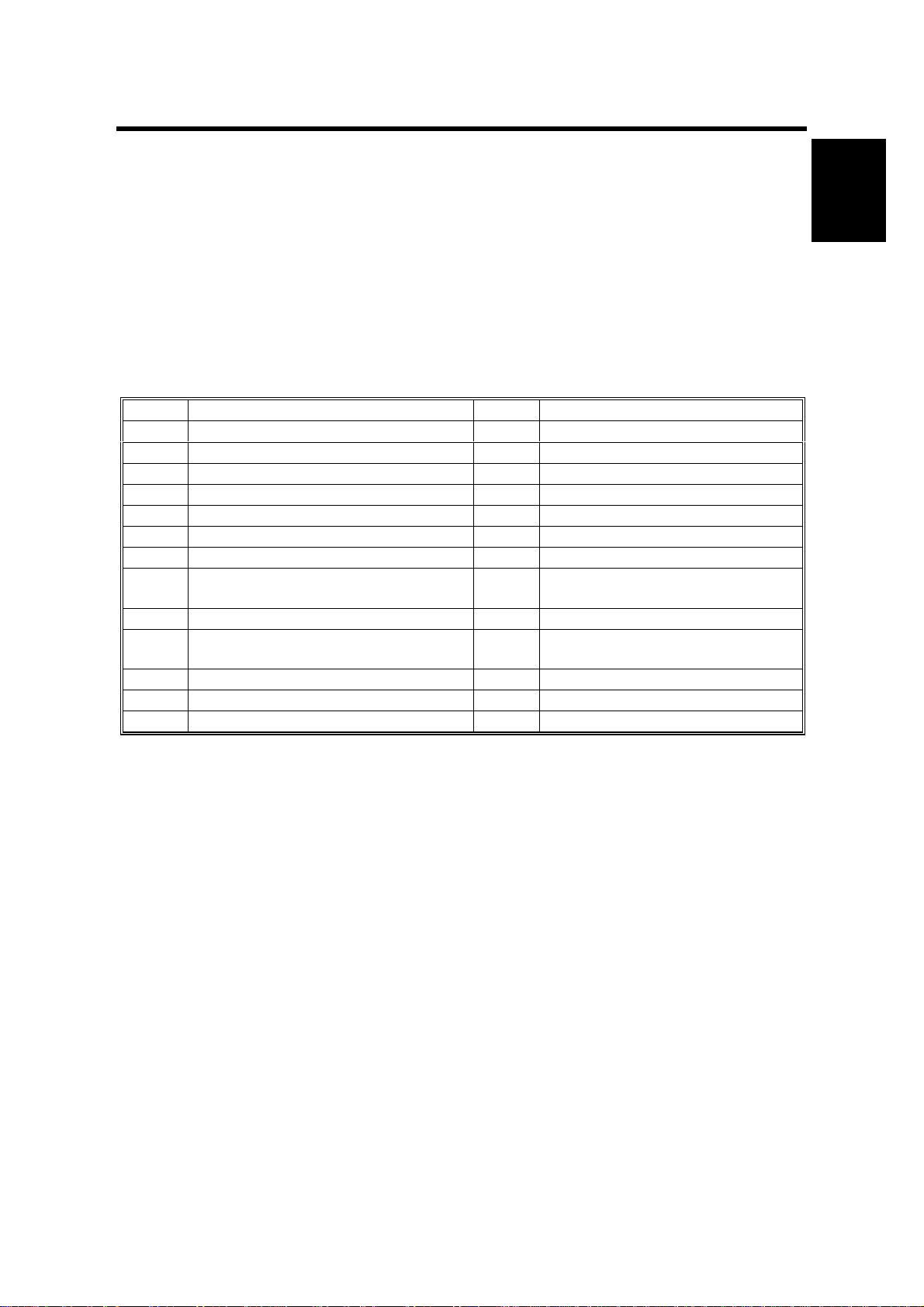

No. Description Q’ty Note

1Cable 1

2 Paper Height Sensors 4

3 Edge Clamp 1

4 Cable Clamp 4

5 Paper Height Sensor Fe eler 2

6 Paper Sensor 1

7 Key Top - Printer 1

8 Key Top - Scanner 1 Included only in the B 362 (printer

and scanner) model

9 Paper Limit Sensor Unit 1

10 Tapping Screw - M3x8 2 To secure the paper limit sensor

unit

11 Pan Head Screw - M3x8 1 To secure the paper sensor

12 Installation Procedure 1

13 FCC Label 1 Included only in t he USA models.

Installation

1-1

Page 6

PRINTER INSTALLATION 19 January, 2001

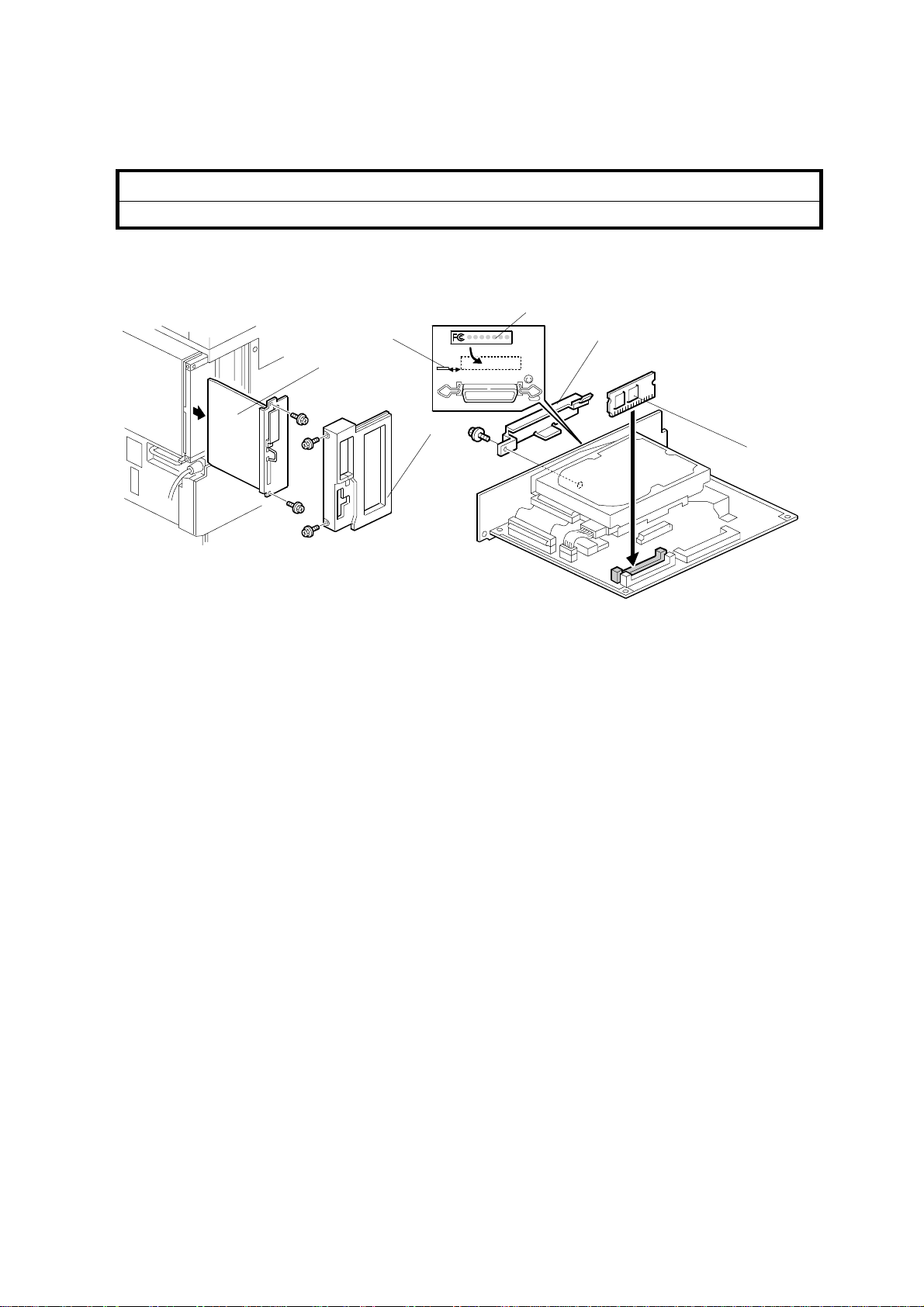

Printer Controller Installation

!

CAUTION

Unplug the main machine power cord before starting the following procedure.

[E]

[F]

[D]

[B]

[A]

[C]

B361I101.WMF

B361I107.WMF

1. Remove the left rear cover [A] (2 screws) and slide out the controller board [B]

(2 screws).

2. Install the printer ROM DIMM [C] on the controller board.

3. Remove the parallel interface cover [D].

4. This step is required only in the USA models.

Attach the FCC label [E] on the controller panel board aligned with the slot [F]

so the label is hidden when the left rear cover is replaced.

NOTE: If the NIB (G574), Postscript kit (G577), memory board (G578/G579), or

IEEE1394 Interface (G590) are to be installed, remove the HDD and install

them before proceeding to the next step.

5. Put back the controller board and replace the left rear cover.

1-2

Page 7

19 January, 2001 PRINTER INSTALLATION

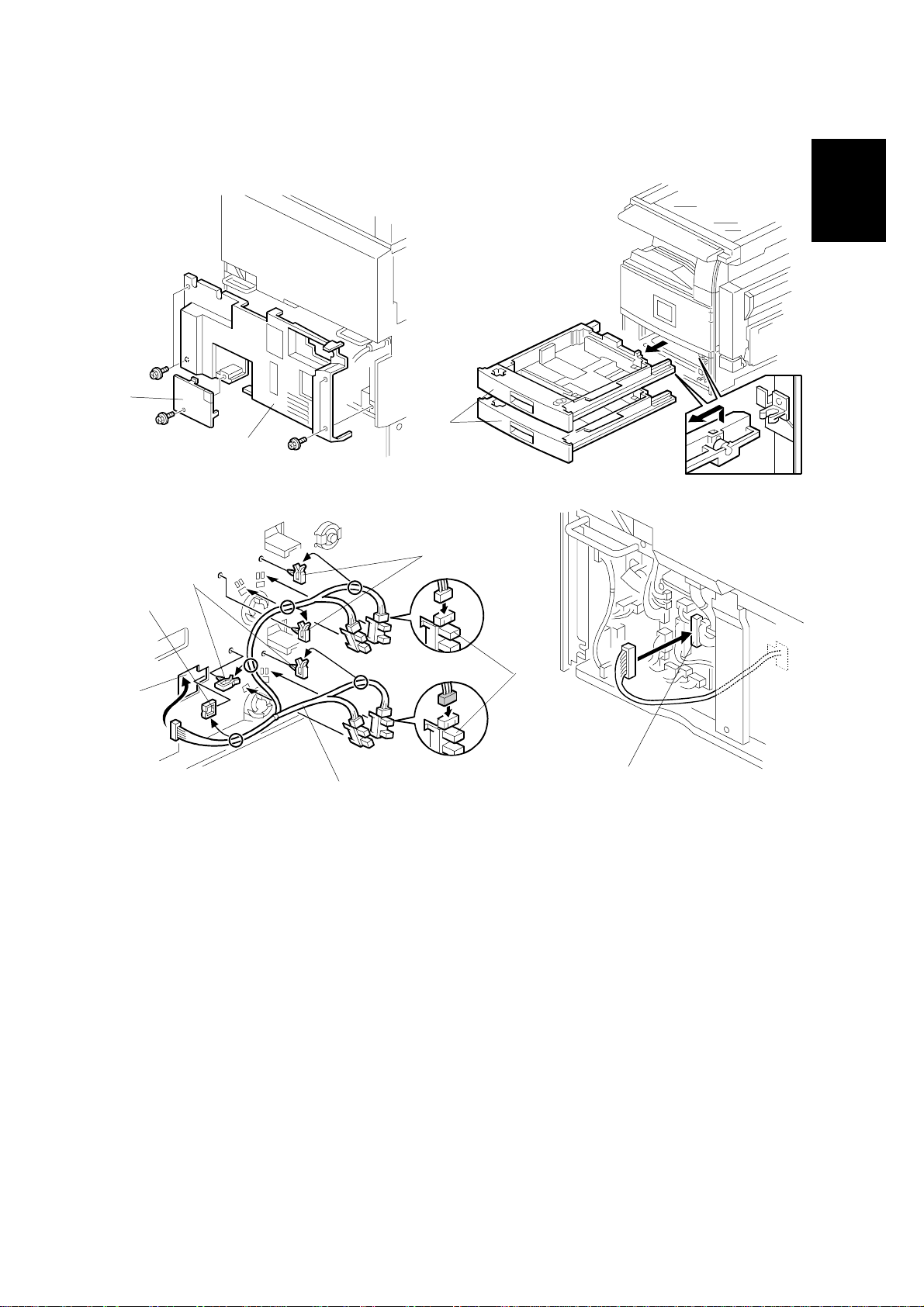

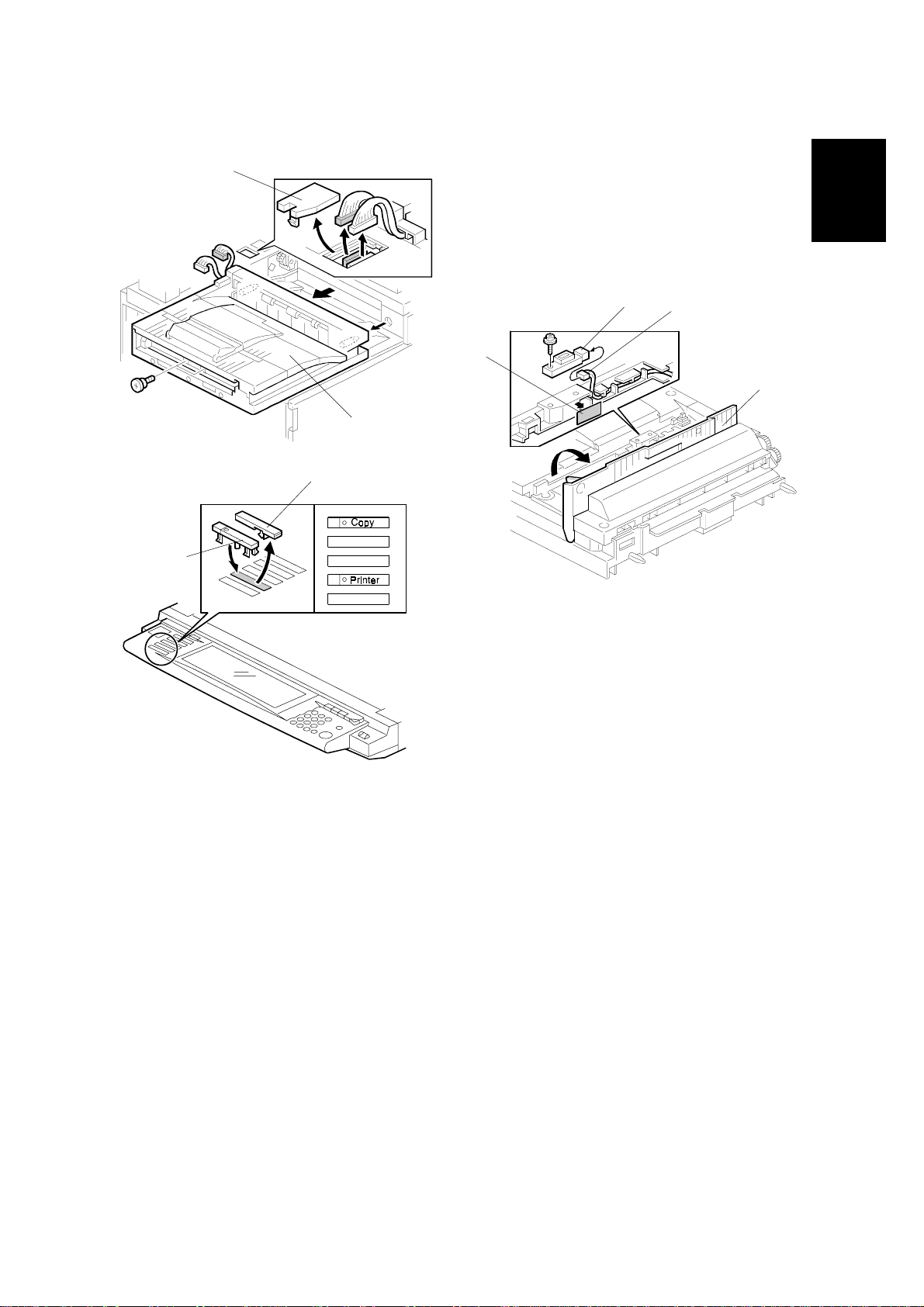

Paper Height Sensor Installation

[A]

[C]

[B]

B361I112.WMF

B361I113.WMF

Installation

[G]

[G]

[D]

[E]

[H]

[I]

[F]

B361I108.WMF

6. Remove the connector cover [A] and lower rear cover [B] (5 screws).

7. Pull out the two paper trays [C].

8. Install edge clamp [D] in the opening.

9. Connect the four paper height sensors [E] to the cable [F].

10. Install the four paper height sensors [E] as shown.

B361I109.WMF

11. Install the four cable clamps [G], then clamp the cable as shown.

12. Lead the cable through the opening [H]. Secure the cable in place with the

edge clamp attached in step 8.

13. Connect the cable to CN234 on the PCB [I].

1-3

Page 8

PRINTER INSTALLATION 19 January, 2001

[B]

[D]

[E]

[A]

B361I114.WMF

[F]

[C]

B361I115.WMF

[G]

B361I116.WMF

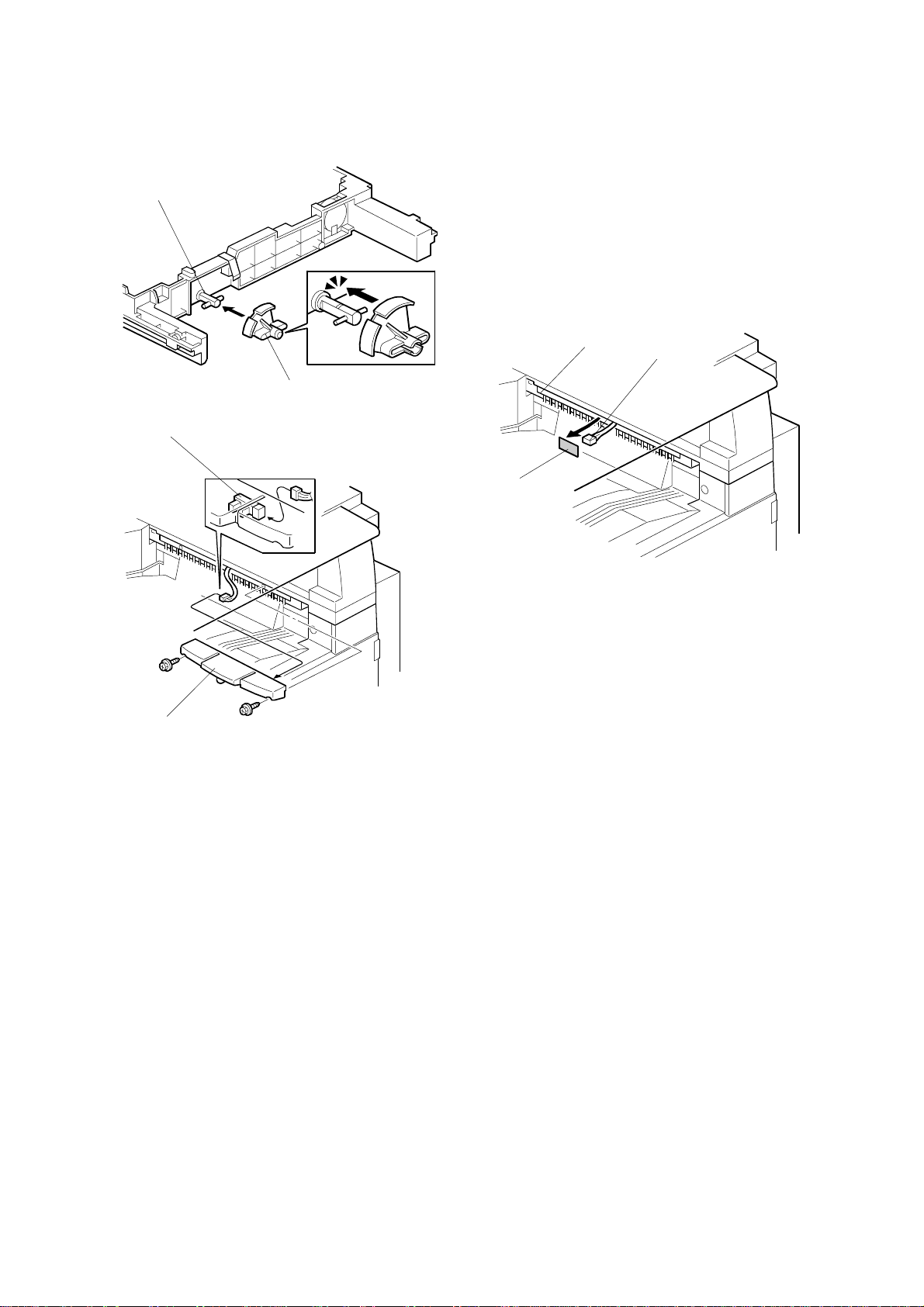

14. Install the paper height sensor feeler [A] on the bottom plate shaft [B] of each

paper tray.

15. Reassemble the machine.

Paper Limit Sensor Installation

If the optional bridge unit has been installed, skip steps 16 and 17.

16. Peel off the black tape [C] from the anti-static brush [D], then pull out the cable

[E].

17. Connect the cable to the sensor [F], then install the paper limit sensor unit [G]

(2 screws).

1-4

Page 9

19 January, 2001 PRINTER INSTALLATION

Paper Sensor Installation

[A]

[F]

[E]

[D]

[C]

[B]

Installation

B358I518.WMF

[G]

[H]

B358I517.WMF

B361I110.WMF

Perform steps 18 to 20 only if the optional bridge unit has been installed.

If it has not been installed, go on to step 21.

18. Remove the connector cover [A] and bridge unit [B] (2 screws, 2 connectors).

19. Open the right cover [C] of the bridge unit and peel off the black tape [D], then

pull out the connector [E].

20. Install the paper sensor [F] (1 screw, 1 connector) and reinstall the bridge unit.

Completion

21. Remove the bottom cap [G] of the operation panel. Install the Printer key [H]

on the operation panel as shown.

1-5

Page 10

PRINTER INSTALLATION 19 January, 2001

22. Do not connect the parallel cable at this point. Turn the machine on and check

the setting of the following copier SP mode:

• SP5-907: Plug & Play Name - select the correct one.

23. Print out the configuration page to check if the printer controller is installed

properly.

(Configuration page : User Tools/ Printer Settings/ List Test Print/ Config. Page)

24. If the parallel cable is going to be connected, first turn off the machine. After

connecting the cable, turn the machine back on.

1-6

Page 11

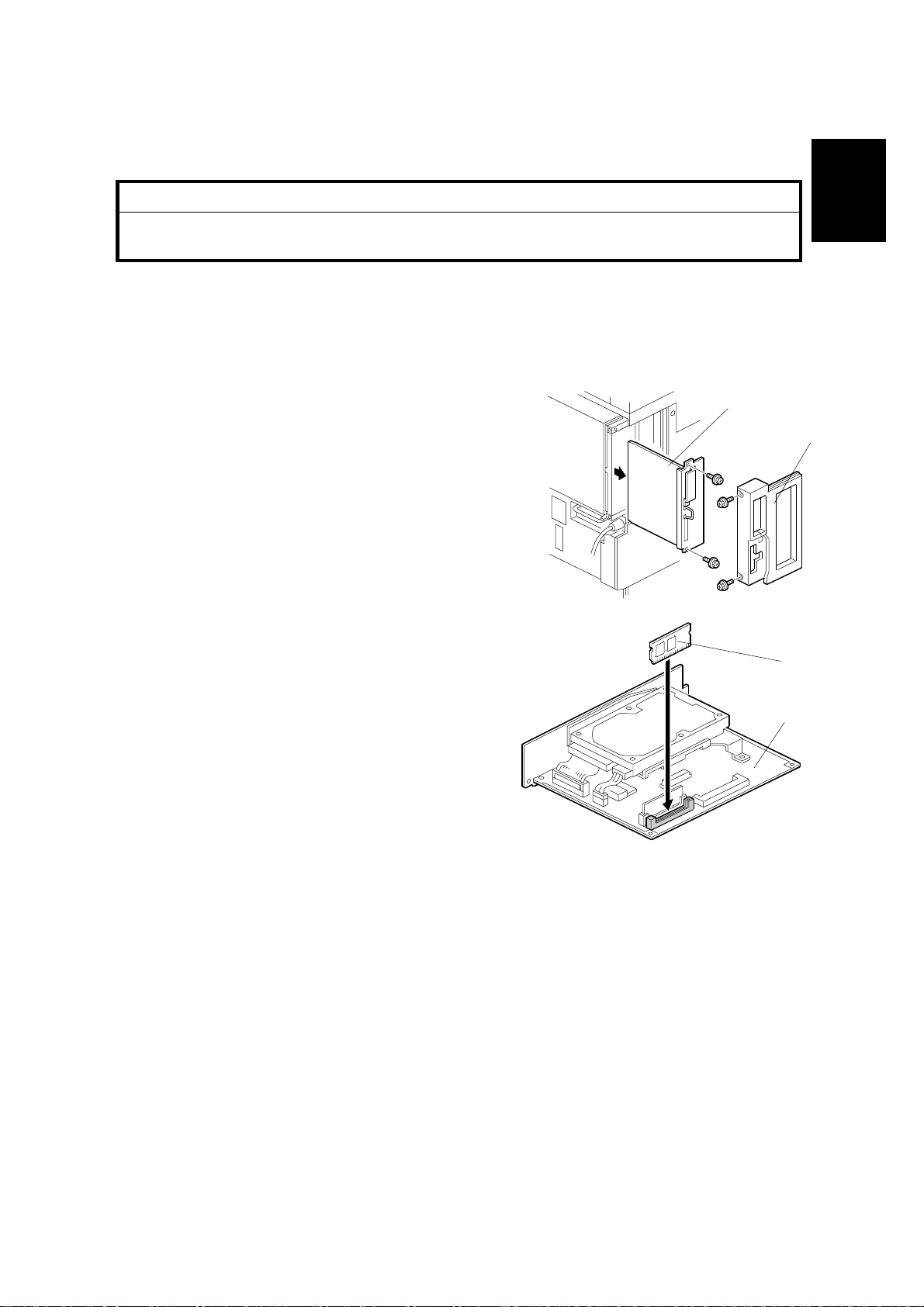

19 January, 2001 POSTSCRIPT UNIT (G577)

1.3 POSTSCRIPT UNIT (G577)

!

CAUTION

Unplug the main machine power cord before starting the following

procedure.

NOTE: To install the Postscript option, the printer option (B361) must be installed

first. Please refer to section 1.2 for detail s of the pri nter optio n inst all ati on

procedure.

1. Remove the left rear cover [A] (2 screws).

[B]

Installation

2. Remove the controller board [B] (2 screws).

3. Install the Postscript DIMM [C] onto the

controller board [D].

4. Put back the controller board and replace

the left rear cover.

[A]

B361I101.WMF

[C]

[D]

B361I104.WMF

1-7

Page 12

MEMORY (G578/G579) 19 January, 2001

1.4 MEMORY (G578/G579)

!

CAUTION

Unplug the main machine power cord before starting the following

procedure.

NOTE: To install the memory option, the printer option (B361) must be installed

first. Please refer to section 1.2 for detail s of the pri nter optio n inst all ati on

procedure.

1. Remove the left rear cover [A] (2 screws).

[A]

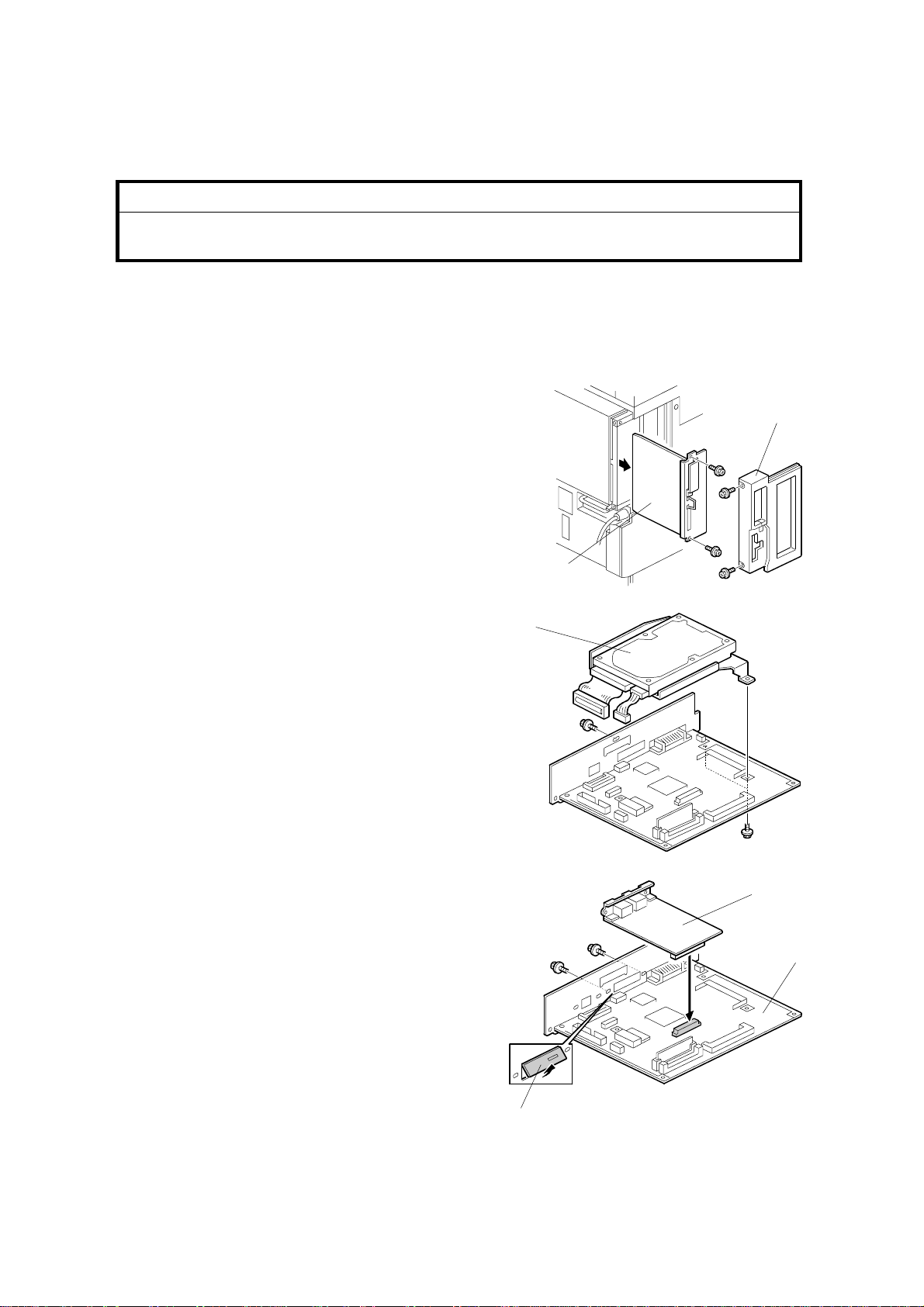

2. Remove the controller board [B] (2 screws).

3. Remove the HDD [C] (2 connectors,

3 screws).

4. Install the memory DIMM [D] onto the

controller board [E].

5. Re-install the HDD and put back the

controller board.

[B]

B361I101.WMF

[C]

B361I102.WMF

[D]

[E]

6. Replace the left rear cover.

B361I117.WMF

1-8

Page 13

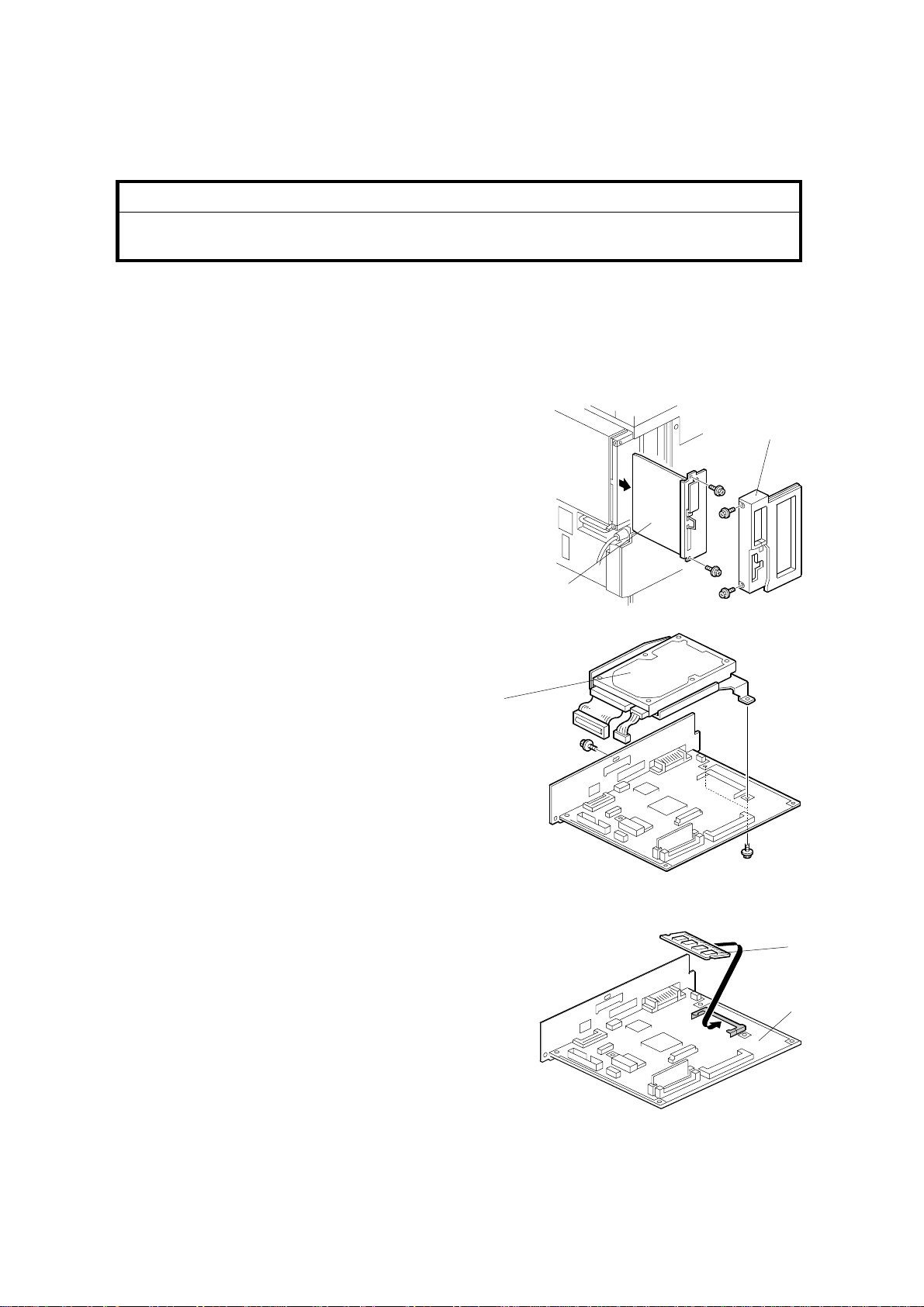

19 January, 2001 NIB (G574)

1.5 NIB (G574)

!

CAUTION

Unplug the main machine power cord before starting the following

procedure.

NOTE: To install the NIB option, the printer option (B361) must be installed first.

Please refer to section 1.2 for details of the printer option installation

procedure.

1. Remove the left rear cover [A] (2 screws).

[A]

2. Remove the controller board [B] (2 screws).

Installation

3. Remove the HDD [C] (2 connectors,

3 screws).

4. Remove the NIB slot cover [D].

5. Attach the NIB [E] to the controller board

[F] (2 screws).

[C]

[B]

[E]

B361I101.WMF

B361I102.WMF

[F]

6. Re-install the HDD and put back the

controller board.

7. Replace the left rear cover.

1-9

[D]

B361I105.WMF

Page 14

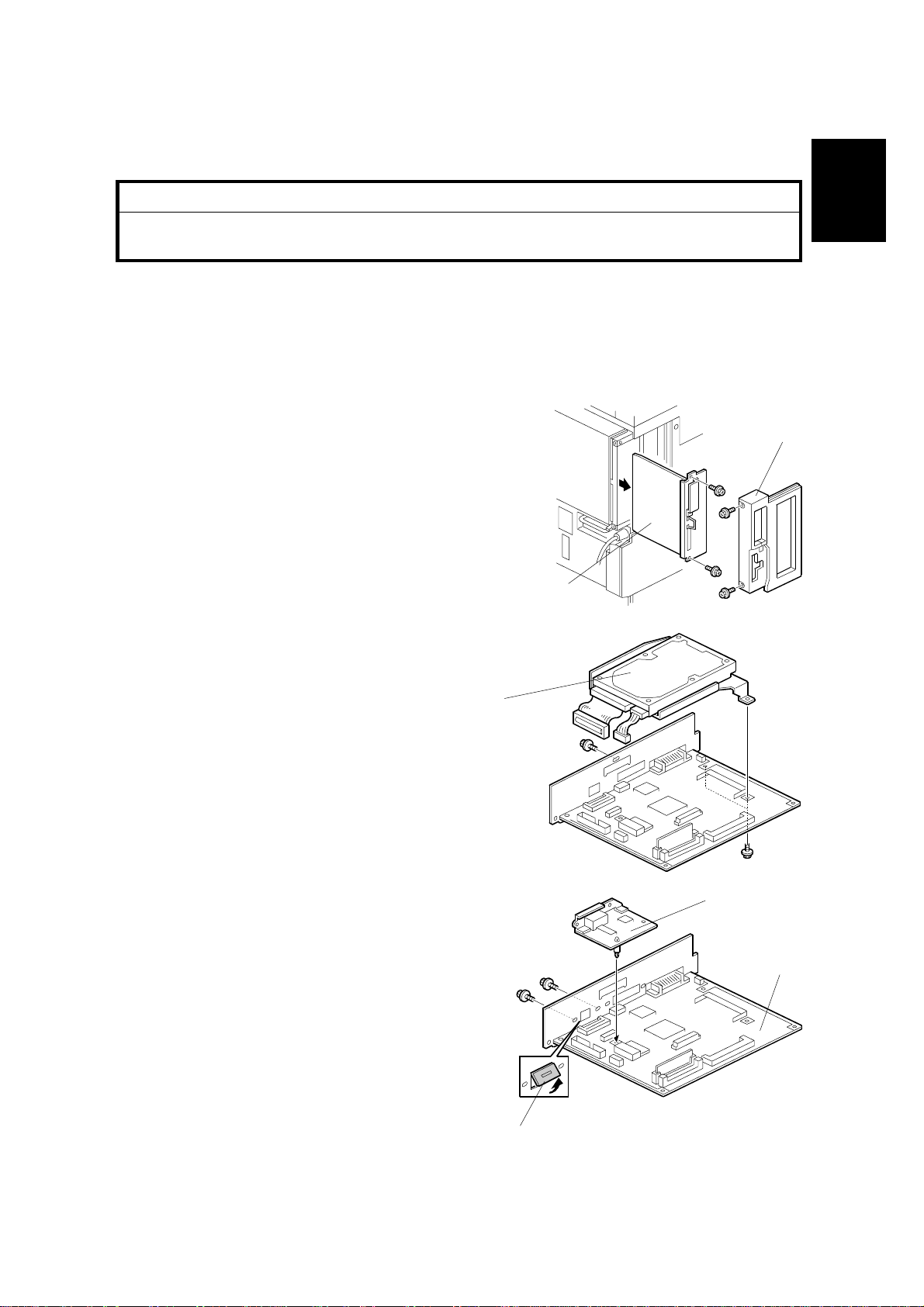

IEEE1394 INTERFACE (G590) 19 January, 2001

1.6 IEEE1394 INTERFACE (G590)

!

CAUTION

Unplug the main machine power cord before starting the following

procedure.

NOTE: To install the IEEE1394 option, the printer option (B361) must be installed

first. Please refer to section 1.2 for detail s of the pri nter optio n inst all ati on

procedure.

1. Remove the left rear cover [A] (2 screws).

[A]

2. Remove the controller board [B] (2 screws).

3. Remove the HDD [C] (2 connectors,

3 screws).

4. Remove the IEEE1394 cover [D].

5. Attach the IEEE1394 board [E] to the

controller board [F] (2 screws).

[B]

B361I101.WMF

[C]

B361I102.WMF

[E]

[F]

6. Re-install the HDD and put back the

controller board.

7. Remove the wire handle on the

controller panel board and place it on

the back side of the left rear cover.

8. Replace the left rear cover.

1-10

[D]

B361I106.WMF

Page 15

19 January, 2001 CHECKING THE CONNECTIONS

1.7 CHECKING THE CONNECTIONS

1. Plug in the power cord and turn on the main switch.

2. Enter the printer user mode and print the configuration page.

(User Tools/ Printer Settings/ List Test Print/ Config. Page)

The same data can also be printed using the printer service mode.

(“Print Summary”: SP1-004)

All installed options are listed in the “System Reference” column.

Installation

1-11

Page 16

19 January, 2001 CONTROLLER ERRORS

2. TROUBLESHOOTING

2.1 CONTROLLER ERRORS

Refer to section 4.1 of the main unit service manual for descriptions on SC code

information because the GW architecture includes controller SC codes in the main

unit SC code table.

2.2 LEDS AND TEST POINTS

LEDs and test points are not used for this option (except for the NIB ☛ section

4.4).

Trouble-

Shooting

2-1

Page 17

19 January, 2001 SERVICE PROGRAM MODE

3. SERVICE TABLES

3.1 SERVICE PROGRAM MODE

!

CAUTION

Before accessing the service menu, do the following:

Confirm that there is no print data in the printer buffe r (the Data In LED

must not be lit or blinking).

If there is some data in the buffer, wait until all data has been printed.

!

CAUTION

Never turn off the main power switch when the power LED is lit or flashing.

To avoid damaging the hard disk or memory, press the operation power

switch to switch the power off, wait for the power LED to go off, and then

switch the main power switch off.

NOTE: The main power LED ( ) lights or flashes while the platen cover or

ARDF is open, while the main unit is communicating with a facsimile or the

network server, or while the machine is accessing the hard disk or memory

for reading or writing data.

Tables

Service

3.1.1 ENABLING AND DISABLING SERVICE PROGRAM MODE

Entering the SP mode

"

#$%

&

Printer SP

Scanner SP

NOTE: If you switch the machine off, any jobs stored on the hard disk using the

sample print and protected print features will be deleted.

Check first if there are any jobs stored with these features

(Printer mode: View Sample Print Jobs/View Locked Print Job).

Exiting the Service Mode

Press “Exit” on the LCD panel to exit from the service mode.

1. Press the Clear Mode key.

2. Use the keypad to enter “107”.

3. Hold down Clear/Stop for at least 3 seconds.

4. Enter the Service Mode.

Press “Printer SP” to enter printer SP mode.

Press “Scanner SP” to enter scanner SP mode.

3-1

Page 18

PRINTER SERVICE MODE 19 January, 2000

3.2 PRINTER SERVICE MODE

3.2.1 SERVICE MODE TABLE

SP No. Description Function and Setting

1001 BitSw#1 Set Adjusts bit switch settings.

Note: Currently t he bit switches are not being used.

1003 Clear Setting Not used

1004 Print Summary

1005 Display Version Displays the version of the controller firmware.

3.2.2 SP MODES RELATED TO PRINTER CONTROLLER

The following SP modes are located in the copier SP mode. Refer to section 5.1 of

the main unit service manual.

Prints the service summary sheet

(An error log is printed in addition to the configuration

page).

SP No. Description Function and Setting

5104

5801

5907

7832

A3/DLT Double

Count

Memory All Clear

Plug & Play

Detailed Display of

Self-Diagnostics

Specifies whether the counter is doubled for A3/DLT.

0: No, 1: Yes

If # is selected, the total counter and t he current user

code counter count up twice when A3 or DLT paper is

used.

Resets data for process control an d all software counters,

and returns all modes and adjustments to their defaults

values.

☛ section 5.1.8 of the main unit manual for details.

Selects the brand name and the production name for

Windows Plug & Play. This information is stored in

NVRAM.

Displays the controller self-diagnostic result.

☛ section 3.6 of this manual f or det ails.

3-2

Page 19

19 January, 2001 SCANNER SERVICE MODE

3.3 SCANNER SERVICE MODE

3.3.1 SCANNER PROGRAM MODE TABLE

Service Table Key

Notation What it means

[range / default /

step]

italics Comments added for your reference.

*

DFU Denotes “Design or Factory Use”. Do not change this value.

SP1 Mode Number Function and [Setting]

1001

1002 Error Log Display Displays the error log data.

1003* FTP Port Number Changes the FTP port number.

1 Model Name Displays the model name.

2 Scanner Firmware

Version

3 Scanner Firmware

Number

4 Detail Model Na m e Displays the detail model name.

Example: [-9 ~ +9 / +3.0 / 0.1 mm step]. The set t ing can be

adjusted in the range ±9, value reset to +3.0 after an NVRAM

reset, and the value can be changed in 0.1 mm steps with each

key press.

This value is stored in NVRAM. After a RAM res et , t he defa ult

value (factory setting) is restored.

Displays the scanner fir mw are version.

Displays the firmware’s part number.

After changing this valu e, do the following:

Tables

Service

1. Run the Registry Editor

2. Access

/HKEY_LOCAL_MACHINE/SOFTWARE/

Ricoh/NetworkScanner

Change the value of ‘PortNo’ to this SP

3.

mode’s value

[0 – 65535 / 3670 / 1 step]

1004* Compression Type Selects the compression t ype for binary picture

processing.

[1: MH, 2: MR, 3: MMR]

1005* Erase Margin

1006* Auto Reset Timer Adjusts the auto reset timer for the scanner

Creates an erase margin for all edg es of the

scanned image.

If the machine has scanned the edge of the

original, create a margin.

[0 – 5 / 0mm / 1mm step]

function.

If this is “0”, the auto reset function is disabled.

[0, 10 – 99 / 60s / 1s step]

3-3

Page 20

SCANNER SERVICE MODE 19 January, 2000

SP2 Mode Number Function and [Setting]

2002

MTF Filter Coefficient

1*

(Text / Binary / Main scan)

2* MTF Filter Coefficient

(Text / Binary / Sub scan)

3* MTF Filter Strength

(Text / Binary / Main scan)

4* MTF Filter Strength

(Text / Binary / Sub scan)

5* Smoothing Filter

(Text / Binary)

6* Scanner Gamma

(Text / Binary)

7* Brightness – Notch 7

(Text / Binary)

8* Contrast – Notch 7

(Text / Binary)

9* Threshold Level – Notch 7

(Text / Binary)

10* Brightness – Notch 6

(Text / Binary)

11* Contrast – Notch 6

(Text / Binary)

12* Threshold Level – Notch 6

(Text / Binary)

13* Brightness – Notch 5

(Text / Binary)

Contrast – Notch 5

14*

(Text / Binary)

Threshold Level – Notch 5

15*

(Text / Binary)

Brightness – Notch 4

16*

(Text / Binary)

Contrast – Notch 4

17*

(Text / Binary)

Threshold Level – Notch 4

18*

(Text / Binary)

19* Brightness – Notch 3

(Text / Binary)

Selects the MTF filter coefficient in the main

scan direction for Text mode.

Select a higher number for a stronger filter.

If this is “0”, the MTF filter is not applied.

[0-15 / 7 / 1 step]

As above, for sub scan

[0-13 / 6 / 1 step]

Selects the MTF filter stren gt h in t he main scan

direction for Text mode.

Select a higher number for a stronger filter.

[0-7 / 5 / 1 step]

As above, for sub scan

[0-7 / 5 / 1 step]

Selects the smoothing pattern for Text mode

when using binary picture proce ssing mode.

A larger value could cause m oiré t o appear in

the image.

[0-7 / 0 / 1 step]

Selects the scanner gamma type for Text mode

when using binary picture proce ssing mode.

[0-6 / 4 / 1 step]

Adjusts the image densit y for each image

density level for Text mode when using binary

picture processing mode.

[0-255 / 128 / 1 step]

[0-255 / 128 / 1 step]

[0-255 / 160 / 1 step]

[0-255 / 128 / 1 step]

[0-255 / 128 / 1 step]

[0-255 / 145 / 1 step]

[0-255 / 128 / 1 step]

[0-255 / 128 / 1 step]

[0-255 / 135 / 1 step]

[0-255 / 128 / 1 step]

[0-255 / 128 / 1 step]

[0-255 / 128 / 1 step]

[0-255 / 128 / 1 step]

3-4

Page 21

19 January, 2001 SCANNER SERVICE MODE

SP2 Mode Number Function and [Setting]

2002

20* Contrast – Notch 3

(Text / Binary)

Adjusts the image densit y for each image

density level for Text mode when using binary

picture processing mode.

[0-255 / 128 / 1 step]

21* Threshold Level – Notch 3

(Text / Binary)

[0-255 / 100 / 1 step]

22* Brightness – Notch 2

(Text / Binary)

[0-255 / 128 / 1 step]

23* Contrast – Notch 2

(Text / Binary)

Threshold Level – Notch 2

24*

(Text / Binary)

Brightness – Notch 1

25*

(Text / Binary)

Contrast – Notch 1

26*

(Text / Binary)

Threshold Level – Notch 1

27*

(Text / Binary)

Independent Dot Erase

28*

(Text mode)

[0-255 / 128 / 1 step]

[0-255 / 85 / 1 step]

[0-255 / 128 / 1 step]

[0-255 / 128 / 1 step]

[0-255 / 70 / 1 step]

Selects the independent dot erase level.

With a larger SP setting, more dots are detect ed

as independent dots and erased.

If this is “0”, independent dot erase is disabled.

[0-7 / 4 / 1 step]

29* Unevenness correction

(Text mode)

Selects whether the unevenness correction is

done.

This function is like an F CI f unction. If this is “1”,

the edges of characters in scann ed images will

be smoothed.

[0: OFF, 1: ON]

2003

1* MTF Filter Coefficient

(Text/Photo / Binary /

Main scan)

Selects the MTF filter coefficient in the main

scan direction for Text/Photo mode.

Select a higher number for a stronger filter.

If this is “0”, the MTF filter is not applied.

[0-15 / 4 / 1 step]

MTF Filter Coefficient

28*

(Text/Photo / Binary / Sub

As above, for sub scan

[0-13 / 4 / 1 step]

scan)

3* MTF Filter Strength

(Text/Photo / Binary /

Main scan)

Selects the MTF filter stren gt h in t he main scan

direction for Text/Photo mode.

Select a higher number f or a stronger f ilt er.

[0-7 / 5 / 1 step]

4* MTF Filter Strength

(Text/Photo / Binary / Sub

As above, for sub scan

[0-7 / 5 / 1 step]

scan)

5* Smoothing Filter

(Text/Photo / Binary)

Selects the smoothing pattern for Text/Photo

mode when using binary picture pr ocessing

mode.

A larger value could cause m oiré t o appear in

the image.

[0-7 / 0 / 1 step]

Tables

Service

3-5

Page 22

SCANNER SERVICE MODE 19 January, 2000

SP2 Mode Number Function and [Setting]

2003

6* Scanner Gamma

(Text/Photo / Binary)

7* Brightness – Notch 7

(Text/Photo / Binary)

Contrast – Notch 7

8*

(Text/Photo / Binary)

Threshold Level – Notch 7

9*

(Text/Photo / Binary)

Brightness – Notch 6

10*

(Text/Photo / Binary)

11* Contrast – Notch 6

(Text/Photo / Binary)

12* Threshold Level – Notch 6

(Text/Photo / Binary)

13* Brightness – Notch 5

(Text/Photo / Binary)

14* Contrast – Notch 5

(Text/Photo / Binary)

15* Threshold Level – Notch 5

(Text/Photo / Binary)

16* Brightness – Notch 4

(Text/Photo / Binary)

17* Contrast – Notch 4

(Text/Photo / Binary)

18* Threshold Level – Notch 4

(Text/Photo / Binary)

19* Brightness – Notch 3

(Text/Photo / Binary)

20* Contrast – Notch 3

(Text/Photo / Binary)

Threshold Level – Notch 3

21*

(Text/Photo / Binary)

Brightness – Notch 2

22*

(Text/Photo / Binary)

Contrast – Notch 2

23*

(Text/Photo / Binary)

Threshold Level – Notch 2

24*

(Text/Photo / Binary)

Brightness – Notch 1

25*

(Text/Photo / Binary)

26* Contrast – Notch 1

(Text/Photo / Binary)

27* Threshold Level – Notch 1

(Text/Photo / Binary)

Selects the scanner gamma type for Text/Photo

mode when using binary picture pr ocessing

mode.

[0-6 / 5 / 1 step]

Adjusts the image densit y for each image

density level for Text/ Photo mode when using

binary picture processing mode.

[0-255 / 15 / 1 step]

[0-255 / 110 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

[0-255 / 25 / 1 step]

[0-255 / 85 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

[0-255 / 27 / 1 step]

[0-255 / 51 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

[0-255 / 70 / 1 step]

[0-255 / 70 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

[0-255 / 69 / 1 step]

[0-255 / 80 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

[0-255 / 100 / 1 step]

[0-255 / 100 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

[0-255 / 128 / 1 step]

[0-255 / 128 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

3-6

Page 23

19 January, 2001 SCANNER SERVICE MODE

SP2 Mode Number Function and [Setting]

2004

1* MTF Filter Coefficient

(Photo / Binary / Main

scan)

Selects the MTF filter coefficient in the main

scan direction for Photo mode.

Select a higher number for a stronger filter.

If this is “0”, the MTF filter is not applied.

[0-15 / 0 / 1 step]

MTF Filter Coefficient

2*

(Photo / Binary / Sub

As above, for sub scan

[0-13 / 0 / 1 step]

scan)

3* MTF Filter Strength

(Photo / Binary / Main

scan)

Selects the MTF filter stren gt h in t he main scan

direction for Photo mode.

Select a higher number for a stronger filter.

[0-7 / 0 / 1 step]

MTF Filter Strength

4*

(Photo / Binary / Sub

As above, for sub scan

[0-7 / 0 / 1 step]

scan)

5* Smoothing Filter

(Photo / Binary)

Selects the smoothing pattern for Photo mode

when using binary picture proce ssing mode.

A larger value could cause m oiré t o appear in

the image.

[0-7 / 0 / 1 step]

6* Scanner Gamma

(Photo / Binary)

Selects the scanner gamma type for Photo

mode when using binary picture pr ocessing

mode.

[0-6 / 6 / 1 step]

Dither Matr ix Filter

7*

(Photo / Binary)

Selects the dither matrix ty pe for Photo mode

when using binary picture proce ssing mode.

[1-26 / 4 / 1 step]

8* Brightness – Notch 7

(Photo / Binary)

Adjusts the image densit y for each image

density level for Photo mode when using binary

picture processing mode.

[0-255 / 60 / 1 step]

9* Contrast – Notch 7

(Photo / Binary)

Threshold Level – Notch 7

10*

(Photo / Binary)

Brightness – Notch 6

11*

(Photo / Binary)

Contrast – Notch 6

12*

(Photo / Binary)

Threshold Level – Notch 6

13*

(Photo / Binary)

Brightness – Notch 5

14*

(Photo / Binary)

[0-255 / 128 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

[0-255 / 100 / 1 step]

[0-255 / 128 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

[0-255 / 120 / 1 step]

15* Contrast – Notch 5

(Photo / Binary)

16* Threshold Level – Notch 5

(Photo / Binary)

[0-255 / 120 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

17* Brightness – Notch 4

(Photo / Binary)

[0-255 / 128 / 1 step]

Tables

Service

3-7

Page 24

SCANNER SERVICE MODE 19 January, 2000

SP2 Mode Number Function and [Setting]

2004

2005

18* Contrast – Notch 4

(Photo / Binary)

19* Threshold Level – Notch 4

(Photo / Binary)

20* Brightness – Notch 3

(Photo / Binary)

21* Contrast – Notch 3

(Photo / Binary)

Threshold Level – Notch 3

22*

(Photo / Binary)

Brightness – Notch 2

23*

(Photo / Binary)

Contrast – Notch 2

24*

(Photo / Binary)

Threshold Level – Notch 2

25*

(Photo / Binary)

Brightness – Notch 1

26*

(Photo / Binary)

27* Contrast – Notch 1

(Photo / Binary)

28* Threshold Level – Notch 1

(Photo / Binary)

1* MTF Filter Coefficient

(Grayscale / Main scan)

2* MTF Filter Coefficient

(Grayscale / Sub scan)

3* MTF Filter Strength

(Grayscale / Main scan)

MTF Filter Strength

4*

(Grayscale / Sub scan)

Smoothing Filter

5*

(Grayscale)

6* Scanner Gamma

(Grayscale)

Adjusts the image densit y for each image

density level for Photo mode when using binary

picture processing mode.

[0-255 / 128 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

[0-255 / 135 / 1 step]

[0-255 / 135 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

[0-255 / 138 / 1 step]

[0-255 / 133 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

[0-255 / 140 / 1 step]

[0-255 / 133 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

Selects the MTF filter coefficient in the main

scan direction when using graysca le processing

mode.

Select a higher number for a stronger filter.

If this is “0”, the MTF filter is not applied

[0-15 / 0 / 1 step]

As above, for sub scan

[0-13 / 0 / 1 step]

Selects the MTF filter stren gt h in t he main scan

direction when using grayscale processing

mode.

Select a higher number for a stronger filter.

[0-7 / 0 / 1 step]

As above, for sub scan

[0-7 / 0 / 1 step]

Selects the smoothing patt ern when using

grayscale processing mode.

A larger value could cause m oiré t o appear in

the image.

[0-7 / 0 / 1 step]

Selects the scanner gamma t ype when using

grayscale processing mode.

[0-6 / 3 / 1 step]

3-8

Page 25

19 January, 2001 SCANNER SERVICE MODE

SP2 Mode Number Function and [Setting]

2005

7* Brightness – Notch 7

(Grayscale)

Adjusts the image densit y for each image

density level when us ing the grayscale

processing mode.

[0-255 / 98 / 1 step]

8* Contrast – Notch 7

(Grayscale)

9* Threshold Level – Notch 7

(Grayscale)

[0-255 / 98 / 1 step]

This SP is not available.

[0-255 / 98 / 1 step]

10* Brightness – Notch 6

(Grayscale)

Contrast – Notch 6

11*

(Grayscale)

Threshold Level – Notch 6

12*

(Grayscale)

Brightness – Notch 5

13*

(Grayscale)

Contrast – Notch 5

14*

(Grayscale)

Threshold Level – Notch 5

15*

(Grayscale)

[0-255 / 108 / 1 step]

[0-255 / 108 / 1 step]

This SP is not available.

[0-255 / 108 / 1 step]

[0-255 / 118 / 1 step]

[0-255 / 118 / 1 step]

This SP is not available.

[0-255 / 118 / 1 step]

16* Brightness – Notch 4

(Grayscale)

[0-255 / 128 / 1 step]

17* Contrast – Notch 4

(Grayscale)

18* Threshold Level – Notch 4

(Grayscale)

[0-255 / 128 / 1 step]

This SP is not available.

[0-255 / 128 / 1 step]

19* Brightness – Notch 3

(Grayscale)

[0-255 / 138 / 1 step]

20* Contrast – Notch 3

(Grayscale)

21* Threshold Level – Notch 3

(Grayscale)

[0-255 / 138 / 1 step]

This SP is not available.

[0-255 / 138 / 1 step]

22* Brightness – Notch 2

(Grayscale)

[0-255 / 148 / 1 step]

23* Contrast – Notch 2

(Grayscale)

24* Threshold Level – Notch 2

(Grayscale)

[0-255 / 148 / 1 step]

This SP is not available.

[0-255 / 148 / 1 step]

25* Brightness – Notch 1

26*

27*

2006 1*

(Grayscale)

Contrast – Notch 1

(Grayscale)

Threshold Level – Notch 1

(Grayscale)

Compression Rat io

(Normal image)

[0-255 / 158 / 1 step]

[0-255 / 158 / 1 step]

This SP is not available.

[0-255 / 158 / 1 step]

Selects the compression ratio for grayscale

processing mode.

For a lower com p r es sion r at e , input a smaller

value.

[5-95 / 50 / 1 step]

Tables

Service

3-9

Page 26

SCANNER SERVICE MODE 19 January, 2000

SP2 Mode Number Function and [Setting]

2006

SP8 Mode Number Function and [Setting]

8001*

8002

8003* ECabinet IP Address

8004* Network Error Display

2* Compression Ratio

(High Quality imag e)

3* Compression Ratio

(Low Quality image)

Delivery Server IP

Address

1* Delivery Re-t r y

(Interval)

2* Delivery Re-t r y

(Number of re-try)

Time

[5-95 / 60 / 1 step]

[5-95 / 40 / 1 step]

Sets the IP address for the delivery server.

[000.000.000.000]

Sets the delivery re-try interval.

[60-999 / 300s / 1s step]

Sets the number of delivery re-t ries.

If this is “0”, the machine will not re-try to send

an image to the delivery serv er.

[0-99 / 3 times / 1 time step]

Sets the IP address for the eCabin et .

[000.000.000.000]

Selects the length of time that the network error

message for the scanner utilities is displayed.

If this is “0”, the error message is disp layed until

the error is solved.

[0-999 / 300 s / 1 s step]

SP9 Mode Number Function and [Setting]

9001

1Sysop

2Dapp

3Rapp

4Ui

5Nas

6Miw

7Djm

8Hpim

9mib

Bit switches for debugg ing. DFU

3-10

Page 27

19 January, 2001 FIRMWARE UPDATE PROCEDURE

3.4 FIRMWARE UPDATE PROCEDURE

Firmware updating procedure is described in section 5.2 of the main unit service

manual.

3.5 POWER-ON SELF TEST

The controller tests the following devices at power-on. If an error is detected, an

error code is stored in the controller board.

• CPU, ASIC and clock

• Flash ROM

• Resident and optional SDRAM

• Parallel interface

• NIB

• IEEE1394 interface (if installed)

• NVRAM

• HDD

Tables

Service

• Refer to section 4.1.2 of the main unit service manual for how to check the error

codes (SP 7-832).

3.6 SELF DIAGNOSTIC TEST

In addition to the power-on self test, you can set the machine in a more detailed

diagnostic mode to test other components and conditions.

It requires a loop-back connector (P/N: G0219350).

1. Turn off the machine and attach the loop-back connector to the parallel

interface.

2. Turn on the machine while pressing the “On Line” key and “# Enter” key

together.

3. The machine prints the diagnostic report automatically.

• Refer to section 4.1.2 of the main unit service manual for how to check the

error codes (SP 7-832).

3-11

Page 28

USER PROGRAM MODE 19 January, 2000

3.7 USER PROGRAM MODE

3.7.1 PRINTER USER PROGRAM MODE

Press the “Printer” key on the operation panel to enter the printer mode.

Press the “User Tools/Counter “, then select “Printer Settings” to change

printer settings.

User Mode Tree

Printer Mode

(Printer Key pressed)

User Tools/

Printer Settings

View Sample Print Jobs

View Locked Print Jobs

Paper Input

List/Test Print

System

Host Interface

PCL Menu

Bypass Size

Config. Sheet

Menu List

PCL Config. Page

PS Font List

Hex Dump

Panel LockingMaintenance

Misfeed Recovery

Print Error Report

Auto Continue

Memory Overflow

Job Separation (1-bin shift tray required)

Memory Usage

Duplex (optional duplex unit required)

Unit of Measure

Edge Smoothing

Resolution

Toner Saving

I/O Buffer

I/O Timeout

Orientation

Form Lines

Font Source

Font Number

Point Size

Font Pitch

Symbot Set

B362M501.WMF

3-12

Page 29

19 January, 2001 USER PROGRAM MODE

3.7.2 SCANNER USER PROGRAM MODE

Press the “User Tools/Counter “, then select “Scanner Settings” to change

scanner settings.

User Mode Tree

User Tools/

Scanner Features

Basic Settings

Scanner Settings

Subject Settings Program Change

Program Change

Delete

Initial Setup

Program 1 ~ 5

Function Priority

Delivery/Store Connection Time out

Compression (Black & White)

Compression (Grayscale)

Delivery Option

Original Setting

Original Orientation Priority

Mixed Originals Sizes Priority

SADF Auto Reset Timer

Delete

1 ~ 12

B361 M501.WMF

Tables

Service

3-13

Page 30

19 January, 2001 OVERVIEW

4. DETAILED SECTION DESCRIPTIONS

4.1 OVERVIEW

OPTION OPTION OPTION OPTION

IEEE1284 IC Card

HDD

Printer

(Scanner)

DIMM

PS3

RAM

(32/64 MB)

NIB

Flash ROM

(4 MB)

IEEE1394

IC Card I/F IDE Slot 1 Slot 2

Flash ROM DIMM (4/8 MB)

System

Flash ROM

(8 MB)

Resident

SDRAM

(32 MB)

SIMAC

PCI I/F

Mother Board

PCI I/F

BICU

CPU

SDRAM

DIMM

NVRAM

(32 kB)

Controller

B362D501.WMF

This machine uses the GW architecture. To enabl e the pr inter feat ur es, just install

the printer option ROM DIMM on the controller.

Detailed

Descriptions

Main components:

• CPU: QED RM5231

• SIMAC: G W architecture ASIC. It control s al l the functions of the controller

board.

• Flash ROM: 8MB Flash ROM for the system program

• SDRAM (resident): 32 MB SDRAM, expandable with 32 MB or 64 MB optional

SDRAM.

• NVRAM: Stores the controller settings

• HDD: Used to store additional soft fonts. Also used for collation, locked print,

sample print and form overlay

• IEEE 1284 interface

Optional components:

• PostScript3 DIMM

• Memory DIMM

• NIB

• IEEE1394 interface

4-1

Page 31

CONTROLLER FUNCTIONS 19 January, 2001

4.2 CONTROLLER FUNCTIONS

4.2.1 SAMPLE PRINT

This feature was formerly known as “Proof Print”. This function gives users a

chance to check the print results before starting a multiple-set print run.

• The size of the hard disk partition for the sample print feature is 5 GB. This

partition is also used by the collation and locked print features.

• The partition can hold up to 30 files, including files stored using locked print.

• The maximum number of pages is 2,000, including jobs using locked print and

collation.

4.2.2 LOCKED PRINT

Using this feature, the print job is stored in the machine but will not be printed until

the user inputs an ID at the machine’s operation panel. This ID must match the ID

that was input with the printer driver.

• Stored data is automatically deleted after it is printed.

• Stored data can be manually deleted at the operation panel.

• The hard disk can hold up to 30 files, including files stored using sample print.

• The maximum number of pages is 2,000, including jobs using sample print and

collation.

• Locked print uses the same hard disk partiti o n as sample print and collation,

which is 5 GB.

4-2

Page 32

19 January, 2001 CONTROLLER FUNCTIONS

4.2.3 PAPER SOURCE SELECTION

Tray Priority (Auto Tray Select)

The Tray Priority setting determines the start

of the tray search when the user selects

“Auto Tray Select” with the driver.

The machine searches for a paper tray with

the specified paper size and type.

When no tray contains paper that matches

the paper size and type specified by the

driver, the controller stops printing until the

user loads the correct paper.

Priority Tray

Tray 1

Tray 2

LCT (Optional)

Start of Tray Search

The Tray Priority setting can be specified

Tray 3 (Optional)

using the Paper Size Setting in the user tools.

(User Tools/ System Settings/ Paper Size

Tray 4 (Optional)

Settings)

B362D502.WMF

NOTE: The by-pass tray is not part of the tray search.

Tray Lock

If Tray Lock is enabled for a tray, the controller skips the “locked” tray in the tray

search process.

The Tray Lock setting can be specified by selecting “No” for the “Apply Auto Paper

Select” setting in the Paper Size Setting screen in the user tools.

(User Tools/ System Settings/ Paper Size Settings)

NOTE: The by-pass feeder cannot be locked.

Manual Tray Select

If the selected tray does not have the paper size and type specified by the driver,

the controller stops printing until the user loads the correct paper.

Detailed

Descriptions

4-3

Page 33

CONTROLLER FUNCTIONS 19 January, 2001

4.2.4 AUTO CONTINUE

When this function is ena bled, the ma chine stops pr inting and cancels the print job

if there is no paper tray which matches the paper size and paper type specified by

the driver.

If Auto Continue is enabled, the machine waits for a specified period (0, 1, 5, 10,

15 minutes) for the correct size paper to be set in the tray, then cancels the print

job if the interval expires.

• The interval can set with the Printer Settings in the user tools.

(User Tools/ Printer Settings/ System/ Auto Continue)

If Auto Continue is disabled, the machine will not print the job, but will not cancel it,

so the job stays in the print queue.

If no paper tray matches the paper size and paper type specified by the driver:

Auto Continue OFF

Immediately

1 minute

5 minute

10 minute

15 minute

NOTE: The default setting for Auto Continue is “Off.”

Job stays in the printer

Job is immediately canceled

Job is canceled after 1 minute

and so on

B362D512.WMF

4-4

Page 34

19 January, 2001 CONTROLLER FUNCTIONS

4.2.5 PAPER OUTPUT TRAY

The default paper output tray for each application (copy/fax/printer) can be

selected using the System Settings menu in the user tools.

(User Tools/ System Settings/ General Features)

If a print job does not specify an output tray or if the driver specifies the default tray,

the default paper output tray is used.

Output Tray Selected

• If an output tray is specified by the driver, it overrides the default tray setting in

the user tools.

• If the machine cannot print to the selected output tray, it prints to the default

paper output tray.

• If the mailbox unit is installed, paper larger than B4 cannot be printed to the

standard (internal) tray.

• If paper overflow is detected at the selected output tray, the controller stops

printing until the overflow detector goes off.

Sequential Stacking

When the nine-tray mailbox is s elected as the output tray and

“Printer Default” is specified as the output tray in the driver, the

machine automatically sends the output to the top tray (1st

tray). When that tray fills up, the machine sends the output to

the next tray.

This feature is called “Sequential Stacking.”

• If a tray becomes full and paper is detected in the next tray,

the machine displays an error and stops printing.

When paper in the next tray is removed, the machine

automatically resumes printing to the next tray.

• If all trays become full (overflow detected in all trays), the

machine displays an error and stops printing. This time, all

paper in all trays must be removed.

4.2.6 DUPLEX PRINTING

Top tray (1st tray)

2nd tray

3rd tray

4th, 5th, 6th, and so on

8th tray

Lowest tray (9th tray)

B362D509.WMF

Detailed

Descriptions

Duplex printing is available with all output bin options but not all paper sizes. If a

job specifies duplex printing but the paper size to be used cannot be used by the

duplex unit, the job will be printed single-sided.

• When the by-pass feeder is se lected as the paper source, duplex printing is

automatically disabled.

4-5

Page 35

CONTROLLER FUNCTIONS 19 January, 2001

4.2.7 STAPLING

Stapling is available when the two-tray (2250-sheet) finisher or 1000-sheet finisher

is installed.

The finishers have the following stapling positions.

1000 Finisher

Paper Feed Direction

(Printed side)

2 Tray Finisher

Stapled 2 places

Paper Feed Direction

(Printed side)

B362D510.WMF

• Depending on the paper orientation, the image may have to be rotated. The

image rotation is done by the controller.

• There is a limit for the number of sheets which can be stapled. If a job has more

than this number, it will not be stapled.

4.2.8 PUNCHING

Punching is available only when the punch kit is installed with the two-tray finisher.

The number of holes (2, 3, or 4 holes) depends on the type of punch kit.

• There is only one punch position available, so the relationship between the

punching position and the printed image depends on the paper feeding

orientation and image rotation.

2 Tray Finisher

Paper Feed Direction

(Printed side)

Punching Position

B362D511.WMF

4-6

Page 36

19 January, 2001 SCANNER FUNCTIONS

4.3 SCANNER FUNCTIONS

4.3.1 IMAGE PROCESSING FOR SCANNER MODE

The image processing for scanner mode is done in the IPU chip on the BICU

board. The IPU chip chooses the most suitable image processing methods

(gamma tables, dither patterns, etc) depending on the settings made in the driver.

The image compression method can be selected with SP mode (MR/MH/MMR for

binary picture processing, JPEG for grayscale processing).

Whether the user selects the image mode using the driver (TWAIN mode) or from

the operation panel (Delivery mode), the IPU chip does the image processing using

the appropriate image processing methods mentioned above.

Image Data Path

1. Image Store/Image Delivery Mode

Image

Scanning

Image

Processing

Image

Compression

BICU

HDD

NIB

ControllerSBU

File

Server

B361D500.WMF

The user can select the following modes from the LCD.

1) Delivery only

2) Store only

3) Store and delivery

After image processing and image compression, all image data for the job are

stored in the printer controller HDD us ing TIFF file format (binary picture

processing) or JPEG file format (grayscale processing). The type of TIFF format

used depends on the user’s scanner settings.

When delivery mode is selec ted, the controlle r creates a file which contains the

destination and page information, then the controller sends the file to a server.

Image

Scanning

Image

Processing

Compression

BICU

Image

NIB

ControllerSBU

Image

PC

B361D501.WMF

Detailed

Descriptions

2. Twain Mode

After image processing and image compression, the data (TIFF or JPEG) is sent

to the scanner Twain driver directory on the computer.

4-7

Page 37

NIB 19 January, 2001

4.4 NIB

4.4.1 BLOCK DIAGRAM

Flash ROM

4MB

LED

EEPROM

PHY

DP83846

Filter Module

RJ45

Network

Oscillator

NIB

B362D503.WMF

Controller

CN2

NIB I/F (CN12)

LED

• The Flash ROM contains the NIB firmware. The firmware can be upgraded using

an IC card connected to the controller board.

4.4.2 LED INDICATORS

LED2 (Yellow)

LED1 (Green)

B362D508.WMF

Description On Off

LED1 (Green): Link status Link success Link failure

LED2 (Yellow): Data rate 100 Mbps 10 Mbps

4-8

Page 38

19 January, 2001 IEEE1394 INTERFACE

4.5 IEEE1394 INTERFACE

4.5.1 SPECIFICATIONS

Hardware Specification

Interface: IEEE1394 (6 pins)

(no power supply, cable power repeated, IEEE1394a-2000 compliant)

Ports: 2 ports

Data rates: 400Mbps/200Mbps/100Mbps

System Requirements

PC: Windows PC with IEEE1394 port

OS: Microsoft Windows 2000 upgraded with service pack 1

Cable length: 4.5m (15ft)

4.5.2 IEEE1394

IEEE1394, also known as FireWire (a name patented by Apple), is an easy-to-use

peer-to-peer networking technology allowing speeds of up to 400 Mbps.

The current standard contains the following features, which are supported in most

devices:

Detailed

Descriptions

• Hot swapping (cables can be connected and disconnected while the

computer and other devices are switched on)

• Peer-to-peer networking (no hub required)

• No terminator or device ID is required, unlike SCSI

• Automatic configuration of devices upon start-up, or “plug and play.”

• Real-time data transfer at 100, 200, and 400 Mbps

• Common connecto rs for different devices

IEEE1394 I/F

IEEE1394 I/F

IEEE1394 Board

B362D506.WMF

B362V503.WMF

The cable length is limited to 4.5 m (15ft).

However, up to 16 cables and 63 devices can be connected to an IEEE1394

network.

IEEE1394 cables can be either 4-pin (data only) or 6-pin (data and power).

IEEE1394 allows either 6-pin or 4-pin connectors. However, this machine only uses

the 6-pin connectors. The machine has two 6-pin ports.

4-9

Page 39

IEEE1394 INTERFACE 19 January, 2001

4.5.3 BLOCK DIAGRAM

IEEE1394 Board

Oscillator

1394 I/F

PC

1394 I/F

TSB41AB2

• PHY: Physical layer control device

• Link: Link layer control device

• EEPROM: 256-byte ROM

4.5.4 PIN ASSIGNMENT

Pin 1

Clock

PHY

EEPROM

Link

TSB12LV23A

Controller

Option I/F (CN4)

B362D505.WMF

Pin assignment

Pin 1 Pin 4

Pin 2 Pin 3

Pin 5 Pin 6

Pin

No.

Signal Description

1Cable Power

2GND

3 Receive strobe

4 Transmit data

5 Receive data

6 Transmit strobe

Pin 6

B362D507.WMF

4-10

Page 40

19 January, 2001 IEEE1394 INTERFACE

4.5.5 REMARKS ABOUT THIS INTERFACE KIT

Note the following points about this unit.

• The machine does not print reports specifically for IEEE1394. Just print the

Configuration Page at installation to check that the machine recognizes the card.

• There is no spooler or print queue. If a computer tries to print over the IEEE1394

while the printer is busy, the IEEE1394 interface card inside the printer will return

a busy signal.

• After starting a job using IEEE1394, do not switch the printer off until the job has

been completed. Even though the printer may appear to be dead, it may be in

the middle of an IEEE1394 protocol exchange with the computer.

• When using IEEE1394, it is not possible to check the printer status from the

computer with a utility such as Printer Manager for Client.

4.5.6 TROUBLESHOOTING NOTES

If there are problems printing using the IEEE1394 interface, check the following.

• Is the computer using Windows 2000 with service pack 1?

• Has the interface card been replaced recently? Each card has an individual

address, similar to the MAC address in an Ethernet card. If the card was

changed, the driver cannot find the old card. The new card is another device and

a new printer appears in Windows Control panel, and this must be configured in

the same way as the printer that was replaced (the old printer icon in Windows

Control Panel should be deleted) has to be reconfigured.

• Is there a loop somewhere in the network? An IEEE1394 network must be a

chain or a branched chain. There can be no loops.

• Try to find out where in the chain the problem is occurring. Test the machine

one-to-one with the computer to determine if the printer is defective (when the

printer’s interface cable is plugged in, the computer should see ‘Printer Ready’;

when the cable is disconnected, the computer should see ‘Offline’).

Detailed

Descriptions

4-11

Page 41

19 January, 2001 SPECIFICATIONS

SPECIFICATIONS

1. GENERAL SPECIFICATIONS

1.1 PRINTER

Printing Speed: Maximum 45 ppm (A4/LT LEF): B004/B007 model

Maximum 35 ppm (A4/LT LEF): B003/B006 model

Printer Languages: PCL6/PCL5e

PostScript 3 (option)

RPCS (Refined Printing Command Stream) - an original

Ricoh PDL)

Resolution: 600 dpi (PCL 6/PCL5e/PS3/RPCS)

300 dpi (PCL5e/PS3)

Resident Fonts: PCL:

35 Intellifonts

10 True Type fonts

PS3:

136 fonts (24 Type 2 fonts, 112 Type 14 fonts)

Host Interfaces: Bi-directional IEEE1284 parallel x 1 (standard)

Ethernet (100 Base-TX/10 Base-T) (opt ion)

IEEE1394 (option)

Network Protocols:

Memory:

TCP/IP, IPX/SPX, NetBEUI, Apple Talk

Maximum 96 MB

(Standard 32 MB + 32 MB/64MB optional DIMM)

Spec.

Spec-1

Page 42

SPECIFICATIONS 19 January, 2000

Supported Paper Sizes

Paper Size (W x L)

Paper Trays

Main Unit/Option

By-pass

Tray

LCT Duplex

US Eur/Asia

A3 297 x 420 mm Y#/Y

B4 257 x 364 mm Y#/Y

#

#

Y/Y Y

#

Y#/Y

A4 SEF 210 x 297 mm Y/Y Y/Y Y

A4 LEF 297 x 210 mm Y/Y Y/Y Y

B5 SEF 182 x 257 mm Y#/Y

B5 LEF 257 x 182 mm Y#/Y

A5 SEF 148 x 210 mm Y#/Y

#

#

#

#

Y#/Y

#

Y#/Y

Y/Y Y

A5 LEF 210 x 148 mm N N Y

B6 SEF 128 x 182 mm N N Y

B6 LEF 182 x 128 mm N N N N N

A6 SEF 105 x 148 mm N N Y

Ledger 11 x 17” Y/Y Y#/Y

Legal 8.5 x 14“ Y/Y Y#/Y

#

#

Letter SEF 8.5 x 11” Y/Y Y/Y Y

Letter LEF 11 x 8.5” Y/Y Y/Y Y

Y#/Y

#

#

Half Letter SEF 5.5 x 8.5” Y/Y Y#/Y

Half Letter LEF 8.5 x 5.5” N N N N N

Executive SEF 7.25 x 10.5” Y#/Y

#

Executive LEF 10.5 x 7.25” N N Y

F 8 x 13” Y#/Y

Foolscap 8.5 x 13” Y#/Y

Folio 8.25 x 13” Y#/Y

#

#

#

Y#/Y

Y#/Y

Y#/Y

#

#

#

#

#

Y

#

#

#

Y

#

Y

#

#

C

C

#

Y

#

Y

#

#

#

Y

#

Y

#

#

Y

#

Y

#

Y

NY

NY

NY

YY

NY

NY

NY

NN

NN

NN

NY

NY

NY

YY

NY

NY

NY

NY

NY

NY

Com10 Env. 4.125 x 9.5” N N N N N

Monarch Env. 3.875 x 7.5” N N N N N

C6 Env. 114 x 162 mm N N N N N

C5 Env. 162 x 229 mm N N N N N

DL Env. 110 x 220 mm N N N N N

8K 267 x 390 mm Y#/Y

16K SEF 195 x 267 mm Y#/Y

16K LEF 267 x 195 mm Y#/Y

#

#

#

Y#/Y

Y#/Y

Y#/Y

#

#

#

#

Y

#

Y

#

Y

NY

NY

NY

Custom Minimum:

100 x 297 mm

Maximum:

NNY

C

NN

148 x 600 mm

Remarks:

Y Supported. The paper size sensor detects the paper size.

#

Y

C

Y

N Not supported.

Supported. The user has to select t he correct paper size for the tray.

Supported. The user has to enter the width and length of the paper.

Spec-2

Page 43

19 January, 2001 SPECIFICATIONS

1.2 SCANNER

Standard Scanner

Resolution:

Available scanning

Resolution Range:

Main scan/Sub scan

600 dpi

Twain Mode:

Book Mode (Main scan/Sub scan)

100 ~ 2400 dpi

ADF Mode (Main scan/Sub scan)

100 ~ 1200 dpi

Delivery Mode:

Book and ADF Mode (Main scan/Sub scan)

100 ~ 600 dpi

Grayscales: 8 bits/pixel

Scanning

Throughput:

25 spm for TWAIN

53 spm for Delivery mode

(A4L, ADF mode)

Interface: Ethernet (100 Base-TX/10 Base-T for TCP/IP)

Compression

Method:

Video Memory

Capacity:

MH, MR, MMR (Binary Picture Processing)

JPEG (Grayscale Processing)

8.3 MB (Twain)

24.9 MB (Delivery mode)

Image Storage

Capacity:

Number of originals per file: Maximum 160 pages

Maximum of files: 3000 files

Spec.

Spec-3

Page 44

SPECIFICATIONS 19 January, 2000

2. SOFTWARE ACCESSORIES

2.1 PRINTER

The printer drivers and utility software are provided on one CD-ROM. An auto-run

installer allows you to select which components to install.

PRINTER DRIVERS

Printer Langua ge

PCL 6 Yes Yes Yes No

PCL 5e Yes Yes Yes No

PS3 Yes Yes Yes Yes

RPCS Yes Yes Yes No

Windows

95/98/ME

Windows NT4.0 Windows 2000 Macintosh

NOTE: 1) The printer drivers for Windows NT 4.0 are only for the Intel x86

platform. There is no Windows NT 4.0 printer driver for the PowerPC,

Alpha, or MIPS platforms.

2) The PS3 drivers are all genuine AdobePS drivers, except for Windows

2000, which uses Microsoft PS. A PPD file for each operating system is

provided with the driver.

UTILITY SOFTWARE

Software Description

Agfa Font Manager

(Win 95/98/ME, NT4, 2000)

SmartNetMonitor for Admin

(Win 95/98/ME, NT4, 2000)

SmartNetMonitor for Client

(Win 95/98/ME, NT4, 2000)

1394 Utility (Win 2000)

DeskTopBinder V2 Lite

(Win 95/98/ME, NT4, 2000)

LAN-Fax M1

(Win 95/98/ME, NT4, 2000)

Address Book

(Win 95/98/ME, NT4, 2000)

Printer Utility for Mac

A font management utilit y with screen fonts for the printer.

A printer management util it y for network administrators. NIB

setup utilities are also available.

A printer management util it y for client users. Peer-to-peer

printing utility and parallel/recovery printing funct ions are

included.

A utility for removal IE EE 1394 printers.

A utility for document mana gement

PC LAN FAX driver

A utility for PC LAN FAX.

This software provides several convenient functions for printing

from Macintosh clients.

Spec-4

Page 45

19 January, 2001 SPECIFICATIONS

2.2 SCANNER

The scanner driver and utility software are provided on one CD-ROM.

SCANNER DRIVER

• Network Twain Driver for Win95/98/ME/NT3.51/NT4.0/2000

SCANNER UTILITIES

• Scan Router V2 Lite (Cherry-Lite) for Win95/98/ME/NT4.0/2000

• Desk Top Binder V2 Lite (Plumeri a- Li t e) for Win95/98/ME/NT4.0/2000

Spec.

Spec-5

Page 46

SPECIFICATIONS 19 January, 2000

3. MACHINE CONFIGURATION

3.1 SYSTEM COMPONENTS

Memory DIMM

5

7

Parallel I/FIC Card I/F

CPU

CN12

SIMAC

NVRAM

Controller Board

CN2

CN1

CN7 (SLOT1)

CN8 (SLOT2)

6

NIB

3

1

B362V502.WMF

2

4

IEEE1394 Board

Printer DIMM

or

Printer/

Scanner

DIMM

B362V501.WMF

PS3

DIMM

Item Machine Code No. Remarks

Printer Module

(ROM DIMM)

B362 1

Printer/Scanner

Module

B361 1

(ROM DIMM)

Option

Mailbox G909 6

Mailbox Bridge Unit G912 7

Internal Option

NIB G574 3

PostScript3 G577 2

Memory 64 MB G579

IEEE1394 G590 4

Spec-6

Used in common with the N AD and

Adonis-C1 (USA only).

Used in common with the mode l J

and K-P1.

Loading...

Loading...