Page 1

SCANNER KIT

(Code: B359)

The B359 scanner kit option has a network interface, but there is

no SCSI interface.

Both hardware and software are completely different from the

A695 scanner option for the NAD30/40.

Therefore, the only comparison with the A695 in this manual is

the specification table, which compares the B359 with the A695.

.

Page 2

TABLE OF CONTENTS

1. OVERALL MACHINE INFORMATION........................................1-1

1.1 SPECIFICATIONS.................................................................................... 1-1

1.1.1 SCANNER CONTROL BOARD....................................................... 1-1

1.1.2 DRAM SIMM.................................................................................... 1-2

1.2 SOFTWARE ............................................................................................. 1-3

1.2.1 SCANNER DRIVERS ...................................................................... 1-3

1.2.2 SCANNER UTILITIES...................................................................... 1-3

1.2.3 SCANNER UTILITY (OPTION)........................................................ 1-3

2. DETAILED SECTION DESCRIPTIONS.......................................2-1

2.1 HARDWARE OVERVIEW ........................................................................ 2-1

2.2 SCANNER FUNCTIONS .......................................................................... 2-3

2.2.1 SELF DIAGNOSTICS...................................................................... 2-3

2.2.2 IMAGE PROCESSING IN THE SCANNER CONTROLLER............ 2-3

3. INSTALLATION PROCEDURE...................................................3-1

4. SERVICE TABLE........................................................................ 4-1

4.1 SERVICE PROGRAM MODE................................................................... 4-1

4.1.1 SERVICE PROGRAM ACCESS PROCEDURE.............................. 4-1

1.1.2 SERVICE PROGRAM MODE TABLES........................................... 4-1

4.2 DOWNLOADING NEW SOFTWARE........................................................ 4-3

4.2.1 SOFTWARE DOWNLOAD PROCEDURE....................................... 4-3

4.2.2 ERROR MESSAGES DURING THE SOFTWARE DOWNLOAD .... 4-4

5. REPLACEMENT AND ADJUSTMENT........................................ 5-1

5.1 PRECAUTION.......................................................................................... 5-1

5.2 NOTE FOR REPLACING THE SCANNER CONTROLLER BOARD........ 5-1

6. TROUBLESHOOTING.................................................................6-1

6.1 SERVICE CALL CONDITION................................................................... 6-1

6.1.1 SC CODE DESCRIPTIONS............................................................. 6-1

6.2 LEDS........................................................................................................ 6-2

i

Page 3

14 January, 2000 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

1.1.1 SC ANNER CONTROL BOARD

B359 A695

Standard Scanner

Resolution:

Available Scanning

Resolution Range:

8 bits/pixel 8 bits/pixel 8 bits/pixel

Scanning Speed: 0.8 s/200 dpi

Scanning

Throughput:

Interface: Network interface x 1

Compression

Method:

Video Memory

Capacity:

Power: DC 5 V, 3 A

Main scan/Sub scan

600 dpi

Main scan/Sub scan

Book Mode

Binary processing:

100 ~ 2400 dpi (in 1 dpi step)

Grayscale Processing:

100 ~ 600 dpi (in 1 dpi step)

ADF Mode

Binary processing:

100 ~ 2400 dpi (in 1 dpi step)

Grayscale Processing:

100 ~ 600 dpi (in 1 dpi step)

(A4 lengthwise, Binary, Book

mode, MMR Compression)

30 spm for TWAIN

(Adonis-C1b/C1c)

(local peer-to-peer scanning)

33 spm for Delivery mode

(Adonis-C1b/C1c)

(network scanning to a server)

(A4 lengthwise, Binary, ADF

mode, MMR Compression)

Ethernet (100 base-TX/10 base-T

for TCP/IP )

MH, MR, MMR

(Binary Picture Processing)

JPEG (Grayscale Processing)

9 MB (Standard – 4 MB for image

storage, 5MB for a work area)

1 DRAM SIMM slot (16 MB or 32

MB)

Up to 36 MB (4MB + 32 MB)

(from the main machine)

Main scan/Sub scan

400 dpi

Main scan/Sub scan

Binary Processing:

100 ~ 1600 dpi (in 1 dpi steps)

Grayscale Processing:

100 ~ 400 dpi (in 1 dpi steps)

4 s/200 dpi

(A4 lengthwise, Binary, Book

mode)

Simplex mode (ADF):

NAD30S/30: 19 ppm/200 dpi

(A4 lengthwise, Binary)

NAD40: 21 ppm/200 dpi

(A4 lengthwise, Binary)

Duplex mode (ARDF):

NAD30S/30: 17 ppm/200 dpi

(A4 lengthwise, Binary)

NAD40: 18 ppm/200 dpi

(A4 lengthwise, Binary)

SCSI-2, high density

Interface Connector:

50 pin, half-pitch (x 1)

2 MB

DC 5 V, 2 A

(from the main machine)

KIT

SCANNER

1-1

Page 4

SPECIFICATIONS 14 January, 2000

1.1.2 DRAM SIMM

Number of Pins: 72 pins

Access Speed: 60 ns or faster

Capacity: 16 or 32 MB

Parity: Any setting is OK

Type: EDO required

1-2

Page 5

14 January, 2000 SOFTWARE

1.2 SOFTWARE

1.2.1 SCANNER DRIVERS

The following scanner drivers are included on the CD-ROM.

· Network TWAIN Driver for Windows 95/98/NT4.0/NT3.51

1.2.2 SC ANNER UTILITIES

The following scanner utilities are included on the CD-ROM.

· Scan Router for Windows 95/98/NT4.0

· Aficio Manager for Admin/Client (Windows 95/98/2000/NT4.0)

1.2.3 SC ANNER UTILITY (OPTION)

· Scan Router Professional (Windows NT4.0 and service pack 4)

1-3

KIT

SCANNER

Page 6

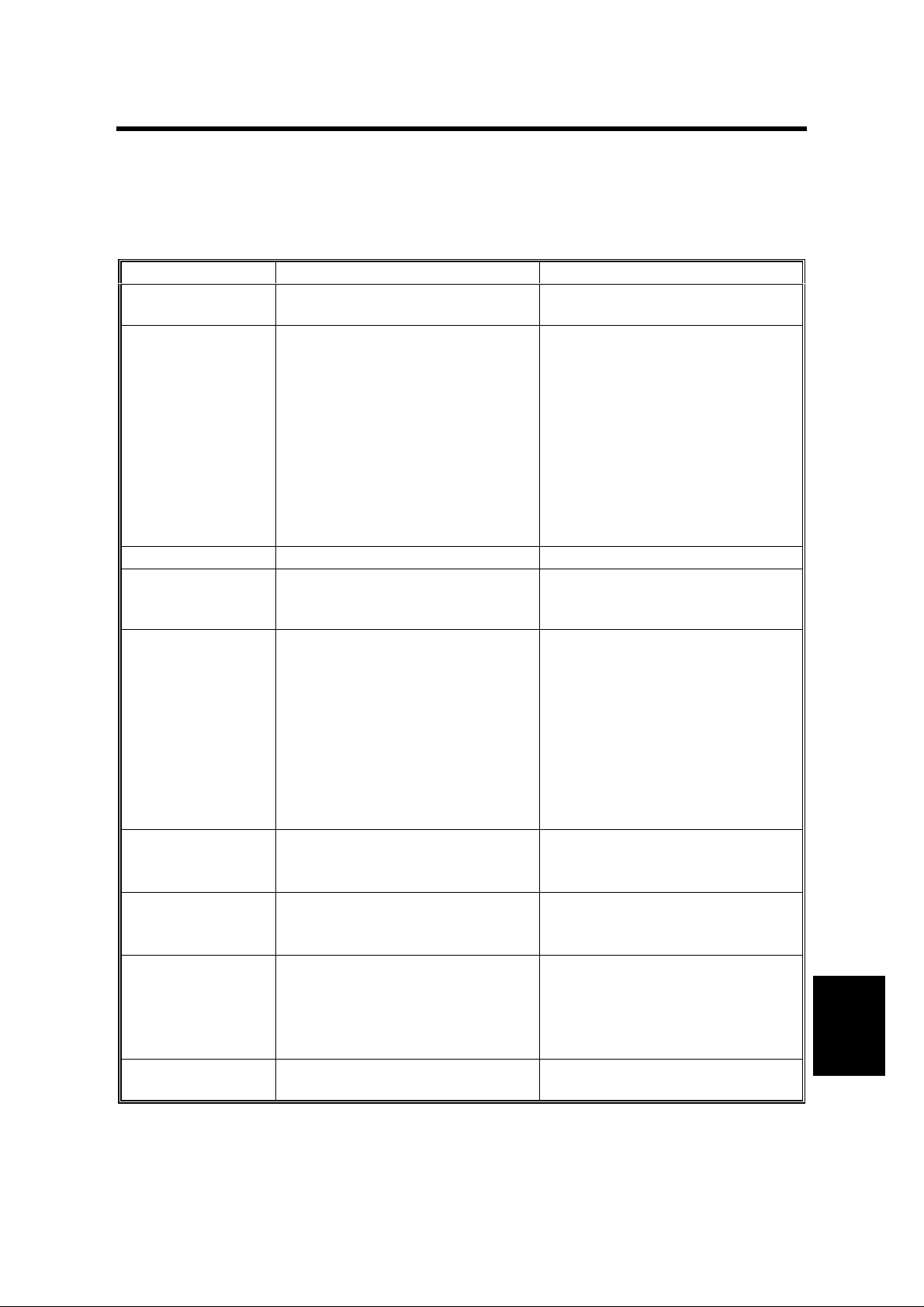

14 January, 2000 HARDWARE OVERVIEW

2. DETAILED SECTION DESCRIPTIONS

2.1 HARDWARE OVERVIEW

MBBICU

SCANNER CONTROL

BOARD

- Image Input Circuit -

CPU

UPD705101GM

(33.3 MHz)

Flash

ROM

(2 MB)

UPD65842

DRAM

(16 MB)

ASIC

DRAM

SIMM

Slot

FIFO

(256 kB)

Flash

Memory

Card

Slot

- Network Interface Circuit -

DRAM

(2 MB)

ASIC

DISCII

CPU

MC68340VP

(25.166 MHz)

SRAM

EEPROM

Bridge

AG1001V

Flash

ROM

(2 MB)

MAC

AM79C971

PHY

ICS1892

RJ45

Network

A844D500.WMF

The scanner controller contains image input and network interface circuits.

The image data from the BICU is compressed in the image input circuit, then the

data goes to the network through the network interface circuit.

Each circuit has a CPU and flash memory IC. The functions of each major

component are as follows.

2-1

KIT

SCANNER

Page 7

HARDWARE OVERVIEW 14 January, 2000

1. Image input circuit

CPU: UPD705101GM

· Sequence control for the image input circuit

· Clock/time control

· DMA control

ASIC: UPD65842

· Stores the image data from the BICU board in the main machine into the

buffer memory (DRAM)

· Address control when recalling the data from the memory

· DMA control for the network interface circuit

DRAM:

Compresses and stores the image data from the main machine (Total 16 MB.

9MB for work area, 4MB for buffer area, 3 MB for the working program)

Flash ROM:

Contains the scanner controller program and stores the UP/SP settings for

the scanner (2 MB)

2. Network interface circuit

CPU: MC58340VP

· Sequence control for the network interface circuit

· Clock/time control

· DMA control

ASIC (DISCII):

· Bus interface between the image input circuit and network interface circuit

Bridge: AG1001V

This is an ISA-PCI bridge; it corrects the timing and decodes the commands

between the ISA bus and the PCI bus.

MAC: AM79C971

This is a LAN controller; it covers the same functions as the Data Link Layer

of the OSI model.

PHY:

This device covers the same functions as the Physical Layer of the OSI

model.

Flash ROM:

Contains the program for the network interface (2 MB)

EEPROM:

Contains UP/SP settings for the network interface

2-2

Page 8

14 January, 2000 SCANNER FUNCTIONS

2.2 SCANNER FUNCTIONS

2.2.1 SELF DIAGNOSTICS

Every time the main power switch has just been turned on, the scanner board

performs the self diagnostics and the following items will be d one automatically.

· SRAM read/write test

· Flash ROM read test

· Battery test

· Initializes the network interface circuit

· Application software for scanner controller test

· Connection test between the scanner board and the main bo dy

If an error is detected, an appropriate error message or condition will be generated

(refer to the Troubleshooting section).

2.2.2 IMAGE PROCESSING IN THE SCANNER CONTROLLER

The image processing for scanner mode is done in the IPU chip on the BICU

board. However, the following processes are done in the scanner controller.

· Image compression

· Sub-scan magnification

Also, the scanner controller has a gamma table and dither matrix for scanner

mode. When the user selects the image mode using the scanner driver, the

appropriate gamma table and dither matrix are downloaded to the BICU board.

Then the IPU chip does the image processing using these tables or matrixes.

Image Compression

The image compression method for binary picture processing uses MH, MR, or

MMR, depending on scanner SP mode 002. Grayscale processing uses JPEG.

This is done by the software.

Sub-scan Magnification

Usually, the sub-scan magnification is done by changing the scanner motor speed.

However, when the amount of data being transferred is high (e.g., low resolution in

grayscale processing mode), the scanner controller deletes every other line.

2-3

KIT

SCANNER

Page 9

14 January, 2000 SCANNER FUNCTIONS

3. INSTALLATION PROCEDURE

[D]

[E]

[C]

[A] [B]

B359I502.WMF

B358I503.WMF

[H]

[I]

[F]

[G]

CAUTION

I

B359I507.WMF

B359I505.WMF

Unplug the main machine power cord before starting the following procedure.

NOTE:

If either the Printer Controller Type 450e or Fax Option Type 450e has

been installed, skip steps 1 through 8.

1. Remove the connector cover [A], rear cover [B] (4 screws), and left cover [C] (4

screws).

2. Remove the cutout [D] in the left cover.

3. Remove the HDD [E] (4 screws, 2 connectors).

4. Remove the bracket [F] (1 screw).

5. Remove the plate [G] from the expansion box (4 screws).

6. Connect the cable [H] to the expansion box [I], then install the expansion box (4

screws).

7. Reinstall the HDD.

8. Reinstall the left, rear, and connector covers.

3-1

KIT

SCANNER

Page 10

SCANNER FUNCTIONS 14 January, 2000

[C]

[A]

B359I503.WMF

[D]

[B]

B359I510.WMF

[E]

B359I601.WMF

Scanner Controller Installation

NOTE:

9. Remove plate [A] (4 screws).

10. Attach the guide plate [B] to the scanner controller board (3 screws).

11. Short TB4 [C] on the scanner board with the jumper [D].

12. If requested by the customer, install the optional SIMM memory [E] on the

If either the Scanner Option Type 450e or Fax Option Type 450e has been

installed, perform step 9. If neither have been installed, skip step 9.

scanner board.

3-2

Page 11

14 January, 2000 SCANNER FUNCTIONS

[C]

[B]

[A]

[D]

[E]

B359I509.WMF

B359I512.WMF

[I]

[H]

[F]

[J]

Copy

S

c

a

n

n

e

r

Printer/Scanner

[G]

B359I511.WMF

B359I513.WMF

13. Install the scanner controller board [A] in the third slot from the right of the

expansion box [B].

If the ISDN Option Type 450 has not been installed, skip steps 14 through 16.

14. Slide out the ISDN board [C].

15. Thread the ISDN modular cable [D] through the opening [E] in the scanner

board, as shown.

16. Insert the scanner board and ISDN board into the expansion box at the same

time.

17. Remove the cutout [F] in the plate [G] and file down any sharp edges. Reinstall

the plate.

18. Remove the bottom cap [H] of the operation panel.

NOTE:

If both Printer Controller Type 450e and Fax Option Type 450e have

not been installed, also remove the top cap of the operation panel.

19. Install the

Printer

key [I] on the operation panel and attach the

Scanner

label

[J] to the Printer key as shown.

NOTE:

If both Scanner Option Type 450e and Fax Option Type 450e have not

been installed, install the

Copy

key on the operation panel as well (see

the illustration).

3-3

KIT

SCANNER

Page 12

SCANNER FUNCTIONS 14 January, 2000

[A]

B359I514.WMF

20. Turn the machine on. If SC4003 occurs, perform the following procedure to

clear the SC condition:

NOTE:

SC4003 indicates that the battery is worn out. Even if TB4 has been

shorted with the jumper, the battery level will be low the first time the

machine is turned on after the scanner controller board is installed.

This SC condition will not occur about 30 minutes after TB4 has been

shorted.

1) Enter SP mode (

^

® a ® j ® g ® o), pressing

o

for more than

3 seconds.

2) Select 4 (Scanner SP mode).

3) Press the Next button 4 times to access SP005 (Error Log Indication).

4) Exit the SP mode.

5) Turn the machine off and on. If SC4003 still occurs, check the jumper

position.

21. Make sure that the parallel cable is not connected to the printer controller and

check the setting of the following copier SP mode (enter SP mode and select

1):

· SP5-907: Plug & Play Brand Name and Production Name Setting – select the

correct one.

22. Attach the core [A] to the STP (Shielded Twisted Pair) cable, then connect the

cable to the scanner controller.

NOTE:

The STP cord should be coiled twice inside the core as shown.

23. If the customer wishes to use the machine as a delivery fax, perform the

following.

1) Install the Fax Option Type 450e (A874) and PC Fax Expander (B368).

2) Enter the Fax SP mode and check that bit 0 of System Switch 1C is at “1”.

3) Set bit 6 of System Switch 1F to “1”.

4) Set bits 0 and 1 of User Parameter Switch 31 to “1” depending on the

delivery fax function (refer to the ScanRouter Professional Operation

Instructions Scanner & Fax Reference Type 450e for more detail).

3-4

Page 13

14 January, 2000 SERVICE PROGRAM MODE

4. SERVICE TABLE

4.1 SERVICE PROGRAM MODE

4.1.1 SERVICE PROGRAM ACCESS PROCEDURE

The service program access procedure, such as “Entering Service Program (SP)

Mode” and “Exiting SP Mode” is the same as for copier and fax, as follows.

Entering SP mode

K

® a ® j ® g ® o (hold it for more than 3 seconds.)

Exiting SP mode

Press the “Back” and “Exit” keys until the standby mode display appears.

4.1.2 SERVICE PROGRAM MODE TABLES

NOTE:

1) In the Function column, comments are in italics.

2) In the Settings column, the default value is in bold letters.

No. Function Setting

Changes the FTP port number.001 FTP Port Number

After changing this value, do the

following:

1. Run the Registry Editor.

2. Access

/HKEY_LOCAL_MACHINE/SOF

TWARE/Ricoh/NetworkScanner

3. Change the value of PortNo to

this SP mode’s value.

002 Com pr ession Type Selects the compression type for

binary picture processing.

003 Sof tware Version Displays the software version.

004 Pr ogram Number

006 Scan Dat a Reset

Displays the program’s part

number.

Displays the error logging data005 Er ror Log Display

Check this data when SC4005

occurs. Then inform it to the

service center.

Resets all scanner data (UP and

SP modes) except for the network

interface data (UP-Network-1 ~ 8)

Press “1” three times to reset.

Resets all UP and SP settings007 All Data Reset

Press “1” three times to reset.

00000 ~ 65536

1/step

3670

1: MH

2: MR

3: MMR

KIT

SCANNER

4-1

Page 14

SERVICE PROGRAM MODE 14 January, 2000

No. Function Setting

008 NIC Data Reset

Resets all network interface data

(UP-Network-1 ~ 8)

Press “1” three times to reset.

009 Density Adjustment 1 0 ~ 255

010 Density Adjustment 2

011 Density Adjustment 3 0 ~ 255

012 Density Adjustment 4 0 ~ 255

013 Density Adjustment 5

014 Density Adjustment 6 0 ~ 255

015 Density Adjustment 7

Adjusts the image density for each

image density level which can be

selected with UP mode (UP-ScanDensity)

Initializes the flash ROM.016 ROM Disk Format

1/step

40

0 ~ 255

1/step

70

1/step

100

1/step

130

0 ~ 255

1/step

160

1/step

190

0 ~ 255

1/step

220

Press “1” three times to initialize.

4-2

Page 15

14 January, 2000 DOWNLOADING NEW SOFTWARE

4.2 DOWNLOADING NEW SOFTWARE

4.2.1 SOFTWARE DOWNLOAD PROCEDURE

The software for the scanner controller contains the system software, application

software, and network interface software. The new software can be downloaded

from a flash memory card.

[B]

[A]

B359M500.WMF

1. Prepare a flash memory card that has been programmed with the latest

software.

2. Turn off the machine and disconnect the Ethernet (STP) cable from the

scanner controller.

3. Remove the cover [A], and insert the flash memory card [B] into the slot so that

the “A” side of the card faces the front of the machine.

4. Turn the machine on and press the Scanner Mode key.

5. Press the INSTALL key on the display in reply to the message. Software

download will take several minutes.

6. Make sure that the machine displays the scanner SP mode, then after new

software has been downloaded successfully, turn off the machine, remove the

card, connect the Ethernet cable, and turn the machine back on.

KIT

SCANNER

4-3

Page 16

DOWNLOADING NEW SOFTWARE 14 January, 2000

4.2.2 ERROR M E SSAGES DURING THE SOFTWARE DOWNLOAD

If downloading failed, one of the following error messages appears. At this time,

press the “CONFIRM” bottom in the display to re-try the download.

Message Action

SYS Erasing Failed ADDR:XXXXXXXX

SYS Writing Failed ADDR:XXXXXXXX

SYS Verify Failed ADDR:XXXXXXXX

APL Erasing Failed ADDR:XXXXXXXX

APL Writing Failed ADDR:XXXXXXXX

APL Verify Failed ADDR:XXXXXXXX

NIC board is not equipped

NIC Initialization failed. CODE:XXXX

NIC Download mode is disable

NIC Writing Failed ADDR:XXXXXXXX

NIC Host Service Error CODE:XXXX Re-try the download. If the download fails

Re-try the download. If the download fails

again, replace the scanner controller.

again, replace the scanner controller.

Check whether the STP cable is

disconnected. If it is connected, disconnect

the cable and re-try the downloading.

4-4

Page 17

14 January, 2000 PRECAUTION

5. REPLACEMENT AND ADJUSTMENT

5.1 PRECAUTION

CAUTION

I

Lithium Battery

The danger of explosion exists if a battery of this type is incorrectly

replaced. Replace only with the same or an equivalent type recommended

by the manufacturer. Discard used batteries in accordance with the

manufacturer’s instructions.

5.2 NOTE FOR REPLACING THE SCANNER

CONTROLLER BOARD

The scanner controller does not have a configuration report and cannot

upload/download settings to an IC card. So, before replacing the scanner controller

board, check all UP mode and SP mode settings. After replacing the board, reinput these settings.

5-1

KIT

SCANNER

Page 18

14 January, 2000 SERVICE CALL CO NDI TION

6. TROUBLESHOOTING

6.1 SERVICE CALL CONDITION

The scanner controller board automatically performs the self diagnostics whenever

the main power switch is turned on. If an error is detected, it displays an error

message on the LCD. Turn the main switch off and on to reset the SC condition.

6.1.1 SC CODE DESCRI PTIONS

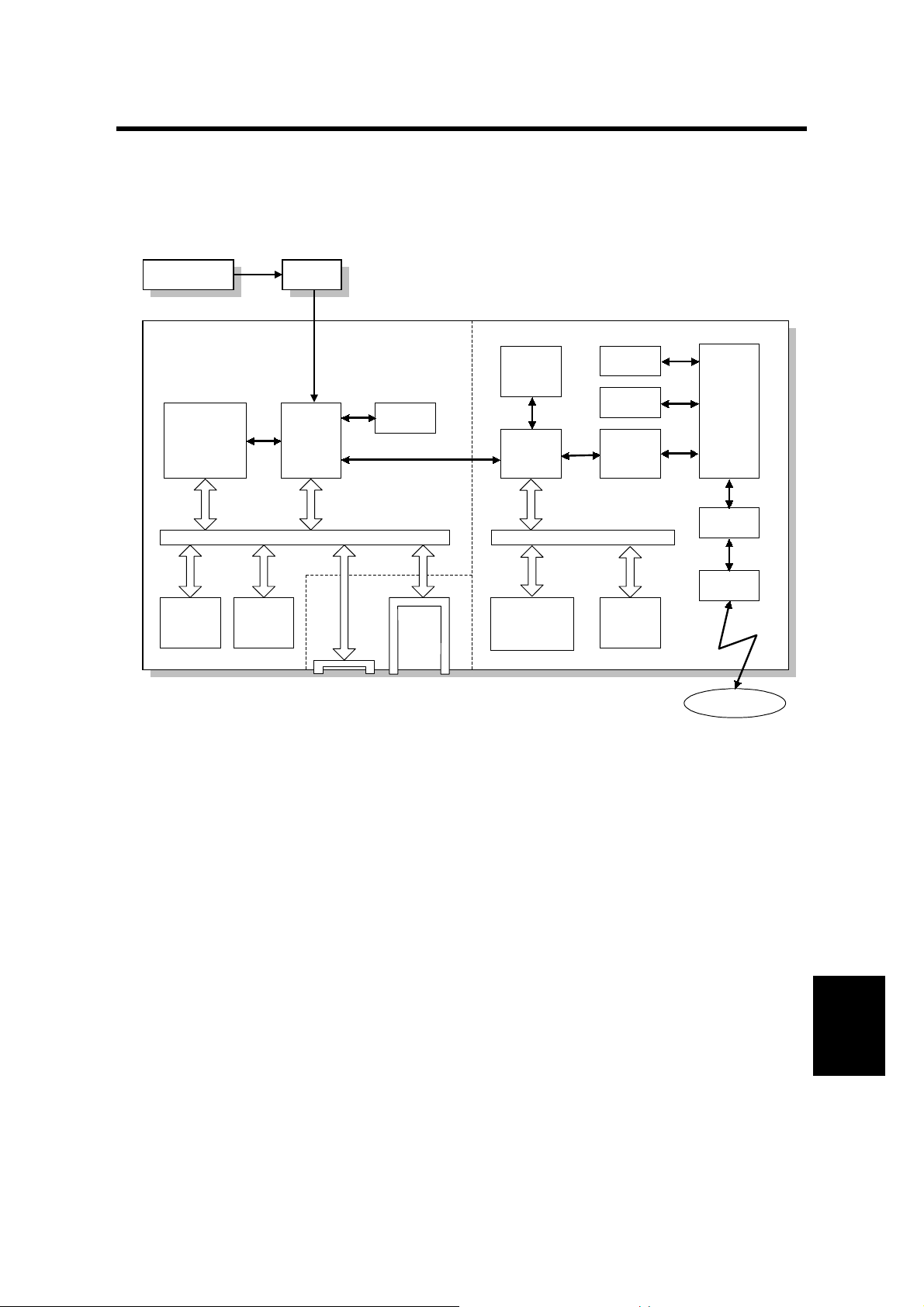

SC code Error Items Conditions Action

Replace or re-install the

SIMM

Replace the scanner

controller board

download the software. If

the download fails, replace

the scanner controller.

Replace the scanner

controller board

Change the jumper position

Replace the scanner

controller board

and on, check the error log

data (SP005), then inform it

to the service center.

SC4001

SC4002

SC4003

SC4004

SC4005

DRAM Error

Flash ROM

Error

Battery Error

NIC Error NIC circuit defective

Application

Error

SIMM defective

·

A SIMM type other than

·

16MB or 32MB SIMM is

installed

Standard SRAM

·

defective

The machine cannot scan Defective firmware; try to

The battery has run out

·

The jumper TB4 is at the

·

off position

Logical error Turn the main switch off

6-1

KIT

SCANNER

Page 19

LEDS 14 January, 2000

6.2 LEDS

B359T500.WMF

LED No. Color Status Condition

LED1 Yellow

LED2 Green

LED3 Green

LED5 Red

Lit The network interface circuit is working properly.

Off The network interface circuit does not work.

Lit

Off

Lit 100 Base-TX

Off 10 Base-T

Lit + 5V is supplied

Off + 5V is not supplied

Blinking

The scanner controller board is connected to the

network properly.

The scanner controller board is not connected to the

network.

Communication error between the scanner controller

board and BICU.

6-2

Loading...

Loading...