Page 1

DUPLEX

(Machine Code: A896/B414)

Page 2

10 August, 2001 SPECIFICATIONS

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Paper Size:

Paper Weight: 64 g/m2 ~ 105 g/m2, 20 lb ~ 28 lb

Tray Capacity: 1 sheet

Power Consumption: 40 W

Power Source: DC 24 V, 5 V

Dimensions (W x D x H): 90 x 495 x 452 mm

Weight: 6 kg

Standard sizes

A5 lengthwise to A3

HLT to DLT

Non-standard sizes

Width: 140 to 297 mm

Length: 182 to 432 mm

B414-1

Options

Page 3

MECHANICAL COMPONENT LAYOUT 10 August, 2001

1.2 MECHANICAL COMPONENT LAYOUT

1

2

3

4

5

6

7

1. Inverter Gate

2. Entrance Sensor

3. Inverter Roller

4. Upper Transport Roller

B414V500.WMF

5. Middle Transport Roller

6. Lower Transport Roller

7. Exit Sensor

B414-2

Page 4

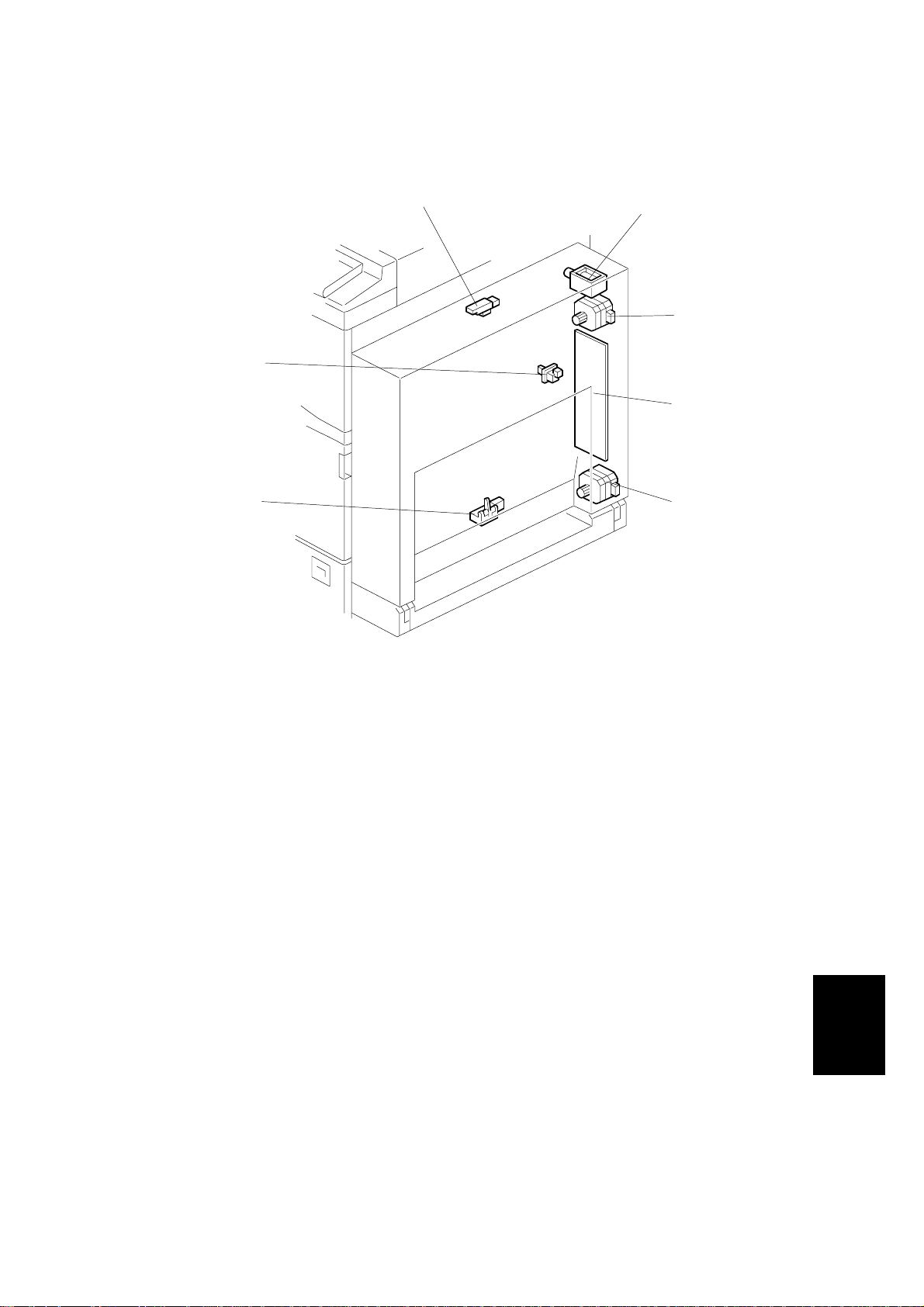

10 August, 2001 ELECTRICAL COMPONENT LAYOUT

1.3 ELECTRICAL COMPONENT LAYOUT

1

2

3

7

4

6

5

1. Entrance Sensor

2. Inverter Gate Solenoid

3. Inverter Motor

4. Main Board

B414V501.WMF

5. Transport Motor

6. Exit Sensor

7. Duplex Unit Open Switch

Options

B414-3

Page 5

ELECTRICAL COMPONENT DESCRIPTION 10 August, 2001

1.4 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index No.

Motors

M1 Inverter Drives the inverter roller. 3

M2 Transport Drives the upper and lower transport rollers. 5

Sensors

Entrance Detects the trailing edge of the copy paper to

S1

S2 Exit Checks for misfeeds. 6

Switches

SW1

Solenoids

SOL1 Inverter Gate Controls the inverter gate. 2

Duplex Unit

Open

turn on the inverter gate solenoid and turn on

the inverter motor in reverse. Checks for

misfeeds.

Detects whether the duplex unit is opened or

not.

1

7

PCBs

PCB1

Main Controls the duplex unit and communicates

with the copier.

4

B414-4

Page 6

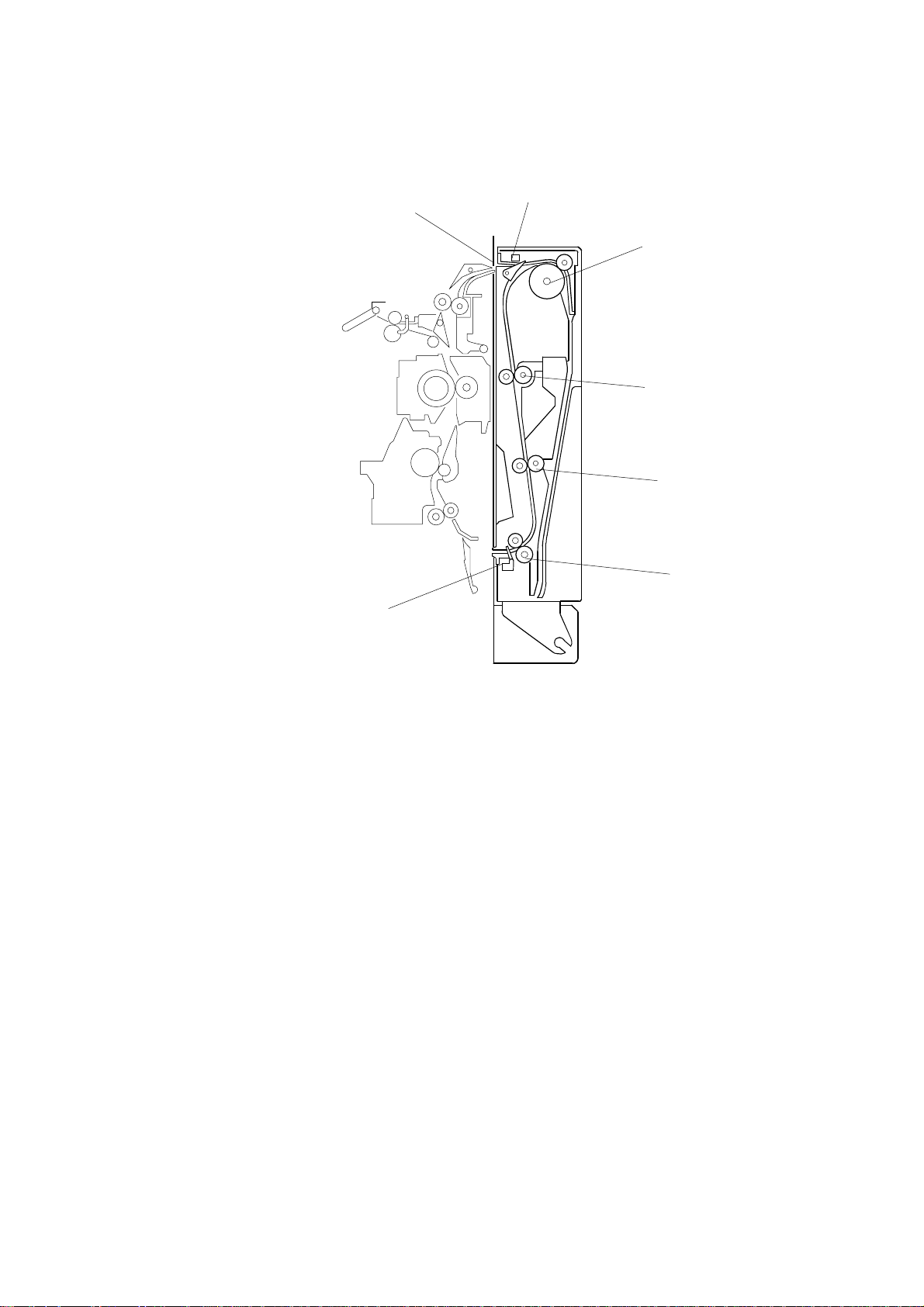

10 August, 2001 DRIVE LAYOUT

1.5 DRIVE LAYOUT

1

2

3

4

1. Inverter Roller

2. Inverter Motor

3. Upper Transport Roller

5

6

B414V502.WMF

4. Transport Motor

5. Lower Transport Roller

6. Middle Transport Roller

Options

B414-5

Page 7

BASIC OPERATION 10 August, 2001

2. DETAILED DESCRIPTIONS

2.1 BASIC OPERATION

To increase the productivity of the duplex unit, copies are printed as follows.

Longer than A4 sideways/LT sideways

The duplex unit can store only one sheet of copy paper.

Example: 8 pages. The number [A] in the illustration shows the order of pages. The

number [B] in the illustration shows the order of sheets of copy paper (if

shaded, this indicates the second side).

⇒⇒4⇒⇒6⇒⇒8⇒

1 1 42 2 3 3 4

5312

7

B414D519.WMF

B414-6

B414D518.WMF

Page 8

10 August, 2001 BASIC OPERATION

Up to A4 sideways/LT sideways

The duplex unit can store two sheets of copy paper

Example: 8 pages. The number [A] in the illustration shows the order of pages. The

number [B] in the illustration shows the order of sheets of copy paper (if

shaded, this indicates the second side).

⇒⇒⇒⇒6⇒⇒8⇒

4 1 532

1 423 3412

B414D520.WMF

7

B414-7

Options

B414D517.WMF

Page 9

FEED IN AND EXIT MECHANISM 10 August, 2001

2.2 FEED IN AND EXIT MECHANISM

[A]

[B]

[G]

[D]

[C]

[E]

[F]

B414D504.WMF

B414D505.WMF

When paper is fed into duplex unit:

As soon as the paper arrives from the interchange unit, it is sent to the inverter

section [C] (the inverter gate solenoid [A] remains off during this process).

The inverter section can hold a sheet of paper up to A3 size. Because of this, the

cover guide used in the previous model has become obsolete and has been

eliminated from the design.

Inversion and Exit:

Shortly after the trailing edge of the paper passes the entrance sensor [G], the

inverter gate solenoid [A] switches on and the inverter gate [B] switches over to

direct the paper to the exit path [E]. The inverter roller [D] then changes its rotation

direction and the paper goes to the exit transport area [F]. The paper is then sent

to the registration rollers in the main copier via the transport rollers.

B414-8

Page 10

10 August, 2001 COVER REMOVAL

3. REPLACEMENT AND ADJUSTMENT

3.1 COVER REMOVAL

[A]

1. Remove the duplex unit cover [A] (4 screws).

B414R501.WMF

Options

B414-9

Page 11

ENTRANCE SENSOR REPLACEMENT 10 August, 2001

3.2 ENTRANCE SENSOR REPLACEMENT

[A]

B414R502.WMF

1. Remove the duplex unit cover. (Refer to section 3.1.)

2. Remove the sensor holder [A] (1 screw).

3. Replace the entrance sensor [B] (1 connector, 1 screw).

[B]

B414-10

Page 12

10 August, 2001 EXIT SENSOR REPLACEMENT

3.3 EXIT SENSOR REPLACEMENT

[B]

[C]

[A]

1. Open the duplex unit [A].

2. Remove the sensor bracket [B] (1 screw).

3. Replace the exit sensor [C] (1 connector).

B414R503.WMF

Options

B414-11

Loading...

Loading...