Page 1

DUPLEX UNIT (G694)

Page 2

1 August 1996 SPECIFICATIONS

1. SPECIFICATIONS

Copy Paper Size : Width

Max. 297 mm, Min. 182 mm

Length

Max. 432 mm, Min. 148 mm

Paper Weight : 60 g to 90 g

Capacity: 1 sheet

Power Source : 24 Vdc from the copier

Power Consumption : 25 W

Dimensions (W x D x H) : Duplex Tray - 530 x 565 x 255 mm

Inverter Unit - 75 x 428 x 101 mm

Weight : Duplex Tray - 4.1 kg

Inverter Unit - 1 kg

G694-1

Page 3

COMPONENT LAYOUT 1 August 1996

2. COMPONENT LAYOUT

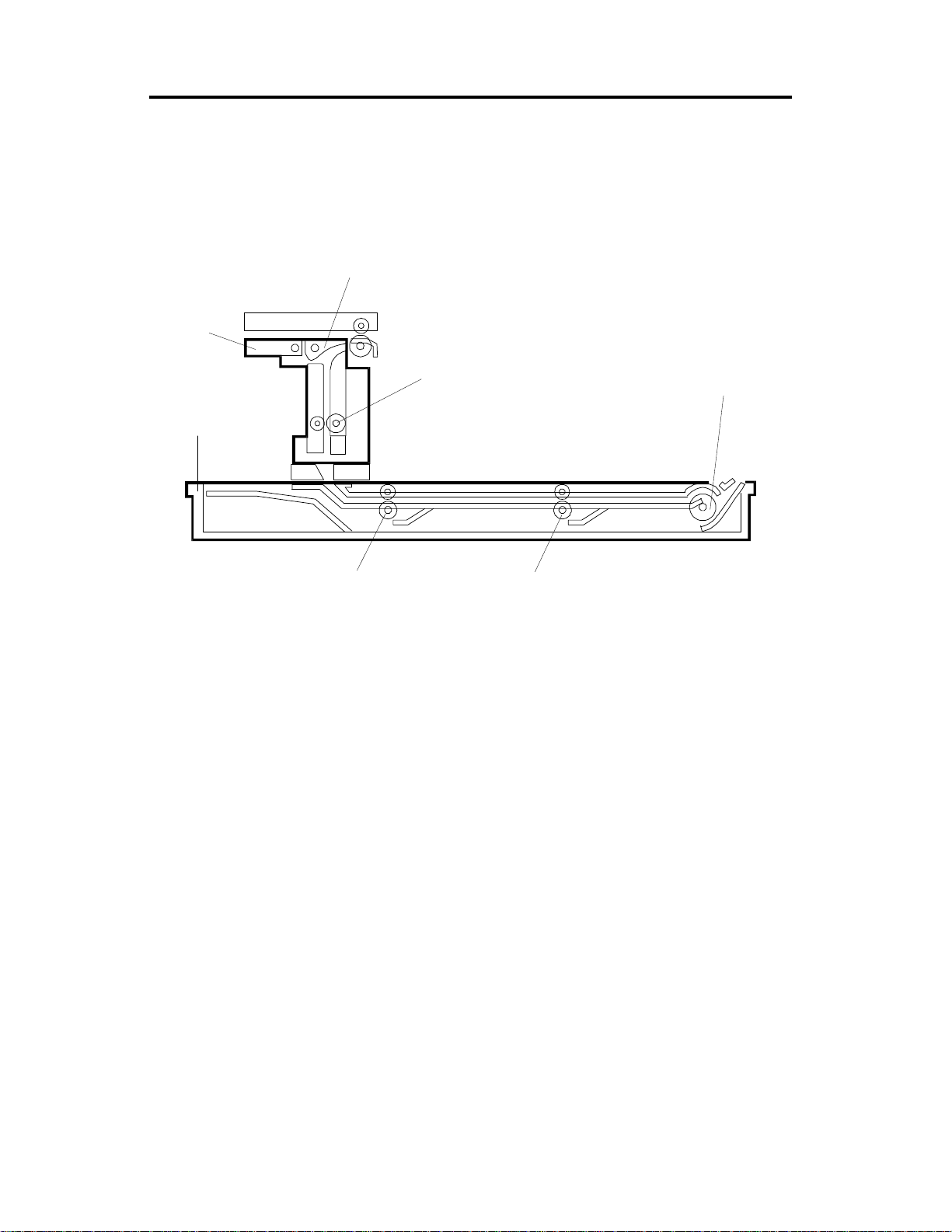

2.1 MECHANICAL COMPONENT LAYOUT

1

7

6

1. Duplex Junction Gate

2. Inverter Unit Transport Roller

3. Duplex Feed Roller

2

45

5. Left Transport Roller

6. Duplex Tray

7. Inverter Unit

3

G694O006.wm f

4. Central Transport Roller

G694-2

Page 4

1 August 1996 COMPONENT LAYOUT

2.2 ELECTRICAL COMPONENT LAYOUT

1

5

4

G694O002.wmf

2

3

6

1. Duplex Control Board

2. Duplex Turn Sensor

3. Duplex Exit Sensor

4. Duplex Feed Motor

7

G694O003.wmf

5. Duplex Transport Motor

6. Duplex Junction Gate Solenoid

7. Duplex Entrance Sensor

G694-3

Page 5

COMPONENT LAYOUT 1 August 1996

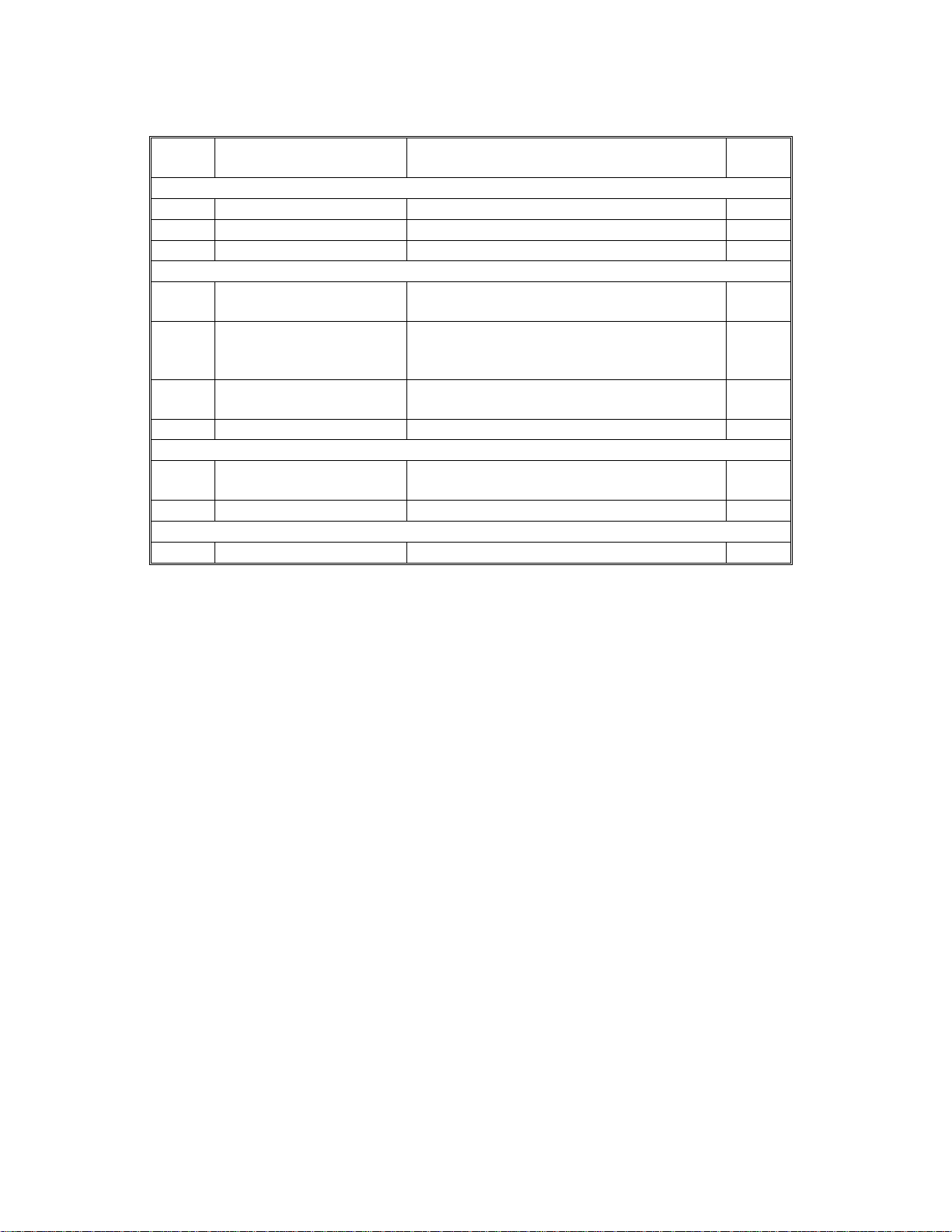

2.3 ELECTRICAL COMPONENT DESCRIPTION

Symbol

Motors

M1 Duplex Transport Drives the left and central tran sport rollers. 5

M2 Duplex Feed Drives the duplex feed roller. 4

Sensors

S1 Duplex Entrance

S2 Duplex Turn

S3 Duplex Exit

Solenoid

SOL1

PCBs

PCB1 Duplex Control Controls the overal l duplex tray oper at ion. 1

Duplex Juncti on Gate

Control

Name Function

Detects misfeeds and controls the transport

motor speed.

Detects misfeeds, controls the paper stop

position, and cont rols the duplex fee d roller

timing.

Detects misfe eds and controls the duplex

feed roller off timing.

Controls the dupl ex junction gate. 6

Index

No.

7

2

3

G694-4

Page 6

1 August 1996 DRIVE LAYOUT

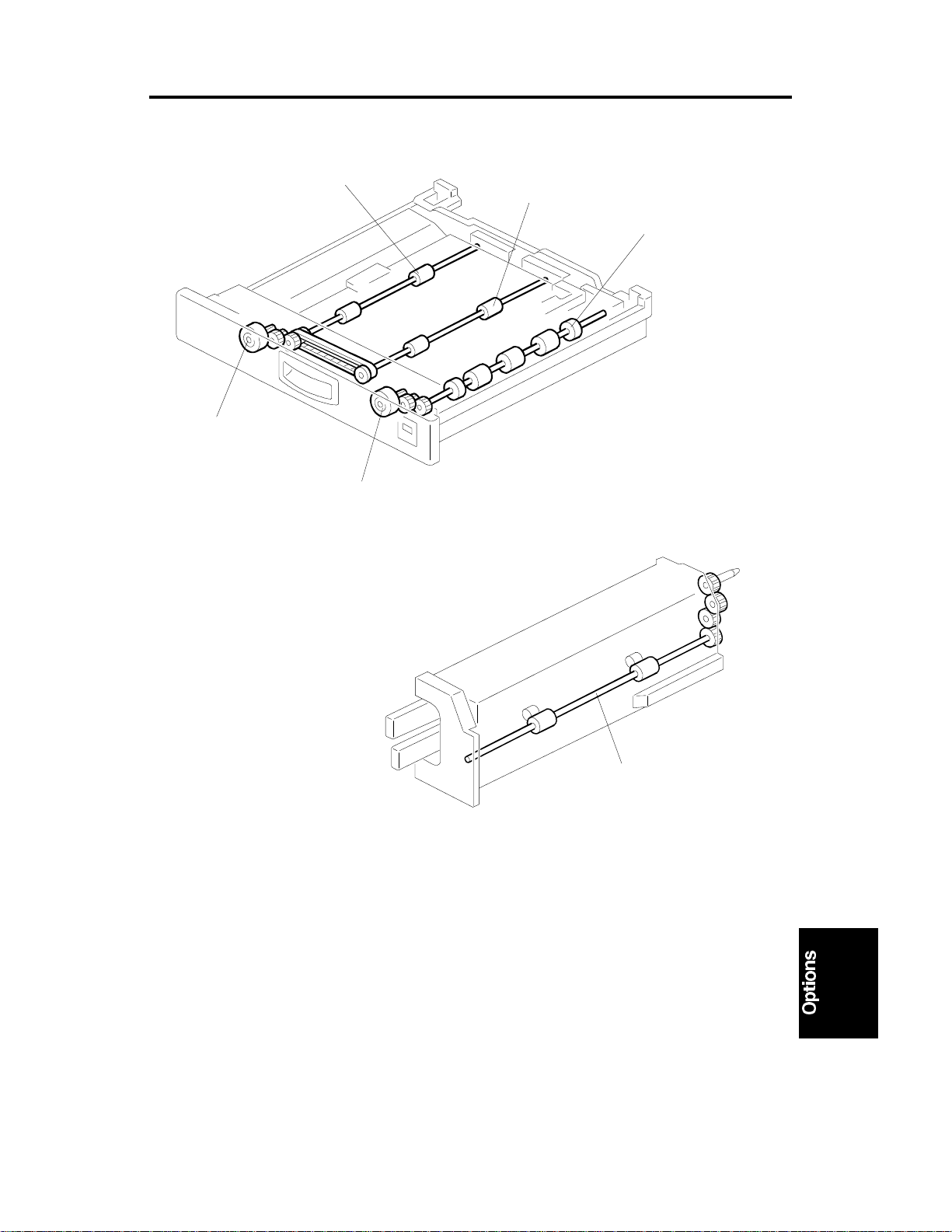

3. DRIVE LAYOUT

1

5

2

3

1. Left Transport Roller

4

G694o004.wmf

6

G694O005.wmf

4. Duplex Feed Motor

2. Central Transport Roller

3. Duplex Feed Roller

5. Transport Motor

6. Inverter Unit Transport Roller

G694-5

Page 7

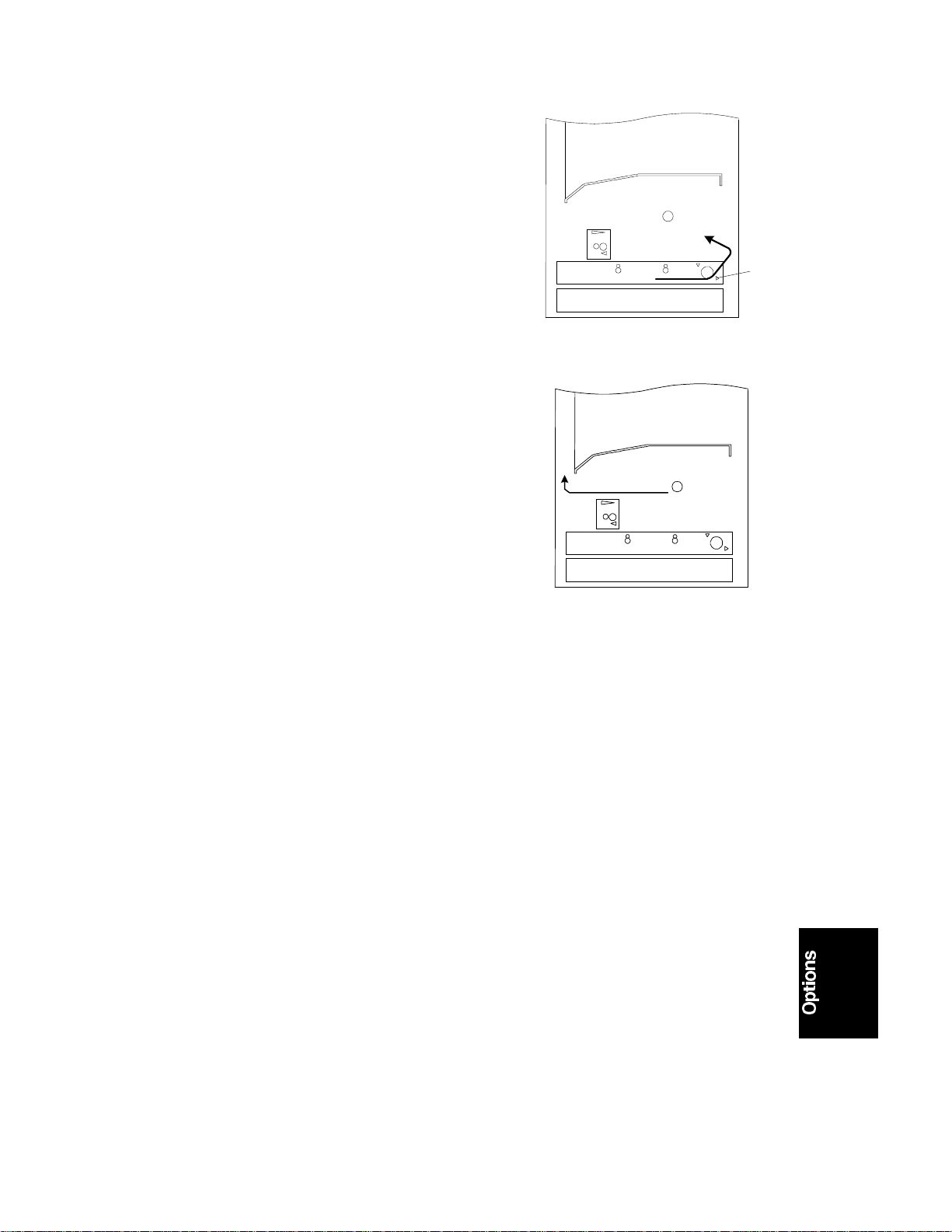

BASIC OPERATION 1 August 1996

4. BASIC OPERATION

4.1 A3 PAPER SIZE

1. When the leading edge of the paper [A]

has passed through the fusing unit, the

junction gate solenoid energizes and the

junction gate [B] is opened. The paper is

guided to the inverter unit [C]. The on

timing of the junction gate solenoid is

controlled by the registration sensor.

2. The paper is fed to the duplex tray [D] by

the inverter unit transport roller [E], and

to the duplex feed roller [F] by the left

and central transport rollers ([G], [H]) in

the duplex tray. When the trailing edge of

the paper has passed through the duplex

entrance sensor [I], the speed of the

paper doubles.

[B]

[D]

[A]

[C]

G694O506.wmf

[E]

[F]

[I]

3. The paper is inverted by the duplex feed

roller [F]. The duplex feed motor turns off

shortly after the trailing edge of the paper

passes through the duplex turn sensor

[J].

[G] [H]

G694O507.wmf

[J]

G694O508.wmf

[F]

G694-6

Page 8

1 August 1996 BASIC OPERATION

4. Almost immediately after stopping, the

duplex feed motor turns on again in

reverse, and the inverted paper is fed

back to the copier. When the trailing

edge of the paper passes through the

duplex exit sensor [K], the duplex feed

motor turns off.

[K]

G694O509.wmf

5. The paper is transported to the exit area.

G694O521.wmf

G694-7

Page 9

BASIC OPERATION 1 August 1996

4.2 SHORTER THAN A4 LENGTHWISE (MEMORY COPY)

á

8 Original (

1. Two sheets of paper [A] [B] are fed from

the lower paper tray and the first paper

transported to the duplex tray in the

same way as for A3.

2. The first sheet [A] of paper is reversed by

the duplex turn roller and the second

sheet [B] is transported to the duplex unit

in the same way as for A3 size.

~ º)

[A]

2

G694O510.wmf

[B]

3. The first sheet [A] is fed out to the copier

from the duplex tray in the same way as

for A3 size. The transport motor stops

when the leading edge of the second

sheet [B] turns on the duplex turn sensor

[C]. The second sheet [B] stops in the

waiting position.

[B]

[B]

4

2

G694O511.wmf

[A]

[C]

4

2

G694O512.wmf

[A]

G694-8

Page 10

1 August 1996 BASIC OPERATION

4. The second sheet [B] starts again when

the trailing edge of the first sheet [A]

passes through the duplex exit sensor

[D], and it is reversed. The second sheet

is being reversed, the third sheet [E] is

fed out from the lower tray after the first

sheet has reached the registration roller.

[A]

1

2

4

[E]

[D]

5. The first sheet [A] is fed out to the copy

tray. The second sheet [B] is fed out from

the duplex tray. The third sheet [E] is

transported to the duplex tray.

6. The second sheet [B] is transported to

the exit section. The third sheet [E] is

reversed. While the third sheet is being

reversed, the fourth sheet [F] is fed out

from the lower tray after the second

sheet [B] has reached the registration

roller.

[A]

2

1

[E]

[B]

6

3

4

G694O513.wmf

4

G694O514.wmf

[B]

[B]

[F]

G694-9

[E]

6

G694O515.wmf

Page 11

BASIC OPERATION 1 August 1996

7. The second sheet [B] is fed out to the

copy tray. The third sheet [E] is fed out

from the duplex tray. The fourth sheet [F]

is transported to the duplex tray.

8. The third sheet [E] is transported to the

exit section. The fourth sheet [F] is

reversed.

[F]

[B]

4

3

8

6

G694O516.wmf

[E]

[E]

5

6

8

[F]

9. The third sheet [E] is fed out to the copier

exit tray. The fourth sheet [F] is fed out

from the duplex tray.

[E]

G694O517.wmf

6

5

8

G694O518.wmf

[F]

G694-10

Page 12

1 August 1996 BASIC OPERATION

10. The fourth sheet [F] is transported to the

exit section.

7

8

[F]

G694O519.wmf

11. The fourth sheet [F] is fed out to the

copier exit tray.

[F]

8

7

G694O520.wmf

G694-11

Page 13

DETAILED DESCRIPTIONS 1 August 1996

5. DETAILED DESCRIPTIONS

5.1 DUPLEX JUNCTION GATE MECHANISM

[A]

[C]

[B]

To the inverter

G694O007.wmf

The paper that is fed out from the fusing unit [A] is delivered to the copier exit

section or to the inverter unit.

When the duplex junction gate solenoid [B] energizes, the junction gate [C]

opens, and the paper is fed to the inverter unit.

G694-12

Page 14

1 August 1996 DETAILED DESCRIPTIONS

5.2 PAPER TRANSPORT AND FEED MECHANISM

[B]

[C]

[E]

[A]

[D]

G694O004.wmf

[B]

[C]

[F]

G694O008.wmf

The duplex transport motor [A] drives the left and central transport rollers ([B],

[C]) and the duplex feed motor [D] drives the duplex feed roller [E].

The paper sent from the inverter unit is fed by the left and central transport

rollers to the duplex feed roller.

The duplex feed roller inverts the paper. The duplex feed roller stops shortly

after the trailing edge of the paper turns off the duplex turn sensor [F].

Immediately after this, the duplex feed roller [E] turns in reverse and the

inverted paper is fed out to the copier.

G694-13

Page 15

DETAILED DESCRIPTIONS 1 August 1996

5.3 TIMING CHARTS

5.3.1 A3 (without memory)

G694-14

G694O500.wmf

Page 16

1 August 1996 DETAILED DESCRIPTIONS

5.3.2 A4 sideways (Memory)

G694-15

G694O501.wmf

Page 17

DETAILED DESCRIPTIONS 1 August 1996

5.4 OVERALL ELECTRICAL CIRCUIT

Copier IOCSS

Board

Duplex Tray

Duplex Control Board

Motors

Duplex Tray

Connection

Sensors

Solenoid and

Sensor

Inverter Unit

A694O502.wmf

The solenoid and sensor in the inverter unit are directly connected to the

copier. The motors and sensors in the duplex tray are controlled by the

duplex control board.

When the duplex tray connector is connected (this happens when the duplex

tray is slid into the machine), the duplex tray connection signal to the copier is

grounded. Then the copier detects that the duplex tray has been inserted.

G694-16

Page 18

1 August 1996 DIP SWITCHES

6. DIP SWITCHES

6.1 DUPLEX CONTROL BOARD : DSW1

SW No. Function

1

Adjustment Value

2

3Free Run

4 Adjustmen t Di r ect i on

SW1 SW2 Value

OFF OFF 0 mm

ON OFF 2 mm

OFF ON 4 mm

ON ON 6 mm

SW4

ON: [–] direction

OFF: [+] direction

[A]

G694O505.wmf

Adjustment of the paper stop position at the duplex feed roller [A]

(SW1,2,4)

If paper jams occur after changing the duplex turn sensor, because the

sensor was not installed correctly, adjust the paper stop position at the

duplex feed roller [A].

Free run (SW3)

The duplex transport and feed motor turn on with A4 sideways timing.

G694-17

Page 19

REPLACEMENT AND ADJUSTMENT 1 August 1996

7. REPLACEMENT AND ADJUSTMENT

7.1 DUPLEX TRANSPORT UNIT REMOVAL

[B]

[D]

[A]

[C]

G694O503.wmf

1. Remove the inner cover [A] of the duplex tray (2 screws).

2. Remove the duplex control board cover [B] (2 screws).

3. Release the hook and remove the front cover [C].

4. Remove the duplex transport unit [D] (4 screws, 4 connectors).

G694-18

Page 20

1 August 1996 REPLACEMENT AND ADJUSTMENT

7.2 DUPLEX TRANSPORT AND FEED MOTOR REPLACEMENT

[C]

[A]

[B]

G694O504.wmf

1. Remove the transport unit.

2. Replace the duplex transport motor [A] (2 screws, 1 connector).

Replace the duplex feed motor [B] (2 screws, 1 connector).

7.3 DUPLEX TURN AND DUPLEX EXIT SENSORS

1. Remove the duplex transport unit.

2. Replace the duplex turn sensor [C] (1 connector).

Replace the duplex exit sensor [D] (1 connector).

[D]

G694-19

Page 21

REPLACEMENT AND ADJUSTMENT 1 August 1996

7.4 DUPLEX JUNCTION GATE SOLENOID AND DUPLEX

ENTRANCE SENSOR REPLACEMENT

[A]

[C]

[B]

G694O012.wm f

1. Remove the inverter unit [A] (1 screw).

2. Replace the junction gate solenoid [B] (2 screws, 1 connector)

Replace the duplex entrance sensor [C] (1 connector).

G694-20

Page 22

1 August 1996 COPIER INSTALLATION

DUPLEX UNIT INSTALLATION

[A]

G694I500.wmf

[C]

G694I508.wmf

[B]

[D]

G694I502.wmf

CAUTION

Unplug the copier power cord before starting the following procedure.

1. Unpack the inverter unit and duplex unit and remove the tapes (7 tapes)

and two knob screws [A].

2. Open the front cover [B].

3. Slide the two hinges [C] inward and remove them as shown in the

illustration. Then, remove the front cover.

4. Remove the inverter unit cover [D] (1 screw).

3-13

Page 23

COPIER INSTALLATION 1 August 1996

[A]

G694I503.wmf

G694I504.wmf

[B]

G694I505.wmf

5. Swing the lower transport guide plate [A] down as shown in the illustration.

6. Remove the lower transport guide plate and pull it out as shown in the

illustration.

7. Push the inverter unit [B] in until the pin is completely inserted in the pin

hole.

8. Secure the inverter unit with the screw which was removed in step 4.

3-14

Page 24

1 August 1996 COPIER INSTALLATION

[B]

[A]

G694I506.wmf

[C]

[D]

G694I507.wmf

9. Swing the upper inverter guide plate [A] up as shown in the illustration

and secure it with the magnets [B] at front and rear.

10. Reinstall the front cover.

11. Pull out the 1st paper tray [C].

12. Push the duplex unit [D] into the place where the 1st paper tray was.

13. Turn the ac and main switches on and check if the duplex unit works

properly.

3-15

Page 25

Duplex (G694)

1

5

4

G694S500.wmf

2

3

6

7

G694S501.wmf

Page 26

Duplex (G694)

Symbol Index No. Description P to P (1/2)

Motors

M1 5 Duplex Transport B9

M2 4 Duplex Feed C9

Sensors

S1 7 Duplex Entrance B11

S2 2 Duplex Tur n C12

S3 3 Duplex Exit C12

Solenoid

SOL1 6 Duplex Junction Gate Control B11

PCBs

PCB1 1 Duplex Contr ol C11

Loading...

Loading...