Page 1

SERVICE DOCUMENTATION

RICOH GROUP COMPANIES

B174

001955MIU

Page 2

Page 3

SERVICE DOCUMENTATION

®

®

B174

RICOH GROUP COMPANIES

Page 4

Page 5

B174

SERVICE

DOCUMENTATION

001955MIU

Page 6

Page 7

A

f

r

It is the reader's responsibility when discussing the information contained

within this document to maintain a level of confidentiality that is in the best

interest of Ricoh Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

ll product names, domain names or product illustrations, including

desktop images, used in this document are trademarks, registered

trademarks or the property of their respective companies.

They are used throughout this book in an informational or editorial fashion

only and for the benefit of such companies. No such use, or the use o

any trade name, or web site is intended to convey endorsement or othe

affiliation with Ricoh products.

2004 RICOH Corporation. All rights reserved.

Page 8

Page 9

p

t

r

g

l

y

p

WARNING

The Service Manual contains information

regarding service techniques, procedures,

rocesses and spare parts of office equipmen

distributed by Ricoh Corporation. Users of this

manual should be either service trained o

certified by successfully completing a Ricoh

Technical Training Program.

Untrained and uncertified users utilizin

information contained in this service manual to

repair or modify Ricoh equipment risk persona

injury, damage to property or loss of warrant

rotection.

Ricoh Corporation

Page 10

Page 11

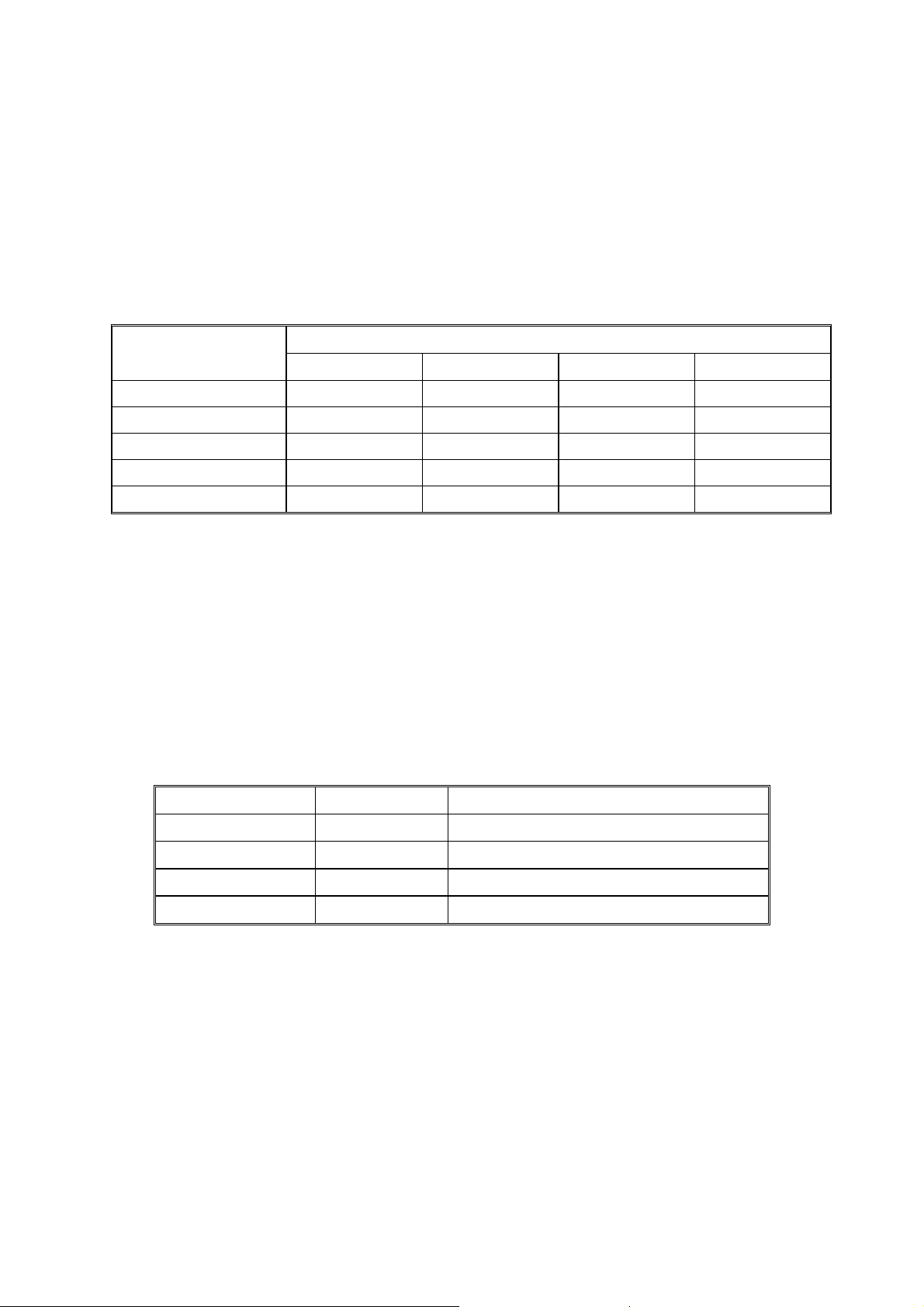

LEGEND

PRODUCT CODE COMPANY

B174 DSm515pfd AC106d AC204 AC204

GESTETNER LANIER RICOH SAVIN

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

6/2004 Original Printing

Page 12

Page 13

B174

TABLE OF CONTENTS

INSTALLATION

1. INSTALLATION............................................................................ 1-1

PREVENTIVE MAINTENANCE

2. PREVENTIVE MAINTENANCE.................................................... 2-1

REPLACEMENT AND ADJUSTMENT

3. REPLACEMENT AND ADJUSTMENT ........................................ 3-1

3.1 GENERAL PRECAUTIONS ON DISASSEMBLY ......................................3-1

Releasing Plastic Latches.....................................................................3-1

3.2 REAR COVER...........................................................................................3-2

3.3 SCANNER ASS'Y...................................................................................... 3-3

3.4 ADF ASS'Y ................................................................................................3-9

3.5 OPE ASS'Y (ALSO KNOWN AS ‘OP-PORT’) .........................................3-11

3.6 RIGHT COVER ASS'Y ............................................................................3-12

Multi Purpose (MP) Tray (Also known as Bypass Tray)......................3-13

Duplex Ass’y ....................................................................................... 3-14

Transfer Roller Ass’y...........................................................................3-14

3.7 FUSER ASS'Y (ALSO KNOWN AS ‘FUSING UNIT’) ..............................3-15

3.8 EXIT ASS'Y ............................................................................................. 3-17

3.9 COPY TRAY............................................................................................3-18

3.10 DRIVE ASS'Y ........................................................................................3-19

3.11 SMPS & HVPS (ALSO KNOWN AS ‘PSU’ AND ‘POWER PACK) ........3-20

3.12 LSU (LASER SCANNING UNIT) ...........................................................3-21

3.13 LEFT COVER ........................................................................................ 3-22

3.14 MAIN FRAME ASS'Y.............................................................................3-23

3.15 MP ASS'Y (MULTI PURPOSE ASS’Y) ..................................................3-25

3.16 FEED ASS'Y..........................................................................................3-27

3.17 PICK UP ASS'Y.....................................................................................3-28

3.18 MAIN BOARD........................................................................................3-29

3.19 LIU BOARD ...........................................................................................3-30

TROUBLESHOOTING

4. TROUBLESHOOTING ................................................................. 4-1

4.1 ERROR MESSAGES ................................................................................4-1

4.2 ABNORMAL IMAGE PRINTING AND DEFECTIVE ROLLERS.................4-3

4.3 TROUBLESHOOTING ..............................................................................4-4

4.3.1 SCANNER ........................................................................................ 4-4

SM i B174

Page 14

COPY....................................................................................................4-4

PC-SCAN..............................................................................................4-5

4.3.2 FAX...................................................................................................4-6

FAX/TELEPHONE PRECAUTIONS .....................................................4-6

4.3.3 PRINT QUALITY...............................................................................4-7

No Image ............................................................................................4-10

All Black .............................................................................................. 4-12

Vertical White Line (Band) ..................................................................4-13

Dark Image .........................................................................................4-14

Background.........................................................................................4-15

Ghost ..................................................................................................4-16

Black Spot...........................................................................................4-17

Horizontal Band ..................................................................................4-18

Irregular Density .................................................................................4-19

White Spot .......................................................................................... 4-20

Trembling at the End When OHP Printing ..........................................4-21

Poor Fusing Grade..............................................................................4-22

4.3.4 MALFUNCTION.............................................................................. 4-23

No Power (LCD NO display LED Off) .................................................4-26

Fuser Error..........................................................................................4-27

Paper Jam (Mis-Feeding) ...................................................................4-28

Paper Jam (Jam 1) .............................................................................4-29

Engine Error........................................................................................4-30

4.3.5 TONER CARTRIDGE AND DRUM CARTRIDGE SERVICE ..........4-31

Precautions on Safe-keeping of the Drum Cartridge ..........................4-31

Service for the Life of Toner Cartridge ................................................4-31

Symptoms of a defective toner cartridge.............................................4-32

4.3.6 PROBLEMS CAUSED BY SOFTWARE.........................................4-35

The printer is not working (1) ..............................................................4-35

The printer is not working (2) ..............................................................4-36

Abnormal Printing ...............................................................................4-37

Spooling Error.....................................................................................4-38

SERVICE TABLES

5. SERVICE TABLES....................................................................... 5-1

5.1 USER MODE .................................................................................................5-1

5.2 TECH MODE .............................................................................................5-3

5.2.1 HOW TO ENTER SERVICE MODE .................................................5-3

5.2.2 SETTING UP THE SYSTEM IN TECH MODE .................................5-3

5.2.3 SYSTEM DATA ................................................................................5-5

DIALING MODE....................................................................................5-5

MODEM SPEED...................................................................................5-5

ERROR RATE ......................................................................................5-5

SET TX LEVEL .....................................................................................5-5

SILENCE TIME.....................................................................................5-5

5.2.4 MEMORY CLEAR.............................................................................5-6

CLEAR ALL MEMORY .........................................................................5-6

B174 ii SM

Page 15

5.2.5 MAINTENANCE ...............................................................................5-6

CLEAN DRUM ......................................................................................5-6

NOTIFY TONER LOW ..........................................................................5-6

SWITCH TEST .....................................................................................5-6

MODEM TEST......................................................................................5-7

SRAM TEST .........................................................................................5-7

DRAM TEST .........................................................................................5-7

ROM TEST ...........................................................................................5-7

PATTERN TEST...................................................................................5-7

CLEAR COUNT ....................................................................................5-7

ANSWER ON CNG...............................................................................5-7

ADJUST SHADING...............................................................................5-8

FLASH UPGRADE................................................................................5-8

PROGRAM DIAL ..................................................................................5-8

REMOTE TEST ....................................................................................5-8

5.2.6 REPORTS/HELP..............................................................................5-9

PROTOCOL DUMP LIST......................................................................5-9

SYSTEM DATA ....................................................................................5-9

5.3 IDENTIFY SALE DATE .............................................................................5-9

5.4 FIRMWARE DOWNLOAD.......................................................................5-10

5.4.1 LOCAL MACHINE UPDATE...........................................................5-10

RCP (Remote Control Panel) mode....................................................5-10

To get the system data list .................................................................. 5-10

5.4.2 RE-PROGRAMMING PROCEDURE AFTER DOWNLOAD ........... 5-11

5.4.3 RECOVERY PROCEDURE............................................................5-11

5.4.4 REMOTE MACHINE UPDATE .......................................................5-11

How to update firmware by remote fax ...............................................5-11

5.5 PROCEDURE TO SET COUNTRY CODE.............................................. 5-12

Procedure ........................................................................................... 5-12

5.6 ENGINE TEST MODE.............................................................................5-13

5.6.1 TO ENTER THE ENGINE TEST MODE.........................................5-13

5.6.2 DIAGNOSTIC ................................................................................. 5-13

5.6.3 STATUS PRINT.............................................................................. 5-14

DETAILED DESCRIPTIONS

6. DETAILED DESCRIPTION .......................................................... 6-1

6.1 MAIN PBA (ALSO KNOWN AS MAIN BOARD) ........................................6-1

6.1.1 SUMMARY ....................................................................................... 6-1

6.2 CIRCUIT OPERATION..............................................................................6-2

6.2.1 FAX TRANSCEIVER ........................................................................6-2

General .................................................................................................6-2

Modem (u44) ........................................................................................6-2

6.3 SCANNER .................................................................................................6-2

6.3.1 SUMMARY .......................................................................................6-2

CCD ......................................................................................................6-2

SM iii B174

Page 16

6.3.2 KEY FEATURES ..............................................................................6-3

Overview...............................................................................................6-3

Pixel processing structure.....................................................................6-3

Shading Correction ...............................................................................6-3

Gamma Correction................................................................................6-3

Binary conversion (mono) ..................................................................... 6-4

Scaling of input image...........................................................................6-4

Intelligent scan motor controller ............................................................6-4

Auto-Run...............................................................................................6-4

Processed data output format in DTM (Data Transfer Module) ............6-4

Others ...................................................................................................6-4

6.4 SMPS & HVPS (ALSO KNOWN AS PSU AND POWER PACK)...............6-5

6.4.1 SUMMARY OF SMPS ......................................................................6-5

6.4.2 SUMMARY OF HVPS.......................................................................6-5

6.5 ENGINE CONTROLLER ...........................................................................6-5

6.5.1 FUSING CONTROL/THERMISTOR CIRCUIT .................................6-5

6.5.2 PAPER DETECTION CIRCUIT ........................................................ 6-6

1) Cover Open Detection ......................................................................6-6

2) Paper Empty Detection.....................................................................6-6

3) Paper Feeding ..................................................................................6-6

4) Paper Exit Detection .........................................................................6-6

6.6 LIU (ALSO KNOWN AS NCU)...................................................................6-7

6.6.1 SUMMARY ....................................................................................... 6-7

6.6.2 DIALER.............................................................................................6-7

TONE DIAL...........................................................................................6-7

PULSE DIAL .........................................................................................6-7

SPECIFICATIONS

SPECIFICATIONS

1. GENERAL SPECIFICATIONS.....................................................................7-1

2. PRINT SPECIFICATION ............................................................................. 7-2

3. SCAN SPECIFICATION .............................................................................. 7-2

4. COPY SPECIFICATION..............................................................................7-3

5. TELEPHONE SPECIFICATION ..................................................................7-3

6. FAX SPECIFICATION ................................................................................. 7-3

7. PAPER HANDLING.....................................................................................7-4

8. CONSUMABLES .........................................................................................7-4

APPENDIX

APPENDIX

BLOCK DIAGRAMS.........................................................................................8-1

CONNECTION DIAGRAMS.............................................................................8-2

PARTS CATALOG

SEE PARTS CATALOG SECTION FOR DETAILED TABLE OF CONTENTS

B174 iv SM

Page 17

PRECAUTIONS

Please carefully read the cautions below to prevent accidents while servicing the

machine.

WARNING FOR SAFETY

1. Request the service by qualified service person.

The service for this machine must be performed by a qualified service person.

It is dangerous if an unqualified service person or user tries to repair the

machine.

2. Do not rebuild it discretionary.

Do not disassemble, fix, and rebuilt the machine. If you do, the machine may

not work and an electric shock or a fire can occur.

3. Laser Safety Statement

The Printer is certified in the U.S. to conform to the requirements of DHHS 21

CFR, chapter 1 Subchapter J for Class 1(1) laser products, and elsewhere, it is

certified as a Class I laser product conforming to the requirements of IEC 825.

Class I laser products are not considered to be hazardous. The laser system

and printer are designed so there is never any human access to laser radiation

above a Class I level during normal operation, user maintenance, or prescribed

service condition.

WARNING

Never operate or service the printer with the protective cover removed from

Laser/Scanner assembly. The reflected beam, although invisible, can

damage your eyes. When using this product, these basic safety

precautions should always be followed to reduce risk of fire, electric shock,

and injury to persons.

CAUTION - INVISIBLE LASER RADIATION

WHEN THIS COVER OPEN.

DO NOT OPEN THIS COVER.

VORSICHT - UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GE…FFNET.

ATTENTION - RAYONNEMENT LASER INVISIBLE EN CAS

ATTENZIONE - RADIAZIONE LASER INVISIBILE IN CASO DI

PRECAUCION - RADIACION LASER IVISIBLE CUANDO SE ABRE.

ADVARSEL. - USYNLIG LASERSTR LNING VED BNING, N R

ADVARSEL. - USYNLIG LASERSTR LNING N R DEKSEL

VARNING - OSYNLIG LASERSTR LNING N R DENNA DEL

VARO! - AVATTAESSA JA SUOJALUKITUS OHITETTAESSA

NICHT DEM STRAHL AUSSETZENz

DÕOUVERTURE. EXPOSITION DANGEREUSE

AU FAISCEAU.

APERTURA. EVITARE LÕESPOSIZIONE AL

FASCIO.

EVITAR EXPONERSE AL RAYO.

SIKKERHEDSBRYDERE ER UDE AF FUNKTION.

UNDG UDSAETTELSE FOR STR LNING.

PNES. STIRR IKKE INN I STR LEN.

UNNG EKSPONERING FOR STR LEN.

R PPNAD OCH SP RREN R URKOPPLAD.

BETRAKTA EJ STR LEN. STR LEN R FARLIG.

OLET ALTTIINA N KYM TT M LLE LASERS TEILYLLE L KATSO S TEESEEN.

CAUTION.WMF

Page 18

CAUTION FOR SAFETY

PRECAUTION RELATED NOXIOUS MATERIAL

It is possible to be harmed from noxious material if you ignore the below

information.

1. Do not touch the damaged LCD. Noxious liquid to a human body exists in the

LCD. If it is got into the mouth, immediately see a doctor. If it gets into the eyes

or on the skin, immediately wash off with flowing water for 15 minutes and then

see a doctor.

2. The toner in a printer cartridge contains a chemical material, if swallowed,

might harm a human body.

Please keep the toner cartridge away from children.

PRECAUTION RELATED ELECTRIC SHOCK OR FIRE

It is possible to get an electric shock or burn by fire if you don't follow the

instructions of the manual.

1. Use the exact voltage and wall socket. If not, a fire or an electric leakage can

occur.

2. Use an authorized power cord. Use the power code supplied with machine. A

fire can occur when an over current condition flows in the power cord.

3. Do not insert many cords into an outlet. A fire can occur due to an over current

condition in the outlet.

4. Do not put water or other liquid, pin, clip, etc in the machine. It can cause a fire,

electric shock, or malfunction. If this occurs, immediately turn off the power off

and remove the power plug from outlet.

5. Do not touch the power plug with a wet hand. When servicing, remove the

power plug from the outlet.

6. Use caution when inserting or unplugging the power plug. The power plug has

to be inserted completely. If not, a fire can occur due to a poor contact. When

unplugging the power cord, grip the plug, not the wire.

7. Do not bend, twist, bind or place other materials on the power cord. Do not use

staples around machine. If the power cord becomes damaged, a fire or electric

shock can occur. A damaged power code must be replaced immediately. Do

not attempt to repair the damaged cord or reuse it. Repairing the cord with

plastic tape can cause a fire or electric shock. Do not spread chemicals or

insecticide on the power cord

8. Check whether the power outlet and the power plug are damaged, compressed

or cracked. When such inferiorities are found, replace it immediately. Do not roll

over the cord when moving the machine.

Page 19

9. Use caution during lightning storms. It may cause a fire or electric shock.

Unplug the power plug off under these conditions. Do not touch cable and

device during a lightning storm.

10. Avoid damp or dusty areas. Do not install the machine in dusty areas or around

humidifiers. A fire can occur. Clean the plug with dried fabric cloth to remove

dust.

11. Avoid direct sunlight. Do not install the machine near to a window where it is in

direct sunlight. If the machine operates in direct sunlight for a long periods, the

machine may not work correctly, because the increased inner temperature of

machine.

12. Turn off the machine and unplug the power cord when smoke, a strange smell,

or sound is detected from the machine. A fire can occur if the machine is used

under these conditions.

13. Do not insert steel or metal pieces inside/outside of the machine. Do not insert

metal pieces into the ventilator slots. An electric shock can occur.

PRECAUTION RELATED TO HANDLING THE MACHINE

If you ignore this information, you could get harm and machine could be damaged.

1. Do not install the machine on an uneven surface or slanted floor. Confirm that

the machine is correctly balanced after installation. The machine may fall over if

not balanced correctly.

2. Be careful not to insert a finger or hair in the rotating unit (motor, fan, paper

feeding part, etc) while the machine is operation.

3. Do not place any containers of water or chemical or small metals on top of the

machine. If these objects spill into the machine, a fire or electric shock can

occur.

4. Do not install the machine in areas where moisture or dust exists. For example,

do not install machine near open windows.

5. Do not place candles, burning cigarettes, etc. on the machine. Do not install it

near to a heater.

Page 20

PRECAUTIONS FOR WHEN ASSEMBLY/DISASSEMBLY

Replace parts very carefully. Remember the location of each cable before

removing parts, in order to reconnect it afterwards. Please perform the steps below

before replacing or disassembling any parts.

1. Check the contents stored in the memory. Either print a copy of stored data or

write down all of the needed information. All the stored information will be

erased when the main board is replaced.

2. Disconnect the power cord before servicing or replacing electrical parts.

3. Remove the printer cable.

4. Use formal parts and same standardized goods when replacing parts. Check

the product name, part code, rated voltage, rated current, operating

temperature, etc.

5. Do not use excessive force when loosening or tightening plastic components.

6. Be careful not to drop small parts or objects in the machine.

ESD PRECAUTIONS

Certain semiconductor devices can be easily damaged by static electricity. Such

components are commonly called “Electro statically Sensitive (ES) Devices”, or

ESD’s. Examples of typical ESD’s are: integrated circuits, some field effect

transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of

component damage caused by static electricity.

CAUTION

Be sure no power is applied to the chassis or circuit, and observe all other

safety precautions.

1. Immediately before handling a semiconductor component or semiconductorequipped assembly, drain off any electrostatic charge on your body by touching

a known earth ground. Alternatively, use a commercially available wrist strap

device, which should be removed for your personal safety reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD’s, place the

assembly on a conductive surface, such as aluminum or copper foil, or

conductive foam, to prevent electrostatic charge buildup in the vicinity of the

assembly.

3. Use only a grounded tip soldering iron to solder an ESD’s.

Page 21

4. Only use an “anti-static” solder removal device. Some solder removal devices

not classified as “anti-static” and can generate an electrical charge sufficient to

damage ESD’s.

5. Do not use Freon-propelled chemicals. When sprayed, these can generate

electrical charges sufficient to damage ESD’s.

6. Do not remove a replacement ESD from its protective packaging until

immediately before installing it. Most replacement ESD’s are packaged with all

leads shorted together by conductive foam, aluminum foil, or a comparable

conductive material.

7. Immediately before removing the protective shorting material from the leads of

a replacement ESD, touch the protective material to the chassis or circuit

assembly into which the device will be installed.

8. Maintain continuous electrical contact between the ESD and the assembly into

which it will be installed, until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackaged replacement ESD’s.

Normal motions, actions such as brushing together of clothing fabric or lifting

one’s foot from a carpeted floor, can generate static electricity sufficient to

damage an ESD.

Page 22

Page 23

INSTALLATION

PREVENTIVE MAINTENANCE

REPLACEMENT AND ADJUSTMENT

TROUBLESHOOTING

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

TAB

POSITION 4

SERVICE TABLES

DETAILED DESCRIPTIONS

SPECIFICATIONS

APPENDIX

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

Page 24

Page 25

INSTALLATION

Page 26

Page 27

INSTALLATION

1. INSTALLATION

Refer to the operating instructions.

Installation

SM 1-1 B174

Page 28

Page 29

PREVENTIVE MAINTENANCE

Page 30

Page 31

PREVENTIVE MAINTENANCE

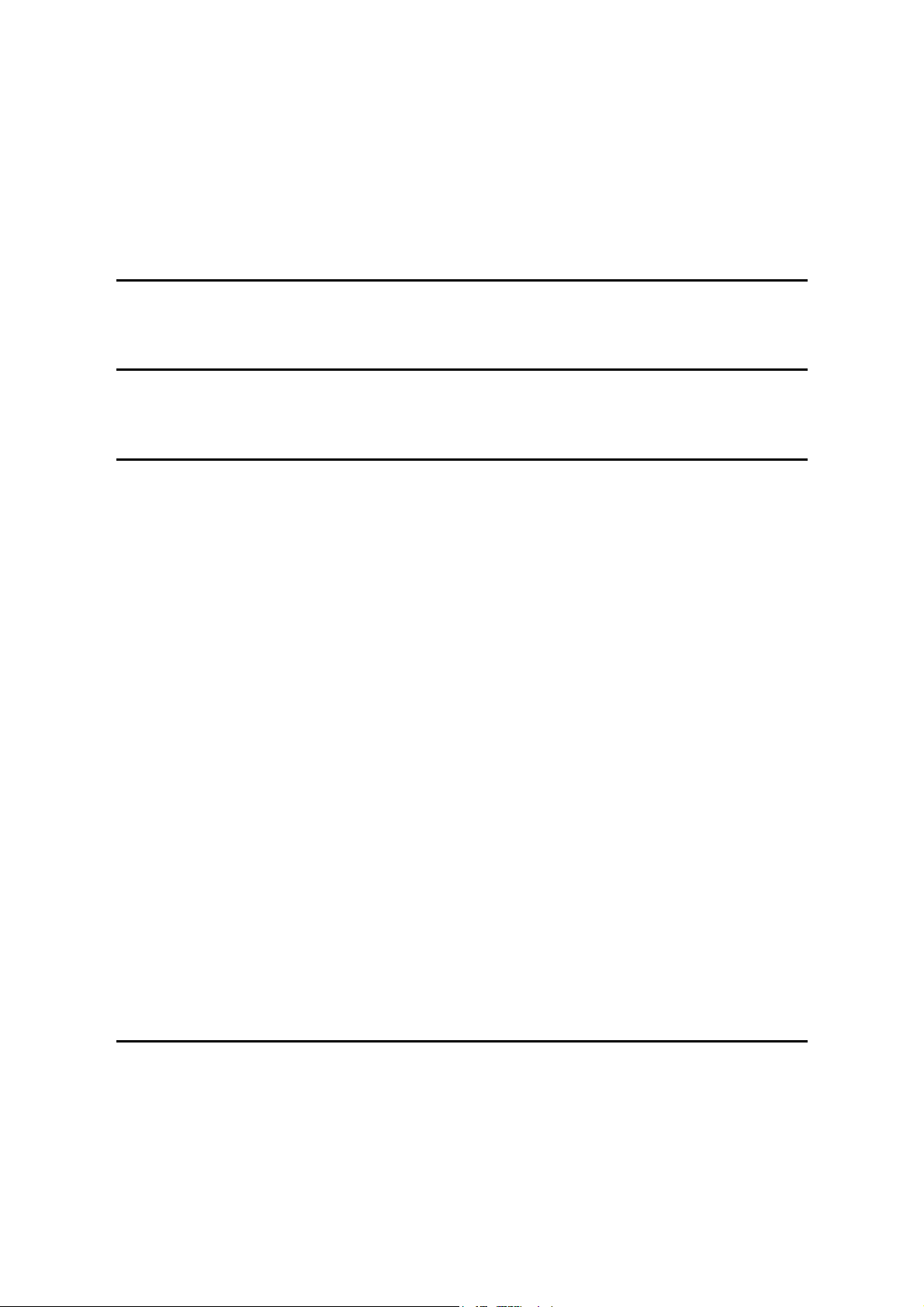

2. PREVENTIVE MAINTENANCE

The replacement cycle interval shown below is for maintenance.

Environmental conditions and differences in how the machine is used will change

this interval.

The cycle period shown is for reference only.

Component Replacement Cycle Done by

Scanner

Printer

ADF Rubber Pad Ass’y 20,000 Pages Service

ADF Pick-up Ass’y 50,000 Pages Service

Rubber - Paper Pick-up - Right

Rubber - Paper Pick-up - Left

Transfer Roller 75,000 Pages Service

Fuser 75,000 Pages Service

75,000 Pages Service

Preventive

Maintenance

SM 2-1 B174

Page 32

Page 33

REPLACEMENT AND ADJUSTMENT

Page 34

Page 35

GENERAL PRECAUTIONS ON DISASSEMBLY

3. REPLACEMENT AND ADJUSTMENT

3.1 GENERAL PRECAUTIONS ON DISASSEMBLY

When you disassemble and assemble components, you must use extreme caution.

Cables are near parts that move. Because of this, install the cables carefully. If

components are removed, cables moved during the procedure must be put as near

as possible to their initial positions. Before you remove a component from the

machine, make a note of the cable routing.

Before you do work on the machine, you must do these steps:

1. Make sure that no documents are stored in memory.

2. Disconnect the power cord.

3. Remove the toner and drum cartridges before you disassemble parts.

4. Use a flat and clean surface.

5. Replace only with approved components.

6. Be careful when you remove plastic components. Do not use force.

7. Make sure that all components are in their correct positions.

Releasing Plastic Latches

Many parts set in their positions with plastic latches. The latches break easily.

Release them carefully. Push the hook end of the latch away from the part to which

it is latched to remove these parts.

Adjustment

Replacement

B174R979.WMF

SM 3-1 B174

Page 36

REAR COVER

3.2 REAR COVER

1. Remove the six screws that hold

the Rear Cover.

2. Remove the Rear Cover [A] as

shown.

B174R900.WMF

[A]

B174 3-2 SM

Page 37

SCANNER ASS'Y

3.3 SCANNER ASS'Y

1. Before you remove the Scanner Ass'y

[A], you must remove:

- Rear Cover (!3.2)

2. Disconnect the connector and the

CCD cable [B].

NOTE: To prevent damage to the

CCD cable connector, pull the

cable out carefully. Pull in a

line with the connector, not at

an angle.

3. Remove the three screws, as shown.

[B]

[A]

B174R902.WMF

Adjustment

Replacement

4. Open the Right Cover assembly [C]

first to open the Front Cover [D].

• Close the front cover first when you

assemble the machine.

B174R903.WMF

[C]

2

1

[D]

B174R904.WMF

SM 3-3 B174

Page 38

SCANNER ASS'Y

5. Remove two screws.

B174R905.WMF

6. Pull up the Scanner Ass'y [A] in the

direction of the arrow.

[A]

7. Disconnect the connector [B] from the

Platen Ass'y.

B174R906.WMF

[B]

B174R907.WMF

B174 3-4 SM

Page 39

SCANNER ASS'Y

[A]

8. Open the Platen Ass’y [A] as shown by

the arrow.

Pull up the Platen Ass'y and remove it.

9. Remove the three screws securing the

Platen Ass’y.

10. Pull up the OPE Ass'y [B] and remove

it ( x 1).

[B]

B174R909.WMF

B174R908.WMF

Adjustment

Replacement

B174R978.WMF

SM 3-5 B174

Page 40

SCANNER ASS'Y

11. Remove the five screws that hold the

Scan Upper Ass'y [A].

12. Remove the Scan Upper Ass'y that

holds the platen glass [B]. (Release one

hook [C].)

NOTE: When you disassemble the

Scan Ass’y, make sure that

your work area is clean. Dirt or

dust on the scan head can

cause unsatisfactory scanned

image quality.

[A]

[B]

B174R910.WMF

13. Remove the Dummy Upper Ass’y [D]

( x 2).

B174R911.WMF

[C]

[D]

B174R912.WMF

B174 3-6 SM

Page 41

SCANNER ASS'Y

14. Remove the Channel Base Frame [A]

( x 4).

[A]

15. Remove the Dummy Scan-Lower [B]

( x 5).

B174R913.WMF

Adjustment

Replacement

16. Remove the CCD cable [C].

[B]

B174R914.WMF

[C]

B174R915.WMF

SM 3-7 B174

Page 42

SCANNER ASS'Y

17. Pull up the Shaft CCD [A], and remove

the Scanner Unit [B].

18. Remove the Motor Bracket [C] ( x 3).

[B]

[A]

B174R916.WMF

[C]

19. Disconnect the OPE Harness [D] from

the Platen board [E]. Remove the

Platen board ( x 2).

NOTE: Be very careful when you attach the

CCD Unit back to the Platen

Ass'y. The CCD Unit is on the

right side of the Belt Tension

Spring [F].

[D]

B174R917.WMF

[E]

B174R918.WMF

[F]

B174 3-8 SM

B174R919.WMF

Page 43

ADF ASS'Y

3.4 ADF ASS'Y

1. Before you remove the ADF Ass'y [A], you must remove:

- Rear Cover (! 3.2)

- Scanner Ass'y (! 3.3)

2. Remove the five screws from the

Platen Ass’y.

[A]

3. Open the ADF Upper Cover [B].

Remove Side Cover R [C]. Release

Side Cover L [D]. To do this, use a

sharp tool or small screwdriver as

shown [E]. Then remove Side Cover L.

4. Pull up the ADF Ass'y [F] and remove

it.

[E]

[D]

[F]

[B]

[C]

B174R920.WMF

B174R921.WMF

Adjustment

Replacement

B174R922.WMF

SM 3-9 B174

Page 44

ADF ASS'Y

5. Remove the ADF Upper Cover [A].

6. Remove the ADF Pick-up Ass’y [B] (!

2). Remove the ADF Upper [C] ( x 4).

[D]: ADF Rubber Pad Ass’y (! 2)

[A]

B174R923.WMF

7. Remove the ADF Motor ass'y [E]

( x 3).

[B]

[D]

[C]

B174R924.WMF

[E]

B174R925.WMF

B174 3-10 SM

Page 45

OPE ASS'Y (ALSO KNOWN AS ‘OP-PORT’)

3.5 OPE ASS'Y (ALSO KNOWN AS ‘OP-PORT’)

1. Before you remove the OPE Ass'y, you must remove:

- Rear Cover (! 3.2)

- Scanner Ass'y (! 3.3)

2. Remove the OPE board [A] and the

LCD Module [B] from the OPE Cover

[C] ( x 10).

[B]

[A]

3. Remove the contact rubbers [D] from

the unit.

[C]

[D]

B174R926.WMF

B174R927.WMF

Adjustment

Replacement

4. Remove the key pad [E] from the unit.

SM 3-11 B174

[E]

B174R928.WMF

Page 46

RIGHT COVER ASS'Y

3.6 RIGHT COVER ASS'Y

1. Remove two screws to release the

Stopper [A] (Main Frame side) that

holds the Right Cover [B] to the Main

Frame.

2. Fully open the Right Cover door [C].

Lift the left hand hinge " to release

it. Then push the door assembly to

the left to release the right hand

hinge #.

[A]

[B]

B174R929.WMF

2

1

[C]

B174R930.WMF

B174 3-12 SM

Page 47

RIGHT COVER ASS'Y

Multi Purpose (MP) Tray (Also known as Bypass Tray)

1. To disassemble the MP tray, release

the lower hinges ".

2. As shown at ", align the door supports

in a horizontal position. This will let you

remove the Tray-Case [A] from the Tray

Links. To remove the Tray-Links [B],

adjust the position of the Tray Links to a

45-degree angle to align the slot in the

link correctly, as shown at #.

1

1

B174R931.WMF

2

1

Adjustment

Replacement

B174R932.WMF

[A] [B]

SM 3-13 B174

Page 48

RIGHT COVER ASS'Y

Duplex Ass'y

1. Remove the Duplex Ass'y [A] from the

[A]

Side Door Ass'y [B] (release the plastic

clips, 2 on each side).

Transfer Roller Ass'y

1. Remove the Transfer Roller Ass’y [B]

(!2).

[B]

[B]

B174R933.WMF

B174R934.WMF

B174 3-14 SM

Page 49

FUSER ASS'Y (ALSO KNOWN AS ‘FUSING UNIT’)

3.7 FUSER ASS'Y (ALSO KNOWN AS ‘FUSING UNIT’)

CAUTION

The fusing unit has tapping screws. Assembly/disassembly should be kept

to a minimum. Adjustments again and again can cause failure. To avoid

hazardous situations, do not replace any components inside the fusing unit

such as thermistor, thermostat, hot roller, stripper pawls, fusing lamp, etc.

1. Before you remove the Fuser Ass'y, you must make sure that power is off.

Then remove:

- Rear Cover Ass'y (! 3.2)

- Right Cover Ass'y (! 3.6)

2. Remove the Connector Cover [A]

and the Cover Bracket [B] ( x 1

each).

[B]

Adjustment

Replacement

3. Disconnect one connector [C].

[A]

B174R935.WMF

[C]

B174R936.WMF

SM 3-15 B174

Page 50

FUSER ASS'Y (ALSO KNOWN AS ‘FUSING UNIT’)

4. Remove the Fuser Ass'y [A] ( x 3).

(! 2)

[A]

B174R937.WMF

B174 3-16 SM

Page 51

EXIT ASS'Y

3.8 EXIT ASS'Y

1. Before you remove the Exit Ass'y, you must remove:

- Rear Cover (! 3.2)

- Scanner Ass'y (! 3.3)

2. Remove four screws. Then, remove the

harness from the Exit Upper.

Disconnect four connectors and unlatch

the Dummy Base Frame [A], as shown.

[A]

3. Move the Exit Roller Release Lever [B]

to the vertical position as shown in the

diagram. Then, lift the Exit Ass'y [C] to

remove it.

B174R941.WMF

[C]

Adjustment

Replacement

SM 3-17 B174

[B]

B174R942.WMF

Page 52

COPY TRAY

3.9 COPY TRAY

1. Before you remove the Copy Tray, you must remove:

- Rear Cover (! 3.2)

- Scanner Ass'y (! 3.3)

2. Remove the Copy Tray [A] ( x 2).

[A]

B174R943.WMF

B174 3-18 SM

Page 53

DRIVE ASS'Y

3.10 DRIVE ASS'Y

1. Before you remove the Drive Ass'y, you must remove:

- Rear Cover (! 3.2)

2. Unplug two connectors.

(for Main Motor [A]: 9-pin, for Duplex

Solenoid [B]: 2-pin)

[B]

[A]

3. Remove the Fan [C] and Duct - Fan

[D] ( x 1).

4. Remove the Drive Ass'y [E] ( x 5).

B174R944.WMF

B174R945.WMF

Adjustment

Replacement

[C]

[D]

[E]

B174R946.WMF

SM 3-19 B174

Page 54

SMPS & HVPS (ALSO KNOWN AS ‘PSU’ AND ‘POWER PACK)

3.11 SMPS & HVPS (ALSO KNOWN AS ‘PSU’ AND ‘POWER PACK)

1. Before you remove the SMPS & HVPS, you must remove:

- Rear Cover (! 3.2)

- Scanner Ass'y (! 3.3)

- Copy Tray (! 3.9)

2. Remove the Shield SMPS Upper [A]

( x 3).

3. Disconnect all the connectors.

[A]

B174R947.WMF

B174R948.WMF

4. Remove the SMPS & HVPS [B].

[B]

B174R949.WMF

B174 3-20 SM

Page 55

LSU (LASER SCANNING UNIT)

3.12 LSU (LASER SCANNING UNIT)

1. Before you remove the LSU, you must remove:

- Rear Cover (! 3.2)

- Scanner Ass'y (! 3.3)

- Copy Tray (! 3.9)

2. Disconnect two connectors.

B174R950.WMF

Adjustment

Replacement

3. Remove the LSU [A] ( x 3).

[A]

B174R951.WMF

SM 3-21 B174

Page 56

LEFT COVER

3.13 LEFT COVER

1. Before you remove the Left Cover, you must remove:

- Rear Cover (! 3.2)

- Scanner Ass'y (! 3.3)

- Exit Ass'y (! 3.8)

- Copy Tray (! 3.9)

- SMPS (! 3.11)

2. Remove the Interface Panel [A]

( x 1).

[A]

3. Remove the Left Cover [B] ( x 1).

[B]

B174R952.WMF

B174R953.WMF

B174 3-22 SM

Page 57

MAIN FRAME ASS'Y

3.14 MAIN FRAME ASS'Y

1. Before you remove the LSU, you must remove:

- Rear Cover (! 3.2)

- Scanner Ass'y (! 3.3)

- Right Cover Ass'y (! 3.6)

- Fuser (! 3.7)

- Exit Ass'y (! 3.8)

- Copy Tray (! 3.9)

- SMPS (! 3.11)

- LSU (! 3.12)

2. Remove the Dummy Base Frame [A]

( x 5), the Front Cover [B], and the

Paper Exit Cam [C].

[A]

[C]

3. Remove the Deve Lock Lever [D].

Then remove the Cover Motor

Bracket [E] ( x 1).

[B]

B174R954.WMF

[E]

Adjustment

Replacement

[D]

SM 3-23 B174

B174R955.WMF

Page 58

MAIN FRAME ASS'Y

4. Disconnect all the connectors.

B174R956.WMF

5. Remove the Main Frame Ass'y [A] (

[A]

x 7).

B174R957.WMF

B174 3-24 SM

Page 59

MP ASS'Y (MULTI PURPOSE ASS’Y)

3.15 MP ASS'Y (MULTI PURPOSE ASS’Y)

1. Before you remove the MP Ass’y, you must remove:

- Rear Cover (! 3.2)

- Shield Main Upper (! 3.3)

- Right Cover Ass'y (! 3.6)

2. Disconnect two connectors.

Adjustment

Replacement

3. Remove the Feed Cover [A] ( x 1).

B174R958.WMF

B174R959.WMF

[A]

SM 3-25 B174

Page 60

MP ASS'Y (MULTI PURPOSE ASS’Y)

4. Remove three screws.

5. Release the SMPS by hand from

below, as shown. Pull the MP Ass'y

[A] up and remove it.

B174R960.WMF

[A]

B174R961.WMF

B174 3-26 SM

Page 61

FEED ASS'Y

3.16 FEED ASS'Y

1. Before you remove the Feed Ass’y, you must remove:

- Rear Cover (! 3.2)

- Scanner Ass'y (! 3.3)

- Right Cover Ass'y (! 3.6)

- Exit Ass'y (! 3.8)

- Copy Tray (! 3.9)

- LSU (! 3.12)

- Main Frame Ass’y (! 3.14)

2. Remove three screws.

3. Pull the Feed Ass'y [A] up and

remove it.

B174R962.WMF

[A]

Adjustment

Replacement

B174R963.WMF

SM 3-27 B174

Page 62

PICK UP ASS'Y

3.17 PICK UP ASS'Y

1. Before you remove the Pick Up Ass’y, you must remove:

- Rear Cover (! 3.2)

- Shield Main Upper (! 3.3)

- Drive Ass'y (! 3.10)

2. Disconnect three connectors.

3. Remove the Cassette Rail [A] ( x 2).

4. Remove the Pick Up Ass'y [B] ( x 4).

[C]: Rubber – Paper Pick-up (2)

[D]: Quenching (PTL) Lamp

B174R964.WMF

B174R965.WMF

[A]

[C]

[B]

B174 3-28 SM

[D]

B174R966.WMF

Page 63

MAIN BOARD

3.18 MAIN BOARD

1. Before you remove the Main Board, you must remove:

- Rear Cover (! 3.2)

- Right Cover Ass'y (! 3.6)

- Copy Tray (! 3.9)

- SMPS (! 3.11)

2. Remove the Shield Plate [A] ( x 2).

[A]

3. Remove the Main Board [B] from the

Shield Plate ( x 5).

B174R967.WMF

[B]

Adjustment

Replacement

B174R968.WMF

NOTE: Do a memory clear after you replace the main board. If not, the system

possibly will not operate correctly. (! 5.2.4)

SM 3-29 B174

Page 64

LIU BOARD

3.19 LIU BOARD

1. Before you remove the LIU Board, you must remove:

- Rear Cover (! 3.2)

- Right Cover Ass'y (! 3.6)

- Copy Tray (! 3.9)

- SMPS (! 3.11)

- Main Board (! 3.18)

2. Remove one screw and unlatch the LIU

Board [A] from the Main Board [B].

[A]

[B]

B174R969.WMF

B174 3-30 SM

Page 65

TROUBLESHOOTING

Page 66

Page 67

ERROR MESSAGES

4. TROUBLESHOOTING

This chapter includes problem diagnosis and troubleshooting. It shows how to find

and repair print quality problems.

4.1 ERROR MESSAGES

Error Message Description Solution

RETRY REDIAL?

COMM. ERROR

The machine is waiting for the

programmed interval to

automatically redial.

A problem with fax communications

has occurred.

You can press START to

immediately redial, or

STOP to cancel the redial

operation.

Try again.

DOCUMENT JAM

DOOR OPEN

GROUP NOT

AVAILABLE

LINE ERROR

LOAD DOCUMENT

MEMORY FULL The memory is full.

NO ANSWER

A document has jammed in the

scanner document feeder

The side cover is not correctly

latched

You tried to select a group location

where only a single location

number can be used (for example,

when you add locations for a multidial operation).

Your unit cannot connect with the

remote machine, or is disconnected

because of a problem on the phone

line.

You tried to set up a sending

operation with no document in the

feeder.

The remote machine did not

answer after all the redial attempts.

Remove the document jam.

The side door and front

door must be closed in the

correct order. Open both

doors. Close the front door

first, then close the side

door.

Try again. Check the

location for the group.

Usually caused by a

telephone line problem. Try

again. If failure continues,

wait an hour for the line to

clear then try again

Insert a document and try

again.

Do one of these:

A. Delete documents that

are not necessary.

B. Transmit again after

more memory becomes

available

C. Divide the transmission

into more than one

operation.

Try again. Make sure the

remote machine is OK.

Trouble-

shooting

SM 4-1 B174

Page 68

ERROR MESSAGES

Error Message Description Solution

NO. NOT ASSIGNED

NO PAPER

[ADD PAPER]

The speed dial location you tried to

use has no number stored in it.

There is no paper in the paper

cassette. Printing stops until paper

is loaded.

Dial the number manually

with the keypad, or store

the number.

Put paper in the paper

cassette.

OVERHEAT The printer has overheated.

PAPER JAM 0

OPEN/CLOSE DOOR

PAPER JAM 1/2

OPEN/CLOSE DOOR

TONER LOW

TONER EMPTY The toner cartridge is empty Replace the toner cartridge.

DRUM WARNING The OPC drum is almost at the end

Printing paper is jammed in paper

feeding area or the pick-up unit

Printing paper is jammed in the

machine main body or in the paper

exit unit.

The toner cartridge is almost

empty, or toner particles are not

equally applied in the cartridge

of its life (14,000 sides)

Your unit will automatically

return to the standby mode

when it cools down to

normal operating

temperature. If failure

continues, replace the

fusing unit or the main PBA.

Press STOP and remove

the jam.

Remove the jam.

Remove the toner cartridge

and carefully rock it from

side to side.

Try again. If problem

continues, replace the

cartridge.

You have 1000 pages of

print life left in the OPC

Drum. Continue to use, or

install a new OPC drum.

REPLACE DRUM The OPC drum life is expired

(15,000 sides)

NO CARTRIDGE A toner cartridge is not installed. Install the cartridge.

BYPASS JAM Paper feed problem from the

bypass (Manual feed) Tray.

DUPLEX JAM Paper feed problem in the duplex

return path

LINE BUSY The remote fax didn’t answer Try again.

OPEN HEAT ERROR No power to the fusing lamp Check the thermostat,

B174 4-2 SM

Replace the OPC drum

cartridge.

Open the side cover and

remove the jam.

Release the output feed

lever and check the output

area. Also, open the side

door and check the duplex

unit.

thermistor, fuser lamp and

fuser connector and related

wiring. Also check the

‘Fuser On’ signal from main

PWA to Power Supply.

Check the cable from Main

PWA to Power Supply

Page 69

ABNORMAL IMAGE PRINTING AND DEFECTIVE ROLLERS

Error Message Description Solution

Heating Error During operation, Temperature

does not go up

Scanner Locked Scanner head does not move. Check the transit lock.

Check the thermistor

contact point & the fusing

lamp.

Check that the scanner

cables are connected.

Check the scanner home

sensor, scanner motor or

drive belt.

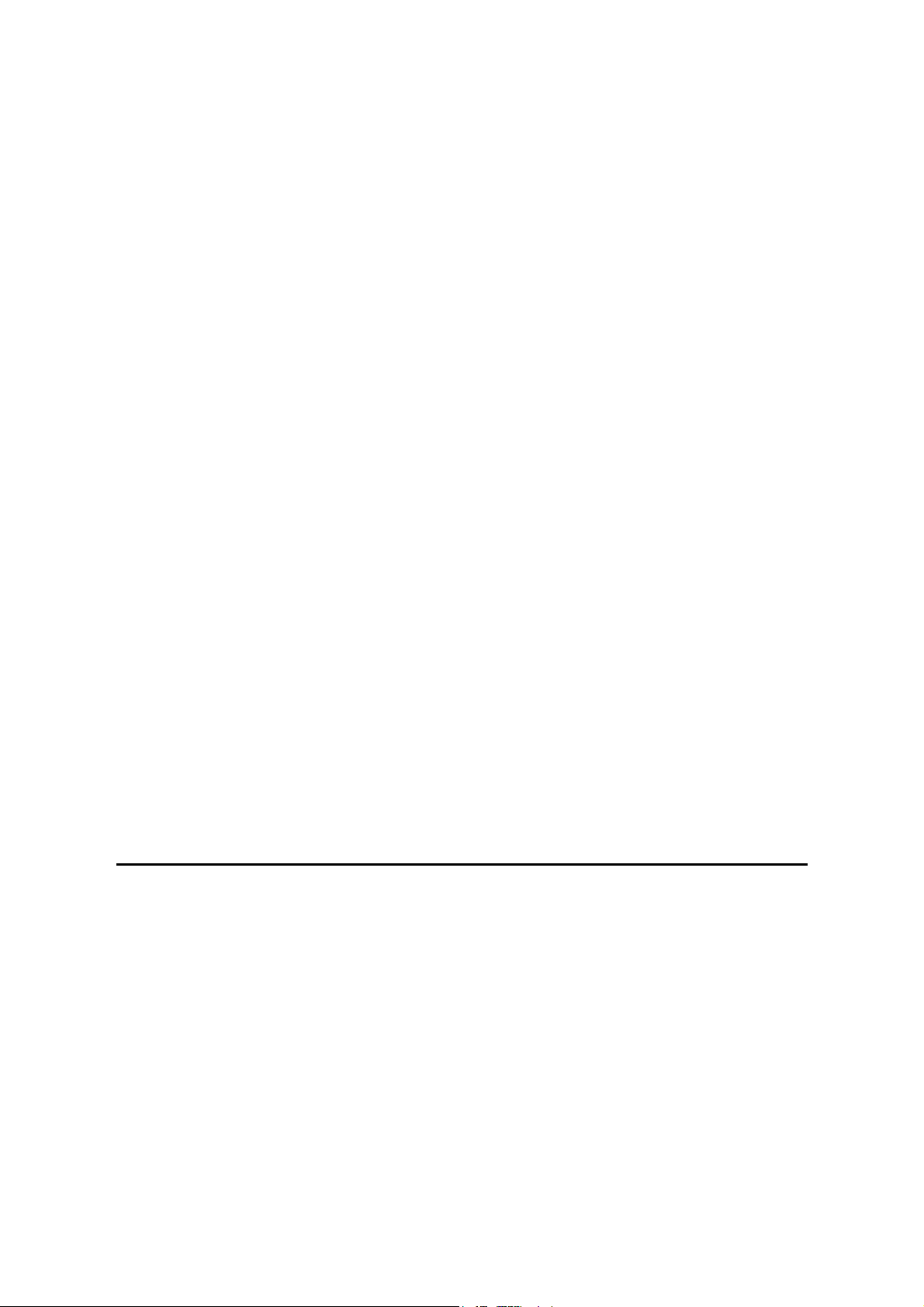

4.2 ABNORMAL IMAGE PRINTING AND DEFECTIVE

ROLLERS

If an abnormal image occurs at regular intervals, check the parts shown below.

NO Roller

1 OPC Drum 94.3 mm White spot. Black spot

2 Charge Roller 37.7 mm White spot. Black spot

3 Supply Roller 35.8 mm Horizontal dark band

4 Develop Roller 44.8 mm Horizontal dark band

5 Transfer Roller 57.8 mm

6 Hot Roller 82.5 mm Black spot, White spot

7 Pressure Roller 78.5 mm Contamination on reverse side of paper

Abnormal

image period

Kind of abnormal image

Contamination on reverse side of paper /

transfer fault

Trouble-

shooting

SM 4-3 B174

Page 70

TROUBLESHOOTING

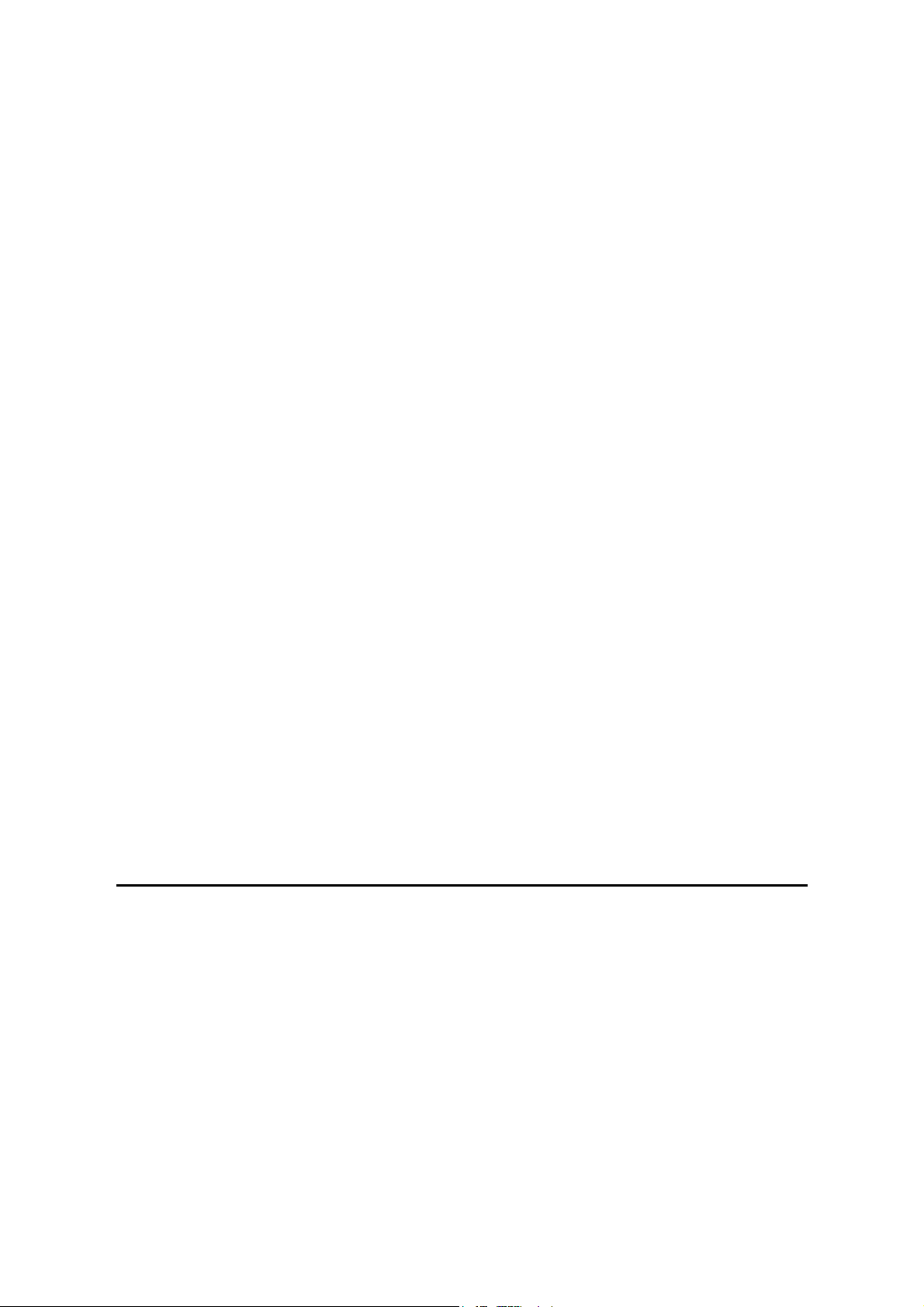

4.3 TROUBLESHOOTING

4.3.1 SCANNER

COPY

Problem Items to be checked How to solve

White copy

Black copy

Defective image

quality

Abnormal noise

• Make sure that the scanner

cover is closed.

• Check the shading profile • Do the “Adjust Shading”

• Check the CCD problem in

Main PBA.

• Check shading profile. • Do the “Adjust Shading”

• Check shading profile. • Do the “Adjust Shading”

• Check the original is lying flat

on the scanner glass.

• Check the printing quality. • See “Print” troubleshooting.

• Check the scanner drive

mechanism.

• Check the Motor Driver chip on

the Main PBA.

• Room lighting can go through

thin paper. This causes quality

problems

procedure in Tech mode

• Check the CCD harness

contact.

procedure in Tech mode.

procedure in Tech mode

• A gap above 0.5 mm can

cause a blurred image.

• Check for mechanical

problems in the scanner

carriage, motor, gearbox, belt

and belt tension spring.

• Make sure that the scanner

motor position is correct.

• If a driver is defective, replace

the Main PBA.

B174 4-4 SM

Page 71

TROUBLESHOOTING

PC-SCAN

Problem Items to be Checked. How to Solve

Scanning

Error

• Check the printer cable is correctly

installed.

• Use a standard IEEE1284

cable.

Defective

image Quality

• Check that the TWAIN driver is

installed.

• Remove all other scanner

drivers.

• Reboot after you reinstall the

TWAIN driver.

• Check the printer port (Parallel) BIOS

settings.

• Check the parallel port

related items in the CMOS

Setup. For a printer port,

make sure that ECP is

selected.

• Check the harness connection. • Check CN12 connection on

the Main PBA

• Check the IEEE1284 signal levels. • If a signal level is defective,

replace the Main PBA.

• Check the USB signal level. • If the USB signal level is

defective, replace the Main

PBA.

• Check shading profile. • Do the “Adjust Shading”

procedure in Tech mode.

• Check the gap between original and

scanner glass.

• A gap above 0.5 mm can

cause a blurred image.

Trouble-

shooting

Abnormal

noise

• Check the Scanner Motor and

mechanical problems in the scanner.

• Check the motor driver in the Main

PBA.

• Check for mechanical

problems in the scanner

carriage, motor, gearbox,

belt and belt tension spring.

• Make sure that the scanner

motor position is correct.

• If a driver is defective,

replace the Main PBA.

SM 4-5 B174

Page 72

TROUBLESHOOTING

4.3.2 FAX

FAX/TELEPHONE PRECAUTIONS

Problem Items to be Checked. How to Solve

TEL LINE CANNOT

BE ENGAGED (NO

DIAL TONE)

Tone dial is not

possible

Tone dial is possible

but not pulse dial

Defective fax

transmission

Defective automatic

fax reception

• When you press the “OHD” key:

a) Check the line cord connection.

b) Check the MAIN LIU harness,

and CN1

c) Check the relay operation of the

LIU PBA: Is the control signal of

CN18 (main) low?

• Check CN18 (main PBA), MAIN-

LIU harness, and CN1 (LIU PBA)

• Check DP control signal of CN18-

11 of MAIN PBA and the circuit

around R15. U6 and Q2 of Liu

PBA.

• Check CN18 (main PBA), MAIN

LIU harness, and CN1 (LIU PBA).

• Is the external phone off hook?

• Check ‘hook off’ : Refer to ‘TEL

LINE CANNOT BE ENGAGED’

above.

• Check the transmission path:

Check output of CN20-3.4 and

T2-4(LIU PBA).

• Check the reception path: Check

output CN1-1 (LIU PBA) and input

of CN18-1 (main PBA).

• Is the ring detected?

Check the ring signal at CN1-9

(LIU PBA).

• Refer to ‘“Defective

Transmission”.

(LIU PBA).

a) Insert it correctly into the

connection jack called

“Line”.

b) Replace defective parts.

c) Replace the main PBA

IF the control signal of

N18 (main) is high.

Replace the LIU PBA if high

but the phone line cannot

be connected.

• Replace defective parts.

• Replace the LIU PBA.

• Replace defective parts.

• Replace the LIU PBA if

low.

• Refer to ‘TEL LINE

CANNOT BE ENGAGED’

above.

• Replace the main PBA, if

abnormal.

• Replace the LIU PBA if

CN1-1(LIU PBA) is not

confirmed.

• Replace the main PBA if

CN20-1(MAIN PBA) is

not confirmed.

• Replace the LIU PBA if it

cannot be checked.

• Refer to “Defective

Transmission”.

B174 4-6 SM

Page 73

TROUBLESHOOTING

4.3.3 PRINT QUALITY

Error Status Check Solution

Vertical black line

and band

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Vertical white line

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B174T921.WMF

No image

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B174T922.WMF

Light image

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B174T923.WMF

1. Faulty toner cartridge

2. LSU

1. Change the toner cartridge

2. Replace LSU

1. LSU window dirty

2. Toner cartridge

1. Clean the LSU window

2. If not the LSU, change the

toner cartridge.

1. Is the seal tape removed?

2. OPC is properly

grounded?

3. LSU running well?

4. Toner low?

5. Is there video data from

the Main PBA?

1. Is the seal tape removed?

2. LSU light power normal?

3. Enough toner?

4. High charger voltage?

5. Lower bias voltage

6. Transfer voltage and roller.

7. Contamination of high

voltage contact.

1. Check and remove tape

2. Measure the resistance

between frame ground and

the OPC ground spring

attached to the frame.

Confirm good ground. If

faulty, check the ground

path through the frame.

3. Replace the LSU

4. Shake the toner cartridge

and print. If an image

appears, the toner cartridge

is empty

5. Print the engine test

pattern. If no pattern is

printed, replace the Main

PBA.

1. Check and remove tape

2. Checking LSU light power

is difficult. Compare with a

new one.

3. Check the toner counter

4~6. Change the HVPS (SMPS)

Board.

6. Clean or replace the transfer

roller.

7. Stray toner can increase

contact resistance and cause

a bad contact. Clean the

contaminated area.

Trouble-

shooting

SM 4-7 B174

Page 74

TROUBLESHOOTING

Error Status Check Solution

Dark image

Digital Printer

Digital Printer

1. LSU light power normal?

2. Video data is always

supplied?

1. Checking LSU light power

is difficult. Compare with a

new one.

2. Replace defective board(s)

Digital Printer

Digital Printer

Digital Printer

B174T924.WMF

Background

Digital Printer

Digital Printer

1. High voltage output is

normal?

2. C/R of toner cartridge is

dirty?

1. Change the HVPS (SMPS)

Board.

2. Replace the toner cartridge.

Digital Printer

Digital Printer

Digital Printer

B174T925.WMF

Ghost

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

1. High voltage output.

2. Quenching Lamp.

3. Bad high voltage contact.

1. Change the HVPS Board.

2. Check the quenching lamp

comes on – replace the

quenching lamp if

necessary.

3. Clean inside the machine

or replace the toner

cartridge.

B174T926.WMF

Stains on back of

paper

1. Dirty transfer roller.

2. Toner debris in the paper

path

3. Pressure roller dirty

1. Clean the transfer roller

with a vacuum cleaner.

2. Clean the paper path with a

cloth or air brush.

3. Replace the fusing unit

Poor Fusing

Partial blank image

(not periodic)

B174 4-8 SM

1. Paper quality and finish?

2. Check the fusing unit

temperature.

3. The machine was kept at a

low temperature for a long

time?

1. Toner is low?

2. The toner cartridge is out

of position?

1. Should use recommended

paper.

2. Measure the thermistor

voltage to the Main PBA. It

is 2.3V±5% when printing is

correct. If not, replace the

fusing unit.

3. Re-check after you let the

machine come up to room

temperature.

1. Replace the toner cartridge.

2. Check and adjust.

Page 75

TROUBLESHOOTING

Error Status Check Solution

Partial blank image

(periodic)

1. Developer roller scar or

particle. (45 mm)

2. OPC scar or particle. (95

mm)

3. Transfer roller scar or

1. Replace the toner cartridge.

2. Replace the drum cartridge.

3. Replace the transfer roller.

particle. (58 mm)

Different image

density (left and

right)

B174T929.WMF

Horizontal band

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B174T928A.WMF

1. Charge roller’s pressure not

balanced

2. Dev. roller and OPC or Dev.

roller and blade’s pressure

not balanced

3. Transfer roller’s pressure

not balanced on each side

1. Replace the drum cartridge.

2. Replace the drum and/or

toner cartridge.

3. Check the left and right

springs of the transfer roller

and the spring that pushes

the development unit inside

1. Unstable high voltage

contact

2. .Charge roller dirty

3. .Dirty hot roller

4. Malfunction of LSU

the machine

1. Clean each contact and

check good contact

2. Clean the charge roller.

3. Replace the fusing unit

4. Check the Main PBA

Trouble-

shooting

SM 4-9 B174

Page 76

TROUBLESHOOTING

No Image

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B174T922.WMF

No Image?

Yes

Self testing

is possible ?

Yes Yes

Check connection to

computer or replace

main board

No

No No

Take out the cartridge and

prepare the tester for

electronic connection

Self test

pattern prints?

Is the OPC

terminal of machine

correctly connected

to the frame?

Yes

No

A on next

page

Retest after replacing the

connector or main board

Repair or replace the

GND terminal

Does the

video data line to

LSU change High/Low

when printing?

Yes

The mirror in the LSU might

be misplaced, so the light

path to the OPC deviates Replace the LSU or remove

defective parts in the

machine

No

Check the path between

main board and HVPS.

Replace the defective

board

B174T901.WMF

B174 4-10 SM

Page 77

TROUBLESHOOTING

A

Transfer

voltage OK? (on the

transfer roller

shaft)

Yes

Dev. roller

(-300V) and toner supply

(-450V) voltages

are OK?

Yes

No

No

Are the connection

terminal and connection

correct?

Yes

Replace the HVPS

Is the connection

terminal OK?

Yes

No

No

Repair or replace terminal

Repair or replace terminal

Trouble-

shooting

Is the toner

cartridge life expired (see

the counter)?

Yes

Replace the toner cartridge

No

Replace the HVPS

The transfer roller might be out of its location

→ Put the roller into its correct place

The power of the LSU might be low or the light

intensity is low due to dirt on the window

→ Replace the LSU or clean the window

B174T902.WMF

SM 4-11 B174

Page 78

TROUBLESHOOTING

All Black

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B174T924.WMF

All black in

printing area?

Yes

Is charge

voltage supplied

from HVPS?

Yes

Is the Hsync/

signal received in

LSU?

Yes

The charge terminal

contact is bad

→ Replace the drum

cartridge

No

No

No

Does the

video data line to LSU

change High/Low when

printing?

Yes

Replace the LSU

Replace the HVPS

Replace the LSU

Check the path between

video controller, engine

No

board, HVPS, LSU for a

short or open circuit

→ Replace the defective

board or wiring

B174T903.WMF

B174 4-12 SM

Page 79

TROUBLESHOOTING

Vertical White Line (Band)

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B174T921.WMF

Ribs in the fusing unit or

toner on the roller may

cause this problem

-> Replace the fusing unit

White line missing

definitely?

Yes

No

Check

if the printout

has the same problem just

after it passed

the transfer roller

Yes

No

or the defective part

The image is originally

black or the black part is

too close to the top of the

page

→ Print an image that

has black more than 10

mm from the top

Trouble-

shooting

Dirt or dust stuck on the

window of the internal lens of

the LSU

→ Clean it or replace the LSU

Obstacles between OPC or

developer and LSU

→ Remove the obstacles

Toner might be stuck to the

toner metering blade and this

prevents toner supply

→ Replace the toner

cartridge

Check if the toner cartridge

counter is over its guaranteed

life and check the amount of

remaining toner

→ Replace the toner

cartridge

B174T904.WMF

SM 4-13 B174

Page 80

TROUBLESHOOTING

Dark Image

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B174T924.WMF

No

Dark selected via

Remote Control

Panel?

Yes

Change to Normal and test

Yes

Same at Normal?

Yes

Works correctly

with -300V of bias

voltage?

Yes

Works correctly

after replaced

LSU?

Yes

The power of the LSU is

too high or there is an

internal problem

→ Replace the LSU

No

No

No

END

Replace the defective

component

Toner over-supply due to

incorrect adjustment of metering

blade

→ Replace the toner cartridge

B174T905.WMF

B174 4-14 SM

Page 81

TROUBLESHOOTING

Background

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B174T925.WMF

Replace HVPS

after checking

the terminals'

contacts

Recommended paper

used?

No

storage atmosphere is too

Solve the problem under

the recommended

operating condition

(10-32 degrees Centigrade)

Transfer,

charge and developing

voltage are OK?

Operating/

hot/humid?

Yes

Yes

Yes

No

Print 20 to 30 pages using

recommended paper

Yes

No

Same problem

occurs?

Dirt or

dust around the

charge roller?

Yes

Clean the charge roller or

replace the drum cartridge

No

No

END

Replace the

toner cartridge

Trouble-

shooting

Check that each terminal or contact are in the correct posiiton

and not dirty.

→

Repair or replace components.

Check if the LED of the quenching lamp in the pick up ass'y is

on when you push the top cover switch

→

If not, replace the quenching lamp.

No

Works OK?

Yes

END

B174T906.WMF

SM 4-15 B174

Page 82

TROUBLESHOOTING

Ghost

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B174T926.WMF

Replace the PTL

assembly

Check the HVPS

contacts and HVPS

output test mode

(see section 5-6)

→

If failed, replace

the HVPS

Replace the

HVPS

Is it at a regular

interval of 95mm?

No

(Quenching) lamp

No

Transfer voltage is

set to standard?

No

Bias voltage is OK?

Yes

PTL

works OK?

Yes

Yes

(-300V)

Yes

No

Is it at a regular

interval of 45mm?

Dev. roller/

supply roller voltages

(-300V/-450V)

Irregularity of the nip

between rollers in the toner

cartridge → Replace the

toner cartridge

OK?

Yes

Yes

No

A specific part of the

transfer roller is damaged

or its resistance is changed

→ Replace the transfer

roller

The transfer roller cannot

turn correctly due to

eccentricity of the transfer

roller gears

→ Replace the defective

component

! Replace the HVPS

! Check and repair or

No

Is it at a regular

interval

of 58 mm? (transfer

roller interval)

Yes

replace the terminal

contacts

Operating/

storage temperature is too

low or not recommended

paper used?

Yes

Use the machine with

recommended paper and

conditions

No

There may be a problem

with toner layer control in

the toner cartridge

→ Replace the toner

cartridge

B174T907.WMF

B174 4-16 SM

Page 83

TROUBLESHOOTING

Black Spot

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B174T927.WMF

The problem

Is it a regular

interval of 38 mm?

Yes

No

When taking

out the cartridge,

toner leaks?

Yes

No

Bad image

removed by

scratching?

Yes

randomly occurred

No

due to falling toner

→ Clean the

machine

Foreign objetcs stuck

to the charge roller

→ Clean the charge

roller.

Toner leaks and a lot of

toner dropped onto the

paper

→ Replace the toner

cartridge

Check if toner is stuck onto

the pressure roller or hot

roller in the fusing unit

→ Clean or replace the

fusing unit

B174T908.WMF

Trouble-

shooting

SM 4-17 B174

Page 84

TROUBLESHOOTING

Horizontal Band

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B174T928A.WMF

Black band?

The black

band has a regular

interval?

Yes

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B174T928B.WMF

No

No

Black band is

about 95mm from white

band?

Yes

Problem with internal

contacts in the OPC

→ Replace the drum

cartridge

No Hsync/ at the LSU

→ Replace the LSU

The OPC is damaged

under direct sunlight for

No

around 5 minutes

→ If the same problem

persists after 10 hours,

replace the drum cartridge

Yes

95 mm interval?

Yes

The OPC is damaged

due to incorrect transfer

voltage from the HVPS

→ Replace the HVPS

→ If the same problem

persists, replace the

drum cartridge

No

Every 83mm

at a specific

place?

Yes

Hot roller defective

→ Replace the fusing

unit

No

Problems of terminal

contact, transfer voltage

supply, and transfer roller

because the charge roller is

defective (38 mm)

→ Replace the HVPS and/

or drum cartridge

B174T909.WMF

B174 4-18 SM

Page 85

TROUBLESHOOTING

Irregular Density

B174T929.WMF

OK after

taking out and rocking

the toner

cartridge?

Yes Yes

The guaranteed life of the

toner cartridge is over

(Check the counter and

replace it)

No

Clean the window of the

PTL

When

printing a gray pattern,

irregular density

persists?

PTL lamp

(Quenching lamp)

works OK?

Any dust

on the PTL lamp?

Yes

Yes

No No

Check the high voltage

output and repair/

replace terminals, HVPS

No

No

Light distortion due to a

defective mirror or

diffused reflection from

the LSU

→ Replace the LSU

Transfer/

charge/development

voltage drops while

printing?

Yes

Replace the lamp

Bad images

around no-image

areas?

Yes

Defective agitator

in the toner supply

mechanism

→ Replace the

toner cartridge

Irregular toner

No

supply

→ Replace the

toner cartridge

B174T910.WMF

Trouble-

shooting

SM 4-19 B174

Page 86

TROUBLESHOOTING

White Spot

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

B174T930.WMF

Is it at a regular

interval of 95 mm?

Yes

Dirt on the OPC surface

→ Clean the OPC and the

machine, or replace the

drum cartridge

When installing or removing

the drum cartridge, a scratch

was made

→ Replace the cartridge

No

Transfer

voltage is normal?

Yes

Development roller defective

→ Replace the toner

cartridge

No

Too much voltage supplied

due to a setting error for the

transfer voltage

→ Replace the HVPS

B174T911.WMF

B174 4-20 SM

Page 87

TROUBLESHOOTING

Trembling at the End When OHP Printing

Recommended

OHP film used?

Inserted more

than 10 films into

the MPF?

When multi-page OHP

printng, less than 10

films are guaranteed.

(Reduce the number of

films and re-insert after

paper check LED is off)

Yes

Yes

No

No

Use recommended film

When OHP

printing, does the fan

stop and start?

Yes

Other parts touch the fan

and prevent it from

turning

→ Check and repair

Use recommended film

B174T912.WMF

Trouble-

shooting

SM 4-21 B174

Page 88

TROUBLESHOOTING

Poor Fusing Grade

After printing

completed, any error

related to fusing?

Yes

Both ends

of the thermostat

open?

Yes

Replace the fusing unit

Yes

Replace the Main PBA

No

Was the machine

stored in a very low

low temperature for

a long time?

Place the machine at

No

normal temperature and

re-test

No

Yes

While printing,

the voltage at pin 60 of U36

(CPU) on the Main PBA is

2.1V - 2.6V?

Open the top

cover. When black printing,

is the fusing nip width

3.0 - 3.5 mm?

Yes

No

No

Thermistor's

contact is OK?

Yes

Replace the fusing unit

Replace the fusing unit

No

Yes

The paper used is too

thick or contains too

much cotton

→ Re-test with

recommended paper

B174T913.WMF

B174 4-22 SM

Page 89

TROUBLESHOOTING

4.3.4 MALFUNCTION

Error

Status

No power

1. Check the supplied

power

2. Check if fuse F1 on the

SMPS is open

Fuser Error

1. Thermostat open

2. AC wire open

3. Thermistor wire open

4. Main PBA

Cover open

1. When you close the side

cover, check that the

lever is pressed

2. Microswitch contact

3. CPU and related circuit

Jam 0 Check where Jam 0 occurs

1. Paper is not picked up

2. Paper is at the feed

sensor

3. Occurred when inserting

specific types of paper

such as envelopes into

the bypass tray?

4. Is the Stacker Extender

folded out?

5. Does the guide bend the

sheets?

Check Solution

1. If the supplied power differs from

machine’s power rating, replace the

machine to the correct type for your

area.

2. Replace SMPS.

1. Detach the AC connector and measure

the resistance between pin 1 and 2. If it

is mega-ohm, the thermostat is open,

Replace it.

2. Check if there is a bad connector

contact or if the wire is cut.

3. Check the thermistor wire and its

connection.

4. Replace the Main PBA

1. Open the side cover and press the lever

with a pen. If the machine detects that

the cover is closed, there is a

mechanical problem with the side cover

and lever assembly. If not, there is an

electrical problem.

2. Check and replace the microswitch

3. Check and replace the main PBA

Trouble-

shooting

1. Check whether the solenoid is working or

not by using Engine test mode

2. Check for a feed sensor malfunction.

3. Re-try inserting fewer sheets.

• Fan the sheets and align them

• Take out the loaded sheets and insert

them in the reverse direction

Take out the loaded sheets and insert

them in the reverse direction

• Inserted sheets as recommended for

Manual Feeding?