Page 1

© 2007 Ricoh Americas Corporation

5 Dedrick Place

West Caldwell, NJ 07006

A

ugust 2007

338550-003C

User’s Guide

Page 2

© 2007 Ricoh Americas Corporation. All rights reserved.

No part of this document may be reproduced without the expressed permission of Ricoh

Americas Corporation.

The material in this document is for informational purposes and is subject to change

without notice. Ricoh Americas Corporation assumes no responsibility for errors or

omissions in this document. No liability is assumed for any damages resulting from the

use of the information it contains.

TRADEMARK

Adobe and Postscript are registered trademarks of Adobe Systems Incorporated. PCL

is the trademark of Hewlett Packard. Ethernet is a trademark of Xerox Corporation.

Windows XP is a trademark of Microsoft Corporation. Digital Document Publisher and

DDP and its associated logo mark are the trademarks of Ricoh Americas Corporation.

Ricoh and the Ricoh trademark are registered trademarks of Ricoh, Ltd. All rights

reserved.

All other terms and product names may be trademarks or register ed trad emarks of their

respective owners and are hereby acknowledged.

NOTICE TO USER

In an effort to meet the demands of a rapidly changing technology, the manufacturer is

continually developing new feat ures and functions to meet changing printing or printer

needs. Please be sure to consult all manual updates or addenda when using this

product’s documentation.

This document contains TrueType fonts from Monotype Imaging Inc. Reproduction of

these fonts is prohibited.

The software embedded in this product is based in part on the work of Independent

JPEG Group.

The software embedded in this product uses so ftware by CMU. Copyright 1988, 1989 by

Carnegie Mellon University. All rights reserved.

The software embedded in this product uses software by Intermate A/S. Copyright 2005.

All rights reserved.

Permission to use, copy, modify, distribute and sell this software and its documentation

for any purpose and without fee is hereby granted, provided that the above copyright

notice appears in all copies and that both the copyright notice and permission notice

appear in supporting documentation, and the name of CMU not be used in advertising

or publicity pertaining to distribution of the software without specific written prior

permission.

The software embedded in this product uses the software by Sam Leffler and Silicon

Graphics.

Copyright (c) 1988-1997 Sam Leffler

Copyright (c) 1991-1997 Silicon Graphics, Inc

Permission to use, copy, modify, distribute and sell this software and its documentation

for any purpose and without fee is hereby granted, provided that the above copyright

notice appear in all copies of the software and related docume ntation, and (ii) the names

of Sam Leffler and Silicon Graphics may not be used in advertising or publicity pertaining

to distribution of the software without specific, written prior permission of Sam Leffler and

Silicon Graphics.

Page 3

Our company, as a partner in the Energy Star Program, considers that this product

satisfies the appropriate standard covered in this program.

NOTE:

The 70 and 92 PPM printers come with the power management mode enabled and

will go into a “Sleep” mode after 7 minutes (70 PPM) or 15 minutes (92 PPM) if there

is no printing or communications with the printer.

These are default settings and should remain in these conditions to get the energy

saving benefits of Energy Star.

Page 4

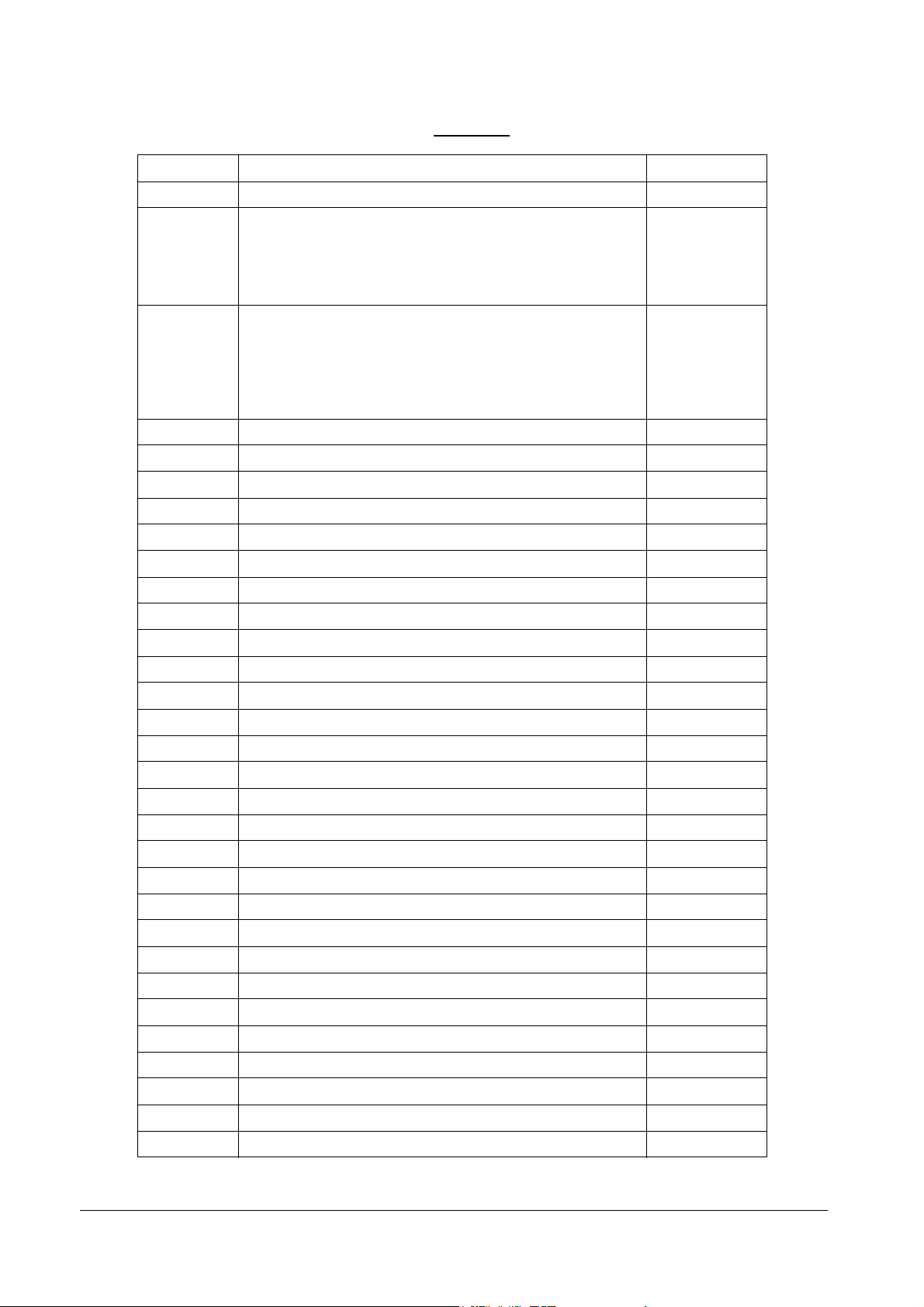

Revisions

Revision Page No. (Contents) Date

A Original Release - ECO-1772 February 2006

B

Page B-2: Corrected Controller processor speed to 800

MHz (Egret 3R);

February 2007

Add rev history page, copyright page;

Page 5-1, add "Network Problems" to bulleted list

C

Page i, Updated Energy Star page to add Power

March 2007

Management feature.

Pages 4-9 and 4-31, added RC number to developer p/n

Page 6-2, updated Web Site layout sheet to include IPDS

i

Page 5

Table of Contents

Introduction

About This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

For More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 1. Printer Overview

What This Chapter Provides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Printer Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

I/O Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Operator Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

External View of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Internal View of the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chapter 2. Operator Control Panel

What This Chapter Provides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

OCP Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Using the Menu Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Printer Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Reports Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Finisher Menu for the Container Stacker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Jobs Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Passwords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

vi

.vii

vii

Chapter 3. Paper Handling

What This Chapter Provides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Paper Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Paper Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Unacceptable Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Storing Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Paper Sizes, Paper Types, and Printer Input Trays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Loading Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Loading Paper in Tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Table of Contents ii

Page 6

Loading Paper in Tray 2 or 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Loading Paper into the MBT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Loading Paper into the HCF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Loading Special Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Pre-punched Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Loading Pre-printed Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Loading Tab Stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Setting the Custom Paper Size Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Setting the Tray Adjust Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Setting the Default Paper Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Setting the Paper Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Setting the Paper Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Setting the Paper Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Ordered Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Define the Ordered Sets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Chapter 4. Care and Maintenance

What This Chapter Provides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Replacing Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Adding Toner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Replacing the Toner Collector Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Replacing the Developer Mix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Exhausting the Developer Mix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Supplying the Developer Mix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-9

Replacing the Drum Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Replacing the Fuser Cleaning Web . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Replacing Staples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Clearing Paper Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Vertical Path (IS) Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Switch Back Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

Paper Feed Block Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Trays 1, 2, and 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Tray 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Tray 2 or 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

Multi-bypass Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

High Capacity Feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Tab Stock Jam Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Cleaning the Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Cleaning the Printer Covers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Cleaning the Inside of the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Cleaning Trays 1, 2 and 3, the MBT, and HCF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-27

Cleaning the Toner Bottle Joint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Cleaning the Conveyance Belt Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

Cleaning the Toner Collector Bottle Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-29

Handling and Storing Supplies and Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

iii Table of Contents

Page 7

Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

When Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

When Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

When Paper Jams Frequently Occur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

Toner and Developer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

When Purchasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31

Chapter 5. Troubleshooting

What This Chapter Provides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Guidelines Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Basic Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

General Printing Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Print Quality Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Duplex Printing Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Printing Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

OCP Display Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Printer Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-16

Network Problems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-18

Chapter 6. Web Utilities

Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Web Utilities Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 -1

Web Site Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Using the Web Utilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Appendix A. Safety Information

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A -1

Laser Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1

Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

FCC Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Canadian Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

VCCI Notice (Japan) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Declaration of Conformity for Safety/EMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

70/92 ppm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-4

Declaration of Conformity for RoHS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

70/92 ppm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

When Installing and Relocating the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Power Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Power Cords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Positioning the Printer Safely . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Environmental Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-8

Operating Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-9

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-9

Care of Printer Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-10

Table of Contents iv

Page 8

Appendix B. Printer Specifications

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

Base Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-2

I/O Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

Appendix C. Paper Specifications

Media Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

General Media Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Paper Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

Paper Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Paper Color . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-3

Paper Composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Paper Cut . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Paper Friction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Paper Smoothness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Paper Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Moisture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Paper Curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

How to Avoid Paper Curl . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

Recycled Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7

Grain Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7

Paper Smoothness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7

Special Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-8

Preprinted Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-8

Ink Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9

Paper Curl in Preprinted Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-9

Prepunched Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-10

Adhesive Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-11

Adhesive Label Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12

Storing Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-12

Adhesive Label Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-13

Perforated Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-14

Tab Stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-15

Transparencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-15

Printing Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-16

Printable Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-16

Preprinted Lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-16

Proper Paper Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-17

Check Paper Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-18

Loading Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-19

v Table of Contents

Page 9

About This Manual

This manual provides easy access to the information you need to operate the 70 PPM or

92 PPM (Pages Per Minute) laser printer.

NOTE:

This User’s Guide is intended to be viewed online. When viewing it online,

use the bookmarks and page reference links for easy navigation

throughout the document.

To find out about a specific topic, refer to:

Chapter 1: Printer Overview – For printer components and features.

Chapter 2: Operator Control Panel – To access and use the liquid crystal display

(LCD) window and the menus screens.

Chapter 3: Paper Handling – For media recommendations and paper handling

procedures.

Chapter 4: Care and Maintenance – For detailed instructions on replacing

consumables, clearing paper jams, and cleaning and maintaining the printer.

Introduction

Audience

This manual is written for those persons responsible for operating the printer. A basic

understanding of computer equipment and its operations is required.

Chapter 5: Troubleshooting – For information on printing problems and printer

error and warning messages.

Chapter 6: Web Utilities – For information on accessing the printer via the

Internet or your company’s Intranet.

Appendix A: Safety Information – For safety information and printer

characteristics, including environmental and electrical requirements.

Appendix B: Printer Specifications – For printer specifications.

Appendix C: Paper Specifications – For media specifications and printing

guidelines.

Glossary – For definitions of terms and acronyms.

Introduction vi

Page 10

Manual Conventions

The following conventions are used in this manual:

Bold and Italics are used sparingly for emphasis.

Information you enter: Looks Like This.

Key Names (or Labels): Look Like This.

System messages: Look Like This.

Variable user information: Looks Like This.

Pay particular attention to Notes, Cautions, and Warnings. These alert you to critical

information, as follows:

NOTE:

Provides important additional information.

CAUTION!

Alerts you to an operating procedure, practice, or condition that, if not

strictly observed, might result in damage to the equipment.

WARNING!

Alerts you to an operating procedure, practice, or condition that, if not

strictly observed, can result in safety hazards to personnel, severe injury,

or loss of life.

For More Information

Refer to the following related documents for more details about your printer.

Read Me First

Unpacking and Setup Instructions

Engine Maintenance Manual

Controller Maintenance Manual

Illustrated Parts List (IPL)

vii Introduction

Page 11

What This Chapter Provides

This chapter describes the parts and functions of the printer.

Printer Features

I/O Configurations

Operator Control Panel

Printer Views

Chapter 1

Printer Overview

Printer Overview 1-1

Page 12

Printer Features

The printers are high-speed, shared-use laser printers for a production printing

environment. They incorporate a wide variety of features:

High-Speed and High-Quality Printing.

Print speed is up to 70 or 92 pages per minute (ppm), A4/Letter (Simplex)

depending on the printer model.

The printing output is at a resolution of 600 dots per inch (dpi), assuring

razor-sharp graphic and text output, even at very small point sizes.

Flexible Paper Source and Delivery.

Paper Source:

Standard – Two 500-sheet universal paper trays and one 2000-sheet universal

paper cassette.

Standard – 150-sheet capacity Multi-bypass Tray (MBT) for automatically

printing small jobs, or manually feeding single sheets (including

transparencies, labels, and odd-sized print media).

Option – High Capacity Feeder with 3000-sheet capacity.

Paper Delivery:

Standard - 2,500-sheet (Elevator Tray), 200-sheet (Upper Tray) capacity

Finisher.

Option – Container Stacker with 1,500 to 6,000-sheet capacity and stacking

capability.

Multiple Original Printing (MOP) – for printing of multiple collated document

sets without multiple file transfers. Processes PCL and PostScript jobs once,

stores the images on disk, and prints each set from disk (after the first set).

Vi rtual Printer T echnology (VPT

®

) – allows a single printer to offer print services,

or virtual printers, each of which is configured by the Network Administrator.

Web Utilities – for remote access to the printer through the Internet or your

company’ s Intranet.

Ergonomic operation.

The easy-to-read display clearly shows the operational status of the printer.

Component-based consumables.

User replaceable toner and staples.

High-volume printing.

Three standard paper cassettes with approximately 3000-sheet capacity total

and the Multi-bypass Tray (MBT) with a 150-sheet capacity.

Optional High Capacity Feeder (HCF) adds up to 3000 additional sheets.

Together they allow continuous printing of up to 6150 sheets.

1-2 Printer Overview

Page 13

Supports a wide-range of media types (copier, bond, letterhead, special

application, recycled, overhead transparencies, labels) and sizes. See “Paper” on

page 2-2 for more information.

Printer Language Support.

Optional PostScript Level III (Adobe) printer language.

Optional IPDS printer language

PCL5e and PCL XL printer language.

TIFF and PDF printer language

Network.

Ethernet 10/100/1000 Base-T.

Network Protocol.

TCP/IP and LPR/LPD with onboard network.

IPP

Easy installation of additional fonts and macros using the PCL Startup File.

I/O Configurations

Bi-directional 1284C Parallel interface with Compatibility, Nibble, Byte, and

ECP Mode support.

Ethernet 10/100/1000 Base-T.

Printer Overview 1-3

Page 14

Operator Control Panel

The Operator Control Panel (OCP) is your physical interface to the printer's features

and functions. From the control panel, you can monitor the printer's operating status

and configure the specific printer functions.

See Chapter 2 for detailed information about the OCP.

1-4 Printer Overview

Page 15

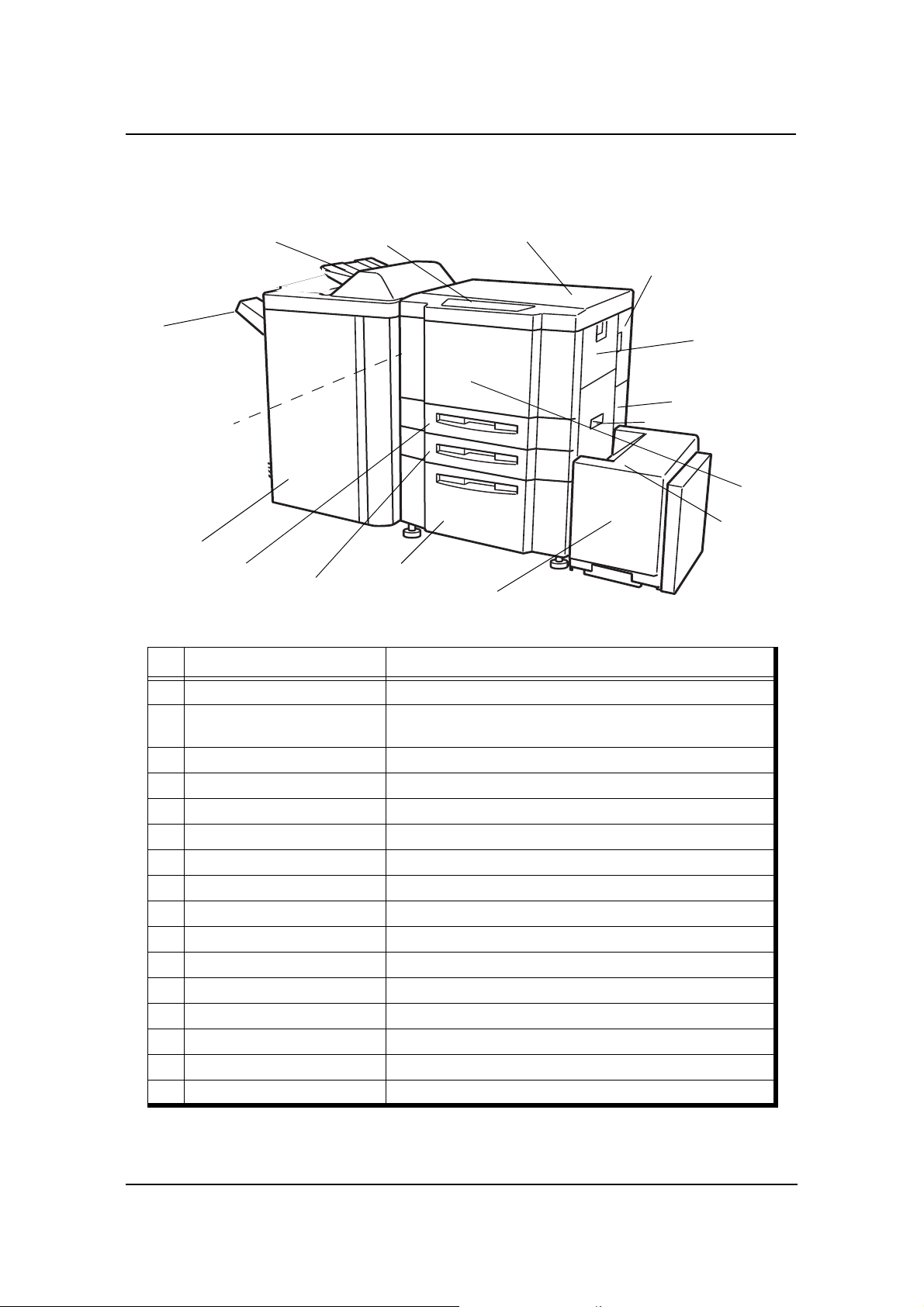

External View of the Printer

16. Upper Tray

6. Operator Control

1 1. Elevator Tray

10. Switch Back Cover

(Not Shown)

15. Finisher

9. Tray 3

8. Tray 2

Key Component Description

Panel

7. Tray 1

5. Toner Supply Cover

12. High Capacity Feeder

14. Toner Collector

Bottle Cover

4. Multi-bypass Tray

1. Power Switch

3. Vertical Path Cover

2. Front Cover

13. HCF Top

Cover

1 Pow er Switch Press to turn the printer on and off.

2 Front Cover

3 Vertical Path Cover Open to clear paper jams.

4 Multi-bypass Tray (MBT) Holds up to 150 sheets of paper.

5 Toner Supply Cover Open to replenish the toner supply.

6 Opera tor Control Panel (OCP) Displays printer status and menu information.

7 Tray 1 Holds up to 2,000 sheets of paper.

8 Tray 2 Holds up to 500 sheets of paper.

9 Tray 3 Holds up to 500 sheets of paper.

10 Switch Back Cover Open to clear paper jams.

11 Elevator Tray Output tray.

12 High Capacity Feeder (HCF) Holds up to 3,000 sheets of paper.

13 HCF Top Cover Open to clear paper jams.

14 Toner Collector Bottle Cover Open to replace the toner collector bottle.

15 Finisher For stacking, job offset, and stapling.

16 Upper Tray Output tray.

Open to replace units, clear paper jams, or clean the inside of

the printer.

Printer Overview 1-5

Page 16

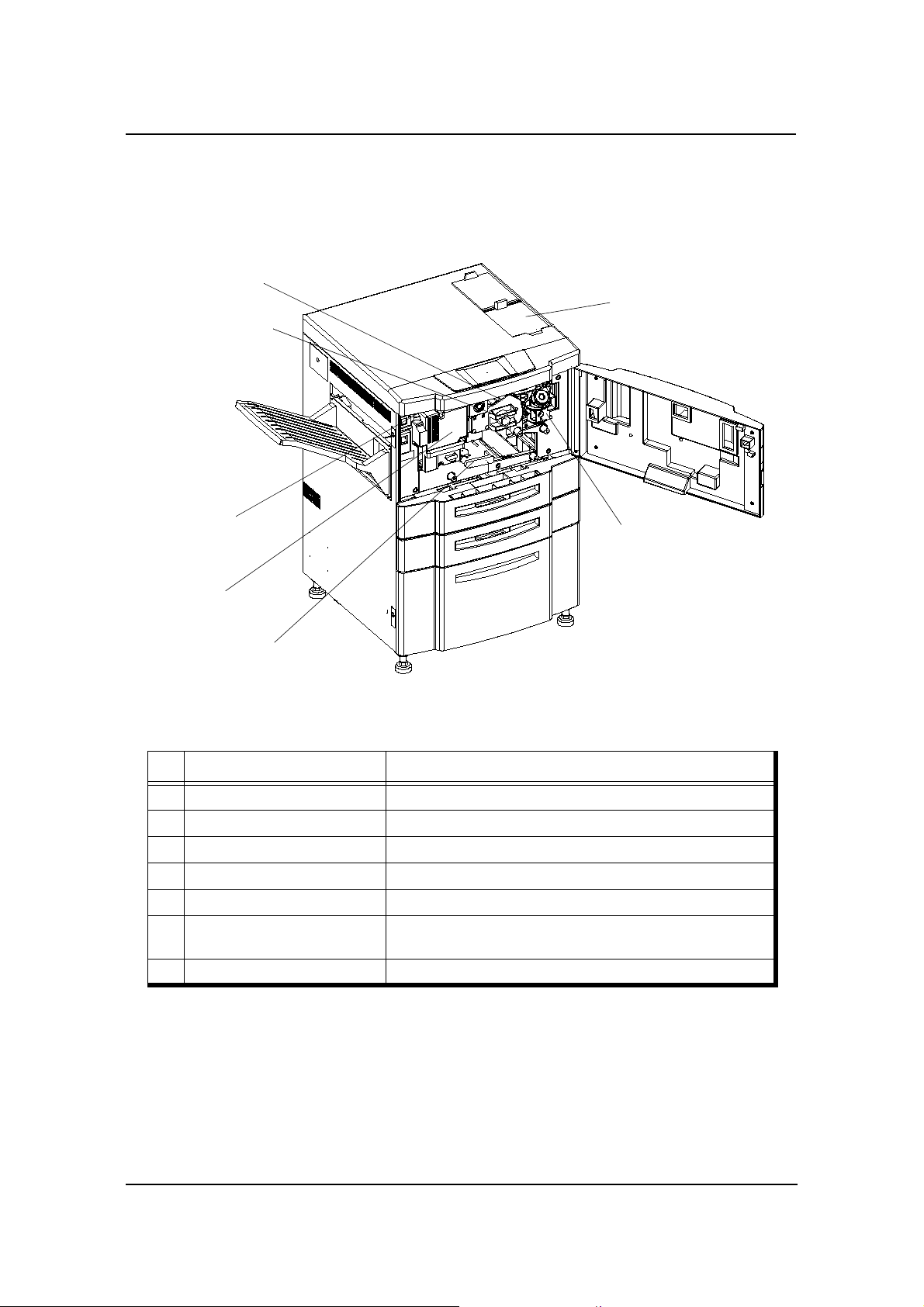

Internal View of the Printer

3. Drum Unit

2. Drum Center Lock

4. Fuser Latch

5. Fuser Unit

1. Toner Hopper Unit

6. Developer Duct

7. TH Handle

Key Component Description

1 Toner Hopper Unit Install the toner bottle here.

2 Drum Center Lock Holds the drum in place.

3 Drum Unit OPC drum.

4 Fuser Latch Provides access to the fuser unit.

5 Fuser Unit Fuses the toner on the paper.

6 Developer Duct

7 TH Handle Handle of the toner transfer unit.

Mount the developer bottle onto the developer duct to replace

consumed developer.

1-6 Printer Overview

Page 17

What This Chapter Provides

This chapter contains information on the following topics.

OCP Description

Menu Structure

Using the Menu Screens

Passwords

Chapter 2

Operator Control Panel

Operator Control Panel 2-1

Page 18

OCP Description

The Operator Control Panel (OCP) is a touch panel display that you use to set up print

options and monitor job and printer status. It is also used by the Network Administrator

to configure the printer and by the Service Technician to perform maintenance on the

printer.

Operator Control Panel

2-2 Operator Control Panel

Page 19

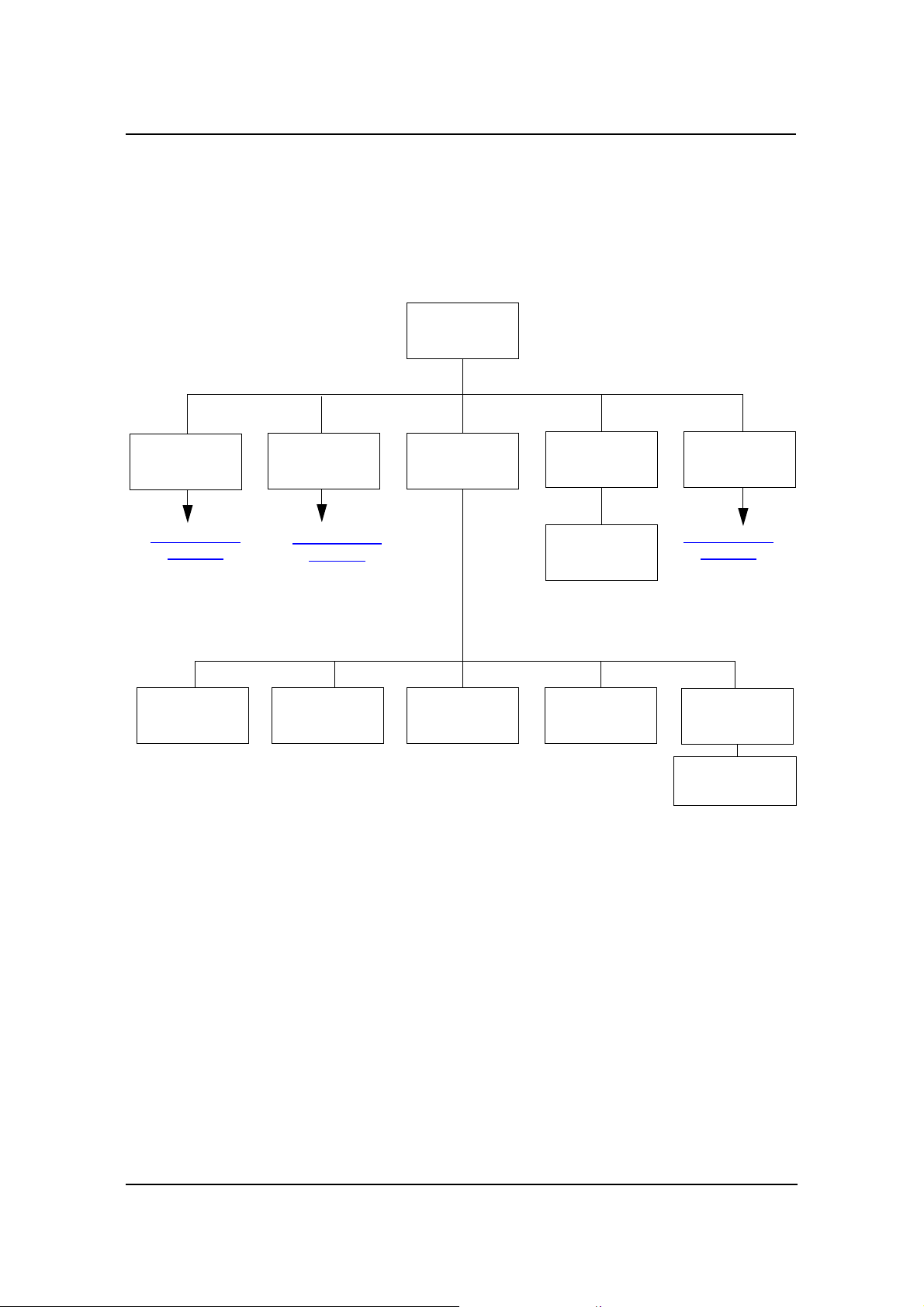

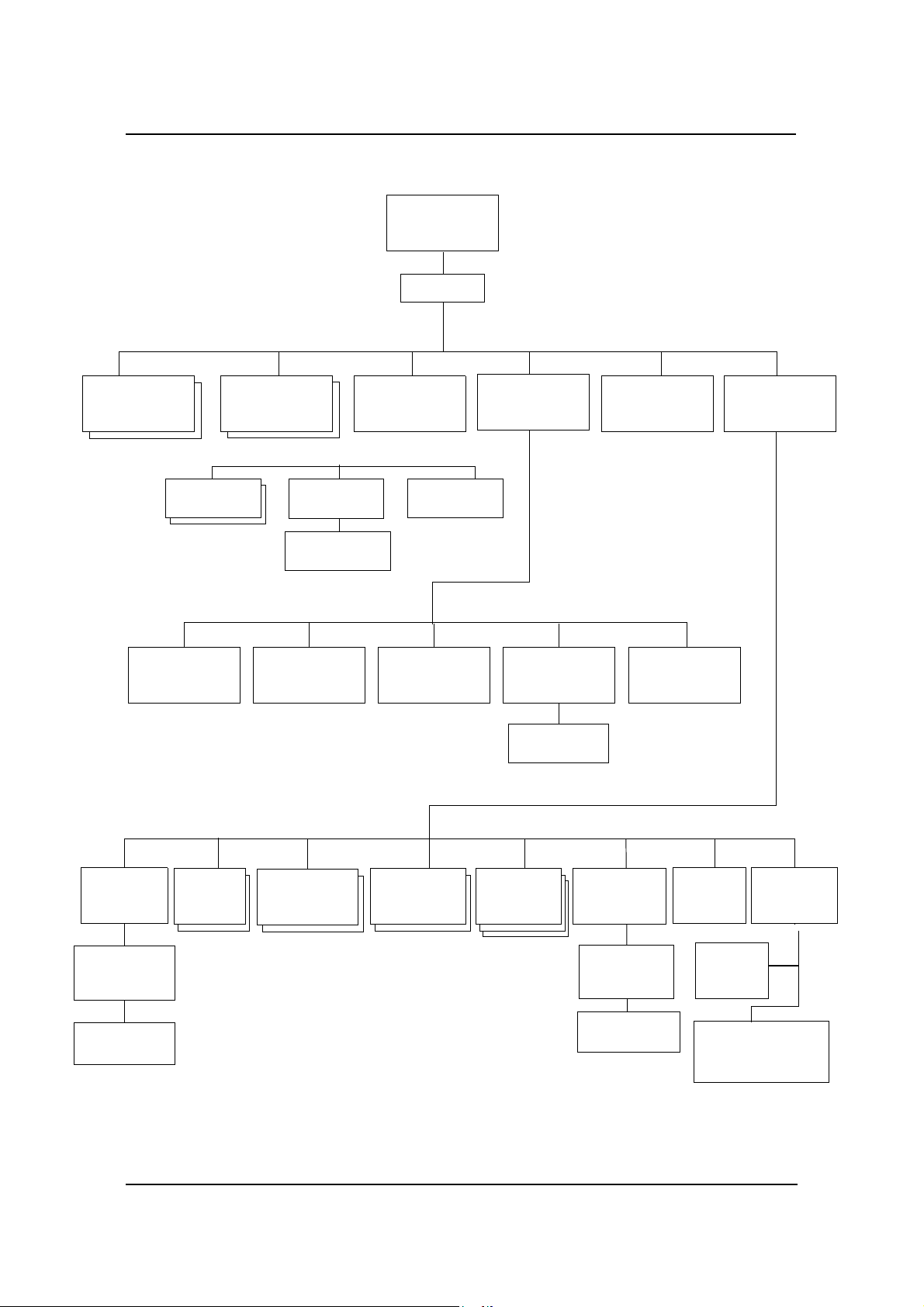

Menu Structure

The OCP menu is structured as shown in the following flowcharts. Each box in the

chart represents an OCP display screen. Use this flowchart to assist you in setting print

job options.

Main Menu

Printer Menu

Continued on

page 2-4

Setup Menu

Continued on

page 2-6

Reports Menu

Jobs Menu

Cancel Printing

Disk DirectorySummaryDemoStatus

Finisher Menu

Continued on

page 2-8

Fonts

• PCL Fonts

• PostScript Fonts

1

2

1

The Finisher Menu is only displayed when a Container Stacker is installed.

2

Available when PostScript is installed.

Operator Control Panel 2-3

Page 20

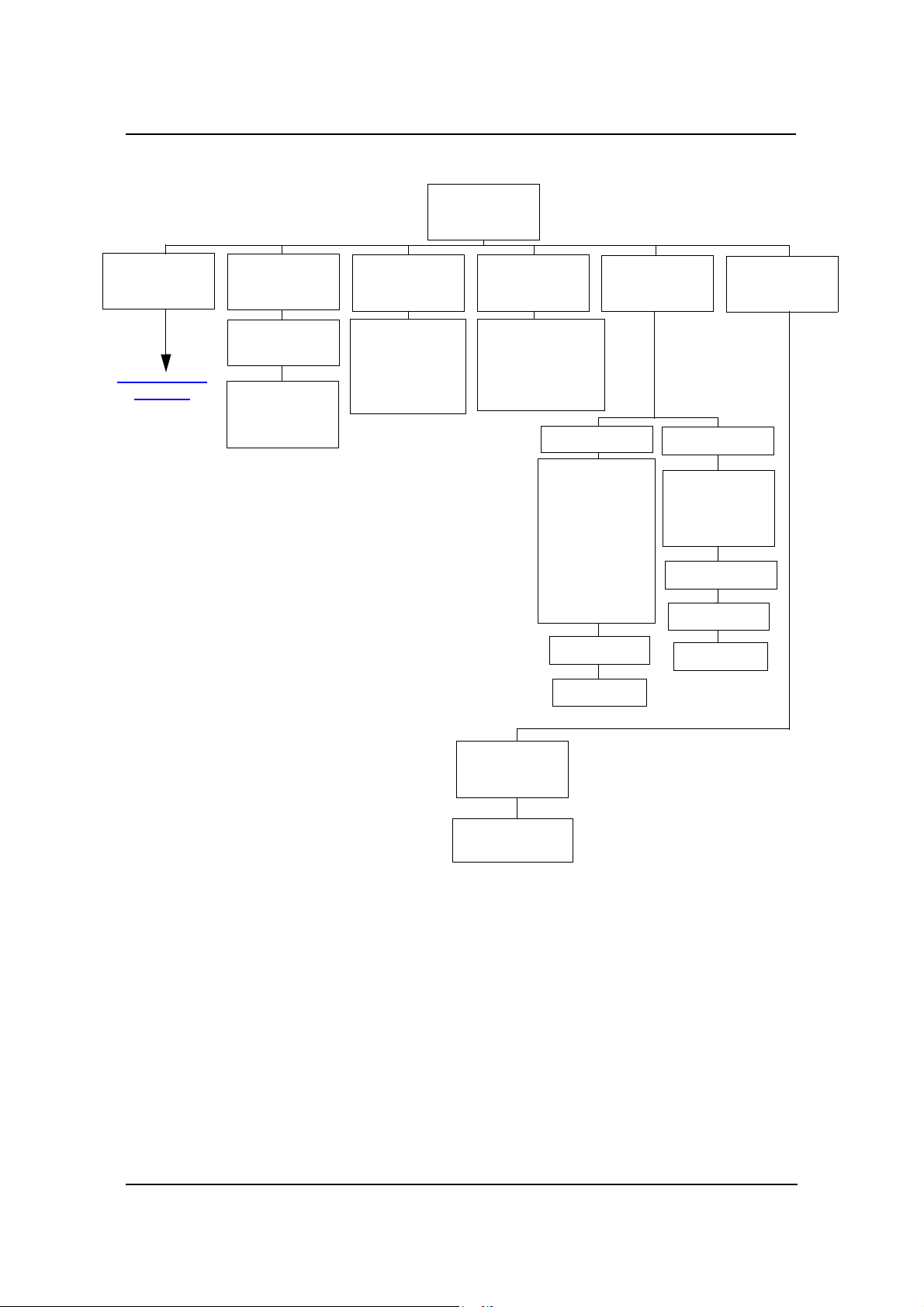

Printer Menu

Paper

Source

Continued on

page 2- 5

Default

Output

• Upper Tray

• Elevator Tray

• Stacker 5

• Stacker 6

• Stacker 7

• Stacker 8

2

2

2

2

Options

• Wait Timeout

• Duplex-Always

• LPD Queuing

• Auto Proof

Sample

PostScript

1

• Print Errors

• Best Fit

• Job Timeout

• Halftone Density

Print Quality

• Solid Black

• SquareBlk/Skew

• Half Tone

• GhostG

• Jitter

• Large Letters

• Diagonal Lines

• Density Scale

• Small to Large

• Text File 4%

• Cross Pattern

Select Paper

Source

Select Paper

Output

Test Print

• Staple:Front

• Staple:Rear

• Staple:Booklet

• Jogging

•

(More Options)

Finishing Test

Jogging

2

Select Paper

Source

Select Paper

Output

3

1

Available when PostScript is installed.

2

Available when the Container Stacker is installed.

2-4 Operator Control Panel

PCL

• Wide A4

• Requested Tray

Page 21

Paper

Source

Default

• AutoSelect

• 1

• 2

• 3

Tray 1

• Folio SEF

• Super B SEF

• Letter Tab LEF

• A4 Tab LEF

• Custom Size

2

Paper Size

• MBT

• HCF

Trays 2, 3

• Folio SEF

• Super B SEF

• Statement SEF

• Custom Size

• LetterTab LEF

• A4 Tab LEF

• Executive LEF

• Plain

• Bond

• Color

• Label

• Letterhead

• Preprinted

• Prepunched

2

• Letter LEF

• Letter SEF

• Ledger SEF

• Executive LEF

• Folio SEF

• Legal SEF

• Statement SEF

Paper Type

Select Paper

Source

1

MBT

MBT

Paper Color

Select Paper

Source

Paper Color

Settings

• Recycled

• Special

• Transparency

• Transparency-pp

• Other

• A4 LEF

• A4 SEF

• A3 SEF

• A5 SEF

• B5 LEF

• B4 SEF

1

(More Options)

1

• Super B SEF

• Letter Tab LEF

• A4 Tab LEF

• Custom Size

• Letter SEF

• A4 SEF

Paper Weight

Select Paper

Source

Paper Weight

Settings

1

Available when MBT is selected.

2

Available when the sensor plate in t he tray is set to the first position.

3

Available when the HCF is installed.

Tra y Adjust

Select Paper

Source

Tray Adjust

Settings

Ordered Sets

• 1

• 2

• 3

• MBT

3

• HCF

Operator Control Panel 2-5

Page 22

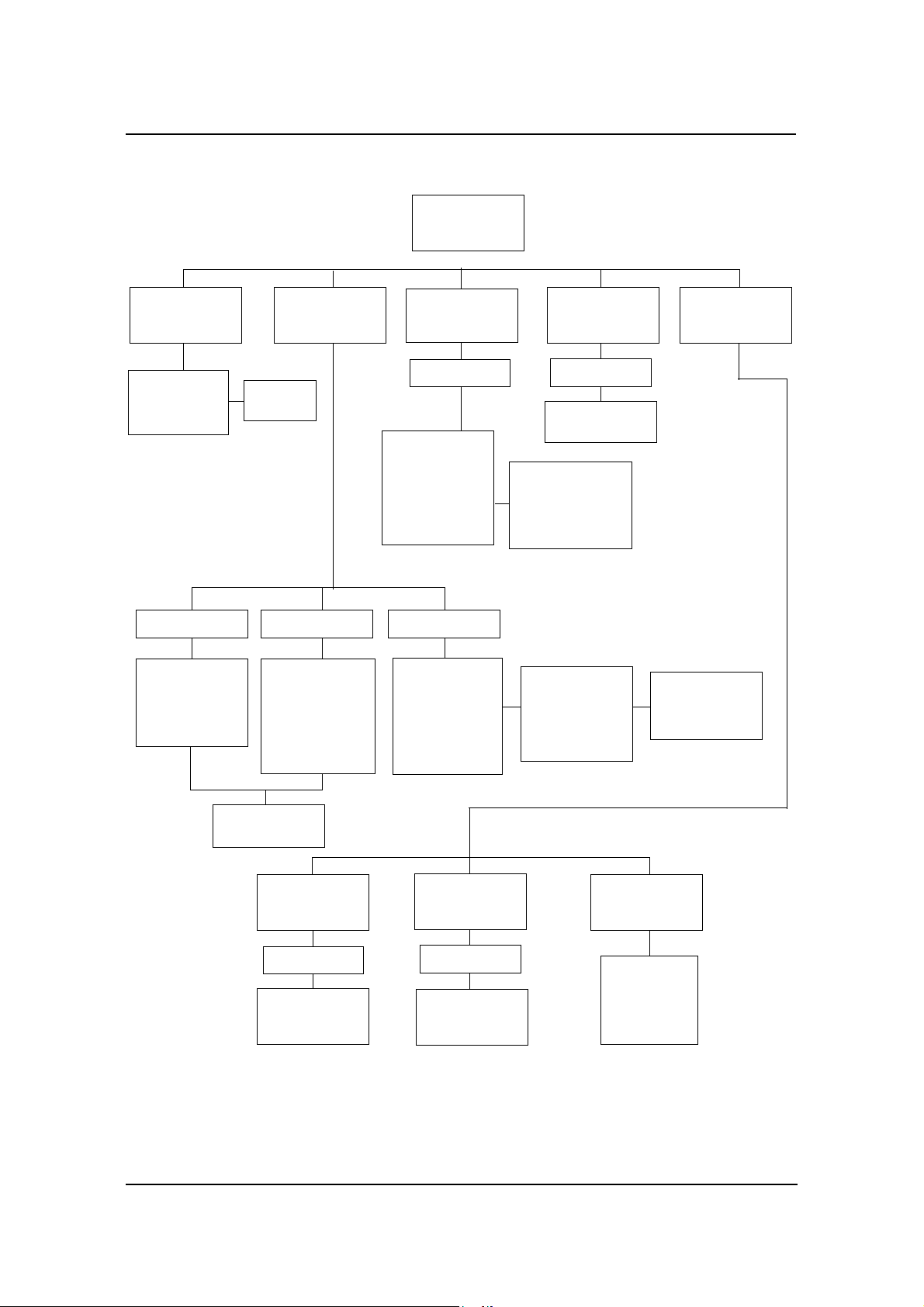

Setup Menu

OCP

• Contrast

• Volume

Service

Password

Developer Mix

• Exhaust

• Supply

1

Password

Continued on

page 2- 7

Drum Unit

ConsumablesSystem

Language

• English

• Deutsch

• Français

• Español

Fuser Web

1

Service menu items are for Service Technicians only and are not discussed in this manual.

2-6 Operator Control Panel

Page 23

System

Password

Reset

Ack Pulse

Width

Software

Log

• Compatible

• Bi-Directional

Subnet MaskIP Address

Mode

Parallel

Capture to

Gateway

Address

File

Network

Boot Method

• DHCP

• STATIC

Exit Jam

Recovery

HTTP Port

(More Options)

Calendar

• Time Zone

• Date

• Time

• Time Zone

Options

1

Available when Energy Save Mode is enabled.

2

Available when the Container Stacker is installed

3

Available when PostScript is installed.

Country

Code

Energy

Save Mode

Energy1

Save Time

Password

Emulation

• AutoSelec

• PostScript

• PCL

• PostScript

• Options

public

R/W

3

3

Online

3

• Auto Backup

• Output Cascade

• Best Fit Mode

(More Options)

Auto

Operator Control Panel 2-7

2

3

Page 24

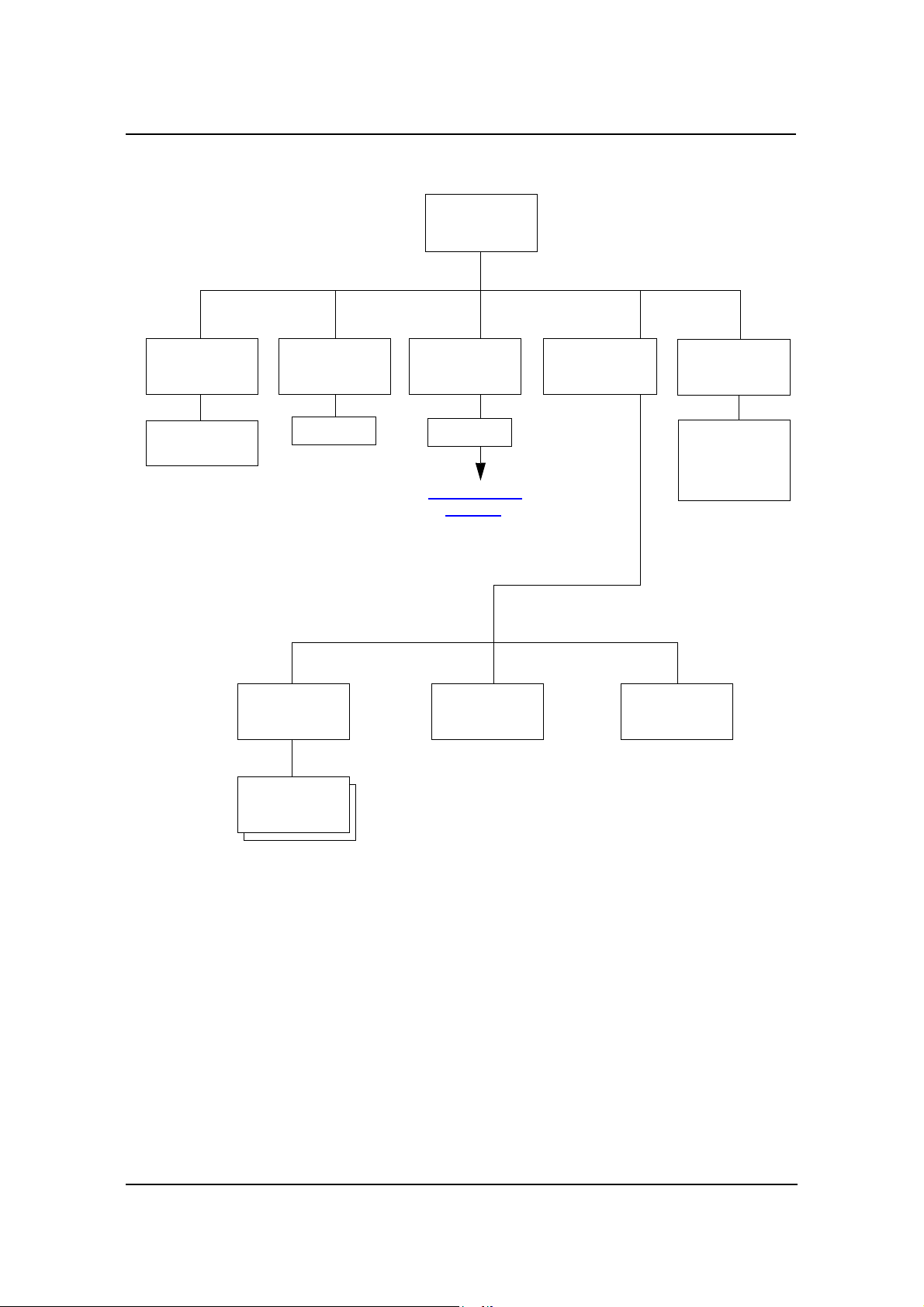

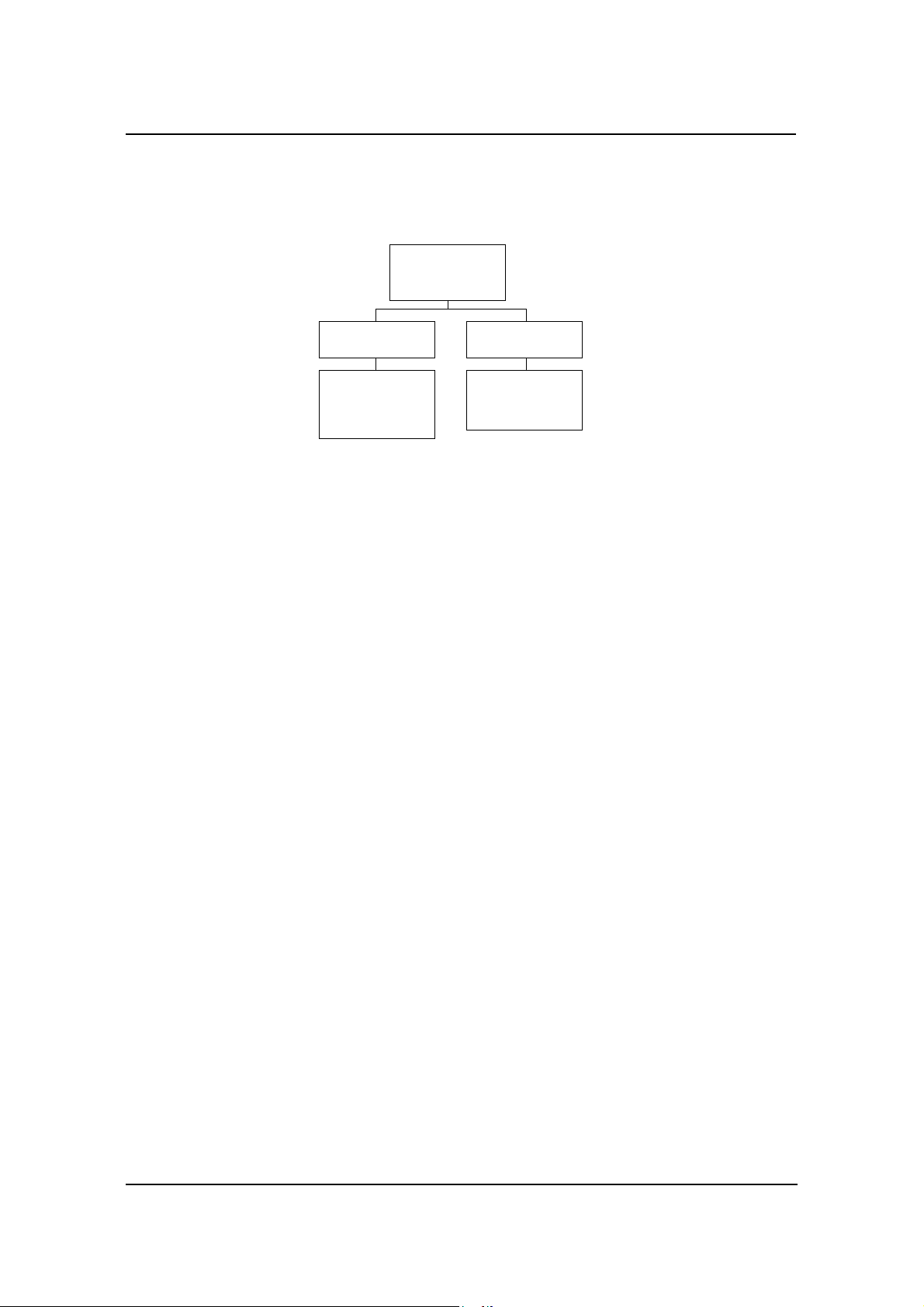

Finisher Menu

1

Short Stacking

• 5

• 6

• 7

• 8

Decurler

• AutoSelect

• Enable

• Disable

1

Available when the Container Stacker is installed.

2-8 Operator Control Panel

Page 25

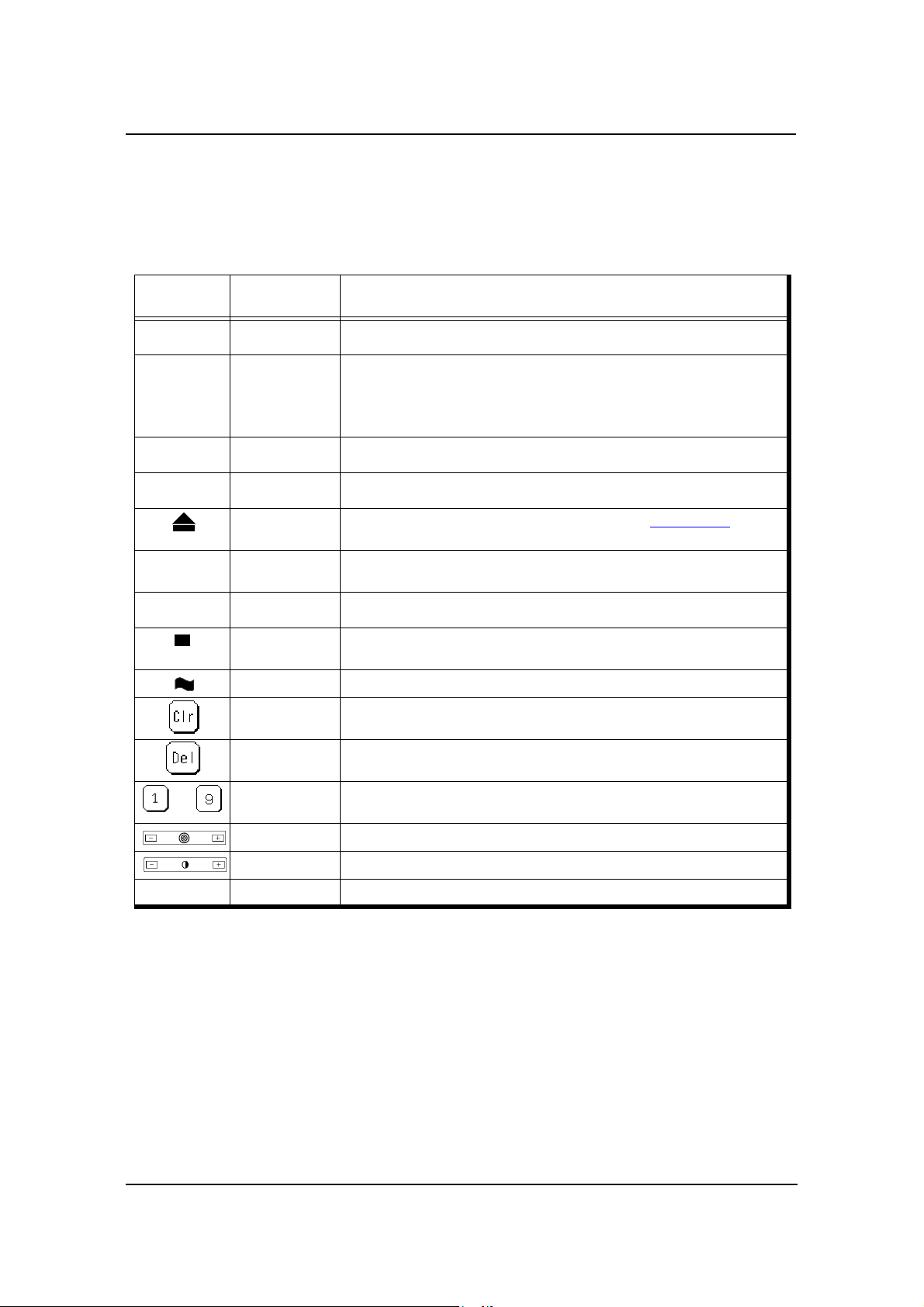

Using the Menu Screens

The menus are accessed via the touch panel. Each OCP screen consists of icons that

you use to make selections. The icons that are used through the OCP screens are shown

below. Examples of the OCP screens are shown on the following pages..

Icon or

Button

?

i

Name Function

Help Touch to display Help on the current screen.

Information From the Main Menu, displays information about the printer and con-

sumables.

From relevant screens, displays an illustration of the paper trays or fin-

isher trays.

Pause/Offline Tou ch to pause the printer.

Resume/Online When the printer is offline, touch to return to Ready status.

Return to Main

Menu/Cancel

Previous Menu Touch to cancel the current selection and return to the previous screen or

More Options Touch to display additional options for the current selection.

Enter or Accept Confirm or Done. Touch to confirm your selection and return to the previous

Sample Touch to duplicate a currently printing page and output to the sample tray.

Clear Button Touch to erase entire entry.

Touch to cancel the current selection and re turn to the

menu.

screen or menu.

Main Menu.

Delete Button Touch to erase last character entered.

–

Ten Key Use to enter numeric values.

Volume Use to adjust volume of the OCP touch pad.

Contrast Use to adjust the contrast level of the OCPdisplay.

Status Bar Displays the current screen name and/or any system messages.

Operator Control Panel 2-9

Page 26

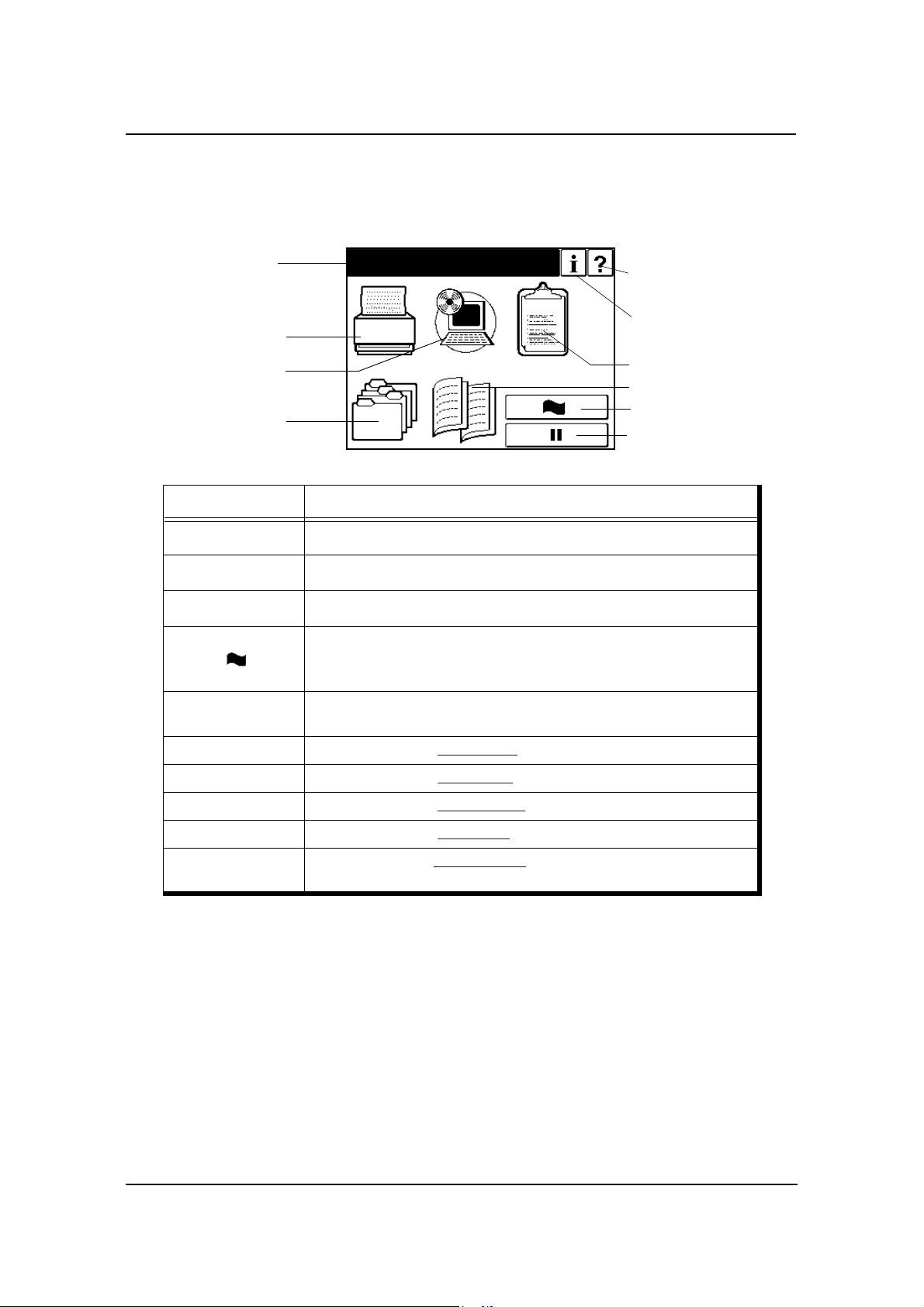

Main Menu

1.The Main Menu screen is shown below . A description of the elements that make up

the screen follows.

Status Bar

Printer Menu

Setup Menu

Jobs Menu

Icon Function

Status Bar

?

i

Ready

Help

Current Screen

Information

Reports Menu

Finisher Menu

Sample

Pause/Offline

Touch to open Main Menu Help.

Touch to display information about the printer and consumables.

Touch to pause the printer.

Touch to duplicate a current printing page and output to the

•Standard Finisher: Upper tray

•Container Stacker: Sample tray

Consists of one or two lines of text for displaying messages and instruc-

tions.

Printer Menu Touch to display the Printer Menu

Setup Menu Touch to display the Setup Menu

Reports Menu Touch to display the Reports Menu.

Jobs Menu Touch to display the Jobs Menu.

Finisher Menu

Touch to display the

Stacker is installed.

Finisher Menu. Available only when a Container

.

.

2-10 Operator Control Panel

Page 27

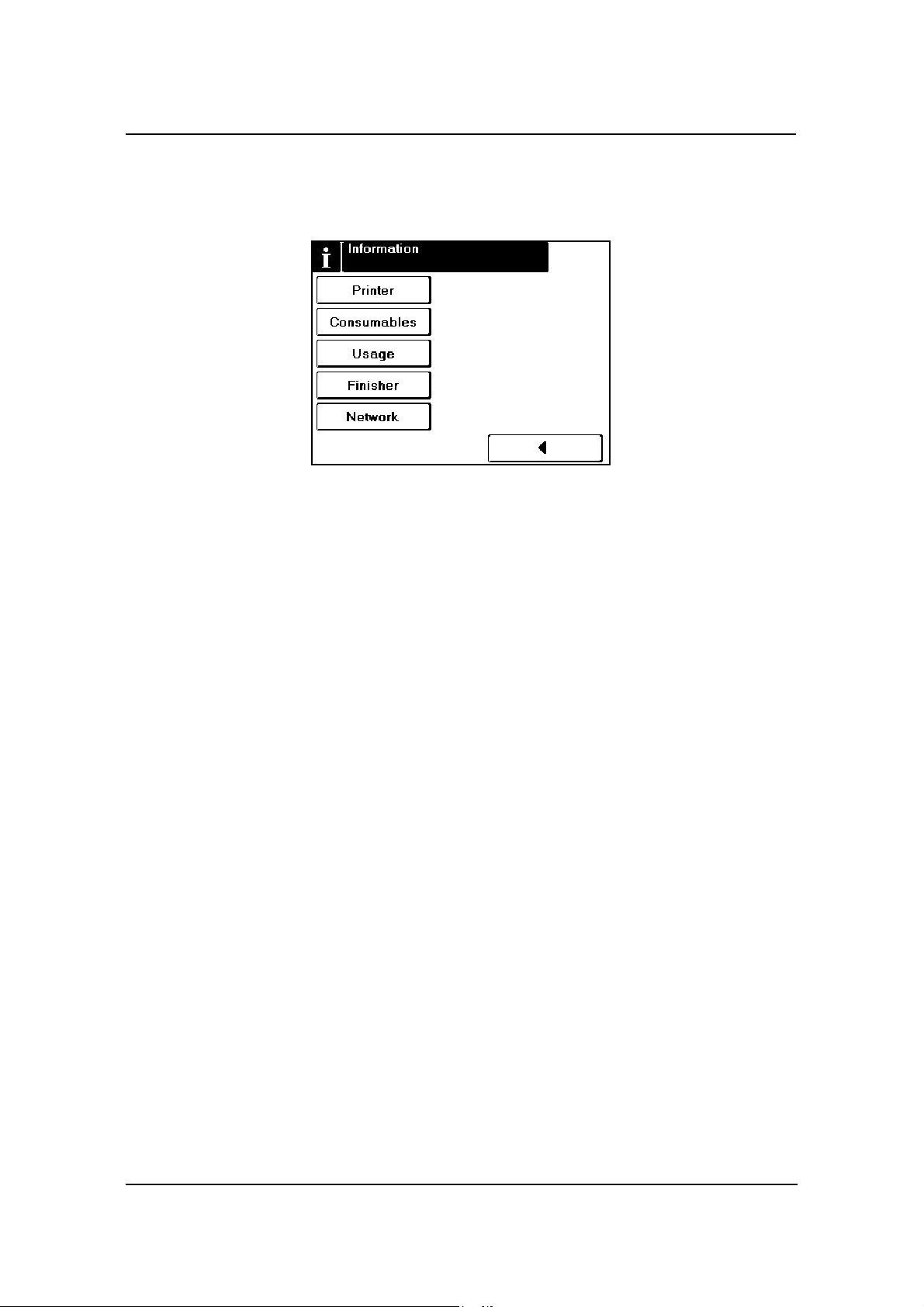

Information

When you select Information from Main Menu, this screen is displayed. You use it to

confirm about printer settings and consumables described as below.

Printer

Consumables

Displays information about the engine and controller software revision, error

counts, and the current paper type and source settings.

Displays the status of the consumables: Toner, Developer Mix., Drum, and Fuser

Web.

Usage

Displays current information regarding print density, preventative maintenance,

and page counts.

Finisher

Displays information regarding the status of the Finisher.

Network

Displays information such as MAC and IP Address, Gateway Address, Subnet

Mask and HTTP Port.

Operator Control Panel 2-11

Page 28

Printer Menu

When you select Printer from the Main Menu, this screen is displayed. You use the

Printer Menu to gain access to the printing options described in the table below.

Paper Source

Default

PCL

Defines the default paper tray. Use this when the paper source is not

designated by a host command. If a command from the host defines the paper

source, the OCP setting is ignored. When “AutoSelect” is selected, tray is

automatically selected according to paper size and/or paper type defined by

host.

Paper Size

When Paper Size is selected the paper size of the currently selected paper

source is displayed. When the “Custom Size Switch” in the tray is set to

“Standard”, paper size is automatically detected. See “Setting the Custom

Paper Size Values” on page 3-16 for more information.

Paper Type

Defines the paper type to desired input tray. The paper type screen displays

currently selected paper type, and the option buttons to select another paper

type. See “Setting the Paper Type” on page 3-17 for more information.

Paper Color

Sets the paper color for the selected input tray . The paper color screen displays

the currently selected paper color, and the option buttons to select another

paper color. There are 7 pre-defined colors and up to 80 custom colors to

choose from. Custom colors are defined using the Web Utilities. See “Setting

the Paper Color” on page 3-17 for more information.

Paper Weight

Defines the paper weight for the input tray. The paper weight screen displays

the currently defined paper weight, and the options to redefine the paper

weight settings. Options include bond, index and g/m

2

. See “Setting the Paper

Weight” on page 3-17 for detailed information and instructions.

2-12 Operator Control Panel

Page 29

Tra y Adjust

The print position can be adjusted vertically and horizontally using the Tray

Adjust option. When printing in duplex mode, you can set different tray adjust

values for the front side and back side of the paper. See “Setting the Tray

Adjust Values” on page 3-16 for detailed information and instructions.

Ordered Sets

You can define an ordered set by specifying the number of pages in the set and

the paper source tray(s) that contain the ordered set pages. The printer will

support input tray cascading for ordered sets based on paper size and media

type. See “Ordered Sets” on page 3-18 for detailed information and

instructions.

Default Output

Use this option when the output tray is not designated by a host command.

Options include Upper Tray, Elevator T ray and Stacker 5, 6, 7 and 8, (if installed).

If a command from the host defines the output tray, the OCP setting is ignored.

Options

Wait Timeout

Defines the time period (in seconds) from reception of last data to the

reception of next data. If data is not received within the defined period, the job

terminated. A command from the host will override the OCP setting.

is

LPD Queuing

Can be set to enable or disable. The factory default is disabled. When enabled

the printer will accept and queue additional print jobs while a data transfer is

in process for another job.

Duplex Always

Can be set to enable or disable. When set to enable, the printer will always

print in duplex mode.

Auto Proof Sample

This function provides automatic proof sample printing instead of manually

pressing the Sample button on the OCP. The auto proof sample interval is

0 - 5,000 pages in 500 sheet increments (0, 500, 1,000, 1,500, ... 5,000). For

example, if the interval is set to “500”, the printer will automatically output a

proof sample to the sample tray every 500 sheets. If the interval is set to “0”,

the function is disabled.

PostScript

Print Errors

Can be set to enable or disable. When set to enable, the printer will print an

error page when a PostScript error occurs.

Operator Control Panel 2-13

Page 30

Best Fit

Can be set to enable or disable. When enabled, if the requested paper size is

not present in any tray, the printer will select the closest available paper size

and scale the image to fit. Best Fit works in conjunction with the Best Fit

Mode option in the System Menu.

Job Timeout

Defines the time limit for processing of the PostScript job. The valid range is

0 or 15 - 999.

Halftone Density

Halftone Density can be adjusted to Light, Medium, Dark or Custom.

NOTE:

The Halftone Density menu is only displayed when the Halftone Selection

in the Service menu is enabled.

Test Print

Use this button to print a test pattern for checking the print quality or the print

position. A list of test patterns is shown on page 2-4.

PCL

Wide A4

Can be set to enable or disable. When set to enable, the printer changes the

margin/printable area of A4 paper so that 80 10-pitch characters may be

printed on a line.

Requested Tray

Exclusively - Printer should print from the requested tray only.

First - Printer should print from the requested tray first.

2-14 Operator Control Panel

Page 31

Setup Menu

When you select Setup from the Main Menu, this screen is displayed. Use it to gain

access to the Setup option screens that are described in the table below.

OCP

Volume

The volume of the OCP touch pad can be adjusted within a range of 0 to 5.

The factory default is 3.

Contrast

The contrast of the OCP can be adjusted within a range of 1 to 16. The factory

default is 10.

Service

The Service option is used by an Authorized Service Technician and is password

protected.

System

The System option is password protected. Contact your System Administrator for

access to these options.

Reset

Press to reboot the printer.

Software Log

Press to create a software log. A power cycle is required after creating the log.

Parallel

Network

Defines the parameters of the network. The network is displayed as

10/100/1000 (AUX). Other Network parameters include: IP Address, Subnet

Mask, Gateway Address, Boot Method, HTTP Port

Calendar

Time Zone - GMT -12:00 to GMT +12:00.

Date - 0000/00/00 (Year/Month/Day)

Time - Set printer clock

Operator Control Panel 2-15

Page 32

Country Code

Select the appropriate country code used in international phone numbers. A

complete list is available in your telephone book or on the Internet. Country

Code is not necessarily related to language. The default setting is 1.

Energy Save Mode

Can be set to enable or disable.

Energy Save Time

When Energy Save Mode is enabled use this option to set the wait time (in

minutes) before the printer enters Energy Save Mode.

Password

Use to change the System password. The system password is used by your

System Administrator and provides access to the system parameters.

Emulation

Options are AutoSelect, PostScript and PCL.

Public R/W

Can be set to enable or disable. Enable allows read/write when SNMP

community name is Public.

Auto Online

Can be set to enable or disable. When disabled, if the offline button is pressed

the printer will remain in an offline status until the button is pressed again.

When enabled, the printer will automatically return to an online status within

3-5 minutes without pressing the button.

Auto Backup Time

Valid range is 0 - 23 (corresponding to the hour of the day). A system data

backup will be performed if the printer is on at the set time.

Best Fit Mode

Can be set to Standard or Compatible. Best Fit Mode works in conjunction

with the Best Fit setting.

Standard: Mode for PostScript Version 3015 command sets.

Compatible: Mode for PostScript Version 3011 command sets.

Output Cascade

Lower to Upper - The lower trays are given priority within each stacker.

Upper to Lower- The upper trays are given priority within each stacker.

Available only when the optional Container Stacker is attached. When two

Container Stackers are attached the setting applies to both. The priority

between Container Stackers is Container Stacker 1 first, then Container

Stack er 2.

Consumables

Use to replace the Developer Mix, Drum Unit, and Fuser Web

Language

Use to set the OCP language to English, Deutsch, Français, or Español.

2-16 Operator Control Panel

Page 33

Reports Menu

When you select Reports from the Main Menu, this screen is displayed. You use it to

print the reports described below.

Status

Touch to print a status report and return to the Main Menu. The status report

shows the current configuration of the printer and printer usage information.

Demo

Touch to print a demo report and return to the Main Menu. The demo report

shows the printer specifications such as speed, paper handling, resolution, etc.

Summary

Touch to print a summary report and return to the Main Menu. The summary

report shows processor, connectivity, RAM and other miscellaneous information.

Disk Directory

Touch to print a disk directory report and return to the Main Menu.

Fonts

Touch to print the fonts summary options (PCL fonts and Postscript fonts).

Operator Control Panel 2-17

Page 34

Finisher Menu for the Container Stacker

When you have the optional Container Stacker installed and you select the Finisher

icon from the Main Menu, this screen is displayed. You use it to gain access to the

Container Stacker options.

For additional information on the Container Stacker, refer to the Container Sta c ker

User’s Guide.

Short Stacking

Can be set to enable or disable. When enabled, the paper stack is limited to 75%

of the stacker capacity.

Decurler

The options for the Decurler are AutoSelect, enable, or disable. Activating the

decurler may cause paper jams when printing with 28 lb. bond or heavier paper.

2-18 Operator Control Panel

Page 35

Jobs Menu

When you select Jobs icon from the Main Menu, this screen is displayed. You use the

Jobs Menu to cancel print jobs in the printer.

List of Jobs

Job-01 1/3-12 ““ 16:02 P

Job-02 0/1-1

Text-fil 0/1-1

““ 16:03 P

““ 16:08 P

Scroll Bar

““ 16:02 P

Time

User Name

Job Name

Current Copy

Total Copy

Scroll Bar

Job-01

Page Count

1/3-12

Touch to scroll the list of jobs.

Select All

To cancel all print jobs, press Select All, then press Delete.

Clear All

Press Clear All to deselect all print jobs.

Delete

To cancel a single job, touch the job name, then press Delete.

Job Status

P: Pause A: Active

C: Cancel

Operator Control Panel 2-19

Page 36

Passwords

Passwords provide security to restrict access to system parameters and certain printer

maintenance functions. Two types of passwords are available with your printer: a

system password and a service password.

The system password is used by your System Administrator and provides access to the

system parameters. The service password is used by your Service Technician and

provides access to service and maintenance functions as well as the system parameters.

For additional information, contact your System Administrator.

NOTE:

If the system password is lost it must be set up again. Contact your

authorized Service Technician.

2-20 Operator Control Panel

Page 37

What This Chapter Provides

This chapter contains information on the following topics.

Paper Weights

Unacceptable Paper

Storing Paper

Paper Sizes, Types, and Trays

Loading Paper

Setting Custom Paper Size Values

Setting Tray Adjust Values

Setting the Default Paper Source

Setting the Paper Type

Chapter 3

Paper Handling

Setting the Paper Weight

Setting the Paper Color

Ordered Sets

Paper Handling 3-1

Page 38

Paper

T o obtain good print quality , use the recommended paper and properly position it in the

correct trays. For the desired paper orientation, see the labels on the trays. Refer to

Appendix C for detailed information about paper specifications and printing on special

print media.

Paper Weight s

The printer accepts the following paper weights in all paper trays, including the MBT

and HCF:

Bond paper: 16-53 lb (60-199 g/m

Index paper: 90-110 lb (163-199 g/m

Paper Color

The printer accepts color paper in all paper trays, including the HCF. The seven predefined colors are listed below. Additionally, you can define up to 80 custom colors

using the Web Utilities.

White

Pink

2

)

2

)

Yellow

Buff

Goldenrod

Blue

Green

Unacceptable Paper

Avoid using the following media as they cause paper jams and print quality problems.

Excessively thick or thin paper

Paper that has already been printed (preprinted letterhead is allowed)

Wrinkled, torn, or bent paper

Moist or wet paper

Curled paper

Paper with an electrostatic charge

Glued paper

Paper with special coating

Colored paper with surface treatment

Paper unable to withstand temperature of 302°F (150° C)

Thermal paper

3-2 Paper Handling

Page 39

Carbon paper

Paper with paper fasteners, ribbons, tape, etc., attached

Heavily textured paper

Label stock with exposed backing sheets

Storing Paper

Store the paper properly to avoid print quality problems and paper jams.

Store paper horizontally, in a flat, dry location to avoid wrinkling, bending,

curling, etc.

Store paper away from direct sunlight.

Store any unused paper in its original packing.

Paper Handling 3-3

Page 40

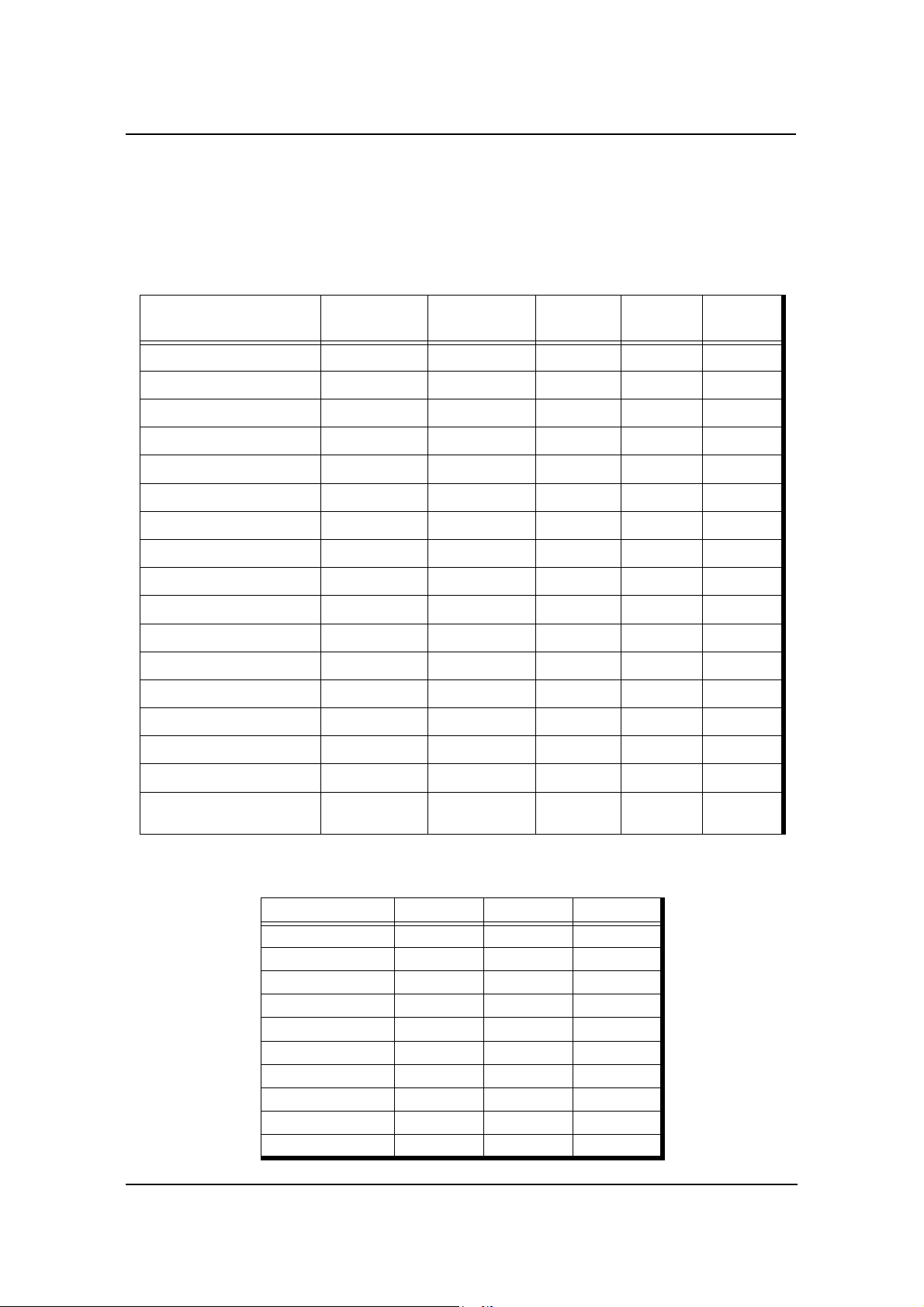

Paper Sizes, Paper Types, and Printer Input Trays

The following tables show which paper sizes and types can be used with the printer's

input trays. The paper size is shown in both millimeters and inches. The term SEF

indicates the paper is being fed into the printer short edge first and the term LEF

indicates the paper is being fed into the printer long edge first.

Paper Size

A5 (SEF) 149.0/5.83 210.0/8.26 2, 3 only

B5 (LEF) 257.0/10.13 182.0/7.17

A4 (SEF) 210.0/8.3 297.0/11.7

A4 (LEF) 297.0/11.7 210.0/8.3

B4 (SEF) 257.0/10.1 364.0/14.3

A3 (SEF) 297.0/11.7 420.0/16.5

Letter (LEF) 279.0/11.0 216.0/8.5

Letter (SEF) 216.0/8.5 279.0/1 1.0

Tabstock (Letter LEF) 374.0/11.0 279.0/9.0

Tabstock (A4 LEF) 297.0/11.7 225/8.85

Folio (SEF) 216.0/8.5 330.0/13.0

Legal (SEF) 216.0/8.5 356.0/14.0

Ledger (SEF) 279.0/11.0 432.0/17.0

Super B (SEF) 305.0/12.0 457.0/18.0

Statement (SEF) 216.0/8.5 140.0/5.5

Executive (LEF) 267.0/10.5 184.0/7.255

Custom

(0.1 mm/0.1 in. increments)

Leading Edge

mm/inch

139.7 to 304.8/

5.5 to 12.0

Side Edge

mm/inch

182.0 to 457.2/

7.2 to 18.0

Tray

1, 2, 3

99

99

999

99

99

999

99

99

9

99

99

99

99

2, 3 only

2, 3 only

9

*

HCF MBT

9

9

9

9

* Tray 1 can be adjusted; however, the physical settings are limited to standard paper sizes. Use

of custom size paper may result in skewing.

Paper Type Tray 1, 2, 3 HCF MBT

Label

Letterhead

Pre-printed

Pre-punched

Plain

Bond

Color

Special

Other

Transparencies

3-4 Paper Handling

999

999

999

999

999

999

999

999

9

9

Page 41

Loading Paper

Load paper into the trays according to the instructions that follow. See “Loading

Special Media” on page 3-12 for directions on loading prepunched and preprinted

paper, as well as tab stock. Paper can be loaded while a print job is running, except into

the tray that is currently in use.

Loading Paper in Tray 1

WARNING!

Do not open T ray 1 if the Fuser Unit is pulled out. The printer may tip over

causing personal injury or damage to the printer.

1. Open the tray by pulling it by the handle.

2. Adjust the size guide to the proper size. The available sizes are marked on the tray.

Paper Handling 3-5

Page 42

3. Adjust the sensor plate to the proper size. Size markers are located on the sensor

plate in the following order: triangle (special), B5, A5, LGR, LGL, LTR, B4, A3,

and A4.

If the paper size you need is not listed, set the sensor plate to triangle (the first

position). Then, in Step 6, you will select the paper size from the OCP display.

4. Place the paper into the tray.

NOTE:

The paper should be loaded no higher than the Max. level indicator. The

Max. level indicator is located inside the tray.

5. Close the tray.

6. If you set the sensor plate to triangle in Step 3, select the paper size from the OCP

by making the following selections:

Printer / Paper Source / Paper Size / tray #/ paper size

7. Adjust the paper weight. The default paper weight is 20 lb. bond. If necessary,

change the paper weight by making the following selections:

Printer / Paper Source /

8. Select Index, Bond, or g/m

3-6 Paper Handling

/ Paper Weight / tray #

2

, then use the keypad to input the weight and press .

Page 43

Loading Paper in Tray 2 or 3

1. Open the tray.

2. Adjust the size guide to the proper size. The available sizes are marked on the

bottom of the tray.

3. Adjust the sensor plate to the proper size. Size markers are located on the sensor

plate in the following order: triangle (special), B5, A5, LGR, LGL, LTR, B4, A3,

and A4.

If the paper size you need is not listed, set the sensor plate to triangle (the first

position). Then, in Step 6, you will select the paper size from the OCP display.

Paper Handling 3-7

Page 44

4. Place the paper into the tray.

NOTE:

The paper should be loaded no higher than the Max. level indicator. The

Max. level indicator is located inside the tray.

5. Close the tray.

6. If you set the sensor plate to triangle in Step 3, select the paper size from the OCP

by making the following selections:

Printer / Paper Source / Paper Size / tray # / paper size

7. Adjust the paper weight. The default paper weight is 20 lb. bond. If necessary,

change the paper weight by making the following selections:

Printer / Paper Source /

8. Select Index, Bond, or g/m

/ Paper Weight / tray #

2

, then use the keypad to input the weight and press .

3-8 Paper Handling

Page 45

Loading Paper into the MBT

1. Open the MBT by pulling it by the handle.

2. Adjust the size guide to the proper size. The paper size positions are marked on

the bottom of the tray and on the top of the size guide.

Paper Handling 3-9

Page 46

3. Push down the paper tray.

4. Set the paper onto the tray.

3-10 Paper Handling

Page 47

Loading Paper into the HCF

WARNING!

The table inside the HCF automatically descends when you open the door

of the HCF. Do not allow anything to be caught between the table and the

bottom of the HCF.

1. Open the door of the HCF by pulling it by the handle. The table inside the HCF

automatically moves to its lowermost position and stops.

2. Set the paper into the HCF. (The HCF is set to handle Letter LEF or A4 LEF size

only. A service call is required to change from one size to the other.)

NOTE:

The paper should be loaded no higher than the Max. level indicator. The

Max. level indicator is located inside the HCF.

3. Close the door.

Refer to graphic i

Paper Handling 3-11

Page 48

Loading Special Media

Pre-punched Paper

Load pre-punched paper as indicated in the following diagrams. Refer to Appendix C

for more information about using pre-punched paper.

Table 0-1. Simplex Printing (Single-sided)

Paper Size Orientation

Loading into

Tray 1 - 3 MBT or HCF

Letter/A4

Ledger/A3 Portrait

Ledger/A3 Landscape

Letter/A4 Portrait

Letter/A4 Landscape

Portrait and

Landscape

Ledger/A3

Portrait and

Landscape

Arrows indicate paper feed direction.

3-12 Paper Handling

Page 49

Table 0-2. Duplex Printing (Double-sided)

Paper Size Orientation

Portrait and

Letter/A4

Ledger/A3

Ledger/A3

Ledger/A3

Landscape

(Long Edge Bind)

Portrait

(Short Edge Bind)

Landscape

(Short Edge Bind)

Portrait and

Landscape

(Long Edge Bind)

Loading into

Tray 1 - 3 MBT or HCF

Letter/A4

Letter/A4

Portrait

(Short Edge Bind)

Landscape

(Short Edge Bind)

Arrows indicate paper feed direction.

Paper Handling 3-13

Page 50

Loading Pre-printed Paper

Load pre-printed paper as indicated in the following table. Refer to Appendix C for

more details about using pre-printed paper.

Paper Type

Front/Back Side

Predetermined

Page Number

Predetermined

Print

Mode

Simplex Front side down Front side up

Paper up to 9 in. (feed direction),

Duplex

Simplex First sheet on top, face down First sheet on top, face up

Duplex

front side down

Paper longer than 9 in. (feed

direction), front side up

Paper up to 9 in. (feed direction),

first sheet on top, face down

Paper longer than 9 in. (feed

direction), first sheet on top, face

up

Tray 1 - 3 MBT/HCF

Loading Into

Front side up

First sheet on top, face up

3-14 Paper Handling

Page 51

Loading Tab Stock

1. Load tab stock as shown in the illustration below.

NOTE:

Avoid bending the tabs or the corners of the tab dividers as this will

increase the likelihood of a jam occurring during the printing process. If a

jam does occur, refer to page 4-25 for instructions on jam recovery.

In the main paper trays, place the straight edge of the tab stock against the straight

right leading edge of the paper tray. The tabs should be on the left, also known as

the trailing edge. In the MBT, place the straight edge into the machine. Tab stock

cannot be used in the HCF.

Top

Bottom

Load only complete tab sets. The first tab in the set should be on top of the stack

and the last tab on the bottom. Adjust the paper guides so that they hold the tab

stock securely in position in the tray.

NOTE:

You must set the sensor plate in the tray to the first position (denoted by a

triangle).

2. Select the paper size from the OCP by making the following selections. (If the tab

stock is not 9 in. by 11 in., select Custom Size.)

Printer / Paper Source / Paper Size / tray number / LetterTab or Custom Size

3. If you selected Custom Size in step 2, see “Setting the Custom Paper Size Values”

on page 3-16 for instructions on entering the custom paper size.

Paper Handling 3-15

Page 52

Setting the Custom Paper Size Values

If the paper size you have selected is a custom size you must set the paper size using

the OCP. First, follow the steps for loading paper into the desired tray, then perform

these steps.

1. On the Custom Paper Size screen, touch the value box for the leading edge (the

arrow in the illustration points to the leading edge). The Custom Paper Size Input

screen is displayed.

2. Using the number pad, enter the value for the leading edge of the paper.

3. Press the

entered is shown.

4. Touch the value box for the side edge. The display returns to Custom Paper Size

Input.

5. Using the number pad, enter the value for the side edge of the paper.

6. Press the

you have entered are displayed.

7. Press the

key . The display returns to Custom Paper Size and the value you have

key. The display returns to Custom Paper Size and now both values

key. Your custom paper size settings are now saved.

Setting the Tray Adjust Values

The tray adjust feature is used when it is necessary to shift the image on the printed

page. You can shift the image feed direction +1.0 in (25.4 mm) or -0.5 in (12.6 mm)

and you can shift the image ±0.5 in. (12.6 mm) in the scan direction. When pri nting in

duplex mode, you can set different tray adjust values for the front side and back side of

the paper.

1. To display the Tray Adjust screen, make the following selections from the OCP:

Printer / Paper Source/

2. On the Tray Adjust screen, touch the left-most value box. The Tray Adjust Input

screen is displayed.

/ Tray Adjust / tray number

3. Using the number pad, enter the value for the feed direction of the paper. For

example, entering +1.0 moves the image 1.0 in. to the right on the printed page.

4. Press the

have entered is shown.

5. Touch the bottom-most value box. The display returns to Tray Adjust Input.

6. Using the number pad, enter the value for the scan direction of the paper. For

example, entering +0.5 moves the image 0.5 in. to the top of the printed page.

7. Press the

values you have entered are displayed.

8. Press the

3-16 Paper Handling

key. The display returns to the Tray Adjust screen and the value you

key. The display returns to the Tray Adjust screen and now both

key. Your tray adjust settings are now saved.

Page 53

Setting the Default Paper Source

The Default Paper Source feature is used when the paper source is not specified in the

job.

1. To set the Default Paper Source make the following selections from the OCP:

Printer / Paper Source / Default / Tray # or AutoSelect /

Setting the Paper Type

The Paper T ype feature is used when the type of paper being used is anything other than

Plain.

1. To set the paper type for each tray make the following selections from the OCP:

Printer / Paper Source / Paper Type / Tray # / desired paper type /

Setting the Paper Weight

The Paper Weight feature is used when the paper weight being used is anything other

than 20 lb..

1. T o set the paper weight for each tray make the following selections from the OCP:

Printer / Paper Source / >> / Paper Weight / T ray #

Using the number pad, enter the value for paper weight and press the

Setting the Paper Color

The Paper Color feature is used when the paper color being used is anything other than

white.

key.

1. To set the paper color for each tray make the following selections from the OCP:

Printer / Paper Source / Paper Color / >> / Tray #

Paper Handling 3-17

Page 54

Ordered Sets

Using the OCP or the WEB you can define an ordered set by specifying the number of

pages (12 max.) in the set and the paper source tray(s) that contain the ordered set

pages. The printer will support input tray cascading for ordered sets based on paper size

and media type

NOTE:

The printer can support only one ordered set size at a time; therefore, make

sure the paper size and media type for each tray in the cascade are the same.

PCL tray grouping is also supported for ordered sets. All trays in a group must have the

same configuration to allow cascading. Trays not included in the group must have a

different configuration.

NOTE:

For more information on PCL Tray Grouping refer to the Web Utilities

Guide and/or the PCL Programming Guide.

In the event that a paper jam, job cancellation, or other recoverable printer error occurs

while printing ordered sets, the printer will prompt you to clear the paper path. When

the paper path is clear, press Continue on the OCP. The printer will automatically

remove the remaining sheets of the ordered set to the sample tray , reprint the set(s) that

were in the paper path, and complete the job.

Some examples of ordered sets are:

Tabs

NCR

Prenumbered pages

Special forms

3-18 Paper Handling

Page 55

Define the Ordered Sets

1. From the OCP make the following selections:

Printer / Paper Source /

The Ordered Sets and Size screen will be displayed.

2. Select the tray(s) and the number of pages in the set.

3. Press the

4. Load the ordered set pages into the tray(s).

NOTE:

When loading ordered media to a tray you must load the paper in complete sets

If you print a subset of the complete set the unused pages will be delivered to the

sample tray.

key. Your settings are now saved.

/ Ordered Sets

Paper Handling 3-19

Page 56

3-20 Paper Handling

Page 57

What This Chapter Provides

This chapter contains the following information:

Replacing Consumables

Clearing Paper Jams

Cleaning the Printer

Handling and Storing Consumables

Chapter 4

Care and Maintenance

Care and Maintenance 4-1

Page 58

Replacing Consumables

When a consumable needs to be replaced, the printer stops printing and displays an

error message indicating which consumable should be replaced. The following table

shows the life expectancy of each consumable.

Consumable Average Life Expectancy

Toner 36,000 images (5% coverage

Developer Mix 480,000 images (600,000 drum rotations)

Drum Unit 400,000 images (500,000 drum rotations)

• 1,600,000 images, or

• 4,000 hours (time that heater of fuser unit has

Fuser

Fuser Cleaning Web 320,000 images

Toner Collector Bottle Every other refill of the toner

NOTE:

been turned on) (70ppm)

• 3,000 hours (time that heater of fuser unit has

been turned on) (92ppm)

1

)

“Image” means paper size of Letter/A4 LEF. Other page sizes will have

“images” based on Length of Form/8.5”.

Standard toner collector bottle replacement is every other toner supply.

However, depending on print density requirements, the replace toner

collector bottle message may be displayed at varying frequencies.

External factors can affect the average yield of consumables. Some of these factors are:

Humidity

Temperature

Type of paper

Run length of jobs

Adequate ventilation around equipment

Image coverage on page

Print Utilization - if less than 80%, projected consumable life may become shorter

Print density

1

Coverage is calculated per printed sheet and is defined as the ratio of area with toner to the total area of the sheet.

Toner usage is based on 5% coverage when the toner density level is set to the default value. The following items

affect toner coverage: the printed image content, the paper used, and the condition and calibration of the printer.

Actual toner usage may vary due to these factors.

4-2 Care and Maintenance

Page 59

Adding Toner

1. Open the Toner Supply Cover.

2. Make sure that the mouth of the toner bottle is closed. Shake the toner bottle up

and down about six times, then turn the toner bottle upside down and shake it

again.

Toner Supply Cover

Toner Hopper Unit

5 - 6 times 5 - 6 times

CAUTION!

Toner is not harmful to the human body, but if some toner has come in

contact with your skin or clothes, you should wash it immediately with

cold water.

Care and Maintenance 4-3

Page 60

3. Peel the toner seal film.

NOTE:

Before peeling the toner seal film, make sure that the projection of the

toner bottle cap is located at the click point. If it is not, turn the bottle cap

counterclockwise to move the projection to the click point as shown in the

figure below, and then peel the seal film.

4. Install the toner bottle into the T oner Hopper Unit so that the triangle marks on the

bottle mouth and the Toner Hopper Unit line up. Turn the bottle in a half circle

until the triangle mark on the bottle comes to fit the circle mark on the Toner

Hopper Unit.

Toner Bottle

Circle Mark

4-4 Care and Maintenance

Page 61

5. Hold the top of the bottle and tap the side to transfer the toner into the Toner

Hopper Unit.

6. When the toner bottle is empty, turn it back in a half circle and take it out.

Empty Toner Bottle

180°

7. Close the Toner Supply Cover and discard the empty toner bottle.

Care and Maintenance 4-5

Page 62

Replacing the Toner Collect or Bottle

When the OCP displays the message Toner Bottle Full, replace the Toner

Collector Bottle with a new empty bottle.

1. Open the Toner Collector Bottle Cover and the Inner Cover. (The Toner Cover

Door is located at the right side of the printer next to the MBT.)

2. Remove the old Toner Collector Bottle.

Inner Cover

Install Remove

Toner Collector

Bottle Cover

Empty Toner Bottle

3. Remove the cap from the side of the Toner Collection Bottle and place it on top of

the bottle to seal it.

Cap

4. Install a new Toner Collector Bottle. (See illustration for Step 2.)

5. Close the Inner Cover and the Toner Collector Bottle Cover.

4-6 Care and Maintenance

Page 63

6. Dispose of the full toner bottle properly.

WARNING!