Page 1

© 2005 Ricoh Printing Systems, Ltd.

March, 2007

N904116

Installation

Manual

Page 2

Page 3

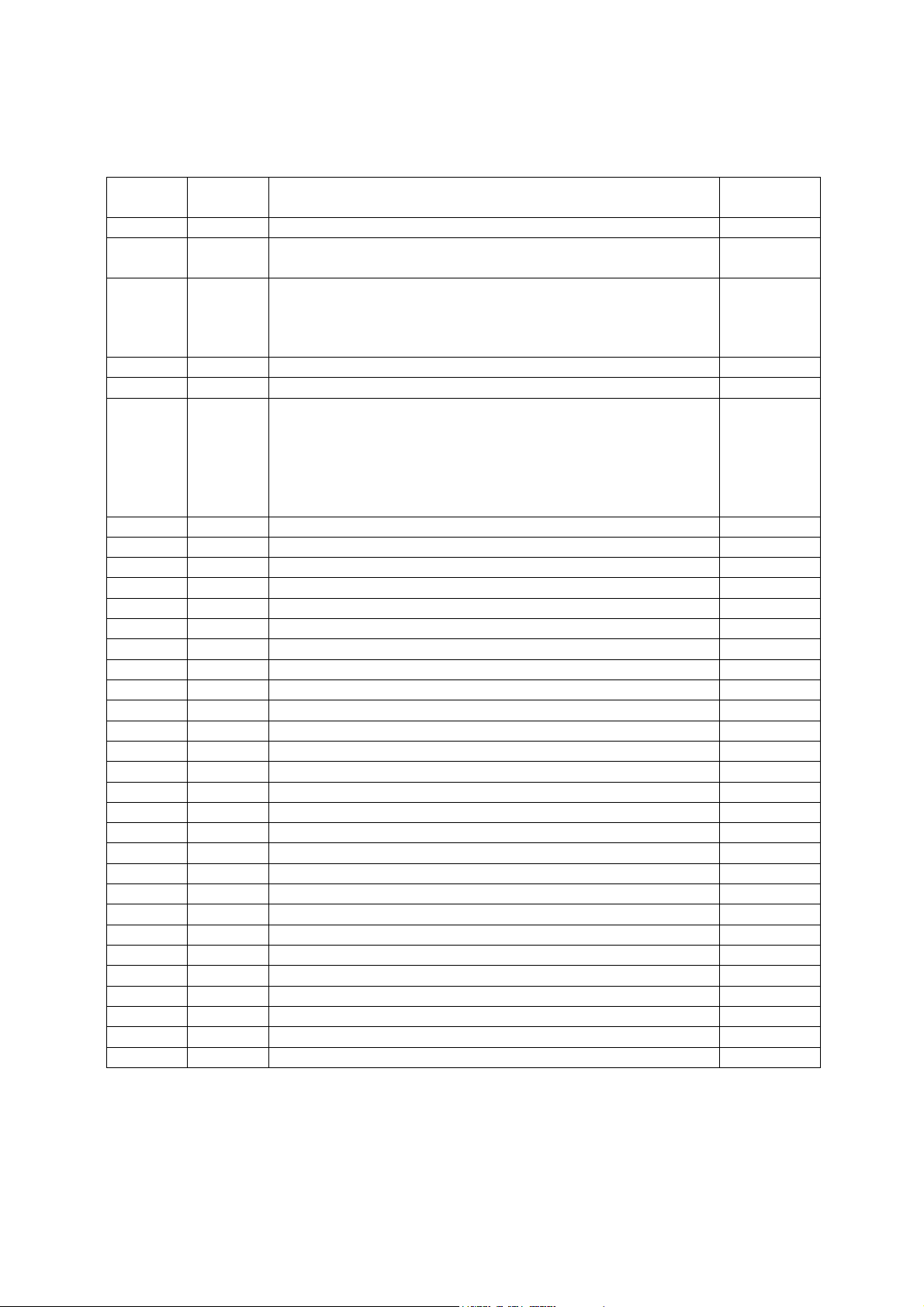

Revision Table for manual

Rev. for

Manual

00 - First Edition May, 23. ’05

01 - Table of Contents ii(01) 2-3(01), 2-4(01), 2-5(01),

02 U5 RoHS Compliance. 2-4(02),2-5(02),2-7(01) to 2-10(01),2-16(01)

03 - 2-4(03),2-5(03) Mar, 5. ‘07

04 - 5-8(00) Jan,22.’08

05 - Table of Contents i(01),ii(02),1-1(01),1-2(01) ,4-1(01), 4-37(02),

06 - 2-17(01),4-17(01),4-18(01) Apl, 10.’08

07 - 2-17(02),2-18(01) ,4-17(02),4-18(02), 4-48(01),4-49(01) Jun, 18.’08

Machine

Rev.

Page No.(Contents) Date

Oct, 21. ’05

4-4(01), 4-15(01), 5-1(01), 5-2(00) to 5-7(00)

Mar, 24. ‘06

3-2(01),3-4(01),3-9(01) to 3-11(01),3-15(01),4-5(01),4-7(01),

4-10(01) to 4-12(01),4-19(01),4-21(01) to 4-23(01),4-25(01),

4-27(01) to 4-29(01),4-32(01) to 4-35(01),

Mar,28.’08

Added pages : 2-17(00),2-18(00),2-19(00),3-16(00) ,

4-5(00),4-14(00),4-15(00),4-16(00),4-17(00),4-18(00),4-19(00),

4-20(00),4-44(00),4-45(00),4-46(00),4-47(00),

4-48(00),4-49(00),4-50(00), 4-51(00),Appendix9(00),

Appendix10(00),Appendix11(00), Appendix12(00)

Page 4

© 2005 Ricoh Printing Systems, Ltd. All rights reserved.

No part of this document may be reproduced without the expressed permission of Ricoh Printing

Systems, Ltd.

The material in this document is for informational purposes and is subject to change without notice.

Ricoh Printing Systems, Ltd. assumes no responsibility for errors or omissions in this document. No

liability is assumed for any damages resulting from the use of the information it contains.

This manual describes information for handling and operating the DDP184 laser printer.

NOTICE TO USER

In an effort to meet the demands of a rapidly changing technology, the manufacturer is continually

developing new features and functions to meet your changing printing or printer needs. As a result,

this manual may not exactly reflect future changes made to the product. Please be sure to consult

all manual updates or addenda when using this product’s documentation.

INTRODUCTION

This manual provides essential information to install the DDP70 laser printer.

Carefully read and understand the safety instructions in this manual before starting installation.

Keep this manual on hand for reference.

DDP70 represent the model LB070B### laser printer.

(#:0-9, A-Z or blank).

Page 5

BLANK

Page 6

Table of Contents

SAFETY SUMMARY

1. General Safety Guidelines …………………………………………………………………. Safety-1

2. Hazard Warning Statements ……………………………………………………………… Safety-2

2.1 WARNING Statement …………………………………………………………………. Safety-2

CHAPTER 1. INSTALLATION REQUIREMENTS ........................................1-1

1.1 A

1.2 I

1.3 I

1.4 T

1.5 E

1.6 I

PPLICATION

NSTALLATION AREA

NSTALLATION UNIT

OOLS REQUIRED

NVIRONMENTAL CONDITIONS

NPUT LINE VOLTAGE

......................................................................................................................1-1

...........................................................................................................1-1

............................................................................................................1-1

.............................................................................................................1-2

.........................................................................................................1-2

...........................................................................................1-2

CHAPTER 2. UNPACKING ............................................................................2-1

2.1 U

2.2 U

2.3 U

2.4 U

2.5 U

2.6 U

NPACKING OF THE ENGINE

2.1.1 Components in the package................................................................................................ 2-1

2.1.2 Unpacking Procedures ........................................................................................................ 2-2

2.1.3 Parts Check in the Accessory Box ...................................................................................... 2-4

NPACKING OF THE FINISHER

2.2.1 Components in the package................................................................................................ 2-6

2.2.2 Unpacking Procedures ........................................................................................................ 2-7

2.2.3 Parts Check in the Accessory Box ...................................................................................... 2-9

NPACKING OF THE HIGH CAPACITY HOPPER

2.3.1 Confirmation of Parts Quantities.........................................................................................2-11

2.3.2 Unpacking Procedures .......................................................................................................2-11

NPACKING OF THE CONTAINER STACKER 1 OR

2.4.1 Confirmation of Parts Quantities........................................................................................ 2-13

2.4.2 Unpacking Procedures ...................................................................................................... 2-14

2.4.3 Parts Check in the Accessory Box .................................................................................... 2-16

NPACKING OF THE TRANSIT PASS UNIT TYPE

2.5.1 Confirmation of Parts Quantities........................................................................................ 2-17

2.5.2 Confirmation of the Accessories Parts .............................................................................. 2-17

2.5.3 Unpacking Procedures ...................................................................................................... 2-18

NPACKING OF THE FINISHER

2.6.1 Confirmation of Parts Quantities........................................................................................ 2-19

2.6.2 Unpacking Procedures ...................................................................................................... 2-19

...............................................................................................2-1

............................................................................................2-6

..................................................................2-11

2............................................................2-13

DDP .......................................................2-17

SR5000............................................................................2-19

CHAPTER 3. PREPARATION FOR INSTALLATION...................................3-1

3.1 P

REPARATION FOR INSTALLATION OF THE PRINTER

II L 01

Table of Contents i

.............................................................3-1

Page 7

3.1.1 Removing the Protection Tape and Mat from the Engine.................................................. 3-1

3.1.2 Set the PS Air Filter for the Engine Rear Cover.................................................................. 3-2

3.1.3 Removing the Protection Tape from 2000 Sheet Hopper. ................................................. 3-3

3.1.4 Removing the Protection Tape from 500 Sheet Hopper ; 2 portion................................ 3-3

3.2 P

3.3 P

3.4 P

3.5 P

REPARATION FOR INSTALLATION OF THE FINISHER

REPARATION FOR INSTALLATION OF THE HIGH CAPACITY HOPPER

REPARATION FOR INSTALLATION OF THE CONTAINER STACKER 1 OR

REPARATION FOR INSTALLATION OF THE TRANSIT PASS UNIT TYPE

............................................................3-4

..................................3-12

2............................3-14

DDP ......................3-16

CHAPTER 4. INSTALLATION.........................................................................4-1

4.1 I

NSTALLATION IN THE COMPOSITION OF THE PRINTER AND FINISHER

NSTALLATION IN THE COMPOSITION WITH THE HIGH CAPACITY HOPPER

4.2 I

4.3 I

NSTALLATION IN THE COMPOSITION WITH THE CONTAINER STACKER 1 OR

4.3.1 Connection of the Engine and Container Stacker 1 or 2..................................................4-24

4.3.2 Connection of the Container Stacker 1 and Container Stacker 2.................................... 4-32

4.3.3 Connection of the Container Stacker 2 and Finisher / Finisher SR5000......................... 4-37

/ F

INISHER

SR5000 ...4-1

...........................4-21

2.....................4-24

CHAPTER 5. CHECKS...................................................................................5-1

5.1 C

5.2 P

5.3 C

5.4 C

5.5 A

ONFIRMATION OF THE PAPER SIZE INDICATION

RINTING OF THE STATUS REPORTS

HECK THE PRINT CONTAMINATION

ONFIRMATION OF THE STAPLING

DJUSTMENT OF PAPER FEEDING POSITION OF TRAY

...................................................................................5-4

....................................................................................5-5

.......................................................................................5-5

..................................................................5-1

1.......................................................5-6

APPENDIX 1. INSTALLATION AREA INFORMATION....................................1

APPENDIX 2. LOCATIONS OF THE LEVELING BOLT AND CASTER ......10

II L 02

Table of Contents ii

Page 8

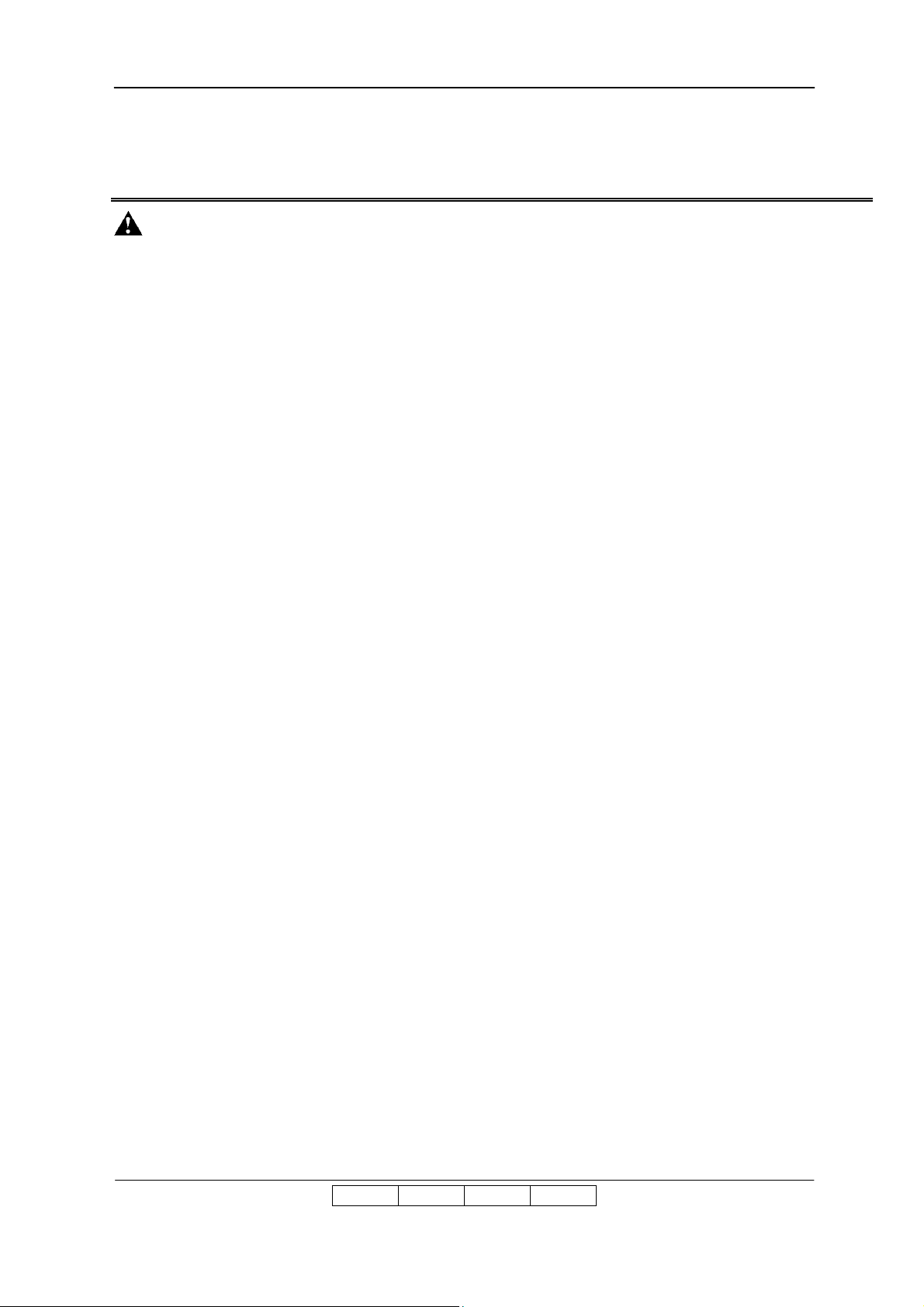

SAFETY SUMMARY

The hazard warnings which appear on the warning labels on the machine or in the manual have one of

the following alert headings consisting of an alert symbol and a signal word, DANGER, WARINIG, or

CAUTION.

This is the safety alert symbol. It is used to alert you to potential personal

injury hazards. Obey all safety messages that follow this symbol to avoid

possible injury or death.

DANGER: Indicates an imminently hazardous situation which, if not avoided, will result

in death or serious injury.

WARNING: Indicated a potentially hazardous situation which, if not avoided, can result

in death or serious injury.

CAUTION: Indicates a hazardous situation which, if not avoided, will or can result in

minor or moderate injury, or serious damage of product.

CAUTION: Indicates a potentially hazardous situation which, if not avoided, may result

in property damage.

1. General Safety Guidelines

Before operating the machine, read the following instructions carefully:

• Follow all the installation procedures provided in this manual.

• Pay special attention to and follow all the hazard warnings on the machine and in the manual.

Failure to do so can cause injury to yourself or damage to the machine.

• Do not perform any installation in any way other than as provided in this manual.

• Keep in mind that the hazard warnings in this manual or on the machine cannot cover every

possible case, as it is impossible to predict and evaluate all circumstances beforehand. Be alert

and use your common sense.

II L 00

Safety 1

Page 9

SAFETY SUMMARY (Continued)

2. Hazard Warning Statements

The following are the hazard warning statements contained in this manual.

2.1 WARNING Statement

• Leave over than 400mm at the rear of the Printer for ventilation. Otherwise print quality may be

degraded.

(Section 1.2,Page 1-1)

• Be careful when unpacking using the crane or forklift. Do not to drop device, hit it

against something, or turn it over on its side.

(Section 2.1,Page 2-1)

(Section 2.2,Page 2-6)

(Section 2.4,Page 2-11)

• Perform unpacking where there is no dust or water leaking.

(Section 2.1,Page 2-1)

(Section 2.2,Page 2-6)

(Section 2.3,Page 2-9)

(Section 2.4,Page 2-11)

(Section 2.5,Page 2-15)

• Do not place heavy objects which weigh 5 kg or more on device.

(Section 2.1,Page 2-1)

(Section 2.2,Page 2-6)

(Section 2.3,Page 2-9)

(Section 2.4,Page 2-11)

• Be careful when lifting device with the forklift so device is well-balanced on the arms of

the lift. Also put the packing (cushion) between device and the forklift so device is not

damaged.

(Section 2.1,Page 2-1)

(Section 2.2,Page 2-6)

(Section 2.4,Page 2-11)

II L 00

Safety 2

Page 10

SAFETY SUMMARY (Continued)

• Observe the speed limit of 300 mm/sec. (1.08 km/hr) when moving device. Do not

move device on unleveled floor. Do not tilt device 15 ° or more.

(Section 2.1,Page 2-1)

(Section 2.2,Page 2-6)

(Section 2.3,Page 2-9)

(Section 2.4,Page 2-11)

• Choose the location to place device where the slope is less than 15 °. (Only left and right

direction from view of operator’s side.)

(Section 2.1,Page 2-1)

(Section 2.2,Page 2-6)

(Section 2.3,Page 2-9)

• Choose the location to place device where there is no condensation.

(Section 2.1,Page 2-1)

(Section 2.2,Page 2-6)

(Section 2.3,Page 2-9)

(Section 2.4,Page 2-11)

• Choose the location to place device where the slope is less than 15 °.

(Section 2.4,Page 2-11)

• The voltage is constantly in unless the machine is unplugged or Breaker Switch is turned off.

(Section 4.1,Page 4-3)

• Unplug the Power Supply Cable prior to connecting the power supply source.

(Section 4.1,Page 4-3)

• Be careful not to have other personnel plug in the power cable while performing the connecting.

(Section 4.1,Page 4-3)

(Section 4.1,Page 4-4)

II L 00

Safety 3

Page 11

SAFETY SUMMARY (Continued)

• Unplug the Power Supply Cable prior to connecting.

(Section 4.1,Page 4-4)

• Be careful not to have other personnel plug in the power cable while performing the connecting.

(Section 4.1,Page 4-4)

• Be sure to use power supply cable which complies with the following specification :

Power plug rating ; Min. AC 250V, Min. 15A (2-Pole, 3-Wire, Grounded)

Power cable rating ; Min. AC 250V, Min. 15A

• Use the Power Supply Cable which is approximately 50 mm longer for the FG. The cable should be

designed as below, so the FG power cable remains connected if the other cables are accidentally

disconnected.

• Make sure that the power cables are connected to the correct terminals (“L”, “N” ) on the power plug

and Terminal Block. ( FG power cable is connected to chassis.)

6-15P UL Listed, CSA Certified in North America

Type CA, Conformed to IEC 950 in Europe

Type SJT or SVT, UL Listed, CSA Certified in North America

Conformed to IEC 950 in Europe

(Section 4.1,Page 4-4)

(Section 4.1,Page 4-4)

(Section 4.1,Page 4-4)

• The socket-outlet shall be installed near the printer and be easily accessible.

(Section 4.1,Page 4-4)

II L 00

Safety 4

Page 12

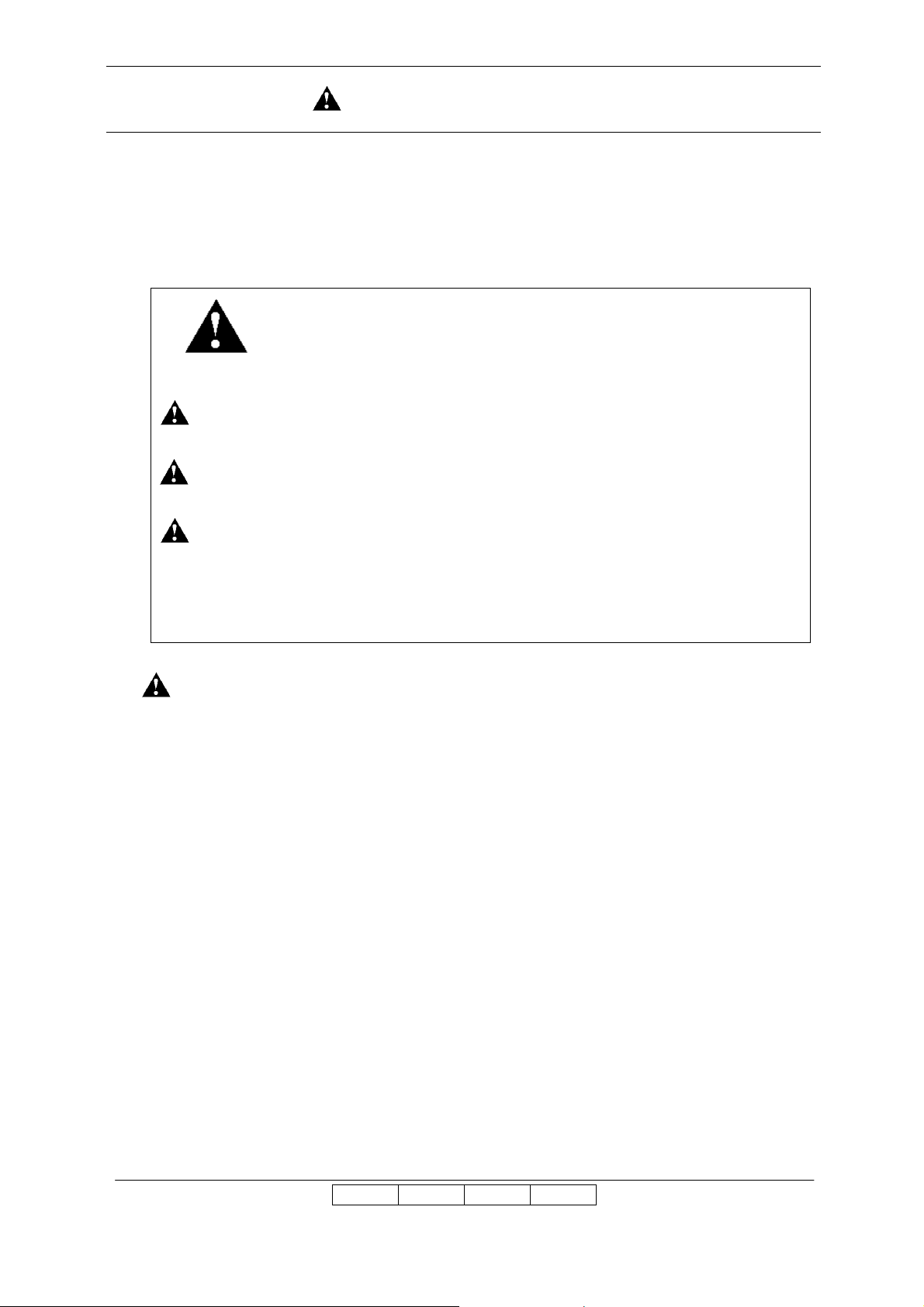

Chapter 1. Installation Requirements

WARNING

1.1 Application

This specification is applied to the DDP70 Printer for Unpacking, Installing and Adjustment.

1.2 Installation Area

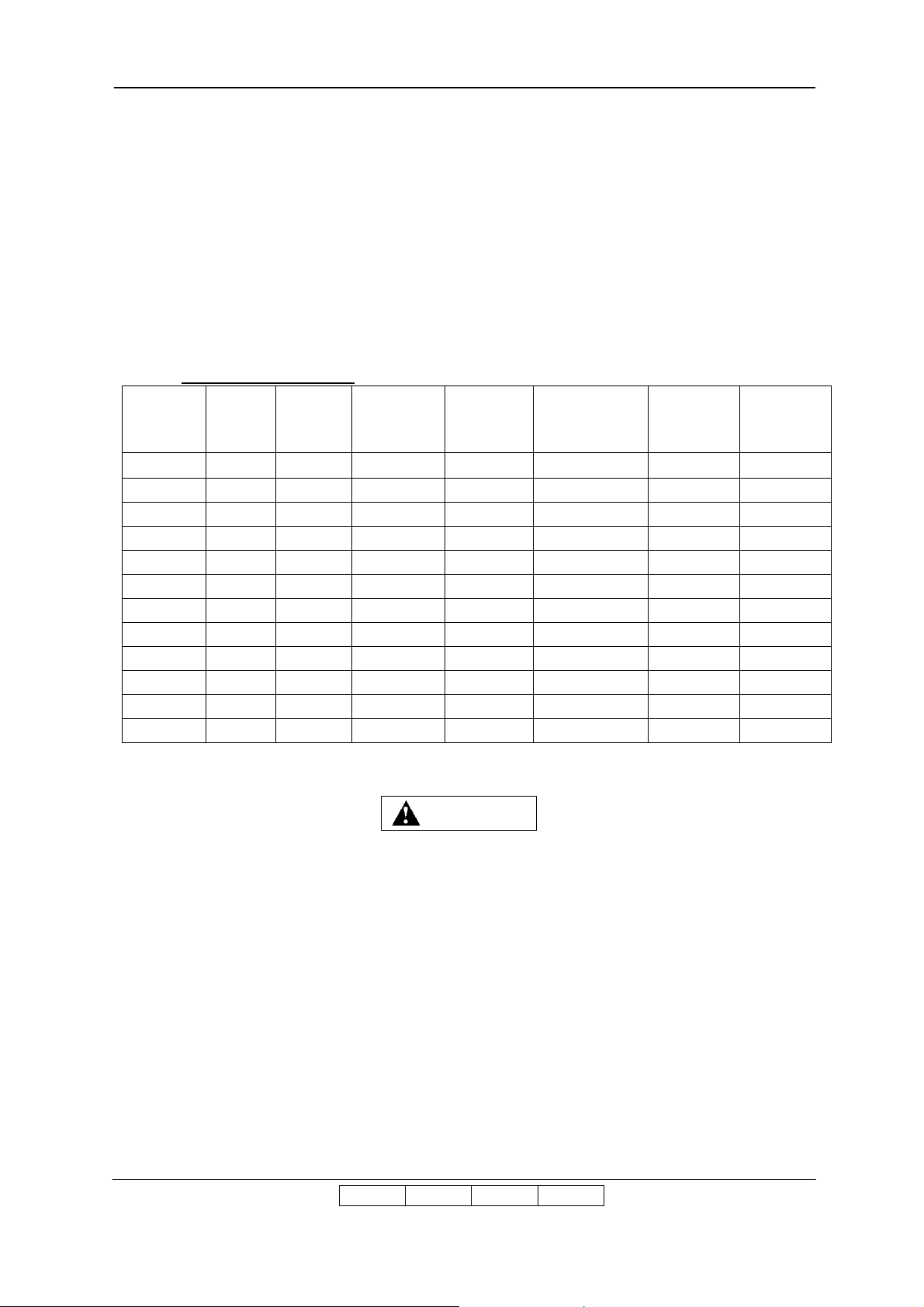

Installation area is shown in Appendix 1.1–1.12 corresponding to Table 1.1.

Table 1.1 Installation area

Appendix Printer Finisher

Transit Pass

Unit Type

DDP

Finisher

SR5000

High Capacity

Hopper

Container

Stacker 1

Container

Stacker 2

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.9

1.10

1.11

1.12

X X

X X X

X X

X X X

X X X

X X X X

X X X

X X X X

X X X

X X X X

X X X X

X X X X X

Leave over than 400mm at the rear of the Printer for ventilation. Otherwise

print quality may be degraded.

X: Composed

1.3 Installation Unit

Locations of the leveling bolt and Caster is shown in Appendix 2.1–2.4.

II L 01

II L 00

Installation Requirements 1-1

Page 13

1.4 Tools Required

Table 1.2 Tools Required

Item Name Usage

1 Cutter Unpacking

2 Phillips Screw Driver NO.2 shaft

length; approx. 40 and 100mm

3 Adjustable Open End Wrench Leveling the bolt

4 Level Meter Installation the Container Stacker

1.5 Environmental Conditions

Table 1.3 Environmental Conditions

Items Value

Temperature 10 ~32 °C (50 ~ 89.6°F)

Humidity 20 ~80 %RH

(Wet Bulb 26 °C (78.8 °F ) max.)

Altitude 0 to 2,100 m (0 to 7,000 feet) max.

Removing and installing the screw for covers

Fixing the leveling the bolts

1.6 Input Line Voltage

Table 1.4 Print Engine Input Line Voltage

Input Line Voltage AC 200V ~ AC 240V

Phase Single Phase, two wires and grounding wire

Frequency 50/60 Hz ±1Hz

Transient (Static) ±10%

Transient (Dynamic) –18% / +15% 500ms

Drop out -100%, 20ms

II L 00

II L 01

Installation Requirements 1-2

Page 14

Chapter 2. Unpacking

WARNING

2.1 Unpacking of the Engine

1) Be careful when unpacking using the crane or forklift. Do not to drop

device, hit it against something, or turn it over on its side.

2) Perform unpacking where there is no dust or water leaking.

3) Do not place heavy objects which weigh 5 kg or more on device.

4) Be careful when lifting device with the forklift so device is well-balanced

on the arms of the lift. Also put the packing (cushion) between device

and forklift so device is not damaged.

5) Observe the speed limit of 300 mm/sec. (1.08 km/hr) when moving

device. Do not move device on unleveled floor. Do not tilt device 15 ° or

more.

6) Choose the location to place device where the slope is less than 15 °.

(Only left and right direction from view of operator’s side.)

7) Choose the location to place device where there is no condensation.

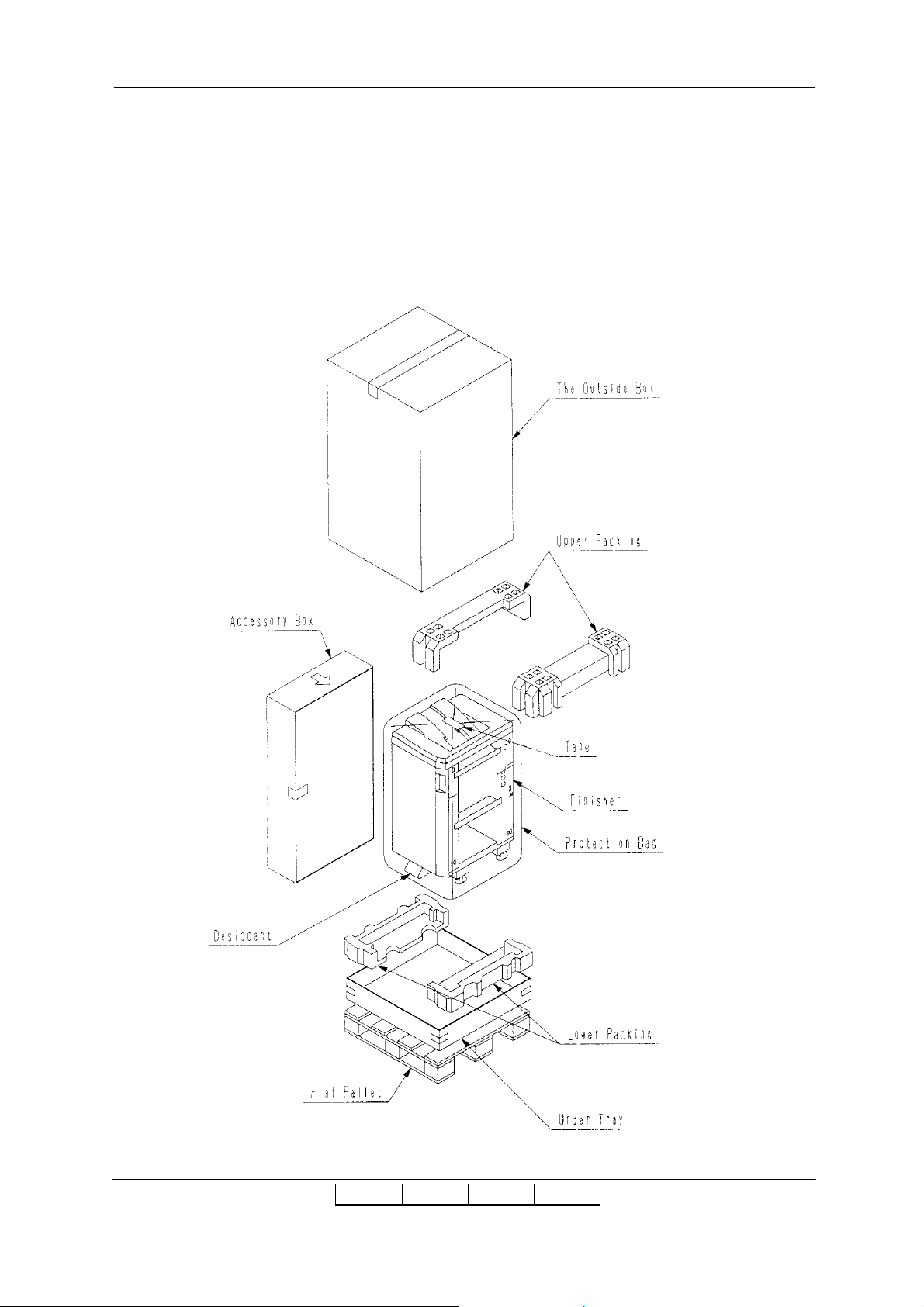

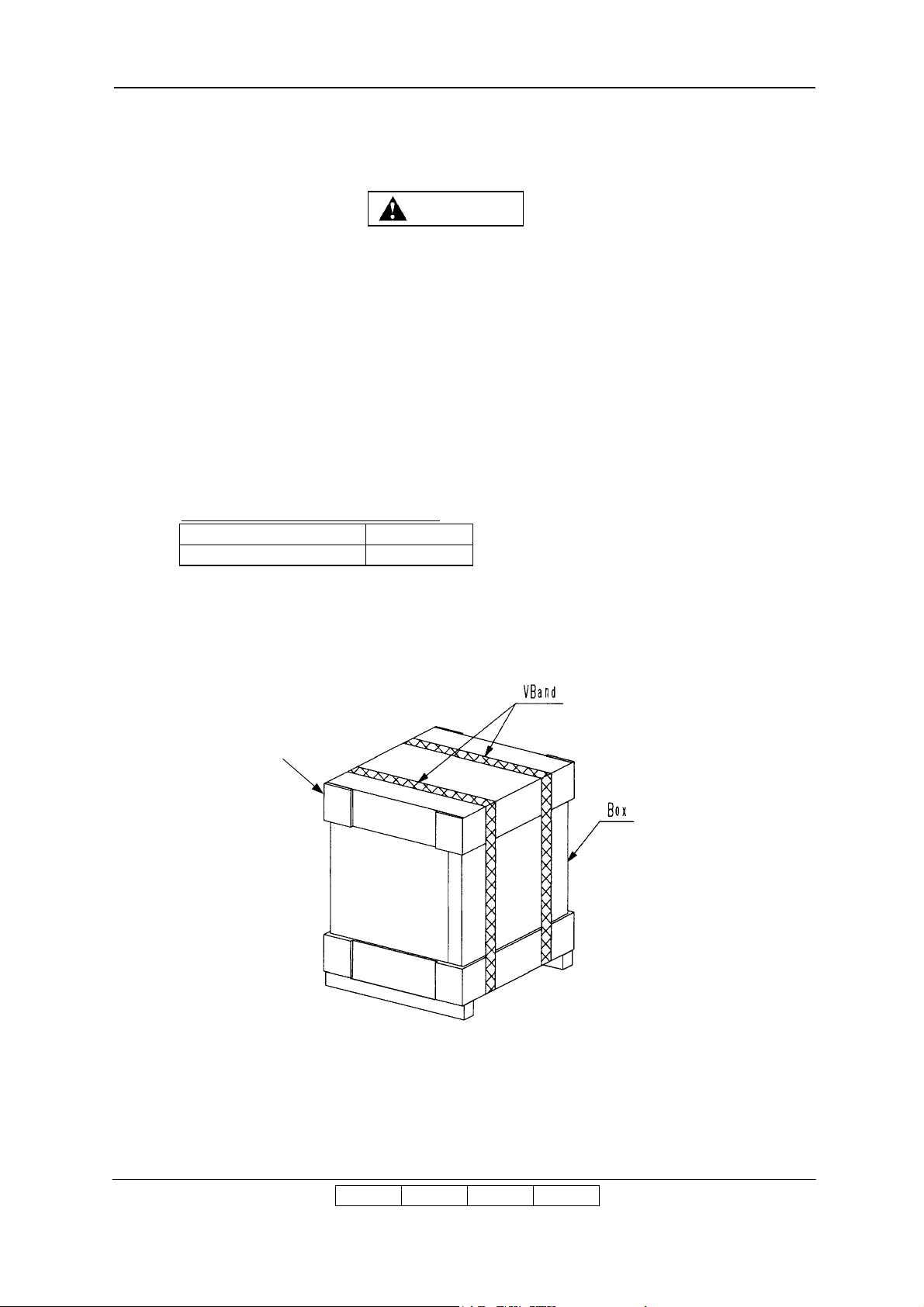

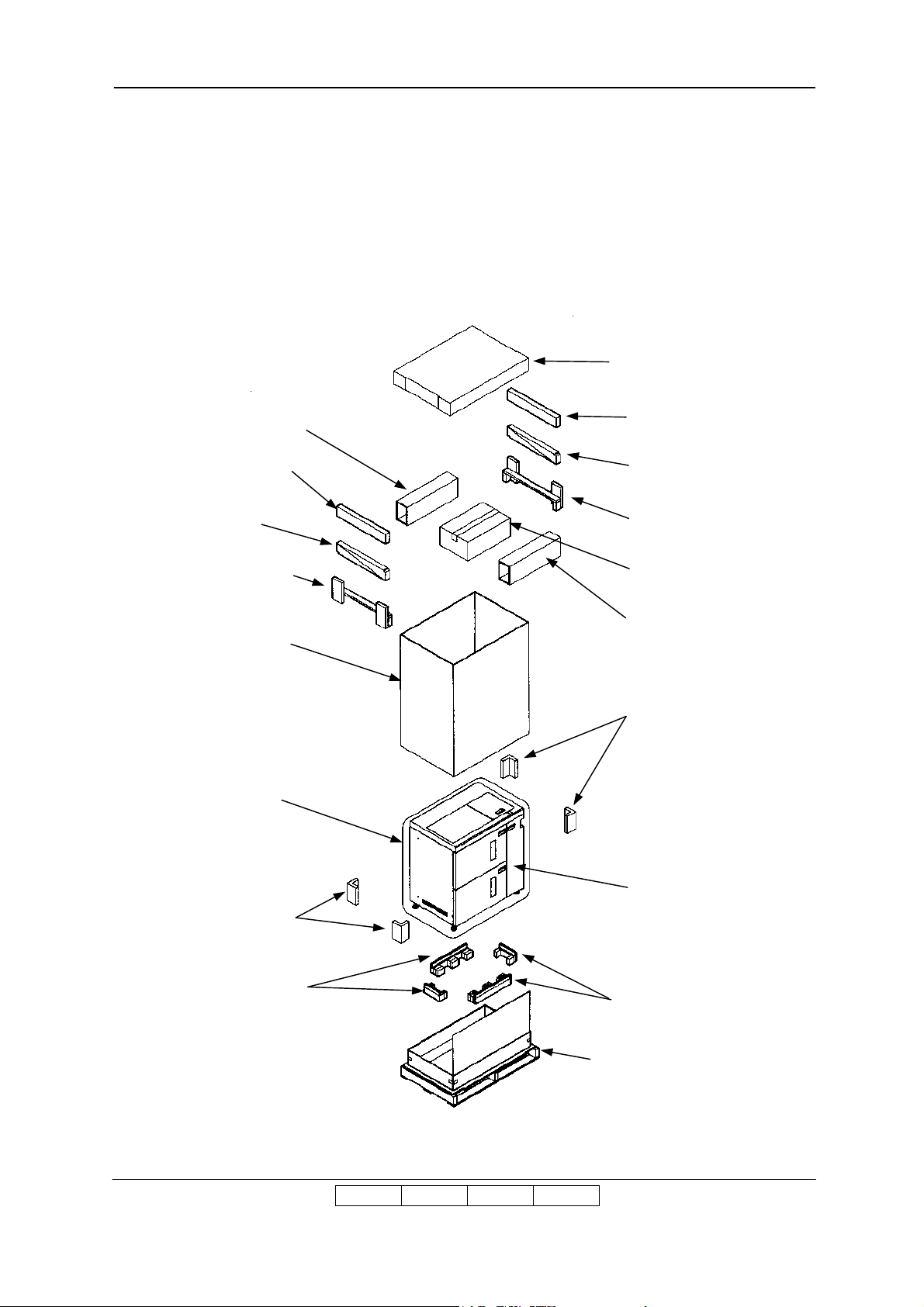

2.1.1 Components in the package

Table 2.1 Components in the package

Unit of Packing Quantity

Engine 1

Accessory Box 1

II L 00

Unpacking 2-1

Page 15

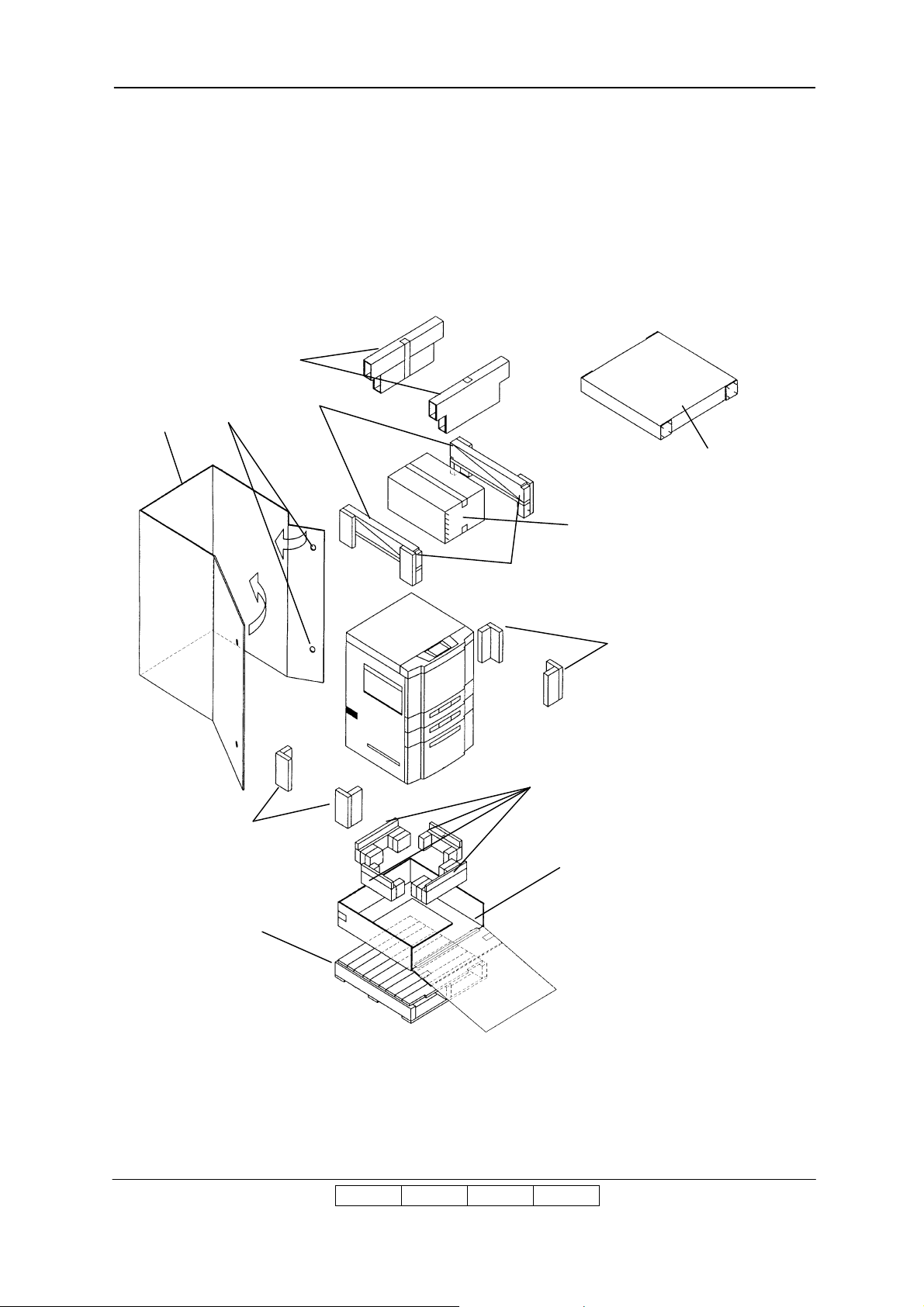

2.1.2 Unpacking Procedures

1) Cut the V Bands and remove the Cap.

2) Remove the screws.

3) Remove the Packing, Accessory box, Ramps, Upper Packing.

4)

Remove the Box, Corner Packing.

Packing

Ramp

Box

Screw

Upper Packing

Cap

Accessory Box

Corner Packing

Flat Pallet

Corner Packing

Base Packing

Under Tray

II L 00

Unpacking 2-2

Page 16

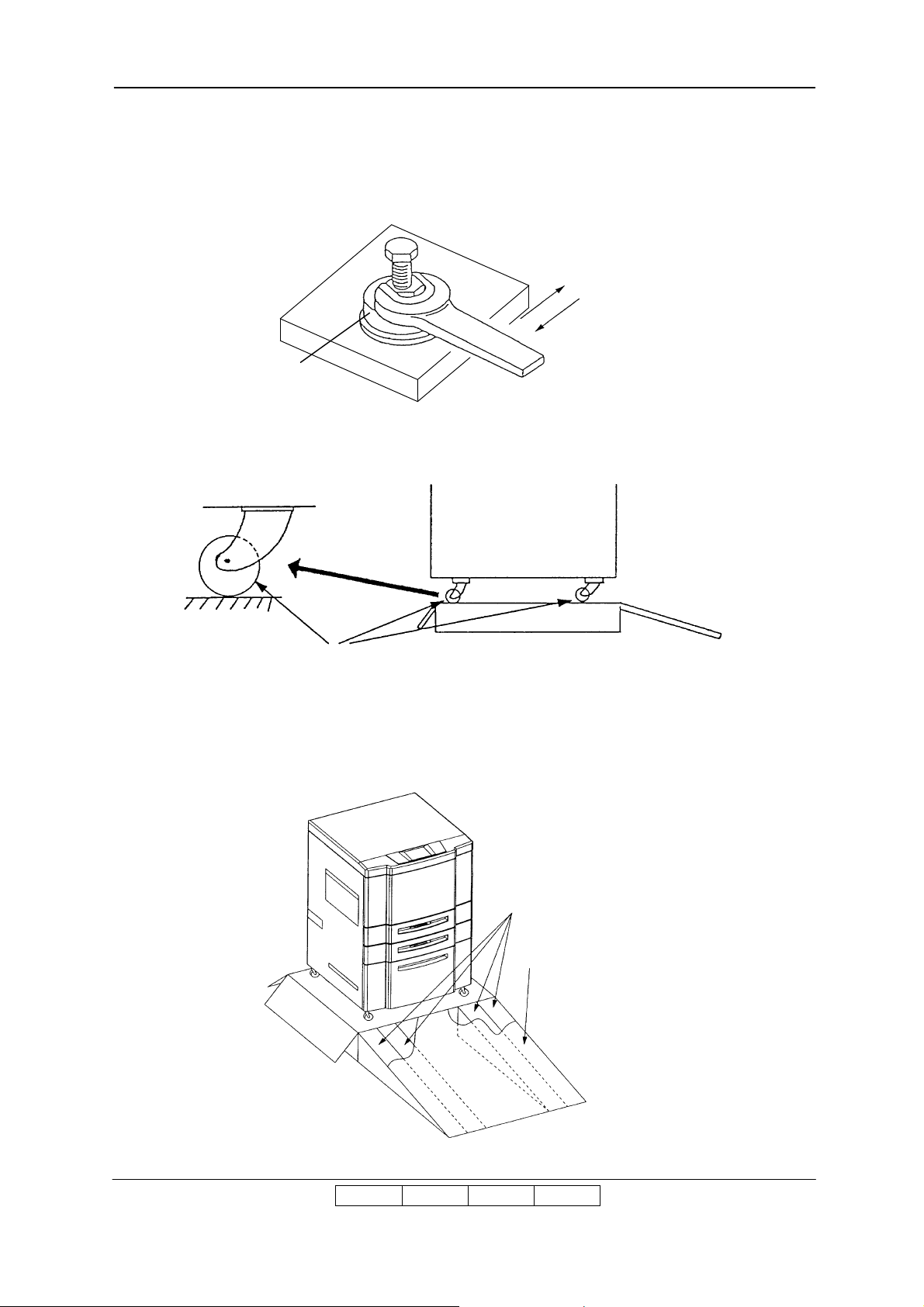

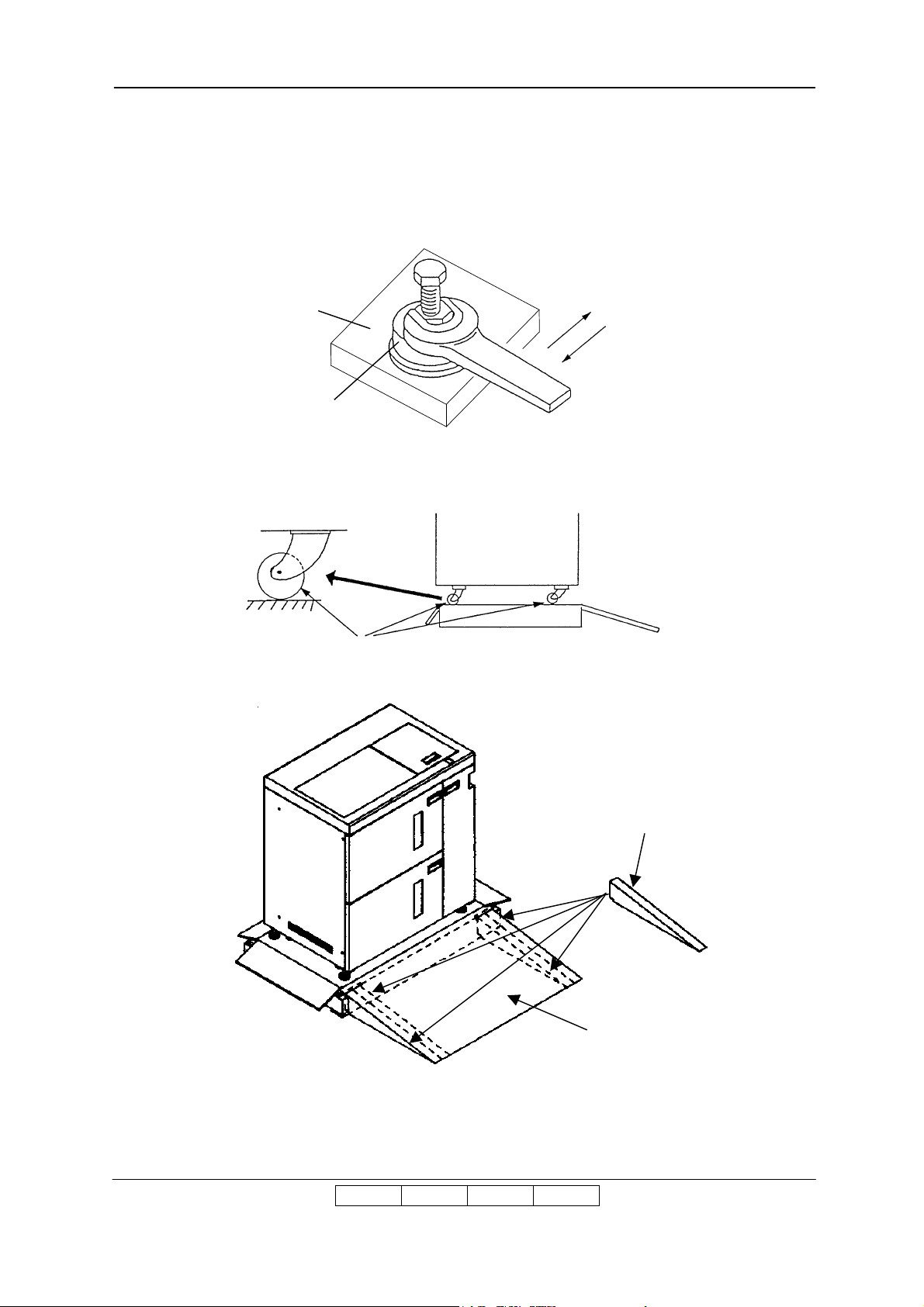

5) Jack up the Engine by rotating the leveling bolts.

Put the wood spacer (It is taken out from the accessories box.) under four leveling bolts.

Jack up the Engine by rotating the leveling bolts.

Down

Up

Leveling Bolt

6) Remove the Base Packing.

7) Place all Casters in the same direction.

Caster

8) Lower the Engine on the Under Tray and screw the leveling bolts in all the way.

9) Attach the four Ramps under the Platform.

10) Carefully roll the Engine off the Tray.

Ramp

Platform

II L 01

II L 00

Unpacking 2-3

Page 17

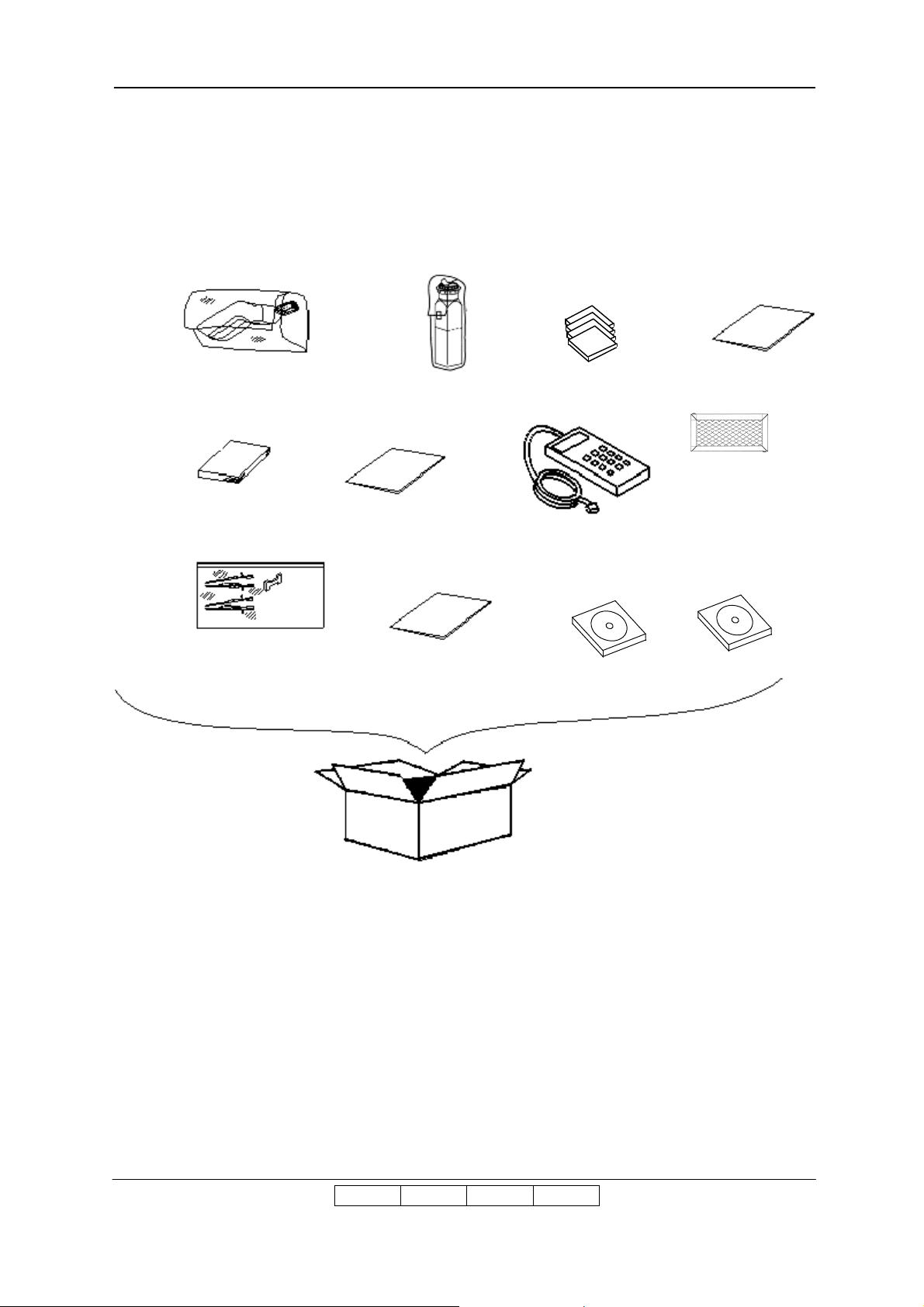

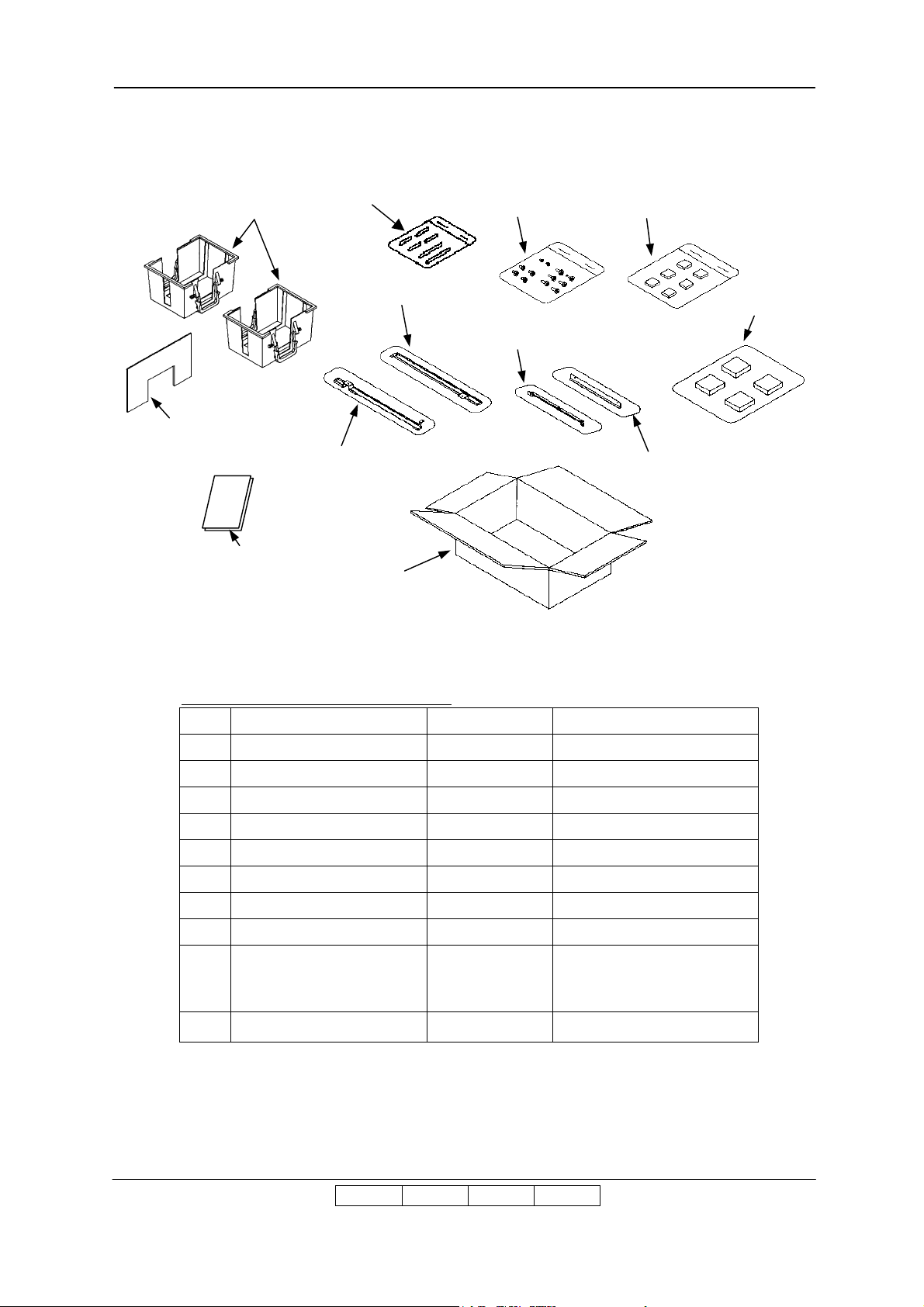

2.1.3 Parts Check in the Accessory Box

Wood Spacer

PS Air Filter

Toner(Black)

Developer Bottle

User’s Guide

Wire Cleaning Tool

Interlock Stopper

Installation Manual

Special Tool

Software License

Cable Clamp

Agreement

Screws

Maintenance Panel Ass’y

CD-ROM

(S/W & Manual)

Notes For Users

CD-ROM

(Documentation)

CD-ROM

(Driver / JT)

II L 00

II L 03

Unpacking 2-4

Page 18

Table 2.2 Parts list in the Accessory Box

No. Parts Name Qty Use

1 USER’S GUIDE 1 For Customer

2 DEVELOPER BOTTLE 1 For Developer exhaust

3 MAINTENANCE PANEL ASSY 1 For Customer Engineer

4 WIRE CLEANING TOOL 1 For Customer Engineer

5 INTERLOCK STOPPER 1 For Customer Engineer

6 TONER(BLACK) 1 For Customer

7 INSTALLATION MANUAL 1 For Customer Engineer

SOFTWARE LICENSE

8

AGREEMENT

9 CD-ROM (DOCUMENTATION) 1 For Engineer

10 CD-ROM (DRIVER / JT) 1 For Engineer

11 WOOD SPACER 4 For Customer Engineer

12 PS AIR FILTER 1 For Customer Engineer

13 NOTES FOR USERS 1 For Customer

1 For Customer

II L 03

II L 00

Unpacking 2-5

Page 19

2.2 Unpacking of the Finisher

WARNING

1) Be careful when unpacking using the crane or forklift. Do not to drop

device, hit it against something, or turn it over on its side.

2) Perform unpacking where there is no dust or water leaking.

3) Do not place heavy objects which weigh 5 kg or more on device.

4) Be careful when lifting device with the forklift so device is well-balanced

on the arms of the lift. Also put the packing (cushion) between device

and forklift so device is not damaged.

5) Observe the speed limit of 300 mm/sec. (1.08 km/hr) when moving

device. Do not move device on unleveled floor. Do not tilt device 15 ° or

more.

6) Choose the location to place device where the slope is less than 15 °.

(Only left and right direction from view of operator’s side.)

7) Choose the location to place device where there is no condensation.

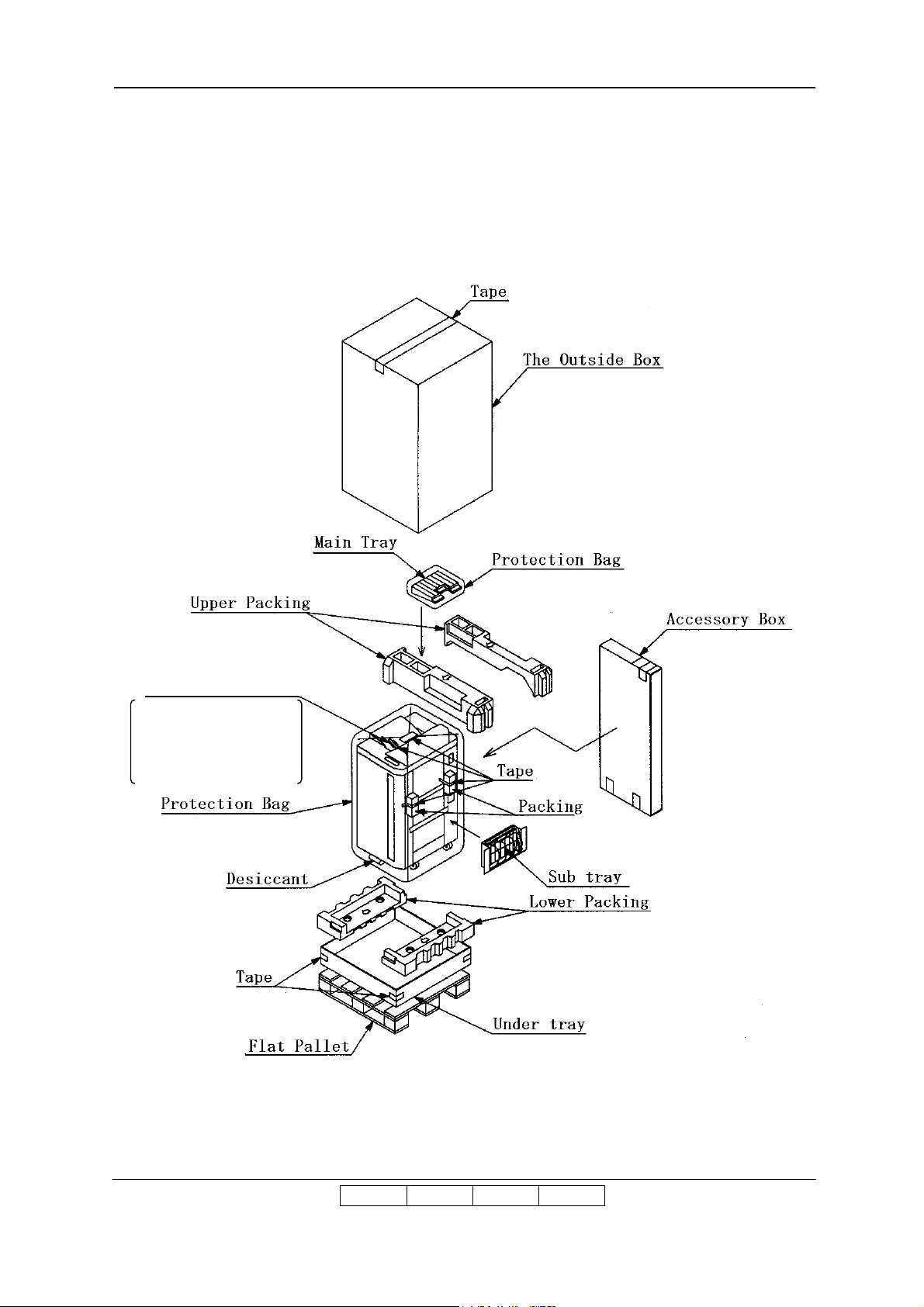

2.2.1 Components in the package

Table 2.3 Components in the package

Unit of Packing Quantity

Finisher 1

Accessory Box 1

II L 00

Unpacking 2-6

Page 20

2.2.2 Unpacking Procedures

[FS-104H] (No RoHS Compliance Unit)

1) Cut the V Bands and remove the Outside Box.

2) Remove the two Upper packing, Accessory Box.

3) Remove the Tape of Protection Bag and take down the Protection Bag.

4) Carefully lift the Finisher by two persons and stand on Floor.

II L 01

II L 00

Unpacking 2-7

Page 21

[FS-108R] (RoHS Compliance Unit)

Main Fixed Plate/1

: 2

Screws Packing

Booklet Tray (Booklet model only)

1) Cut the V Bands and remove the Outside Box.

2) Remove the two Upper packing, Accessory Box.

3) Remove the Tape of Protection Bag and take down the Protection Bag.

4) Carefully lift the Finisher by two persons and stand on Floor.

M4 Truss Screw : 3

M4 TP Screw : 9

M3 SEMS Screw : 2

II L 01

II L 00

Unpacking 2-8

Page 22

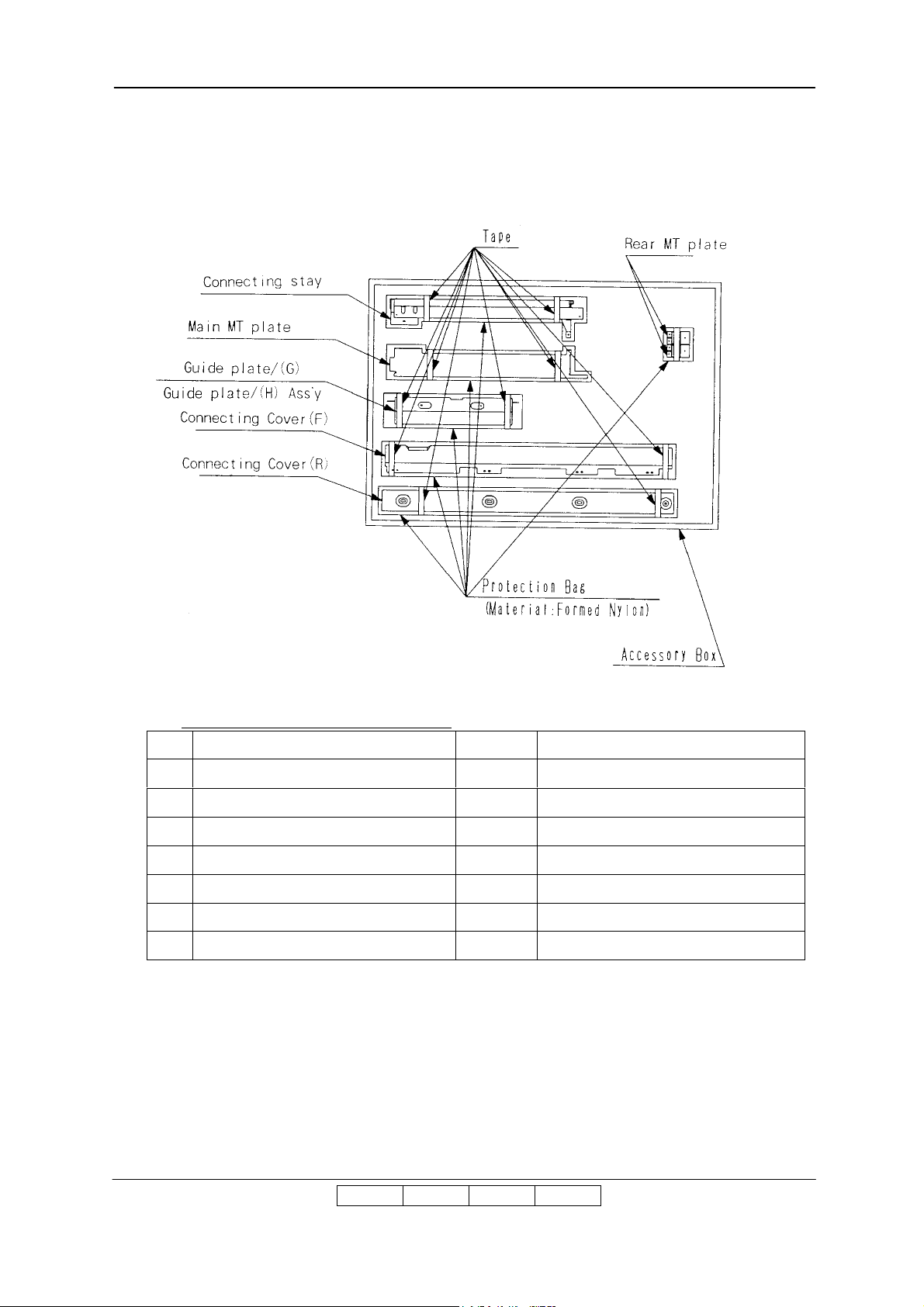

2.2.3 Parts Check in the Accessory Box

[FS-104H] (No RoHS Compliance Unit)

Table 2.4 Parts list in the Accessory Box

No. Parts Name Qty Use

1 Connecting stay 1 ---

2 Main MT Plate 1 ---

3 Guide plate/(G) 1 ---

4 Guide plate/(H) Ass’y 1 ---

5 Connecting Cover(F) 1 ---

6 Connecting Cover(R) 1 ---

7 Rear MT plate 2 ---

II L 01

II L 00

Unpacking 2-9

Page 23

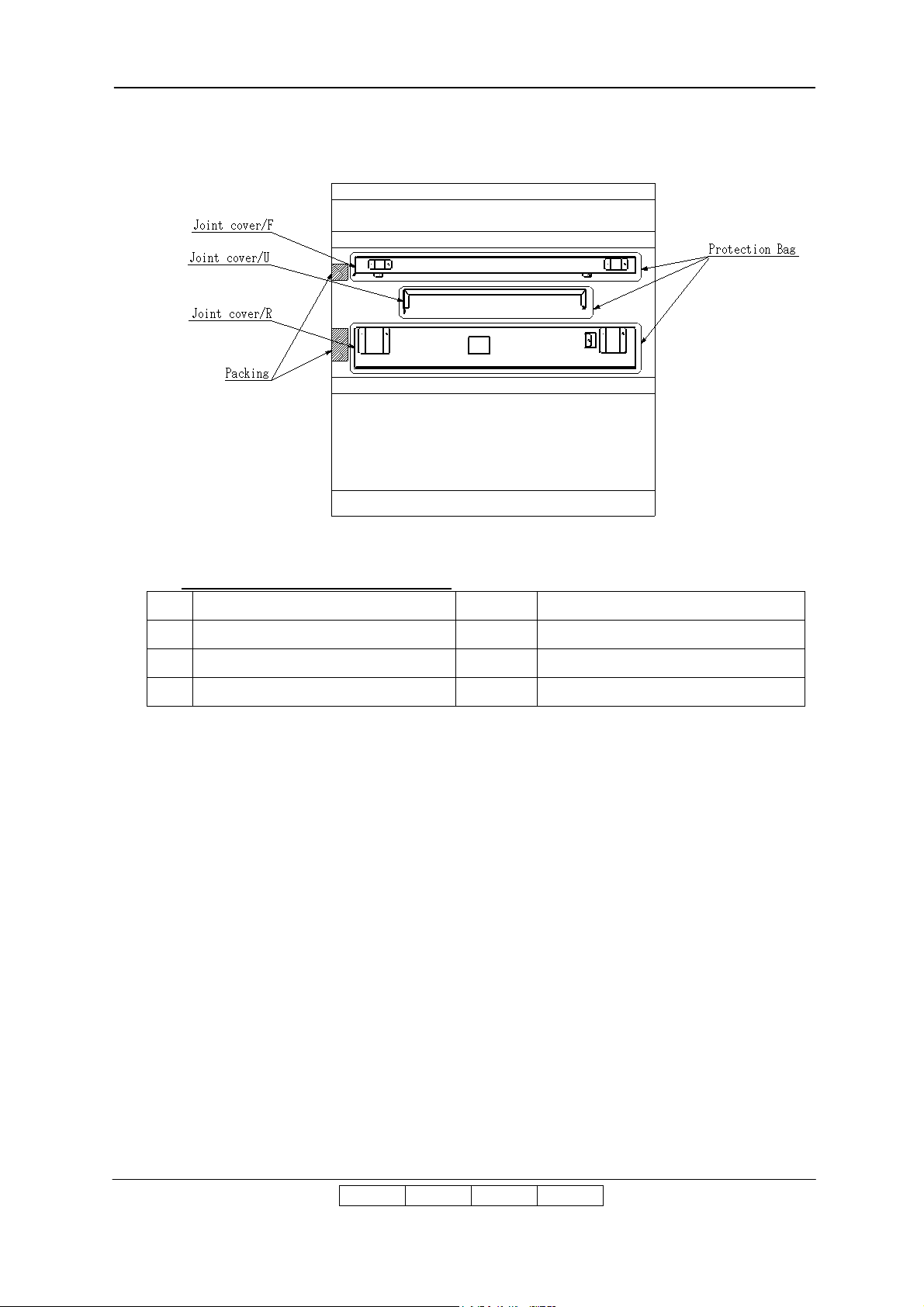

[FS-108R] (RoHS Compliance Unit)

Table 2.5 Parts list in the Accessory Box

No. Parts Name Qty Use

1 JOINT COVER /F 1 ---

2 JOINT COVER /U 1 ---

3 JOINT COVER /R 1 ---

II L 01

II L 00

Unpacking 2-10

Page 24

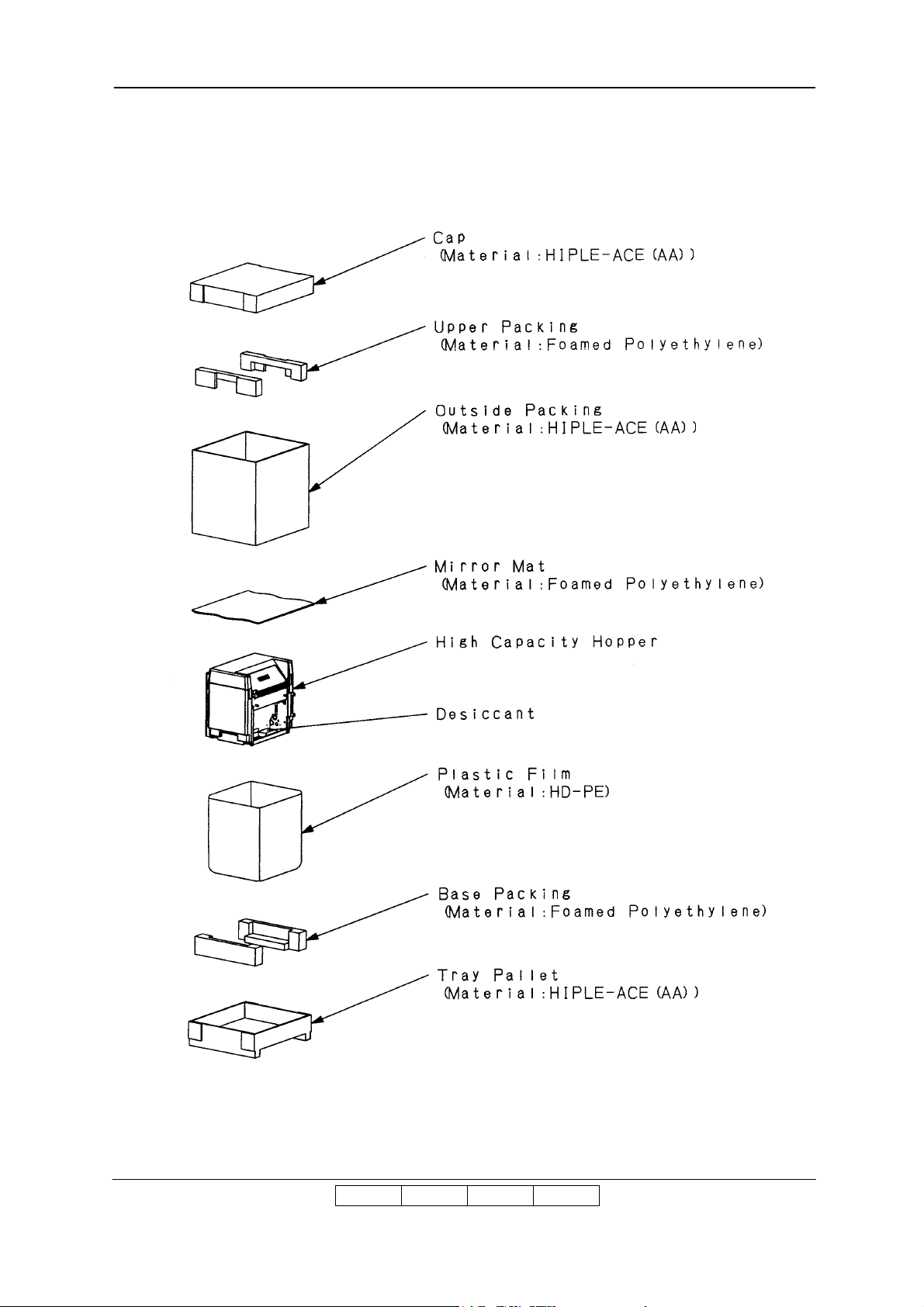

2.3 Unpacking of the High Capacity Hopper

WARNING

Cap

1) Perform unpacking where there is no dust or water leaking.

2) Do not place heavy objects which weight 5 kg or more on device.

3) Observe the speed limit of 300 mm/sec. (1.08 km/hr) when moving

device. Do not move device on unleveled floor. Do not tilt device 15 ° or

more.

4) Choose the location to place device where the slope is less than 15 °.

(Only left and right direction from view of operator’s side.)

5) Choose the location to place device where there is no condensation.

2.3.1 Confirmation of Parts Quantities

Table 2.6 Components in the package

Unit of Packing Quantity

High Capacity Hopper 1

2.3.2 Unpacking Procedures

1) Cut the V Bands and remove the Cap.

II L 00

Unpacking 2-11

Page 25

2) Remove the two Upper Packing, Outside Packing.

3) Remove the High Capacity Hopper.

II L 00

Unpacking 2-12

Page 26

2.4 Unpacking of the Container Stacker 1 or 2

WARNING

1) Be careful when unpacking using the crane or forklift. Do not to drop

device, hit it against something, or turn it over on its side.

2) Perform unpacking where there is no dust or water leaking.

3) Do not place heavy objects which weigh 5 kg or more on device.

4) Be careful when lifting device with the forklift so device is well-balanced

on the arms of the lift. Also put the packing (cushion) between device

and forklift so device is not damaged.

5) Observe the speed limit of 300 mm/sec. (1.08 km/hr) when moving

device. Do not move device on unleveled floor. Do not tilt device 15 ° or

more.

6) Choose the location to place device where the slope is less than 15 °.

7) Choose the location to place device where there is no condensation.

2.4.1 Confirmation of Parts Quantities

2.4.2

Table 2.7 Components in the package

Unit of Packing Quantity

Container Stacker 1 or

Container Stacker 2

Accessory box 1

1

II L 00

Unpacking 2-13

Page 27

2.4.3 Unpacking Procedures

1) Remove the V band from the shipping box using a cutter and remove the cap.

2) Remove the accessory box, spacer box, spacer packing, ramp, and upper packing.

3) Remove the shipping box, P.P band and four corner packing.

4) Peeling off the adhesive tapes, remove the plastic bag.

5) Cut the tape for corner on pallet, and push down the side of pallet to outside.

Cap

Spacer box

Spacer packing

Ramp

Upper packing

Shipping box

Plastic bag

Spacer packing

Ramp

Upper packing

Accessory box

Spacer box

Corner packing

Corner packing

Base packing

Container Stacker

Base packing

Pallet

II L 00

Unpacking 2-14

Page 28

6) Remove the tape for leveling bolt, and take out four wood spacers from accessory box, it puts

Caster

on the bottom of leveling bolts (under plastic bag), turned the leveling bolt by using the

Adjustable Open End Wrench, and raised the Container Stacker.

7) Remove the four base packing.

Wood spacer

Down

Up

Leveling bolt

8) Turned the all casters in the same direction.

9) Install the ramp to the bottom of an inclination board. (Ramp is two pieces to both sides).

10) Raised the leveling bolt and remove the wood spacer.

11) Carefully lift down the Container Stacker on the floor.

II L 00

Unpacking 2-15

ramp

Inclination board

Page 29

2.4.4 Parts Check in the Accessory Box

Cover Guard

Basket (small)

(Only Container Stacker2)

Screw *

Hopper spacer *

Joint bracket (L)

Guide plate (L) *

Partition

Joint bracket (U)

User’s Guide

Accessory box

Table 2.8 Parts list in the Accessory Box

No. Parts Name Qty Note

JOINT BRACKET (L)

1

JOINT BRACKET (U)

2

GUIDE PLATE (L)

3

GUIDE PLATE (U)

4

COVER GUARD

5

BASKET (SMALL)

6

HOPPER SPACER

7

WOOD SPACER

8

1

1

1

1

6

2

6

4

Wood spacer

Guide plate (U)

(1) M3 x 8 2 pieces

SCREW

9

12

(2) M4 x 8 4 pieces

(3) M4 x 12 6 pieces

10 USER’S GUIDE 1

[Note]

In the case of composition of that the Container Stacker 1 and 2 connect, the Hopper

Spacer and the Guide plate (L) and the two M3 x 8 Screws in one of the two

Accessories are not used.

II L 01

II L 00

Unpacking 2-16

Page 30

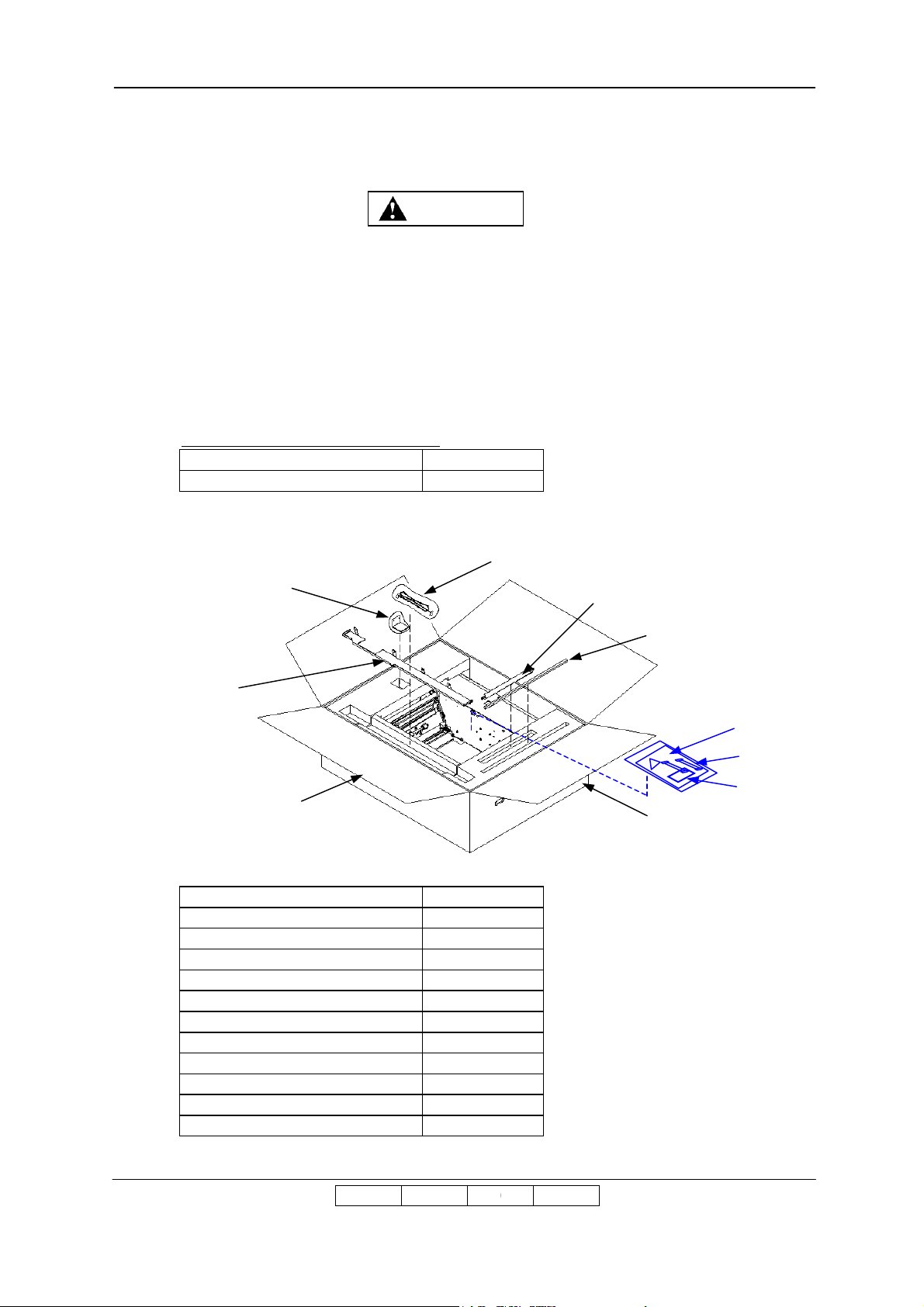

2.5 Unpacking of the Transit Pass Unit Type DDP

WARNING

1) Perform unpacking where there is no dust or water leaking.

2) Do not place heavy objects which weight 5 kg or more on device.

3) Observe the speed limit of 300 mm/sec. (1.08 km/hr) when moving

device.

4)

Choose the location to place device where there is no condensation.

2.5.1 Confirmation of Parts Quantities

Table 2.9 Components in the package

Unit of Packing Quantity

Transit Pass Unit Type DDP 1

2.5.2 Confirmation of the Accessories Parts

Ground Plate and

Screws

Signal Cable (CS)

SB Cover Paper Guide

FC Cover

Transit Pass Unit Type DDP

Table 2.10 List of the Accessories Parts

Unit of Packing Quantity

Ground Plate 1

FC Cover 1

SB Cover Paper Guide 1

M4x10 Tapping Screw 4

M4x8 Screw 6

M3x6 Screw 2

Block Sponge 1

Signal Cable (CS) 1

N.P 1

Relay Cable 2

Sheet 1

Block Sponge

Sheet

Relay Cable x 2

N.P

Shipping box

II L 00

Unpacking 2-17

2

Page 31

2.5.3 Unpacking Procedures

1) Open the Shipping box.

2) Remove the Accessories parts and two Upper Packing.

3) Remove the Transit Pass Unit Type DDP.

Corner Packing

Corner Packing

Signal Cable (CS)

Ground Plate and Screws

FC Cover

Upper Packing

Side Packing

Plastic bag

Lower Packing

SB Cover Paper Guide

Block Sponge

Upper Packing

Transit Pass Unit Type DDP

Sheet

Relay Cable x 2

N.P

Lower Packing

Shipping box

II L 00

Unpacking 2-18

Palette

1

Page 32

2.6 Unpacking of the Finisher SR5000

WARNING

1) Perform unpacking where there is no dust or water leaking.

2) Do not place heavy objects which weight 5 kg or more on device.

3) Observe the speed limit of 300 mm/sec. (1.08 km/hr) when moving device.

4)

Choose the location to place device where there is no condensation.

2.6.1 Confirmation of Parts Quantities

Table 2.11 Components in the package

Unit of Packing Quantity

Finisher SR5000 1

2.6.2 Unpacking Procedures

1) According to the Unpacking Procedure of the Finisher SR5000.

II L 00

Unpacking 2-19

Page 33

Chapter 3. Preparation for Installation

Tape

Tape

Tape

Tape

3.1 Preparation for Installation of the Printer

3.1.1 Removing the Protection Tape and Mat from the Engine

1) Remove the Tapes and Mats from the Engine.

Mat

Tape

2) Open the Front Cover.

3) Remove the Tapes and TH Packing.

Tape

Mat

Mat

Tape

Hopper Cover

Front Cover

TH Packing

II L 00

Preparation for Installation 3-1

Page 34

4) Turn the TH handle clockwise to open the TH Unit.

TH

Unit

5) Remove the Tapes and Mat.

TH handle

6) Turn the TH Handle counterclockwise to close the TH Unit.

Tape

Mat

3.1.2 Set the PS Air Filter for the Engine Rear Cover

1) Take out the PS Air Filter from Accessory Box.

2) Install the PS Air Filter to Engine Rear Cover.(Refer to shown below)

PS Air Filter

Engine Rear Cover

II L 01

II L 00

Preparation for Installation 3-2

Page 35

3.1.3 Removing the Protection Tape from 2000 Sheet Hopper.

500 Sheet Hopper

Tape

2000 Sheet Hopper

Tape

2000 Sheet Hopper

3.1.4 Removing the Protection Tape from 500 Sheet Hopper ; 2 portion

Tape

Tape

II L 00

Preparation for Installation 3-3

Page 36

3.2 Preparation for Installation of the Finisher

[FS-104H] (No RoHS Compliance Unit)

1) Remove the Protection Tapes from the Finisher.

2) Remove the Shift Tray and Screws from the Finisher.

II L 01

II L 00

Preparation for Installation 3-4

Page 37

Unscrew the five screws to remove the Rear cover of the Finisher.

3) Remove two Lock materials attached to the Staple portion.

(Loosen the M3 x 6 Screws.)

II L 00

Preparation for Installation 3-5

Page 38

4) Remove three Lock materials from each guide plate.

(Loosen the M3 x 6 Screws.)

5) Remove the Lock material from the Staple plate unit.

(Loosen the M3 x 6 Screws.)

II L 00

Preparation for Installation 3-6

Page 39

6) Install the Rear MT plate.

7) Install the Connecting Cover (F).

II L 00

Preparation for Installation 3-7

Page 40

8) Install the Shift Tray to the up-down portion (paper exit side) of Finisher.

Shift Tray

(Truss screw M4x6: 2)

CAUTION

When installing the Shift tray, fit the four auxiliary fittings to the guide holes of the

Main tray before fixing screws.

II L 00

Preparation for Installation 3-8

Page 41

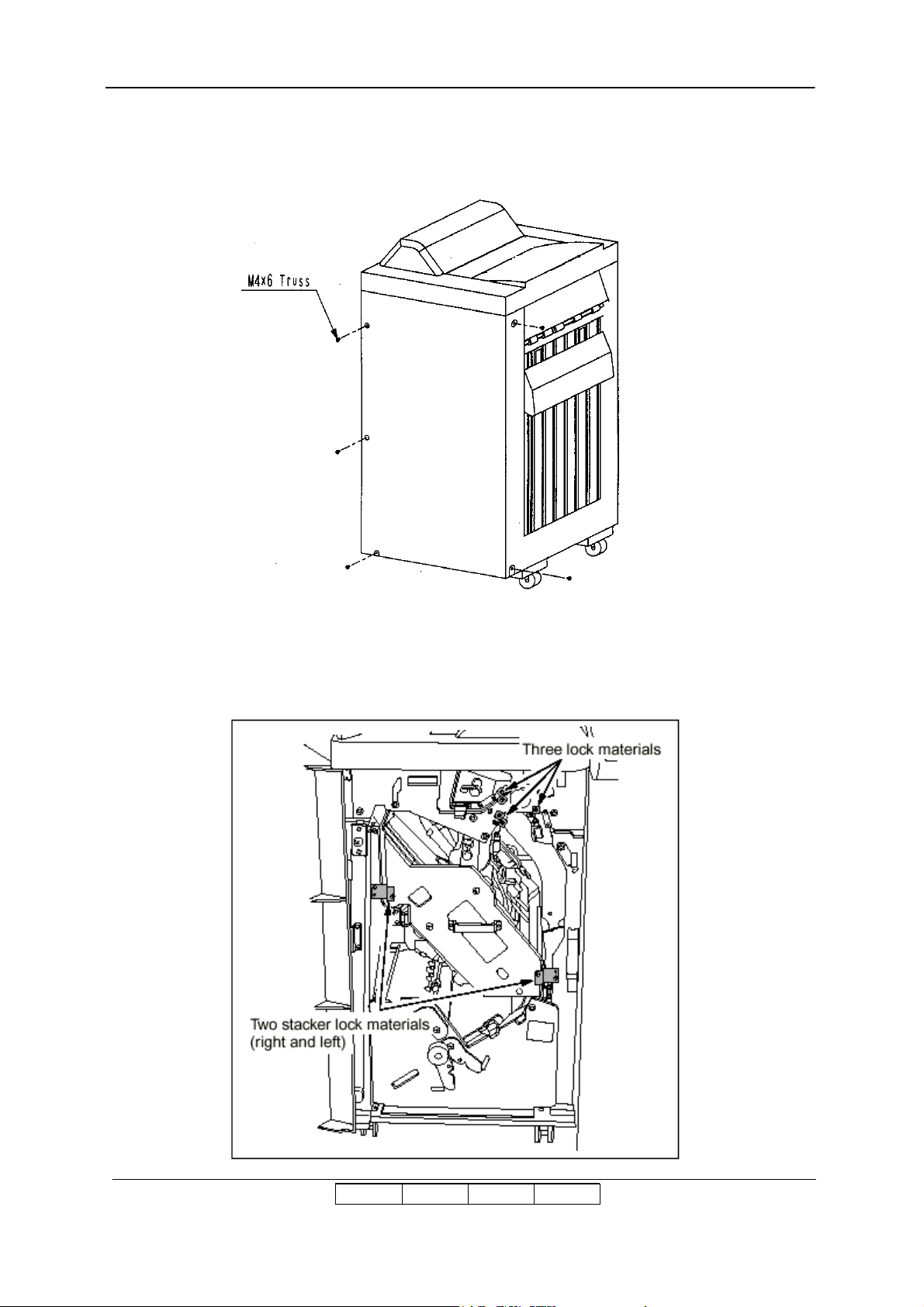

[FS-108R] (RoHS Compliance Unit)

1) Unscrew the five screws to remove the Rear cover of the Finisher.

2) Remove three lock materials from each guide plate.

3) Remove two stacker lock materials (right and left).

II L 00

II L 01

Preparation for Installation 3-9

Page 42

4) Remove two lock materials inside the stacker (on the side to be joined to the main body).

5) Remove two lock materials inside the stacker (lower).

II L 00

II L 01

Preparation for Installation 3-10

Page 43

6) Install the Main tray on the up-down portion (paper exit side) of the Finisher.

(Truss screw M4x6: 2)

CAUTION

When installing the Main tray, fit the four auxiliary fittings to the guide holes of the

Main tray before fixing screws.

Main tray

II L 00

II L 01

Preparation for Installation 3-11

Page 44

3.3 Preparation for Installation of the High Capacity Hopper

1) Remove the Protection Tapes from the High Capacity Hopper.

2) Remove the Paper.

Tape High Capacity Hopper

Tape

3) Remove the Protection Tape and Mirror Mat from the High Capacity Hopper.

Tape

High Capacity Hopper

Paper

II L 00

Preparation for Installation 3-12

Page 45

4)

M4 Screw

Paper Guide

Size Guide Sensor

Front Door

Paper Guide

M4 Screw

Confirm the Paper Guide position of

the High Capacity Hopper. (LT or A4)

Usually, Paper Guide position is set in “LT” at the shipment. When the customer wish to use

the High Capacity Hopper in A4 paper, change the Paper Guide position according to the

following steps.

[Change procedure of the Paper Guide Position]

Open the Front door, and remove two M4 Screws.

1.

2.

Lift up the Paper Guide and move to the outside.

3.

Insert the upper and lower of the Paper Guide to a Guide hole for“A4”. At that time, the Paper

Guide is outside of the Size Guide Sensor.

4.

Fix the M4 Screw in a Screw hole for “A4”.

A Screw hole

for “A4” (Outside)

Upper Guide hole

for “A4”(Outside)

Lower Guide hole

for “A4”(Outside)

A Screw hole

for “LT” (Inside)

Size Guide Sensor

Upper Guide hole

for “LT”(Inside)

Lower Guide hole

for “LT”(Inside)

A Screw hole

for “A4” (Outside)

Upper Guide hole

for “A4”(Outside)

Lower Guide hole

for “A4”(Outside)

II L 00

Preparation for Installation 3-13

Page 46

3.4 Preparation for installation of the Container Stacker 1 or 2

A

Adhesive tape

tape

1) Peel off the Protection Tapes and cushion from the Container Stacker 1 or 2.

2) Open the Front Cover L and peel off the Protection Tapes.

3) Peel off the mat under the Basket.

Adhesive tape

< Opening procedure of the Front Cover L >

1) Open the front cover R.

2)

Push A section in the direction of the arrow with Philips screwdriver and open the front

cover L.

Front Cover L

Basket

Front cover L

Cushion

Adhesive

Adhesive

tape

Adhesive

tape

Adhesive tape

Front cover L

Container Stacker 1 or 2

Phillips Screwdriver

Front Cover R

Arrow

II L 00

Preparation for Installation 3-14

Page 47

4) Take the CP417 P/K(No RoHS Compliance Unit) or CP627 P/K(RoHS Compliance Unit)

out of the lower basket.

CP417 P/K

(No RoHS Compliance Unit)

CP627 P/K

(RoHS Compliance Unit)

Basket

II L 00

II L 01

Preparation for Installation 3-15

Page 48

3.5 Preparation for installation of the Transit Pass Unit Type DDP

1) Remove the Protection Tapes from the Transit Pass Unit Type DDP.

Tape

Tape

Tape

II L 00

Preparation for Installation 3-16

Page 49

Chapter 4. Installation

4.1 Installation in the composition of the Printer and Finisher / Finisher

SR5000

CAUTION

Don't install the Printer in any place where it will be subjected to direct sunlight since

it may cause adverse effects on performance of the Printer.

1) Releasing the Rear Cover

(2) Unscrew the six M4 Screws.

(3) Unhook the bottom of the Rear Cover and release the Rear Cover.

(Release the Rear Cover by lifting up and pulling forward.)

M4 screws

Rear cover

M4 screws

II L 00

II L 01

Preparation for Installation 4-1

Page 50

[FS-104H] (No RoHS Compliance Unit)

2) Remove the two M3 x 8 Screws and Static electricity eliminator from Printer.

3) Install the Guide plate/(G) with the Static electricity eliminator by using the two

M3 x 8 Screws.

4) Install the Guide plate/(H) Ass’y.

II L 00

II L 01

Preparation for Installation 4-2

Page 51

5) Install the Connecting stay and Main MT plate.

II L 00

Preparation for Installation 4-3

Page 52

[FS-108R] (RoHS Compliance Unit)

6) Install the Joint cover/U, Joint cover/F, and the Joint cover/R. and install the Main Fixed

plate/1.

II L 00

II L 01

Preparation for Installation 4-4

Page 53

[Finisher SR5000] with Transit Pass Unit Type DDP

7) Install the SB Cover Paper Guide to the Printer.

SB Cover Paper Guide

M3x6 Screw

II L 00

Preparation for Installation 4-5

Page 54

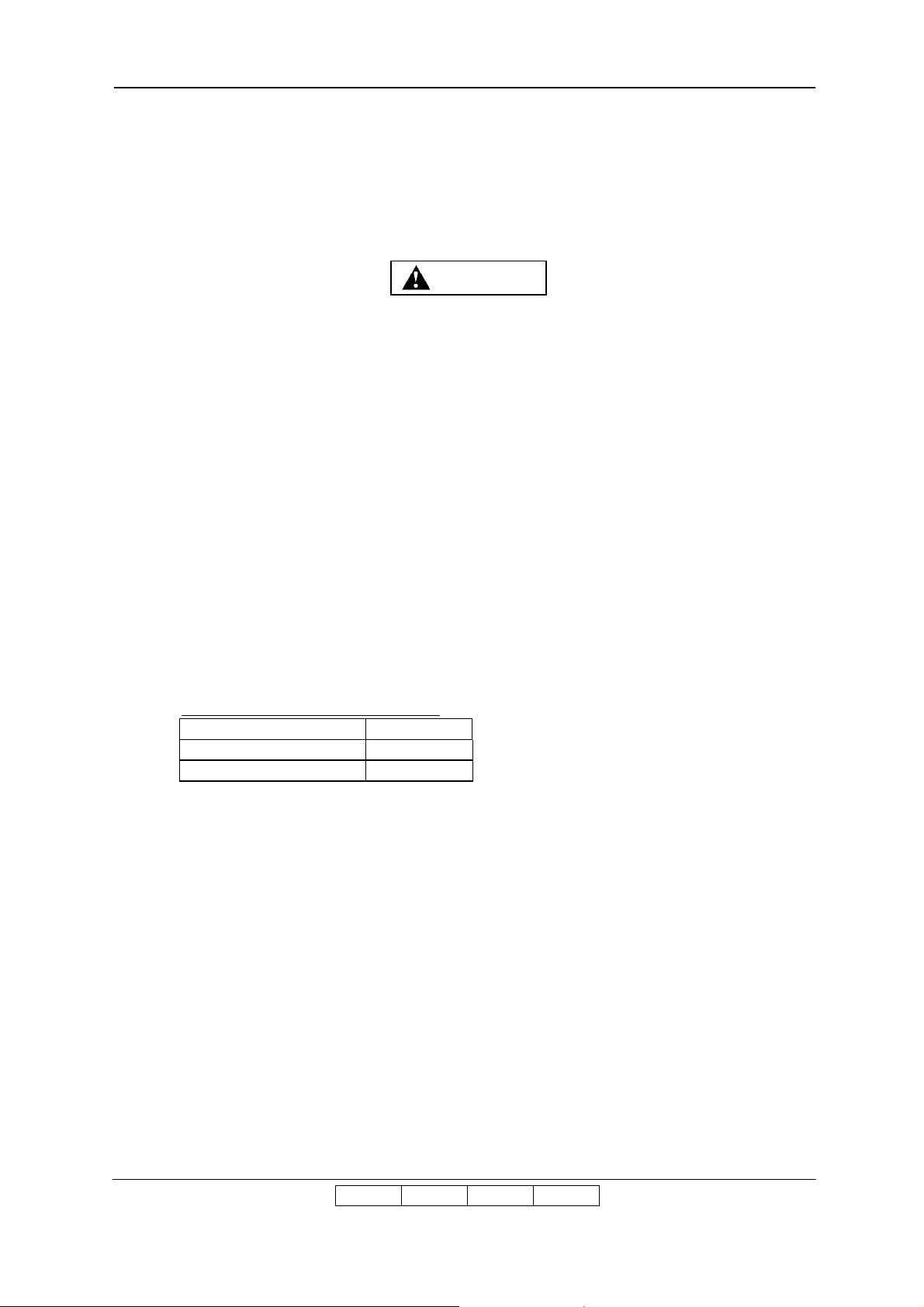

8) Connecting the Power Supply Cable

WARNING

View of Power Supply

Please connect the cable according to this procedure when you use cables other than the

cable appended to the machine.

(1) Put the Power Supply Cable and put it through the Cord Lock and pull it out of the

Terminal Block.

(2) Connect the Power Supply Cable to the Terminal Block and chassis.

(3) Fasten the Power Supply Cable by the Cord Lock.

1) The voltage is constantly in unless the machine is unplugged or Breaker

Switch is turned off.

2) Unplug the Power Supply Cable prior to connecting the power supply

source.

3) Be careful not to have other personnel plug in the power cable while

performing the connecting.

Cord Lock

Power Supply Cable

Rear internal view of Printer

Cord Lock

Star Washer

Protective Erathing Symbol

II L 01

II L 00

Preparation for Installation 4-6

M4

Power Supply Cable

Page 55

1) Unplug the Power Supply Cable prior to connecting.

Approx. 50mm

WARNING

2) Be careful not to have other personnel plug in the power cable while

performing the connecting.

3) Be sure to use power supply cable which complies with the following

specification :

Power plug rating ; Min. AC 250V, Min. 15A (2-Pole, 3-Wire, Grounded)

Power cable rating ; Min. AC 250V, Min. 15A

6-15P UL Listed, CSA Certified in North America

Type CA, Conformed to IEC 950 in Europe

Type SJT or SVT, UL Listed, CSA Certified in North

America

Conformed to IEC 950 in Europe

4) Use the Power Supply Cable which is approximately 50 mm longer for

the FG. The cable should be designed as below, so the FG power cable

remains connected if the other cables are accidentally disconnected.

L

N

FG

Power Cable

5) Make sure that the power cables are connected to the correct terminals

(“L”, “N” ) on the power plug and Terminal Block. ( FG power cable is

connected to chassis.)

6) The socket-outlet shall be installed near the printer and be easily

accessible.

II L 00

Preparation for Installation 4-7

Page 56

[FS-104H] (No RoHS Compliance Unit)

9) Install the Finisher to the Printer.

Adjust the gap between Finisher and Printer by turning the adjustment bolt of Finisher.

(1)

Adjust the gap between Finisher’s paper guide and Printer’s paper guide become 0 to

3mm.

(2)

Adjust the gap between Finisher and Printer is equal from the top through the bottom.

CAUTION

II L 00

II L 01

Preparation for Installation 4-8

Page 57

10) Connect the connectors of Printer with the Finisher.

Cable Cramp

Cable

Tube

CAUTION

1) When connecting the connectors of printer with the finisher, pass the cable

through the Hole of the Printer and clamp the cable with the cable clamp to

protect the cable from the flame edge.

2) Switch on No.8 of SW1 of on the print circuit board of the Printer.

Flame

Edge

CN10

CN9

II L 00

Preparation for Installation 4-9

Page 58

11) Install the Connecting Cover(R).

12) Install the Rear cover of Printer and Finisher.

II L 00

Preparation for Installation 4-10

Page 59

[FS-108R] (RoHS Compliance Unit)

Printer

Printer

A

M4x6 TP

13) Install the Finisher to the Printer.

(4) Fit the hooks on the main body installation plates (upper and lower) into the upper and

lower holes on the Finisher as illustrated below, then lock them by pushing the Finisher

to the back.

When installing the Finisher, don’t hit following “A” part to the Printer.

Confirm the SB cover opens and shuts smoothly after attaching.

CAUTION

(3 Places)

II L 01

II L 00

Preparation for Installation 4-11

Page 60

CAUTION

A

If the gap between the Finisher and Printer is not equal from the top through the

bottom, adjust it by the height of the front and rear casters on the paper exit side of

the Finisher.

The jack of the printer is adjusted when the SB cover doesn't open and shut

smoothly, the printer is lowered, and the SB cover opens and shuts smoothly.

A=B

(5)

Fix the Finisher to the Printer (front side only).

B

(TP screw M4x6: 3)

II L 00

II L 01

Preparation for Installation 4-12

Page 61

14) Connect the connectors of the Printer with the Finisher.

8

765

4

2

3

1

MKK

ON

OFF

OFF

SW1

8

765

4

2

3

1

MKK

ON

OFF

OFF

SW2

Cable Cramp

Print Circuit Board

SW1

(1) When connecting the connectors of printer with the Finisher, pass the two cables

through the Hole of the Printer and Finisher.

(2) Connect the I/F Cable to the CN7 connector on the Print Circuit Board through the

cable clamps with other cables like following figure.

(3) Connect the Power Cable to the Relay Connector like following figure.

(4) Switch on No.8 of SW1 of on the Print Circuit Board of the Engine.

(5) Switch on No.8 of SW2 on the Print Circuit Board of the Printer.

(6) Switch off No.7 of SW2 on the Print Circuit Board of the Printer.

(7) Turn on the “L” of the SW1 mounted on the P/K of the Standard Finisher(FS-108R)

(8) Install the Rear Covers of the Printer and Finisher.

Flame

I/F

Cable

Power

Cable

CN7

Relay Connector

II L 00

II L 01

Preparation for Installation 4-13

Page 62

[Finisher SR5000] with Transit Pass Unit Type DDP

15) Releasing the Rear Cover of the Transit Pass Unit Type DDP.

(1) Unscrew the three M4 Screws.

(2) Unhook the lower hook of the Rear Cover and release the Rear Cover.

(3) (Release the Rear Cover by lifting up and pulling forward.)

16) Install the Block Sponge to the Transit Pass Unit Type DDP.

Block Sponge

M4x8 Screw

Transit Pass Unit Type DDP

17) Open the Front Cover and Lower paper guide.

Rear Cover

Lower paper guide

Front Cover

II L 00

Preparation for Installation 4-14

Page 63

18) Install the Transit Pass Unit Type DDP to the Printer.

NOTE

Install it carefully so that Upper Paper Guide and SB Cover Paper Guide do not collide

SB Cover Paper Guide

Upper Paper Guide

Projection

Transit Pass Unit Type DDP

M4x8 Screw

Projection

M4x8 Screw

(1) Insert the two Projections in the Gap.

Printer Cover

Printer Cover

Gap

Projection of Transit Pass Unit Type DDP

II L 00

Preparation for Installation 4-15

Gap

Page 64

CHECK

Adjust arrow direction

CHECK

Open and close the SB Cover.

When the SB cover does not open, adjust Transit Pass Unit Type DDP to an arrow direction.

Lower Paper Guide

Transit Pass Unit Type DDP

SB Cover

(2) Install the Transit Pass Unit Type DDP by using the four M4x8 Screws.

(3) Close the Lower paper guide and Front Cover.

Open and close the Lower paper guide. When Lower Paper Guide and SB Cover Paper

Guide collide, repair it by hand because SB Cover Paper Guide may transform it.

Lower Paper Guide

Upper Paper Guide

Lower Paper Guide

SB Cover Paper Guide

SB Cover Paper Guide

II L 00

Preparation for Installation 4-16

Page 65

19) Connect the connector of cables to the Printer and Transit Pass Unit Type DDP.

(1) Pass the three cables through the Hole of Printer and Transit Pass Unit Type DDP from

Transit Pass Unit Type DDP to Printer.

- AC cable (white 2pin connector) x2

- Signal cable (black 20pin (small) / black 14pin connector / black 22pin)

- GND cable

(2) Pass the one cable through the Hole of Printer and Transit Pass Unit Type DDP from Printer

to Transit Pass Unit Type DDP.

- FNS IF cable (white 4pin / black 20pin connector)

(3) Remove OCxxx PK.

(4) Connect the Signal Cable to the connector on the CP board as follows.

(Connection 1)

- black 20pin connector (small size ) -> J747 (another side is not be connected)

- black 22pin connector -> between J717 and the original cable

- black 14pin connector -> J791(another side is not be connected)

(5) Attach the OCxxx PK.

(6) Discinnect the CE AC cable from J236 on the Low Voltage Power Supply of Printer.

Connect the AC cable to the J236 on the Low Voltage Power Supply of Printer.

And connect the CE AC cable that is disconnected from J236 to the white 2pin connector of

the AC cable.

(Connection 2)

(7) Mount the FG cable on Printer frame by using M4 screw.

(Connection 3)

(8) Connect the FNS IF cable to the white 4pin connector in the Transit Pass Unit Type DDP.

(Connection 4)

(9) Connect the FNS IF cable to the black 20pin (plug type with lock) connector in the Transit

Pass Unit Type DDP.

(Connection 5)

(10) Switch on No.8 of SW1 on the CP board of the Printer.

(11) Switch on No.6 of SW2 on the CP board of the Printer.

Note 1) Signal Cable (CS) in the Transit Pass Unit Type DDP is not used.

II L 00

02

Preparation for Installation 4-17

Page 66

AC cable

CP board

connection 3 connection 4,5

CP board

J717

J791

J747

Location of connection 1 and DIP SW

CE AC cable

L.V.P.S

connector : white 2pin

J236

connector : white 2pin

Location of connection 2

II L 00

02

Preparation for Installation 4-18

Page 67

20) Install the Rear Cover of the Printer and Transit Pass Unit Type DDP.

M4x8 Screw

M4x8 Screw

M4x8 Screw

Rear Cover of

the Printer

21) Install the Ground Plate to the Transit Pass Unit Type DDP.

Ground Plate

Rear Cover of

the Transit Pass Unit Type DDP

M4x8 Screw

II L 00

Preparation for Installation 4-19

Page 68

22) Install the Finisher SR5000 to the Transit Pass Unit Type DDP.

(1) Refer to the Installation Procedure of the Finisher SR5000.

(2) Install the FC Cover to the front door on the Finisher SR5000.

Finisher SR5000

M4x8 Screw

FC Cover

Transit Pass Unit Type DDP

Front door

II L 00

Preparation for Installation 4-20

Page 69

4.2 Installation in the composition with the High Capacity Hopper

1) Install components other than the High Capacity Hopper.

2) Draw the 2000 Sheet Hopper of the Engine.

3) Remove the two M4 screws and Side Cover.

II L 00

Preparation for Installation 4-21

Page 70

4) Connecting the two connectors (3pin and 14pin) to the HPxxx Ass’y of the Engine.

5) Connecting the High Capacity Hopper.

(1) Put the Positioning Pin in the hole A and slide the High Capacity Hopper in the arrow

direction.

(2) Make sure that the Cable does not get caught between the Printer and High Capacity

Hopper.

6) Tighten the two M4 screws.

7) Return the 2000 Sheet Hopper.

II L 00

Preparation for Installation 4-22

Page 71

8) Remove the six M4 screws and Rear Cover.

9) Switch on No.6 of SW1 on the CP P/K of the Engine.

10) Install the Rear Cover.

M4 Screw

11) Turn the leveling bolt ( 2 Places) to make the bottom of the High Capacity Hopper parallel with

the floor, judging by your eyes.

II L 00

Preparation for Installation 4-23

Page 72

4.3 Installation in the composition with the Container Stacker 1 or 2

Lever

4.3.1 Connection of the Engine and Container Stacker 1 or 2

1) Drawer the 2000 Sheets Hopper and set the paper guide at the position of 8.5” paper size.

2) Remove the M4 Screw and the 2000 Sheets Hopper.

Paper guide

M4 Screw

2000 Sheets Hopper

3) Turn the four leveling bolts until casters are floated.

4) Adjust the horizontal level of the printer with the Level Meter putting on the frame.

Caster

Level Meter

Leveling Bolt

Floor

Gap

(Max 1mm)

II L 00

Preparation for Installation 4-24

Page 73

5) Install the 2000 Sheets Hopper.

M4 Screw

2000 Sheets Hopper

6) Remove the two M3x8 Screws and Electrostatic Eraser from the Engine.

7) Install the Guide plate (U) with the Electrostatic Eraser (“FRONT” letter is surface.) by using

the two M3x8 Screws. (Be careful that the hair of the Electrostatic Eraser does not fall.)

8) Install the Guide plate (L) by using the two M3x8 Screws with washer.

9) Install the Joint Bracket (U) and Joint Bracket (L) by using the two M4x8 Screws.

Guide plate (L)

M3x8 Screw

M3x8 Screw with washer

M4x8 Screw

M4x8 Screw

Guide plate (U)

Static electricity eliminator

Joint bracket (L)

Joint bracket (U)

Guide Plate (L)

view from front side.

II L 00

Preparation for Installation 4-25

Guide Plate (U)

view from front side.

Page 74

10) Releasing the Rear Cover of the Engine.

(1) Unscrew the six M4 Screws.

(2) Unhook the lower hook of the Rear Cover and release the Rear Cover.

(3) (Release the Rear Cover by lifting up and pulling forward.)

M4 screws

M4 screws

Rear cover

11)

Remove the six M4 screws and the Rear Cover of the Container Stacker

Container Stacker

M4 screws

Rear cover

II L 00

Preparation for Installation 4-26

Page 75

12) Attach the Container Stacker to the Engine.

Opening

”B”

(1) Pass the AC Relay cable (2-pin white connector) and FNS IF cable (20-pin black

connector) through opening “A” in the Engine, and then through opening “B” in the

Container Stacker.

(2) Pass the CST FG cable and CST AC cable (2-pin white connector) through opening

“B” in the Container Stacker, and then through opening “A” in the engine.

(3) Attach the Engine to the Container Stacker (6 M4x12 screws).

Important: Do not tighten the screws all the way.

M4x12 Screws

Engine

M4x12

Screws

Frame

projection part

Opening ”A”

13) In order to adjust the height of Container stacker, turn 180 degrees each of four leveling bolts,

and satisfy the following conditions, and bolt the screw of a temporary tight.

(1) When the Front cover R is shut and it looks into the space between the Printer and

Container stacker from front side, the height of the Frame’s projection of Container

stacker and the Guide plate U’s projection is the same.

[Note] As for the way of opening front cover L, refer to the item 3.3.

Level Meter

Stacker frame

Guide plate U

Projection

Front cover R

Front cover L

II L 00

II L 01

Leveling bolts

Preparation for Installation 4-27

Projection

Same height

Connection part Details

Page 76

(2) It looks into the space between Printer and Container stacker from a rear side, the

B

C

D

height of the Frame’s upper part of Container stacker and the Guide plate U’s upper

part is the same.

(3) Put the Level Meter on two places of Container stacker is level.

Guide plate (U)

CHECK

Check the Gaps of A,B,C,D are nearly equal each other.

Frame

Connection part details

Adjust the gap in parallel

II L 00

Preparation for Installation 4-28

Page 77

CHECK

CP P/K Holder

(No RoHS Compliance

Open the L paper guide A of the Container Stacker make sure that the SB cover can be

opened.

When not open, re- adjusts to implement the item 4.3.1.12) and to lift the Container

Stacker.

L paper guide A

SB cover

14) Remove the OC P/K ass’y from the printer. Remove the CPXXX P/K and CP P/K holder.

15) Remove the nv-RAM from the CPXXX P/K by using IC gripper. Install the removed nv-RAM

into the CPXXX P/K(No RoHS Compliance Engine only)

M4 Screw

OC P/K Ass’y

M4 Screw

CPXXX P/K

Engine only)

CST AC Cable

CST FG Cable

M4 Screw

Dent side

nv-RAM

II L 00

II L 01

Preparation for Installation 4-29

Page 78

16) Connect the CST AC cable coming from the Container Stacker to the J236 on the power

PS

(4 pin white)

(4 pin white)

J236

CST AC Cable

CE AC Cable

PS

8

7

6

54231

MKK

ON

OFF

OFF

SW1

8

7

6

54231

MKK

ON

OFF

OFF

SW2

supply of the printer (Connection 1 on the below figure). At this time, connect CE AC cable that

is disconnected from the J236 to the connector of the CST AC cable (Connection 2 on the

below figure)

17) Mount the CST FG cable coming from Container Stacker side on the printer frame by using

M4 screw (Connection 3 on the below figure).

18) Install the CPXXX P/K on the CP P/K holder, and then install it with OC P/K ass’y in the

Engine.

19) Connect FNS IF cable of 20 pin black connector coming from the printer to the J680

connector of ST09X P/K board in Container Stacker (Connection 4 on the below figure).

(Do not use the 4 pin white connector Disconnection 2 on the below figure).

20) Disconnect the 4 pin white connector of the DC IF cable of the printer from the FNS IF cable

(Disconnection 1 on the below figure). Then connect it to the RB cable of 4 pin white connector

coming from Container Stacker. (Connection 5 on the below figure)

[Note] Put the cable through the opening “A” of the Engine for connection.

CTS AC cable

[No RoHS Compliance Unit]

M4 screw

(Connection 3)

Opening “A”

Engine Container

Connection 1

PS

Connection 2

CE AC cable

Details of Connection 1 and Connection2.

CST FG cable

DC IF cable

FNS IF cable

RB cable

Connection 5

Disconnection 2

Connection 4

(20 pin black)

Disconnection 3

Disconnection 1

(4 pin white)

[RoHS Compliance Unit]

Connector : 2 pin white

Connector : 2 pin white

II L 00

II L 01

Preparation for Installation 4-30

Page 79

21) Turn on the No.5 and Turn off the No.2 and 8 of the SW1 mounted on the CPXXX P/K of the

Engine. (No RoHS Compliance Unit)

22) Turn on the No.5 and turn off the No.2 and 8 of the SW1 mounted on the CPXXX P/K of the

Engine. Turn off the No.7 and 8 of the SW2 mounted on the CPXXX P/K of the Engine.

(RoHS Compliance Unit)

23) Install the Rear Cover of the Engine and Container Stacker.

M4 screw

II L 00

II L 01

Preparation for Installation 4-31

Page 80

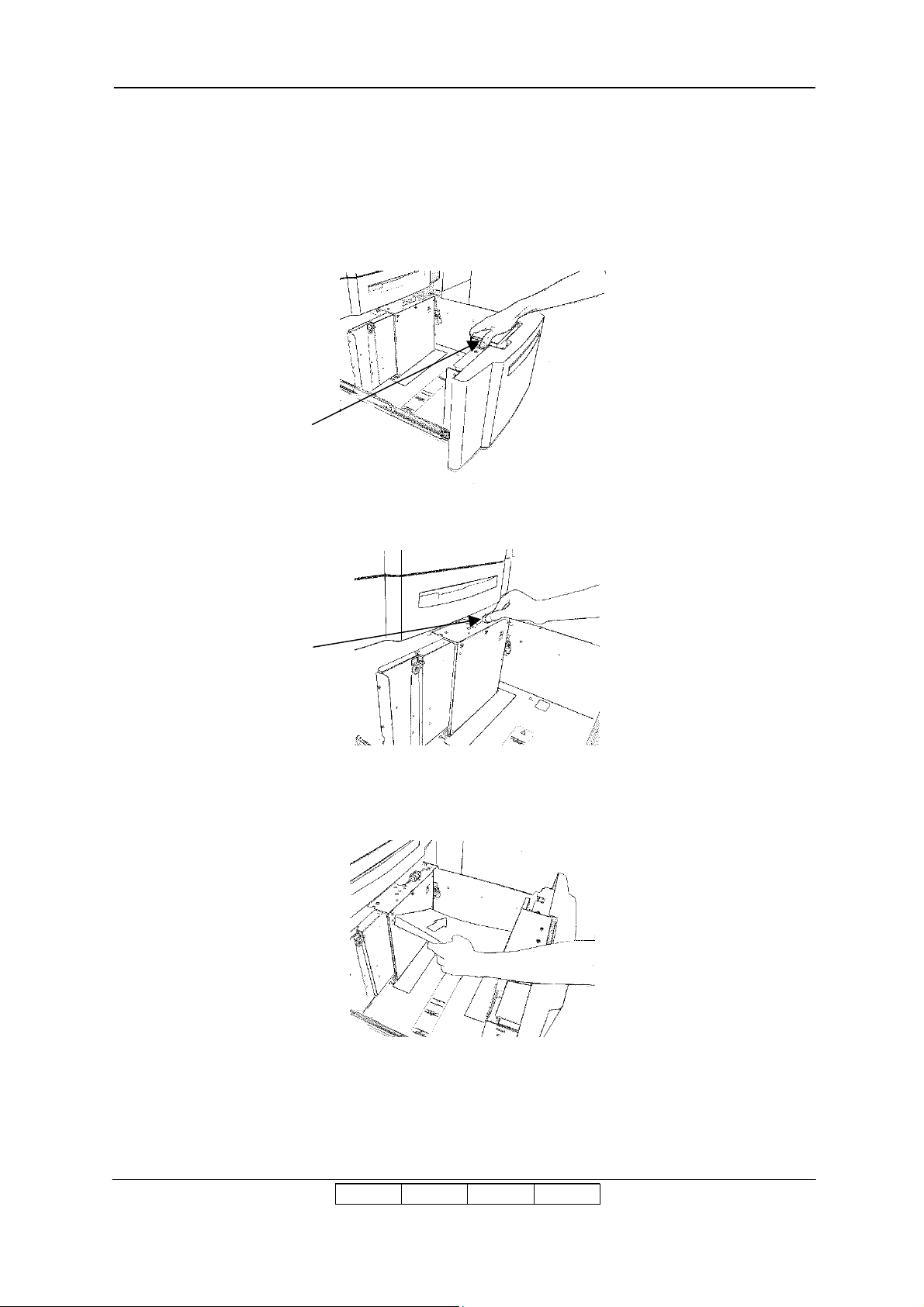

4.3.2 Connection of the Container Stacker 1 and Container Stacker 2

1) Perform item 4.3.1.

2) Remove the two M3x8 Screws and Electrostatic Eraser from the Container stacker 2.

3) Install the Guide plate (U) with the Electrostatic Eraser (“FRONT” letter is surface.) by using

the two M3 Screws. (Be careful that the hair of the Electrostatic Eraser does not fall.)

4) Install the Joint Bracket (U) and Joint Bracket (L) by using the two M4x8 Screws.

5) Remove the six M4 screws and remove the rear cover from the Container Stacker 1.

Container Stacker 1

M4 screws

Rear Cover

II L 00

Preparation for Installation 4-32

Page 81

6) Install the Container Stacker 1 to the Container Stacker 2. The screw is the thing of the

temporary stopping.

Container stacker 1

M4x12 screws

Frame projection part

M4x12 screws

M4x12 screws

Container stacker 2

7) In order to adjust the height of Container stacker, turn 180 degrees each of four leveling bolts,

and satisfy the following conditions, and bolt the screw of a temporary tight.

(1) When Front cover R is shut and it looks into the space between Container stacker 2

and Container stacker 1 from a front side, the height of the Frame’s projection of

Container stacker and the Guide plate U’s projection is the same.

[Note] As for the way of opening front cover L, refer to the item 3.3.

Level Meter

Front cover L

Preparation for Installation 4-33

Stacker frame

Projection Projection

Front cover R

Leveling bolt

II L 00

II L 01

Guide plate U

Same height

Connection part details

Page 82

(2) It looks into the space between the Container stacker 2 and Container stacker 1 from a

rear side, the height of the Frame’s upper part of Container stacker 1 and the Guide

plate U’s upper part is the same.

(3) Put the Level Mater on two places of Container stacker is level.

Guide plate (U)

CHECK

Check the Gaps of A,B,C,D are nearly equal each other.

Adjust the gap in parallel

Frame

Connection part details

A

C

B

D

II L 00

Preparation for Installation 4-34

Page 83

8) Connect the FNS IF cable (4 pin white connector) coming from the Container Stacker 2 to the

RB cable

RB cable

8

7

6

542

3

1

MKK

ON

OFF

OFF

SW2

8

7

6

542

3

1

MKK

ON

OFF

OFF

SW1

J680 on the ST09X P/K of the Container Stacker 1. (Connection 1 on the below figure)

9) Take out the CST AC cable (2 pin white connector) from the Container Stacker 1 and connect

it to the CST AC cable (2 pin white connector) of the Container Stacker 2. (Connection 2 on the

below figure)

10) Take out the RB cable (4 pin white connector) from the Container Stacker 1 and connect it to

the RB cable (4 pin white translucence) of the Container Stacker 2. (Connection 3 on the

below figure)

11) Mount the CST FG cable coming from the Container Stacker 1 on the frame of the Container

Stacker 2 by using M4 screw (Connection 4 on the below figure).

12) Turn on the No. 4 and 5 and turn off the No. 2 and 8 of the SW1 mounted on the CPXXX P/K

of the Engine. (No RoHS Compliance Unit)

13) Turn on the No.4 and 5 and turn off the No.2 and 8 of the SW1 mounted on the CPXXX P/K

of the Engine. Turn off the No.7 and 8 of the SW2 mounted on the CPXXX P/K of the Engine.

(RoHS Compliance Unit)

[Note] Put the cable through the opening “A” of the Engine for connection.

14)

Engine

(For Container Stacker 2)

M4 screw

Connection 4

Container Stacker

(W/ Through path)

CST FG cable

Disconnection 1(4 pin white)

Connection 3

(4 pin white)

2

Connection 2

(2 pin white)

(For Container Stacker 1)

AF cable

Container Stacker 1

(W/ Sample tray)

Opening “A”

CST AC cable

Connection 1

(20 pin black)

Disconnection 2

(2 pin white)

No RoHS Compliance

Unit

RoHS Compliance Unit

II L 00

II L 01

Preparation for Installation 4-35

Page 84

14) Install the Rear Covers of the Engine, Container Stacker 1 and Container Stacker 2.

M4 screws

Rear Cover of

the Engine

M4 screws

Rear Cover of the

Container Stacker 1

Rear Cover of the

Container Stacker 2

M4 screws

II L 00

II L 01

Preparation for Installation 4-36

Page 85

4.3.3 Connection of the Container Stacker 2 and Finisher / Finisher SR5000

with washer

[FS-104H] (No RoHS Compliance Unit)

1) Remove the two M3 screws and the discharging brush from the Container Stacker 2.

2) Install the Guide plate (G) with the Static electricity eliminator (“FRONT” letter is surface.)

by using the two M3 Screws. (Be careful that the hair of the Static electricity eliminator

does not fall.)

3) Install the guide plate (H), connecting stay and main MT plate.

Connecting stay

M4 screws

M3 screws

M3 screws

Container stacker 2

Guide plate (G)

Static electricity eliminator

M4 screws

Guide plate (H)

Main MT plate

4) Remove the rear covers from the Engine, Container Stacker 2 and Finisher.

II L 02

II L 00

Preparation for Installation 4-37

Page 86

5) Install the Standard Finisher to the Container Stacker 2.

Adjustment bolt

Container stacker 2

M4 screws

Finisher paper

guide

Standard finisher

M4 screws

Container stacker 2 paper guide

0 to 3 mm

Adjust the gap in parallel.

A

Loosen

CHECK

Adjust a difference between the paper guide of stacker side and printer side by 0-3 mm.

Check the Gaps of A, B, C, D are nearly equal each other.

If they are not, re-adjust by adjusting leveling bolts.

II L 00

Preparation for Installation 4-38

Page 87

6) Connect the FNS IF cable (4 pin white connector) coming from the Container Stacker 2 to the

4 pin white connector in the Finisher (Connection 1 on the below figure).

7) Connect the FNS IF cable (20 pin black connector) coming from the Container Stacker 2 to

the CN7 connector on the Finisher main P/K (Connection 2 on the below figure).

8) Turn on the No. 5 and 8 and turn off the No. 2 of the SW1 mounted on the CPXXX P/K of the

Engine.

[Note] Put the cable through the opening “A” of the Container Stacker 2 for connection.

Printer

Opening “A”

Container Stacker 2

(W/ Through path)

Disconnection 1

(4 pin white)

AF cable

Disconnection 2

(2 pin white)

Connection 2

(20 pin black)

Standard Finisher

Connection 1

(4 pin white)

9) Install the Rear Covers of the Printer, Container Stacker 2 and Finisher.

II L 00

Preparation for Installation 4-39

Page 88

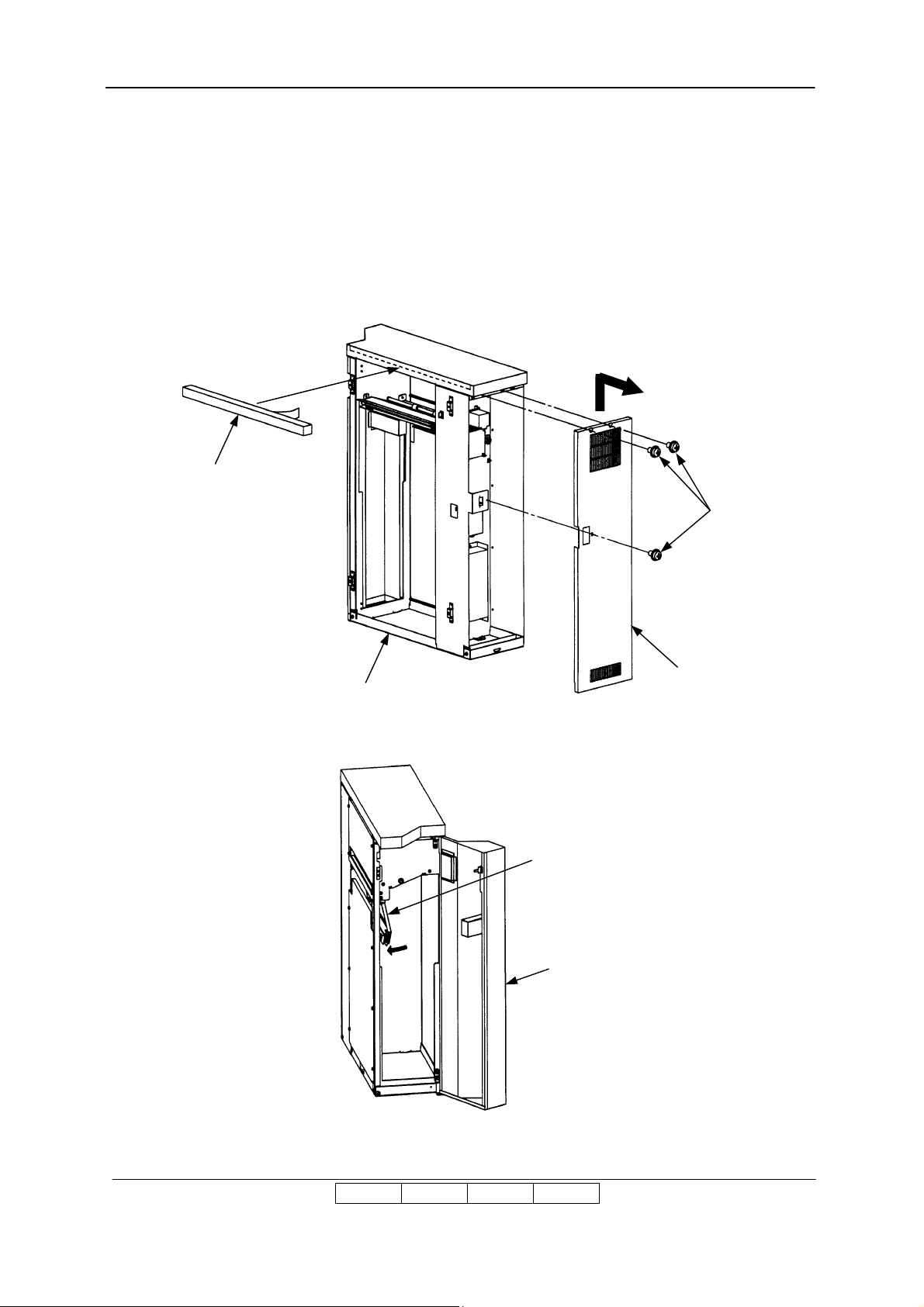

[FS-108R] (RoHS Compliance Unit)

Joint cover / F

10) Install the Joint Cover /F, Joint Cover /U and Joint Cover /R to the Container Stacker 2, and

install the two Main Fixed Plate/1 to the Joint Cover /R.

M4x6 Truss screw

6-M4x6 TP screws

Main Fixed Plate/ 1

Joint cover / R

Joint cover / U

Main Fixed Plate/ 1

11) Remove the rear covers from the Engine, Container Stacker 2 and Finisher.

Container Stacker 2

II L 00

II L 01

Preparation for Installation 4-40

Page 89

12) Install the Finisher to the Container Stacker

Lower view

(1) Fit the hooks on the Container Stacker installation plates (upper and lower) into the

upper and lower holes on the Finisher as illustrated below, then lock them by pushing

the Finisher to the back.

When installing the Finisher, don’t hit following “A” part to the Printer.

Confirm the SB cover opens and shuts smoothly after attaching.

M4x6 screws

3 Places

Upper view

Finisher

Container Stacker 2

CAUTION

Holes

Finisher

Hooks

Container Stacker 2

II L 00

II L 01

Preparation for Installation 4-41

Page 90

CAUTION

If the gap between the Finisher and Container Stacker is not equal from the top

through the bottom, adjust it by the height of the front and rear casters on the paper

exit side of the Finisher.

The jack of the printer is adjusted when the SB cover doesn't open and shut

smoothly, the printer is lowered, and the SB cover opens and shuts smoothly.

A=B

(2)

Fix the Finisher to the Printer (front side only).

(TP screw M4x6: 3)

A

B

II L 01

II L 00

Preparation for Installation 4-42

Page 91

13) Connect the FNS IF cable (4 pin white connector) coming from the Container Stacker 2 to

H

L

SW1

8

7

65423

1

MKK

ON

OFF

OFF

SW1

8

7

65423

1

MKK

ON

OFF

OFF

SW2

423

1

MKK

O

FF

OFF

O

N

SW1

the 4 pin white connector in the Finisher (Connection 1 on the below figure).

14) Connect the FNS IF cable (20 pin black connector) coming from the Container Stacker 2 to

the CN7 connector on the Finisher main P/K (Connection 2 on the below figure).

15) Turn on the No. 5 and 8 and turn off the No. 2 of the SW1 mounted on the CPXXX P/K of the

Engine.

Turn on the No.8 and Turn off the No.7 of the SW2 mounted on the CPXXX P/K of the

Engine.

Turn on the No.2 and 4 of the SW1 mounted on the ST09X P/K of the Container Stacker 2.

Turn on the “L” of the SW1 mounted on the P/K of the Standard Finisher(FS-108R).

[Note] Put the cable through the opening “A” of the Container Stacker 2 for connection.

Printer

Opening “A”

Container Stacker 2

(W/ Through path)

Disconnection 1

(4 pin white)

AF cable

Disconnection 2

(2 pin white)

Connection 2

(20 pin black)

Standard Finisher

Connection 1

(4 pin white)

16) Install the Rear Covers of the Printer, Container Stacker 2 and Finisher.

II L 00

II L 01

Preparation for Installation 4-43

Page 92

[Finisher SR5000] with Transit Pass Unit Type DDP

17) Install the SB Cover Paper Guide to the Container Stacker.

SB Cover Paper Guide

M3x6 Screw

II L 00

Preparation for Installation 4-44

Page 93

18) Releasing the Rear Cover of the Transit Pass Unit Type DDP.

(1) Unscrew the three M4 Screws.

(2) Unhook the lower hook of the Rear Cover and release the Rear Cover.

(3) (Release the Rear Cover by lifting up and pulling forward.)

19) Install the Block Sponge to the Transit Pass Unit Type DDP.

Block Sponge

M4x8 Screw

Transit Pass Unit Type DDP

20) Open the Front Cover and Lower paper guide.

Rear Cover

Lower paper guide

Front Cover

II L 00

Preparation for Installation 4-45

Page 94

21) Install the Transit Pass Unit Type DDP to the Container Stacker.

M4x8 Screw

M4x8 Screw

Projection

Projection

Transit Pass Unit Type DDP

Projection of Transit Pass Unit Type DDP

Gap

Gap

Container Stacker Cover

NOTE

Install it carefully so that Upper Paper guide and SB Cover Paper Guide do not collide

Upper Paper Guide

(1) Insert the two Projections in the Gap.

SB Cover Paper Guide

Container Stacker Cover

(2) Install the Transit Pass Unit Type DDP by using the four M4x8 Screws.

II L 00

Preparation for Installation 4-46

Page 95

(3) Close the Lower paper guide and Front Cover.

CHECK

Open and close the Lower paper guide. When Lower Paper Guide and SB Cover Paper

Guide collide, repair it by hand because SB Cover Paper Guide may transform it.

Lower Paper Guide

Upper Paper Guide

Lower Paper Guide

SB Cover Paper Guide

SB Cover Paper Guide

II L 00

Preparation for Installation 4-47

Page 96

22) Connect the connector of cables to Container Stacker and Transit Pass Unit Type DDP.

(1) Disconnect the Signal Cable from EDxxx PK in the Transit Pass Unit Tyoe DDP.

(white 8pin connector and black 22pin connector)

(2) Connect the Signal Cable(CS) to EDxxx P/K of the Transit Pass Unit Type DDP.

(white 8pin connector and black 22pin connector)

(3) Pass the three cables through the Hole of Container Stacker and Transit Pass Unit Type

DDP from Transit Pass Unit Type DDP to Container Stacker.

- AC cable (white 2pin connector) x2

- Signal cable(CS) (black 20pin (big size) / black 20pin (small size) / black 14pin

/ black 22pin connector)

- GND cable

(4) Pass the one cable through the Hole of Container Stacker and Transit Pass Unit Type

DDP from Container Stacker to Transit Pass Unit Type DDP.

- FNS IF cable (white 4pin / black 20pin connector)

(5) Disconnect the FNS I/F cable from J681 connector on the ST board. (Disconnection 1)

Connect the Signal Cable(CS) to the connector on the ST board as follow. (Connection 1)

- black 20pin connector (big size) -> J681

(6) Pass the one cable through the Hole of Printer and Container Stacker from Container

Stacker to Printer.

- Signal cable(CS) (black 20pin (small size) / black 14pin connector / black 22pin

connector)

(7) Remove the OCxxx PK.

(8) Connect the Signal Cable(CS) to the connector on the CP board as follows.

(Connection 2)

- black 22pin connector -> between J717 and the original cable

- black 20pin connector (small size) -> J747(another side is not be connected)

- black 14pin connector -> J791(another side is not be connected)

(9) Attach the OCxxx PK.

(10) Connect the AC cable (white 2pin connector).

Then, another side connector of AC cable is not used.

(Connection 3)

(11) Mount the FG cable on Container Stacker frame by using M4 screw.

(Connection 4)

(12) Connect the FNS IF cable to the white 4pin connector in the Transit Pass Unit Type DDP.

(Connection 5)

(13) Switch on No.5 of SW1 on the CP board of the Printer.

(14) Switch on No.8 of SW1 on the CP board of the Printer.

(15) Switch on No.6 of SW2 on the CP board of the Printer.

Note 1) Green flat cable (20pin) of FNS IF cable in the Container Stacker and Transit Pass

Unit Type DDP is not used.

II L 00

01

Preparation for Installation 4-48

Page 97

0201

CP board

J717

connection 2

CP board

J791

connection 4

SW2 SW1

J747

Location of connection 2 and DIP SW

II L 00

Preparation for Installation 4-49

connection 3disconnection 1 / connection1

connection 5

Page 98

23) Install the Rear Cover of the Printer, Container Stacker and Transit Pass Unit Type DDP.

M4x8 Screw

M4x8 Screw

Rear Cover of

the Printer

M4x8 Screw

Rear Cover of

the Container Stacker

24) Install the Ground Plate to the Transit Pass Unit Type DDP.

M4x8 Screw

Rear Cover of

the Transit Pass Unit Type DDP

Ground Plate

M4x8 Screw

II L 00

Preparation for Installation 4-50

Page 99

25) Install the Finisher SR5000 to the Transit Pass Unit Type DDP.

(1) Refer to the Installation Procedure of the Finisher SR5000.

(2) Install the FC Cover to the front door on the Finisher SR5000.

Finisher SR5000

M4x8 Screw

FC Cover

Transit Pass Unit Type DDP

Front door

II L 00

Preparation for Installation 4-51

Page 100

Chapter 5. Checks

5.1 Confirmation of the paper size indication

1) Adjust the size guide of tray 1 to the A4 size or the Letter size.

Size Guide

2) Adjust the sensor plate of tray 1 to A4 or LTR.

Sensor Plate

3) Place the A4 size paper or the Letter size paper into the tray 1.

II L 00

II L 01

Installation 5-1

Loading...

Loading...