Page 1

SECTION 1

OVERALL MACHINE

INFORMATION

Page 2

30 November 1990

1. SPECIFICATIONS

- Item - - Specifications Configuration : Console

Copying Process: Dry electrostatic transfer system

Original: Book/Sheet

Original Size: Maximum A3, 11" x 17"

Reproduction Ratios: 5 reduction ratios, 3 enlarg ement ratios

(One more reduction ratio and

enlargement ratio can be set by SP mode)

zoom :— from 60% to 155% in 1% steps

- A4 Version 5R: 93%, 82%, 75%, 71%, and 65%

3E: 115%, 12 2%, and 141%

- Letter Version 5R: 93%, 85%, 77%, 74%, and 65%

3E: 121%, 12 9%, and 155%

Reproduction Ratio Cha nge: Maximum 6.5 seconds

Warm-Up Time: Within 5 minutes (Room Temp. 200C,

680F)

Copy Paper Size: — Maximum A3, 11" x 17"

— Minimum A6, 51/2" x 81/2"

Weight: — 52 g/m2 to 157 g/m2 (14 lb

to 42 lb)

Copying Speed: 52 cpm/11" x 81/2"

53 cpm/A4 sideways

25 cpm/A3, 11" x 17"

First Copy Time: 3.6 seconds (A4 or 81/ 2 " x 11") (LCT feed)

Copy Number Input: Number keys, 1 to 999 (count up or down)

Special Functions:

•

Auto duplexing (3 modes)

•

Margin adjustment (0 to 16 mm [5/8"]

on both sides)

•

Auto image density selection (ADS)

1-1

Page 3

30 November 1990

•

Automatic paper selection (APS)

•

Automatic reduction/e nla rge ment (AMS)

•

2 single copies mode (Copies facing

pages of a bound original)

•

Cover sheet mode (with ADF or RDH)

Manual Image Density

7 steps

Selection:

Automatic Reset: 1 minute standard setting; can also be set

to 3 minutes or no auto reset.

All functions canceled except cassette

selection. Quantity en te red returns to "1",

and reproduction ratio re tu rns to full size.

Paper Feed:

•

3000 sheet large capacity tray (LCT)

•

Dual 500 sheet universal cassettes

•

Manual feed table

Paper Feed System: Feed and reverse roller

Exposure System: Slit exposure, moving optics

Lens: Through lens, F5, f=215 m m

Light Source:

•

Halogen lamp (85 V, 160 W; control

range 50 to 80 volts RMS)

•

Automatic voltage change (VL Sensor)

Photoconductor: Selenium drum (F-type)

Charge System: Dual wire dc coron a

Erase: LED lamp unit (80 segments)

Development System:

•

Magnetic brush roller

•

Double roller development

Development: Automatic voltage change (The control

board monitors the sele cte d image density

level, drum temperature, and rest time.)

Toner Replenishment: Cartridge exchange (480 g/bottle)

Toner Consumption: 12,000 copies/bottle (7%/A4)

Cleaning System: Blade and brush, pre-cleaning corona

Quenching System: Photo-quenching (cold cathode tube) and

dc corona

1-2

Page 4

30 November 1990

Image Transfer: Single wire dc corona, pre-transfer lamp

Paper Separation: Dual wire ac corona and pick-off pawls

Image Fusing: Heat and pressure rollers

Fusing Lamp: Halogen lamp (820 W)

Oil Consumption: More tha n 80,0 00 copie s per oil tank

(519 cc)

Electronic Control System: 8-bit microprocessor

Copy Tray Capacity: 250 sheets (all sizes)

Self-diagnostics: 34 codes for the main copie r

8 codes for the finisher

Service Programs: 100 programs controlled from the

operatio n panel

Power Source: 110V/60Hz ⇒ 15A (for Taiwan)

115V/60Hz ⇒ 15A (for N.A.)

220V/50Hz ⇒ 8A (for EU.)

220V/60Hz ⇒ 8A (for EU.)

240V/50Hz ⇒ 8A (for EU.)

Power Consumption

(copier only)

Dimensions:

Weight:

See the following table. Numbers are in

kilowatts per hour.

Warm-up Copying Stand-by Max

0.82 1.26 0.7 1.5

Width Depth Height

Copier only with

platen cover

Full System

(DH, Finisher)

Copier Only 210kg (463lb) 220 kg (485lb)

DF, Sorter 240.5kg (530lb) 250.5 kg (552.3lb)

DH, Finisher 273 kg (601.9lb) 283 kg (623lb)

909mm (35.8") 743mm

(29.3")

1,494 mm

(58.9")

115V version: 220V version:

743mm

(29.3")

1,072 mm

940mm

(37.0")

(42.3")

1-3

Page 5

14

10

9

7

30 November 1990

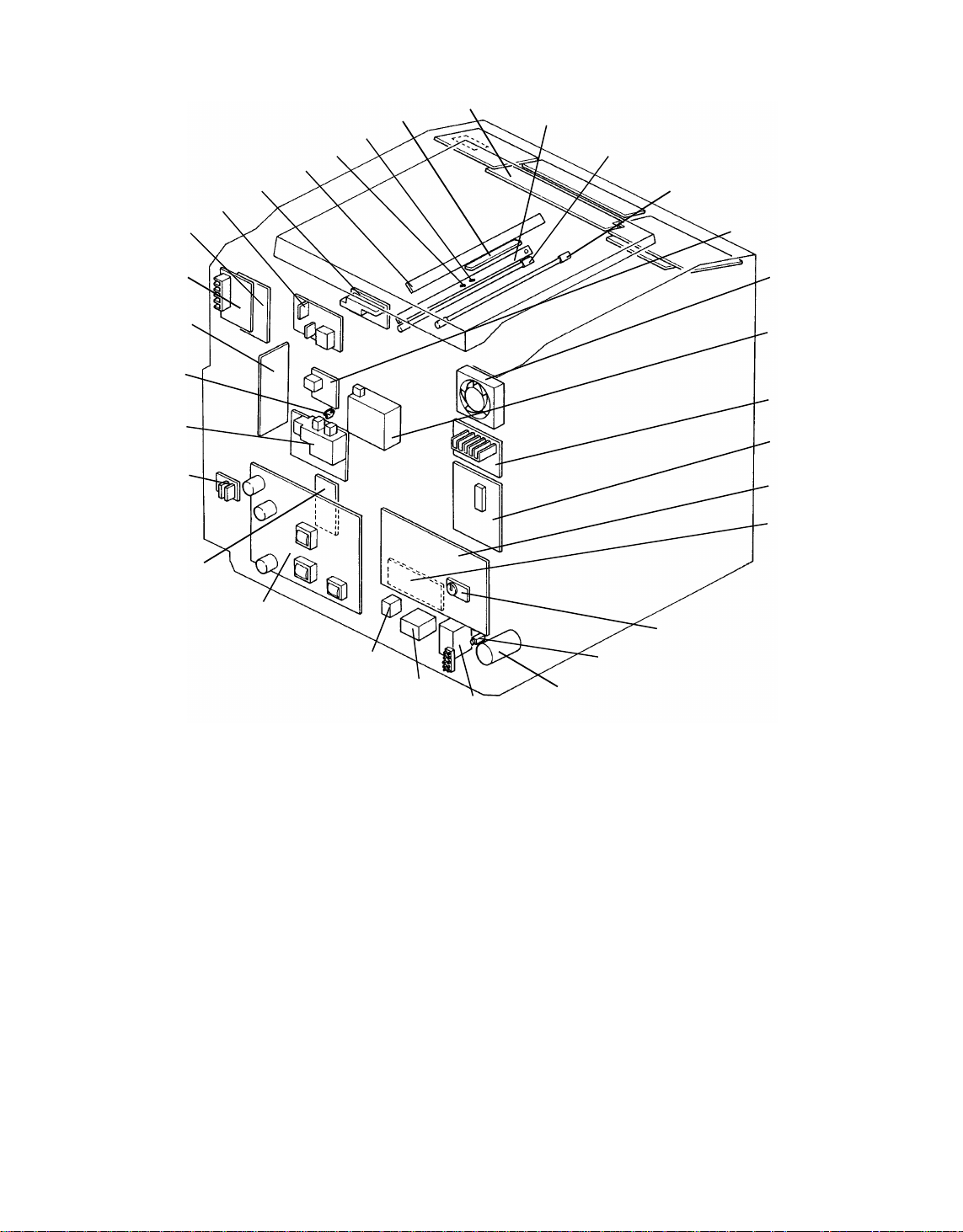

2. GUIDE TO COMPONENTS

2.1 INTERNAL & EXTERNAL

5

4

3

2

1

16

6

8

11

12

13

1. Left Door

Open to access the inside of th e

copier.

2. Oil Bottle

Add silicone oil to this bottle.

3. Main Switch

Switches the copier between on

and stand-by condition s.

4. Operation Panel

Operator controls and indicators

are located here.

15

5. Exposure Glass

Position originals here for cop ying .

6. Platen Cover

Lower this cover over originals for

copying.

7. Toner Bottle

Toner is supplied from this bottle.

8. Toner Bottle Holder

Install the toner bottle here.

9. Key Counter Holder

Insert the optional key cou nter here.

1-4

Page 6

30 November 1990

10. By-pass Feed table

Open to copy on to paper of

non-standard size or weight.

11. Large Capacity Tray

This tray can hold 3,000 sheets of

copy paper. (A4/81/2" x 11"

sideways)

12. Right Door

Open to access the inside of th e

copier.

13. Total Counter

Shows the total number of copies

made.

14. A3/DLT Counter

Shows the total numb er of A3/ DLT

copies made.

15. Cassette Bank

This bank can hold two 500-sheet

cassettes.

16. Paper Cassette

These two cassettes can ho ld

500-sheets of copy paper e ach .

1-5

Page 7

2

1

13

30 November 1990

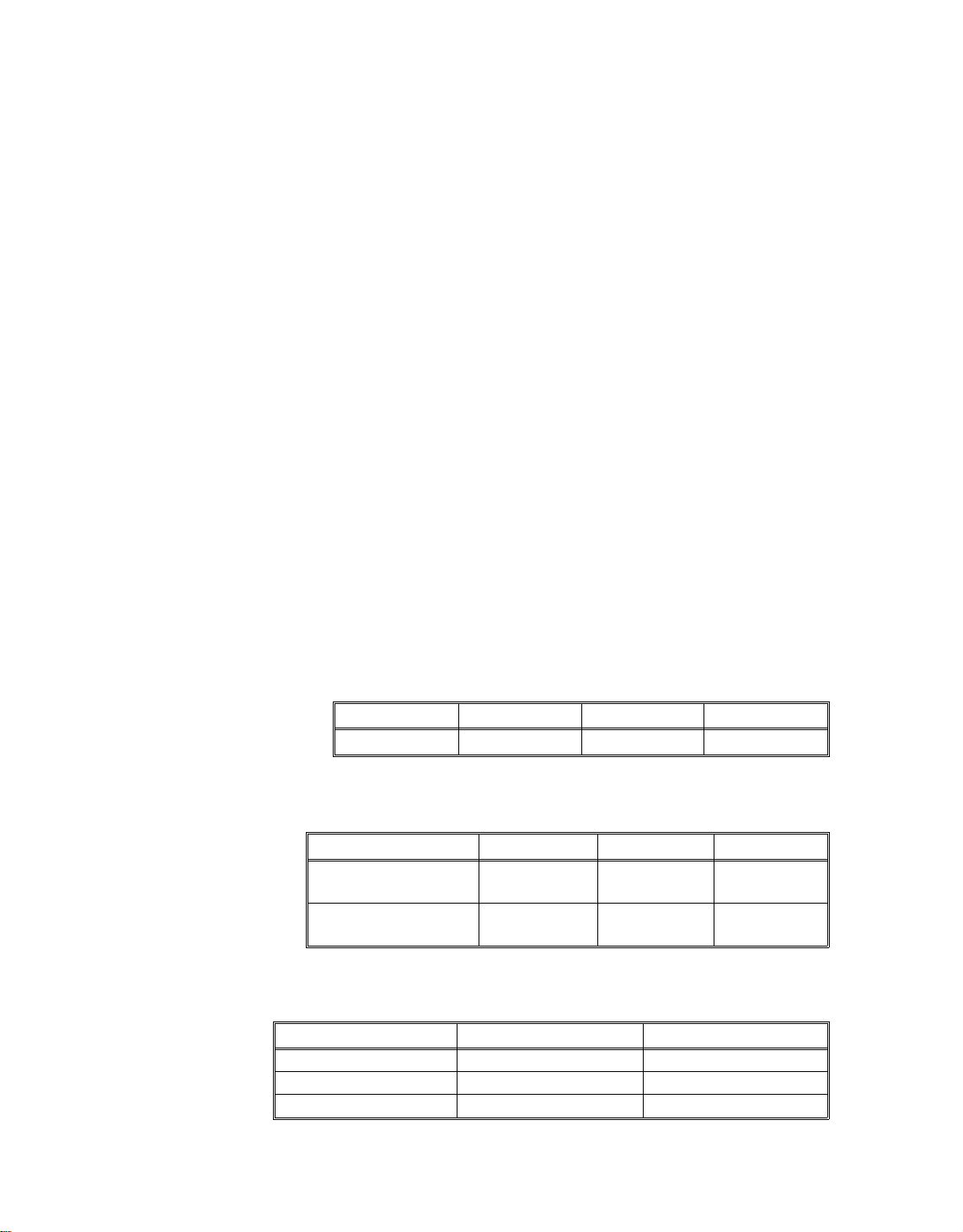

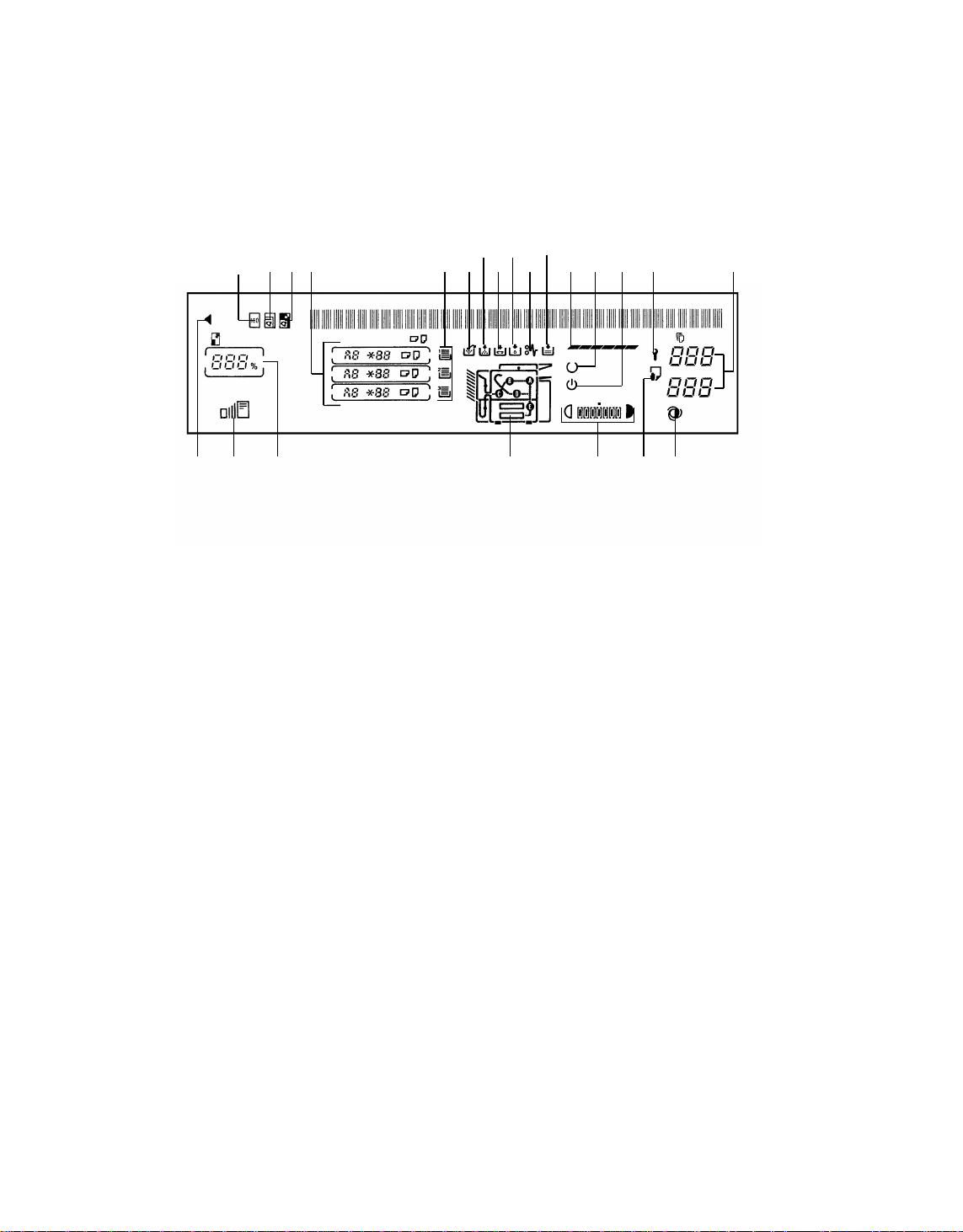

2.2 OPERATION PANEL

2.2.1 Keys and Indicators for Basic Functions

A4/A3 Version

34567

21 171820 19

16

1. Guidance Indicator

Lights when in guidance mode.

2. Guidance Key

Press to select guidance mod e.

3. Enter Key

Use to enter or change data in

selected modes.

4. Program Indicator

Lights when the copier is in user

program mode.

5. Program key

Press to input or recall user

program.

6. Timer Indicator

Lights when the mach ine has been

turned off by the weekly timer or

automatic shut-off timer.

15

14

12

891011

7. Timer Key

Press to operate the copier after it

has been turned off by the weekly

timer or automatic shut-off timer.

8. Clear Modes Key

Press to clear the copier of

previously entered settings and

modes.

9. Start Key

Press to start copying.

10. Interrupt key

Press to make interrupt copies

during a copy run.

11. Interrupt Indicator

Lights when interrupt mo de is

selected.

12. Clear/Stop Key

Press to cancel the copy number.

While copying press to stop

copying.

1-6

Page 8

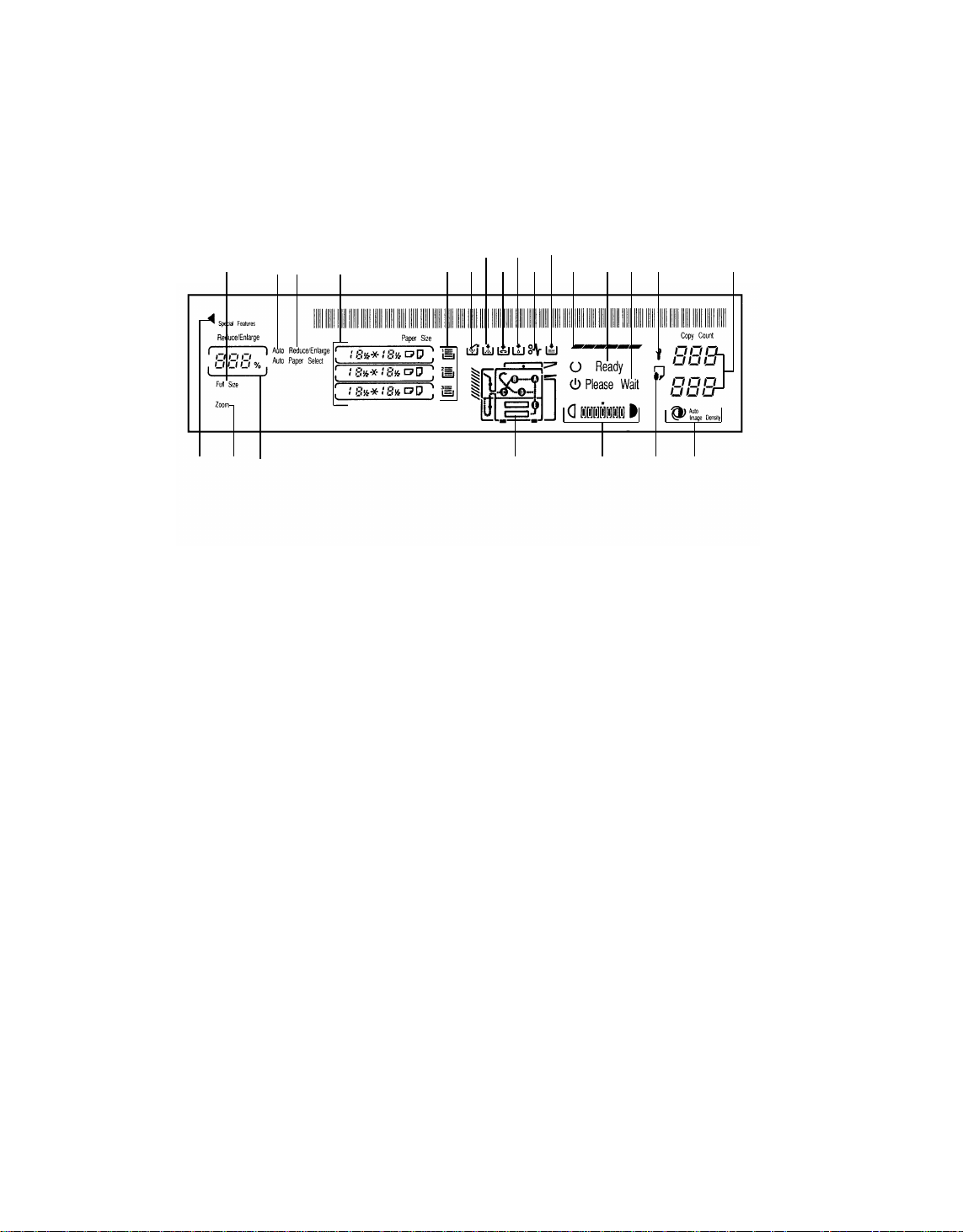

LT/DLT Version

2

1

13

30 November 1990

34567

21 171820 19

16

13. Decimal Point Key

Use to input data for selected

modes.

14. Number Keys

Use to enter the desired number of

copies. They are also used to en te r

data for selected modes.

15.Auto Image Density Key

Press to select/cancel aut oma tic

image density mode.

16. Manual Image Density Keys

Use to cancel automatic control and

manually select the image density

level.

15

14

12

11

910

8

17. Auto Paper Select Key

Press to select/cance l aut o pa pe r

select mode.

18. Select Cassette Key

Press to select a cassette for paper

feed.

19. Full Size Key

Press to make the copy image s the

same size as these of the orig ina ls.

20. Enlarge Key

Press to make enlarged copies.

21. Reduce Key

Press to make reduced cop ies.

1-7

Page 9

17

30 November 1990

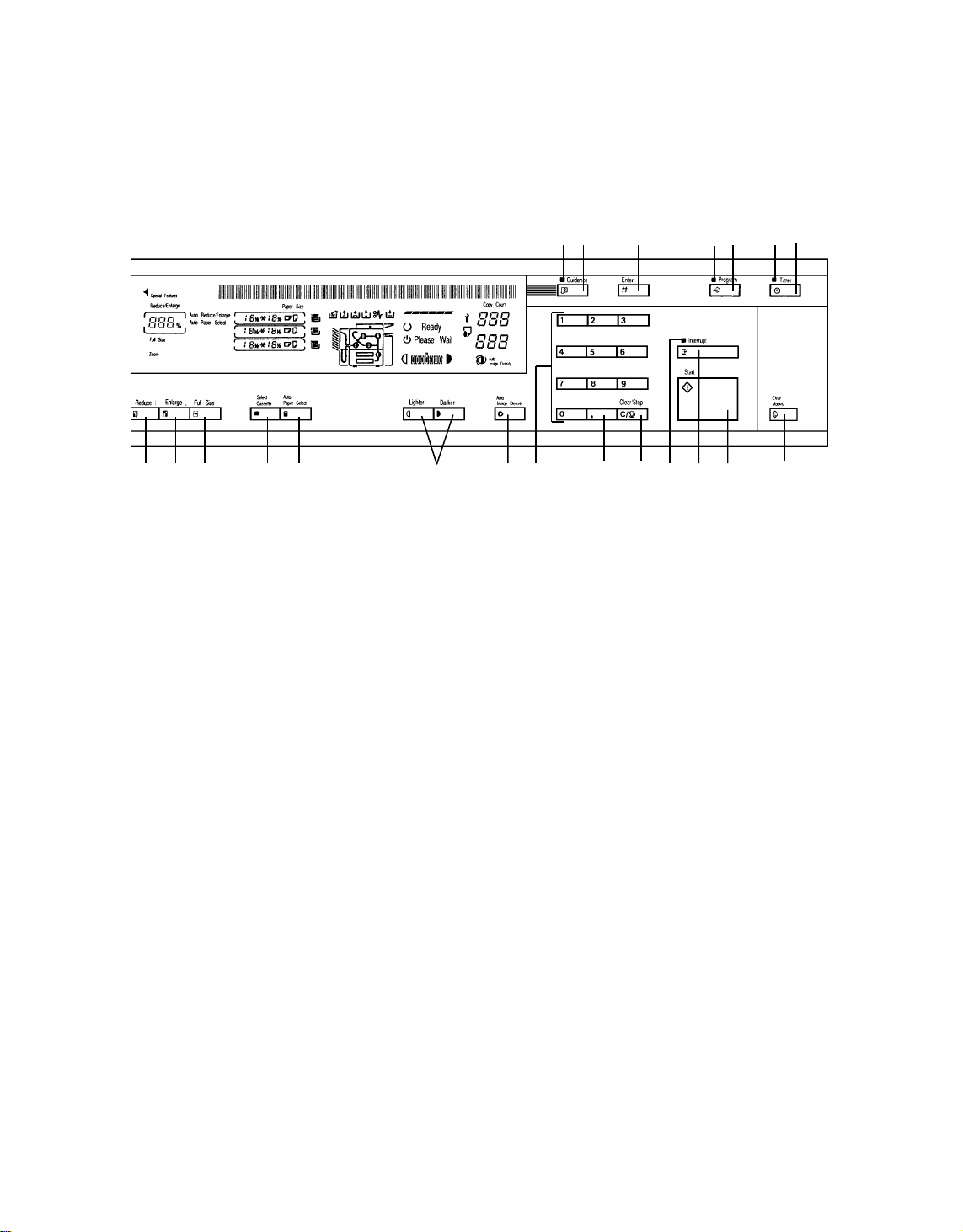

2.2.2 Keys and Indicator for Special/Optional Functions

A4/A3 Version

56

7

8

910111213

4

3

14

1

2

1. Staple Key

Press to select one of three staple

modes. (Optional recycling

document handler and finisher are

required.)

2. Staple Indicators

Show which staple mode is

selected.

3. Sorter Key

Press to select sort or stack mode.

(Optional sorter, or finishe r and

recycling document handler are

required.)

4. Stack Indicator

Lights when in stack mode.

5. Sort Indicator

Lights when in sort mode.

6. Duplex Indicators

Show which duplex mode is

selected.

22

23 21

7. Duplex Key

Press to select one of three duplex

modes.

8. Margin Adjustment Indicator

Lights when margin adjust men t

mode is selected.

9. Margin Adjustment Key

Press to set the margin on copy.

10. Centering lndicator

Lights when cente ring mode is

selected.

11. Centering Key

Press to vertically center an original

image on a copy.

12. Size Magnification Indicator

Lights when size magnificat ion

mode is selected.

20

19

18

16

15

1-8

Page 10

LT/DLT version

3

4

567

30 November 1990

8

910111213 14

12

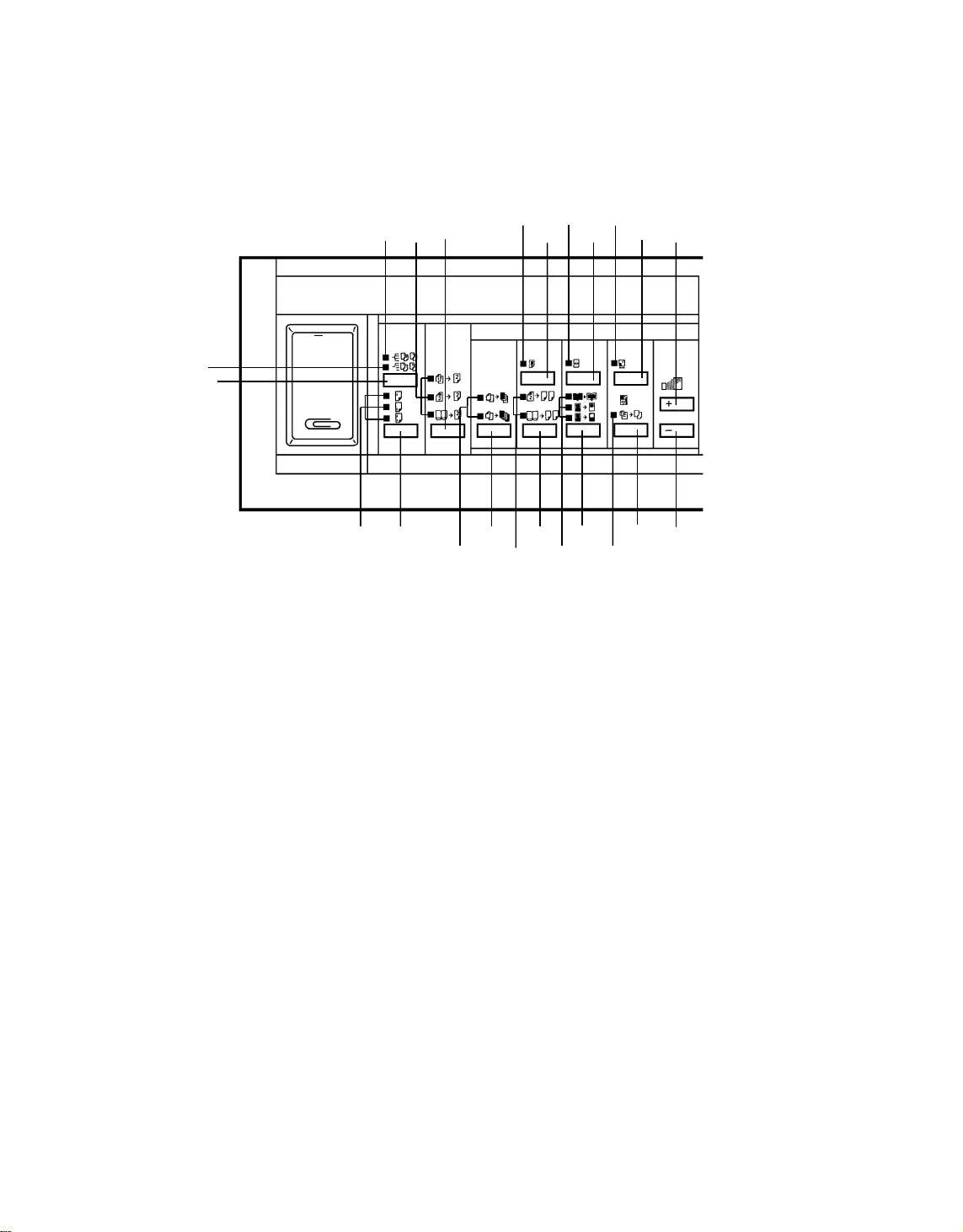

13. Size Magnification Key

Press to select size magnification

mode.

14. Zoom Up Key

Press to increase the rep rod uction

ratio in 1% steps.

15. Zoom Down Key

Press to reduce the reproduction

ratio in 1% steps.

16. Auto Reduce/Enlarge Key

Press to select auto reduce /enlarge

mode.

17. Auto Reduce/Enlarge

Indicator

Lights when auto redu ce/enlarge

mode is selected.

18. Edit Image Key

Press to select one of three edit

image modes.

22

23 21

20

19

17

151618

19. Edit Image Indicators

Show which edit image mode is

selected.

20. Series Copies Key

Press to make copies from book

originals or 2-sided originals.

21. Series Copies Indicators

Show which series copies mode is

selected.

22. Cover Insertion Key

Press to select cover insertion

mode. (Optional document feeder

and sorter, or recycling document

handler and finisher are require d. )

23. Cover Insertion Indicators

Show which cover insertion mode is

selected.

1-9

Page 11

15

17

30 November 1990

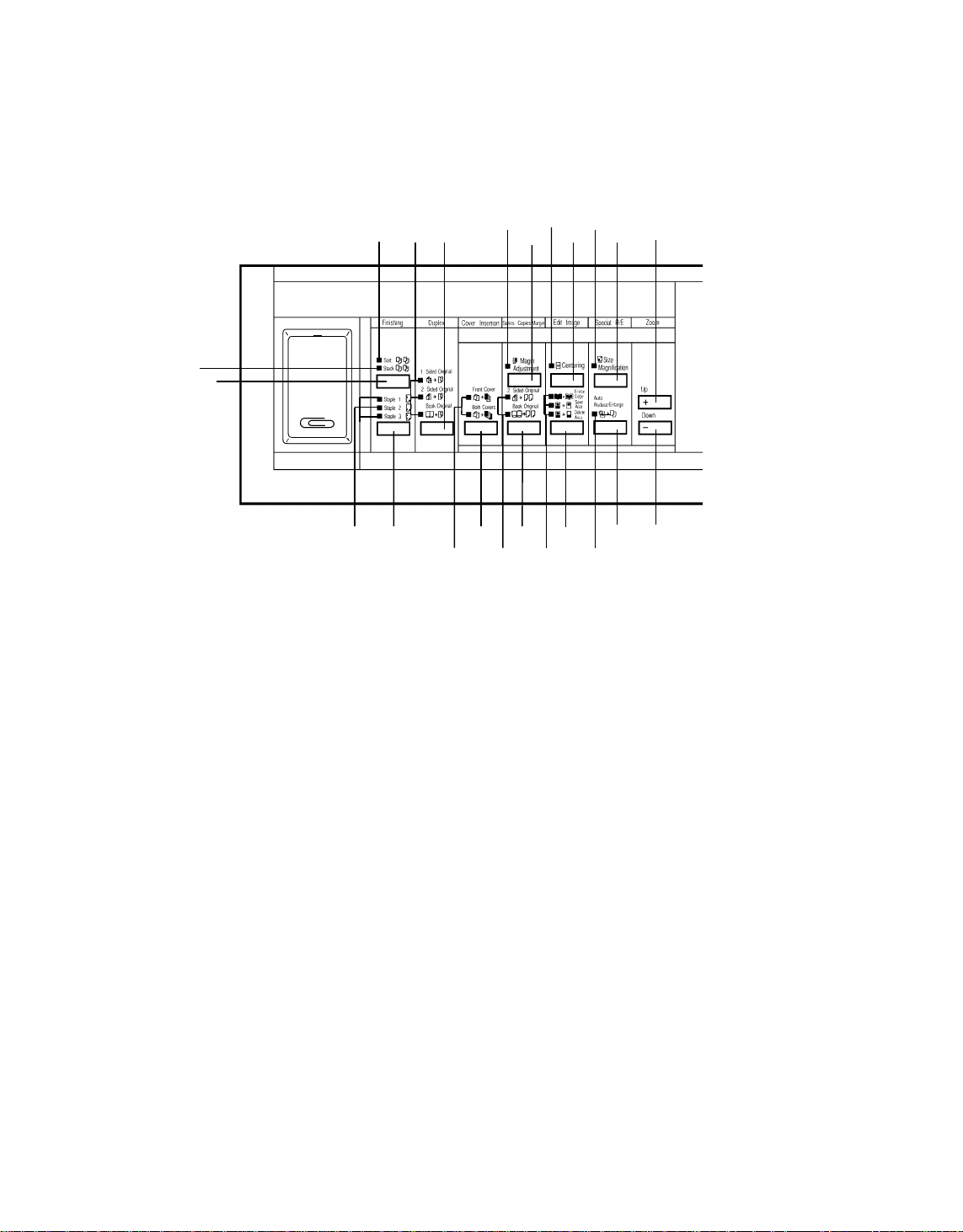

2.2.3 Indicator Screen

A4/A3 version

1234 5678910111213 14

1. Full Size Indicator

Lights when full size mode is selected.

2. Auto Paper Select Indicator

Lights when auto pap er sele ct

mode is selected.

3. Auto Reduce/Enlarge Indicator

Lights when auto redu ce/enlarge

mode is selected.

4. Paper Size Indicators

Show the size and direction of the

paper.

5. Paper Volume Indicators

When the amount of paper remaining in cassettes.

6, Used Toner Bottle Indicator

Lights when the use d toner bottle is

full. Call your service representative.

16

181920212223

7. Add Toner Indicator

Blinks when it is time to change the

toner bottle. When it is continuously

lit, the copier cannot be used until a

new bottle is installed.

8. Add Staple Indicator

Lights when the staple cartridge

runs out of staples.

9. Add Oil Indicator

Lights when the silicone oil level

gets too low. Add silicone oil to the

bottle.

10. Check Paper Path Indicator

Lights if there is a misfeed within

the machine.

11. Load Paper Indicator

Lights when the cassette or tray in

use runs out of paper.

1-10

Page 12

LT/DLT version

15

17

18

1234 56

7

91011

8

12 1314

1920212223

30 November 1990

16

12. Copy Cycle Indicator

Displays the stage of the copy cycle

in progress.

13. Ready Indicator

Lights when the mach ine is ready to

make copies.

14. Wait Indicator

Lights when the mach ine is not

ready to copy.

15. Call Service Indicator

Lights when there is a funct ional

problem within the machine . Call

your service representative .

16. Copy Counter

(Upper) Displays the number of

copies entered.

(Lower) While copying, it sho ws the

number of copies made.

17. Auto Image Density Indica tor

Lights when the copier is

automatically controlling the image

density.

18. By-pass Feed Indicator

Lights when the by-pass feed table

is open.

19. Manual Image Density

Indicator

Shows the manually selected image

density.

20. Misfeed Location Display

Shows the location(s) of misfed

paper.

21. Magnification Ratio Indicator

Shows the selected rep rod uction

ratio.

22. Zoom Indicator

Lights when in zoom mode.

23. Special Features Indic ator

Lights when special/optional

function is selected.

1-11

Page 13

DEVELOPMENT

30 November 1990

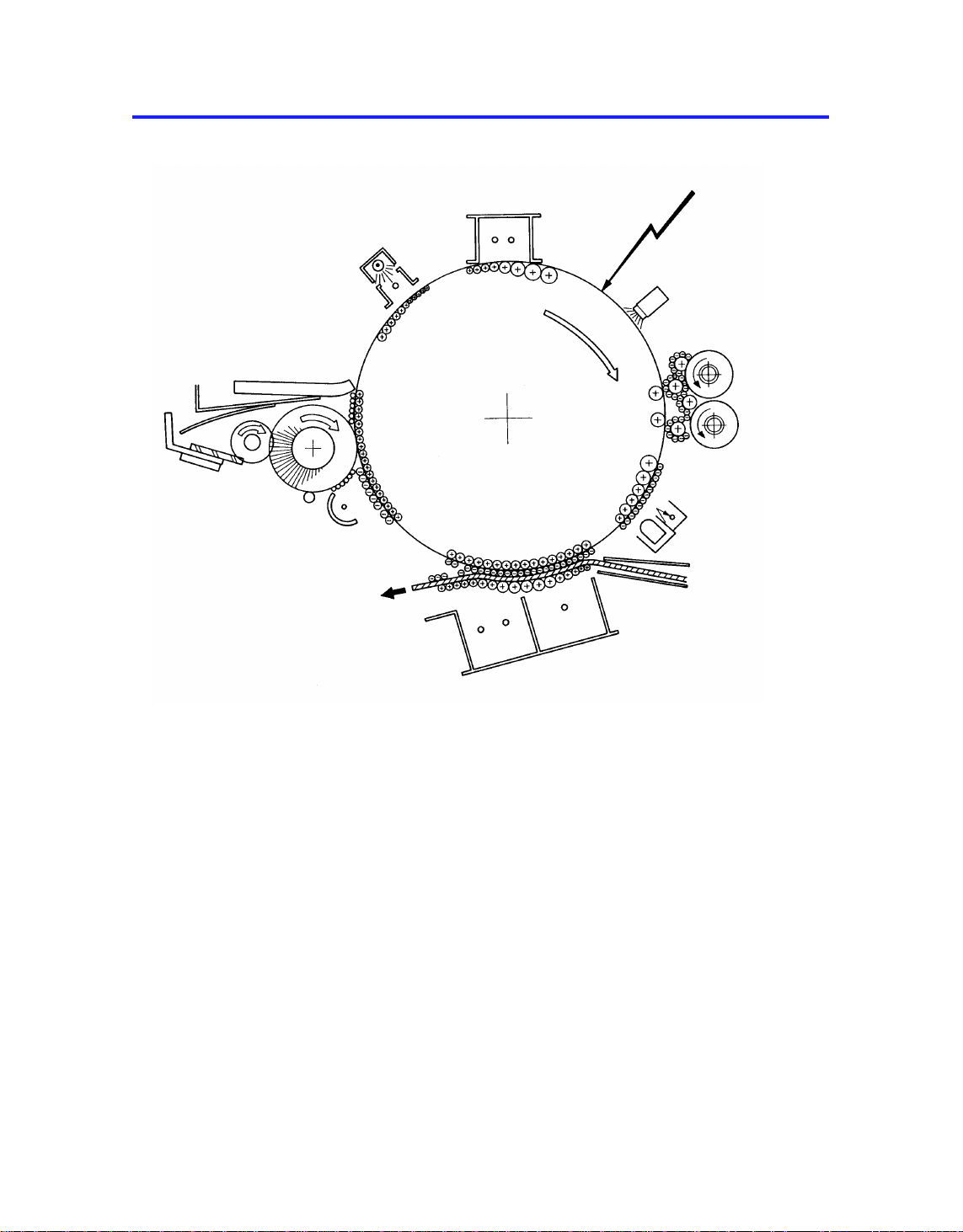

3. COPY PROCESSES AROUND THE DRUM

EXPOSURE

DRUM CHARGE

QUENCHING

CLEANING

PRE-CLEANING

PAPER SEPARATION

ERASE

PRE-TRANSFER

LAMP (PTL)

IMAGE TRANSFER

DRUM CHARGE

In the dark, the charge corona unit gives a uniform positive charge to the

selenium drum. The charge rema ins on the surface of the drum because the

photo conductive seleniu m has ele ctrical resistance in the dark.

EXPOSURE

An image of the original is reflected to the selenium drum surface via the

optics assembly. The charge on the drum surface is dissipated in direct

proportion to the intensity of the reflected light, thus producing an elect rical

latent image on the drum surface.

ERASE

The erase lamp illuminates the areas of th e cha rge d dru m su rfa ce th at will

not be used for the copy image. The resistance of the drum in the illuminated

areas drops and the charge on those areas dissipates.

1-12

Page 14

30 November 1990

DEVELOPMENT

Negatively charged toner is attract ed to the positive ly charg ed area s of the

drum, thus developing the late nt image . (The negat ive tu rbo electric charge is

caused by friction between the carrier and toner pa rticle s.)

PRE-TRANSFER LAMP (PTL)

The PTL illuminates the drum to remove all positive charge from the exposed

areas of the drum. This prevents th e tone r particles from being reattracted to

the drum surface during paper separation and makes paper separation

easier.

IMAGE TRANSFER

Paper is fed to the drum surface at the prop er time so as to align the copy

paper and the develope d image on the drum surface. Then, a stron g po sitive

charge is applied to the back side of the copy pape r, pro viding an electrical

force which pulls the toner particles from the drum surface to the copy paper.

At the same time, the copy paper is electrically attracted to the drum surfa ce.

PAPER SEPARATI ON

A strong ac corona discharge is applied to the back side of the cop y pap er,

reducing the positive cha rge on the copy paper and breakin g th e electrical

attraction betwee n the paper and the drum. Then, th e stiffness of the copy

paper causes it to separate fro m the drum surf ace . The pick-off pawls help to

separate paper which has low stiffness.

PRE-CLEANING

The pre-cleaning corona (PCC) a pplies an ac coron a with a negat ive bia s to

the drum. This removes the positive cha rge from the drum and makes the

negative charge on the toner remaining on the dru m even .

CLEANING

The cleaning brush remo ves most of the toner on the drum and loosens the

remainder. Then, the bias roller, which has a positive potential, attracts the

toner particles from the cleaning brush to keep it clean. Finally, th e clea nin g

blade scrapes off th e loosened toner.

QUENCHING

The pre-quenching corona applies a positive corona cha rge to th e selenium

drum to eliminate any negative charge remainin g from t he pre-cle aning

corona. Then, light fro m the quench ing lamp electrically neutralizes the drum .

1-13

Page 15

30 November 1990

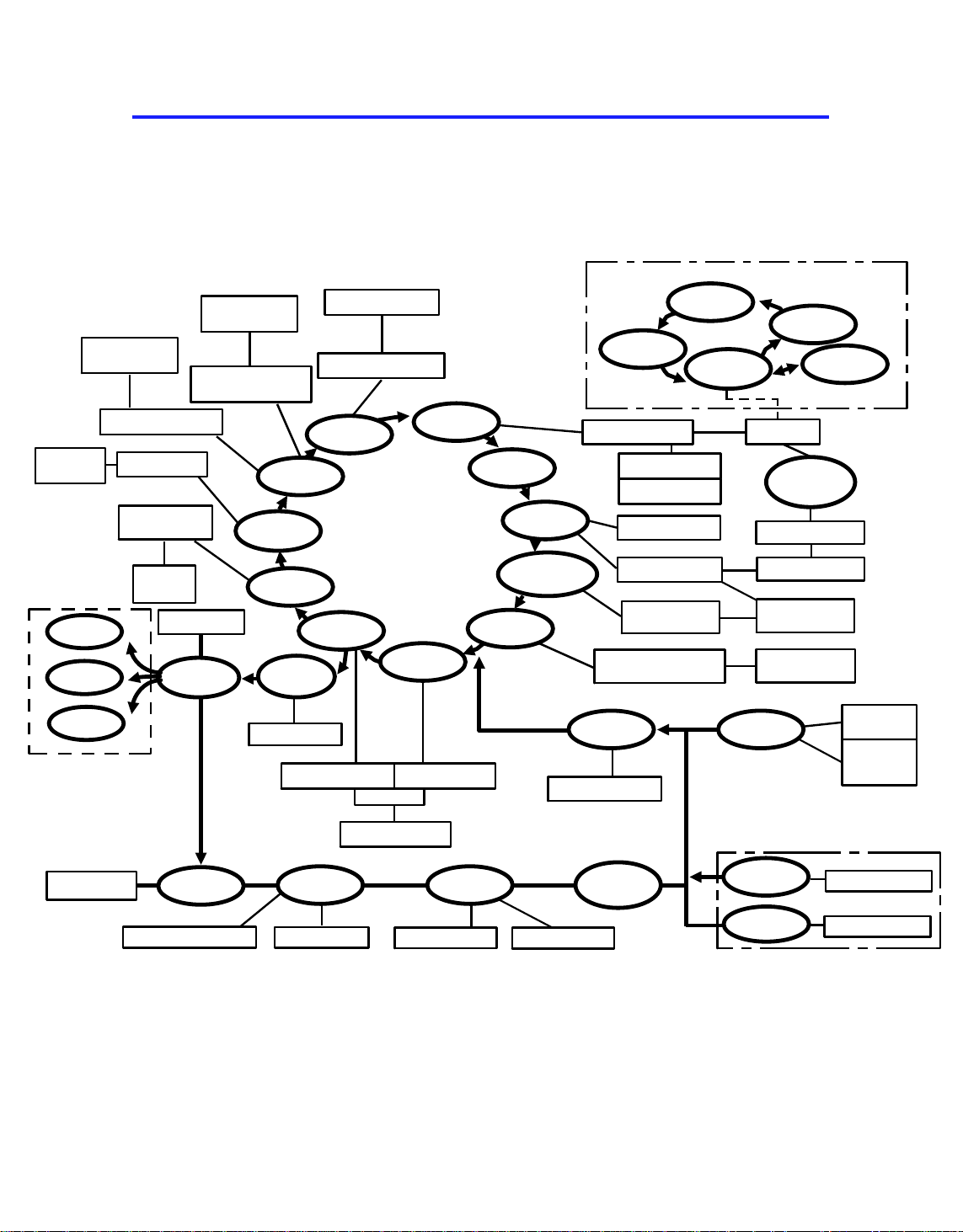

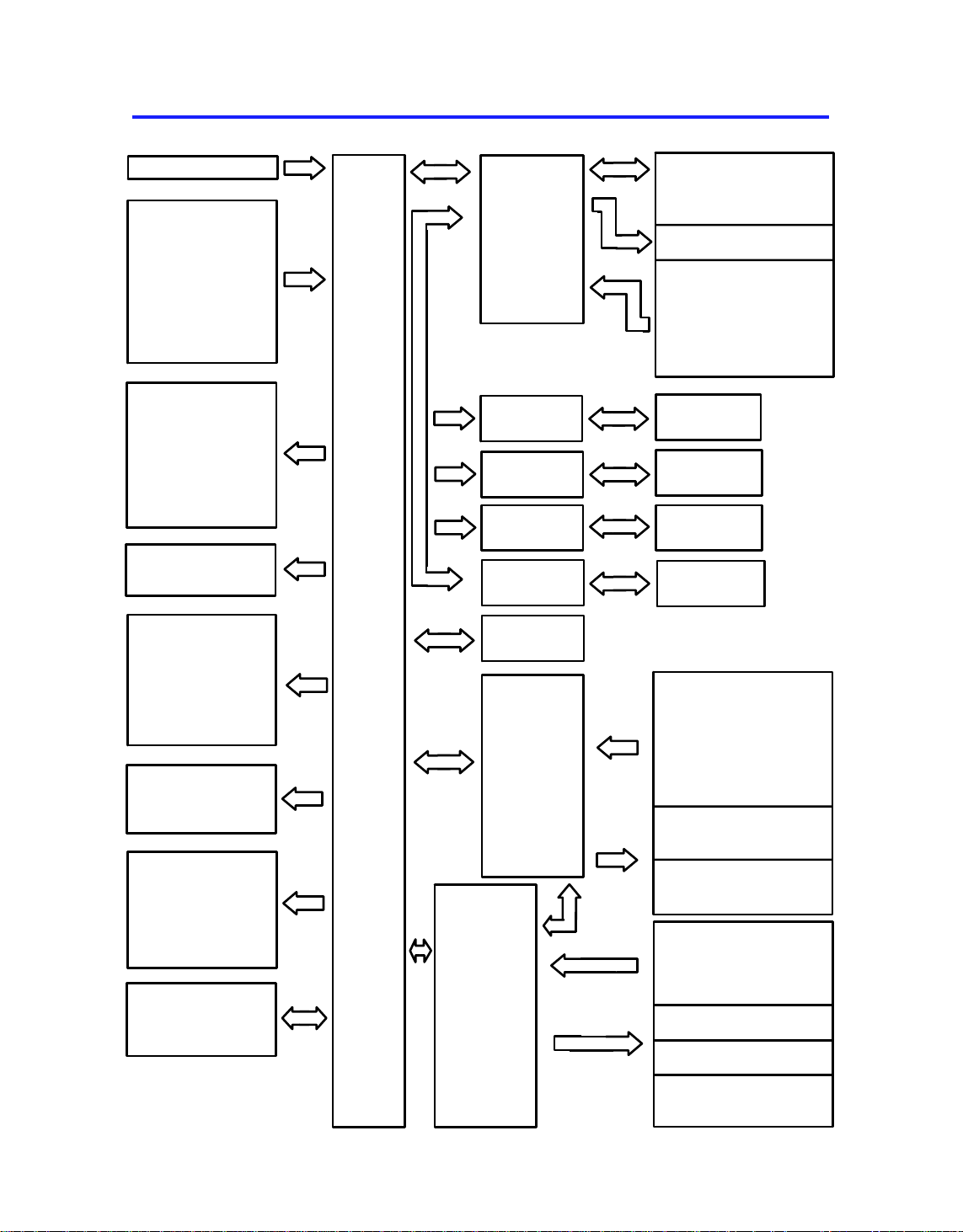

4. COPY CYCLE

RDH/ARDF

Lamp Stabilizer

Power Pack

PQC/CB

Finisher/Sorter

Sort

Stack

Staple

Q/PTL

QL (Cathode Tube)

Cleaning Unit

Pre-Cleaning

Corona

Power

Pack-PCC

Fusing Unit

Image

Fusing

Power Pack

PQC/CB

Pre-Quenching

Charge Unit

Cleaning

Transport Unit

Power Pack-C/B

Charge Corona Unit

Drum Charge

Quenching

PCC

Paper

Separation

Paper

Transport

Separation Corona

Exposure

Image

Transfer

Transfer Corona

Erase

Development

Toner Density

Detection

PTL

Original

Feed-in

Optics Assembly

ID Sensor Pattern

VL sensor Pattern

Erase Lamp Unit

Development Unit

Image Density

Sensor

PTL

(Cold Cathode Tube)

Registration

Registration Roller

Original

Stacking

Original

Positioning

Original

Auto-ID Sensor

Power Pack-C/B

Toner Supply

Mechanism

Lamp Stabilizer

Q/PTL

1st

Paper Feed

Original

Feed-out

Original

Density

Detection

Original

Inversion

Manual

Feed Table

Large

Capacity

Tray

Inverter

Mechanism

Inversion

Duplex Transport Unit

Duplex

Transport

Fork Gate Unit

Power Pack-T/S

Delivery Tray

Duplex

Stacking

1-14

Jogger Unit

Duplex Paper

Feed

Cassette Bank

2nd

Paper Feed

3rd

Paper Feed

Cassette

Cassette

Page 16

30 November 1990

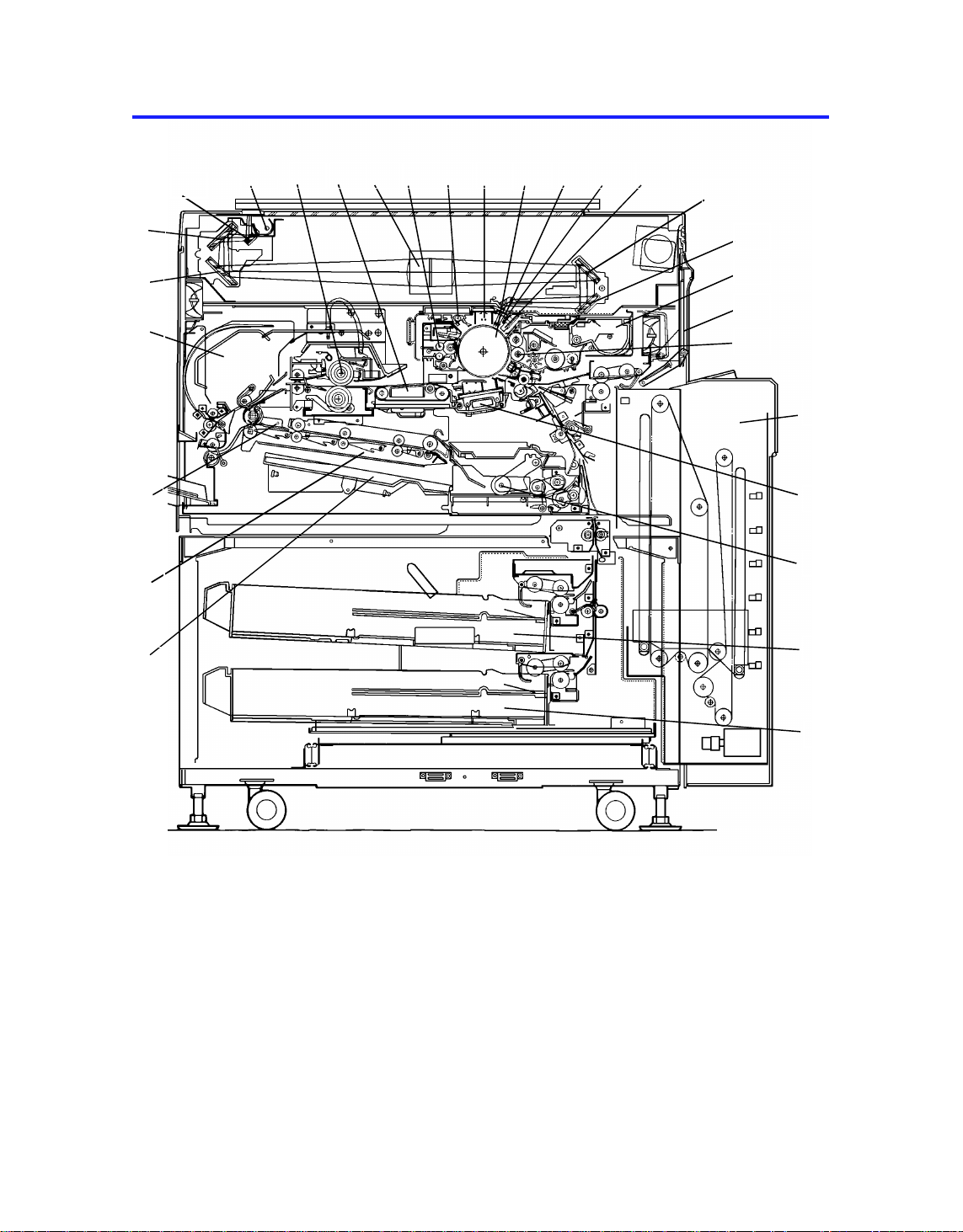

5. MECHANICAL COMPONENT LAYOUT

3

2

1

28

27

26

4

5 6 7 8109

11 12 13 14 15

16

17

18

19

20

21

22

23

24

1. Inverter Unit

2. Third Mirror

3. Second Mirror

4. First Mirror

5. Exposure Lamp

6. Fusing Unit

7. Transport Unit

8. Lens

9. Cleaning Unit

10. Quenching Unit

11. Charge Corona Unit

12. Drum

13. Toner Shield Glass

14. Sixth Mirror

25

15. Erase Lamp Unit

16. Fourth Mirror

17. Fifth Mirror

18. Toner Tank

19. Manual Feed Table

20. Development Unit

21. Large Capacity Tray

22. T/ S Corona Unit

23. Jogger Unit

24. Third Cassette

25. Second Cassette

26. Duplex Delivery Tray

27. Fork Gate Unit

28. Duplex Transport Unit

1-15

Page 17

30 November 1990

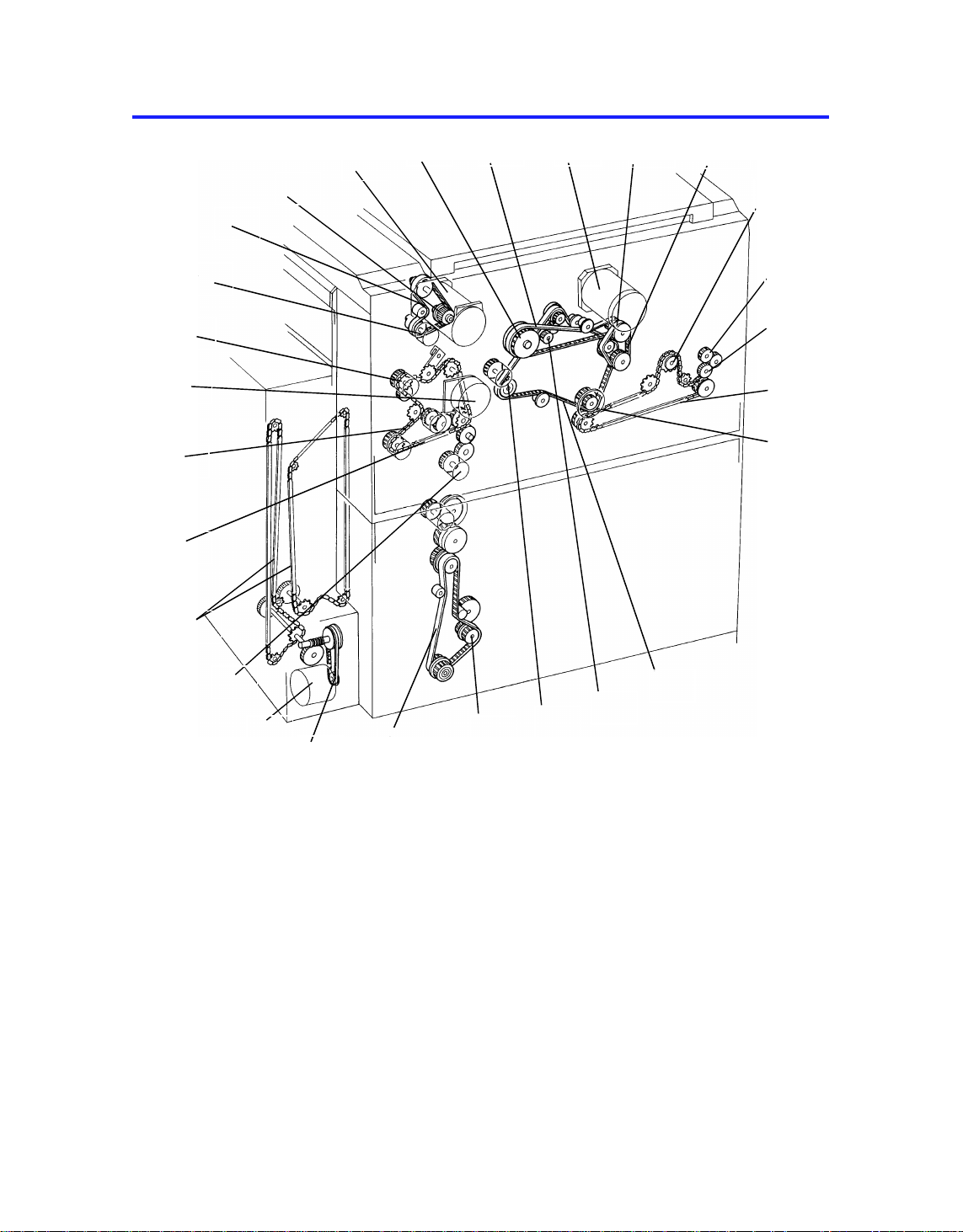

6. DRIVE LAYOUT

26

25

24

23

22

27

3

4

2

1

5 6

7

8

9

10

11

12

13

21

20

19

1. Development Drive Belt

2. Development Drive Gear

3. Development Motor

4. Drum Drive Pulley

5. Drum Drive Belt

6. Main Motor

7. Fusing/Duplex Drive Gear

8. Main drive Belt

9. Exit relay Roller Drive Sprocket

10. Inverter Roller Drive Gear

11. Exit Roller Drive Gear

12. Exit Drive Chain

13. Pulse Generator Drive Pulley

18

14

17

16

14. Registration Roller Drive Belt

15. Cleaning Drive Gear

16. Registration Clutch

17. 3rd Paper Feed Drive Gear

18. Cassette Bank Drive Belt

19. LCT Bottom Plate Drive Belt

20. LCT Motor

21. Duplex Paper Feed Clutch

22. LCT Bottom Plate Drive Chains

23. Relay Roller Clutch

24. Paper Feed Drive Chain

25. Paper Feed Motor

26. 1st Paper Feed Clutch

27. Toner Supply Clutch

15

1-16

Page 18

21

30 November 1990

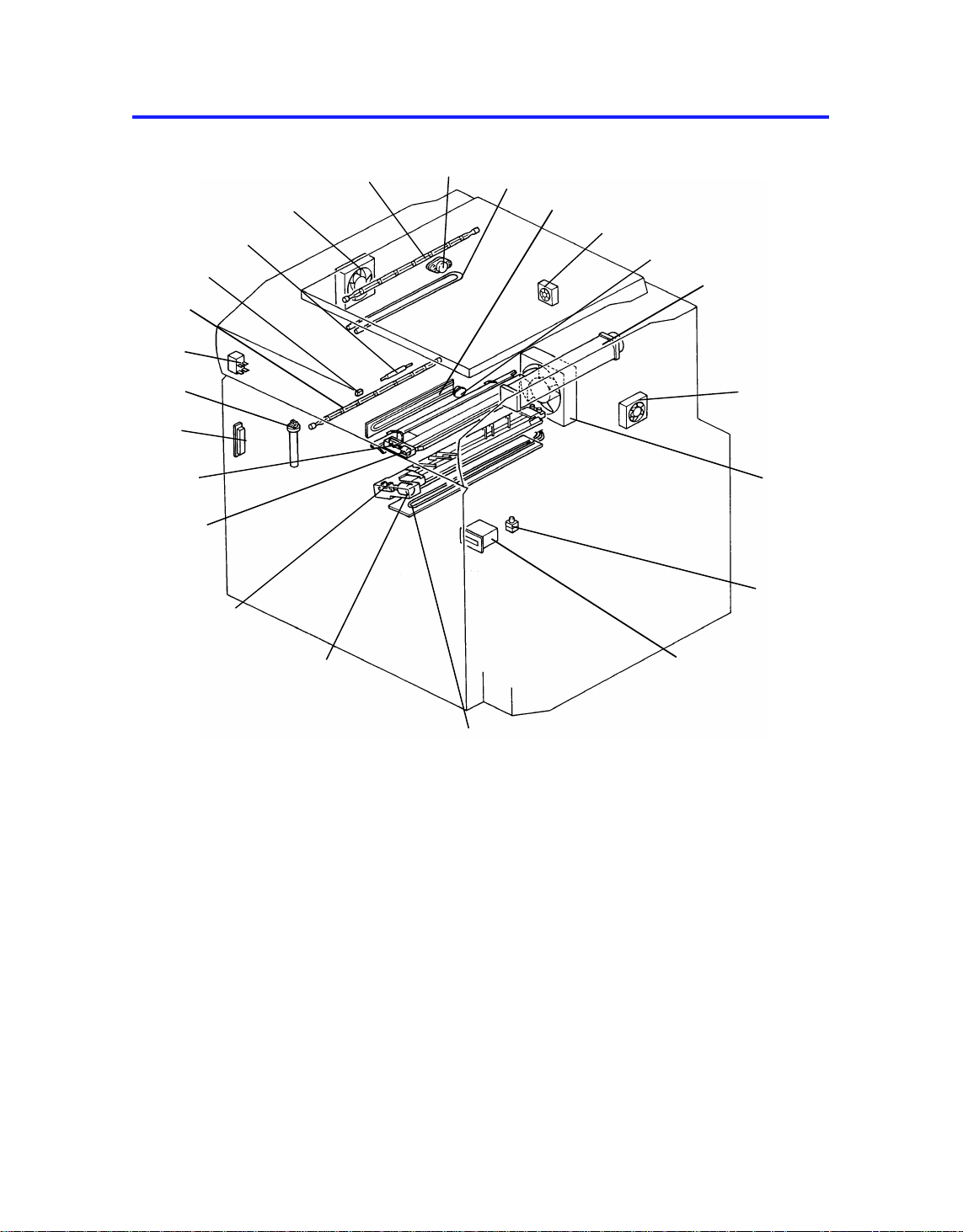

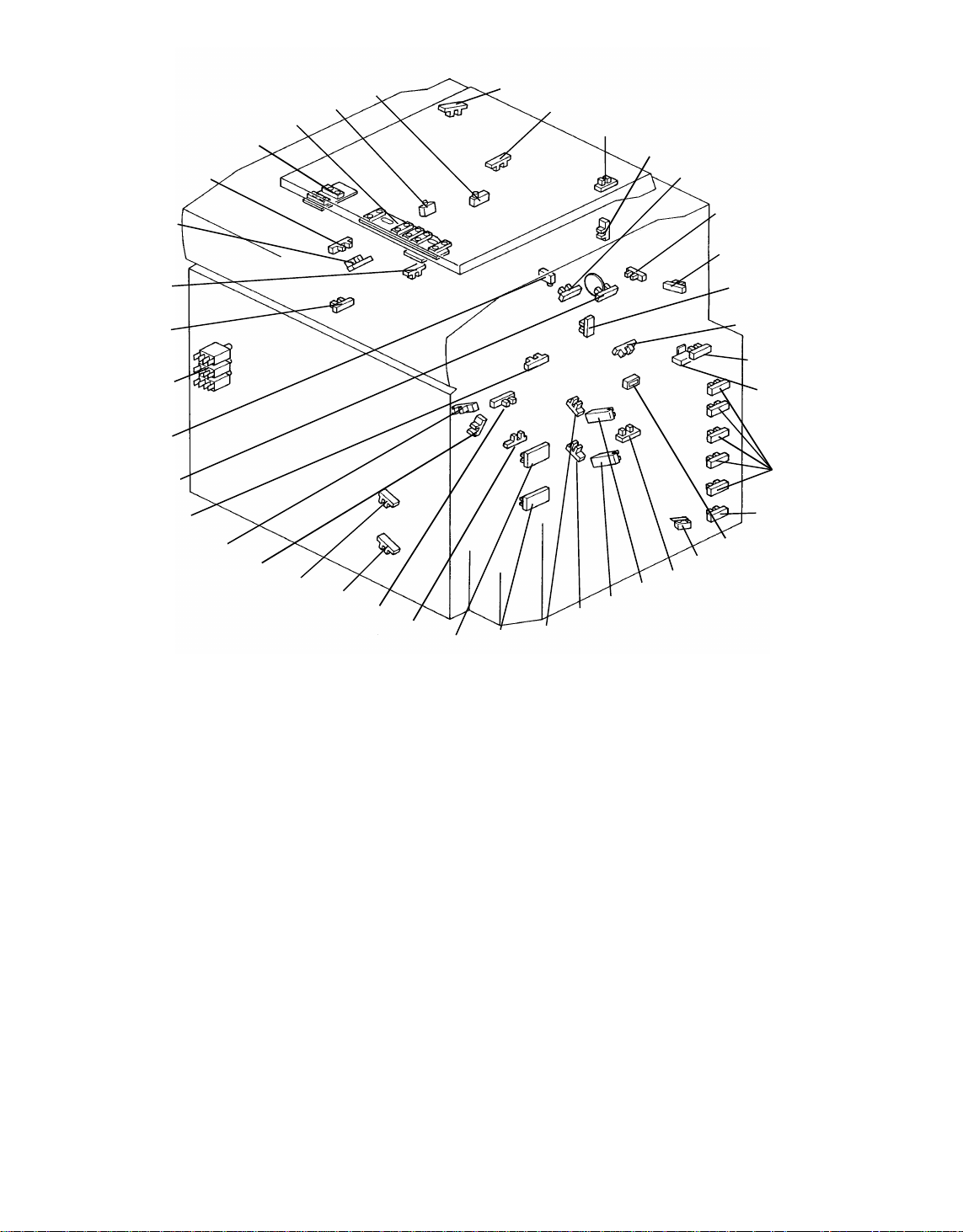

7. ELECTRICAL COMPONENT LAYOUT

23

22

1

20

19

5

4

3

2

18

6

7

8

9

10

11

12

13

14

17

1. Fusing Lamp

2. Fusing Thermistor

3. Thermofuse

4. Fusing Exhaust Fan Motor

5. Exposure Lamp

6. Optics Thermoswitch

7. Anticondensation Heater

8. Cleaning Heater

9. Charge Fan Motor

10. Cleaning Thermoswitch

11. Cooling Blower Motor

12. Development Cooling Fan Motor

13. Vacuum Fan Motor

15

16

14. LCT Down Switch

15. Total Counter

16. Drum Heater

17. SC Cleaner Motor

18. SC Cleaner Home Position

Sensor

19. CC Cleaner Motor

20. CC Cleaner Home Position

Sensor

21. Printer Connector (RS232C)

22. Oil End Se nsor

23. Main switch

1-17

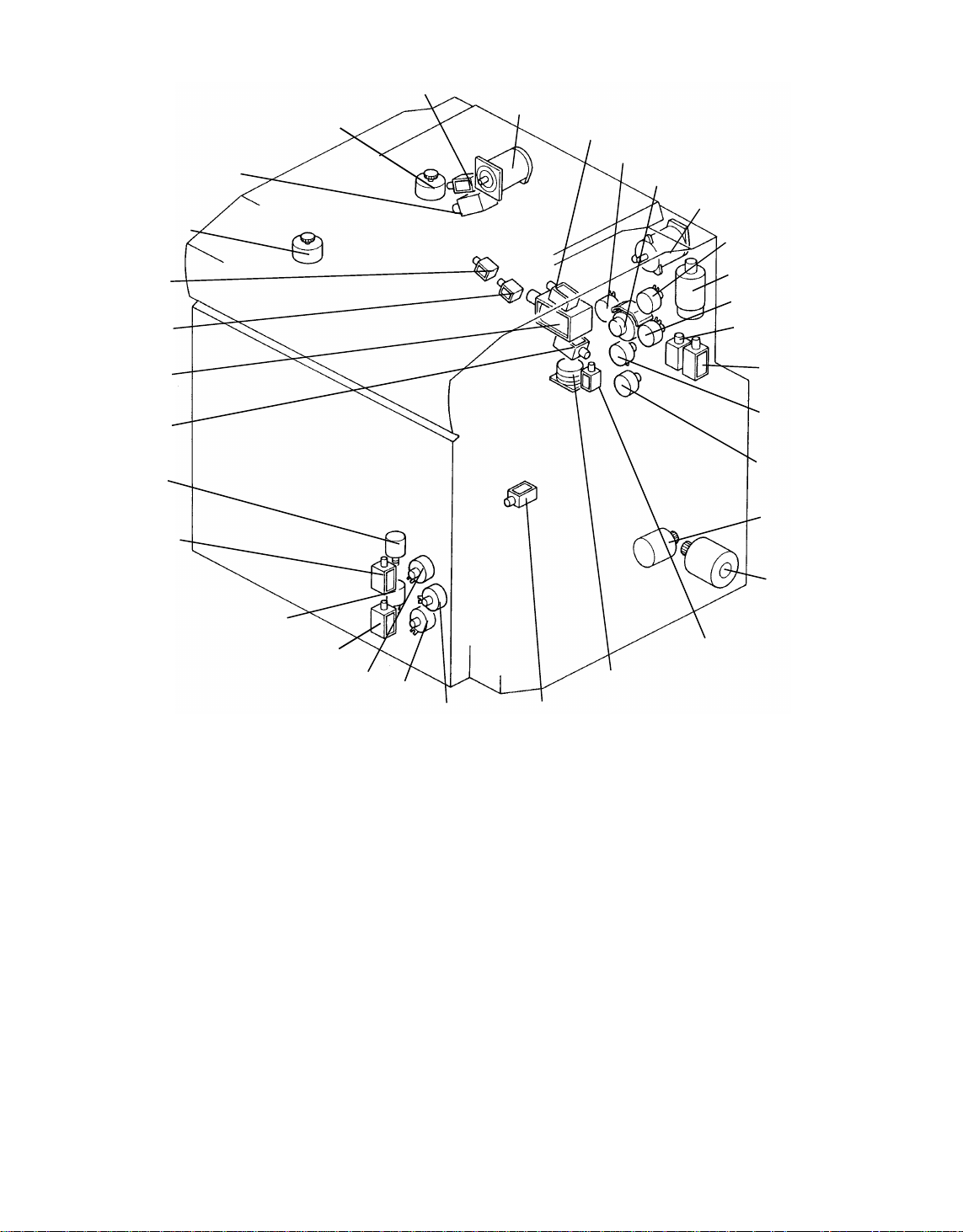

Page 19

30 November 1990

25

26

27

28

29

30

31

32

55

54

53

52

51

50

24

49

48

47

46

45

33

34

35

36

37

38

39

40

41

42

43

44

24. 4th and 5th Mirror Drive Motor

25. Junction Gate Sol.

26. Lens Drive Motor

27. Inverter Pressure Sol.

28. Main Motor

29. Pick-off Sol.

30. Registration MC

31. Paper Feed Motor

32. Development Motor

33. Toner Supply MC

34. Scanner Drive Motor

35. 1st Paper Feed MC

36. 1st Pick-up Sol.

37. Manual Feed Pick-up Sol.

38. 1st Feed Relay MC

39. Duplex Paper Feed MC

40. Cassette Bank Drive Motor

41. LCT Motor

42. Duplex Positioning Roller Sol.

43. Jogger Motor

44. Duplex Stopper Sol.

45. 2nd Feed Relay MC

46. 3rd Paper Feed MC

47. 2nd Paper Feed MC

48. 3rd Pick-up Sol.

49. 3rd Lift Motor

50. 2nd Pick-up Sol.

51. 2nd Lift Motor

52. Duplex Pick-up Sol.

53. Cleaning Sol.

54. Fork Gate Sol. 2

55. Fork Gate Sol. 1

1-18

Page 20

30 November 1990

85

84

83

82

81

86

80

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

79

78

56. Power Pack-CC/Bias

57. Power Pack-PQC/Cleaning

Bias

58. Erase Lamp

59. Bias Thermister

60. Drum Thermister

61. Registration Sensor

62. Operation Panel PCB

63. Image Density Sensor PCB

64. Pre-transter Lamp

65. Quenching Lamp

66. PTL/QL Stabilizer

67. Fusing Cooling Fan

68. Power Pack-PCC

69. Main Motor PCB

70. Optics PCB

77

73

74

75

76

71. Main PCB

72. AC Drive PCB

73. Memory Board

74. Circuit Breaker

75. Noise Filter

76. Main Transformer

77. Power Relay

78. Condition Relay

79. DC Power Supply PCB

80. Cassette Bank PCB

81. SSR PCB

82. Power Pack-T/S

83. Toner Overflow Sensor

84. Paper Feed PCB

85. Development Motor PCB

86. Paper Feed Motor PCB

1-19

Page 21

105

30 November 1990

90

89

88

87

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

87. Original Width Sensor

88. Original Length Sensor

89. Auto Density Sensor

90. Fork Gate Unit Safety Switch

91. Lens Home Position Sensor

92. Scanner Home Position Sensor

93. Scanner VL Position Sensor

94. 4th/5th Mirror Home

Position Sensor

95. Duplex Entrance Sensor

96. Toner End Sensor

97. 1st Lift Sensor

98. Jogger Home Position Sensor

99. 1st Relay Sensor

100. LCT Cover Sensor

101. LCT Cover Switch

102. 1st Paper Volume

103. LCT Lower Limit Sensor

104. Paper Position Sensor

105. LCT Lower Limit Safety Switch

91

92

93

94

95

96

97

98

99

104

106

107

108

109

110

111

106. 3rd Relay Sensor

107. 2nd Paper Volume Sensor

108. 3rd Paper Volume Sensor

109. 3rd Paper End Sensor

110. 2nd Paper End Sensor

111. 3rd Paper Size Sensor

112. 2nd Paper Size Sensor

113. 2nd Relay Sensor

114. Manu al Fee d Sensor

115. 3rd Lift Sensor

116. 2nd Lift Sensor

117. 1st Paper End Sensor

118. Manual Paper End Sensor

119. Duplex Paper Sensor

120. Pulse Generator

121. Transport Unit Safety Swit ch

122. Front Door Safety Switch

123. Exit Sensor

124. Fusing Exit Sensor

125. Exit Relay Sensor

126. Inverter Exit Sensor

100

101

102

103

1-20

Page 22

30 November 1990

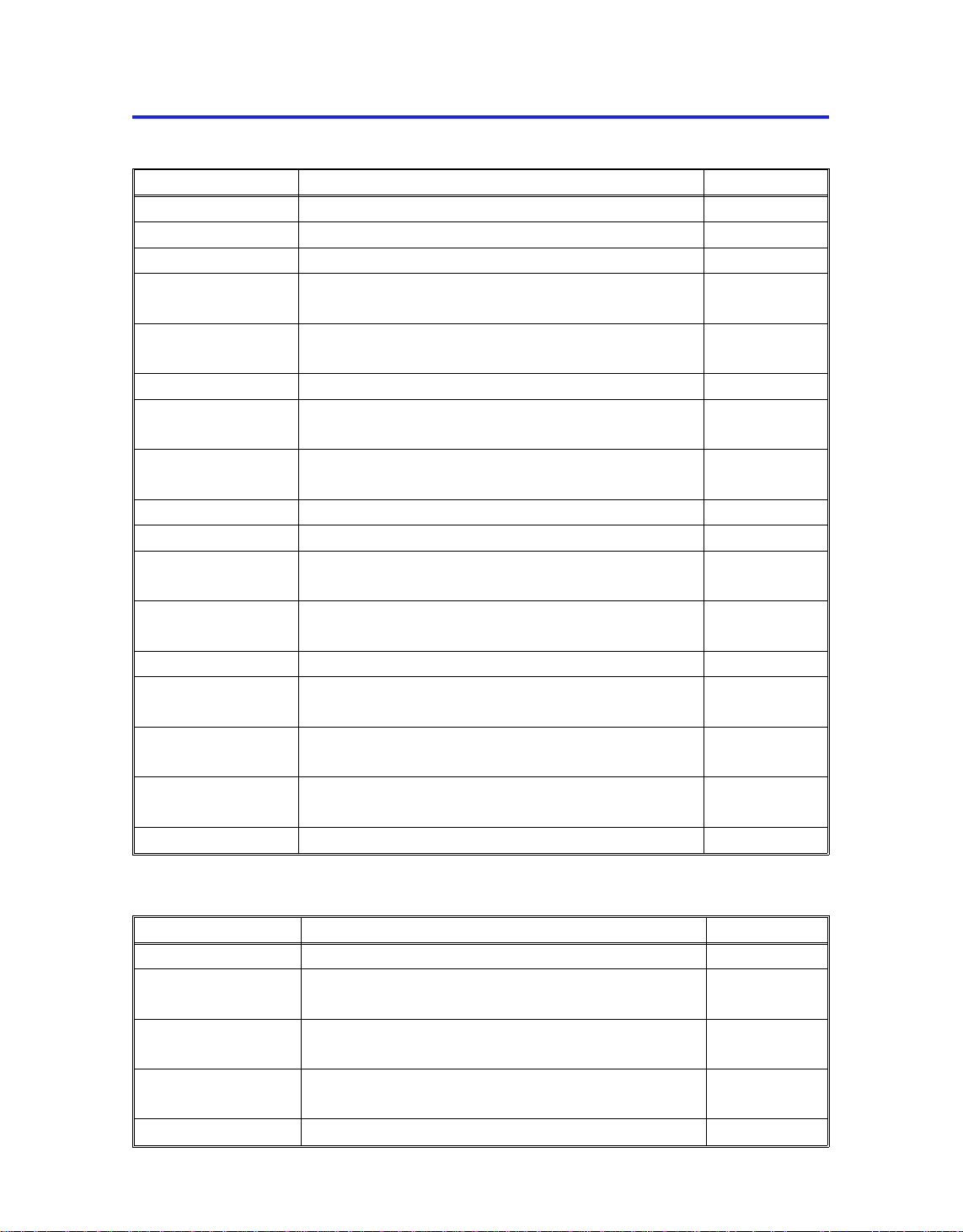

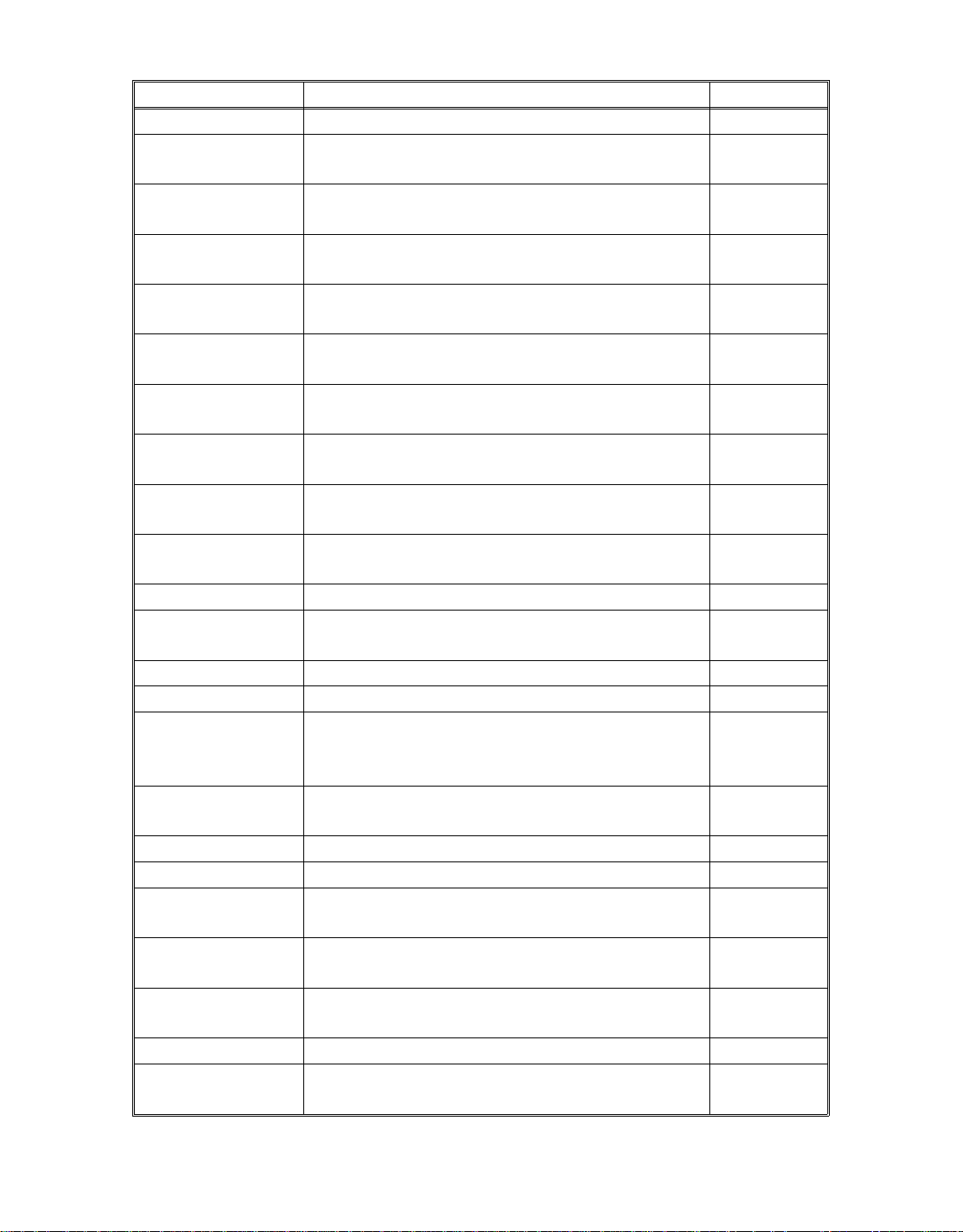

8. ELECTRICAL COMPONENT DESCRIPTIONS

MOTORS

NAME FUNCTION LOCATION

Main Drives the main unit components. 28

Development Drives the development unit. 32

Paper Feed Drives the feed sectio n. 31

Development

Cooling Fan

Fusing Exhaust

Fan

Fusing Cooling Removes heat from around the fusing unit. 67

Cooling Blower Prevents build up of hot air in the optics

Vacuum Fan Provides suction so paper is held firmly on

Scanner Drive Drives the scanner. (dc servo) 34

Lens Drive Positions the lens. (dc stepper) 26

4th / 5th Mirror

Drive

Jogger Drives the jogger plates to keep paper

Cleaner Motors Clean charge and separation wires. 17, 19

Charge Fan Ensures even charge on the surface of the

LCT Rises and lowers the LCT bottom plate.

Cassette Bank

Drive

Lift Motors Lift paper to the appropriate feed position. 49, 51

Blows air to the developme nt unit bottom

plate.

Removes heat from around th e fu sing unit. 4

cavity.

the transport belt.

Positions the 4th/5t h mirror assembly. (dc

stepper)

evenly stacked on the duple x t ray.

drum.

(ac motor)

Drives the 2nd/3rd paper feed sections. 40

12

11

13

24

43

9

41

MAGNETIC CLUTCHES

NAME FUNCTION LOCATION

Registration Drives the reg istra tio n rolle r 30

Paper Feed

Clutches

Feed Relay

Clutches

Duplex Paper

Feed

Toner Supply Drives toner supply roller. 33

Starts paper feed from each feed stat ion. 35, 96, 47

Drives the relay rollers. 38, 45

Feeds paper from the duplex tray. 39

1-21

Page 23

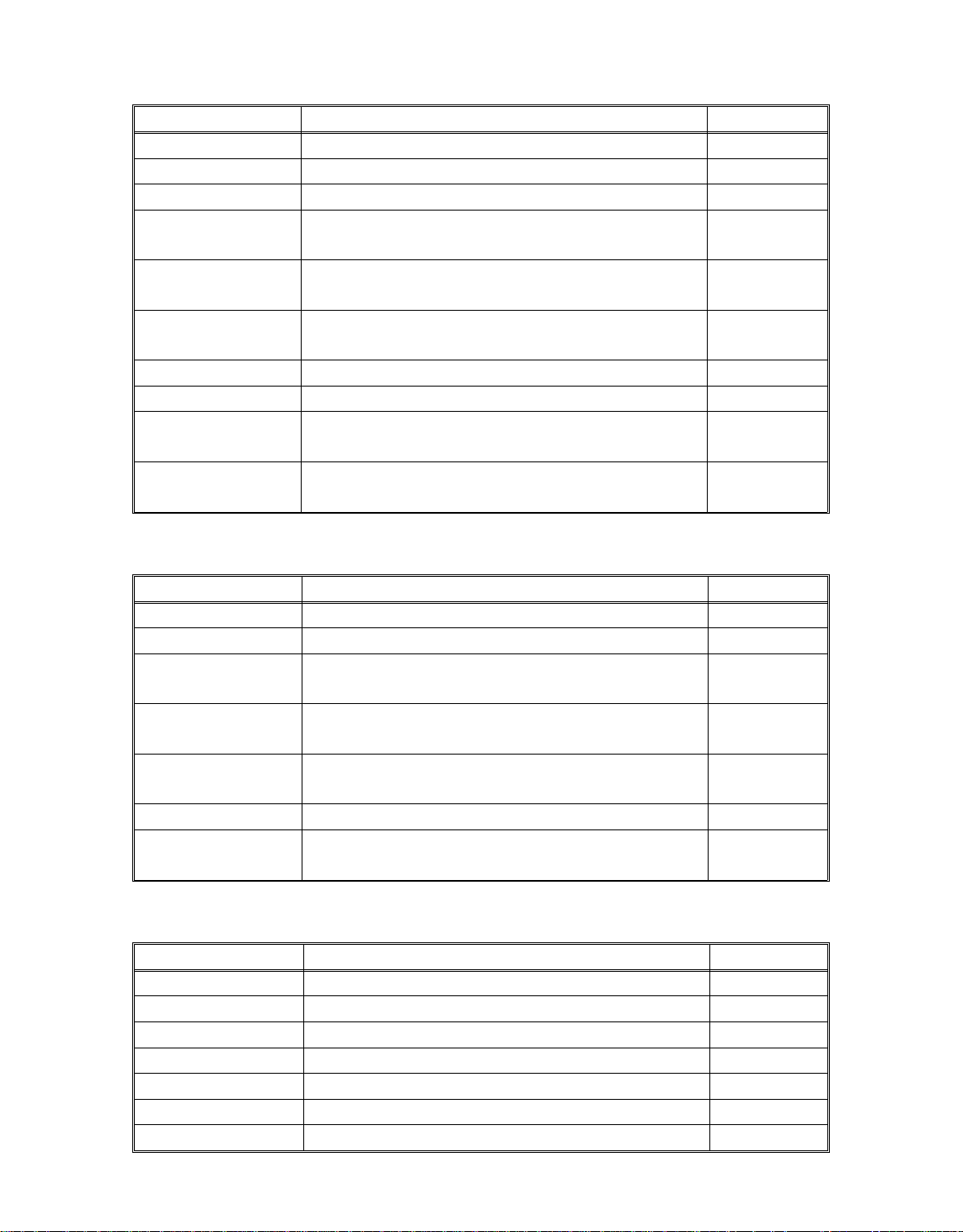

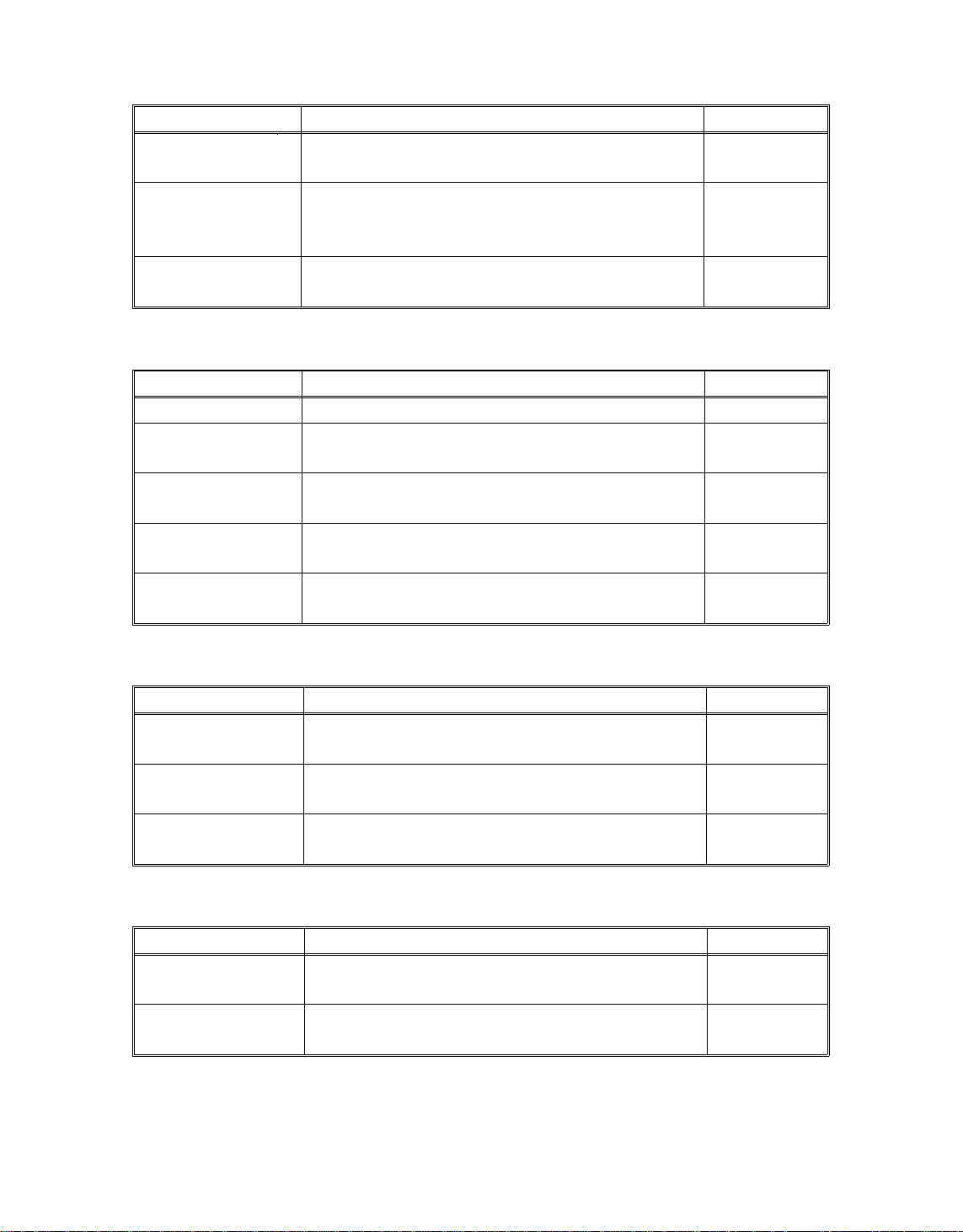

30 November 1990

SOLENOIDS

NAME FUNCTION LOCATION

Cleaning Moves the clean ing blade against the drum. 53

Pick-off Moves the pick-off pawls against the drum. 29

Junction Gate Energizes to direct copies to the duple x tray. 25

Fork Gate

Solenoids

In unison, open and close the appropriate

fork gates according to pap er size.

54, 55

Duplex Pick-up Start s fee d from duplex an d aids the

stopper solenoid.

Duplex

Lowers positioning roller. 42

Positioning

Inverter Pressure Controls the inverter pressure roller. 27

Duplex Stopper Stops copy in the jogger unit. 44

Pick-up

Picks paper up from each feed sta tio n. 36, 48, 50

Solenoids

Manual Feed

Pick-up

Raises the pick-up roller when paper is fed

from the manual feed table.

52

37

SWITCHES

NAME FUNCTION LOCATION

Main Supplies power to the copier. 23

Front Door Safety Cuts ac power line. 122

Transport Unit

Cuts 24-volt lines. 121

Safety

Fork Gate Unit

Cuts 24-volt lines. 90

Safety

LCT Lower Limit

Cuts the signal line of the tray down. 105

Safety

LCT Down Lowers the LCT bottom plate. 14

LCT Cover Cuts power to the LCT when LCT cover is

101

opened.

SENSORS

NAME FUNCTION LOCATION

Pulse Generator Supplies timing pulses to the main board. 120

Exit Detects misfeeds. 123

Exit Relay Detects misfeeds. 125

Oil End Detects the low oil condition. 22

Toner Overflow Det ect s when the used ton er bo tt le is full. 83

Toner End Detects when it is time to add toner. 96

Registration Detects misfeeds. 61

1-22

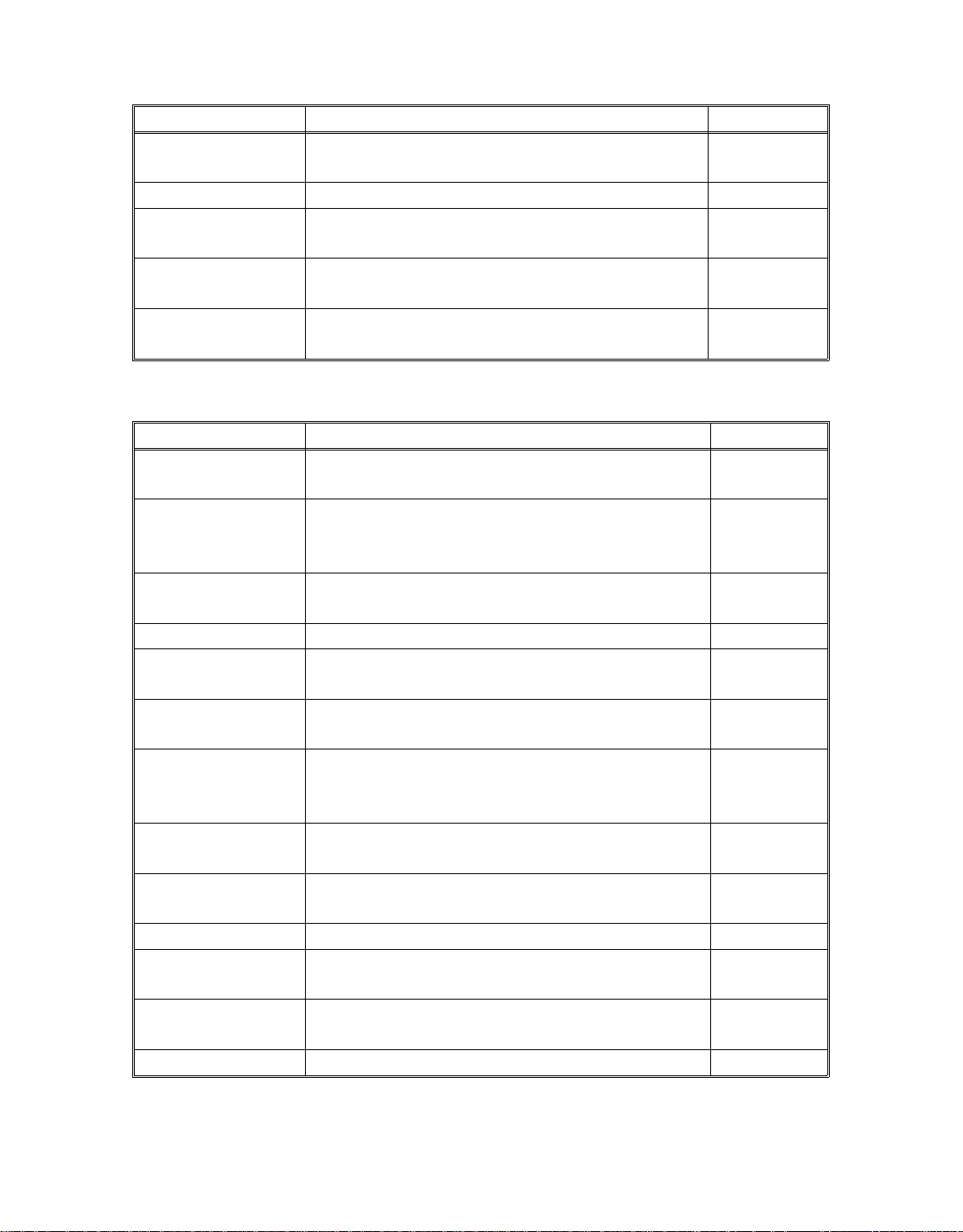

Page 24

30 November 1990

NAME FUNCTION LOCATION

Manual Feed Detects when the manual feed table is open. 114

Scanner Home

Position

Lens Home

Position

4th/5th Mirror

Home Position

Paper Size

Informs the CPU when the scanner is at the

92

home position.

Informs the CPU when the lens is at the full

91

size position.

Informs the CPU when the 4th / 5th mirror

94

assembly is at the full size position.

Detects the paper size in the cassette. 111, 112

Sensors

Paper End

Sensors

Scanner VL

Position

Informs the CPU when the copy paper runs

out.

Informs the CPU when the scanner reaches

the VL pattern sensing position.

109, 110,

117

93

Relay Sensors Detects misfeeds. 99, 106,

113

Jogger Home

Position

Duplex Paper Detects whether or not paper is in the

Informs the CPU when the jogger plates are

at the home position.

98

119

duplex tray.

Duplex Entrance Misfeed detector 95

Auto Density Senses the background density of the

89

original.

Original Width Detects the original width. 87

Original Length Detects the original length. 88

Charge Cleaner

Home Position

Informs the CPU when the charge wire

cleaner has reached home po sitio n.

18, 20

Sensors

Manual Feed

Paper End

Informs the CPU that there is no paper in

the manual feed tray.

118

Fusing Exit Detects misfeeds. 124

Inverter Exit Detects misfeeds. 126

Lift Sensors Detects whether paper has been raised to

the proper paper feed position.

LCT Cover Informs the CPU when the LCT cover is

97, 115,

116

100

closed.

LCT Lower Limit Informs the CPU when the LCt bottom plate

103

reaches the lower limit position.

Paper Position Detects the paper position. 104

Paper Volume Detects the amount of paper in

LCT/cassettes.

102, 107,

108

1-23

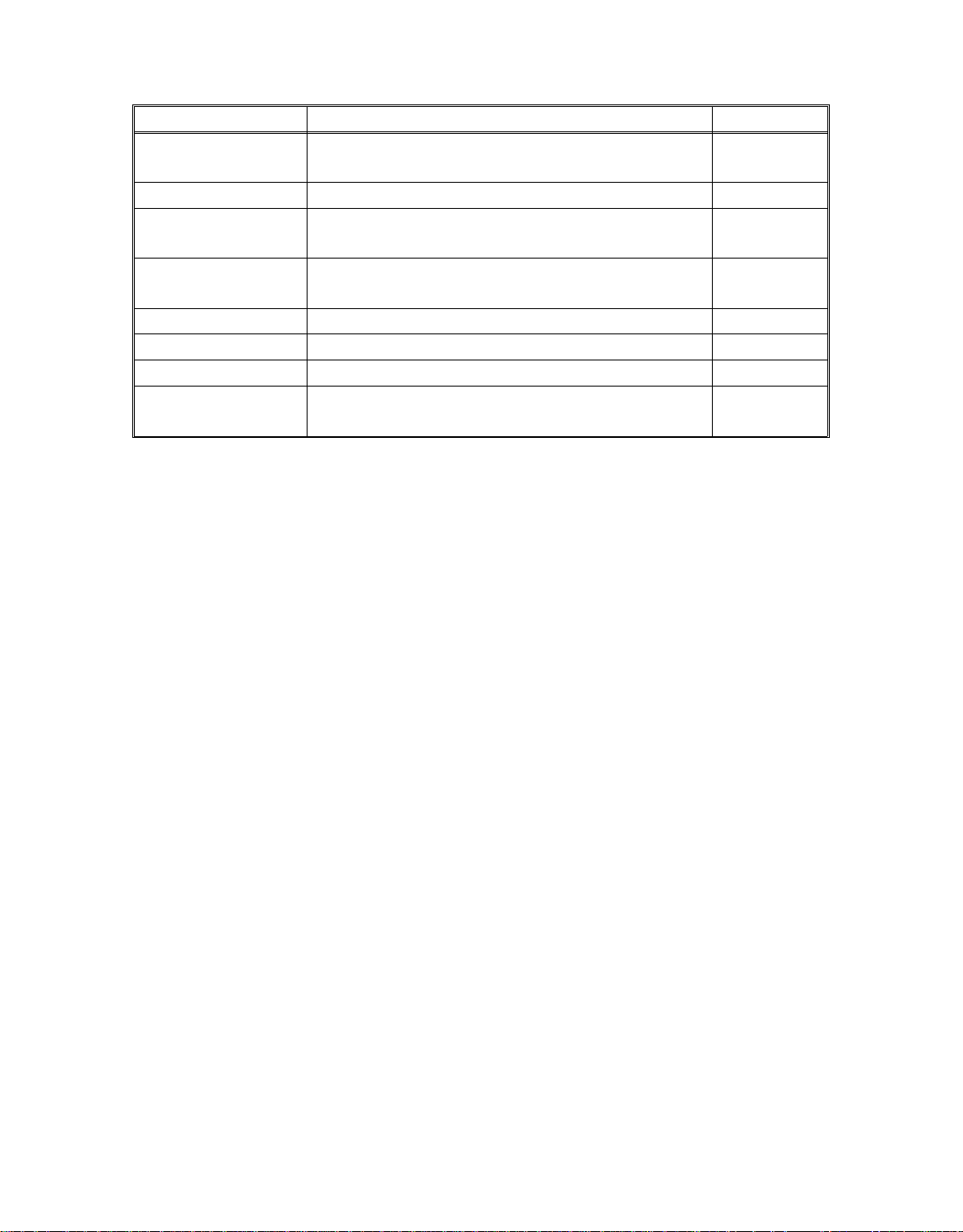

Page 25

30 November 1990

THERMISTORS

NAME FUNCTION LOCATION

Drum Monitors the temp era tu re around the drum

and controls the rest-time comp ensation.

Bias Monitors the temperature aroun d the drum

and controls developmen t rest time bia s

compensation.

Fusing Monitors the fusing temperature and turns

the fusing lamp on/off.

POWER PACKS/STABILIZER

NAME FUNCTION LOCATION

Power Pack - T/S Provides high voltage for th e T/S coronas. 82

Power Pack CC/Bias

Power Pack PQC/Cleaning

Power Pack PCC

Provides high voltage for the charge corona

and the development roller bias.

Provides high voltage for the quenching

corona and the cleaning bias roller.

Provides high voltage for the pre-cleaning

corona.

PTL/QL Stabilizer Provides high voltage for the quenching

and pre-transfer lamps.

60

59

2

56

57

68

66

HEATERS

NAME FUNCTION LOCATION

Drum Warms the drum when the main switch is

off.

Cleaning Warms the cleaning section when the main

switch is off.

Anticondensation Prevents moisture from forming on the

optics.

THERMOSWITCHES

NAME FUNCTION LOCATIO N

Optics Provides overheat protection in the optics

unit.

Cleaning Provides overheat pro te ctio n in the

cleaning unit.

16

8

7

6

10

1-24

Page 26

30 November 1990

LAMPS

NAME FUNCTION LOCATION

Exposure Applies high intensity light to the original for

exposure.

Fusing Provides heat to the fusing unit. 1

Erase Discharges the drum outside the image

58

area. Erases lead/trail edge.

Quenching Neutralizes any charge remaining on the

65

drum surface after cleaning.

Pre-transfer Reduces charge on the drum surface

64

before transfer.

PRINTED CIRCUIT BOARDS

NAME FUNCTION LOCATION

Main Controls all copier functions both directly

71

and through other PCB s.

Optics Controls the speed of the scanner, the

70

position of the lens, and the position of the

mirrors.

Operation Panel Contro ls the LED mat rix, and mon ito rs the

62

key matrix.

Main Motor Controls the speed of the main motor. 69

Development

Motor

Paper Feed Motor Controls the speed of the paper feed drive

Controls the speed of the development

motor.

85

86

motor.

Paper Feed Interfaces with overall pap er fe ed ; rece ives

84

input from paper size and paper end

sensors.

DC Power Supply Rectifies 100 Vac input and outputs dc

79

voltages.

Image Density Detects the density of the image on the

63

drum.

Cassette Bank Interfaces with overa ll cassette bank drive. 80

AC Drive Drives the exposure lamp and the fusing

72

lamp.

Memory Controls weekly timer and memory

73

functions.

SSR Switches the LCT bottom plate up/down 81

5

1-25

Page 27

30 November 1990

OTHERS

NAME FUNCTION LOCATION

Circuit Breaker G uards against voltage surges in the input

power.

Main Transformer Steps down the wall voltage to 100 Vac. 76

Thermofuse Provides back-up overheat protection in the

fusing unit.

Total Counter Keeps track of the total number of cop ies

made.

Power Relay Controls main power. 77

Condition Relay Controls the heaters on/off. 78

Noise Filter Removes electrical noise. 75

Printer Connector Used for connection to the printer

(RS 232C serial interface).

74

3

15

21

1-26

Page 28

9. OVERALL MACHINE CONTROL

30 November 1990

Pulse Generator

Sensors

-Toner Overflow

-Exit

-Inverter Exit

-Duplex entrance

-Duplex Paper

-Jogger H.P.

-Toner End

-Oil End

-Image Density

Solenoids

-Fork Gate

-Inverter Return

-Junction Gate

-Duplex Positioning

-Duplex Stopper

-Duplex Pick-up

-Pick-off

-Cleaning

Magnetic Clutches

-Duplex Paper Feed

-Toner Supply

Motors

-Jogger

-Vacuum Fan

-Fusing Exhaust

-Charge Fan

-Development

Cooling Fan

-Ozon Fan

Counters

-Total

-Key

-A3/LDG

Erase Lamp

Power Packs

-PQC/Cleaning Bias

-CC/Development

Blas

Quenching Lamp

Stabilizer

ARDF/Sorter

RDH/Finisher

Menu Sheet Reader

RS232C Interface

Main PCB

Optics PCB

Main Motor

Development

Motor PCB

Paper Feed

Motor PCB

AC Drive

Operation

Panel PCB

Paper Feed

Casstte Bank

(2nd/3rd Feed)

PCB

PCB

PCB

PCB

Motors

-Scanner Drive

-Lens Drive

-4th/5th Mirror Drive

-CC Cleaner Motor

-SC Cleaner Motor

Sensors

-Scanner Home Position

-Scanner Overrun

-Lens H.P.

-4th/5th Mirror H.P.

-CC Cleaner H.P.

-SC Cleaner H.P.

Main Motor

Development

Motor

Paper Feed

Motor

Exposure Lamp

Fusing Lamp

Sensors

-Registration

-1st Relay

-Manual Feed

-Manual Feed Paper End

-Paper End

-Lift

-Paper Volume

Solenoids

-Manual Feed

-Pick-up

Magnetic Clutch

-Paper Feed

-Relay

Sensors

-Paper End (2)

-Paper Volume (2)

-Paper Size (2)

-Lift Relay (2)

Moters

-Lift (2)

Solenoids

-Pick-up (2)

Magnetic Clutch

-Paper Feed (2)

-Relay

1-27

Page 29

30 November 1990

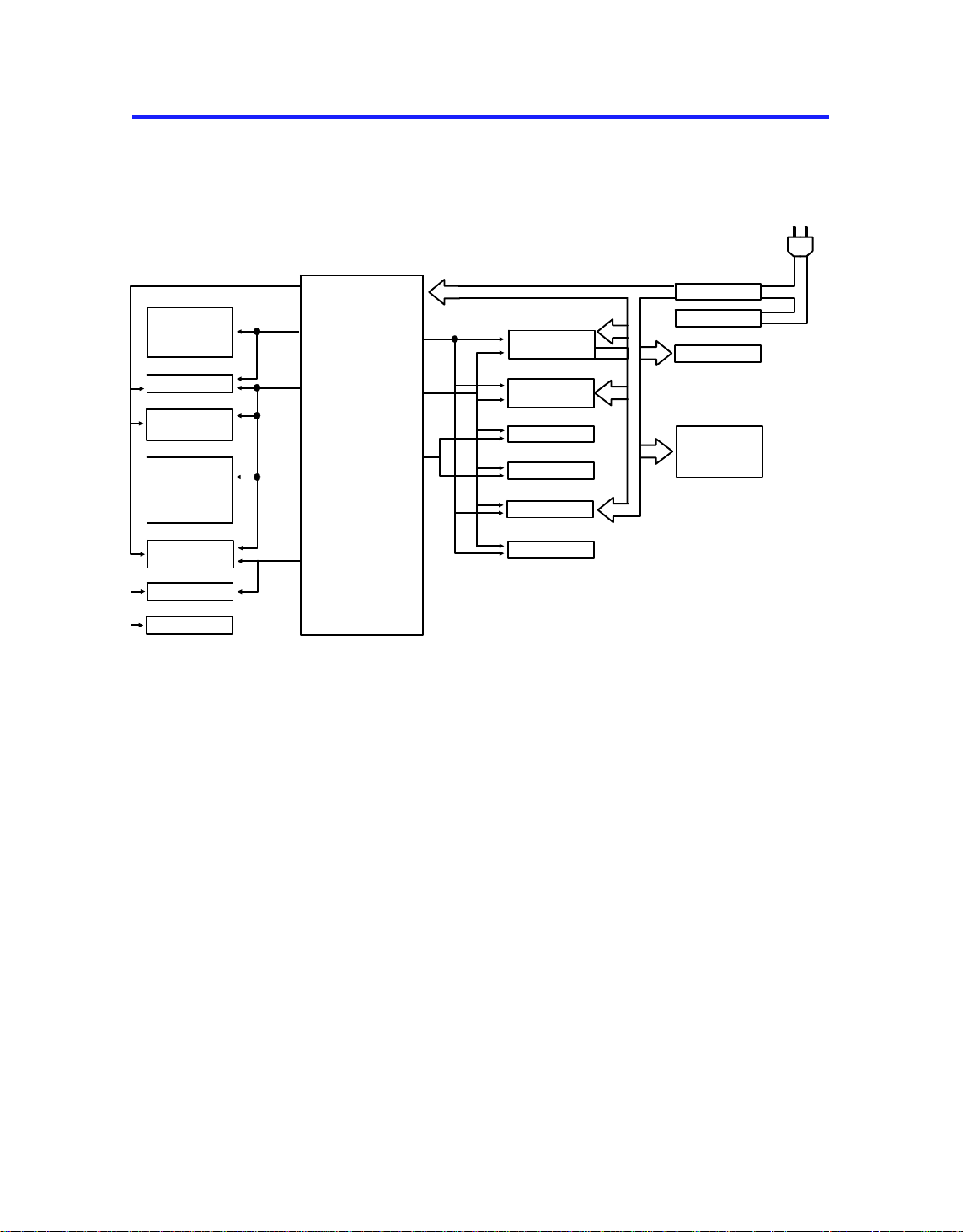

10. AC AND DC POWER DISTRI BUTI ON

AC Power

Main Motor PCB

Dev. Motor PCB

Paper Feed Motor

Optics PCB

Main PCB

Paper Feed PCB

Clutches

Motors

Solenoids

Counters

Relays

Operation Panel

Power Packs

Erase Unit

PCB

PCB

5V (VC)

24V (VM)

24V (VA)

24V (VP)

DC

Power

Supply

5V (VC)

24V (VF)

24V (VA)

AC Drive

PCB

Cassette Bank

(2nd /3rd Feed)

ARDF/RDF

Finisher

Sorter

Menu Reader

Transformer

Fusing Lamp

Exp Lamp

Drum Heater

Anticondensation

Heater

Cleaning Heater

The illustration on this page shows the electrical power dist ribution in block

form.

AC power (115/220 volts) is supplied from the wall outlet directly to the fusing

lamp and the step-down tran sfo rmer. The transformer supplies 100 volts ac

to the power supply unit, the ac drive board , the pa per ban k (2nd /3 rd pa per

feed station)and sorter.

The power supply unit produ ces fo ur 24 volts an d on e 5 volt s t o operate the

PCB’s, the clutches, the moto rs, the solenoids, the counters, th e rela ys, the

power packs and the era se unit.

1-28

Page 30

SECTION 2

SECTIONAL DESCRIPTION

Page 31

30 November 1990

1. DRUM

1.1 SELENIUM DRUM CHARACTERISTICS

Selenium has the following charact erist ics:

• Accepts a high positive electrical charge in the dark. (The ele ctrical

resistance of selenium is high in the abse nce of ligh t.)

• Dissipates the electrical charge when exposed to lig ht. (Exposure to light

greatly enhances the condu ctivit y of sele nium.)

• Dissipates the electrical charge in direct proportion to the intensit y of the

light.

That is, where stronger light is direct ed to the selenium surface, a smaller

voltage remains on the selenium.

The sensitivity of selenium chan ge s slight ly wit h varia tions in the surface

temperature of the drum. (Unde r cool con ditions, the drum conductivity

decreases. This will result in background or excessive image density.) As a

countermeasure, the development bias is change d to compensate for

temperature varia tio ns around the drum. Also, while the copie r is of f, the

drum heater warms the drum.

Drum sensitivity also depends on how long the drum has rested between

copy runs. The copier’s CPU compe nsa te s fo r cha ng es in dru m sensitivity

due to rest time by changing the deve lop men t bia s. This prevents variations

in image density at the beginning of copy runs.

The selenium drum used in th is mode l has hig h sen sitivity, good color

reproduction, and good rep rod uction of low contrast originals (pen cil

originals, etc.)

2-1

Page 32

30 November 1990

1.2 DRUM HEATER CONTROL

AC Power

Transformer

100VAC

Thermo

Switch

Drum Heater

Anticondensation

Heater

Cleaning Heater

RA2

Main Switch

The drum heater receives 100 volts ac only when the main switch is turned

off. When the main switch is turned on, the 100 volt ac current stop s flowin g.

2-2

Page 33

2. DRUM CHARGE

2.1 OVERVIEW

[B]

30 November 1990

[A]

[C]

[D]

This copier uses a dual wire corotron un it and a highly sensitive selenium

drum. The corona wires [A] generate a flow of positive ions when the charge

power pack applies a high positive volt ag e to the coron a unit. The drum

coating [B] receive s a unif orm po sitive charge as it rotates past the corona

unit.

The charge fan [C] provides a smooth flow of air to the interior of the charge

corona unit [D] to prevent un eve n build up of positive ions. (An uneven build

up of positive ions could cause uneven image density.)

2-3

Page 34

30 November 1990

2.2 WIRE CLEANER

[B]

[A]

[B]

[A]

[D]

[C]

Paper dust or toner particles on the coron a wires [A ] may interfere with

charging. The wire cleaner [B] corrects this problem by automatically wiping

the charge corona wires clean. Pa ds on the wire clean er bra cket clean the

corona wires as the dc motor [C] drives th e cleaner bracket from the home

position to the rear e nd of th e coro na unit and the n back a gain.

Operation of the wire cleane r is based on copy coun t. A RAM co unter keeps

track of the number of copies made since the last time the wires were

cleaned. The CPU checks this counte r each time th e cop ier is turn ed on. If

the count is greater than 5,000 at that time , th e CPU tu rns on the clean er

motor to clean the coro na wire s. Simu ltaneously, it resets the count er to zero.

During a cleaning cycle, the clea ne r motor drives the wire cleaner toward the

rear endblock. After 30 seconds, the motor reverses to drive the wire cleaner

to the home position. Normally, the cleaner reache s the rear en dblock in

about 10 seconds, but th e mot or stays on for 20 seconds to ensure that the

cleaner moves the full distan ce. Th e mot or turns off when the cleaner

activates the home position sensor [D].

2-4

Page 35

2.3 WIRE CLEANER MOTOR

30 November 1990

Optics PCB

C

P

U

Driver

Driver

( 5)

( 5)

( 5)

( 5)

( 5)

( 5)

CN306-1

CN306-4

CN306-5

CN306-6

CN306-7

CN306-2

REV

FWD

REV

FWD

5V(Vc)

CC

Cleaner

H.P.

Sensor

C C

M

SC

M

5V(Vc)

SC

Cleaner

H.P.

Sensor

Small dc motor in the corona fron t end block drives the corona wire cleaner.

When a cleaner motor is energized, the CPU supplies forward drive for 30

seconds from CN306-4. Then , it reve rses th e po larit y of the motor drive

voltage to return the coron a wire clea ne r to th e ho me position (CN306-5).

When the home position senso r t urn s o n, the CN306 -1 dro ps to zero and it

stops.

This mechanism is used also for the sepa rat ion corona wire cleaner.

If the home position sensor is not activate d with in 20 secon ds af te r reverse

drive is initiated, the CPU stops the moto r and adds 1 to the cou nt er stored in

SP mode 121. Copies can still be made and there is n o service call indica tion

on the opera tio n panel.

SP #121 SC 85: C.C. Home Position Sensor does not turns on .

SC 86: C.C. Home Position Sensor do es not turns off.

SC 87: S.C. Home Position Sensor does not turns on.

SC 88: S.C. Home Position Sensor does not turns off.

2-5

Page 36

30 November 1990

2.4 CHARGE CORONA POWER PACK

+24V(Vp)

Front Door Safety SW

CC/Bias P.P

CN1-1

CN1-5

DC/DC

Converter

Main PCB

Charge( 5)

5V DC

CN2-3

CN102-B18

CN2-5

TC/SC P.P.

( 24)

P-GND

CN1-2

CN1-1

The circuit operation for the charge corona begins with the input of +5 volts

(Vc) at CN2-3. This voltage powers the LED of the photocoupler.

Additionally, 24 volts (Vp) enters the power pack at CN1-1. This po wer sup ply

is used to produce the high vo lta ge corona. This voltage is interrupt ed if the

front door safety switch opens.

The charge corona turns on 543 milliseconds before the registration MC is

turned on. A LOW signal from the CP U (CN101 -B1 8) is sent to the CC/B

power pack through the TC/SC po wer pa ck.

The OFF timing of the charg e coro na powe r pack varies according to the

paper size being used.

2-6

Page 37

3. OPTICS

3.1 OVERVIEW

30 November 1990

[C]

[B]

[A]

[D]

[I]

During the copy cycle, an image of the origin al is refle cted onto the surface of

the drum [I] via the optics assembly. The op tics asse mbly con sists of the

following parts:

1. First Scanner [A]:

Exposure lamp [B] (85 V, 160 W )

First mirror

AD (Auto Density) sensor fiber optics cable [C]

2. Second Scanne r [ D]:

Second mirror

Third mirror

3. Lens (F5, f = 215 mm) [E]

[E]

[F]

[G]

[H]

4. Fourth and Fifth Mirror Assembly [F]:

Fourth Mirror

Fifth Mirror

5. Sixth Mirror [G]:

6. Toner Shield Glass [H]

2-7

Page 38

30 November 1990

This copier has nine stand ard reproduction ratios: five red uctions, three

enlargements and full size. In additio n, it has a zoom fun ctio n. The

reproduction ratio can be selected in one percent ste ps fro m 60% to 15 5% .

A servomotor drives the first and secon d scanners during the copy cycle.

This motor is controlled by the opt ics PCB, which changes the motor speed

depending on the reproduction ratio. Two stepper motors chan ge the posit ion

of the lens and the fourth and fifth mirror assembly to change the

reproduction ratio. The sixth mirror is fixe d.

The fiber optic cable used for the auto density sensor (ADS) is mounted on

the first scanner. The ADS collects ligh t ref lected from the original in auto

density sensing mode.

2-8

Page 39

3.2 EXPOSURE LAMP CONTROL

Optics PCB

E

Feed back signal

CPU

24V

C

B

0V

0V

Trigger Pulse

CN303-2

CN303-1

CN303-4

CN303-3

CN304-4

CN303-9

CN501-2

CN501-1

CN501-4

CN501-3

CN501-9

CN501-6

AC Drive PCB

Zero

Cross

Detect

Lamp

Monitor

Lamp Control

CN503-1

CN503-2

A

CN503-3

CN503-5

D

30 November 1990

Front

Door

Safety

Switch

RA1

AC (N)

AC (H)

TH. Switch

Exposure Lamp

AC power

Zero cross

Trigger pulse

Lamp power

Feedback

signal

A

B

C

D

E

Feedback

The optics board controls and mon ito rs t he expo sure lamp circuit, instead of

the main board. The ac drive board receives 100 volts ac from the

transformer [A] and it is used for th e zero cross signal, which is sent to the

optics board [B]. The optics board sends the lamp trigger pulses to the ac

drive board from CN303-9 [C]. This lamp trig ger pulse activa te s the triac on

the ac drive board, which provides th e ac power to the exposure lamp [D].

The voltage applied to the expo sure lamp is also provided to the lamp

monitor circuit, which rectif ies and smoothes it.

The main CPU monitors the lowe st po int of th is smoot he d wave (f eedb ack

signal) which is directly proport ion al to the actu al lamp voltage, and then

changes the timing of th e trig ge r pulse in response to the feed ba ck volta ge .

If the lamp voltage is too low, the main CPU sends the trigger pulse earlier,

so that more ac power can be app lied to th e exposure lamp. This feedback

control is performed instantly; so the lamp voltage is always stable even

under fluctuating as power conditions.

The voltage applied to the expo sure lamp can be changed with SP mo de #48

and displayed with sp mode #5 1.

2-9

Page 40

30 November 1990

3.3 SCANNER DRIVE

[D]

[B]

[A]

[E]

This model uses a dc servomotor [A ] to drive the first [B] and second [C]

scanners.

[C]

This first scanner is attached to the scanner drive wire by the wire clamp [D].

The second scanner is connected to the scanner drive wire by a movable

pulley [E] (the second scanner pulley).

The second scanner pulley move s the second scanner at half the velocity of

the first scanner. This maintains th e focal distance between the original and

the lens during scanning. This rela tio nship can be expressed as follows:

V1r = 2(V2r) = VD/r

where r: Reproduction

V1r: First Scanner Velocity (when the Reproduction ratio is "r")

V2r: Second Scanner Velocity (when the Reproduction ratio is "r")

VD: Drum Peripheral Velo city (30 0 mm/s)

The first scanner wire clamp also actuat es the home position sensor. The

CPU on the optics board controls both the registration and return timing.

2-10

Page 41

3.4 SCANNER MOTOR CONTROL

Scanner Home Sensor

24V(VM)

30 November 1990

M-GND

Timing Pulse

Reset

5V(VC)

C-GND

Main PCB

CN307-1

CN302-5

CN302-4

CN302-7

CN302-3

CN302-2

CN302-8

CN302-9

5V

TXD

RXD

LE

S/R

RST

-2

-3

Optics CPU

Speed data

CN304-1

F

R

Optics PCB

Driver

Timer IC

PWM

CN304-2

E-A

E-B

CN308-1

CN308-3

CN301-1

CN301-2

CN301-3

CN301-4

Scanner drive

M

The scanner drive motor is a dc servomoto r. The CPU o n the op tics bo ard

controls the speed of this servomotor. The main CPU and the optics CPU

communicate through a serial interf ace bus (TXD/ RXD).

Encoder

After the main CPU sends the scann er sta rt signal to the optics CPU, the

optics CPU receives the drum speed data from the main PCB (pulse

generator).

An encoder on the servomotor has two magn et ic senso rs t hat ge nerate two

pulse signals. The optics CPU monit ors th e scan ne r spee d an d dire ctio n by

these pulse signals.

Based on the drum speed and encoder data, the optics CPU determines the

proper speed for the scan ner drive motor to obtain proper vertical

magnification. The optics CPU sends the spe ed data to the timer IC, which

controls the scanner moto r circu it.

The home position sensor informs the optics board when the first scanner is

in the home position.

2-11

Page 42

30 November 1990

3.5 LENS/MIRROR POSI TI O NING

[C]

[D]

[B]

[A]

Lens Drive

The lens drive motor (stepper mot or) [A ] cha ng es th e len s posit ion according

to the selected reproduction ratio to provide the prop er ho rizontal

magnification between the lens an d the dru m’s surface.

The output gear of the lens drive motor en gage s the gears [B] of th e lens

drive pulley. The lens drive wire [C] is wrapped around the lens drive pulley

and is connected to the lens drive bracket [D]. The rotation of the lens drive

pulley moves the lens back and forth in discrete steps.

2-12

Page 43

Lens Positioning

[A]

30 November 1990

[C]

[B]

[D]

[A] Lens Drive Pulley

[B] Lens Housing

The lens home position senso r [C] informs the optics PCB when the lens [D]

is at the full-size position (home position). The optics PCB determines the

lens stop position in reduct ion and enlargement modes by counting the

number of steps from the home position. When the repro duction ratio is

changed, the lens move s directly to the selected magnif icat ion position.

2-13

Page 44

30 November 1990

Operation

Panel

PCB

TXD/RXD

Main PCB

Home position is checked by

moving the lens from the

enlargement side towa rds the

reduction side. So, whe n ho me

position is checked, a LO W to

HIGH to LOW signal is present

at CN307-5 of the optics board.

This occurs when the actua to r

blade enters and exits the lens

home position sensor. The lens

only references home posit ion

when going to full size (at powe r

up, when modes are cleared,

when full size is selected.) The

lens always overshoots the

selected magnification ratio

position by 40 steps to eliminate

mechanical play when go ing

from enlargement to reduction.

RXD

TXD

Optics

CPU

Reduction

Optics PCB

Driver

5V(VC)

( 5)

Home Position (100%)

40pls

40pls

40pls

24V(VM)

CN305-2

CN305-3

CN305-4

CN305-5

CN305-1.6

CN307-1

CN307-5

CN307-2

M-GND

Lens motor

M

24V(VA)

Lens H.P. sensor

Enlargement

2-14

Page 45

3.6 FOURTH AND FIFTH MIRROR ASSEMBLY

[E]

[F]

30 November 1990

[B]

[D]

[C]

[A]

When the reproduction rat io is chan ged, the stepper motor [A] moves the

fourth and fifth mirror assembly [B ] usin g the wire [C] and pulleys [D]. This

provides the proper focal distance between the original and the drum.

When the fourth and fifth mirror assembly is in the full-size position, the

actuator [E] on the assembly actuates the fourth/fifth mirro r home posit ion

sensor [F]. This signal goes to the optics CPU.

2-15

Page 46

30 November 1990

Fourth and Fifth Mirror Assembly Positioning

Optics PCB

Operation

PCB

TXD/RXDPanel

Main PCB

RXD

TXD

Optics

CPU

Driver

24V(VM)

CN305-8

CN305-9

CN305-10

CN305-11

M-GND

CN305-7,12

24V(VM)

M

Mirror

Motor

High

Power up

Home

Position

Signal

Low (Reduction/Enlargenent)

40pls

100% Mag Ratio

(Home Position)

Power up

100%

40pls

Away from H.P.

Reduction

Towards H.P.

( 5)

5V

CN307-1

CN307-6

CN307-2

Mirror

Sensor

The mirror home position sensor informs the optics CPU when the fourt h and

fifth mirror assembly is at the home positio n. The ho me po sitio n is

determined by a LOW to HIGH to LOW change on CN307-6 of the optics

board.

When a reproduction rat io is se lect ed , the operation panel PCB sen ds th is

information to the main board. The main board th en send s the app rop riat e

trigger signals through the serial line to the optics board.

When moving away from the home posit ion, the mirror drive pulley turns

clockwise and moves directly to the sele cte d po sitio n. However, when

moving towards the home position (pulley turns counterclockwise), the mirror

assembly overshoots the selected position once and th en returns to the

selected position. This ta kes out an y mechanical play.

2-16

Page 47

30 November 1990

3.7 ORIGINAL SIZE DETECTION IN PLATE N MODE

[A]

[B]

There are seven reflective sen sors in the optics cavity for the original size

detection. Two of the m a re use d for sensing the original wid th [A] and the

other five sense the original len gt h [B ].

While the main switch is on, these sensors are active and the origin al size

data is always sent to the main cpu. Howe ver, the main CPU che cks the dat a

only twice when in platen mode.

2-17

Page 48

30 November 1990

1st Check

[A]

15 cm

15cm

2nd Check

P3 P4 P5 P6 P7

1st

Original Length

Sensor

ONONONONOFFONOFFONOFF

2nd

ON

First check is done when the pla te n po sition sensor [A] turns on. This is when

the platen is positioned about 15 cm above the expo sure glass. At th is time,

only the sensor(s) locate d unde rneath the original receive the reflected light

and are on. Other sensor(s) a re of f. Through the on/off data of th e seven

sensors, the main CPU can reco gn ize th e orig inal size.

Second check is done when th e platen cover is closed. (The plate n cover

switch is on.) This is to confirm that the original size detected at the first

check is correct. At the check, all senso rs shou ld be on becau se of the white

color of the platen shee t. This d ou ble check prevents mis-detection of the

original size due to a black solid area being positioned just above a sensor.

In case the copy is made with the open plat en condition, the main CPU

decides the origina l size only th rough the data when the Print key is p resse d.

No second check can be perf orme d.

This original size detection method eliminat es the necessit y for a pre -scan

and increases the machine ’s prod uctivity.

2-18

Page 49

3.8 VL DETECTION

Vsl ≈ 2.0

30 November 1990

[E]

Vsg ≈ 4.0

A: VL Position Sensor

B: VL Pattern

C: Right Scale

D: ID Sensor

E: VL Pattern Image

[D]

[C]

[B]

[A]

In order to compensate for cha ng es in th e cop y image density cau sed by

dirty optics, the main CPU checks the image density of the VL pattern when

the main switch is turned on. This is done only when the fusin g temperature

is lower than 100 °C.

After the machine idles for 30 seconds, the scanner moves un til the scanner

VL position sensor [A] tu rns on . The VL pattern [B] is located un de rne at h th e

right scale [C], about 30 mm from the scanner fu ll-return position. (At this

time, the lens also moves in th e red uction direction to prevent the scanner

guide from striking the lens.) Then, the VL patt ern is exposed.

The ID sensor [D] checks the reflectivity of the VL patt ern ima ge and the ID

sensor pattern image [E ] on the drum surf ace in the same way. The CPU

receives two voltage values dire ctly from the ID sensor: the value for t he bare

drum (Vsg) and the value for the pattern image (Vsl). The main CPU stores

Vdat (Vdat = Vsl/Vsg) in memory an d comp are s it with the VL reference

value (Vref). Vref was sto red in memory by SP mode #67 at machine

installation when the light intensity was adjusted.

2-19

Page 50

30 November 1990

(Vref Setting: SP mod e #6 7)

When SP mode #67 is set, the scann er move s t o th e VL pat te rn po sitio n. The

main CPU collects both Vsl and Vsg data and store s t hese values in memory

as the VL reference (Vref = Vsl/ Vsg ). This Vre f is st ore d in memo ry unt il the

next Vref setting is performed.

NOTE: P erform Vref setting after adju stin g the ligh t intensity or Vsg.

When the Vdat value is monitore d, a fixed bias (80 volts) is app lied to th e

development rollers; however, when Vref is set by SP mode #67, the

development bias is automatically shifted to 50 volts. This 30 volt differen ce

corresponds to one half step of the manual ID level.

If Vdat is less than Vref, th e exposure lamp voltage is increase d 2 volts. If

Vdat is greater than Vref, the volta ge is decrea sed 1 volt.

Vref ≥ Vdat Dark copy image (2 volts is incr ea se d.)

Vref < Vdat Light copy image (1 volt is decreased.)

At VL detection, the scan ne r moves to the VL sen sor position two times: The

first scan checks Vsl and Vsg for VL det ect ion and the second scan monitors

changes in the exposure lamp ligh t int en sity fo r ADS compensation.

2-20

Page 51

4. ERASE

30 November 1990

El

A

B

Lo

Lc

Es

ON

OFF

ON

Es

g

4.1 OVERVIEW

A: Lead Edge Erase Margin

B: Side Margins --- 2 ± 2 mm each (For full-size copies the total of

both side margins is less than 4 mm.)

Lo: Original Image Width

Lc: Charged Width on the Drum

El: Lead Edge Erase

Es: Side Erase

R: Paper Lead Edge Registration --- 0 ± 2 mm

A+R: Lead Edge Blank Margin --- 3.5 ± 2.5 mm

The erase unit consists of a PCB with 10 registe rs a nd a row of 80 LEDs

mounted in a plastic casing. The LEDs emit light in the yellow-gre en part of

the spectrum.

The erase lamp performs th e fo llowing functions: lead ed ge erase, side

erase, trail edge erase, ima ge dens ity pa tt ern [g], and the editing fu nct ions.

Trail edge erase begins after the trailing edge of the copy paper; therefore,

the trailing edge will not appear on the copy.

2-21

Page 52

30 November 1990

4.2 LEAD EDGE AND TRAILING EDGE ERASE

The entire bank of erase lamp s turns on to erase the drum before and after

the image area. Leading edge erase overlaps the paper an d the image

slightly. The leading edge marg in he lps pre ven t fusing jams by making it

easier for the stripper pawls to separate the paper from the hot roller. Trailing

edge erase turns on about 2 mm after the trailing edge of the copy paper.

The width of the lead edg e marg in can be ad just ed by SP mod e #4 1.

Mode No. Function Data

41 Lead Edge

Erase Margin

Adjustment

During image density detection cycles (once eve ry ten cycles), th e cen ter

block of erase lamps turns of f lon g en ou gh for th e sensor pattern to be developed [g].

Adjusts the

lead edge

margin

0 - 15 8

Factory

Setting

Comments

0.6mm per

step (max.

-4.8mm to

+4.2mm)

4.3 SIDE ERASE

Side erase overlaps the imag e sligh tly on eith er side . The CP U calcula tes the

side erase margins from the pap er size and the selected reproduction ratio.

As the paper is fed to the cen te r o f th e dru m , th e LEDs for side erase turn on

in pairs. The erase lamp is not used for side era se with A3 or 11 x 17 paper.

For these paper sizes, side erase occurs due to the end block covers of the

charge corona.

The CPU adjusts the side erase margin to be as near as possible to th e

actual image size, even wh en using the zoom function. Howe ver, since the

erase lamp LEDs will not work in precise one millimeter int erva ls, the side

erase margin varies slightly depend ing on th e rep rod uction ratio.

SP 27 increase the side margin s by 5 mm.

Also, the position of the entire erase lamp unit can be adjusted by turning an

adjustment screw at th e rear side of the unit.

This adjustment is neccessary wh en the side era se margins are uneven.

2-22

Page 53

4.4 EDGE ERASE FUNCTION

Edqe

Paper

size

A3

11"

B4

10"

8-1/2"

A4

8"

B5

A5

5-1/2"

B6

A6

Erase

1-3

78-80

1-6

78-80

74-80

1-13

68-80

1-15

66-80

1-16

65-80

1-20

61-80

1-26

55-80

1-27

54-80

1-28

53-80

1-30

51-80

1

80

1-7

5 mm

(0.2")

) 3.5mm

)4.7

)3.5

)4.5

)3

)5

)4.1

)3.5

)4

)4.85

)4

)2.5

79 -80

77-80

1-8

73-80

1-8

73-80

1-15

66-80

1-17

64-80

1-18

63-80

1-22

59-80

1-27

54-80

1-28

53-80

1-29

52-80

1-31

50-80

1-2

1-4

10 mm

(0.4")

)8.5mm

)9.7

)11

)9.5

)8

)10

)9.1

)8.5

)9

)9.85

)9

)7.5

1-3

78-80

1-6

75-80

1-9

72-80

1-10

71-80

1-17

64-80

1-19

62-80

1-20

61-80

1-24

57-80

1-28

53-80

1-29

52-80

1-30

51-80

1-32

49-80

15 mm

(0.6")

)13.5mm

)14.7

)13.5

)14.5

)13

)15

)14.1

)13.5

)14

)14.85

)14

)12.5

30 November 1990

20 mm

(0.8")

1-4

)18.5mm

77-80

1-8

)22.2

73-80

1-11

)18.5

70-80

1-12

)19.5

69-80

1-19

)18

62-80

1-21

)20

60-80

1-22

)19.1

59-80

1-26

)21

55-80

1-29

)19

52-80

1-30

)19.85

51-80

1-31

)19

50-80

1-33

)17.5

48-80

The edge erase function erases a border around the copy. The border is

adjustable in 4 steps using SP mode #38. These borders are approximately

5, 10, 15, and 20 millimeters wide, but vary slightly according to paper size

and the selected repro duction ratio. The table shows the ON/OFF condition

of the erase lamp LEDs for the various paper sizes. The factory setting is 10

millimeters.

2-23

Page 54

30 November 1990

4.5 ERASE LAMP CIRCUIT

LED

23456

IC 1

GND SI L R CK E VCC SO

78

9

LED

10 11 12

GND SI L R CK E VCC SO

CN37-F

CN37-6

CN37-A

CN37-1

CN37-5

CN37-2

CN37-3

CN37-4

IC 2

13

14

5V(VC)

C-GND

CLOCK

ENABLE

LATCH

ERASE DATA

15 16

B-GND

5V(VB)

73

LED

GND SI L R CK E VCC

CN102-B1

CN102-A16

CN102-B17

CN102-B18

CN102-A18

CN102-A17

This copier uses 80 LEDs in the era se lamp unit. The large number of LEDs

allows precise control of the side erase margins.

Shift register drivers contro l the LEDs. Init ially, the ENAB LE signal (LOW

active) sets all shift registers t o OFF. Th en the main board sends ERASE

DATA to the shift registers fro m CN1 02-A17.

74 75 76 77 78 79 80

IC 10

ERASE UNIT

MAIN BOARD PCB

After the ENABLE sign al goes ba ck to HIG H, th e shift registers start

accepting data. The dat a bit fo r LE D 1 is set at each CLOCK pulse. If the

data line is HIGH at the time of the CLOCK pulse, the shift regist er is set to

turn the LED on; if it is LOW, the shift register is set to keep the LED off. The

data in the shift registers is shifted right one positio n each clock pulse; so, it

takes 80 CLOCK pulses to set the shift registers for all the LE Ds.

After all data bits have been sent, th e main boa rd sen ds th e LATCH sig nal to

turn on the erase lamp unit. Simultaneously, the shift registers turn on all

LEDs for which data bits have been set.

To turn off the erase lamp unit, the ENABLE signal is reset to LOW.

2-24

Page 55

5. DEVELOPMENT

5.1 OVERVIEW

[D]

[E]

30 November 1990

[C]

This copier uses a double roller develop men t (DRD) system. This system

differs from single roller develo pment system in that (1) it develop s the image

in a narrower area, (2) it develops the image twice, and (3) the relative speed

of each development roller ag ain st the drum is reduced. Also, finer toner and

developer (smaller particle size) are used . Both DRD system and new

supplies improve the image, especially of thin horizont al line s, th e tra iling

edges of the half-tone areas, and black cross points.

When the main board sends the trigg er sign al to the development motor

PCB, the development mot or (dc motor) is energized. When it turns on, the

agitators [A], paddle roller [B] and two development rollers [C] start turning.

The paddle roller picks up developer in it s paddles and transports it to the

lower development roller. Internal permanent magnets in the development

rollers attract the develo pe r to th e development roller sleeve. The turning

sleeve of the lower deve lop ment roller carries the developer t o th e up pe r

development roller. The upper de velo pment roller carries the developer past

the doctor blade [D]. The do cto r b lad e trims the developer to the desired

thickness and creates backsp ill to th e cross mixing me cha nism.

The development rollers con tin ue to turn, carrying the developer to the

selenium drum [E]. When the developer brush contacts the drum surface, the

positively charged areas of the drum surface attract and hold the negatively

charged toner. In th is wa y, th e latent image is developed.

[A]

The development roller is given a posit ive bia s to pre ven t the toner from

being attracted to the non-imag e are as on the drum surf ace that may have a

slight residual positive charge.

After turning another 100 degrees, the developer is released to the

development unit.

2-25

Page 56

30 November 1990

5.2 DRIVE MECHANISM

[B]

[C]

[A]

[A]: Development Drive Ge ar

[B]: Auger Gear

[C]: Development Roller Gears

The gears of the develop ment unit and the toner agit at or ge ar are driven by

the development drive gear [A] when the development motor turns. The

rotation is transmitted as follows:

[A] ⇒ [B] ⇒ [C]

The above gears are helical gears. Helical gears are more quiet than normal

gears. The teeth of the de velo pment drive gear are chamfere d so th at they

smoothly engage with the develo pment roller gears [C] when the unit is

installed.

2-26

Page 57

5.3 CROSSMIXING

[E]

[C]

30 November 1990

[A]

[D]

[B]

[F]

[B]

[D]

[A]

[E]

[C]

[F]

This copier uses a standard cross-mixing mechanism to keep the toner and

developer evenly mixed . It also he lps ag ita te the developer to prevent

developer clumps from forming and help s creat e th e turbo electric charge.

The developer on the tu rning development roller is split int o two parts by the

doctor blade [A]. The part tha t stays on the development roller [B] forms the

magnetic brush and develops the latent image on the drum. The part that is

trimmed off by the doctor blade goes to the backspill plate [C].

As the developer slides down the backspill plate to the agit ator [D], the mixing

vanes [E] move it slightly to ward the rear of the unit. Part of the developer

falls into the auger inlet and is transp ort ed to the fro nt of the unit by th e auge r

[F].

The agitator moves th e de velo pe r slig ht ly t o th e fro nt as it turns, so the

developer stays level in th e de velo pment unit.

2-27

Page 58

30 November 1990

5.4 IMAGE DENSITY CONTROL

Image density is contro lled in two ways: 1) by changing the streng th of th e

bias voltage applied to the develop ment roller sleeve, and 2) by changing the

strength of the volta ge app lied to th e exposure lamp.

Applying a bias voltage to the development sleeve reduce s the pot en tia l

between the develo pment roller and the drum, which redu ces the amount of

toner transferred; so, the stronger the bia s volta ge , the lighter the copy

image. Similarly, increasing th e volt ag e to the expo sure lamp causes an

increase in light intensity, which also results in lighter copies.

The control method is dif fe rent depending on whether the image density is

selected manually or the automatic ID system is used .

Manual Image Density Control

LIGHT<--------------------------------------------------------------> DARK

ID Level 7 6 5 4 3 2 1

V1:Bias 350 320 290 290 260 260 260

V2: Lamp

Voltage

Vo+4.5 Vo+3.5 Vo+2.5 Vo V o– 1 Vo–3.5 Vo–5

Vo = 50 to 80 volts ac

When image density is set manually, the de velo pment bias (base level) and

the exposure lamp voltag e vary as shown in the above table. The lamp

voltage at ID level 4 (Vo) can be adjust ed wit h SP mode #48.

2-28

Page 59

Auto Image Density Control

Leading edge of original

30 November 1990

14 mm

Exposure Lamp

36 mm

Fiber Optic Cable

When automatic image density cont rol is se lect ed , the exp osure lamp voltage

is set at position 4. Image density is contro lled only by cha ng ing the bias

voltage.

At the start of the copy cycle the original sensing mechan ism measures the

background density of the origin al imag e. It does this by measuring the

strength of the light reflected fro m a 36 mm strip. This strip sta rts 14 mm from

the leading edge of the original. A fiber optic cable pipes the reflected light to

a photodiode on th e main board. The photod iod e is t he inpu t element of the

auto ID circuit.

2-29

Page 60

30 November 1990

500

400

Bias Voltage

(V1)

300

200

530

500

470

440

410

380

350

320

290

Auto

ID

Input

Voltage

0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0

Auto ID Peak Hold Input Voltage

Leading edge of original

14 mm

Forward scan

36 mm

Peak hold

Auto ID data

Vod/Vod (ref.)

The CPU checks the voltage output by the auto ID circuit. This circuit ha s a

peak hold function. The peak hold volt ag e corre spo nd s to the maximu m

reflectivity of the origina l. Based on the peak hold voltage, the CPU

determines the proper bias ba se leve l and send s a 5 -bit con tro l sig nal t o th e

power pack. The power pack then applie s the prop er bia s to th e de velo pment

roller.

During ADS 1 voltage adjust ment at SP mode #56, the scanner moves to the

VL pattern position aft er the volt ag e is aut oma tica lly se t to 3.0 volts at the

pure white original. At this time, the main CPU checks the reflected light from

the VL pattern through the fib er op tic cab le an d kee ps this va lue in memory

as the Vsl reference fo r the ADS. At the second scan of every VL det ect ion,

the main CPU also monitors th e Vsl da ta through the fiber optic cable an d

compare it with the Vsl referen ce da ta .

If the Vsl data voltage diff ers fro m it s refe rence, the main CPU compensates

the ADS reference voltage automatically.

2-30

Page 61

30 November 1990

Bias Compensation Factors

As discussed previously, the bia s base level is set either by the automatic

image density system or by the operator through the image density keys. The

CPU increases the base bias level as ne cessa ry t o compen sat e for the rest

time between copy runs and the drum temperature, both of which affect drum

sensitivity.

1) Rest Time Compensation

10 ∼ 20°C

# of copies

Rest Time

0 ∼ 3 min

3 ∼ 50 min

50 min ∼ 2 hr

123

Same as previous copy

3030000

30 30 30 0 0

Copies

4 ∼ 56 ∼ 10

>2 hr 60 3 0 30 30 0

20 ∼ 45°C

# of copies

Rest Time

0 ∼ 10 sec

10 sec ∼ 3 min

3 ∼ 50 min

50 min ∼ 2 hr

123

Same as previous copy

30 30 30 0 0

60 60 30 30 0

90 60 60 30 30

Copies

4 ∼ 56 ∼ 10

>2 hr 12090906030

Note: Figures are in + Vdc.

The drum sensitivity often drops slightly ove r the first few cycles of a cop y

run. This is because the light fro m t he expo sure lamp fatigues the drum

slightly, and it takes a few co pie s f or th e selenium to restabilize. The amo un t

that the sensitivity drops depen ds on the rest time between copy runs (the

longer the rest time, the greate r the change . Se e above tab le).

The time at which each copy cycle is completed is stored in RAM. The CPU