Ricoh 5733 Service Manual

FT5733/5433

(contains FT4727/4427 Information)

FIELD SERVICE

MANUAL

SECTION 1

SPECIFICATIONS

1. SPECIFICATIONS

Configuration: Desktop

Copy Process: Dry electrostatic transfer system

Originals: Sheet/Book

Original Size: Maximum 11" x 17"

Copy Paper Size: Maximum 11" x 17"

Minimum 51/2" x 81/2" (lengthwise)

(Duplex Copying)

Multiple:

Single/Overlay:

Copy Paper Weight: • 250-sheet paper tray and 1000-sheet large

81/2" x 11" (sideways)

Maximum 11" x 17"

Minimum 81/2" x 11"

capacity tray:

14 _34lb

• By-pass feed table:

14 _43lb

• Duplex and overlay:

17 _28lb

Reproduction Ratios: 4 Enlargement and 6 Reduction

FT5733/5433

200%

Enlargement

Full Size 100%

Reduction

155%

129%

121%

93%

85%

77%

74%

65%

50%

Receiving Tray

Capacity:

250 sheets (81/2" x 14" and smaller)

100 sheets (11" x 17")

Power Source: 115V, 60HZ, more than 12A

FT5733/5433 1-1 FSM

Rev. 10/92

Power Consumption: Maximum: 1.5 KW

Warm-up: 0.77 KW

Stand-by: 0.14 KW

Copy Cycle (average): 1.2 KW

Noise Emission: Stand-by: less than 40 dB

Copy Cycle (average):

less than 57 dB (copier only)

less than 59 dB (full system)

Maximum:

less than 62 dB (copier only)

less than 63 dB (full system)

Dimensions:

Width Depth Height

FT5733 34.3" (42.2") 23.6" 21.3" (22.6")

FT5433 34.3" (42.2") 23.6" 21.3" (22.6")

( ): When the by-pass feed table is opened, the copy tray is

extended, and the platen cover is installed.

Weight: Copier only (Without the optional platen

cover=Approximately 2 kg)

FT5733: approximately 194.0 lb

FT5433: approximately 185.2 lb

Zoom: From 50% to 200% in 1% steps

Copying Speed: 33 copies/minute (81/2" x 11" sideways)

18 copies/minute (11" x 17")

Warm-up Time: Less than 2 minutes (20°C, 68°F)

FSM 1-2 FT5733/5433

Rev. 1/94

First Copy Time: Black copy:

4.9 seconds (81/2" x 11" sideways)

FT5733/5433: (Large capacity tray feed)

Color copy:

7.0 seconds

FT5733/5433: (Large capacity tray feed)

Copy Number Input: Ten keys, 1 to 999 (count up or count down)

Manual Image Density: 7 steps

Automatic Reset: 1 minute standard setting; can also be set to

3 minutes or no auto reset.

Copy Paper Capacity: • By-pass feed table; approx. 20 sheets

• Paper tray: approx. 250 sheets

• Large capacity tray; approx. 1000 sheets

Toner Replenishment: Black: cartridge exchange

(320 g/cartridge) yield 10,500 copies

Color: cartridge exchange

(60 g/cartridge) yield 1300 copies

Black: (1000 g/bag) yield 80,000 copies

Developer

Replenishment: Color: (400 g/bag) yield 15,000 copies

Optional Equipment: • Platen cover

• DF56, Document feeder

• PS250, Paper tray unit with three paper tray

• CS2090, 20 bin mini sorter

• ST22, 20 bin sorter stapler

• TYPE G Sorter adapter (needed when

installing the mini, or the sorter stapler)

• TYPE G Interface PCB (needed when

installing the sorter stapler or the menu

reader)

• MR20, Menu reader

• RE12, Editor (only for FT5733)

• TYPE B, Editing interface adapter (needed

when installing the editor)

• CU150, Color development unit

• Key counter

• DLT counter (service part)

FT5733/5433 1-3 FSM

SECTION 2

COMPONENT LAYOUT

AND DESCRIPTIONS

1. MACHINE CONFIGURATION

1.1 COPIER

FT5733(A074) FT5433(A073)

UPPER TRAY DUPLEX 250

LOWER TRAY 250 250

LCT 1,000 1,000

1.2 OPTIONAL EQUIPMENT

Rev. 11/92

MR20

MENU READER (A952)

CS2090

20 BIN SORTER

(A423)

DF56

ARDF (A497)

RE12

EDITOR (A916)

SORTER ADAPTER

(A328)

ST22

SORTER STAPLER

(A366)

SYSTEM TABLE

(438-MIU)

PS250

PAPER TRAY UNIT

(A326)

FSM 2-1 FT5733/5433

COPIER

REQUIRED OPTIONAL

EQUIPMENT

SORTER

1 TRAY

PAPER

TRAY UNIT

SORTER

DOCUMENT

FEEDER

EDITOR (A916) x o x * **

MENU READER (A952) o o o **

COLOR DEVELOPMENT

UNIT (A337)

(A325)

3 TRAY

(A326)

10 BIN

(A327)

20 BIN MINI

(A423)

20 BIN MIDI

(A411)

20 BIN

STAPLER

(A366)

ARDF

(A497)

TYPE 1

(A069)

TYPE 2

(A074)

TYPE3

(A073)

ADAPTER

(A328)

o o o

o o o

o o o *

o o o *

o o o * **

o o o

o o o

INTERFACE

PCB

(A344)

EDITING

INTERFACE

ADAPTER

(A345)

NOTE1: * The sorter adapter is required to install the 20 bin

mini sorter, 20 bin midi sorter or sorter stapler.

* * The I/F board is required to install the sorter stapler

or Menu Reader.

** *(1) The editing interface adapter is required to

install

the editor.

(2) The editing interface adapter can be installed

independently when more precise erasing is

desired.

NOTE 2: When installing the sorter stapler, the copier must be placed

on the paper tray unit or a table of exactly the same height.

FT5733/5433 2-2 FSM

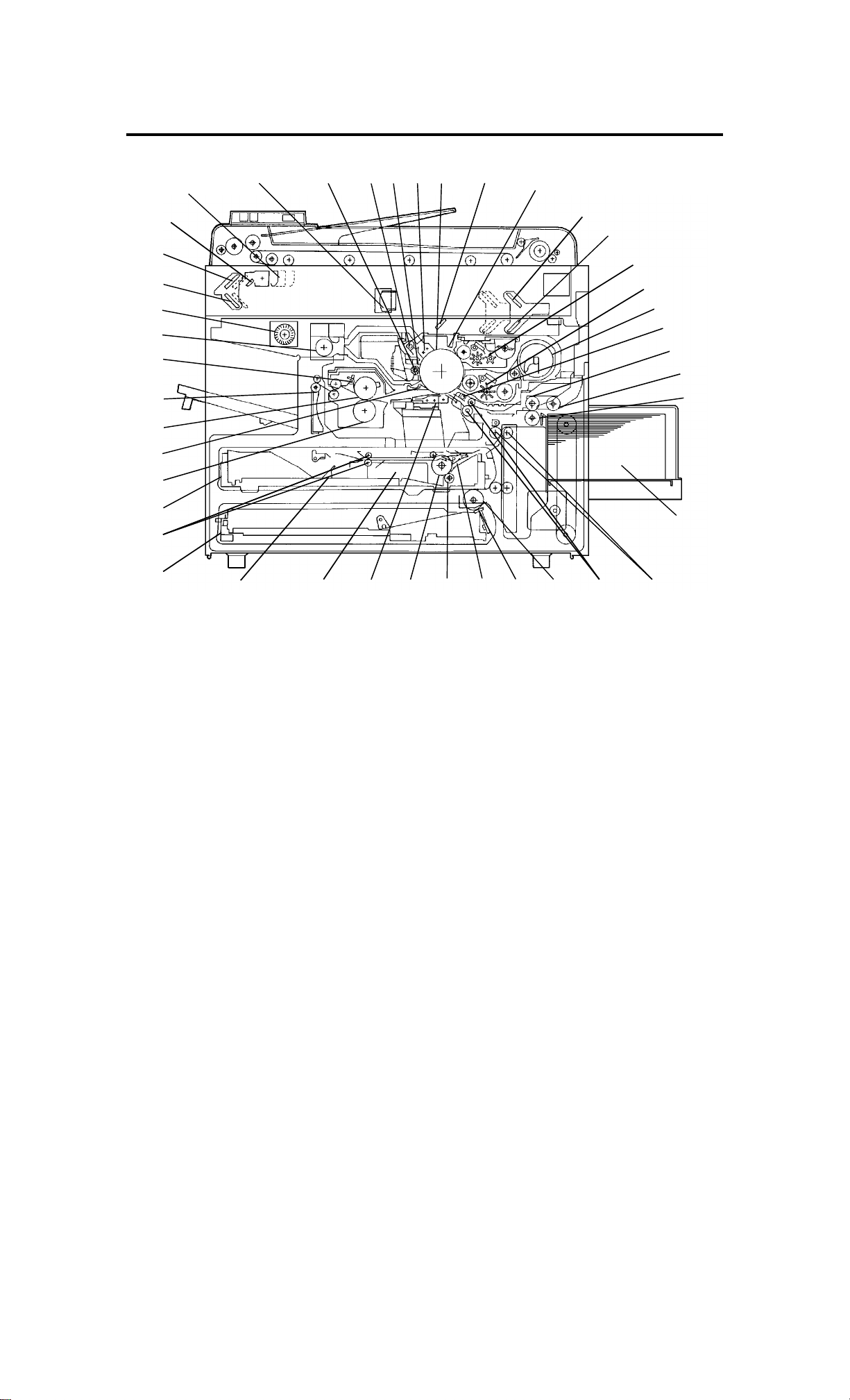

2. MECHANICAL COMPONENT LAYOUT

424142

40

39

38

37

36

35

34

111098765

4

3

2

1

12

13

14

15

16

17

18

19

20

21

22

33

32 31 30

1. 3rd Mirror

2. 2nd Mirror

3. 1st Mirror

4. Exposure Lamp

5. Lens

6. Cleaning Brush

7. Quenching Lamp

8. Cleaning Blade

9. Change Corona Unit

10. OPC Drum

11. 6th Mirror

12. Erase Unit

13. 4th Mirror

14. 5th Mirror

15. Color Development Unit

16. Black Development Unit

17. Black Toner Supply Unit

18. Pre-Transfer Lamp

19. Feed Roller

20. Pick-up Roller

21. Separation Roller

29 28 27

26 25 24 23

22. Large Capacity Tray

23. Relay Rollers

24. Registration Rollers

25. Paper Tray Feed Roller

26. Friction Pad

27. Turn Gate

28. Duplex Friction Roller

29. Duplex Feed Roller

30. Transfer & Separation

Corona Unit

31. Jogger Fences

32. End Fence

33. Lower Paper Tray

34. Entrance Rollers

35. Duplex Tray

36. Pressure Roller

37. Pick-off Pawls

38. Hot Roller

39. Junction Gate

40. Hot Roller Strippers

41. Transport Fan

42. Fusing Exhaust Fan

FSM 2-3 FT5733/5433

3. DRIVE LAYOUT

23

22

21

20

1

26

25

24

2

19

18

17

16

13

1015

12

5

10

11

6

7

8

9

14

134

FT5733/5433 2-4 FSM

1: Main Motor Pulley

3: Fusing Drive Belt 2: Drum Drive Belt

4: Drive Distribution

Gear/Pulley

23: Drive Distribution Belt Cleaning drive Gear 9: Fusing Unit

12: Drive Distribution

Gear/Pulley

25: Drum Drive Pulley 24: Development Drive

Drum Development

Cleaning Unit Fusing

20: Toner Supply Drive

Gear/Pulley

22: Toner Supply

CL Gear

21: Development Unit

Shift Gears

26: Development Drive

Belt

CL Pulley

Drive Gear

6: Copier Exit Roller

Gear

7: Duplex Transport

Drive Belt

8: Duplex Transport

Roller Pulley

19: Paper Feed

Drive

16: Paper Feed

Drive Belt

14: Lower paper

Feed CL Gear

10: Registration CL Gear

11: Upper Paper Feed

13: Feed Relay CL Gear

17: Relay Roller

18: By-pass Feed

CL Gear

15: Tray Unit drive

Gear

5: Sorter Adapter Gears

FSM 2-5 FT5733/5433

4. ELECTRICAL COMPONENT DESCRIPTION

Refer to the electrical component layout on the reverse side of the

Point to Point (Water proof paper) for symbols and index numbers.

Symbol Name Function Index

No.

Motors

M1 Main Drives the main unit components. 1

M2 Exhaust blower Blows the ozone built up around the

charge section through the ozone

filter.

M3 Upper tray lift

(non-duplex

machine only)

M4 Lower tray lift Raises the bottom plate in the lower

M5 Transport fan Provides air flow to the transport

M6 Fusing exhaust

fan

Raises the bottom plate in the upper

paper tray.

paper tray.

section so that paper is held on the

transport guide. Also the air flow

isolates the toner collection tank from

fusing heat.

Provides air flow to the charge

corona section as well.

Removes the heat from around the

fusing unit.

6

31

28

65

66

M7 Scanner drive Drives the 1st and 2nd scanners (dc

stepper).

M8 3rd scanner

drive

M9 Optics cooling

fan

M10 Lens drive Positions the lens. 100

M11 Duplex feed

(duplex

machine only)

M12 Jogger (duplex

machine only)

Drives the 3rd scanner (dc stepper). 75

Removes heat from the optics unit. 77

Drives the feed roller and moves the

bottom plate up and down (24 V dc

stepper).

Drives the jogger fences to square

the paper stack in the duplex tray (dc

stepper).

67

103

107

FT5733/5433 2-6 FSM

Symbol Name Function Index

No.

M13 LCT lift Lifts up and lowers the LCT bottom

plate.

Circuit Board

PCB1 dc power supply Drives the exposure and fusing

lamps and rectifies 100 Vac or

220/230/240 Vac input and outputs

dc voltages.

PCB2 Main control Controls all copier functions both

directly and through the other control

boards.

PCB3 Scanner motor

control

PCB4 Main motor

control

Controls the speed of the scanner

drive motor.

Controls the rotation of the main

motor.

79

44

10

69

71

PCB5 Operation panel Controls the LED matrix, and

monitors the key matrix.

PCB6 ADS sensor Senses the background density of

the original.

PCB7 High voltage

supply - CTBG

Supplies high voltage for the charge

corona, grid bias, transfer corona,

and development bias.

PCB8 High voltage

supply - D

PCB9 PTL/QL

stabilizer

PCB10 Duplex control

(duplex

Supplies high voltage for the

separation corona.

Provides high voltage for the

quenching and pre-transfer lamps.

Controls the rotation of the duplex

feed motor.

machine only)

93

90

9

8

73

106

PCB11 LCT interface

(LCT machine

only)

PCB12 Guidance

Interfaces the LCT control signal

80

between the main control board and

the LCT.

Controls the guidance display board. 92

display control

(duplex

machine only)

PCB13 Guidance

display (duplex

Displays guidance for machine

operation.

94

machine only)

FSM 2-7 FT5733/5433

Symbol Name Function Index

No.

PCB14 Interface - type

G (option for

sorter stapler

and menu

reader)

Switches

SW1 Upper paper

size - 1

(non-duplex

machine only)

SW2 Upper paper

size - 2

(non-duplex

machine only)

SW3 Upper paper

size - 3

(non-duplex

machine only)

Interfaces the sorter stapler and

menu reader with the main control

board.

Determines what size paper is in the

upper paper tray.

Determines what size paper is in the

upper paper tray.

Determines what size paper is in the

upper paper tray.

16

2

3

4

SW4 Upper paper

size - 4

Determines what size paper is in the

upper paper tray.

(non-duplex

machine only)

SW5 Lower paper

size - 1

SW6 Lower paper

size - 2

SW7 Lower paper

size - 3

SW8 Lower paper

size - 4

Determines what size paper is in the

lower paper tray.

Determines what size paper is in the

lower paper tray.

Determines what size paper is in the

lower paper tray.

Determines what size paper is in the

lower paper tray.

SW9 Color detection Detects if color development unit is

set or not and which color toner

development unit is installed.

5

36

34

33

32

13

SW10 Exit cover

Cuts the ac power line. 64

(Duplex

machine only)

SW11 Platen cover Informs the CPU when the platen

88

cover is closed.

FT5733/5433 2-8 FSM

Symbol Name Function Index

No.

SW12 Front door safety Cuts the ac power line through RA1

91

and detects if the front door is open

or not.

SW13 Main Supplies power to the copier. 95

SW14 LCT cover - 1 Detects if the LCT cover is open or

83

not.

SW15 LCT cover - 2 Cuts the dc power line of the LCT lift

84

motor.

SW16 LCT down Sends a signal to the CPU to lower

85

the LCT bottom plate.

Lamps

L1 Quenching Neutralizes any charge remaining on

47

the drum surface after cleaning.

L2 Pre-transfer Reduces the charge on the drum

49

surface before transfer.

L3 Fusing Provides heat to the hot roller. 60

L4 Exposure Applies high intensity light to the

99

original exposure.

L5 Erase Eliminates the charge for

48

unnecessary areas of the image on

the drum surface before exposure.

Magnetic

Clutches

MC1 Development

Drives the development roller. 11

drive

MC2 Toner supply Drives the toner supply roller. 14

MC3 By-pass feed Starts paper feed from the by-pass

17

feed table or LCT.

MC4 Feed relay Drives the relay rollers. 19

MC5 Registration Drives the registration rollers. 20 No.

MC6 Upper paper

feed

Starts paper feed from the upper

paper tray.

22

(non-duplex

machine only)

FSM 2-9 FT5733/5433

Symbol Name Function Index

No.

MC7 Lower paper

feed

Starts paper feed from the lower

paper tray.

Solenoids

SOL1 Development

unit change

Changes the position of the black

development unit and color

development unit.

SOL2 Pick-up roller Picks paper up from the by-pass

feed table or LCT.

SOL3 Duplex tray lock

(duplex

Locks the duplex tray in the main

copier.

machine only)

SOL4 Upper tray lock

(non-duplex

Locks the upper paper tray in the

main copier.

machine only)

24

12

18

29

39

SOL5 Lower tray lock Locks the lower paper tray in the

main copier.

SOL6 Junction gate

(duplex

machine only)

SOL7 Duplex turn

gate (duplex

machine only)

Moves the junction gate to direct

copies to the duplex tray or to the

paper exit.

Moves the duplex turn gate to direct

copies to the duplex tray or to the

relay rollers.

Sensors

S1 By-pass feed

table

S2 Upper tray set

(non-duplex

Detects if the by-pass feed table is

open or closed.

Detects if the upper paper tray is set

or not.

machine only)

37

43

105

15

21

S3 Lower tray set Detects if the lower paper tray is set

26

or not.

S4 By-pass feed

paper end

S5 Upper tray

paper end

Informs the CPU that there is no

paper in the by-pass feed table.

Informs the CPU when the upper

paper tray runs out of paper.

53

23

(non-duplex

machine only)

FT5733/5433 2-10 FSM

Symbol Name Function Index

No.

S6 Lower tray

paper end

S7 Upper tray

upper limit

(non-duplex

Informs the CPU when the lower

paper tray runs out of paper.

Detects the upper position of the

paper stack in the upper tray to stop

the upper lift motor.

machine only)

S8 Lower tray

upper limit

Detects the upper position of the

paper stack in the lower tray to stop

the lower lift motor.

S9 Lower relay Detects the lead edge of paper from

the lower paper tray to determine the

stop timing of the lower paper feed

clutch and detects misfeeds.

S10 Upper relay Detects the lead edge of paper from

the upper paper tray to determine the

stop timing of the upper paper feed

clutch and detects misfeeds.

25

30

27

51

50

S11 Registration Detects the lead edge of paper to

52

determine the stop timing of the feed

relay clutch and detects misfeeds.

S12 Image density

(ID)

Detects the density of the ID sensor

pattern on the drum to control the

57

toner density.

S13 V Detects the VR and VL patterns. 58

S14 Fusing exit Detects misfeeds. 62

S15 Junction gate

Detects misfeeds. 63

(duplex

machine only)

S16 Scanner H.P. Informs the CPU when the 1st

68

scanner is at the home position.

S17 Lens H.P. Informs the CPU when the lens is at

72

the full-size position.

S18 Platen position Informs the CPU when the platen

74

cover is positioned. When the angle

between, the platen cover and the

exposure glass is about 30 degrees.

S19 3rd scanner H.P. Informs the CPU when the 3rd

76

scanner is in the full size position.

FSM 2-11 FT5733/5433

Symbol Name Function Index

No.

S20 Original length Detects the original length. 89

S21 Original width Detects the original width. 96

S22 Duplex entrance

(duplex

machine only)

S23 Duplex turn

gate (duplex

machine only)

S24 Duplex paper

end (duplex

machine only)

S25 Jogger H.P.

(duplex

machine only)

S26 LCT paper end

(LCT machine

only)

Detects misfeed. 109

Detects the trail edge of paper to

101

determine the reverse timing of the

duplex motor and detects misfeed.

Detects copy in the duplex tray. 102

Detects if the jogger fences are at

108

home position.

Informs the CPU when the LCT runs

82

out of paper.

S27 LCT lower limit

(LCT machine

Sends signal to CPU to stop lowering

the LCT bottom plate.

only)

S28 LCT upper limit

(LCT machine

Sends signal to CPU to stop lifting up

the LCT bottom plate.

only)

Heaters

H1 Drum Turns on when the main switch is off

to prevent moisture around the drum.

H2 Optics

anti-condensation

(option)

H3 Upper tray

(option)

Turns on when the main switch is off

to prevent moisture from forming on

the optics.

Turns on when the main switch is off

to keep paper dry in the upper paper

tray.

81

78

54

97

55

H4 Lower tray

(option)

Turns on when the main switch is off

to keep paper dry in the lower paper

87

tray.

FT5733/5433 2-12 FSM

Symbol Name Function Index

No.

Thermistor

TH1 Drum Monitors the temperature around the

drum.

TH2 Fusing Monitors the temperature of the hot

roller.

TH3 Optics Monitors the temperature of the

optics cavity.

TH4 Duplex motor

(duplex

Monitors the temperature of the

duplex motor.

machine only)

Thermofuse

TF1 Fusing Provides back-up overheat

protection in the fusing unit.

56

59

98

104

61

Thermoswitch

TS1 Optics Provides overheat protection in the

70

optics unit.

Noise filter

NF1 Removes electrical noise. 40

Fuse

FU1 Main (115 V

machine only)

Provides back-up high current

protection in the electrical

42

components.

FU2 Sorter line (115

V machine only)

Provides back-up high current

protection in the electrical

46

components of the sorter.

FU3 DF line (115 V

machine only)

Provides back-up high correct

protection in the electrical

7

components of the ARDF.

Circuit Breaker

CB1 (230 V machine

only)

Provides back-up high current

protection in the electrical

41

components.

FSM 2-13 FT5733/5433

Symbol Name Function Index

No.

Relay

RA1 Main power Controls main power. 45

Transformer

TR1 Main Steps down the wall voltage to 100 V

ac.

Counter

CO1 Total Keeps track of the total number of

copies made.

38

86

FT5733/5433 2-14 FSM

SECTION 3

INSTALLATION

1. INSTALLATION REQUIREMENT

1.1 ENVIRONMENT

1. Temperature Range: 10oC to 30oC (50oF to 86oF)

2. Humidity Range: 15% to 90% RH

3. Ambient Illumination: Less than 1,500 lux (do not expose to direct

sunlight)

4. Ventilation: Minimum space 20 m3. Room air should turn over at

least 30 m3/hr/person.

5. Ambient Dust: Less than 0.15 mg/m3 (4 x 10-6 oz/yd3)

6. If the machine location is air-conditioned or heated, place the

machine:

a) where it will not be subjected to sudden

temperature changes.

b) where it will not be directly exposed to cool

air from an air-conditioner in the summer.

c) where it will not be directly exposed to

reflected heat from a space heater in winter.

7. Avoid placing the machine in an area filled with corrosive gas.

8. Avoid any places higher than 2,000 meters (6,500 feet) above

sea level.

9. Place the machine on a strong and level base.

10. Avoid any area where the machine may be frequently subjected

to strong vibration.

FSM 3-1 FT5733/5433

1.2 MACHINE LEVEL

1. Front to back level: within 5 mm (0.2")

2. Right to left level: within 5 mm (0.2")

Use a carpenter’s level to level the machine

1.3 MINIMUM SPACE REQUIREMENTS

Copier only

a

d

a: more than 10 cm/3.9"

(When the micro sorter is

installed: 15 cm/5.9")

b: more than 40 cm/15.7"

c: more than 80 cm/31.5"

d: (When you use the copy

tray): more than 30

cm/11.8"

c

b

Full system

e

h

f

g

e: more than 10 cm/3.9" (When the

micro sorter is installed: 15

cm/5.9")

f: more than 40 cm/15.7"

g: more than 80 cm/31.5"

h: more than 20 cm/11.8" (When

the sorter stapler is installed: 10

cm/3.9")

NOTE: When the micro sorter is equipped, make sure there is at

least 15 cm (6.0") clearance on the back side, in order to

avoid damaging the sorter when it is opened.

FT5733/5433 3-2 FSM

1.4 POWER REQUIREMENTS

1. Input voltage level:

110V/60Hz : More than 15A (for Taiwan)

115V/60Hz : More than 15A (for N.A.)

220V/230V/240V/50Hz : More than 8A (for EU.)

220V/60Hz : More than 8A

2. Permissible voltage fluctuation: ±10%

3. Do not set anything on the power cord.

NOTE: a) Make sure the plug is firmly inserted in the outlet.

b) Avoid multi-wiring.

FSM 3-3 FT5733/5433

2. COPIER INSTALLATION

2.1 COPIER INSTALLATION

2.1.1 Accessory Check

1. Receiving Tray.................................................................1

2. Outer Decal - Symbol Explanation..................................1

3. Sorter Key Top and Cover...............................................1

4. Counter Set Key (--17 machine only) ..............................1

5. Installation Procedure......................................................1

6. Operating Instructions (Except --27 machine).................1

7. Now Equipment Condition Report

(--17, --19, --27, --29 machine only)..................................1

8. Envelope for NECR (--17 machine only) ......................... 1

9. User Survey Card (--17 machine only)............................1

FT5733/5433 3-4 FSM

2.1.2 Installation Procedure

[A]

[A]

[B]

[G]

[F]

[C]

[H]

[D]

[E]

[A]

NOTE: Keep the shipping retainers after installing the machine.

They will be reused if in the future the machine is

transported to another location.

Proper reinstallation of the shipping retainers is required in

order to avoid any transport damage. It is important to

replace the scanner lock pins and the scanner lock plate

before transporting this copier. If it is not done, skewed

image may result.

1. Remove the 7 strips of tape [A] as shown.

2. Open the front door and remove 4 strips of tape [B] as shown.

3. Pull out the paper tray [C], and remove a strip of tape [D] and the

foam block [E] (1 tray for the duplex machine and 2 trays for the

non-duplex machine).

4. Pull out the duplex tray [F] and remove the 2 strips of tape [G]

and 3 sheets of paper [H] (duplex machine only).

FSM 3-5 FT5733/5433

[B]

[A]

[D]

[C]

[E]

5. Remove the left scale [A] (2 shoulder screws).

6. Remove the scanner lock pin [B] simply by pulling it up from the

front and the rear side of the left scale bracket.

7. Reinstall the left scale.

8. Remove the left optics cover [C] (1 screw).

9. Remove the scanner lock plate [D] (1 screw) by pulling and lifting

it up and reinstall the left optics cover.

10. Remove the shipping retainer [E] holding the ozone filter. The

retainer is taped on the upper exit cover.

FT5733/5433 3-6 FSM

[C]

[B]

[A]

[C]

[D]

[E]

[F]

11. Push the development unit lock lever [A] to the right (to the lock

position).

12. Move the development release lever [B] to the right and pull out

the black development unit [C] half way. Holding the toner supply

unit [D] with your right hand and the bottom of the development

unit with your left hand, pull the unit all the way out . Place the unit

on a clean sheet of paper.

13. Separate the toner supply unit from the development unit (3

screws).

14. Pour one pack of black developer [E] into the development unit

while turning the development roller knob [F] counterclockwise.

This will distribute the developer inside the unit.

15. Remount the toner supply unit on the development unit.

FSM 3-7 FT5733/5433

[B]

Rev. 10/92

[C]

[A]

[E]

16. Lower the transfer & separation corona unit by pulling down the

release lever [A].

17. Turn the cleaning unit release lever [B] counterclockwise to the

upright position. (The cleaning unit is released from the drum.)

18. Remove the drum protective sheet [C] from the development unit

opening.

CAUTION: To avoid damaging the pick-off pawls, remove the

drum protective sheet by pulling the lower side as

shown in the figure.

[D]

19. Turn the cleaning unit release lever clockwise to the set position.

20. Remove the cleaning blade lock plate [D].

21. Reset the transfer & separation corona unit [E].

FT5733/5433 3-8 FSM

[C]

[E]

[B]

[A]

[C]

[D]

[F]

22. Install the black development unit [A] in the copier, and remove

the cover sheet [B] from the toner supply unit.

NOTE: • When installing the development unit, be sure that the

development unit rail is placed directly on the

development unit guide rail.

• Make sure that the development release lever [C] is in

its original position after the development unit is set.

23. Shake the toner cartridge [D] well from side to side. While

pushing the toner cartridge in, insert it halfway into the holder with

the seal [E] up.

24. As you peel off the seal, insert the cartridge completely. While

pushing the toner cartridge in, turn it counterclockwise until it

stops.

25. Slide out the charge corona unit [F] until it is fully extended and

push it back in to the original position. Repeat this action several

times.

FSM 3-9 FT5733/5433

Loading...

Loading...