Ricoh 3013, 3213, 3513, 3713 Service Manual

A151/A152/A202/A203

SERVICE MANUAL

RICOH GROUP COMPANIES

PN: RCFM3213

®

®

A151/A152/A202/A203

SERVICE MANUAL

RICOH GROUP COMPANIES

A151/A152/A202/A203

FIELD SERVICE

MANUAL

PN: RCFM3213

It is the reader's responsibility when discussing the information contained within this

document to maintain a level of confidentiality that is in the best interest of Ricoh

Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including desktop images,

used in this document are trademarks, registered trademarks or the property of their

respective companies.

They are used throughout this book in an informational or editorial fashion only and for

the benefit of such companies. No such use, or the use of any trade name, or web

site is intended to convey endorsement or other affiliation with Ricoh products.

2000 RICOH Corporation. All rights reserved.

WARNING

The Field Service Manual contains information

regarding se rvice techniques, procedures, processes

and spare parts of office equ ipment distributed by

Ricoh Corporation. Users of this manual should be

either service trained or certified by successfully

completing a Ricoh Technical Training Program.

Untrained and uncertified users utilizing information

contained in this service manual to repair or modify

Ricoh equip ment risk person al injury, damage to

property or loss of warranty protection.

Ricoh Corporation

LEGEND

PRODUCT CODE COMPANY

GESTETNER RICOH SAVIN

A151 2613 FT3013 9013

A152 2613Z FT3213 9013Z

A202 2713 FT3513 9113

A203 2613 FT3713 9013Z

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

*

1 6/96 Reprint

2 4/97 A202/A203 Addition

3 7/98 Reprint

9/94 Original Printing

Table of Contents

SECTION 1 OVERALL MACHINE INFORMATION

1. SPECIFICATIONS . . . . . . . . . . . . . . . 1-1

SECTION 2 GUIDE TO COMPONENTS

1. MECHANICAL COMPONENT LAYOUT . . . . . . 2-1

2. ELECTRICAL COMPONENT LAY OUT . . . . . . . 2-2

3. ELECTRICAL COMPONENT DESCRIPTIONS . . . . 2-3

4. DRIVE LAYOUT . . . . . . . . . . . . . . . . 2-6

SECTION 3 INSTALLATION

1. INSTALLATION REQUIREMENTS . . . . . . . . 3-1

1.1 ENVIRONMENT . . . . . . . . . . . . . . . . . . . 3-1

1.2 MACHINE LEVEL . . . . . . . . . . . . . . . . . . 3-1

1.3 MINIMUM SPACE REQUIREMENTS . . . . . . . . . . . 3-2

1.4 POWER REQUIREMENTS . . . . . . . . . . . . . . . 3-2

2. INSTALLATION PROCEDURE . . . . . . . . . . 3-3

2.1 ACCESSORY CHECK . . . . . . . . . . . . . . . . 3-3

2.2 COPIER INSTALLATION PROCEDURE . . . . . . . . 3-4

2.3 KEY COUNTER HOLDER INSTALLAT ION (OPTION) . . . . 3-10

SECTION 4 SERVICE TABLES

1. SERVICE REMARKS . . . . . . . . . . . . . . 4-1

1.1 GENERAL CAUTION . . . . . . . . . . . . . . . . . 4-1

1.2 DRUM . . . . . . . . . . . . . . . . . . . . . . . 4-1

1.3 CHARGE CORONA . . . . . . . . . . . . . . . . . 4-2

1.4 OPTICS . . . . . . . . . . . . . . . . . . . . . . 4-3

FSM i A151/A152/A202/A203

1.5 DEVELOPMENT . . . . . . . . . . . . . . . . . . . 4-4

1.6 TONER SUPPLY . . . . . . . . . . . . . . . . . . . 4-4

1.7 TRANSFER AND SEPARATION . . . . . . . . . . . . . 4-5

1.8 CLEANING UNIT . . . . . . . . . . . . . . . . . . . 4-5

1.9 FUSING UNIT . . . . . . . . . . . . . . . . . . . . 4-5

1.10 PAPER FEED . . . . . . . . . . . . . . . . . . . 4-6

1.11 DOCUMENT FEEDER . . . . . . . . . . . . . . . . 4-6

1.12 OTHERS . . . . . . . . . . . . . . . . . . . . . 4-6

2. SERVICE PROGRAM MODE . . . . . . . . . . . 4-8

2.1 SERVICE PROGRAM MODE OPERATION . . . . . . . . 4-8

2.1.1 Service Program Access Procedure . . . . . . . . . 4-8

2.1.2 Change Adjustment Values or Modes . . . . . . . . 4-9

2.1.3 Memory Clear Procedure . . . . . . . . . . . . . 4-10

2.2 SERVICE PROGRAM MODE TABLE . . . . . . . . . . . 4-13

2.3 SP MODE 8–INPUT CHECK . . . . . . . . . . . . . . 4-21

2.4 SP MODE 9–OUTPUT CHECK . . . . . . . . . . . . . 4-22

2.5 SERVICE CALL AND USER CODE TABLE . . . . . . . . 4-23

3. SERVICE TABLES . . . . . . . . . . . . . . . 4-25

3.1 TEST POINTS . . . . . . . . . . . . . . . . . . . . 4-25

3.2 DIP SWITCHES AND JUMPER SWITCHES . . . . . . . . 4-26

3.3 VARIABLE RESISTORS . . . . . . . . . . . . . . . . 4-27

4. SPECIAL T OOLS AND LUBRICANTS . . . . . . . 4-28

5. PREVENTIVE MAINTENANCE SCHEDULE . . . . 4-29

5.1 PM TABLE . . . . . . . . . . . . . . . . . . . . . 4-29

5.2 EXPLANATION OF REGULAR PM . . . . . . . . . . . 4-32

5.3 REGULAR PM PROCEDURE . . . . . . . . . . . . . 4-34

6. DEFECTIVE COMPONENT TABLES . . . . . . . 4-36

A151/A152/A202/A203 ii FSM

6.1 DEFECTIVE SENSOR TABLE . . . . . . . . . . . . . 4-36

6.2 DEFECTIVE SWITCH ES OR OTHER EL ECTRICAL COMPONE NTS 4-37

6.3 OPEN FUSE & CIRCUIT BREAKER TABLE . . . . . . . . 4-38

SECTION 5 REPLACEMENT & ADJUSTMENT

1. EXTERIOR AND INNER COVERS . . . . . . . . 5-1

1.1 EXTERIOR COVER REMOVAL . . . . . . . . . . . . . 5-1

1.1.1 Front Cover . . . . . . . . . . . . . . . . . . 5-1

1.1.2 Right Cover . . . . . . . . . . . . . . . . . . 5-1

1.1.3 Upper Left Cover . . . . . . . . . . . . . . . . 5-2

1.1.4 Lower Left Cover . . . . . . . . . . . . . . . . 5-2

1.1.5 Upper Rear Cover . . . . . . . . . . . . . . . . 5-2

1.1.6 Lower Rear Cover . . . . . . . . . . . . . . . . 5-2

1.1.7 Upper Cover . . . . . . . . . . . . . . . . . . 5-3

1.2 INNER COVER REMOVAL . . . . . . . . . . . . . . . 5-4

2. OPTICS . . . . . . . . . . . . . . . . . . . 5-5

2.1 EXPOSURE GLASS REMOVAL . . . . . . . . . . . . . 5-5

2.2 1ST MIRROR REMOVAL . . . . . . . . . . . . . . . 5-6

2.3 2ND AND 3RD MIRROR REMOVAL . . . . . . . . . . . 5-8

2.4 4TH AND 5TH MIRROR REPLACEMENT . . . . . . . . . 5-10

2.5 EXPOSURE LAMP REPLACEMENT . . . . . . . . . . . 5-11

2.6 THERMOFUSE REPLACEMENT . . . . . . . . . . . . 5-13

2.7 SCANNER DRIVE WIRE REPLACEMENT . . . . . . . . 5-14

2.7.1 Wire Removal . . . . . . . . . . . . . . . . . 5-14

2.7.2 Wire Installation . . . . . . . . . . . . . . . . . 5-15

2.8 SCANNER MOTOR REPLACEMENT . . . . . . . . . . 5-21

2.9 LENS DRIVE MOTOR REPLACEMENT (FT3213 Copier only) 5-22

2.10 4TH/5TH MIRROR MOTOR REPLACEMENT (FT3213 Copier Only) 5-24

FSM iii A151/A152/A202/A203

3. DEVELOPMENT AND TONER SUPPLY . . . . . . 5-25

3.1 DEVELOPMENT UNIT REMOVAL . . . . . . . . . . . . 5-25

3.2 TONER SUPPLY UNIT REMOVAL . . . . . . . . . . . . 5-26

3.3 DEVELOPER REPLACEMENT . . . . . . . . . . . . . 5-27

3.4 INLET SEAL REMOVAL . . . . . . . . . . . . . . . . 5-28

3.5 TONER SUPPLY CLUTCH REPLACEMENT . . . . . . . . 5-29

3.6 DEVELOPMENT BIAS VOLTAGE ADJUSTMENT (SP9-38) . . 5-30

4. CLEANING . . . . . . . . . . . . . . . . . . 5-31

4.1 CLEANING UNIT REMOVAL . . . . . . . . . . . . . . 5-31

4.2 CLEANING BLADE REPLACEMENT . . . . . . . . . . . 5-32

4.3 USED TONER COLLECTION . . . . . . . . . . . . . 5-33

4.4 ENTRANCE SEAL REPLACEMENT . . . . . . . . . . . 5-34

5. PAPER FEED . . . . . . . . . . . . . . . . . 5-35

5.1 FEED ROLLER REPLACEMENT . . . . . . . . . . . . 5-35

5.2 PAPER TRAY SWITCH REPLACEMENT . . . . . . . . . 5-37

5.3 RELAY SENSOR AND REGISTRATION SENSOR REPLACEMENT 5-38

5.4 RELAY ROLLER CLUTCH, PAPER FEED CLUTCH AND

REGISTRATION CLUTCH REPLACEMENT . . . . . . . . 5-40

6. AROUND THE DRUM . . . . . . . . . . . . . 5-42

6.1 DRUM REPLACEMENT . . . . . . . . . . . . . . . . 5-42

6.2 QUENCHING LAMP REPLACEMENT . . . . . . . . . . 5-44

6.3 ERASE LAMP REPLACEMENT . . . . . . . . . . . . . 5-4 5

6.4 CHARGE CORONA WIRE REPLACEMENT . . . . . . . . 5-46

6.5 CHARGE CORONA GRID PLATE REPLACEMENT . . . . . 5-47

6.6 TRANSFER/SEPARATION CORONA WIRE REPLACEMENT . 5-48

6.7 ID SENSOR REPLACEMENT . . . . . . . . . . . . . 5-51

6.8 PICK-OFF PAWL REPLACEMENT . . . . . . . . . . . . 5-52

6.9 TRANSFER/SEP ARATION POWER P ACK REPLACEMENT . 5-53

A151/A152/A202/A203 iv FSM

6.10 CORONA CURRENT ADJUSTMENT . . . . . . . . . . 5-55

6.10.1 Charge Corona Current Adjustment (SP9-2) . . . . . 5-57

6.10.2 Grid Voltage Adjustment (SP9-48) . . . . . . . . . 5-59

6.10.3 Transfer Corona Current Adjustment (SP9-5) . . . . . 5-60

6.10.4 Separation Corona Current Adjustment (SP9-6) . . . . 5-61

7. FUSING . . . . . . . . . . . . . . . . . . . 5-62

7.1 EXIT UNIT REMOVAL . . . . . . . . . . . . . . . . . 5-62

7.2 FUSING UNIT REMOVAL . . . . . . . . . . . . . . . 5-63

7.3 HOT ROLLER REPLACEMENT . . . . . . . . . . . . . 5-66

7.4 PRESSURE ROLLER REPLACEMENT . . . . . . . . . . 5-68

7.5 FUSING LAMP REPLACEMENT . . . . . . . . . . . . 5-69

7.6 FUSING THERMOSWITCH REPLACEMENT . . . . . . . 5-70

7.7 FUSING THERMISTOR REPLACEMENT . . . . . . . . . 5-71

7.8 FUSING PRESSURE ADJUSTMENT . . . . . . . . . . . 5-72

8. COPY QUALITY ADJUSTMENT . . . . . . . . . 5-73

8.1 LIGHT INTENSITY ADJUSTMENT . . . . . . . . . . . . 5-74

8.2 SIDE-TO-SIDE EXPOSURE ADJUSTMENT . . . . . . . . 5-75

8.3 IMAGE BIAS VOLTAGE ADJUSTMENT . . . . . . . . . . 5-76

8.4 TONER DENSITY ADJUSTMENT . . . . . . . . . . . . 5-77

8.5 FIXED TONER SUPPLY MODE SELECTION . . . . . . . 5-77

8.6 TONER SUPPLY RATIO SELECTION . . . . . . . . . . 5-77

8.7 ID SENSOR (Vsg) ADJUSTMENT . . . . . . . . . . . . 5-78

8.8 ADS (Auto Image Density Sensor) ADJUSTMENT . . . . . 5-79

8.9 HORIZONTAL MAGNIFICATION ADJUSTMENT . . . . . . 5-80

8.10 VERTICAL MAGNIFICATION ADJUSTMENT . . . . . . . 5-81

8.11 FOCUS ADJUSTMENT . . . . . . . . . . . . . . . . 5-82

8.12 LEADING EDGE ERASE MARGIN ADJUSTMENT . . . . . 5-83

FSM v A151/A152/A202/A203

8.13 REGISTRATION ADJUSTMENT . . . . . . . . . . . . 5-83

8.14 SIDE-TO-SIDE REGISTRATION ADJUSTMENT . . . . . . 5-84

8.15 4TH/5TH MIRROR HEIGHT ADJUSTMENT . . . . . . . 5-87

9. OTHERS . . . . . . . . . . . . . . . . . . . 5-88

9.1 OZONE FILTER REPLACEMENT . . . . . . . . . . . . 5-88

9.2 220∼230/240V CONVERSION . . . . . . . . . . . . . 5-89

9.3 OPTIONAL EQUIPMENT INSTALLATION . . . . . . . . . 5-90

9.3.1 Optics Anti-condensation Heater Installation . . . . . . 5-90

9.3.2 Drum Anti-condensation Heater Installation . . . . . . 5-91

9.3.3 Pre-transfer Lamp (PTL) Installation . . . . . . . . . 5-92

9.3.4 Optics Cooling Fan Installation (FT3013 Copier Only) . . 5-93

9.4 TORSION BAR FORCE ADJUSTMENT . . . . . . . . . . 5-94

SECTION 6 TROUBLESHOOTING

1. COPY QUALITY . . . . . . . . . . . . . . . . 6-1

1.1 BLANK COPY (WHITE COPY) . . . . . . . . . . . . . 6-1

1.2 DIRTY BACKGROUND . . . . . . . . . . . . . . . . 6-4

1.3 UNEVEN IMAGE DENSITY . . . . . . . . . . . . . . 6-7

1.4 VERTICAL BLACK BANDS . . . . . . . . . . . . . . 6-8

1.5 VERTICAL BLACK LINES . . . . . . . . . . . . . . . 6-9

1.6 VERTICAL WHITE LINES OR BANDS—1 (DULL OR BLURRED) 6-10

1.7 VERTICAL WHITE LINES OR BANDS—2 (THIN, DISTINCT) . 6-11

1.8 HORIZONTAL BLACK/WHITE LINES . . . . . . . . . . . 6-12

1.9 JITTER . . . . . . . . . . . . . . . . . . . . . . 6-13

1.10 BLACK SPOTS ON THE COPY IMAGE . . . . . . . . . 6-14

1.11 SKEWED (OPTICAL) COPY IMAGE . . . . . . . . . . 6-15

1.12 TONER DENSITY TOO HIGH . . . . . . . . . . . . . 6-16

1.13 TONER DENSITY TOO LOW . . . . . . . . . . . . . 6-18

1.14 TONER SCATTERING . . . . . . . . . . . . . . . . 6-20

A151/A152/A202/A203 vi FSM

1.15 UNFUSED COPY IMAGE . . . . . . . . . . . . . . . 6-21

1.16 PAPER MISFEED . . . . . . . . . . . . . . . . . . 6-22

1.17 TRANSFER FAILURE . . . . . . . . . . . . . . . . 6-23

1.18 DF ORIGINAL MISFEED OR SKEW . . . . . . . . . . 6-24

2. SERVICE CALL CONDITIONS . . . . . . . . . . 6-25

2.1 CODE #11 — EXPOSURE LAMP ERROR . . . . . . . . . 6-25

2.2 CODE #12 — EXPOSURE LAMP ERROR . . . . . . . . 6-27

2.3 CODE #13 — ZERO CROSS SIGNAL ERROR . . . . . . . 6-28

2.4 CODE #21 — SCANNER HOME POSITION ERROR . . . . 6-29

2.5 CODE #22 — SCANNER HOME POSITION ERROR . . . . 6-31

2.6 CODE #28 — LENS HOM E POSITION ERROR

(FT3213 COPIER ONLY) . . . . . . . . . . . . . . . . 6-33

2.7 CODE #29 — LENS HOM E POSITION ERROR

(FT3213 COPIER ONLY) . . . . . . . . . . . . . . . . 6-35

2.8 CODE #2A — 4TH/5TH MIRROR HOME POSITION ERROR

(FT3213 COPIER ONLY) . . . . . . . . . . . . . . . 6-37

2.9 CODE #2B — 4TH/5TH MIRROR HOME POSITION ERROR

(FT3213 COPIER ONLY) . . . . . . . . . . . . . . . 6-39

2.10 CODE #40 – OPTICS THERMISTOR ERROR . . . . . . . 6-41

2.11 CODE #52 — FUSING WARM-UP ERROR . . . . . . . . 6-42

2.12 CODE #53 — FUSING OVERHEAT . . . . . . . . . . . 6-44

2.13 CODE #55 — FUSING THERMISTOR OPEN . . . . . . . 6-45

2.14 CODE #96 — DF TIMING PULSE ERROR . . . . . . . . 6-47

2.15 DF COMMUNICATION ERROR . . . . . . . . . . . . 6-49

2.16 ABNORMAL CONDITION IN TONER DENSITY DETECTION 6-50

2.17 OPTICS OVER HEAT PROTECTION (FT3013 Copier Only) . 6-52

3. ELECTRICAL COMPONENT DEFECTS . . . . . . 6-53

3.1 DEFECTIVE SENSOR TABLE . . . . . . . . . . . . . 6-53

3.2 DEFECTIVE SWITCHES OR OTHER ELECTRICAL

COMPONENTS . . . . . . . . . . . . . . . . . . . 6-54

3.3 OPEN FUSES & CIRCUIT BREAKERS . . . . . . . . . . 6-55

FSM vii A151/A152/A202/A203

SECTION 7 DOCUMENT FEEDER A365

1. SPECIFICATIONS . . . . . . . . . . . . . . . 7-1

2. COMPONENT LAY OUT . . . . . . . . . . . . . 7-2

2.1 MECHANICAL COMPONENTS . . . . . . . . . . . . . 7-2

2.2 ELECTRICAL COMPONENTS . . . . . . . . . . . . . 7-2

3. ELECTRICAL COMPONENT DESCRIPTIONS . . . . 7-3

4. INSTALLATION PROCEDURE . . . . . . . . . . 7-4

5. REPLACEMENT AND ADJUSTMENT . . . . . . . 7-8

5.1 TRANSPORT BELT REPLACEMENT . . . . . . . . . . 7-8

4.2 FEED-IN UNIT REMOVAL . . . . . . . . . . . . . . . 7-10

4.3 PICK-UP ROLLER REPLACEMENT . . . . . . . . . . . 7-11

4.4 FEED ROLLER REPLACEMENT . . . . . . . . . . . . 7-12

4.5 FRICTION BELT REPLACEMENT . . . . . . . . . . . . 7-13

4.6 PICK-UP SOLENOID ADJUSTMENT . . . . . . . . . . . 7-14

SECTION 8 A202/A203 COPIER

MAJOR DIFFERENCES BETWEEN THE A202/A203 AND

A151/A152 COPIERS . . . . . . . . . . . . . . . 1

1. SPECIFICATIONS . . . . . . . . . . . . . . . 8-1

2. COPY PROCESS CONTROL . . . . . . . . . . 8-4

3. MECHANICAL COMPONENT LAYOUT . . . . . . 8-5

4. ELECTRICAL COMPONENT LAY OUT . . . . . . . 8-6

5. ELECTRICAL COMPONENT DESCRIPTIONS . . . . 8-7

6. DRIVE LAYOUT . . . . . . . . . . . . . . . . 8-8

7. POWER DISTRIBUTION . . . . . . . . . . . . 8-10

8. DRUM CHARGE . . . . . . . . . . . . . . . . 8-12

8.1 GRID VOLTAGE CORRECTION . . . . . . . . . . . . . 8-12

A151/A152/A202/A203 viii FSM

8.2 GRID VOLTAGE FOR IMAGE DENSITY CONTROL . . . . . 8-12

8.2.1 Standard Image Density Grid Voltage . . . . . . . . 8-12

8.2.2 Auto Image Density Level Factor (SP34) . . . . . . . 8-12

8.3 GRID VOLTAGE FOR TONER DENSITY DETECTION . . . . 8-13

9. OPTICS . . . . . . . . . . . . . . . . . . . 8-14

9.1 LENS POSITIONING . . . . . . . . . . . . . . . . . 8-14

9.2 BASE LAMP VOLTAGE IN MANUAL IMAGE DENSITY MODE . 8-15

9.3 EXPOSURE LAMP CONTROL CIRCUIT . . . . . . . . . 8-15

10. DEVELOPMENT . . . . . . . . . . . . . . . 8-16

10.1 DEVELOPMENT BIAS CIRCUIT . . . . . . . . . . . . 8-16

11. TONER DENSITY DETECTION AND TONER SUPPLY 8-17

11.1 ID Sensor Control Circuit . . . . . . . . . . . . . . . 8-17

11.2 TONER SUPPLY AND AGITATOR DRIVE MECHANISM . . . 8-18

12. PAPER FEED . . . . . . . . . . . . . . . . 8-19

12.1 PAPER LENGTH DETECTION (Paper Feed Station) . . . . 8-19

13. IMAGE FUSING . . . . . . . . . . . . . . . 8-20

13.1 FUSING LAMP CONTROL CIRCUIT . . . . . . . . . . 8-20

13.2 OVERHEAT PROTECTION . . . . . . . . . . . . . . 8-20

14. INSTALLATION . . . . . . . . . . . . . . . 8-21

14.1 COPIER (A 202/ A2 03) ACCESSORY CHECK . . . . . . . 8-21

14.2 COPIER (A202/A203) INSTALLATION PROCEDURE . . . . 8-22

14.3 DOCUMENT FEEDER (A662) ACCESSORY CHECK . . . . 8-28

14.4 DOCUMENT FEEDER (A662) INSTALLATION PROCEDURE 8-29

15. SERVICE PROGRAM MODE . . . . . . . . . . 8-34

15.1 ACCESS PROCEDURE 1-KEY OPERATION . . . . . . . 8-34

15.2 MEMORY CLEAR PROCEDURE . . . . . . . . . . . . 8-35

15.3 CLEAR ALL MEMORY PROCEDURE . . . . . . . . . . 8-36

15.4 SERVICE PROGRAM MODE TABLE . . . . . . . . . . 8-38

15.5 SP MODE 8-INPUT CHECK . . . . . . . . . . . . . . 8-46

15.6 SP MODE 9–OUTPUT CHECK . . . . . . . . . . . . 8-47

FSM ix A151/A152/A202/A203

15.7 SERVICE CALL AND USER CODE TABLE . . . . . . . . 8-48

16. SERVICE TABLES . . . . . . . . . . . . . . 8-50

16.1 TEST POINTS . . . . . . . . . . . . . . . . . . . 8-50

16.2 DIP SWITCHES AND JUMPER SWITCHES . . . . . . . 8-50

16.3 VARIABLE RESISTORS . . . . . . . . . . . . . . . 8-50

17. PREVENTIVE MA INTENANCE SCHEDULE . . . . 8-51

17.1 PM TABLE . . . . . . . . . . . . . . . . . . . . . 8-51

18. REPLACEMENT AND ADJUSTMENT . . . . . . 8-52

18.1 TONER SUPPLY MOTOR REPLACEMENT . . . . . . . 8-52

18.2 QUENCHING LAMP REPLACEMENT . . . . . . . . . . 8-53

18.3 CHARGE CORONA CURRENT ADJUSTMENT . . . . . . 8-54

18.4 GRID VOLTAGE ADJUSTMENT (SP9-46) . . . . . . . . 8-55

18.5 DEVELOPMENT BIAS VOLTAG E ADJUSTMENT (SP9-38) . 8-56

18.6 TRANSFER CORONA CURRENT ADJUSTMENT (SP9-5) . . 8-57

18.7 SEPARATION CORONA CURRENT ADJUSTMENT (SP9-6) . 8-58

SECTION 9 DOCUME N T FEEDER A662

1. SPECIFICATIONS . . . . . . . . . . . . . . . 9-1

2. COMPONENT LAY OUT . . . . . . . . . . . . . 9-2

2.1 MECHANICAL COMPONENTS . . . . . . . . . . . . . 9-2

2.2 ELECTRICAL COMPONENTS . . . . . . . . . . . . . 9-2

3. ELECTRICAL COMPONENT DESCRIPTIONS . . . . 9-3

4. POWER DISTRIBUTION . . . . . . . . . . . . 9-4

5. BASIC OPERATION . . . . . . . . . . . . . . 9-5

6. INTERFACE CIRCUIT . . . . . . . . . . . . . 9-6

7. ORIGINAL FEED . . . . . . . . . . . . . . . 9-7

7.1 ORIGINAL PICK-UP MECHANISM . . . . . . . . . . . . 9-7

7.2 ORIGINAL SEPARATION MECHANISM . . . . . . . . . 9-8

A151/A152/A202/A203 x FSM

7.3 ORIGINAL FEED-IN MECHANISM . . . . . . . . . . . . 9-9

7.4 ORIGINAL FEED-OUT MECHANISM . . . . . . . . . . . 9-10

7.5 DF MOTOR CIRCUIT . . . . . . . . . . . . . . . . . 9-11

7.6 ORIGINAL FEED AND MISFEED DETECTION TIMING . . . 9-12

8. SERVICE TABLES . . . . . . . . . . . . . . . 9-13

8.1 DIP SWITCHES . . . . . . . . . . . . . . . . . . . 9-13

8.2 VARIABLE RESISTORS . . . . . . . . . . . . . . . . 9-13

8.3 FUSE . . . . . . . . . . . . . . . . . . . . . . . 9-13

9. REPLACEMENT AND ADJUSTMENT . . . . . . . 9-14

9.1 TRANSPORT BELT REPLACEMENT . . . . . . . . . . 9-14

9.2 FEED-IN UNIT REMOVAL . . . . . . . . . . . . . . . 9-16

9.3 PICK-UP ROLLER REPLACEMENT . . . . . . . . . . . 9-17

9.4 FEED ROLLER REPLACEMENT . . . . . . . . . . . . 9-18

9.5 FRICTION BELT REPLACEMENT . . . . . . . . . . . . 9-19

9.6 PICK-UP SOLENOID ADJUSTMENT . . . . . . . . . . . 9-20

FSM xi A151/A152/A202/A203

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the copier power co rd is unplugged.

2. The wall ou tlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers

off or open while the main switch is turned on, keep hands away from

electrified or mechanically driven components.

5. If the hot roller temperature is low when the main switch is turned on, the

copier starts idling automatically when the warm-up period is completed.

Keep hands away from the mechanic al and the electrical components to

avoid any injury.

6. If the start key is pressed before the copier completes the warm-up

period (Ready indicator starts blinking), keep hands away fro m the

mechanical and the electr ical components as the copier starts making

copies as soon as the warm-up period is completed.

7. The inside and the metal parts of the fusing unit become extr emely hot

while the copier is operating. Be careful to avoid touching those

components with your bare hands.

HEALTH SAFETY CONDITIONS

1. Never operate the copier without the ozone filters installed.

2. Always replace the ozone filters with the specified ones at the specified

intervals.

3. Toner and developer are non-toxic, but if you get either of them in your

eyes by accident, it may cause temporary eye discomfort. Try to remove

with eye drops or flush with water as first aid. If unsuccessful, get

medical attention.

FSM a A151/A152

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

1. The copier and its peripherals must be installed and maintained by a

customer service representative who has completed the training course

on those models.

- CAUTION -

The RAM board on the main control board has a lithium battery which

can explode if rep laced incorrectly. Replace the battery only with an

identical one. The manufact urer recommends replacing the entire RAM

board. Do not recharge or burn this battery. Used batteries must be

handled in accordance with local regulations.

SAF ETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate the toner cartridge or the used toner. Toner dust may

ign ite suddenly w hen exposed to open flame.

2. Dispose of used toner, developer, and organic photoconductor

according to local regulations. (These are non-toxic supplie s.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do

not put more than 100 batteries per sealed box. Storing larger numbers

or not sealing them apart may lead to chemic al reactions and heat

build-up.

A151/A152 b FSM

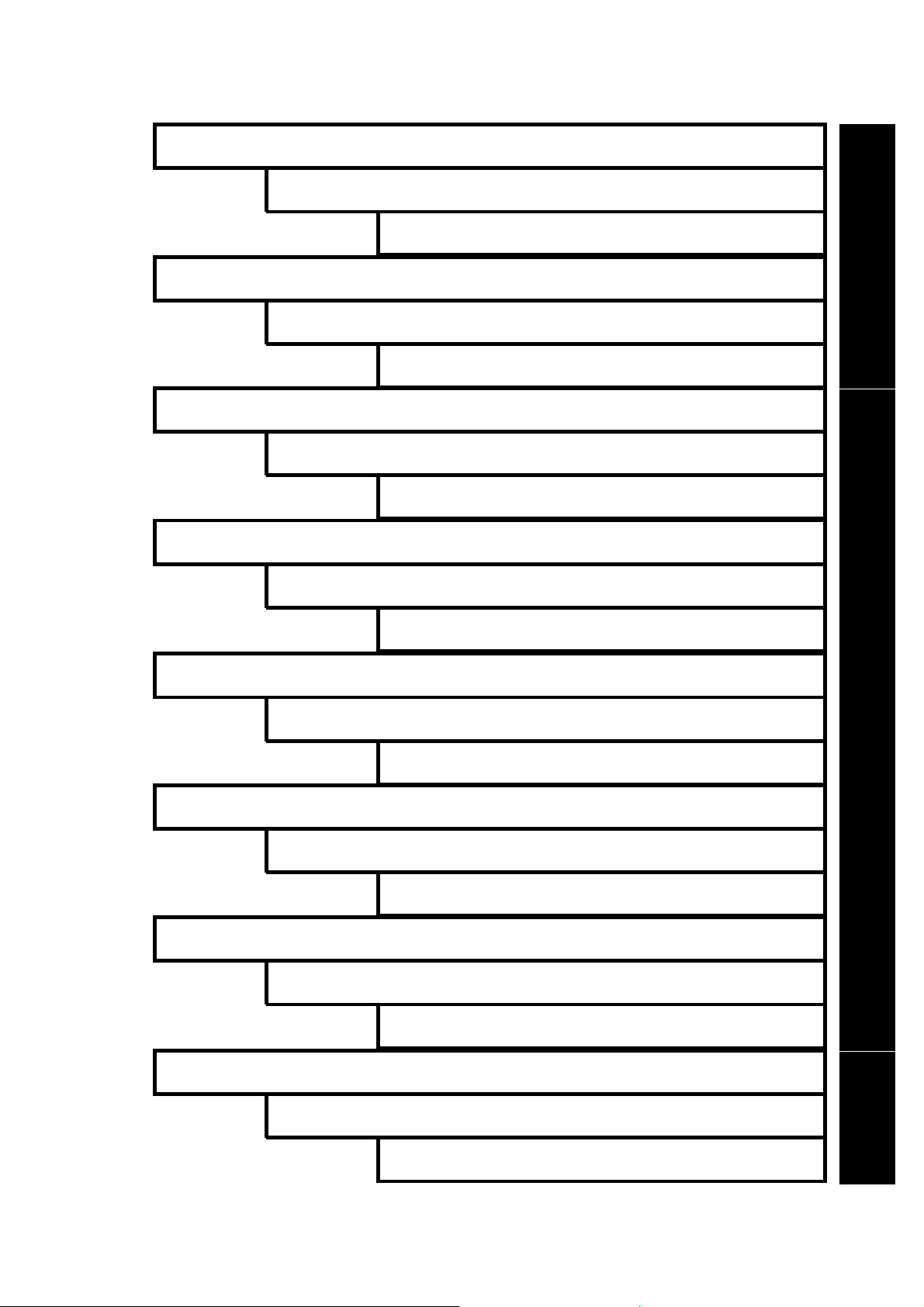

TAB INDEX

A151/A152 OVERALL MACHINE INFORMATION

DOCUMENT FEEDER A662

A151/A152 GUIDE TO COMPONENTS

A151/A152 INSTALLATION

Rev. 4/97

TAB POSITION 1

TAB POSITION 2TAB POSITION 3

A151/A152 SERVICE TABLES

A151/A152 REPLACEMENT AND ADJUSTMENT

A151/A152 TROUBLESHOOTING

DOCUMENT FEEDER A296

TAB POSITION 4

TAB POSITION 5TAB POSITION 6TA B PO SIT I ON 7TAB POSITION 8

A202/A203 SERVICE MANUAL

OVERALL MACHINE

INFORMATION

1. SPECIFICATIONS

Configuration: Desk top

Copy Process: Dry electrostatic transfer system

Original Type: Sheet/Book

Original Alignment: Left center

Original Size: Maximum: A3/11" x 17" (lengthwise) – FT3213

copier

B4/10" x 14" (length wise) – FT30 13

copier

Copy Paper Size: Maximum: B4/ 10" x 14" (length wi se)

Minimum:

Paper Tray: A5/5

Bypass Feed: A6/5

Copy Paper Weight: Paper tray feed – 64 to 90 g/m2 (17 to 24 lb)

Bypass feed – 52 to 105 g/m2 (14 to 28 lb)

Reproduction Ratios: 2 E n l a r g e m en t a n d 3 R e d u c t i on ( F T 3 2 1 3 co p i e r o n l y)

1/2

" x 8

1/2

" (lengthwise)

1/2

" x 8

" (lengthwise )

1/2

MACHINE

OVERALL

INFORMATION

A4 Version Letter Version

Enlargement

141%

122%

Full size 100% 100%

93%

Reduction

82%

71%

Zoom: From 61% to 141% in 1% steps

(FT3213 copier only)

Copying Speed: 13 copies/minute (A4/8

10 copies/minute (B4/8

" x 11" lengthwise)

1/2

" x 14")

1/2

Warm-Up Time: 30 seconds (at 20°C/68°F)

First Copy Time: 9 seconds (A4/8

" x 11" lengthwise)

1/2

Copy Number Input: Number keys, 1 to 99

Manual Image Density: 7 steps

Toner Type: Type 320

129%

121%

93%

74%

65%

Developer Type: Type 310

FSM 1-1 A151/A152

Automatic Reset: 1 minute standard setting; can also be set to 3

minutes or no automatic reset.

Energy Saver Function: Automatic

Paper Capacity: Paper tray – 250 sheets

Bypass feed table – 1 sheet

Toner Repleni shme nt: Cartridge exchange (32 0 g/ cart ridg e)

Copy Tray Capacity: 100 sheets (B4/10" x 14" or smaller)

Power Source: 110V/ 60Hz/ 15A (for Taiwan)

115V/ 60Hz/ 15A (for North Amer ica)

220V – 240V/ 50Hz/ 8A (for Europ e)

220V/ 60Hz / 8A (for Middle East)

220V/ 50Hz/ 8A (for Asia)

(Refer to the serial number plate (rating plate) to

determine the power source required by the

machine.)

Power Consumptio n:

Copier Only With DF*

Maximum 1.4 kVA 1.5 kV A

Warm-up 620 VA (average) 640 VA (average)

Copy cycle 810 VA (average) 860 VA (average)

Ready 160 VA (average) 180 VA (average)

Noise Emission:

Copier Only With DF*

Maximum 58 db 60 db

Copy cycle Less than 55 db Less than 55 db

Ready Less than 39 db Less than 39 db

Dimensions:

Width Depth Height

Copier with platen cover and

copy tray

Copier with document feeder

and copy tray*

713 mm (28.1") 592 mm (23.3") 400 mm (15.7")

713 mm (28.1") 592 mm (23.3") 463 mm (18.2")

*NOTE: The document feeder can be installed only on the FT3213 copier.

FSM 1-2 A151/A152

Loading...

Loading...