Page 1

®

®

®

RICOH GROUP COMPANIES

B039/B040/B043/B120

SERVICE MANUAL

001129MIU

Page 2

Page 3

B039/B040/B043/B120

SERVICE MANUAL

RICOH GROUP COMPANIES

Page 4

Page 5

B039/B040/B043/B120

SERVICE MANUAL

001129MIU

Page 6

Page 7

It is the reader's responsibility when discussing the information contained within this

document to maintain a level of confidentiality that is in the best interest of Ricoh

Corporation and its member companies.

NO PART OF THIS DOCUMENT MAY BE REPRODUCED IN ANY

FASHION AND DISTRIBUTED WITHOUT THE PRIOR

PERMISSION OF RICOH CORPORATION.

All product names, domain names or product illustrations, including desktop images,

used in this document are trademarks, registered trademarks or the property of their

respective companies.

They are used throughout this book in an informational or editorial fashion only and for

the benefit of such companies. No such use, or the use of any trade name, or web

site is intended to convey endorsement or other affiliation with Ricoh products.

2001 RICOH Corporation. All rights reserved.

Page 8

Page 9

LEGEND

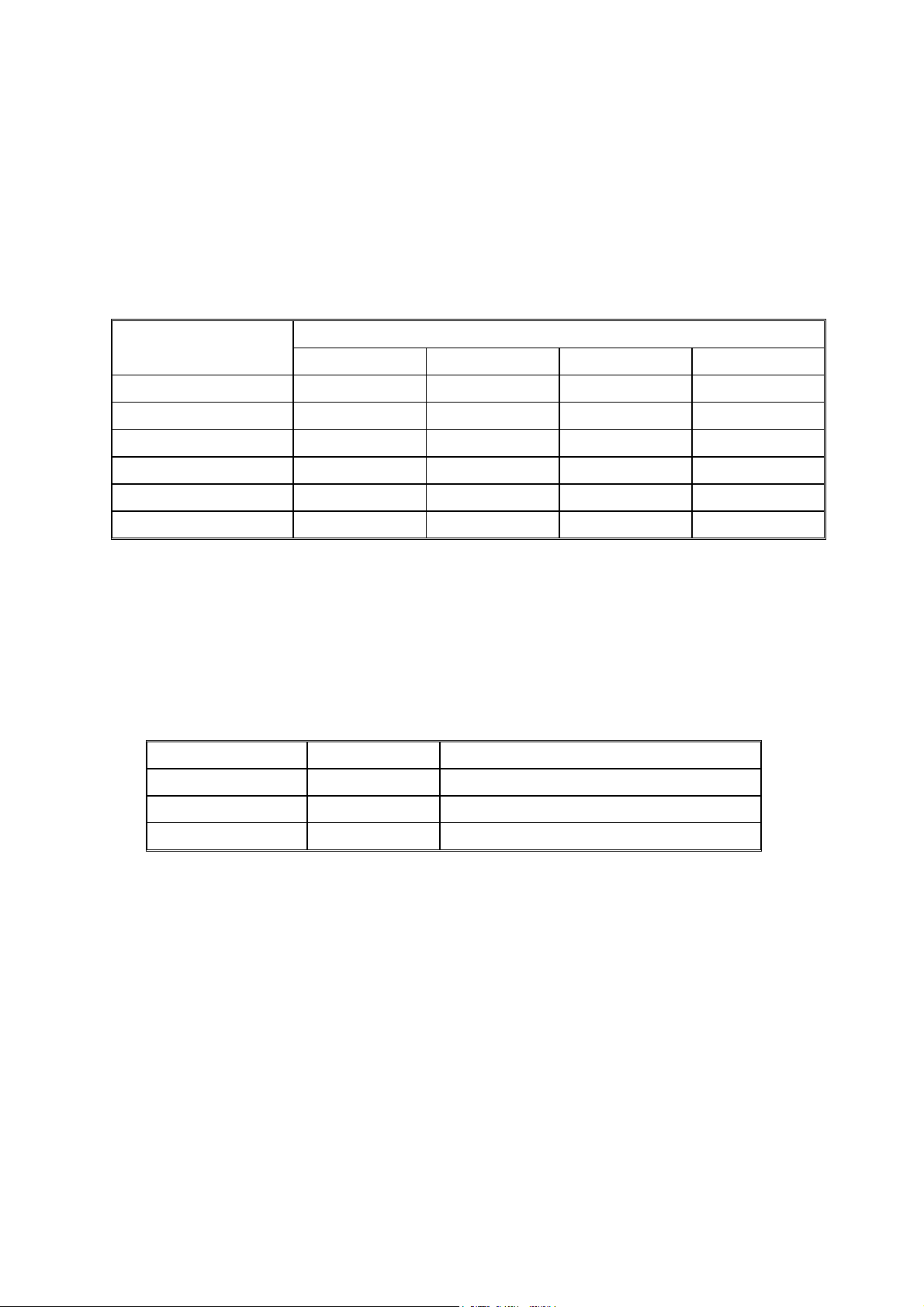

COMPANY PRODUCT CODE

GESTETNER LANIER RICOH SAVIN

B039 1502 5515 Aficio 1015 2515

B040 1802 5518 Aficio 1018 2518

B043 1802d 5518D Aficio 1018D 2518d

B120 (RLA only) 1312 LD013 Aficio 1113 -

DOCUMENTATION HISTORY

REV. NO. DATE COMMENTS

* 06/01 Original Printing

1 06/03 B120 (RLA only)

Page 10

Page 11

B039/B040/B043

TABLE OF CONTENTS

INSTALLATION

1 INSTALLATION ........................................................................... 1-1

1.1 INSTALLATION REQUIREMENTS...........................................................1-1

1.1.1 ENVIRONMENT...............................................................................1-1

1.1.2 MACHINE LEVEL.............................................................................1-2

1.1.3 MINIMUM SPACE REQUIREMENTS...............................................1-3

1.1.4 POWER REQUIREMENTS..............................................................1-3

1.2 COPIER INSTALLATION..........................................................................1-4

1.2.1 POWER SOCKETS FOR PERIPHERALS.......................................1-4

1.2.2 ACCESSORY CHECK......................................................................1-4

1.2.3 INSTALLATION PROCEDURE........................................................1-5

1.3 PLATEN COVER INSTALLATION............................................................1-8

1.3.1 ACCESSORY CHECK......................................................................1-8

1.3.2 INSTALLATION PROCEDURE........................................................1-8

1.4 ARDF INSTALLATION..............................................................................1-9

1.4.1 ACCESSORY CHECK......................................................................1-9

1.4.2 INSTALLATION PROCEDURE........................................................1-9

1.5 ADF INSTALLATION...............................................................................1-11

1.5.1 ACCESSORY CHECK....................................................................1-11

1.5.2 INSTALLATION PROCEDURE......................................................1-11

1.6 TWO-TRAY PAPER TRAY UNIT INSTALLATION..................................1-13

1.6.1 ACCESSORY CHECK....................................................................1-13

1.6.2 INSTALLATION PROCEDURE......................................................1-13

1.7 ONE-TRAY PAPER TRAY UNIT INSTALLATION...................................1-16

1.7.1 ACCESSORY CHECK....................................................................1-16

1.7.2 INSTALLATION PROCEDURE......................................................1-16

1.8 IMB INSTALLATION................................................................................1-19

1.8.1 ACCESSORY CHECK....................................................................1-19

1.8.2 INSTALLATION PROCEDURE......................................................1-19

1.9 DRAM INSTALLATION ...........................................................................1-20

1.10 ANTI-CONDENSATION HEATER INSTALLATION..............................1-21

1.11 TRAY HEATERS...................................................................................1-22

1.11.1 UPPER TRAY HEATER...............................................................1-22

1.11.2 LOWER TRAY HEATER (TWO-TRAY MODEL ONLY)................1-23

1.11.3 TRAY HEATERS FOR THE OPTIONAL PAPER FEED UNITS...1-24

1.12 KEY COUNTER INSTALLATION..........................................................1-27

PREVENTIVE MAINTENANCE

2 PREVENTIVE MAINTENANCE ................................................... 2-1

2.1 PM TABLES ..............................................................................................2-1

2.2 HOW TO CLEAR THE PM COUNTER......................................................2-3

SM i B039/B040/B043

Page 12

REPLACEMENT AND ADJUSTMENT

3 REPLACEMENT AND ADJUSTMENT......................................... 3-1

3.1 GENERAL CAUTIONS..............................................................................3-1

3.1.1 PCU (PHOTOCONDUCTOR UNIT) .................................................3-1

3.1.2 TRANSFER ROLLER.......................................................................3-1

3.1.3 SCANNER UNIT...............................................................................3-1

3.1.4 LASER UNIT ....................................................................................3-2

3.1.5 FUSING UNIT...................................................................................3-2

3.1.6 PAPER FEED...................................................................................3-2

3.1.7 IMPORTANT ....................................................................................3-2

3.2 SPECIAL TOOLS AND LUBRICANTS......................................................3-2

3.3 EXTERIOR COVERS & OPERATION PANEL..........................................3-3

3.3.1 REAR COVER..................................................................................3-3

3.3.2 REAR LOWER COVER (TWO-TRAY MODELS ONLY)...................3-3

3.3.3 COPY TRAY.....................................................................................3-4

3.3.4 LEFT UPPER COVER......................................................................3-4

3.3.5 FRONT UPPER LEFT COVER AND OPERATION PANEL.............3-4

3.3.6 RIGHT UPPER COVER...................................................................3-4

3.3.7 TOP REAR COVER..........................................................................3-4

3.3.8 LEFT COVER...................................................................................3-5

3.3.9 FRONT LONG COVER....................................................................3-5

3.3.10 FRONT RIGHT COVER .................................................................3-6

3.3.11 RIGHT REAR COVER....................................................................3-6

3.3.12 RIGHT DOOR.................................................................................3-7

3.3.13 BY-PASS TRAY..............................................................................3-8

3.3.14 LEFT LOWER COVER (TWO-TRAY MODELS ONLY)..................3-9

3.3.15 RIGHT LOWER COVER (TWO-TRAY MODELS ONLY)...............3-9

3.3.16 PLATEN COVER SENSOR............................................................3-9

3.4 SCANNER SECTION..............................................................................3-10

3.4.1 EXPOSURE GLASS/DF EXPOSURE GLASS...............................3-10

Exposure Glass ..................................................................................3-10

DF Exposure Glass.............................................................................3-10

3.4.2 LENS BLOCK.................................................................................3-11

3.4.3 EXPOSURE LAMP, LAMP STABILIZER BOARD..........................3-11

3.4.4 ORIGINAL WIDTH SENSOR..........................................................3-12

3.4.5 ORIGINAL LENGTH SENSOR.......................................................3-12

Sensor Positions.................................................................................3-12

3.4.6 CHANGING THE ORIGINAL SENSOR POSITIONS (8K/16K) ......3-13

Procedure...........................................................................................3-14

3.4.7 SCANNER MOTOR........................................................................3-15

3.4.8 SCANNER H.P. SENSOR..............................................................3-15

3.4.9 ADJUSTMENT OF 2ND SCANNER POSITION.............................3-16

3.4.10 ADJUSTMENT OF 1ST AND 2ND SCANNER ALIGNMENT.......3-17

3.5 LASER UNIT...........................................................................................3-18

3.5.1 LOCATION OF “CAUTION” DECAL...............................................3-18

3.5.2 TONER SHIELD GLASS................................................................3-19

3.5.3 LASER UNIT ..................................................................................3-19

B039/B040/B043 ii SM

Page 13

3.5.4 LD UNIT..........................................................................................3-20

3.5.5 POLYGONAL MIRROR MOTOR....................................................3-20

3.5.6 LASER UNIT ALIGNMENT ADJUSTMENT....................................3-21

3.6 PCU SECTION........................................................................................3-22

3.6.1 PCU................................................................................................3-22

3.6.2 PICK-OFF PAWLS.........................................................................3-22

3.6.3 TONER DENSITY SENSOR ..........................................................3-22

3.6.4 OPC DRUM....................................................................................3-23

3.6.5 CHARGE ROLLER AND CLEANING BRUSH................................3-24

3.6.6 CLEANING BLADE.........................................................................3-24

3.6.7 DEVELOPER..................................................................................3-25

3.6.8 AFTER REPLACEMENT OR ADJUSTMENT.................................3-26

3.7 TONER SUPPLY MOTOR ......................................................................3-27

3.8 PAPER FEED SECTION.........................................................................3-28

3.8.1 PAPER FEED ROLLER..................................................................3-28

3.8.2 FRICTION PAD..............................................................................3-28

3.8.3 PAPER END SENSOR...................................................................3-28

3.8.4 EXIT SENSOR ...............................................................................3-29

Non-duplex Models.............................................................................3-29

Duplex Models....................................................................................3-29

3.8.5 BY-PASS FEED ROLLER AND

BY-PASS PAPER END SENSOR..................................................3-30

3.8.6 REGISTRATION ROLLER .............................................................3-31

3.8.7 BY-PASS PAPER SIZE SENSOR..................................................3-32

3.8.8 REGISTRATION CLUTCH.............................................................3-32

3.8.9 REGISTRATION SENSOR.............................................................3-33

3.8.10 UPPER PAPER FEED CLUTCH AND

BY-PASS FEED CLUTCH............................................................3-33

3.8.11 RELAY CLUTCH..........................................................................3-34

3.8.12 RELAY SENSOR..........................................................................3-34

3.8.13 LOWER PAPER FEED CLUTCH

(TWO-TRAY MODELS ONLY) .....................................................3-34

3.8.14 VERTICAL TRANSPORT SENSOR

(TWO-TRAY MODELS ONLY) .....................................................3-35

3.8.15 PAPER SIZE SWITCH.................................................................3-35

3.9 IMAGE TRANSFER.................................................................................3-36

3.9.1 IMAGE TRANSFER ROLLER ........................................................3-36

3.9.2 IMAGE DENSITY SENSOR ...........................................................3-36

3.10 FUSING.................................................................................................3-37

3.10.1 FUSING UNIT...............................................................................3-37

3.10.2 THERMISTOR..............................................................................3-37

3.10.3 FUSING LAMP.............................................................................3-38

3.10.4 HOT ROLLER...............................................................................3-38

3.10.5 THERMOFUSE AND THERMOSTAT ..........................................3-39

3.10.6 HOT ROLLER STRIPPER PAWLS ..............................................3-39

3.10.7 PRESSURE ROLLER AND BUSHINGS......................................3-40

3.10.8 NIP BAND WIDTH ADJUSTMENT...............................................3-41

3.11 DUPLEX UNIT (DUPLEX MODELS ONLY)..........................................3-42

3.11.1 DUPLEX EXIT SENSOR..............................................................3-42

SM iii B039/B040/B043

Page 14

Rev. 03/2002

3.11.2 DUPLEX ENTRANCE SENSOR.................................................. 3-42

3.11.3 DUPLEX INVERTER SENSOR.................................................... 3-42

3.11.4 DUPLEX TRANSPORT MOTOR ................................................. 3-43

3.11.5 DUPLEX INVERTER MOTOR ..................................................... 3-43

3.11.6 DUPLEX CONTROL BOARD....................................................... 3-43

3.12 OTHER REPLACEMENTS ................................................................... 3-44

3.12.1 QUENCHING LAMP..................................................................... 3-44

3.12.2 HIGH-VOLTAGE POWER SUPPLY BOARD............................... 3-44

3.12.3 IMB (MEMORY BOARD).............................................................. 3-45

3.12.4 BICU (BASE-ENGINE IMAGE CONTROL UNIT) ........................ 3-45

3.12.5 IOB (I/O BOARD) ......................................................................... 3-46

3.12.6 MAIN MOTOR.............................................................................. 3-46

3.12.7 REAR EXHAUST FAN ................................................................. 3-46

3.12.8 LEFT EXHAUST FAN .................................................................. 3-47

3.12.9 PSU (POWER SUPPLY UNIT) .................................................... 3-47

3.12.10 GEARBOX ................................................................................. 3-48

Replacement Procedure..................................................................... 3-48

Gear Arrangement Within the Gearbox .............................................. 3-49

3.13 COPY ADJUSTMENTS: PRINTING/SCANNING.................................. 3-50

3.13.1 PRINTING .................................................................................... 3-50

Registration - Leading Edge/Side-to-Side .......................................... 3-50

Blank Margin ...................................................................................... 3-51

Main Scan Magnification .................................................................... 3-51

3.13.2 SCANNING .................................................................................. 3-52

Registration: Platen Mode .................................................................. 3-52

Magnification ...................................................................................... 3-53

Standard White Density Adjustment................................................... 3-54

3.13.3 ADF IMAGE ADJUSTMENT ........................................................ 3-55

Registration and Blank Margin ........................................................... 3-55

Sub-scan Magnification ...................................................................... 3-55

TROUBLESHOOTING

4 TROUBLESHOOTING ................................................................. 4-1

4.1 SERVICE CALL CONDITIONS................................................................. 4-1

4.1.1 SUMMARY....................................................................................... 4-1

4.1.2 SC CODE DESCRIPTIONS............................................................. 4-2

4.2 ELECTRICAL COMPONENT DEFECTS.................................................. 4-8

4.2.1 SENSORS........................................................................................ 4-8

4.2.2 SWITCHES ...................................................................................... 4-9

4.3 BLOWN FUSE CONDITIONS................................................................. 4-10

4.4 LED DISPLAY......................................................................................... 4-10

4.4.1 BICU............................................................................................... 4-10

4.4.2 IOB................................................................................................. 4-10

4.5 FIRMWARE MODIFICATION HISTORY…………………………………...4-11

SERVICE TABLES

5 SERVICE TABLES....................................................................... 5-1

B039/B040/B043 iv SM

Page 15

5.1 USING SERVICE PROGRAM MODES.....................................................5-1

Accessing SP Modes............................................................................5-1

Accessing Copy Mode from within an SP Mode...................................5-1

How to Select a Program Number........................................................5-2

To Input a Value or Setting for an SP Mode .........................................5-2

5.1.1 SP MODE TABLES..........................................................................5-3

SP1-XXX (Feed)...................................................................................5-3

SP2-XXX (Drum)...................................................................................5-6

SP4-XXX (Scanner)............................................................................5-11

SP5-XXX (Mode) ................................................................................5-17

SP6-XXX (Peripherals) .......................................................................5-24

SP7-XXX (Data Log)...........................................................................5-26

5.1.2 TEST PATTERN PRINTING (SP5-902).........................................5-31

5.1.3 INPUT CHECK (SP5-803)..............................................................5-32

5.1.4 OUTPUT CHECK (SP5-804)..........................................................5-36

Output Check Table............................................................................5-36

5.1.5 COPY JAM HISTORY (SP7-903)...................................................5-37

5.1.6 SMC PRINTING (SP5-992)............................................................5-38

5.1.7 ORIGINAL JAM HISTORY DISPLAY (SP7-905)............................5-38

5.1.8 MEMORY ALL CLEAR (SP5-801)..................................................5-39

Using a Flash Memory Card...............................................................5-39

Without Using a Flash Memory Card..................................................5-40

5.1.9 PROGRAM UPLOAD/DOWNLOAD...............................................5-41

Program Download (SP5-827)............................................................5-41

Program Upload (SP5-826) ................................................................5-42

5.1.10 NVRAM DATA UPLOAD/DOWNLOAD........................................5-43

NVRAM Data Download (SP5-825)....................................................5-43

NVRAM Data Upload (SP5-824).........................................................5-44

5.1.11 APS AND PLATEN/ADF COVER SENSOR

OUTPUT DISPLAY (SP4-301) .....................................................5-45

5.1.12 ADF APS SENSOR OUTPUT DISPLAY (SP6-901).....................5-46

5.1.13 SERIAL NUMBER INPUT (SP5-811) ...........................................5-47

5.1.14 ID SENSOR ERROR ANALYSIS (SP2-221)................................5-48

5.2 USER TOOLS.........................................................................................5-49

5.2.1 HOW TO ENTER AND EXIT USER TOOLS..................................5-49

5.2.2 USER TOOLS TABLE....................................................................5-49

System Setting Table..........................................................................5-49

Copy Features Table..........................................................................5-50

DETAILED SECTION DESCRIPTIONS

6 DETAILED SECTION DESCRIPTIONS ....................................... 6-1

6.1 OVERVIEW...............................................................................................6-1

6.1.1 COMPONENT LAYOUT...................................................................6-1

6.1.2 PAPER PATH...................................................................................6-3

6.1.3 DRIVE LAYOUT...............................................................................6-4

6.2 BOARD STRUCTURE...............................................................................6-5

6.2.1 BLOCK DIAGRAM............................................................................6-5

SM v B039/B040/B043

Page 16

1. BiCU (Base Engine and Image Control Unit)....................................6-6

2. IOB (I/O Board).................................................................................6-6

3. SBU (Sensor Board Unit)..................................................................6-6

4. IMB (IMAC and Memory Board)........................................................6-6

6.3 COPY PROCESS OVERVIEW .................................................................6-7

6.4 SCANNING................................................................................................6-9

6.4.1 OVERVIEW......................................................................................6-9

Lamp Stabilizer Fuse............................................................................6-9

6.4.2 SCANNER DRIVE..........................................................................6-10

6.4.3 ORIGINAL SIZE DETECTION IN PLATEN MODE.........................6-11

6.5 IMAGE PROCESSING............................................................................6-13

6.5.1 OVERVIEW....................................................................................6-13

6.5.2 SBU (SENSOR BOARD UNIT).......................................................6-14

6.5.3 AUTO IMAGE DENSITY (ADS)......................................................6-15

In the SBU ..........................................................................................6-15

In the IPU............................................................................................6-15

By Original Type.................................................................................6-15

6.5.4 IPU (IMAGE PROCESSING UNIT).................................................6-16

Overview.............................................................................................6-16

Image Processing Modes ...................................................................6-17

Image Processing Path.......................................................................6-18

Original Modes....................................................................................6-19

SP Modes for Each Image Processing Step.......................................6-19

Auto Shading......................................................................................6-21

White Line Erase ................................................................................6-22

Black Line Erase.................................................................................6-22

Scanner Gamma (γ) Correction..........................................................6-23

Main Scan Magnification.....................................................................6-24

Mirroring for ADF Mode ......................................................................6-24

Filtering...............................................................................................6-25

ID Gamma (γ) Correction....................................................................6-26

Gradation Processing.........................................................................6-27

6.5.5 IMB (MEMORY CONTROLLER AND DRAM)................................6-28

6.5.6 VIDEO CONTROL UNIT (VCU)......................................................6-29

Fine Character and Image (FCI).........................................................6-29

Printer Gamma Correction..................................................................6-29

6.6 LASER EXPOSURE................................................................................6-30

6.6.1 OVERVIEW....................................................................................6-30

6.6.2 AUTO POWER CONTROL (APC)..................................................6-31

6.6.3 LD SAFETY SWITCH.....................................................................6-32

6.7 PHOTOCONDUCTOR UNIT (PCU)........................................................6-33

6.7.1 OVERVIEW....................................................................................6-33

6.7.2 DRIVE.............................................................................................6-34

6.8 DRUM CHARGE .....................................................................................6-35

6.8.1 OVERVIEW....................................................................................6-35

6.8.2 CHARGE ROLLER VOLTAGE CORRECTION..............................6-36

Correction for Environmental Conditions............................................6-36

6.8.3 ID SENSOR PATTERN PRODUCTION TIMING............................6-37

6.8.4 DRUM CHARGE ROLLER CLEANING..........................................6-38

B039/B040/B043 vi SM

Page 17

6.9 DEVELOPMENT .....................................................................................6-39

6.9.1 OVERVIEW....................................................................................6-39

6.9.2 DRIVE.............................................................................................6-40

6.9.3 DEVELOPER MIXING....................................................................6-40

6.9.4 DEVELOPMENT BIAS...................................................................6-41

6.9.5 TONER SUPPLY............................................................................6-42

Toner Bottle Replenishment Mechanism............................................6-42

Toner Supply Mechanism...................................................................6-43

6.9.6 TONER DENSITY CONTROL........................................................6-44

Overview.............................................................................................6-44

Toner Density Sensor Initial Setting....................................................6-46

Toner Concentration Measurement....................................................6-46

Vsp/Vsg Detection..............................................................................6-46

Toner Supply Reference Voltage (Vref) Determination.......................6-46

Toner Supply Determination...............................................................6-46

Toner Supply Motor On Time Determinations.....................................6-47

6.9.7 TONER SUPPLY IN ABNORMAL SENSOR CONDITIONS...........6-48

ID Sensor............................................................................................6-48

TD Sensor...........................................................................................6-48

6.9.8 TONER NEAR END/END DETECTION AND RECOVERY ............6-49

Toner Near End Detection..................................................................6-49

Toner Near End Recovery..................................................................6-49

Toner End Detection...........................................................................6-49

Toner End Recovery...........................................................................6-49

6.10 DRUM CLEANING AND TONER RECYCLING.....................................6-50

6.10.1 DRUM CLEANING........................................................................6-50

6.10.2 TONER RECYCLING...................................................................6-50

6.11 PAPER FEED........................................................................................6-51

6.11.1 OVERVIEW..................................................................................6-51

6.11.2 PAPER FEED DRIVE MECHANISM............................................6-52

6.11.3 PAPER FEED AND SEPARATION MECHANISM........................6-52

6.11.4 PAPER LIFT MECHANISM..........................................................6-53

6.11.5 PAPER END DETECTION...........................................................6-53

6.11.6 PAPER SIZE DETECTION...........................................................6-54

Paper Tray..........................................................................................6-54

By-pass Tray.......................................................................................6-55

6.11.7 SIDE FENCES..............................................................................6-56

6.11.8 PAPER REGISTRATION..............................................................6-56

6.12 IMAGE TRANSFER AND PAPER SEPARATION.................................6-57

6.12.1 OVERVIEW..................................................................................6-57

6.12.2 IMAGE TRANSFER CURRENT TIMING......................................6-58

6.12.3 TRANSFER ROLLER CLEANING................................................6-59

6.12.4 PAPER SEPARATION MECHANISM...........................................6-59

6.13 IMAGE FUSING AND PAPER EXIT......................................................6-60

6.13.1 OVERVIEW..................................................................................6-60

6.13.2 FUSING DRIVE AND RELEASE MECHANISM...........................6-60

6.13.3 FUSING ENTRANCE GUIDE SHIFT............................................6-61

6.13.4 PRESSURE ROLLER...................................................................6-61

6.13.5 FUSING TEMPERATURE CONTROL..........................................6-62

SM vii B039/B040/B043

Page 18

Rev. 03/2002

Overview ............................................................................................ 6-62

Fusing Lamp Control .......................................................................... 6-64

Fusing Temperature Control for Thick Paper at the By-pass Tray ..... 6-65

Pre-heat Mode (Fusing Idling) ............................................................ 6-65

To Prevent Offset when Making Multiple Copies

on Small-width Paper ......................................................................... 6-65

Reduced Copy Speed with Narrow Paper.......................................... 6-65

6.13.6 OVERHEAT PROTECTION ......................................................... 6-66

6.14 DUPLEX UNIT ...................................................................................... 6-67

6.14.1 OVERALL..................................................................................... 6-67

6.14.2 DRIVE MECHANISM ................................................................... 6-68

6.14.3 BASIC OPERATION .................................................................... 6-69

Larger than A4 Short-edge/LT Short-edge ......................................... 6-69

Up to A4 Short-edge/LT Short-edge................................................... 6-70

6.14.4 FEED IN AND EXIT MECHANISM............................................... 6-71

6.15 ENERGY SAVER MODES.................................................................... 6-72

6.15.1 OVERVIEW.................................................................................. 6-72

6.15.2 LOW POWER MODE................................................................... 6-73

Entering Low Power Mode ................................................................. 6-73

What Happens in Low Power Mode ................................................... 6-73

Returning to Stand-by Mode............................................................... 6-74

6.15.3 NIGHT/OFF MODE ...................................................................... 6-74

Entering Night/Off Mode..................................................................... 6-74

What Happens in Night/Off Mode....................................................... 6-75

Returning to Stand-by Mode............................................................... 6-75

AUTO REVERSE DOCUMENT FEEDER B379

1 OVERALL MACHINE INFORMATION ......................................... 7-1

1.1 MECHANICAL COMPONENT LAYOUT................................................... 7-1

1.2 ELECTRICAL COMPONENT LAYOUT .................................................... 7-2

1.3 DRIVE LAYOUT........................................................................................ 7-3

2 DETAILED SECTION DESCRIPTIONS........................................ 7-4

2.1 ORIGINAL SIZE DETECTION .................................................................. 7-4

2.2 PICK-UP AND SEPARATION................................................................... 7-6

2.3 ORIGINAL TRANSPORT AND EXIT ........................................................ 7-7

2.3.1 SINGLE-SIDED ORIGINALS ........................................................... 7-7

2.3.2 DOUBLE-SIDED ORIGINALS.......................................................... 7-8

2.3.3 ORIGINAL TRAILING EDGE SENSOR ........................................... 7-9

2.4 STAMP.................................................................................................... 7-10

2.5 TIMING CHARTS.................................................................................... 7-11

2.5.1 SINGLE-SIDED ORIGINAL MODE (A3) ........................................ 7-11

2.5.2 SINGLE-SIDED ORIGINAL MODE (A3, STAMP MODE) .............. 7-12

2.5.3 DOUBLE-SIDED ORIGINAL MODE .............................................. 7-13

2.5.4 DOUBLE-SIDED ORIGINAL MODE (STAMP MODE) ................... 7-14

2.6 JAM DETECTION ................................................................................... 7-15

B039/B040/B043 viii SM

Page 19

2.7 OVERALL ELECTRICAL CIRCUIT .........................................................7-16

2.8 FREE RUN.............................................................................................. 7-17

Procedure...........................................................................................7-17

One-sided Free Run Process.............................................................7-17

Two-sided Free Run Process.............................................................7-17

3 REPLACEMENT AND ADJUSTMENT....................................... 7-18

3.1 DF EXIT TABLE AND COVER................................................................7-18

3.2 ORIGINAL FEED UNIT ...........................................................................7-19

3.3 LEFT COVER..........................................................................................7-20

3.4 PICK-UP ROLLER...................................................................................7-21

3.5 FEED BELT.............................................................................................7-22

3.6 SEPARATION ROLLER..........................................................................7-23

3.7 ORIGINAL SET/ORIGINAL REVERSE SENSORS.................................7-24

3.8 ORIGINAL L/W SENSOR, TRAILING EDGE SENSOR..........................7-25

3.9 FEED CLUTCH, PICK-UP SOL, TRANSPORT MOTOR,

FEED MOTOR.........................................................................................7-26

Exterior ...............................................................................................7-26

DF Feed Clutch...................................................................................7-26

Pick-up Solenoid.................................................................................7-26

Transport Motor..................................................................................7-26

DF Feed Motor....................................................................................7-26

3.10 REGISTRATION SENSOR....................................................................7-27

3.11 STAMP SOLENOID AND ORIGINAL EXIT SENSOR...........................7-28

DOCUMENT FEEDER B387

1 OVERALL INFORMATION .......................................................... 8-1

1.1 MECHANICAL COMPONENT LAYOUT ...................................................8-1

1.2 ELECTRICAL COMPONENT LAYOUT.....................................................8-2

1.3 DRIVE LAYOUT........................................................................................8-3

2 DETAILED SECTION DESCRIPTIONS ....................................... 8-4

2.1 ORIGINAL SIZE DETECTION...................................................................8-4

2.2 PICK-UP AND SEPARATION...................................................................8-6

2.3 ORIGINAL TRANSPORT AND EXIT MECHANISM..................................8-7

2.4 STAMP......................................................................................................8-8

2.5 TIMING CHARTS......................................................................................8-9

2.5.1 A3.....................................................................................................8-9

2.5.2 A3, STAMP MODE.........................................................................8-10

2.6 JAM DETECTION....................................................................................8-11

2.7 OVERALL ELECTRICAL CIRCUIT .........................................................8-12

2.8 FREE RUN..............................................................................................8-13

Procedure...........................................................................................8-13

Free Run Process...............................................................................8-13

SM ix B039/B040/B043

Page 20

3 REPLACEMENT AND ADJUSTMENT....................................... 8-14

3.1 EXTERIOR COVERS..............................................................................8-14

3.1.1 REAR COVER................................................................................8-14

3.1.2 ORIGINAL TABLE..........................................................................8-14

3.1.3 FRONT COVER .............................................................................8-14

3.1.4 ORIGINAL ENTRANCE GUIDE .....................................................8-14

3.1.5 DF FEED COVER...........................................................................8-15

3.2 FEED UNIT..............................................................................................8-15

3.3 SEPARATION ROLLER..........................................................................8-15

3.4 PICK-UP ROLLER...................................................................................8-16

3.5 FEED BELT.............................................................................................8-16

3.6 ORIGINAL SENSORS (WIDTH, LENGTH, TRAILING EDGE)................8-17

3.7 ORIGINAL SET SENSOR.......................................................................8-18

3.8 TRANSPORT MOTOR............................................................................8-18

3.9 DF COVER OPEN SENSOR/FEED CLUTCH/ROM/

DF DRIVE BOARD..................................................................................8-19

Exterior ...............................................................................................8-19

Feed Cover Open Sensor...................................................................8-19

Feed Clutch ........................................................................................8-19

ROM ...................................................................................................8-19

DF Drive Board...................................................................................8-19

3.10 REGISTRATION SENSOR....................................................................8-21

3.11 PICK-UP SOLENOID ............................................................................8-21

3.12 STAMP SOLENOID............................................................................... 8-22

PAPER TRAY UNIT B384

1 OVERALL MACHINE INFORMATION......................................... 9-1

1.1 MECHANICAL COMPONENT LAYOUT ...................................................9-1

1.2 ELECTRICAL COMPONENT LAYOUT.....................................................9-2

1.3 DRIVE LAYOUT........................................................................................9-3

2 DETAILED DESCRIPTIONS........................................................ 9-4

2.1 PAPER FEED AND SEPARATION MECHANISM....................................9-4

2.2 PAPER LIFT MECHANISM.......................................................................9-5

2.3 PAPER END DETECTION........................................................................9-7

2.4 PAPER HEIGHT DETECTION..................................................................9-8

PAPER SIZE DETECTION...................................................................9-9

2.5 SIDE AND END FENCES .......................................................................9-10

Side Fences........................................................................................9-10

End Fence ..........................................................................................9-10

3 REPLACEMENT AND ADJUSTMENT....................................... 9-11

3.1 FEED ROLLER REPLACEMENT............................................................9-11

3.2 TRAY MAIN BOARD REPLACEMENT ...................................................9-12

3.3 TRAY MOTOR REPLACEMENT.............................................................9-12

B039/B040/B043 x SM

Page 21

3.4 RELAY CLUTCH REPLACEMENT.........................................................9-13

3.5 UPPER PAPER FEED CLUTCH REPLACEMENT.................................9-14

3.6 LOWER PAPER FEED CLUTCH REPLACEMENT................................9-15

3.7 LIFT MOTOR REPLACEMENT...............................................................9-16

3.8 PAPER END SENSOR REPLACEMENT................................................9-17

3.9 VERTICAL TRANSPORT SENSOR REPLACEMENT............................9-17

3.10 PAPER SIZE SWITCH REPLACEMENT ..............................................9-18

PAPER TRAY UNIT B385

1 OVERALL MACHINE INFORMATION....................................... 10-1

1.1 MECHANICAL COMPONENT LAYOUT .................................................10-1

1.2 ELECTRICAL COMPONENT LAYOUT...................................................10-2

1.3 DRIVE LAYOUT......................................................................................10-3

2 DETAILED DESCRIPTIONS...................................................... 10-4

2.1 PAPER FEED AND SEPARATION.........................................................10-4

2.2 PAPER LIFT MECHANISM.....................................................................10-5

2.3 PAPER END DETECTION......................................................................10-7

2.4 PAPER HEIGHT DETECTION................................................................10-8

2.5 PAPER SIZE DETECTION......................................................................10-9

2.6 SIDE AND END FENCES .....................................................................10-10

Side Fences......................................................................................10-10

End Fence ........................................................................................10-10

3 REPLACEMENT AND ADJUSTMENT..................................... 10-11

3.1 FEED ROLLER REPLACEMENT..........................................................10-11

3.2 TRAY MAIN BOARD REPLACEMENT .................................................10-12

3.3 TRAY MOTOR REPLACEMENT...........................................................10-13

3.4 LIFT MOTOR REPLACEMENT.............................................................10-14

3.5 PAPER END SENSOR REPLACEMENT..............................................10-15

3.6 PAPER SIZE SWITCH REPLACEMENT ..............................................10-15

SPECIFICATIONS

SPECIFICATIONS.......................................................................... 11-1

1. GENERAL SPECIFICATIONS..................................................................11 -1

Duplex Unit (B043 only).....................................................................11 -4

2. MACHINE CONFIGURATION..................................................................11 -5

3. OPTIONAL EQUIPMENT.........................................................................11 -6

ARDF.................................................................................................11 -6

ADF....................................................................................................11 -7

ONE-TRAY PAPER TRAY UNIT.......................................................11 -8

TWO-TRAY PAPER TRAY UNIT.......................................................11 -9

16MB IMB (Copier Memory Unit)*......................................................11 -9

SM xi B039/B040/B043

Page 22

Rev. 06/2003

B120 (RLA ONLY)

B120 (RLA ONLY)

12.1 INSTALLATION .................................................................................... 12-1

12.2 PREVENTIVE MAINTENANCE SCHEDULES .................................... 12 -1

12.3 REPLACEMENT AND ADJUSTMENT ................................................ 12 -1

12.4 TROUBLESHOOTING......................................................................... 12 -1

12.5 SERVICE TABLES .............................................................................. 12 -1

12.5.1 SP MODE TABLES....................................................................... 12-1

12.5.2 COPY FEATURES TABLE (USER TOOLS) ................................. 12-2

System Setting Table ......................................................................... 12-2

Copy Features Table.......................................................................... 12-2

12.6 DETAILED SECTION DESCRIPTIONS............................................... 12 -3

12.7 SPECIFICATIONS .............................................................................. 12 -3

B039/B040/B043 xii SM

Page 23

Rev. 06/2003

B404

TABLE OF CONTENTS

INSTALLATION

1 INSTALLATION............................................................................. 1-1

1.1 INSTALLATION REQUIREMENTS ...........................................................1-1

1.1.1 ENVIRONMENT ...............................................................................1-1

1.1.2 MACHINE LEVEL.............................................................................1-1

1.1.3 MINIMUM SPACE REQUIREMENTS...............................................1-1

1.1.4 POWER REQUIREMENTS ..............................................................1-1

1.2 FAX UNIT ..................................................................................................1-2

1.2.1 ACCESSORY CHECK......................................................................1-2

1.2.2 INSTALLATION PROCEDURE ........................................................1-3

1.3 HANDSET .................................................................................................1-7

1.3.1 ACCESSORY CHECK......................................................................1-7

1.3.2 INSTALLATION PROCEDURE ........................................................1-7

PREVENTIVE MAINTENANCE

2 PREVENTIVE MAINTENANCE..................................................... 2-1

2.1 SPECIAL TOOLS AND LUBRICANTS ......................................................2-1

2.2 PM TABLE................................................................................................. 2-1

REMOVAL AND REPLACEMENT

3 REMOVAL AND REPLACEMENT................................................ 3-1

3.1 PRECAUTION ...........................................................................................3-1

3.2 FCU ...........................................................................................................3-1

3.3 NCU...........................................................................................................3-2

3.4 SPEAKER..................................................................................................3-3

TROUBLESHOOTING

4 TROUBLESHOOTING .................................................................. 4-1

4.1 ERROR CODES........................................................................................4-1

4.2 FAX SC CODES........................................................................................4-9

4.2.1 OVERVIEW ......................................................................................4-9

4.2.2 SC1201.............................................................................................4-9

4.2.3 FAX SC CODE TABLE ...................................................................4-10

4.3 FAX OPTION FIRMWARE MODIFICATION HISTORY…………………..4-11

SM xiii B039/B040/B043

Page 24

Rev. 06/2003

SERVICE TABLES

5 SERVICE TABLES........................................................................ 5-1

5.1 SERVICE LEVEL FUNCTIONS ................................................................ 5-1

5.1.1 HOW TO ENTER AND EXIT SERVICE MODE ............................... 5-1

5.1.2 FUNCTION NO. ............................................................................... 5-1

(1) 01. BIT SW ..................................................................................... 5-1

(2) 02. PARAMETER LIST................................................................... 5-2

(3) 03. ERROR CODE ......................................................................... 5-2

(4) 04. SERVICE REPORT .................................................................. 5-2

(5) 05. PROTOCOL DUMP .................................................................. 5-3

(6) 06. MEMORY.................................................................................. 5-3

(7) 07. RAM CLEAR............................................................................. 5-4

(8) 08. NCU.......................................................................................... 5-4

(9) 09. ROM VERSION ........................................................................ 5-5

(10) 10. FILE PRINTOUT..................................................................... 5-5

(11) 11. JOURNAL (ALL) ..................................................................... 5-5

(12) 12. RAM TEST.............................................................................. 5-6

(13) 13. S.S. NUMBER ........................................................................ 5-6

(14) 14. SERIAL # ................................................................................ 5-6

(15) 15. HISTORY................................................................................ 5-7

5.2 DATA TRANSFER.................................................................................... 5-8

5.2.1 FAX SOFTWARE DOWNLOAD....................................................... 5-8

5.2.2 FAX SRAM DOWNLOAD ................................................................ 5-9

5.2.3 FAX SRAM UPLOAD..................................................................... 5-10

5.3 BIT SWITCHES ...................................................................................... 5-11

5.3.1 SYSTEM SWITCHES .................................................................... 5-11

5.3.2 SCANNER SWITCHES ................................................................. 5-22

5.3.3 PLOTTER SWITCHES .................................................................. 5-27

5.3.4 COMMUNICATION SWITCHES .................................................... 5-32

5.3.5 G3 SWITCHES .............................................................................. 5-37

5.4 NCU PARAMETERS .............................................................................. 5-45

5.5 DEDICATED TRANSMISSION PARAMETERS ..................................... 5-56

5.5.1 PROGRAMMING PROCEDURE ................................................... 5-56

5.5.2 PARAMETERS .............................................................................. 5-57

5.6 SERVICE RAM ADDRESSES ................................................................ 5-60

DETAILED SECTION DESCRIPTIONS

6 DETAILED SECTION DESCRIPTIONS ........................................ 6-1

6.1 OPERATION DUMP LIST......................................................................... 6-1

6.2 PCBS ........................................................................................................ 6-2

6.2.1 FCU ................................................................................................. 6-2

6.2.2 NCU (US)......................................................................................... 6-4

6.2.3 NCU (EUROPE/ASIA) ..................................................................... 6-5

B039/B040/B043 xiv SM

Page 25

Rev. 06/2003

SPECIFICATIONS

SPECIFICATIONS............................................................................. 7-1

1. GENERAL SPECIFICATIONS.....................................................................7-1

2. FEATURES .................................................................................................7-2

2.1 FEATURES LIST................................................................................. 7-2

2.2 CAPABILITIES OF PROGRAMMABLE ITEMS ...................................7-5

3. OVERALL MACHINE CONTROL ................................................................7-6

3.1 SYSTEM CONTROL ...........................................................................7-6

3.2 POWER DISTRIBUTION.....................................................................7-6

3.3 MEMORY BACK-UP............................................................................7-6

4. VIDEO DATA PATH ....................................................................................7-7

4.1 TRANSMISSION ................................................................................. 7-7

Memory Transmission and Parallel Memory Transmission...................7-8

Immediate Transmission.......................................................................7-8

4.2 RECEPTION........................................................................................7-9

5. MACHINE CONFIGURATION................................................................... 7-10

FIRMWARE HISTORY

FIRMWARE HISTORY ...................................................................... 8-1

1. FIRMWARE MODIFICATION HISTORY .....................................................8-1

SM xv B039/B040/B043

Page 26

Page 27

!

IMPORTANT SAFETY NOTICES

PREVENTION OF PHYSICAL INJURY

1. Before disassembling or assembling parts of the copier and peripherals,

make sure that the power cord is unplugged.

2. The wall outlet should be near the copier and easily accessible.

3. Note that some components of the copier and the paper tray unit are

supplied with electrical voltage even if the main power switch is turned off.

4. If a job has started before the copier completes the warm-up or initializing

period, keep hands away from the mechanical and electrical components

because the starts making copies as soon as the warm-up period is

completed.

5. The inside and the metal parts of the fusing unit become extremely hot while

the copier is operating. Be careful to avoid touching those components with

your bare hands.

HEALTH SAFETY CONDITIONS

Toner and developer are non-toxic, but if you get either of them in your eyes by

accident, it may cause temporary eye discomfort. Try to remove with eye drops

or flush with water as first aid. If unsuccessful, get medical attention.

OBSERVANCE OF ELECTRICAL SAFETY STANDARDS

The copier and its peripherals must be installed and maintained by a customer

service representative who has completed the training course on those models.

SAFETY AND ECOLOGICAL NOTES FOR DISPOSAL

1. Do not incinerate toner bottles or used toner. Toner dust may ignite suddenly

when exposed to an open flame.

2. Dispose of used toner, developer, and organic photoconductors in

accordance with local regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

Page 28

LASER SAFETY

The Center for Devices and Radiological Health (CDRH) prohibits the repair of

laser-based optical units in the field. The optical housing unit can only be repaired

in a factory or at a location with the requisite equipment. The laser subsystem is

replaceable in the field by a qualified Customer Engineer. The laser chassis is not

repairable in the field. Customer engineers are therefore directed to return all

chassis and laser subsystems to the factory or service depot when replacement of

the optical subsystem is required.

!

WARNING

Use of controls, or adjustment, or performance of procedures other than

those specified in this manual may result in hazardous radiation exposure.

!

WARNING FOR LASER UNIT

WARNING: Turn off the main switch before attempting any of the

procedures in the Laser Unit section. Laser beams can

seriously damage your eyes.

CAUTION MARKING:

Symbols and Abbreviations

This manual uses several symbols and abbreviations. The meaning of those

symbols and abbreviations are as follows:

☛

!

"

#

SEF

LEF

See or Refer to

Clip ring

Screw

Connector

Short Edge Feed

Long Edge Feed

Page 29

INSTALLATION B039/B040/B043

Rev. 06/2003

PAPER TRAY UNIT B384

PREVENTIVE MAINTENANCE B039/B040/B043

PAPER TRAY UNIT B385

REPLACEMENT AND ADJUSTMENT B039/B040/B043

SPECIFICATIONS

TROUBLESHOOTING B039/B040/B043

FAX UNIT B404

TAB

POSITION 1

TAB

POSITION 2

TAB

POSITION 3

TAB

POSITION 4

SERVICE TABLES B039/B040/B043

B120 (RLA only)

DETAILED SECTION DESCRIPTION B039/B040/B043

AUTO REVERSE DOCUMENT FEEDER B379

DOCUMENT FEEDER B387

TAB

POSITION 5

TAB

POSITION 6

TAB

POSITION 7

TAB

POSITION 8

Page 30

Page 31

INSTALLATION

Page 32

Page 33

INSTALLATION REQUIREMENTS

1. INSTALLATION

!

CAUTION

Before installing options, please do the following:

1. If there is a fax unit in the machine, print out all messages stored in the

memory, the lists of user programmed items, and the system parameter

list.

2. If there is a printer option in the machine, print out all data in the printer

buffer.

3. Turn off the main switch and disconnect the power cord, the telephone

line, and the network cable.

1.1 INSTALLATION REQUIREMENTS

1.1.1 ENVIRONMENT

Installation

–Temperature and Humidity Chart–

Humidity

80%

54%

Operation range

15%

10°C

(50°F)

27°C

(80.6°F)

32°C

(89.6°F)

Temperature

B039I502.WMF

SM 1-1 B039/B040/B043

Page 34

INSTALLATION REQUIREMENTS

1. Temperature Range:

10°C to 32°C (50°F to 89.6°F)

2. Humidity Range: 15% to 80% RH

3. Ambient

Less than 1,500 lux (do not expose to direct sunlight).

Illumination:

4. Ventilation: Room air should turn over at least 30 m3/hr/person

5. Ambient Dust: Less than 0.075 mg/m3 (2.0 x 10-6 oz/yd3)

6. Avoid areas exposed to sudden temperature changes:

1) Areas directly exposed to cool air from an air conditioner.

2) Areas directly exposed to heat from a heater.

7. Do not place the machine where it will be expo s ed to corrosive gases.

8. Do not install the machine at any location over 2,000 m (6,500 ft.) above sea

level.

9. Place the copier on a strong and level base. (Inclination on any side should be

no more than 5 mm.)

10. Do not place the machine where it may be subjected to strong vibrations.

1.1.2 MACHINE LEVEL

Front to back: Within 5 mm (0.2") of level

Right to left: Within 5 mm (0.2") of level

B039/B040/B043 1-2 SM

Page 35

INSTALLATION REQUIREMENTS

1.1.3 MINIMUM SPACE REQUIREMENTS

Place the copier near the power source, providing clearance as shown:

[C]

[D][B]

A: Front > 750 mm (29.6")

B: Left > 10 mm (0.4")

C: Rear > 10 mm (0.4")

D: Right > 10 mm (0.4")

Installation

[A]

B039I145.WMF

NOTE: 1) The recommended 750 mm front space is sufficient to allow the paper

tray to be pulled out. Additional front space is required to allow

operators to stand at the front of the machine.

2) The recommended 10 mm right space is for installation only. Additional

right space is required to allow operators to fix paper jams and use the

by-pass tray.

1.1.4 POWER REQUIREMENTS

!

CAUTION

1. Make sure that the wall outlet is near the copier and easily accessible.

After completing installation, make sure the plug fits firmly into the

outlet.

2. Avoid multi-wiring.

3. Be sure to ground the machine.

1. Input voltage:

America, Taiwan:110 – 120 V, 50/60 Hz, 12 A

Europe, Asia: 220 – 240 V, 50/60 Hz, 7 A

SM 1-3 B039/B040/B043

Page 36

COPIER INSTALLATION

1.2 COPIER INSTALLATION

1.2.1 POWER SOCKETS FOR PERIPHERALS

!

CAUTION

Rated voltage for peripherals

Make sure to plug the cables into the correct sockets.

ADF/ARDF

Rated voltage output connector

for accessory Max. DC24 V

Paper Tray Unit

Rated voltage output connector

for accessory Max. DC24 V

1.1.2 ACCESSORY CHECK

Check that you have the accessories indicated below.

No. Description Q’ty

1 Operation Instructions - Sy st em Set t ings 1

2 Operation Instructions - Co py Reference 1

3 New Equipment Condition Report (NECR) - English

(-10, -17)

4

5 Model Nameplate (-10, -17, -22) 1

6 Model Name Decal (-22) 1

New Equipment Condition Report ( NECR) - Multi

Language (-19, -27, -29, -69)

B039I119.WMF

1

1

B039/B040/B043 1-4 SM

Page 37

COPIER INSTALLATION

1.1.3 INSTALLATION PROCEDURE

!

CAUTION

When installing the copier, make sure that the copier is unplugged.

1. Remove the strips of tape.

Installation

B039I102.WMF

2. Open the front door and remove the

toner bottle holder [A].

3. Open the right door, and remove the

PCU (Photoconductor Unit) [B].

[A]

B039I107.WMF

[B]

B039I108.WMF

SM 1-5 B039/B040/B043

Page 38

COPIER INSTALLATION

4. Separate the PCU into two sections

as shown (5 screws).

5. Distribute one pack of developer [A]

evenly across the width of the

development unit, into all openings.

NOTE: 1) To prevent foreign material

from getting on the sleeve

rollers, place a sheet of

paper under the

development unit.

2) Make sure not to spill the

developer on the gears [B].

3) If it is necessary to turn the

gear [B] to distribute the

developer, make sure to do

so very minimally, otherwise

the developer may spill.

6. Reassemble and reinstall the PCU.

7. Shake the toner bottle [C] several

times.

NOTE: Be sure not to remove the toner

bottle cap [D] until after

shaking.

B039I114.WMF

[A]

[B]

B039I115.WMF

[C]

[E]

[D]

8. Unscrew the bottle cap [D] and insert

the bottle into the holder.

NOTE: Do not touch the inner bottle

cap [E].

9. Reposition the holder and press down

the holder lever to secure the bottle.

B039I504.WMF

10. Pull out the paper tray and turn the

paper size dial to the appropriate size. Adjust the end and side guides to match

the paper size.

NOTE: To move the side guides, first release the green lock on the rear side

guide.

B039/B040/B043 1-6 SM

Page 39

COPIER INSTALLATION

11. Install the optional ARDF, ADF, or platen cover (☛ 1.3/1.4/1.5).

12. Plug in the main power cord and turn on the main switch. Perform TD Sensor

Initialization (SP2-214).

13. Select the correct display language using UP Mode (Language).

14. Load the paper in the paper tray and make a full size copy, and check if the

side-to-side and leading edge registrations are correct. If they are not, adjust

the registrations (☛ 3.13 Copy Adjustments: Printing/Scanning).

15. Initialize the electric total counter using SP7-825 in accordance with the type of

service contract.

NOTE: Select 1, then press the Original Type and OK keys at the same time. If

the reset is successful, “Action completed” will appear on the LCD.

Installation

SM 1-7 B039/B040/B043

Page 40

PLATEN COVER INSTALLATION

1.3 PLATEN COVER INSTALLATION

1.3.1 ACCESSORY CHECK

Check that you have the accessories indicated below.

No. Description Q’ty

1 Stepped Screw 2

1.3.2 INSTALLATION PROCEDURE

!

CAUTION

Unplug the machine power cord before starting the following procedure.

1. Install the platen cover [A] (2 screws).

[A]

B039I120.WMF

B039/B040/B043 1-8 SM

Page 41

1.4 ARDF INSTALLATION

1.4.1 ACCESSORY CHECK

ARDF INSTALLATION

Check the quantity and condition of the accessories against the following list.

No. Description Q’ty

1 Scale Guide 1

2DF Exposure Glass 1

3 Stud Screw 2

4 Knob Screw 2

5 Original Size Decal 2

6 Screwdriver Tool 1

34

6

1

2

5

B379I500.WMF

Installation

1.1.2 INSTALLATION PROCEDURE

1. Remove the strips of tape.

B379I101.WMF

SM 1-9 B039/B040/B043

Page 42

ARDF INSTALLATION

2. Remove the left scale [A] (2

screws).

3. Place the DF exposure glass

[B] on the glass holder.

NOTE: When installing the DF

exposure glass, make

sure that the white

point [C] is face down.

4. Peel off the backing [D] of the

double-sided tape attached to

the rear side of the scale guide

[E], then install it (2 screws

removed in step 2).

5. Install the two stud screws [F].

6. Mount the DF on the copier,

then slide the DF to the front.

7. Secure the DF unit with two

screws [G].

[C] [D]

[E]

[B]

[F]

B379I103.WMF

[A]

[F]

8. Connect the cable [H] to the

copier.

9. Attach the appropriate scale

decal [I] as shown.

10. Turn the main power switch

on. Then check if the

document feeder works

properly.

11. Make a full size copy, and

check that the side-to-side and

leading edge registrations are

correct. If they are not, adjust

the side-to-side and leading

edge registrations. (☛ 3.13.3

ADF Image Adjustment)

[G]

[H]

B379I104.WMF

[I]

B379I501.WMF

B039/B040/B043 1-10 SM

Page 43

1.5 ADF INSTALLATION

1.5.1 ACCESSORY CHECK

ADF INSTALLATION

Check the quantity and condition of the accessories against the following list.

No. Description Q’ty

1 Scale Guide 1

2DF Exposure Glass 1

3 Stud Screw 2

4 Fixing Screw 2

5 Original Size Decal 2

6 Screwdriver Tool 1

34

6

1

2

5

B387I500.WMF

Installation

1.5.2 INSTALLATION PROCEDURE

1. Remove the strips of tape.

B387I151.WMF

SM 1-11 B039/B040/B043

Page 44

ADF INSTALLATION

2. Remove the left scale [A] (2

screws).

3. Place the DF exposure glass

[B] on the glass holder.

NOTE: When installing the DF

exposure glass, make

sure that the white

point [C] is face down.

4. Peel off the backing [D] of the

double-sided tape attached to

the rear side of the scale guide

[E], then install it (2 screws

removed in step 2).

5. Install the two stud screws [F].

6. Mount the DF on the copier,

then slide the DF to the front.

7. Secure the DF unit with two

screws [G].

[C]

[D]

[E]

[B]

[F]

B387I103.WMF

[A]

[F]

8. Connect the cable [H] to the

copier.

9. Attach the appropriate scale

decal [I] as shown.

10. Turn the main power switch on.

Then check if the document

feeder works properly.

11. Make a full size copy, and

check that the side-to-side and

leading edge registrations are

correct. If they are not, adjust

the side-to-side and leading

edge registrations. (☛ 3.13.3

ADF Image Adjustment).

[G]

[H]

B387I104.WMF

[I]

B387I501.WMF

B039/B040/B043 1-12 SM

Page 45

TWO-TRAY PAPER TRAY UNIT INSTALLATION

1.6 TWO-TRAY PAPER TRAY UNIT INSTALLATION

1.6.1 ACCESSORY CHECK

Check the quantity and condition of the accessories against the following list.

No. Description Q’ty

1 Screw – M4x10 10

2 Unit Holder 4

3Adjuster 1

4 Unit Holder 2

1

2

3

4

B384I500.WMF

1.6.2 INSTALLATION PROCEDURE

Installation

[A]

B384I158.WMF

1. Remove the strips of tape.

NOTE: After removing the tape that secures the peripheral components and

cardboard to the paper tray, make sure that there is no tape and/or

tape residue remaining on the tray.

2. Attach the adjuster [A] to the base plate, as shown.

NOTE: If a table is installed, this step is unnecessary.

B384I001.WMF

SM 1-13 B039/B040/B043

Page 46

TWO-TRAY PAPER TRAY UNIT INSTALLATION

3. Remove the cover [A] (1 rivet).

4. Set the copier on the paper tray unit.

NOTE: When installing t he copier, be

careful not to pinch the

connecting harness.

[A]

B384I109.WMF

B384I117.WMF

5. One-tray copier model (B039):

Remove the 1st tray cassette [B].

Two-tray copier models

(B040/B043):

Remove the 2nd tray cassette

[B].

6. Install the two screws [C].

7. Reinstall the tray cassette.

B039/B040/B043 1-14 SM

[B]

[C]

B384I106.WMF

Page 47

8. Install the two brackets [A] (1

stepped screw each).

9. Connect the connecting harness

[B] to the copier.

NOTE: There are cutouts in the

plug on both sides. The

left side has one cutout,

and the right side has

two.

TWO-TRAY PAPER TRAY UNIT INSTALLATION

[A]

Installation

10. Reinstall the cover removed in

step 3 (1 rivet).

11. Install the four brackets [C] (2

screws each).

NOTE: If a table is installed, this

step is unnecessary.

12. Rotate the adjuster [D] to fix the

machine in place.

NOTE: If a table is installed, this

step is unnecessary.

13. Load the paper in the paper trays

and make full size copies from

each tray. Check if the side-toside and leading edge

registrations are correct. If they

are not, adjust the registrations

(☛ 3.13 Copy Adjustments:

Printing/ Scanning).

[B]

B384I105.WMF

[C]

B384I007.WMF

[D]

B384I002.WMF

SM 1-15 B039/B040/B043

Page 48

ONE-TRAY PAPER TRAY UNIT INSTALLATION

1.7 ONE-TRAY PAPER TRAY UNIT INSTALLATION

1.7.1 ACCESSORY CHECK

Check the quantity and condition of the accessories against the following list.

No. Description Q’ty

1 Screw – M4x10 2

2 Stepped Screw – M4x10 2

3 Unit Holder 2

1 2

1.7.2 INSTALLATION PROCEDURE

3

B385I500.WMF

B385I159.WMF

1. Remove the strips of tape.

NOTE: After removing the tape that secures the peripheral components and

cardboard to the paper tray, make sure that there is no tape and/or

tape residue remaining on the tray.

B039/B040/B043 1-16 SM

Page 49

ONE-TRAY PAPER TRAY UNIT INSTALLATION

2. Remove the cover [A] (1 rivet).

3. Set the copier on the paper tray unit.

NOTE: When installing t he copier, be

careful not to pinch the

connecting harness.

Installation

[A]

B385I109.WMF

B385I112.WMF

4. One-tray copier model (B039):

Remove the 1st tray cassette [B].

Two-tray copier models

(B040/B043):

Remove the 2nd tray cassette [B].

[B]

B385I120.WMF

SM 1-17 B039/B040/B043

Page 50

ONE-TRAY PAPER TRAY UNIT INSTALLATION

5. Install the two screws [A].

6. Reinstall the tray cassette.

[A]

B385I118.WMF

7. Install the two brackets [B]. (1 stepped

screw each).

8. Connect the connecting harness [C] to

the copier.

NOTE: There are cutouts in the plug

on both sides. The left side has

one cutout, and the right side

has two.

9. Reinstall the cover removed in step 2.

10. Load the paper in the paper tray and

make full size copies from tray. Check

if the side-to-side and leading edge

registrations are correct. If they are not,

adjust the registrations (☛ 3.13 Copy

Adjustments: Printing/Scanning).

[B]

[C]

B385I105.WMF

B039/B040/B043 1-18 SM

Page 51

1.8 IMB INSTALLATION

1.8.1 ACCESSORY CHECK

IMB INSTALLATION

Click the quantity and condition of the accessory against the following list:

No. Description Q’ty

1 Screw – M3x6 3

1.8.2 INSTALLATION PROCEDURE

[A]