Page 1

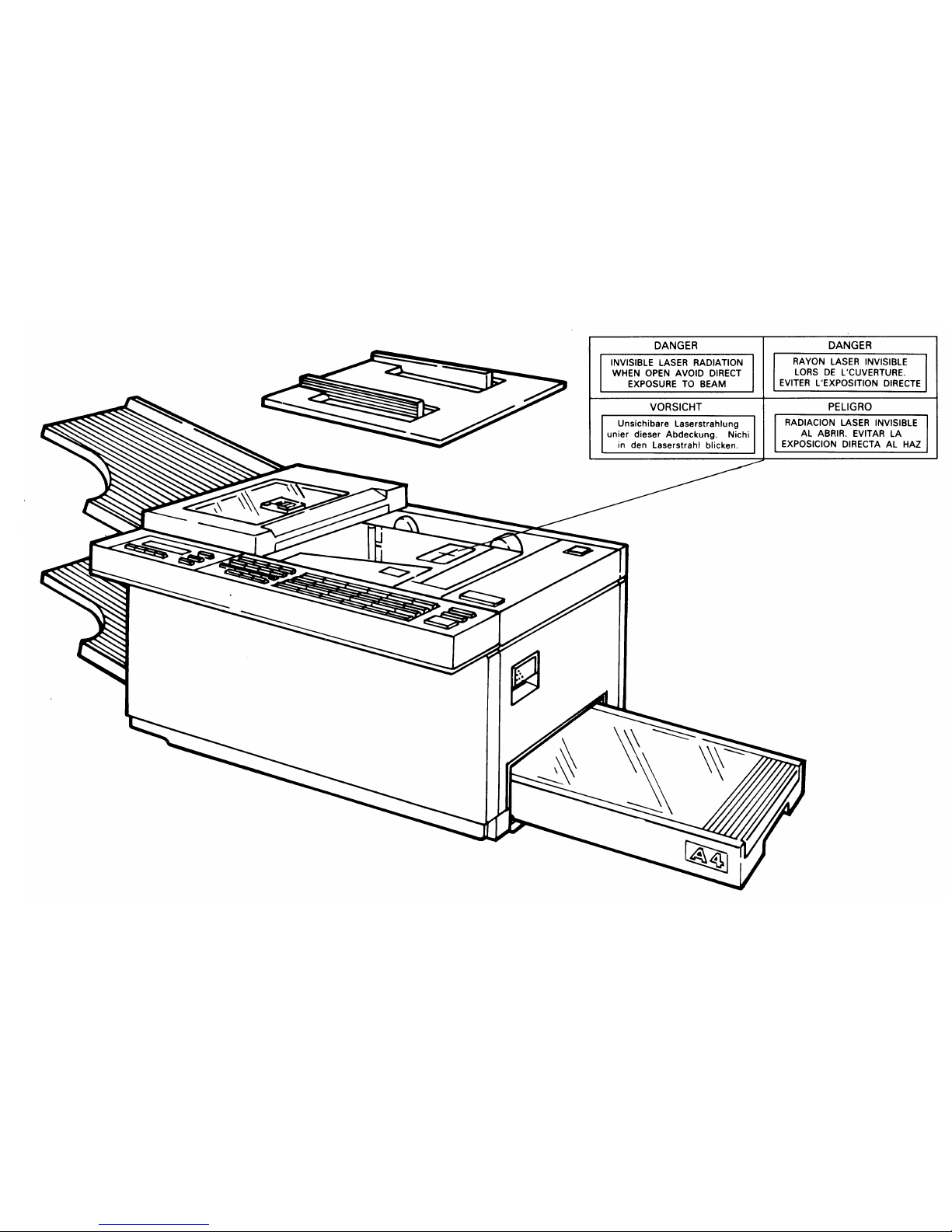

RICOH

FACSIMILE

RICOH

FAX

1000L

FIELD SERVICE MANUAL

WARNING

RICOH FAX 1000L CONTAINS A LASER BEAM GENERATOR.

LASER BEAMS CAN CAUSE PERMANENT EYE DAMAGE.

DO NOT OPEN THE LASER DIODE OR LOOK ALONG THE

LASER BEAM PATH WHILE THE MAIN POWER IS ON.

Page 2

Page 3

TABLE OF CONTENTS

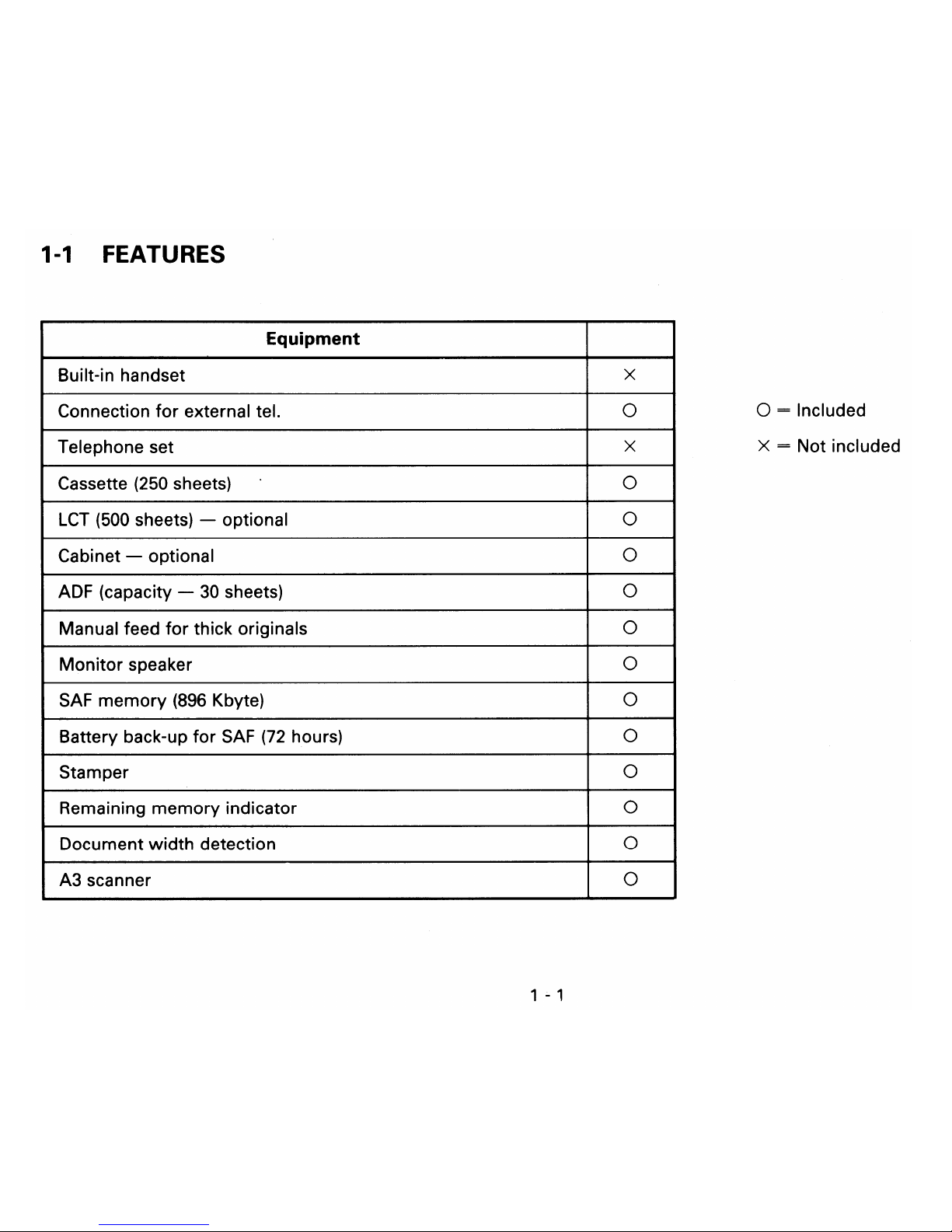

SECTION 1 FEATURES AND SPECIFICATIONS

1-1 Features

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1- 1

1-2 Specifications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-15

SECTION 2 UNPACKING

2-1 Installation Requirements

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2- 1

2-2 Unpacking Procedure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2- 2

2-3 Accessories

Check Li~t

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2- 3

SECTION 31NSTALLATION

3-1 Assembly

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3- 1

3-2 Power Connection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3- 6

3-3 Master Belt Rotation Counter Initializing

. . . . . . . . . . .

3- 7

3-4 Sub-documentTable

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3- 8

3-5 Cleaning

Padlnstallation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3- 8

3-6 Filling the Stamp

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3- 9

SECTION 4 COMPONENT GUIDE

4-1 External View

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4- 1

4-2 Internal Components

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4- 2

Drive Layout

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4- 2

Mechanical Component Layout

. . . . . . . . . . . . . . . . . . . . . . . . .

4- 4

Electrical Component Layout

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4- 8

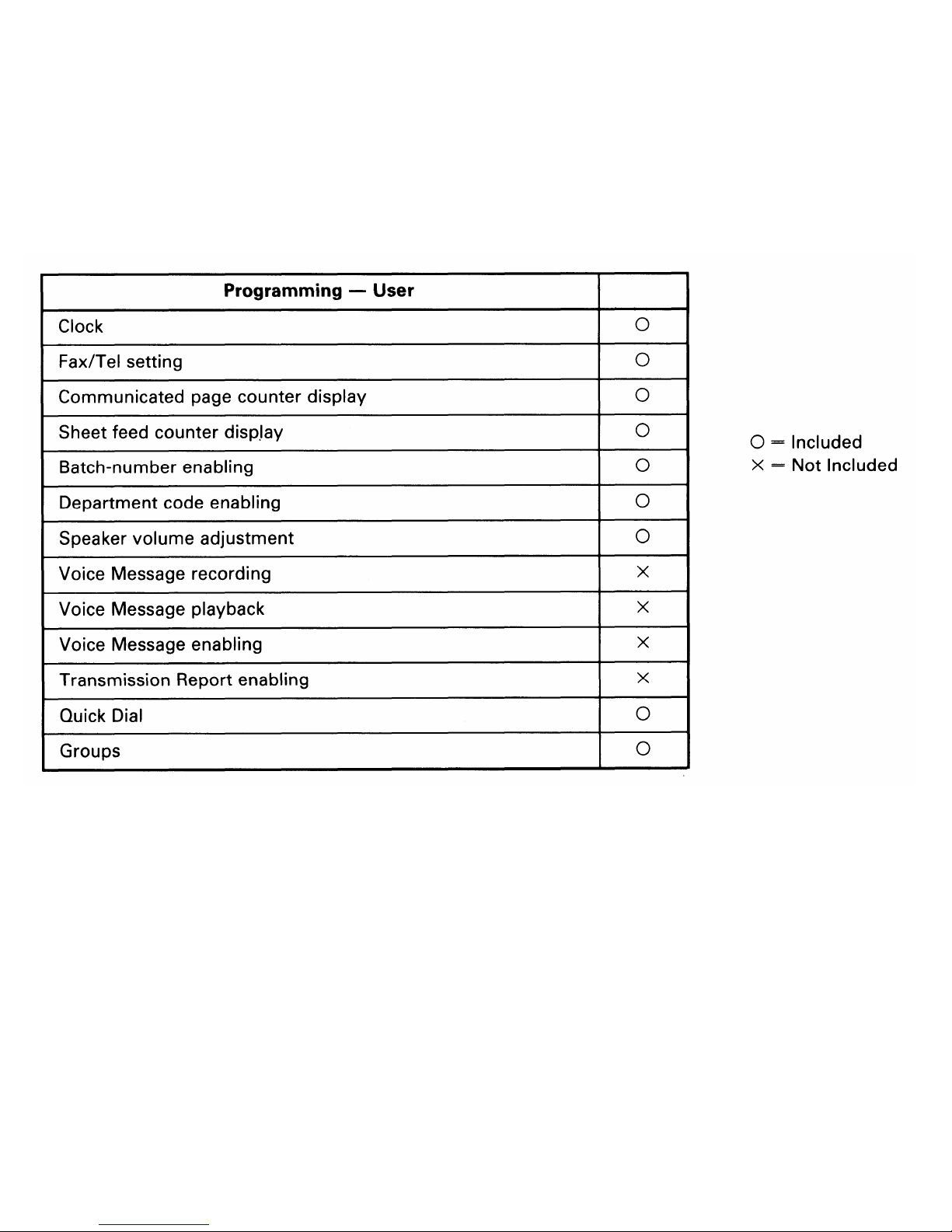

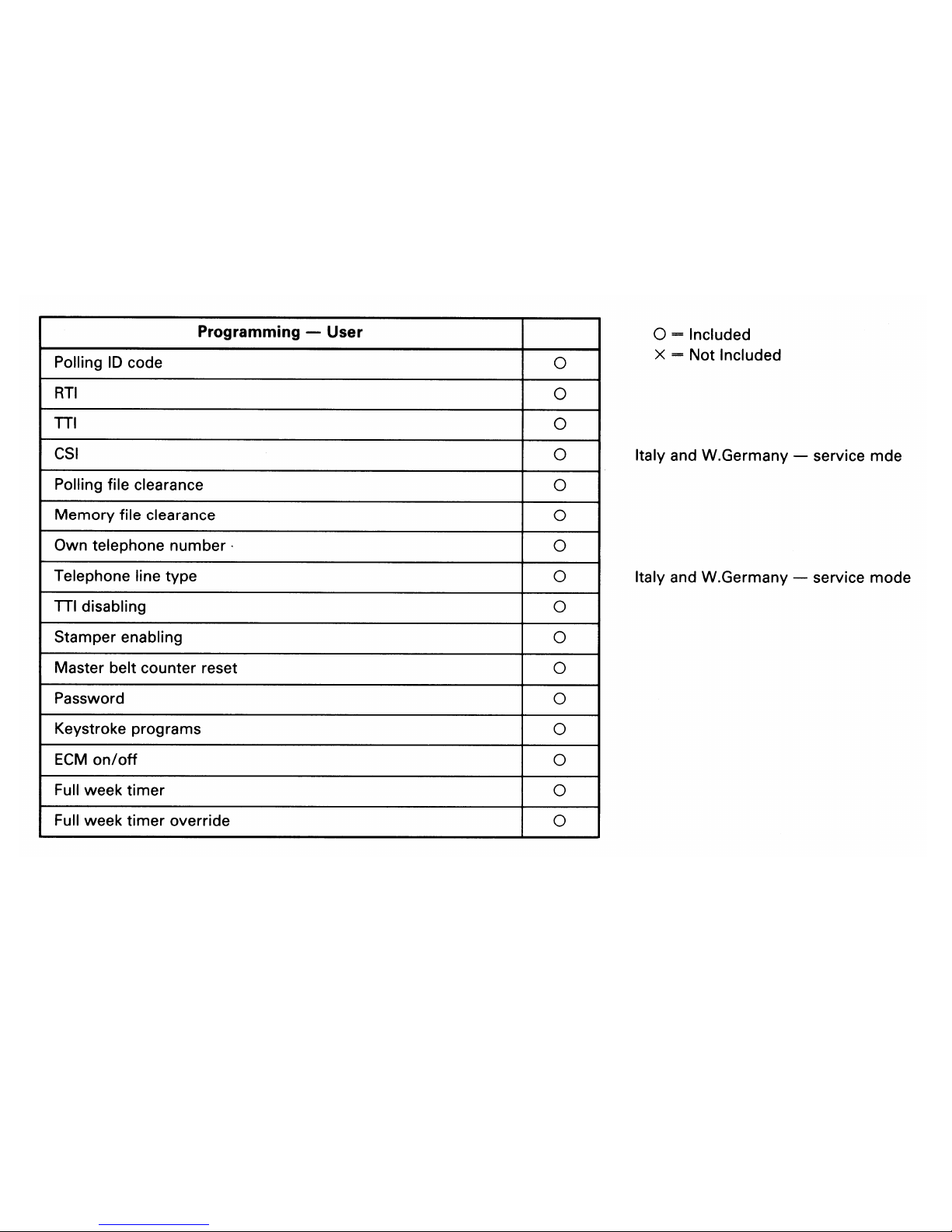

SECTION 5 PROGRAMMING AND TESTING

5-1 Operation Panel

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5- 1

5-2 User Level Programming

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5- 5

5-3 Service Level

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-12

5-3-1

1.

2.

3.

5-3-2

1.

2.

3.

4.

5.

5-3-3

5-3-4

5-3-5

Service Functions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering and Exiting Service Mode . . . . . . . .

Function Table

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bit Switch Programming

ROM and RAM Display, RAM Rewriting

System Report

ROM and RAM Printout

Error Code Display

Service Report

CC1l’Tand

Maker Codes

Service Station Telephone Number

Recovery from Printer System Crashes

NCU Parameter Programming

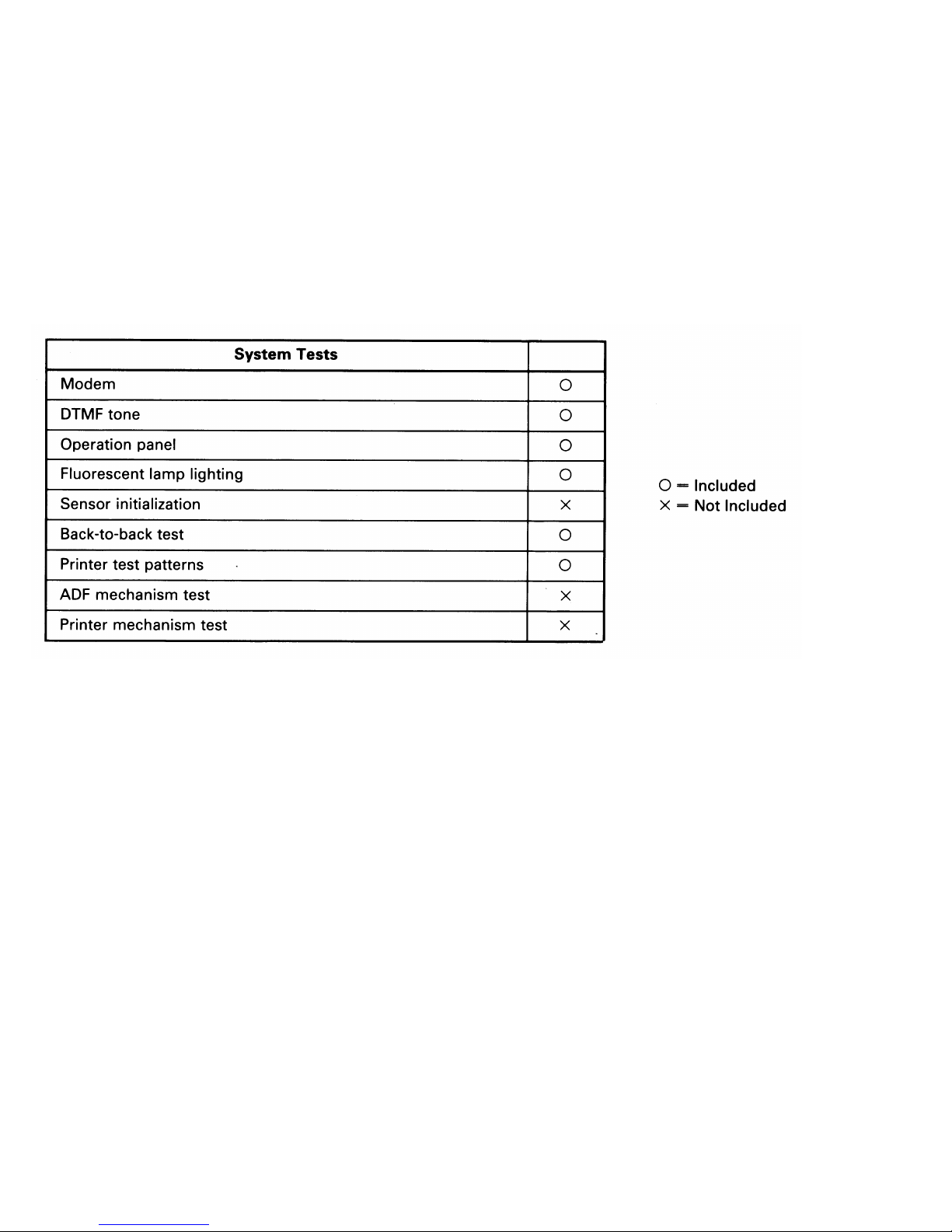

Test Mode

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering and Exiting Test Mode

. . . . . . . . . . . . .

Modem Test

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation Panel Test

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fluorescent Lamp Lighting

. . . . . . . . . . . . . . . . . . . . .

Tone Test

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printer Test

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dedicated Transmission Parameter

Programming

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Confidential File Printout . . . . . . . . . . . . . . . . . . . . . . .

5-12

5-12

5-13

5-14

5-25

5-25

5-26

5-27

5-28

5-28

5-30

5-31

5-34

5-4 Quality Checks

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-35

—l—

Page 4

SECTION 6 REMOVAL AND REPLACEMENT

6- 1

6- 2

6- 3

6- 4

6- 5

6- 6

6- 7

6- 8

6- 9

6-10

Cover Removal

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6- 1

ADF and Scanner Components . . . . . . . . . . . . . . . 6- 5

Charge

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6- 9

Exposure

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-10

Paper Feed

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-15

Development

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-17

Transfer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-20

Fusing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-22

Quenching

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-28

PCBs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6-29

SECTION 7 ADJUSTMENTS

7-1 ADF

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7- 1

7-2 Scanner

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7- 2

7-3 Printer

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7- 7

7-4 VPU

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-10

SECTION 8 MAINTENANCE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8- 1

SECTION 9 TROUBLESHOOTING

9-1 Service Call Conditions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9- 1

9-2 Copy Quality Problems

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9- 6

9-3 Mechanical Problems

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-29

9-4 Error Codes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9-40

APPENDIX

A. Bit Switches

B. Jumpers, Test Points, and VRs

C. Timing Charts

D. Sensor Table

E. Block Diagrams

F. Glossary

PAPER FEED UNIT TYPE 1000L

POINT-TO-POINT DIAGRAM

— 2 —

Page 5

SECTION 1

FEATURES AND SPECIFICATIONS

Page 6

Page 7

1 - 2

Page 8

Page 9

1 - 4

Page 10

1 - 5

Page 11

1 - 6

Page 12

Page 13

1 - 8

Page 14

1 - 9

Page 15

1 - 10

Page 16

1 - 11

Page 17

1 - 12

Page 18

1 - 13

Page 19

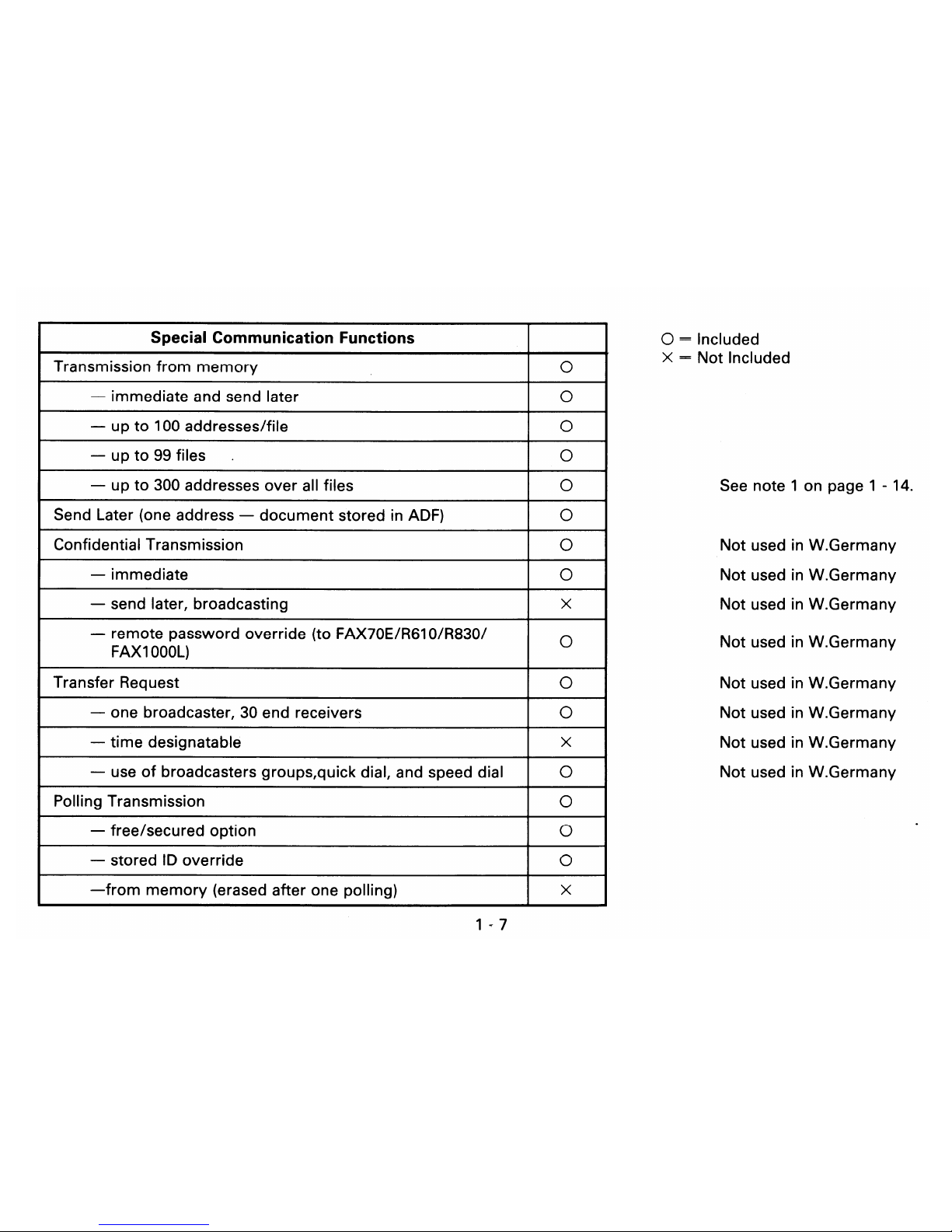

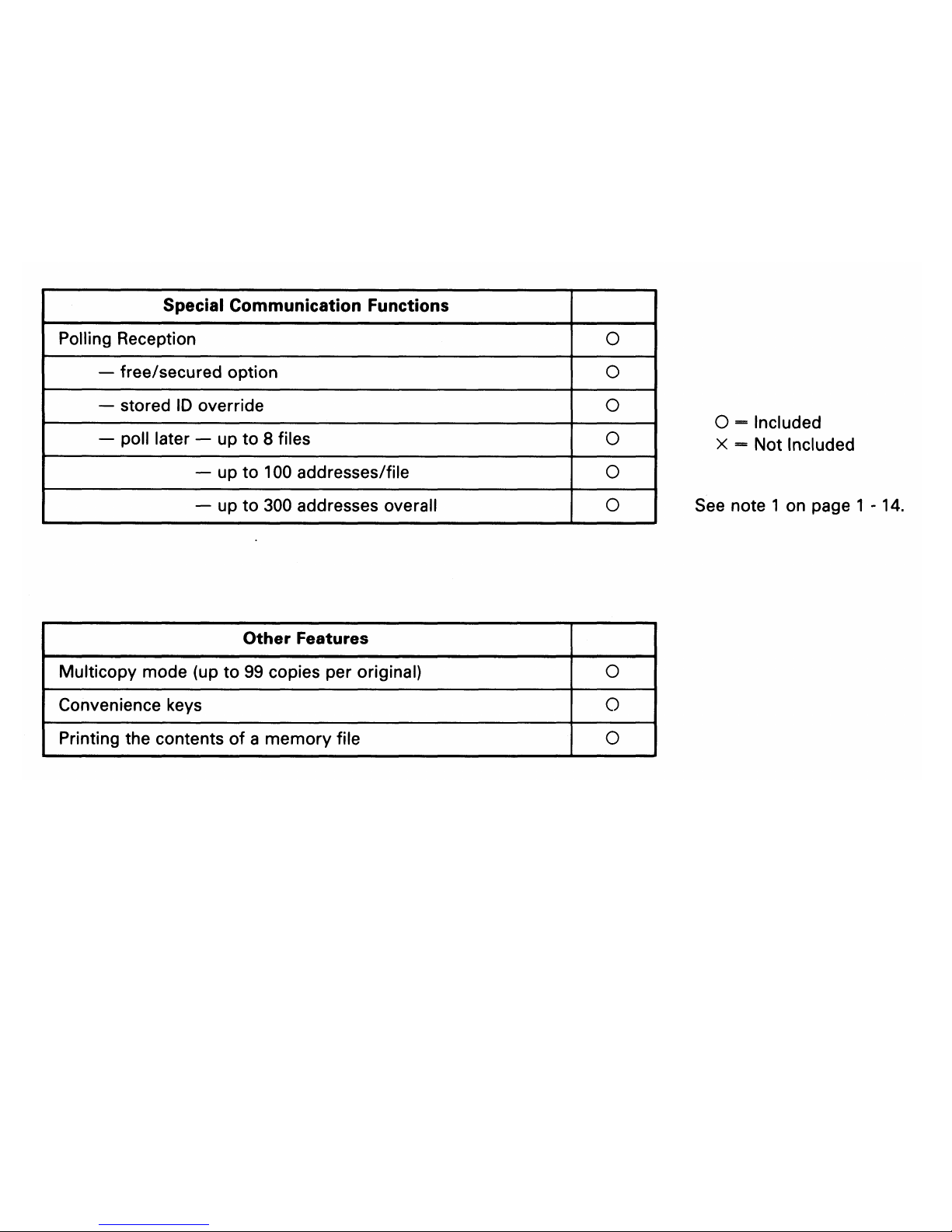

Note 1:

The total number of addresses stored in the machine for polling reception and memory transmission, when

added together, cannot exceed 300.

1 - 14

Page 20

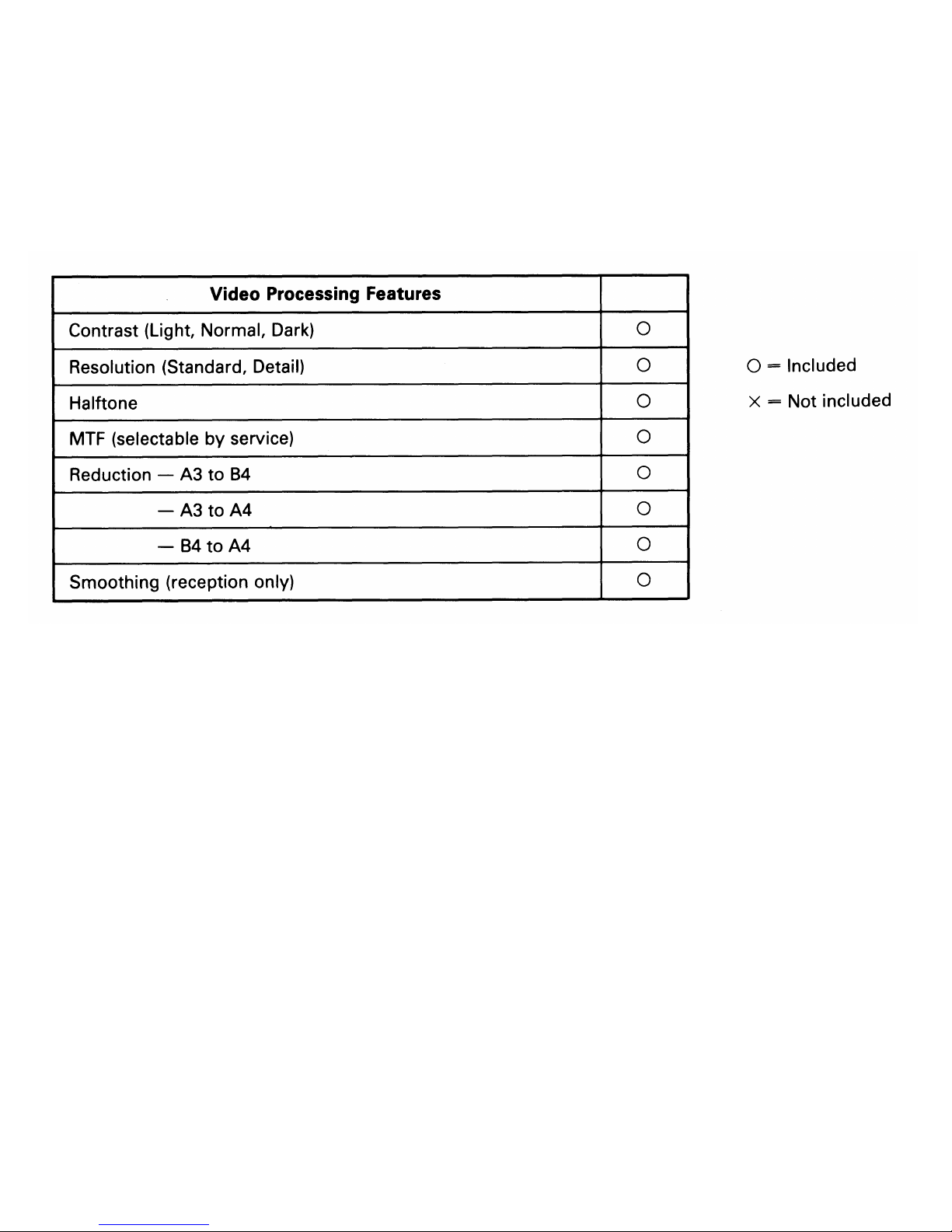

1-2 SPECIFICATIONS

Type

Circuit

Connection

Document size

Document feed

ADF capacity

Scanning method

Scan resolution

SAF capacity

Compression

Modulation

Protocol

Desk-top transceiver

PSTN, PABX

Direct coupling

Length:

105 —

1200 mm

Up to 14 m available

Width:

148

— 301 mm

Thickness: 0.05

— 0.2 mm

Automatic feed, face down

Manual feed for thick documents

30 sheets

Flat bed with CCD

Main scan:

8 pixels/mm

Sub scan:

3.85 lines/mm (Standard)

7.7 lines/mm (Detail)

896 kbytes (about 49 CClTT #1 test charts at standard resolution)

MH, MR, EFC

QAM, PHM, AM-PM-VSB

Groups 2 and 3; automatic compatibility

1 - 15

Page 21

Data rate

Transmission time

Printing system

Paper size

Maximum printout width

Printer resolution

Power supply

Power consumption

(average)

Power consumption

(maximum)

Dimensions

Weight

9600/7200/4800/2400 bps

Automatic fallback

15 s for one CClTT #1 test chart using standard resolution, 9600 bps,

and EFC (no TTI, MTF, or ECM)

Laser printing, plain paper, dry toner

B4, A4

250 mm (B4)

Main scan:

16 dots/mm

Sub scan:

15.4 lines/mm

230 ± 30 Vac, 50 Hz, single phase

Standby:

30 w

Transmission:

60 W

Reception:

300 W (upper cassette)

310 W (lower cassette)

Copying:

360 W (upper cassette)

370 W (lower cassette)

520 W

435 x 550 x 295 mm (W x D x H)

Excluding trays, handset, and cabinet

About 28 kgs

Excluding trays, handset, and cabinet

1 - 16

Page 22

SECTION 2

UNPACKING

Page 23

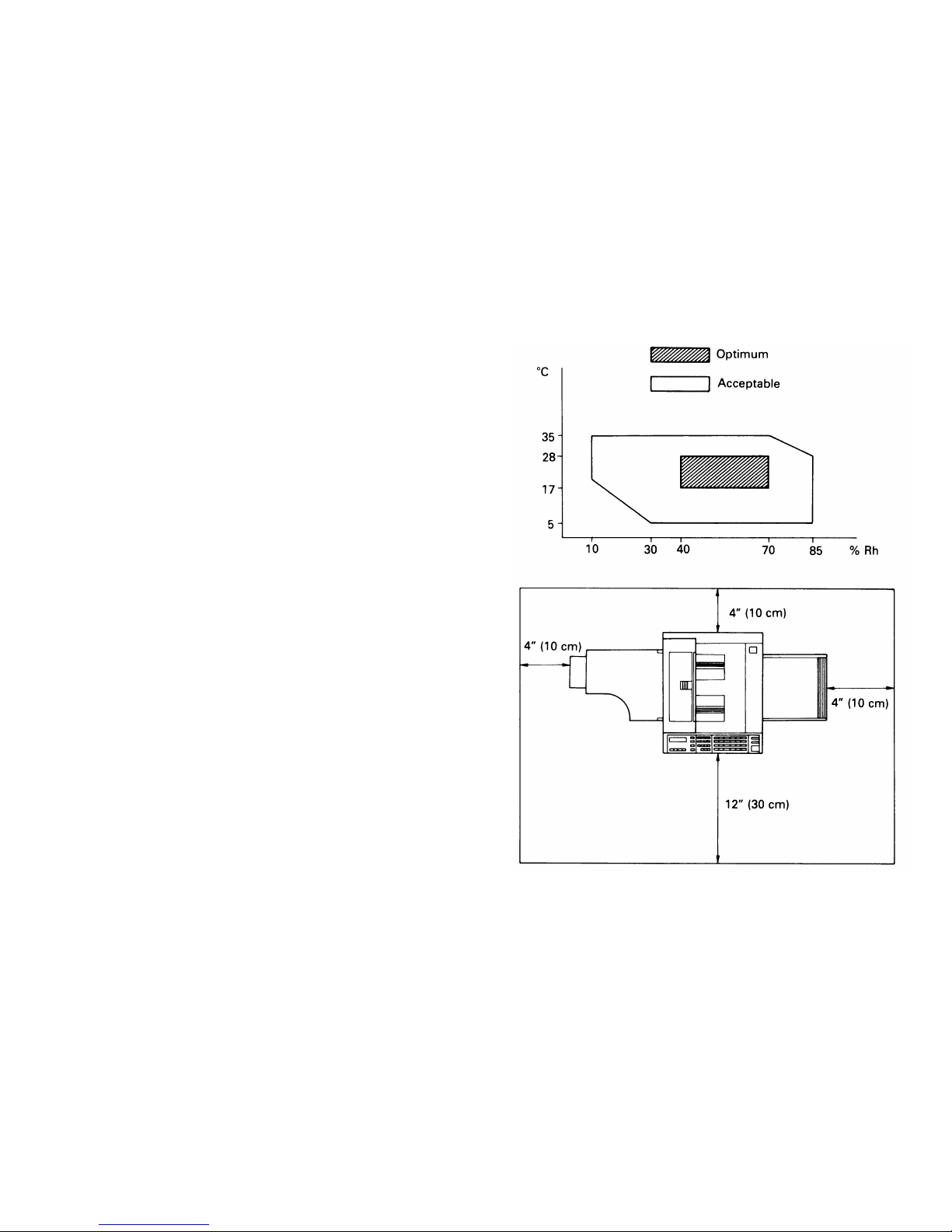

2-1 INSTALLATION REQUIREMENTS

Install in a place which satisfies the following conditions.

• Not exposed to direct sunlight.

• Away from areas containing corrosive gas.

• Well ventilated (air turnover at least three times per hour).

• Not subject to vibration.

• Ambient dust 0.15 mg/m

3

(4 X 10

–3

oz/yd3)

• Condensation-free

• Temperature 17 to 28°C (63 to 82° F)

• Humidity 40 to 70% RF (without condensation)

• Away from other electronic equipment, to avoid

interference.

• Away from heaters and air conditioners, to avoid sudden

changes of temperature.

• With clearance as shown to the right.

• On a strong and level base.

2 - 1

Page 24

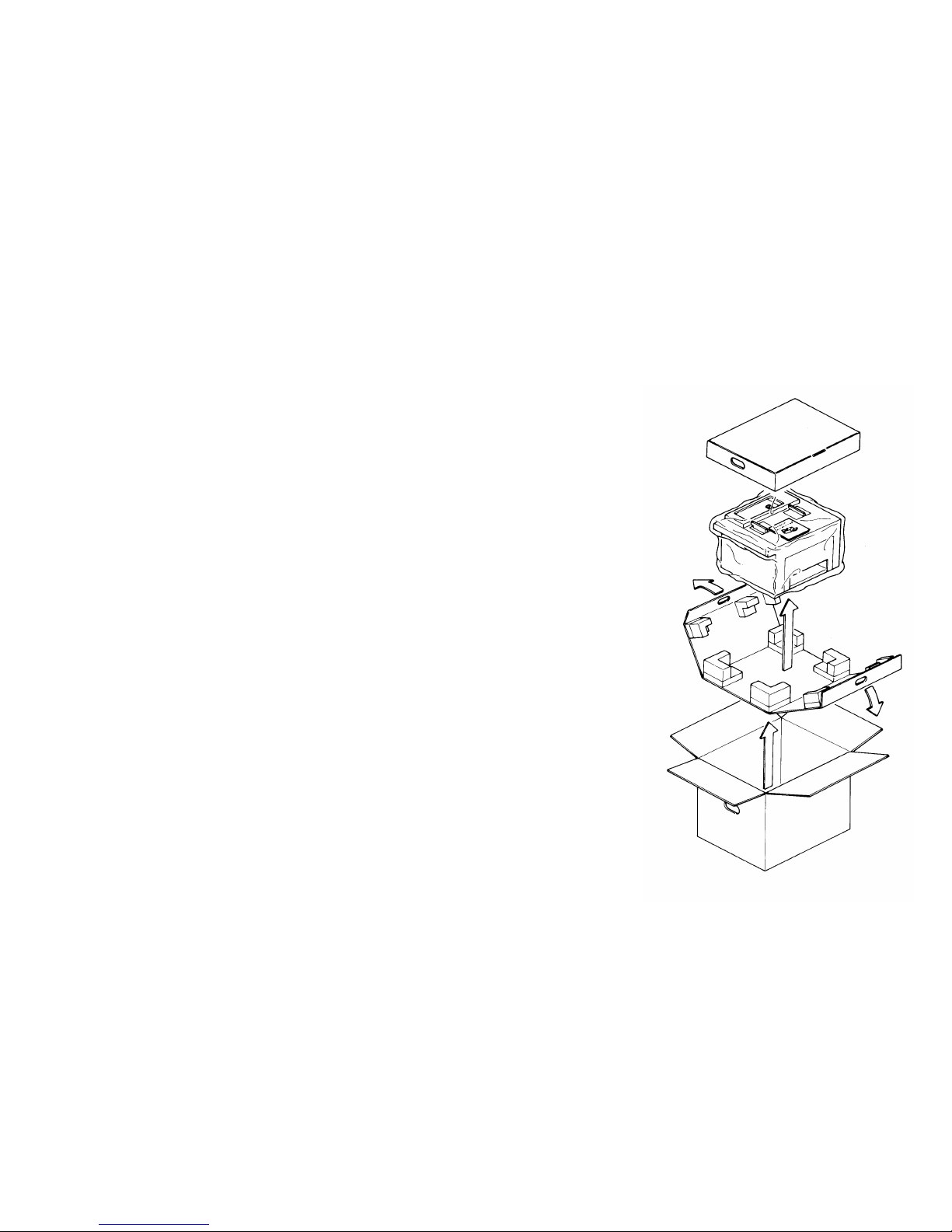

2-2 UNPACKING PROCEDURE

1. Take out the accessory box and the machine.

2. Open the vinyl envelope and take out the machine.

Caution: Put the machine on the optional table or a

table that is horizontally level within 2

degrees.

2 - 2

Page 25

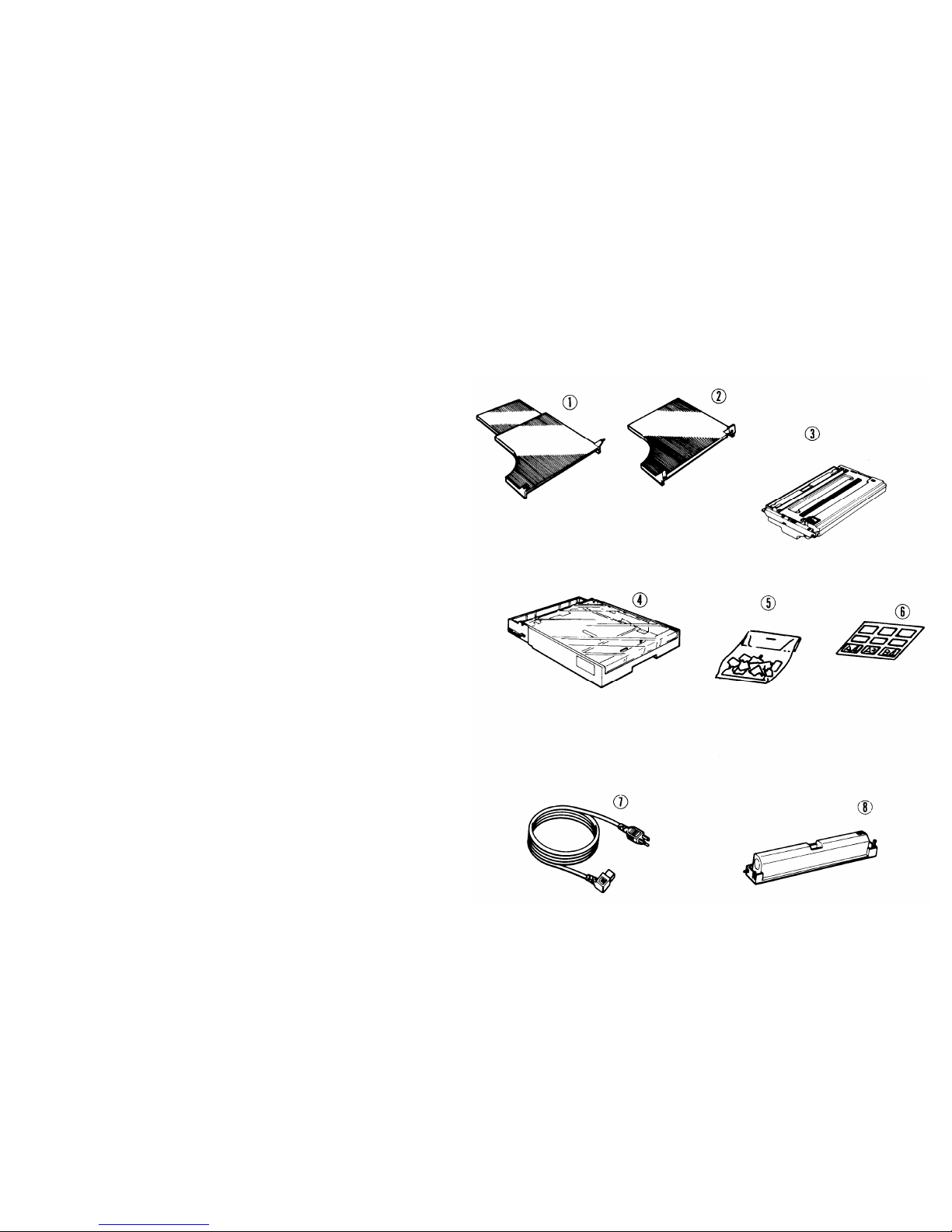

2-3 ACCESSORIES CHECK LIST

1. Open the accessory box and check the following

accessories.

1) Document Tray

(1 pc)

2) Copy Tray

(1 pc)

3) Master Unit

(1 pc)

4) Cassette

(1 pc)

5) Paper Size Actuators

(1 pc)

6) Paper Size Decals

(1 sheet)

7) Power Supply Cord

(1 pc)

8) Toner Cartridges

(2 pcs)

2 - 3

Page 26

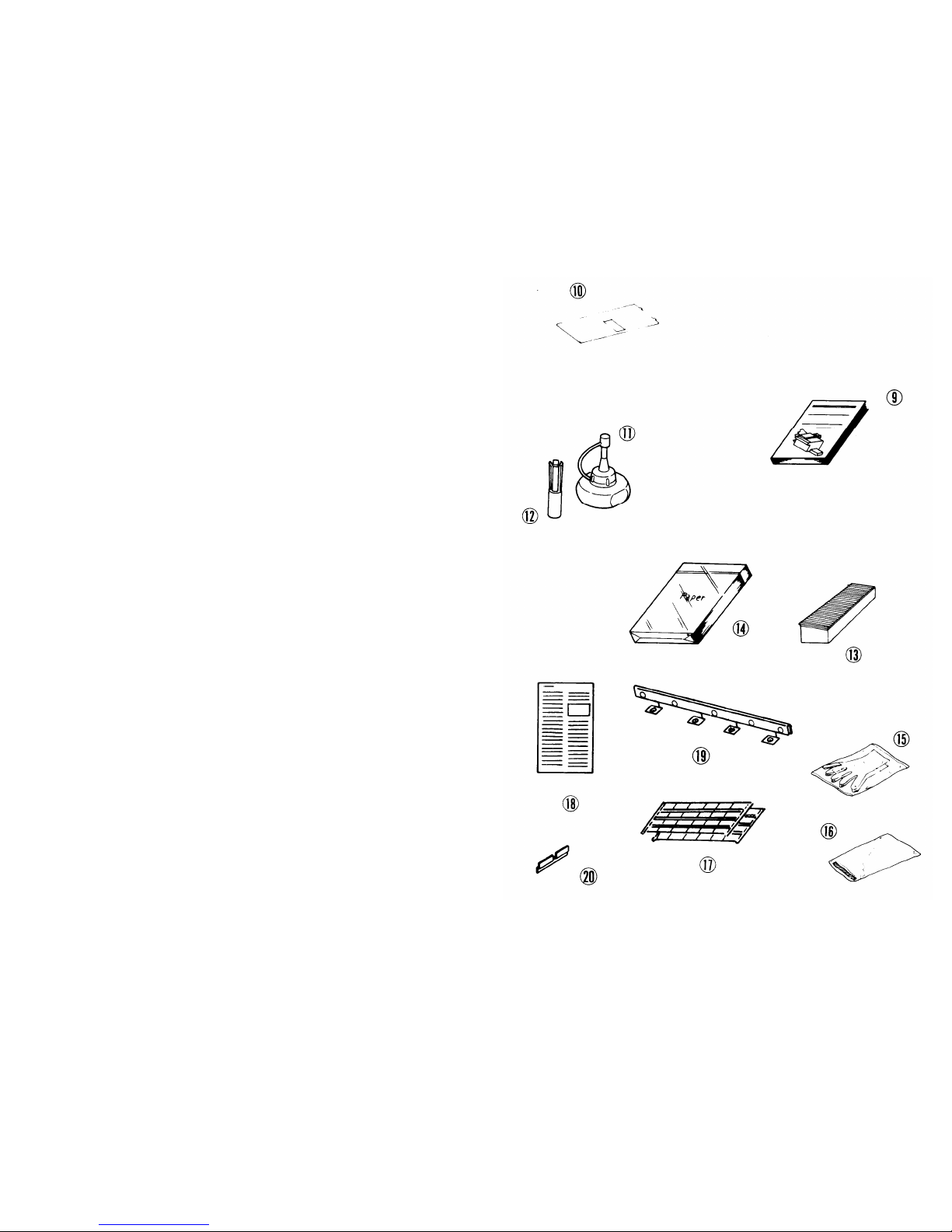

9)

10)

11)

12)

13)

14)

15)

16)

17)

18)

19)

20)

Operators Manual

Speed Dial Label Cover

Refill Ink

Stamper Removal Tool

Sub-document Table

Paper

Vinyl Gloves

Plastic bag

Quick Dial Labels

Speed Dial Label

Cleaning Pad and Screws

Sub-document Table Bracket

(1 pc)

(1 pc)

(1 pc)

(1 pc)

(1 pc)

(1 pc)

(2 pcs)

(1 pc)

(2 pcs)

(1 pc)

(1 pc)

(1 pc)

2 - 4

Page 27

SECTION 3

INSTALLATION

Page 28

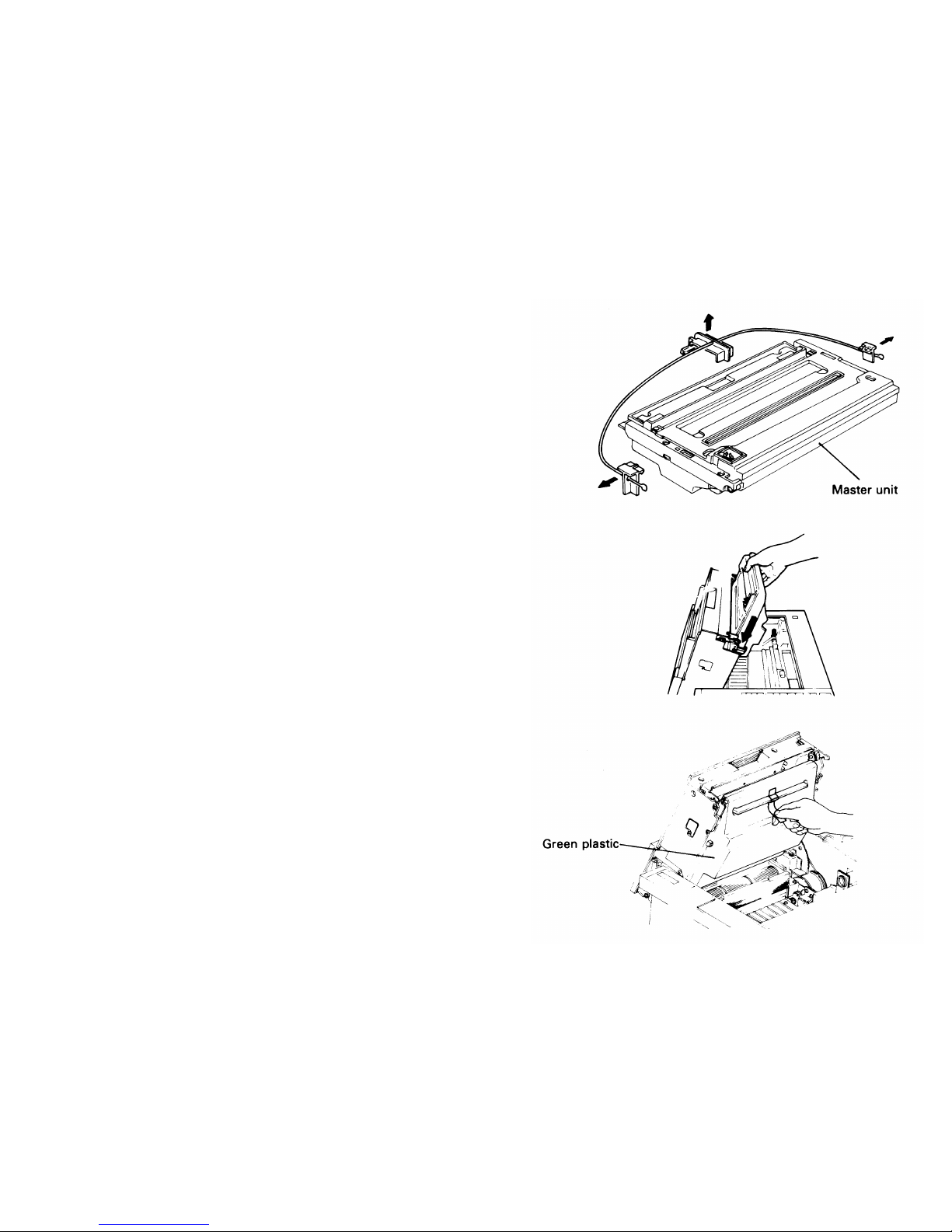

3-1 ASSEMBLY

1. Remove the three wedges from the master unit.

Caution:

Do not touch the master belt (purple material)

and avoid exposing it to light.

2. Open the upper unit and insert the master unit into the

machine along the guide until the unit stops.

3. Peel off the green plastic cover that protects the master.

4. Close the upper unit.

Caution:

The master belt counter should be reset.

(Please refer to page 3 - 7.)

3 - 1

Page 29

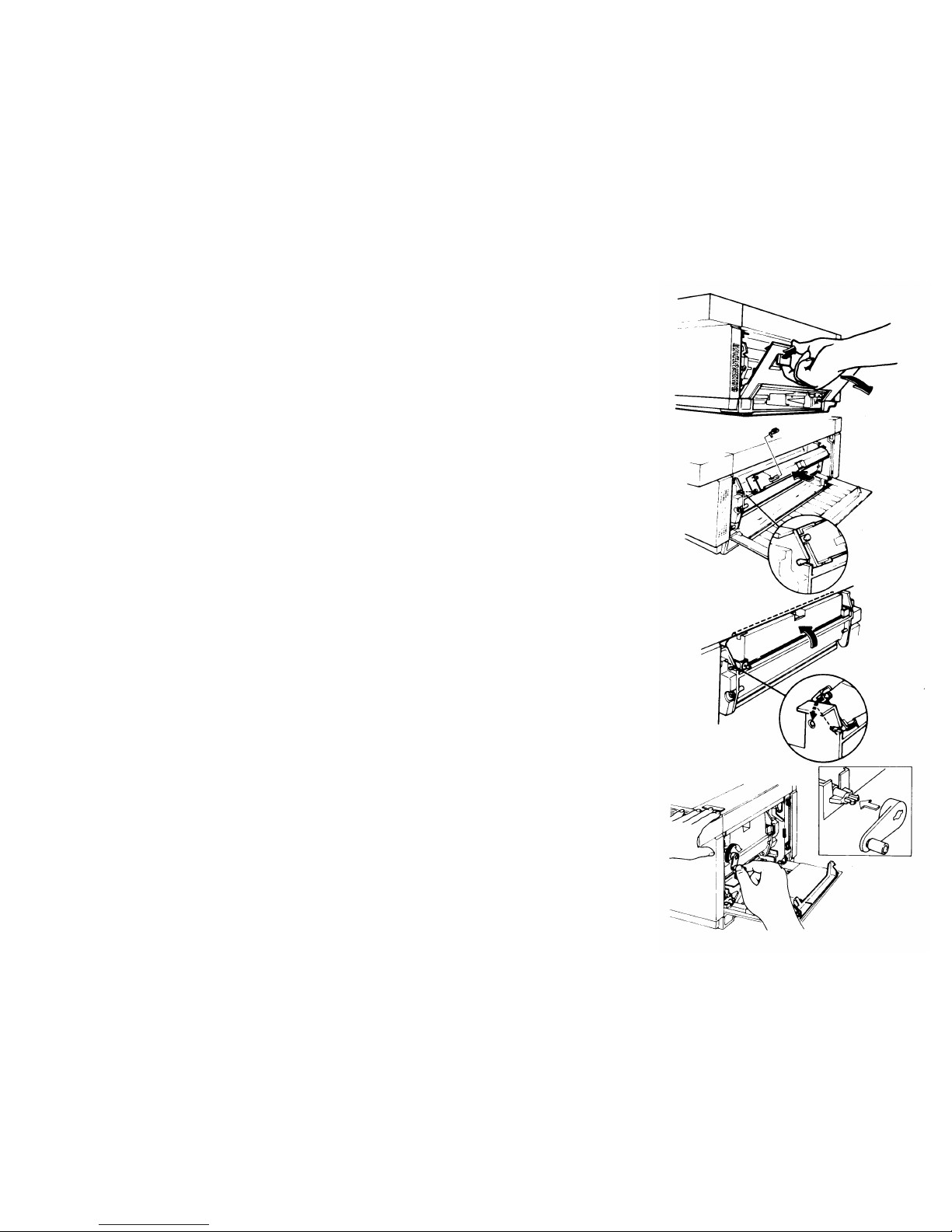

5. Open the right cover.

6. Shake a toner cartridge well.

7. Remove the cartridge crank from the cartridge.

8. Set the pins on the toner cartridge into the slots on the

development unit. Then rotate the cartridge upwards

until it snaps into place.

9. Install the cartridge crank on the shaft.

Then turn the crank clockwise to strip off the cartridge

seal. Remove the cartridge crank.

10. Remove the toner cartridge and install another toner

cartridge (refer to steps 6 to 9).

Note: When adding toner during normal operation,

only one cartridge should be replaced.

11. Close the right cover.

3 - 2

Page 30

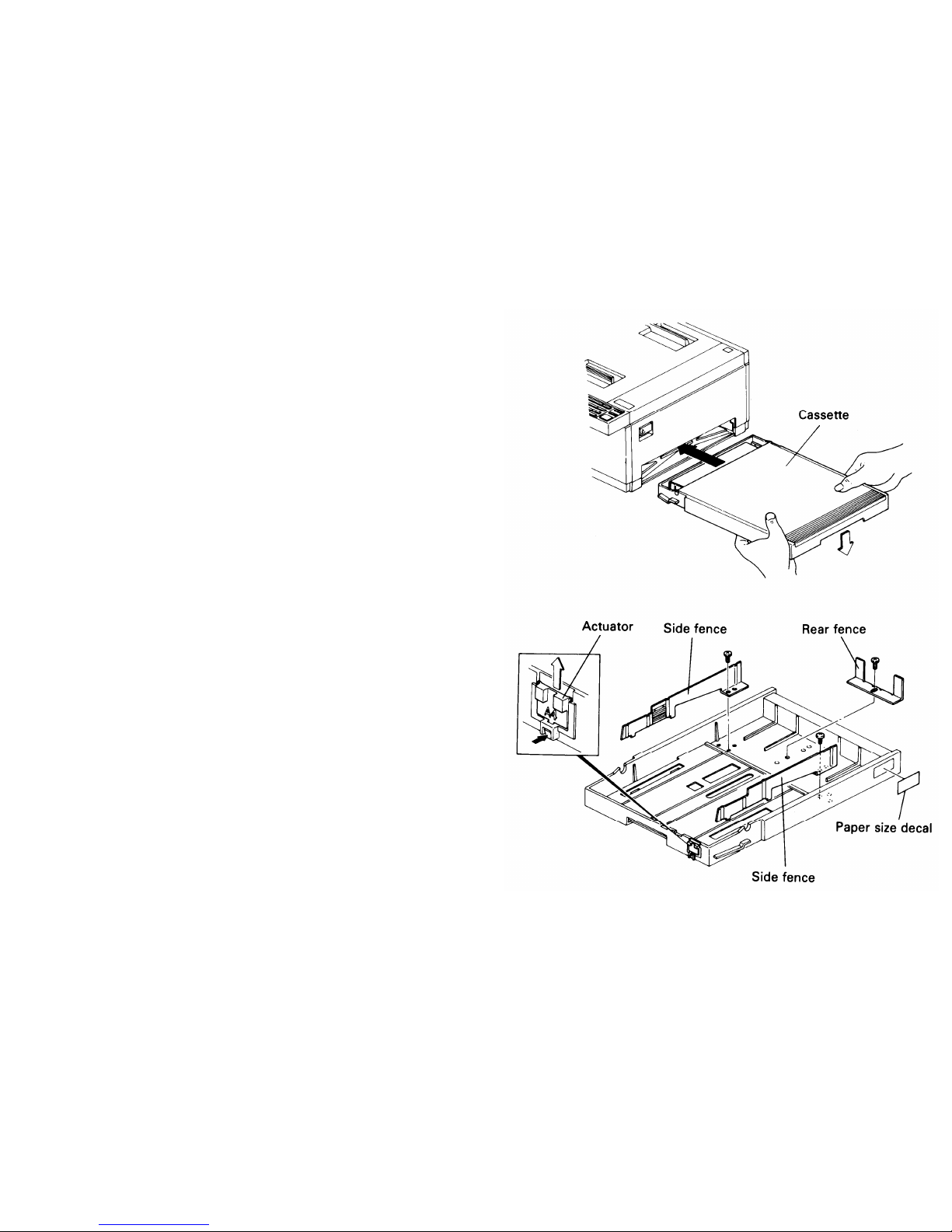

12. Install the cassette.

Note:

If the paper size which the customer will use is

different from the initial size, modify the

cassette as follows.

1) Move the rear and side fences to the appropriate

positions.

2) Attach the appropriate paper size decal to the tray.

3) Install the appropriate actuator.

4) Attach the top cover.

5) Add paper and install the tray.

3 - 3

Page 31

13. Quick Dial Labels

1) Remove the quick dial label cover.

2) Install the quick dial labels.

3) Replace the quick dial label cover.

3 - 4

Page 32

14. Speed Dial Label

1) Install the speed dial label.

2) Install the speed dial label cover.

15. Install the cleaning pad (see page 3-8).

16. Install the copy tray.

17. Install the document tray.

18. Put some ink in the stamper (see page 3-9).

3 - 5

Page 33

3-2 POWER CONNECTION

1.

2.

3.

4.

Connect the power cord to a 115V 50/60 Hz power source

(or 230V 50Hz depending on the model) capable of supplying more than 10A.

Wall voltage must not fluctuate more than 10%.

Make sure that the plug is firmly inserted into the outlet.

A dedicated circuit is recommended.

3 - 6

Page 34

3-3 MASTER BELT ROTATION COUNTER INITIALIZATION

When the master is installed at installation or when changing the master, the counter should be initialized, as follows.

1.

Turn on the main switch.

2. Press the Function key.

3. Enter 87 at the keypad.

4. Press the Yes key.

5. Press the Yes key again.

READY

100% 11 : 30

SET DOCUMENT

3 - 7

Page 35

3-4 SUB-DOCUMENT TABLE

If the sub-document table is needed, please install it as follows.

1. Take the tape off the adhesive strip on the sub-document

table bracket.

2. Attach the sub-document table bracket to the center of

the top cover.

Note: The top of the top cover must be flush with the

top of the sub-document table.

3. Attach the sub document table to the bracket.

3-5 CLEANING PAD INSTALLATION

1. Open the exit cover.

2. Attach the cleaning pad (4 screws).

3 - 8

Page 36

3-6

1.

2.

3.

4.

5.

FILLING THE STAMPER

Open the ADF cover.

Remove the stamper as follows with the tool provided in

the accessories box.

1)

2)

3)

Move the slotted end of the tool over the stamper.

Push down the tool until the hooks click into place

around the bottom of the stamper.

Lift out the tool and stamper.

Add a few drops of ink.

The inlet is in the bottom of the stamper.

The ink is provided in the accessories box.

Caution: The ink should not be taken internally.

Replace the stamper as follows.

1) Place the stamper in position manually.

2) Check that the stamper is in with the red end facing up.

Close the ADF cover.

3 - 9

Page 37

SECTION 4

COMPONENT GUIDE

Page 38

4-1 EXTERNAL VIEW

4 - 1

Page 39

4-2 INTERNAL COMPONENTS

1. Drive Layout

4 - 2

Page 40

No.

Name

No.

Name

1

R2 Idle Gear — 18T

20

Fan Drive Pulley —

Large/Main Drive Gear — Small

2

Reverse Idle Gear

21

Main Drive Pulley

3

ADF Idle Gear — T40

22

Tensioner Roller — T16

4

ADF Idle Gear — T45

23

Registration Clutch

5

ADF Idle Gear — T48

24 Registration Drive Pulley

6

ADF Clutch

25

Belt Pulley

7

R1 Gear 26

Feed Pulley

8

Belt Tensioner Idler

27

Development Clutch

9

R1 Pulley

28

Sleeve Gear

10

R2 Pulley

29

Idle Gear —

Toner Supply

11

Idler 2 — T14

30

Toner Supply Gear

12

Fan Drive Pulley — Medium

31

Agitator Idle Gear

13

Fan Drive Pulley — Small

32

Agitator Gear

14

Exit Gear — T18

33

Master Belt Rotation Gear — T20

15

Idle Gear — Z20

34

Master Drive Gear — T23

16 Fusing Unit Gear – T35

35

Master Drive Pulley — T20

17

Idle Gear — T33

36

Tensioner Pulley — Master Drive

18

Idle Gear — T44/T16

37

Idle Gear —

Master Drive — T20

19

Main Drive Idler — T51

4 - 3

Page 41

2. Mechanical Component Layout

4 - 4

Page 42

No.

Name

Function

1

R2 Roller

Feeds the document through the scanner.

2

R2 Pressure Roller

Feeds the document through the scanner.

3

Scanner Mirror

Reflects light from the document to the SBU.

4

Exposure Glass Exposes the document to the scanner.

5

Fluorescent Lamp

Illuminates the document.

6 R1 Roller

Feeds the document through the scanner.

7

R1 Pressure Roller

Feeds the document through the scanner.

8

Document Feed Roller

Feeds the document into the scanner.

9

Document Separation Roller

Feeds and separates documents.

10

Document Pick-up Roller

Picks up a document from the document table.

11

Direct the laser beam to the master belt.

12

Quenching Lamp

Removes residual charge from the master belt.

13

Charge Corona Unit

Gives the master an evenly distrubuted charge.

14

Second Cylindrical Lens

Focuses the laser beam; keeps dust out of the laser unit.

15

Mirror

Reflects the laser beam onto the master.

16

Master Unit

Contains the organic photoconductor master belt.

4 - 5

Page 43

No.

Name Function

17

Lens Block A’ssy Focuses light from the scanner onto the CCD.

18

Development Roller

Transfers toner to the latent image on the master.

19

Toner Mixing Bar

Agitates toner; used for toner end detection.

20

Toner Agitator

Agitates toner in the toner cartridge.

21

Paper Lift Arm

Lifts the paper.

22

Pickup Roller

Picks up a sheet of copy paper from the stack.

23

Separation Roller

Feeds and separates copy paper.

24 Paper Feed Roller

Feeds the copy paper into the machine.

25

Registration Roller Corrects copy paper skew.

26

Lower Registration Roller As above.

27

Transfer Guide Plate

Guides copy paper into the transfer area.

28

Transfer Corona Unit

Transfers toner from the master to the copy paper.

29

Transport Guide Plate Ensures transfer of small sheets to the fusing unit.

30

Hot Roller

Feeds the copy and fuses toner onto the copy paper.

31

Pressure Roller Forces the copy against the hot roller.

4 - 6

Page 44

No.

Name

Function

32

Lower Exit Roller

Feeds the copy out of the fusing unit.

33

Fusing Exit Roller As above.

34

Hot Roller Strippers

Separate the copy from the hot roller.

35

Printer Fan Removes ozone from the fusing unit.

36

Ozone Filter

Absorbs ozone.

37

Pentagonal Mirror Motor Drives the pentagonal mirror in the laser unit.

38

Pentagonal Mirror

Reflects the laser beam towards the master.

4 - 7

Page 45

3. Electrical Component Layout

4 - 8

Page 46

4 - 9

Page 47

No.

Name

Function

1

Thermostat

Cuts power to the fusing lamp at about 245°C.

2

Thermistor

Detects hot roller temperature.

3

Copy Exit Sensor

Detects when paper leaves the fusing unit.

4

PSU Fan Cools the PSU.

5

Main Motor Drives the fusing unit, cassette paper feed, paper lift,

and development units.

6

Main Switch

Switches on the main power.

7

Inlet Filter

Removes noise from the main power supply.

8

Charge Corona Fan

Removes ozone generated by the charge corona.

9

Scanner Motor Connector

Connects the scanner motor to the DRU board.

10

Development Clutch

Transfers main motor drive to the development roller.

11

NCU

Controls the communication system.

12

Paper Lift Solenoid

Activates the paper lift mechanism.

13

Paper Feed Solenoid

Activates the paper feed mechanism.

14

Registration Clutch

Activates the lower registration roller.

15

Rear Transfer Fan

Removes ozone generated by the transfer corona.

4 - 10

Page 48

No.

Name

Function

16

Paper Height Sensor

Detects when the paper level has fallen below the paper feed position.

17

Paper End Sensor

Detects when the cassette is empty.

18

DRU

Drives the scanner motor, paper feed and paper lift solenoids,

registration clutch, and some of the fans; contains the registration sensor.

19

Paper Near-end Sensor Detects when the cassette is almost empty.

20

Power Pack Drives the corona units and development bias.

21

Paper Size Sensor Detects the size of paper in the cassette.

22

Front Transfer Fan Removes ozone generated by the transfer corona.

23

Transfer Corona Unit

Transfers toner from the master to the copy paper.

24 PSU

Supplies power to all parts of the machine.

25

Fusing Lamp Provides heat for the fusing unit.

26

Pentagonal Mirror Motor Drives the pentagonal mirror in the laser unit.

27

Stamper Assembly Contains the stamper and stamper solenoid.

28

SB-2 Sensor (Scan Line Sensor)

Detects when the document leading edge reaches the scan line.

29

LDDR

Contains the laser diode.

30

SB-1 Sensor (Document Sensor)

Detects when a document is placed in the ADF.

31

Toner Overflow Sensor

Detects when the toner collection tank is full.

4 - 11

Page 49

No.

Name

Function

32

ADF Clutch

Activates the document feed mechanism.

33

Varistor

Limits the charge given to the master belt.

34

Scanner Motor

Drives the document feed mechanism.

35

Master Belt Motor

Drives the master belt.

36

Toner End Sensor

Detects when the toner cartridge is empty; detects when the right

and Right Cover Switch cover is open.

37

SBU

Converts optical images into an analog signal.

38 UIB

Links the FCU to the components in the upper unit.

39

VPU

Processes video signals from the SBU.

40 Master Home Position Sensor

Detects when the master belt is at home position or if the upper unit is open.

41

Right Cover Interlock Switch

Cuts the + 24VD supply when the right cover is open.

42

Master Set Sensor

Disables the laser diode power supply if a master is not installed.

43

R96F Modem

Modulates and demodulates; G2 and G3 only.

44 MIF

Interface board between Modem and FCU.

45

FCU

Controls the system.

4 - 12

Page 50

No.

Name

Function

46

LSD

Detects the laser printer main scan start position.

47

PMU

Contains page memory.

48 MBU Contains the programmed ROMs for controlling the system.

49

Upper Unit Interlock Switch

Detects when the upper unit or copy exit cover is open and cuts the

+ 24VD Supply.

50

Monitor Speaker

Monitors the telephone line condition.

51

OPU-1

Drives the operation and display panels.

52

OPU-3 As above.

53 OPU-2

Drives the operation and display panels.

54

SM-DR Drives the pentagonal mirror motor.

55

FL Driver

Drives the fluorescent lamp.

56

BSR

Contains SAF and ECM double buffer memory, with battery backup.

57 DSB

Drives the master belt motor and scanner drive components

other than the scanner motor; contains the document sensor,

document width sensors, and the scanner cover switch.

4 - 13

Page 51

SECTION 5

PROGRAMMING AND TESTING

Page 52

5-1 OPERATION PANEL

5 - 1

Page 53

No.

Name Function

1

On Line Indicator Lights during communication.

2

Confidential File Indicator Lights when a confidential message has been received.

3

Tel Mode Indicator Lights when the machine is in manual receive mode.

4

Receive File Indicator

Lights when a message was received but could not be printed out

because the printer was out of order (copy jam or no paper).

5

Line Fail Indicator Lights when communication fails.

6

Replace Master Indicator

Lights when it is time to replace the master unit or when the

toner collection tank is full.

7

Call Service Indicator

Lights when the machine diagnostics detect a problem that

requires service.

8

Close Cover Indicator Lights when a door or cover is open.

9

Clear Original Indicator Lights when a document jams in the scanner.

10

Toner Collection Indicator Lights when the toner collection tank is full.

11

Clear Copy Indicator Lights when a copy jams in the printer.

12

Add Toner Indicator Lights when the toner tank is empty.

13

Add Paper 1 Indicator Lights when the cassette is empty.

14

Add Paper 2 Indicator Lights when the optional large capacity tray is empty.

5 - 2

Page 54

No.

15

16

17

18

19

20

21

22

23

24

25

26

Name

Speed Dial Key and Indicator

Ten-key Pad

Quick Dial Keypad

Power Indicator

Stop Key

Copy Key

Start Key

Clear Key

Pause/Redial Key

Function Key

Yes/No Keys

Standard, Detail Indicators

and Key

Function

Press the key to change the mode of the ten-key pad;

see the next item.

Acts as a telephone ten-key pad when the Speed Dial indicator is off;

used to enter Speed Dial codes otherwise.

Use to input a single phone number or a sequence of features and phone

numbers with one touch.

Lights when the power switch is on and ac is supplied to the machine.

Stops operation and returns the machine to standby.

Press to copy a document.

Press to start communication.

Press to clear the previously entered character or use as a cursor key,

depending on the mode in use.

Press to insert a pause when entering a telephone number, or press

to redial the last number dialed.

Press to enter the programming mode.

Use to answer questions on the character display.

Use to select the resolution — “Standard” for normal text, “Detail” for

drawings or fine print.

5 - 3

Page 55

No.

Name

Function

27

Halftone, Light, Normal,

Use to select the contrast —

“Halftone” for photographs,

Dark Indicators and Key “Light” for light originals, “Normal” for normal originals,

“Dark” for dark originals.

28

Voice Request During communication, press this key to request voice contact

Indicator and Key

with the other terminal’s operator.

29

Memory Indicator and Key

Press this key to use the memory.

30

Character Display Displays prompts, status, and selected modes.

5 - 4

Page 56

5-2 USER LEVEL PROGRAMMING

— Initial Set Up –

The following items should be programmed or registered before starting operation. If these items are not set, the machine will

not function at optimum potential. Refer to the operation manual for details.

Ž RTI/TTl/CSl

• Polling ID code

• Date and time

• One-touch Keys

a) Keystroke programs

b) Quick Dial Keys (any number of vacant keys)

• Speed Dial codes

• Groups

• Local terminal telephone number

• FAX/TEL setting

• Local terminal telephone type

• Password

5 - 5

Page 57

— Function List —

No.

1

2

3

4

50

51

52

53

54

55

56

60

61

62

63

64

Function

Confidential Transmission

Send Later

Transfer Request

Polling

Clock Adjustment

Fax/Tel Setting

Communicated Page Counter Check

Scanned and Printed Sheet Counter Check

Batch-number Enabling

Department Code Enabling

Speaker Volume Adjustment

Quick Dial Programming

Group Programming

ID Code Programming

RTI Programming

TTI Programming

No.

65

66

70

71

72

73

74

75

76

77

80

81

82

83

84

85

86

87

88

89

Function

Clearing Polling Files

Clearing Memory Files

Journal Printing

Telephone List Printing

Polling File Printing

Program List Printing

SAF File List Printing

File Output

Confidential File Output

Multicopying

Entering Own Tel. No.

TTI Disabling

Password Programming

ECM on/off

Stamp Enabling

Full Week Timer Setup

Full Week Timer Override

Master Belt Counter Reset

Programming the CSI (not used in W.Germany)

Programming the Telephone Line Type

(not used in W.Germany)

5 - 6

Page 58

No. Purpose

Remarks

1

To make a confidential transmission You can specify the password if you wish.

2

To make a Send Later transmission

Enter the required transmission time in 24-hour

clock format.

3

To send a message to more than one location

All numbers must contain international dial and

through a broadcaster

country codes. Function 80 must be programmed.

4

To poll or to set up your machine to be polled

50

To enter the date and time

Increment with #, decrement with *, and move the

cursor with Clear.

51

To select either automatic or manual reception

Press * to select FAX, and # to select TEL.

52

To view the communicated page counters

Press Yes after viewing.

53

To view the sheet feed counters

Press Yes after viewing.

54

To select the type of page numbering on the

Press * for batch-numbering and # for simple

printout at the remote terminal

numbering.

5 - 7

Page 59

No.

55

56

60

61

62

63

64

Purpose

To allow the user to use department codes

To adjust the speaker volume

To program Quick Dial keys and Speed Dial codes

To program groups

To program the ID code needed for polling, transfer,

and closed network communication

To program the Remote Terminal Identifier.

This is displayed on the remote terminal’s

operation panel during communication

To program the Transmitting Terminal Identifier.

This is printed on the top of pages

received at the remote terminal.

5 - 8

Remarks

Press * to enable and # to disable.

Increase with # and decrease with *.

Press the key or enter the code that you want to

program.

Then enter the number.

For Quick Dial keys, you can also program a label.

The method is the same as for RTI (see function 63).

Groups can be labeled. There can be up to 7 groups.

Enter the required code at the keypad.

Do not use 0000 or FFFF.

Enter the identifier from the left. Use the ten-key pad

(for numbers), Quick Dial keys (A – X), contrast key

(Y) and resolution key (Z). Store the identifier by

pressing Yes. Enter up to 20 characters.

Up to 32 characters. Enter in the same way as the

RTI.

Page 60

No. Purpose

Remarks

65

66

70

To erase a polling file

Enter the file number of the file to be erased. Refer

to the Polling File List.

To erase a memory file Enter the file number of the file to be erased. Refer

to the SAF File List.

To print the Journal

71

To print the Telephone List Details on Quick Dial keys, and Speed Dial Codes,

groups, and full telephone numbers will be printed.

72

To print the Polling File List

Prints information on all stored polling files.

73

To print the Program List

Prints information on keystroke programs and the

Quick Dial keys they are allocated to.

74

To print the SAF File List

Prints information on all memory files.

75

To print the contents of a memory file

76

To print a confidential file

The correct password must be entered. This will

not be the same as the password programmed in

function 82 if the sender specified a password.

5 - 9

Page 61

No.

Purpose

Remarks

77

To make more than one copy of a document

Up to 99 copies can be made.

80

To enter the terminal’s telephone number

This must be programmed if you want to use

Transfer Request. A pause must be entered and the

international dial and country codes must also be

entered.

81

To enable/disable TTl printout on copies at the

Press * to enable and # to disable.

remote terminal

82

To program the password to be used for printing

Before storing a password, the old password must

confidential files

be entered. In a new machine, this password is

0000.

83

To enable or disable ECM

Press * to enable and # to disable.

84

To enable/disable the stamp

Press * to enable and # to disable.

85

To program the fusing lamp on/off timer

86

To override the timer

Program on/off times for each day. Use # to

increment and * to decrement the item at the cursor.

Use the 24-hour clock. To keep the power on all day,

enter 00:00 for the on and off times. To keep the

power off all day, the display for on and off times

should be blank (press the Pause/Redial key).

key).

When asked for a password enter 2222.

Press * to start the fusing unit. After use,

use function 86 again to disable the fusing unit

(press # instead of *).

5 - 10

Page 62

No. Purpose

Remarks

87

To reset the master belt rotation counter

Reset the counter after changing the master

88

To program the Called Subscriber Identifier. This is

Enter the telephone number (up to 20 numbers and

used in place of the RTI when communicating with

spaces) at the keypad, then press #, then Yes.

a non-Ricoh machine.

89

To match the unit’s dialing mode with the

Press * for DTMF and # for pulse dialing.

connected Iine

5 - 11

Page 63

5-3 SERVICE LEVEL

5-3-1 Service Functions

1. Entering and Exiting the Service Mode

To enter the service mode, press 1, 2, 3, 4, and 5 simultaneously.

Note: If you cannot access the service functions, short JP12 on the NCU.

To exit the service mode, press 6, 7, 8, and 9 simultaneously.

Note:

If you wish to disable service mode, remove JP12 on the NCU.

Note:

After entering the service mode, the service mode is disabled auto-

matically if the keypad is not touched for 3 minutes.

5 - 12

Page 64

2. Function Table

Number

88

89

90

91

92

93

94

95

96

97

98

Function

Programming the CSI (W.Germany)

Programming the Telephone Line Type (W.Germany)

Bit switch programming

ROM/RAM display, local RAM rewrite

System report

ROM/RAM printout

Error code display

Service report

CClTT and maker codes

Service station telephone number

Recovery from printer system crashes

NCU parameter programming

Caution:

Do not use function 99.

5 - 13

Page 65

3.

Functions

To enter the service mode, press 1, 2, 3, 4, and 5

simultaneously.

To exit the service mode, press 6, 7, 8, and 9 simultaneously.

Note:

After entering service mode, the service mode is

disabled automatically if the keypad is not

touched for 3 minutes.

1. Bit Switch Programming

1)

2)

3)

Press the Function key then enter 90.

Press Yes.

The first line on the display indicates the factory

settings; the second line indicates the present settings.

Make your changes.

* Press # to increment the bit switch number; press*

to decrement.

Hold down #/* for fast increment/decrement.

Example: Press # once.

* Press the numeric keypad key corresponding to the

bit that you want to change. Bits are numbered from

7 at the left to 0 at the right.

Example: Change bit 0 to 1; press 1.

MODE NO. 90

Y / N

DISPLAY BITSW ?

DEFAULT : 0000 0000

BITSW 1 : 0001 0001

5 - 14

Page 66

4) Either:

Change more bit switches using step 3.

Or:

Press the Function key to return to standby.

CAUTION: Refer to Appendix A (Bit Switch Functions)

before changing any setting.

READY

100% 14 : 00

SET DOCUMENT

2. ROM and RAM Display, RAM Rewriting

1) Press the Function key then enter 91.

2) Press Yes.

3) Enter the address at the keypad.

4) Change the data, if necessary, using the keypad.

The machine automatically prevents you from changing ROM areas.

5) Either:

Change more addresses; go back to step 3.

Or:

Press the Function key to return to standby.

READY

NO. 91

Y / N

DISPLAY

ROM, RAM ?

ADDRESS = 00B2

DATA = 80

5 - 15

Page 67

Useful RAM Addresses

Redialing without SAF

— Number of redials

7079 (hex code)

— Redial interval

707A (hex code, minutes, acceptable range: 1 —> 60)

Redialing with SAF

Max 7 redials, interval can be from 1 —> 15 minutes

(entered in hex code)

Example:

Three redials at intervals of 5, 10, and 15 minutes.

79D0

79D1

0 = Stop Code Redial Interval

1: 79D0, lower 4 bits

79D2

x

= Don’t care

2: 79D0, higher 4 bits

79D3

3: 79D1, lower 4 bits

4: 79D1, higher 4 bits

and so on

Contrast

Dark

14E7

Settings are in hex code, from 0 —> F.

Normal

14E8

The higher the value, the darker the

Light 14E9

contrast

Error Code Memory

6E71 —> 6EB1

Password

7032 —> 7033

5 - 16

Page 68

3.4.System Report

This report lists counter totals, programmed parameters,

ID codes, and other items.

1)2)Press the Function key and enter 92.

Press Copy to print the report.

ROM and RAM Printout

1) Press the Function key and enter 93.

2) Press Yes.

3) Enter the start and end adresses at the keypad.

Example:

1230, 123F

4) Press Copy.

5 - 17

Page 69

5.

Error Code Display

This displays the most recent 32 error codes. All types of

error are included.

1) Press the Function key and enter 94.

2) Press Yes.

3) Either:

Press # to display the next four codes.

Note:

If # is pressed more than 7 times, the

machine returns to standby.

Or:

Press No to go on to print the service report.

Or:

Press the Function key to return to standby.

5 - 18

Page 70

6. Service Report

1) Press the Function key and enter 95.

2) Press Copy.

The Error Code column lists communication errors.

The Error Code List area gives all types of error codes

(the most recent 32 errors only).

7. CClTT and Maker Codes

1) Press the Function key and enter 96.

2) Press Yes.

3) Enter the correct codes.

CClTT = 0000; MAKER = 25

Note:

If incorrect codes are programmed, communi-

cation using NSF(S) is disabled, and pro-

prietary functions

such as confidential

transmission cannot be used.

CCITT MAKER

0001 25

4) Press the Function key to return to standby.

5 - 19

Page 71

8. Service Station Telephone Number

If bit 6 of bit switch 1F is 0, the machine will send an auto service call to the service station on the following occasions:

• LD power control failure

• Master home position failure

• pentagonal mirror motor lock failure

• Main motor lock failure

• Lower paper feed motor lock failure

• Fusing lamp failure

• Transfer corona leak

• Toner overflow

• Time to replace the master

The service station’s facsimile number must be programmed using function 97.

1) Press the Function key then enter 97.

2) Press Yes.

5 - 20

Page 72

3)

Enter the service station’s telephone number.

Insert a pause after the area code.

Example: 213-555-9872

To correct errors:

* Press No to erase the entire number.

* Press Clear to erase the last digit only.

If a number has already been stored, press Yes to

confirm it, or press Clear to erase it and enter a new number.

4) Press Yes to store this number. The next function

begins (from section 9, step 3).

9. Recovery from Printer System Crashes

When the printer software crashes, carry out the

following procedure.

1) Press the Function key and enter 97.

2) Press No.

3) Press Yes.

The system will recover.

MODE NO. 97

Y / N

lNPUTSERVICE TEL # ?

5 - 21

Page 73

10. NCU Parameter Programming

1) Press the Function key and enter 98.

2) Press Yes.

3) Either:

Change the value of the displayed parameter, if

required.

Enter the new value at the keypad.

Example: 075

Or:

Go on to step 4.

4) Go on to change another parameter.

Press Yes until the desired parameter is displayed.

Example: Press Yes once.

5) After you have finished, press the Function key to

return to standby.

MODE NO. 98

Y / N

SET NCU PARAMETER ?

NCU PARAMETER KPAD / Y

NO. 00 064

NCU PARAMETER KPAD / Y

NO. 01 127

Consult a senior service technician before changing any

of these parameters. For a table of parameters and their

functions, refer to the following page.

5 - 22

Page 74

Parameter

No.

00

01

02

03

04

05

06

07

08

09

10

11

Description

Acceptable ringing signal frequency

: Range 1, upper limit

Acceptable ringing signal frequency

: Range 1, lower limit

Acceptable ringing signal frequency

: Range 2, upper limit

Acceptable ringing signal frequency

: Range 2, lower limit

Number of rings until a call is detected

Minimum required length of the first ring

Minimum required length of the second and

subsequent rings

Reset time

Time between the closing of relay DS and the

opening of relay DI (T0)

Time that relay DI is open. (T1)

Time that relay DI is closed. (T2)

Time between the final closure of relay DI

and the opening of relay DS. (T3)

5 - 23

Formula

(Hz)

(Hz)

(Hz)

(Hz)

N (times)

Nx20 (ms)

Nx20 (ms)

Nx40 (ms)

Nx1 (ms)

Nx1 (ms)

Nx1 (ms)

Nx1 (ms)

Remarks

Note 3

Notes 1, 2

Note 1

Note 1

Notes 1, 2

Page 75

Parameter

No.

12

13

14

15

16

Notes:

Description

Pause between dial digits (T4)

Time waited when a pause is input

DTMF tone on time (D0)

DTMF tone off time (D1)

DTMF tone transmission level

Formula

Remarks

Nx20 (ms)

Notes 1, 2

Nx20 (ms)

Nx1 (ms)

Nx1 (ms)

– (15 – N)

Note 4

1.

The above pulse dialing times (T0, T1, T2, T3, T4) are the values for 10 pps.

Times for T0 to T3 for 20 pps are half those for 10 pps. For T4, the time for 20 pps is 3/4 of that for 10 pps.

2. DS relay control should only be done for the Europe type NCU which has a ground start selection.

3. The first ring may not be detected until Parameter 05 + Ringing Signal wavelength x (1 to 2.5).

4. N must be between 0 and 15.

5 - 24

Page 76

5-3-2 TEST MODE

This machine has the following function tests.

* Modem test (G2 and G3 signal transmission)

* Operation panel test

* Fluorescent lamp lighting

* Tone transmission (DTMF signals)

1. Entering and Exiting the Test Mode

1. Hold down the Stop key and switch the power on.

2. When “ENABLE SERVICE FUNC.” is displayed, press the Start key immediately. The following will appear.

DENSITY : MDM, LCD, LAMP

TEL : DTMF

The meaning of this display is as follows:

* Light the “Normal” LED to test the modem.

* Light the “Dark” LED to test the operation panel.

* Light the “Light” LED to light the fluorescent lamp.

* Light the “Speed Dial” LED to make a tone test.

3. Make the required tests according to the next few pages.

5 - 25

Page 77

4. After testing, press 6, 7, 8, 9 simultaneously.

Make sure that the Speed Dial LED is off.

2. Modem Test

1.

2.

3.

4.

5.

MODEM TEST

Select “Normal” contrast, then press Start.

The unit will go into off-hook mode.

Press the required keys to test the desired signal

(refer to the following table).

Example: 9600 bps; press Speed Dial then Start.

Note:

* The machine will return to standby after any one tone has been on for 8 minutes.

* If more than one LED is lit, the priority is:

Speed Dial > Voice Request > Detail > Contrast

Press Stop to return to step 3.

Press Stop once more to return to standby.

5 - 26

Page 78

— Signal Generation —

Signal

9600 bps

7200 bps

4800 bps

2400 bps

300 bps

2100 Hz

(CED)

1850 Hz

1650 Hz

1100 Hz

462 Hz

2100 Hz

(G2 video)

3. Operation Panel Test

1. Make sure that the Speed Dial LED is off.

Operation

Light the Speed Dial LED then press Start.

Select “Detail” resolution then press Start.

Select “Dark” contrast then press Start.

Select “Normal” contrast then press Start.

Select “Light” contrast then press Start.

Select “Light” contrast then press Copy.

Select “Normal” contrast then press Copy.

Select “Dark” contrast then press Copy.

Select “Detail” resolution then press Copy.

Light the Speed Dial LED then press Copy.

Light the Voice Request LED then press Copy.

LCD ALL DISPLAY

2. Select “Dark” contrast then press Start.

The indicators above keys should be lit and the green and

red indicators should be blinking.

3. Press the Stop key to return to standby.

5 - 27

Page 79

4.

5.

Fluorescent Lamp Lighting

1.

2.

3.

Make sure that the Speed Dial LED is off.

Select “Light” contrast then press Start.

The fluorescent lamp will light. It will remain lit for 8

minutes.

Press Stop to return to standby.

Tone Tests

1.

2.

3.

4.

Light the Speed Dial LED then press Start.

Press the key that corresponds to the required tone (see

the table on the next page).

Example: 697 Hz, press A.

Note:

The machine will return to standby if no key is

pressed for 8 minutes.

Press Stop after testing this tone.

Either:

Return to standby —

press Stop once more.

Or:

Test another tone —

go to step 2.

FLU LAMP ON

DTMF TONE

DTMF TONE

697HZ

DTMF TONE

5 - 28

Page 80

— Tone Generation —

Tone

DTMF 0

DTMF 1

DTMF 2

DTMF 3

DTMF 4

DTMF 5

DTMF 6

DTMF 7

DTMF 8

DTMF 9

Operation

Press 0

Press 1

Press 2

Press 3

Press 4

Press 5

Press 6

Press 7

Press 8

Press 9

Tone

DTMF *

DTMF #

697 Hz

770 Hz

852 Hz

941 Hz

1209 Hz

1336 Hz

1477 Hz

1633 Hz

Operation

Press *

Press #

Press A

Press B

Press C

Press D

Press E

Press F

Press G

Press H

Note: If any of keys A through H do not generate a tone, a keystroke program is stored in that key.

Print a Program list (function 73), erase the program (function 60), make the required tests, then re-input the

keystroke program.

5 - 29

Page 81

5-3-3 Printer Tests

It is not necessary to enter the Service Mode.

From standby:

* Press the Copy key, then immediately press a specified

key, depending on the desired printout.

Do not release the keys until the printer has started.

• Thin, closely spaced lines

Copy key + 1

• Thick, vertical stripes

Copy key + 2

• Pattern

Copy key + 3

• Dense diagonal stripes

Copy key + 4

5 - 30

Page 82

5-3-4 Dedicated Transmission Parameter Programming

Each telephone number programmed as a Quick Dial key or Speed Dial code has three bytes in RAM allocated for

transmission parameters.

Byte 1

Initial modem rate (bps)

(0, 0) = 9600 (0, 1) = 7200

(1,0) = 4800 (1, 1 )= 2400

Transmission level

Example: (1, 1, 0, 0) = –12 dB

Byte 2

Bit 0

Bit 1

Bit 7

Byte 3

compression

0: MH/MR 1: MH

Program Enable/Disable

0: Transmissions to this remote terminal will

DIS detection

0: First

use parameters as specified by the bit

1: Second (First DIS is ingored)

switch settings.

1:

The dedicated parameters in bytes 1 —> 3

ECM 0: Used 1: Not used

Short preamble

0: Not used 1: Used

will be used.

CCITT T1 time, in units of 2.56 seconds

Example: 60 seconds

60/2.56 = 24 approx

Byte 3 contains 18 (H) = 00011000

5 - 31

Page 83

The RAM addresses are as follows

ADDRESS

7850

NO NO ADDRESS NO ADDRESS NO ADDRESS NO ADDRESS NO ADDRESS

*1

I

786B

R

7886

12

78A1

21

78BC 30 78D7

7851

786C 7887

78A2 78BD 78D8

7852

786D 7888 78A3

78BE 78D9

A 7853

J

786E

S

7889 13 78A4 22 78BF

31

78DA

7854 786F 788A 78A5 78C0

78DB

7870 788B

78A6

78C1

78DC

K

7871

T 788C

14

78A7 23 78C2

32

78DD

7872 788D 78A8 78C3

78DE

7873

788E 78A9 78C4 78DF

L

7874

U

788F 15 78AA

24 78C5 33 78E0

785A 7875 7890 78AB 78C6

78E1

785B

7876 7891

78AC 78C7 78E2

D

785C M 7877 V 7892 16 78AD 25 78C8 34 78E3

785D 7878 7893 78AE 78C9

78E4

785E 7879

7894 78AF

78CA 78E5

E

785F

N

787A

W 7895 17 78B0 26 78CB 35

78E6

7860 787B 7896 78B1 78CC

78E7

7861

787C 7897

78B2 78CD 78E8

F

7862

O

787D

X 7898 18 78B3 27 78CE 36 78E9

7863 787E 7899 78B4 78CF

78EA

7864 787F

789A 78B5

78D0 78EB

G

7865

P

7880

10

789B

19 78B6 28 78D1

37

78EC

7866 7881 789C

78B7 78D2 78ED

7867 7882 789D 78B8 78D3

78EE

H

7868

Q

7883

11

789E 20 78B9

29 78D4

38

78EF

7869 7884 789F

78BA 78D5 78F0

786A

7885

78A0 78BB 78D6

78F1

*1: Service Station (Auto Service Call)

5 - 32

Page 84

NO ADDRESS

NO

ADDRESS

NO

ADDRESS NO ADDRESS NO ADDRESS NO ADDRESS

39

78F2

49 7910 59 792E 69 794C

79

796A 89 7988

78F3

7911

792F 794D 796B 7989

78F4 7912 7930 794E 796C 798A

40 78F5 50 7913 60 7931

70

794F 80 796D 90 798B

78F6 7914 7932 7950 796E 79BC

78F7 7915 7933 7951 796F

798D

41

78F8

51

7916

61

7934

71

7952

81

7970

91

798E

78F9 7617 7935 7953 7971 798F

78FA 7918 7936 7954 7972 7990

42 78FB

52

7919 62 7937 72 7955 82 7973 92 7991

78FC 791A 7938 7956

7974 7992

78FD 791B

7939 7957 7975 7993

43 78FE

53

791C

63

793A 73 7958 83 7976 93 7994

78FF

791 D

793B 7959

7977 7995

7900 791E 793C 795A 7978 7996

44

7901

54

791F

64

793D 74 795B 84 7979 94 7997

7902 7920 793E 795C

797A 7998

7903

7921

793F

795D 797B 7999

45

7904

55

7922

65

7940 75 795E 85 797C 95 799A

7905 7923 7941 795F 797D 799B

7906 7924 7942

7960 797E 799C

46 7907

56

7925

66

7943 76 7961 86 797F 96 799D

7908 7926 7944

7962 7980 799E

7909 7927 7945 7963 7981 799F

47 790A

57

7928

67

7946 77 7964 87 7982 97

79A0

790B

7929 7947 7965 7983 79A1

790C 792A 7948 7966 7984

79A2

48

790D

58

792B

68

7949 78 7967 88 7985 98 79A3

790E 792C 794A 7968

7986 79A4

790F

792D 794B 7969 7987 79A5

99 79A6

79A7

79A8

5 - 33

Page 85

5-3-5 Confidential File Printout

If the user has forgotten the password, you can find it on the system report (function 92).

However, if the user cannot find out the personal ID specified by the sender, which overrides the password, then use the

following procedure.

1.

2.

3.

4.

When the machine is in standby, simultaneously press 1, 2, 3, 4 and 5 to enter the service mode.

Press the Function key, enter 75, then press Yes.

Enter # 0.

Press Copy.

All memory files will be printed, including confidential files. However, they will not be erased from memory.

To erase the confidential files from memory:

1.

2.

3.

Change the data in RAM address 15E6 to 00, using function 91.

Switch the machine off, wait for

Re-store files for transmission.

ten seconds, then switch back on.

5 - 34

Page 86

5-4 QUALITY CHECKS

1. Copy Quality

1) Copy density

Method:

Visually check the density in the left, right and center.

Standard:

Density must be even in the left, right and center.

2) Skew

Method: Copy an R1 test chart using standard resolution.

Standard:

The difference in length between A and B must be as follows.

A4 or larger:

Less than 1% of the document length.

Smaller than A4: Less than 3% of the document length.

Correction: Clean the R1 and R2 rollers.

3) Intelligibility

Method: Copy an R1 test chart using standard resolution.

Check the characters in frame F

(see the chart on page 5-37).

Standard:

No characters must be missing in the subscan direction.

Correction: Check and adjust the following.

• Flatness

• Reduction rate

• MTF

Refer to section 7-2 for details.

5 - 35

Page 87

4)

Make another copy. If the copy is still defective, make a

printer test (see page 5-30) and check the SBU wave-

forms if necessary (refer to page 7-2).

5 - 36

Page 88

Page 89

2.

3.

4.

Test the operation panel display. Refer to page 5-27.

Check ADF and printer operation.

Communication Tests.

No.

1

2

3

Procedure

Call a remote unit and send 2 test charts,

one in standard and the other in detailed

resolution.

Receive 2 test charts.

Test the special communication functions

Check Items

1. Resolution selection.

2. RTI display.

3. Voice request function.

1 - RTI display.

2. Copy quality.

3. Automatic reception function

4. Voice request function.

1. Polling transmission.

2. Polling reception.

3. Turnaround polling.

4. Memory transmission.

5. Confidential reception.

6. Substitute reception.

7. Closed network.

5 - 38

Page 90

SECTION 6

REMOVAL AND REPLACEMENT

Page 91

Note:

If you will switch off the machine for more than 72

hours, do the following, if it is possible.

• Print out confidential rx files (see page 5-34)

• Print out files stored for transmission, and a SAF

File List. Note which documents were stored in

which files.

After switching the machine back on, re-store the files

for transmission.

Page 92

6-1 COVER REMOVAL

6-1-1 Front Cover

1. Remove the document tray (A) and copy tray (B).

2. Remove the cover plate (C) below the document exit (2

screws).

3 Open the copy exit cover.

4. Remove the small cover plate (D) to the front of the copy

exit cover (1 screw).

5. Open the right cover (E).

6. Remove the front cover (F) – remove 4 screws and dis-

connect the monitor speaker.

When replacing the cover plate (C), be sure that the hooks on

the bottom of the plate clip under the plate on the left end of

the upper unit.

6 - 1

Page 93

6-1-2 Rear Cover

See the diagram on page 6-1.

1. Remove the document and copy trays.

2. Remove the cover plate (C) below the document exit (2

screws).

3. Remove the small cover plate (G) to the rear of the copy

exit cover (1 screw). Open the copy exit cover to remove

the plate.

4. Disconnect the handset.

5. Open the right cover (E).

6. Remove the rear cover (H) – remove 4 screws.

6 - 2

Page 94

6-1-3 Top Cover

See the diagram on page 6-1.

1. Open the upper unit.

2. Remove the top cover securing brackets (I) – 2

screws.

3. Take off the top cover (J).

6-1-4 Operation Panel

See the diagram on page 6-1.

1. Remove the front cover (see section 6-1-1).

2. Remove the top cover (see section 6-1-3).

3. Remove the operation panel (K) – 2 screws, 1 ground

wire, 1 connector.

6 - 3

Page 95

6-1-5 Document Table

1.

2.

3.

4.

5.

6.

7.

Open the upper unit.

Take out the master unit (do not touch the master belt).

Remove the right inner cover strip (A) – 3 screws.

Remove the bracket (B) exposed after taking out the right

inner cover strip (2 screws).

Remove the two screws (C) holding the rear inner cover

(D). Do not take off the cover.

Open the ADF.

Remove the document table (E) – 2 screws.

Pull the top of the rear inner cover (D) towards the rear to

allow you to remove the document table.

While replacing, be sure to fit the three tabs (F) on the docu-

ment table into the three slots on the right edge of the document guide plate.

6 - 4

Page 96

6-2 ADF AND SCANNER

6-2-1 Feed and Pick-up Rollers

1.

2.

3.

4.

5.

6.

7.

Remove the document table (see section 6-1-5).

Remove the ADF clutch covers (4 screws).

See section 6-2-3.

Remove the rear inner cover (3 screws).

See section 6-1-5.

Remove the front inner cover (5 screws).

See section 6-9-1

Remove the lower document guide plate (5 screws).

CAUTIONS:

• Put the exposure glass and the two retaining plates in

a safe place.

• Do not lose the leaf spring from on top of the ADF

clutch.

• On reassembly, don’t forget to connect the ground

wire to the front exposure glass retaining plate.

Take out the pick up/feed roller and shaft assembly (A).

1) Push the roller shaft towards the DSB

2) Remove 2 E-rings

3) Slide the two bushings towards the rollers until they

are free of the pickup bracket (B)

4) Lift out the shaft

Take off the paper feed roller (C) and pick-up roller (D)

(1 clip each, 1 belt).

6 - 5

Page 97

6-2-2 Separation Roller

1. Remove the document tray and copy tray.

2. Remove cover (A) — 2 screws.

3. Open the ADF cover.

4. Remove ground wire (B) — 1 screw.

5. Open the upper unit.

6. Disconnect hinge (C) – 1 screw.

7. Remove the ADF cover (D) — 1 screw.

8. Remove the upper document guide plate (E) from the ADF

covver — 5 screws (F).

Caution:

Do not lose the ground wire.

9. Remove the two screws holding the separation roller

bracket (G).

10. Take out the separation roller (H).

Take care not to lose the spring (I) at the front end.

11. Remove the separation roller (2 screws).

When replacing:

• The spring (I) at the front end of the separation roller

must be fit into the circular depression (J) on the

separation roller shaft bracket.

• The two springs (K) on the upper document guide

plate must be fit into their respective circular depressions (L) on the ADF cover.

• Do not touch the rubber surface of the new roller, or

paper feed errors will develop sooner than normal.

6 - 6

Page 98

6-2-3 Fluorescent Lamp

1. Remove the document tray.

2. Open the ADF cover (A).

3. Open the upper unit.

(See section 6-1-5.)

4. Remove the ADF clutch covers (B)

— 4 screws.

5. Remove the screw holding the fluorescent lamp terminal

(c).

6. Slide out the lamp (D).

6 - 7

Page 99

6-2-4 SBU

1. Remove the top cover (see section 6-1-3).

2. Remove the adjustment knobs (A) — 1 screw each.

3. Remove the SBU (B) – 2 screws, 1 connector.

After replacement, carry out the scanner adjustment procedures in section 7-2, and copy a test chart.

6-2-5 VPU

1. Remove the top cover (see section 6-1-3).

2. Remove the VPU (A) — 2 screws, 2 connectors.

6 - 8

Page 100

6-3 CHARGE

6-3-1 Charge Corona Unit and Wire

1. Remove the operation panel (see section 6-1-4).

2. Remove the document table (see section 6-1-5).

3. Remove the front inner cover —

5 screws. See page 6-28.

4. Remove the front master unit guide rail (A) — 3 screws.

5. Remove the ozone duct (B) — 3 screws.

6. Remove the charge corona unit (C) – 2 screws.

7. Prise off the front endblock cover (D).

8. Carefully slide off the rear endblock cover (E).

9. Unhook the corona wire from the tension spring inside the

rear endblock cover.

10. Unhook the corona wire from the screw in the front endblock cover.

Do not remove the screw.

On reassembly:

• Do not touch the new corona wire with your bare

hands.

• Hook the new corona wire onto the rear endblock first.

• Set the corona wire in the front endblock groove (F).

• After installing both ends of the new wire, test the

action of the tension spring.

6 - 9

Loading...

Loading...