Page 1

UMC600

Digital Weight Indicator

Installation Manual

30261

Page 2

Contents

About This Manual................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 1

1.1 Front Panel Keypad and Annunciators................................................................................................ 2

2.0 Installation and Wiring................................................................................................................ 4

2.1 Unpacking and Assembly ................................................................................................................... 4

2.2 Enclosure Disassembly ....................................................................................................................... 4

2.3 Cable Connections ............................................................................................................................. 4

2.4 Power Connections ............................................................................................................................ 4

2.4.1 AC Units and External DC Units ................................................................................................................. 4

2.4.2 AC/Battery Units ........................................................................................................................................ 4

2.5 VAC Conversion ................................................................................................................................ 5

2.6 Board Removal................................................................................................................................... 5

2.7 Instrumentation Setup ........................................................................................................................ 6

2.8 Load Cell Wiring ................................................................................................................................. 6

2.9 Standard Surge Protection Board....................................................................................................... 7

2.10 Hardware Configuration .................................................................................................................... 8

2.11 Serial Port Wiring............................................................................................................................... 9

2.11.1 Serial Port #1 Wiring: CPU KGR8924–1.................................................................................................. 10

2.11.2 Serial Port #2 Wiring: CPU KGR8924–1.................................................................................................. 11

2.12 Digitial I/O Wiring............................................................................................................................. 11

3.0 Configuration.............................................................................................................................. 13

3.1 Digital Configuration.......................................................................................................................... 13

3.1.1 Parameter Overview................................................................................................................................. 13

3.1.2 Configuration Procedure .......................................................................................................................... 13

3.1.3 Digital Configuration Parameters .............................................................................................................. 13

3.1.4 Normal Configuration Setup Parameters .................................................................................................. 19

3.2 Serial Configuration........................................................................................................................... 20

4.0 Options Configuration................................................................................................................ 22

4.1 Option 1 – Expanded Resolution ...................................................................................................... 23

4.2 Option 2 – Analog Output Option...................................................................................................... 24

4.2.1 Specifications........................................................................................................................................... 24

4.2.2 Test Modes.............................................................................................................................................. 24

4.2.3 Error Checking......................................................................................................................................... 24

4.2.4 Communication Verification...................................................................................................................... 24

4.2.5 Analog Wiring to Host Indicator................................................................................................................ 27

4.2.6 Analog Module Serial Pass-Through......................................................................................................... 27

4.3 Option 3 – Time and Date................................................................................................................. 28

4.4 Option 4 – Accumulator.................................................................................................................... 29

4.5 Option 5 – Expanded Serial Communications ................................................................................... 30

4.6 Option 6 – Linear Calibration............................................................................................................. 32

4.7 Option 7 – Serial I/O ......................................................................................................................... 33

4.7.1 Customizing Files..................................................................................................................................... 33

4.7.2 Macro File Setup...................................................................................................................................... 35

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.rlws.com or obtained by

Copyright © 2003 Condec. All rights reserved. Printed in the United States of America.

calling 715-234-9171 and asking for the training department.

Specifications subject to change without notice.

February 2003

Page 3

ii

4.7.3 Standard Serial Configuration................................................................................................................... 36

4.7.4 Option 7 Configuration ............................................................................................................................. 36

4.8 Option 8 – Analog Output/Relay Option............................................................................................ 38

4.8.1 Analog Output Option Wiring.................................................................................................................... 38

4.9 Option 9 – Front Panel Key Lockout Option...................................................................................... 39

4.10 Option 10 – Setpoints..................................................................................................................... 40

4.11 Option 11 – Remote Input Option.................................................................................................... 40

4.12 Additional Options........................................................................................................................... 41

4.12.1 Relay Output Board KHL8924................................................................................................................. 41

4.12.2 Relay Output/Input Board (KJN8924–) .................................................................................................... 43

4.12.3

Serial Command Option Parameters ................................................................... 46

5.0 Calibration.................................................................................................................................. 47

5.1 Zero Calibration ................................................................................................................................ 47

5.2 Single Slope Span Calibration........................................................................................................... 47

5.3 Five-Point Linear Calibration ............................................................................................................. 48

6.0 Normal Weighing Mode Operations.......................................................................................... 49

6.1 Display Test...................................................................................................................................... 49

6.1.1 Display Check.......................................................................................................................................... 49

6.1.2 EPROM Verification.................................................................................................................................. 49

6.2 LED Annunciators............................................................................................................................. 49

6.3 Function Keys................................................................................................................................... 49

6.4 Gross/Tare/Net Weighing Operations ............................................................................................... 49

6.4.1 Display Mode on Power Up...................................................................................................................... 49

6.4.2 ZERO Key Function.................................................................................................................................. 49

6.4.3 TARE Key Function .................................................................................................................................. 50

6.4.4 Overload and Underrange Conditions....................................................................................................... 50

6.5 Fixed Tare Entry................................................................................................................................ 50

6.5.1 Lb/Kg Conversion.................................................................................................................................... 50

6.6 Serial Output .................................................................................................................................... 51

6.6.1 Serial Data Formats.................................................................................................................................. 51

6.6.2 Demand Mode versus Continuous Data Output ....................................................................................... 52

6.6.3 Demand Print with Identification Number.................................................................................................. 52

6.7 Truck Weighing Mode....................................................................................................................... 53

7.0 Setpoints.................................................................................................................................... 55

8.0 Optional and Advanced Features............................................................................................... 62

8.1 Expanded Serial Communications .................................................................................................... 62

8.1.1 Demand Output Serial Data Format.......................................................................................................... 62

8.1.2 Continuous Condec Output Serial Data Format........................................................................................ 63

8.1.3 RS485 Data Formats................................................................................................................................ 63

8.1.4 Port 1 Remote Serial Commands............................................................................................................. 64

8.1.5 Full Duplex Parameter Entry/Recall........................................................................................................... 65

8.2 Delay Demand Print.......................................................................................................................... 65

8.3 Battery Option .................................................................................................................................. 65

9.0 Appendix.................................................................................................................................... 66

9.1 ASCII Character Chart ...................................................................................................................... 66

9.2 Parameter Control Code Chart ......................................................................................................... 67

9.3 Display and Error Messages ............................................................................................................. 67

9.4 Specifications ................................................................................................................................... 68

UMC600 Limited Warranty..................................................................................................................... 70

UMC600 Installation Manual

Page 4

About This Manual

This manual is intended for use by service technicians

responsible for installing and servicing the UMC600

digital weight indicator. This manual provides

information on installation, calibration, configuration,

Authorized distributors and their

employees can view or download this

manual from the Condec distributor

site at www.4condec.com .

and operation of the UMC600.

1.0 Introduction

The UMC600 is a single-channel digital weight indicator designed to operate in a wide variety of scale and

weighing applications. The indicator is housed in a NEMA 4X stainless steel sealed case. The standard unit is

equipped with a tilt stand base for tabletop or wall mounting applications. The indicator front panel consists of a

21-button keypad, six se ven-segment display digits and six LED annunciators (see Figure 1-1 on page 2).

Standard features of the UMC600 include:

• Full front panel digital configuration and calibration.

• Zero and span temperature compensation to ensure compliance with NTEP and Canadian temperature range

requirements (–10 to 40°C).

• Nonvolatile memory stores data for calibration, temperature compensation, configuration parameters, auto or fixed

tare values, PAZ and AZM values, and setpoint values.

•Ten-thousand displayed graduations; 80,000 graduation expansion available.

Note: Use of more than 20,000 graduations may cause undesirable display instability in some applications.

µ

• Analog sensitivity to 0.3

•Ten updates per second, with selectable digital averaging and auto averaging; 5 Hz active analog filter for smooth

response.

• Excitation for eight 350

• Operable from AC, internal rechargeable battery with AC charger, or external DC input.

•Time and date print selection.

V/grad at 20,000 graduations.

Ω

load cells at 10 VDC.

Introduction

1

Page 5

2

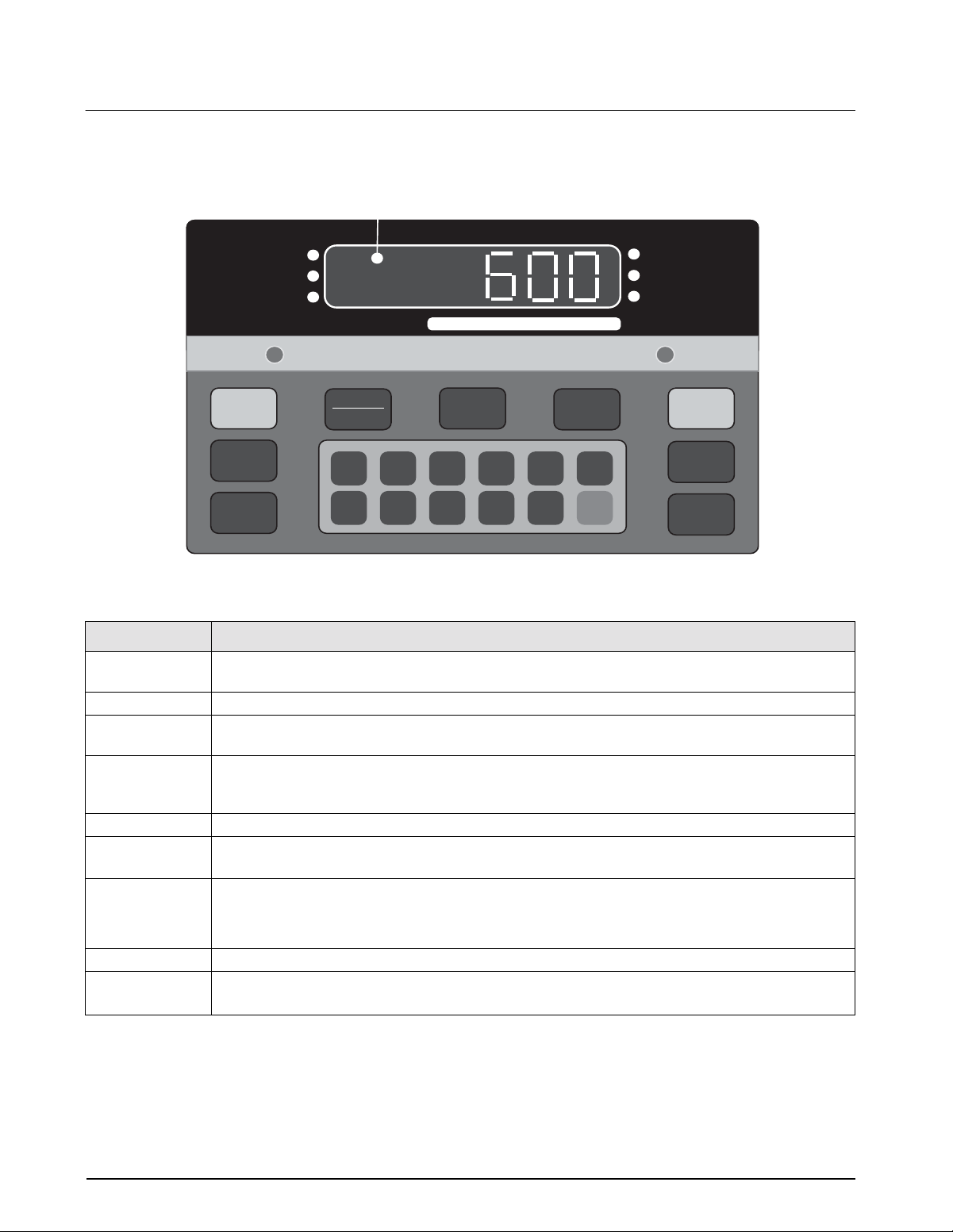

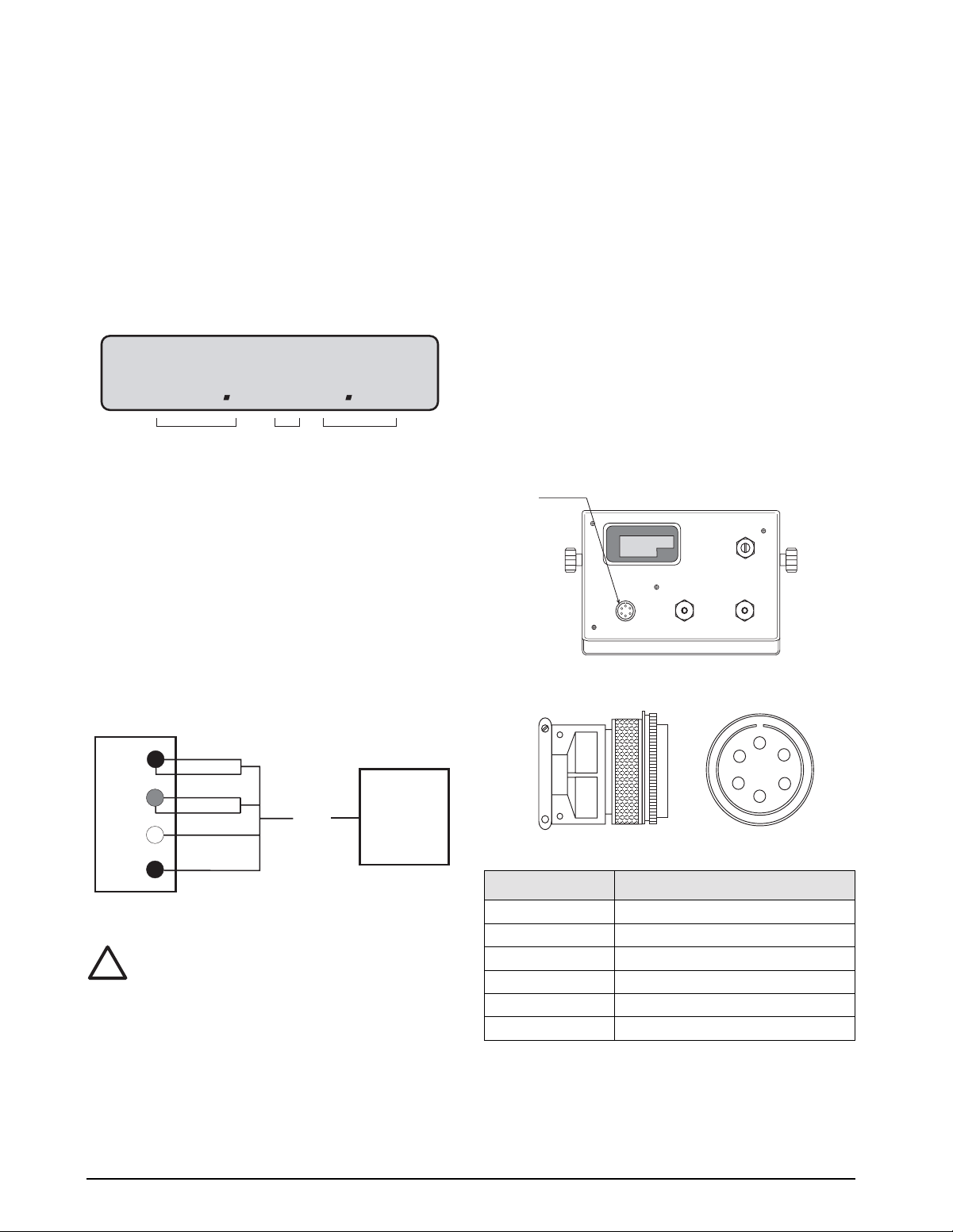

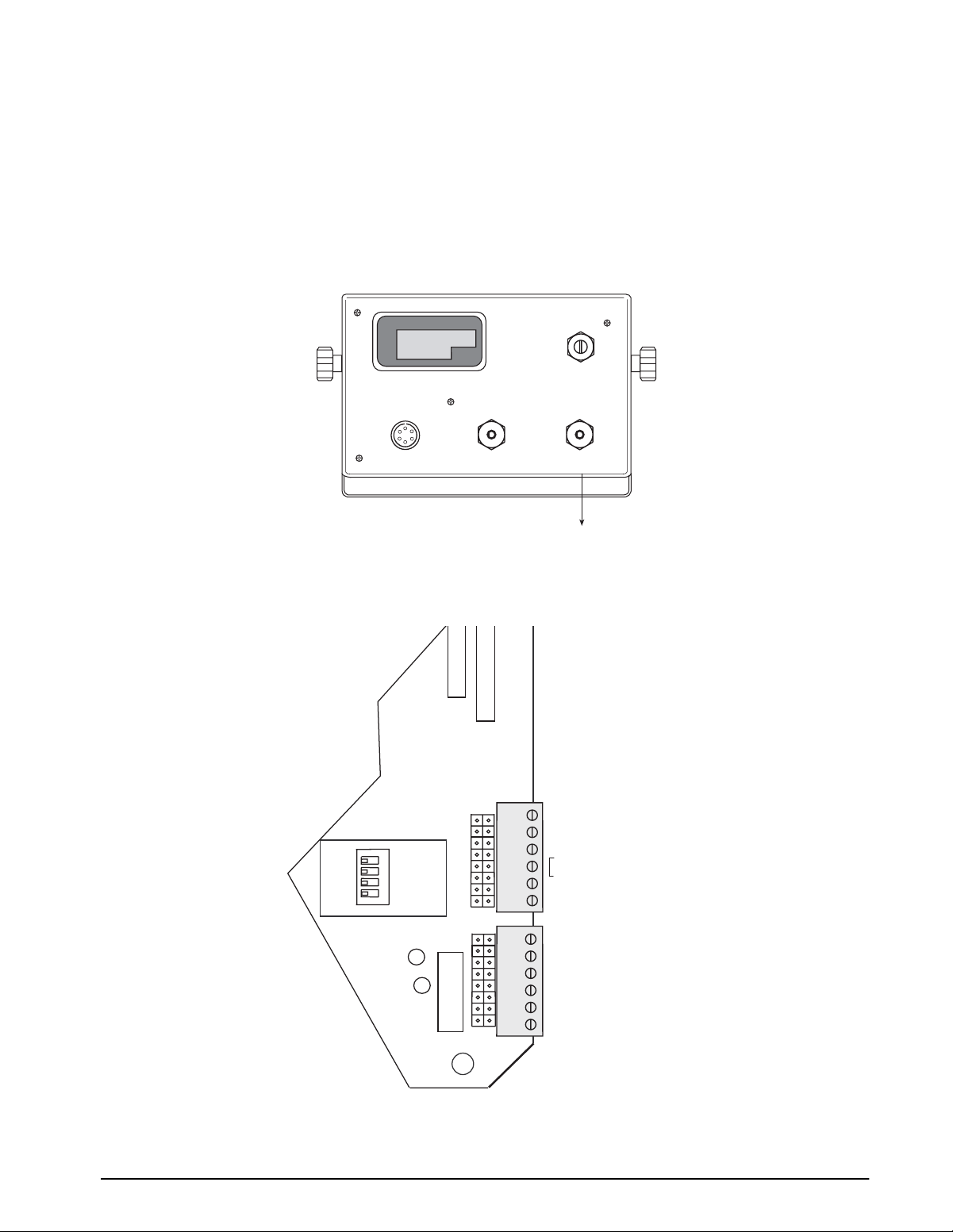

1.1 Front Panel Keypad and Annunciators

Figure 1-1 shows the UMC600 front panel. The UMC600 display consist of six seven-segment display digits.

Table 1-1 lists the front panel keys and their functions.

Low Battery Annunicator

lb

kg

MOTION

PRINT

1 SET

POINT

2 SET

POINT

ZERO

TARE

RECALL

ZERO

NET

GROSS

CAPACITY

NET

GROSS

5000 lb. X 0.5

TARE

162738495

0

lb/kg

CONV

CE

ENT

Figure 1-1. UMC600 Front Panel

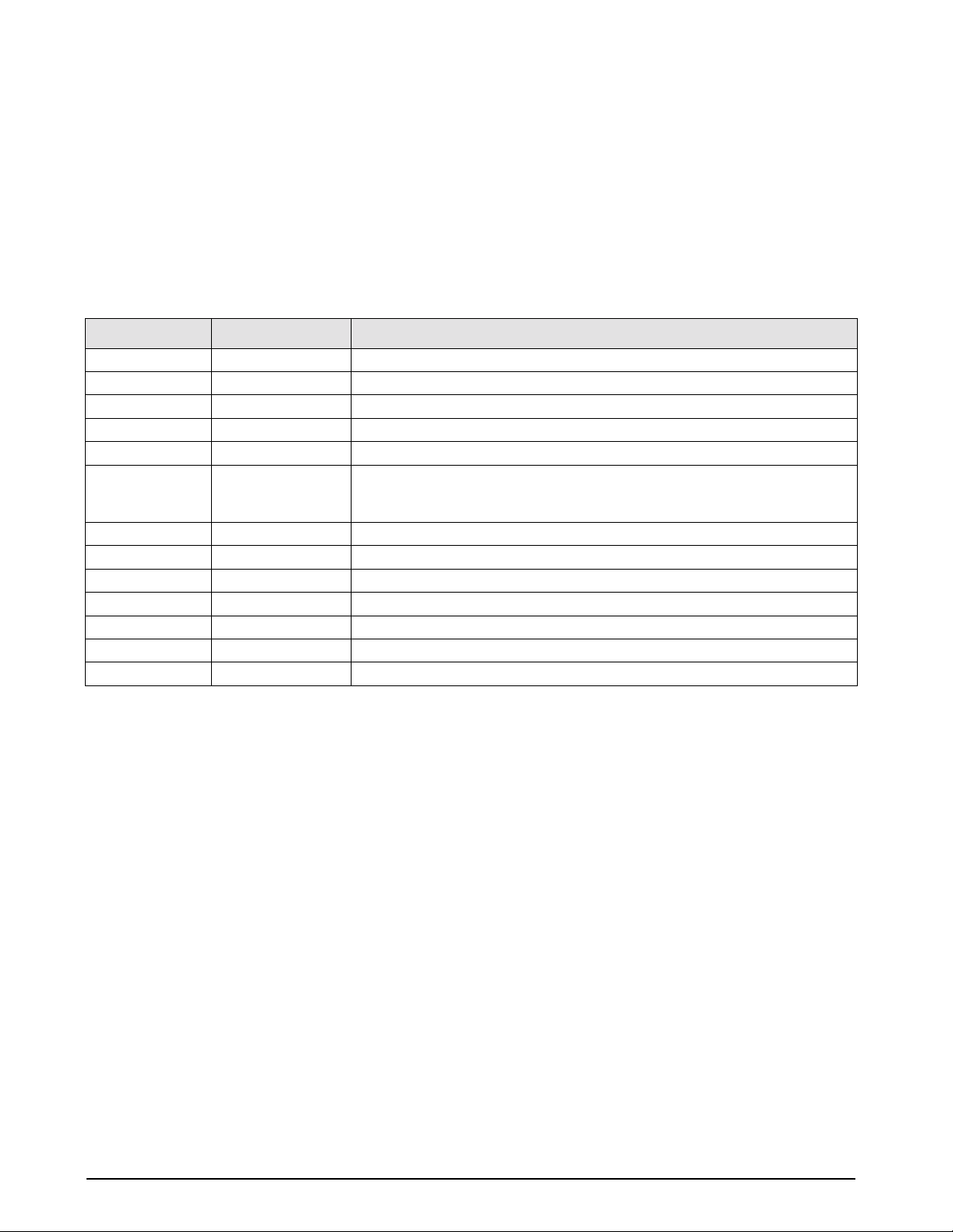

Panel Key

ZERO Provides push-button auto zero (PAZ) over ±1.9% or 100% full scale capacity. Operates only in gross

weighing mode.

GROSS/NET Switches the unit between gross and net weighing modes.

TARE Provides push-button tare entry over 100% of scale capacity. Pressing TARE key switches to net mode

and enters tare.

PRINT Provides a manual print function if unit is wired to serial printer or other data device. Also initiates truck

in/out weighing function if that feature is enabled. See Section 3.2 on page 20 for serial output

specifications.

lb/kg CONV Switches the displayed weight unit between pounds and kilograms.

TARE RECALL Press to recall tare value; LED annunciator lit when tare value is displayed. Also used as ID RECALL in

t

ruck weighing mode.

ON/OFF Provides power to the indicator.

Function

NOTE: On AC units, the ON/OFF switch is replaced by the blank key which becomes a start

key in setpoint batching modes.

SETPOINT 1 & 2 Push to enter or recall associated setpoint values.See Section 6.0 on page 49 for details.

0–9, CE, ENT

Numeric keyboard for entry of manual tare, setpoint values, and calibration data.

ENT

(Enter) keys.

(Clear Entry) and

CE

Table 1-1. Front Panel Key Functions

UMC600 Installation Manual

Page 6

Table 1-2 summarizes the front panel annunciator functions.

Annunciator

LOW BATTERY On when 12 VDC input voltage drops to approximately 11.4 VDC.

ZERO On when scale weight is within ±0.25 displayed graduations of zero. Used in gross or net weighing mode.

NET On when the indicator is in net weighing mode.

GROSS On when the indicator is in gross weighing mode.

lb/kg lb or kg LED is lit to show the current displayed weight units.

MOTION On when scale is in motion.

1 SETPOINT

2 SETPOINT

TARE RECALL Part of the TARE RECALL key, LED flashes when tare value is displayed.

ON/OFF On when the scale is operational.

On when the appropriate setpoint is energized or are flashing when the appropriate setpoint is recalled on

the display.

Function

Table 1-2. Front Panel Annunciators

Introduction

3

Page 7

4

2.0 Installation and Wiring

This section describes the procedures for installing the UMC600 indicator, including connecting the load cell,

digital input and serial communications cables to the indicator. Instructions for CPU board replacement are

included, along with assembly drawings and parts list for the service technician.

Use a wrist strap to ground yourself

!

Caution

and protect components from

electrostatic discharge (ESD) when

working inside the indicator.

2.1 Unpacking and Assembly

All indicators are configured and tested prior to

shipment to ensure that they are fully functional.

Immediately after unpacking, visually inspect the

UMC600 to ensure all components are included and

undamaged. The shipping carton should contain the

indicator, tilt stand, the manual, and a parts kit. If any

parts were damaged in shipment, notify Condec and the

shipper immediately .

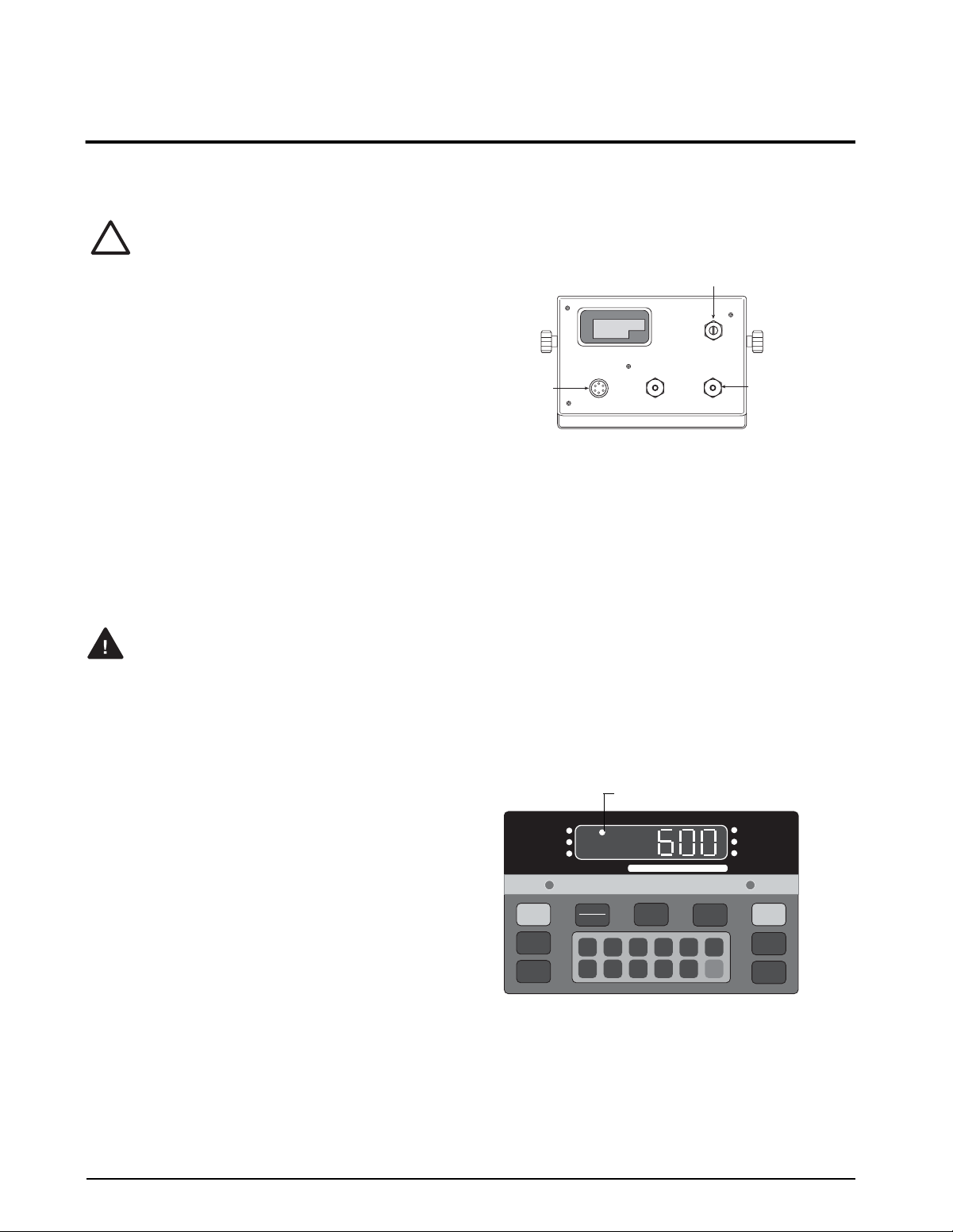

2.2 Enclosure Disassembly

The indicator enclosure consists of a load cell

connector and cord grips for communications cables.

the enclosure must be opened to connect the

communications cables.

The UMC600 has no on/off switch.

Warning

Before opening the unit, ensure the

power cord is disconnected from the

power outlet.

Ensure power to the indicator is disconnected then

remove the screws that hold the front bezel to the

enclosure body. Place the indicator face-down on an

antistatic work mat, then lift the enclosure away from

the front bezel. Set the enclosure aside.

2.3 Cable Connections

The UMC600 provides a load cell connector and three

cord grips for cabling into the indicator; one for the

power, and two to accommodate communications,

digital input, and analog output cables.

One of the two free cord grips comes with a plug

installed to prevent moisture from entering the

enclosure. Depending on your application, remove the

plug from the appropriate cord grip and install cables as

required.

Figure 2-1 shows the recommended assignments for the

UMC600 cord grips.

REAR VIEW

Analog Ouput, Digital Input

TB3 & 5

Load Cell

Connector

TB1

POWER

TB2 & 4

Serial

Communications

Figure 2-1. UMC600 Backplate

2.4 Power Connections

Standard units are powered by one of the following

options.

2.4.1 AC Units and External DC Units

Units are powered by standard 115 VAC power. The AC

power cord must be plugged into a 3-prong grounded

AC wall socket.

2.4.2 AC/Battery Units

The battery operated version of the UMC600 uses a 2.3

amp/hour rechargeable gel cell mounted inside the unit.

A low battery LED annunciator indicates when the

battery needs to be recharged (shown below) and

automatically shuts down when the battery output can

no longer maintain accurate weighing. Refer to Section

8.3 on page 65 for more information on the battery

option.

Low Battery Annunicator

lb/kg

CONV

ENT

lb

kg

MOTION

PRINT

1 SET

CE

POINT

2 SET

POINT

ZERO

NET

ZERO

TARE

RECALL

GROSS

NET

GROSS

CAPACITY

5000 lb. X 0.5

TARE

162738495

0

Figure 2-2. Low Battery LED Annunciator

UMC600 Installation Manual

Note: The unit can be operated while charging

however will take longer to recharge than the

recommended 12 to 16 hours of charging time.

,

Page 8

2.5 VAC Conversion

The UMC600 can be converted from 115VAC to

230VAC. The following steps are necessary to

complete this conversion.

Before beginning, be sure to

Warning

1. Disconnect power to the indicator. Loosen cord

grips and remove enclosure as described in

Section 2.2

2. See Section 2.6 for CPU board removal and

replacement instructions.

3. Remove the protective insulator panel from the

solder side of the CPU assembly .

4. Cut circuit traces between E7/E8 and E9/E10 as

indicated with a sharp instrument like a razor

blade or an x-acto knife. Refer to Figure 2-3.

Converting from 115V AC to 230V AC

Cut between

E7 and E8

disconnect the AC power source.

Failure to do so can result in injury

or death.

Jumper E8 to E9

Cut between

E9 and E10

2.6 Board Removal

If you must remove the UMC600 CPU board, use the

following procedure:

1. Disconnect power to the indicator. Loosen cord

grips and remove enclosure as described in

Section 2.2

2. Unplug all connections to the CPU board noting

where they are connected.

3. Remove the four screws from the corners of the

CPU board.

4. Remove the CPU board from the enclosure.

To replace the CPU board, reverse the above procedure.

Be sure to reinstall tie wraps to secure all cables inside

the indicator enclosure. Replace enclosure and torque

screws to 10 in - lb (1.13 N-m).

E8 E9 E10

E7

Circuit Side of CPU Board

Figure 2-3. Circuit Trace Setup

5. Add jumper, E8 to E9 using a properly insulated

wire with a minimum size of #22 AWG.

6. Replace the protective insulator panel.

7. Change the power cord.

8. Reassemble the unit, test, and label unit for

230VAC.

Installation and Wiring

5

Page 9

6

2.7 Instrumentation Setup

All indicators are configured and tested prior to

shipment to ensure that they are fully functional. The

unit can be turned on immediately after connecting the

input power and the load cells.

The UMC600 operates with the EPROM program

KDA1921-1(27C512). To verify the program installed

in the indicator, turn on the indicator and observe the

displayed value at the EP prompt (see Figure 2-4). The

EP prompt displays the family, set, and version level of

the installed EPROM.

EP–1.15

EPROM

Figure 2-4. EPROM Display

Set 1

To ensure that the UMC600 is in proper operating

condition, the indicator can be tested with a load cell

simulator. The input signal should be as close as

possible to the normal system millivolt value.

Figure 2-5 shows the simulator-to-indicator wiring

connection in a six-wire configuration. See Section 2.9

for more information.

Note: Six-wire configuration requires that the +SEN

lead be shorted to +EXC and the –SEN lead be shorted

to –EXC at the simulator only.

LOAD CELL

SIMULATOR

–EXC

+EXC

+SIG

–SIG

Figure 2-5. Wiring Connection to Simulator

Caution

!

–EXC

–SEN

+EXC

+SEN

+SIG

–SIG

Exceeding rated load cell load or

shorting excitation wires may

damage power supply.

Version 15

TO J1

CONNECTOR

UMC600

Notes:

•Test weights should be used to verify scale

performance.

• The tilt stand should be secured with 1/4-20 inch

screws. The location should be selected to of fer some

degree of protection for the indicator and its

associated hardware.

• Unprotected cable runs need to be installed in a

method to protect the cable from damage.

• All wiring must conform to the National Electrical

Code and RP 12.6.

2.8 Load Cell Wiring

All units are equipped with a six-wire load cell

connector. The UMC600 is supplied with a six-pin

connector that needs to be attached to the existing load

cell cable by the installer.

Figure 2-6 shows the load cell output connector and the

location of J1 on the back of the indicator. Table 2-1

shows load cell connector pin assignments.

J1

Load Cell

Connector

TB3 & 5

TB1

Figure 2-6. J1 Load Cell Connector - facing

Pin

A +EXCITATION

B –EXCITATION

C +SIGNAL

D –SIGNAL

E +SENSE

F –SENSE

POWER

REAR VIEW

TB2 & 4

B

C

Function

A

F

E

D

UMC600 Installation Manual

Table 2-1. Load Cell Connector Pin Assignments

Page 10

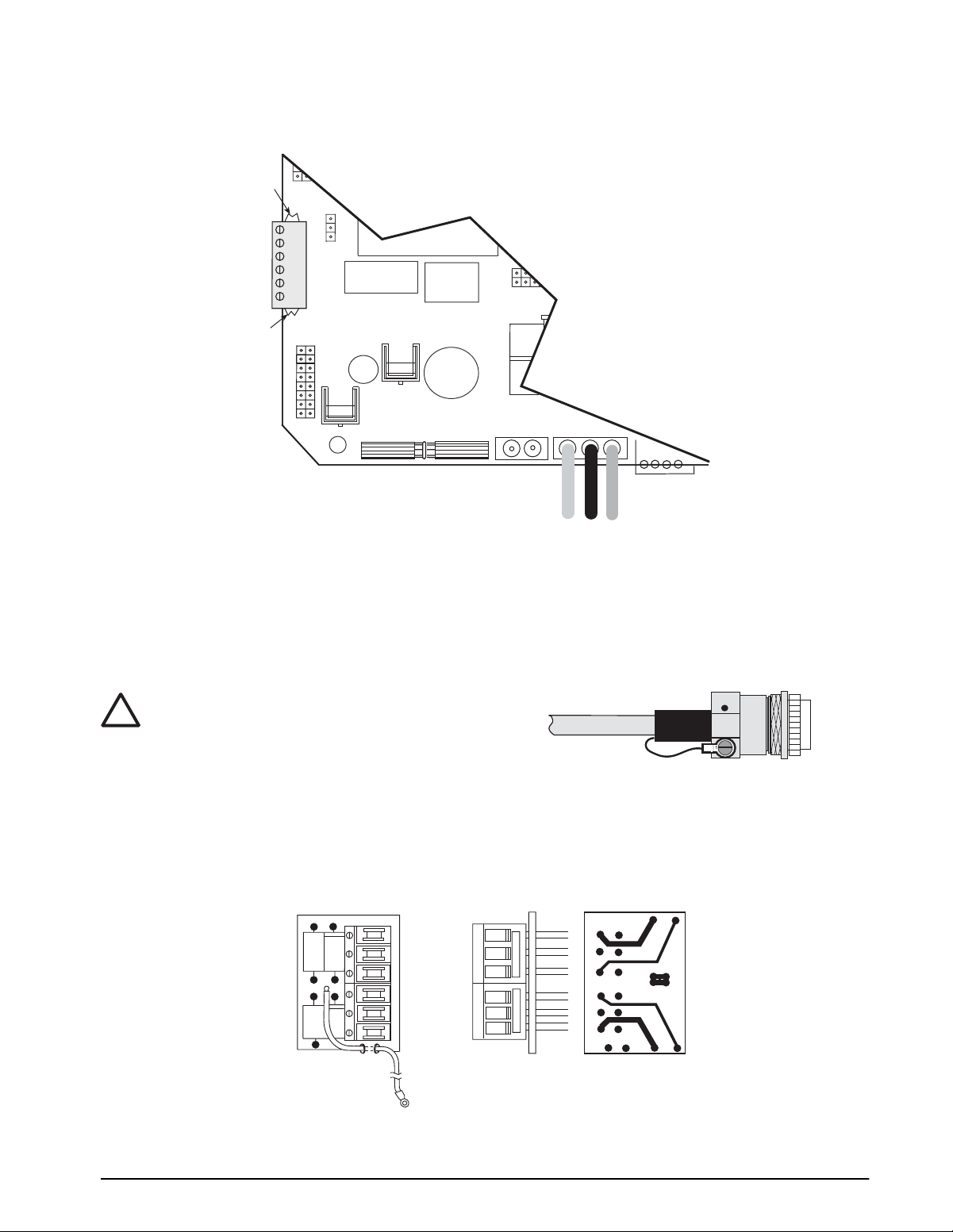

The standard connection is designed for 4-wire (non remote sensing) use. To convert to 6-wire (remote sensing)

applications, cut the two PC traces on each end of TB1 as shown in Figure 2-7.

Traces

J5

TB1

+EXC

+SEN

+SIG

–SIG

–SEN

–EXC

Traces

Note: The load cell shield wire should be connected to

one of the load cell cable clamp screws located on the

load cell mating connector.

LOAD CELL CONNECTOR

654321

J3

S3

U18

Q5

U2

F1

K1

Figure 2-7. Load Cell Wiring From Indicator

J7

J6

+ Batt -

Check load cell

color code for

proper wiring.

GND LO HI

TO POWER SUPPLY

1

2

TB5

Six-Pin Female

Shielding is connected at only one end

!

Caution

(typically at the indicator end). If

connected at the strain gauge end,

disregard Figure 2-8.

Figure 2-8. Load Cell Shield Wire Connection

2.9 Standard Surge Protection Board

The UMC600 comes with a factory installed surge suppression board. The suppression board stops the flow of

excess voltage to the CPU board and attaches to TB1 on the CPU board just by pressing it into TB1 and tightening

the connector screws.

COMPONENT SIDE RIGHT SIDE CIRCUIT SIDE

CR3

CR2

CR4

CR1

+EXC

+SENSE

+SIG

–SIG

–SENSE

–EXC

Figure 2-9. Surge Protection Diagram

E1

E2

E3

E4

E5

E6

E7

CHGND

Installation and Wiring

7

Page 11

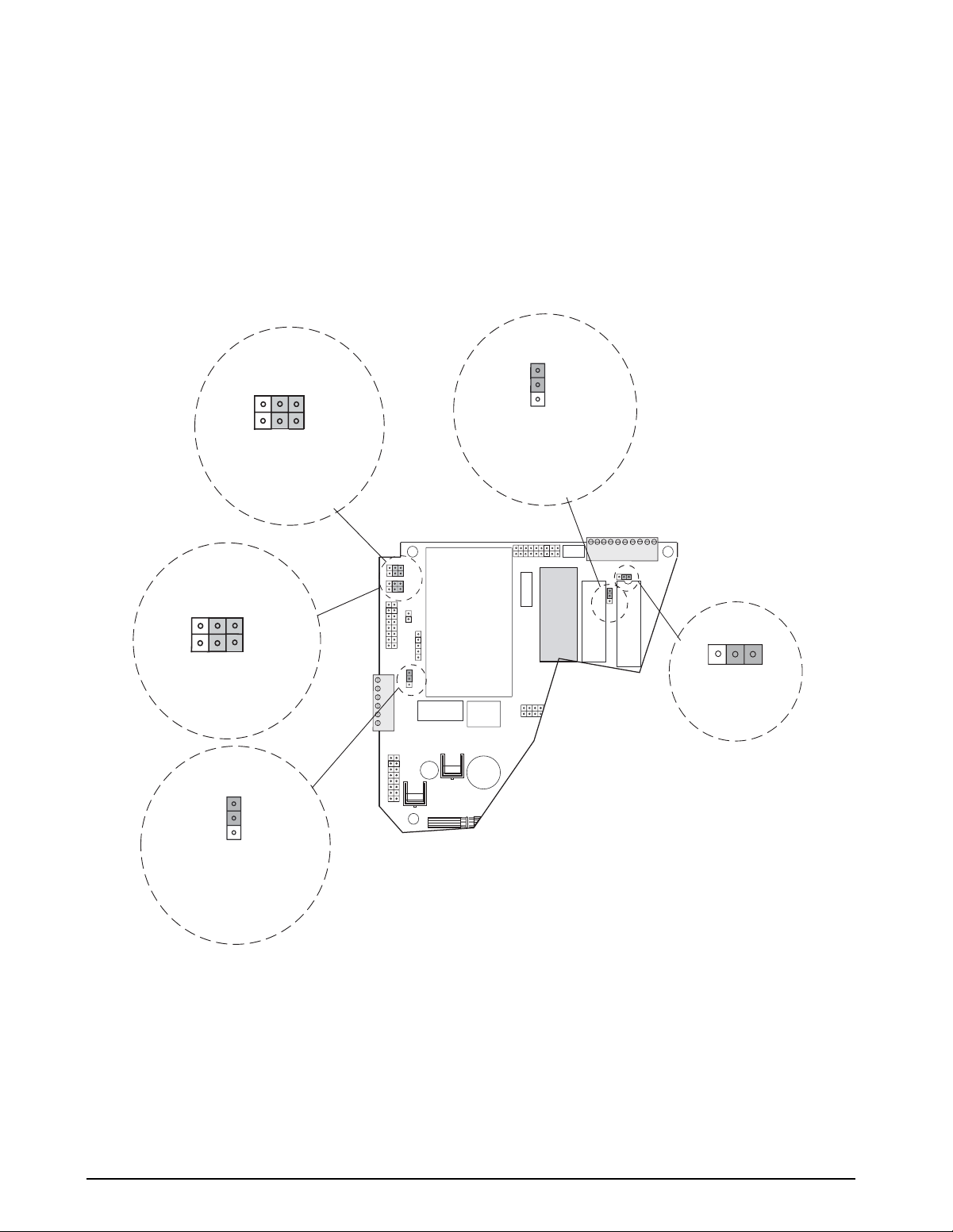

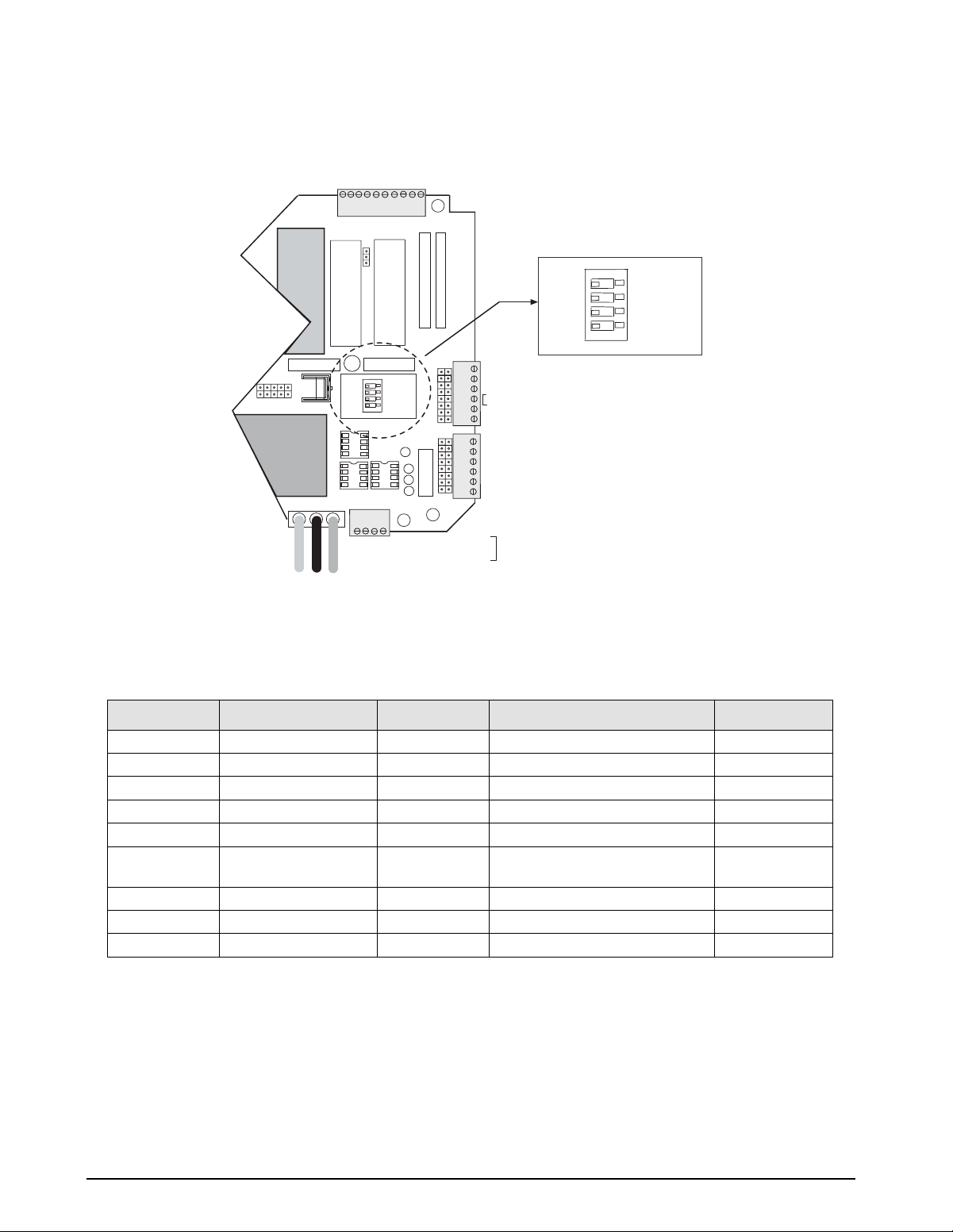

2.10 Hardware Configuration

Jumper pins are provided for:

• EPROM chip selection

• Front panel switch configuration (DC on/off or batch start)

•Power on/off relay configuration

• Dual channel (optional)

•Time and date option (SRAM selection)

These features are dependent on installed options and software. The location and jumper positions are noted in

Figure 2-10.

8

Dual Channel

(optional)

l 2 3

S7

S6

1 2 3

Enable Jumper 1-2

Disable Jumper 2-3

Front Panel On/Off

Switch Function

1 2 3

S4

S5

1 2 3

DC On/Off Jumper 1-2

Batch Start Jumper 2-3

Power On/Off

Relay

3

2

S3

1

Enable Jumper 1-2

Disable Jumper 2-3

For Toggle Switch Omit Jumper

TB1

+SIG

+SENSE

–SENSE

SHIELD

+EXC

Time and Date Option

3

2

S2

1

Enable Jumper 1-2 –

(1243 SRAM U4)

Disable Jumper 2-3 –

(1220 SRAM U4)

TB3

3

8

9

5

2

1

6

4

1

7

10

U20

S7

S6

S4

S5

R6

J4

J5

LOAD CELL CONNECTOR

–SIG

S3

654321

J3

U2

U18

F1

RF1

SHIELDED

A/D

Q5

U5

U7

J7

K1

DIGITAL OUTPUT

3

1

S2

U11

U4

EPROM Select

12 3

256k Jumper 1-2

512k Jumper 2-3

Figure 2-10. Jumper Pin Placement

Note: The lower left corner switch (S21) on the front panel, is used for the Start command in the standard setting of

S4 and S5, however, it becomes a power on/off switch when S4 and S5 are set to DC On/Off and S3 is set to the

Enable position.

UMC600 Installation Manual

Page 12

2.11 Serial Port Wiring

The UMC600 has two serial communications ports.

Port 1 supports full-duplex RS-232, or 20mA current loop (active or passive), or half-duplex RS-485. Switch S1

(shown in Figure 2-12), selects the interface protocol of Port 1.

Port 2 supports simplex (output only) RS-232, or 20mA current loop (active or passive).

Access to the serial communication ports is through the cord grips (TB2 and TB4) located on the back of the

enclosure (see Figure 2-11). See Figure 2-12 for serial I/O wiring termination assignments.

TB3 & 5

TB1

POWER

REAR VIEW

Figure 2-11. Serial Port TB2 Connector

U9

U13

J11

6

5

J10

4

3

2

1

1

SERIAL COMMUNICATIONS - 1

6

5

4

3

2

1

SERIAL COMMUNICATIONS - 2

S1

PASS

PORT 1 RECEIVE

1

2

3

4

RS232

20MA

RS485

ACTIVE

U8

TB2 & 4

Serial

Communications

TB4

RX+ (20 mA passive Port 1)

RX- (20 mA passive Port 1)

RX+ (20 mA active Port 1)

TX- (20 mA Port 2)

TX+ (20 mA Port 2)

TX- (20 mA active Port 1)

GND or RX 20 mA active Port 1

TX+ (20 mA active Port 1)

RX1 (RS-232 duplex Port 1) RD1

TX1 (RS-232 duplex Port 1) TD1

TX2 (RS-232 Port 2) TD2

TB2

Figure 2-12. Serial I/O Wiring Locations

Installation and Wiring

9

Page 13

2.11.1 Serial Port #1 Wiring: CPU KGR8924–1

Serial Port 1 supports full-duplex RS-232, or 20mA current loop (active or passive), or half-duplex RS-485. Switch

S1 (shown below), selects the interface protocol of Port 1..

TB3

3

8

9

5

2

1

6

4

10

7

DIGITAL OUTPUT

1

U9

U13

U7

U10

U1

GND LO HI

U4

C15

S1

3 41 2

PASS

PORT 1 RECEIVE

U15

U22 U21

J2

DIGITAL OUTPUT

1

2

1

3

TB5

U11

U19

RS232

20MA

RS485

ACTIVE

4

J11

J10

U8

1 – +TD1 20mA passive/RS-485A

2 – -TD1 20mA passive/RS-485B

3 – +TD2 20mA passive

4 – -TD2 20mA passive

TB4

6

5

4

RX+ (20mA passive Port 1)

RX- (20mA passive Port 1)

3

RX+ (20mA active Port 1)

2

TX- (20mA Port 2)

1

TX+ (20mA Port 2)

1

SERIAL COMMUNICATIONS - 1

6

TX- (20mA active Port 1)

5

GND or RX 20mA active Port 1

4

TX+ (20mA active Port 1)

3

RX1 (RS-232 duplex Port 1) RD1

TX1 (RS-232 duplex Port 1) TD1

2

1

TX2 (RS-232 Port 2) TD2

SERIAL COMMUNICATIONS - 2

TB2

optional

S1

PASS

RS232

20MA

3 41 2

RS485

ACTIVE

PORT 1 RECEIVE

TO POWER SUPPLY

Figure 2-13. Serial Port #1 Switch Location

Port Connector/Pin # RS-232 20mA Current Loop RS-485

1 TB2 - 2 TxD

1 TB2 - 3 RxD

1 TB2 - 4 +20mA TX+ OUT (active) *2

1 TB2 - 5 GND -20mA RX- IN (active) *1

1 TB2 - 6 -20mA TX- OUT (active)

1 TB4 - 3 +20mA RX+ IN (active)

-20mA RX- IN (passive)

1 TB4 - 4 +20mA RX+ IN (passive)

1 TB5 - 1 +20mA TX+ OUT (passive) RS-485-A *1 *3

1 TB5 - 2 -20mA TX- OUT (passive) RS-485-B *2 *3

Table 2-2. TB2, TB4, TB5 Pin Assignments (Serial Port #1 Communications)

*) Notes:

(

1. A pull-down biasing resistor (100K OHMS typical) should be installed between TB5-1 and TB2-5.

2. A pull-down biasing resistor (100K OHMS typical) should be installed between TB5-2 and TB2-4.

3. If the UMC600 is the last device (node) on the RS-485 network, a termination resistor (100 OHMS typical) should

be installed across TB5-1 and TB5-2.

10 UMC600 Installation Manual

Page 14

2.11.2 Serial Port #2 Wiring: CPU KGR8924–1

Serial port #2 supports simplex (output only) RS-232, or 20mA current loop (active or passi v e). The follo wing chart

illustrates Serial Port 2 pin assignments.

Port Connector/Pin # RS-232 20mA Current Loop

2 TB2 - 1 TxD

2 TB2 - 5 GND

TB2 - 6

2 TB4 - 1 +20mA TX+ OUT (passive)

2 TB4 - 2 -20mA TX- OUT (active)

TB5 - 3 +20mA TX+ OUT (passive)

TB5 - 4 -20mA TX- OUT (passive)

Table 2-3. TB2, TB4, TB5 Pin Assignments (Serial Port #2 Communications)

2.12 Digitial I/O Wiring

The standard unit has four outputs for setpoint and zero band control and four discrete inputs that allow the zero,

net/gross, and print function to be operated remotely by contact closure of these inputs to digital ground. Wire any

active digital input and outputs to connector TB3 on the CPU board. Table 2-4 shows the digital I/O assignments for

the TB3 connector and their description.

TB3 Pin Signal Description

Outputs

1 +5 VDC

2 DIG OUT 4 Dribble control assigned to setpoint 2 (defined in parameter 11), or a zero band output

when parameter 12 is selected for 1-50.

3 DIG OUT 3 Setpoint 2 output (defined in parameter 11).

4 DIG OUT 2 Dribble control assigned to setpoint 1 (defined in parameter 11).

5 DIG OUT 1 Setpoint 1 output (defined in parameter 11).

Inputs

Normal Mode Batch Mode

6 GND

7 DIG IN 4 Net/gross Abort

8 DIG IN 3 Zero Zero

9 DIG IN 2 Tare Start Batch

10 DIG IN 1 Print Print

Table 2-4. TB3 Pin Assignments (Digital I/O)

Inputs 7 through 10 allow the zero, net/gross, tare, and print functions to be operated remotely by contact closure of

these inputs to digital ground.

Installation and Wiring 11

Page 15

Typically, digital outputs control relays which operate other equipment. Outputs 1 through 4 allow for setpoint and

zero band control.

Operational Mode

Relay Board TB3

Tare Start Batch TB3-6 IN2

Zero Zero TB3-5 IN3

Net/Gross Abort TB3-4 IN4

Print Print TB3-3 IN5

TTL Inputs J11

KGR8924 CPU Normal Batch

Table 2-5. Relay Input Wiring

12 UMC600 Installation Manual

Page 16

3.0 Configuration

ZERO

NET

GROSS

TARE

lb/kg

CONV

Prior to calibration, the UMC600 must be digitally

configured, or assigned a set of operating parameters.

The three parameters listed in Section 3.1.1 are directly

related to calibration and must be set before proceeding

to calibration mode.

3.1 Digital Configuration

3.1.1 Parameter Overview

Table 3-1 on page 14 lists configuration parameters and

describes their values. The following paragraphs give

the procedure for configuring the UMC600.

3.1.2 Configuration Procedure

1. Unscrew the two screws on the face plate

bracket (Figure 3-1). The bracket drops down,

exposing four program switches on the left side

of the indicator.

CE

ENT

lb

kg

MOTION

PRINT

1 SET

POINT

2 SET

POINT

342

1

OPEN

ZERO

TARE

RECALL

ZERO

NET

GROSS

CAPACITY

NET

GROSS

5000 lb. X 0.5

TARE

162738495

0

lb/kg

CONV

When configuration is complete, set SW1-2 down to

return the unit to normal operating mode.

DEAD LOAD (3)

CONF (2)

CAL (1)

NORM

Parameter

Identifier

ZERO

NET

GROSS

NET

ZERO

GROSS

TARE

RECALL

1

342

OPEN

162738495

Figure 3-2. Closing Switch 2

CAPACITY

5000 lb. X 0.5

TARE

0

Selected Data

lb/kg

CONV

CE

ENT

lb

kg

MOTION

PRINT

1 SET

POINT

2 SET

POINT

Figure 3-3 defines the functional operation of each key

on the front panel of the indicator when the unit is in the

the setup mode.

Zero Net/Gross Tare Units

Parameter

Select

NOTE: The TARE RECALL key functions as a previous

screen key in CONFIG mode.

Parameter Data

Select

Subparameter

Select

Subparameter

Data Select

Figure 3-3. Front Panel Key Functions

Figure 3-1. Accessing the Program Switches

2. Temporarily remove the unit’s flexible black

display overlay by gently pushing down and

lifting the panel up and out at its center to expose

the configuration and calibration instructions

printed on the surface below. The switch

function table defines the appropriate front panel

switch settings for the CONF and CAL modes.

3. Close switch SW1-2, marked

CONF (2), by

moving to the up position (see Figure 3-2). A

prompt appears with a parameter number and

data value.

The parameter identifier is a number, 1–14, that

correlates to the

CONFIG chart on the upper left of the

switch map panel. Selected data represents the value

being entered into the unit configuration data. For

example, 1 100 sets the indicator to 10,000 graduations

(see Table 3-2 on page 16).

Configuration 13

Page 17

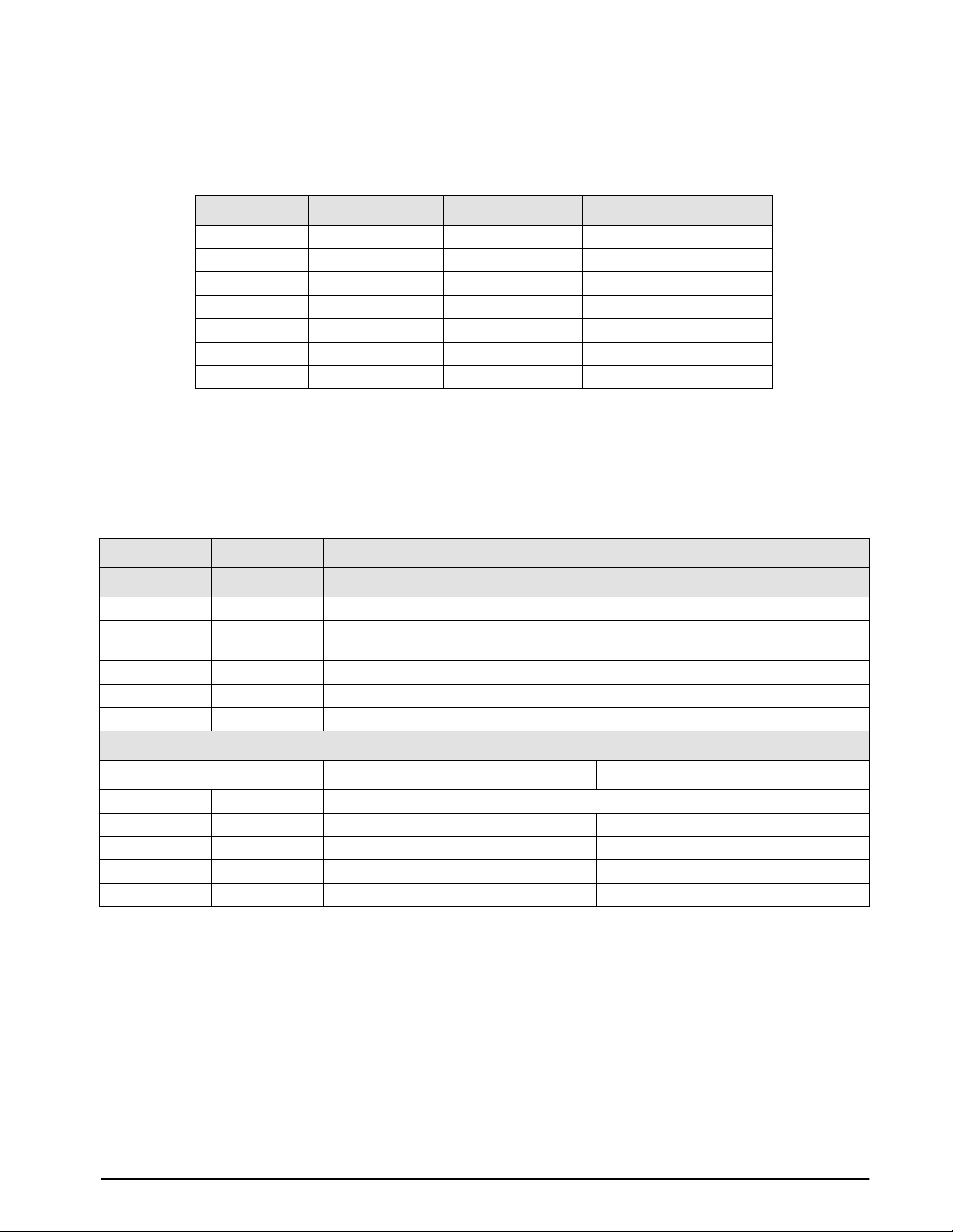

3.1.3 Digital Configuration Parameters

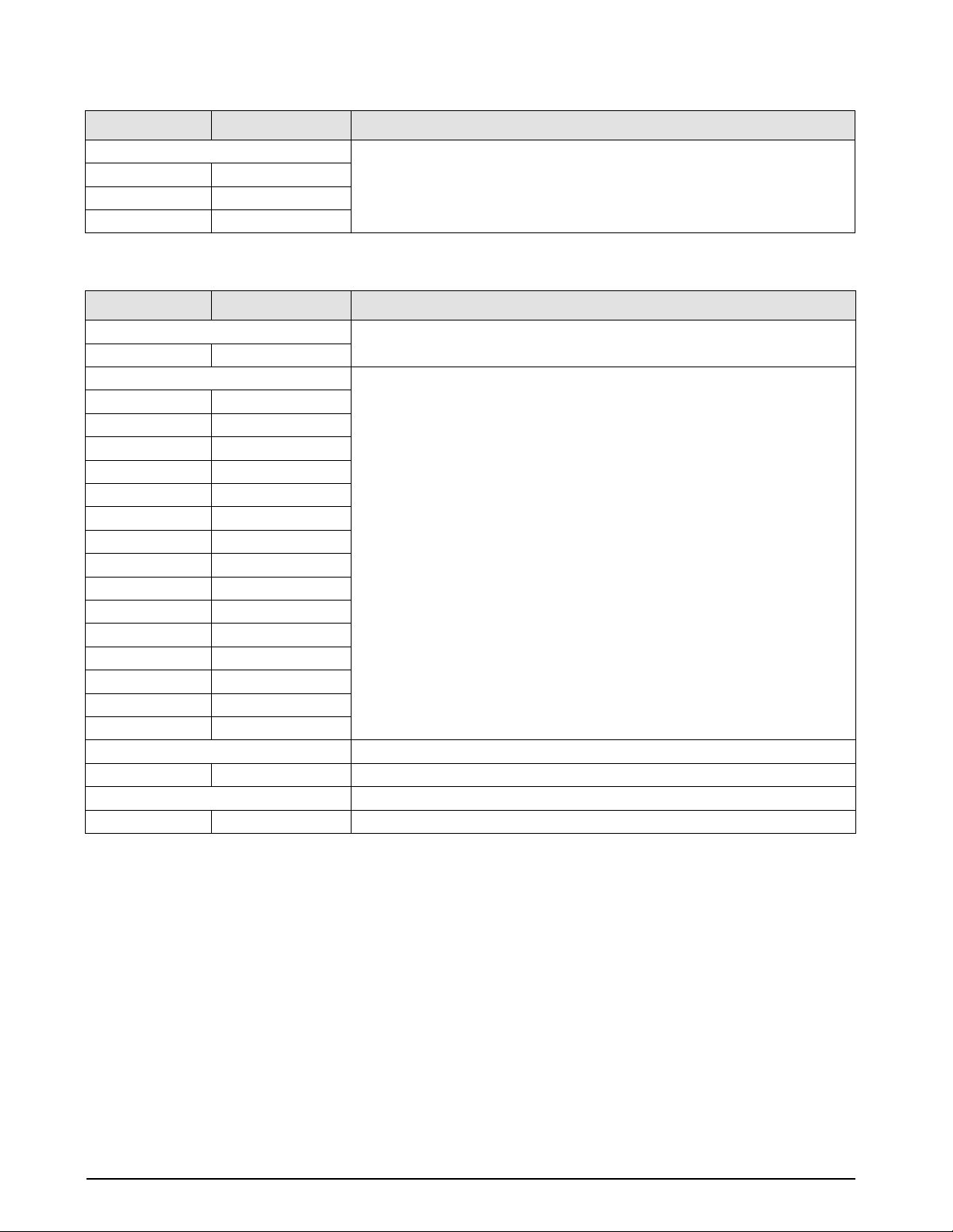

Table 3-1 (shown below) shows an overview of the 14 configuration parameters and their description.

Table 3-2 on page 16 lists the configuration display prompts (Prompt 1), and their value selections for displayed

graduations. Prior to calibration, the UMC600 must be digitally configured, or given its set of operating parameters.

The first three parameter selections are directly related to calibration and must be set up before proceeding to the

calibration mode. These parameters include;

• number of graduation

• resolution

• decimal point location in the weight data, all of which define the scale capacity.

Parameter Description Values

1 Graduations NTEP to 10,000 (up to 80,000 available).

2 Display resolution 1, 2, 5, 10, 20, 50, 100

3 Decimal point 0.0, 0.00, 0.000, 0.0000, no decimal

5 Digital averaging 1, 2, 4, 8, 16, 32, A1 = 8-4-2; A2 = 16-8-4

6Tare mode ATNR, AUTO, FIXED, BOTH (inhibit with motion)

7 AZM band Off, 0.5, 1, 3, 5, and 10 divisions

Use 0.5 for H-44, bench, counter and livestock applications; use 3 for vehicle,

axle-load, and railroad scales

8 AZM/PAZ aperture ±1.9%, 100% of capacity includes push-to-zero, H-44: 1.9%

9 Motion Off, 1, 3, 5 divisions H-44: vehicle, axle, livestock, RR, 3.0; all other 1.0

10 Displayed units Lb, kg, con

11 Setpoint mode See Section 7.0 on page 55 for settings

12 Zero band Off, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, 20, 30, 40, 50

13 Weigh mode Normal, truck mode with transaction cancelled/stored, fixed/auto tare

14 Serial output Port 1, Port 2, demand, continuous, baud rate, G/T/N, or display

Table 3-1. Parameter Overview

14 UMC600 Installation Manual

Page 18

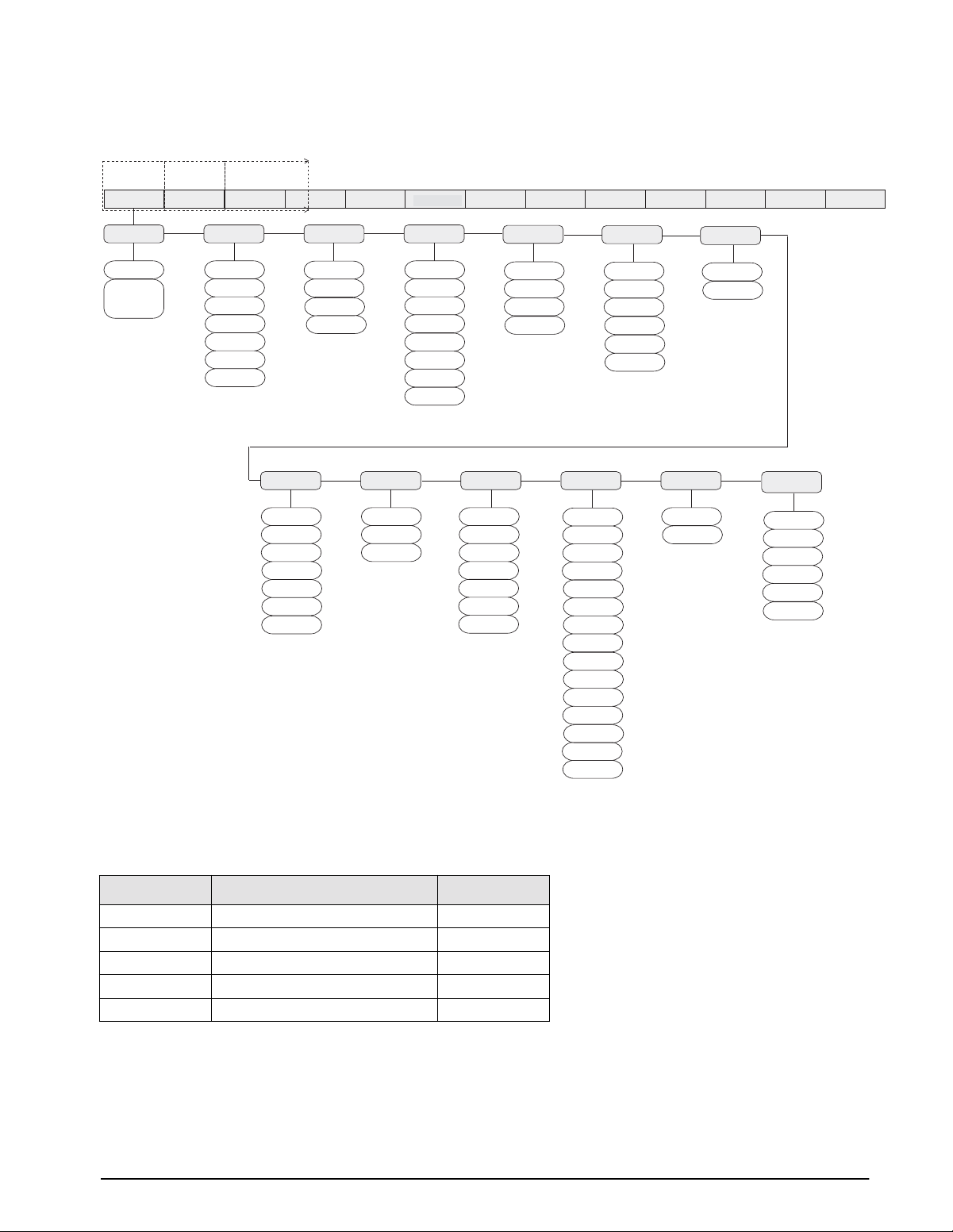

Figure 3-4 provides a graphic representation of the 14 configuration parameters associated with the UMC600.

Shown only if

SW1-2 is on

CONFIG

GRADS

100

selection

list,

see table 3-2

on page 16

Shown only if

SW1-1 is on

CALIBR

Options 1-11

shown only if

SW1-2 & 3 are on

OPTION 1 OPTION 2

RES

resolution

1

2

5

10

20

50

100

MOTION

band

Off

1

3

5

10

20

50

DECPT

decimal point

0.0

0.00

0.000

0.0000

OPTION 3

DISPLAY

kg

lb. conversion

digital average

A2=16-8-2

lb

OPTION 4

AVERAGE

1

2

4

8

16

32

A1=8-4-2

XXXXXXX XXXXXXXXXXXXXX

OPTION 5

ST PT

setpoint

off

SP

over/under

batch 1

batch 2

modes A - G

output

pos/neg

OPTION 6 OPTION 7 OPTION 8 OPTION 9 OPTION 10

TARE

enable tare

ATNR

AUTO

FIXED

BOTH

ZERO BAND

control output

AZM

band

OFF

0.5

1

3

5

10

Off

1

2

3

4

5

6

7

8

9

10

20

30

40

50

WEIGHT

mode

normal

truck

AZM/PAZ

band

1.9

FS

SERIAL

serial output

port 1 & 2

demand

continous

baud rate

G/T/N

display

OPTION 11

Figure 3-4. Configuration Menu

Refer to the following table numbers on the following pages for configuration display prompts.

Table Number Configuration Display Prompts Page

3-2 1 16

3-3 2-3 16

3-4 5-7 17

3-5 8-10 17

3-6 11-14 18

Configuration 15

Page 19

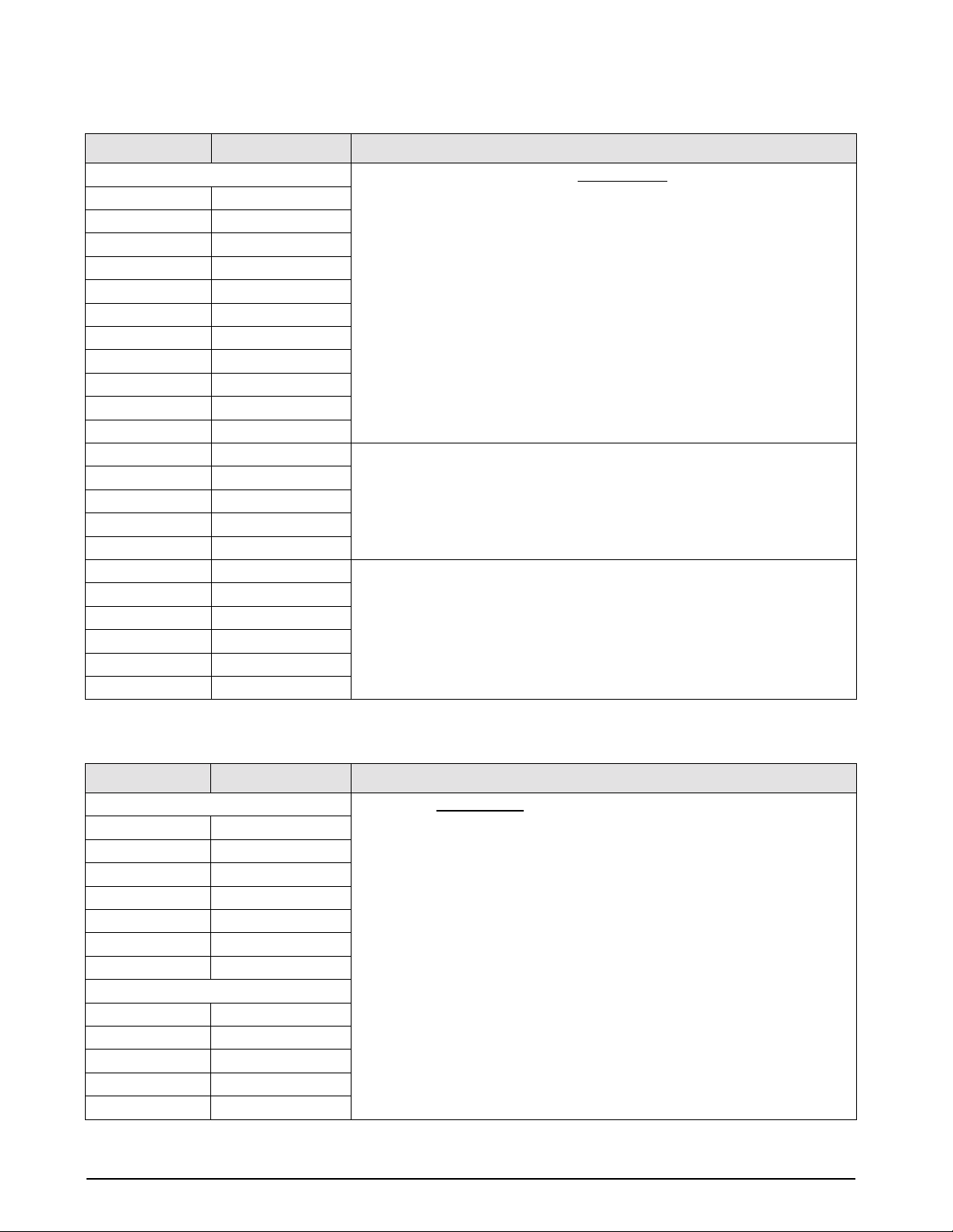

Prompt Display Interpretation Notes

Displayed Graduations Number of Displayed Graduations = Scale Capacity

15 500

110 1000

115 1500

120 2000

125 2500

130 3000

140 4000

150 5000

160 6000

180 8000

1 100 10000

1 120 12000 Not valid in NTEP legal-for-trade applications

1 140 14000

1 160 16000

1 180 18000

1 200 20000

1 300 30000 Not valid in legal-for-trade applications

1 400 40000

1 500 50000

1 600 60000

1 700 70000

1 800 80000

Resolution

Legal for trade values: 500–10000 graduations

These selections available only if option 1 (expanded resolution) is enabled (see

Section 4.1)

Table 3-2. Configuration Display Prompt 1

Prompt Display Interpretation Notes

Resolution / display divisions Resolution = Scale capacity

21 1

22 2

25 5

210 10

220 20

250 50

2 100 100

Decimal Point Location

30 No decimal point

3 0.0 xxxxx.x

3 0.00 xxxx.xx

3 0.000 xxx.xxx

3 0.0000 xx.xxxx

Displayed grads

Resolution is determined by the combination of parameters 2 and 3.

For example:

• If Parameter 2 = 1 and Parameter 3 = 0.00, display resolution is 0.01

• If Parameter 2 = 5 and Parameter 3 = 0.0, display resolution is 0.5

• If Parameter 2 = 10 and Parameter 3 = 0, display resolution is 10

Table 3-3. Configuration Display Prompts 2 – 3

16 UMC600 Installation Manual

Page 20

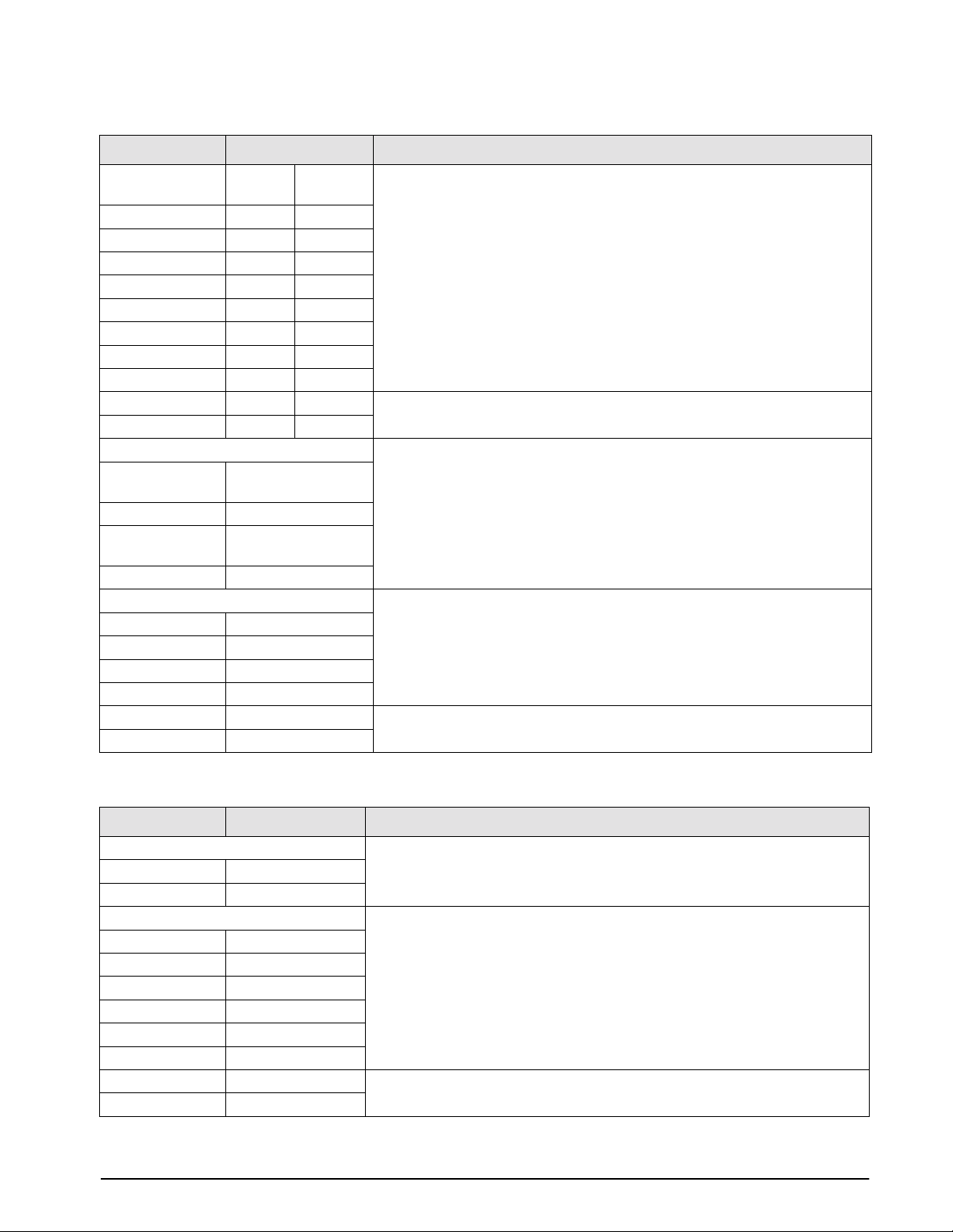

Prompt Display Interpretation Notes

No.

Digital Averaging

51 1 10/sec

52 2 5/sec

54 4 2.5/sec

58 8 1 sec

516 16 2 sec

532 32 4 sec

5A1 8-4-2 Variable

5A2 16-8-4 Variable

5A3 8-4-2 Variable Selection available when option 1 is enabled. see Section 4.1.

5A4 16-8-2 Variable

Tare Enable Selection of either fixed tare (Ft) or fixed tare and auto tare (both) in parameter 6

6 Atnr Auto (stored) tare only

6 Auto Auto (stored) tare only

6Ft Fixed (manual) tare

6 both Auto or fixed tare

AZM Capture Band (Displayed Grads)

7 oFF Off

7 0.5 ±0.5

71 ±1.0

73 ±3.0

75 ±5.0 Selection available when option 1 is enabled. See Section 4.1.

710 ±10.0

Averages

– no recall

only

Update

Rate

Display rate. Sets the update rate for displayed values.

allows up to a six digit fixed tare entry to be made using the numeric front panel

keys or, when configured for full duplex serial communication, a fixed tare entry

can be down loaded through the serial port.

Table 3-4. Configuration Display Prompts 5 – 7

Prompt Display Interpretation Notes

PAZ Aperture

8 1.9 ±1.9% of full scale

8FS 100% of full scale

Motion Band

Display Grads/sec

9 oFF Off

91 ±1.0

93 ±3.0

95 ±5.0

910 ±10.0

920 ±20.0 Selections available when option 1 is enabled

950 ±50.0

Table 3-5. Configuration Display Prompts 8 –10

Configuration 17

Page 21

Prompt Display Interpretation Notes

Display Base (lb/kg) lb/kg CONV key functions only if parameter 10 is set to 10 Con

10 lb lb display only

10 kg kg display only

10 Con lb (base) conversion

Table 3-5. Configuration Display Prompts 8 –10(Continued)

Prompt Display Interpretation Notes

Setpoint mode Four independent modes, three dependent modes. See Section 7.0 on page 55

11

Zero band control output Parameter 12 (zero band output) is not functional in certain setpoint

12 oFF off

12 1 ±1

12 2 ±2

12 3 ±3

12 4 ±4

12 5 ±5

12 6 ±6

12 7 ±7

12 8 ±8

12 9 ±9

12 10 ±10

12 20 ±20

12 30 ±30

12 40 ±40

12 50 ±50

Truck mode See “Truck Weighing Mode” in Section 6.7, page 53, for details

13

Serial configuration Section 3.2 for details

14

for settings.

configurations. See Section 7.0 on page 55 for details.

18 UMC600 Installation Manual

Table 3-6. Configuration Display Prompts 11 – 14

Page 22

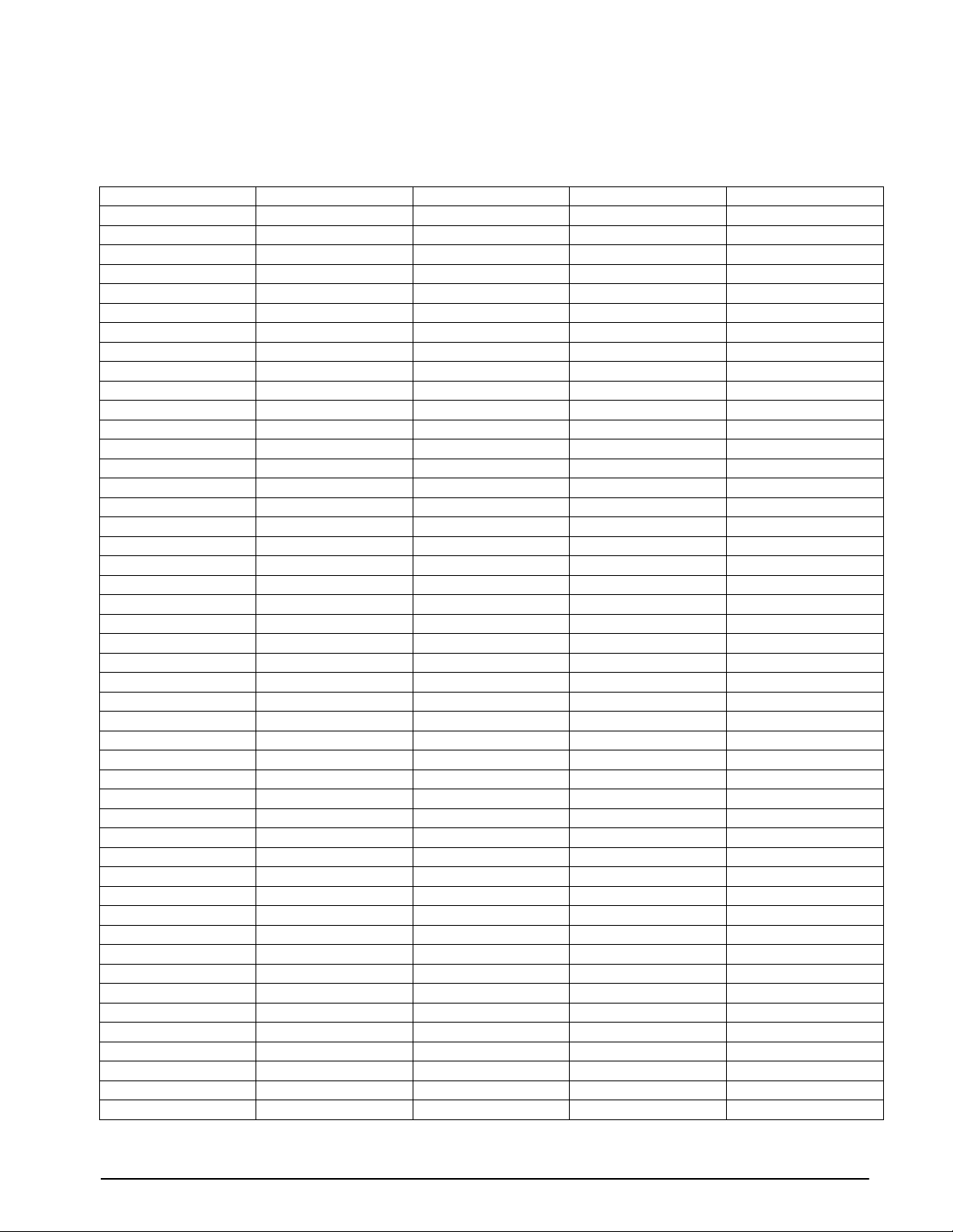

3.1.4 Normal Configuration Setup Parameters

You must be in the configuration mode (SW1-2 closed to set the indicator from the PC) to be able to write

configuration parameters. To write commands the following Jxxyyzz<CR> sequence must be used. The following

parameters and their setup numbers are as follows:

Parameter 1 = Grads J0600 03 = Both J1100 02 = Ov.Un J1103 06 = 6 J1200 14 = 50

J0100 00 = 500 J1101 00 = HL J1103 07 = 7

J0100 01 = 1000 Parameter 7 = AZM Capture J1101 01 = TGT J1103 08 = 8 Parameter 13 = Truck in/out

J0100 02 = 1500 J0700 00 = Off J1103 09 = 9 J1300 00 = Nor

J0100 03 = 2000 J0700 01 = .5 J1102 00 = Pos J1103 10 = 10 J1300 01 = Tru

J0100 04 = 2500 J0700 02 = 1 J1102 01 = Zer J1301 00 = Can

J0100 05 = 3000 J0700 03 = 3 J1103 00 = Off J1301 01 = Str

J0100 06 = 4000 J1103 00 = Pos J1103 01 = 1

J0100 07 = 5000 Parameter 8 = Zero Range J1103 01 = Zer J1103 02 = 2 J1302 00 = Off

J0100 08 = 6000 J0800 00 = 1.9 J1103 03 = 3 J1302 01 = On

J0100 09 = 8000 J0800 01 = FS J1104 00 = Pos J1103 04 = 4.

J0100 10 = 10000 J1104 01 = Zer Parameter 14 = Serial

J0100 11 = 12000 Parameter 9 = Motion Band J1104 00 = Off J1400 00 = Off

J0100 12 = 14000 J0900 00 = Off J1100 03 = Bat 1 J1104 01 = S1 J1400 01 = SI

J0100 13 = 16000 J0900 01 = 1 J1101 00 = Off J1104 02 = S1.P J1400 02 = DU

J0100 14 = 18000 J0900 02 = 3 J1101 01 = S1 J1104 03 = S1.D (J1401 – 1405 for SI and DU)

J0100 15 = 20000 J0900 03 = 5 J1101 02 = S1.P J1104 04 = S.P.D. J1401 00 = Net

J0900 04 = 10 J1101 03 = S1.D J1401 01 = GTN

Parameter 2 = Resolution J1101 04 = S.P.D. J1105 00 = Pos

J0200 00 = 1 Parameter 10 = Units J1105 01 = Zer J1402 00 = Off

J0200 01 = 2 J1000 00 = Lb only J1102 00 = Pos J1402 01 = 1

J0200 02 = 5 J1000 01 = Kg only J1102 01 = Zer J1106 00 = Off J1402 02 = 2

J0200 03 = 10 J1000 02 = Lb/Kg Conversion J1106 01 = 1 J1402 03 = 3

J0200 04 = 20 J1103 00 = Off J1106 02 = 2 J1402 04 = 4

J0200 05 = 50 Parameter 11 - Setpoints J1103 01 = S2 J1106 03 = 3

J0200 06 = 100 J1100 00 = Off J1103 02 = S2.P J1106 04 = 4. J1403 00 = Off

J1100 01 = SP J1103 03 = S2.D J1106 05 = 5 J1403 01 = Co

Parameter 3 = Decimal Point J1101 00 = Off J1103 04 = S.P.D. J1106 06 = 6 J1403 02 = De

J0300 00 = 0 J1101 01 = S1 J1106 07 = 7

J0300 01 = 0.0 J1101 02 = S1.P J1104 00 = Pos J1106 08 = 8 J1404 00 = 3

J0300 02 = 0.00 J1101 03 = S1.D J1104 01 = Zer J1106 09 = 9 J1404 01 = 6

J0300 03 = 0.000 J1101 04 = S.P.D. J1106 10 = 10 J1404 02 = 12

J0300 04 = 0.0000 J1100 04 = Bat2 J1404 03 = 24

J1102 00 = Pos J1101 00 = Off Parameter 12 = Zero Band J1404 04 = 48

Parameter 5 = Digital Averaging

J0500 00 = 1 J1101 02 = S1.P J1200 01 = 1

J0500 01 = 2 J1103 00 = Off J1101 03 = S1.D J1200 02 = 2 J1405 00 = Off

J0500 02 = 4 J1103 01 = S2 J1101 04 = S.P.D. J1200 03 = 3 J1405 01 = Co

J0500 03 = 8 J1103 02 = S2.P J1200 04 = 4 J1405 02 = De

J0500 04 = 16 J1103 03 = S2.D J1102 00 = Pos J1200 05 = 5

J0500 05 = 32 J1103 04 = S.P.D. J1102 01 = Zer J1200 06 = 6 (J1406 for SI only)

J0500 06 = A1 J1103 05 = tol. J1200 07 = 7 J1406 00 = 3

J0500 07 = A2 J1103 00 = Off J1200 08 = 8 J1406 01 = 6

Parameter 6 = Tare J1104 01 = Zer J1103 02 = 2 J1200 10 = 10 J1406 03 = 24

J0600 00 = ATNR J1103 03 = 3 J1200 11 = 20 J1406 04 = 48

J0600 01 = Auto J1103 04 = 4. J1200 12 = 30 J1406 05 = 96

J0600 02 = FT J1103 05 = 5 J1200 13 = 40

J1102 01 = Zer J1101 01 = S1 J1200 00 = Off J1404 05 = 96

J1104 00 = Pos J1103 01 = 1 J1200 09 = 9 J1406 02 = 12

Table 3-7. Configuration Setup Parameters

Configuration 19

Page 23

3.2 Serial Configuration

The UMC600 has two serial ports. Both serial ports 1 and 2 are ASCII-compatible, 20 mA current loop, or RS-232

outputs. The serial format is compatible with most printers, scoreboards, and other remote devices. Each output can

be disabled, set for print on demand mode, or set to output data continuously .

Table 3-8 shows the configuration selections for parameter 14, which control the configuration of ports 1 and 2.

Note: Settings for simplex (14.S1) and duplex (14.dU) are the same except that ports 1 and 2 must have the same

baud rate when in duplex mode.

Subparameter

Parameter

Net/Gross Tare Lb/Kg Conversion Key which affects associated parameters

14. oFF Serial communications disabled

14. SI Port 1 and 2: simplex

Selection

14.1 Demand print configuration in net mode

14.2 Delay after carriage return (CR) enable

14.3 Port 1 configuration

14.4 Port 1 baud rate

14.5 Port 2 configuration

14.6 Port 2 baud rate

Subparmeter Data

Selection

14.1Gtn

14.1nEt

14.2oFF

14.2 1

14.2 2

14.2 3

14.2 4

14.3oFF

14.3 Co

14.3 dE

14.4 3

14.4 6

14.4 12

14.4 24

14.4 48

14.4 96

14.5oFF

14.5 Co

14.5 dE

14.6 3

14.6 6

14.6 12

14.6 24

14.6 48

14.6 96

Explanation

Three-line output G-N-T

Single line, net print

No delay after CR

1 second delay after CR

2 seconds delay after CR

3 second delay after CR

4 second delay after CR

Port 1 disabled

Continuous output

Demand print

300 bps

600 bps

1200 bps

2400 bps

4800 bps

9600 bps

Port 2 disabled

Continuous output

Demand print

300 bps

600 bps

1200 bps

2400 bps

4800 bps

9600 bps

20 UMC600 Installation Manual

Table 3-8. Parameter 14 Configuration Parameters

Page 24

Parameter

Net/Gross Tare Lb/Kg Conversion Key which affects associated parameters

14. dU Port 1 duplex

Subparameter

Selection

14.1 Demand print configuration in net mode

14.3 Port 1 configuration

14.4

In full duplex 14.4

is the baud

selection for ports

1 and 2

14.5 Port 2 configuration

Subparmeter Data

Selection Explanation

14.1Gtn

14.1nE

14.2oFF

14.2 1

14.2 2

14.2 3

14.2 4

14.3oFF

14.3 Co

14.3 dE

14.6 3

14.6 6

14.6 12

14.6 24

14.6 48

14.6 96

14.3oFF

14.3 Co

14.3 dE

Three line output G-N-T

Single line, NET print

No delay after CR

1 second delay after CR

2 seconds delay after CR

3 second delay after CR

4 second delay after CR

Port 1 disabled

Continuous output

Demand print

Ports 1 and 2 baud rate

300 bps

600 bps

1200 bps

2400 bps

4800 bps

9600 bps

Port 2 disabled

Continuous output

Demand print

Table 3-8. Parameter 14 Configuration Parameters

All serial characters in the data format are in ASCII and consist of the following default settings:

Data Formats

1 Start Bit

7 Data Bits

1 Parity Bit (Odd Parity)

1 Stop Bit

Table 3-9. Data Formats

The transmission of serial data can be initiated in either demand mode, continuous mode, or RS485. Refer to

Section 6.6 on page 51 for advanced detailed information on serial configuration options.

Configuration 21

Page 25

4.0 Options Configuration

The UMC600 offers a selection of optional features that

are available in the configuration of the indicator. The

options setup mode allows the operator to expand the

capabilities of the indicator. The available features are:

• Option 1 - Expanded resolution

• Option 2* - Analog output

• Option 3 - Time and date

• Option 4 - Accumulator

• Option 5* - Local area network\tag\id\counter

• Option 6 - Five-point linearization

• Option 7 - Smart serial I/O

• Option 8* - Analog output relay

• Option 9 - Keyboard lockout

• Option 10 - Setpoints

• Option 11 - Remote Input

NOTE: *Options 2, 5, and 8 require additional

hardware support. Options 1 through 11 are currently

available in the standard EPROM version 15.

To access digital option configuration, close switches

SW1-2 and 3 (Figure 4-1). Press and hold the ENT key

until OPtion appears on the display. If the option mode

is not enabled (all options turned off), dashes appear

across the display (- - - - -).

lb/kg

CONV

ENT

lb

kg

MOTION

PRINT

1 SET

POINT

CE

2 SET

POINT

ZERO

NET

GROSS

DEAD LOAD (3)

CONF (2)

CAL (1)

NORM

1

OPEN

CAPACITY

TARE

NET

GROSS

162738495

342

ZERO

RECALL

600 x 0.1

TARE

0

Figure 4-1. Close Switches SW1-2 and 1-3 for Option

Configuration

In the option mode, primary function keys (ZERO,

GROSS/NET, etc.) operate as secondary function keys

(Figure 4-2).

lb/kg

CONV

CE

ENT

lb

kg

MOTION

PRINT

1 SET

1 SET

POINT

POINT

PARAMETER

SELECT

2 SET

POINT

ZERO

NET

GROSS

ZERO

RECALL

SELECT

MODEL

OPTION

700

TARE

CAPACITY

NET

GROSS

162738495

ENABLE

1 2 4 5

DISABLE

TARE

600 lb. X 0.1

OPTION

MENU

0

Figure 4-2. Front Panel Keys with Alternate Functions in

Options Menu

Use the ZERO key to select options 1 through 11 or the

TARE RECALL key to scroll backward through the

options. To enable a selected option, use the

GROSS/NET key .

Some options, once enabled, may have an option

submenu available. Use the

TARE key to access the

option submenu. To make parameter selections in the

option submenu, use the

lb/kg CONV key. Display

prompting is provided in each case.

Key Functions Summary

Use the list below (Figure 4-3), as a quick reference

when selecting and configuring the options.

ZERO

ZERO

GROSS

TARE

lb/kg

CONV

PRINT

RECALL

ZERO – Increments option number

NET

NET/GROSS – Turns options ON/OFF

TARE – Steps through subparameters or functions as

ENTER for numeric changes

UNITS – Selects subparameters or digit position/decrements

digit for numeric changes

PRINT – Increments digit for numeric entries

TARE

TARE RECALL – Provides backstep in configuration mode

22 UMC600 Installation Manual

162738495

Figure 4-3. Quick Key Functions

0 – 9 – Used to enter numeric values directly ,

CE

including ZERO/SPAN values in Option 2

0

or TIME/DATE in Option 3 mode

ENT

Page 26

4.1 Option 1 – Expanded Resolution

XXXXXXX XXXXXXXXXXXXXXXXXXXXX OPTION 5

OPTION 4

OPTION 3

OPTION 2

CALIBR

CONFIG

OPTION 6 OPTION 7 OPTION 8 OPTION 9 OPTION 10

OFF

ON

EXPANDED

RESOLUTION

OPTION 1

OPTION 11

Enabling option 1 increases the indicator resolution by allowing display graduation selections beyond the normal

20,000 in parameter 1 of the configuration mode.

Up to 80,000 displayed graduations are available when this option is on; however, applying such high gains to the

data may cause undesirable display instability in some applications.

The expanded resolution (OP.1) is shown in T able 4-1

Prompt Display Interpretation

Expanded Resolution

OP.1 oF

OP.1 on

Option 1 Menu

Off

On (expanded up to 80,000 displayed graduations)

Table 4-1. Expanded Resolution Options

Figure 4-4. Option 1 Menu

and its menu structure in Figure 4-4.

Refer to Section 4.12.3 on page 46 for individual serial command option parameters for Option 1.

Options Configuration 23

Page 27

4.2 Option 2 – Analog Output Option

Indicator option 2 provides settings for zero, span, and trim adjustments for the analog output. The settings are all

digital therefore no potentiometers are required. During the trim adjustments for zero/span, the analog output is

forced to the zero/span previously selected in option mode parameters 2.5 and 2.6. While reading the analog output,

the trim is increased or decreased from 0 to ± 175 until the reading corresponds with the values entered in

parameters 2.5 and 2.6.

Option 2 enables the analog output option. The following features of analog output are:

• Converts serial data into analog: 0–10 VDC or 4–20 mA.

• Ordered as a kit, it must be operated remotely from the digital weight indicator.

• Self powered, 115/230 VAC provides isolated output.

• Automatic data checking/verification.

• Analog output tracks gross, net, or displayed weight.

• Full digital calibration (indicator front panel).

Serial data from the indicator is modified to include scaled information specifically for the analog output module.

The standard communications are also included to allow the module to pass-through printer or scoreboard

information.

NOTE: The serial pass-through does not have duplex capability.

The analog output is fully isolated with its own power supply and current loop communications. The analog module

can be located remotely up to 1000 feet from the indicator. After wiring and setting the module’s baud rate, the

remaining setup and calibration is done at the indicator.

4.2.1 Specifications

Current output is 4–20 mA with a maximum impedance less than or equal to 600Ω.

Voltage output is 0–10 VDC with a minimum load resistance of 1kΩ.

4.2.2 Test Modes

Switch settings are provided to force the analog output to zero, full scale, or to provide a continuous sawtooth

waveform for system checking.

4.2.3 Error Checking

Serial data is continually checked for parity, valid characters, and presence of communication. Loss of data is

indicated by forcing the analog output to a minimum value of -0.5 VDC or 3.2 mA (approximate). If the indicator is

in an overload condition, the analog output is forced to 5% over full scale. With the 4–20 mA output, an additional

alarm is provided to detect the lack of current (break) in the loop.

4.2.4 Communication Verification

An LED (DS1) is provided on the analog module:

• ON = Communications OK

• Pulse = Communications errors

• OFF = No power

24 UMC600 Installation Manual

Page 28

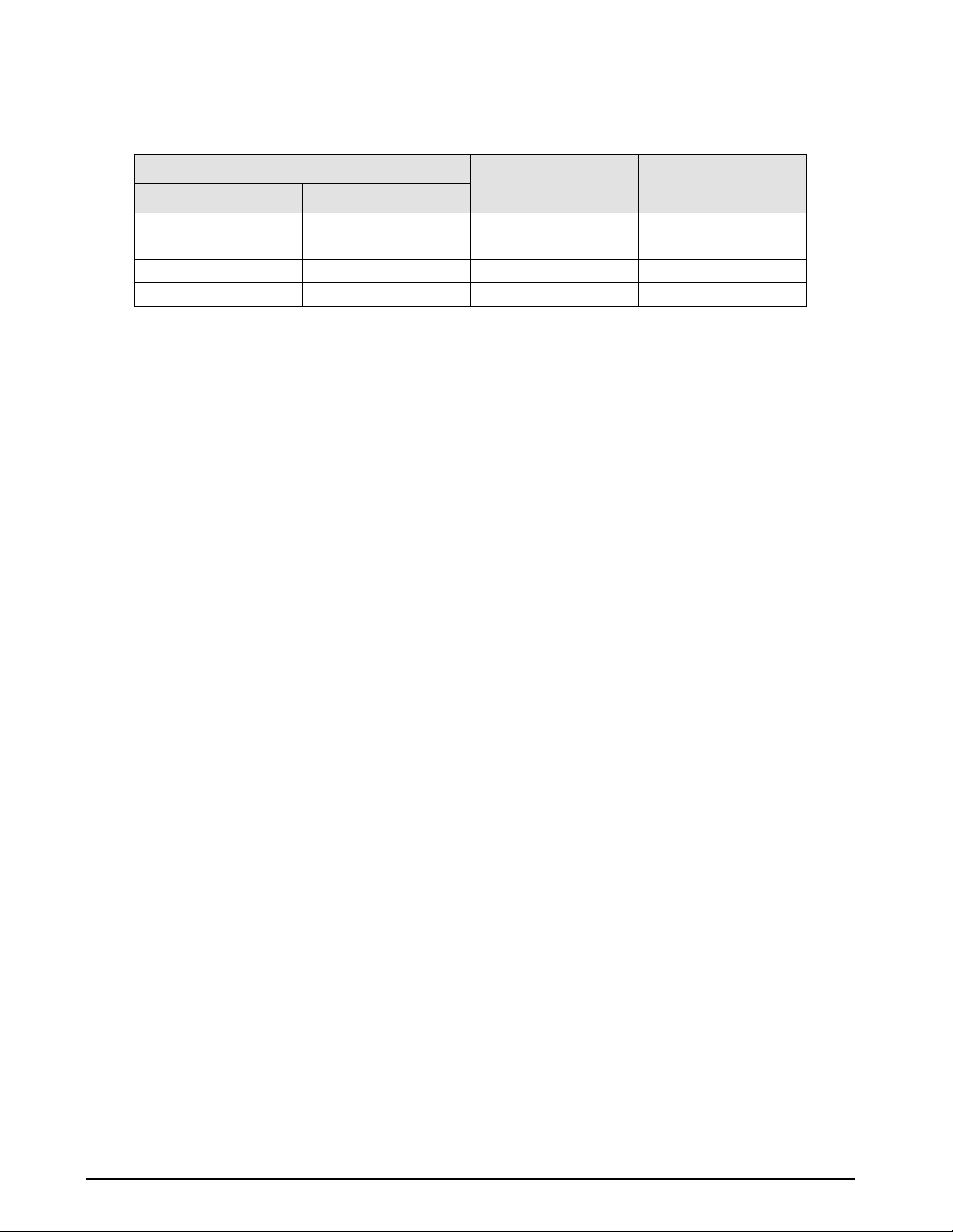

Table 4-2 shows the option 2 configuration parameters.

Prompt

Option

Display

Interpretation Notes

All off -------- Mode not enabled (options 1 through 10

turned off)

OP.2 OP.2 o F

OP.2 o n

2.1 dSP

2.2 P.1

2.3 OFF

2.4

2.5 Zr Enter weight value for analog zero using

2.6 FS Use the same procedure as 2.5 to enter

2.7 Zr.A ZERO TRIM: While measuring analog

Off Analog option disabled

On Analog option enabled

Analog tracks display

Gr

Analog tracks gross weight

net

Analog tracks net weight

Indicator data out on port 1 (to analog)

P.2

Indicator data out on port 2 (to analog)

Analog module does not pass serial data

dE

Analog module outputs serial on demand

Co

Analog module outputs serial continuously

Pass-through serial output baud rate

1200 baud

12

2400 baud

24

4800 baud

48

9600 baud

96

the numeric keys. The TARE key stores

new value; the display responds with

ENTER.

analog full scale value.

output, use lb/kg CONV and PRINT keys

to increment/decrement the zero value.

Increment/decrement function forces an

analog cal mode zero output. The TARE

key stores the new value.

—

—

—

Use standard indicator setup for serial configuration

under menu 14 (configuration Switch S-2 closed) to

establish communications before using the option 2

menu. Port 1 from the indicator to the analog module

must be set for the desired baud rate and be in

continuous output mode. In the option 2 menu, set the

indicator port to 1. On analog board S1, set baud rate

switches (1 and 2) to match menu 14.

—

The display for parameters 2.5 through 2.8 alternate

between the parameter selection and the actual data

value currently entered. This alternation will continue

until the data for the parameter has been increased or

decreased.

TARE key to store. The display will again resume

switching between parameter and data.

NOTE: After entering new data, use

2.8 SP.A SPAN TRIM: Same as 2.7 except a span

analog cal mode output is provided.

Table 4-2. Option 2 Configuration

Options Configuration 25

Page 29

S2

S

Figure 4-5. Analog Module Setup and Wiring

1 23456789

456

2

1

3

SW1 Setting

7

89

Baud rate

1 2

1200 Off Off

2400 On Off

4800 Off On

9600 On On

Mode 3 4

Normal operation Off Off

0 VDC/4 mA (test only) On Off

10 VDC/20 mA (test only) Off On

0–10 VDC/4–20 mA ramp (test only) On On

Table 4-3. Baud Rate and Switch SW1 Settings

TB1 Description TB2 Description

1 4–20 mA 1 Zero

2Ground 2 Gross/Net

3 0–10 Vdc output 3 Tare

4 Alarm 4 Start

5Ground A 5 Ground (–20 mA input) common

6 +20 mA TXD 6 RS-232 TXD

7 –20 mA TXD 7 +5 VDC

8 +20 mA RXD 8 –20 mA

9 -20 mA RXD (input) 9 Demand print

NOTE: Jumper TB1-8 to TB2-7 (5 VDC) to make the analog output module an active device.

Table 4-4. Description of Terminal Boards TB1 and TB2

26 UMC600 Installation Manual

Page 30

4.2.5 Analog Wiring to Host Indicator

The following diagram illustrates the wiring layout to the host indicator.

RX+

TX+

RXTX-

Active 20 mA

TB4

3

4

5

6

TX+

6

RX+ (passive)

8

TX- (analog)

7

9

RX-

TX+

active

TX-

PORT 2

20 mA

TB4

▲

1

2 Rx - (analog)

▲

Rx+ (passive)

8

9

TB2

PORT 1

Figure 4-6. Analog Wiring to Indicator

4.2.6 Analog Module Serial Pass-Through

The serial data from the host digital weight indicator is provided as a simplex output with the same format as the

host.

ANALOG TB2

DEMAND

COMMON

+5 (-TD)

TX(-TD)

9

5

7

8

➤

➤

PRINT

20 mA

6

TX

RET

5

RS-232

KBY7116/4

Figure 4-7. Pass Through Wiring

The Option 2 configuration parameters are graphically illustrated in Figure 4-8, shown below.

CONFIG

OFF

CALIBR

OPTION 1

ON

2.1

dSP

Gr

net

OPTION 2

2.2

P.1

P.2

OPTION 3

OPTION 4

2.3

OFF

dE

Co

Figure 4-8. Option 2 Menu

XXXXXXX XXXXXXXXXXXXXXXXXXXXX OPTION 5

OPTION 6 OPTION 7 OPTION 8 OPTION 10

2.4

12

24

48

96

2.5

Zr

2.6

FS

OPTION 9

2.7 2.8

Zr.A

Refer to Section 4.12.3 on page 46 for individual serial command option parameters for Option 2.

OPTION 11

SP.A

Options Configuration 27

Page 31

4.3 Option 3 – Time and Date

The main purpose for time and date is to allow the operator to quickly change the time when the time changes

between standard and daylight savings time.

The time and date clock is attached to the battery-backed memory (U4) and will continue running when the

indicator is off.)

Prompt Display Interpretation Notes

Time and date option Time and date settings can be directly

OP.3 oFF Off (time and date disabled)

OP.3 On On (time and date enabled)

3.1 Std

dLs

3.2 12

Standard Time

Daylight Savings Time

Selects 12- or 24-hour time display

24

3.3 A

AM (A) or PM (P) setting when 12-hour clock is selected

P

3.4 Un

Ab

Selects the location of printed time and date data: under (Un),

above (Ab), or on the same line (On) as weight data.

on

3.5 LEtnOPrints date in letters (LEt) or numbers (nO).

For example: Sept 1, 1999 vs. 09/01/99

3.6 tI Time. Use numeric keys to enter the time in hours, minutes and

seconds (HHMMSS), then press the

ENTER key (see Note

below)

3.7 dA Date. Use numeric keys to enter the date in month, day and

year format (MMDDYY), then press the

ENTER key (see Note

below)

accessed in normal running mode by

holding down both the

0 and 3 keys for

a few seconds. The operator can then

make changes without using option

switches. To exit, press the

0 key.

The display for parameters 3.5 and 3.6

alternates between the parameter and

the current data value. This continues

until new data is entered using the

numeric keys. After entering new data,

press

ENTER again to alternate the

display.

Table 4-5. Option 3 Configuration Selections

NOTES:

• Prior to setting the time and date, select the current time (dLs–daylight savings or Std–standard). This

feature selection allows the operator to increment or decrement the time by one hour when clocks are

changed from dLs or Std without having to re-program the entire time.

•Time and date can be directly accessed in normal running mode by pressing both the

0 and 3 keys for a fe w

seconds. This allows the time or date to be changed without using the option switches. To exit you must be

at 3.1 to 3.5 and then press the 0 key. This sequence does not work with 3.6 or 3.7.

Option 3 configuration parameters are graphically illustrated in Figure 4-9.

CONFIG

OFF

CALIBR

OPTION 1

ON

TIME/DATE

Off

On

OPTION 2

DLS

Std.

dLs

OPTION 3

OPTION 4

HR

12

24

XXXXXXX XXXXXXXXXXXXXXXXXXXXX OPTION 5

Figure 4-9. Option 3 Menu

OPTION 6 OPTION 7 OPTION 8 OPTION 10

A–PT

Am

Pm

POS

Under

Above

On

TYPE

LEt

letter

nO

number

OPTION 9

hh.mm.ss

OPTION 11

TI DATE

mm/dd/yy

Refer to Section 4.12.3 on page 46 for individual serial command option parameters for Option 3.

28 UMC600 Installation Manual

Page 32

4.4 Option 4 – Accumulator

The accumulate function is used to add weight data to a register for later access by the user. The accumulator can

keep a running total of weights entered, either automatically using setpoints, or manually pressing the

when the accumulate function is active.

The UMC600 has a ten digit accumulator available when Option 4 is enabled. To protect against multiple

accumulations of data, the accumulator option has a selectable return to

ZERO ACCUMULATION BAND feature.

This feature ensures that the weight display must return to a value inside the zero band before the accumulator can

be performed.

Caution

!

Option Prompt Display Description

OP.4 OP.4 oF

Parameter 10 in the configuration mode should be set for lb or kg base only. This avoids adding

incorrect data to the accumulator when switching between lb base and kg conversion. Clear the

total whenever the capacity is changed.

off

OP.4 on

4.1 oFF

on – accumulator enabled

Zero band “off” data accumulator, anytime the

1

± 1 Display graduations

2

± 2 Display graduations

3

± 3 Display graduations

4

± 4 Display graduations

5

± 5 Display graduations

6

± 6 Display graduations

7

± 7 Display graduations

8

± 8 Display graduations

9

± 9 Display graduations

10

± 10 Display graduations

20

± 20 Display graduations

30

± 30 Display graduations

40

± 40 Display graduations

50

± 50 Display graduations

PRINT key is pressed.

Table 4-6. Option 4 Configuration Parameters

PRINT key

Accumulation

Accumulators are activated in the following ways.

• Activated by pressing the

• Activated by the

PRINT COMMAND in the auto batch mode (parameter 11 bAt2).

PRINT key.

• If the data is valid (not in motion, overload, etc.) the display data is added to the content of the accumulator

and the display prompts with

To prevent multiple accumulations of weight data, a

PRINT when configured for demand print or Acc if not in demand.

ZERO threshold detection band (in display graduations),

requires the display data to return to zero before another accumulation/print can be performed.

Total Recall

To view the contents of the accumulation register on the display, use the following steps: press TARE RECALL

which is redefined as TOTAL RECALL key when option 4 is enabled. The tare recall LED flashes indicating the

instrument is in the total recall mode. While in total recall, the contents of the accumulator can be printed out when

the

PRINT key is pressed. If the serial output is configured for continuous output, the total is continuously printed

out anytime the indicator is placed in total recall mode.

Total Reset

The total can be cleared to zero when in the TOT AL RECALL display mode by:

1. Press the

2. Press

Clear.

CE key. The unit prompts with the display message Sure.

CE a second time to clear the contents of the accumulator resetting it back to zero. The display prompts

Refer to Section 4.12.3 on page 46 for individual serial command option parameters for Option 4.

Options Configuration 29

Page 33

4.5 Option 5 – Expanded Serial Communications

The expanded serial communications options provide RS-485 communications for the UMC600. Option 5 features

include:

• Duplex communication for up to two weight indicators on a single serial port.

• RS-485 half-duplex with U21 installed.

• RS-485 full-duplex available with U21 and the

• Direct keyboard access to the indicator address in normal operating mode.

• Poll/answer protocol.

• Unit address 1 - 98.

•Tag mode that adds the programmed address to standard serial output format.

• Stored ID mode allows an identification number to be held until written over by a new one.

• Counter sequentially counts on each valid print. Counts from 1 – 999,999.

TAG/LAN

Under option 5 there are two modes of serial operation that can be selected:

•TAG mode – Adds a two digit address to the standard serial format which “tags” printed data with the

UMC600’s address. This feature is useful when more than one indicator is set up on a site and serial data

needs to be identified with the indicator from which it was generated.

• LAN mode – Local Area Network can be configured as a two wire (half duplex) RS-485 serial

communication by installing the driver chip into socket U21 or 5.2 LAN (full duplex) RS-485/RS422 with

the additional installation of the KBT7116-13 kit.

Option Prompt Display Explanation Additional Notes

OP.5 OP.5 oF

OP.5 on

5.1. tAg

LAn

5.2. Addr Allows selection of indicator address from

5.3. oF

on

5.4. oF

on

5.5. cnt Preset initial counter value from 0 – 999,999 See notes from 5.2

off

on Option 5 enabled

Tag mode (data labeled with an address

Local Area Networking (RS-485)

1 – 98).

ID held option off

ID option enabled

Counter off

Counter option enabled

KBT7116-13 kit installed.

When either 5.2 or 5.5 is selected, the display

alternates between 5.2 Addr or 5.5 cnt, respectively

and its current numeric value. The alternation of the

display occurs until a new value is selected.

Addresses can be accessed in the normal

operating mode by pressing

simultaneously. Pressing

seconds allows changes to be made without having

to access the dip switches. To exit, press

RECALL for several seconds.

0 and 5

0 and 2 for several

TARE

Table 4-7. Option 5 Configuration

NOTE: Port 1 configuration (parameter 14) must be set for duplex, (du), demand mode (de), and the appropriate