Page 1

DOT MATRIX PRINTER

SP500 SERIES

USER’S MANUAL

MODE D’EMPLOI

BEDIENUNGSANLEITUNG

MANUALE DI ISTRUZIONI

Page 2

Federal Communications Commission

Radio Frequency Interference

Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device must

accept any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful interfer-ence

to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at his own

expense.

This statement will be applied only for the equipments marketed in U.S.A.

FCC WARNING

Changes or modifications not expressly approved by the party responsible for compliance

could void the user’s authority to operate the equipment.

For compliance with the Federal Noise Interference Standard, this equipment requires a

shielded cable.

For RF interference suppression, if a ferrite core is provided with this device, affix it to the

interface cable.

Statement of

The Canadian Department of Communications

Radio Interference Regulations

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

The above statement applies only to printers marketed in Canada.

Trademark acknowledgments

SP500 Series: Star Micronics Co., Ltd.

ESC/POS: Seiko Epson Corporation

Notice

• All rights reserved. Reproduction of any part of this manual in any form whatsoever,

without STAR’s express permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the

time of going to press. However, should any errors be detected, STAR would greatly

appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this

manual.

©

Copyright 2002-2010 Star Micronics Co., Ltd.

Page 3

TABLE OF CONTENTS

1. Outline ...............................................................................................................1

2. Unpacking and Installation ................................................................................2

2-1. Unpacking ..............................................................................................2

2-2. Locating the Printer ...............................................................................3

2-3. Handling Care ........................................................................................3

2-4. Maintenance ...........................................................................................3

3. Parts Identification and Nomenclature ..............................................................4

4. Connecting Cables and Power Cord .................................................................. 6

4-1. Connecting the Interface Cable .............................................................. 6

4-2. Connecting to a Peripheral Unit ............................................................. 7

4-3. Connecting the Power Cord ...................................................................8

4-4. Turning Power On .................................................................................9

4-5. Attaching the Rear Cover....................................................................... 9

4-6. Installing the Cable .............................................................................. 10

4-7. Switch Blind Installation .....................................................................11

5. Loading the Ribbon Cartridge and Paper ........................................................12

5-1. Tear Bar Model ....................................................................................12

5-2. Auto Cutter Model ...............................................................................15

5-3. Installing the Roll Paper Guide ............................................................18

5-4 Clearing Paper Jams.............................................................................19

6. Control Panel and Other Functions ................................................................. 20

6-1. Control Panel .......................................................................................20

6-2. Basic Indicators .................................................................................... 20

6-3. Errors ...................................................................................................21

6-4. Adjustment Mode ................................................................................23

Appendix A: General Specifications .................................................................104

Appendix B: Serial Interface .............................................................................107

B-1. Pins and Signal Names ......................................................................107

B-2. Interface Connections ........................................................................108

Appendix C: Parallel Interface ..........................................................................109

C-1. Table of Connection Signals for Each Mode ..................................... 109

Appendix D: DIP Switch Setting ......................................................................111

D-1. Parallel Interface ................................................................................ 111

D-2. Serial Interface ...................................................................................112

Appendix E: Memory Switch Settings ..............................................................114

Appendix F: Peripheral Unit Driver Circuit ......................................................115

Appendix G: Adjusting the Dot Alignment Mode ............................................117

Appendix H: Black Mark Sensor Alignment Mode ..........................................119

Page 4

1. Outline

ENGLISH

The SP500 Series Serial Impact Dot Matrix Printer is designed for use with

electronic instruments such as POS, banking equipment, computer peripheral

equipment, etc.

The major features of the SP500 series are as follows:

1. Bi-directional printing at approx. 4 lines/sec.

2. Serial interface or parallel interface.

3. The data buffer allows the unit to receive print data even during printing.

4. Peripheral unit drive circuit enables control of external devices such as cash

drawers.

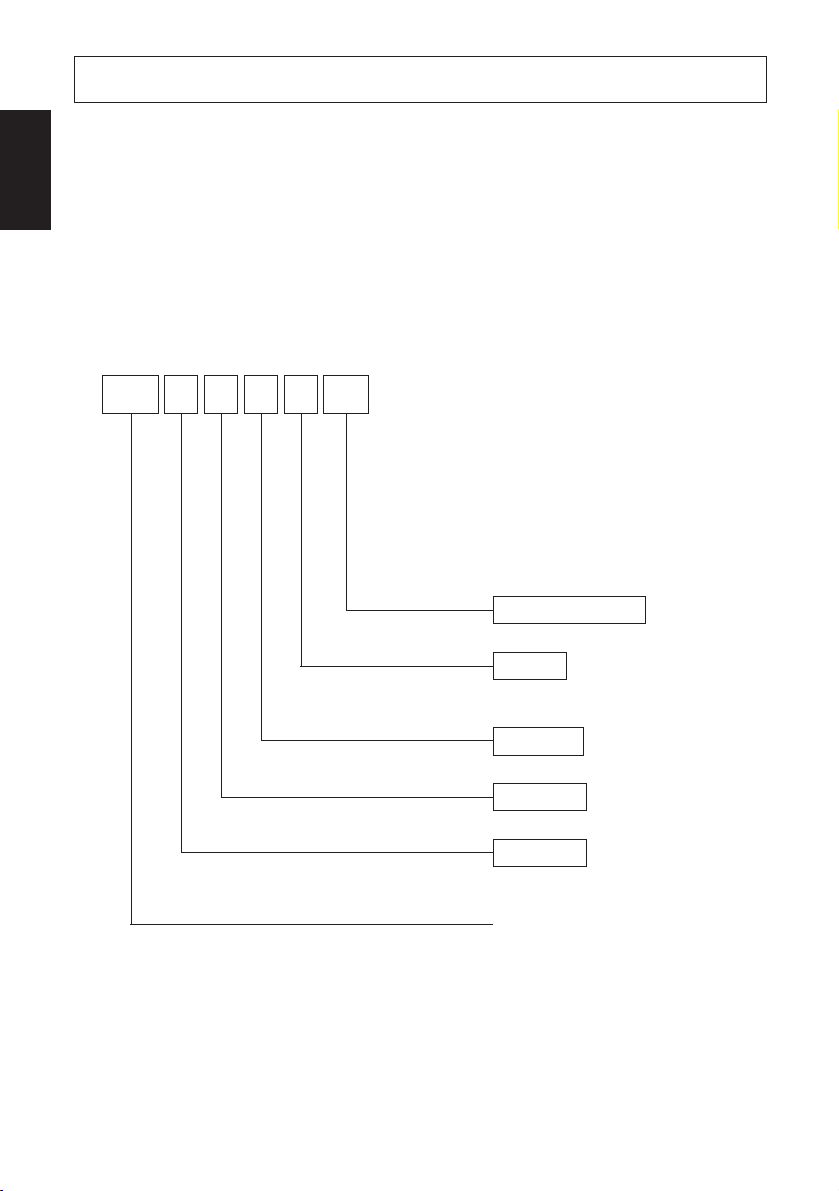

SP5 1 2 M D 42

No. of print columns

42 : 42 columns (16.9 CPI)

Interface

D : Serial interface (RS-232C)

C : Parallel interface

Paper feed

M : Friction paper feed method

Mechanism

2 : Single color, 42 columns (16.9 CPI)

Printer type

1 : Tear bar type

4 : Auto cutter equipped type

SP500 series printer

– 1 –

Page 5

OFF

ON

ERROR

POWER

FEED

2. Unpacking and Installation

OFF

ON

ERROR

POWER

FEED

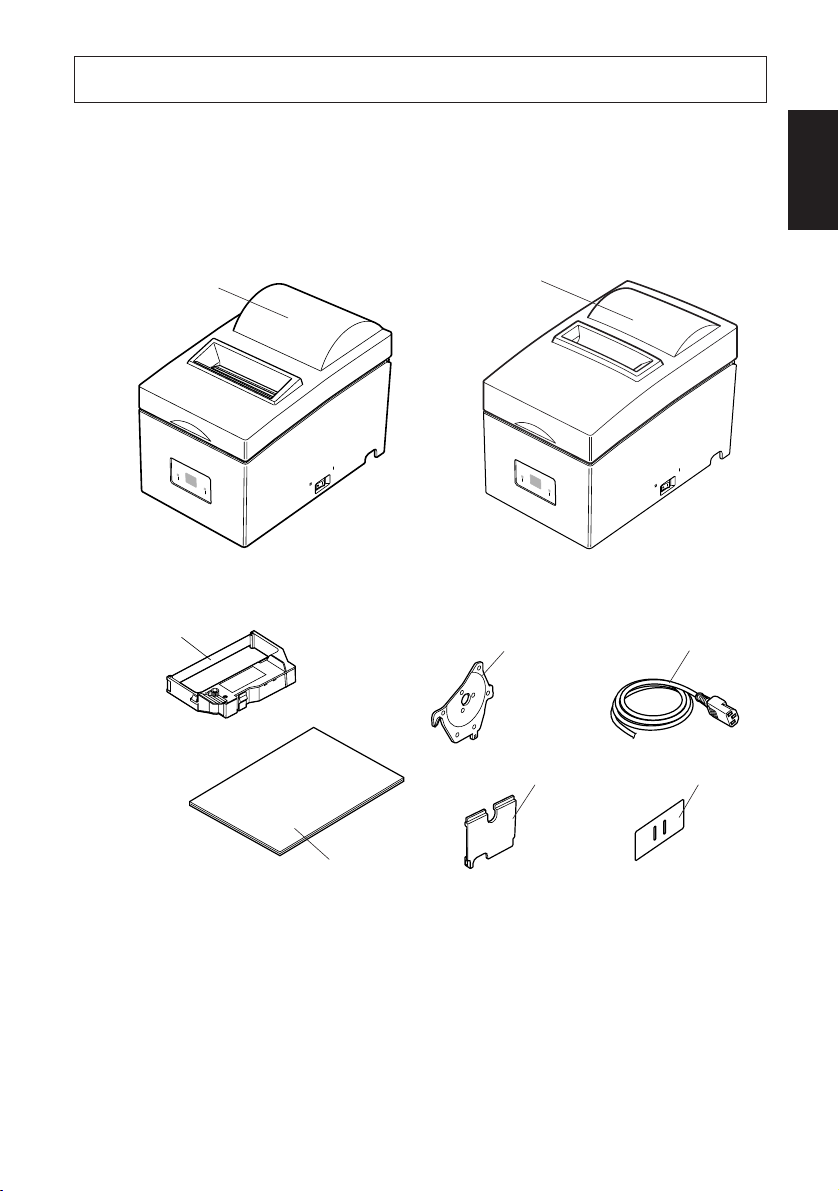

2-1. Unpacking

After unpacking the unit, check that all the necessary accessories are included in

the package.

Tear bar model Auto cutter model

Printer

Printer

ENGLISH

E

R

R

O

R

F

E

E

D

P

O

W

E

R

Ribbon cartridge

V

H

ON

OFF

User’s manual

Fig. 2-1 Unpacking

ERRO

R

F

E

E

D

POW

ER

Rear cover

V

H

N

O

F

F

O

Power cordRoll paper guide

Switch blind

If anything is missing, contact the dealer where you bought the printer and ask

them to supply the missing part. Note that it is a good idea to keep the original box

and all the packing materials just in case you need to pack the printer up again and

send it somewhere at a later date.

– 2 –

Page 6

2-2. Locating the Printer

When you locate your printer, keep the following tips in mind:

ENGLISH

1. Protect your printer from excessive heat such as direct sunlight or heaters, and

keep it away from moisture and dust.

2. Place the printer on a firm, level surface which is fairly vibration-free.

3. A steady power supply that is not subject to power surges should be connected

to the printer.

For example, do not connect it to the same circuit as a large, noise-producing

appliance such as a refrigerator or an air conditioner.

4. Make sure the line voltage is the voltage specified on the printer’s identification plate.

5. To disconnect the printer, the plug has to be disconnected from the wall socket,

which has to be located close to the printer, and easy to access.

2-3. Handling Care

1. Be careful not to drop paper clips, pins or other foreign matter into the unit as

these cause the printer to malfunction.

2. Do not attempt to print when either paper or ribbon cartridge is not located in

the printer, otherwise the print head can be damaged.

3. Do not open the cover while printing.

4. Do not touch the print head immediately after printing as it gets very hot.

5. Use only roll paper that is not glued to the core.

6. When the paper end mark appears on the paper, replace the roll paper before

it runs out.

2-4. Maintenance

Essentially, your printer is a robust piece of equipment, but should be treated with

a modicum of care in order to avoid malfunctions. For example:

1. Keep your printer in a “comfortable” environment. Roughly speaking, if you

feel comfortable, then the environment is suitable for your printer.

2. Do not subject the printer to physical shocks or excessive vibration.

3. Avoid over-dusty environments. Dust is the enemy of all precision mechanical devices.

4. To clean the exterior of the printer, use a cloth barely dampened with either

water with a little detergent or a little alcohol, but do not allow any liquid to

fall inside the printer.

5. The interior of the printer may be cleaned with a small cleaner or a compressed-air aerosol (sold for this purpose). When performing this operation,

be sure not to bend or damage any cable connections or electronic components.

– 3 –

Page 7

ON

OFF

OFF

ON

ERROR

POWER

FEED

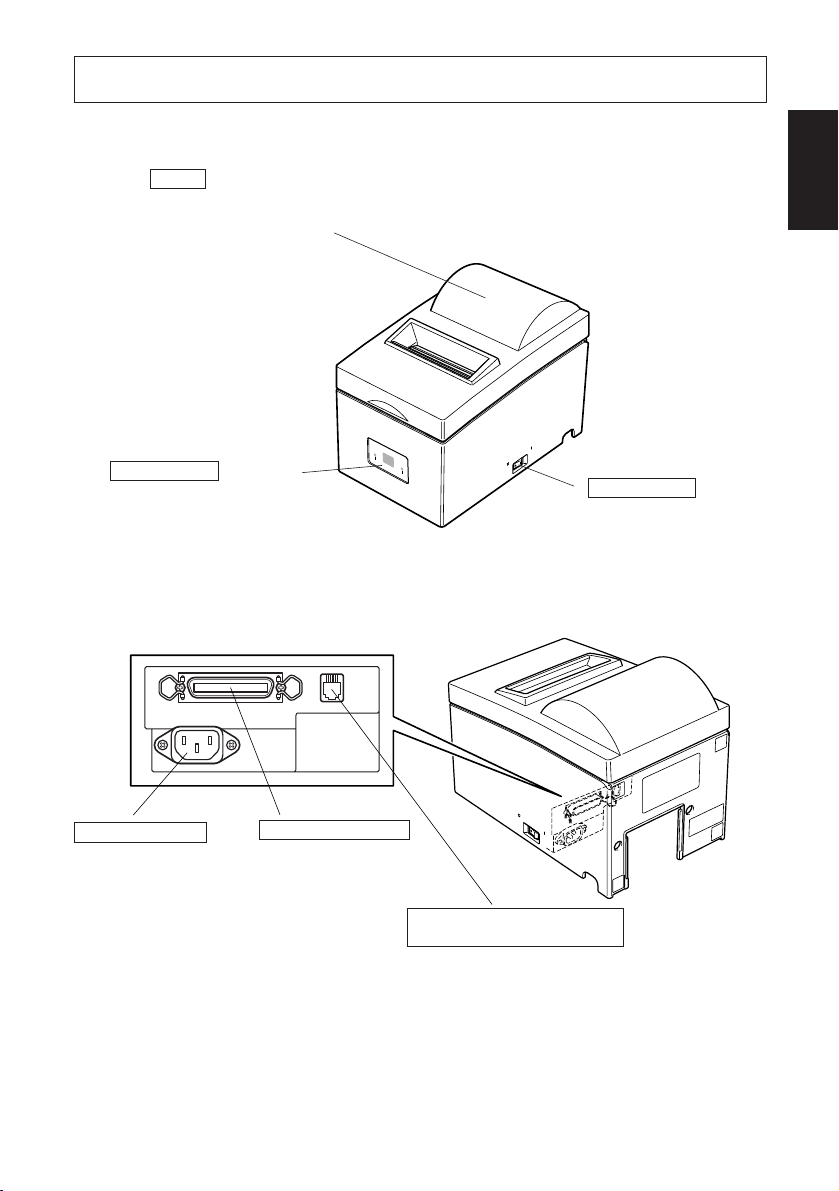

3. Parts Identification and Nomenclature

Tear bar model

Cover

Protects the printer from dust and reduces noise.

Do not open the cover while printing.

Control panel

Features one control switch and

two indicators to indicate printer

status.

ENGLISH

V

H

N

E

R

R

O

R

F

E

E

D

P

O

W

E

R

O

F

F

O

Power switch

Turns printer power on

and off.

Power connector

For connection of

the power cord.

O

F

Interface connector

Connects the printer with

F

O

N

host computer.

Peripheral unit drive circuit

connector

Connects to peripheral units

such as cash drawers, etc.

Do not connect this to a

telephone.

Fig. 3-1 External view of the printer (Tear bar model)

– 4 –

Page 8

ON

OFF

OFF

ON

ERROR

POWER

FEED

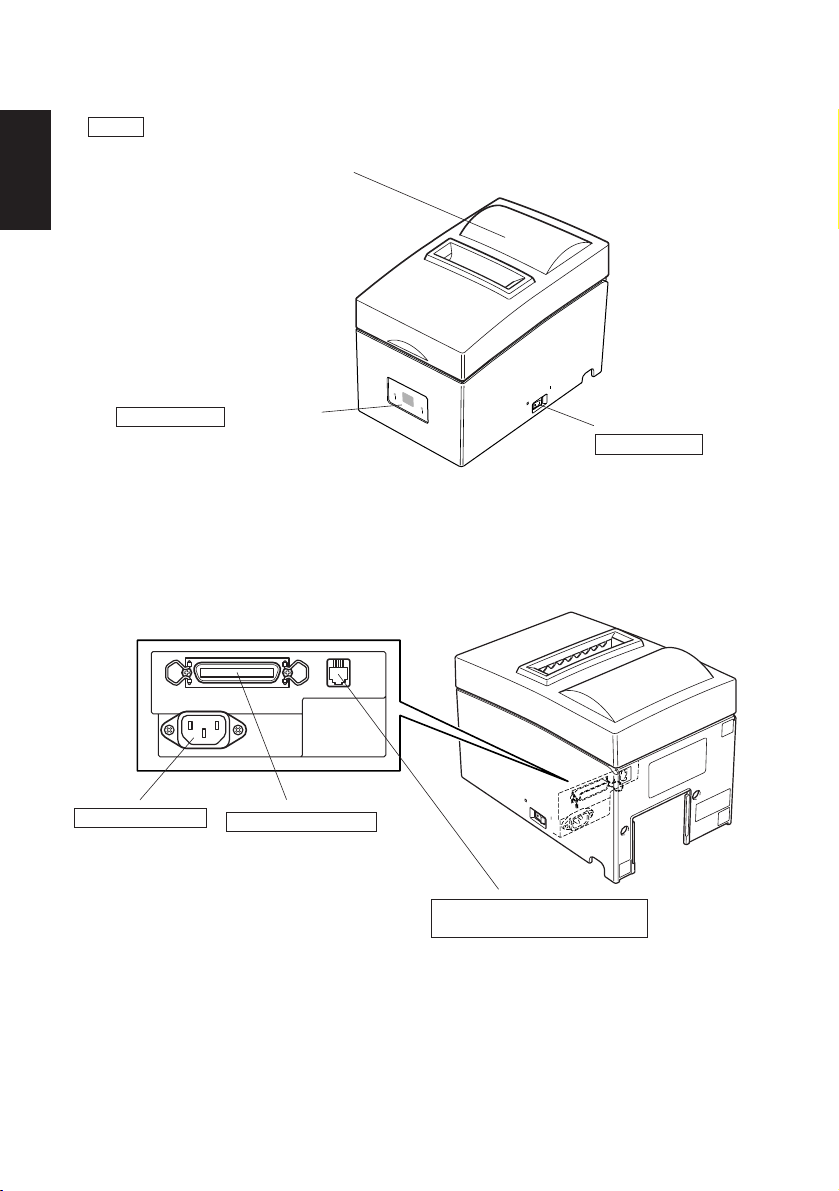

Auto cutter model

ENGLISH

Cover

Protects the printer from dust and reduces noise.

Do not open the cover while printing.

Control panel

Features one control switch and

two indicators to indicate printer

status.

V

H

N

E

R

R

O

R

F

E

E

D

P

O

W

E

R

O

F

F

O

Power switch

Turns printer power on

and off.

Power connector

For connection of

the power cord.

Fig. 3-2 External view of the printer (Auto cutter model)

Interface connector

Connects the printer with

host computer.

OFF

ON

Peripheral unit drive circuit

connector

Connects to peripheral units

such as cash drawers, etc.

Do not connect this to a

telephone.

– 5 –

Page 9

ON

4. Connecting Cables and Power Cord

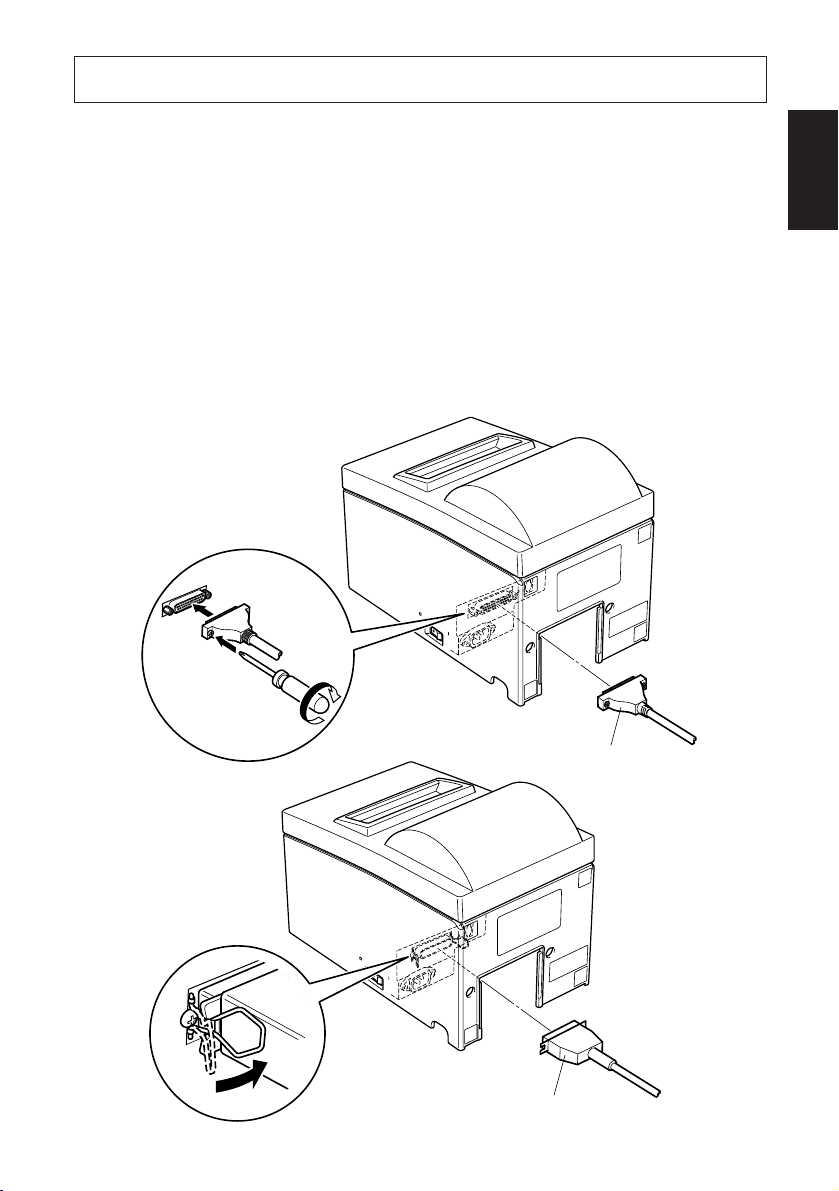

4-1. Connecting the Interface Cable

Note: Before connecting/disconnecting the interface cable, make sure that

power to the printer and all the devices connected to the printer is

turned off.

Also make sure the power cable plug is disconnected from the

AC outlet.

(1)Connect the interface cable to the connector on the rear panel of the printer.

(2)In the case of a serial interface, tighten the connector screws. In the case of a

parallel interface, fasten the connector clasps.

OFF

ON

ENGLISH

Serial interface cable

OFF

ON

Parallel interface cable

– 6 –

Page 10

4-2. Connecting to a Peripheral Unit

You can connect a peripheral unit to the printer using a modular plug. The

ENGLISH

following describes how to install the ferrite core and make the actual connection.

See “Modular plug” on page 115 for details about the type of modular plug that

is required. Note that this printer does not come with a modular plug or wire, so

it is up to you to obtain one that suits your needs.

Important!

Make sure that the printer is turned off and unplugged from the AC outlet

and that the computer is turned off before making connections.

(1)Connect the peripheral drive cable to the connector on the rear panel of the

printer.

Important!

Do not connect a telephone line into the peripheral drive connector.

Failure to observe this may result in damage to the printer.

Also, for safety purposes, do not connect wiring to the external drive

connector if there is a chance it may carry peripheral voltage.

OFF

ON

– 7 –

Page 11

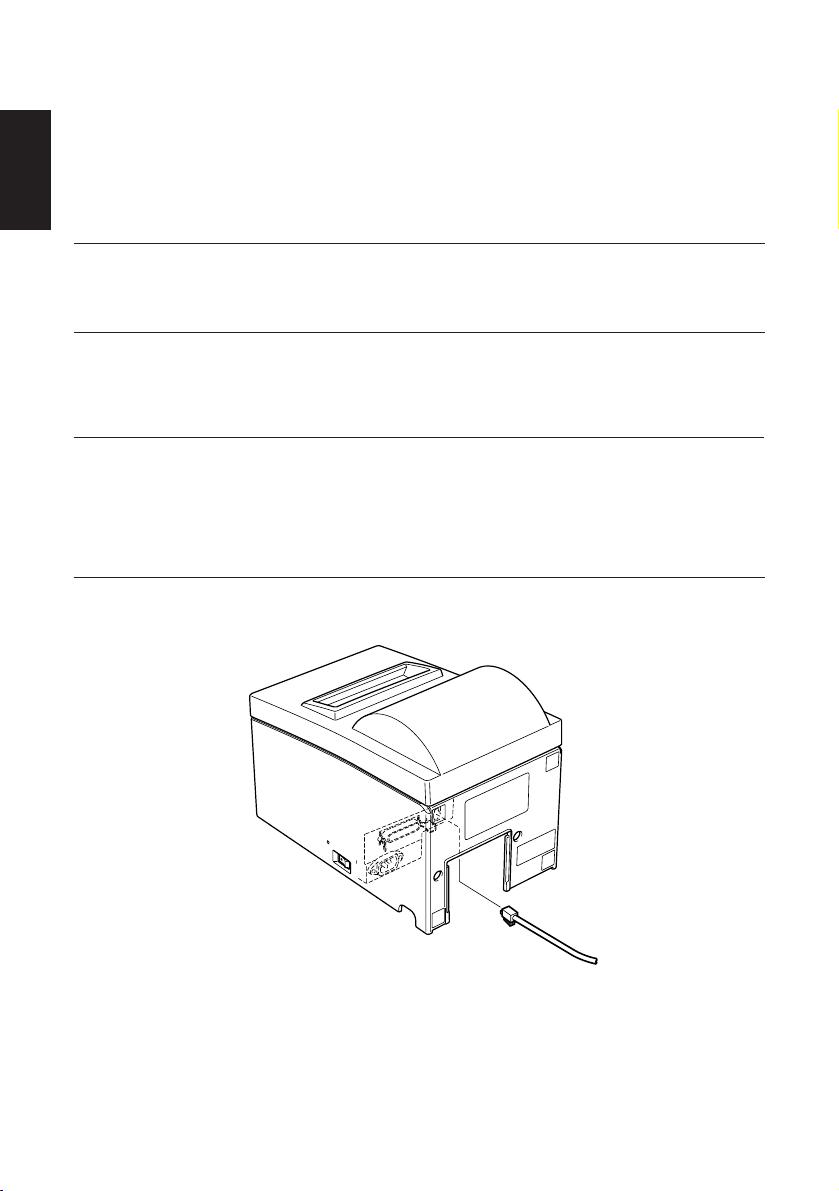

4-3. Connecting the Power Cord

Note: Before connecting/disconnecting the power cord, make sure that

power to the printer and all the devices connected to the printer is

turned off. Also make sure the power cable plug is disconnected from

the AC outlet.

(1)Check the label on the back or bottom of the printer to make sure its voltage

matches that of the AC outlet. Also make sure the plug on the power cord

matches the AC outlet.

(2)If the power cord is not attached to the printer, plug the appropriate end into

the AC inlet on the back of the printer.

(3)Plug the power cord into a properly grounded AC outlet.

OFF

ON

ENGLISH

Important!

If the voltage shown on the label on the of your

printer does not match the voltage for your area,

contact your dealer immediately.

– 8 –

Page 12

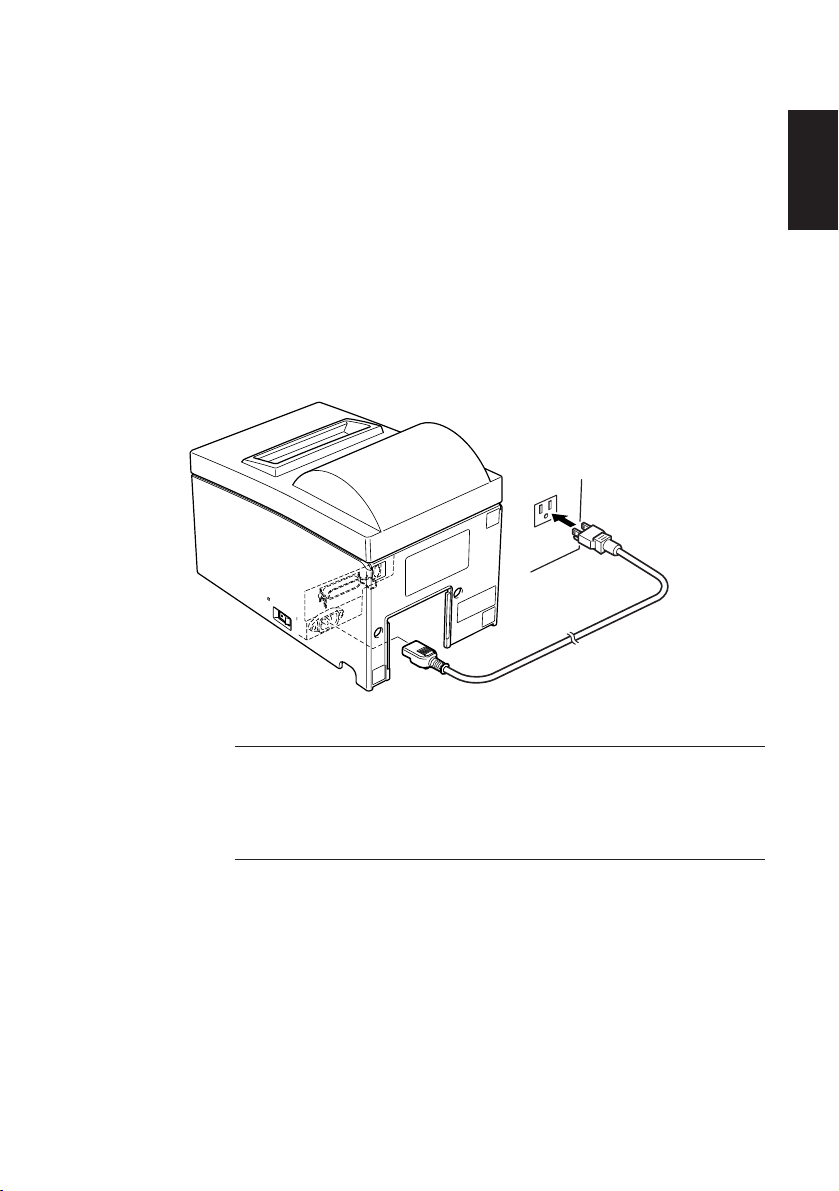

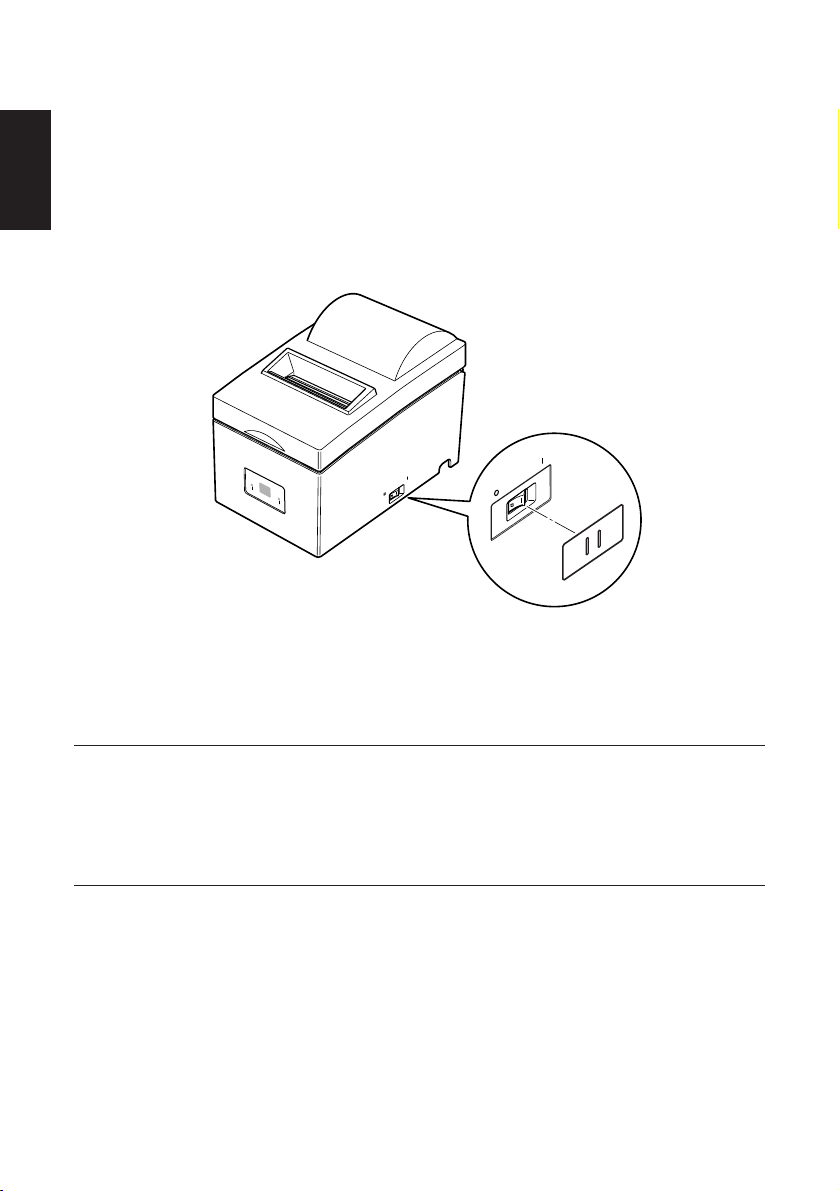

4-4. Turning Power On

OFF

ON

ERROR

POWER

FEED

OFF

ON

OFF

ON

Make sure that the power cord has been connected as described in 4-3.

ENGLISH

(1)Set the power switch located on the right side of the printer to on.

The POWER lamp on the control panel will light up.

V

H

N

O

F

F

O

Power switch

Important!

We recommend that you unplug the printer from the power outlet

whenever you do not plan to use it for long periods. Because of this, you

should locate the printer so that the power outlet it is plugged into is

nearby and easy to access.

E

R

R

O

R

F

E

E

D

P

O

W

E

R

4-5. Attaching the Rear Cover

Attach the rear cover if necessary.

O

F

F

O

N

OFF

ON

– 9 –

Page 13

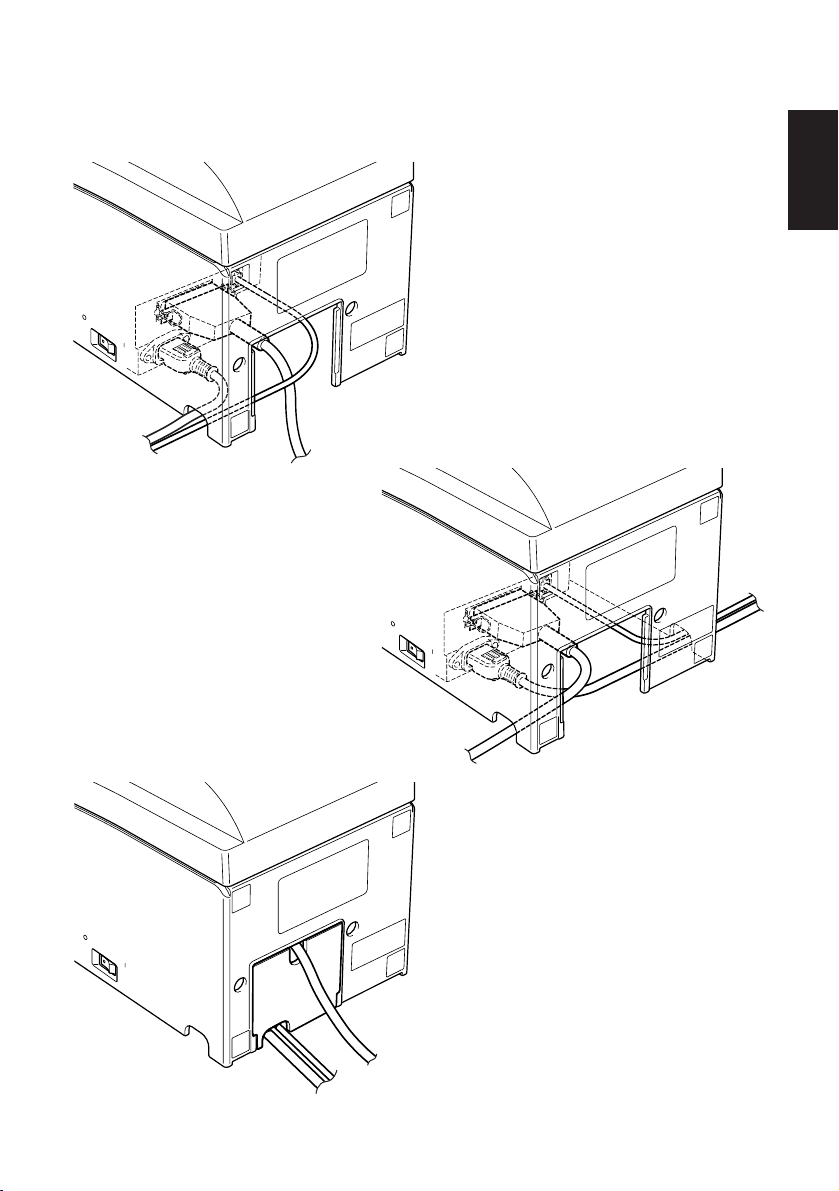

4-6. Installing the Cable

OFF

ON

OFF

ON

OFF

ON

Install the cable as shown in the diagram below.

O

F

F

O

N

O

F

F

O

N

ENGLISH

O

F

F

O

N

– 10 –

Page 14

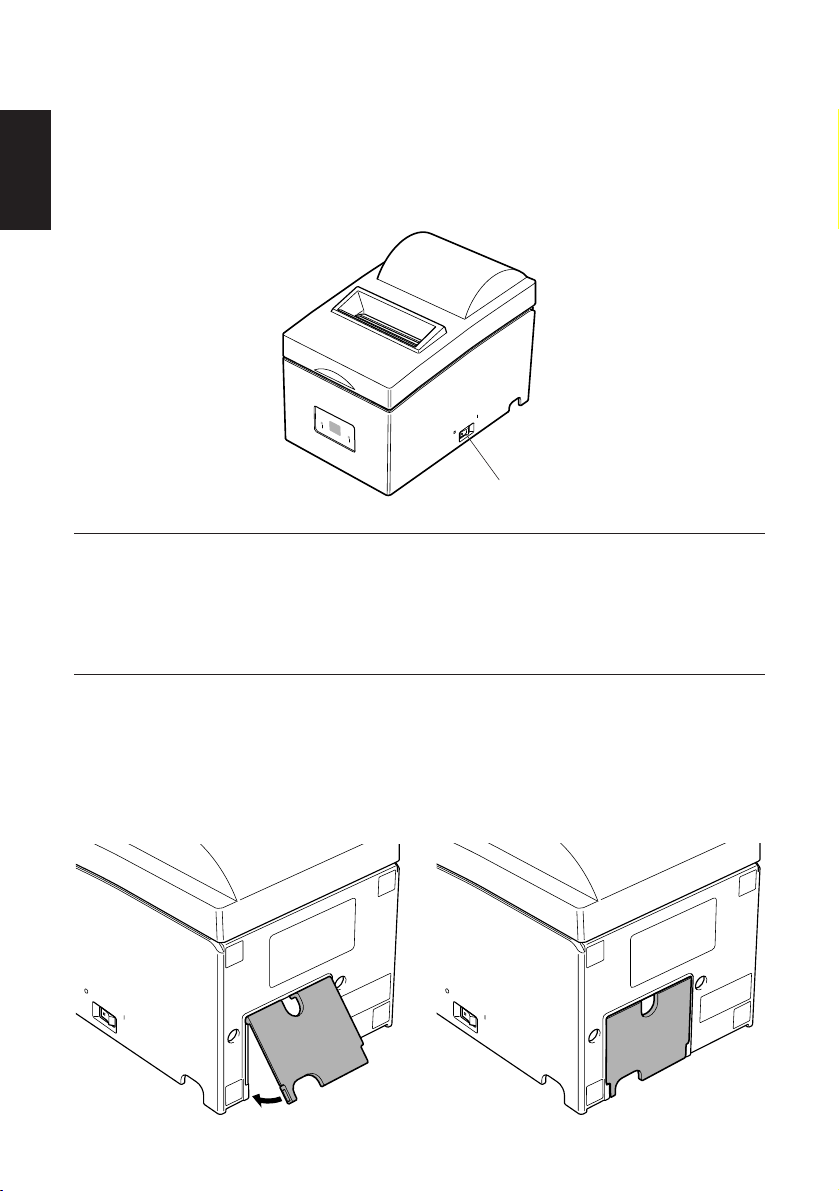

4-7. Switch Blind Installation

OFF

ON

ERROR

POWER

FEED

OFF

ON

It is not necessary to install the switch blind. Only install it if it is necessary for

ENGLISH

you. By installing the switch blind, the following become possible.

• Preventing the power switch from being operated by mistake.

• Ensuring that other people can not easily operate the power switch.

Install the switch blind as shown in the diagram below.

V

H

E

R

R

O

R

F

E

E

D

P

O

W

E

R

ON

OFF

N

O

F

F

O

The power switch can be turned ON (!) and OFF (O) by inserting a narrow

instrument (ball pen etc) in the holes in the switch blind.

Important!

We recommend that you unplug the printer from the power outlet

whenever you do not plan to use it for long periods. Because of this, you

should locate the printer so that the power outlet it is plugged into is

nearby and easy to access.

– 11 –

Page 15

H

V

OFF

ON

OFF

ON

ERR

OR

PO

WER

FEED

5. Loading the Ribbon Cartridge and Paper

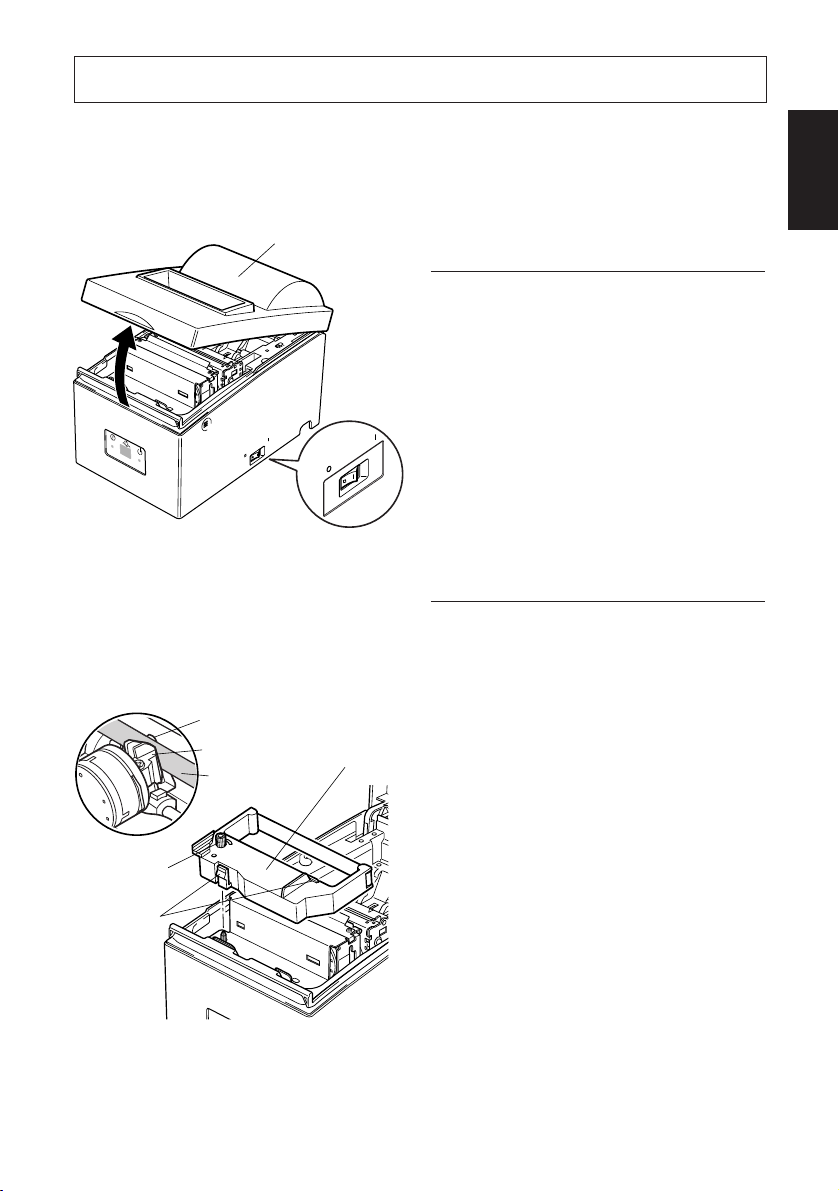

5-1. Tear Bar Model

5-1-1. Loading the Ribbon Cartridge

Cover

V

H

N

E

R

R

O

R

FE

ED

P

O

W

E

R

Fig. 5-1 Opening the cover

O

F

F

O

Power off

ON

OFF

1 Turn off power to the printer.

2 Open the cover.

Important!

1. Do not touch the print head immediately after printing as it can be

extremely hot.

2. Do not touch the cutter blade.

· There is a cutter inside the pa-

per outlet slot. Not only should

you not put your hand in the

paper outlet slot while printing

is in progress, never put your

hand into the outlet even when

printing is not in progress.

ENGLISH

Ribbon separator

Print head

Ribbon

cartridge

Ink ribbon

Ribbon

feed knob

Notched part

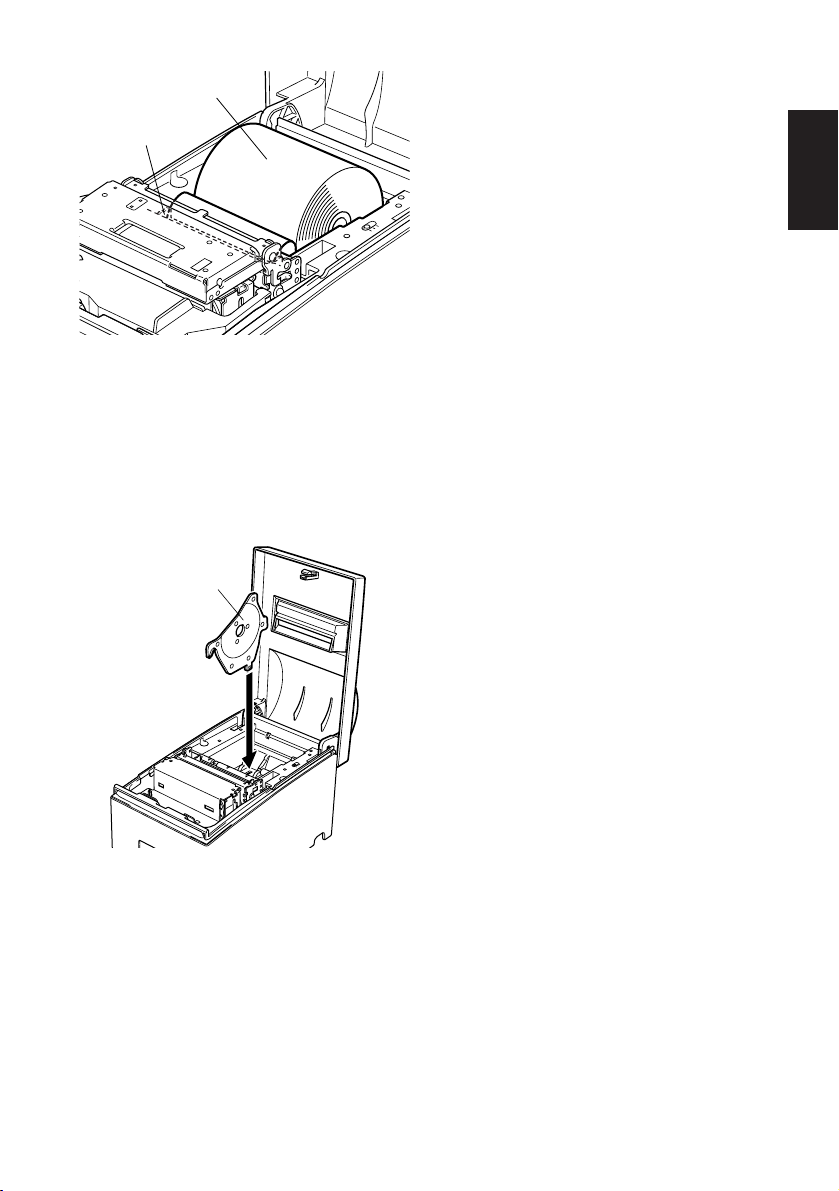

Fig. 5-2 Loading the ribbon cartridge

3 Place the ribbon cartridge in the

direction shown in Fig. 5-2 and press

it down to load it. If loading of the

ribbon cartridge is not satisfactory,

press down the cartridge while rotating the ribbon feed knob in the

direction of the arrow.

4 Turn the ribbon feed knob of the

ribbon cartridge in the direction of

the arrow to remove slack in the

ribbon.

5 Close the cover.

– 12 –

Page 16

ENGLISH

H

V

A

B

Fig. 5-3 Removing the ribbon cartridge

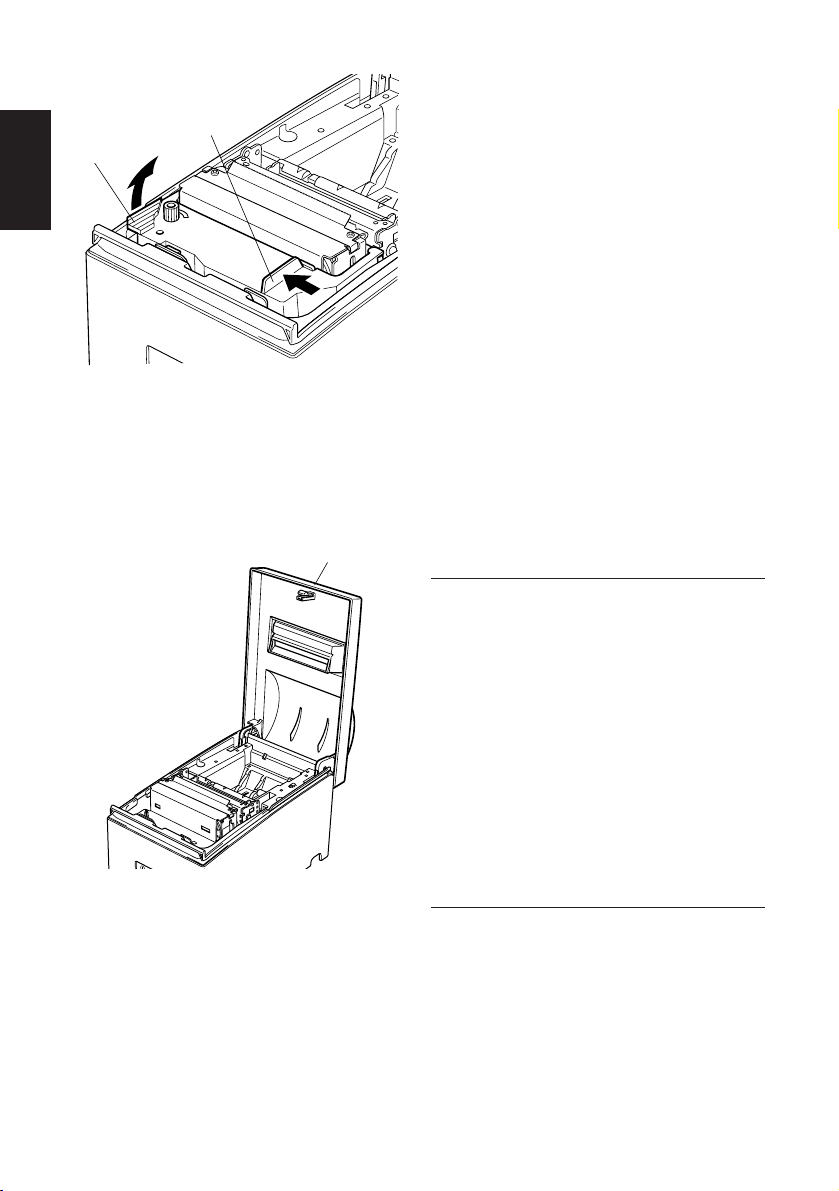

5-1-2. Loading the paper

Note: When removing the ribbon

cartridge, raise the A section

and then remove it by holding the B section as shown in

Fig. 5-3.

Cover

V

H

Fig. 5-4 Removing the cover

1 Open the cover.

Important!

1. Do not touch the print head immediately after printing as it can be

extremely hot.

2. Do not touch the cutter blade.

· There is a cutter inside the pa-

per outlet slot. Not only should

you not put your hand in the

paper outlet slot while printing

is in progress, never put your

hand into the outlet even when

printing is not in progress.

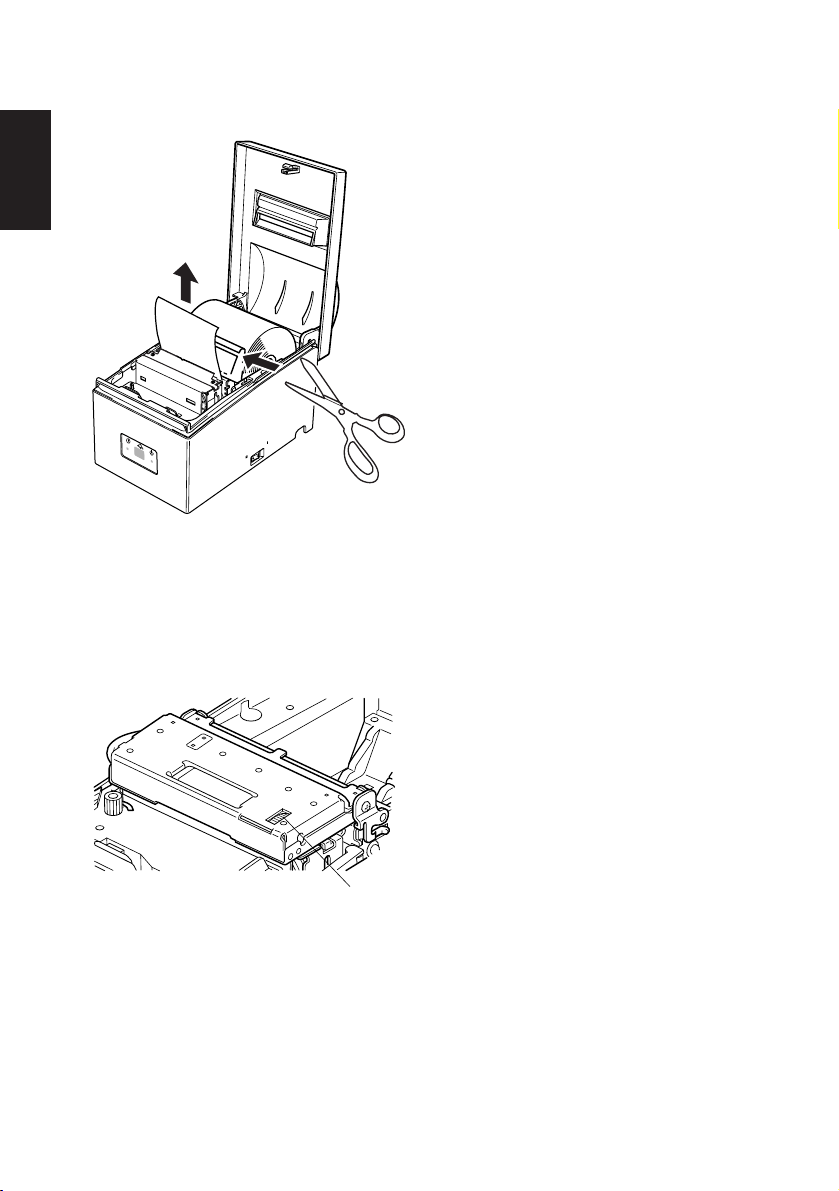

2 Cut off the front edge of the roll

paper perpendicularly.

3 Confirm that the power of the printer

is turned on.

– 13 –

Page 17

H

V

OFF

ON

ERROR

POWER

FEED

Roll paper

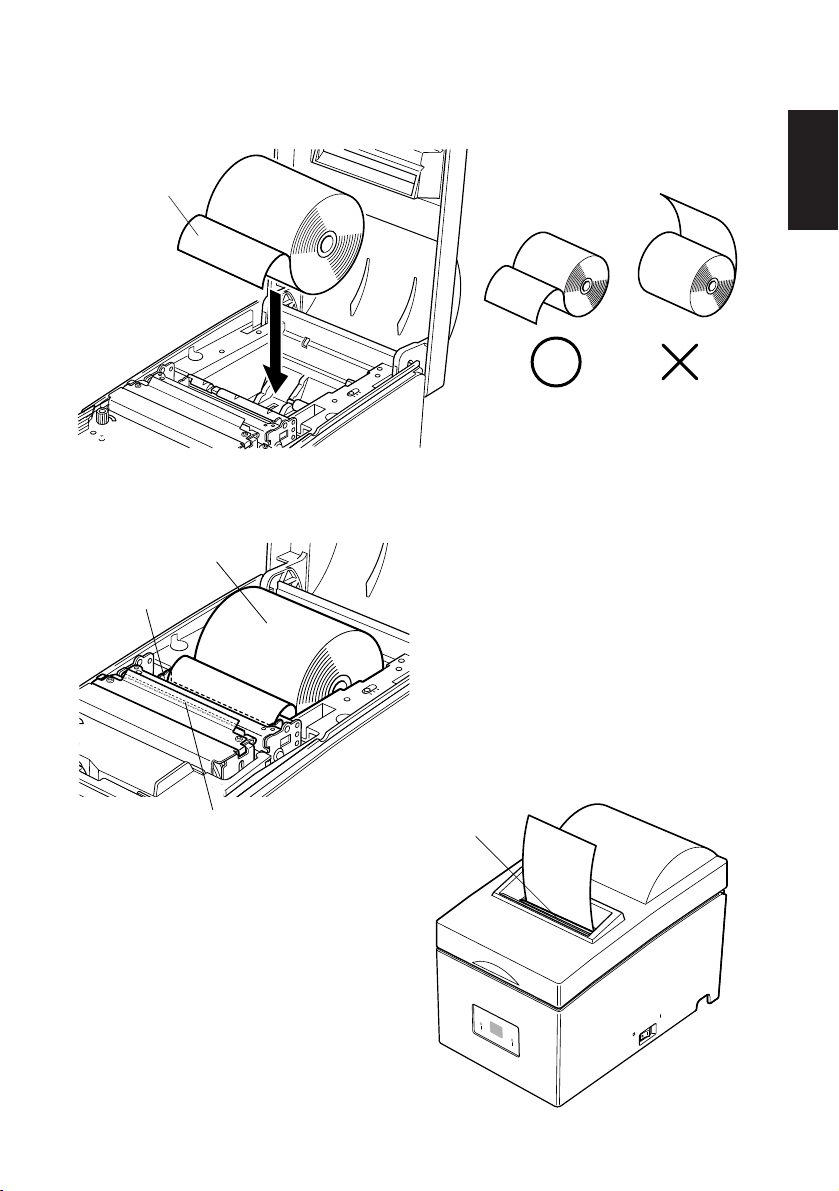

Fig. 5-5 Setting the paper

Roll paper

Paper feeder

4 While observing the direction of the

roll, set the paper roll into the hollow as shown in Fig. 5-5.

ENGLISH

V

H

5 Insert the edge of the paper into the

paper feeder (black plastic part). If

inserted correctly, the edge of the

paper will pass through the paper exit.

6 Insert the top edge of the paper into

the tear bar slot, then mount the cover

by reversing the procedure for opening the cover in step 1 above.

Note: When the paper end mark ap-

pears on the paper, replace the

roll paper before it runs out.

Paper exit

Fig. 5-6 Loading the paper

Tear bar

V

H

N

E

R

R

O

R

F

E

E

D

P

O

W

E

R

– 14 –

Fig. 5-7

O

F

F

O

Page 18

H

V

ONON

E

R

R

O

R

ERROR

F

E

FEED

OFF

ON

ERROR

POWER

FEED

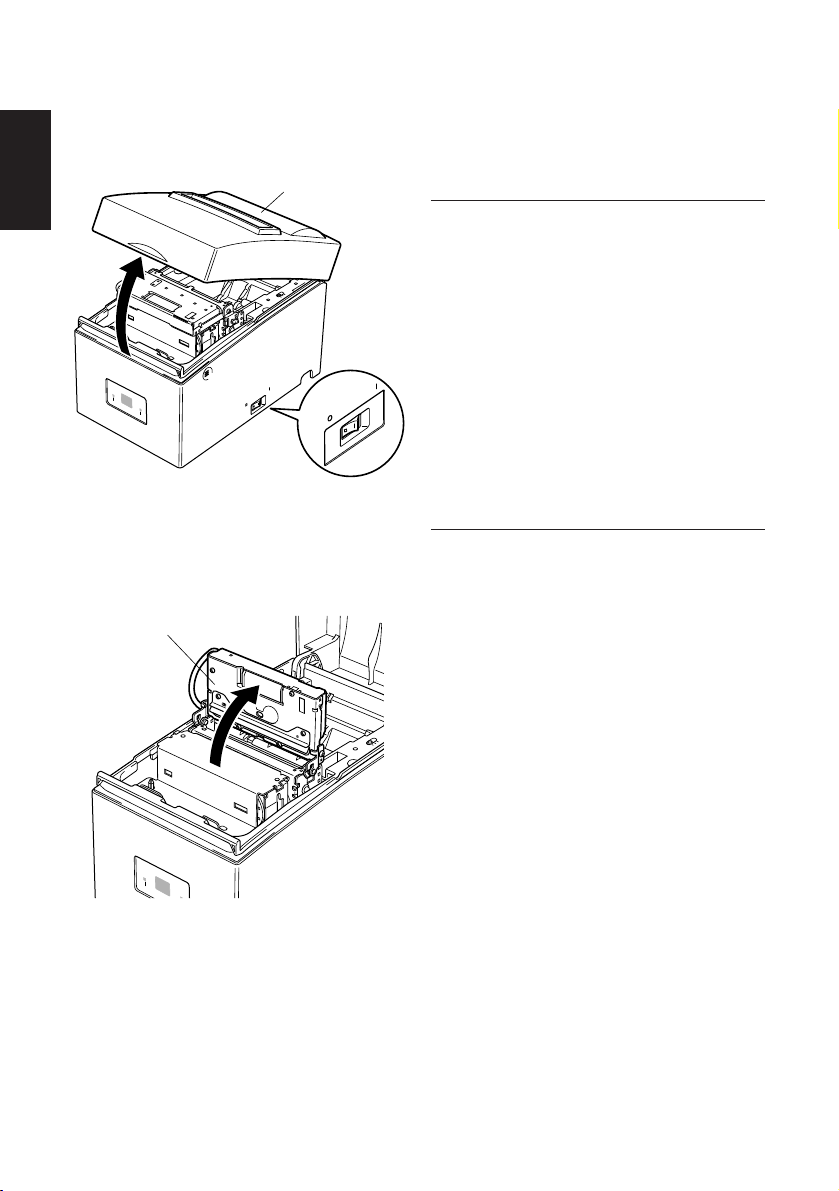

5-2. Auto Cutter Model

5-2-1. Loading the Ribbon Cartridge

ENGLISH

Cover

V

H

N

E

R

R

O

R

F

E

E

D

P

O

W

E

R

Fig. 5-8 Opening the cover

O

F

F

O

Power off

1 Turn off power to the printer.

2 Open the cover.

Important!

1. Do not touch the print head immediately after printing as it can be

extremely hot.

2. Do not touch the cutter blade.

· There is a cutter inside the pa-

per outlet slot. Not only should

ON

OFF

you not put your hand in the

paper outlet slot while printing

is in progress, never put your

hand into the outlet even when

printing is not in progress.

Auto cutter

Fig. 5-9 Raise the auto cutter

3 Lift up the auto cutter and put it in a

vertical position, as shown in Fig. 5-

9.

– 15 –

Page 19

H

V

Ribbon separator

H

V

Print head

Ink ribbon

Ribbon

feed knob

Notched

part

Auto cutter

Ribbon

cartridge

Fig. 5-10 Loading the ribbon cartridge

B

A

4 Place the ribbon cartridge in the

direction shown in Fig. 5-10 and

press it down to load it. If loading of

the ribbon cartridge is not satisfactory, press down the cartridge while

rotating the ribbon feed knob in the

direction of the arrow.

5 Turn the ribbon feed knob of the

ribbon cartridge in the direction of

the arrow to remove slack in the

ribbon.

6 Close the Auto Cutter.

7 Close the cover.

Note: When removing the ribbon

cartridge, raise the A section

and then remove it by holding the B section as shown in

Fig. 5-11.

ENGLISH

Fig. 5-11 Removing the ribbon cartridge

– 16 –

Page 20

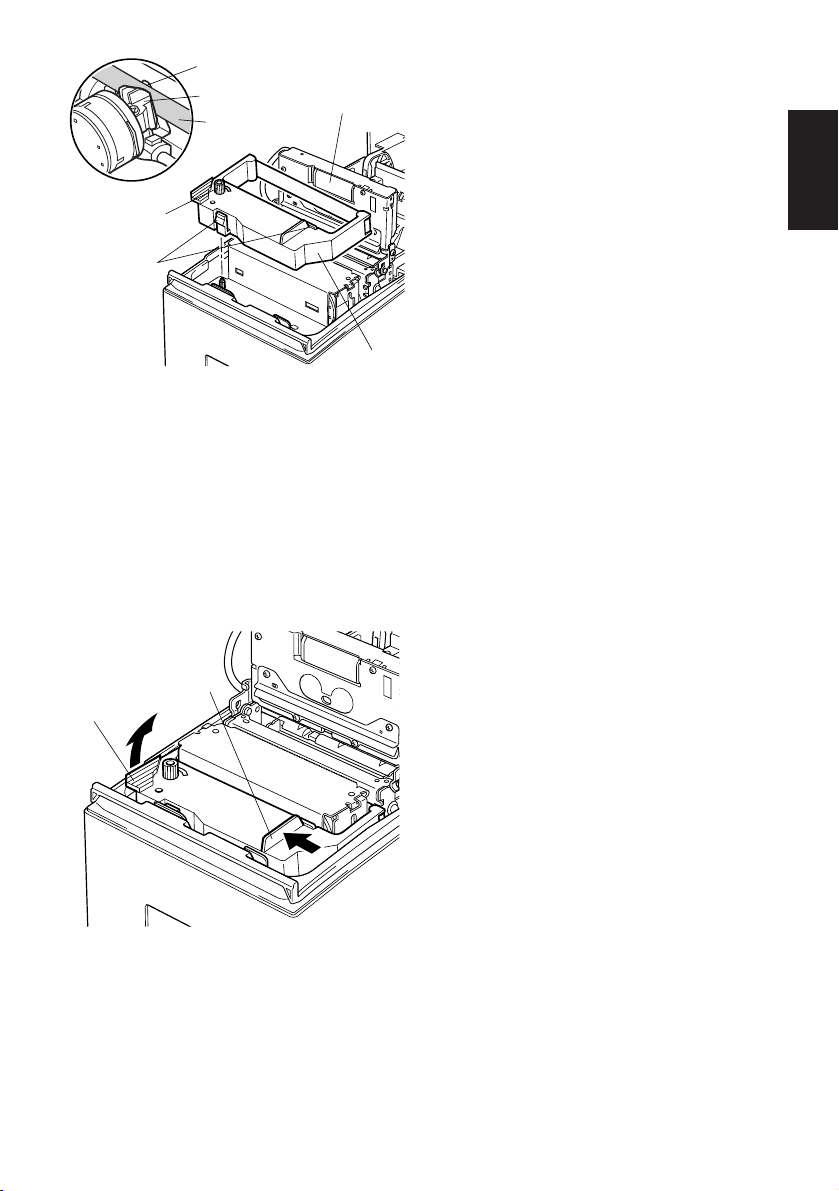

5-2-2. Loading the Paper

H

V

ENGLISH

Cover

V

H

Fig. 5-12 Removing the cover

1 Open the cover.

Important!

1. Do not touch the print head immediately after printing as it can be

extremely hot.

2. Do not touch the cutter blade.

· There is a cutter inside the pa-

per outlet slot. Not only should

you not put your hand in the

paper outlet slot while printing

is in progress, never put your

hand into the outlet even when

printing is not in progress.

2 Cut off the front edge of the roll

paper perpendicularly.

3 Confirm that the power of the printer

is turned on.

4 While observing the direction of the

roll, set the paper roll into the hollow as shown in Fig. 5-13.

Roll paper

Fig. 5-13 Setting the paper

– 17 –

Page 21

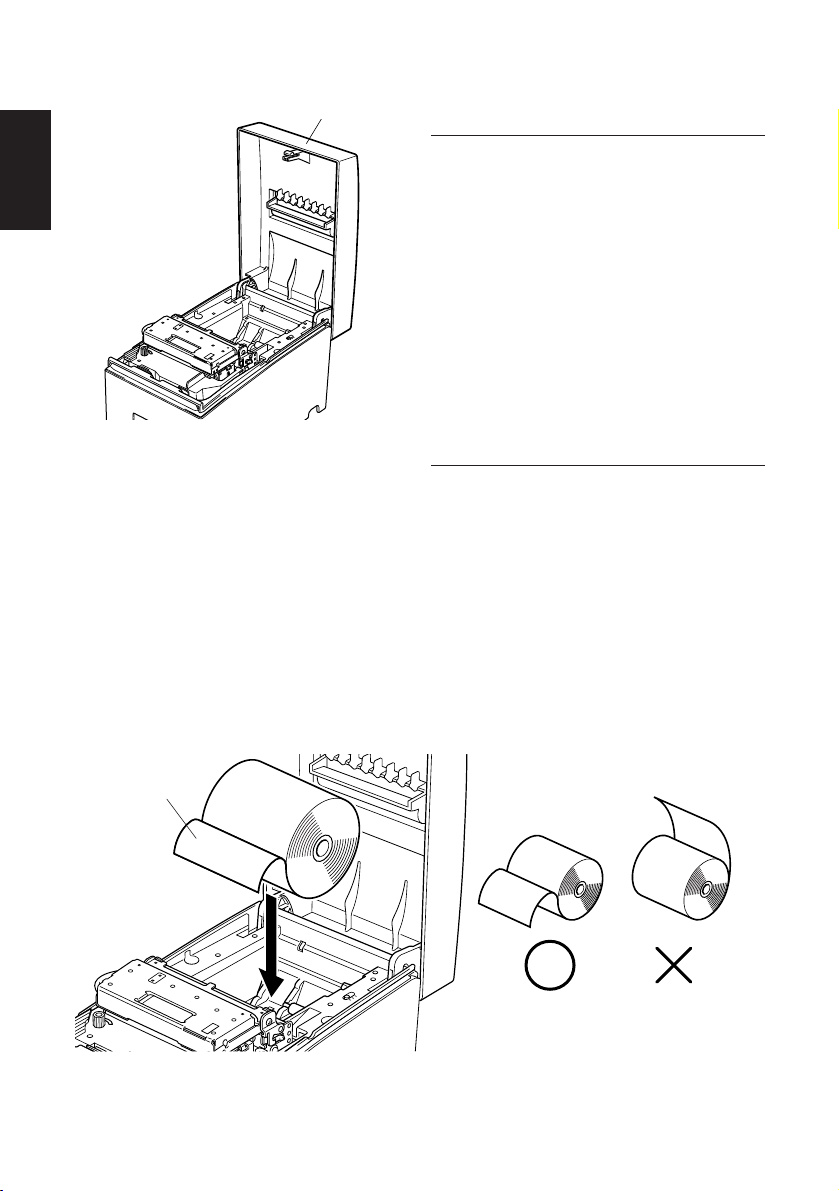

Roll paper

Paper feeder

5 Insert the edge of the paper into the

paper feeder (black plastic part). If

inserted correctly, the edge of the

paper will pass through the auto

cutter paper slit. Press the FEED

button to cut the paper.

V

6 Remove the cut piece of paper and

H

close the cover.

Note: When the paper end mark

Fig. 5-14 Loading the paper

5-3. Installing the Roll Paper Guide

When using a paper roll with an 58 mm

Roll paper guide

V

H

width, install the attached roll paper

guide in the groove in the printer.

The setting for memory switch 2-A and

2-B must be changed to change the

print width from 63 mm to 45 mm.

For instructions on setting the memory

switch, please refer to the separate

Specification Manual.

ENGLISH

appears on the paper, replace

the paper roll before it runs

out.

Fig. 5-15 Installing the roll paper guide

– 18 –

Page 22

5-4. Clearing Paper Jams

OFF

ON

ERROR

POWER

FEED

ENGLISH

V

H

Cut

E

R

R

O

R

FEED

P

O

W

E

R

ON

OFF

Fig. 5-16 Cutting the paper

1 Turn the printer off and unplug the

power cord from the AC outlet.

2 Open the cover.

Note: Do not touch the print head

immediately after printing,

as it can be extremely hot. In

addition, do not touch the

cutter blade on models

equipped with the auto cutter.

3 For auto cutter models, lift up the

auto cutter and put it in a vertical

position as shown in Fig. 5-9.

4 Cut the paper before the paper feeder

as shown in Fig. 5-16.

5 Remove the jammed paper and re-

load the roll paper.

Note:

1) When paper is jammed in the

auto cutter, use a flat-head screwdriver or similar tool to turn the

knob and move the cutter blade

in order to remove the jammed

paper.

Knob

Fig. 5-17 Auto cutter knob

– 19 –

2) Do not touch any metal edges.

Personal injury could result.

Page 23

6. Control Panel and Other Functions

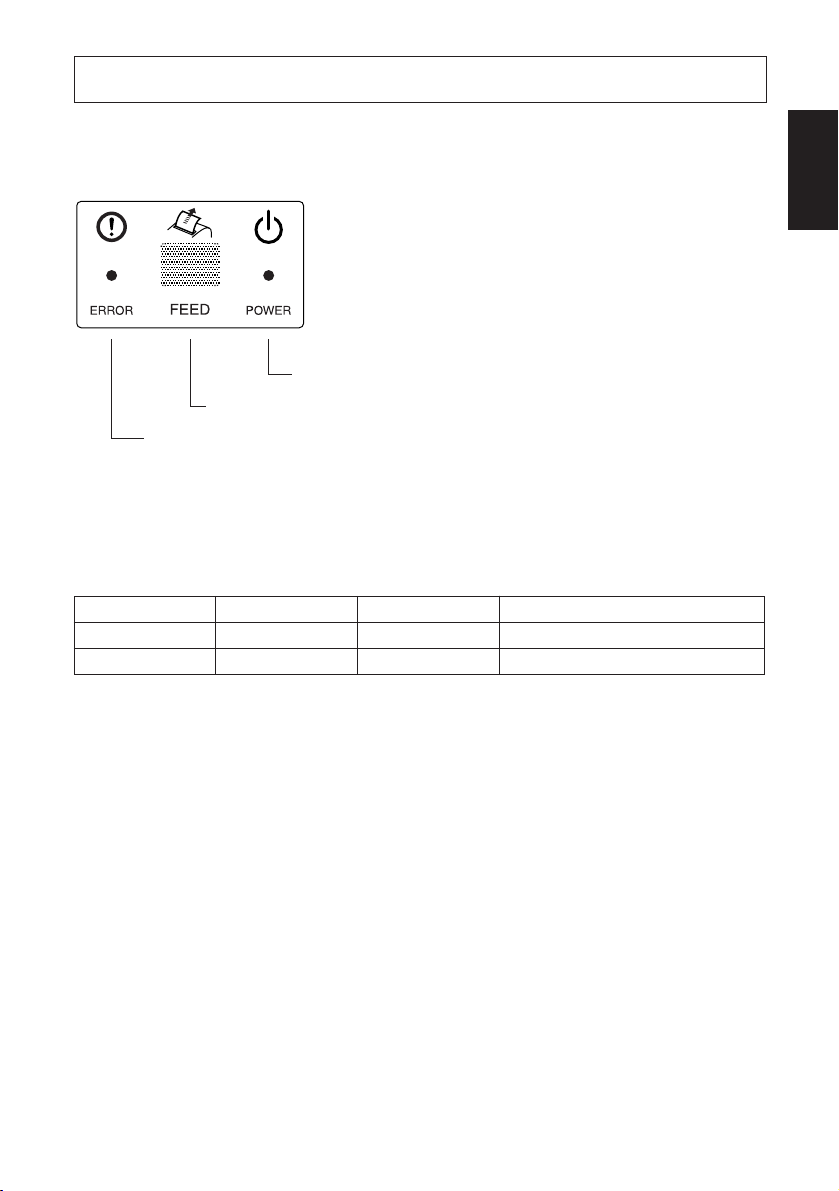

6-1. Control Panel

1 POWER lamp (Green LED)

Lights when the power is ON

2 FEED button

Press the FEED button to feed roll

paper.

ENGLISH

2 FEED button

3 ERROR lamp

(Red LED)

6-2. Basic Indicators

POWER lamp

Power On/Off

No Error

On/Off

On

1 POWER lamp

(Green LED)

ERROR lamp

Off

3 ERROR lamp (Red LED)

Indicates various errors in combination with POWER lamp

Buzzer

—

—

—

– 20 –

Page 24

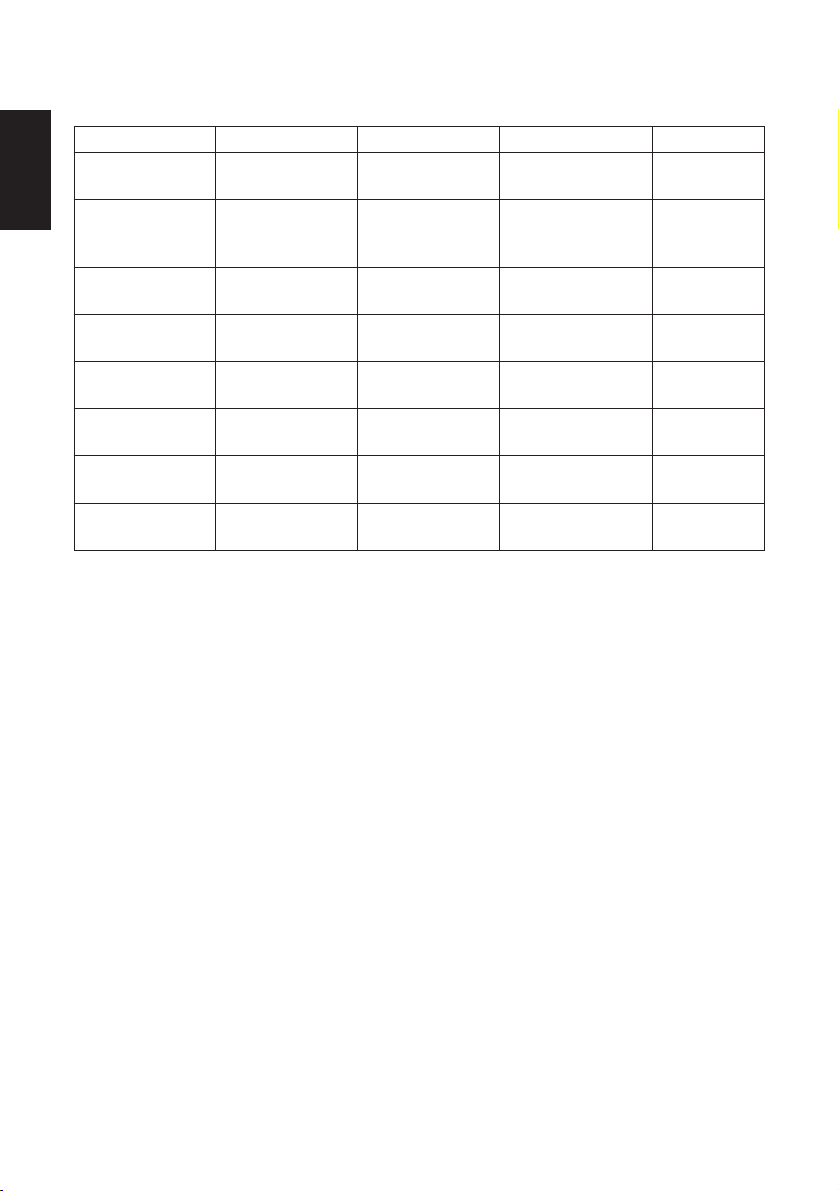

6-3. Errors

1) Recoverable error

ENGLISH

Error Description

Paper end error

Waiting for recovery of the

printer to be able to print

after loading the roll paper

Paper near end error (Option)

Head high temperature detection

Board high temperature detection

Cutter error (on

models with cutter)

Mechanical error (other

than cutter error)

Black mark detection error

POWER lamp

On

Flashes (On: 0.25

sec./Off: 0.25 sec.)

On

Flashes (On: 1

sec./Off: 1 sec.)

Flashes (On: 2 sec./

Off: 2 sec.)

On

On

On

*1 After you insert the paper in the paper entrance, the printer loads the paper

automatically.

Confirm that the POWER lamp is flashing, and then press the FEED button.

*2 Press the FEED button.

*3 Refer to the separate installation manual of the optional near end sensor for

details.

Because the near end sensor is not installed at the time of shipment (factory

setting), the error is not displayed if the sensor is not installed.

*4 Automatically the printer is recovered after the print head has cooled.

A print head temperature error is not abnormal.

*5 Automatically the printer is recovered after the board has cooled.

*6 Automatically the printer is recovered if the cutter returns to the home position

after turning the power OFF and ON.

Restoration is also possible with the <DLE> <ENQ> n command when in the

ESC/POS mode.

ERROR lamp

On

Off

Flashes (On: 2 sec./

Off: 2 sec.)

Off

Off

Flashes (On: 0.125

sec./Off: 0.125 sec.)

Flashes (On: 0.25

sec./Off: 0.25 sec.)

Flashes (On: 0.5

sec./Off: 0.5 sec.)

Buzzer

4 short beeps (0.13

sec.) repeated twice

None

None

None

None

3 short beeps (0.13 sec.

+ 0.13 sec. + 0.5 sec.)

2 short beeps (0.13 sec.

+ 0.5 sec.)

3 short beeps (0.13 sec.

+ 0.13 sec. + 0.13 sec.)

Recovery Conditions

*1

*2

*3

*4

*5

*6

*7

*8

– 21 –

Page 25

Note

1) If the cutter doesn’t return to the home position, or doesn’t perform the

initial movement, it cannot be recovered.

2) If the paper is jammed, turn the power OFF, clear the jammed paper, then

turn the power ON.

3) When the error occurs:

STAR Mode: Non recoverable error

ESC/POS Mode: Recoverable error

*7 Turn the power OFF, clear the jammed paper or remedy another problem and

then turn the power ON. Automatically the printer is recovered if the carriage

returns to the home position after turning the power OFF and ON.

Restoration is also possible with the <DLE> <ENQ> n command when in the

ESC/POS mode.

When the error occurs:

STAR Mode: Non recoverable error

ESC/POS Mode: Recoverable error

*8 For paper jam errors:

Clear the jammed paper and change the paper roll if necessary.

For incorrect paper format errors:

Change the paper roll and use a paper roll with the correct black mark.

2) Non recoverable error

Error Description

Thermistor failure

error

Flash memory

write error

RAM R/W error

Power supply error

CPU error

POWER lamp

Off

Off

Off

Off

Off

ERROR lamp

Flashes (On: 0.25

sec./Off: 0.25 sec.)

Flashes (On: 1 sec./

Off: 1 sec.)

On

Flashes (On: 2 sec./

Off: 2 sec.)

On

Buzzer

2 short beeps (0.13 sec. + 0.5 sec.)

None

None

None

One long beep (2 sec.)

ENGLISH

Note

If a non-recoverable error occurs, turn the power OFF, wait at least 10 seconds,

and turn the power back ON. If the non-recoverable error continues to be

indicated, consult a dealer for repairs.

– 22 –

Page 26

6-4. Adjustment Mode

There are the following four adjustment modes.

ENGLISH

The device will enter the adjustment mode if your turn it on while pressing the

FEED switch.

The Self Printing Mode is entered by releasing the FEED switch after the buzzer

sounds once.

(Holding down for 2 more seconds)

▼

Adjusting the Dot Alignment Mode is entered by releasing the FEED switch after

the buzzer sounds twice.

(Refer to Appendix G.)

(Holding down for 2 more seconds)

▼

The Hexadecimal Dump Mode is entered by releasing the FEED switch after the

buzzer sounds three times.

(Holding down for 2 more seconds)

▼

The Black Mark Sensor Alignment Mode is entered by releasing the FEED switch

after the buzzer sounds four times.

(Refer to Appendix H.)

▼

If the buzzer sounds five times or more, immediately turn the power off as the

adjustment mode is cancelled.

– 23 –

Page 27

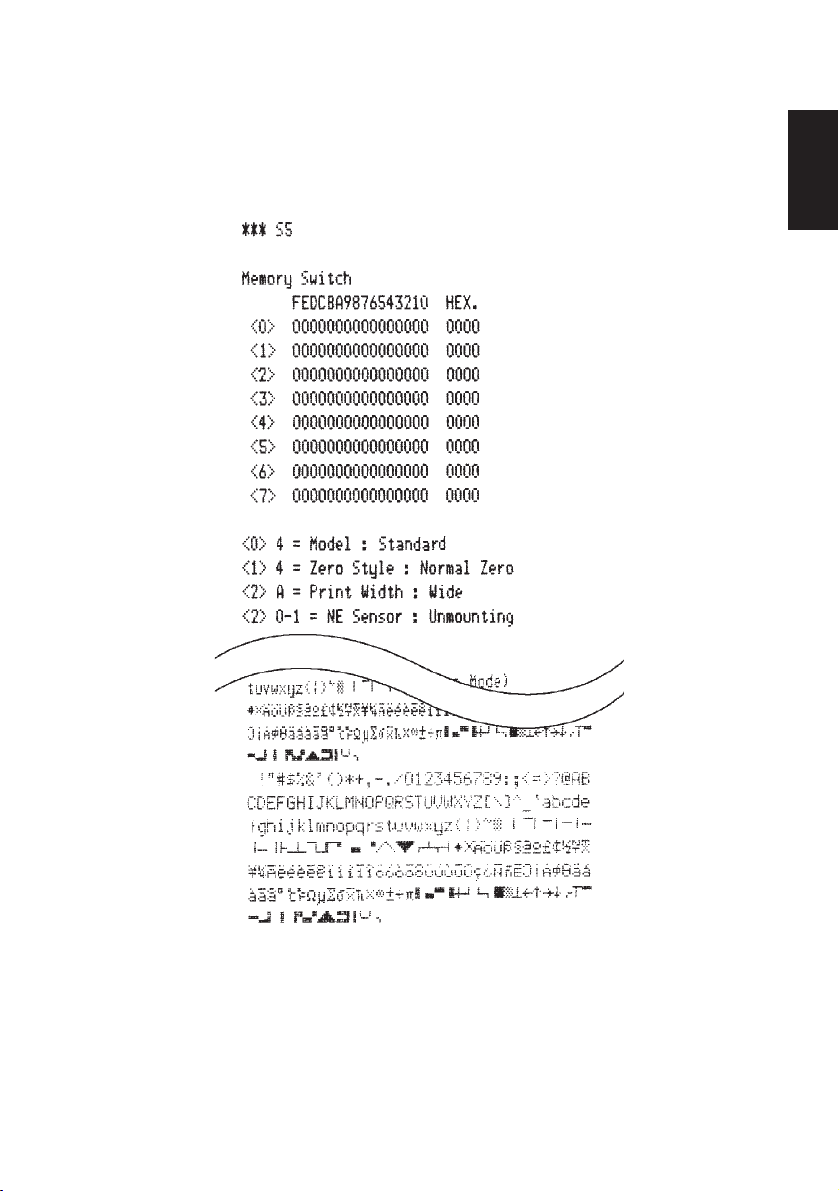

6-4-1. Self Printing Mode

Self-printing will be performed according to the VER. NO., Memory switch

settings, DIP switch settings and character order. When the FEED switch is held

continuously or when the FEED switch is depressed at the time of the end of selfprinting, only the characters will be printed out repeatedly.

ENGLISH

– 24 –

Page 28

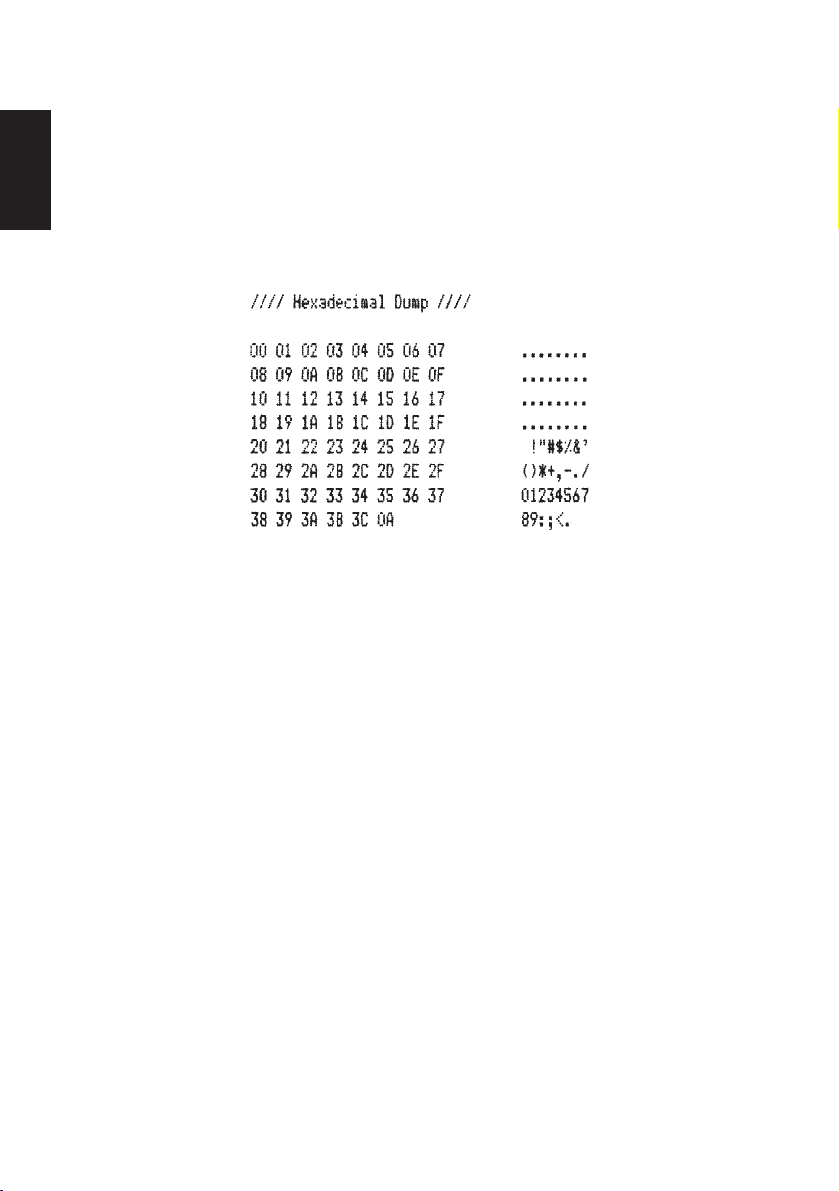

6-4-2. Hexadecimal Dump Mode

Each of the signals sent from the computer to the printer will be printed out in

ENGLISH

hexadecimal code.

This function allows you to check if a control code sent to the printer by the

program being used is correct or not. The last line is not printed if its data is less

than one full line. However, if the FEED switch is pressed, the last line will be

printed. To turn off the mode, it is necessary to turn off the printer completely.

– 25 –

Page 29

TABLE DES MATIERES

1. Introduction ..................................................................................................... 27

2. Déballage et inspection....................................................................................28

2-1. Déballage .............................................................................................28

2-2. Emplacement de l’imprimante .............................................................29

2-3. Précautions de manipulation ................................................................29

2-4. Entretien ...............................................................................................29

3. Identification des pièces et nomenclature........................................................30

4. Câbles de connexion et câble d’alimentation ..................................................32

4-1. Connexion du câble d’interface ........................................................... 32

4-2. Raccordement d’un appareil périphérique ...........................................33

4-3. Connexion de câble d’alimentation secteur optionnel .........................34

4-4. Mise sous découpage de l’imprimante ................................................. 35

4-5. Placement de la plaque arrière .............................................................35

4-6. Installation du câble .............................................................................36

4-7. Installation du cache de l’interrupteur .................................................37

5. Installation d’une cartouche à ruban et chargement du papier ........................38

5-1. Modèle avec barre de découpage .........................................................38

5-2. Modèle avec coupe-papier automatique ..............................................41

5-3. Installation du guide du rouleau de papier ...........................................44

5-4. Dégagement des bourrages de papier .................................................. 45

6. Panneau de commande et autres fonctions ......................................................46

6-1. Panneau de commande ......................................................................... 46

6-2. Indicateurs de base ...............................................................................46

6-3. Erreurs ..................................................................................................47

6-4. Mode de réglage ................................................................................... 49

APPENDICE .....................................................................................................104

FRANÇAIS

L’appendice n’est pas traduit.

– 26 –

Page 30

1. Introduction

L’imprimante série à impact et matrice de points est conçue pour une utilisation

avec des instruments électroniques tels que des terminaux points de vente, du

matériel bancaire, du matériel périphérique pour ordinateurs, etc.

Les caractéristiques principales des modèles de la série SP500 sont les suivantes:

FRANÇAIS

1. Impression bi-directionnelle à 4 lignes/sec. environ.

2. Interface série ou parallèle.

3. Tampon de données permettant à l ’appareil de recevoir des données d’impres-

sion même pendant le travail d’impression.

4. Circuit de contrôle d’appareils périphériques permettant la commande de

dispositifs extérieurs tels que des tiroirs-caisses.

SP5 1 2 M D 42

Nombre de colonnes d’impression

42 : 42 colonnes (16, 9 ccp)

Interface

D : Interface série (RS-232C)

C : Interface parallèle

Alimentation de papier

M : Alimentation de papier par friction

Mécanisme

2 : Une couleur, 42 colonnes

(16, 9 ccp)

Type d’imprimante

1 : Type avec barre de découpage

4 : Type avec coupe-papier

automatique

Imprimante de la série SP500

– 27 –

Page 31

OFF

ON

ERROR

POWER

FEED

2. Déballage et inspection

OFF

ON

ERROR

POWER

FEED

2-1. Déballage

Après avoir déballé l’appareil, vérifiez si tous les accessoires nécessaires se

trouvent dans la boîte.

Modèle avec barre de découpage

Imprimante

V

H

E

R

R

O

R

F

E

E

D

P

O

W

E

R

Cartouche à ruban

ON

OFF

Modèle avec coupe-papier automatique

Imprimante

FRANÇAIS

V

H

N

ERRO

R

F

E

E

D

Guide du rouleau

de papier

Plaque arrière

POW

ER

Câble d’alimentation

O

F

F

O

Cache de

l’interrupteur

Mode d’emploi

Fig. 2-1 Déballage

Si l’un des éléments mentionnés ci-dessus ne se trouve pas dans la caisse,

adressez-vous au magasin où vous avez acheté l’imprimante et demandez que la

pièce manquante vous soit fournie. Il est préférable de conserver la caisse

d’origine ainsi que tous les emballages. Ceux-ci vous seront utiles s’il vous faut

emballer l’imprimante ou la transporter.

– 28 –

Page 32

2-2. Emplacement de l’imprimante

Pour installer correctement l’imprimante, gardez à l’esprit les conseils suivants:

1. Mettez l’imprimante à l’abri de températures excessivement élevées comme en plein

soleil ou à proximité d’un appareil de chauffage, et à l’abri de l’humidité et de la

poussière.

2. Installez l’imprimante sur une surface stable et de niveau sur laquelle l’imprimante

FRANÇAIS

ne sera pas soumise à des vibrations.

3. Veillez à ce que l’imprimante soit branchée sur une source secteur stable.

Par exemple, ne pas brancher l’imprimante sur la prise secteur d’un circuit alimentant

déjà un appareil électroménager gros consommateur de courant et producteur de

parasites, tel qu’un réfrigérateur ou un climatiseur.

4. Veillez à ce que la découpage du secteur corresponde bien à la découpage spécifiée

sur la plaque d’identification de l’imprimante.

5. Pour débrancher l’imprimante, la fiche doit être débranchée de la prise murale, et

celle-ci doit être située à proximité de l’imprimante et facile d’accès.

2-3. Précautions de manipulation

1. Faites attention à ne pas laisser tomber de trombones, punaises ou autres objets dans

l’imprimante. Un dysfonctionnement pourrait en résulter.

2. Ne pas essayer d’imprimer quand il n’y a pas de papier ou de cartouche à ruban dans

l’imprimante. La tête d’impression pourrait être endommagée.

3. Ne pas ouvrir le capot pendant l’impression.

4. Ne pas toucher la tête d’impression immédiatement après un travail d’impression car

elle devient très chaude.

5. Utilisez seulement un rouleau de papier dont l’extrémité n’est pas collée au tube

central.

6. Quand le repère de fin de papier apparaît sur le papier, remplacez le rouleau de papier

avant qu’il soit terminé.

2-4. Entretien

Avant tout, cette imprimante est un appareil robuste, mais un minimum de précautions

sont à prendre pour éviter les dysfonctionnements. Par exemple:

1. Laissez l’imprimante dans un environnement “confortable”. En gros, si vous êtes à

l’aise, l’environnement sera acceptable pour l’imprimante.

2. Ne pas soumettre l’imprimante à des chocs ou à des vibrations excessives.

3. Évitez les environnements excessivement poussiéreux. La poussière est l’ennemi de

tous les appareils mécaniques de précision.

4. Pour nettoyer l’extérieur de l’imprimante, utilisez un chiffon légèrement imbibé

d’eau ou d’alcool, mais ne laissez aucun liquide pénétrer à l ’intérieur de l’imprimante.

5. L’intérieur de l’imprimante peut être nettoyé avec une petite brosse de nettoyage ou

un aérosol à air comprimé (vendu à cet effet). Pendant cette opération, veillez à ne pas

plier ni endommager les connexions ou les composants électroniques.

– 29 –

Page 33

ON

OFF

OFF

ON

ERROR

POWER

FEED

3. Identification des pièces et nomenclature

Modèle avec barre de découpage

Capot

Protège l’imprimante de la poussière et réduit le bruit.

Ne pas ouvrir le capot pendant l’impression.

V

H

N

O

F

F

O

Interrupteur d’alimen-

tation

Cet interrupteur vous

permet de mettre

l’imprimante sous

Panneau de commande

Comprend un commutateur de

commande et trois témoins indiquant

le statut de l’imprimante.

E

R

R

O

R

F

E

E

D

P

O

W

E

R

découpage et hors

découpage.

O

F

Connecteur

d’alimentation

Pour la connexion

du câble d’alimen-

tation.

Connecteur d’interface

Ce connecteur vous permet de

raccorder l’imprimante à

l’ordinateur hôte.

Connecteur de pilotage

F

O

N

d’appareils périphériques

Ce connecteur vous permet

de raccorder l’imprimante à

des appareils périphériques

tels que des tiroirs-caisses,

etc. Ne pas raccorder à un

téléphone.

Fig. 3-1 Vue externe de l’imprimante (Modèle avec barre de découpage)

– 30 –

FRANÇAIS

Page 34

ON

OFF

OFF

ON

ERROR

POWER

FEED

Modèle avec coupe-papier automatique

Capot

Protège l’imprimante de la poussière et réduit le bruit.

Ne pas ouvrir le capot pendant l’impression.

FRANÇAIS

Panneau de commande

Comprend un commutateur de

commande et trois témoins indiquant

le statut de l’imprimante.

V

H

N

E

R

R

O

R

F

E

E

D

P

O

W

E

R

O

F

F

O

Interrupteur d’alimen-

tation

Cet interrupteur vous

permet de mettre

l’imprimante sous

découpage et hors

découpage.

Connecteur

d’alimentation

Pour la connexion

du câble d’alimen-

tation.

Connecteur d’interface

Ce connecteur vous permet de

raccorder l’imprimante à

l’ordinateur hôte.

Connecteur de pilotage

OFF

ON

d’appareils périphériques

Ce connecteur vous permet

de raccorder l’imprimante à

des appareils périphériques

tels que des tiroirs-caisses,

etc. Ne pas raccorder à un

téléphone.

Fig. 3-2 Vue externe de l’imprimante (Modèle avec coupe-papier automatique)

– 31 –

Page 35

ON

4. Câbles de connexion et câble d’alimentation

4-1. Connexion du câble d’interface

Remarque:Avant de connecter ou déconnecter le câble d’interface, veillez à

ce que l’imprimante et tous les appareils qui y sont connectés

soient hors découpage.

Veillez également à débrancher le câble d’alimentation

de la prise secteur.

(1)Connectez le câble d’interface à la borne figurant sur le panneau arrière de

l’imprimante.

(2)Dans le cas d’une interface série, resserrez les vis du connecteur. Dans le cas

d’une interface parallèle, fixez le connecteur avec les fermoirs.

OFF

ON

FRANÇAIS

Câble d’interface série

OFF

ON

Câble d’interface parallèle

– 32 –

Page 36

4-2. Raccordement d’un appareil périphérique

Vous pouvez raccorder un appareil périphérique à l’imprimante à l’aide d’une

fiche modulaire. Nous expliquons ci-dessous comment installer le tore de ferrite

et faire le raccordement proprement dit. Pour les détails sur le type de fiche

modulaire à utiliser, reportez-vous à la page 115. Notez que le fil ou la fiche

modulaires ne sont pas fournis avec l’imprimante. Vous devrez donc vous les

FRANÇAIS

procurer.

Attention!

Assurez-vous que l’imprimante est hors découpage, qu’elle est débran-

chée de la prise secteur et que l’ordinateur est hors découpage avant

d’effectuer les connexions.

(1) Connectez le câble de pilote de périphérique à la borne figurant sur le panneau

arrière de l’imprimante.

Attention!

Ne connectez pas une ligne de téléphone à la borne du pilote de

périphérique, sous peine de risquer d’endommager l’imprimante.

Pour des raisons de sécurité, il convient également de ne pas brancher

d’appareil périphérique en cas de risque de survoltage.

OFF

ON

– 33 –

Page 37

4-3. Connexion de câble d’alimentation secteur optionnel

Remarque:Avant de connecter ou déconnecter câble d’alimentation, veillez

à ce que l’imprimante et tous les appareils qui y sont connectés

soient hors découpage. Veillez également à débrancher le câble

d’alimentation de la prise secteur.

(1)Vérifiez, sur l’étiquette apposée à l’arrière ou au bas de l’imprimante, que la

découpage de l’appareil et de la prise secteur correspondent.

Veillez également à ce que la fiche à l’extrémité du câble d’alimentation soit

adaptée à la prise secteur.

(2)Si le câble d’alimentation n’est pas connecté à l’imprimante, branchez

l’extrémité adéquate dans l’entrée secteur à l’arrière de l’appareil.

(3)Branchez le câble d’alimentation dans une prise secteur mise à la terre.

OFF

ON

FRANÇAIS

Attention!

Si la tension indiquée sur l’étiquette de votre imprimante ne correspond pas à celle de votre secteur,

contactez immédiatement votre revendeur.

– 34 –

Page 38

4-4. Mise sous découpage de l’imprimante

OFF

ON

ERROR

POWER

FEED

OFF

ON

OFF

ON

Assurez-vous d’avoir bien connecté le câble d’alimentation comme décrit à la

section 4-3.

(1)Placez l’interrupteur d’alimentation, situé sur le côté droit de l’imprimante,

sur la position sous découpage.

FRANÇAIS

La DEL POWER s’allume au panneau des commandes.

V

H

N

E

R

R

O

R

F

E

E

D

P

O

W

E

R

O

F

F

O

Interrupteur d’alimentation

Attention!

Nous vous recommandons de débrancher l’imprimante du secteur lorsque vous ne comptez pas l’utiliser pendant une période prolongée. Par

ailleurs, veillez lors de l’installation à ce que la prise secteur alimentant

l’imprimante soit proche et d’accès facile.

4-5. Placement de la plaque arrière

Au besoin, placez la plaque arrière.

O

F

F

O

N

OFF

ON

– 35 –

Page 39

4-6. Installation du câble

OFF

ON

OFF

ON

OFF

ON

Installez le câble, comme indiqué sur le schéma ci-dessous.

O

F

F

O

N

O

F

F

O

N

FRANÇAIS

O

F

F

O

N

– 36 –

Page 40

4-7. Installation du cache de l’interrupteur

OFF

ON

ERROR

POWER

FEED

OFF

ON

L’installation de ce cache n’est pas nécessaire.

Ne l’installez que si vous souhaitez :

•éviter que l’interrupteur d’alimentation ne soit actionné par erreur ;

• vous assurer que personne ne peut l’actionner facilement.

FRANÇAIS

Installez le cache, comme indiqué sur le schéma ci-dessous.

V

H

E

R

R

O

R

F

E

E

D

P

O

W

E

R

ON

OFF

N

O

F

F

O

L’interrupteur peut être activé ON (!) et désactivé OFF (O) en insérant un

instrument étroit (stylo à bille, par ex.) dans les orifices du cache de l’interrupteur.

Attention!

Nous vous recommandons de débrancher l’imprimante du secteur lorsque vous ne comptez pas l’utiliser pendant une période prolongée. Par

ailleurs, veillez lors de l’installation à ce que la prise secteur alimentant

l’imprimante soit proche et d’accès facile.

– 37 –

Page 41

H

V

OFF

ON

OFF

ON

ERR

OR

PO

WER

FEED

5. Installation d’une cartouche à ruban et chargement du papier

5-1. Modèle avec barre de découpage

5-1-1. Installation d’une cartouche à ruban

E

R

R

O

R

FE

ED

P

O

W

E

R

F

F

O

Hors tension

Fig. 5-1. Ouvrez le capot

Séparateur de ruban

Tête d’impression

Ruban encreur

Bouton

d’alimentation

du ruban

Parties avec

encoches

Fig. 5-2 Mise en place de la

cartouche à ruban

Capot

V

H

N

O

OFF

Cartouche

à ruban

1 Mettez l’imprimante hors décou-

page.

2 Ouvrez le capot.

Attention!

1. Ne touchez pas la tête d’impres-

sion immédiatement après une

impression ; en effet, celle-ci peut

être très chaude.

ON

2. Ne pas toucher la lame du coupepapier.

· Une lame se trouve dans la fente

de sortie de papier. Il est fortement déconseillé de mettre sa

main dans la fente de sortie de

papier non seulement pendant

l’impression mais aussi en toute

autre circonstance, même quand

l’impression n’est pas effectuée.

3 Mettez la cartouche à ruban en place

dans le sens indiqué dans la figure

5-2 et appuyez légèrement sur la

cartouche afin qu’elle se mette en

place. Si la mise en place de la

cartouche n’est pas satisfaisante,

appuyez sur la cartouche tout en

faisant tourner le bouton d’alimen-

tation du ruban de la cartouche dans

le sens de la flèche.

4 Pour tendre le ruban, faites tourner

le bouton d’alimentation du ruban

de la cartouche dans le sens de la

flèche.

5 Refermez le capot.

– 38 –

FRANÇAIS

Page 42

H

V

B

A

FRANÇAIS

Fig. 5-3 Dégagement de la

cartouche du ruban

5-1-2. Chargement du papier

Remarque: Pour enlever la cartouche à

ruban, soulevez la partie A,

puis enlevez la cartouche en la

tenant par la partie B comme

indiqué dans la figure 5-3.

Capot

V

H

Fig. 5-4 Dépose du capot

1 Ouvrez le capot.

Attention!

1. Ne touchez pas la tête d’impres-

sion immédiatement après une

impression ; en effet, celle-ci peut

être très chaude.

2. Ne pas toucher la lame du coupepapier.

· Une lame se trouve dans la fente

de sortie de papier. Il est fortement déconseillé de mettre sa

main dans la fente de sortie de

papier non seulement pendant

l’impression mais aussi en toute

autre circonstance, même quand

l’impression n’est pas effectuée.

2 Coupez l’extrémité du papier per-

pendiculairement.

3 Vérifiez si l’imprimante est bien

sodécoupageion.

– 39 –

Page 43

H

V

OFF

ON

ERROR

POWER

FEED

Rouleau de

papier

Fig. 5-5 Chargement du papier

Rouleau de papier

Fente de

sortie de

papier

Mécanisme d’avance

de papier

Fig. 5-6 Chargement du papier

4 En faisant attention au sens du rou-

leau, mettez le rouleau de papier en

place dans le creux, comme indiqué

dans la figure 5-5.

FRANÇAIS

V

H

5 Insérer le bord du papier dans le

mécanisme d’avance de papier (partie en plastique noir). S’il est inséré

correctement, le bord du papier ressortira par la fente de sortie de papier.

6 Insérez l’extrémité du papier dans la

fente de sortie où se trouve la barre de

découpage, puis remettez le capot en

place en suivant la procédure

d’ouverture du capot décrite à l ’étape

1 ci-dessus dans le sens inverse.

Remarque:Quand le repère de fin

de papier apparaît sur

le papier, remplacez le

rouleau de papier avant

qu’il soit terminé.

Barre de

découpage

V

H

N

E

R

R

O

R

F

E

E

D

P

O

W

E

R

– 40 –

Fig. 5-7

O

F

F

O

Page 44

H

V

ONON

E

R

R

O

R

ERROR

F

E

FEED

OFF

ON

ERROR

POWER

FEED

5-2. Modèle avec coupe-papier automatique

5-2-1. Installation d’une cartouche à ruban

1 Mettez l’imprimante hors décou-

Capot

page.

2 Ouvrez le capot.

FRANÇAIS

E

R

R

O

R

F

E

E

D

P

O

W

E

R

Fig. 5-8 Ouvrez le capot

Coupe-papier

automatique

V

H

N

O

F

F

O

Hors tension

Attention!

1. Ne touchez pas la tête d’impres-

sion immédiatement après une

impression ; en effet, celle-ci peut

être très chaude.

2. Ne pas toucher la lame du coupe-

ON

OFF

papier.

· Une lame se trouve dans la fente

de sortie de papier. Il est fortement déconseillé de mettre sa

main dans la fente de sortie de

papier non seulement pendant

l’impression mais aussi en toute

autre circonstance, même quand

l’impression n’est pas effectuée.

3 Soulevez le coupe-papier automati-

que pour la mettre en position verticale, comme indiqué dans la figure

5-9.

Fig. 5-9 Redressement du coupe-

papier automatique

– 41 –

Page 45

H

V

Séparateur

H

V

de ruban

Tête d’impression

Ruban encreur

Bouton

d’alimentation du ruban

Parties

avec

encoches

Fig. 5-10 Mise en place de la

cartouche à ruban

B

A

Coupepapier

automatique

Cartouche

à ruban

4 Mettez la cartouche à ruban en place

dans le sens indiqué dans la figure

5-10 et appuyez légèrement sur la

cartouche afin qu’elle se mette en

place. Si la mise en place de la

cartouche n’est pas satisfaisante, appuyez sur la cartouche tout en faisant tourner le bouton d’alimenta-

tion du ruban de la cartouche dans le

sens de la flèche.

5 Pour tendre le ruban, faites tourner

le bouton d’alimentation du ruban

de la cartouche dans le sens de la

flèche.

6 Refermez le coupe-papier automa-

tique.

7 Refermez le capot.

Remarque:Pour enlever la cartou-

che à ruban, soulevez

la partie A, puis enlevez la cartouche en la

tenant par la partie B

comme indiqué dans la

figure 5-11.

FRANÇAIS

Fig. 5-11 Dégagement de la

cartouche du ruban

– 42 –

Page 46

5-2-2. Chargement du papier

H

V

FRANÇAIS

Fig. 5-12 Dépose du capot

Rouleau de

papier

H

V

Capot

1 Ouvrez le capot.

Attention!

1. Ne touchez pas la tête d’impres-

sion immédiatement après une

impression ; en effet, celle-ci peut

être très chaude.

2. Ne pas toucher la lame du coupepapier.

· Une lame se trouve dans la fente

de sortie de papier. Il est fortement déconseillé de mettre sa

main dans la fente de sortie de

papier non seulement pendant

l’impression mais aussi en toute

autre circonstance, même quand

l’impression n’est pas effectuée.

2 Coupez l’extrémité du papier per-

pendiculairement.

3 Vérifiez si l’imprimante est bien

sous découpage.

4 En faisant attention au sens du rou-

leau, mettez le rouleau de papier en

place dans le creux, comme indiqué

dans la figure 5-13.

Fig. 5-13 Chargement du papier

– 43 –

Page 47

Rouleau de

papier

Fente de sortie

de papier

5 Insérez l’extrémité du papier dans

le mécanisme d’avance de papier

(partie en plastique noir). S’il est

inséré correctement, le bord du papier passera par la fente coupe-papier automatique. Appuyez sur la

V

H

touche FEED pour couper le papier.

6 Enlevez le morceau de papier coupé

et refermez le capot.

Remarque:Quand la marque de fin

de papier apparaît sur

le papier, remplacez le

Fig. 5-14 Chargement du papier

rouleau avant qu’il soit

épuisé.

5-3. Installation du guide du rouleau de papier

Lors de l’utilisation d’un rouleau de

papier de 58 mm de large, installez le

Guide du rouleau

de papier

V

H

guide du rouleau de papier fourni dans

le logement prévu dans l’imprimante.

Réglez ensuite le commutateur mémoire

2-A et 2-B de sorte que la largeur d’im-

pression passe de 63 mm à 45 mm.

Pour obtenir des instructions sur le ré-

glage du commutateur, reportez-vous

au manuel des caractéristiques intitulé

“Specification Manual”, fourni séparément.

FRANÇAIS

Fig. 5-15 Installation du guide du

rouleau de papier

– 44 –

Page 48

5-4. Dégagement des bourrages de papier

OFF

ON

ERROR

POWER

FEED

FRANÇAIS

V

H

Couper

E

R

R

O

R

FEED

P

O

W

E

R

ON

OFF

1 Mettez l’imprimante hors décou-

page et débranchez le câble d’ali-

mentation de la prise secteur.

2 Ouvrez le capot.

Remarque:Ne touchez pas la tête

d’impression immédiatement après une impression, car elle risque d’être très chaude.

De même, ne touchez

pas la lame du coupepapier automatique

pour les modèles qui en

sont équipés.

Fig 5-16 Coupure du papier

Fig 5-17 Bouton du coupe-papier

automatique

Bouton

3 Pour les modèles munis d’un coupe-

papier automatique, relevez ce dernier de sorte à ce qu’il soit à la verti-

cale, comme illustré à la Fig. 5-9.

4 Coupez le papier devant le méca-

nisme d’avance de papier, comme

illustré à la Fig. 5-16.

5 Dégagez le papier bourré, puis met-

tez le bout du papier rouleau en

place dans le mécanisme d’avance.

Remarque:

1) Si le papier est bourré dans le

coupe-papier automatique, dé-

placez la lame du coupe-papier

en tournant le bouton à l’aide

d’un tournevis à lame plate ou

d’un outil semblable, puis dégagez le papier bourré.

2) Ne touchez en aucun cas les arê-

– 45 –

tes métalliques, sous peine de

risquer de vous blesser.

Page 49

6. Panneau de commande et autres fonctions

6-1. Panneau de commande

1

Témoin

POWER

2

Témoin FEED

3

(avance de papier)

Témoin ERROR

(erreur)

6-2. Indicateurs de base

(alimentation)

1 Témoin POWER (DEL verte)

S’allume quand l’appareil est sous

découpage.

2 Témoin FEED

Appuyez sur la touche FEED pour

faire avancer le papier.

3 Témoin ERROR (DEL rouge)

Indique des erreurs variées en combinaison avec le témoin POWER.

FRANÇAIS

Sous tension/hors

tension

Pas d’erreur

Témoin POWER

Allumé/éteint

Allumé

Témoin ERROR

—

Éteint

– 46 –

Avertisseur sonore

—

—

Page 50

6-3. Erreurs

1) Erreur récupérable

Description de

l’erreur

Erreur de fin de

papier

FRANÇAIS

Attente de

récupération de

l’impression après

chargement du papier

Erreur de proximité

de fin de papier

(option)

Témoin POWER

Allumé

Clignote

(Allumé : 0,25 s/

Éteint : 0,25 s)

Allumé

Témoin ERROR

Allumé

Éteint

Clignote (Allumé :

2s/Éteint : 2 s)

Avertisseur sonore

4 bips courts (0,13 s)

répétés deux fois

Aucun

Aucun

Conditions de

récupération

*1

*2

*3

Détection de

température élevée

de la tête

Détection de

température élevée

de la carte

Erreur de coupepapier (sur les

modèles avec

coupe-papier)

Erreur mécanique

(autre qu’une erreur

de coupe-papier)

Erreur de détection

du repère noir

Clignote

(Allumé : 1 s/

Éteint : 1 s)

Clignote

(Allumé : 2 s/

Éteint : 2 s)

Allumé

Allumé

Allumé

Éteint

Éteint

Clignote (Allumé :

0,125 s/ Éteint :

0,125 s)

Clignote (Allumé:

0,25 s/ Éteint :

0,25 s)

Clignote (Allumé :

0,5 s/ Éteint : 0,5 s)

Aucun

Aucun

3 bips courts (0,13 s

+ 0,13 s + 0,5 s)

2 bips courts (0,13 s

+ 0,5 s)

3 bips courts (0,13 s

+ 0,13 s + 0,13 s)

*4

*5

*6

*7

*8

*1 Une fois le papier inséré, l’imprimante le charge automatiquement.

Vérifiez que le témoin POWER clignote, puis appuyez sur la touche FEED.

*2 Appuyez sur la touche FEED.

*3 Pour plus de détails, reportez-vous au manuel de mise en place du capteur de

proximité de fin de papier vendu en option.

Comme ce capteur est optionnel, cette erreur ne s’affiche pas si l’imprimante

n’est pas équipée d’un capteur.

*4 La récupération de l’imprimante est automatique une fois la tête refroidie. Une

erreur de température de la tête est normale.

*5 La récupération de l’imprimante est automatique une fois la carte refroidie.

*6 La récupération de l’imprimante est automatique si le coupe-papier revient

dans sa position d’origine une fois l’appareil mis hors puis sous découpage.

La restauration est également possible avec la commande <DLE> <ENQ> n

en mode ESC/ POS.

– 47 –

Page 51

Remarque

1) Si le coupe-papier ne revient pas dans sa position d’origine ou n’exécute

pas le mouvement initial, la récupération est impossible.

2) Si le papier est coincé, mettez l’appareil hors découpage, dégagez le

bourrage de papier, puis mettez l’appareil sous découpage.

3) En cas d’erreur:

Mode STAR : Erreur non récupérable

Mode ESC/ POS : Erreur récupérable

*7 Mettez l’appareil hors découpage, dégagez le bourrage de papier ou remédiez

à un autre problème, puis mettez l’appareil sous découpage. La récupération

de l’imprimante est automatique si le chariot revient dans sa position d’origine

une fois l’appareil mis hors puis sous découpage.

La restauration est également possible avec la commande <DLE> <ENQ> n

en mode ESC/ POS.

En cas d’erreur:

Mode STAR : Erreur non récupérable

Mode ESC/ POS : Erreur récupérable

*8 Pour les erreurs de bourrage de papier :

Retirez le papier coincé et changez le rouleau de papier, le cas échéant.

Pour les erreurs de format de papier incorrect :

Remplacez le rouleau de papier par un autre disposant du repère noir correct.

2) Erreur non récupérable

Description de

l’erreur

Erreur de thermistor

Témoin POWER

Éteint

Témoin ERROR

Clignote (Allumé :

0,25 s/ Éteint : 0,25 s)

Avertisseur sonore

2 bips courts (0,13 s + 0,5 s)

FRANÇAIS

Erreur d’écriture de la

mémoire flash

Erreur lecture/écriture

mémoire vive

Erreur d’alimentation

Erreur d’unité

centrale

Éteint

Éteint

Éteint

Éteint

Clignote (Allumé :

1 s/ Éteint : 1 s)

Allumé

Clignote (Allumé :

2 s/ Éteint : 2 s)

Allumé

Aucun

Aucun

Aucun

Un bip long (2 s)

Remarque

Si une erreur non récupérable se produit, mettez l’appareil hors découpage,

attentez 10 secondes minimum et remettez-le sous découpage. Si l’erreur non

récupérable continue de s’afficher, contactez votre revendeur pour des réparations.

– 48 –

Page 52

6-4. Mode de réglage

Quatre modes de réglage sont disponibles.

L’appareil passe en mode de réglage si vous le mettez sous découpage tout en

appuyant sur le commutateur FEED.

Vous pouvez passer en mode Auto-impression en relâchant le commutateur

FRANÇAIS

FEED dès que l’avertisseur sonore retentit une fois.

(maintenez-le enfoncé au moins 2 secondes)

▼

Passez en mode de réglage d’alignement des points en relâchant le commutateur

FEED dès que l’avertisseur sonore retentit deux fois.

(Reportez-vous à l’Appendice G.)

(maintenez-le enfoncé au moins 2 secondes)

▼

Vous pouvez passer en mode de vidage hexadécimal en relâchant le commutateur

FEED dès que l’avertisseur sonore retentit trois fois.

(maintenez-le enfoncé au moins 2 secondes)

▼

Vous pouvez passer en mode d’alignement du capteur de repère noir en relâchant

le commutateur FEED dès que l’avertisseur sonore retentit quatre fois.

(Reportez-vous à l’Appendice H.)

▼

Si l’avertisseur sonore retentit cinq fois minimum, mettez immédiatement

l’appareil hors découpage ; le mode de réglage est en effet annulé.

– 49 –

Page 53

6-4-1. Mode Auto-impression

Le test d’impression sera effectué conformément au réglage du numéro de

vérification, du commutateur mémoire des commutateurs DIP et de l’ordre des

caractères. Si vous maintenez la pression sur la touche FEED ou si vous appuyez

sur la touche FEED à la fin du test d’impression, seuls les caractères seront

imprimés à plusieurs reprises.

FRANÇAIS

– 50 –

Page 54

6-4-2. Vidage hexadécimal

Chacun des signaux envoyés de l’ordinateur à l’imprimante sera imprimé en code

hexadécimal.

Cette fonction vous permet de vérifier si un code de contrôle envoyé à l’impri-

mante par le programme utilisé est correct ou non. La dernière ligne n’est pas

imprimée si les données correspondantes ne remplissent pas une ligne complète.

FRANÇAIS

Néanmoins, si vous appuyez sur la touche FEED, la dernière ligne sera imprimée.

Pour sortir de ce mode, il est nécessaire de mettre l’imprimante hors tension.

– 51 –

Page 55

INHALTSVERZEICHNIS

1. Kurzbeschreibung ............................................................................................ 53

2. Auspacken und Aufstellen ............................................................................... 54

2-1. Überprüfen ...........................................................................................54

2-2. Wahl eines Aufstellungsorts für den Drucker ...................................... 55

2-3. Hinweise zum Umgang ........................................................................55

2-4. Wartung ............................................................................................... 55

3. Beschreibung und Bezeichnung der Geräteteile..............................................56

4. Anschlußkabel und Netzkabel .........................................................................58

4-1. Anschließen des Schnittstellenkabels .................................................. 58

4-2. Anschluß an ein Peripheriegerät ..........................................................59

4-3. Anschließen des optionalen Netzkabels...............................................60

4-4. Einschalten ...........................................................................................61

4-5. Anbringen der hinteren Abdeckung .....................................................61

4-6. Installieren der Kabel ...........................................................................62

4-7. Einsetzen der Schalterabdeckung ........................................................ 63

5. Einlegen von Farbbandkassette und Papier .....................................................64

5-1. Abreißkantenmodell ............................................................................. 64

5-2. Auto-Schneidwerkmodell .................................................................... 67

5-3. Einsetzen der Papierrollenführung ....................................................... 70

5-4. Beheben von Papierstaus .....................................................................71

6. Bedienfeld und andere Funktionen .................................................................. 72

6-1. Bedienfeld ............................................................................................72

6-2. Standardanzeigen .................................................................................72

6-3. Fehler ...................................................................................................73

6-4. Einstellungsmodus ...............................................................................75

ANHANG .......................................................................................................... 104

DEUTSCH

Der Anhang dieser Bedienungsanleitung ist nur in englischer Sprache.

– 52 –

Page 56

1. Kurzbeschreibung

Der serielle Nadeldrucker der Serie SP500 ist zur Verwendung mit elektronischen Instrumenten wie POS, Bankgeräte, Computerzubehör, etc. gedacht.

Die wichtigsten Merkmale der Serie SP500 sind:

1. Bidirektioneller Druck mit ca. 4 Zeilen/s

2. Serielle oder parallele Schnittstelle

3. Pufferspeicher erlaubt, Druckdaten auch während des Druckvorgangs zu

empfangen.

4. Peripherie-Steuerschaltung zur Steuerung von externen Geräten wie Registrier-

DEUTSCH

kassen:

SP5 1 2 M D 42

Anzahl der Druckspalten

42 : 42 Spalten (16,9 cpi)

Schnittstelle

D : Serielle Schnittstelle (RS-232C)

C : Parallele Schnittstelle

Papiervorschub

M : Walzenvorschub

Mechanismus

2 : Einfarbig, 42 Spalten (16,9 cpi)

Druckertyp

1 : Abreißkantenmodell

4 : Mit automatischem Schneidwerk

Drucker Serie SP500

– 53 –

Page 57

OFF

ON

ERROR

POWER

FEED

2. Auspacken und Aufstellen

OFF

ON

ERROR

POWER

FEED

2-1. Überprüfen

Sie den Kartoninhalt, und vergewissern Sie sich, daß alle unten abgebildeten

Teile vorhanden sind.

Abreißkantenmodell Auto-Schneidwerkmodell

Drucker

Drucker

E

R

R

O

R

F

E

E

D

P

O

W

E

R

Farbbandkassette

V

H

ON

OFF

Bedienungsanleitung

Abb. 2-1 Auspacken

ERRO

R

F

E

E

D

POW

ER

Hintere Abdeckung

V

H

N

O

F

F

O

NetzkabelPapierrollenführung

Schalterabdeckung

DEUTSCH

Falls Teile fehlen, wenden Sie sich zwecks Nachlieferung bitte an den Fachhandel, bei dem das Gerät gekauft wurde. Im Hinblick auf einen eventuellen

zukünftigen Transport des Druckers empfiehlt es sich, den Lieferkarton und das

gesamte Verpackungsmaterial aufzubewahren.

– 54 –

Page 58

2-2. Wahl eines Aufstellungsorts für den Drucker

Bevor Sie den Drucker auspacken, sollten Sie einige Minuten damit verbringen,

einen geeigneten Aufstellungsort auszusuchen. Denken Sie dabei an die folgenden

Punkte:

1. Den Drucker vor Hitzequellen wie direktem Sonnenlicht oder Heizkörpern

schützen und von Feuchtigkeit und Staub fernhalten.

2. Den Drucker auf einem flachen, aber festen Untergrund aufstellen, wo keine

Vibrationen vorhanden sind.

3. Sicherstellen, daß der Drucker an eine einwandfreie Stromzufuhr angeschlossen ist.

Er sollte nicht an Steckdosen angeschlossen werden, an denen bereits Geräte mit

möglichen Netzstörungen wie Kopierer, Kühlschränke u.a. angeschlossen sind.

4. Die Versorgungsspannung muß dem Spannungswert auf dem Typenschild an der

DEUTSCH

Unterseite des Druckers entsprechen.

5. Die verwendete Steckdose soll in der Nähe und frei zugänglich sein.

2-3. Hinweise zum Umgang

1. Achten Sie darauf, keine Papierclips oder anderen Fremdkörper in den Drucker

fallen zu lassen. Diese können Betriebsstörungen oder Schäden am Gerät hervorrufen.

2. Versuchen Sie nicht zu drucken, wenn kein Papier oder keine Farbbandkassette

eingelegt ist, da sonst der Druckkopf beschädigt werden kann.

3. Öffnen Sie nicht die Frontabdeckung während des Druckens.

4. Berühren Sie nicht den Druckkopf sofort nach dem Druckvorgang, da dieser sehr

heiß wird.

5. Verwenden Sie nur Rollenpapier, das nicht am Rollenkern festgeklebt ist.

6. Wenn die Papierende-Markierung erscheint, tauschen Sie die Papierrolle aus,

bevor sie ganz verbraucht ist.

2-4. Wartung

Ihr Drucker ist ein robust gebautes Gerät, sollte aber trotzdem mit einem gewissen

Maß an Vorsicht behandelt werden, um Fehlfunktionen zu vermeiden. Zum Beispiel:

1. Stellen Sie den Drucker in einer “komfortablen” Betriebsumgebung auf. Als

Faustregel gilt: Wo Sie sich wohlfühlen, fühlt sich der Drucker ebenfalls wohl.

2. Setzen Sie den Drucker keinen Erschütterungen oder starken Vibrationen aus.

3. Vermeiden Sie sehr staubige Umgebungen. Staub ist der Erzfeind aller Präzisions-

geräte.

4. Zum Reinigen des Gehäuses verwenden Sie einen nur leicht mit Wasser, sehr

milder wässriger Seifenlösung oder ein wenig Alkohol angefeuchteten Lappen.

Lassen Sie auf keinen Fall Flüssigkeiten in das Innere des Druckers geraten.

5. Das Innere des Druckers kann mit einem kleinen Reiniger oder einem Luftspray

(in Fachgeschäften erhältlich) gereinigt werden. Bei dieser Arbeit darauf achten,

keine Kabelverbindungen oder elektronische Bauteile zu verbiegen oder zu

beschädigen.

– 55 –

Page 59

ON

OFF

OFF

ON

ERROR

POWER

FEED

3. Beschreibung und Bezeichnung der Geräteteile

Abreißkantenmodell

Abdeckung

Schüzt den Drucker vor Staub, und reduziert das

Betriebsgeräusch. Nicht die Frontabdeckung

während des Druckens öffnen.

V

H

Bedienfeld

Hat einen Steuerschalter und

zwei Anzeigen zur Anzeige des

Druckerzustands.

Netzanschluß

Zum Anschließen

des Netzkabels.

Schnittstellenbuchse

Zum Anschluß des Druckers

an den Hostcomputer.

Abb. 3-1 Außenansicht des Druckers (Abreißkantenmodell)

N

E

R

R

O

R

F

E

E

D

P

O

W

E

R

O

F

F

O

DEUTSCH

Netzschalter

Zum Ein-und

Ausschalten des

Druckers.

O

F

F

O

N

PeripheriegerätSteueranschluß

Zum Anschluß an

Peripheriegeräte wie

Registrierkassen etc.

Nicht zum Anschluß an

ein Telefon!

– 56 –

Page 60

ON

OFF

OFF

ON

ERROR

POWER

FEED

Auto-Schneidwerkmodell

Abdeckung