Page 1

SCT Weight Transmitter

10 Series

Installation & Operator’s Manual

131129 Rev A

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

1.0 Introduction............................................................................ 1

1.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Safety Symbol Definitions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.2 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.3 Equipment Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.4 Correct Installation Of Weighing Instruments . . . . . . . . . . . . . . . . . . . 2

1.1.5 Correct Installation Of The Load Cells. . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Load Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.1 Load Cell Input Test (Quick Access) . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.2 Load Cell Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.5 LED and Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.6 Instrument Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.6.1 If The Instrument Has Not Been Calibrated. . . . . . . . . . . . . . . . . . . . . 8

2.0 Configuration ......................................................................... 9

2.1 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.1 Theoretical Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1.2 Maximum Capacity (NASS ) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.1.3 Zero Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1.4 Zero Value Manual Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1.5 Weight (Span) Calibration (With Test Weights) . . . . . . . . . . . . . . . . . 16

2.1.6 Setting Units of Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.1.7 Display Coefficient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.2 Filter On The Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.3 Zero Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.4 Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5 Serial Communication Settings . . . . . . . . . . . . . . . . . . . . . . . 23

2.5.1 RS-485 Serial Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.6 Outputs And Inputs Configuration . . . . . . . . . . . . . . . . . . . . . 26

2.7 Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.8 Setpoints Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2.9 Reserved For The Installer . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.9.1 Default Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.9.2 Program Selection - Reverse:. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.9.3 Keypad Or Display Locking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Rice Lake Weighing Systems is an ISO 9001 registered company.

December 27, 2013

Page 4

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

3.0 Operation.............................................................................. 32

3.1 Semi-Automatic Tare (Net/Gross) . . . . . . . . . . . . . . . . . . . . . 32

3.2 Preset Tare (Subtractive Tare Device) . . . . . . . . . . . . . . . . . . 32

3.3 Semi-Automatic Zero (Weight Zero-setting For Small Variations)

33

3.4 Peak. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.5 Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.6 Modbus-RTU Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.7 ASCII Bidirectional Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.8 Fast Continuous Transmission Protocol . . . . . . . . . . . . . . . . 46

3.9 Continuous Transmission Protocol To Remote Displays . . . 46

3.10 Communication Examples . . . . . . . . . . . . . . . . . . . . . . . . . . 48

SCT Weight Transmitter Limited Warranty ................................... 51

For More Information .................................................................... 53

ii SCT Weight Transmitter Operator’s Manual

Page 5

1.0 Introduction

WARNING

Important

WARNING

1.1 Safety

1.1.1 Safety Symbol Definitions:

Indicates a potentially hazardous situation that, if not avoided

could result in death or serious injury, and includes hazards

that are exposed when guards are removed.

Indicates information about procedures that, if not observed,

could result in damage to equipment or corruption to and

loss of data.

1.1.2 Safety Precautions

Do not operate or work on this equipment unless you have

read and understand the instructions and warnings in this

manual. Contact any Rice Lake Weighing System dealer for

replacement manuals. Proper care is your responsibility.

Failure to heed may result in serious injury or death.

Risk of electrical shock. No user serviceable parts. Refer to qualified service

personnel for service.

The unit has no power switch, to completely remove D/C power from the unit,

disconnect the D/C power cable from the main socket.

DO NOT allow minors (children) or inexperienced persons to operate this unit.

DO NOT operate without all shields and guards in place.

DO NOT use for purposes other then weighing applications.

DO NOT place fingers into slots or possible pinch points.

DO NOT use this product if any of the components are cracked.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

DO NOT use near water.

Introduction 1

Page 6

1.1.3 Equipment Recommendations

Important

Failure to follow the installation recommendations will be

considered a misuse of the equipment

To Avoid Equipment Damage

• Keep away from heat sources and direct sunlight.

• Protect the instrument from rain.

• Do not wash, dip in water or spill liquid on the instrument.

• Do not use solvents to clean the instrument.

• Do not install in areas subject to explosion hazard.

1.1.4 Correct Installation Of Weighing Instruments

• The terminals indicated on the instrument’s wiring diagram to be connected

to earth must have the same potential as the scale structure (ground). If you

are unable to ensure this condition, connect a ground wire between the

instrument and the scale structure.

• The load cell cable must be run separately to the instrument input and not

share a conduit with other cables. A shielded connection must be continuous

without a splice.

• Use “RC” filters (quench-arcs) on the instrument-driven solenoid valve and

remote control switch coils.

• Avoid electrical noise in the instrument panel; if inevitable, use special

filters or sheet metal partitions to isolate.

• The panel installer must provide electrical protection for the instruments

(fuses, door lock switch, etc.).

• It is advisable to leave equipment always switched on to prevent the

formation of condensation.

• Maximum Cable Lengths:

- RS-485: 1000 metres with AWG24, shielded and twisted cables

- RS-232: 15 metres for baud rates up to 19200

1.1.5 Correct Installation Of The Load Cells

Installing Load Cells:

The load cells must be placed on rigid, stable structures within .5% of plumb and

level. It is important to use mounting modules for load cells to compensate for

misalignment of the support surfaces.

Protection Of The Load Cell Cable:

Use water-proof sheaths and joints in order to protect the cables of the load cells.

Mechanical Restraints (pipes, etc.):

When pipes are present, we recommend the use of hoses, flexible couplings and

rubber skirted joints. In case of rigid conduit and pipes, place the pipe support or

anchor bracket as far as possible from the weighed structure (at a distance at least

40 times the diameter of the pipe).

Welding:

Avoid welding with the load cells already installed. If this cannot be avoided,

place the welder ground clamp close to the required welding point to prevent

sending current through the load cell body.

2 SCT Weight Transmitter Operator’s Manual

Page 7

Windy Conditions - Shocks - Vibrations:

Uses ground plate

to continue ground.

Uses structure to continue ground.

PRINT

MENU

0

ESC

The use of weigh modules is strongly recommended for all load cells to

compensate for misalignment of the support surfaces. The system designer must

ensure that the scale is protected against lateral shifting and tipping relating to

shocks and vibration, windy conditions, seismic conditions and stability of the

support structure.

Grounding The Weighed Structure:

By means of a 10ga solid or braided wire or braided grounding strap, connect the

load cell upper support plate with the lower support plate, then connect all the

lower plates to a single earth ground. Once installed electrostatic charges

accumulated are discharged to the ground without going through or damaging the

load cells. Failure to implement a proper grounding system might not affect the

operation of the weighing system; this, however, does not rule out the possibility

that the load cells and connected instrument may become damaged by ESD. It is

forbidden to ensure grounding system continuity by using metal parts contained

in the weighed structure.(see Figure 1-1.)

1.2 Load Cells

1.2.1 Load Cell Input Test (Quick Access)

1. From the weight display, press for 3 seconds.

2. The display will read NU-CEL. Press .

3. The response signal of the load cell is displayed, expressed in mV with

four decimals. Press three times to exit set-up mode.

Figure 1-1. Installation Recommendations

Introduction 3

Page 8

1.2.2 Load Cell Testing

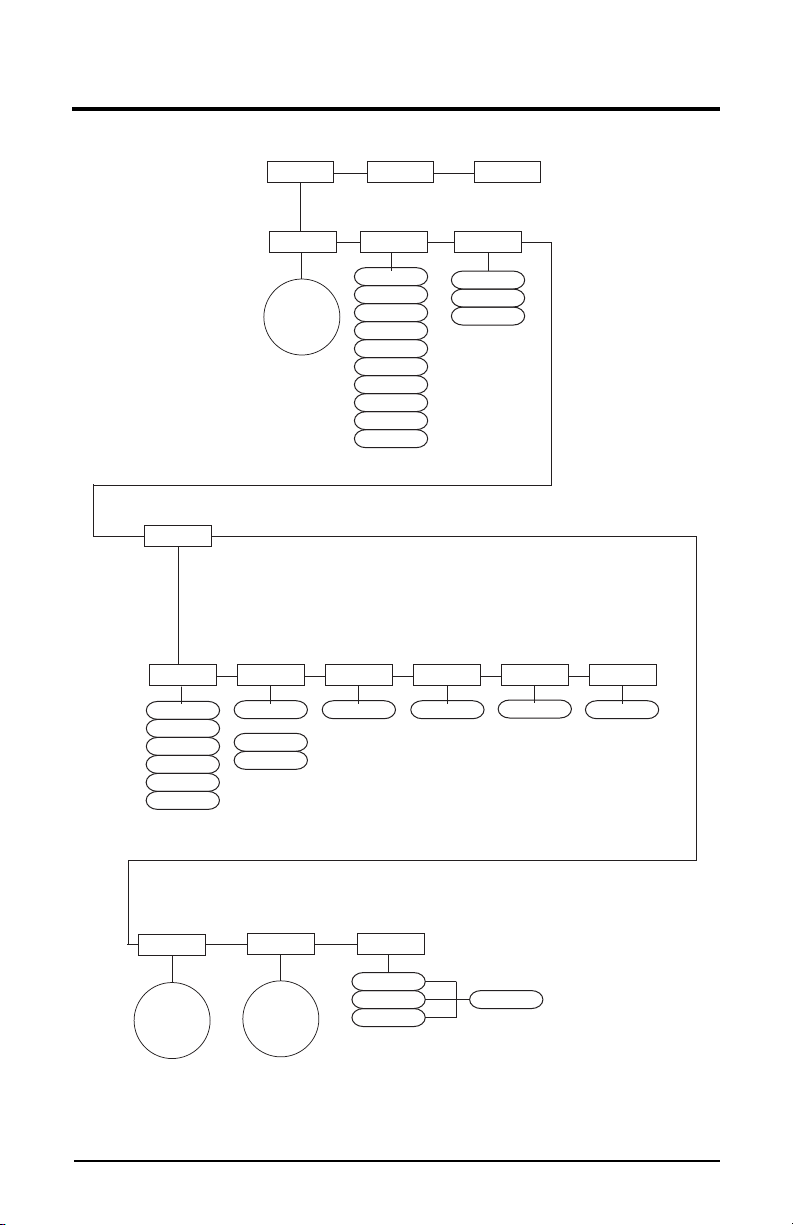

Important

ANALOG OUTPUT

(Current and Voltage)

PLC

PLC or FIELD SIGNALS

2 DIGITAL INPUTS

(Optoisolated,

Externally supplied)

2 RELAY

MAX 8 LOAD CELLS IN

PARALLEL

RS-485

RS-232

Modbus RTU

SERIAL PORT

DC power

supplier

(12-24 Volt )

Load Cell Resistance Measurement (Use A Digital Multimeter):

• Disconnect the load cells from the instrument and check that there is no

moisture in the load cell junction box caused by condensation or water

infiltration. If so, drain the system or replace it if necessary.

• The value between the positive signal wire and the negative signal wire must

be equal or similar to the one indicated in the load cell data sheet (output

resistance).

• The value between the positive excitation wire and the negative excitation

wire must be equal or similar to the one indicated in the load cell data sheet

(input resistance).

• The insulation value between the shield and any other load cell wire and

between any other load cell wire and the body of the load cell must be higher

than 20 Mohm (mega ohms).

Load Cell Voltage Measurement (Use A Digital Multimeter):

• Remove weight of scale from load cell to be tested.

• Make sure that the excitation wires of the load cell connected to the

instrument is 5 Vdc +/- 3%.

• Measure the millivolt signal between the positive and the negative signal

wires by directly connecting them to the multi-meter, and make sure it reads

between 0 and 0.5 mV (thousandths of a Volt).

• Apply load to the load cell and make sure that there is a signal increment.

If one of the above conditions is not met, please contact the

technical assistance service.

1.3 Specifications

• Weight indicator and transmitter for Omega/DIN rail mounting suitable for

back panel; space saving vertical shape. Six-digit semi alphanumeric display

(18mm h), 7 segment. Four-key keyboard. Dimensions: 25x115x120 mm.

• Displays the gross weight; with an external contact capable of remote

zeroing and gross/net switching.

• IP67 box version (dimensions: 170x140x95mm). Four fixing holes diameter

4mm (center distance 122x152mm).

• Peak weight function.

4 SCT Weight Transmitter Operator’s Manual

Page 9

• Transmits the gross or net weight via opto-isolated analog output 16 bit,

current 0-20mA, 4-20mA or voltage 0-10V, 0-5V (±0V / ±5V by closing a

soldered jumper).

• Transmits the gross or net weight via RS-485 serial port, by means of

protocols:

- Modbus RTU

- ASCII bidirectional protocol

- Continuous transmission

Power Supply And Consumption (VDC) 12 - 24 VDC (standard)+/- 10% ; 5 W

No. Of Load Cells In Parallel and

Supply

Linearity / Analog Output Linearity < 0.01% F.S. ; < 0.01% F.S.

Thermal Drift / Analog Output Thermal

Drift

A/D Converter 24 bit (16.000.000 points)

Max Divisions (With Measurement

Range: +/-10mv = Sens. 2mv/v)

Measurement Range +/- 19.5 mV

Max Sensitivity Of Usable Load Cells +/-3mV/V

Max Conversions Per Second 80 conversions/second

Display Range - 999999 ; + 999999

No. of Decimals / Display Increments 0 - 4 / x 1 x 2 x 5 x 10 x 20 x 50 x 100

Digital Filter / Readings Per Second 0.080 – 7.5 sec / 5 - 80 Hz

Relay Logic Outputs N.2 - max 24 VAC ; 60mA

Logic Inputs N.2 - optoisolated 5 - 24 VDC PNP

Serial Ports RS-485 (RS-232)

Baud Rate 2400, 4800, 9600, 19200, 38400,

Humidity (Non Condensing) 85 %

Storage Temperature - 30°C + 80°C

Working Temperature - 20°C + 60°C

Optoisolated Analog Output 16 Bit -

65535 Divisions

max 8 ( 350 ohm ) ; 5VDC/120mA

< 0.0005 % F.S. /°C ; < 0.003 % F.S./°C

+/- 999999

115200

0-20 mA; 4-20 mA (max 300 ohm); 0-10

VDC; 0-5 VDC; +/- 10 VDC; +/- 5 VDC

(min 10 kohm).

Table 1-1. Technical Specifications

Introduction 5

Page 10

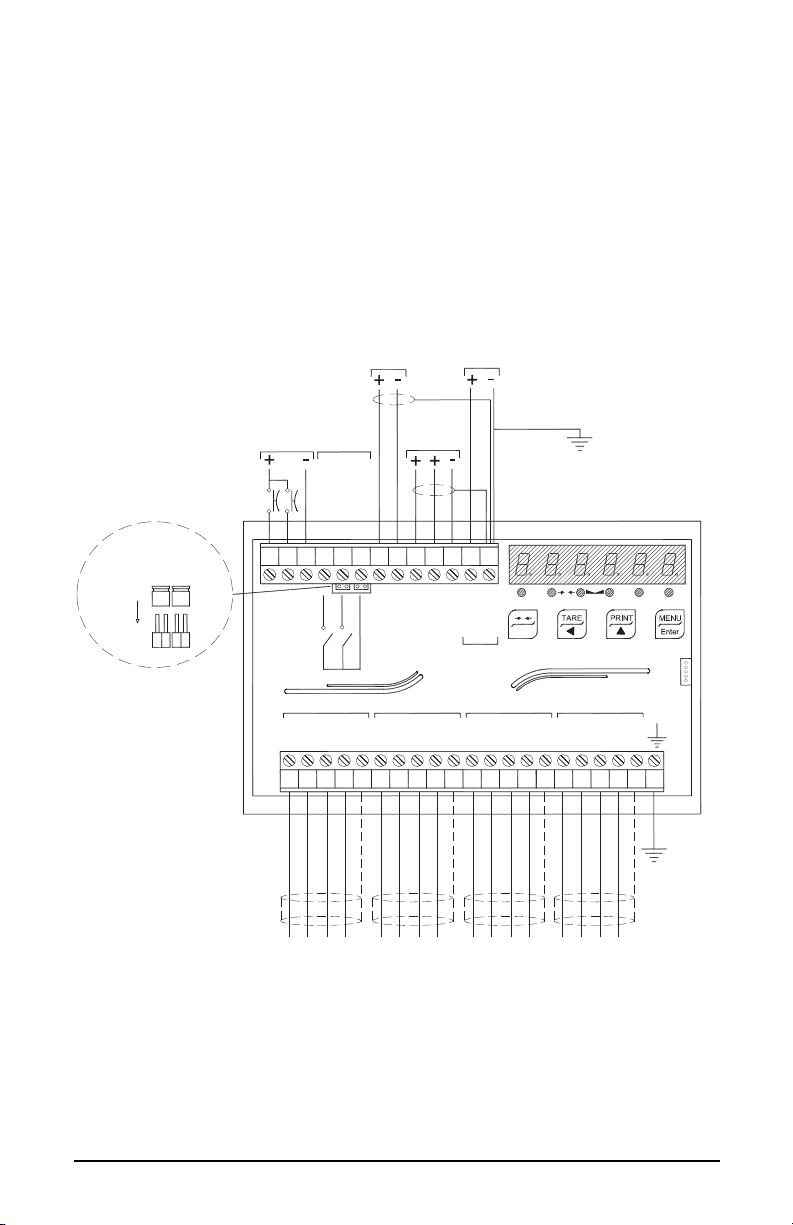

1.4 Electrical Connections

13123456789 111210

21

141516 17 18 19 20

SH

LOAD CELLS IN PARALLEL

IN1

IN2

IN COM

OUT1

OUT2

+ RS485

-

RS485

mA

V

mA-V COM

NET 0

kg

g

L

INPUTS

5-24Vdc

OUTPUTS

24Vdc

60mA

RS485

OUTPUT

12-24Vdc

ANALOG

RS485 termination

0

ESC

333130 322827252324 26 2922 34

+ 12-24

0 VDC

POWER

+ EX

-

EX

-

SIG

+ SIG

-

EX

+ EX

-

SIG

+ SIG

SH

-

EX

+ EX

-

SIG

+ SIG

SH

-

EX

+ EX

-

SIG

+ SIG

SH

J1

J2

SCT

Current output: max load 300 Ohm

Voltage output: min. load 10 kOhm

- EXCITATION

+ EXCITATION

- SIGNAL

+ SIGNAL

- EXCITATION

+ EXCITATION

- SIGNAL

+ SIGNAL

- EXCITATION

+ EXCITATION

- SIGNAL

+ SIGNAL

- EXCITATION

+ EXCITATION

- SIGNAL

+ SIGNAL

• It is recommended that the negative side of the power supply be grounded.

• It is possible to power up to eight 350 ohm load cells or sixteen 700 ohm

load cells.

• Connect terminal “0 VDC” to the RS-485 common of the connected

instruments in the event that these receive alternating current input or that

they have an opto-isolated RS-485.

• In case of an RS-485 network with several devices it is recommended to

activate the 120 ohm termination resistance on the two devices located at the

ends of the network, see Section 2.5.1 “RS-485 Serial Communication” on

page 25

2 outputs: configurable setpoints or remote output management via protocol.

2 inputs (Default: SEMI-AUTOMATIC ZERO input 1; NET/GROSS input

2): settable to have the following functions: SEMI-AUTOMATIC ZERO,

NET/GROSS, PEAK, or REMOTE CONTROL (see Section 2.6 “Outputs

And Inputs Configuration” on page 26).

6 SCT Weight Transmitter Operator’s Manual

Page 11

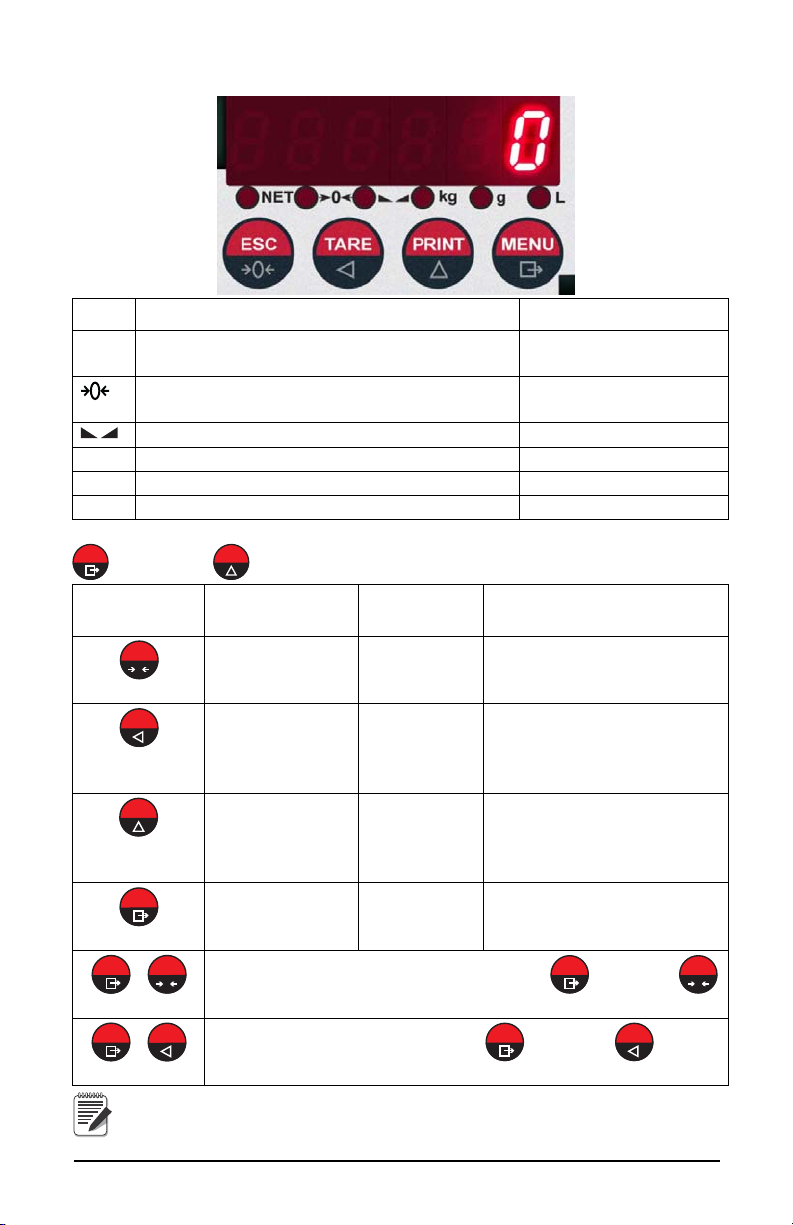

1.5 LED and Key Functions

MENU

PRINT

0

ESC

TARE

PRINT

MENU

MENU

0

ESC

MENU

0

ESC

MENU

TARE

MENU

TARE

Note

LED Main function Secondary function *

NET Net weight LED: net weight display (semi-

automatic tare or preset tare)

Zero LED (deviation from zero not more than +/-

0.25 divisions)

Stability LED LED lit: output 1 closed

kg Unit of measure: kg LED lit: output 2 closed

g Unit of measure: g No meaning

L Unit of measure:lb No meaning

* To activate the secondary LED function, during weight display press and hold

, then press .

Long press

Key Short press

(3 sec) Into menus

Zero Setting Cancel or return to previous

Escape

Captures Tare

Gross Net

Removes Tare

Net Gross

Scroll/

Backspace

mV load cell

test

Next/ Data

Entry

Setting setpoints

and hysteresis

Enter

LED lit: input 1 cosed

LED lit: input 2 closed

menu

Select figure to be modified or

return to previous menu item

Modify selected figure or go

to next menu item

Confirm or enter in submenu

+ Setting general parameters (press and hold then press

to enter set-up menu.

+ Setting preset tare (press and hold then press to enter

set-up menu.

The LEDs light up in sequence to indicate that a setting and not a

weight is being viewed.

Introduction 7

Page 12

1.6 Instrument Commissioning

Note

1. Plug power cord in to outlet to turn on indicator, the display shows in

sequence:

-“SU” followed by the software code (e.g.: SU S );

-- “r” followed by the software version (e.g.: r 1.04.01 );

-- “HU” followed by the hardware code (e.g.: HU 104 );

- - the serial number (e.g.:1005 15 );

2. Check that the display shows the weight and that when loading the load

cells there is an increase in weight.

3. If there is not, check and verify the connections and correct positioning

of the load cells.

If instrument has NOT been calibrated complete Section 2.1 before

proceeding to next step.

4. Reset to zero. See Section 2.1.3 “Zero Setting” on page 15.

5. Check the calibration with test weights and correct the indicated weight

if necessary. See Section 2.1.5 “Weight (Span) Calibration (With Test

Weights)” on page 16.

6. If you use the analog output, set the desired analog output type and the

full scale value. See Section 2.4 “Analog Output” on page 21.

7. If you use serial communication, set the related parameters. See Section

2.5 “Serial Communication Settings” on page 23.

8. If setpoints are used, set the required weight values and the relevant

parameters. See Section 2.8 “Setpoints Programming” on page 29 and

Section 2.6 “Outputs And Inputs Configuration” on page 26.

1.6.1 If The Instrument Has Not Been Calibrated

Missing plant system identification tag, proceed with calibration:

1. If load cells data are unknown, follow the procedure in Section 2.1.5

“Weight (Span) Calibration (With Test Weights)” on page 16.

2. Enter the rated data of load cells following the procedure given in

Section 2.1.1 “Theoretical Calibration” on page 14.

8 SCT Weight Transmitter Operator’s Manual

Page 13

2.0 Configuration

CALIB FILTER PARA 0

SERIAL

0 SET

AUTO 0

TRAC 0

TESTOut-In

2

3

4

5

1

0

8

9

7

6

See

Serial

Submenu

See

Calib

Submenu

See

Serial

Submenu

IN

OUT

NU CEL

Enter #

ANALOG

MODE

TYPE

Enter #

0-10 V

0-20 mA

4-20mA

ANA 0 ANA FS COR FSCOR 0

Enter #

Enter #

Enter #Enter #

-5+5 V

-10+10 V

0-5 V

Gross

Net

000000

PtArE

SEtP1

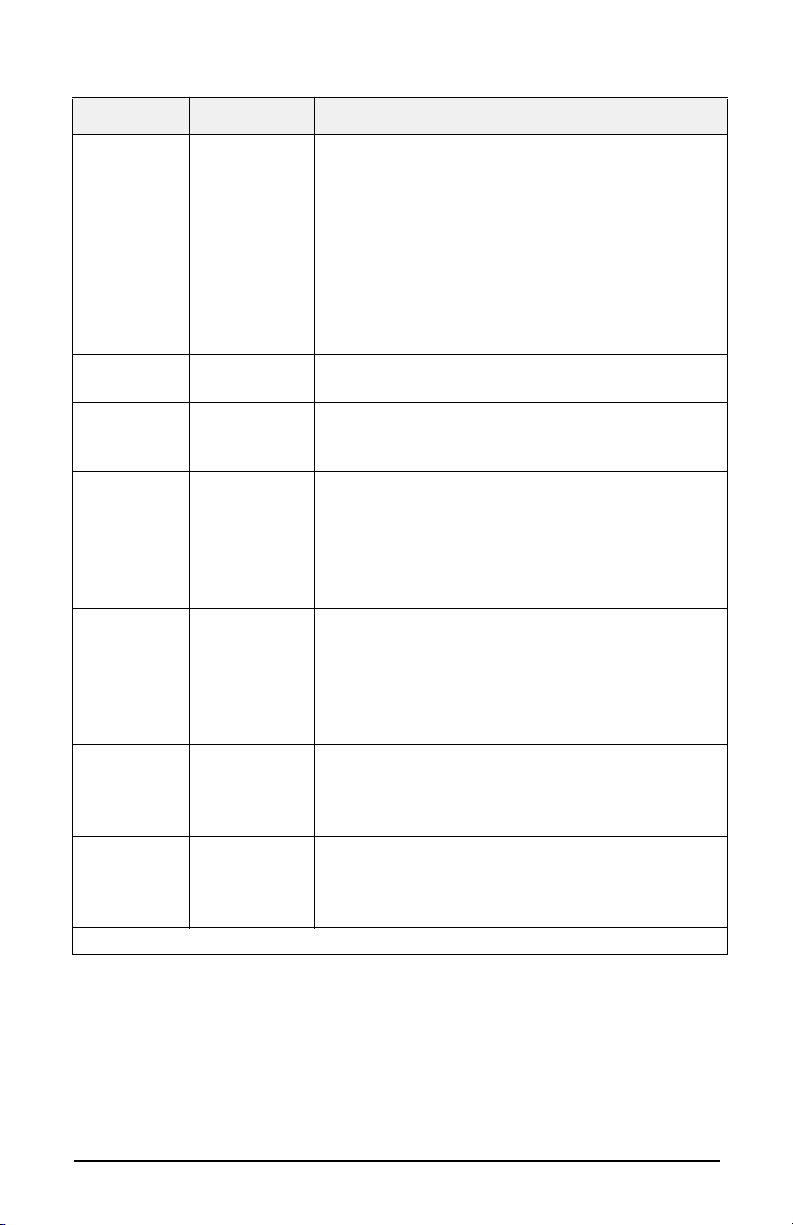

Figure 2-1. Scale Menu Structure

Configuration 9

Page 14

Parameter Choices Description

CALIb FS-tEO

See Section 2.1“Calibration” on page 11.

SEnS I b

dI UI S

NASS

ZErO

1 NP 0

WEIGHt

unIt

COEFF

FILTER 0-9

4 *

PArA 0 0 SEt

AuTO 0

trAC 0

ANALOG tYPE

NOdE

ANA 0

ANA FS

COr 0

COr FS

SErIAL rS-485

bAud

Addr

dELAY

PArItY

STOP

Out-In Out 1

Out 2

In 1

In 2

tESt In

Out

ANALOG

NU-CEL

*

- indicates default value.

Allows a stable weight display to be obtained.

See Section 2.2 “Filter On The Weight” on page 19.

See Section 2.3 “Zero Parameters” on page 20.

See Section 2.4 “Analog Output” on page 21.

See Section 2.5 “Serial Communication Settings”

on page 23.

See Section 2.6 “Outputs And Inputs

Configuration” on page 26.

See Section 2.7 “Test” on page 28.

Table 2-1. Scale Menu

10 SCT Weight Transmitter Operator’s Manual

Page 15

2.1 Calibration

dI UI S

WEIGHt

unIt

COEFF

LItrE

bAr

AtN

PI ECE

nEUton

lb

OtHEr

HI LOG

HI LO-N

nEU-N

G

t

FS-tEO

Enter #

SEnS Lb

Enter #

NASS

Enter #

ZErO

Enter #

Enter # Enter #

I NP 0

Enter #

50

100

0.0001

0.0002

20

10

0.002

0.005

0.001

0.0005

2

5

0.02

0.05

0.01

0.2

0.5

0.1

1

FILtEr

PArA 0 SErIAL

tESt

Out-In

ANA LOG

000000

SEtP1

CALIb

PtArE

Note

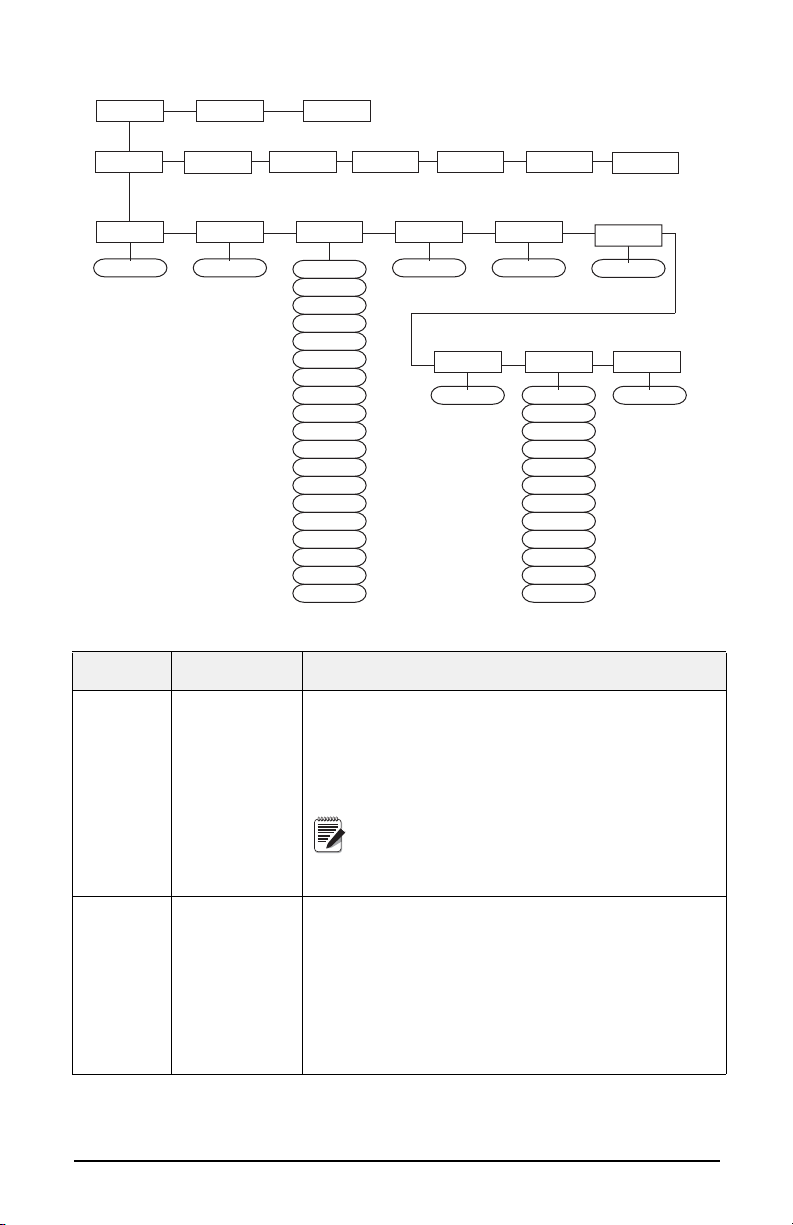

Figure 2-2. Calibration Menu Structure

Parameter Choices Description

FS-TED Enter #

deno *

System Full Scale is determined by multiplying one

load cell capacity by the number of load cells used.

Example of system full scale value calculation:

4 cells of 1000kg ---->

FULL SCALE = 1000 X 4 = 4000

The instrument is supplied with a

theoretical full scale value deno

SENS LB Enter #

0.50000

to

7.00000

2.00000 *

Sensitivity is a load cell rated parameter expressed

in mV/V. Set the average sensitivity value indicated on

the load cells. I

Example of 4-cell system with sensitivity

2.00100, 2.00150, 2.00200, 2.00250;

calculated as (2.00100 + 2.00150 + 2.00200 +

Table 2-2. Calibration Menu

corresponding to 10000. To restore

factory values, set 0 as full scale.

enter 2.00175,

2.00250) / 4.

Configuration 11

Page 16

Parameter Choices Description

TARE

dI UI S 1

2 *

5

10

Division (resolution) - the weight increment (display

division size) that the scale counts by.

Selections are: 0.0001 and 100 with x1 x2 x5 x10

increments.

20

50

100

0.0001

0.0002

0.0005

0.001

0.002

0.005

0.01

0.02

0.05

0.1

0.2

0.5

NASS Enter #

0 *

to

max full scale

Maximum capacity (Live Load/Product) that can

be displayed. When the weight exceeds this value by

9 divisions, the display will go to dashes, indicating

overload.

Setting this value to 0 will disable the over capacity

function.

ZErO

0

Used to capture the deadload of the scale

system. With the scale empty, the displayed value

can be zeroed off. This menu may also be accessed

directly from the weighing mode to compensate for

zero changes or variations.

Press to display the accumulated weight that

has been zeroed off.

INP 0 Enter #

0 to 999999

0 *

Estimated dead load value of the scale when a

scale contains product that cannot be removed. The

value entered is the dead load. This value will be

replaced if the zero function is performed later.

Table 2-2. Calibration Menu

12 SCT Weight Transmitter Operator’s Manual

Page 17

Parameter Choices Description

Note

Note

WEIGHT Enter #

0 *

UNIT G

COEFF Enter #

*

- indicates default value.

t

Lb *

nEUton

LI trE

bAr

AtN

PI ECE

nEU-N

HI LO-N

OtHEr

HI LOG

0-99.9999

0 *

Weight (Span) Calibration - after the Theoretical

Calibration has been completed and zero is set, the

calibration can be adjusted with actual test weights

by changing the displayed value in this parameter.

If changes are made to the theoretical

Full Scale (

SEnSIb

(

parameters, the weight (span) calibration is

cancelled and the theoretical calibration is

initiated and applied.

If the theoretical full scale (

capacity full scale (

(span) calibration (

currently in use is theoretical; if they are different,

the calibration in use is the weight (span)

calibration based on calibration weights.

If changes are made to the theoretical full scale

(

FS-tEO

divisions (

parameters containing a weight value will be set

to default values (setpoints, hysteresis, etc.).

Unit of Measure - select to determine what unit of

measure is displayed and printed.

See Section 2.1.6 “Setting Units of Measure” on

page 17 for description of units.

Multiplier Value entered will display an alternative

unit of measure if the digital input is set for COEFF

and is in a closed state.

), the capacity full scale (

dI UI S

FS-tEO

) or Divisions (

FS-tEO

NASS

) are equal in weight

WEIGHt

), then the calibration

) parameters, all the system’s

), the Sensitivity

dI UI S

)

) and the

NASS

) or

Table 2-2. Calibration Menu

To calibrate the instrument, the “Theoretical Calibration” on

page 14 must be completed first. After Theoretical Calibration is

set, the scale can be set with actual weights (see Section 2.1.5

“Weight (Span) Calibration (With Test Weights)” on page 16).

Configuration 13

Page 18

2.1.1 Theoretical Calibration

Note

MENU

0

ESC

MENU

MENU

TARE

PRINT

MENU

TARE

PRINT

MENU

TARE

PRINT

MENU

TARE

PRINT

MENU

TARE

PRINT

MENU

0

ESC

Note

MENU

0

ESC

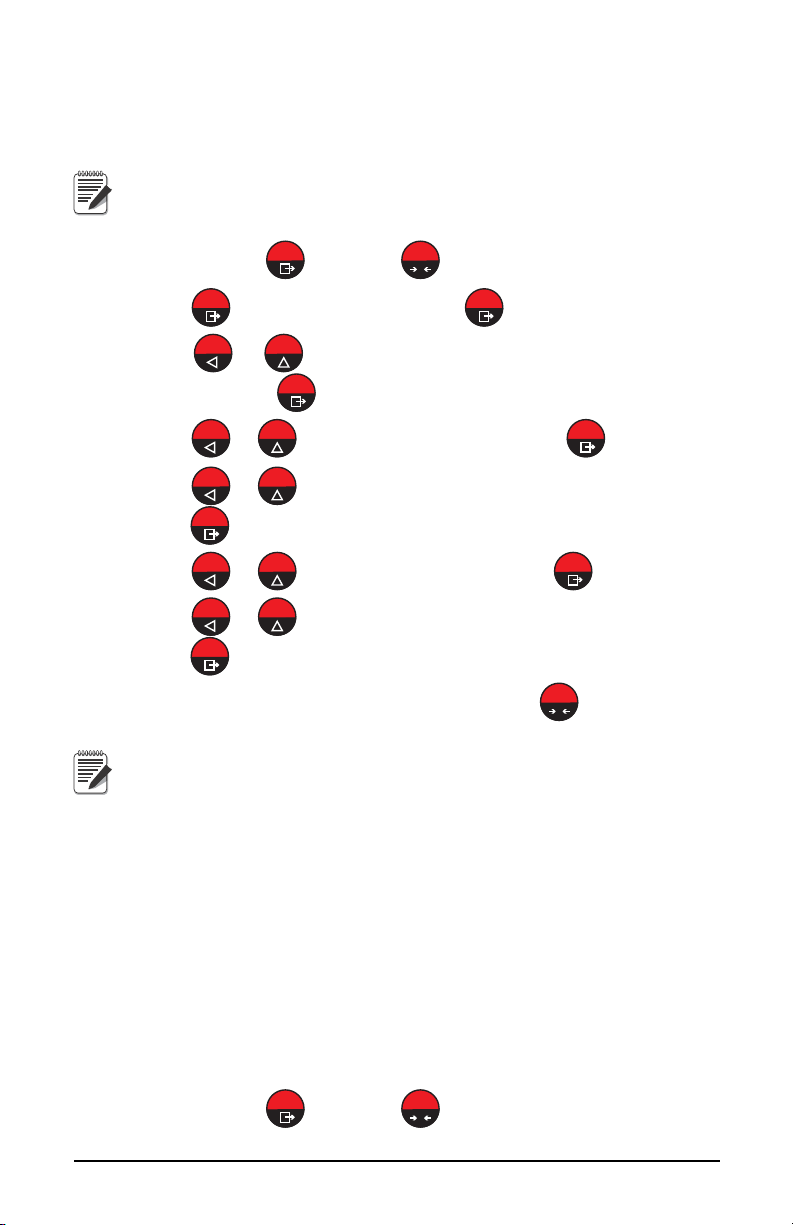

This function allows load cell rated values to be set.

To perform the theoretical calibration set FS-tED, SEnS lb and dI UI S in

sequence:

When entering a menu, the LED’s will begin scrolling, when

selection is made and confirmed the LED’s will be off.

1. Press and hold , then press , CALIb will be displayed.

2. Press , FS-tEO is displayed. Press .

3. Press or

until total load cell capacity (system full scale) is

displayed, press .

4. Press or

5. Press or

until SEnS lb is displayed, press .

until desired load cell mV/V is displayed,

press .

6. Press or

7. Press or

until dI UI S is displayed, press .

until desired display division size is displayed,

press .

8. This complete the Theoretical Calibration, press twice to exit setup menu or continue to Section 2.1.2.

By modifying the theoretical full scale, the sensitivity or divisions,

the weight (span) calibration is cancelled and the theoretical

calibration only is considered valid.

If the theoretical full scale and the recalculated full scale in weight

(span) calibration (see Section 2.1.5) are equal, this means that the

calibration currently in use is theoretical; if they are different, the

calibration in use is the weight (span) calibration based on test

weights.

By modifying the theoretical full scale, the sensitivity or divisions

and all the system’s parameters containing a weight value will be

set to default values (setpoints, hysteresis, etc.).

2.1.2 Maximum Capacity (NASS )

Maximum capacity (live load/product) that can be displayed. When the weight

exceeds this value by 9 divisions the following is displayed ‘

overload. To disable this function, set to 0.

------

’, indicating

1. Press and hold , then press . CALIb will be displayed.

14 SCT Weight Transmitter Operator’s Manual

Page 19

2. Press , FS-tEO is displayed.

MENU

TARE

PRINT

MENU

TARE

PRINT

MENU

0

ESC

Note

0

ESC

MENU

0

ESC

MENU

TARE

PRINT

MENU

MENU

0

ESC

Note

TARE

Important

MENU

0

ESC

MENU

TARE

PRINT

MENU

TARE

PRINT

MENU

0

ESC

3. Press or until NASS is displayed, press . LED’s will

begin scrolling.

4. Press or until desired capacity is displayed, press .

5. Press twice to exit set-up menu.

2.1.3 Zero Setting

Perform this procedure after having set the “Theoretical Calibration” on page 14.

This menu may also be accessed directly from the weight display,

press and hold for 3 seconds.

1. Press and hold , then press . CALIb will be displayed.

2. Press , FS-tEO is displayed.

3. Press or until ZErO is displayed, press .

4. The weight value to be set to zero is displayed. In this phase all of the

LEDs are flashing. Press , the weight is set to zero (the value is

stored to the permanent memory).

5. Press twice to exit set-up menu.

Press to display the accumulated deadload that has been

zeroed off by the instrument, displaying the sum of all of the

previous zero settings.

2.1.4 Zero Value Manual Entry

Perform this procedure only if it is not possible to reset the

weighed structure tare, for example because it contains

product that can not be unloaded.

Set in this parameter the estimated zero value.

1. Press and hold , then press . CALIb will be displayed.

2. Press , FS-tEO is displayed.

3. Press or until INP 0 is displayed, press . LED’s will

begin scrolling.

4. Press or until desired dead load is displayed, press .

5. Press twice to exit set-up menu.

Configuration 15

Page 20

2.1.5 Weight (Span) Calibration (With Test Weights)

MENU

0

ESC

MENU

TARE

PRINT

MENU

TARE

PRINT

MENU

MENU

0

ESC

Important

Note

After performing Section 2.1.1 “Theoretical Calibration” on page 14 and Section

2.1.3 “Zero Setting” on page 15, this function allows correct calibration to be

done using test weights of known value, if necessary, any deviations of the

indicated value from the correct value to be corrected.

1. Load the test weight onto the scale, use as high a percentage of the

maximum quantity to be weighed as possible.

2. Press and hold , then press . CALIb will be displayed.

3. Press , FS-tEO is displayed.

4. Press or

until UEIGHt is displayed, press .

5. The value of the weight currently on the system will be flashing on the

display. All of the LEDs are off. (If adjustment is not required, skip to

step 8.)

6. Adjust the value on display to match weight loaded on the scale if

necessary, by pressing or . The LED’s will begin scrolling.

7. Press , the new set weight will appear with all the LEDs flashing.

8. Press again, UEIGHt will be displayed.

9. Press twice to exit set-up menu.

Example:

For a system of maximum capacity of 1000 kg and 1 kg division, two test

weights are available, one 500 kg and one 300 kg. Load both weights onto the

system and correct the indicated weight to 800. Now remove the 300 kg

weight, the system must show 500; remove the 500 kg weight, too; the system

must read zero. If this does not happen, it means that there is a mechanical

problem affecting the system linearity.

Identify and correct any mechanical problems before

repeating the procedure.

If theoretical full scale and recalculated full scale in weight (span)

calibration are equal, it means that the theoretical calibration is

currently in use; otherwise, the weight (span) calibration based on

test weights is in use.

If the correction made changes the previous full scale for more

than 20%, all the parameters with settable weight values are reset

to default values.

Linearization Option On Max 5 Points:

It is possible to perform a linearization of the weight repeating the abovedescribed procedure up to a maximum of five points, using five different test

weights.

16 SCT Weight Transmitter Operator’s Manual

Page 21

The procedure ends by pressing or after entering the fifth value; at this

0

ESC

PRINT

MENU

0

ESC

MENU

TARE

PRINT

MENU

TARE

PRINT

MENU

0

ESC

Note

MENU

0

ESC

MENU

TARE

PRINT

MENU

point it will no longer be possible to change the calibration value, but only to

perform a new weight (span) calibration. To perform a new calibration, should

return to the weight display and then re-entering into the calibration menu.

By pressing after having confirmed the test weight that has been set, the full

scale appears, recalculated according to the value of the maximum test weight

entered and making reference to the cell sensitivity set in the theoretical

calibration (SEnSI b).

2.1.6 Setting Units of Measure

1. Press and hold , then press . CALIb will be displayed.

2. Press , FS-tEO is displayed.

3. Press or

until unIt is displayed, press .

4. Press or until desired unit is displayed, press .

5. Press twice to exit set-up menu.

HI LOG kilograms bAr bar*

G grams AtN atmospheres*

t tons PI ECE pieces*

Lb pounds* nEU-N newton metres*

nEUton newton* HI LO-N kikgram metres*

LI tre litres* OtHEr

other generic units of measure

not included in list*

* Indicates it is possible to set the display coefficient. To use COEFF it is

necessary to enable it, closing the COEFF input. See Section 2.1.7 “Display

Coefficient” on page 17.

If the print function is enabled, the symbol of the selected unit of

measure will be printed after the measured value.

2.1.7 Display Coefficient

By setting the coefficient the display is changed accordingly.

If one of the inputs is set to COEFF mode (see Section 2.6 “Outputs And Inputs

Configuration” on page 26) when the input is closed the value will be displayed

modified according to the coefficient; when the input is opened the standard

weight display will be restored.

1. Press and hold , then press . CALIb will be displayed.

2. Press , FS-tEO is displayed.

3. Press or

until COEFF is displayed, press . LED’s will

begin scrolling.

Configuration 17

Page 22

4. Press or until desired number is displayed, press .

TARE

PRINT

MENU

0

ESC

Important

5. Press twice to exit set-up menu.

HI LOG kilograms

G grams

t tons

Lb

nEUton

LI tre

bAr

AtN

pounds Value set in COEFF will be multiplied by the weight value

currently displayed

newton Value set in COEFF will be multiplied by the weight value

currently displayed

litres in COEFF set the specific weight in kg/l, assuming that

the system is calibrated in kg

bar Value set in COEFF will be multiplied by the weight value

currently displayed

atmospheres Value set in COEFF will be multiplied by the weight value

currently displayed

PI ECE pieces in COEFF set the weight of one piece

nEU-N

HI LO-N

OtHEr

newton metres Value set in COEFF will be multiplied by the weight value

currently displayed

kikgram metres Value set in COEFF will be multiplied by the weight value

currently displayed

other generic units

of measure not

Value set in COEFF will be multiplied by the weight value

currently displayed

included in list

Table 2-3. Coefficient Value by Unit of Measure

All other settings (setpoints, hysteresis, calibration ...) are

expressed in weight value. If you want to convert them to the

new unit of measurement, perform one of the following

procedures for changing the system calibration.

The parameter must remain set to 1.0000.

Theoretical Calibration For Other Units Of Measure

Set in the parameter the F.SCALE value divided by the conversion coefficient

from kg to the new unit of measure.

Example: The 4 load cells of 1000 kg are placed under a scale for oil, which

has a specific gravity of 0.916 kg / l. Setting the F.SCALE = (4x1000) / 0916 =

4367, the system works in liters of oil. If you set the unit to liters, the system

will display and print the symbol ‘l’ instead of ‘kg’. See Section 2.1.6 “Setting

Units of Measure” on page 17.

Weight (Span) Calibration For Other Units Of Measure

Load a known quantity of product liters on the scale (equal to at least 50% of the

maximum amount that you must weigh) and enter in the parameter UEI GHt, the

product loaded value in liters. If you set the units to liters, the system will

display and print the symbol ‘l’ instead of ‘kg’. See Section 2.1.6 “Setting Units

of Measure” on page 17.

18 SCT Weight Transmitter Operator’s Manual

Page 23

2.2 Filter On The Weight

MENU

0

ESC

TARE

PRINT

MENU

TARE

PRINT

MENU

MENU

MENU

0

ESC

Note

The filtering selection is used to eliminate environment noise, and is typically a

compromise between responsiveness and stability. The lower the number, the

more responsive the display will be to weight changes. The filter is used to

stabilize a weight as long as the variations are smaller than the corresponding

“Response Time”. The filter setting is dependent on the type of application and

the required update rate.

Setting this parameter allows a stable weight display to be obtained. To increase

the effect (weight more stable), increase the value.

1. Press and hold , then press . CALIb will be displayed.

2. Press or until FILtEr is displayed, press . LED’s will

begin scrolling.

3. Press or until desired filter value is displayed, press

4. The weight is displayed (all LED’s will be flashing) and the displayed

stability can be experimentally verified. Press .

5. If stability is not satisfactory, press , this returns indicator to FILtEr

option and the filter may be modified again until an optimum result is

achieved.

6. Press to exit set-up menu.

The filter enables to stabilize a weight as long as its variations are

smaller than the corresponding “Response Time”. It is necessary

to set this filter according to the type of application and to the full

scale value set.

Filter Value

Response times

[ms]

Display and serial port refresh frequency

[Hz]

080 80

1190 80

2260 40

3450 26

4* 900 13

5 1700 13

6 2500 13

7 4200 10

8 6000 10

9 7500 5

* indicates default value.

Table 2-4. Filter Settings

.

Configuration 19

Page 24

2.3 Zero Parameters

MENU

0

ESC

TARE

PRINT

MENU

TARE

PRINT

MENU

TARE

PRINT

MENU

0

ESC

1. Press and hold , then press . CALIb will be displayed.

2. Press or until PArA 0 is displayed, press .

3. Press or until desired parameter (see Table 5 ) is displayed,

press . The currently programmed value is displayed and LED’s

will be scrolling.

4. Press or until desired value is displayed, press .

5. Press twice to exit set-up menu.

Parameter Choices Description

0 SEt Enter #

0-max full scale

300 *

Considered decimals: 300

– 30.0 – 3.00 – 0.300

AutO 0 Enter #

0 - max 20% of full scale

0 *

trAC 0 nOnE *

1-5

*

- indicates default value.

Table 2-5. Zero Parameters Settings

Resettable Weight setting for small

weight change.

Indicates the maximum weight value

resettable by external contact, keypad or

serial protocol

Automatic zero setting at power-on

If when indicator is powered on the

weight value is lower than the value set

in this parameter and does not exceed

the 0 SEt value, the weight is reset.

To disable this function set to 0.

Zero tracking

When the zero weight value is stable

and, after a second, it deviates from zero

by a figure in divisions smaller or equal to

the figure in divisions set in this

parameter, the weight is set to zero.

To disable this function, set to none

Example: if the parameter dI UI

set to 5 and trAC 0 is set to 2, the

weight will be automatically set to

zero for variations smaller than or

equal to 10 (dI UI S x trAC 0 ).

S

is

20 SCT Weight Transmitter Operator’s Manual

Page 25

2.4 Analog Output

Note

Parameter Choices Description

tYPE 4-20 mA *

0-20 mA

0-10 V

0-5 V

-10 +10 V

-5 +5 V

NodE Enter #

Gross

Net

ANA 0 Enter # Set the weight value for the minimum analog output

ANA FS Enter # Set the weight value for the maximum analog output

COr 0 Analog output correction to zero: if necessary adjust

COr FS Full scale analog output correction: if necessary

*

- indicates default value.

Selects the analog output type.

See “Soldered Jumper” on page 22

See “Soldered Jumper” on page 22

Select mode to be tracked, gross or net. If the net

function is not active, the analog output varies

according to gross weight.

value.

Only set a value different from zero to

limit the analog output range.

E.G.:: for a full scale value of 10000 kg, a 4 mA

signal at 5000 kg is required, and 20 mA at 10000

kg, in this case, instead of zero, set 5000 kg.

value; it must correspond to the value set in the PLC

program (default: calibration full scale).

E.g.: if using a 4-20 mA output and in the PLC

program a 20 mA = 8000 kg is desired, set the

parameter to 8000.

the analog output, allowing the PLC to indicate 0.

The sign ‘-‘ can be set for the last digit on the left.

E.g.: For a 4-20 mA output and a minimum

analog setting, the PLC or tester reads 4.1 mA.

Set the parameter to 3.9 to obtain 4.0 on the PLC

or tester. (See “Analog Output Type Scale

Corrections” on page 22)

adjust the analog output, allowing the PLC to

indicate the value set in the AnA FS parameter.

E.g. For a 4-20 mA output with the analog set to

full scale and the PLC or tester reads 19.9 mA,

set the parameter to 20.1 to obtain 20.0 on the

PLC or tester. (See “Analog Output Type Scale

Corrections” on page 22)

Table 2-6. Analog Output Menu

Configuration 21

Page 26

Soldered Jumper

Note

For the output -10 +10 V and -5 +5 V the soldered jumper J7 must be closed:

• Remove the face plate of the instrument by removing the screws that attach

it to the little columns on the printed circuit board.

• On the circuit board, locate the jumper J7, situated above the 3 and 4

terminals at about mid board.

• Scrape away the solder from the jumper bay, until the copper underneath is

uncovered.

• Close the jumper short circuiting the bays, it is also recommended that a

small piece of copper wire without insulation or a leg wire be used to

facilitate the operation.

Analog Output Type Scale Corrections

Minimum and maximum values which can be set for the zero and full

scale corrections

Analog Output Type Minimum Maximum

0–10 V -0.150 10.200

0–5 V -0.150 5.500

-10 +10 V -10.300 10.200

-5 +5 V -5.500 5.500

0-20 mA -0.200 22.000

4-20 mA -0.200 22.000

The analog output may also be used in the opposite manner, i.e.

the weight setting that corresponds to the analog zero may be

greater than the weight set for the analog full scale. The analog

output will increase towards full scale as the weight decreases; the

analog output will decrease as the weight increases.

E.g.: analog output type having selected 0-10V

ANA 0 = 10000 ANA FS = 0

Weight = 0 kg analog output = 10 V

Weight = 5000 kg analog output = 5 V

Weight = 10000 kg analog output = 0 V

22 SCT Weight Transmitter Operator’s Manual

Page 27

2.5 Serial Communication Settings

Addr

bAud

HErt2

dELAY

PArItY

StOPrS485

nOnE

NodbUS

ASCII

Cont In

rI P

HdrI P

HdrI Pn

Enter #

9600

19200

38400

115200

4800

2400

30

40

50

60

20

10

80

70

Enter #

EUEn

Odd

nOnE

2

3

4

5

1

0

8

9

7

6

CALIb

FILtEr

PArA 0

SErIAL

tESt

Out-In

ANA LOG

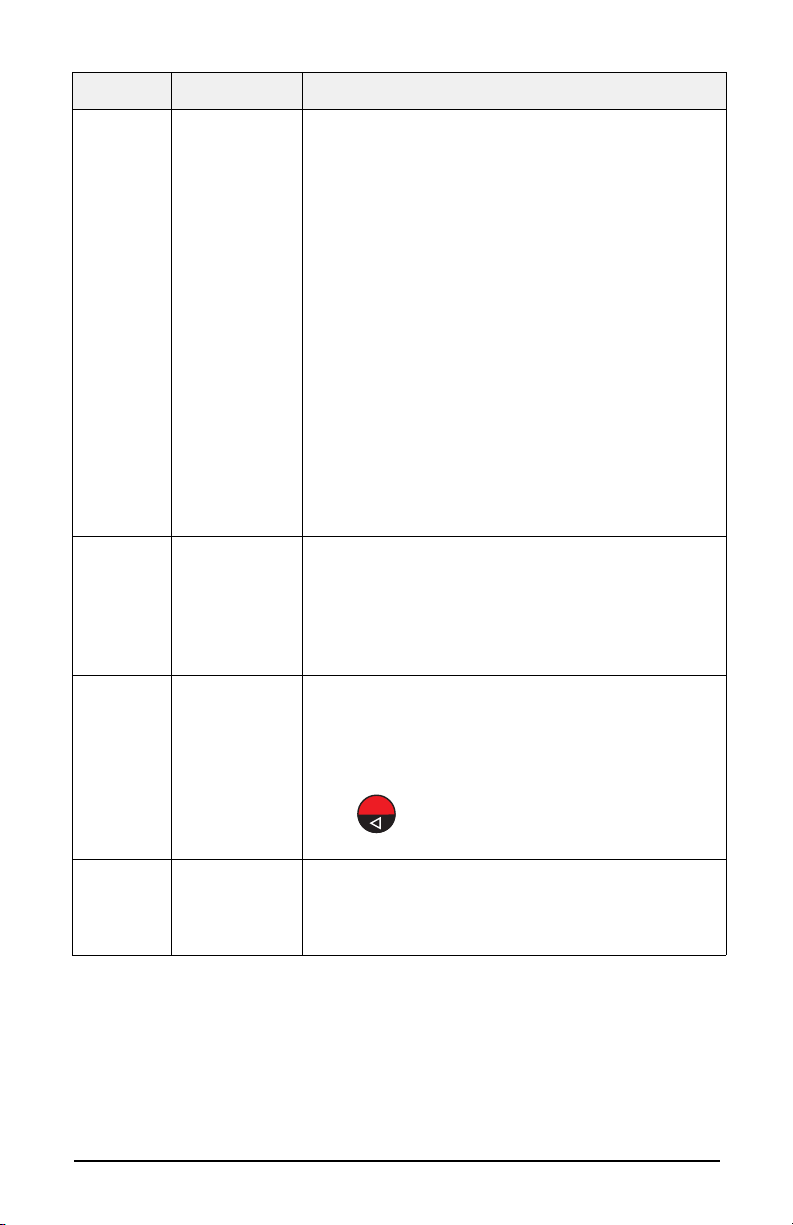

Figure 2-3. Serial Communications Menu Structure

According to the chosen protocol only the necessary settings will be displayed

in sequence.

Parameter Choices Description

rS-485

(Communitcation

Port)

None * Disables any type of communication (default).

NOdbuS MODBUS-RTU protocol; possible addresses: from

1 to 99 (see Section 3.6)

ASCII ASCII bidirectional protocol; possible addresses:

from 1 to 99 (see Section 3.7)

NOdU6-

NOd td

COntIn Continuous weight transmission protocol (see

Section 3.8), at the frequency set in HERTZ

parameter (from 10 to 300).

NOd t(set: PARITY=none, STOP=1)

NOd td(set: PARITY=none, STOP=1)

rI P Continuous weight transmission protocol, streams

net and gross (see Section 3.9)

(set: BAUD=9600,PARITY=none, STOP=1)

Hdr1 P Continuous weight transmission protocol, streams

net and gross including decimal (see Section 3.9)

(set: BAUD=9600,PARITY=none, STOP=1)

Table 2-7. Serial Communications Menu

Configuration 23

Page 28

Parameter Choices Description

rS-485 (cont) Hdr1 PN Continuous weight transmission protocol (see

Section 3.9)

When the remote display is set to gross weight:

- if the instrument displays the gross weight, the

remote display shows the gross weight.

- if the instrument shows the net weight the remote

display shows the net weight alternated with the

message “net”

bAud 2400

4800

9600 *

19200

38400

115200

Addr 1-99

1 *

HErTZ Maximum Transmission Frequency - to be set

10Hz *

20Hz Max setting with min 2400 baud rate

30Hz

40Hz Max setting with min 4800 baud rate

50Hz

60Hz

70Hz

80Hz Max setting with min 9600 baud rate

dELAY 0-200

msec

0 *

PArItY nOnE *

EVEn

odd

StOP 1 *

2

*

- indicates default value.

Transmission speed.

Instruments address

when the CONTIN transmission protocol is

selected. (see Table 2-4 on page 19)

Delay in milliseconds which elapses before the

instrument replies

parity none

even parity

odd parity

Stop bit

Table 2-7. Serial Communications Menu

24 SCT Weight Transmitter Operator’s Manual

Page 29

2.5.1 RS-485 Serial Communication

SCTSCT

SCT

RS485 +

RS485 -

max 500 m

RS485 +

RS485 -

PC RS232

RX+

RX-

TX-

TX+

Converter

24 Vcc

+

-

0

TX

RX

VIN

RS485 +

RS485 -

RS485 termination

34

0 VDC

RS485 +

RS485 -

0 VDC

RS485 +

RS485 -

0 VDC

5 2 3

28 29

34

28 29 34

28 29

J2 J1

Figure 2-4. RS-485 Serial Communications

Configuration 25

Page 30

If the RS-485 network exceeds 100 metres in length or baud-rate

Note

Note

OUt 1

OUt 2 In 1 IN 2

CLOSE

OPEn

SEt 1

PLC

GrOSS

NEt

2ErO

PEAH

COntI n

PLC

nE-lO

COEFF

2Er0

PEAH

COntI n

PLC

nE-lO

COEFF

CLOSE

OPEn

SEt 2

StAbLE

POS/nEG

POS

nEG

OFF

On

CALIb

FILtEr

PArA 0 SErIAL

tESt

Out-In

ANA LOG

StAbLE

PLC

over 9600 are used, close the two jumpers, called "RS-485

termination", to activate two 120 ohm terminating resistors

between the ‘+’ and ‘–’ terminals of the line, on the terminal strip of

the furthest instrument. Should there be different instruments or

converters, refer to the specific manuals to determine whether it is

necessary to connect the above-mentioned resistors.

Direct Connection Between RS-485 And RS-232 Without Converter

Since a two-wire RS-485 output may be used directly on the RS-232 input of a

PC or remote display, it is possible to implement instrument connection to an RS232 port in the following manner:

Instrument RS-232

RS-485 - RXD

RS-485 + GND

This type of connection allows a SINGLE instrument to be used in a

ONE WAY mode.

2.6 Outputs And Inputs Configuration

Figure 2-5. Outputs and Inputs Menu Structure

26 SCT Weight Transmitter Operator’s Manual

Page 31

Parameter Choices Description

OUt 1

OUt 2

OUt 1

OUt 2

SEt 1

SEt 2

SEt 1

SEt 2

OPEn Normally Open: the relay is de-energized and the

contact is open when the weight is lower than the

programmed setpoint value; it closes when the weight

is higher than or equal to the programmed setpoint

value.

CLOSE * Normally closed: the relay is energized and the

contact is closed when the weight is lower than the

programmed setpoint value; it opens when the weight

is higher than or equal to the programmed setpoint

value.

SEt 1

SEt 2

PLC The contact will not switch on the basis of weight, but is

StAbLE Relay switching occurs when the weight is stable.

POSnEG * Relay switching occurs for both positive and negative

POS Relay switching occurs for positive weight values only.

NEG Relay switching occurs for negative weight values only.

OFF * Relay switching will not occur if the setpoint value is ‘0’.

On Setpoint = ’0’ and nodbus=posneg, relay switching

Number corresponds with OUT 1or 2.

The contact will switch on the basis of weight,

according to setpoints (see Section 2.8 “Setpoints

Programming” on page 29)

Select:

Gross (default) - the contact will switch on the basis

of gross weight.

or

Net - the contact will switch on the basis of net

weight (If the net function is not active, the

contact will switch on the basis of gross weight).

controlled by remote protocol commands.

weight values.

occurs when the weight is ‘0’; the relay will switch

again when the weight is different from zero, taking

hysteresis into account (both for positive and for

negative weights).

Setpoint = ’0’ and nodes=pos, relay switching occurs

for a weight higher than or equal to ‘0’, the relay will

switch again for values below ‘0’, taking hysteresis

into account.

Setpoint = ’0’ and nodes=neg, relay switching occurs

for a weight lower than or equal to ‘0’, the relay will

switch again for values above ‘0’, taking hysteresis

into account.

Table 2-8. Output and Input Menu

Configuration 27

Page 32

Parameter Choices Description

MENU

0

ESC

TARE

PRINT

MENU

TARE

PRINT

MENU

MENU

TARE

PRINT

MENU

0

ESC

In 1

In 2

*

- indicates default value.

nE-LO *

(In 2

default)

(NET/GROSS): by closing this input for less than one

second, it performs a SEMI-AUTOMATIC TARE and the

display will show the net weight. To display the gross

weight again, hold the NET/GROSS input closed for 3

seconds.

2ErO *

(In 1

default)

By closing the input for less than one second, the

weight is set to zero (see Section 3.3 “Semi-Automatic

Zero (Weight Zero-setting For Small Variations)” on

page 33).

PEAH With the input closed the maximum weight value

reached remains on display. Opening the input the

current weight is displayed.

PLC Closing the input no operation is performed, the input

status may however be read remotely by way of the

communication protocol.

COntin Closing the input for less than one second the weight is

transmitted via the serial connection according to the

fast continuous transmission protocol one time only

(only if contin is set in the item serial).

COEFF When the input is closed the weight is displayed based

on the set coefficient (see Section 2.1.6 “Setting Units

of Measure” on page 30 and Section 2.1.7 “Display

Coefficient” on page 31), otherwise the weight is

displayed.

Table 2-8. Output and Input Menu

2.7 Test

1. Press and hold , then press . CALIb will be displayed.

2. Press or until tEst is displayed, press . The currently

programmed value is displayed.

3. Press or until desired parameter is displayed, press .

4. For In and NU-CEL, current reading is displayed, press .

For Out, press until corresponding value of the out you want to

change is flashing, press to change the value, press .

5. Press twice to exit set-up menu.

28 SCT Weight Transmitter Operator’s Manual

Page 33

Parameter Choices Description

MENU

TARE

PRINT

MENU

TARE

PRINT

MENU

0

ESC

Note

In N/A Input Test - for each open input 0 is displayed, 1 is

displayed when the input is closed.

Out 0 *

1

Output Test Setting 0 - the corresponding output opens.

Setting 1 - the corresponding output closes.

ANALOG ANALOG Allows the analog signal to range between the minimum

and the maximum values starting from the minimum.

NA current output test

UOLt1 voltage output test

NU-CEL N/A Millivolt Test - displays the load cell response signal in

mV with four decimals.

*

- indicates default value.

Table 2-9. Test Menu

2.8 Setpoints Programming

1. Press to enter setpoints and hysteresis settings.

2. Press or

until desired setpoint or hysteresis parameter is

displayed, press .

3. Press or until desired value is displayed, press .

4. Press to exit setpoints and hysteresis settings.

These values are set to zero if the calibration is changed

significantly (see Section 2.1.1 “Theoretical Calibration” on

page 14 and Section 2.1.5 “Weight (Span) Calibration (With Test

Weights)” on page 16).

Parameter Choices Description

SEtP 1

SEtP 2

HYStE 1

HYStE 2

*

- indicates default value.

0-Full Scale

0 *

0-Full Scale

0 *

Setpoint; relay switching occurs when the weight

exceed the value set in this parameter. The type of

switching is settable (see “Outputs And Inputs

Configuration” on page 26).

Hysteresis, value to be subtracted from the setpoint to

obtain contact switching for decreasing weight. For

example with a setpoint at 100 and hysteresis at 10,

the switching occurs at 90 for decreasing weight.

Table 2-10. Setpoints

Configuration 29

Page 34

2.9 Reserved For The Installer

Important

0

ESC

MENU

MENU

Note

0

ESC

MENU

TARE

MENU

0

ESC

Note

2.9.1 Default Scale

Operation must only be performed after contacting technical

assistance

1.With power off, press and hold , then power on.

Display shows PrOG .

2. Press , display shows bASE.

3. Press , display shows UAIt.

4. Instrument will reboot.

By confirming the displayed program, the system variables are set

with default values.

2.9.2 Program Selection - Reverse:

Scale capacity is displayed when scale is empty. As weight is added display will

count down.

1. With power off, press and hold , then power on.

Display shows PrOG .

2. Press , display shows bASE.

3. Press , display shows rEuEr.

4. Press , display shows UAIt.

5. Instrument will reboot.

By pressing you will quit the program without introducing any changes and

without deleting any of the set variables.

If you do not have a specific manual for the newly set program, you

can request it from technical assistance.

30 SCT Weight Transmitter Operator’s Manual

Page 35

2.9.3 Keypad Or Display Locking

0

ESC

PRINT

TARE

MENU

1. Press immediately followed by , hold them down for about 5

seconds (this operation is also possible via the MODBUS and ASCII

protocols):

2. Press or until desired parameter is displayed, press .

Parameter Description

FrEE no lock

KEY keypad lock: if active, when key is pressed the message bLOC is

displayed.

dI SP Keypad and Display lock: if active, the keypad is locked and the

display shows the instrument model (weight is not displayed); by

pressing a key the display shows bLOC for 3 seconds.

Configuration 31

Page 36

3.0 Operation

Note

TARE

TARE

Note

PRINT

PRINT

MENU

TARE

MENU

TARE

PRINT

MENU

0

ESC

Note

PRINT

PRINT

TARE

3.1 Semi-Automatic Tare (Net/Gross)

The semi-automatic tare value is lost upon instrument power-off.

The semi-automatic tare operation is not allowed if the gross

weight is zero.

1. To capture tare and weigh in net mode (SEMI-AUTOMATIC TARE),

close the NET/GROSS input or press for 3 seconds. The

instrument displays the net weight (zero) and the NET LED lights up.

2. To display the gross weight again, keep the NET/GROSS input closed

or press for 3 seconds.

3. This operation can be repeated by the operator to allow the loading of

several products.

Press and hold to display the gross weight temporarily. When

is released, the net weight will be displayed again.

3.2 Preset Tare (Subtractive Tare Device)

It is possible to manually set a preset tare value to be subtracted from the display

value provided that the P-tArE ≤ max capacity.

1. Press and hold and to display P-tArE, press .

2. Press or until desired value is displayed, press .

3. Press to exit P-tArE.

4. After setting the tare value, go back to the weight display, the display

shows the net weight (subtracting the preset tare value) and the NET

LED lights up to show that a tare has been entered.

Press and hold for 3 seconds to display the gross weight

temporarily. When is released, the net weight will be

displayed again.

To delete a preset tare and return to the gross weight display:

1. Press hold for 3 seconds or keep the NET/GROSS input (if any)

closed for the same length of time (3 seconds). The preset tare value is

set to zero. The NET LED is turned off when the gross weight is

displayed once again.

32 SCT Weight Transmitter Operator’s Manual

Page 37

If a semi-automatic tare (net) is entered, it is not possible to access

Note

Note

0

ESC

the enter preset tare function.

If a preset tare is entered, it is still possible to access the

semiautomatic tare (net) function. The two different types of tare

are added.

All the semi-automatic tare (net) and preset tare functions will be

lost when the instrument is turned off.

3.3 Semi-Automatic Zero (Weight Zero-setting For Small Variations)

By closing the SEMI-AUTOMATIC ZERO input, the weight is set to zero. The

zero setting will be lost when the instrument is turned off.

This function is only allowed if the weight is lower than the 0 set value (see 0

SET in Section 2.3 “Zero Parameters” on page 20), otherwise the t

-----

alarm

appears and the weight is not set to zero.

3.4 Peak

By keeping the input closed the maximum weight value reached remains

displayed. Opening the input the current weight is displayed.

If you wish to use this input to view a sudden variation peak, set

the FILTER ON THE WEIGHT (see Section 2.2) to 0.

3.5 Alarms

Display Description

ErCEL Load cell is not connected or is incorrectly connected; the load cell signal

Er OL Weight display exceeds 110% of the full scale.

Er Ad Internal instrument converter failure; check load cell connections, if

---------

Er OF Maximum displayable value exceeded (value higher than 999999 or lower

-------

t

NAH-PU This message appears in the test weight setting, in weight (span)

Err0r The value set for the parameter is beyond the permitted values; press

bLOC Lock active on menu item, keypad or display.

nOdl SP It’s not possible to display properly the number because is greater than

exceeds 39 mV; the conversion electronics (A/D converter) is

malfunctioning.

necessary contact Technical Assistance.

Weight exceeds the maximum weight by 9 divisions.

than -999999).

Weight too high: zero setting not possible.

calibration, after the fifth test weight value has been entered.

to quit the setting mode leaving the previous value unchanged.

Examples:

-a number of decimals is selected for full scale which exceeds the

instrument's display potential;

-value above the maximum setting value;

-the weight value set in test weight verification does not match the

detected mV increase.

999999 or less than -999999.

Table 3-1. Alarm Descriptions

Operation 33

Page 38

-----

Note

The response

to the zero

command is a

'value not

valid' error

(error code 3)

MODE

Bit LSB

Status

Register

MODBU

S RTU

ASCII

RIP *

HDRIP-N

CONTIN

ErCEL Er OL Er Ad --------- Er OF t

76543210

xxxxxxx1

__O-F_ __O-L_ __O-F_ __O-L_ __O-F_ &aa#CR

__O-F_ __O-L_ __O-F_ __O-L_ __O-F_ __O-F_

_ERCEL _ER_OL _ER_AD ###### _ER_OF O__SET

_ERCEL _ER_OL _ER_AD ^^^^^^ _ER_OF O__SET

76543210

xxxx1xxx

76543210

xxxxxx1x

76543210

xxxxx1xx

76543210

On gross:

xxx1xxxx

On net:

xx1xxxxx

Table 3-2. Serial Protocols Alarms

* For RIP remote displays, if the message exceeds 5 digits the display

------

reads

Range 0/20mA 4/20 mA 0/5 V 0/10 V -10/10 V -5/5 V

Output

Value

.

If an alarm becomes active the relays open and the analog outputs

go to the lowest possible value according to the following table:

-0.2 mA 3.5 mA -0.5 V -0.5 V 0 V 0 V

3.6 Modbus-RTU Protocol

The MODBUS-RTU protocol enables to manage the reading and writing of the

registers listed here below according to the specifications contained in the

reference document for this standard Modicon PI-MBUS-300.

To select the communication with MODBUS-RTU, refer to Section 2.4 “Analog

Output” on page 21.

When specifically indicated certain data will be written directly to EEPROM

type memories. This memory has a limited number of writing operations

(100.000), therefore unnecessary operations at said locations must be avoided.

The instrument, in any case, ensures that no writing occurs if the value to be

stored is equal to the stored value.

The numerical data listed below are expressed in decimal notation, or

hexadecimal notation if preceded by 0x.

Modbus-RTU Data Format

The data received and transmitted via MODBUS-RTU protocol have the

following characteristics:

- 1 start bit

- 8 data bits, least significant bit sent first

- Instrument settable parity bit

- Instrument settable stop bit

34 SCT Weight Transmitter Operator’s Manual

Page 39

Modbus Supported Functions

Among the commands available in the MODBUS-RTU protocol, only the

following are used to manage communication with the instruments. Other

commands may not be interpreted correctly and could generate errors or system

shut-downs:

FUNCTIONS DESCRIPTION

03 (0x03) Read Holding Register (Programmable Register Reading)

16 (0x10) Preset Multiple Registers (Write Multiple DI Register)

The interrogation frequency is linked with the preset communication rate (the

instrument will stand by for at least 3 bytes before beginning to calculate a

possible response to the query). The dELAY parameter (see Section 2.4 “Analog

Output” on page 21) allows for a further delay in the instrument response, and

this directly influences the number of possible queries in the unit of time.

For additional information on this protocol, refer to the general technical

specification PI_MBUS_300. The functions supported relative to the MODBUS

standard are the READ HOLDING REGISTER and the PRESET MULTIPLE

REGISTERS.

In general, the query and response to and from a slave instrument are organized

as follows:

Function 3: Read Holding Registers (Programmable Register Reading)

QUERY

Address Function Add. Reg. 1 No. register 2 bytes

A 0x03 0x0000 0x0002 CRC

Tot. bytes = 8

RESPONSE

Address Function No. bytes Register1 Register 2 2 bytes

A 0x03 0x04 0x0064 0x00C8 CRC

Tot. bytes = 3+2*No. registers+2

Function 16: Preset Multiple Registers (Multiple Register Writing)

QUERY

Address Function

A 0x10 0x0000 0x0002 0x04 0x0000 0x0000 CRC

Add.

reg. 1 No. reg.

No.

bytes

Val .

reg.1

Val .

reg.2 2 bytes

Tot. bytes = 7+2*No. registers+2

RESPONSE

Address Function Add. Reg. 1 No. register 2 bytes

A 0x10 0x0000 0x0002 CRC

Tot. bytes = 8

No. REGS: Number of registers to write beginning from the address.

Operation 35

Page 40

N° BYTES: Number of bytes transmitted as a value of the registers (2

bytes per register)

VAL. REG.: Contents of the register beginning from the first.

The answer contains the register identification modified after the command has

been executed.

Communication Error Management

The communication strings are controlled by CRC (Cyclical Redundancy

Check).

In case of a communication error the slave will not respond with any string. The

master must allow for a time-out before response reception. If no response is

received it infers that a communication error has occurred.

In the event of a string received correctly but not executable, the slave responds

with an EXCEPTIONAL RESPONSE. The "FUNCTION" field is transmitted

with the MSB at 1.

EXCEPTIONAL RESPONSE

Address Function Code 2 bytes

A Funct + 80h CRC

CODE DESCRIPTION

1 ILLEGAL FUNCTION (Function not valid or not supported)

2 ILLEGAL DATA ADDRESS (The specified data address is not available)

3 ILLEGAL DATA VALUE (The data received have no valid value)

List Of Usable Registers

The MODBUS-RTU protocol implemented on this instrument can manage a

maximum of 32 registers read and written in a single query or response.

R = the register can be read only

W = the register can be written only

R/W = the register can be both read and written

H = high half of the DOUBLE WORD forming the number

L = low half of the DOUBLE WORD forming the number

36 SCT Weight Transmitter Operator’s Manual

Page 41

REGISTER

Important

40001 Firmware version - R

40002 Type of instrument - R

40003 Year of Production - R

40004 Serial Number - R

40005 Active program - R

40006 Command Register NO W

40007 Status Register - R

40008 Gross Weight H - R

40009 Gross Weight L - R

40010 Net Weight H - R

40011 Net Weight L - R

40012 Peak Weight H - R

40013 Peak Weight L - R

40014 Divisions and Units of measure - R

40015 Coefficient H R

40016 Coefficient L R

40017 SETPOINT 1 H

40018 SETPOINT 1 L R/W

40019 SETPOINT 2 H R/W

40020 SETPOINT 2 L R/W

40021 HYSTERESIS 1 H R/W

40022 HYSTERESIS 1 L R/W

40023 HYSTERESIS 2 H

40024 HYSTERESIS 2 L

40025 INPUTS - R

40026 OUTPUTS NO R/W

40037 Test weight for calibration H Use with command

40038 Test weight for calibration L R/W

40043 Weight value corresponding to

ZERO of the analog output H

40044 Weight value corresponding to

ZERO of the analog output L

40045 Weight value corresponding to

Full Scale of the analog output H

40046 Weight value corresponding to

Full Scale of the analog output L

DESCRIPTION

At the time of writing, the setpoints, hysteresis values are

saved to the RAM and will be lost upon the next power-off; to

store them permanently to the EEPROM so that they are

maintained at power-on, the ‘99’ command of the Command

Register must be sent.

Saving to EEPROM ACCESS

Only after command

‘99’ of the COMMAND

REGISTER

‘101’ of the

COMMAND REGISTER

Only after command

‘99’ of the

Command Register.

R/W

R/W

R/W

R/W

R/W

R/W

Operation 37

Page 42

Weight (Span) Calibration Commands (With Test Weights)

The instrument calibration can be changed via MODBUS. To carry out this

procedure, the system must be unloaded and the weight value display reset to

zero with the command ‘100’ of the Command Register. Then, a load must be

placed on the system and the correct weight value must be sent to the registers

40037-40038; to save this value, send the control ‘101’ from the Command

Register. If the operation is successfully completed, the two test weight registers

are set to zero.

Analog Output Setting

Write the weight in the registers “Weight value corresponding to the Full Scale of

analog output H” (40045) and “Weight value corresponding to the Full Scale of

analog output L” (40046) or write the weight in the registers “weight value

corresponding to the ZERO of the analog output H” (40043) and “weight value

corresponding to the ZERO of the analog output L” (40044). After writing the

value, send the command 99 from the Command Register to save it to EEPROM

memory.

Status Register

Bit 0

Bit 1

Bit 2

Bit 3

Bit 4

Bit 5

Bit 6

Bit 7

Bit 8

Bit 9

Bit 10

Bit 11

Bit 12

Bit 13

Bit 14

Bit 15

Cell Error

AD Convertor Malfunction

Maximum weight exceeded by 9 divisions

Gross weight higher than 110% of full scale

Gross weight beyond 999999 or less than -999999

Net weight beyond 999999 or less than -999999

Gross weight negative sign

Net weight negative sign

Peak weight negative sign

Net display mode

Weight stability

Weight within +/-¼ of a division around ZERO

38 SCT Weight Transmitter Operator’s Manual

Page 43

Inputs Register (40025)

Note

(Read Only)

Bit 0 INPUT 1 Status Bit 0 OUTPUT 1 Status

Bit 1 INPUT 2 Status Bit 1 OUTPUT 2 Status

Bit 2 Bit 2

Bit 3 Bit 3

Bit 4 Bit 4

Bit 5 Bit 5

Bit 6 Bit 6

Bit 7 Bit 7

Bit 8 Bit 8

Bit 9 Bit 9

Bit 10 Bit 10

Bit 11 Bit 11

Bit 12 Bit 12

Bit 13 Bit 13

Bit 14 Bit 14

Bit 15 Bit 15

The output status can be read at any time but can be set (written)

only if the output has been set as or (see Section 2.6 “Outputs And

Inputs Configuration” on page 26); otherwise, the outputs will be

managed according to the current weight status with respect to

the relevant setpoints.

Divisions And Units Measure Registry (40014)

Outputs Register (40026)

(Read And Write)

This register contains the current setting of the divisions (parameter dI UI S ) and

of the units of measure (UnI t parameter).

H Byte L Byte

Units of measure division

Use this register together with the Coefficient registers to calculate the value

displayed by the instrument.

Operation 39

Page 44

Least significant byte

(L Byte)

Division

value

0 100 0 0 Kilograms Does not intervene

1 50 0 1 Grams Does not intervene

2 20 0 2 Tons Does not intervene

3 10 0 3 Pounds Does not intervene

4 5 0 4 Newton Multiples

520 5 Litres Divides

6 1 0 6 Bar Multiples

7 0.5 1 7 Atmspheres Multiples

8 0.2 1 8 Pieces Divides

90.11 9 Newton

10 0.05 2 10 Kilogram

11 0.02 2 11 Other Multiples

12 0.01 2

13 0.005 3

14 0.002 3

15 0.001 3

16 0.0005 4

17 0.0002 4

18 0.0001 4

Divisor Decimals

Units of

measure

value

Most significant byte

(H Byte)

Utilization of the

Coefficient value

Units of

measure

description

Meter

Meter

with the different

units of measure

settings compared

to the gross weight

Multiples

Multiples

detected

40 SCT Weight Transmitter Operator’s Manual

Page 45

Possible Command To Send To The Command Register (40006)

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

No command

NET display

SEMI-AUTOMATIC ZERO

GROSS display

Reserved

Reserved

Reserved

Reserved

Reserved