Page 1

DeckHand

TM

Portable Floor Scale

Installation and

Service Manual

43978 Rev C

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

1.0 Introduction..................................................................................................................................... 1

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Operating Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.0 Installation ...................................................................................................................................... 3

2.1 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Installing Optional Pivoting Ramp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Mounting and Wiring the Mast and Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Corner Trimming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5 Configuring the Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.6 Calibrating with Test Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.0 Service Information ........................................................................................................................ 6

3.1 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.3 Load Cell Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Installing Protective Clamshells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5 Mounting Indicator Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 Ramps and Replacement Load Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.0 Replacement Parts ....................................................................................................................... 12

4.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

DeckHand Limited Warranty..................................................................................................................... 15

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America

Specifications subject to changes without notice. Rice Lake Weighing Systems is an ISO Registered Company.

November 17, 2014

Contents i

Page 4

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

ii DeckHand Portable Floor Scale

Page 5

1.0 Introduction

The DeckHand™ Portable Floor Scales are fully electronic, NTEP-certified floor scales allowing one-person

portability on large rubber wheels. Available in painted steel or stainless steel construction, these rugged scales

come in 500 lb, 1000 lb, and 2000 lb capacity.

The heavy diamond-tread platform is 30-1/2 in x 24-1/4 in (0.77 m x 0.62 m) with an overall base height of only

4 1/2 in (0.11 m). The addition of an optional low-angle ramp allows one person to easily roll on a barrel or wheel

on a hand truck. The free-floating ramp pivots back over the deck and rests on the mast for compact storage or

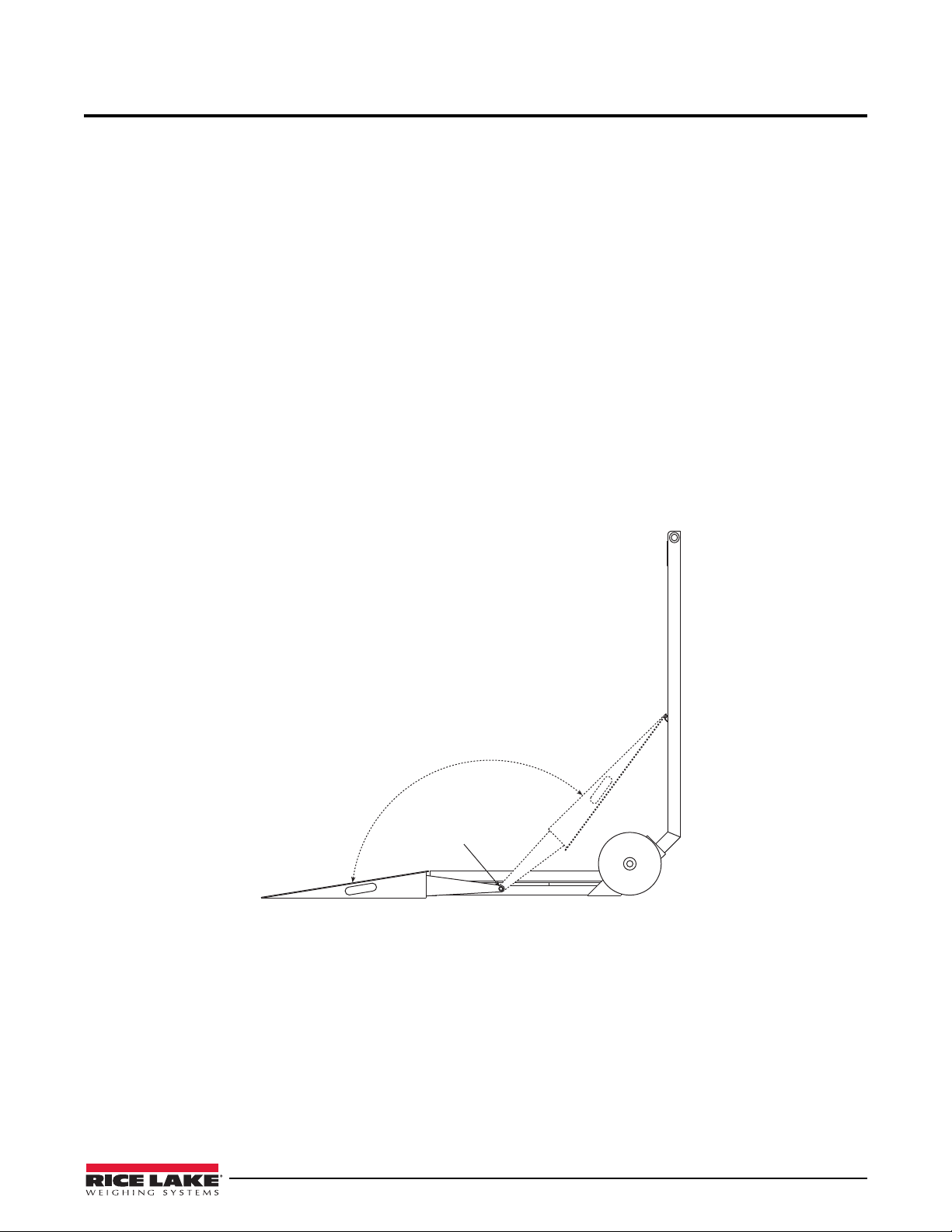

balanced portability.

Figure 1-1. Optional Pivoting Ramp and Indicator

An efficient off-center arrangement of two high-capacity, single-point load cells yields Legal for Trade accuracy.

Electronic components are double-protected from rough use. A RoughDeck™ stainless steel NEMA 4X junction

box is further protected by mounting within the m ast. The optional indicator mounts on a s wivel bracket high

enough on the 59 in (1.50 m) mast to clear the tallest loads.

In addition to ramps, available options include stainless steel load cell guards (clamshell) and indicator brackets for

any Rice Lake IQ series indicator. Other indicators can be readily mast-mounted with slight modifications.

Authorized distributors and their employ ees can view or download this manual from the Rice Lake

Weighing Systems distributor site at www.ricelake.com.

Introduction 1

Page 6

1.1 Safety

DANGER

WARNING

CAUTION

Important

WARNING

Important

Load Cell Excitation

Rated Excitation: 10 VDC

Maximum Excitation: 15 VDC

mV/V Signal Output: 2 mV/V

Grade Level Requirements

The bubble level built into the platform should indicate

a level condition in use. On uneven floors, place

temporary shims under feet not contacting the floor.

Safe Static Overloading Capacity

Maximum: 150% of scale capacity

Safety Symbol Definitions

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation that, if not avoided could result in serious injury or

death, and includes hazards that are exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided may result in minor or moderate

injury.

Indicates information about procedures that, if not observed, could result in damage to

equipment or corruption to and loss of data.

General Safety

Do not operate or work on this equipment unless you have read and understand the

instructions and warnings in this manual. Contact any Rice Lake Weighing Systems dealer

for replacement manuals. Proper care is your responsibility.

Before attempting to operate this unit, make sure every individual who operates or works with this unit has

read and understands the following safety information.

Failure to heed may result in serious injury of death.

DO NOT allow minors (children) or inexperienced persons to operate this unit.

DO NOT operate without all shields and guards in place.

DO NOT jump on the scale.

DO NOT use for purposes other then weight taking.

DO NOT place fingers into slots or possible pinch points.

DO NOT use any load bearing component that is worn beyond 5% of the original dimension.

DO NOT use this product if any of the components are cracked.

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

DO NOT use near water.

Before opening the unit, ensure the power cord is disconnected from the outlet.

Keep hands, feet and loose clothing away from moving parts.

1.2 Operating Requirements

Electrical Grounding

Rolling or wheeling loads onto the scale can build up large static charges that may damage the attached indicator

unless it is properly grounded to prevent ESD. This is especially true in dry environments where charges drain off

slowly, or if wheeling on materials which already contain a static charge, like rolls of paper or plastic film material

that have been recently spooled.

To prevent ESD damage, the indicator requires a three-prong 120 VAC outlet plug with continuous earth

ground. Do not attempt to use the scale with two-prong 120 VAC power without a ground.

2 DeckHand Portable Floor Scale

Page 7

2.0 Installation

Shoulder Bolts,

Pivot Washers

Overview

Assembly of the scale consists of the following steps:

1. Unpacking

2. Assembling mast onto scale base

3. Installing optional pivoting ramp

4. Mounting and wiring the indicator

5. Configuring the indicator

6. Calibrating the unit with test weights

2.1 Unpacking

The standard scale, with no added options, is shipped with load cells and indicator cable pre-wired into the junction

box on the mast. The indicator can be mounted and wired after the mast is in place.

Remove all packing material and inspect base and mast components for visible damage caused during shipment.

2.2 Installing Optional Pivoting Ramp

If the optional ramp is to be installed, set it flat on the floor in position in front of the scale so the holes in the base

align with the holes in the ramp pivot arms.

Figure 2-1. Pivoting Ramp

Insert a shoulder bolt with a single washer through an arm pivot hole. Slide three plastic pivot washers onto the bolt

for clearance between the arm and the base. See Figure 3-5. After the bolt engages the threads in the base, tighten

the shoulder bolt snugly. Repeat for the other side.

Installation 3

Page 8

2.3 Mounting and Wiring the Mast and Indicator

Plastic Pivot Washer

Swivel Bracket

Threaded Insert

Thumbscrew Bolt

Load Cell Cable

AC Power

Indicator Enclosure

Mounting Plate

Assembling Mast to Base

Remove back plate from mast. Carefully insert mast into window in base. Align holes and secure with fasteners

(refer to Figure 4-1). Wrap excess cable around hooks in mast. Re-assemble back plate to mast.

Attaching Indicator Bracket to Mast

The DeckHand is supplied with a swivel bracket for a variety of RLWS indicators. If using a different bracket, bolt

it onto the mounting plate on the mast with the bolts, washers, and nuts provided.

Set the two large plastic washers provided near the thumbscrew bolts used to hold the indicator in the bracket. Put

the bolts and washers within close reach of the bracket—they are needed for the next step.

Mounting the Indicator

Spread the bracket arms enough to slide the indicator between the bracket arms. Line up the bracket holes with the

threaded enclosure holes. Slide a plastic pivot washer between each arm and the indicator enclosure at the holes.

Insert the thumbscrew bolts through the bracket arm s, through the washers, and into the threaded holes of the

indicator enclosure. Tighten bolts snugly so the indicator remains at the desired viewing angle.

Wiring Load Cell Cable to Indicator

The load cell cable from the J-box is pre-wired to the indicator terminal inside the j-box. Attach the loose end of

this cable to the indicator’s load cell input terminal according to the corresponding pin functions on the j-box

indicator terminal. When completed, tighten the cord grip around the cable where it passes through the indicator

case.

2.4 Corner Trimming

The DeckHand scales are factory-trimmed so each load cell shares an equal part of the weight load.

Further corner-trimming is unnecessary unless a load cell is replaced. See Section 3.0 for complete information on

corner-trimming after load cell replacement.

Figure 2-2. Top View of Indicator and Bracket

Load Cell Cable

Color Code

Green + Excitation Green/Blue

Black – Excitation Black/Brown

Red + Signal Red

White – Signal White

Bare Shield Yellow

J-Box Terminal

Table 2-1. Load Cell Cable Wiring Code

Load Cell Cable Color

(load cells to j-box)

4 DeckHand Portable Floor Scale

Page 9

2.5 Configuring the Indicator

Refer to the indicator manual for information on configuring the indicator for your application.

If using the DeckHand for a Legal for Trade application, do not configure the indicator for more divisions than the

NTEP Class III maximums below:

500 lb capacity 2500 divisions

1000/2000 lb capacity 2000 divisions

The following sample configuration parameters will yield those maximum divisions:

Scale Capacity 500 lb 1000 lb 2000 lb

Grads 25,000 20,000 20,000

Decimal Point 0.00 0.00 0.0

Display Divisions 2 5 1

Units lbs lbs lbs

Table 2-2. Sample Configuration

2.6 Calibrating with Test Weights

Refer to the indicator operating manual to determine correct calibration procedure.

Before beginning calibration, put the scale in the same temperature environment where it will be used. Power up

the indicator so it can warm up for at least 20 minutes before starting calibration.

The scale should be “exercised” before calibration to be certain that everything is seated. Load the scale to near

capacity two or three times.

The following test weights are recommended for the most accurate calibration of the various models:

Scale Capacity 500 lb 1000 lb 2000 lb

Test Weights (75%) 375 lb 750 lb 1500 lb

Table 2-3. Sample Configuration

With the scale base level and no load on the scale, place the indicator in calibration mode and do a zero calibration

according to the indicator manual.

Place test weights on the platform equal to the value shown in Table 3 (75% of the scale’s capacity). Do a span

calibration according to the indicator manual.

Remove the test weights and check the zero reading. Repeat the calibration process if necessary.

The calibrated DeckHand scale is now ready for operation.

Installation 5

Page 10

3.0 Service Information

Important

3.1 Troubleshooting Guide

Symptom Possible Problem Solution

System does not operate—

no display

Display stays at zero Indicator faulty. Service indicator.

Erratic weights Vibration near scale. Remove source of vibration or increase digital

Consistently high or low

weights

Power disconnected. Check and reconnect.

Indicator fuse blown. Check for cause. Replace.

Interface cable cut or disconnected. Repair.

Signal leads incorrectly connected at indicator. Install according to indicator installation

manual.

Load cell connections faulty. Check cable connections in junction box and

at indicator.

Load cell overload screws turned fully in. Loosen overload screws to 0.020” gap.

filtering.

Platform not level. Level scale by shimming if necessary.

Load cell or cable water damage. Replace.

Debris under load cells or platform. Clean.

Indicator faulty. Use simulator to test indicator for stability.

Service indicator.

Indicator not properly adjusted to zero. Zero the indicator according to operating

manual.

Platform binding. Obtain adequate clearance for free platform

movement.

Indicator not calibrated. Calibrate according to indicator manual and

Section 2.6.

Load cells cables pinched between platform and

base.

Load cells faulty. Test and replace load cells if necessary.

Reroute cables to provide clearance.

Table 3-1. Troubleshooting

3.2 Periodic Maintenance

Two important spaces – between the platform side and frame, and beneath the platform – should be periodically

cleaned to prevent debris build up.

The platform can be removed for periodic cleaning by unscrewing the lock nuts from the four welded studs on the

underside of the platform. The platform can then be lifted off the load cell channels for cleaning.

When cleaning beneath the platform, be careful not to move the load cell cables to a new position where they can

be pinched by the platform in operation.

Do not attempt to spray wash scales with non-hermetically sealed load cells. Water damage is a

common cause of failure in non-hermetically sealed load cells.

Use care with hot water wash downs for hermetically-sealed load cells. The hot water may not damage the load

cells, but the elevated temperatures can cause incorrect readings until the unit cools to room temperature.

When replacing the platform, tighten the four locknuts on the welded studs only until the flat washers beneath them

contact the channel surface. Do not tighten the nuts further and compress the cushion pads between platform and

channels. The platform must be free-floating on resilient pads for continued accuracy.

6 DeckHand Portable Floor Scale

Page 11

3.3 Load Cell Replacement

Disassembly

1. Remove the four locknuts and washers that secure the platform to load cell channels. Lift off the platform.

Remove the column back plate to gain access to the j-box.

2. Determine which load cell is defective. Use a hardened hex-drive bit and large ratchet wrench to remove

the four hex-drive countersunk machine screws holding the channel to the defective load cell underneath.

Lift off the channel and the spacer on top of the load cell. Note how the load cell cable is routed on its cable

hold downs.

3. Cut the plastic tie at each hold-down to free the cable. Remove the load cell wires from the load cell

terminal in the J-box. Loosen the cord grip and pull the cable out of the J-box. Unwind the excess cable

from the cable-storage studs and pull it out of the mast cavity.

4. Turn the scale on its side to remove the lower load cell screws. With the hex-drive bit and ratchet wrench,

remove the four cap screws and lock washers that hold the cell to the mounting plate. Lift off the cell and

spacer plate beneath.

Reassembly

Tilt and block the scale base enough to have comfortable access to the load cell screws from underneath the base.

Position the new load cell with the cable to the inside and the label readable from the outside. Be sure the load cell

body is not contacting the overload stop screw. Back the screw off if necessary (it was secured with Loctite at the

factory and will turn hard).

1. Set the spacer block and load cell into position. Insert the four load cell screws from the bottom finger-tight

only; final adjustments in load cell position are necessary before the screws are torqued down.

2. Run the new load cell cable to the J-box using exactly the path dictated by the cable existing ties. The

existing cable hold downs keep the cables under the middle of each load cell channel, where they are

protected from accidental crimping between the flexing channels and the frame. When new cable ties are

attached, feed the cable through the cutout in the frame and into the mast cavity. Do not shorten the load

cell cable; it is temperature-compensated for the supplied cable length. Wind the excess cable around the

cable-storage studs, leaving enough free to wire into the junction box.

3. With the load cell still loose enough for final adjustment, set the top spacer block and load cell channel on

the cell and insert the self-centering countersunk load cell screws. Tighten these screws alternately with a

hex-drive bit and ratchet wrench to a final torque of 20 ft-lb for mild steel models and 12 ft-lb for stainless

steel models.

4. Adjust the load cell/channel assembly so it is parallel with the other channel. Measure across the holes in

the front and rear of the channels. Adjust the new cell so that distance is equal, then tighten the load cell

cap screws from underneath to a final torque of 20 ft-lb for mild steel models and 12 ft-lb for stainless steel

models. Check again to be certain the cable will not be pinched by the flexing channel in operation.

5. Finally, put a drop of Loctite on the overload stop screw and set it for a 0.020" gap with the load cell.

Wiring Load Cells into J-Box

Feed the load cell cable into the j-box cord grip closest to its terminal. When facing the scale, the left load cell is

wired to terminal 4 of the j-box, and the right load cell is wired to terminal 1.

Note that the wire traces for cells 2 and 3 (JU-2, JU-3 ) have been cut, making those unused channels inactive.

Connect wires according to Table 2-1 on page 4. Pull excess cable out of the J-box and tighten the cable cord grip

snugly. The rubber seal will protrude slightly from the cord grip when tightened enough to be waterproof.

Service Information 7

Page 12

CELL 1

CELL 4

CELL 2

CELL 3

INDICATOR

+EX

–EX

+SI

–SI

100 K

+SE

–SE

+EX

+EX

+EX

+EX

–EX

–EX

–EX

–EX

+SI

+SI

+SI

+SI

–SI

–SI

–SI

–SI

SHD

SHD

SHD

SHD

23126

Rev. A

SHD

JU1

JU2

JU3

JU4

100 K

100 K

100 K

(Cells 2 & 3 disabled)

Figure 3-1 DeckHand Junction Box Cutaway

Replacing Deck Platform

Put the scale flat on the floor and set the platform on the channels so the welded studs drop into the channel holes.

Tilt and block the scale up again and install a flat washer and locknut on each stud. T urn the lock nut onto each stud

until the washer just contacts the channel underside. Do not tighten the lock nuts so the cushioning pads are

compressed. The platform must be free floating for accuracy; the lock nuts merely serve as lift off protection.

8 DeckHand Portable Floor Scale

Page 13

Corner Trimming

CELL 1

CELL 4

+EX

–EX

+SI

–SI

100 K

+EX

–EX

+SI

–SI

SHD

SHD

JU1

JU4

100 K

All DeckHand scales are delivered with the junction box trimmed, but re-trimming to equalize loading is necessary

after replacing a load cell.

To trim the scale, the output from each load cell must be matched by adjusting the signals with potentiometers at

the junction box—a process known as trimming.

The indicator must be connected and approximately calibrated, but it need not indicate the exact weight value. An

exact calibration will be done after trimming.

A test weight is required for corner trimming. The recommended minimum test weight for all DeckHand models is

25% of scale capacity.

1. Remove the junction box cover and identify the correct load cell terminal corresponding to each side of the

scale (labeled CELL 1, and CELL 4).

Figure 6: Cell 1 and Cell 4 Potentiometers

2. With scale level and no weight on the scale, zero the indicator. Then turn potentiometers for cells 1 and 4

fully clockwise to get the maximum signal from each load cell. A clicking sound can be heard when full

signal is reached.

3. With both potentiometers at full signal, place the test weight over left or right side of platform and record

the indicated weight reading. Repeat the process for the other side. The load cell with the lowest reading

will be used as the reference cell and will not be trimmed.

4. Place the test weight over the side reading high and turn that cell’s potentiometer to adjust the cell output

down to the reference cell output.

5. Rezero the indicator and repeat the test until both sides are within ±0.1% of the test weight being used.

Adjustments are somewhat interactive, so adjusting the higher output may affect the reference cell output.

6. Secure extra cable length by wrapping it around the cable storage pegs inside the mast.

7. When corner trimming is complete, pull any excess cable out of the junction box enclosure and tighten the

strain relief hubs snugly with a wrench. T o be watertight, the hubs must be tightened to the point where the

rubber sleeving begins to protrude out of the hub (SST models).

8. Replace the J-box cover and column back plate.

9. Recalibrate per Section 2.6.

Service Information 9

Page 14

3.4 Installing Protective Clamshells

Overload Screw, 0.020” gap Bottom Spacer Block

Top Spacer Block

Stainless steel clamshells—load cell protectors—are mounted around the load cells to provide an extra degree of

spray protection. The lower protector is slightly smaller than the upper one which overlaps on all sides. The load

cell cable exits through the bottom surface of the lower clamshell then through a hole in the mounting plate.

Figure 3-2 Clamshell Load Cell Protectors

1. To attach clamshells, remove all channels, load cell screws and load cells. Place lower clamshell directly

on mounting plate with overload stop screw centered in the clamshell’s largest hole.

2. Add mounting spacer and align all four holes. Position load cell on spacer and insert load cell screws and

lock washers from beneath mounting plate through the clamshell and spacer and into the load cell. Tighten

the four screws finger tight only so the cell can still be moved slightly for final positioning.

3. For final positioning, measure to ensure load cells are parallel to each other and to the frame. It may be

easier to mount one load cell first so it is parallel to the frame, then measure equal distances between the

ends of the two load cells to get them parallel with each other. When correctly positioned, re-tighten the

load cell screws to original torque specifications (20 ft-lb for mild steel screws, 12 ft-lb for stainless steel

screws).

4. Position top spacer blocks on load cells, then set upper clamshells on spacer blocks and align holes. Place

load cell channels so all four holes line up, then turn in the self-centering countersunk screws. Tighten to

same torque settings as lower load cell screws.

5. Replace scale deck onto load cell channels.

6. Reset overload stop screws by turning them in until they just contact the load cell, then back off 0.020".

7. Calibrate scale according to Section 2.6.

3.5 Mounting Indicator Brackets

A universal mount plate is welded to the DeckHand mast. The plate is predrilled to match the bracket of most

indicators and are supplied with the appropriate painted or stainless steel mounting hardware.

Figure 3-3 Indicator Bracket

10 DeckHand Portable Floor Scale

Page 15

3.6 Ramps and Replacement Load Cells

31

30.5

41

27

24.25

25

Socket head

shoulder bolt

3 plastic washers

Ramp arm Plastic washer

Scale deck

Figure 3-4 Scale and Ramp Dimensions

When attaching a ramp to a DeckHand scale, place one plastic pivot washer under the head of the shoulder

bolt and three washers on the bolt in the space between the ramp arm and the scale deck.

DeckHand

Model

DH-500 41293 31"W 41"L 24.25"W 30.5"L 41024 250 kg b)l(550 43376 25"W 27"L 44 lb

DH-1000 41294 31"W 41"L 24.25"W 30.5"L 41026 500 kg b)l(1100 43376 25"W 27"L 44 lb

DH-2000 41295 31"W 41"L 24.25"W 30.5"L 41027 635 kg b)l(1397 43378 25"W 27"L 57 lb

DH-500SS 41296 31"W 41"L 24.25"W 30.5"L 41024 250 kg b)l(550 43377 25"W 27"L 44 lb

DH-1000SS 41297 31"W 41"L 24.25"W 30.5"L 41026 500 kg b)l(1100 43377 25"W 27"L 44 lb

DH-2000SS 41298 31"W 41"L 24.25"W 30.5"L 41027 635 kg b)l(1397 43379 25"W 27"L 57 lb

Scale PN

Overall

Size

Figure 3-5 Ramp Pivot Bolt

Platform Deck

Size

Load

Cell PN

Load Cell

Capacity

Table 3-2. DeckHand Specifications

Ramp

PN

Service Information 11

Ramp

Deck Size

Ramp

Weight

Page 16

4.0 Replacement Parts

29

2930

31

32

37

36

38

35

1

39

40

43

22

41

23

25

28

50

27

19

6

46

8

9

10

11

12

13

15

16

17

18

51

34

52

2

3

4

5

26

14

7

53

12 DeckHand Portable Floor Scale

Figure 4-1 Replacement Parts Illustration

Page 17

Part No.

Ref. Description

1 Cable, 6-Conductor, 3 1/2 ft 15494 44187

2 Mount, Indicator, 310A 41011 41206

3 Grommet, Rubber 1/2 x 1/4 15398 15377

4 Flat Washer, 1/4 15145 15149

5 Cap Screw, 1/4-20NC x 3/4 14965 41251

6 Upper Platter (DH-500, DH-1000) 40986 41181

Upper Platter (DH-2000) 42654 42655

7 Cap Screw, 5/16-18 NC x 1 14996 41250

8 Load Cell Channels (DH-500) 41002 41197

Load Cell Channels (DH-1000) 41002 42665

Load Cell Channels (DH-2000) 42664 42653

9 Flat Washer, 5/16 21939 44237

10 Lock Nut, 5/16-18 NC, Hex 14646 35170

11 Shim, Load Cell 41003 41198

12 Load Cell See Table 3-2 on page 11

13 Base Platform (DH-500, DH-1000) 40983 41178

Base Platform (DH-2000) 42616 42617

14 Cap Screws, 5/16-18NC x 1 26667 26670

15 Overload Stop Set Screw, 5/16 x 18NC x 1/2 14989 21933

16 Base Shim, Ramp End 41004 41199

17 Scale Base Bumper, 3/4 41267 41267

18 Cap Screw, 1/4-20NC x 3/4 14964 41251

19 Lock Washer, 5/16 15153 15154

22 Cable Tie Mount 15658 15658

23 Cable Tie, 3" 15631 15631

25 Lock Nut, 5/8-11NC 40181 41249

26 Wheel, 10 Dia. x 5/8 Bore 41268 41268

27 Axle, 5/8-11 x 6 41005 41200

28 Jam Nut, 5/8-11NC 14676 14680

29 Handle Grip, 3/4 I.D. 41266 41266

30 Mast, 57-13/16 x 15 40987 41182

31 Lock Washer, 1/4 15147 15148

32 Hex Nut, 1/4-20NC 14641 14642

35 Junction Box, Four Channel 43612 23127

36 Flat Washer, 3/8 21938 15161

37 Lock Washer, 3/8 15159 15160

38 Hex Nut, 3/8-16NC 14656 14655

39 Dampener Strip, Ramp Stop 41108 41108

40 Cap Screw, 10-32NF x 3/4 14908 41253

41 Cap Screw, 3/8-16NC x 6 41254 41257

43 Bubble Level 15410 15410

46 Bumper Cushion, Self-Adhesive 44149 44149

50 Nylon Washer, 5/8 15176 15176

51 Column Back Plate 46259 46260

52 Cap Screw, 10-32NF x 3/8 14932 46337

53 Base Shim, All Corners 47726 47727

Mild Steel

Part N0.

Stainless

Table 4-1. Repair Parts List

Replacement Parts 13

Page 18

4.1 Specifications

t

N

A

T

I

O

N

A

L

C

O

N

F

E

R

E

N

C

E

t

O

N

W

E

I

G

H

T

S

A

N

D

M

E

A

S

U

R

E

S

CC# 98-004

Class III

n

max

= 2500

APPROVED

LOAD CELLS

End Load Capacity

100% end loading

mV/V Output

2mV/V

Cable Length

9 ft 10 in (3 m)

Height

Weighing platter: 4.5 in H when in weigh mode

Column Height

59 in

Warranty

Deckhand weldment five years

Load cells two years

All other components one year

Approvals

Measurement Canada

Approval AM-5218

14 DeckHand Portable Floor Scale

Page 19

DeckHand Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by the

Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects in materials

and workmanship for one year.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized by

RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment fails

to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the warranty

period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to prevent

electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a publication,

Protecting Your Components From Static Damage in Shipment, available from RLWS Equipment Return

Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was not

caused by accident, misuse, neglect, alteration, improper installation, improper repair or improper testing;

RLWS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other than RLWS or its duly

authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible for

shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMIT ATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. NEITHER RLWS NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS

LIMITED TO REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY,

THE BUYER WAIVES ANY AND ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE

SELLER FOR WARRANTY CLAIMS.

NO TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO MODIFY

THE TERMS OF THIS WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN

WRITING AND SIGNED BY A CORPORATE OFFICER OF RLWS AND THE BUYER.

© 2013 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

Replacement Parts 15

Page 20

16 DeckHand Portable Floor Scale

Page 21

Page 22

© Rice Lake Weighing Systems 11/2014 PN 43978 Rev C

230 W. Coleman St. • Rice Lake, WI 54868 • USA

U.S. 800-472-6703 • Canada/Mexico 800-321-6703 • International 715-234-9171 • Europe +31 (0)26 472 1319

www.ricelake.com www.ricelake.mx www.ricelake.eu www.ricelake.co.in m.ricelake.com

Loading...

Loading...