Page 1

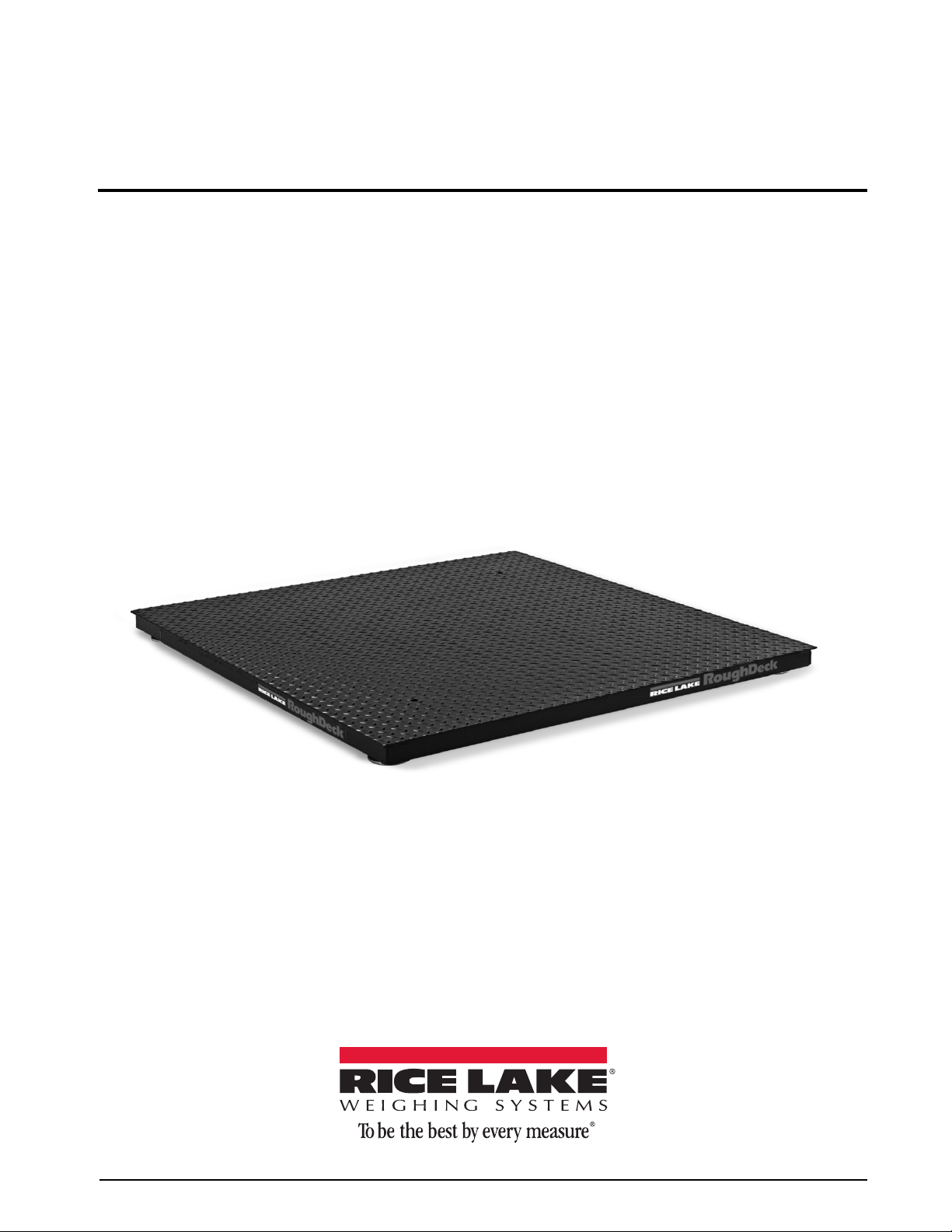

RoughDeck

Low Profile Floor Scale

HP, HP-H, HC and ROUGH-N-READY

Installation Manual

®

PN 66662 Rev E

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

1.0 Introduction..................................................................................................................................... 1

1.1 Model Designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Operating Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.0 Installation ...................................................................................................................................... 3

2.1 Installation Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Site Preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4.1 Installing and Adjusting Feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4.2 Mounting Plate Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5 Junction Box Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5.1 Electrical Interface to Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.6 Pit Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.7 Access Ramps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.0 Adjustments and Calibration .......................................................................................................... 8

3.1 Mechanical Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Corner Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.0 Service Information ........................................................................................................................ 9

4.1 Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Periodic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Load Cell Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3.1 Load Cell Wiring to Junction Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.4 Replacement Parts List and Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4.1 Pit Frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4.2 Access Ramps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . 1

. . . . . . . 2

. . . . . . . . . . 3

. . . . . . . . . . 3

. . . . . . . . . . . . 4

. . . . . . . . . 7

. . . . . . . . . 8

. . . . . . . . . 8

. . . . . . . 9

. . . . . . 10

RoughDeck Limited Warranty................................................................................................................... 14

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Rice Lake Weighing Systems is an ISO 9001 registered company.

Specifications subject to change without notice.

December 26, 2014

Contents i

Page 4

ii RoughDeck Low Profile Floor Scale Installation Manual

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

Page 5

1.0 Introduction

Note

Important

CAUTION

WARNING

DANGER

The RoughDeck® Floor Scales are fully electronic, low profile load receivers. The RoughDeck scales are available

in sizes from 30 in x 30 in (.76 m x .76 m) to 96 in x 120 in (2.44 m x 3.05 m), and capacities from 2K- to 30K-lb

(1000–15000 kg).

All models use four corner-mounted, FM-approved load cells, wi

protection. Also included is a signal-trim summing board enclosed in a stainless steel, NEMA 4X junction box for

any necessary corner corrections. All models come pre-trimmed; corner corrections should not be necessary.

Load cell cables are enclosed in conduit through the main channe

each corner, eliminating the possibility of cable damage in portable applications. Also useful for portable

applications are threaded corner holes in the deck for removable eye bolts to allow lifting the scale from above with

chains. Because of the possibility of foot and load cell damage from forklift tines, the scale should always be lifted

from above with chains through the eye bolts.

The adjustable feet are used to allow leveling the scale to make up

installations, two of the four feet can be held in place on the floor with optional floor mounting plates to guard

against deck movement.

Other available options include custom frames for pit

installations, and access ramps for all sizes and models of the

RoughDeck. Decks designed for use in pits can be ordered

for adjusting foot height with a screwdriver from above. See Section 4.4 on page 12 for replacement part and

optional equipment part numbers.

1.1 Model Designations

The model identification label is located on the side of the frame next to the slide-out junction box. Include both

model number and serial number when ordering replacement parts.

th the cells recessed into the frame channels for

ls, and held down with replaceable cable ties near

for minor floor irregularities. For permanent

with holes drilled in the deck directly above each foot

A duplicate label is affixed inside the junction box opening.

The following model designations are used to describe the different scale versions:

HP (

Rough-n-Ready)— Mild steel, high precision, NTEP-certified as “legal-for-trade” and FM-approved load

cells.

HP-H

HC

— 20K- and 30K-lb capacity HP models.

— Similar to HP models, the HC includes overload stops at each corner of the platform. This model is

approved by Measurement Canada (formerly LMB) and available for use in Canada.

1. 2 S af et y

Safety Symbol Definitions

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious

injury.

Indicates a potentially hazar

death, and includes hazards that are exposed when guards are removed.

Indicates a potentially hazardous situation that, if not

injury.

Indicates information about proced

equipment or corruption to and loss of data.

dous situation that, if not avoided could result in serious injury or

avoided may result in minor or moderate

ures that, if not observed, could result in damage to

Introduction 1

Page 6

General Safety

WARNING

Do not operate or work on this equipment unless you have read and understand the

instructions and warnings in this manual. Failure to follow the instructions or heed the

warnings could result in injury or death. Contact any Rice Lake Weighing Systems dealer for

replacement manuals. Proper care is your responsibility.

Before attempting to operate this unit, make sure every individual who operates or works with this unit has

read and understands the following safety information.

Failure to heed may result in serious injury of death.

DO NOT allow minors (children) or inexpe

DO NOT operate without all shields and guards in place.

DO NOT jump on the scale.

DO NOT use for purposes other

DO NOT place fingers into slots or p

DO NOT use any load bearing component that is worn beyond 5% of the original dimension.

DO NOT use this product if any of the components are cracked.

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

DO NOT use near water.

Before opening the unit, ensure the power cord is disconnected from the outlet.

Keep hands, feet and loose clothing away from moving parts.

then weight taking.

rienced persons to operate this unit.

ossible pinch points.

1.3 Operating Requirements

The following are basic operating requirements for the RoughDeck floor scale.

Electrical Grounding

For systems where the scale is connected to a 115 VAC circuit, the indicator must be directly connected to an earth

ground with a ground interface cable of no more than 3Ω resistance throughout its length.

Load Cell Excitation

Rated Excitation: 10 VDC

Maximum Excitation: 15 VDC

Grade Level Requirements

The supporting surface for the four feet of the scale must be level within 1/4 in. of horizontal.

End Load Capacity

200% full scale at 1000 lbs

100% full scale at 2000 lbs, 5000 lbs, and 20,000 lbs

80% full scale at 10,000 lbs

66% full scale at 30,000 lbs

Nominal Scale Height

2K–10K lb (1000–5000 Kg) models: 3.5 in (89 mm)

20K lb (10000 kg) models: 4.0 in (102 mm)

30K lb (15000 kg) models: 5.0 in (127 mm)

2 RoughDeck Low Profile Floor Scale Installation Manual

Page 7

2.0 Installation

Large Platform

(Larger then 5

’

x 5’, and /or more than 10,000lb capacity)

Use two 3/4” eye bolts, insert into threaded holes in

opposite corners of top plate for lifting.

Small Platform

(5

’

x 5’ or smaller and/or 10,000lb or less capacity)

Use one 1/2” eye bolt, insert into threaded hole in

center of top plate for lifting.

WARNING

Important

2.1 Installation Overview

Standard installation of the RoughDeck floor scale consists of the following steps:

1. Select a site

2. Check levelness and smoothness of site

3. Unpack scale

4. Adjust the four feet on the scale

5. Install mounting plates to the floor

6. Connect cable to junction box and indicator

7.

Calibrate the unit

Pit installations and access ramps are described in Section 2.6 and Section 2.7 on page 7.

2.2 Site Preparation

The scale must not be loaded beyond its capacity, even momentarily. Do not select a site where overweight loads

would have to maneuver to avoid crossing the platform. Avoid areas where the scale might receive damaging side

impacts from wheels or forklift tines, or shock damage from falling objects. Avoid areas where water may damage

a scale not meant for a washdown environment.

The interface cable between the scale and the indicator must be protected against crushing, cutting, or moisture

damage. If the chosen site h

conduit, will be necessary.

In operation, the scale must be level within 1/4 inch. Either choose a site

avoid excessive shimming, or modify the floor at the chosen site to meet this standard.

as such potential dangers, some method of protection, such as running the cable in

where the floor is close to this standard to

2.3 Unpacking

Remove all packing material and inspect scale for visible damage caused during shipment.

All Rough

when lifting the scale with chains or using a spreader bar.

Deck models have threaded holes in the deck to allow installation of eye bolts with shoulders for use

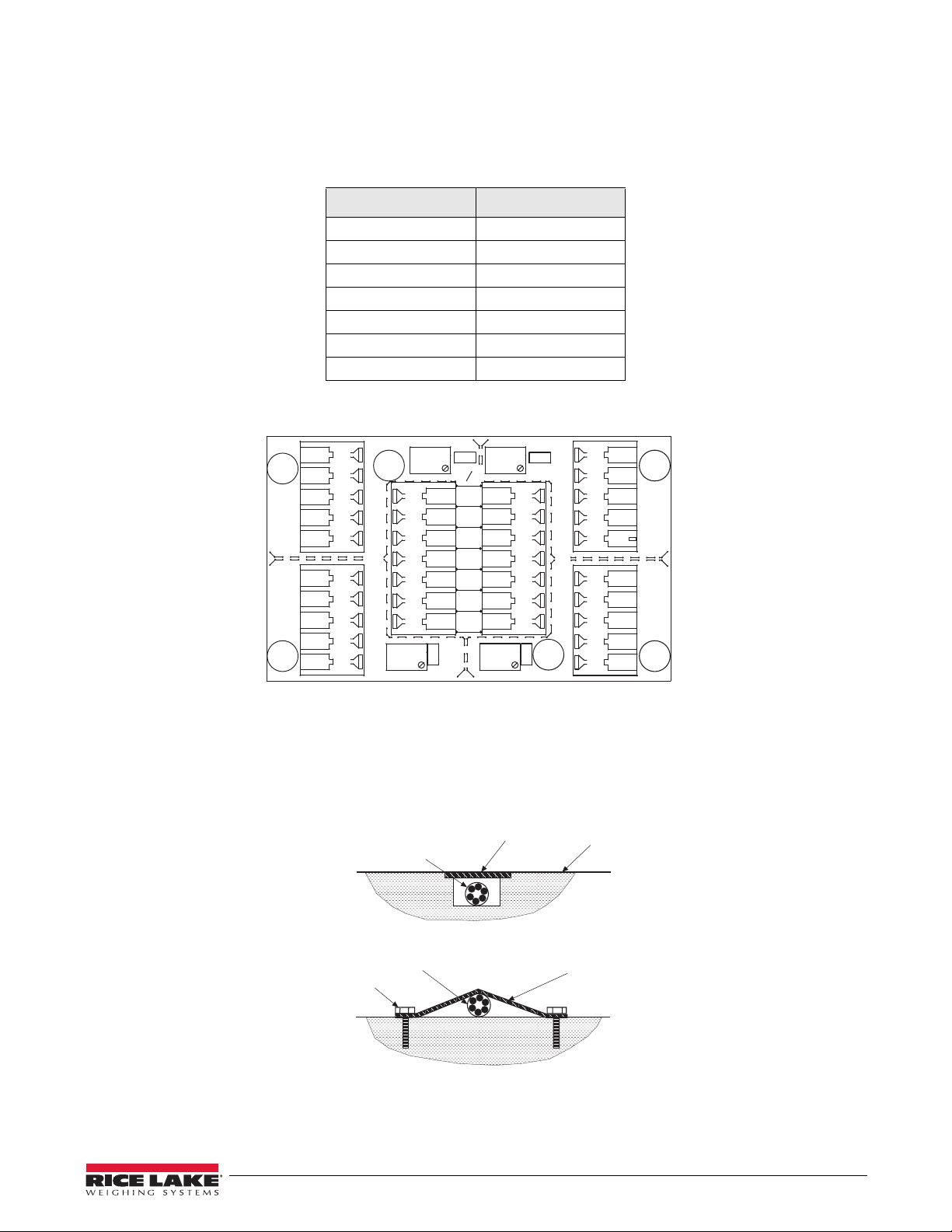

Lift the scale only with a properly designed spreader bar as shown in Figure 2-1.

Lifting force must be vertical to avoid bending the eye bolts.

Eye bolts must always be inserted into the top of the scale.

the top plate facing up and the eye bolts securely attached through the nuts welded to the

bottom side of the top plate. Lifting from the bottom of the plate could cause nuts to break

loose and the scale to fall.

Lifting should always occur with

Figure 2-1. Proper Lifting Technique

Installation 3

Page 8

2.4 Assembly

4.50"

.812" DIA

MOUNTING PLATE

SCALE DECK

FOOT

The following paragraphs present instructions for installing and adjusting the scale feet and mounting plate

installation.

2.4.1 Installing and Adjusting Feet

For load cell protection during shipping, the scale feet are shipped detached from the load cells. The feet are

secured to the bottom of the shipping pallet along with the load cell cable, strain relief fitting and product literature.

Remove all parts from the envelope.

Screw one foot into each load cell and turn all t

of the deck. Then unscrew each foot three complete turns.

Place a spirit level on the deck. Adjust any

on those corners until they just contact the floor surface. When all feet are in contact with the floor, check the deck

with the spirit level to be sure the scale is within 1/4 inch of level.

2.4.2 Mounting Plate Installation

For permanent applications, the scale should be secured to the floor to prevent sideways movement. Two mounting

plates, with holes that slightly exceed the foot diameter, are available as an option for that purpose.

Lift the scale so that the feet are appro

ximately one inch off the floor. Slide mounting plates under two diagonally

opposed feet. Lower the scale back to the floor, and position the plates as shown in Figure 2-2 so that the bolt down

holes are accessible from above.

Using the mounting plates as templates, drill pilot holes into the floor for suitable anchor bolts. Bolt th

the floor using 1/2 inch anchor bolts (3/4 inch bolts for 20K and 30K-lb capacity scales). Recheck foot adjustment

and deck level after this operation.

For installations using access ramps, mounting plates are not necessary as the ramps have built-in mounting plates

cure the scale feet.

to se

he way in until the foot touches either the load cell or the underside

high corners not in contact with the floor by further unscrewing the feet

e plates to

Figure 2-2. Mounting Plate Installation

4 RoughDeck Low Profile Floor Scale Installation Manual

Page 9

2.5 Junction Box Connections

JP4

JP 2

PT4

PT3

JP3

PT1

EXP

PT2

JP1

1

CELL4

1

CELL1

1

CELL3

1

CELL2

IND

-EX

-SI

SHD

+SI

+EX

M

R

N

I

-SI

S2C

I

A

G

+EX

+SI

-SI

SHD

-EX

I

S

G

A

L

T

+SI

M

S

I

N

L

T

R

+EX

-EX

-SI

SHD

+SI

+EX

+SI

-EX

-SI

SHD

-EX

SHD

+SE

-SE

+EX

LOAD CELL CABLE

STEEL COVER

FLOOR

SCREW

LOAD CELL CABLE

STEEL COVER

The indicator terminal strip is used to connect the main cable to the indicator which is shown in Figure 2-3

Determine the indicator’s load cell inpu

terminal into the junction box and make the connections. The following table shows the correct junction box

connections using the cable color code.

t connections from the operating manual. Run a cable from your indicator

Cable Color Code Junction Box

Red + Excitation

Black - Excitation

Green + Signal

White - Signal

Brown Shield

Yell ow + Sense

Blue - Sense

Table 2-1. Junction Box Connections

Figure 2-3. Junction Box Indicator Terminal

2.5.1 Electrical Interface to Indicator

Twenty feet of 6-wire cable to connect the scale to the weight indicator is supplied with each scale. The cable must

be routed to the indicator in a manner that will protect the cable from damage. Two methods of cable protection in

non-washdown applications are shown. When planning cable routing with either of these two methods, leave a

loose coil of excess cable under the scale to facilitate future lifting of the scale for servicing or cleaning.

When the interface cable is protected and in its final position, complete connections to the indicator. See indicator

installation manual for wiring information.

Figure 2-4. Electrical Interface to Indicator

Installation 5

Page 10

If necessary, trim corners as described in Section 3.2 on page 8.

COVER PLATE

1:24 SLOPE

LOAD CELL

CUP

FOOT ASSEMBLY

GROUT

Note

Check all strain relief fittings for tightness.

Slide the junction box assembly into the cu

tout and secure it with the two #10 x 3/8 inch screws provided.

2.6 Pit Installation

Any of the RoughDeck models can be installed in a shallow pit using the optional RoughDeck Pit Frame. Optional

height-adjustment holes are available. The following site considerations and pit frame drawings are meant only as

a brief overview of the principles involved with mounting the scale in a floor-level pit. The pit must be installed in

a suitable poured-concrete foundation according to standard construction practices.

Figure 2-5. Section Showing Installed Heavy Capacity (HP-H Model) RoughDeck and Pit Frame

Site Considerations

Debris, floor sweepings, or material spills may accumulate in the pit and interfere with scale operation. You should

periodically clean the pit. All RoughDeck models have threaded holes for eye bolts so the scale can be easily lifted

from the pit.

Weight overloads, even momentary ones such as driving a loade

d forklift over a scale corner, will damage load

cells. Plan the pit location out of main traffic areas to prevent such accidental damaging overloads.

A 1:24 slope is recommended for the

Corner pads must be fully grouted.

pit, with full grouting under the corner pads as shown in Figure 2-4.

6 RoughDeck Low Profile Floor Scale Installation Manual

Page 11

2.7 Access Ramps

Longitudinal axis

of load cells

Access ramps for RoughDeck floor scales are designed to bolt to the floor, with built-in mounting plates that attach

to the scale feet. When used with access ramps, side movement of the scale is automatically eliminated, and no

other mounting plates are necessary.

Access ramps can only be attached to the scale on one of the tw

longitudinal axis of the load cells. For example, the scale shown in Figure 2-5 could have an access ramp on the left

side as shown, and/or on the right side. The top and bottom sides, will not

o scale sides that are perpendicular to the

accept the ramp mounting plates.

Figure 2-6. Optional Access Ramps

See Tabl e 4-3 and Table 4-4 on page 12 for information about available access ramps.

Installation 7

Page 12

CAUTION

JP4

JP2

PT4

PT3

JP3

PT1

EXP

PT2

JP1

1

CELL4

1

CELL1

1

CELL3

1

CELL2

IND

-EX

-SI

SHD

+SI

+EX

M

R

N

I

-SI

S2C

I

A

G

+EX

+SI

-SI

SHD

-EX

I

S

G

A

L

T

+SI

M

S

I

N

L

T

R

+EX

-EX

-SI

SHD

+SI

+EX

+SI

-EX

-SI

SHD

-EX

SHD

+SE

-SE

+EX

Potentiometers

Jumper Locations

JP1 and JP2

Shaded

Jumper Locations

JP3 and JP4

Shaded

Potentiometers

Figure 3-1. Trim Potentiometers

3.0 Adjustments and Calibration

3.1 Mechanical Adjustments

To accommodate minor floor unevenness, scale feet can be used to adjust scale height up or down a fraction of an

inch. Adjust the feet by hand (lift the scale corner slightly with a pry bar) until all feet are contacting the floor

equally. No jam nuts are supplied for locking the feet, as there is a slight decrease in accuracy when jam nuts are

tightened. If the application requires the feet to be secured, use Teflon tape or Loctite.

When adjusting scale feet, use care to prevent scale foot from bottoming out against the underside of the

load cell. Also, the foot stem may be damaged by bendi

maximum height adjustment.

When height adjustments are complete, recheck level of the deck with a spirit level. The deck must be level within

1/4".

3.2 Corner Correction

All assembled RoughDeck scales are delivered

with the junction box corner-trimmed. Corner

trimming is only necessary after replacing a load

cell.

To calibrate the scale, the output from each load

cell must be matched by adjusting the signals

with potentiometers at the junction box. This

process is known as trimming.

Remove the junction box cover and identify the

correct load cell terminal

corner (labeled CELL 1, CELL 2, and so on).

See Figure 4-4 on page 11 for scale deck corner

numbering.

The indicator must be connected and calibrate

approximately, but it need not indicate the exact

weight value. A test weight will be required. The

recommended test weight for all RoughDeck

models is 25% of scale capacity: for example,

500 lbs for 2K-lb models, 5000 lb for 20K-lb

models.

With no weight on the scale, zero the indicator.

Then turn all four

potentiometers (shaded areas

of Figure ) to increase the reading until a clicking sound is heard

maximum signal from each load cell.

With all potentiometers at full signal, place the test weight ov

the process for each of the other three corners. The load cell with the lowest corner reading will be used as a

reference point and will not be trimmed.

Next, place the test weight over one of the other three co

output down to the reference cell output. Repeat this procedure with the other two high corners.

Adjustments are somewhat interactive, and adjusting the

especially in smaller scale decks. Rezero the indicator and repeat the test until all corners read within ±.1% of the

test weight used.

3.3 Calibration Procedure

Refer to the indicator manual to determine correct calibration procedures.

It is recommended that the scale be “exercised” before calibration to be certain t

scale to near capacity two or three times.

Then, with no load on the scale, place the indicator in its calibration

place test weights on the platform equal to 70% - 80% of the scale’s capacity. If several weights are used, they

should be evenly distributed around the platform. Perform a span calibration.

Remove the test weights and check the zero reading. Re

corresponding to each

d

er one corner and record the indicated weight. Repeat

rners and use that cell’s potentiometer to adjust the cell

three higher outputs may affect the reference cell output,

peat the calibration process if necessary.

ng or stripping threads if extended beyond the

from each potentiometer. This ensures the

hat everything is seated. Load the

mode and perform a zero calibration. Now

8 RoughDeck Low Profile Floor Scale Installation Manual

Page 13

4.0 Service Information

CAUTION

4.1 Troubleshooting Guide

Issue Possible Cause Solution

System does not operate no display

Display stays at zero

Erratic weights

Consistently high or low

weights

Power disconnected. Check and reconnect.

Indicator fuse blown. Replace fuse. Check for cause.

Interface cable cut or disconnected. Repair.

Signal leads incorrectly installed at indicator. Install according to indicator installation manual

Indicator faulty. Service indicator

Load cell connections faulty. Check cable connections in junction box and at

Vibration near scale. Remove source of vibration or move scale.

Platform not level to within 1/4 inch Level scale by adjusting

Load cell or cable water damage Replace

Debris under load cells or platform Clean

Indicator faulty Use simulator to test indicator for stability.

Indicator not properly adjusted to zero: Zero the indicator according to indicator

Platform binding. Obtain adequate clearance for free platform

Indicator not calibrated. Calibrate according to indicator manual and

Load cells faulty. Test and replace load cells if necessary.

Feet touching deck underside. Adjust feet downward to provide clearance.

Table 4-1. Troubleshooting

in

dicator

necessary.

Service indicator

manual.

movement.

Section 3.3 on page 8

.

feet or shimming if

4.2 Periodic Maintenance

The space between the platform side and pit frame, and the surface beneath the platform must be periodically

cleaned to prevent debris build up. More frequent cleaning of these areas is necessary with scales mounted in pits.

Do not attempt to use scales with load cells that are not hermetically sealed in washdown applications.

Water damage is a common cause of failure in non-hermetically-sealed load cells. Use care with high

pressure steam

but the elevated temperatures may cause incorrect readings until the unit cools to room temperature.

wash downs for hermetically-sealed load cells. The steam may not damage the load cells,

Service Information 9

Page 14

4.3 Load Cell Replacement

CELL 4

CELL 3CELL 2

CELL 1

1 4

2 3

Lift scale with chains and proper spreader bar and remove foot, then remove defective load cell. Disconnect load

cell cable from junction box and cut cable ties. When the cable is freed, pull cable out of the scale frame channels.

Figure 4-1. Load Cell Assembly

Follow the directions given below to install new load cells.

For Canadian HC models, overload stops should be loosened two full turns before installing

reset overload stops after load cell installation, place a weight equal to 25% of the load cell capacity on the affected

scale corner. Screw in the overload stop until the indicator reading changes. Then back off the overload stop 1/6

turn. Repeat for each corner where the load cell has been changed.

Lay out the four load cells near the corners whe

re they are to be installed. Thread the cable from each load cell

through the conduit tubing in the frame and into the junction box according to the wiring diagram in Figure 4-2.

Note that in Figure 4-2 both the scale and the junction box are viewed from the bottom. T

cell/junction box terminal matching, see the numbers on the terminals inside the junction box and the corner

mbering diagram in Figure 4-4.

nu

new load cells. To

o verify correct load

Figure 4-2. Bottom View of Scale

Check that the threaded holes for the load cell screws are free of debris. Use compressed air to blow out holes if

necessary. Position load cells with alignment arrows point up toward the deck and loosely install the hex head cap

screws provided, as shown in Figure 4-1. If the base is used with a pit frame or access ramp, position the l

to maintain the dimensio

first):

n shown in Figure 4-3. With the torque wrench, tighten all bolts as follows (outboard bolts

oad cell

• 2K–10K-lb capacities: Torque to 75 ft-lbs.

• 20K-lb and 30K-lb capacities: Torque to 250ft-lbs.

10 RoughDeck Low Profile Floor Scale Installation Manual

Page 15

2K – 10K models: 1.625"

20K models: 2.16"

30K models: 1.66"

Figure 4-3. Foot Pad - Side View

1

4

2

3

Route the load cell cables near each corner so that the cable is free from possible contact with each foot. Hold the

cable in position with the adhesive-backed cable ties supplied in the hardware kit.

Do not cut load cell cables. Coil extra ca

ble before it enters the junction box, tie with cable ties, and insert the

coils into the channel.

After coiling excess cable, pass each individual end of load cell cable through its

cord grip in the NEMA 4X

junction box.

Corner correction trimming and calibration is

necessary after load cell replacement. Follow instruction in

Section 3.2 and Section 3.3 on page 8.

4.3.1 Load Cell Wiring to Junction Box

The four load cells are each wired to their respective terminals in the junction box according to the corner

numbering system shown in Figure 4-4, and the coloring code in Table 4-2.

Pull excess cable out of the junction box enclosure and tighten the cord

grip dome nuts with a wrench. To be

watertight, the nuts must be tightened to the point where the rubber sleeving begins to protrude out of the nut.

Finally, pull on each of the four cables to make sure that they do not slip.

Figure 4-4. Corner Numbering - Top View

Color Cable Code J-Box Terminal

Red + Excitation

Black - Excitation

Green + Signal

White - Signal

Bare or Clear Shield

Table 4-2. Load Cell Wiring

Service Information 11

Page 16

4.4 Replacement Parts List and Accessories

The following table list the pit frames, access ramps, and replacement part numbers for HP, HC, and HP-H model

RoughDeck floor scales.

4.4.1 Pit Frames

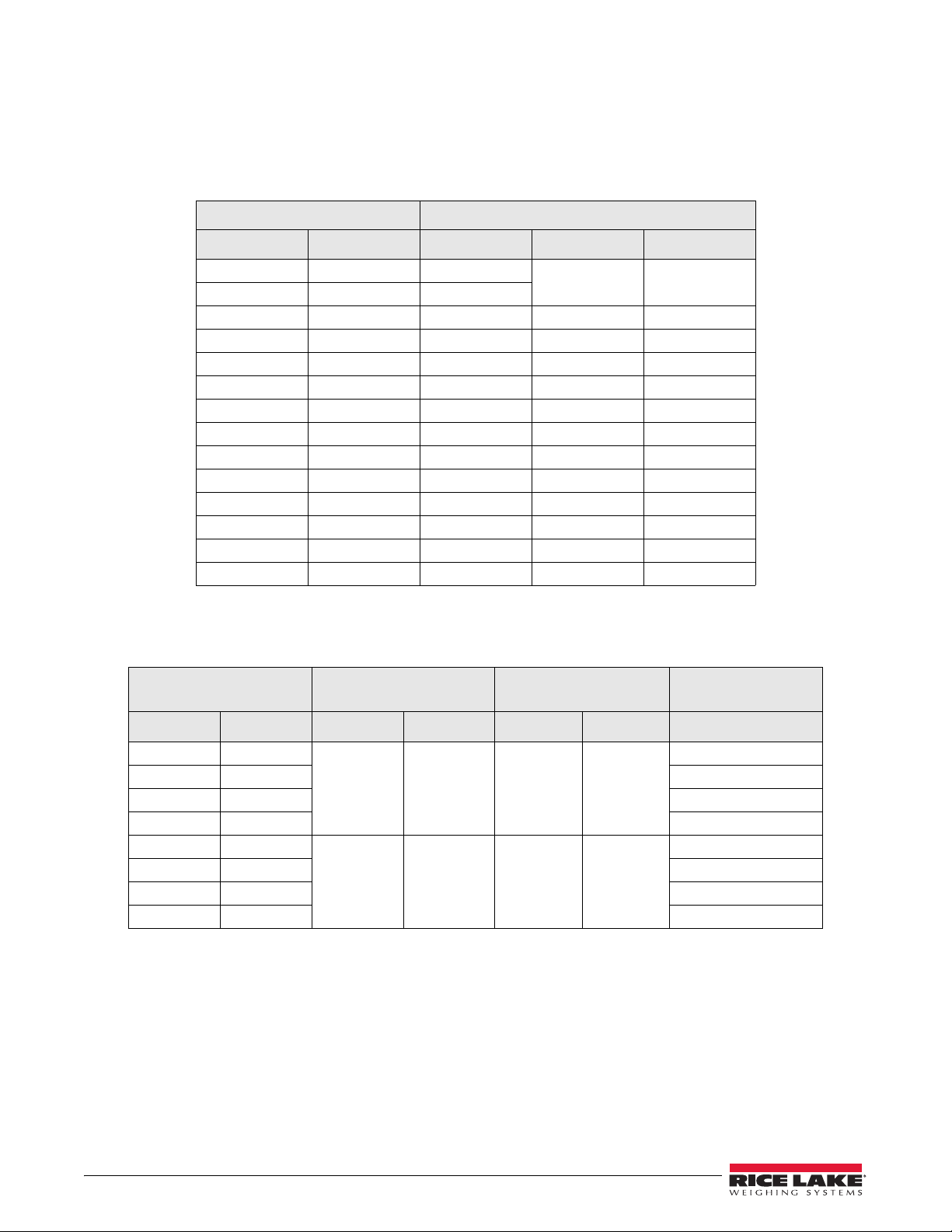

Tabl e 4-3 shows the pit frames available for RoughDeck scales.

Platform Size Pit Frame for Model

ft. m HP/HC HP-H 20k HP-H 30k

2.5 x 2.5 .76 x .76 18757

3 x 3 .92 x .92 18759

4 x 4 1.22 x 1.22 18761 39595 39608

4 x 5 1.22 x 1.53 18765 39596 39609

4 x 6 1.22 x 1.83 18767 39597 39610

4 x 7 1.22 x 2.13 39598 39611

5 x 5 1.53 x 1.53 18763 39599 39612

5 x 6 1.53 x 1.83 18769 39600

5 x 7 1.53 x 2.13 18771 39601 39614

6 x 6 1.83 x 1.83 39602 39615

6 x 8 1.83 x 2.44 39604

7 x 9 2.13 x 2.74 39605

7 x 10 2.74 x 3.05 39606 39619

8 x 10 2.44 x 3.05 39607 39620

Table 4-3. RoughDeck Pit Frames

4.4.2 Access Ramps

Tabl e 4-4 shows the standard access ramps available for the 2K-10K lb-capacity RoughDeck scales.

Access Ramp for

Ramp Width Ramp Length Ramp Height

ft. m ft. m ft. m HP/HC

2.5 .76 3 .92 3.5 89 69040

3 .92 69041

4 1.22 69042

5 1.53 69043

2.5 .76 4 1.22 3.5 89 69184

3 .92 69185

4 1.22 69186

5 1.53 69187

Table 4-4. RoughDeck Access Ramps (2K - Through 10K lb Models)

Model

12 RoughDeck Low Profile Floor Scale Installation Manual

Page 17

Tabl e 4-5 shows the standard access ramps available for the 20K and 30K lb-capacity RoughDeck scales (HP-H

models).

Platform Size Pit Frame for Model

ft. m HP/HC HP-H 20k HP-H 30k

2.5 x 2.5 .76 x .76 18757

3 x 3 .92 x .92 18759

4 x 4 1.22 x 1.22 18761 39595 39608

4 x 5 1.22 x 1.53 18765 39596 39609

4 x 6 1.22 x 1.83 18767 39597 39610

4 x 7 1.22 x 2.13 39598 39611

5 x 5 1.53 x 1.53 18763 39599 39612

5 x 6 1.53 x 1.83 18769 39600

5 x 7 1.53 x 2.13 18771 39601 39614

6 x 6 1.83 x 1.83 39602 39615

6 x 8 1.83 x 2.44 39604

7 x 9 2.13 x 2.74 39605

7 x 10 2.74 x 3.05 39606 39619

8 x 10 2.44 x 3.05 39607 39620

Table 4-5. RoughDeck Pit Frames

Service Information 13

Page 18

RoughDeck Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by the

Distributor/OEM and accepted by RLWS. RoughDeck fabricated platforms and weldments are warranted against

defects in materials and workmanship for five (5) years. Load cells and all other components are warranted for two

(2) years.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized by

RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment fails

to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the warranty

period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to prevent

electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a publication,

“Protecting Your Components From Static Damage in Shipment,” available from RLWS Equipment

Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was not

caused by accident, misuse, neglect, alteration, improper installation, improper repair or improper testing;

RLWS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other than RLWS or its duly authorized repair

agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible for

shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER RLWS

NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’ SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO REPAIR

OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER

CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE SELLER FOR

WARRANTY CLAIMS.

No terms, conditions, understanding, or agreements purporting to modify the terms of this warranty shall have any

legal effect unless made in writing and signed by a corporate officer of RLWS and the Buyer.

© Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

14 RoughDeck Low Profile Floor Scale Installation Manual

Page 19

Page 20

230 W. Coleman St. • Rice Lake, WI 54868 • USA

U.S. 800-472-6703 • Canada/Mexico 800-321-6703 • International 715-234-9171 • Europe +31 (0)26 472 1319

www.ricelake.com www.ricelake.mx www.ricelake.eu www.ricelake.co.in m.ricelake.com

© Rice Lake Weighing Systems December 26, 2014 PN 66662 Rev E

Loading...

Loading...