Page 1

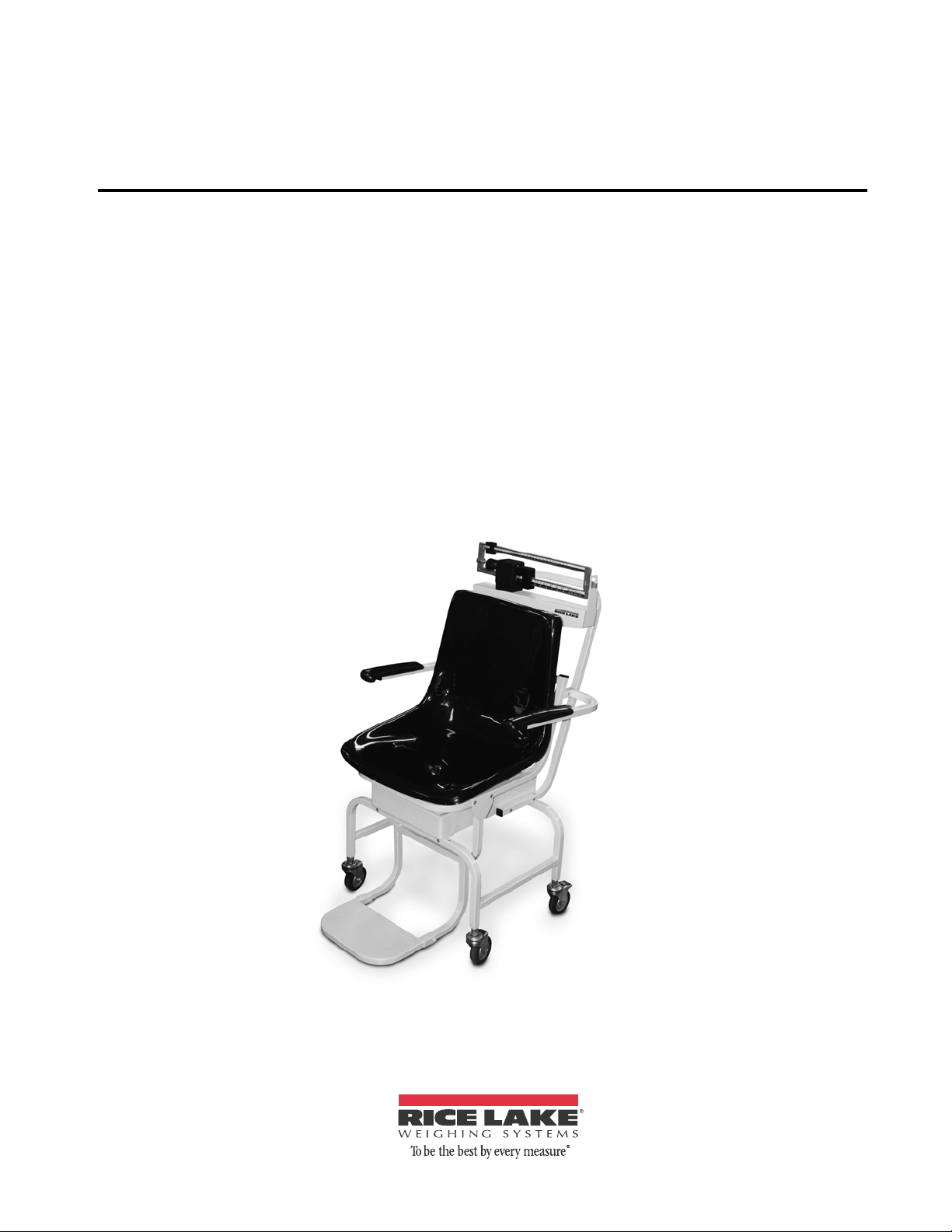

Rice Lake Mechanical Chair Scale

Model RL-MCS, RL-MCS-10

Operation Instructions

111372

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com or obtained

by calling 715-234-9171 and asking for the training department

1.0 Introduction................................................................................................................................. 1

2.0 Installation Instructions............................................................................................................... 2

2.1 Pillar and Beam Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Steelyard Rod Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Installing Transport Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 Seat and Footrest Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Arm Rest Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.0 Zero Adjustment........................................................................................................................... 8

For More Information ............................................................................................................................... 9

Chair Scale Limited Warranty ............................................................................................................... 10

© 2012 Rice Lake Weighing Systems. All rights reserved. Specifications subject to change without notice.

Rice Lake Weighing Systems is an ISO 9001 Registered Company. Model RL-MCS

October 2012

Page 4

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

ii Mechanical Chair Scale Installation and Operation Instructions

Page 5

1.0 Introduction

Internet

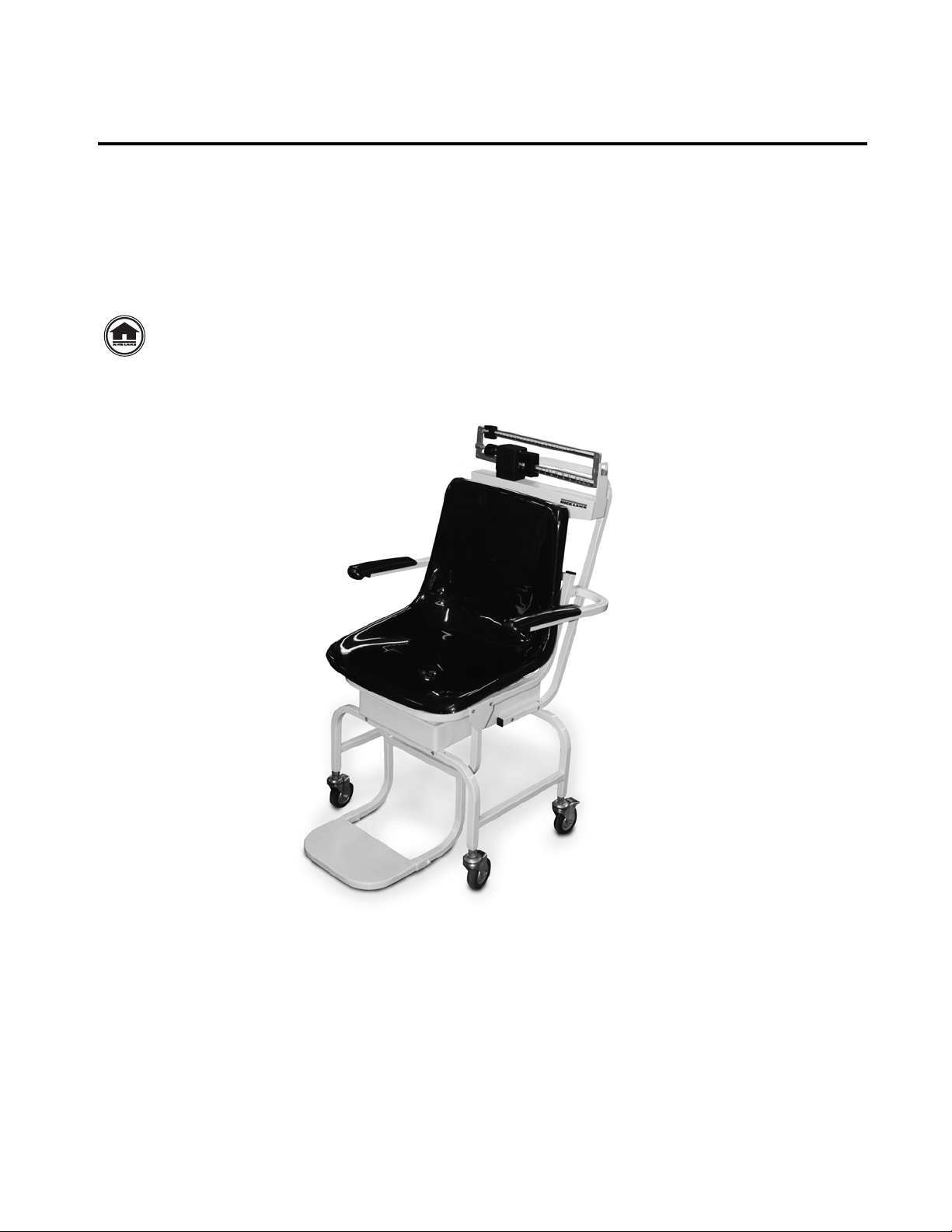

The Rice Lake Mechanical Chair Scale is designed for the mobile challenged who have a difficult time standing

on a conventional scale. It is ideal for use in clinics and nursing facilities. The scale is durable, having a sturdy

enameled steel body, a durable molded plastic seat, heavy-duty footrest, and heavy-duty caster wheels for easy

portability

The Rice Lake Mechanical Chair Scale comes in two models:

• RL-MCS: lb/kg (440 lb (200 kg) capacity)

• RL-MCS-10: lb only (450 lb capacity)

This manual can be viewed and downloaded from the Rice Lake Weighing Systems web site

at www.ricelake.com/health. Rice Lake Weighing Systems is an ISO 9001 registered

company.

Figure 1-1. Mechanical Chair Scale

1

Page 6

2.0 Installation Instructions

Beam

Pillar

Push down on latching

assembly to lock

wheels and prevent

scale from rolling.

You will receive your Mechanical Chair Scale partially assembled. Those items that need additional assembly

are:

• Pillar and beam assembly to scale base

• Steelyard rod connection

• Transport handle onto scale base

• Seat and footrest installation

• Arm rest installation

Remove all components from the shipping crate and lay out in a convenient place.

2.1 Pillar and Beam Installation

The pillar and beam comes separate from the scale base and must be attached prior to use.

Use the following steps to attach the pillar and beam to the scale base.

1. Have the scale sitting on the floor in an area that allows you to work freely.

2. Lock casters on the frame to eliminate the unit from rolling while assembling the scale.

Figure 2-1. Pillar and Beam Components

Figure 2-2. Lock Casters to Keep From Rolling

2 Mechanical Chair Scale Installation and Operation Instructions

Page 7

3. Remove the eight screws from the scale base using a Phillips head screwdriver (as shown in the left hand

Steelyard rod (not

shown)

Steelyard rod

hook

photo) and set screws aside in a safe place.

Figure 2-3. Remove Screws From Scale Base and Insert Pillar and Beam into Scale Base Assembly

Insert, but don’t fasten the pillar and beam into the scale base assembly as shown in Figure 2-3 (right hand

side photo).

2.2 Steelyard Rod Connection

The steelyard rod is located inside the pillar. Remove the wire tie(s) holding the steelyard rod during

shipment. Insert the pillar into the base. Once the pillar is inserted to the scale base, the steelyard rod must be

attached to the bottom of the scale. The two photos in

photo of the ring in the scale bottom. Latch the hook onto the D-shaped ring shown in the right hand side picture.

Figure 2-4 show the hook of the steelyard rod and an inside

Figure 2-4. Attach The Steelyard Rod To the Scale Base D-Ring

Fasten the eight screws once the pillar and beam is connected to the scale base and the steelyard rod is hooked.

Figure 2-5. Insert and Tighten The Eight Screws

Mechanical Chair Scale Installation and Operation Instructions - Installation Instructions 3

Page 8

2.3 Installing Transport Handle

Transport handle

Side screws x 4

Once the pillar and beam are attached to the scale support frame and secured, it’s time to attach the transport

handle to the scale support frame (transport handle is illustrated in

1. Remove the four side screws (two on each side as shown in left hand side of Figure 2-6) from the scale

support frame and set aside. The transport handle will attach to the scale support frame using those

screws.

Figure 2-6. Transport Handle Installation

Figure 2-6).

2. Insert the transport handle into the two sides of the scale support frame (shown in right side of

Figure 2-6).

3. Insert and tighten the four screws using a Phillips screwdriver as shown in Figure 2-7.

Figure 2-7. Insert and Tighten Four Screws for Securing the Transport Handle to the Scale Support Frame

The transport handle should fit snuggly against the scale support frame.

4 Mechanical Chair Scale Installation and Operation Instructions

Page 9

2.4 Seat and Footrest Installation

Four screws on scale support

frame - only one screw

shown

Remove four screws from chair

frame (two on each side) and tilt the

chair upwards before installing

footrest assembly.

Once the transport handle is attached the next step is to install the molded seat to the scale support frame.

1. Remove the four screws from the movable scale support frame platform and set aside.

Figure 2-8. Removable Screws on The Movable Scale Support Frame

2. Set the chair onto the scale support frame platform but do not fasten the screws as the footrest assembly

will also have to be put into place prior to tightening all screws.

3. Remove screws from the chair frame (shown in Figure 2-9) and set aside.

4. Tilt the chair upwards as shown in Figure 2-9. This will allow the installer to get the footrest assembly in

place prior to securing the chair to the platform.

5. Slide the footrest assembly onto the chair scale base as shown in Figure 2-9.

Note that the footrest assembly for the footrest is hanging on the metal chair channel and lined up with

the screw holes on the channel of the chair scale frame as shown in

Figure 2-9. Tilt the Chair Upward Before Installing the Footrest Assembly

Figure 2-10.

Mechanical Chair Scale Installation and Operation Instructions - Installation Instructions 5

Page 10

Push footrest assembly back

so that the holes line up.

Secure screws (only one

shown)

Figure 2-10. Slide the Footrest Assembly So That Holes Line Up

Once the footrest is secured and the screws tightened for it, secure the molded seat onto the chair scale

frame.

6. Secure the four screws (shown below).

2.5 Arm Rest Installation

The last item to be installed on the mechanical chair scale are the two arm rests.

Use the following steps to attach the two arm rests to the mechanical chair scale molded seat.

6 Mechanical Chair Scale Installation and Operation Instructions

Figure 2-11. These Scr ews Hold The Molded Chair to the Scale Base

Figure 2-12. Detachable Arm Rest for the Mechanical Chair Scale

Page 11

1. Locate the bolt hole (x 4) location on the back of the molded chair.

two bolts for each arm rest

Figure 2-13. Hole Location and Four Bolts Used for Securing Arm Rest to Chair

2. Secure the arm rests to the molded chair using the four bolts (provided and shown in Figure 2-13), using

the 5mm allen wrench that’s been provided in this packaging.

Figure 2-14. Secure Arm Rests to the Molded Chair

3. The arm rests are now in position and can be moved up and down.

Figure 2-15. Arm Rests Are Secured to the Molded Chair Seat

Mechanical Chair Scale Installation and Operation Instructions - Installation Instructions 7

Page 12

3.0 Zero Adjustment

Eye Loop

Area

Zero

Adjusting

Screw

Scale pointer

T o ensure accurate weighments, a zero adjustment should be done to the scale upon arrival and setup. To perform

a zero adjustment, perform the following steps.

1. Ensure the scale is sitting on a level surface.

2. Check the eye loop area of the scale to ensure that the scale pointer is equally balanced between the eye

loop area.

Figure 3-1. Eye Loop Area and Zero Adjusting Screw Location (Lb/Kg model shown)

3. If the scale is not balancing properly, then the small zero balance weight must be adjusted. Turn the zero

adjusting screw (shown in Figure 3-1) using a flat head screwdriver. By adjusting the screw, the zero

balance weight will move accordingly.

4. The scale is now ready to weigh patients.

5. Have the patient sit down on the molded seat. The patient should be completely seated in the chair,

not leaning forward, and having feet firmly positioned on the footrest assembly.

8 Mechanical Chair Scale Installation and Operation Instructions

Page 13

For More Information

Literature

• Medical Scales - Mechanical Chair Scale, PN 114086

Web Site

• http://www.ricelake.com/medical

• http://www.ricelake.com/health

Contact Information

Hours of Operation

Knowledgeable customer service representatives are available 6:30 a.m. - 6:30 p.m. Monday through Friday and

8 a.m. to 12 noon on Saturday. (CST)

Telephone

• Sales/Technical Support 800-472-6703

• Canadian and Mexican Customers 800-321-6703

• International 715-234-9171

Fax

• Fax Number 715-234-6967

Email

• U.S. sales and product information at prodinfo@ricelake.com

• International (non-U.S.) sales and product information at intlsales@ricelake.com

Mailing Address

Rice Lake Weighing Systems

230 West Coleman Street

Rice Lake, WI 54868 USA

Mechanical Chair Scale Installation and Operation Instructions - Zero Adjustment 9

Page 14

Chair Scale Limited Warranty

Rice Lake Weighing Systems warrants that all RLWS equipment and systems properly installed by a Distributor

or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by the

Distributor/OEM and accepted by RL WS. All systems and components are warranted against defects in materials

and workmanship for two years.

RLWS warrants that the equipment sold hereunder will conform

by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment

fails to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity

, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Examination of such equipment by RLWS confirms that

not caused by accident, misuse, neglect, alteration, improper installation, improper repair or

improper testing; RLWS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or ch

duly authorized repair agents.

• RLWS will have a reasonable time to repair or replac

for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location r

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

T

HESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PUR POSE. NEITHER

RLWS

RLWS

REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND

ALL OTHER CLAIMS TO WARRANTY.

S

WARRANTY CLAIMS.

N

WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN WRITING AND SIGNED BY A CORPORATE

OFFICER OF RLWS AND THE BUYER.

NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO

HOULD THE SELLER BE OTHER THAN RLWS, THE BUYE R AGREES TO LOOK ONLY TO THE SELLER FOR

O TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORT IN G TO MODIFY THE TERMS OF THIS

to the current written specifications authorized

the nonconformity actually exists, and was

anged by any person other than RLWS or its

e the defective equipment. Buyer is responsible

epairs, including assembly or

© 2012Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

10 Mechanical Chair Scale Installation and Operation Instructions

Page 15

Page 16

PN 111372 10/12

Loading...

Loading...