Page 1

RL-22DT/RL-42DT

Thermal Printer

Version 3.007

Operation Manual

108222

Page 2

Page 3

Contents

5FDIOJDBMUSBJOJOHTFNJOBSTBSFBWBJMBCMFUISPVHI3JDF-BLF8FJHIJOH4ZTUFNT

$PVSTFEFTDSJQUJPOTBOEEBUFTDBOCFWJFXFEBUXXXSJDFMBLFDPNPSPCUBJOFECZ

DBMMJOHBOEBTLJOHGPSUIFUSBJOJOHEFQBSUNFOU

About This Manual ................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 1

1.1 Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Printer Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Installation ................................................................................................................................... 4

2.1 Label Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Label Roll Core Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 PC Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.1 Store Format - Autoform Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.2 Deleting the AUTOFR Form From the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.0 Accessories ................................................................................................................................. 9

3.1 Stripper Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Cutter Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.0 Control Panel ............................................................................................................................. 16

4.1 LED Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.2 Feed Key Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.3 Self-Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.4 Auto-Sensing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.5 Dump Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.6 See-Through Sensor On/Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.7 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.0 Maintenance and Adjustments.................................................................................................. 19

5.1 Print Head module Installation/Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2 Thermal Print Head Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Cutter Adjustment (Paper Jams) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.0 Appendix .................................................................................................................................... 22

6.1 Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3 Compliance Statements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6.4 Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.5 USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.6 Internal Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.7 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

RL-22DT/42-DT Limited Warranty........................................................................................................... 26

© 2011 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

February 2011

i

Page 4

ii RL-22DT/RL-42DT Operation Manual

Page 5

About This Manual

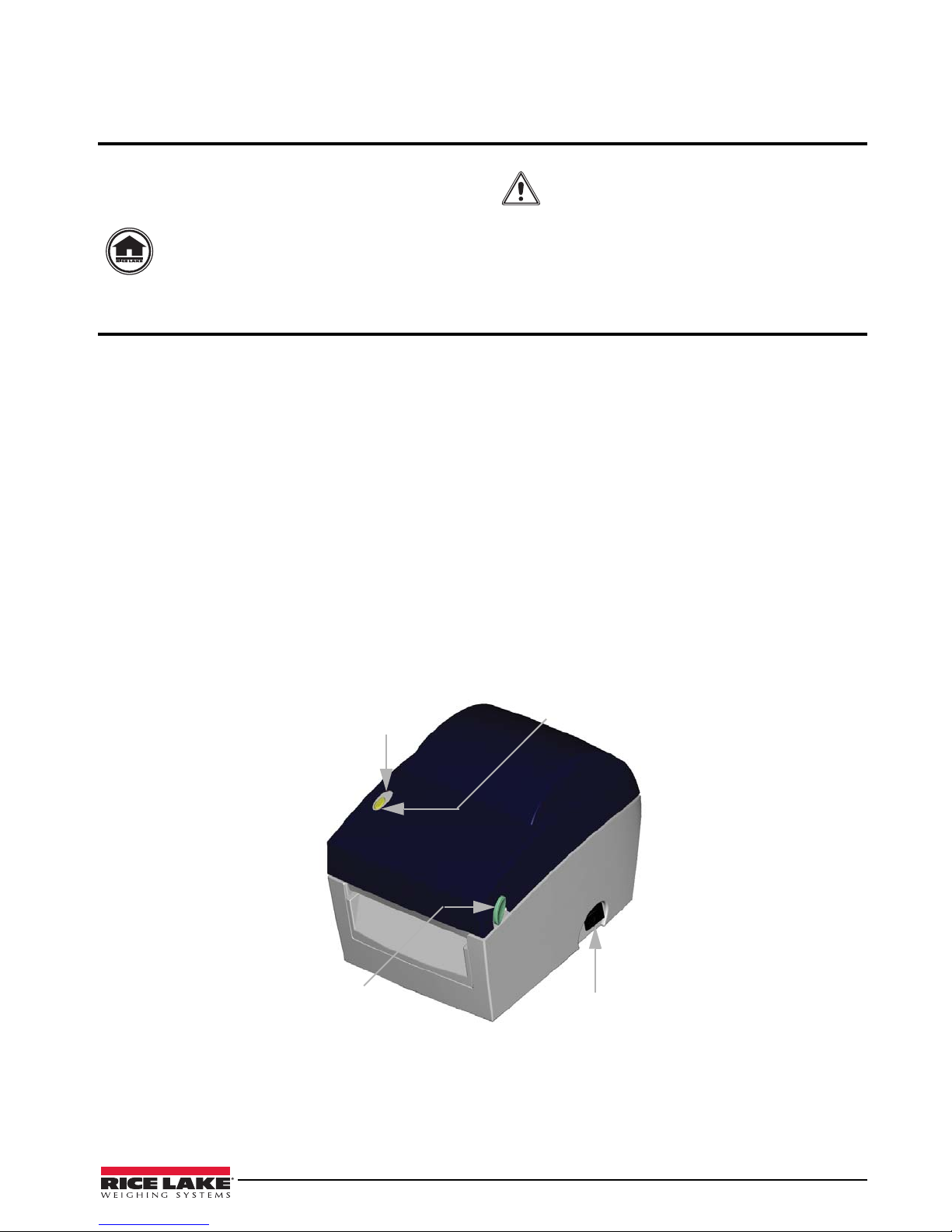

Warning

LED Light

Feed key

Power Switch

Cover Option

button

This manual is intended for use by qualified service

technicians responsible for installing and servicing the

RL-22DT/RL-42DT printers.

Authorized distributors and their employees

Danger of explosion if battery is incorrectly

replaced. Replace only with the equivalent

type recommended by the manufacturer.

Dispose of batteries according to the

manufacturer’s instructions.

can view or download this manual from the

Rice Lake Weighing Systems distributor

www.ricelake.com.

site at

1.0 Introduction

After unpacking, check to make sure all accessories are included:

• Barcode printer

• Power cord

• Switching power

1.1 Safety Instructions

• Keep the equipment away from humidity.

• Before you connect the equipment to the power outlet, check the voltage of the power source.

• Disconnect the equipment from the voltage of the power source to prevent possible transient

over-voltage damage.

• Don’t pour any liquid near the equipment, as it may result in electric shock.

• Only qualified service personnel should open the equipment.

• Don’t repair or adjust energized equipment alone under any circumstances. Someone capable of

providing first aid must always be present for your safety.

•USB cable

• Label

1.2 Printer Parts

Figure 1-1. Outside of printer

RL-22DT/42DT Operation Manual - Introduction 1

Page 6

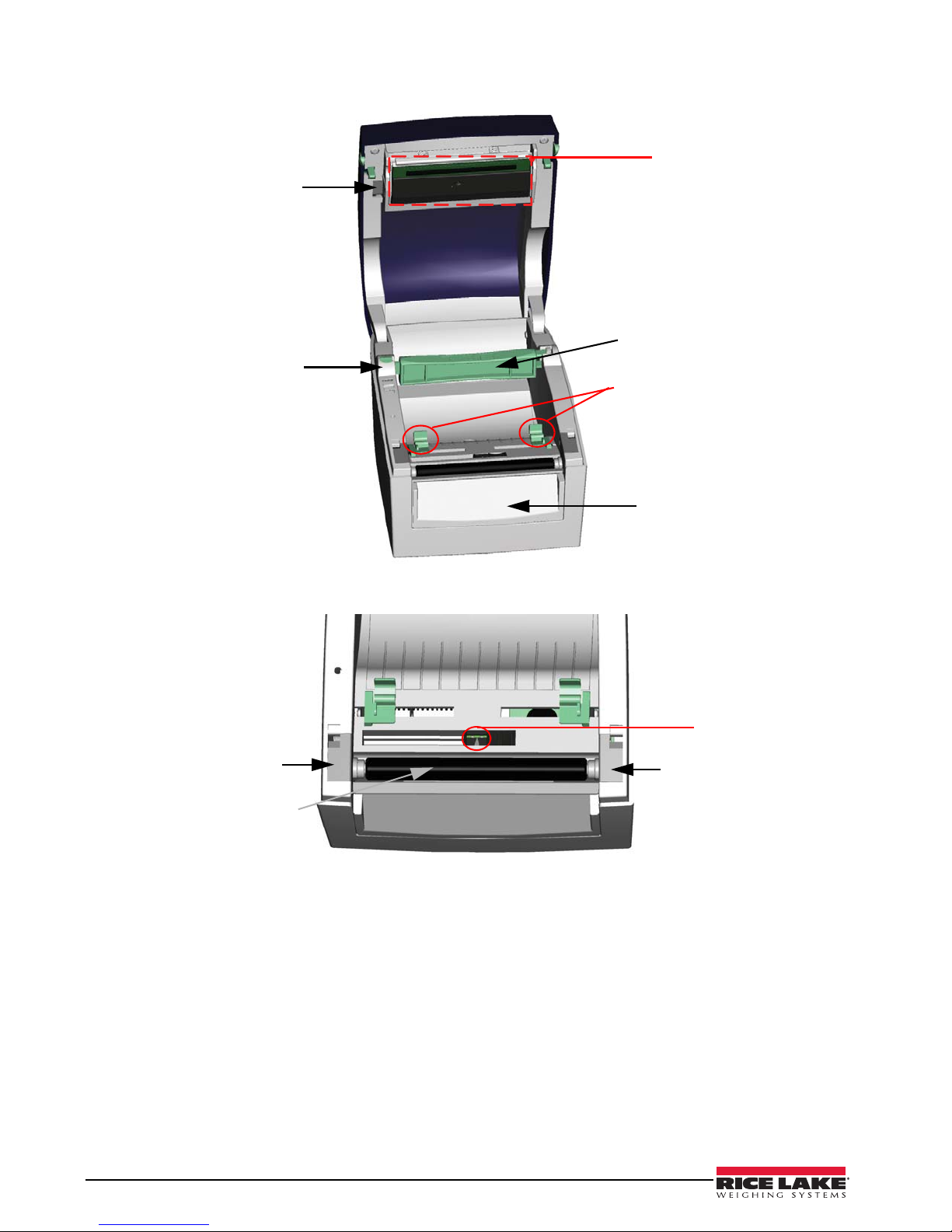

Print Head Lift

Label Roll Holder

Print Mechanism

Label Roll Core

Label Guides

Front Cover Piece

Platen Cover

Platen Cover

Label Sensor

Label Roller

Figure 1-2. Inside of printer

Figure 1-3. Inside of printer

2 RL-22DT/42DT Operation Manual

Page 7

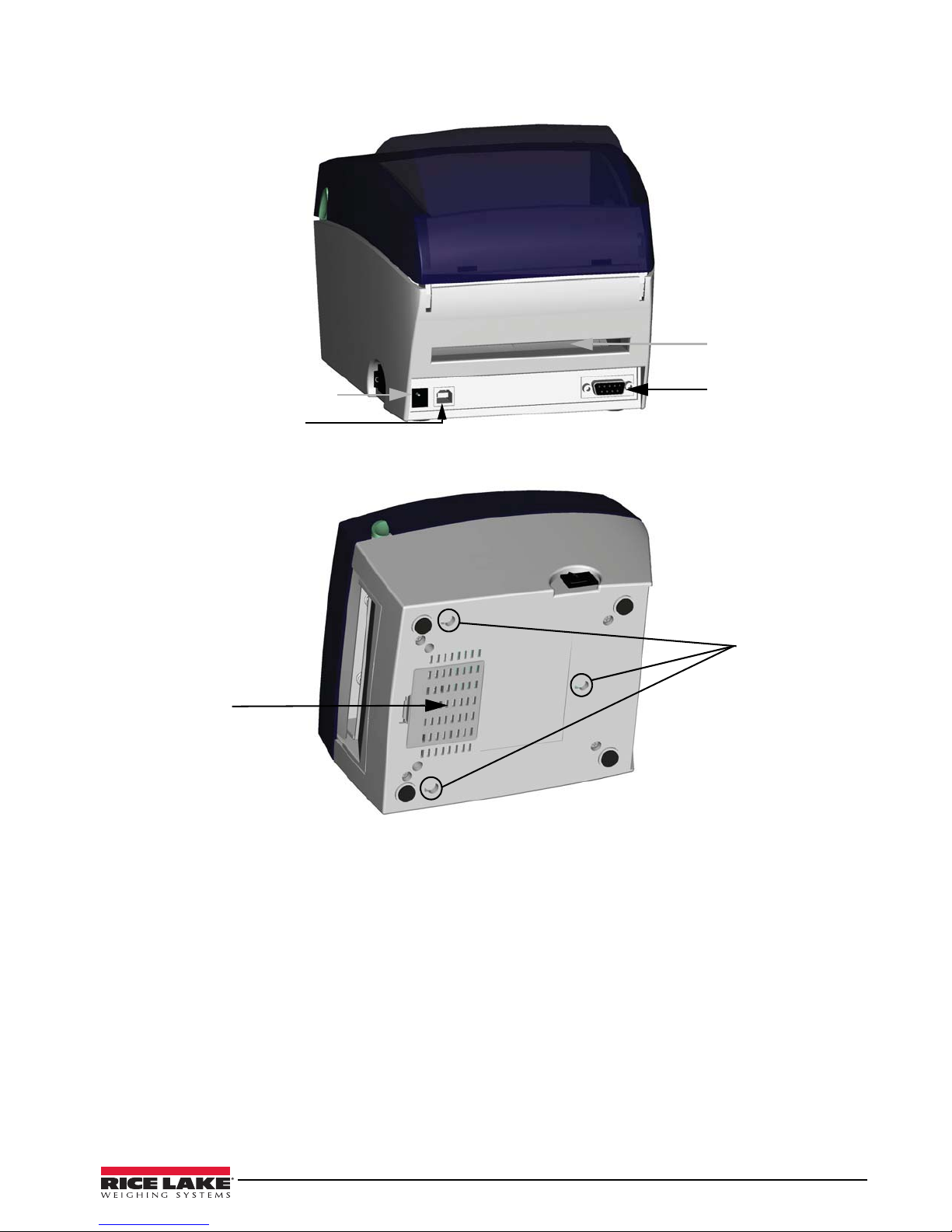

Figure 1-4. Back of printer

Power Socket

USB Port

Fan-Fold Label Insert

Serial Port (RS-232)

Bottom Case Cover

Hang Holes

Figure 1-5. Bottom of printer

RL-22DT/42DT Operation Manual - Introduction 3

Page 8

2.0 Installation

This section contains instructions on installing labels, the label roll core switch, and software and driver

installation.

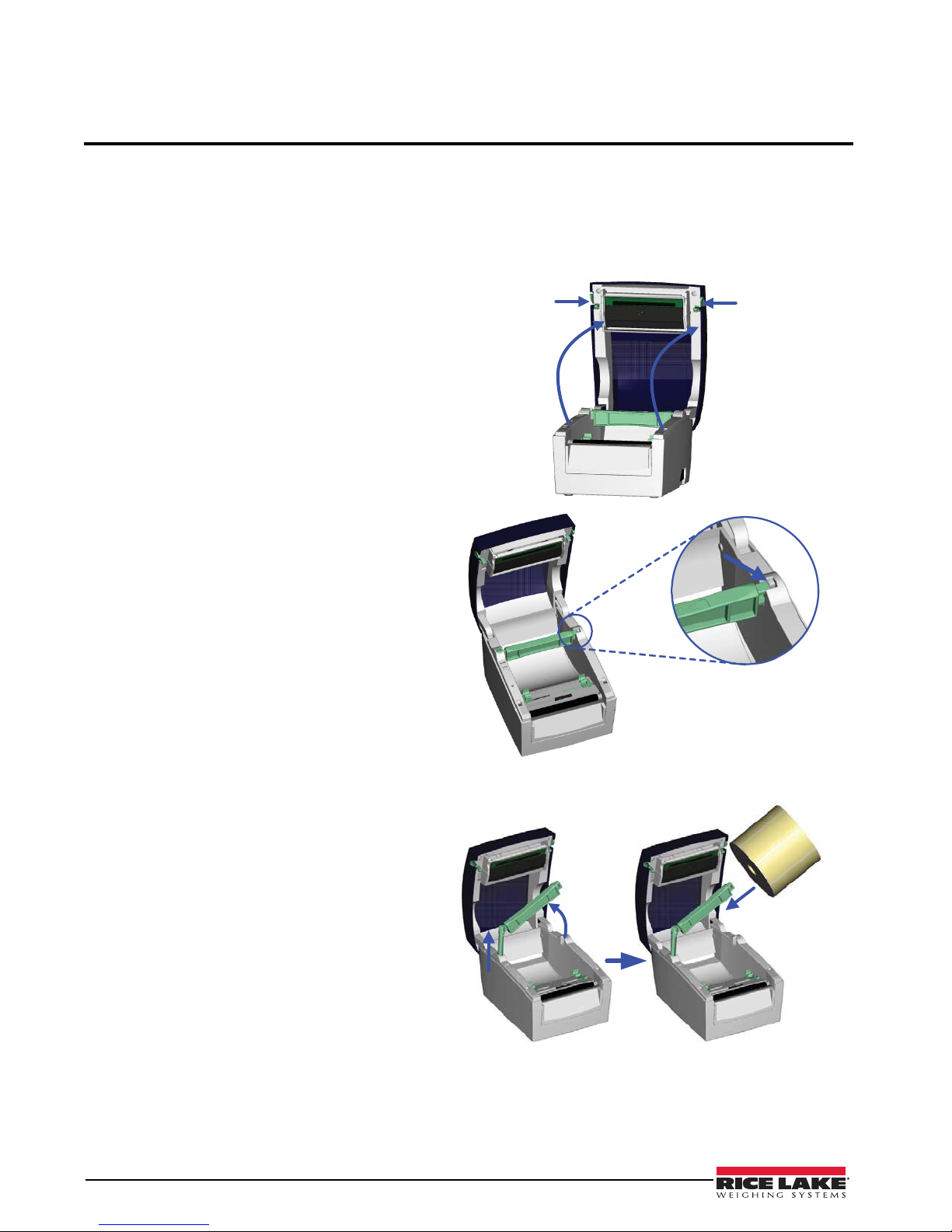

2.1 Label Installation

1. Place the printer on a horizontal surface

and open the top cover.

2. Press and release the lock of the label roll

core.

3. Pull up the label roll holder and lift the

label roll core upward.

4. Place a new label roll onto the label roll

core.

4 RL-22DT/RL-42DT Operation Manual

Page 9

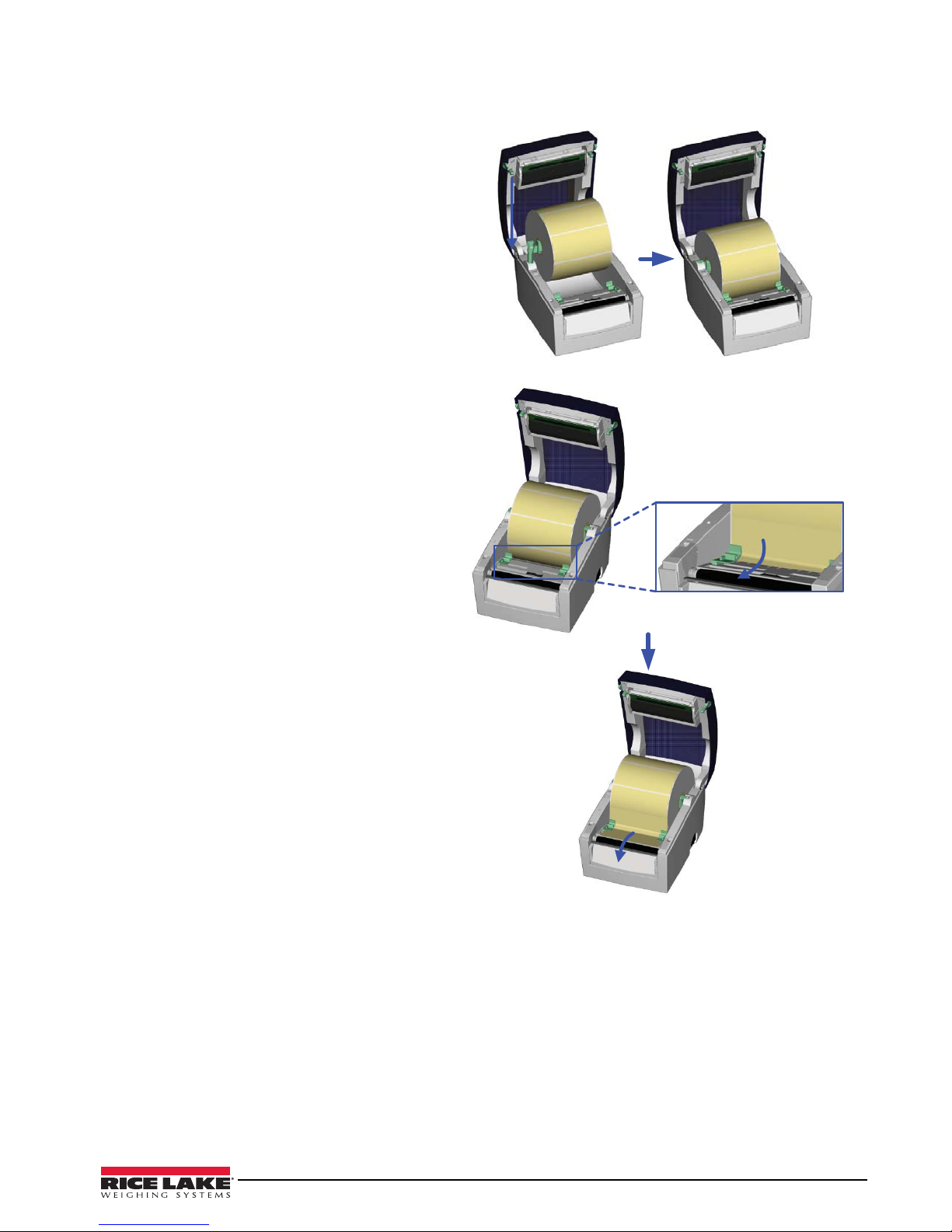

5. Flip the label roll core downward and

pull back the label roll holder.

6. Pull and lock the label roll core to the

original position.

7. Put the label under the label guide and

stretch it frontward.

RL-22DT/RL-42DT Operation Manual - Installation 5

Page 10

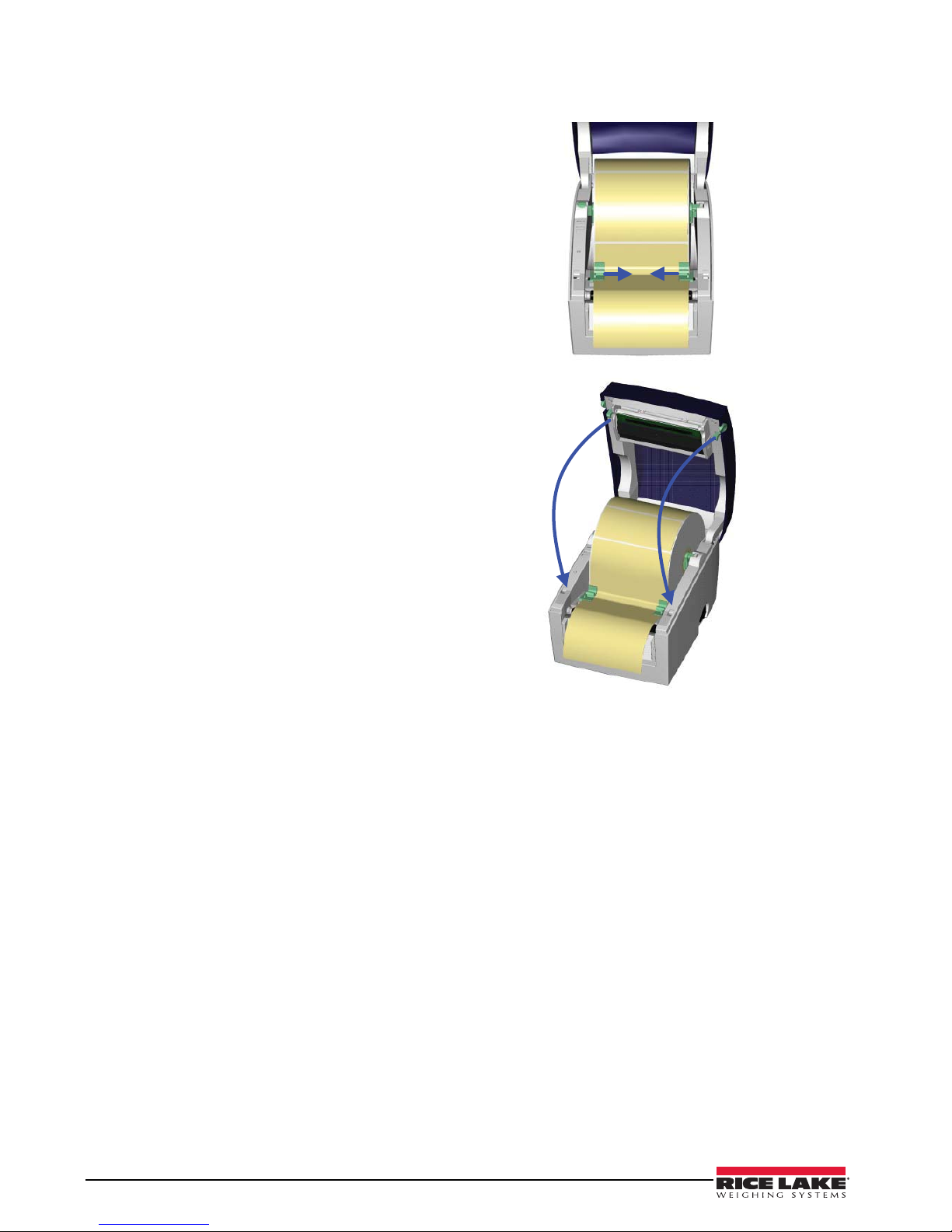

8. Pull the label guide inward and make it

fit the edge of the label.

9. Close the top cover to complete the label

installation.

6 RL-22DT/RL-42DT Operation Manual

Page 11

2.2 Label Roll Core Switch

1” Core

1.5” Core

1. Pull the label roll holder to the topmost

point, then lift the label roll core upward.

2. Turn the label roll core outward as the

figure to the right illustrates.

3. Whirl the label roll core back to the

original position.

NOTES: When the lock hole of the label roll core is on

the upper side, it applies to a 1” core.

When the lock hole of the label roll core is on the lower

side, it applies to a 1.5” core.

You can also distinguish it by the index on the label roll

core as shown in the figure to the right.

RL-22DT/RL-42DT Operation Manual - Installation 7

Page 12

2.3 PC Connection

To connect the printer to a PC, follow these steps:

1. Ensure the printer is powered off.

2. Take the power cable, plug the cable switch to the power socket, then connect the other end of the cable

to the printer power socket.

3. Connect the cable to the USB/Serial port on the printer and an available port on the PC.

4. Power on the printer and the LED light will turn on.

Figure 2-1. PC connection illustration

2.3.1 Store Format - Autoform Capability

1. Design the form in Label View and save it as AUTOFR.

2. Generate a command file.

3. Exit Label View and bring up the file in Dos Edit (the file is AUTOFR.EJF).

4. Add a line at the beginning and add the interrupt command. This is added by holding do wn the CTRL

key and pressing the P, and then the S keys. Two exclamation points should appear at the beginning of

the line.

5. Add before PE the command PA1.

6. Turn the printer off for a minute and then on again to make sure the buffer is empty.

7. Download the form to the printer by choosing Print from Dos Edit.

This is now the form that will be printed every time the print button is pushed. This example works with only one

variable field, which means that only gross or only net weight can be printed. Once this form is loaded in the

printer the customer cannot use the printer any other label format.

2.3.2 Deleting the AUTOFR Form From the Printer

1. Turn the printer off for a minute, then turn it back on.

2. Send the interrupt command, CTRL S, and then FK“*”.

This will delete all stored forms from the printer memory.

This will open up doors for a simple label application, and works with most devices that are sending a single

weight and capable of 9600 baud, 8 data bits.

8 RL-22DT/RL-42DT Operation Manual

Page 13

3.0 Accessories

Note

2

1

Note

3.1 Stripper Module

The stripper module separates a label from its backing, allowing the user to apply a label without peeling.

To install the stripper module, follow these instructions:

1. Make sure you have the module and two

provided screws.

2. Power off the printer before installing the

stripper module.

Label liner thickness is recommended to be

0.06mm ± 10% with basic weight 65g/m2 ±

6%.

The maximum width for the stripper is 110

mm.

When using the stripper module, it is

recommended to set the stop position to 9

in. QLabel and the E value is 9.

3. Place the printer on a horizontal surface

and open the top cover.

4. Remove the front cover piece.

You can use a coin or screwdriver to open

the front cover piece.

RL-22DT/RL-42DT Operation Manual - Accessories 9

Page 14

5. Push the stripper connector into the

Note

printer through the cable hole as shown

in the figure to the right.

6. Place the stripper module on the fillister.

7. Turn the printer around and tighten

screws to secure the stripper module.

8. Unlock the bottom case cover to see the

main board of the printer.

You can use a coin or screwdriver to open

the bottom case cover.

10 RL-22DT/RL-42DT Operation Manual

Page 15

9. Plug the connector into the main board.

Note

There are two sockets on the main board;

one is for the stripper module installation

and the other is for the cutter installation.

Before plugging the connector into the

socket, check the pin first.

10. Lock the bottom case cover.

11. Turn the printer back to proceed with

label installation.

12. Flip the stripper module downward to

open it.

13. Follow the instructions in Section 2.1 on

page 4 to install the label.

RL-22DT/RL-42DT Operation Manual - Accessories 11

Page 16

14. Peel off the first label and feed the liner

through the roller and the striper module

bar.

15. Follow the direction shown in the figure

to the right to feed the liner across the

stripper module.

16. Flip the stripper module upward to close

it.

17. Press the FEED key to adjust the position

of the label and complete the installation.

12 RL-22DT/RL-42DT Operation Manual

Page 17

3.2 Cutter Installation

Note

2

1

Note

The RL-22DT/RL-42DT printers feature a photo-eye, which detects gaps between labels. When a gap is detected,

the cutter will separate the label from the roll. To install the cutter, follow these instructions:

1. Make sure you have the cutter module

and two provided screws.

2. Power off the printer before installing the

cutter module.

Do not cut self-adhesive labels! The traces

of adhesive will pollute the rotary knife and

impair safe operation.

The service life of the cutter is 1,000,000

cuts for paper weights up to 120g/m2, and

500,000 cuts for paper weights 120g/m

170g/m

2

.

3. Place the printer on a horizontal surface

and open the top cover.

2

to

4. Remove the front cover piece.

You can use a coin or screwdriver to open

the front cover piece.

RL-22DT/RL-42DT Operation Manual - Accessories 13

Page 18

5. Push the cutter connector into the printer

Note

through the cable hole as shown in the

figure to the right.

6. Place the stripper module on the fillister.

7. Turn the printer around and tighten

screws to secure the cutter module.

8. Unlock the bottom case cover to see the

main board of the printer.

You can use a coin or screwdriver to open

the bottom case cover.

14 RL-22DT/RL-42DT Operation Manual

Page 19

9. Plug the connector into the main board.

Note

There are two sockets on the main board;

one is for the stripper module installation

and the other is for the cutter installation.

Before plugging the connector into the

socket, check the pin first.

10. Lock the bottom case cover.

11. Turn the printer back to proceed with

label installation.

12. Follow the instructions in Section 2.1 on

page 4 to install the label.

13. Feed the label through the cutter and

press the FEED key to complete the

installation.

RL-22DT/RL-42DT Operation Manual - Accessories 15

Page 20

4.0 Control Panel

Note

The control panel allows access to printer diagnostics and settings. This section provides information on LED

status, the FEED key, self-tests, auto-sensing, dump mode, see-through sensor, and error messages.

4.1 LED Status

Below descriptions apply only to firmware version G3.000 or later.

Press and hold the FEED key then power on the printer, the printer will beep 3 times and enter into Self-Test

status. If you keep holding the FEED key, the status will change in sequence to Auto Sensing Mode, Dump

Mode, See-through Sensor on/off, and then return to Self-Test again. These different statuses can change the

setting of printer; they are described as follows:

LED LIGHT BEEP STATUS DESCRIPTION

Green 1 Standby Mode Normal status

Press and hold the FEED key, then power on the printer.

Red (flash) 3 Auto-Sensing Mode Printing self-test page. For operation

instructions, refer to

Section 4.3 on page 17.

Orange (flash) 1 Auto-Sensing Mode The printer is currently in auto-sensing mode.

For operation instructions, refer to

on page 17.

Green (flash) 1 Dump Mode The printer is currently in dump mode. For

operation instructions, refer to

Orange 1 See-through sensor

on/off

Return to Self-Test

Red (flash) Printer is currently downloading firmware.

Set the see-through sensor on or off. For

operation instructions, refer to

page 18.

page 18.

Section 4.4

Section 4.5 on

Section 4.6 on

Table 4-1.

4.2 Feed Key Introduction

After pressing the FEED key , printer will send the media (according to media type) to the specified stop posi tion.

When printing with continuous media, pressing the FEED key will feed media out to a certain length. When

printing with labels, pressing the FEED key will feed one label at a time. If the label is not sent out in a correct

position, please proceed with the Auto sensing (see

Section 4.4 on page 17).

16 RL-22DT/RL-42DT Operation Manual

Page 21

4.3 Self-Test

LRXXXX : VX.XXX

Serial port :96,N,8,1

1 DRAM installed

Image buffer size : 1500K

000 FORM(S) IN MEMORY

000 GRAPHIC (S) IN MEMORY

000 FONT(S) IN MEMORY

000 ASIAN FONT(S) IN MEMORY

000 DATABASE(S) IN MEMORY

2048K BYTES FREE MEMORY

^S4 ^H10 ^R000 ~R200

^W10 ^Q48,3

Option : ^D0 ^O0 ^AD

See-through Sensor: OFF

Reflective Sensor AD : 146 186 223 (2)

Code Page: 850

Model & Version

Serial port setup

Test pattern

Number of DRAM installed

Image buffer size

Number of forms

Number of graphics

Number of fonts

Number of Asian fonts

Number of Databases

Free memory size

Speed, Density, Ref. Point, Print direction

Label width, Form length

Cutter, Stripper, Mode

See-through Sensor status

Reflective Sensor status

Code Page

Self-Test includes the internal printer data setting.

The Self-Test function in a printer will help user to figure out whether the printer is operating normally. In the

Self-Test Mode, the printer will print out a test sample as below figure. The printer will go back to standby mode

after printing out the test sample. Below are the Self-Test procedures:

1. Power off the printer, then press and hold the FEED key.

2. Power on the printer (while still holding the FEED key); release the FEED key after the printer beeps 3

times.

3. After about 1 second, printer would automatically print out the following. This means the printer is

operating normally.

Figure 4-1. Self-test print page

4.4 Auto-Sensing

The printer can automatically detect the label and store the result of detecting. By doing this, the printer will

calibrate the printing position of the label and the user can print without setting label length. To perform

Auto-Sensing:

1. Check if the label is correctly loaded in the printer.

2. Power off the printer, press and hold the FEED key.

3. Power on the printer (while still holding the FEED key). Keep holding the FEED key , wait until the LED

flashes red and then release the FEED key. The printer will automatically detect the label size/length and

record it.

4. A Self-Test page will be printed after Auto-Sensing is complete. The printer will then return to Standby

mode.

RL-22DT/RL-42DT Operation Manual - Control Panel 17

Page 22

4.5 Dump Mode

Note

When the label setting and the print result don't match, it is recommended to go into the Dump Mode to check for

mistakes in data transmission between the printer and the PC. Test procedures to enter the Dump Mode are as

follows:

1. Power off the printer, press and hold the FEED key.

2. Power on the printer (while still holding the FEED key) and the printer will beep 3 times.

3. Release the FEED key when LED flashes green. Printer will automatically print “DUMP MODE

BEGIN.” This means the printer is in Dump Mode.

4. Send commands to the printer, and check if the print result matches the commands sent.

5. To cancel (get out of the Dump Mode), press the FEED key, the printer will automatically print out

“OUT OF DUMP MODE”. This indicates that printer is back in the standby mode. Powering off the

printer is another way to exit the Dump Mode.

4.6 See-Through Sensor On/Off

There are two types of sensor in RL22DT/RL42DT printer - Reflective Sensor and See-through Sensor. Users

can set one of them as active sensor. By default, the Reflective Sensor is turned on and the See-throug h Sen sor is

turned off. However, the reflective sensor may not be able to detect the label gap on special label materials. For

example, when printing on labels with thick liner, colored liner, or back graphics, then the see-through sensor

would need to be enabled. To turn the See-through Sensor on:

1. Power off the printer, press and hold the FEED key.

2. Power on the printer (while still holding the FEED key) and the printer will beep 3 times. Keep holding

the FEED key, wait for the LED light turn to orange and then release the FEED key. The printers will

automatically print “SEE-THROUGH SENSOR IS ON”. This indicates that the See-Through Sensor is

turned on (and the Reflective Sensor is turned off).

3. To turn off the See-Through Sensor, please repeat above-mentioned procedures. Then the printer will

print “SEE-THROUGH SENSOR IS OFF” to indicate that the See-Through Sensor is turned off.

4. For checking the status of See-through Sensor (on or off), please perform Auto Sensing once. If LED

light is green when doing Auto Sensing, then the See-through Sensor is on. If LED light is orange, then

the See-through Sensor is off.

When the See-through Sensor is enabled, the Label Sensor must be placed in the center of the printer.

4.7 Error Messages

LED LIGHT BEEP DESCRIPTION SOLUTION

Red 4 beeps twice Print head is not firmly closed. Re-open print head and make sure it closes tightly.

Red (flash) None Print head temperature is too high. Wait for the print head temperature to drop to normal range. The

Red 2 beeps twice • Unable to detect paper

• Paper is used up

Red 2 beeps twice Abnormal paper feed Possible causes: card tags or paper fell into the gap behind the

Red 2 beeps twice Memory is full; printer will print “memory full” Delete unnecessary data in the memory by powering the printer

Red 2 beeps twice Can’t find the file; printer will print “Filename

Red 2 beeps twice File name is repeated; printer will print

18 RL-22DT/RL-42DT Operation Manual

cannot be found.”

“Filename is repeated”

Table 4-2. Error messages

printer will go back to standby mode and the LED light will stop

flashing.

• Make sure the movable sensor mark is at the correct

position. If the sensor is still unable to detect paper, repeat

auto-sensing.

• Replace with new label roll.

platen roller; can’t find label gap/black mark; black mark paper

out. Please adjust according to actual usage.

off/on, then sending the P1 command.

Use “~X4” command to print out all the files, then check

whether the file exists and the names are correct.

Change the file name and download again, or delete the file.

Page 23

5.0 Maintenance and Adjustments

Occasionally, you may need to install a new print head, clean the thermal print head, or adjust the cutter.

5.1 Print Head module Installation/Removal

1. Power off the printer before removing or

installing the print head.

2. Open the top cover to see the print head

lift, which is on the left side of the top

cover.

3. Flip the print head lift downward to

release it.

4. The print head bracket can be flipped

downward after the print head lift is

released.

RL-22DT/RL-42DT Operation Manual - Maintenance and Adjustments 19

Page 24

5. Remove the print head connector.

6. Remove the print head screws.

7. From the underneath of the print head

bracket, hold the front end of the print

head to remove it and install a new one.

8. After the new print head is installed,

tighten the print head screws, plug the

print head connector, restore the print

head bracket, and lock the print head lift

to complete installation.

9. Clean the print head to remove any

finger prints, etc.

20 RL-22DT/RL-42DT Operation Manual

Page 25

5.2 Thermal Print Head Cleaning

Note

Unclear printouts may be caused by a dusty print head, ribbon stain, or label liner glue. Therefore, when printing,

it is necessary to keep the top cover closed. Also, check and prevent paper/label from being stained or dusty to

ensure print quality and to prolong the print head life. To clean the print head:

1. Power off the printer.

2. Open the top cover.

3. If there are label pieces or other stains on

the print head (see arrow in figure at

right), use a soft cloth with industrial use

alcohol to wipe away the stain. Make

sure there are no metal or hard particles

on the print head before cleaning.

Weekly cleaning for the print head is

recommended.

5.3 Cutter Adjustment (Paper Jams)

When using the cutter module, paper jams may occur from time to time. Paper jams can be resolved by adjusting

the cutter.

1. Turn the printer around to see the cutter

cover screw.

2. Unscrew the cutter cover screw to

remove the cutter cover.

3. The cutter adjustment screw is on the

side of the cutter. Use a screwdriver to

turn the cutter adjustment screw

counter-clockwise for releasing the

paper-knife of the cutter. Then, remove

the jammed label.

4. After the jammed label is removed, turn

the cutter adjustment screw clockwise to

restore the paper-knife.

RL-22DT/RL-42DT Operation Manual - Maintenance and Adjustments 21

Page 26

6.0 Appendix

Note

6.1 Control Commands

Dump Mode

Syntax ~S,DUMP

Parameter None

Description When the printout result doesn’t match to the label format setting, it is recommended to go into the Dump Mode to

ˆGn - Enable/Disable See-Through Sensor

Syntax ˆGn

Parameter n = 0, disable see-through sensor

Description The reflective sensor may not be able to detect the label gap on special label materials. For example, when printing on

troubleshoot data transmission between the printer and the PC. When in Dump Mode, the printer will not process

commands; it will only print out the contents of the commands. This will confirm whether the commands were received

correctly. To get out from the Dump Mode, please press the FEED key, and then the printer will automatically print out “OUT

OF DUMP MODE” and return to standby mode. You can also power off the printer to exit Dump Mode.

Table 6-1. Dump mode

n = 1, enable see-through sensor

n = 2, Auto Mode

labels with thick liner, colored liner, or back graphics, the see-through sensor would need to be enabled since the reflective

sensor may not work correctly.

When the see-through sensor is enabled, the moveable sensor must be placed in the center of the printer.

Table 6-2. See-through sensor

ˆHx - Print Darkness Setting

Syntax ˆHx

Parameter x = 00 ~ 19

Description Sets the darkness of printing

Table 6-3. Print darkness setting

22 RL-22DT/42-DT Operation Manual

Page 27

6.2 Specifications

Feature RL-22DT RL-42DT

Resolution 203 dpi (8 dot/mm)

Print Mode Direct Thermal

CPU 32 Bit

Memory 4MB Flash, 8MB SDRAM

Print Speed 2 IPS ~ 4 IPS

Print Length Max.1727mm (68") Min.12.7mm(0.5")

Print Width Max.54 mm (2.12") Max.108 mm (4.25")

Sensor Type Adjustable Reflective sensor; Fixed transmissive, center aligned

Sensor Detection Type: Label gap and black mark sensing.

Detection: Label length auto sensing and / or program command setting

Media Label Roll OD: Max. 127mm (5")

Core Diameter: 1" (25 mm), 1.5" (40 mm)

Width: 15 mm (0.6 ") ~ 60 mm (2.36")

Thickness: 0.06~0.20 mm

Printer Language EZPL (Firmware downloadable)

Resident Fonts 9 resident Windows bit mapped fonts (6, 8,10,12,14,18,24,30 and 16X26), can be rotated in 8 orientations and

expandable 8 times horizontally and vertically.

Scalable Font (Code Page 850 & 852) in 4 orientations.

Fonts Download Windows bit mapped font: can be rotated in 8 orientations and expandable 8 times horizontally and vertically.

Asian font: can be rotated in 4 orientations and expandable 8 times horizontally and vertically.

True Type Font: can be rotated in 4 orientations.

Image Handling BMP, PCX, Support ICO, WMF, JPG, EMF file through software.

Barcodes Code 39, Code 93, Code 128 (subset A, B, C), UCC/EAN-128 K-Mart, UCC/EAN-128, UPC A / E (add on 2 & 5), I 2 of

5, I 2 of 5 with Shipping Bearer Bars, EAN 8 / 13 (add on 2 & 5), Codabar, Post NET, EAN 128, DUN 14, MaxiCode,

HIBC, Plessey, Random Weight, Telepen, FIM, China Postal Code, RPS 128, PDF417, Datamatrix code & QR code

Interfaces Serial port: RS-232 ( Baud rate : 4800 ~ 115200 , XON/XOFF , DSR/CTS )

USB port: V2.0

Control Panel One Tri-color LED: Power

Function Key: FEED

Power Auto Switching 100/240VAC, 50/60 Hz

Environment Operation: 41°F to 104°F (5°C to 40°C)

Storage: -4°F to 122°F (-20°C to 50°C)

Cert. Approval CE, FCC Class A, CCC, CB, cUL, BSMI

Humidity Operation: 30-85%, non-condensing. Free air.

Storage: 10-90%, non-condensing. Free air.

Printer Dimensions Length: 218 mm (8.58")

Height: 172 mm (6.77")

Width: 100 mm (3.94")

Weight: 1.2 Kg

Options Rotary Cutter Module

Stripper Module

RTC

Internal Ethernet Adapter Card

Label Roll OD: Max. 127mm (5")

Core Diameter: 1" (25 mm), 1.5" (40 mm)

Width: 25 mm (1 ") ~ 118 mm (4.65")

Thickness: 0.06~0.20 mm

Length: 218 mm (8.58")

Height: 166 mm (6.53")

Width: 168 mm (6.61")

Weight: 1.5 Kg

Rotary Cutter Module

Stripper Module

Internal Ethernet Adapter Card

Parallel port

Table 6-4. Printer specifications

RL-22DT/42-DT Operation Manual - Appendix 23

Page 28

6.3 Compliance Statements

Warning

FCC COMPLIANCE STATEMENT FOR AMERICAN USERS

This equipment has been tested and found to comply with the limits for a CLASS A digital de vice, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses, and

can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. Operation of this equipment in a residential area is likely to cause

harmful interference in which case the user will be required to correct the interference at own expense.

EMS AND EMI COMPLIANCE STATEMENT FOR EUROPEAN USERS

This equipment has been tested and passed with the requirements relating to electromagnetic compatibility based

on the standards EN 55022:1998+A1:2000+A2:2003, CISPR 22, Class A EN 55024:1998+A1:2001+A2:2003,

IEC 61000- 4 Series EN 61000-3-2 / 2000 & EN 61000-3-3 / 1995. The equipment also tested and passed in

accordance with the European Standard EN55022 for the both Radiated and Conducted emissions limits.

RICE LAKE SERIES TO WHICH THIS DECLARATION RELATES IS IN CONFORMITY WITH THE FOLLOWING STANDARDS

EN55022 : 1998,CLSPR 22, Class A / EN55024 : 1998IEC 61000-4 Serial / EN61000-3-2 : 2000 / EN 6100-3-3

: 1995 / CFR 47, Part 15/CISPR 22 3rd Edition : 1997, Class A / ANSI C63.4 : 2001 / CNS 13438 / IEC60950-1

: 2001 / GB4943 : 2001 / GB9254 : 1998 / GB17625.1 : 2003 /EN60950-1 : 2001

Danger of explosion if battery is incorrectly replaced

Replace only with the equivalent type recommended by the manufacture.

Dispose of used batteries according to the manufacturer's instructions.

24 RL-22DT/42-DT Operation Manual

Page 29

6.4 Serial Interface

Note

The serial default setting is: 9600 baud rate, no parity,

8 data bits, 1 stop bit, and XON/XOFF protocol.

The total current output from the serial port

cannot exceed 500mA.

PC PRINTER

DB9 Socket DB9 Plug

--- 1_____________1 +5V, max 500mA

RXD 2_____________2 TXD

TXD 3_____________3 RXD

DTR 4_____________4 N/C

GND 5_____________5 GND

DSR 6_____________6 RTS

RTS 7_____________7 CTS

CTS 8_____________8 RTS

RI 9_____________9 N/C

Table 6-5. RS232 Housing (9-pin to 9-pin)

6.5 USB Interface

RL-22DT/RL-42DT printers use a Type B connector

type.

Pin Number 1 2 3 4

Function VBUS D- D+ GND

Table 6-6. USB interface Specs

6.6 Internal Interface

.

UART1 wafer Ethernet module

N.C 1_____________1 N.C

TXD 2_____________2 RXD

RXD 3_____________3 TXD

CTS 4_____________4 RTS

GND 5_____________5 GND

RTS 6_____________6 CTS

E_MD 7_____________7 E_MD

RTS 8_____________8 CTS

E_RST 9_____________9 E_RST

+5V 10____________10 +5V

GND 11____________11 GND

+5V 12____________12 +5V

Table 6-7. Internal interface specs

6.7 Troubleshooting

Symptom Remedy

LED light is not lit Check the power connector

LED light indicates error

messages after printing

stops

Nothing is printed on

label

Label is jammed Clean the label jam; if the label is stuck on

Only some of the

contents is printed

Part of the label isn’t

printed completely

Printout is not in the

desired position

Page skipping occurs • Check if error occurs on label height

Unclear printout • Check print darkness setting

Label isn’t cut straight Check if label is set up straight

Label isn’t cut Make sure label thickness does not exceed

Label couldn’t feed or

unexpected cutting

occurs

The stripper module isn’t

working correctly

• Check for software setting or

program command errors

• Replace with suitable label

• Check if label may run out

• Check if label is jammed/tangled up

• Check if mechanism is closed

(Thermal Print Head not positioned

correctly)

• Check if sensor is blocked by label

• Check for abnormal cutter function or

of no actions (if cutter is installed)

• Check if label is placed upside down

or if label is not suitable for the

applicationSelect the correct printer

driver

• Select the correct label and print type

the thermal print head, remove by using a

soft cloth and alcohol

• Check if label is stuck on the Thermal

Print Head

• Check if application software has

errors

• Check if start position setting has

errors/paper width/length

• Check if power supply is correct

• Check if Thermal Print Head is

stained or dusted

• Use internal command “~T” to check

Thermal Print Head can print

completely

• Check the media quality/size

• Check if sensor is covered by paper

or dust

• Check if liner is suitable for use,

please contact reseller for more

information

• Check if label roll edge is aligned with

Label Width Guide

setting

• Check if sensor is covered by dust

• Check if Thermal Print Head is

covered with glue or stain

0.16 mm

• Check if cutter is installed properly

• Check if paper feed is working

normally

• Check if stripper module sensor is

covered with dust

• Check if label is installed properly

Table 6-8. Troubleshooting

RL-22DT/42-DT Operation Manual - Appendix 25

Page 30

RL-22DT/42-DT Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by

the Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects in

materials and workmanship for two years.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized

by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment

fails to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to

prevent electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a

publication, Protecting Your Components From Static Damage in Shipment, available from RLWS

Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was

not caused by accident, misuse, neglect, alteration, improper installation, improper repair or

improper testing; RLWS shall be the sole judge of all alleged non-conformities.

• S uch equipment has not been modified, altered, or changed by any person other than RLWS or its

duly authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible

for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER

RLWS

NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE TH AT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO

REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCE PT ING THIS WARRANTY, THE BUYER WAIVES ANY AND

ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYE R AGREES TO LOOK ONLY TO THE SELLER FOR

WARRANTY CLAIMS.

NO TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO MODIFY THE TERMS OF THIS

WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN WRITING AND SIGNED BY A CORPORATE

OFFICER OF RLWS AND THE BUYER.

© 2011 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

26 RL-22DT/42-DT Operation Manual

Page 31

Page 32

PN 108222 02/11

Loading...

Loading...