Page 1

RL2200

Load Cell Mounting Kit

Installation

Guide

49596 Rev A

Page 2

Copyright © Rice Lake Weighing Systems. All rights reserved.

Printed in the United States of America.

Specifications subject to change without notice.

July 31, 2013

Page 3

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2 Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

General Installation Guidelines for Tank Mounts . . . . . . . . . . . . . . . . . . . 3

Installing the RL2200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Load Cell Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

4 Junction Box Connections, Adjustments & Calibration . . . . . . . . .7

5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

6 Maintenance and Replacement Parts . . . . . . . . . . . . . . . . . . . . . .8

7 RL2200 Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

© Rice Lake Weighing Systems. All rights reserved.

Printed in the United States of America.

Specifications subject to change without notice.

July 31, 2013

RL2200 Load Cell Mounting Kit Installation i

Page 4

ii RL2200 Load Cell Mounting Kit Installation

Page 5

1.0 Introduction

Thermal

Expansion

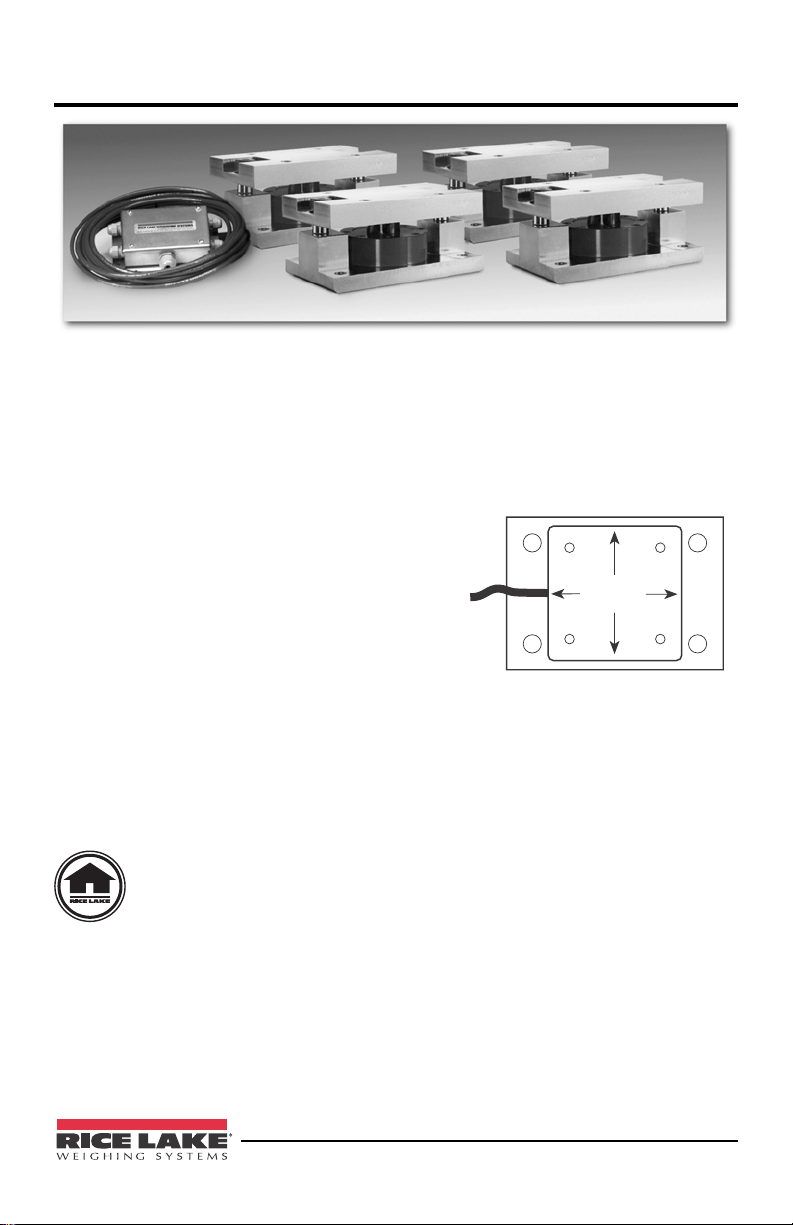

Figure 1-1 RL 2200 Load Cell Mounting Kit

The RL2200 Load Cell Mounting Kit provides an extremely accurate method for

weighing

mal expansion/contraction or vibration forces. The design

pression disk load cell (350Ω bridge) and transmits the load with a rocker pin on the

load-bearing hub of the cell. This design is very effective in providing for thermal

expansion/contraction with little friction.

In most applications, the assemblies are selfchecking and held captive with no need for check

or

areas with frequent seismic activity. The rocker

pin design eases load cell installation and replacement without the need to raise the weighed vessel

a

large amount, which could disturb piping and

other connections.

The RL2200 is available in mild steel or

steel, in capacity sizes from 5,000-50,000 lb. The RL2200 is also available with hermetically-sealed stainless steel

lb to 50,000 lb.

The installation should be planned by a qualified structural engineer. Each installation

is uniq

tion.

medium and large capacity tanks and hoppers that are subject to large ther-

uses a low profile com-

stay rods, making this mount a good choice for

stainless

load cells which are available in capacities from 5,000

ue, and this manual is meant to serve only as a general guideline for installa-

Authorized distributors and their employees can view or download this

manual from the Rice Lake Weighing Systems distributor site at

www

.rlws.com.

RL2200 Load Cell Mounting Kit Installation 1

Page 6

WARNING

Safety

Failure to heed may result in serious injury or death.

The installation should be planned by a qualified structural engineer. Each installation is unique, and this manual is meant to serve only as a general guideline for

installation.

Do NOT install or work on this equipment unless you have read and understand the

instructions and warnings in this manual.

DO NOT use for purposes other than weight measurement.

DO NOT use any load-bearing component that is worn beyond 5% of the original

dimension.

DO NOT use this product if any of the components are cracked.

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

Contact Rice Lake Weighing Systems for replacement manuals. Proper care is

your responsibility.

2 RL2200 Load Cell Mounting Kit Installation

Page 7

2.0 Mechanical Installation

Level - 0.5

Flexible Piping

J-Box

2.1 General Installation Guidelines for Tank Mounts

1. The mounting surface for base and top plate must be level. After installation, the

top and bottom plates must be level within ±0.5°. If the mounting surfaces are not

level, then shims and or grout may be used to level the mount.

If possible, check that the mount is level

excessive deflections in legs and supporting structures may cause additional side

forces which greatly affect accuracy. Deflection of the mount’s top or base plate

due to loading should not exceed ±0.5°. Reinforcement of legs or other support

structures may be necessary to correct this. Vessels with long legs should have

cross bracing applied between adjacent legs to keep them from spreading under

load.

2. Compression mounting systems use three, four, or more mounts. More than

t-mount systems should be avoided as even weight distribution becomes

eigh

extremely difficult to achieve. The load on each mount assembly should vary by

no more than 20%. Add shims where necessary to achieve correct load distribution.

3. If the actual load cells are used during in

overload damage. A tank or hopper can exert huge forces when dropped only a

fraction of an inch. Dummy load cells can be used during installation.

It is crucial that all piping or

4.

conduit be horizontal and flexible. If flexible piping is not

used,

make sure distance from

vessel to the first pipe support is

20-30 times pipe diameter. In

smaller, lower capacity tanks

and hoppers, isolating resultant

forces becomes extremely

critical. For details, see our

Weigh Modules & Vessel Weighing Systems man

ual, P/N 43918.

5. Load cells should not be

led in mounts until all

instal

welding is completed. The heat generated from welding current passing through

a load cell can damage the adhesive holding the strain gauge to the body. If possible, use a dummy load cell when welding to maintain finished height. If welding

is unavo

idable after load cell installation, connect the ground in such a way that

the current does not flow through the load cell. For example, if welding on the

mount top plate, the ground must be connected to the vessel, not to the mount

base or support structure. Also, protect the load cell and cable from weld splatter.

6. Use only “hermetically sealed” load cell

mentally protected” load cells are not suitable fo

damaged. If tanks and surrounding equipment are frequently steam cleaned or if

the load cell is subjected to direct washdown, a protective shroud for the weighing assembly is recommended. Proper drainage is

assembly is not standing in water.

7. All support points should be equally stiff so that they deflect by the same amount

as the ves

sel is loaded.

when the vessel is fully loaded because

stallation, take extreme care to prevent

s in washdown applications. “Environ-

r such applications and will be

necessary so the weighing

RL2200 Load Cell Mounting Kit Installation 3

Page 8

2.2 Installing the RL2200

Top Plate Rocker Pin

Set Screw

Shoulder

Screw

Load Cell

Base Plate

Subplate

(1” Recommended)

Load Cell Screws

Bearing, Upper Insert

Dust Boot

1. The type of installation and strength of the mounting surface governs the method

of locating, attaching, and assembling the RL2200 assembly. Carefully consider

three areas which commonly cause accuracy problems:

• Are the supporting legs adequately braced s

system is fully loaded?

• Does the supporting structure have the necessary strength to prevent excessive

deflection when the

system is fully loaded?

• Is there attached equipment such as skirting, venting, or piping which is likely

to cause bin

ding or lack of flexibility?

2. Determine where to position each mount. The RL2200

lateral movement in any direction. Sample mounting orientations to accommodate different vessel shapes are as follows:

o they will not spread when the

is designed to allow for

4 RL2200 Load Cell Mounting Kit Installation

Page 9

3. Make necessary preparations to the mounting surfaces. A 1" sub plate is recommended to ensure a good mounting surface.

4. The mounts are normally factory assembled. If mounts are not already assembled, complete the assembly by placing the rocker pin and boot in the load cell

hub socket, place the top plate on top with the rocker pin in the top plate socket,

and install the shoulder screws through the top plate into the base plate risers.

Torque the shoulder screws to 100 ft-lb. Tighten the shoulder screw set screws.

5. Lift and block the vessel to the same height as the assembled mounts.

6. Remove the block from one support point and slide that mount into position.

7. If the mount is being fitted under the leg of a vessel, verify that the leg’s center

line passes through the center of the top plate (through the center of the load cell).

8. Lower the corner or side of the vessel carefully onto the top plate. The force of a

vessel weighing several tons can damage a load cell if dropped only a fraction of

an inch.

9. With the top plate positioned approximately level, mark holes for attaching the

top plate to the vessel’s mounting surface. Drill holes and attach top plate loosely

to vessel with suitable fasteners.

10. Repeat steps 4-10 for the mounting assemblies at the remaining corners or sides.

11. Verify that there is no initial misalignment between the base plate and top plate

and that the rocker pin is in the center of the hole in the top plate.

12. Attach the base plates to the foundation using suitable anchors for concrete or by

bolting or welding to a steel structure or subplate. Verify that the base plates are

as level as possible. They should be fully supported. Shimming is not recom

-

mended.

13. Check that the top plates are no more than ±.5° out or level. Shim if necessary

and fully tighten mounting bolts.

14. To achieve equal load distribution, final height adjustments can be made with

shims between the top plate loading bracket and the weighing vessel. The varia

tion in load among the cells should be no more than 20%. The load distribution

can be checked accurately by exciting each load cell in turn and measuring the

output with a voltmeter..

-

RL2200 Load Cell Mounting Kit Installation 5

Page 10

3.0 Load Cell Wiring

Drip Loop

1. Route the load cell cables so they will not be damaged or cut. Cable should not be

routed near heat sources greater than 150 °F. Do not shorten any load cell cable.

The load cell is temperature compensated with the supplied length of cable. Cutting the cable will affect temperature compensation. C

cable so it will not be mechanically damaged or be sitting in water.

2. Provide a drip loop in all cables so that water or other liquids will not run directly

dow

n the cables onto either the load cells or the junction box. Attach load cell

cable to the dead structure, not the vessel.

3. If conduit protection is necessary against

mechanical or rodent damage to the

load cell cables, use flexible conduit and conduit adapters at the load cells.

4. Connect cables for load cells to the summing board in the junction box

to the guide shown below and the labels on the terminal strips of the junction

box. To verify the wiring scheme, see the certification shipped with each load

cell.

5. For better performance, use positive and negative remote sense lines if the wiring

ru

nning from the junction box to the indicator is longer than 25 feet.

oil and protect excess

according

Load Cell Wire Colors

Wire Color

Red +EXC +EXC

Black -EXC -EXC

Green +SIG -SIG

White -SIG +SIG

Gray or Bare Shield Shield

6 RL2200 Load Cell Mounting Kit Installation

Function

Negative Reading Positive Reading

Page 11

4.0

Junction Box Connections, Adjustments & Calibration

1. Refer to junction box manual for trimming details.

2. Refer to indicator manual for system calibration details.

5.0 Troubleshooting

If the system powers up and gives some type of stable digital readout that varies with

the load on the system, any system problems are probably caused by factors other

than the load cells. The load cells are often blamed for a malfunctioning system, but

90% of the time, the problem lies elsewhere. Look for mechanical causes for your

problem first.

If the system can be calibrated but doesn’t return to zero, loses calibration, or demonstrates non-linearity or non-repeatability, see the following chart for possible causes

and

do the following checks.

Symptom Possible Cause

No return zero

Non-linearity

Non-repeatability

Lost calibration Out of level or plumb; moisture problem; mechanical binding

Drifting readout Moisture in junction box, cables, or

1. Check load cell mount for debris restricting load cell movement or debris

between scale and structure.

2. Check that tank/vessel and mounts are plumb, level,

3. Check all piping and conduit for connections which restrict vessel movement.

4. If check rods are used, loosen all connect

5. Check load cell cables for physical or water damage.

6. Check all electrical connections, esp

If the problem still is not found:

7. Check possible indicator malfunction by using a load cell simulator to input a

kno

wn good signal into the indicator.

8. Disconnect each load cell’s signal leads at the

load cell outputs with a multimeter. Then check input/output impedances for

comparison with load cell manufacturer’s specifications.

9. If after all these checks the problem still ca

load cell. Replace load cell with a load cell simulator. Alternate so that each load

cell is individually disconnected and replaced with a simulator. If there is a problem with a particular load cell, the symptom should disappear when that load cell

is disconnected and replaced with simulator

Mechanical binding or debris in seals or under load cells; may have

lost system calibration

Thermal expansion or deflection under l

load

Loose load cell mount; drifting caused by moistur

or shock damage; mechanical binding

oad causing binding or side

e; load cell overload

load cell; mechanical binding

and square at critical areas.

ions to finger tight only for testing.

ecially in the junction box.

junction box and check individual

nnot be isolated, reconnect all but one

.

RL2200 Load Cell Mounting Kit Installation 7

Page 12

6.0 Maintenance and Replacement Parts

RL2200 Mild Steel Mounts

No. Description Replacement Part Numbers

A* B* C* D*

1 Top Pl a t e 45562 45562 45547 45547

2 Shoulder Screw 45567 45567 45553 45553

3 Load Cell Bolts 45569 45569 45554 45554

4 RL2200 Load Cell 45708 45709 45710 45711

5 Bearing, Upper Insert 45564 45564 45549 45549

6 Base Plate 45556 45556 45541 45541

7 Rocker Pin 45565 45565 45550 45550

8 Dust Boot 45566 45566 45566 45566

9 Set Screws 14949 14949 45696 45696

RL2200 Stainless Steel Mounts

No. Description Replacement Part Numbers

A* B* C* D*

1 Top Plate 45563 45563 45548 45548

2 Shoulder Screw 45568 45568 45552 45552

3 Load Cell Bolts 45570 45570 45555 45555

4 RL2200 Load Cell 45712 45713 45714 45715

5 Bearing, Upper Support 45564 45564 45549 45549

6 Base Plate 45557 45557 45542 45542

7 Rocker Pin 45565 45565 45550 45550

8 Dust Boot 45566 45566 45566 45566

9 Set Screws 14950 14950 45697 45697

*A-size mounts use load cel

*B-size mounts use load cells with a capacity of 10,000 lb.

*C-size mounts use load cells with a capacity of 25,000 lb.

*D-size mounts use load cells with a capacity of 50,000 lb.

ls with a capacity of 5,000 lb.

8 RL2200 Load Cell Mounting Kit Installation

Page 13

7.0 RL2200 Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS brand load cells properly installed by a Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications. All load cell products are warranted against defects in

materials and workmanship for two (2) years. Products marked as “waterproof” are

warranted against defects in materials and workmanship relating to moisture ingress.

RLWS warrants that the equipment sold hereunder will conform to the current written

specifications authorized by RLWS. RLWS warrants the equipment against faulty

workmanship and defective materials. If any equipment fails to conform to these war

ranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such non-conformity, RLWS will be given prompt

written notice with a detailed explanation of the alleged deficiencies.

• Examination of such equipment by RLWS confirms that the non-conformity

actually exists, and was not caused by accident, misuse, neglect, alteration,

improper installation, improper repair or improper testing; RLWS shall be the

sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other

than RLWS or its duly authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment.

Buyer is responsible for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs,

including assembly or disassembly of equipment, nor will RLWS be liable for the

cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING WITHOUT LIMITATION WARRANTIES OF MER

CHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER

RLWS NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO REPAIR OR REPLACEMENT OF SUCH

GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND

ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO

LOOK ONLY TO THE SELLER FOR WARRANTY CLAIMS.

No terms, conditions, understanding, or agreements purporting to modify the terms of

this warranty shall have any legal effect unless made in writing and signed by a corporate officer of RLWS and the Buyer.

-

-

© 2003 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET

RICE LAKE, WISCONSIN 54868 • USA

RL2200 Load Cell Mounting Kit Installation 9

Page 14

10 RL2200 Load Cell Mounting Kit Installation

Page 15

Page 16

Rice Lake Weighing Systems

July 31, 2013 49596 Rev A

Loading...

Loading...