Page 1

RL1200

Portable Beam Scale

Installation & Operation

Manual

157986

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

1.0 Introduction.................................................................................................................................. 1

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Safety Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.0 Installation Instructions............................................................................................................... 3

2.1 Unpacking the Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Repacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Setting Up Your Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.1 Assemble Wheels onto Frame. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3.2 Attach Pillar to Scale Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3.3 Trig Loop Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.0 Operation.................................................................................................................................... 13

4.0 Mechanical to Electronic Installation Instructions................................................................... 19

4.1 Unpacking The Conversion Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Indicator and Load Cell Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.3 Final Adjustment, Calibration and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.0 Appendix .................................................................................................................................... 24

5.1 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

For More Information ............................................................................................................................. 24

RL1200 Portable Beam Scale Limited Warranty................................................................................... 25

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Rice Lake Weighing Systems is an ISO 9001 registered company.

Specifications subject to change without notice.

19 November 2014

Page 4

2 RL1200

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

Page 5

1.0 Introduction

This manual provides assembly and operating instructions for the RL1200 portable beam scale, which is available in both avoirdupois and metric. Please read all instructions carefully before as

This manual covers the installation and setu

• Mechanical assembly of RL1200

• Mechanical to electronic conversion option for the RL1200

Instructions on assembling the mechanical to electron

page 15.

This manual can be viewed and downloaded from the Rice Lake Weighing Systems website at

www.ricelake.com. Rice Lake Weighing Syste

p of two versions of the RL1200:

ic version of the RL1200 can be viewed in Section 4.0 on

ms is an ISO 9001 registered company.

sembling the scale.

Figure 1-1. RL1200 Portable Beam Scale (Mechanical and Electronic Conversion Models shown)

1

Page 6

1.1 Safety

Important

CAUTION

WARNING

DANGER

CAUTION

There are certain precautions that should be taken to prevent personal injury to the user and damage to the scale.

Care should be exercised to assure proper assembly and operation of the RL1200. The RL1200 should be assembled only by a trained scale technician. Untrained personne

l should not attempt to assemble this scale, nor make

any adjustments not specified in these instructions.

1.2 Safety Signals

Safety Signal Definitions:

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious

injury.

Indicates a potentially hazardous situation that,

injury.

Indicates a potentially hazardous situation that,

injury.

Indicates information about procedures that, if not observed, could result in damage to

equipment

.

if not avoided, could result in death or serious

if not avoided, may result in minor or moderate

1.3 Safety Precautions

Do not operate or work on this equipment unless you have read and understand the

instructions in this manual. Failure

in injury or death. Contact any Rice Lake Weighing Systems dealer for replacement manuals.

Proper care is your responsibility.

Before attempting to operate this unit, make sure every individual who operates or works with

this unit has read and understands the following safety information.

instructions carefully.

• Do not drop the scale or subject it to violent shocks.

• For accurate weighing, the scale must be placed on a flat, stable surface.

• Do not transport the scale while someone is standing on it.

• Weight exceeding the maximum capacity (1

• Avoid contact with excessive moisture.

• Do not allow minors (children) or inexpe

rienced persons to operate this scale.

• Do not jump up and down on the scale.

• Do not make alterations or modifications

to the scale.

to follow the instructions or heed the warnings could result

Please follow these

000 lb/ 500 kg) may damage the scale.

2 RL1200

Page 7

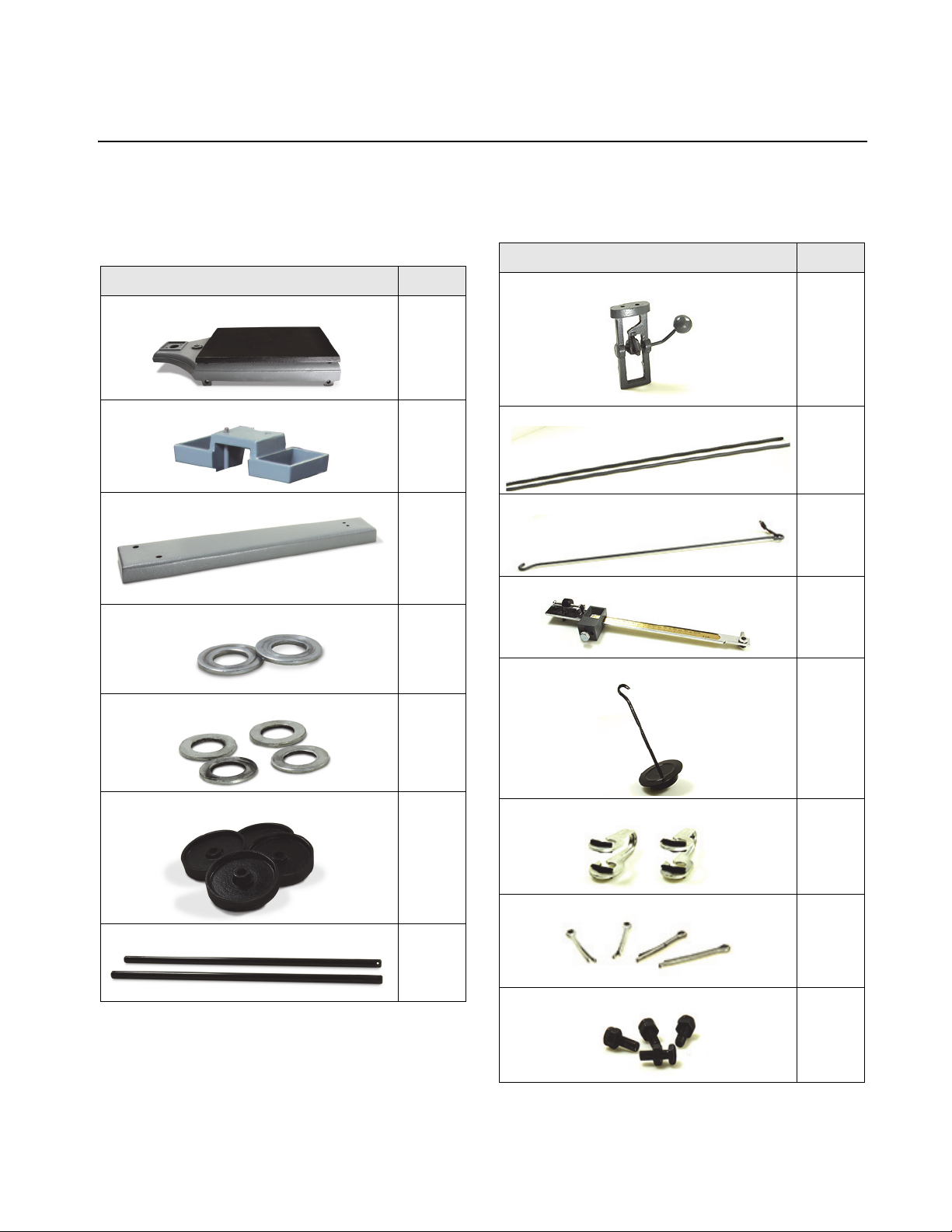

2.0 Installation Instructions

2.1 Unpacking the Scale

Place the unopened box in an open area that has ample room for unpacking the scale. Remove all parts from the

box. Parts contained in the shipping box include:

Item Description Quantity

Scale Base

Item Description Quantity

1

trig loop assembly 1

Weight rack

Beam cap assembly

Beam cap washers

Axle washers 4

Wheel 4

1

Pillar rod

1

2

Steelyard rod

Beam assembly 1

Counterpoise assembly 1

Loop clamp

2

1

2

Wheel axle

Axle cotter pins

2

Axle locking bolts

4

2

Table 2-1: RL1200 Parts

Table 2-1: RL1200 Parts (Continued)

1

Page 8

Important

Item Description Quantity

Cap nut for beam cap

Counterpoise weights, 100 lb (1), 200 lb (2),

400 lb (1)

Steel shot for counterpoise 1

Pillar

2

1

Trig loop mounting plate

Trig loop mounting bolts

Trig loop mounting washers

1

2

2

Table 2-1: RL1200 Parts (Continued)

2.2 Repacking

If the RL1200 must be returned for modification or repair, it must be properly packed with sufficient packing materials. Whenever possible, use

Damage caused by improper packaging is not covered by the warranty.

original carton when shipping the scale back.

4 RL1200

Page 9

2.3 Setting Up Your Scale

Note

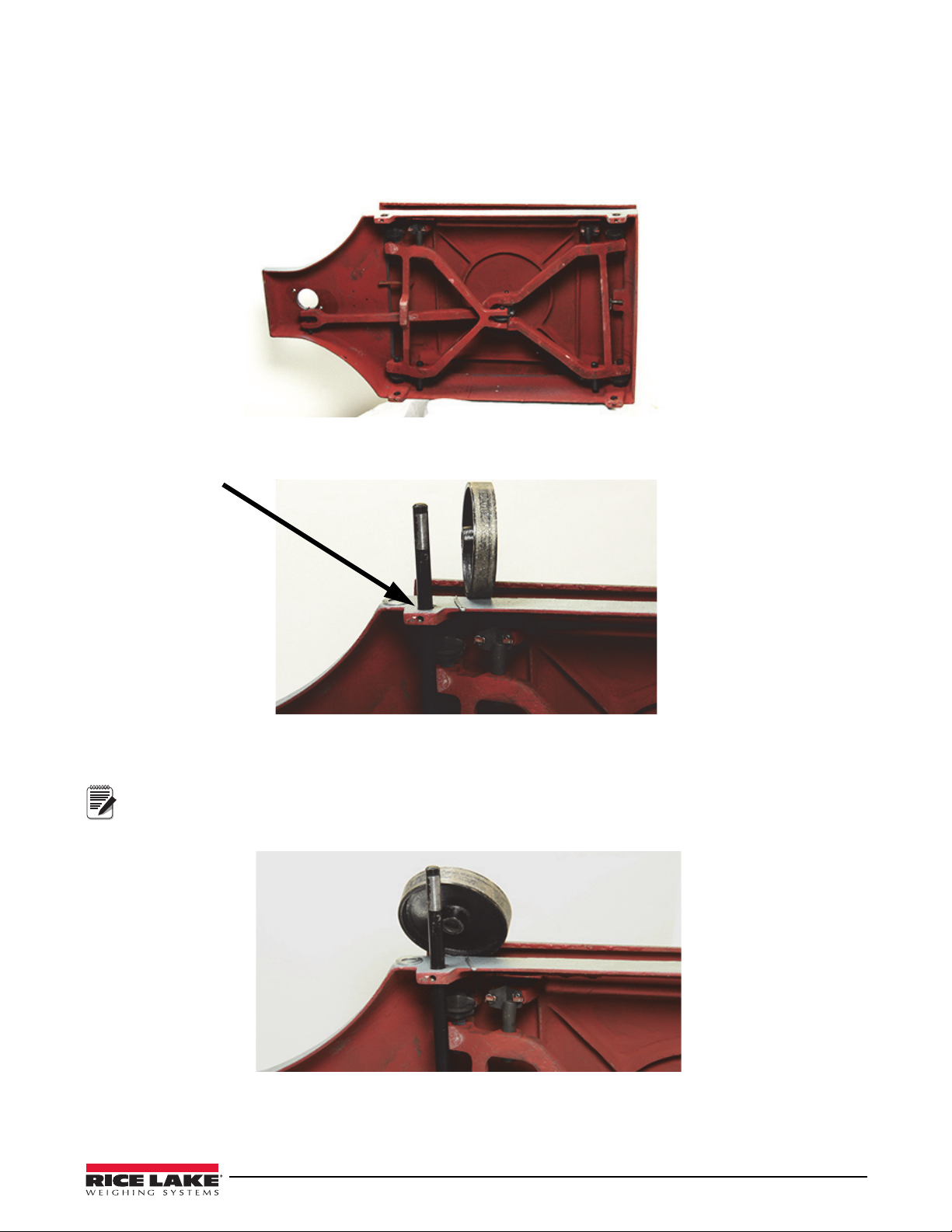

2.3.1 Assemble Wheels onto Frame

1. It is preferable to set the scale base on a box or other item to keep the scale base up off the floor. Tip the scale

base on its side.

Figure 2-1. Scale Base on its Side

2. Place wheel axles through the holes in the frame.

Figure 2-2. Run Axle Through Scale Base Frame Holes

3. Place the wheels and washers on the axles.

Washers must be placed on the insides of the wheels next to the scale frame.

Wheels must be placed with the extended hub next to the scale frame.

Figure 2-3. Place Washers and Wheels on Each Axle

Setting Up Your Scale 5

Page 10

4. Place the washers and wheels against the frame and insert cotter pins in the holes in the axles. Bend the cotter

pin with pliers to prevent it from slipping out.

Figure 2-4. Run Cotter Pins Through Wheel Axle Holes to Prevent Slipping

5. Finish the wheel assembly by securing axles to frame by securing wheel axle rods with axle locking bolts and

lock nuts. Center the axle and tighten bolt and locknut.

Figure 2-5. Secure Wheel Axle to Frame Using Axle Locking Bolts on Each Wheel

6. Stand the scale base on the floor on its wheels.

Figure 2-6. Place Scale Base on Floor

6 RL1200

Page 11

2.3.2 Attach Pillar to Scale Base

Use the following steps to attach the pillar to the scale base.

1. Screw the pillar rods into the scale base

to place the beam weight rack and beam cap assembly on the pillar.

Figure 2-7. Screw Pillar Rods into Scale Platform

2. Place the pillar over the rods with the label facing the scale platform and the serial model label facing out-

wards as shown in Figure 2-8.

frame approximately three turns. Ensure ample threads are available

Figure 2-8. Place Pillar Over Pillar Rods

Setting Up Your Scale 7

Page 12

3. To put the connecting steelyard rod into position inside the pillar, raise the long lever under the scale base and

Hook loop onto the

nose iron assembly

under scale base

Important

Hook and

steelyard

hook should

both face as

shown.

hook the lower end of the rod with loop in the nose iron assembly.

Figure 2-9. Attach Hook to Nose Iron Assembly

4. Temporarily hang the steelyard rod on the cutout in the pillar as shown.

8 RL1200

Figure 2-10. Steelyard Hook on Pillar Cutout

If assembling the Mechanical to Electronic version of the RL1200, please proceed to

Chapter 5 on page 14 for further assembly instructions.

5. Place the weight rack on top of the pillar with the hook facing as

Figure 2-11. Place Weight Rack on Pillar

shown.

Page 13

6. Place the beam cap assembly over the weight rack (facing same direction as hook and steelyard hook) using

Attach loop clamp (as

shown)

Second loop clamp

attaches here facing upwards (also

see Figure 2-14)

Hook the steelyard upper

hook through the lower

loop clamp as shown.

Hook the

upper loop

clamp to the

weight rack

hook (not

shown)

acorn bolts and washers and snug the beam cap assembly.

Figure 2-12. Attach Beam Cap Assembly

7. Attach the two loop clamps onto beam assembly.

8. Take the beam assembly and put the upper end of the steelyard rod through the lower loop clamp on the beam

and hook the upper loop clamp to the hook on the weight rack (not shown).

Figure 2-13. Attach Loop Clamps to Beam Assembly

Figure 2-14. Hook Loop Clamps to Beam Assembly and Weight Rack

Setting Up Your Scale 9

Page 14

2.3.3 Trig Loop Assembly

1. Insert the trig loop assembly to the end of the beam assembly. The ball handle should face towards the scale

base.

2. Place the trig loop mounting plate on top of trig loop a

Figure 2-15. Inserting the Trip Loop Assembly to Beam Assembly and Adding the Trig Loop Mounting Plate

ssembly prior to attaching to beam cap assembly.

3. Use bolts to secure the trig loop assembly to the beam assembly ensuring that trig loop washers are placed

between beam cap assembly and the mounting bolts..

Figure 2-16. Secure Trig Loop Assembly with Bolts

4. Ensure the trig loop assembly is centered horizontally. Adjustments can be made by readjusting the beam

assembly. The beam must not touch or rub the sides to ensure accurate weighments.

5. Once the trig loop assembly is centered,

tighten the beam cap assembly and weight rack to the pillar.

10 RL1200

Page 15

6. Hang the counterpoise assembly from the loop assembly at the tip of the beam.

Figure 2-17. Hanging Counterpoise Assembly

7. Place the scale on a firm, level surface.

8. Set poise(s) at zero and lock. Release the beam lock. A

djust the back balance assembly to bring the beam to a

horizontal position with the tip centered in the trig loop.

9. The zero adjustment screw must be turned clockwise to make th

e beam go up, and counter-clockwise to make

the beam go down.

Figure 2-18. Zero Adjustment Location

10.If the beam cannot be vertically centered, weight may be added or removed from the counterpoise assembly

as necessary by unscrewing the counterpoise weight and adding iron shot into the cavity.

Figure 2-19. Scale Reading on Zero

Setting Up Your Scale 11

Page 16

11.Hang the counterpoise weights on the weight rack until needed.

Figure 2-20. Add Counterpoise Weights Until Needed

12 RL1200

Page 17

3.0 Operation

Use the following steps to safely and correctly operate the RL1200 platform scale.

1. With no load on the scale platform, position the sliding poise at zero. Unlock the trig loop. The beam should

be centered vertically in the trig loop. Adjust the back balance if necessary (see

2. Lock the beam with the trig loop lock and place the object to be weighed on the platform. Add counterpoise

weights to a value slightly less than the estimated object weight. Release the beam lock.

3. The beam should rise to the top of the trig loop. If it does not rise, reduce the amount of counterpoise weights.

Move the poise along the beam until the beam balances with the tip centered in the trig loop.

4. When the beam balances, the object weight is the value indicated by the sliding poise, plus the face value of

the counterpoise weights used. For example, if there are three pounds of counterpoise weights (equivalent to

300 pounds) and the sliding poise(s) on the beam indicates 54.5 pounds, then the object weighs 354.5 pounds.

For a metric example, if there are three 500 gram counterpoise weights (equivalent to 150 kg) and the sliding

poise on the beam indicates 10.2 kg, then the object weighs 160.2 kg.

5. After the weight has been determined, lock the beam. Remove the object from the platform. Note the poise

may be locked at a desired reading by tightening the poise thumb locking screw if a desired weight is needed

repeatedly, such as bagging ingredients.

Figure 1-18 on page 12).

13

Page 18

14 RL1200

Page 19

15

Page 20

16 RL1200

Page 21

17

Page 22

18 RL1200

Page 23

4.0 Mechanical to Electronic Installation Instructions

The conversion from mechanical to electronic weighing is accomplished by a conversion kit. This kit includes:

• IQ plus 390-DC indicator

• Load cell plus load cell cable

• Pre-drilled mounting bracket

• All necessary conversion hardware

The conversion kit requires no special

Prior assembly of the RL1200 through Step 4, Figure 1-10 on page 9 still applies.

4.1 Unpacking The Conversion Kit

Parts contained in the conversion kit include:

tooling or equipment. Assembly requires only ordinary hand tools.

Item Description Quantity

Indicator

Indicator base plate 1

1

Load cell and load cell cable

Eye bolt

Lock washers 6

Bolts

Table 4-1: Conversion Kits Parts List

1

1

4

Unpacking The Conversion Kit 19

Page 24

Item Description Quantity

Locknuts 2

Long bolt

Long bolt washer 1

Table 4-1: Conversion Kits Parts List

1

4.2 Indicator and Load Cell Installation

Use the following steps to attach the indicator and load cell to the RL1200.

1. Take the indicator base plate and lay it on its side.

2. Note the orientation of the load cell. Put

indicator base plate. Thread on the locknut to the bottom of the bolt.

the 3.5" bolt through the long bolt washer and through the top of the

Figure 4-1. Set Indicator Base Plate on Side and Attach Load Cell

3. Screw the eye bolt and locknut into the bottom of the load cell until flush. Tighten the locknut.

Figure 4-2. Screw Eye-Bolt Into Load Cell

20 RL1200

Page 25

4. Place the indicator base plate on pillar aligning the pillar rods through the base plate holes and handles facing

Pillar rods

Attach the steelyard hook

through eye-bolt

the back of the scale.

Figure 4-3. Mount Base Plate to Pillar and Attach Steelyard Hook

5. Hook the steelyard hook through the eye-bolt as shown in Figure 4-3.

6. Push the load cell cable inside pillar leaving

enough slack inside pillar and draw the cable end up through hole

in the base plate.

7. Tighten the indicator base plate to the pillar by using lock washers and acorn nuts as shown in Figure 4-4.

8. Run load cell cable through the tilt stand on the

Figure 4-4. Run Load Cell Cable Through Base Plate and Tighten Base Plate to Pillar

indicator.

Figure 4-5. Run Load Cell Cable Through Bottom of Indicator Tilt Stand

Indicator and Load Cell Installation 21

Page 26

9. Set indicator on base plate and secure with four bolts and lock washers.

Figure 4-6. Secure Indicator to Base Plate

10.Wrap excess cable around cable hooks on handle.

Figure 4-7. Store Excess Load Cell Cable

11.Connect cable from the load cell through the load cell cable cord grip to connector J1 as shown in Tab le 4-2.

J1 Pin Function

1

2

3

4

5

6

7

For 6-wire load cell connections, remove jumpers JP1

and JP2

Table 4-2: J1 Pin Assignments

+SIG

-SIG

+SENSE

-SENSE

SHIELD

+EXC

-EXC

22 RL1200

Page 27

12.If using a 6-wire load cell cable (with sense wires), remove jumpers JP1 and JP2 before reinstalling connector

R12

C34

C33

D3

D4

RN1

C40

C38

C36

C39

C35

R23

C72

C73

C71

C74

C78

C76

R27

R28

C81

C83

R24

R25

R31

D5

F1

C80

EMI1

R46

R45

R44

R40

R39

R38

R37

C92

C91

C90

R34

R33

R43

C84

C85

U15

C77

VR2

D1

R2

C31

C32

R1

C1

L2

C28

U1

VR1

L1

C13

C6

R7

C10

C9

R26 C79

C75

U6

C14

R32

R29

C82

C2

XT1

C4

C8

C7

C3

C5

R6

R5

R3

R4

C41

R15

R14

C37

C42

Q1

C11

C12

R30

C86

C87

C15

U12

U10

U7

U11

R8

C17

C18

C19

R9

C16

C20

C27

U9

C88

C89

VR4

U8

R49

R50

C95

R48

R42

R41

C94

C93

R35

R36

R47

RICE LAKE WEIGHING SYSTEMS

1

RESET

AGND

DGND

+SIG

–SIG

+SENSE

–SENSE

SHIELD

+EXC

–EXC

1

2

3

4

5

6

7

LOAD CELL

CONNECTOR

J1

JP2

JP1

D2

J5

Keypad Connector

1

J4

J2

TxD

GND

RxD

1

2

3

SERIAL PORT

1

J3

Battery

Input

AC

Adapter

Input

1

J6

To Setup

Switch

A/D Converter

GND

GND

1

J7

VR3

U4

Microcontroller

U5

FLASH RAM

U2

U3

Display Drivers

R11C29R13

C30

RN2

+

+

+

C26

C23

C25

R10

C21

C22

C24

+

J1 (see

Figure 4-8). For 4-wire installation, leave jumpers JP1 and JP2 on.

Figure 4-8. IQ Plus 390-DC Indicator Board

4.3 Final Adjustment, Calibration and Troubleshooting

Final adjustment, calibration and troubleshooting of the IQ Plus 390-DC indicator can be found in the IQ Plus

390-DC Installation Manual, PN 48820.

Final Adjustment, Calibration and Troubleshooting 23

Page 28

5.0 Appendix

Check frequently for correct balance with no load on the platform, the poise(s) set at zero, and no counterpoise

weights applied.

• Keep the beam locked until

• Do not overload the scale.

• Do not oil any part of the scale. Keep the scale as clean and dry as possible at all times.

• Make sure the operation of the scale is checked at regular inte

5.1 Specifications

Construction Cast iron platform, base and levers

Weigh beam Single beam, die-cast aluminum, dual sided

Poise Steel locking screw provided

Pivots and bearings Precision machined hardened tool steel

Counterpoise weights 100 lb / 45 kg (1), 200 lb / 90 kg (2), 400 lb / 181 kg (1)

Overall dimensions 36.13 L (917.7 mm)

Platform dimensions 18 x 24" (457.2 x 609.6 mm)

Platform deck height 6" without wheels attached, 8" wi

Capacity 1000 lb / 500 kg

Approximate shipping weight 230 lb / 104 kg

Warranty 1 year limited

the load has been applied to the platform.

rvals.

beam graduation in .5 lb or

.2 kg increments

25.25 W (641.35 mm)

43 H (1092.2 mm)

th the wheels attached

For More Information

Website

• http://www.ricelake.com

Contact Information

Hours of Operation

Knowledgeable customer service representatives are available 6:30 a.m. - 6:30 p.m. Monday through Friday and 8

a.m. to 12 noon on Saturday. (CST)

Telephone

• Sales/Technical Support 800-472-6703

• Canadian and Mexican Customers 800-321-6703

• International 715-234-9171

Fax

• Fax Number 715-234-6967

Email

• U.S. sales and product information at prodinfo@ricelake.com

• International (non-U.S.) sales and produc

Mailing Address

t information at intlsales@ricelake.com

Rice Lake Weighing Systems

230 West Coleman Street

Rice Lake, WI 54868 USA

24 RL1200

Page 29

RL1200 Portable Beam Scale Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by the

Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects in materials

and workmanship for one year.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized by

RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment fails

to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the warranty

period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to prevent

electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a publication, Pro

tecting Your Components From Static Damage in Shipment, available from RLWS Equipment Return

Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was not

caused by accident, misuse, neglect, alteration, improper installation, improper repair or improper testing;

RLWS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other than RLWS or its duly

authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible for

shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or disas-

sembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT LIM-

ITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER RLWS NOR

DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO REPAIR

OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER

CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE SELLER FOR WAR-

RANTY CLAIMS.

NO TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO MODIFY THE TERMS OF THIS

WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN WRITING AND SIGNED BY A CORPORATE OFFI-

CER OF RLWS AND THE BUYER.

-

© 2014 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

Specifications 25

Page 30

26 RL1200

Page 31

Page 32

230 W. Coleman St. • Rice Lake, WI 54868 • USA

U.S. 800-472-6703 • Canada/Mexico 800-321-6703 • International 715-234-9171 • Europe +31 (0)26 472 1319

www.ricelake.com www.ricelake.mx www.ricelake.eu www.ricelake.co.in m.ricelake.com

© Rice Lake Weighing Systems 11/19/14 PN 157986

Loading...

Loading...