Page 1

RD-300/RD-232

Remote Displays

Version 2.1

Installation/Operation

Manual

33210

Page 2

Contents

1.0 Introduction.................................................................................................................................. 1

1.1 Scale Indicator Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.1 Standard Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.2 Standard Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.1.3 Optional Hardware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.0 Installation ................................................................................................................................... 3

2.1 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Electrical Service Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.1 All Models - AC - Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.2 DC Models Voltages 6.2 - 18 VDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Indicator Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Serial Data Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4.1 RS-232 C - SW2-8 Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4.2 20 mA Active Current Loop - SW2-8 On . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.3 20 mA Passive Current Loop - SW2-8 On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.4 Configuring the RD-300/RD-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.5 Powering up With the RD-300/RD-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3.0 Mounting Procedure for Panel Mount RD-300/232 ................................................................... 15

4.0 Appendix .................................................................................................................................... 19

4.1 RD-300 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 RD-232 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Page 3

1.0 Introduction

3%

3%

The RD-300 is a high performance serial remote data display. It receives digital indicator serial data signals

through either 20 mA Current Loop or RS-232C, and displays weight data on a high contrast, 1" LCD. Status

indicators are provided for LB, Kg, g, GROSS, NET, OZ, PCS, TN, ZERO, and additional specialty

annunciators for COUNT, TOTAL S1, S2, S3, S4, UNDER, OVER, and OK. The RD-300 supports 15 popular

serial scale formats plus a special “Smart Receiver” for indicators not listed. Custom interfaces to other

indicators or instruments are available. The RD-300 is direct-sunlight readable. It features black characters on a

silver reflective background, and is ideal for outdoor applications from 40°C to -25°C (104°F to -13°F). The

RD-300 can monitor up to four scales (S1, S2, S3, S4), and is available for either AC or DC power.

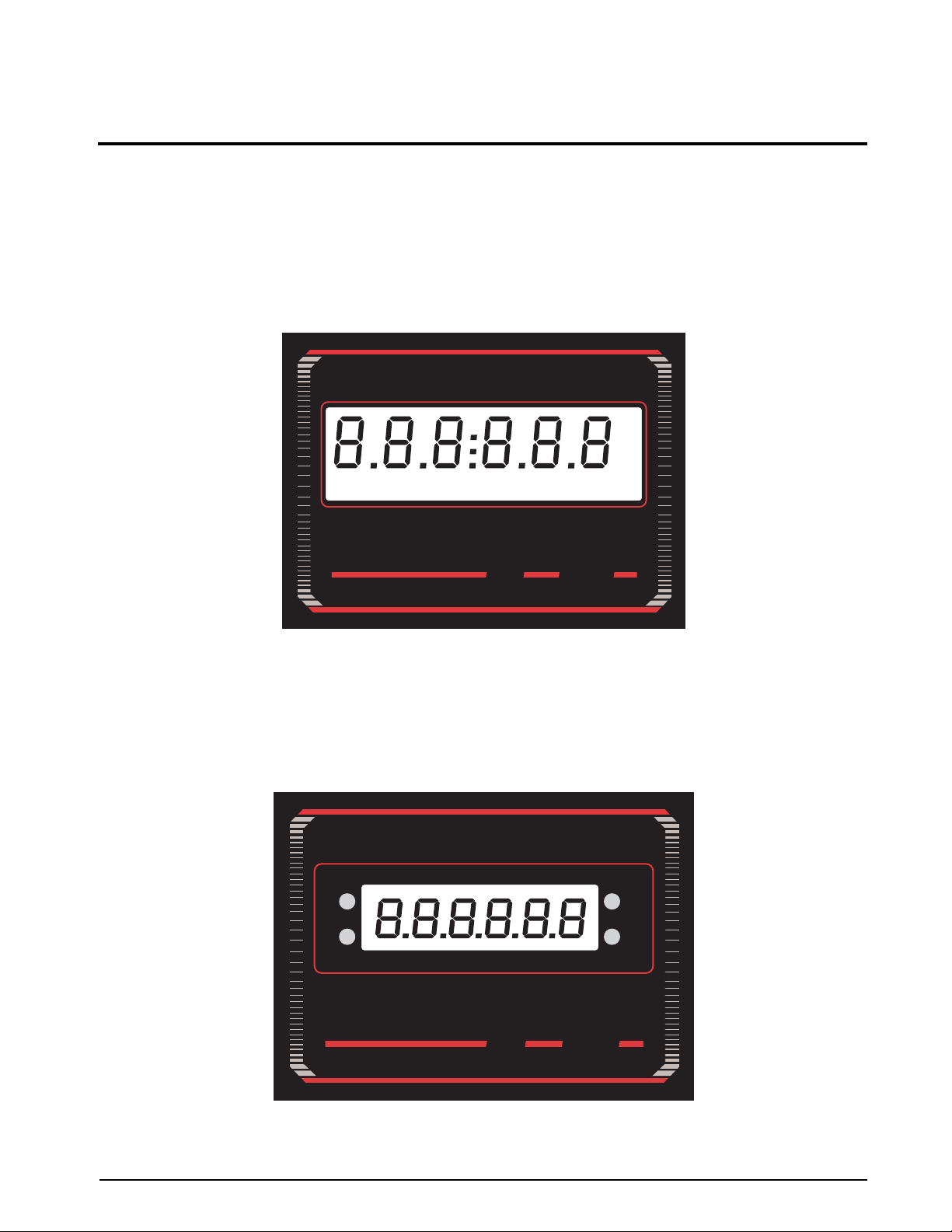

The following diagram illustrates the front panel of an RD-300 remote display.

LH

-#

0;

5/

1$4

505"-4444

;&30 6/%&30,07&3

3&.05&%*41-":

/&5(3044

$06/5

3%

The RD-232 is a high performance serial remote data display designed for indoor use. It displays weight data on

a high contrast 0.8" LED. Status indicators are provided for LB, Kg, GROSS, and NET. The RD-232 supports 15

popular serial scale formats plus a special “Smart Receiver” for indicators not listed. Custom interfaces to other

indicators or instruments are available. The RD-232 features bright red characters and is ideal for indoor display

applications from 40°C to -25°C (104°F to -13°F).

The following diagram illustrates the front panel of an RS-232 remote display.

-#4

6/*54

,(

3&.05&%*41-":

(34

.0%&

/&5

3%

Introduction 1

Page 4

1.1 Scale Indicator Formats

Rice Lake IQ plus 310, IQ plus 800/810 use 20 mA Current Loop only for the RD-300/RD-232.

• Rice Lake IQ 700

• Rice Lake UMC Series

• A&D Instruments 4322, 4323, 4316, 5000

• Weightronix WI-110, WI-120, WI-125, and WI-130

• Toledo Indicators with high-speed data format

• Masstron M-2500 and M-5000

• Flex-Weigh DWM-4

• Analogic AN5315, AN5316, and AN5322 (use 20 mA current loop only for the RD-300/RD-232)

• Fairbanks 90-164 series and meters with continuous scoreboard outputs

• Doran indicators Model 4100 and 4200

• Cardinal 738 and 748

• GSE 450/550 meters

• Sartorious balances with RS-232 continuous serial outputs

• Hardy 2151 indicators

• Computers, PLCs, or terminals with programmable ASCII

• Special generic Smart Receiver

1.1.1 Standard Software

The standard software for the RD-300 or RD-232 receives and displays serial data from 15 different types of

scale indicators. The receiver can accept either RS-232C or a 20 mA active or passive current loop. The standard

unit also re-transmits the data via a 20 mA active current loop. The data is transmitted either “as received” or in a

Condec continuous serial format at the incoming baud rate.

1.1.2 Standard Hardware

The standard RD-300 or RD-232 is comprised of a single circuit board housed in a JIC standard 8" X 6"

Fiberglass Reinforced Plastic (FRP) enclosure that is NEMA 4X rated.

Standard units are powered by eith er 117 VAC 50/60 Hz line power or DC voltages of 8.2 - 18 VDC. Voltages as

low as 6.0 VDC can be used to power the unit with the addition of one jumper.

1.1. 3 O p t io na l H ar dw a r e

Both the RD-300 and RD-232 can be ordered in a stainless steel NEMA 4X enclosure, an explosion-proof

NEMA 7CD, 9EFG, 4-enclosure panel mount, or as a board-only product for OEM applications. Consult the

factory for alternate enclosures.

An optional long-life LCD backlight is available for the RD-300. The LCD color is yellow/green and has a rated

life of 100,000 hours.

2 RD-300/RD-232 Installation & Operation Manual

Page 5

2.0 Installation

The following section describes the installation procedures used with the RD-300/RD-232.

2.1 Mounting

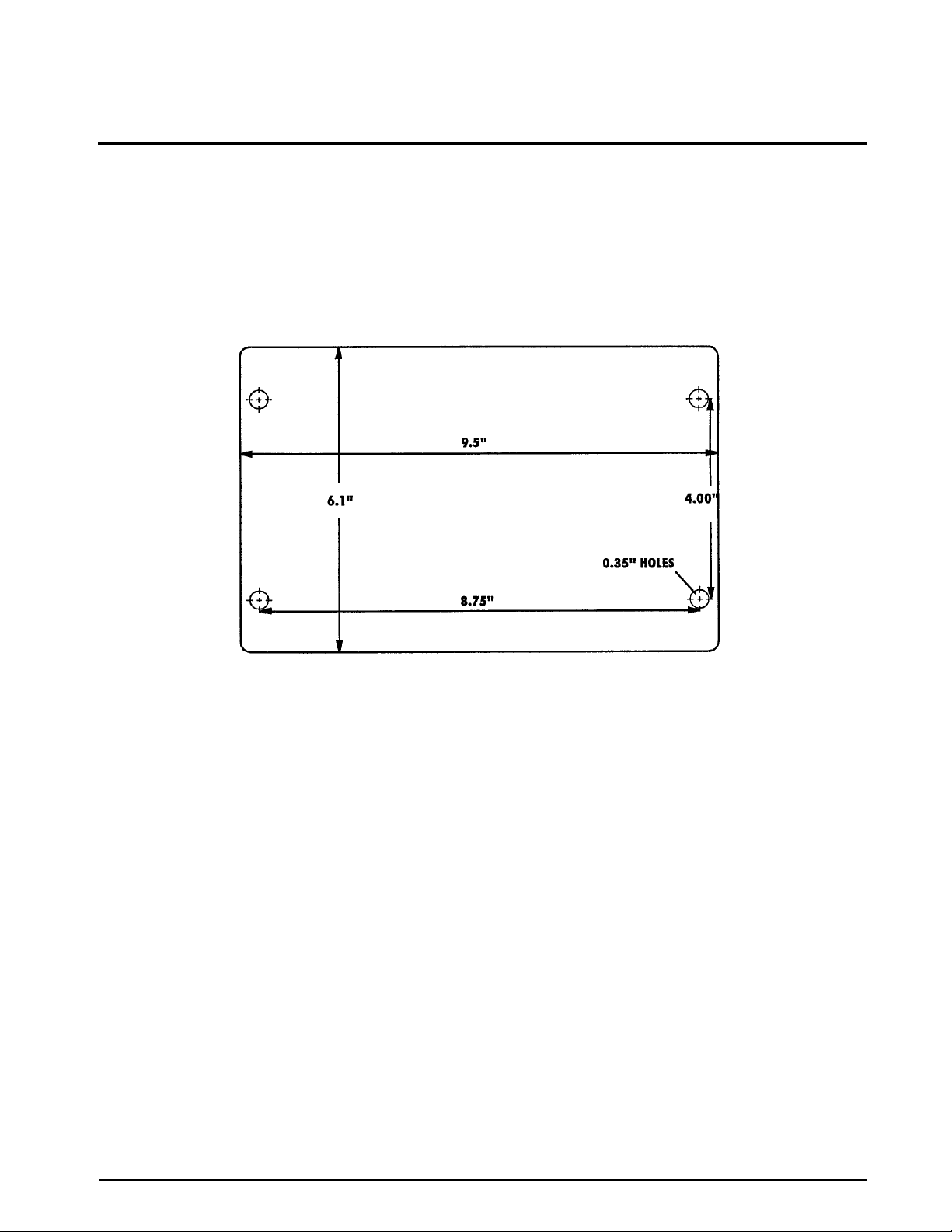

The standard NEMA 4X enclosure is a JIC standard 8" X 6" pattern. It is app roximately 8" high, 9.5" wid e, 5.25"

deep, and weighs 4 lb. Mounting is via four mounting holes on 8.75" horizontal by 4" vertical centers. Use 1/4"

hardware (not furnished) and mount the enclosure securely. The enclosure is hinged on the bottom side of the

box. The installation environment is not critical, but the RD-300/RD-232 should be located as far as practical

from major sources of electromagnetic interference (EMI) or radio frequency interference (RFI). Also, care must

be taken to ensure that the front panel display is easily visible.

Figure 2-1. RD-300 Mounting Footprint

Installation 3

Page 6

2.2 Electrical Service Connections

2.2.1 All Models - AC - Service

You will need a source of 117 VAC ± 10% 60 Hz. 1 Phase to power the RD-300/RD-232. The standard unit has

an 8' #18-3 AWG polarized line cord. This can be plugged into a standard duplex receptacle if the

RD-300/RD-232 is used in a dry area. If the environment around the RD-300/RD-232 is wet or dirty, use a “Bell

Box” or other gasketed receptacle or hard wire the AC directly to the RD-300/RD232. The cord grip furnished is

mounted in a hole suitable for 3/8" NPT fittings.

If you hard wire power to the RD-300/RD-232, you will use the three position connector marked TB-1(shown in

Figure 2-2). Connect the L1 (Black or Hot) wire to terminal #1, the right hand terminal nearest the fuse. Strip the

wire approximately 3/16". Use a small screw driver or ball point pin to press the white latch release. While

holding the lever down, insert the wire and release the lever. Pull on the wire to assure a good connection. You

must use #14 AWG or smaller wire. Strip an d insert the L2 (white or neutral) wire into TB1-3. Pull on the wi re to

assure a good connection. Strip and insert the ground (green) wire into TB1-2. Pull on the wire to assure a good

connection.

)PU-

(/%

-

'64&

AC Power

5#

$

Input

Figure 2-2. AC Power on Input TB1

To prevent injury or product damage, do not turn on the power yet. Wait until you have successfully worked

#AUTION

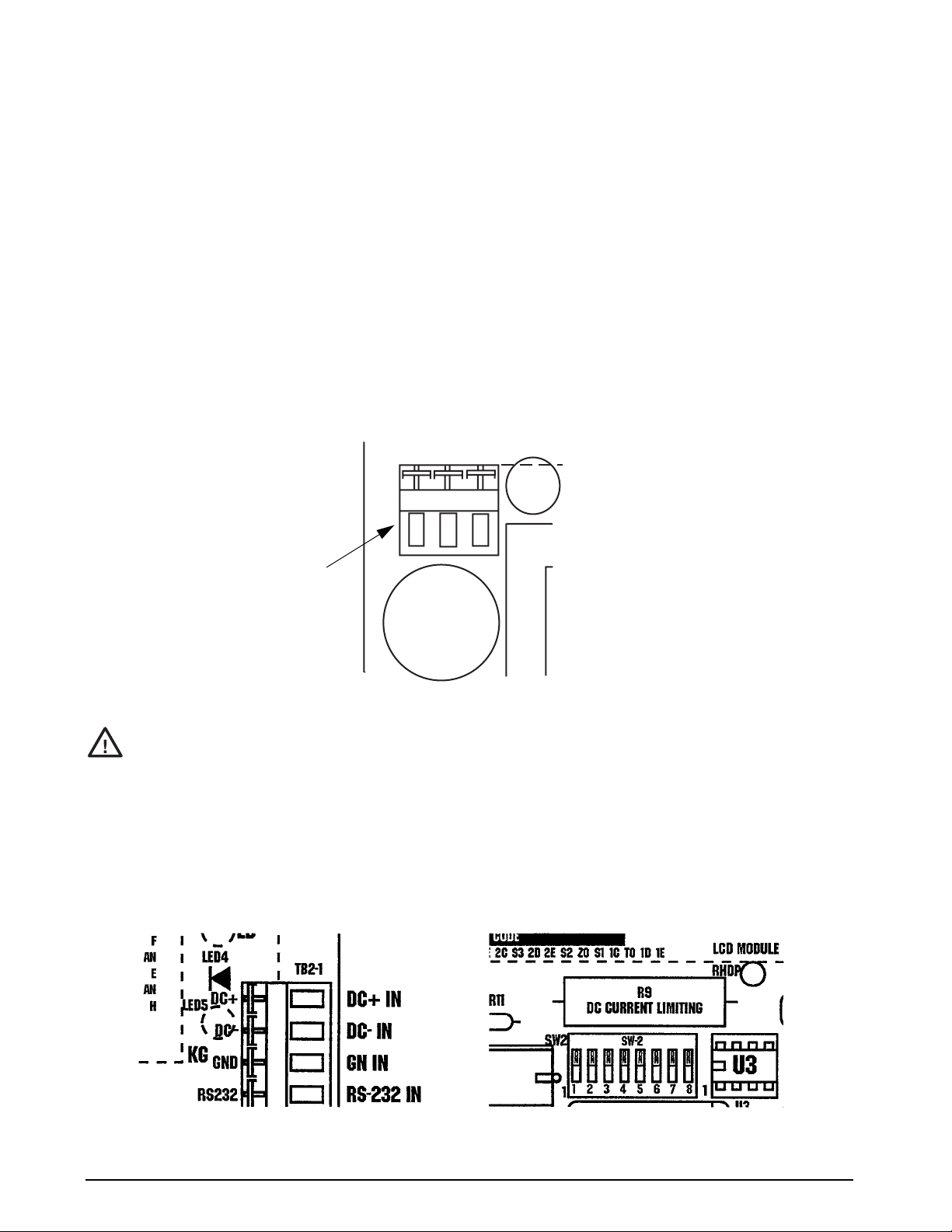

2.2.2 DC Models Voltages 6.2 - 18 VDC

The RD-300/RD-232 will also work on DC power. To use a DC power source between 10 and 18 VDC, connect

the + DC source to terminal TB2-1 and the DC- source to terminal TB2-2 as shown in Figure 2-3. The current

requirement is 30 mA without the backlight option and 160 mA with the LED backlight. If the unit has no

backlight installed, then it will work with voltages of 6.6-24 VDC without modification. If the optional backlight

is installed on the RD-300, the operating voltage range is 8.2 to 18 VDC without modification. Consult the

factory for other voltages.

through this manual and reached the section Powering Up the RD-300.

Figure 2-3. DC Voltage Setti ngs

4 RD-300/RD-232 Installation & Operation Manual

Page 7

2.3 Indicator Setup

Determine what indicator will supply the data to the RD-300/RD-232. Once determined, there are certain setup

parameters which you will need to know. Common indicators are discussed below.

• Rice Lake IQ series (600-700), IQ plus series (810 and 310*) - All of the IQ and IQ plus series indicators

work with the setup for continuous output and have the Consolidated Controls output. The IQ plus 810

set in the stream mode has the same format as the Condec indicators. The IQ plus 310 can match the

format of several indicators: CARDINAL 738, WI 120, AN 5316, the Toledo Hi-Speed output, and

Consolidated Controls (Condec). Match the baud rate you wish to use and program this into the

RD-300/RD-232. Baud rates from 300 to 19,200 are supported. If the meter you are using has a

selectable bit pattern, the preferred is 1 start bit, 8 data bits, and no parity. The RD-300/RD-232 will,

however, receive 7 data bit patterns of any parity as well.

• Condec, Rice Lake IQ plus 310* - All models in the Consolidated Controls line should be set up for

continuous output. Any baud rate from 300 to 38,400 is supported. Condec meters will work with either

the Universal or Condec setting.

• AND Instruments 4322,4321,4316, - These indicators can be set up for either “current loop” (passive) or

“RS232”, using the “stream mode” at 2400 baud, Format 1. The RS-232 can be used with either the

Universal receiver or the AND setting. The passive current loop input requires the current supply from

the current loop output.

• AND Instruments Model 5000 - This indicator can supply either RS-232 or 20 mA active current loop.

Configure port two to transmit continuously in the Condec format. Use the Condec setting for this meter.

• Weigh-Tronix 110 and 120 meters - with continuous data outputs - These indicators can be set up for

either “current loop” or “RS232”, in the continuous mode. Baud rates from 300 - 38,400 are supported.

Both new and old data formats are supported.

Note: a special EPROM may be required from Weigh-tronix for the required continuous serial output. Use the Universal mode or

the Weigh-tronix setting with these indicators. Switch 7 can be used to control unwanted time out if very slow update rates are

chosen.

• Weigh-Tronix Models WI-125 - Connect the RS-232 signals (TB2-1 is ground and TB2-2 is transmit

data) to the RD-300/RD-232. Set the Serial String to Auto = ON and Broad = ON. Layout - 1=Display,

2=ASCII -13-10-3-End, End. Set the baud rate to match the baud rate selected in the meter.

• Weigh-Tronix Models WI-130 - There are two ports, one and two. Port one uses either RS-232 or

RS-485. Port two uses either 20 mA current loop or RS-232. Select one of the two ports. Set

handshaking to off. You must program a BASIC program to get the meter to send the data continuously.

Use the following steps to set up a basic ticket string.

1. Program the string as:

<G OR N><SP><7 WEIGHT BYTES><SP><LB OR KG><SP><CR><LF>

2. Use the sample program given below:

Under system setupSet Timer (2,0.5); set timer 2 to 0.5 seconds

SUB SYSTEM Timer2

If

Actvalue=0 then

GN$="G"

VAL$=GROSS

S

else

GN$="N"

SVAL$=

NET

end if

IF UNIT=0 then

LK$="LB"

else

Installation 5

Page 8

LK$="KG"

end if

DO L

F KEN(SVAL$)<7 then

I

SVAL$= " " +SVAL$

else

exit

DO

end if

LOOP

DISPSTR$ =GN$ + CHR$(32) + SVAL$ + CHR$(32) + LK$ + CHR$(32) + CHR$(13) + CHR$(10)

PRINT #1 DISPSTR$;PRINT TO PORT #1 (#2 FOR PORT 2)

• Toledo Indicators (with high speed data format) - Most Toledo indicators support this format. Older

indicators can only be set up as “current loop” (active) at 4800 baud. RS-232 and 20 mA current loops

are supported. Baud rates of 300 - 19,200 may be used. Use the Toledo receiver for these meters.

• Flex-Weigh DWM-4 - This indicator can be set up for either “current loop” (active or passive) or

“RS232”, using “MODE 1 - Status, Weight, Tare Data”. Baud rates of 300 - 19,200 may be used. Set the

data preamble to “

FF, FF, FF” and the posta mble to “FF, FF, FF”. The LB/KG units display does not

function with this meter. Use the Flex-Weigh receiver for this meter.

• Analogic AN5315, AN5316, AN5322, Rice Lake IQ plus 310* - These indicators can be set up for

“current loop” in the continuous mode. Do not use “RS-232.” Baud rates of 300 - 19,200 can be used.

This meter supports the grams and tons display mode. Use the Analogic receiver mode for these meters.

• Masstron M2500, M5000, Toledo meters with this output (814X) - These indicators are set up for 4800

baud via the continuous remote display output normally used with Masstron accessories. This meter

supports the grams and tons mode. Use the Masstron receiver for these meters.

• Fairbanks 90-164 - This indicator is set up for 1200 baud “current loop” via Port “C”. Enable the

Lampbank output in the continuous mode. Other Fairbanks meters such as the 90-167 will work with the

RD-300/RD-232 if they have continuous data outputs. Use the Fairbanks receiver for these meters.

• Streeter Amet 9000 - This indicator is set up for “current loop”. The baud rate can be 1200, 2400, or

4800. Do not use 9600 baud! Program the output for Gross/Net Weight as 01/10/00 or in the print

program for 03/10/00. Use the Universal receiver for this meter.

• Cardinal 738 and 748, Rice Lake IQ plus 310* - These indicators can be set up for either the “current

loop” or “RS232”, using the “computer” setting (S3=10001010). The baud rate can be 1200, 2400, 4800,

or 9600. This meter supports the tons display annunciator. Use the Cardinal interface for these meters.

• Doran Indicators and Scales - Models 4100 and 4200 are supported. Use either port one or two in either

RS-232 or 20 mA current loop mode. Set the selected output port for continuous data and print format

#11.

Note: The RD-300/RD-232 does not support the lbs and ounces mode!

• GSE 450/550 - Models 450 and 550 are supported. A sample program and port configuration is shown

below:

RS-232

Printer Port - RS-232 or current loop

COM port - RS-232 with no handshake

Set number of characters transmitted per number to 8 <

P208.08>

6 RD-300/RD-232 Installation & Operation Manual

Page 9

Example:

P210.02 - Sets custom transmit 1 to continuous

P211.01 - Sets custom transmit 1 to send through the printer port

Send a custom transmit. Set for continuous transmission mode and the port selected.

Set up custom transmit 1:

1000ASCII - 02

1001DISPLAY DATA - 98

1002STATUS DATA - 97

1003ASCII - 03

The serial data is as follows:

<02><8 WEIGHT BYTES><SP><LB OR KG><SP><GROSS OR NET SP SP><STAT><SP><M OR O OR SP><03>

• Sartorius Balances with RS-232 data output - RS-232 is supported. Set for space parity, 1 stop bit, auto

output print without stability, no ID code, and software handshake. The output data must use the 16

character format.

• Hardy 2151 - Configure the standard serial port for RS-232. You must hardware jumper the RTS to the

CTS pins even if the software handshake is enabled. Select the baud rate and eight data bits with no

parity. To send the gross weight continuously, program

send the net weight continuously, program -

N - - - - into the output parameter value.

G - - - - - into the output parameter value. To

• Universal Data Receiver - This receiver can receive serial data in a wide variety of intuitive formats. It

can be used in either RS-232 or current loop. Use when all else fails. This receiver keys on carriage

returns (CR), end of text (ETX), or end of transmission (EOT) characters in the data string. The receiver

looks for G, g, N, n, K, k, L, l, (-) characters and reconstructs the data string from this information.

When the RD-300/RD-232 senses that the universal receiver has been selected, use switch SW2-6 to tell

the unit if the serial string contains a kilogram sign as a K or a KG. The universal receiver always looks

at the data string from back to front. This keeps the receiver from confusing the “g” in kg with a g for

gross mode. If the string uses a single character for kilograms, SW2-6 should be OFF.

• Other Indicators... Many indicators have programmable serial outputs and can be programmed to work

with the RD-300/RD-232, if , and only if, the output formatting exactly matches what the display has

been programmed to accept. If a computer or terminal is going to be used with an RD-300/RD-232, the

universal format is probably the easiest to use if the data is sent continuously. Several other meters have

been interfaced for use with the RD-300/RD-232. Consult the factory for special application needs.

• Choices- Some meters have multiple outputs. Some can have two or more RS-232 outputs or current

loop outputs which can be active or passive. The preferred interface is an active current loop from the

meter. RS-232 is always the least desirable because the ground planes of the two devices must be tied

together. The output data must be continuous. Demand ports are mostly unusable unless the meter uses

the universal, Condec, Fairbanks, or Cardinal formats. If a demand format must be used or the display

must show the last data transmitted, SW2-4 can be used to disable display timeout. Turn SW2-4 ON to

disable display timeout.

*IQ plus 310 has multiple data formats and can be used with multiple receivers

Installation 7

Page 10

2.4 Serial Data Inputs

The RD-300/RD-232 can accept serial ASCII data sent in RS-232C, or 20 mA active or passive current loop

formats. T o select an RS-232 input signal, Set SW2-8 OFF. To use any current loop signal, set SW2-8 ON. See

Figure 2-4. These formats determine the electrical way that data is transmitted. This has nothing to do with what

data is sent.

37

0''

Figure 2-4. Switch Setting SW-2

The RD-300/RD-232 can read the data transmission strings sent by 15 of the more popular scale indicator

families. It cannot read data from meters not included in this list unless you use universal mode or the formatting

exactly matches one on the list (or you have a custom program). Set up the RD-300 on the bench with the meter

you intend to use before taking it to the installation site.

#AUTION

ground. When the RD-300 or RD-232 Remote Displays are connected to such an indicator sending RS-232, half of the power

supply is being shorted to chassis ground via the offending RS-232 signal ground connection. The result is extreme heat in the

transformer and premature failure.

With Analogic indicators and other products combining RS-232 signal ground and chassis ground, do not use RS-232 output.

Set both the indicator output and the remote display input to 20 mA current loop instead.

Check your indicator’s electrical schematics—or feel for extreme heat at the RD-300/RD-232 transformer—to determine if your

indicator has a combined RS-232 signal and chassis ground. If so, use 20 mA current loop.

2.4.1 RS-232 C - SW2-8 Off

Some indicators are built with their RS-232 serial port signal ground combined with the general chassis

Data is transmitted as a voltage and alternates between

+10 VDC and -11 VDC. Hybrid “RS-232” signals

can swing between other voltage ranges as long as the

positive swing is greater than 4 VDC and the negative

is less than -1VDC. RS-232 is ground referenced and

therefore, connects the ground planes of the sending

and receiving instruments. RS-232 should never be

run more than 50'. It may work, but it may not work

well all the time. Long RS-232 data cables can act as

a conduit for lightning or other electrical noise to the

instrument. If you need longer cable runs, use a 20

mA current loop. If this is not available on your

indicator, consider an optically isolated protocol

convertor to change the RS-232 to 20 mA loop and

'.$

23

).

/54

4"

$#

$#

#,

#,

#,

#,

optically isolate the ground planes of the two

instruments.

Figure 2-5. RS-232 Wiring Assignment

Connect RS-232 wiring as shown in Figure 2-5

(RS-232, GND). Strip the wires approximately 3/16".

Press on the white lever to open the connector. Insert

the wire and release the lever. Test th e tightness by

gently pulling on the wires. Tighten the strain relief

fitting around the RS-232 cable with a wrench or

pliers.

8 RD-300/RD-232 Installation & Operation Manual

Page 11

2.4.2 20 mA Active Current Loop - SW2-8 On

In this mode data is transmitted as a current and is

passed through an optical isolator. This current

causes an LED to emit light onto a phototransistor,

which converts this light into a TTL signal. Current

transmission can be made over long distances and is

quite immune to transient surges or RFI/EMI noise.

The distance a current loop can transmit is limited by

the voltage source available to the current loop and the

speed of transmission which data is sent. The

maximum baud rate is set by the quality of the

indicator transmitter. The RD-300/RD-232 can

receive data at baud rates of up to 38,400.

An active current loop means that the instrument

which sends the data also supplies the voltage to

power the loop. This voltage can be as small as 3.5

VDC to as much as 24 VDC. When the loop goes

through an optocoupler, a “drop” occurs. This drop is

about 2 VDC. A current loop can power as many

drops as there is voltage to power the loop. For

example, if a current loop is powered by 5 VDC, it can

normally drive two “drops”. If the same loop were

powered by 24 VDC, it could power about 11 remote

displays or other devices. Determine that your

indicator has an active current loop and connect it as

shown in figure 6. Strip the incoming wires

approximately 3/16". Press on the white lever to open

the connector. Insert the wire and release the lever.

Test the tightness by gently pulling on the wires.

Tighten the strain relief fitting around the serial data

cable with a wrench or pliers.

The 20 mA receiver in the RD-300/RD-232 is an

HP-4200 high speed current loop receiver. The photo

coupler and requires current swings of less than 4 mA

as a mark and greater than 12 mA for a space. The

output of both the RS-232 and the current loop is sent

through an LED on the circuit board. See Figure 2-6.

This LED will be OFF when nothing is connected to

the board, and will flash when serial data is being

received. Please note that when the LED flashes, it

means that something is being received that looks like

a serial signal. It does not guarantee that the signal is

correct.

Figure 2-6. LED Location

2.4.3 20 mA Passive Current Loop - SW2-8 On

A passive current loops means that the instrument

which sends the data does not supply the voltage

source to power the loop. The voltage must come

from the RD-300/RD-232. To use a passive current

loop, wire the unit in the following way.

1. Jumper TB2-3 to TB2-6 (Gnd to CL- IN).

2. Connect the CL+ from the meter to the CL+

Output (TB2-7) and the CL- Output to TB2-5

(CL+ IN).

3. Strip the incoming wires approximately

3/16".

4. Press on the white lever to open the

connector.

5. Insert the wire and release the lever.

6. Test the tightness by gently pulling on the

wires.

7. Tighten the strain relief fitting around the

serial data cable with a wrench or pliers.

Note: Using this configuration changes the current loop

output to a passive transmitter!

Installation 9

Page 12

2.4.4 Configuring the RD-300/RD-232

The RD-300/RD-232 must be properly configured. To do this, you must know:

• Which indicator?

• What Baud Rate?

• How does the display handle a loss of signal?

• Are you going to use the universal mode?

• Do you want to retransmit data in Condec format or in the format it was received?

Once this information is known, it is entered through SW1 and SW2, DIP switches on the CPU board. (See

Figure 2-7, and table below).

Figure 2-7. DIP Switch Settings

Meter Number Receiver SW1-1 SW1-2 SW1-3 SW1-4

0 Universal On On On On

1 IQ plus, Condec On On On Off

2Toledo OnOnOffOn

3 Flex-Weigh On On Off Off

4 Analogic On Off On On

5 Fairbanks On Off On Off

6Cardinal On Off Off On

7 Masstron On Off Off Off

8AND OffOnOnOn

9 Weigh-tronix Off On On Off

10 Spare Off On Off On

11 Doran Off On Off Off

12 Sartorious Off Off On On

13 GSE Off Off On Off

14 Hardy Off Off Off On

15 Spare Off Off Off Off

Table 2-1. DIP Switch Settings

10 RD-300/RD-232 Installation & Operation Manual

Page 13

Enter the baud rate from the table listed below.

Baud Rate SW2-1 SW2-2 SW2-3

38,400 On On On

19,200 Off On On

9,600 On Off On

4800 Off Off On

2400 On On Off

1200 Off On Off

600 On Off Off

300 Off Off Off

Table 2-2. Baud Rate Settings

Select the interface type, RS-232 or 20 mA with SW2-8.

Input Type SW2-8

20 mA CL On

RS-232 Off

Table 2-3. Interface Type

Note:

IF YOU ARE USING TOLEDO, MASSTRON, FLEX-WEIGH, OR ANALOGIC (or IQ plus 310 IN ANALOGIC MODE) METER

SETTINGS, USE THE FOLLOWING SWITCH DATA

Toledo, Flex-Weigh, Analogic, and Masstron meters all transmit data continuously. They also have special

information available in their formatting which allow the RD-300/RD-232 to perform additonal useful

functions. With these meters, the timeout function is always enabled. SW2-4,5,6 and 7 have the following

meanings:

Retransmit Data Format SW2-4

Condec data format On

As received Off

Table 2-4. SW2-4 Data Format Settings

Display on Time Out SW2-5

“No sig” On

Last data received Off

Table 2-5. SW2-5 Time Out Settings

Displayed Weight Mode SW2-6 SW2-7

Current displayed weight On On

Gross weight only Off On

Net weight only On Off

Tare weight only Off Off

Table 2-6. SW2-6/7 Displayed Weight Settings

The RD-300/RD-232 will display the data selected by SW2-6 and 7 regardless what is showing on the scale

indicator.

IF YOU ARE USING ANY OTHER METER SETTING, USE THE FOLLOWING SWITCH DATA ON PAGE 12.

Installation 11

Page 14

Other meters may transmit data intermittently, slowly, or in a demand mode where the data is only sent once.

Enabling the time out function causes the RD-300/RD-232 to do the following. If new data hasn't been received

for approximately two seconds, then the display shows what is selected by SW2-5, either the last valid weight or

all dashes. If no valid data is received after ten seconds, the RD-300/RD-232 initiates a power on reset, clear all

data, read the switches, and waits for new data. For these meters SW2-4,5,6 and 7 have the following meanings:

Time Out Enable SW2-7

Time out counter disabled (cn dis) Off

Time out counter enabled (cn ena) On

Table 2-7. SW2-7 Time Out Enabled Setting

Display on Time Out SW2-5

“No sig” On

Last data received Off

Table 2-8. SW2-5 Time Out Settings

Universal KG Character Type SW2-6

A single character is sent, K, k Off

KG, Kg, or kg is sent On

Table 2-9. SW2-6 Character Type Settings

Retransmit Data Format SW2-4

Condec data format (rd con) On

As received (rd rec) Off

Table 2-10. SW2-4 Data Format Settings

12 RD-300/RD-232 Installation & Operation Manual

Page 15

2.5 Powering up With the RD-300/RD-232

Make sure all wiring is per the manual and is properly terminated.

APPLY POWER-

The RD-300/RD-232 enters the power on clear mode. All status switches are read at this time and the unit is

configured for baud rate, indicator type, and input signal type. The RD-300/RD-232 display goes through a

power up sequence which provides valuable information about the operating condition and setup.

LAMP TEST-

The first display during power on clear is a lamp test. This test lights all display segments and decimal points.

If the display is too bright, adjust the multi-turn pots located on the RD-232 CPU board (see below). The RD-232

42)-!$*

$2)6%2 $2)6%2

42)-!$*

Trim adjust pots

by using a small

screwdriver to

turn.

,%$"!#+,)'(4

'.$

,

4"

,

()'(6/,4!'%

$)30,!9-/$5,%

,%$

-)#2/02/#%33/2

37

0''

37

0''

23

).

/54

'.$

4"

$#

$#

#,

#,

#,

#,

Figure 2-8. RD-232 Trim Adjusting Pot Location

remote display has two, 20K - 10 turn pots to adjust the intensity of the LED displays. The pots are located on the

backside or component side of the display board located to the top outside of the circuit board. The pot to the

right side adjusts the intensity of the three displays on the right side of the display board. The pot on the left side

adjusts the intensity of the three displays on the left side of the display board.

Note: If the display intensity is adjusted to high, it will cause the micro’s voltage and current to drop causing the remote to

continually cycle it’s power-up sequence. To correct this, turn the pots counter clockwise about half the adjustment or five turns.

Repeat this adjustment on both pots to balance the display intensity.

PRODUCT SOFTWARE ID-

The unit should show rd 300.

SOFTWARE REVISION NUMBER-

Next the software revision number, rev 2.1 is displayed.

CURRENT BAUD RATE SETTING-

The RD-300/RD-232 next shows the current baud rate setting it has read from switch SW1. The display will

baud 3, for 300 baud, baud 6, for 600 baud, baud12, for 1200 baud, baud24 , for 2400 baud, baud48, for 4800

show

baud, or

baud96, for 9600 baud, baud19, for 19,200 baud, or baud38, for 38,400 baud.

INDICATOR TYPE-

The RD-300/RD-232 will show the indicator type you have chosen through SW1. This is displayed as Ind 0

through Ind 15.

INDICATOR INTERFACE TYPE -

The RD-300/RD-232 shows either, C loop or rs 232.

DISPLAY ON LOSS OF SIGNAL -

The RD-300/RD-232 shows either, no sig for no signal, or las da for the last valid data received.

Installation 13

Page 16

RETRANSMIT DATA TYPE -

The RD-300/RD-232 next shows the data format of the retransmission. rE-rec means the data is transmitted as it

was received.

rE-Con means that the data will be converted and retransmitted in Consolidated Controls

continuous data format.

TIME OUT ENABLE -

The RD-300/RD-232 will show, cn ena if the time out counter is enabled, and cn dis if the time out counter is

disabled.

RECEIVING THE DATA FOR THE FIRST TIME-

After the power up sequence, the RD-300/RD-232 synchronizes with the incom ing serial data lin e and looks for

data to receive. If no readable data is received within a few seconds, the display shows

nosig.

When communication is established, the current weight value is displayed. Decimal points are inserted into the

display as indicated by the meter. If the data format from the meter makes LB, kg, Gross or Net status available,

the RD-300/RD-232 displays this information with the appropriate status segments. Some formats do not make

this data available. In this case, the segments are not illuminated.

If you have trouble, remember, you must have continuous data coming from the meter. The most common

problems are non-standard indicator serial outputs, mis-wiring, and mis-programming both in the meter and in

the RD-300/RD-232 setup. Check the LED and see if it is flashing. If it is, then something is being received.

NOTE: This doesn't mean that the format is correct, only that data is appearing at the receiver.

When the display is operating properly, the job is only partially done. Any good installation isn’t finished until

the enclosure mounting is checked and tightened, all conduit and cable entries are wrench tight, and the enclosure

screws have been tightened with a socket or screwdriver.

If the RD-300/RD-232 is located in a wet, damp, or cold environment, it is suggested to use a silica gel desiccant

or better yet, an antioxidant “snowball” made by Hoffman Enclosure Company. These products in the enclosure

will greatly increase product reliability and performance. Change any desiccant at least two times per year.

14 RD-300/RD-232 Installation & Operation Manual

Page 17

3.0 Mounting Procedure for Panel Mount RD-300/232

*OOFS4UBOEPGGT"UUBDI

$JSDVJU#PBSEUP'BDFQMBUF

$JSDVJU#PBSE

0VUFS5ISFBEFE4UVE)PMET

'BDFQMBUFPOUP$VTUPNFST1BOFM

$VTUPNFST

1BOFM

1BOFM.PVOU

'BDFQMBUF

Use the following procedure if panel mounting the RD-300/232. A template for measuring is shown on page 17.

1. Choose a desired location for mounting the RD-300/232. Make sure there are no AC wires or other

obstructions behind the area to be cut out.

2. Use the enclosed template to mark the panel holes. Note that all holes are measured center to center.

3. Transfer the holes onto the desired panel. Start from one side and make all other measurements starting

from that side. Using this method reduces errors. Try to mark the center of the holes. Drill the four

OUTER holes with a #.228 or 15/64" drill bit.

4. Drill the INNER four holes with a #.156 or 5/32" drill bit.

5. When the holes have been drilled and checked for accuracy, cut the hole for the display as shown on the

template. Make the edges as smooth as possible because the front plate must lay flush on top of it.

6. Detach the circuit boa rd from the front plate and remove the nut and lockwashers from the mounting

screws. Place the front plate on the panel from the front and push the mounting screws and studs through

the holes as shown in Figure 3-1.

7. Check from the front to make sure the edges of the cutout do not show through the window and that the

8. Proceed with wiring instructions per manual instructions.

Figure 3-1. Mounting Procedure for Panel Mount

Have someone hold it or secure it with removable tape while putting the lockwashers and nuts back on

the mounting screws and tighten.

Note: you will find that the mounting studs 8-32 x 3/4", have nuts and lockwashers included. If you lose

one, they can be replaced at most local hardware stores.

front plate is lying flat against your panel. Remount the circuit board with the original screw and plastic

washers.

Mounting Procedure for Panel Mount RD-300/232 15

Page 18

16 RD-300/RD-232 Installation & Operation Manual

Page 19

Mounting Procedure for Panel Mount RD-300/232 17

Page 20

18 RD-300/RD-232 Installation & Operation Manual

Page 21

4.0 Appendix

4.1 RD-300 Replacement Parts

The following table list the replacement parts for the RD-300 remote display.

Part Number Description Quantity

32724

32725

32723 Microprocessor, RD-300/MPU revision 2.1 1

16348 IC, 20 mA receiver HP-4200 1

22586 Display driver MC145453 2

22588 Fuse, .25A slo-blo PCB 2

22546 Overlay, front panel, RD-300 1

Board, display/CPU RD-300 R2N 1

Board, display/CPU RD-300 R2B 1

Table 4-1. RD-300 Replacement Parts List

4.2 RD-232 Replacement Parts

The following table list the replacement parts for the RD-232.

Part Number Description Quantity

" LCD serial

" LCD w/ backlight serial

1

1

32726

32723 Microprocessor, RD-232/MPU revision 2.1 1

16348 IC, 20 mA receiver HP-4200 1

16234 Display driver MC145453 2

22588 Fuse, .25A slo-blo PCB 2

Board, display/CPU RD-232 R2N 0.8" LED serial

Table 4-2. RD-232 Replacement Parts List

1

Appendix 19

Page 22

RD-300/RD-232 Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by

the Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects in

materials and workmanship for one year.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized

by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment

fails to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to

prevent electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a

publication, Protecting Your Components From Static Damage in Shipment, available from RLWS

Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was

not caused by accident, misuse, neglect, alteration, improper installation, improper repair or

improper testing; RLWS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other than RLWS or its

duly authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible

for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

T

HESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION

RLWS NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS

REPAIR

OTHER CLAIMS TO WARRANTY.

ALL

S

HOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE SELLER FOR

WARRANTY

N

O TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORT IN G TO MODIFY THE TERMS OF THIS

WARRANTY

OFFICER

WARRA NTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER

AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY H EREUNDER IS LIMITED TO

OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND

CLAIMS.

SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN WRITING AND SIGNED BY A CORPORATE

OF RLWS AND THE BUYER.

© 2005 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

20 RD-300/RD-232 Installation & Operation Manual

Loading...

Loading...