Page 1

M- Class

Operator’s Manual

Page 2

Copyright Information:

CG Trium virate is a trademar k of Agfa Corporation.

CG Times based upon Times New Roman under license from the Monotype Corporation.

Wi ndows i s a r egistered trademar k of t he Microsoft Corporation.

All other brand and product names are trademarks, service marks, r egistered trademar ks, or r egistered service marks of t heir

respective companies.

Firmware (Software) Agreement

The enclosed Firmware (Software) resident in the Printer is owned by Licensor or its suppliers and i s l icensed for used only on a

single printer in the user’s Trade or Business. The User agrees not to, and not t o aut hor ize or permit any other per son or par t y

to, duplicat e or copy the Fir mware or the infor mation contai ned i n t he non-volatile or progr ammabl e memory. The firmware

(Software) is protected by applicable copyright laws and Licensor retains all r i ght s not expressly granted. In no event will Licensor or

its suppliers be liabl e for any damages or loss, includi ng direct, incidental, econom i c, special, or consequential damages, arising out

of the use or inability to use the Firmware (Software).

Inform at ion in this document is subject to change without noti ce and does not represent a commitment on the part of Dat amax

Barcode Products Corporation. No part of this manual may be reproduced or transm i t ted in any form or by any means, for any

purpose other than the purchaser's personal use, without the expressed written permissi on of Dat amax Corporation.

All rights reserved. Printed in the United States of America.

© Copyright 2004 by Datam ax Corporation

Part Number: 88-2313- 01

Revision: C

Page 3

Agency Compliance and Appro vals:

C US

Listed

FCC: This device complies with FCC CFR 47 Part 15 Class A.

Note: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules . T h ese

UL60950 Information Technology Equipment

C22.2 No. 950-M93

EN60950

For 230 Volt Operation (Europe): Us e a cord set, marked "HAR," consisting of a

min H0 5 VV-F cor d which ha s a minimum 0.75 squ are mm diameter condu ct ors,

provided with an IEC 320 receptacle and a male plug for the country of

ins tallation rated 6A, 250V

Für 230 Volt (Europa): Benützen Sie ein Kabel, das mit "HAR" markiert ist,

bestehend mindestens aus einem H05VV-F Kabel, das mindestens 0,75

Quadratmillimeter Drahtdurchmesser hat; sowie eine IEC320 Steckdose und

ein en f ür das Land geeigneten Stecker , 6A, 250 Volt.

As an Energy Star Partner, the manufact urer has determined that this product

meets the Energy Star guidelines for energy efficiency.

The manu fa ct u r er decla r es u nder sol e responsibility that this product conforms to

the following standards or other normative documents:

EMC: EN 55022 (1993) Class B

EN 50024 (1998)

Safety: This product com p lies with the requirem e nts of EN 60950 /A11:1997

Gost-R

lim its ar e d esi gned to pr ovide reas onabl e pr otec ti on agai ns t har mf ul int erf er enc e when t he eq uip ment is oper ated i n a c ommer ci al envi ron ment .

This equipment generates, uses, and can radiate radio frequency energy, and if not installed and used in accordance with the instructions in this

manu al, it may cau se har mf ul in terf eren ce to r adio c ommu nic ations . O perat ion of thi s equi pment in a resi denti al area is likely to cause harmful

interference in which case the user will be required to correct the interference at his own e xpense.

Page 4

Important Safety Instructions

This p rinter has been caref ully designed to provide many years of safe, reliabl e p erforma nc e. As with all electr ic al

equipment, there a re a few b asic precautions you should ta ke t o avoid hurting yourself or damaging the printer:

• Ca refully r ead the inst allation and op erating instr uctions provided with you r printer.

• Read a nd f ollow all war ning instr u c tion lab els on the printer.

• Place the printer on a flat, firm, solid surface.

• To protect your printer from overheating, make sure all openings on the printer a re not bl oc ked.

• Do not place the printer on or nea r a heat source.

• Do not us e you r printer nea r wat er, or spill liqu id into it.

• Be certain that your power sour c e matches t he rat i ng listed on your pr inter. I f you are unsure, c heck with your dealer or

with your local power company.

• Do not place the power c ord where it will be walked on. If t he p ower c ord becomes damaged or fr ayed replace it

immediately.

• Do not insert a nything into the vent ilation s lots or openings on the printer .

• Only qualif ied, tr ained service t echnic i ans should attempt to repair your printer.

Page 5

Printer Overview

1.0 Introduction ........................................................................ 1

1.1 About this Printer................................................................ 2

1.1.1 Standard Features.....................................................2

1.1.2 Optional Features..................................................... 3

Getting Started

2.0 Before Using the Printer...................................................... 5

Setting Up the Printer

3.0 Introduction ........................................................................ 7

3.1 Connecting the Pr inter......................................................... 7

3.1.1 Power Connection .................................................... 7

3.1.2 Inter f ace Connection................................................. 8

3.2 Loading Media.................................................................... 9

3.3 Media Sensor Adjustment.................................................... 12

3.4 Loading Ribbon.................................................................. 13

3.4.1 Ribbon Routing........................................................ 15

Using the Front Panel (non-display printers)

4.0 Introduction ........................................................................ 17

4.01 DMXConfig.............................................................17

4.1 Lights ................................................................................18

4.2 Buttons............................................................................... 18

4.3 Normal Mode - Button Functions ........................................ 19

4.4 Express Setup Mode - Button Functions.............................. 20

4.5 Printer Setup Mode - Button Functions................................ 21

4.5.1 Printer Setup Menu List ........................................... 22

4.5.2 Menu Items and Values............................................ 23

4.5.3 Step by Step Modification of the Printer Setup..........26

4.6 Label Alignment.................................................................. 28

4.6.1 Label Alignment = YES ........................................... 28

4.6.2 Label Alignment = AUTO........................................ 29

4.6.3 Label Alignment = NO............................................. 29

4.6.4 Label Alignment Troubleshoot ing ............................. 30

i

Page 6

4.7 Calibration Mode – Button Functions.................................. 32

4.7.1 Auto Media Sensor Calibration................................. 33

4.7.2 Manual Media Sensor Calibration ............................ 34

4.8 Internal Labels.................................................................... 35

4.8.1 Database Configuration and Dot Check Labels......... 35

4.8.2 Test Label................................................................ 37

Using the Front Panel (display printers)

5.0 Introduction ........................................................................ 39

5.0.1 Ready Mode: Normal Operation............................... 39

5.02 Menu Mode: Configuration.......................................40

5.0.3 Quick Test Mode: Print Test Labels.......................... 41

5.0.4 Indicator Lights........................................................ 42

5.0.5 LCD ........................................................................ 42

5.1 The Menu System............................................................... 43

5.1.1 Entrance and Exit Prompts....................................... 43

5.1.2 Media Settings......................................................... 44

5.1.3 Print Control............................................................ 46

5.1.4 Printer Options......................................................... 47

5.1.5 System Settings........................................................ 49

5.1.6 Communications.......................................................56

5.1.7 Diagnostics .............................................................. 59

5.1.8 MCL Options........................................................... 60

5.2 Display Messages................................................................61

5.2.1 User Prompts a nd Condition M es sages ..................... 61

5.3 Quick Test Mode.................................................................63

5.3.1 Print Quality Label...................................................64

5.3.2 Configuration Label................................................. 65

5.3.3 Quick Ribbon Test Label..........................................66

5.3.4 Validation Label....................................................... 67

5.3.5 Print Last Label ....................................................... 67

5.3.6 User Defined Label................................................... 67

5.4 Media Sensor Calibration.................................................... 68

5.4.1 Quick Calibration..................................................... 68

5.4.2 Standard Calibration................................................ 69

5.4.3 Advanced Entry Calibration......................................72

ii

Page 7

Maintenance and Adjustments

6.0 Introduction ........................................................................ 79

6.1 Cleaning the Printhead.........................................................80

6.1.1 Automated Printhead Cleaning..................................80

6.2 Media Width Adjustment..................................................... 81

6.3 Printhead Burn Line Adjustment .......................................... 82

6.4 Printhead Pressure Adjustment............................................ 83

6.5 Printhead Replacement........................................................ 84

6.6 Darkness Adjustment...........................................................85

6.7 Resetting the Printer............................................................ 85

6.8 Downloading Firmware and Fonts....................................... 87

Troubleshooting

7.0 Problem Resolution ............................................................. 89

7.1 Fault and Warning Messages............................................... 92

7.2 Hex Dump Mode.................................................................96

Specifications ...........................................95

Appendix A

ASCII Control Code Chart.......................................................... 101

Appendix B

Embedded Fonts and Barcodes.................................................... 103

Appendix C

Optional Internal Ethernet Printer Server .................................... 115

iii

Page 8

Appendix D

Menu System Multi-Language Support ....................................... 141

Appendix E

Saving a Configuration File.........................................................147

Appendix F

GPIO Port Description................................................................ 149

Appendix G

Warranty Information ................................................................. 153

Glossary..................................................155

iv

Page 9

1.0 Introduction

Congr atul ations on your purchase of an M-C lass print er. The M-Cl ass family, hereaft er referred to as ‘the printer’, blends

the ru gged du rability of die-cast c onstr uction wit h sta te-of-t he-art electronics and user- f riendly features to redefine the

standard in indust rial thermal printer s. The print ers, available in direct and optional t hermal transf er configurat ions, use

unique front panel designs to simplify operation, while its USB, RS232 serial, IEEE 1284 compliant parallel, and an

optional internal printserver (M-4208 and M-4306 only) inter faces allow eas y c onnection to your host system.

This manual provides all the infor ma tion necessary to opera te the printer.

To print labels or tags simply refer to the instructions included with the software you have chosen to create the labels. A

Windows™ pri nter driver c an be found on our website (www. datamax c orp.com) or on the included CD- ROM . If you wish

to wr ite a cu stom progra m, a cop y of the Class Series Programmer’s Manual can also be found on the CD-ROM.

M-Class 1

Page 10

1.1 About this P rinter

This p rinter offers the following standard and op tional features:

1.1.1 Standard Features

Printing

Direct Ther ma l Print i ng

On Demand and Bat c h Printing

203 DPI (M-4206 and M-4208) 300 DPI (M-4306) Printhead

Date and Time Sta mp

AGFA Scalable Font Engine

2 Resi dent Scal eable fonts, CG Triumvirate™ r egu lar and bold-condens ed (M-4208 and M-4306 only)

Memory

2 MB FLASH Memory

(256K available to user, designated: Module B)

4 MB DRAM Memory (M-4206)

8 MB DRAM Memory (M-4208 and M-4306))

Interfaces

USB i nter face

DB-9 RS-232 serial interface

IEEE 1284 Centronics

Operational

Simple Media L oading

Media Tearbar

Fa n- f old media c ompatible f rom the bottom and rea r of printer

®

parallel inter f ace

2 M-Class

Page 11

1.1.2 Optional Features

Thermal Transfer

A printing method tha t uses ribbon to pr oduce exceptional image cla rity, as c ompared t o most direct therma l media

types. This option mu st be specified for use with either ‘coa ted side in’ r ibbon or ‘ c oated si de ou t’ ribbon.

Media Cutter

A rotary-type mechanism to automatically cut material with a maximum thickness of .010” (.254 mm) into minimum

lengths of 1 .25 inc hes (31.8 mm). Designed f or ease of opera tion, t he M edia Cutter is automatic ally detected,

configured, and enabled when installed on the printer.

Peel and Present Mechanism (requires the Internal Rewind option)

An outp ut contr ol device that automat ically sep ara tes pr inted labels f rom the backing mater ial and allows subsequent

print ing to occu r only af ter the r emoval of a previous ly printed lab el. Minimum label length is 1 .5 inches (38 mm).

Designed for ease of operation, the Peel and Present Mechanism is automatically detected, configured, and enabled

when installed on t he p rinter .

Internal Rewind

An internal mechanism to wind f ou r-inch ou ter dia meter rolls of print ed labels, or the la bel backing ma teria l when u sing

the Peel a n d Pr esent opti o n .

Present Sensor

An outp ut cont rol device tha t allows subsequent printing t o oc c u r only af ter t he removal of a previous ly print ed label.

Designed for ease of operat ion, the Present Sensor is automatic ally detected, configured, a nd enabled when installed on

the printer.

FLASH Memory Expansion (requires new main PCB)

An optiona l ma in PCB assembly is a vailable wit h 4 MB (M-4206) 8MB (M-4208 and M-4306)) Flash memory

expa nsion for I nterna tional Langua ge Print ing Cap ability (ILP C) and/or additiona l f onts a nd grap hic s.

ILPC

The Int ernational La nguage Print C apability consisting of one of the following:

CG-Times (western European) Scalable font

Kanji Gothic B Scalable font

Simplified Chinese GB Scalable font

Korean Hangul font

M-Class 3

Page 12

External Ethernet Connectivity (uses printer’s parallel port)

The DMX100 External Print Server is an external Network Interface Controller (NIC) that enables the printer to

®

provide E thernet

connectivit y.

Internal Ethernet Connectivity (printers with front display only)

The Internal Ethernet Print Server is an internal Network Interface Controller (NIC) that enables the printer to provide

®

Ethernet

connectivit y. Featur es inc lude:

Automatic selection of 10BaseT (Thinnet) or 100BaseT Fast Ethernet connection.

Integr al HTTP Ser ver to a llow monit oring a nd ma nagement fr om a sta ndard W eb brows er pr ogram.

FT P printing to allow printing dir ectly from a Web browser or other FTP client.

LPR/LPD over TCP/IP for UNIX platf orms a nd Micr osoft’ s Windows.

Raw sockets support over selectable TCP/IP port with filters for selected UNIX environment.

IP SNMP support of MIB-2, proprietary NIC MIB and public and proprietary (private) Printer MIB.

SNMP traps to alert administrators of printer errors (paper/ribbon out, head up, etc).

DHCP, BootP, and RARP services supported

MCL (printers with front display only)

A soft ware t ool suite designed for data collection applicat ions. Onc e ena bled, the p rinter c an acc ep t input dat a fr om

periphera l devic es such as barcode scanners, weigh s cales, and keyboards without the need of a host computer,

requesting and s ending data to locally resident looku p files or remote dat aba ses, enhancing communication cap abilit ies

within your system while reducing you r hardware investment.

4 M-Class

Page 13

2.0 Before Using the Printer

Removing the Packaging

Inspect the ship ping container(s ) for damage; if damage is evident not ify the shipping company to report t he nature and

extent of the dama ge.

The printer is carefully packaged t o avoid any damage dur i ng transit. In order to operat e t he p rinter you will need to remove

the packaging materials (i.e., tape and foam) that were placed in the printer for shipment. Complete the following steps prior

to connect ing power or attempting to load media.

Ensure that the arrow on the box is pointing up, and then open the box.

Remove the top piece of pa c king foam.

Lift the printer from the box.

Remove the printer from the plastic bag.

Remove any tape or additional pa c king f oam from the ins ide of the printer.

Note: It is a good idea to save all packaging mat eri al s in the event that shipping the printer is ever required.

M-Class 5

Page 14

Inspecting the Printer

After removing the printer from the pa c kaging material, check the cont ents. The following items s hould be included:

Printer

Power Cord

CD-ROM and Docu mentation

Any special or a dditionally p urchased items.

Additional Requirements

The following items are necessary for generating labels from your printer. Contact your customer support or sales

representa tive for advice on which media a nd software may b es t be su ited for you r applica tion.

Serial, USB or Pa rallel cable

Ether net cab le for opt ional LAN connectivity

Applica ble Media

Applica b le S of tware

6 M-Class

Page 15

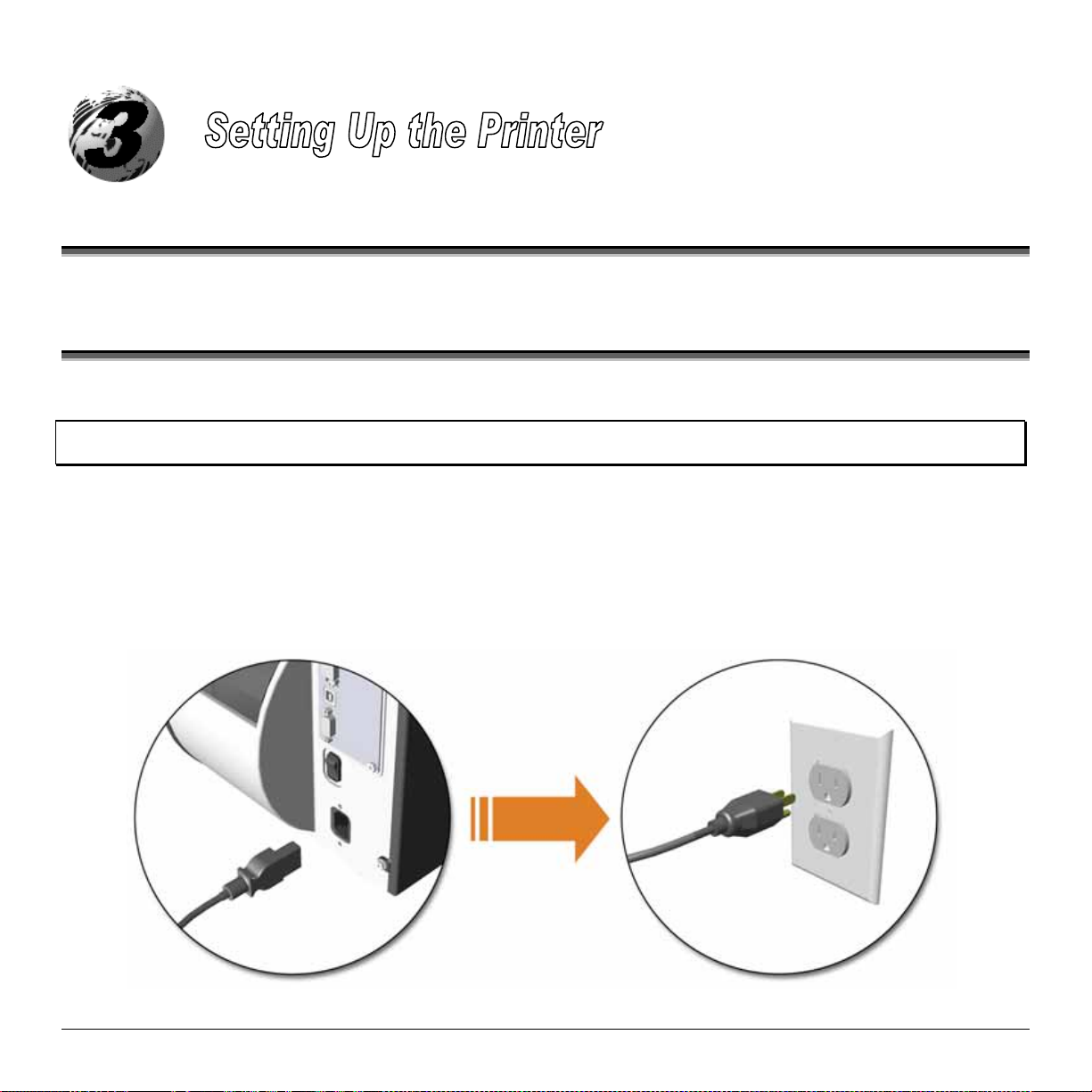

3.0 Introduction

This c hapter explains how to c onnect your printer, load media (and ribbon, if equip ped for t hermal trans f er).

3.1 Connecting the Printer

3.1.1 Power Connection

Note: When connecting the AC Power Cord or interface cables to the printer, ensure the Power On/Off Switch is in the ‘Off’

position.

1. P lace the printer on a fir m, level surface.

2. Ensure that the Power Switch on the Printer is in the ‘Off’ position.

3. Connect t he AC Power Cord to the rec ep tacle on the bac k of the Printer, a nd then plug the AC P ower Cord into a

properly grounded outlet. (The power supply automatically detects and then adjusts to the applied line voltage; see

Section 8.0 f or the a c c ep table voltage ranges. )

M-Class 7

Page 16

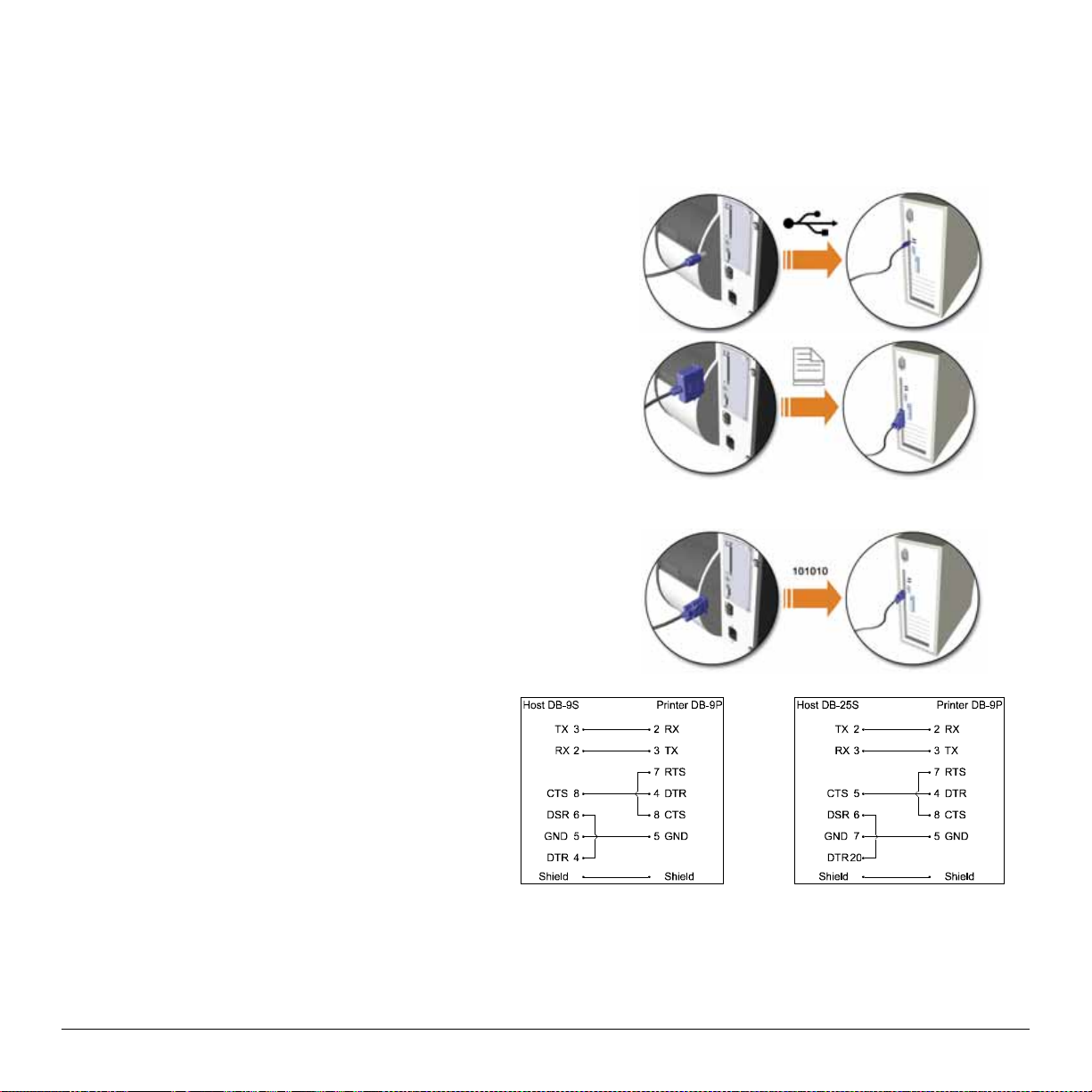

3.1.2 Interface Connection

The printer c an be connect ed to the host via a USB, s erial or pa rallel c able. The Pr inter will automati cally connect to the

first port (USB, serial or pa rallel) that transmits valid dat a. Af ter this connection has been made, the printer’s power must

be cycled ‘Off’ and ‘On’ to change the interface connection.

USB Connection:

The USB Interface is supported in Windows®95 and grea ter.

Depending up on the operating system of your host c omputer,

installat ion ma y dif fer slight ly.

Parallel Connection:

The parallel interface requires a Centronics® IEEE 1284 cable

with a 36 pin male connect or. Bi-direct ional mode is IEEE 1284

Compliant, using forward and reverse channel communications.

In this mode, data can be sent to the host provided it is also IEEE

1284 Compliant and has supporting software. Default is unidirectional, f or pr inters with front display, see C hapter 5.

Serial Connection:

The serial interface supports RS-232C

communicat i ons via a DB-9 connector. The

following list of serial por t sett ings is menuselecta ble and must match the host compu ter’s serial

port sett i ngs; see Chapter 4, f or non-disp lay printers

or C hapter 5 for display print ers.

• Baud Rate (Default 9600 bps)

• Word Length (Default 8 bits)

In addition to the port settings, the serial interface

cab le wiring must have specific connections (pinouts) for prop er dat a exchange between the host and

printer. The differ ent serial ca ble pin-outs a nd par t

numbers ar e in the following ta ble (contact you r

reseller for ordering information).

Optional Internal Ethernet Print Server:

(printers with front display only)

Part # 32-2483-01 Part # 32- 2301- 01

The printer is ava ilable with an optional Internal Ethernet Print Server. When using this connect ion please r ef er to

Appendix C or t he instructions inc l uded with the option for prop er setu p and configuration.

8 M-Class

Page 17

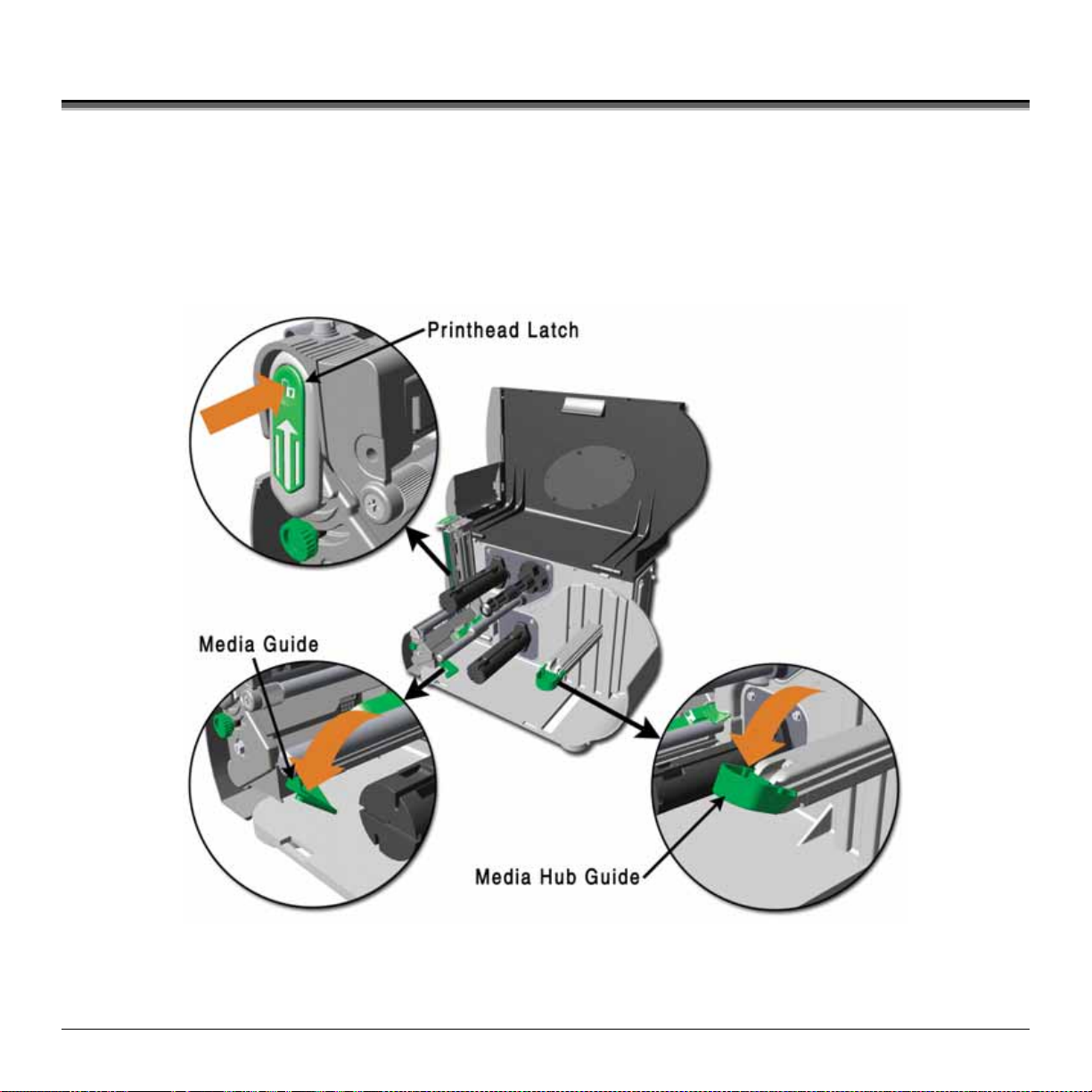

3.2 Loading Media

Load media int o the print er as f ollows :

1. Open the media cover and lower t he M edia Hub G uide and Media Guide.

2. P ress in on the Pr inthead Latch and raise the Printhea d Assembly.

M-Class 9

Page 18

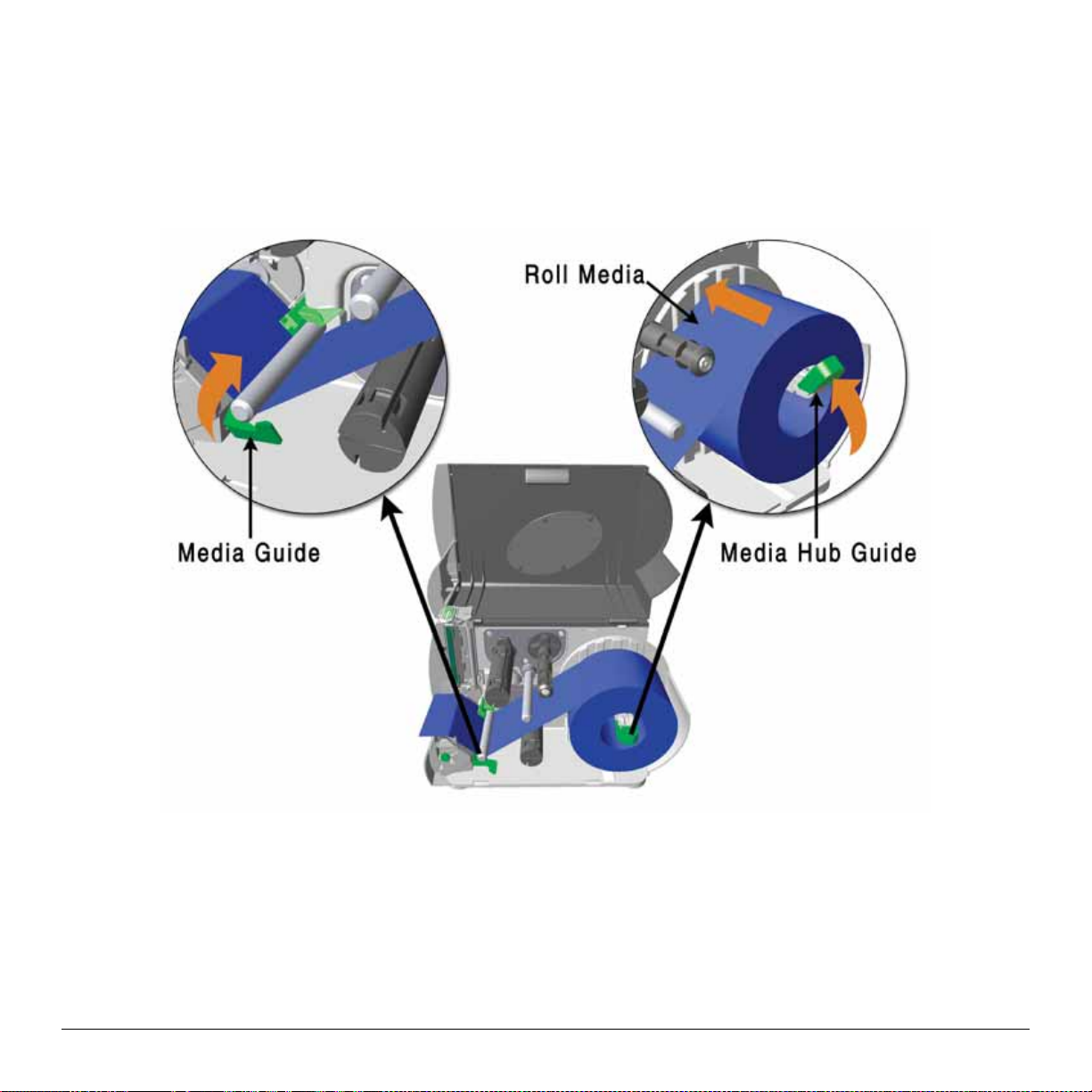

3. S lide the Roll Media onto the Media H ub and rais e the Media Hu b Guide. The Media H ub Gu ide s hou ld be pushed

inward so that it is ju st tou c hing the Roll Media.

4. R oute the Media thr ough the printer as s hown. Ra ise the Media Guide. The Media G uide should be p ushed inward so

that it is just t ouching the edge of the Media .

10 M-Class

Page 19

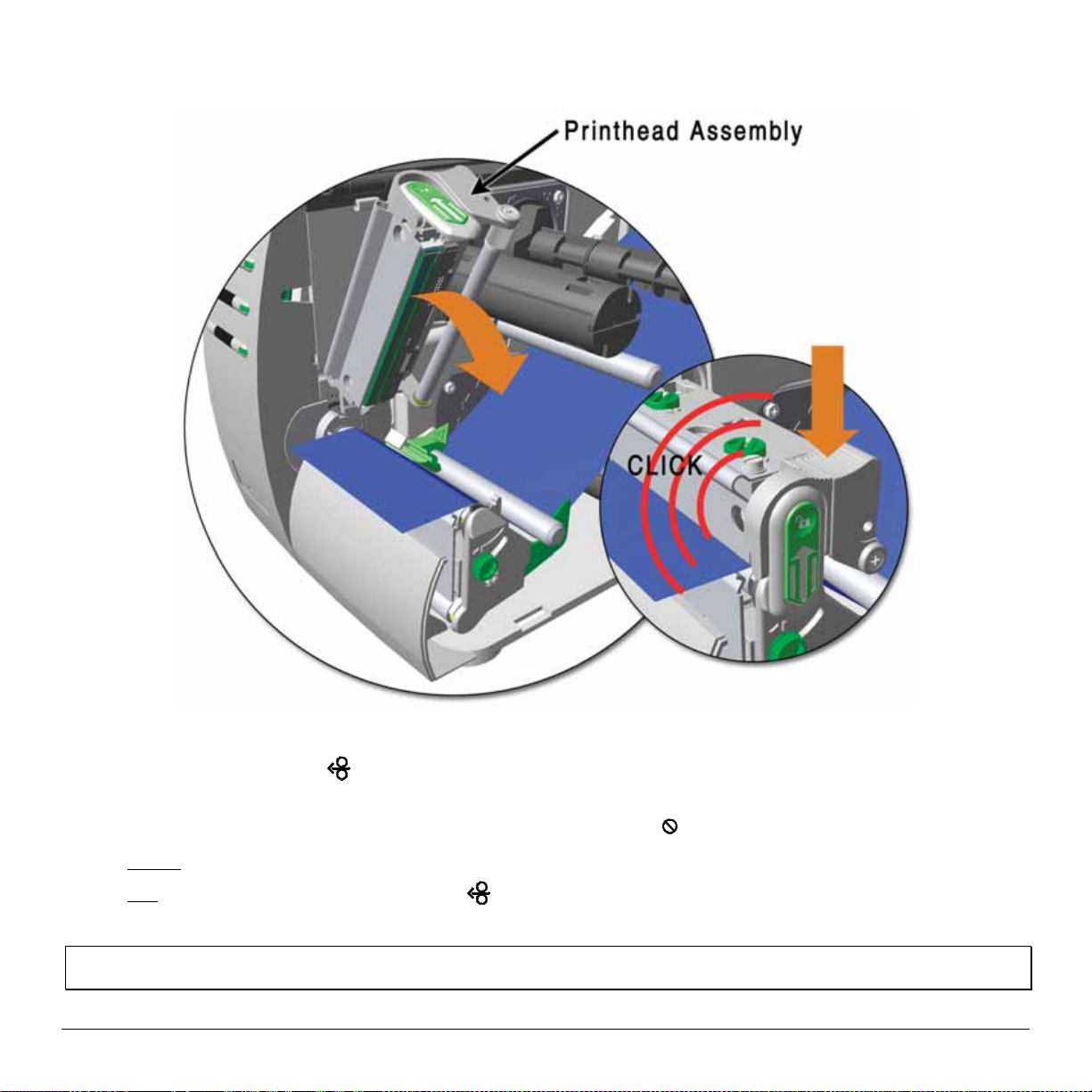

5. C lose the Printhead As sembly and press down until it locks into pla c e.

FEED

6. Close the cover and press the

If the p rinter does not correctly s ens e t he t op of each label, as denoted b y the

Printers without front display: Perf orm the Aut o Media Sensor C alibr ation, see sect ion 4.7.1.

Printers with front display: Pr es s and hold t he

but ton several times to position the media and ensure proper tracking.

ERROR

light, it may be necessary to:

FEED

but ton until at least one lab el gap or ma rk is advanced then

releas e. For additional calib rat i on procedures, see section 5.4

Note: The printer is fact or y set t o use 4-inch media (and ribbon, i f t hermal transfer equipped). When using a different width of

media/ribbon, please refer to section 6.2.

M-Class 11

Page 20

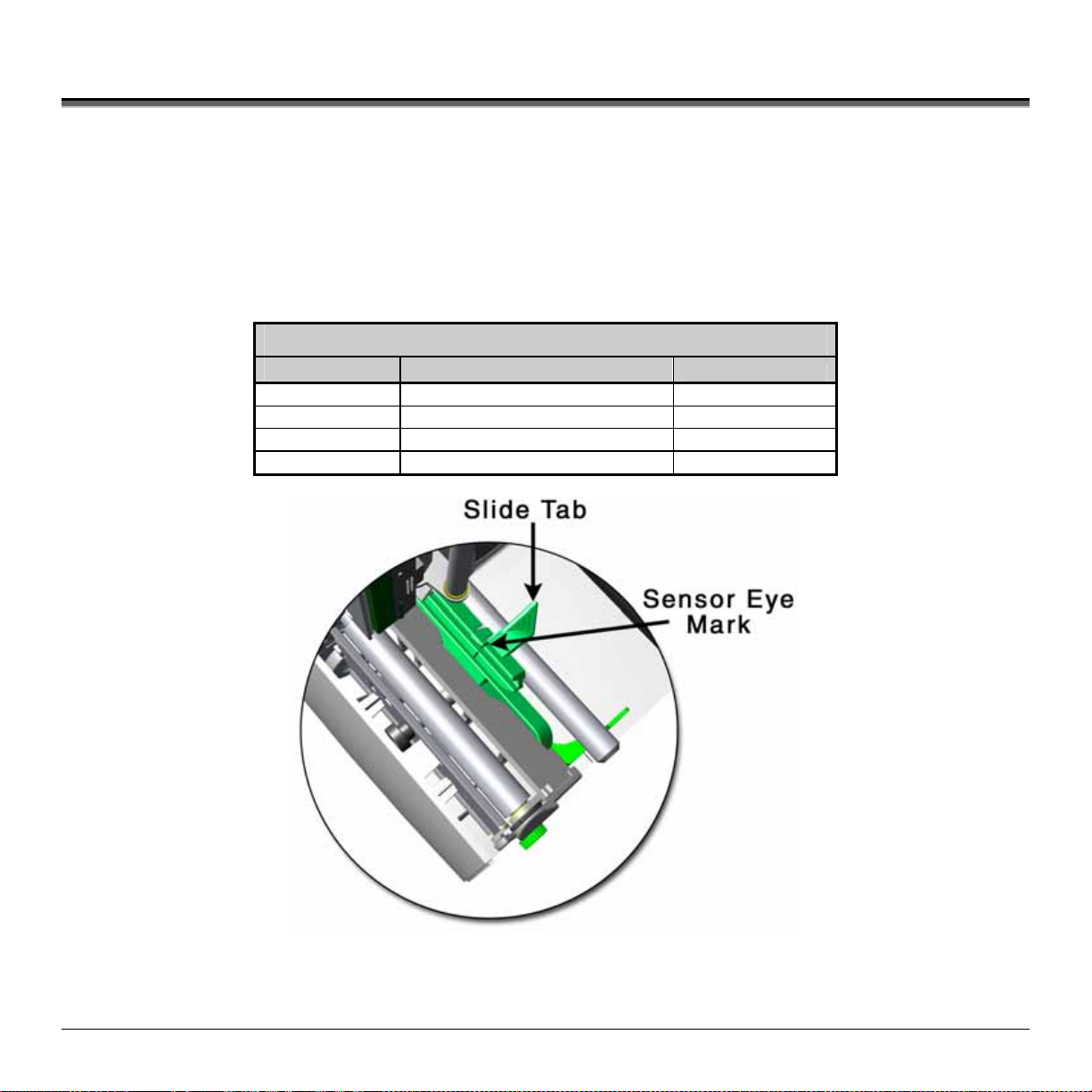

3.3 Medi a Sensor Adjustment

The Media Sensor needs to be positioned so that the printer can detect the presence of media and the top-of-form (except for

continuous stock, where the TO F is set throu gh the front panel.

To a dju s t:

With media loaded, as descr ibed in S ection 3. 2, gr as p t he Slide Ta b a nd move the Sens or E ye Mar k int o posit ion over

media according to the table below.

If loading media, ret urn to the media loading instruc tions.

Media Sensor Selection and Adjustment

Media Type

Die-cut Near the middle of the label Gap

Notched Centered over the notch Gap

Reflective Cent ered over the black mark Reflective

Continuous Near the middle of the media Continuous

Sensor Eye Mark Position

Sensing Required*

12 M-Class

Page 21

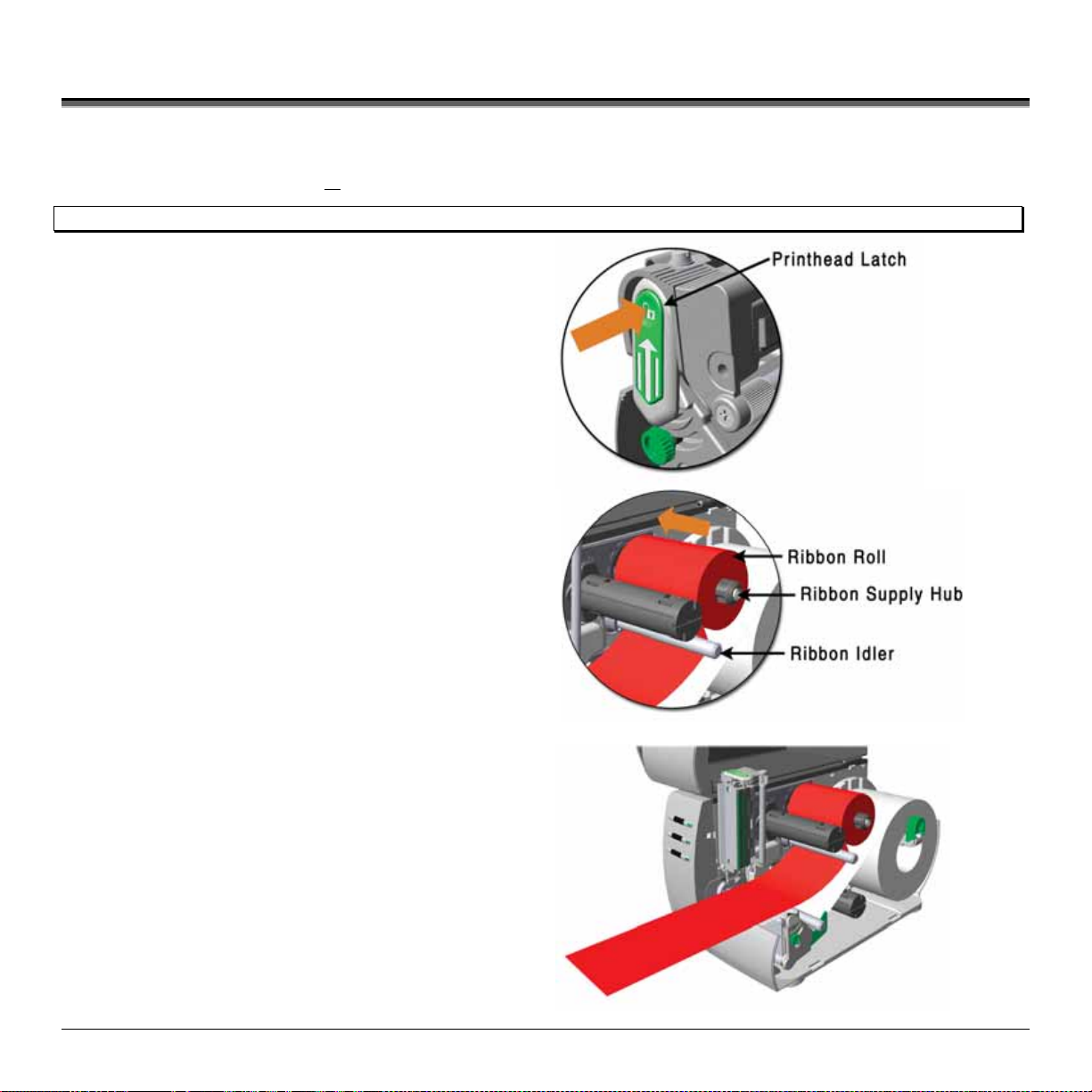

3.4 Loading Ribbon

Ribbon is requ ired with thermal trans f er media. It is r ecommended that the width of the ribbon be slight ly wider than the

media being used. Depending upon the type of Ribbon Supply Hub (see 3.4.1 for examples), the printer must use either

rib bons with the ‘coating side in’ or

Note: Using a ribbon that is slightly wider than your media (and liner, if any) will help protect against printhead wear.

1. Open the media cover. Press in on t he Print head Latch

and ra i se th e pri n thead assemb l y .

rib b ons with the ‘ c oating s ide ou t’. To load:

2. Slide the Ribbon Roll onto the Ribbon Supply Hub until

it r es ts a gainst the hub’s flange. Ensure the r ibbon

unwinds in t he correct direct ion (see 3.4.1 f or

examples ) . Illus trations depi c t a ‘Coat ed Side In’

assembly.

3. R oute t he ribb on under the Ribbon I dler and t hen ou t the

front of the printer approximately 12 inches.

M-Class 13

Page 22

4. C l ose the Pr inthead Assembly and press down u ntil it

locks into p l ace.

5. Route t he ribbon up a nd then ar ound to the Ribbon

Take-Up Hub, winding it several times in a clockwise

direction to secure it in place.

FEED

6. Close the cover and press the

but ton several times t o position the ribbon and ensure proper tracking.

7. The ‘Media Type’ setting within the printer’s setup must be set to ‘Thermal Transfer’ to print using a ribbon;

Printers without front display: See section 4.5.2

Printers with front display: See section 5.1.2

14 M-Class

Page 23

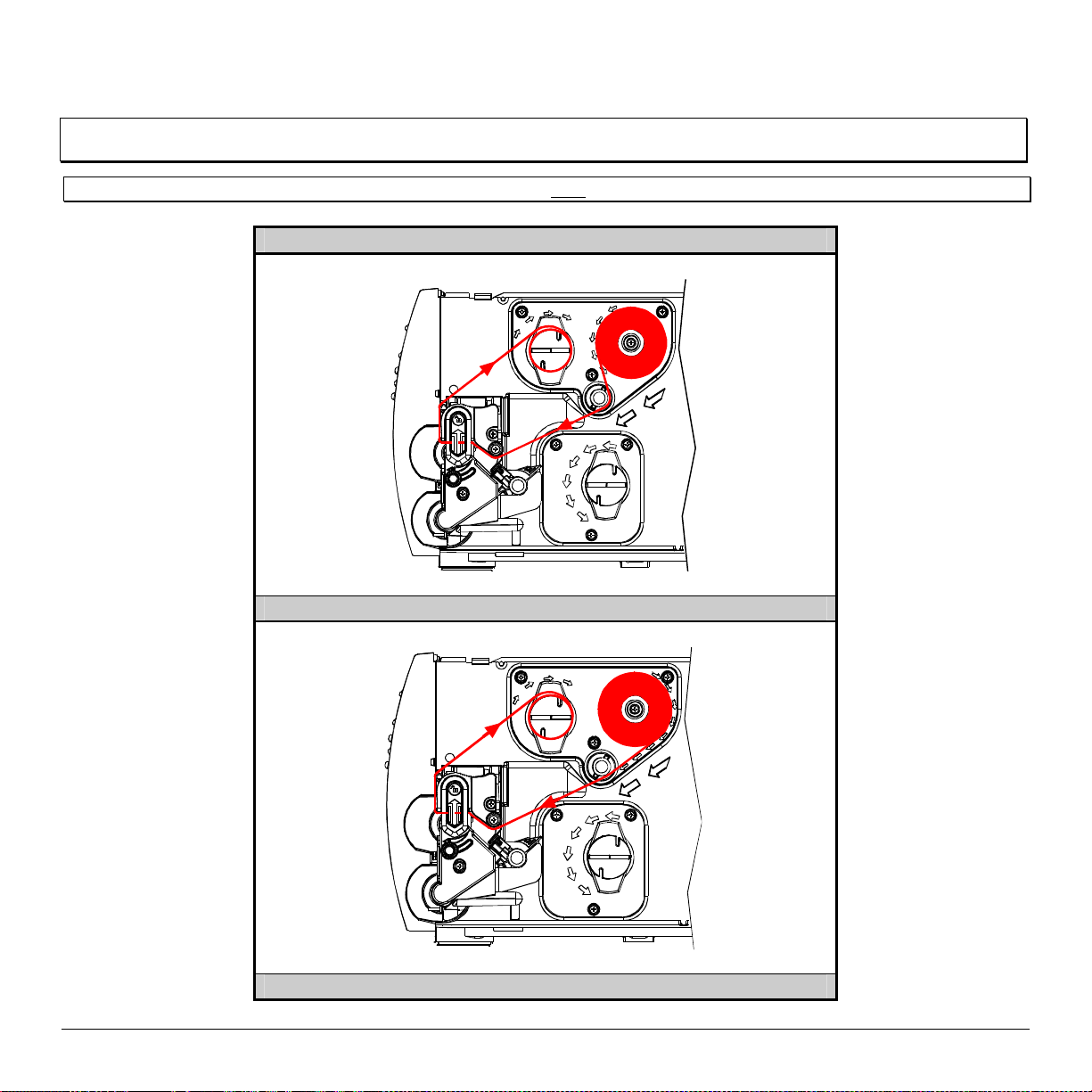

3.4.1 Ribbon Routing (Coated Side In & Coated Side Out)

Note: Directional Arrows near the Ribbon Supply Hub indicate the correct ribbon route. Ribbon types are available with the ink

(coating) layer wound ‘in’ or ‘out’. These types are NOT interchangeable for use with the printer.

Note: Ensure the inked side of the ribbon faces the media and NOT the printhead.

Ribbon Routing Diagrams

‘Coating Side In’ Ribbon Supply Hub

‘Coating Side Out’ Ribbon Supply Hub

M-Class 15

Page 24

16 M-Class

Page 25

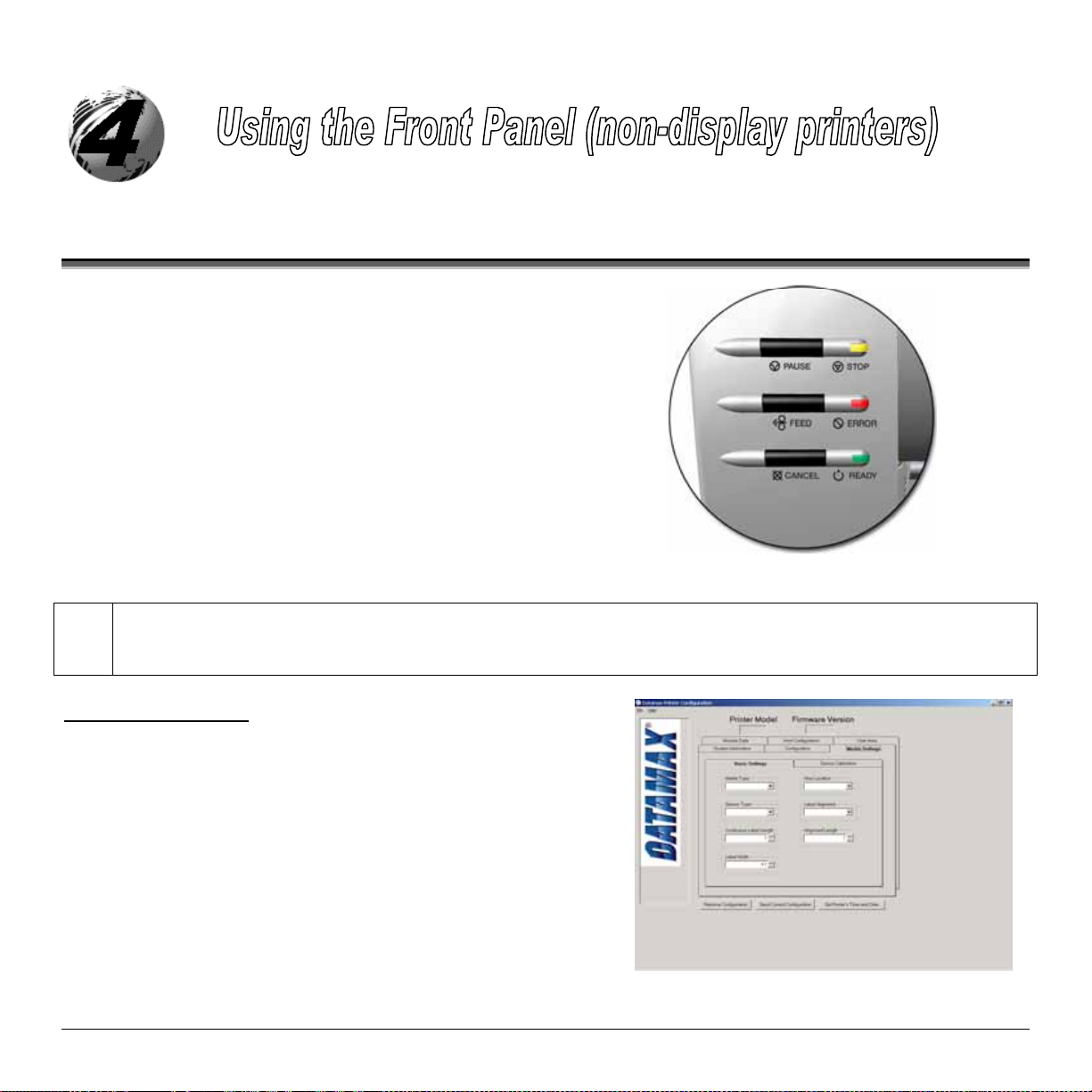

4.0 Introduction

The Front Panel consists of three indica tor light s and t hree funct i on

but tons. The functions of t hes e light s and controls are listed in the

following sect ions.

4.01 DMXConfig

DMXConfig Features:

Simpli fy Printer Setup Process

Allows Real-Time Cont r ol/Query of Print er Configur ation

Defi ne and S ave Optimal Configur ations for Applications i.e.

Sav ed Configurations can be Shared with other P r inters and

Download Files, Format s and Fonts

Query Memory Modules

DMXConfi g (located on the M- c lass CD-R O M) is a windows ba sed configuration utility that c an simplify the

printer setup process. This application allows the user to make changes to the existing printer setup without using

the front panel but tons. Visit our website at www.datamaxc orp.com/soft ware/m-class / for the lates t releases.

Ribbon / Label S tock Combinations

Sent via Email

(sample screenshot)

M-Class 17

Page 26

4.1 Lights

(Normal power-up)

Normal Mode

STOP

ERROR

READY

Solid O n:

Flashing:

a label is presented to the operator.

Indicates a top of form or mechanical error has occurred

Solid On: Indicates the printer is on and ready for printing

Flashing: Indicates the printer is receiving data from the host

Indicates the printer is in the ‘Paused’ state

(When using the Peel & Present Option) Indicates

Both the

READY

and

STOP

Lights will b e on du ring power- up initialization and a warm res et .

4.2 Buttons

The three bu tto ns,

operationa l mode. The pr inter operat es in one of the following modes:

PAU SE

,

FEED

, a nd

Norma l : Normal printer functions. See Section 4.3.

Express Setup: Allows quick access to the most common printer settings, (Sensor Type, Media Type, and Option Control. See

Section 4.4.

Printer Setup: Allows changes to the printer’s operational settings. See Section 4.5.

Calibration: Allows the ‘calibration’ of the media being used for the correct sensing of the top of form. See Section 4.7.

CANCEL

perf orm different f unctions based on the pr inter’s

18 M-Class

Page 27

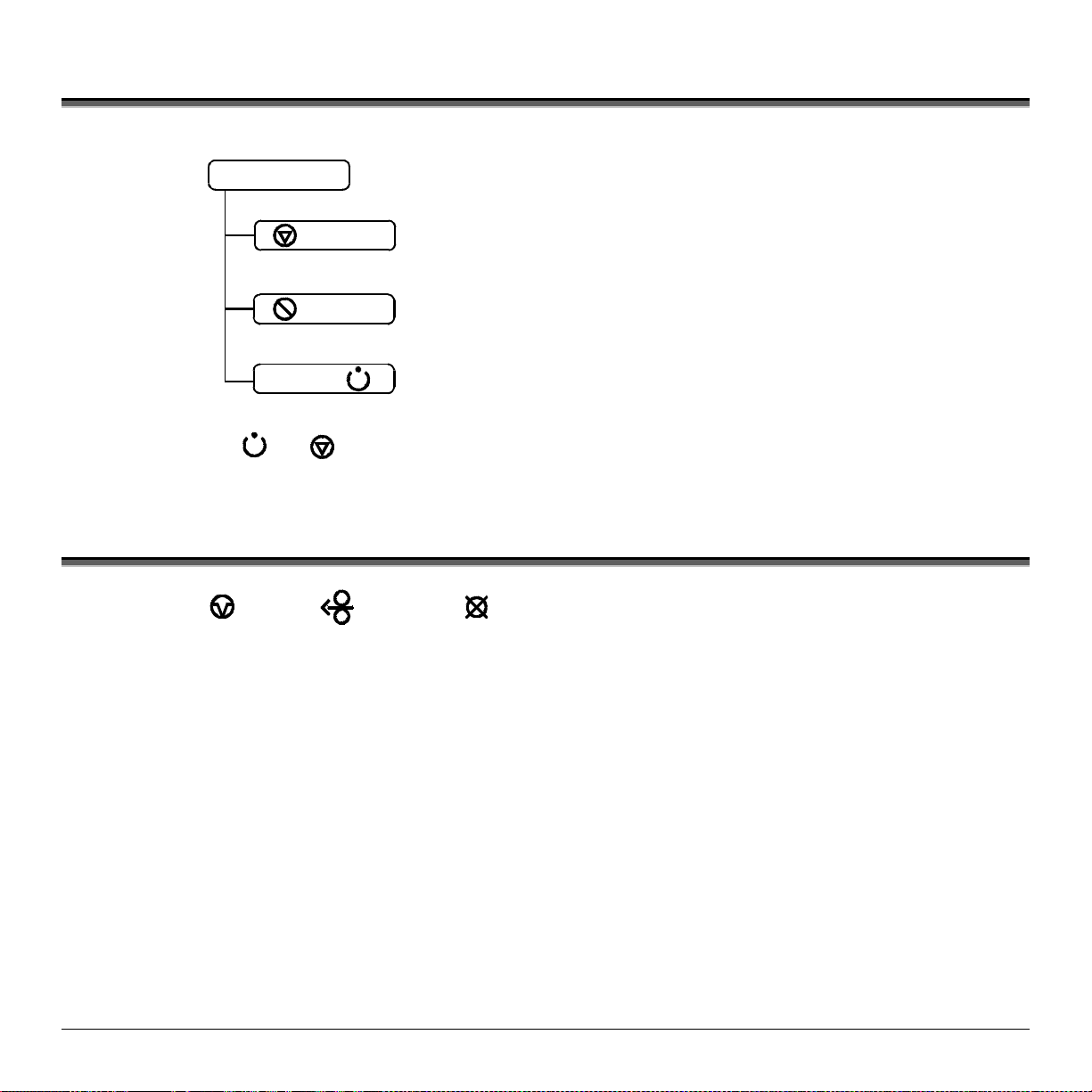

4.3 Normal Mode - Button Funct ions

In ‘Normal’ mode, t he p rinter ’ s buttons control normal oper ations such as pause, f eed, and ca nc el, as well as the t es t and

reset f unctions by using b utton c omb inations as detailed below.

(Normal power-up)

Normal Mode

PAU S E

FEED

Pauses/Un-pauses the printer

Feeds one label. Clears fault conditions

Press and Hold to perform “Label Alignment”, see section 4.6

Button Combinations (push buttons simultaneously)

PAU S E

PAU S E

FEED

+

+

+

FEED

CANCEL

CANCEL

CANCEL

Cancels the current batch of labels. Press the Pause button to

print the next batch of labels in the printer’s buffer

Prints the Test Label, see Section 4.8.2.

Performs a warm reset and returns to the Normal Mode of operation.

Produces Database Configuration an d T est Labels, see Section 4.8.1

M-Class 19

Page 28

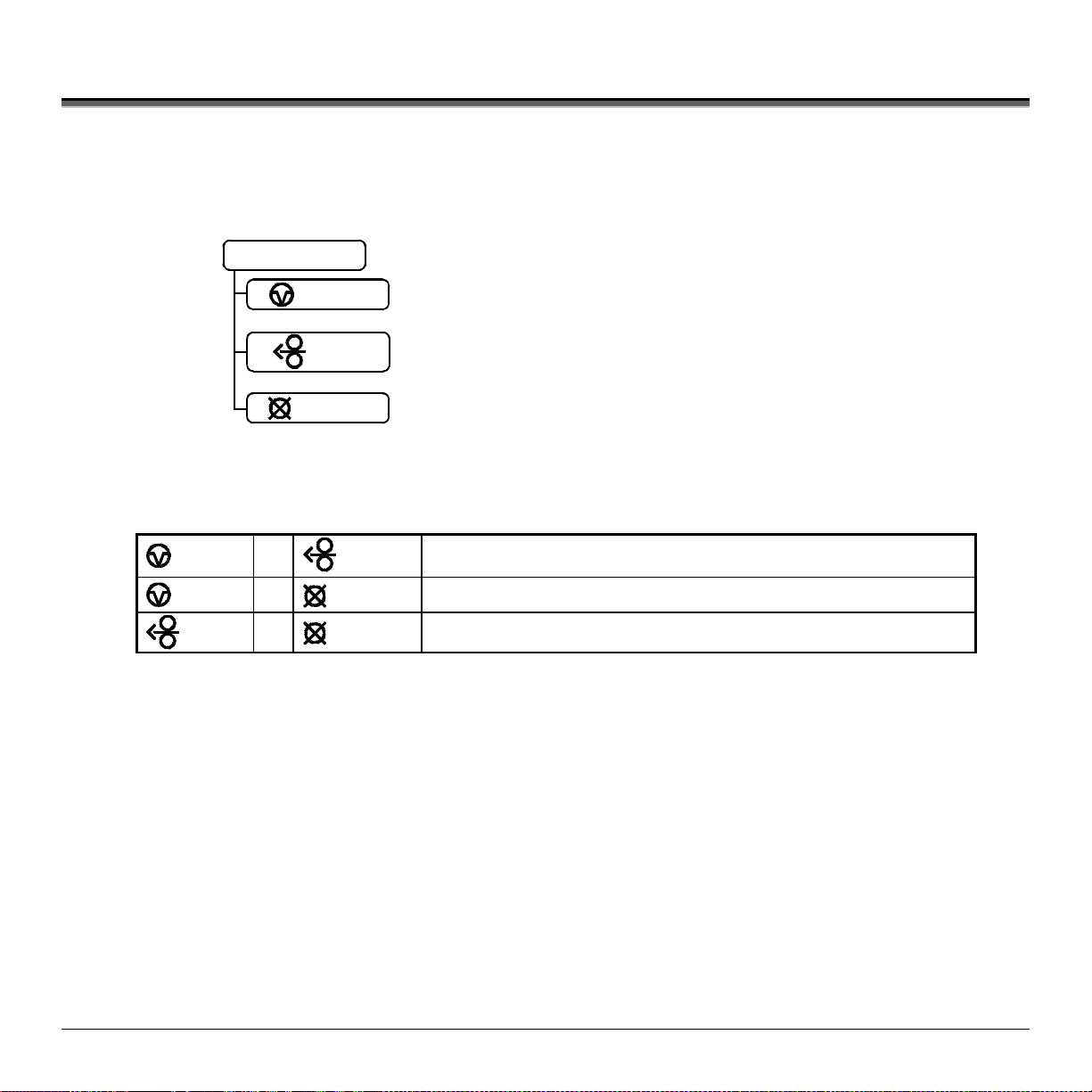

4.4 Expr ess Setup M ode - Button Functions

The Express Setup is a unique printer feature that allows users quick access to the most commonly used printer settings.

The selected setting is repres ent by a specific co mbina tion o f the pri n ter’s in d i cator l ights for ea ch of the three items,

(Sensor Type, Media Type, and Option Control). To enter the Express Setup…

T urn the printer OFF to save settings.

20 M-Class

Page 29

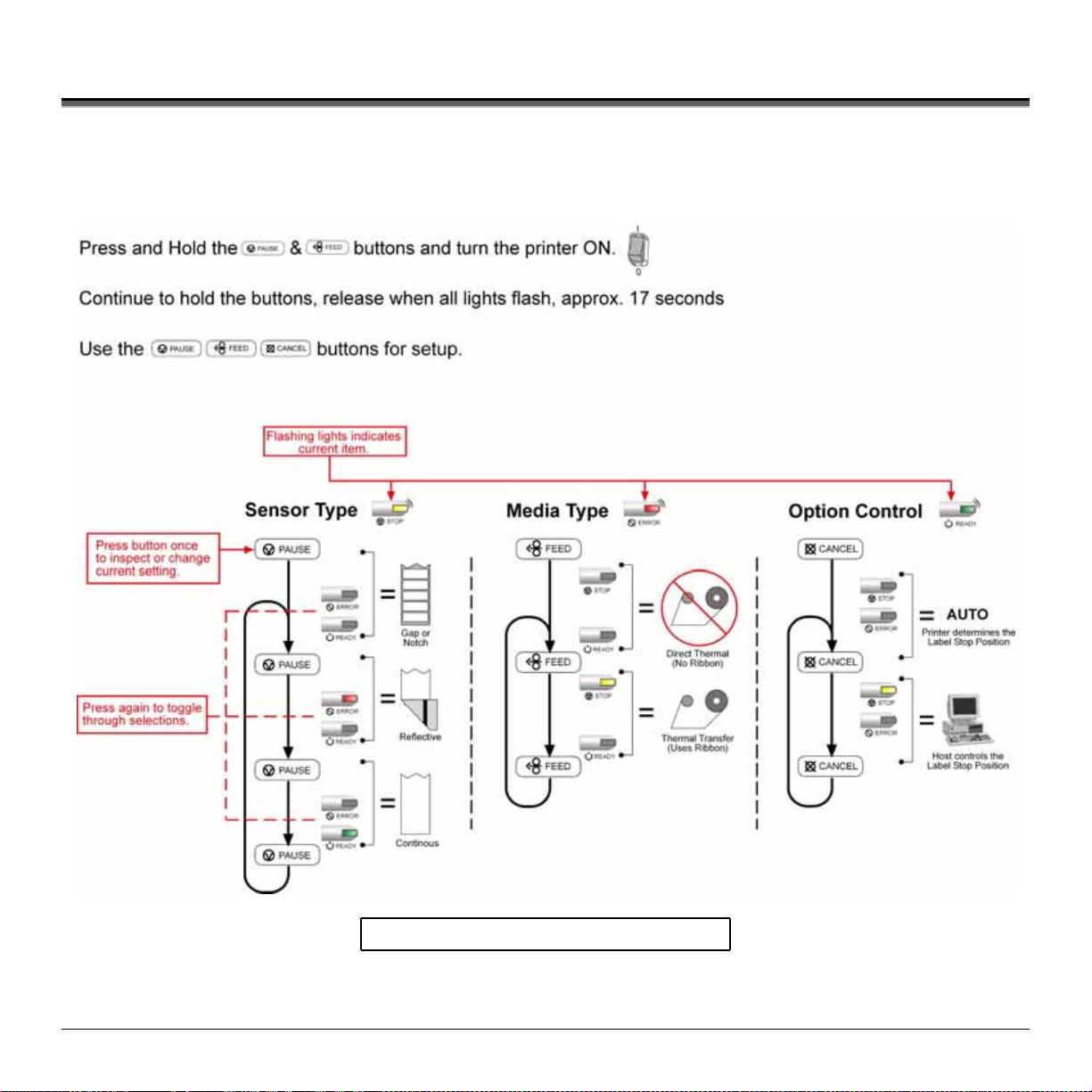

4.5 Print e r Setup Mode - But t on Func t ions

In ‘Printer Setu p’ mode, the buttons contr ol the sett ing of the printer’s opera tional it ems s uch as media settings ,

communicat i ons, a nd options as detailed below.

Notes: It is recommended that the Printer Setup Mode not be entered while in Peel Mode or with the optional Pr esent Sensor

Printer and cutter faults are disabled during

If at any time you wish to discard your changes and revert back to the previous values, simpl y t ur n of f power to the

If you wish to restore Factory Defaults see Section 6.7.

To change Printer Setup:

enabled. Depending on label size this can cause unpredictable results.

but can still occur while printing “test” labels.

,

printer.

PAU SE

(Press and hold during power-up until the light turns off)

Printer Setup Mode

STOP

PAU SE

FEED

FEED

CANCEL

PAU SE

+

Prints the ‘Printer Setup Menu List’, see section 4.5.1

Press and

(

Press and

(

Prints the ‘Test Label’ for “test”

Saves the current values

and resumes

CANCEL

Printer Setup Procedure

PAU SE

FEED

CANCEL

PAU S E

+

CANCEL

Feeds one label for “test”

Release

Increments item’s value

(

(

Decrements item’s value

Accepts the current

values for “test”

)

(Enters Printer Setup)

)

Hold

Normal Mode

(Current Item and Value is printed)

Press and

Release

Press and

Hold

Selects the next menu item

)

”Direct Select” menu item

)

eg. 7 Error light flashes = Baud Rate menu item #7

DONE

M-Class 21

Page 30

4.5.1 Printer Setup Menu List

The Printer Setu p Menu List la bel, shown b elow, contains the p rinter ’ s current values f or each menu it em that can be

modified via the front panel (See Section 4.5 .2 for a detailed item descri p tion.)

The Menu I tem Numbers c orres pond to the it em’s position in the Menu List for selection when pressi ng the

during the Printer Setup Procedure (see Section 4.5). For example to “ Dir ect Select” th e B AUD RATE Menu Item p ress

and hold the

FEED

but ton for 7 flashes of t he

ERROR

light and then releas e or for the TOF GAIN it em hold

for 12 flashes, etc.

FEED

but ton

FEED

Menu Item

Values

Numbers

1) DIRECT = MEDIA TYPE

2) EDGE = SENSOR TYPE

3) NO = PRESENT SENSOR

4) NO = CUTTER EQUIPPED

5) 127 = SOP ADJUST, 0.005 in.

6) 127 = PRESENT ADJUST, 0.005 in.

7) 9600 = BAUD RATE, bps

8) 8 = DATA BITS

9) STD = CONTROL CODES

10) 100 = CONT FORM LENGTH, 0.01 in.

11) 3 = OOS MAXV OLT, 0.1 Vol ts

12) 12 = TOF GAIN

13) 1 0 = TOF DELTA, 0.1 Volts

14) 0 = TOF LOW, 0.1 Volts

15) 426 = LABEL WIDTH, 0.01 in.

16) 6 4 = SCALABLE FONT, 4KB

17) 128 = INTERNAL MODULE, 4KB

18) NO = LABEL ALIGNMENT

19) 100 = ALIGNMENT LENGTH, 0.01 i n.

20) AUTO = OPTION CONTROL

21) DPL = INPUT MODE

22) STANDARD = DPL EMULATION

23) 10 = HEAT

24) NO = EXACT TIME

25) NO = GPIO

26) NO = NO REPRINT

Note: When using narrow media, t he ‘Menu Items’ colum n may be truncated.

Menu

Items

22 M-Class

Page 31

4.5.2 Menu Items and Values

The table below details the Print er Setu p Menu Li st items wit h a brief descr iption of t he it em’s f unction, and the p ossible

values . A “*” denot es the defau lt setting.

1) MEDIA TYPE

Sets printing for direct thermal (no

ribbon) or therma l transfer (r ibbon)

media.

Possible Values:

* DIRECT THERMAL

THERMAL TRANSFER

4) CUTTER EQUIPPED

Enables/Disables the optional

Media Cutter feature.

Possible Values:

* AUTO

NO

YES

7) BAUD RATE

Sets the serial port baud rate. (Must

match the host setting).

Possible Values:

600 to 38.4k; default = *9600 BPS

10) CONT FORM LENGTH

Sets the pag e ( label) s ize when th e

‘SENSOR TYPE’ is set to

continuous media.

Possible Values:

Range: 0 – 9999; default = *100

(Units = .01 inch)

2) SENSOR TYPE

Selects the sensor t ype used to detect

the media’s Top Of Form (TOF) mark.

Possible Values:

* EDGE: gap / notch TOF marks

REFL (Reflective): black marks

CONT (Continuous): no TOF marks

5) SOP ADJUST

Sets the start of print (SOP) location,

relative to the top of form.

Possible Values:

Range: 0 – 255; nominal = *128

(0 = close to edge; 255 = farthest from edge)

8) DATA BITS

Sets the serial data word length (Must

match the host setting).

Possible Values:

* 8

7

11) OOS MAXVOLT

Sets the media sensor level for the Out

Of Stock condition.

Possible Values:

Range: 0 – 16; nominal = *2

(Units = .1 volt)

3) PRESENT SENSOR

Enables/Disables the optional Present

Sensor feature.

Possible Values:

* AUTO

NO

YES

6) PRESENT ADJUST

Specifies an additional amount to feed

the label after printing.

Possible Values:

Range: 0 – 255; nominal = *128

(0 = close to edge; 255 = farthest from edge)

9) CONTROL CODES

Allows code selection listed in

Programmer’s manual.

Possible Values:

* (STD) Standar d Codes

(ALT) Alternate Codes

12) TOF GAIN

Sets media sensor Top of Form gain

value.

Possible Values:

Range: 0 – 15; nominal = *10

M-Class 23

Page 32

13) TOF DELTA

Sets the minimum media sensor

change requir ed to signify a label

gap or mark.

Possible Values:

Range: 0 – 50; nominal = *10

(Units = .1 volt)

16) SCALABLE F ONT

Sets the number of memory blocks

to allocate for scalable fonts.

Possible Values:

Range: 0 – 128; default = *64

(Units = 4K Bytes)

19) ALIGN LENGTH

Lead ing edge distance of two successive labels.

Must be entered if ‘LABEL ALIGNMENT’ is set

to Yes (see Section 4.6).

Possible Values:

0 – 999; default =100*

(Units = .01 inch)

14) TOF LOW

Sets the minimum media sensor

reading for paper (gap/notch) or mark

(reflective).

Possible Values:

Range: 0 – 50; nominal = *0

(Units = 0.1 volt)

17) INTE RNAL MODULE

Sets the number of memory blocks to

allocate for the internal RAM module.

Possible Values:

Range: 0 – 128; default = *128

(Units = 4K Bytes)

20) OPTION CONTROL

Sets label stopping (and in certain cases the starting) location for

different printer configurations.

Possible Values:

* AUTO (Automatically sets the stop location. Installed options

will be ‘auto-sensed’ and the appropriate stop position

will automatically be set. Host commands are ignored.)

HOST (Sets stop position according to options installed. If no

options are installed the printer sets stop location to the

next label’s start of print. Host commands will

override.)

15) LABEL WIDTH

Sets the label width.

Possible Values:

Range: 75 – 426; default = *426

(Units = .01 inch)

18) LABEL ALIGNMENT

Sets the label alignment method (see

Section 4.6)

Possible Values:

.

YES (user manually determines

‘ALIGN LENGTH’)

AUTO (prin ter determines ‘ALIGN

LENGTH’)

* NO (no Label Alignment

used)

24 M-Class

Page 33

21) INPUT MODE

Selects between the standard or template

interpretation of incoming data.

Possible Values:

* DPL (printer constructs the label using the

stand a rd DPL comman d s)

LINE (printer constructs the label using a

preloaded template form)

23) HEAT

Controls the ‘burn-time’ of the printhead. This is

the equivalent of Heat Setting on most label

software programs.

Possible Values:

Range: 0 – 30; default = *10

25) GPIO

Sets the printer’s option port to function for GPIO

applications, (see Appendix F for more

information).

Possible Values:

YES or NO; defaul t = *NO

22) DPL EMULATION

This instructs the firmware to process specific DPL data (Start of

Print, DPI, and Imaging function) according to the selected

printer emulation.

Possible Values:

* STANDARD

ALLEGRO (Allegro Emulation)

P PLUS (Prodigy Plus Emulation)

PRODIGY (Prodigy Emulation)

24) EXACT TIME

Instructs the printer to wait until the system is idle before the next

label’s data and time fields are formatted to eliminate any

discrepancy between the buffered and printed times.

Possible Values:

YES or NO; defaul t = *NO

26) NO REPRINT

When a fault condtions is detected, printing stops and the ERROR

light turns on. After the problem is corrected, the FEED Key must

be pressed to clear the fault. The label in process is not reprinted.

Possible Values:

YES or NO; defaul t = *NO

(NO = NO REPRINT” disabled, reprinting will occur.)

Note: All of the menu items listed in t he previous section are stored in non-volat i le memory.

M-Class 25

Page 34

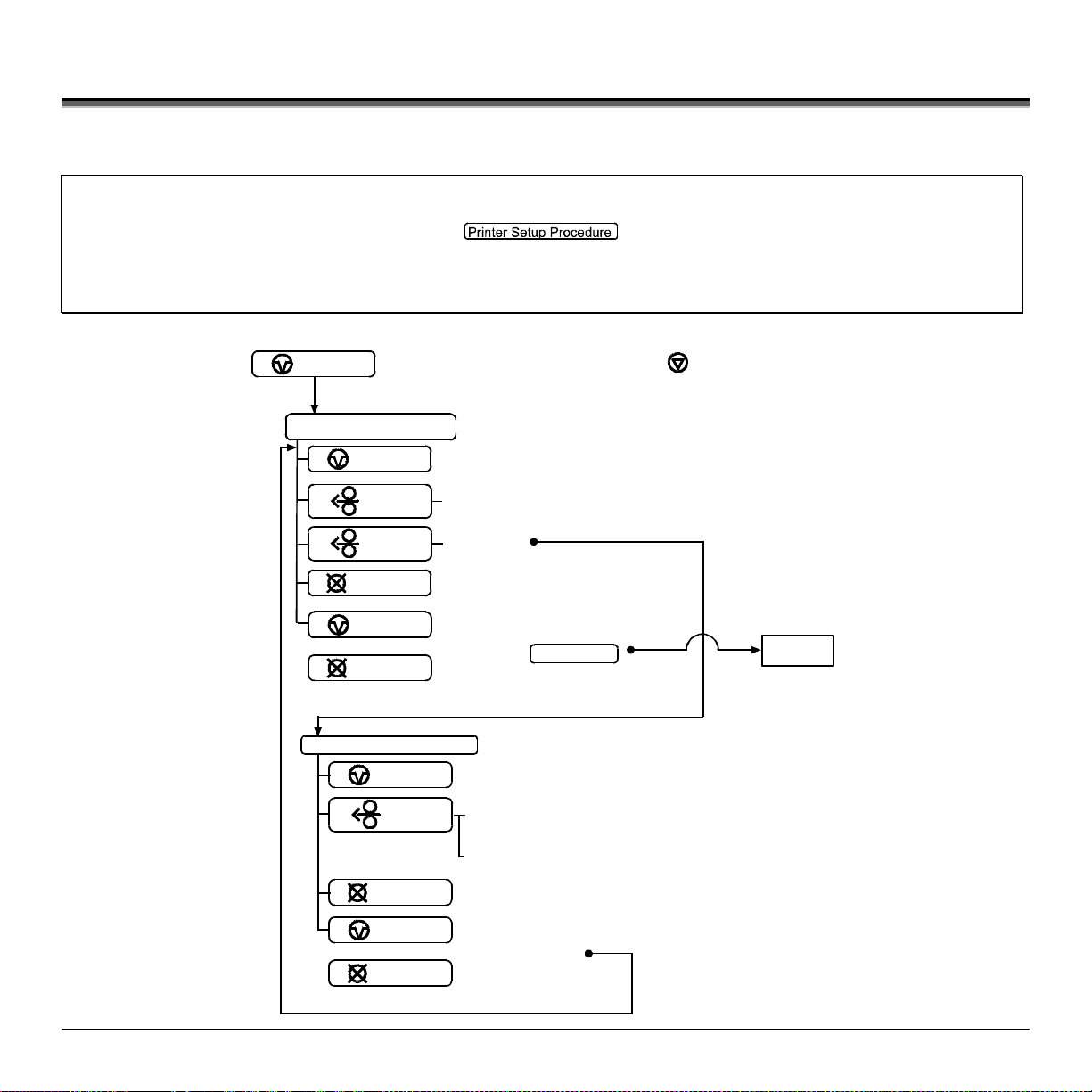

4.5.3 Step by Step Modification of the Printer Setup

The following is an example of Print er Setup modification. Alt hou gh this exa mp le will detail how to modify the ser i al Bau d

Ra te, the s ame method can be u sed to cha nge any of the printer ’s menu item settings.

Note: It is recommended that the Printer Setup Mode not be entered while in Peel Mode or with the optional Present Sensor

1. With printer ‘Off’ and properly loaded with media, press a nd hold the

2. Press and hold the

enabled. Depending on label size this can cause unpredictable results.

STOP

Continue to hold the bu tton until the

FEED

but ton and count 7 f l ashes of the

light tu rns off, then relea se it.

should b e p roduced:

PAU S E

but ton while powering ‘ On’ the printer .

ERROR

light, then release it . The following printou t

3. Press the

PAU S E

button one time to increment to the 19200 bps value. The following printout should be produced:

4. At this point you will accept the current values for “t es t” and exit the Printer Setup Procedu re by simult aneously and

briefl y press i ng the

PAU S E

Note: If you wish to discard your changes and revert back to the previous values simply turn off power to the printer before

Step 5.

5. N ow you can save your cha nges and res ume by simultaneously and briefly pressing the

CANCEL

but tons. W ait until the

CANCEL

+

but tons. W ait until the

STOP

light goes off .

STOP

light goes off .

PAU S E

+

26 M-Class

Page 35

6. To confirm that your changes have b een made p ress the

FEED

+

CANCEL

but tons simult aneously, this will pr int the

Database Configuration Label. The label should show the new Baud Rate value of 19200.

Label 1

WED NOVEMBER 10, 2003 21:41:31 323

VER: M4206 - 05.08 11/07/03

BOOT 83-2383-05E

CODE 83-2385-05H

FPGA 83-2384-05B

FONT 83-2460-01C

UMOD 83-2472-01A

256K FLASH MODULE B

SYSTEM FLASH SIZE_____2 MBYTES

SYSTEM RAM CHECKS____ GOOD

SYSTEM RAM SIZE___ 4096 KBYTES

SYSTEM RAM AVAIL__ 3180 KBYTES

AUTO DETECTION

CUTTER____________NOT DETECTED

PRESENT SENSOR____NOT DETECTED

CURRENT STOP LOC__TEAR

EXPRESS SETUP

MEDIA SENSOR______EDGE

PRINT METHOD______TRANSFER

OPTION CONTROL____AUTO

INPUT VALUES

PAPER_____________ 207

POT_______________ 33

TRAN______________ 157

REFL______________ 0

RIBN______________ 237

TEMP______________ 64

VOLT______________ 218

PRESENT SENSOR____ 0

COUNTER INFORMATION

ABSOLUTE VALUES 7-16-2003

LENGTH____ 773 INCHES

TIME______ 20 HOURS

RESETTABLE VALUES 7-16-2003

LENGTH____ 969 INCHES

TIME______ 56 HOURS

MEMORY CONFIGURATION

INTERNAL MODULE A______ 128

SCALABLE FONTS_________ 64

LABEL SIZE 0426:10912 IN

CONFIGURATION

SERIAL PORT SELECTED

19.2; 8BITS

EDGE

MEDIA TYPE________ TRANSFER

CONT FORM LENGTH__ 0

PRESENT ADJUST____ 128

SOP ADJUST________ 128

TOF LOW___________ 0 0

TOF DELTA_________ 10 10

TOF GAIN__________ 7 5

OOS MAXVOLT_______ 3 2

LABEL ALIGNMENT___ AUTO

ALIGN LENGTH______ 611

OPTION CONTROL____ AUTO

INPUT MODE________ DPL

DPL EMULATION_____ STANDARD

HEAT______________ 10

EXACT TIME________ NO

GPIO______________ NO

NO REPRINT________ NO

SYMBOL SET________ PM

FONT SUBSTITUTION_ NONE

IGNORE COMMANDS

SYMBOL SET SELECT_ NO

CNTRL CODES_______ NO

HEAT______________ NO

SPEED_____________ NO

SOP OFFSET________ NO

Label 2

M-Class 27

Page 36

4.6 Label Alignment

The Label Alignment function is intended for use when the la bel length is less than the dis tance between the print head and

the media sensor or where label waste at power-up is a concern. L abel Alignment (s ee table below) is not r ec ommended for

label lengths grea ter than 6. 5 inches or f or media cont aining 2 or more form lengths.

Label Stock Label Alignment Setti ng

Continuous NO

6.5 inches or less YES or AUTO

6.5 inches or more NO

Multiple length labels NO

The Label Alignment func tion is chos en via the menu system (see Section 4.5) or by host commands. The three poss ible

modes, YES, AUTO, and NO, are detailed in t he following sections .

4.6.1 Label Alignment = YES

In this mode, the operator must supply an ‘ALIGN LENGTH’ value.

This value must be physically measu red from leading edge to lea ding

edge of two suc c essive labels, as shown. The meas urement must be as

accurate as possible. For very short labels, errors as small as 0.01” can

resu lt in noticeable print var i ations on the labels between the media

sensor and t he p rinthea d.

The measured v alu e must be s en t to the printer v i a t h e h ost compu ter o r

entered using the Printer Setup Mode (see Sec tion 4.5).

FEED

Then, in N ormal M ode, pres s and hold t he

seconds). The printer will align the lab el to the top of f orm positi on.

Note: If m edia wit h a different label length is subsequently loaded, the ‘ALIGN LENGTH’ must be recalculated and re-entered.

button (about 4

28 M-Class

Page 37

4.6.2 Label Alignment = AUTO

In this mode, the print er automatically calc ulates the ‘ALIGN LENGTH’ t hu s eliminating the need to physically meas ure

the label. This mode is usu ally pr eferred in a pplica tions that r equ ire frequent media changes to labels of dif ferent lengths .

FEED

To p erform an Auto Alignment, in Normal Mode press and hold the

but ton (ab out 4 seconds). The pr inter will feed

labels to calcu l ate the la bel length. Following the calcu lation, the print er will save t he meas urement and align to the t op of

form position. Auto Alignment ca n result in wasted labels during t he measurement p rocess (the longer t he label length the

greater t he waste).

Auto Alignment with the Present Sensor enabled:

If the printer is equipped wit h the Pres ent Sensor option a nd that f eature is enabled, while the label length is calc ulated t he

printer will pa use and illu mina te the

STOP

light after each movement. The op erat or must pres s the

PAU S E

button for the

alignment to c ontinue. This a llows the operator to r emove any labels a s required; however, labels s hould not be forcibly

removed since they may not actually be posit ioned f or removal, but at an inter im p osition r equ ired for mea surement.

4.6.3 Label Alignment = NO

When Lab el Alignment is not enabled (i.e., set to N O ) , pr inting begins at the curr ent label p osition without a lignment,

assuming the lab el is at t he start of print p osition. Additionally, if the label length is short , lab els between the print head and

the media sensor may be u nused.

M-Class 29

Page 38

4.6.4 Label Alignment Troubleshooting

If you experience lab el alignment problems, the following table offers p ossible causes and solutions.

Proble m Possible Cause Solution

Attempting to perform

Label Alignment results

in no paper movement.

First label is wasted

during alignment. All

labels thereafter print to

the correct start of print

position.

With th e Presen t Sensor

enabled, Label Alignment

cannot be performed

without a Label Length.

Alignment Length is too

long.

~OR~

For labels whose length

and stop position cause

them to stop between

labels on the media

sensor, the alignment

function can result in

wasted labels.

Set Label Alignment to AUTO, press and hold

media moves for the automatic length measurement.

~OR~

Re-measure the Label Alignment Length. Use Printer Setup

mode to enter the new length. Print a Database Configuration

label to ensure the new length has been set.

Set Label Alignment to AUTO, press and hold

paper moves for automatic Label Alignment length

measurement.

~OR~

Re-measure Label Alignment Length, use Menu Setup to set

new length, ensure desired length has been set.

Obtain a slightly different label Alignment Length

measurement. Using the Label Alignment AUTO mode, hold

FEED

the

measurement. Ensuring slack in the label stock may result in a

slightly different measurement. The Alignment Length may

also be set manually via the Setup Menu. Increasing or

decreasing the value by 1 or 2 units (in . / 100) m ay help to

prevent the wasted labels; however, this may result in incorrect

print positions for labels that are short in length.

button to force an alignment and label

FEED

FEED

until

until

Label Alignment is

incorrect . Press ing

FEED

successively

results in a short label

length, one-inch.

Label Alignment Length

is n ot correct . Th e

default Label Alignment

Length is 1.00”, and will

result in this behavior

when any larger label

length is used without

setting the appropriate

FEED

Set Label Alignment to AUTO. Press and hold

until

paper moves for automatic Label Alignment Length

measurement.

~OR~

Measure the label length and use the Setup Menu to set the

new length. Print a Database Configuration label to ensure the

new length has been set.

length.

30 M-Class

Page 39

Problem Possible Cause Solution

Label Alignment is

incorrect . Press ing

FEED

successively

results in a label length

longer than actual, oneinch.

Tear Mode is selected

but the label stop

position (present

position) is not far

enough forward.

Tear Mode is selected

but the label stop

position (present

position) is too far

forward.

The

ERROR

light

illuminates during label

alignment.

Label Alignment Length

is n ot correct . Th e

default Label Alignment

Length is 1.00”, and will

result in this behavior

when any larger label

length is used without

setting the appropriate

Set Label Alignment to AUTO. Press and hold

paper moves for automatic Label Alignment length

measurement.

Measure the label length and use the Setup Menu to set the

new length. Print a Database Configuration label to ensure the

new length has been set.

length

Another present position

has been determined.

Enabling the Present

Sensor causes the label

stop position (present

position) to be

approximately 0.1”

behind the peel bar.

~OR~

The P resent Adjust value

is n ot correct .

Disa bl e the Present Sensor.

Ens u re the host computer is not pr oviding a Present Di s tance

shorter than is required for the Tear Bar.

Use the Setup Menu to modify the Present Adjust value.

Another present position

has been determined.

~OR~

The P resent Adjust value

is n ot correct .

The label supply is empty Load media.

En s u re the host com puter is not p roviding a P resent Dist ance

longer than is required for the Tear Bar.

Use the Setup Menu to modify the Present Adjust value.

~OR~

~OR~

FEED

until

M-Class 31

Page 40

4.7 Calibration M ode – But t on Func t ions

In ‘Calibr ation’ mode, the buttons a llow the printer to adjust to the media b eing u sed. Calibr ation can be performed either

automatically or manually, as detailed below.

Notes: Before calibrating, ensure that the Printhead Carrier Assembly is lat ched down, that t he cover is closed, and that t he

Printer and cutter faults are disabled during

If at any ti me you wish to discard your changes and revert back to the previous calibrati on si mply turn of f power to the

To perform Calibration:

media sensor has been set for the appropriate media type, see Section 4.5.2.

and

printing “ t est” l abels.

printer. Also, Fact or y Default s can be restored, see Section 6.7

CANCEL

(Press and hold during power-up until the light turns off)

STOP

Calibration Mode

PAU SE

, but can still occur while

Auto Media Calibration

FEED

FEED

CANCEL

PAU SE

+

Press and

(

Release

Press and

(

Prints the ‘Test Label’ for “test”

Saves the current values

and resumes

CANCEL

Media Sensor Calibration

PAU SE

FEED

CANCEL

PAU SE

+

CANCEL

(See section 4.7.1)

Feeds one label for “test”

)

(Until Paused light turns off)

)

Hold

Normal Mode

(See section 4.7.2)

Analyze for ‘Paper’

Analyze for ‘Backing or ‘Mark’

Analyze ‘Out of Media’ condition

Accepts the current

values for “test”

DONE

32 M-Class

Page 41

4.7.1 Auto Media Sensor Calibration

Auto M edia Sensor Ca libration a u tomatic ally establishes the optimum sens ing values for the media you are using in the

printer.

Note: Before calibrating, be sure the media sensor is set for the appropriate m edia ty pe, see Section 4.5.2; also, ensure that the

Printhead Carrier Assembly is l at ched down and the cover is closed.

To automatically calibrate the media sensor:

1. With the desired media loaded, hold the

STOP

until the

light tu rns off then release it .

CANCEL

but ton while powering up the printer. C ontinue to hold t he b utton

PAU S E

2. Next press the

but ton. The printer will feed approximately ten inches of media to calculate the TOF Delta

and Low values to be used.

3. Upon c omplet i on, one of the following lights will flash five times to denot e t he result of the auto calib ration attempt:

STOP

Note: If you wish to discard the changes and revert back to the previous calibration si mply turn off the printer before Step 4.

light = Successful calibr ation. Pr oc eed to Step 4.

ERROR

light = Uns uccess f ul calib ration, t ry again. If the calibration continu es to fail proceed to Section 4.7.2.

4. N ow save th e changes a nd resu me

briefly. Wait until the

STOP

light goes off .

by pressing the

PAU S E

CANCEL

+

but tons simultaneously and

M-Class 33

Page 42

4.7.2 Manual Media Sensor Calibration

The Manua l Media S ens or Calibration p rocedure should be u sed in cas es where the pr inter continues to suffer from media

sensing problems a fter performing or attempti ng to perf orm the Auto Media S ens or Calibr ation (see Section 4 .7. 1).

Note: Before calibrat i ng, be sure the media sensor is set for t he appropri at e m edia ty pe, see Section 4.5.2; also, ensure that the

Printhead Carrier Assembly is l at ched down and the cover is closed.

To manu ally calibrate the media sensor:

1. Hold the

releas e the button. Nex t, p ress and hold the

CANCEL

but ton and p ower-up the printer. Continue t o hold the but ton until the

FEED

but ton, continue to hold t he b u tton until the

then release the button.

2. R emove all the mater ial fr om t he media s ensor, ( see Section 3 .3 for the sensor’s loc ation) , close t he P rinthea d Carrier

Assembly, and then press the

CANCEL

but ton. The printer will flash the

ERROR

light as it analyzes the no media

condition.

3. P osition t he b acking mat erial or the black (reflective) mark in the media sens or, cl ose the Printhead Car rier Assembly,

and then p ress th e

FEED

but ton. The printer will flash the

ERROR

light as it analyzes the top of form mark.

4. Place t he media with the ba c king att ached (if any) in the media s ensor, c l ose the Printhead Car rier Assembly, and then

press the

PAU S E

but ton. The printer will flash the

ERROR

light as it analyzes the material.

5. Simultaneously and briefly press the

PAU S E

CANCEL

+

buttons to accept the calibration for “test” and exit the

. One of the following lights will flash five t imes to denote the res ult of t he manual calibr ation

attempt:

STOP

light = Successful calibr ation. Pr oc eed to Step 6.

ERROR

light = Uns uccess f ul calibra tion. Retry the procedu re beginning at St ep 1 .

FEED

6. Use the

Note: If you wish to discard the changes and revert back to the previous calibration simply turn off the printer before Step 7.

but ton (feeds a label), and the

CANCEL

button (prints a test label) to test the current calibration.

7. N ow save th e changes a nd resu me

briefly. Wait until the

STOP

light goes off .

by pressing the

PAU S E

CANCEL

+

but tons simultaneously and

STOP

light tu rns off ; then

STOP

light tu rns on;

34 M-Class

Page 43

4.8 Internal Labels

The following s ection details the pr inter’s interna lly gener ated configura tion and t es t lab els .

4.8.1 Database Configuration and Test Labels

The Data b ase Configuration Label provides valuable p rinter inf ormation inc l uding the fir mwa re version, memory

allocations, enabled op tions, and label-counter dat a.

To print the Database Configuration and Test Labels:

With the printer on, loaded with media (at least 4 inches wide) and ribbon (if printing with thermal transfer media), press

the

FEED

+

CANCEL

buttons simultaneously.

The first label pr inted will be the Dat aba se Configurat ion Label.

Label 1

WED NOVEMBER 10, 2003 21:41:31 323

VER: M4206 - 05.08 11/07/03

BOOT 83-2383-05E

CODE 83-2385-05H

FPGA 83-2384-05B

FONT 83-2460-01C

UMOD 83-2472-01A

256K FLASH MODULE B

SYSTEM FLASH SIZE_____2 MBYTES

SYSTEM RAM CHECKS____ GOOD

SYSTEM RAM SIZE___ 4096 KBYTES

SYSTEM RAM AVAIL__ 3180 KBYTES

AUTO DETECTION

CUTTER____________NOT DETECTED

PRESENT SENSOR____NOT DETECTED

CURRENT STOP LOC__TEAR

EXPRESS SETUP

MEDIA SENSOR______EDGE

PRINT METHOD______TRANSFER

OPTION CONTROL____AUTO

INPUT VALUES

PAPER_____________ 207

POT_______________ 33

TRAN______________ 157

REFL______________ 0

RIBN______________ 237

TEMP______________ 64

VOLT______________ 218

PRESENT SENSOR____ 0

COUNTER INFORMATION

ABSOLUTE VALUES 7-16-2003

LENGTH____ 773 INCHES

TIME______ 20 HOURS

RESETTABLE VALUES 7-16-2003

LENGTH____ 969 INCHES

TIME______ 56 HOURS

MEMORY CONFIGURATION

INTERNAL MODULE A______ 128

SCALABLE FONTS_________ 64

LABEL SIZE 0426:10912 IN

Label 2

CONFIGURATION

SERIAL PORT SELECTED

19.2; 8BITS

EDGE

MEDIA TYPE________ TRANSFER

CONT FORM LENGTH__ 0

PRESENT ADJUST____ 128

SOP ADJUST________ 128

TOF LOW___________ 0 0

TOF DELTA_________ 10 10

TOF GAIN__________ 7 5

OOS MAXVOLT_______ 3 2

LABEL ALIGNMENT___ AUTO

ALIGN LENGTH______ 611

OPTION CONTROL____ AUTO

INPUT MODE________ DPL

DPL EMULATION_____ STANDARD

HEAT______________ 10

EXACT TIME________ NO

GPIO______________ NO

NO REPRINT________ NO

SYMBOL SET________ PM

FONT SUBSTITUTION_ NONE

IGNORE COMMANDS

SYMBOL SET SELECT_ NO

CNTRL CODES_______ NO

HEAT______________ NO

SPEED_____________ NO

SOP OFFSET________ NO

M-Class 35

Page 44

The second label pr inted is the Test Label. This label is us ed to test the condition of t he p rinthea d, as shown below:

Good Print Quality Label:

Even pattern consistency

indicates correct printhead

operation.

Faulty Prin t Quality Label:

Streaks indicate a dirty or

faulty printhead. See Section

6.1 for cleaning instructions.

36 M-Class

Page 45

4.8.2 Test Label

The T es t Label is used t o evaluate the cur rent printer setup f or pr int qua lity, la bel tracking, and pr int positioning.

To print the Test Label:

With the printer loaded with media (at least 4 inches wide), and ribbon (if printing with thermal transfer media),

simultaneously press the

PAU S E

FEED

+

but tons.

M-Class 37

Page 46

38 M-Class

Page 47

5.0 Introduction

Controlling Printer Settings with the Internal Printserver

If your pr inter is equ i p ped with the optional I nternal Print server , many of t he p rinter ’ s setting and parameters can be

modified and controlled via t he b uilt-in H TML pages resident in t he p rinter . Thes e p ages can be accessed us ing any web

browser b y simply enteri ng the IP address in the URL ba r.

The front panel is compr i sed of thr ee indicator lights, a Liqu id Crys tal Display and five mode-dependant keys . The

selectable modes (Rea dy, Menu and Quick Test ) and the r elated func tions of the printer keys are detailed below.

Note: To Adjust the LCD contrast, pr ess and hold the

MENU

key for 10 to 20 seconds to modify the LCD contrast level.

5.0.1 Ready Mode:

Normal Operation (Ready Light ‘On’)

The PAUSE Key temporarily suspends printing. Pressing it again will return the printer to normal

operation.

The F EED Key advances one label, and cl ears any corr ected faul ts.

Pressing and holding causes the printer to perform a Quick Media Calibration; see Section 5.4.1.

The CANCEL Key ‘pauses’ the printer and then prompts you for confirmation. If yes, the current

job is cancelled. The printer remains paused.

Pressing and holding four seconds will reset the printer and clear temporary host settings (soft

reset).

MENU

The ME NU Key toggles between the Ready and Menu Modes. I n the Ready Mode, pressing a nd

holding four seconds will change the display contrast.

The TEST Key enters (or exits) the Quick Test Menu.

M-Class 39

Page 48

5.0.2 Menu Mode: Configuration (Ready Light ‘Flashing’)

REV

The LE FT ARR O W Key s cr olls to t he pr eviou s menu it em on the same menu level. It

also decrements numerical valu es in mos t menu selections.

FWD

The RI GHT ARRO W Key scroll s t o the next menu item. It also inc rement s numerical

values in most menu selections.

The EN TE R Key s elects t he funct ion, it em or disp layed va lue. It als o moves between

selections wit hin multiple pa rameter f ields .

The E SCAPE Key moves to the pr evious menu level, and fina lly back t o the Ready

Mode.

When a pr int job is in p rogress , pres sing the TES T Key will terminate the job. The

printer will prompt you for confirmation; if ‘Yes,’ the curr ent job is cancelled and

then Menu M ode is restored.

40 M-Class

Page 49

5.0.3 Quick Test Mode: Print Test Labels

Note: The Quick Test Mode functions are disabled while processing data from communications interfaces until the Host Timeout

value expires.

REV

The LEFT ARROW Key scrolls to the previous test function.

FWD

The RIGHT ARRO W Key scrolls to the next tes t function.

The ENTER Key will cha nge the select ed test la b el qua ntit y of 2, 100, 1000, or 9999

(except the ‘Configuration Label’, quantity of one). Holding down the key scrolls

quantities.

The ESCAPE Key will exit the Qu ic k Test Mode without print ing.

The T EST K ey will print the selected t est label a t the selected qua ntity. D uring test

label p rint ing, t his key a lso fu nctions as a c ancel key (t he print er will prompt you for

confirmation before cancellation occurs ) .

You can program a time delay between the printing of test labels using the ‘Print Test Rate’ featur e; see Section 5.1.7

M-Class 41

Page 50

5.0.4 Indicator Lights

5.0.5 LCD

‘On’ indica t es tha t t he pr int er is p owered ‘O n’ a nd, a ft er initia liz a tion, it indica t es t he

Ready Mode.

‘Slow Flashing’ indicates Menu Mode.

‘Fast F lash ing’ indicates d ata i s bei ng r eceived an d processed .

‘On’ indicates a ‘Paus ed’ c ondition.

‘Slow Flashing’ indicates a Warning. ‘Fast Flashing’ indic ates a F ault. See Section

7.1 for a listing of associated messages.

Liquid Crystal Display

The disp lay provides several types of information:

• Following a b rief power -up s equ ence (initialization), the ‘R eady’ message.

• The time a nd da te, if t he pr int er ha s r eceived it fr om one of the following: the host,

the fr ont pa nel s etting, or the T i me and Dat e op tion.

• A label counter during a batch print job.

• The Menu System when in Menu Mode.

• Any promp t, condition, downloading, wa rning, or fa ult message.

42 M-Class

Page 51

5.1 The Menu System

Printer operation can be controlled through the user interface, allowing the operator access to these six menu system

branches:

• Media Settings

• Pr int Control

• Printer Options

While in the menu syst em, the cu r r ent s election will b e indica t ed with a n a st er is k (*) next to the displa yed item on the LCD.

Selections designated with a section symbol (§) will require a printer reset before becoming effective. A reset will be

aut omatically invoked when exit ing the menu sys tem and answer ing ‘Yes’ to the ‘Save Cha nges’ pr ompt. Cha nges made

will be saved. When power is removed, the new setti ngs will be restored up on power-up .

The same functional commands from your host computer may, in some cases, override the printer’s menu settings. In

additi on, as a secur ity feat ure for the prevention of accidenta l or una uthor ized changes, the menu system ha s a pa ssword

protection f eature.

Note: In the following subsections, the factory default settings are denoted with the ‘’ symbol. Selections denoted with a

diamond (♦) can only be changed t hrough the menu system - all other selections can be overridden by host software

commands. Consult the Class Series Programmer’s Manual for specific information.

5.1.1 Entrance and Exit Prompts

With ‘Ready’ dis played on the L CD, press the

Note: While in Menu Mode, the printer will stop p rocessing new D PL (or bitmapped) data.

MENU MODE

ENTER PASSWORD

0 0 0 0

KEEP HOST CHANGES?

ENTER = YES

SAVE CHANGES?

ENTER = YES

• System Settings

• Communications

• Diagnostics

MENU

Key to ent er Menu M ode.

Depending up on the conf igur at ion of the p rint er, the following E ntr anc e and Ex it P rompt s

may be disp layed when acces sing or lea ving the Menu S ystem.

You a re a tt empting t o enter Menu Mode. Secu rity ha s been ena bled and now t he corr ect

user - def inable password is r equ ired before access ing the Menu Mode functions .

You are now entering Menu Mode. Existing Host commands have affected the

configuration of the printer. Pressing ENTER will save these changes; otherwise, the

printer will revert to p reviously s aved sett i ngs.

You are now exiting Menu Mode, but have made changes to the printer’s settings.

Pr essing ENT ER will reconf igure your printer accor ding to these cha nges; otherwis e, the

printer will revert to p reviously s aved sett i ngs.

Note: If changes have been made that require a reset, the printer will automatically invoke that reset.

M-Class 43

Page 52

5.1.2 Media Settings

MEDIA TYPE

DIRECT THERMAL

THERMAL TRANSFER

SENSOR TYPE

GAP

CONTINUOUS

REFLECTIVE

LABEL LENGTH

04.00in (0-99.99)

MAXIMUM LABEL LENG TH

16.00in (0-99.99)

PAPER OUT DISTANCE

00.25in (0-99.99)

LABEL WIDTH

203DPI > 04.26in (.75-4.26)

300DPI > 04.16in (.75-4.16)

RIBBON LOW DIAMETER ♦

1.38 in (1.00-2.00)

SENSOR CALIBRATION ♦

PERFORM CALIBRATION

ADVANCED ENTRY

SENSOR LEVELS

SENSOR GAIN

Selects the printing method.

For use with heat sensit ive media.

For use with media r equ iring a ribbon to create an ima ge.

Selects the top-of-form (TOF) sensing method for the media.

The printer recognizes t he TOF by sensing ga ps in the media.

No TOF sens ing. The LAB E L LENGTH setting det ermines the length.

The printer recognizes t he TOF by sensing r efl ective (bla c k) ma rks on t he media.

When the Sensor Type is set to Continuous, this value is used to determine the TOF.

Sets the maximum length between TOF marks (gap or reflective). If this limit is

exceed ed, a top of fo rm fault is d ecla red.

Sets the length of travel b efore an ou t of st oc k c ondition is declared.

Sets the maximum limit for t he printa ble width. Ob jects extending beyond this limit

will be clipped off and not p rinted.

Sets the thr es hold f or a low ribb on indic ation.

Adjust s the printer to sense your media.

The u s er f oll ows s t ep s t o allow t he p rint er t o calcu l a t e t he emp t y, ga p ( or ma rk), and

paper values to s et the media sensor .

The user directly inputs t h e best va l ues to ad j ust the media sensor.

Sets threshold va lues for the media sensor p ara meters. Manua l entry for paper , gap

(or ma rk), and empty thresholds.

Obser ve A/D reading a nd set SE NSOR GAIN. Adjus ts the s ensitivity of t he sensor

for custom la bel stock.

44 M-Class

Page 53

PRINTHEAD CLEANING

CLEAN HEAD SCHEDULE

000 in. (* 1000)

Controls the p rinthea d c leaning routine.

Specifies the inch (or centimeter) count to reach before prompting a printhead

cleaning. If the number specified is exceeded three times, the pr inter will fault until

cleaning is initiat ed.

Notes: The def ault value (zer o) disables this function. Also, the number specified is multiplied by one

thousand.

CLEAN HEAD COUNTER

0 in.

RESET COUNTER

CLEAN HEAD NOW

Indicates the number of inches (or centimeters) since printhead cleaning was last

initiated.

Allows the clean head counter to be set to zero

Initia tes printhead cl eaning and r es ets the C lean Head C ounter.

Notes:

Remove ribbon, if installed.

Enter Menu Mode / Media Settings / Media Type and set the printer for Direct Thermal.

Ensure that full width media is installed.

See Section 6.1 for detailed instructions.

M-Class 45

Page 54

5.1.3 Print Control

HEAT

10 (0-30)

PRINT SPEED

M-4206 > 6 in/s (2 -6)

M-4208 > 8 in/s (2-8)

M-4306 > 6 in/s (2-6)

FEED SPEED

M-4206 > 6 in/s (2 -6)

M-4208 > 8 in/s (2-8)

M-4306 > 6 in/s (2-6)

REVERSE SPEED

M-4206 > 4 in/s (2 -5)

M-4208 > 4 in/s (2-5)

M-4306 > 4 in/s (2-5)

ROW OFFSET

00.00in (0-99.99)

COLUMN OFFSET

00.00in (0-99.99)

PRESENT DISTANCE

0.00in (0-4.00)

CUSTOM ADJUSTMENTS ♦

DARKNESS

32 (1-64)

CONTRAST

32 (1-64)

ROW ADJUST

000 DOTS (-150 -150)

COLUMN ADJUST

000 DOTS (0-128)

PRESENT ADJUST

064 DOTS (0-128)

Contr ols the ‘bur n-time’ of the print head. This is the equivalent of Heat Setting on

most label software programs.

Controls t he rate of label movement during the printing proc ess.

Controls the rat e of label when the FEED Key is pressed.

Controls the rate of label movement during backup positioning for start of print,

cutting or present dista nc e.

Shifts the vertical start of print position. This is the user setting for row adjustment.

Shifts the horizontal, left-justified start of print position to the right without shifting

the Label Width termination point to the right. This is the user setting for Column

Adjust.

Sets the label stop position past the start of print. When the next label format is

received, t he printer will automatically backfeed to the star t position. If the present

distance is set to zero, the pr inter will oper ate withou t reversing.

These fa ctory adjustments independently change the listed parameters to finely tune

the printer and compensate for slight mechanical differences sometimes evident if

multiple printers shar e la bel formats.

Controls the printhead strobe time to fine-tune the HEAT setting.

It a llows r ela t ive pr int edge (gr a y) a djus t ment for t he pr int qu alit y, which a llows fine-

tuning for specif ic media /ribbon mix.

Shift s t he vertic al s ta rt of p rint pos ition in dot s up war d or downwar d to f ine-tu ne the

ROW OFFSET setting.

Shift s bot h the hor izonta l st a rt of pr int p osit ion and t he LABEL WIDT H ter mination

point to the right in dots to fine-tune the COLUMN OFFSET setting.

Adjusts the label stopping position in dots to fine-tune the PRESENT DIS TANCE

setting.

46 M-Class

Page 55

5.1.4 Printer Options

MODULES

PRINT DIRECTORY

PRINT FILE

FORMAT MODULE

DELETE FILE

PACK MODULE

PRESENT SENSOR

MODE

AUTO

ENABLED

DISABLED

RETRACTION DELAY

070 x 10mS (1-255)

CUTTER

AUTO

ENABLED

DISABLED

Memory ava ila b le for u ser s t or a ge of gr a phic s, font s and lab el forma ts . (T he physic a l

presence of the respective memory module must be detected to show the function

selections in the menu system.

Pr ints a la bel dir ect or y of s elected, or of a ll a va ila ble modules, t he a va ila ble sp a ce on

these modules, the files pr es ent , and the type of module and f iles .

The us er may select from a list of available files f or sa mple p rinting.

The us er may s elect fr om a list of a vaila ble modules for for matt ing – a ll dat a will be

erased.

The u ser may s elect f rom a list of ava ila ble files for deleting (p rot ected modules will

not ap p ear ) . Bytes will not b e r etr ieved unt il the module that conta ined the deleted file

is packed.

Packing the module removes files marked as deleted and defragments existing file

structures to recover space.

Used for on- demand la bel dispensing, where a pr inted label blocking t he sensor will

inhibit further printing until removed. (T he physical p resence of the Pr esent Sensor

must be detected to show the ENABLE/DISABLE selections, else NOT

INSTALLED will be displa yed momentarily).

Sets Pres ent Sensor to desired mode of operation.

Enables the present sensor when option is installed – present sensor or peel and

pres ent mechanism. St op loca tion ( pr esent dist a nce is au toma tica lly set appr opr ia tely

for the installed hardware.

Enables the sensor for on-demand printing. Stop location (present distance is

automatically set appropriately for the installed hardware.

Disables the sensor.

Time delay prior to moving label to next start of print in milliseconds.

Used to cut media into separate labels. (The physical presence of a device mu st be

detected to show the ENABLE/DISABLE selections, else NOT INSTALLED will be

displayed momentarily).

Enables the cutter when option is installed. Stop location (present distance is

automatically set appropriately for the installed hardware.

Enables cutting.

Disables cutting.

M-Class 47

Page 56

GPIO PORT ♦

GPIO DEVICE

DISABLED

APPLICATOR

BARCODE VERIFIER

START OF PRINT

ACTIVE HIGH

ACTIVE LOW

END OF PRINT

LOW PUL SE

HIGH PULSE

ACTIVE LOW

ACTIVE HIGH

Used to int erfac e t he p rinter to external c ontrolling devices ( see Appendix D) .

Sets the GPIO Port to work with a specific type of device.

Disables the GPIO Port.

Enab les the GPIO f or a la bel applic ator .