Page 1

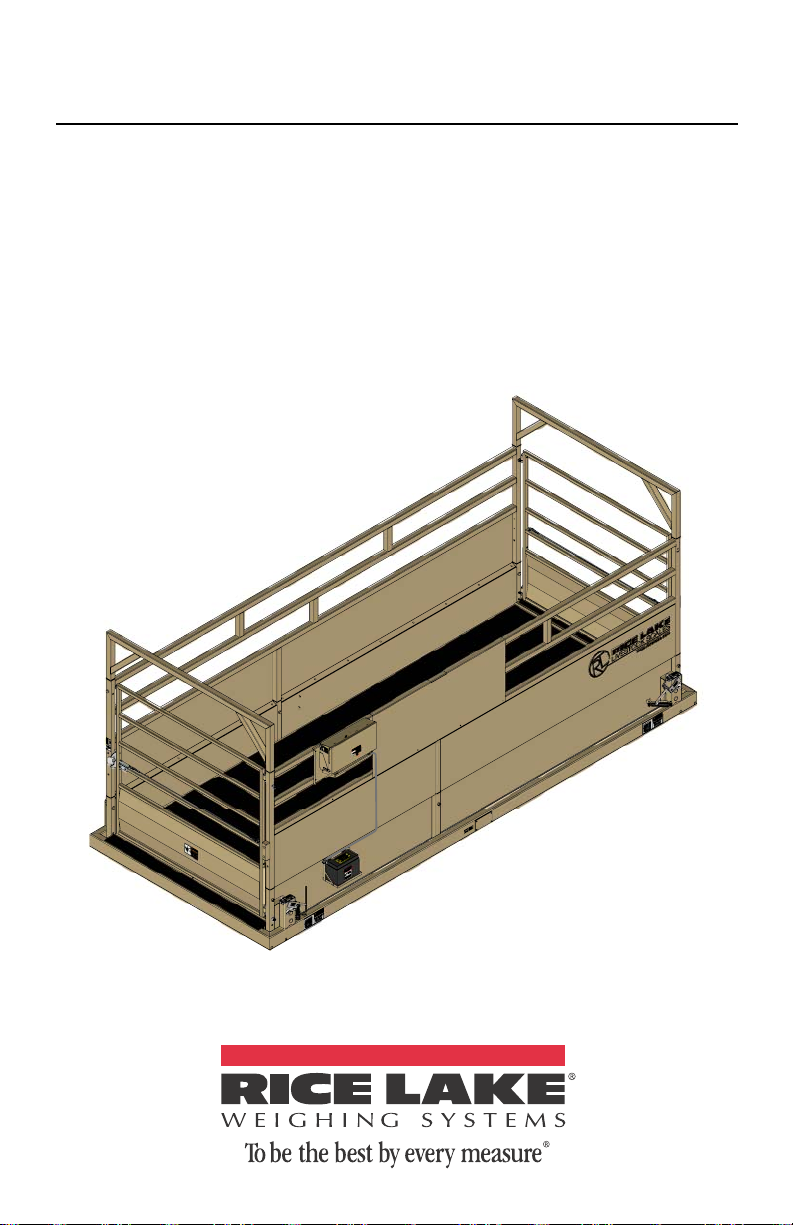

Multiple Animal Scale Portable

Installation/Service

Manual

132795 Rev D

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

1.0 Introduction............................................................................... 1

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1.1 Safety Decals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Lifting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.0 Assembly................................................................................... 1

2.1 Unloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1.1 Install one lifting fixture on each of the four corners.. . . . . . . . . 1

2.1.2 Slinging the scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.1.3 Lift the scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Package Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.3 Cage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3.1 Apply the silicone bead (Mobile scales only). . . . . . . . . . . . . . . 3

2.3.2 Install walls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3.3 Install the Gate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3.4 Complete Cage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Gate and Latch Adjustment Procedure . . . . . . . . . . . . . . . . . . . . 5

2.5 Mount the 920i Weighcenter – Optional. . . . . . . . . . . . . . . . . . . . 6

2.5.1 Battery Mount – Optional. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.0 Installation ................................................................................ 9

3.1 All Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Permanent Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.3 Portable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Switching Between Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4.1 Converting to Weigh Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4.2 Converting to Transport Mode . . . . . . . . . . . . . . . . . . . . . . . 10

4.0 Repair Parts ............................................................................ 11

5.0 Maintenance ........................................................................... 15

5.1 Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Scale Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . . . 15

5.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MAS-P Limited Warranty .................................................................... 19

For More Information .......................................................................... 20

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Rice Lake Weighing Systems is an ISO 9001 registered company.

November 12, 2013

i

Page 4

ii MAS-P Animal Scale Operator’s Manual

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

Page 5

1.0 Introduction

Important

CAUTION

WARNING

DANGER

The Multiple Animal Scale Portable (MAS-P) system is manufactured with top quality components and is engineered using the latest technology to provide operating features and reliability unmatched for years to come.

Please take the time to read this manual completely through before attempting to use

the system

ough understanding of this manual will ensure that you receive the maximum benefit

from the sys

If you have any questions or comments please contact Rice

1. 1 Sa fe t y

. Although the MAS-P has been designed for easy set up and use, a thor-

tem.

Lake Weighing Systems.

Safety Symbol Definitions:

Indicates an imminently hazardous situation that, if not avoided,

will result in death or serious injury.

Indicates a potentially hazardous situation

could result in death or serious injury, and includes hazards that

are exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided may

result in minor or moderate injury.

Indicates information about procedures that, if not observed,

could result in damage to equipment or corruption to

data.

that, if not avoided

and loss of

General Safety

Do not operate or work on this equipment unless you have read

and understand the instructions and warnings in this manual.

Failure to follow the instructions or heed the warnings could

result in injury or death. Contact any Rice Lake Weighing

System dealer for replacement manuals. Proper care is your

responsibility.

Introduction 1

Page 6

WARNING

Failure to heed may result in serious injury of death.

Important

DO NOT allow minors (children) or inexper

DO NOT operate without all shields and guards in place.

DO NOT jump up and down on the scale.

DO NOT use for purposes other than weighing.

DO NOT place fingers into slots or possible pinch points.

DO NOT place hands, feet or any body part underneath the scale at any time. the

scale could be lowered at any time, crushing body parts.

DO NOT use any load bearing component that is

dimension.

DO NOT use this product if any of the components are cracked.

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

Keep hands, feet and loose clothing away from moving parts.

Some procedures described in this manual require work inside the indicator enclosure. These procedures are to be performed by qualified service

personnel only.

Always be certain when lowering the scale that everyone is clear of the scale and

any moving parts.

Use two hands when gripping the lift handl

Be sure the gates are latched or tied inw

Ensure all three hitch lock pins are install

transport position before moving the scale.

This unit is not intended for the transportation of livestock or any other goods. Any

addition of weight to the scale in transport mode may cause premature

component failure and voids the Rice Lake warranty.

ienced persons to operate this unit.

worn beyond 5% of the original

e to raise or lower the scale.

ard before transporting the scale.

ed and the suspension stops are in the

Animal Safety:

Animal safety is a very serious issue and must be observed when handling any

type of animal.

The scale surface may become slippery during use; a build-up of manure on the

e may reduce traction. It is recommended that you take any necessary

scal

precautions to maintain an acceptable level of animal footing.

Calibration:

Do not calibrate this scale with a weight cart having a gross weight in excess of

4,000 lbs or 1,815 kg. This device is designed to be calibrated with single block

weights spread evenly throughout the floor of the scale. Shift tests should not be

done with more than 4,000 lbs or 1,815 kg in a 4’ x 4’ area. Failure to comply with

this warning will result in damage to the scale and void the warranty.

2 MAS-P Animal Scale Operator’s Manual

Page 7

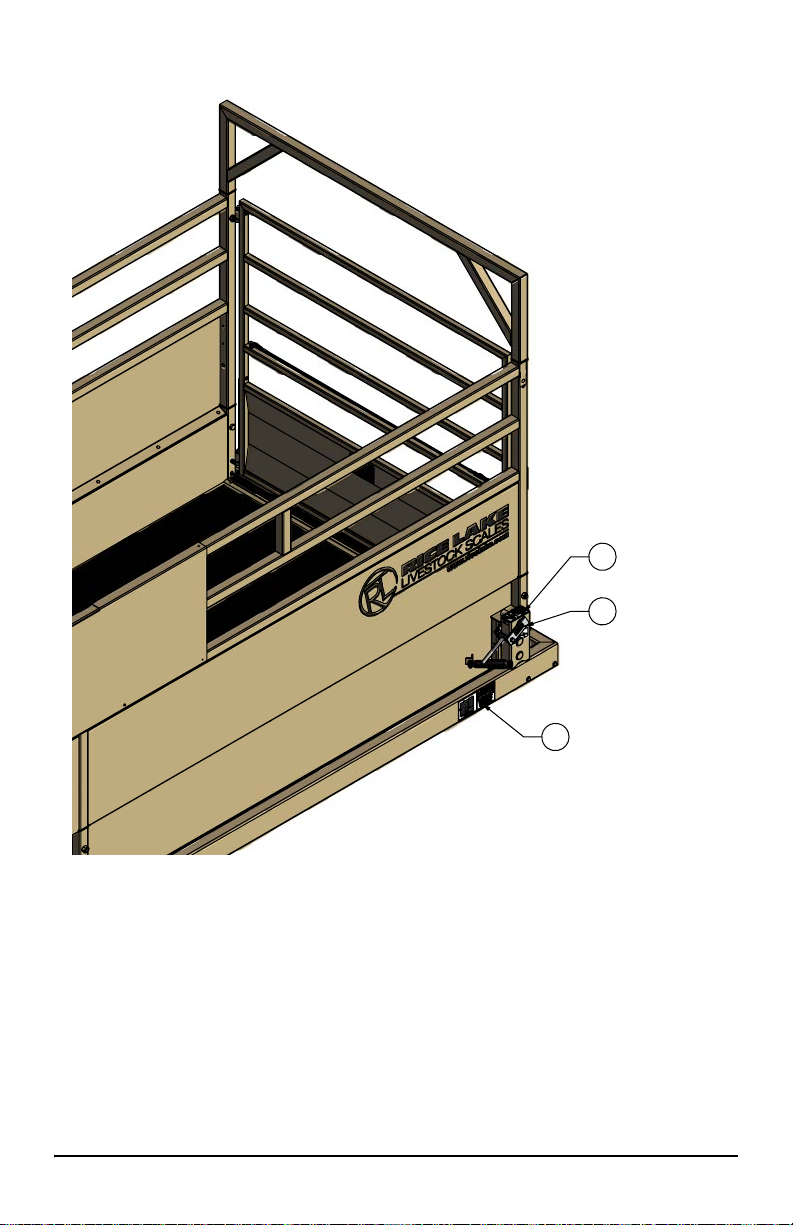

1.1.1 Safety Decals

,QVLGH

:HLJKFHQWHU

)URQW

%DFN

)URQW

%DFN

%RWK

6LGHV

%RWK

%RWK

6LGHV

Items 1-4 are on units equiped

with the 920i Weighcenter only.

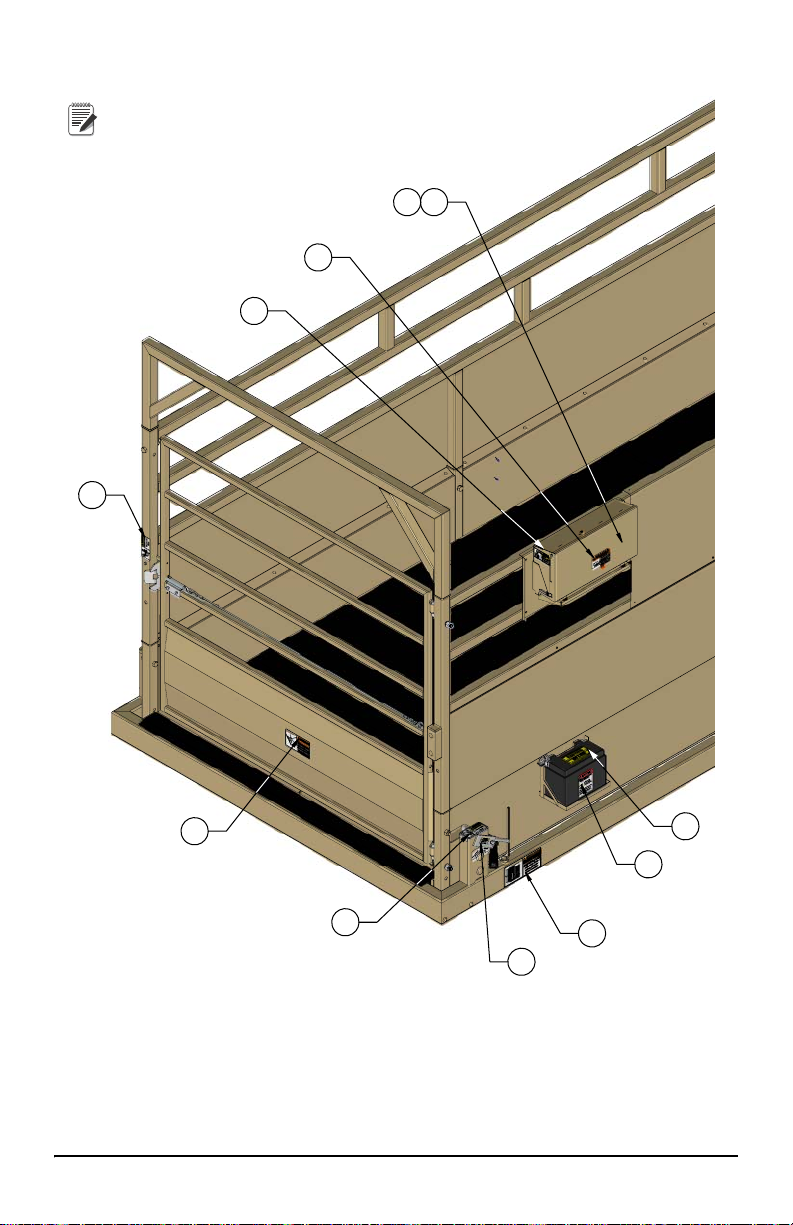

Note

Figure 1-1. Safety Decal Locations

Introduction 3

Page 8

%RWK

6LGHV

%RWK

6LGHV

%RWK

6LGHV

Figure 1-2. Safety Decal Locations (continued)

4 MAS-P Animal Scale Operator’s Manual

Page 9

Figure 1-3. Safety Decals

Item # Part # Description Qty

1 151908

2 151906

3 151907

4 151904

5 151909

6 151910

7 151898

8 151902

9

10 151901

Read Manual

Warning, Do Not Open

Warning, Do Not Leave Tray Down

Caution, Low Clearance

Caution, Pinch Point

Caution, Always Grip With Two Hands

Warning, Crushing Hazard

Warning, Opens Quickly

Warning, Battery

Caution, Not A Step

1

1

2

1

6

4

4

2

1

1

Introduction 5

Page 10

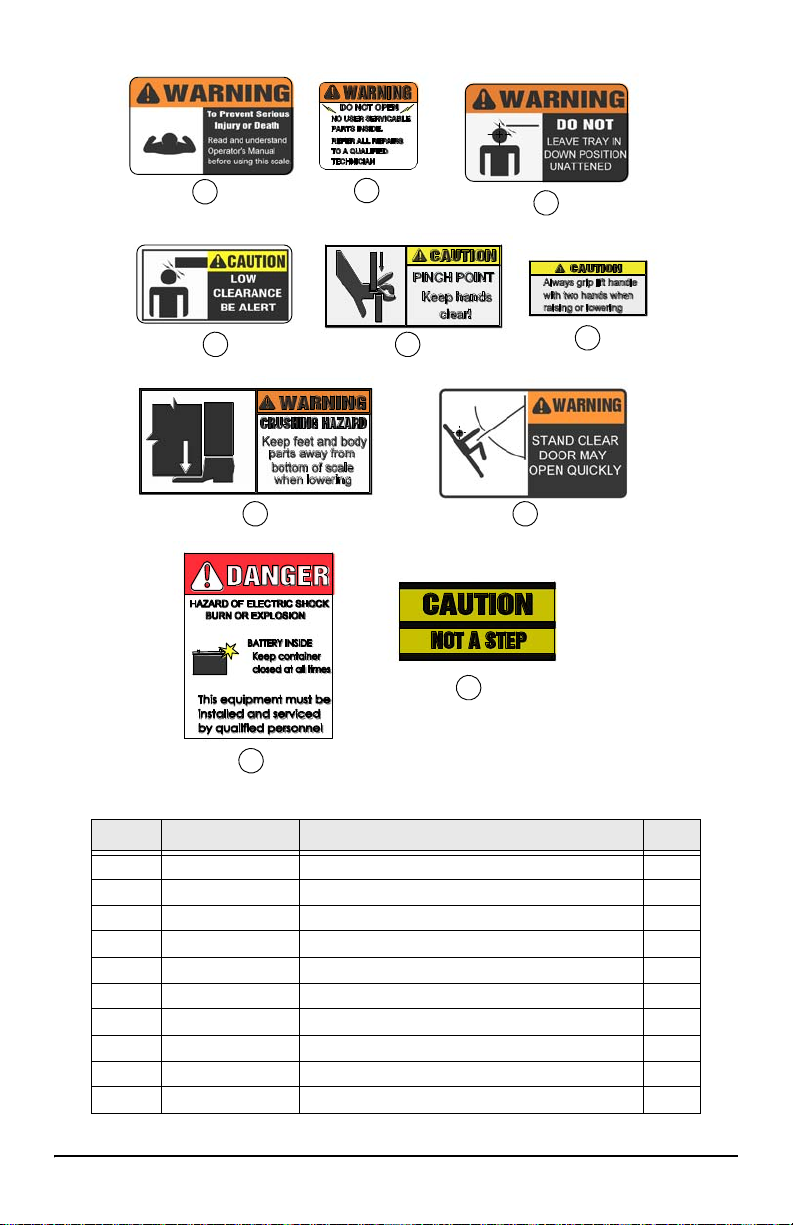

1. 2 Ov e rv ie w

The MAS-P shown below consists of a sheeted animal cage suspended by four S-type

load cells through a cam style On-Board

transport mode, the scale system is locked down, protecting the load cells from damage during transport. The scale is rais

tem. A digital indicator is connected to th

The MA

a low deck height

S-P can be used on any firm surface up to 7% grade (4-degree slope) and has

(6”) for easy step in.

lift system on top a portable base frame. In

ed to the weigh mode using a lever and cam sys-

e scale to display the weight.

Figure 1-4. MAS-P Animal Scale

6 MAS-P Animal Scale Operator’s Manual

Page 11

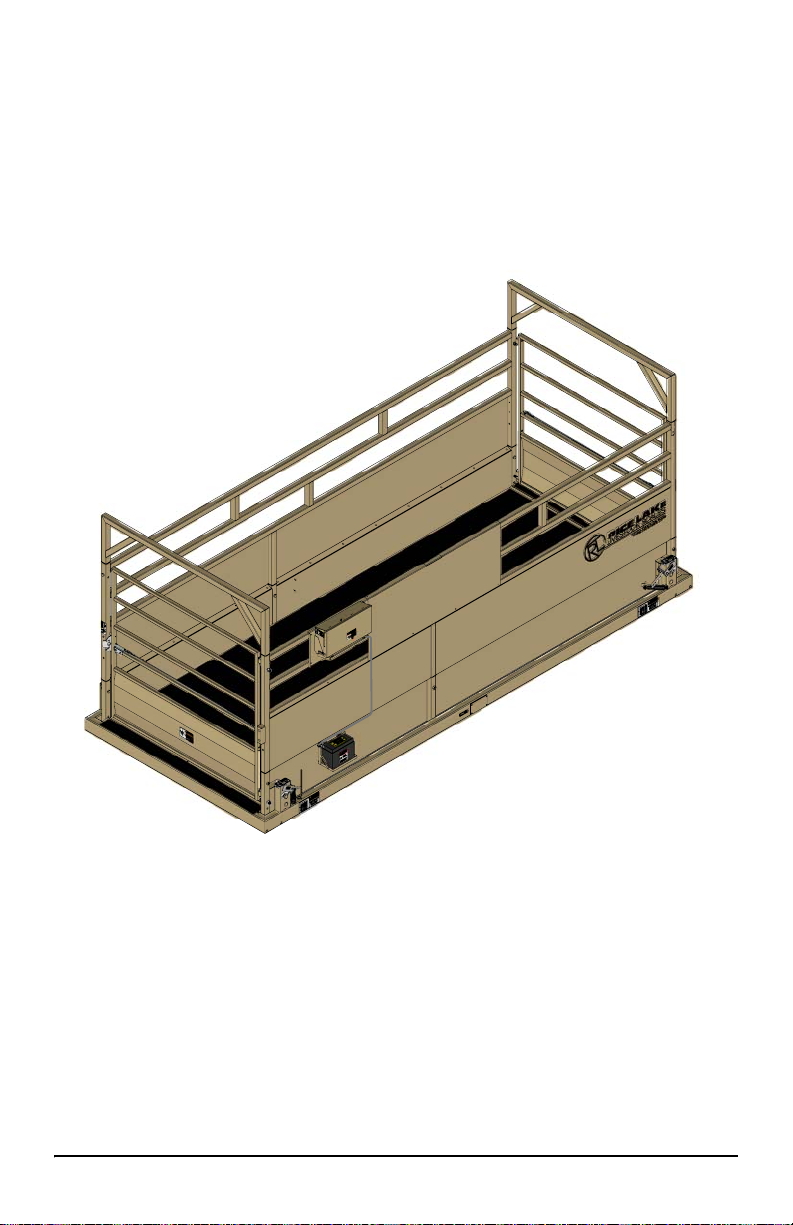

1.3 Lifting Instructions

Lift from here with

forklift or straps

Alternate Strap Location

Lift the scale only in designated locations (see Figure 1-5). The scale may be lifted by

forklift (ensuring the forks reach through both

loader. Ensure the scale is in the transport mode (locked down – see next section)

when loading and transporting the scale.

walls), or by 4 straps and a crane or

Figure 1-5. Lift Points

Introduction 7

Page 12

2.0 Assembly

Note

Lifting

Fixture

Nylon Locknut

9 FEET

11 FEET

2.1 Unloading

2.1.1 Install one lifting fixture on each of the four corners.

If lifting fixtures are in place, skip to Section 2.1.2.

1. Remove the nylon locknut from the bolt installed for shipping.

2. Place the lifting fixture with small hole over the bolt.

3. Reinstall the nut leaving the fixture free to move.

Figure 2-1. Lifting Fixture

2.1.2 Slinging the scale.

MAS-P can be slung with 4 equal length straps connected from the lifting lugs to a

single point in the center.

• Strap length 8 x 13 = 7 ft minimum

• Strap length 8 x 18 = 10 ft minimum

1 MAS-P Animal Scale Operator’s Manual

Figure 2-2. Slinging the Scale

Page 13

2.1.3 Lift the scale.

Shipping Stub

Note

1. If stacked, monitor the four corners directly below the lifting fixtures.

2. Each corner has a shipping stub inserted,

ensure they remain with the lower scale.

3. Once the upper scale of the stack is rem

Figure 2-3. Shipping Stub

these stubs are not bolted in place,

oved the stubs can be discarded.

4. The scale can now be stored as is or placed on a

relatively flat location to be

assembled.

2.2 Package Removal

The indicator is shrink wrapped for transportation. Be careful when removing to

avoid damaging the indicator when removed.

1. Remove indicator, then re-strap the walls if

packaged.

The bolt that holds the walls and the cross members in place during

shipping is not used for assembly.

Please recycle the packaging material.

Place the parts safely and in a location they will not be damaged.

the scale is to be transported while

Assembly 2

Page 14

2.3 Cage Assembly

Silicone

Wall Insert

WARNING

Note

Note

2.3.1 Apply the silicone bead (Mobile scales only)

Before installing the walls a silicone bead must be added.

1. Clean the upper flange of the floor and the low

spirits.

2. Apply an 1/8” bead of silicone along the upper edge of the floor panel along the

enti

re length as shown in Figure 2-4.

er wall flange with mineral

Figure 2-4. Silicon Bead

2.3.2 Install walls

Wall installation should be done with 2 people or an overhead

crane.

1. Lift the first wall by using one sling in the center.

The wall with the operator’s instructions is mounted on the left side.

2. Stand the wall vertical and place the inserts from the wall into the tubes of the

cage floor. The more vertical the wall the easier assembly will be.

3. Repeat for the opposite wall.

4. Install the top cross members.

5. Insert the 3/4 x 3 1/2” bolts through the cage wall and insert s on the indicator

the cage, head of bolt to the inside.

side of

A come-along from the top of the cross member to bottom of the cage

corner post may be required.

For 18 ft scales a 1/2 x 3” bolt and nyl

post with the nut on the outside.

3 MAS-P Animal Scale Operator’s Manual

on locknut is installed on the center

Page 15

2.3.3 Install the Gate

Hook Bolt

Spring Pin

Nut and washer

Cage Wall

Gate

Jam nut and washer

Nylon washer

Install Spring Pins

after gate is in

place.

Note

Install the gate with the hinge bolts on the opposite side of the scale.

Hook bolts must be assembled with lock washer on the inside of gate

and the jam nut on the outside.

Figure 2-5. Lower Hook Bolt

1. Install jam nut and lock washer onto the hook bolts. Screw the nut on about 2”.

2. Insert one hook bolt into the lower and upper holes of the cage wall with the

hoo

k portion pointing upward.

3. Install nut and washer onto the hook bolts s

4. Place nylon washer onto the hook portion of the upper and lower hook bolts

install the gate onto the hooks.

ecuring them to the cage wall.

5. Insert roll pin through the hook bolts.

6. Repeat steps 2-4 for second gate.

7. Adjust the hinge side gap between the gate and the cage wall to about 3” and

nge bolts.

snug hi

Assembly 4

and

Page 16

2.3.4 Complete Cage Assembly

Note

1. Install the 5/16” carriage bolts and serrated nuts with the head of the bolts on the

inside of the cage. Begin by tightening the bolts from the center of the sheet

section working outward.

2. Tighten the 3/4” x 3 1/2” bolts installed in Section 2.3.2.

3. Assemble the latch with 3/8 x 3 1/4” bolts, lock washers, nuts and the latch pin

wit

h the supplied hardware.

Figure 2-6. Latch Assembly

4. Install the 3/4” EVA hose on the latch pin (Mobile units only).

5. Adjust the gates and latches per the adjustment procedure.

2.4 Gate and Latch Adjustment Procedure

The gates shall be assembled following the listed criteria:

• Hook Bolts - Assemble with lock washer on inside of gate and

jam nut on the outside.

• Hinge Side Gap - Approximately 3” between the gate and the

corner post.

• Gate Latch Pin - Install rubber tubing on the latch pin (Mobile

units only).

Adjust gates as follows:

1. Adjust the hook bolts to align the top of the gate on the latch side with the top of

the cage wall.

2. Adjust the hook bolts so the latch side gap is about 1 1/2”.

3. Install and adjust the latch so the gate latch pin does not rub on the top or bottom

of the latch.

5 MAS-P Animal Scale Operator’s Manual

Adjust the hook bolts only if necessary.

Page 17

2.5 Mount the 920i Weighcenter – Optional

Adhesive

Conduit Clamp

9/32Ø

1. Before installing the bracket a bead of silicone must be added. See Figure 2-7.

(Apply silicone where labeled adhesive)

2. Clean the wall tubes where bracket will mount and the s

on the mount bracket with mineral spirits.

3. Install the adhesive tape on the mounting bracket between the holes.

4. Place the mounting brac

to the cage.

5. Secure with four bolts.

ket onto the cage wall by pressing the adhesive tightly

pace between the holes

Figure 2-7. Control Box Mounting

Assembly 6

Page 18

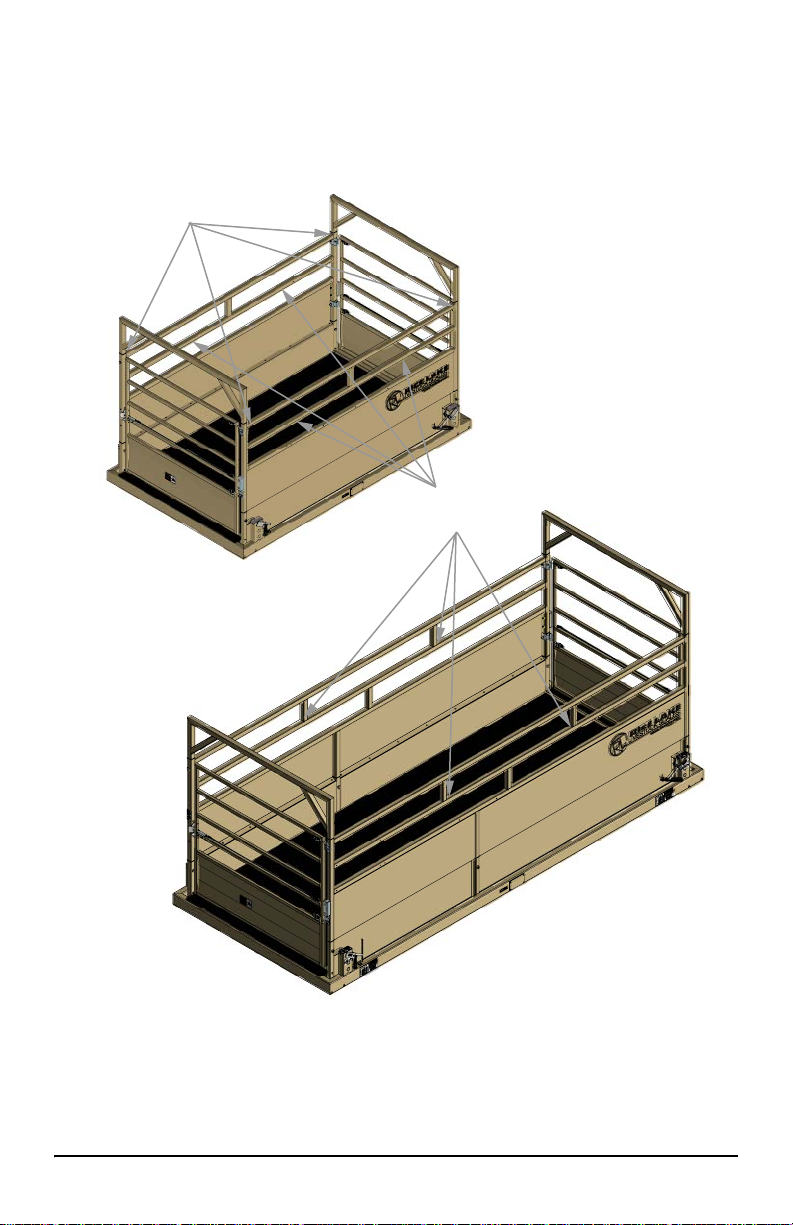

2.5.1 Battery Mount – Optional

Note

8 x 13 Scale

8 x 18 Scale

The mounting of the optional battery box differs slightly depending on

the scale size.

Figure 2-8. Battery Mount

1. Mount the upper mounting bracket with the 5/16 x 3/4” bol ts supplied, uti lizing

the exi

sting wall panel bolt holes. See Figure 2-9.

2. Hang the battery bracket from the upper mount and in stall the 5/16 x 3/4 ” bolts

that are supplied.

3. Drill a 3/8” hole through the wall panel aligned with the lower mounting tab.

4. Sandwich the battery strap between the

5. Install the 5/16 x 1/2” carriage bolt.

6. Route the indicator conduit from the control box to the battery as shown in

Figure 2-9.

7. Install the lower 90° conduit connector into the mounting tab.

8. Route the scale cable to the connector located

9. Route the power wire to the battery, see Figure 2-9.

lower mount and the cage wall.

to the left.

Figure 2-9. Mounting Holes

7 MAS-P Animal Scale Operator’s Manual

Page 19

Battery Box Connections

1. Connect the scale cable and secure with a cable tie.

2. Connect the power wires as shown in Figure 2-10.

3. Replace the battery cover.

Figure 2-10. Battery Connections

Assembly 8

Page 20

3.0 Installation

Scale Cable

Bubble Level

As with any weighing equipment, the accuracy of the scale is dependent on the

installation. The following points must be adhered to when installing the MAS-P

Animal Scale.

3.1 All Installations

In all installations, the scale must be level to ensure proper operation. All MAS-P

Animal Scales are equipped with a bubble level (located on top the base frame – see

Figure 3-1). Ensure the bubble is fully inside the circle marked on the top of the level.

3.2 Permanent Installation

Rice Lake Weighing Systems recommend a concrete foundation (piles or piers) for

permanent installations. The foundation must be able to support the gross weight o f

the scale (scale dead weight plus scale capacity), and the piles or piers must be

situated directly under the load cell stands (see shimming location in Figure 3-1). The

foundation must not be subject to distortion or motion due to frost action. A qualified

local

professional should be consulted to recommend the proper size of foundation for

the location. Foundation dimensional requirements are available from the dealer or

Rice Lake Weighing Systems. Requirements may vary from one Weights and

Measures jurisdiction to another, please contact the local office.

3.3 Portable Installation

The MAS-P is ideal for use in many locations. Simply load and unload the scale as

described in the Section 1.3 on page 7. Locate the scale in as level a location as

possible, and shim (with wood or me tal s hims) under the load

scale is level as described above. Please contact the local Weights and Measures

office regarding the moving of the scale to ensure the validity of the certification.

cell stands to ensure the

Figure 3-1. Shim/Load Cell Stand Locations

3.4 Switching Between Modes

3.4.1 Converting to Weigh Mode

1. Place the scale in as level a location as possible. Ensure there are no obstructions

under the deck that would affect weighing accuracy. Check the bubble level. Use

shims or timbers to ensure the scale is as close to level as possible.

9 MAS-P Animal Scale Operator’s Manual

Page 21

Note

The scale will weigh properly on a slope up to 4 degrees,

Note

WARNING

Note

WARNING

Rotate Cam To

Raise Scale Into

Weigh Position

(See Decal)

approximately 7%).

2. Inspect all four corners of the scale. Although the scale will weigh properly up

to four degrees off level, individual corners of the scale should not be allowed to

teeter. If any of the corners are not contacting the ground, place shims directly

under the base frame, under the load cell stands, to prevent teetering. (See

Figure 3-1)

3. Plug the indicator into the scale cable. The scale

cable runs from the junction

box (inside the base frame) to the indicator. (See Figure 3-1)

4. Connect power to the indicator and switch ON.

NG BOTH HANDS, raise the platform to enable the scale (See Figure 3-2)

5. USI

The lift mechanism is an over center cam style lift and lock. If not

disturbed, the scale will remain “locked” in the up position.

Always grip lift handle with two hands when raising and lowering

the scale.

Cam levers point toward each other in weigh mode and away from each

other in transport. See decals for direction of levers in each mode.

6. You are now ready to weigh.

3.4.2 Converting to Transport Mode

When the scale is not in use the scale should be locked down in transport mode to

prevent any accidental overload of the weigh system.

1. USIN

2. Turn off indicator. A stand alone indicator should be stored indoors when the

G BOTH HANDS disengage and lock the scale in transport mode by

rotating all four cam levers counter clockwise into the fully locked position.

The lift mechanism is an over center cam style lift and lock. If not

disturbed, the scale will remain “locked” in the up position.

Always grip lift handle with two hands when raising and lowering

the scale.

Cam levers point toward each other in weigh mode and away from each

other in transport. See decals for direction of levers in each mode.

scale is not in use. The weigh center should be closed and latch to prevent

damage.

Figure 3-2. Scale Lift

Installation 10

Page 22

4.0 Repair Parts

**Lift Mechanism

*

Figure 4-1. MAS-M

*See Figure 4-2 Details A-D for gate hardware (item 14).

**See Figure 4-2 Detail E for lift mechanism parts.

11 MAS-P Animal Scale Operator’s Manual

Page 23

Item No. Part No. Description

1

130931 Cage Crossmember

2

106387 Bumper

131708 Cage Wall 13’

3

131946 Cage Wall 18’ Right

131708 Cage Wall 13’

4

131947 Cage Wall 18’ Left

6

131782 Gate Short Sheeted

7

126787 Scale T-belting (83” width)

8

127081 Bubble Level Circular

9

127561 Scale Cable Female MS Conn 132”

10

11

12

14

15

16

17

18

19

20

21

22

127740 Cover Plate Scale Frame/J-box

126819 Foam Gasket J-box

131891 Scale Junction Box 4 Cell SS

131707 Cage Floor MAS8-13

131934 Cage Floor MAS8-18

130842 Rice Lake Decal

15097 Bolt 3/1-10 x 3 1/2

14697 Nut, Lock 3/4-10 Hex, Nylon Insert Zinc

130022 Operator Shield

45728 Screw, Self Drilling 12-24 x 7/8

132692 Label MASM Weigh/Transport Mode

127094 Label MASM Transport/Weigh Mode

131436 920i Weighcenter (See Operator’s Manual PN 159192)

Battery

Repair Parts 12

Page 24

34

'HWDLO'

'RRU+DUGZDUH/DWFK

45

19

22

42

36

20

'HWDLO%

'RRU+DUGZDUH+LQJH

13 15

33

24

14

'HWDLO$

'RRU+DUGZDUH/DWFK6LGH

18

20

56

19

'HWDLO(

/LIWLQJ0HFKDQLVP

9

17

2

3

6

57

58

59

60

61

16

16

58

65

62

63

64

'HWDLO&

'RRU+DUGZDUH+LQJH6LGH

43

44

35

42

13 MAS-P Animal Scale Operator’s Manual

Figure 4-2. MAS-M Details

Page 25

Item No. Part No. Description

127184 Upper Notched Load Cell Pin

2

21444 Load Cell S-Type 10K

3

127163 Eyebolt Machined 10K

127668 Lower Load Cell Retainer

6

127200 Load Cell Cam Stand Cover SS

9

127007 Bolt 1/4x1/2

151807 Washer, Plain 3/4in Nylon

13

110950 Pin, Spring 1/4 x 1 1/4

14

151589 Hinge Hanger Bolt Hook

15

127684 Plug Plastic Round 2”

16

127177 Lower Notched Load Cell Pin

17

126926 Pin Spring Slotted 1/4x2-1/4

127033 Cap Screw, 3/8-16 x 3/4

18

15159 Washer, 3/8 Lock

19

132684 Nut, 3/8-16 Grade5

20

131784 Gate Latch

22

127021 Hair Pin 1/8 x 2 9/16

15181 Washer, 3/4

24

132179 Hinge Bracket

31

111074 Nut, 3/4-10NC

33

132217 Jam Nut, 3/4-10NC

34

21939 Washer, 5/16

35

131886 Cable, 1/4” OD x 6 ft

36

71872 Bolt, 3/4-10NC x 4

37

14697 Nut, Lock 3/4-10NC

39

131887 Quick Link 1/4 in

42

131701 Eye Bolt, 5/16-18 x 2 1/2

43

14646 Nut, Lock 5/16-18NC

44

39528 Bolt, 3/8-16NC x 2 1/4

45

132427 Strike Plate

56

131787 Cam with Lockdown

57

127165 Spacer Upper Notched Pin

58

127732 Cam Handle

59

131785 Cam Without Lockdown

60

15167 Lockwasher ½

61

14765 Bolt 1/2 x 4

127561 Scale Cable Female MS Conn 132”

22093 Bolt 3/8 x 2 Grade5

62

15161 Flat washer 3/8 SS SAE

63

126992 Nut 3/8 SS

64

Repair Parts 14

Page 26

5.0 Maintenance

Note

5.1 Maintenance Schedule

Weekly

1. Check entire scale for buildup of debris. Remove any debris found

on, under or around the scale.

2. Check for dirt and debris in the load c

3. Check all external cables and conduit for damage.

Yearly (in addition to weekly and monthly maintenance)

1. Disassemble each load cell location and grease all pins and eyebolts.

5.2 Scale Maintenance Procedures

Cleaning Load Cell Stands

It is very important to keep any excess debris from building up in the load cell

stand. Lift scale and block it up, clean any dirt out of the load cell stands

through the drain holes located at the bottom of the stand.

Disassembly and Greasing

This is very important to ensure the long life of your unit. Use the parts list

drawings for item numbers.

Use quality high-pressure grease.

Avoid bending or twisting the load cell wires.

ell stands and clean accordingly.

a. Remove the cell stand cover (27).

b. Remove the plug covers (34)

c. Remove the bolt which holds together items 26, 39, 38.

d. While holding the cam handle (36),

e. Remove the load cell pin (37)

assembly will be free on top and rest against the inside of the cell

stand.

f. Remove the inner cam (26).

g. Remove the lower retainer (33)

h. Grease all bearing surfaces except where

(upper and lower pins, cams, upper and lower eyebolts).

Reassemble in reverse order as

15 MAS-P Animal Scale Operator’s Manual

described above.

remove the outer cam (38).

and spacers (35). The load cell

the eyebolt contacts the pin

Page 27

26

27

28

35

36

33

37

38

39

40

34

Figure 5-1. Disassembly and Greasing

Maintenance 16

Page 28

Load Cell #1

Load Cell #2

Load Cell #4

Load Cell #3

Scale Cable

Junction Box

Trimmers

Load Cell #4

Load Cell #1

Load Cell #2

Load Cell #3

Indicator

Black

Green

White

Shield

Red

+E

-E

+S

-S

GND

V1 V2 V3 V4

Load cell wiring shown is effective for all models later

then 09/17/2013, models built prior that date should

rewire the scale to the updated configuration. For

information on rewire, download Technical Bulletin

(PN 159193) from www.ricelake.com

Note

DA

B

Indicator

AD

CB

Scale

A -EXC Black

B +SIG Green

C +EXC Red

D -SIG White

Connector

C

Figure 5-2. Load Cell Wiring Diagram

17 MAS-P Animal Scale Operator’s Manual

Figure 5-3. Scale/Indicator System Connection

Page 29

5.3 Specifications

t

N

A

T

I

O

N

A

L

C

O

N

F

E

R

E

N

C

E

t

O

N

W

E

I

G

H

T

S

A

N

D

M

E

A

S

U

R

E

S

MAS8-13 MAS8-18

Length Overall

Length Deck

Width Overall

Width Deck

Deck Height

Height

Deck Covering

Weight

Capacity

Section Cap

Approval Class

Approvals

13’-6” 19’-3”

12’-9” 18’-6”

8’-4” 8’-4”

7’-5” 7’-5”

6” 6”

99” 99”

5/8” Recycled One Piece Molded Rubber

Flooring System

2600 lbs. 3500 lbs.

15000 lbs. 20000 lbs.

10000 lbs. 20000 lbs.

IIIL (IIIHD) IIIL (IIIHD)

99-091A4

AM4*

Grad Size

**Paint

5 lb (2 kg) 5 lb (2 kg)

Powder Coated Galvanized Steel

**Structural Steel is not galvanized.

Notes:

Size / Model # ___________________________

Serial # _________________________________

Date Purchased _________________________

Unit ID # _______________________________

Maintenance 18

Page 30

MAS-P Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and

systems properly installed by a Distributor or Original Equipment Manufacturer

(OEM) will operate per written specifications as confirmed by t he Distributor/OEM

and accepted by RLWS. All systems and components are warranted against defects in

materials and workmanship for two years.

RL WS warrants that the equipment sold hereunder will conform to the current written

specifications authorized by RLWS. RLWS warrants the equipment against faulty

workmanship and defective materials. If any equipment fails to conform to these

warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given

prompt written notice with a detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes

must be packaged to prevent electrostatic discharge (ESD) damage in

shipment. Packaging requirements are listed in a publication, Protecting

Your Components From Static Damage in Shipment, available from RLWS

Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity

actually exists, and was not caused by accident, misuse, neglect, alteration,

improper installation, improper repair or improper testing; RLWS shall be

the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person

other than RLWS or its duly authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective

equipment. Buyer is responsible for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs,

including assembly or disassembly of equipment, nor will RLWS be liable

for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMITATION WARRANTIES OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. NEITHER RLWS NOR DISTRIBUTOR WILL,

IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’ SOLE AND EXCLUSIVE LIABILITY

HEREUNDER IS LIMITED TO REPA I R OR REPLACEMENT OF SUCH GOODS. IN

ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER CLAIMS

TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY

TO THE SELLER FOR WARRANTY CLAIMS.

NO TERMS, CONDIT IONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO

MODIFY THE TERMS OF THIS WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS

MADE IN WRITING AND SIGNED BY A CORPORATE OFFICER OF RLWS AND THE

BUYER.

© Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE,

19 MAS-P Animal Scale Operator’s Manual

WISCONSIN 54868 • USA

Page 31

For More Information

Web Site

• Frequently Asked Questions (FAQs) at

http://www.ricelake.com/faqs.aspx

Contact Information

Hours of Operation

Knowledgeable customer service representatives are available 6:30 a.m. 6:30 p.m. Monday through Friday and 8 a.m. to 12 noon on Saturday. (CST)

Telephone

• Sales/Technical Support 800-472-6703

• Canadian and Mexican Customers 800-321-6703

• International 715-234-9171

Immediate/Emergency Service

For immediate assistance call toll-free 1-800-472-6703 (Canadian and

Mexican customers please call 1-800-321-6703). If you are calling after

standard business hours and have an urgent scale outage or emergency, press

1 to reach on-call personnel.

Fax

Fax Number 715-234-6967

Email

• US sales and product information at

prodinfo@ricelake.com

• International (non-US) sales and product information at

intlsales@ricelake.com

Mailing Address

Rice Lake Weighing Systems

230 West Coleman Street

Rice Lake, WI 54868 USA

Maintenance 20

Page 32

Notes

21 MAS-P Animal Scale Operator’s Manual

Page 33

Notes

Maintenance 22

Page 34

Notes

23 MAS-P Animal Scale Operator’s Manual

Page 35

Page 36

230 W. Coleman St. t Rice Lake, WI 54868 t USA

U.S. 800-472-6703 t Canada/Mexico 800-321-6703 t International 715-234-9171 t Europe +31 (0) 88 2349171

© Rice Lake Weighing Systems 11/2013 PN 132795 Rev D

Loading...

Loading...