Page 1

Multiple Animal Scale Mobile

Installation/Service

Manual

132051 Rev E

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

1.0 Introduction......................................................................... 1

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.3 Lifting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.0 Assembly............................................................................. 8

2.1 Unloading. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.1 Install one lifting fixture on each of the four corners. . . . . . . 8

2.1.2 Slinging the scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1.3 Lift the scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Package Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2.1 Wheel Assembly and Torque Specification. . . . . . . . . . . . 10

2.3 Cage Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.1 Apply the silicone bead . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.2 Install walls. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3.3 Install the Gate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.3.4 Complete Cage Assembly . . . . . . . . . . . . . . . . . . . . . . . . 13

2.4 Gate and Latch Adjustment Procedure . . . . . . . . . . . . . . . 14

2.4.1 Hitch Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.5 Optional 920i Weighcenter Mounting . . . . . . . . . . . . . . . . . 16

2.6 T-Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.0 Towing Instructions .......................................................... 18

3.1 Switching Between Modes . . . . . . . . . . . . . . . . . . . . . . . . 20

3.1.1 Converting to Weigh Mode . . . . . . . . . . . . . . . . . . . . . . . 20

3.1.2 Converting to Transport Mode . . . . . . . . . . . . . . . . . . . . 22

4.0 Repair Parts ...................................................................... 24

5.0 Maintenance ..................................................................... 30

5.1 Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.2 Scale Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . 31

5.2.1 Cleaning Load Cell Stands . . . . . . . . . . . . . . . . . . . . . . . 31

5.2.2 Disassembly and Greasing . . . . . . . . . . . . . . . . . . . . . . . 31

5.3 Scale Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . 32

5.3.1 How to Use The Electric Brakes Properly. . . . . . . . . . . . . 32

5.3.2 Synchronizing The Scale Brakes . . . . . . . . . . . . . . . . . . . 32

5.3.3 Brake Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.3.4 Wheel Assembly and Torque Specification. . . . . . . . . . . . 33

5.3.5 Bearing Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Rice Lake Weighing Systems is an ISO 9001 registered company.

February 28, 2014

Contents i

Page 4

5.3.6 Axle Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

5.4 Gathering Panel Attachment . . . . . . . . . . . . . . . . . . . . . . . 34

5.5 Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.6 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.7 Towing Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Mobile Group Limited Warranty.................................................... 40

For More Information .................................................................... 41

ii MAS-M Operator’s Manual

Page 5

1.0 Introduction

DANGER

WARNING

CAUTION

Important

Congratulations on your purchase of a Multiple Animal Scale Mobile (MAS-M) using

On-Board technology. This system is manufactured with top quality components and

is engineered using the latest technology to provide operating features and reliability

unmatched for years to come.

Please take the time to read this manual completely through before attempting to use

the system. Although the MAS-M has been designed for easy set up and use, a

thorough understanding of this manual will ensure that you receive the maximum

benefit from the system.

If you have any questions or comments please contact Rice Lake Weighing Systems.

1. 1 Sa f et y

Safety Symbol Definitions:

Indicates an imminently hazardous situation that, if not avoided,

will result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided

could result in death or serious injury, and includes hazards that

are exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided may

result in minor or moderate injury.

Indicates information about procedures that, if not observed,

could result in damage to equipment or corruption to and loss of

data.

General Safety

Do not operate or work on this equipment unless you have read

and understand the instructions and warnings in this Manual.

Failure to follow the instructions or heed the warnings could

result in injury or death. Contact any Rice Lake Weighing

System dealer for replacement manuals. Proper care is your

responsibility.

Introduction 1

Page 6

Failure to heed may result in serious injury of death.

WARNING

Important

DO NOT allow minors (children) or inexperienced persons to operate this unit.

DO NOT operate without all shields and guards in place.

DO NOT jump up and down on the scale.

DO NOT use for purposes other than weighing.

DO NOT place fingers into slots or possible pinch points.

DO NOT place hands, feet or any body part underneath the scale at any time. The

scale could be lowered at any time, crushing body parts.

DO NOT use any load bearing component that is worn beyond 5% of the original

dimension.

DO NOT use this product if any of the components are cracked.

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

Keep hands, feet and loose clothing away from moving parts.

Some procedures described in this manual require work inside the indicator enclo-

sure. These procedures are to be performed by qualified service

personnel only.

Always be certain when lowering the scale that everyone is clear of the scale and

any moving parts.

Use two hands when gripping the lift handle to raise or lower the scale.

Be sure the gates are latched or tied inward before transporting the scale.

Ensure all three hitch lock pins are installed and the suspension stops are in the

transport position before moving the scale.

This unit is not intended for the transportation of livestock or any other goods. Any

addition of weight to the scale in transport mode may cause premature

component failure and voids the Rice Lake warranty.

Animal Safety:

Animal safety is a very serious issue and must be observed when handling any

type of animal.

The scale surface may become slippery during use; a build-up of manure on the

scale may reduce traction. It is recommended that you take any necessary

precautions to maintain an acceptable level of animal footing.

Calibration:

Do not calibrate this scale with a weight cart having a gross weight in excess of

4,000 lbs or 1,815 kg. This device is designed to be calibrated with single block

weights spread evenly throughout the floor of the scale. Shift tests should not be

done with more than 4,000 lbs or 1,815 kg in a 4’ x 4’ area. Failure to comply with

this warning will result in damage to the scale and void the warranty.

2 MAS-M Operator’s Manual

Page 7

%RWK

6LGHV

%RWK

6LGHV

%RWK

6LGHV

%RWK

6LGHV

%RWK

6LGHV

,QVLGH:HLJK

&HQWHU%R[

Items 1-4 are on units equiped

with the 920i Weighcenter only.

Note

Figure 1-1. Safety Decal Locations

Introduction 3

Page 8

Figure 1-2. Safety Decal Locations

%RWK

6LGHV

%RWK

6LGHV

%RWK

6LGHV

%RWK

6LGHV

%RWK

6LGHV

4 MAS-M Operator’s Manual

Page 9

Figure 1-3. Safety Decals

Item # Part # Description Qty

1 151908

2 151906

3 151907

4 151904

5 151909

6 151910

7 151898

8 151905

9 151900

10 151902

11 151901

12 128266

13 151987

Read Manual

Warning, Do Not Open

Warning, Do Not Leave Tray Down

Caution, Low Clearance

Caution, Pinch Point

Caution, Always Grip With Two Hands

Warning, Crushing Hazard

Warning, Crushing Hazard, Jack

Warning, Battery

Warning, Opens Quickly

Caution, Not A Step

Do Not Use For Transportation of Goods

Caution, Tripping Hazard

Introduction 5

1

1

2

1

6

4

4

1

1

2

1

2

2

Page 10

1. 2 Ov e rv i ew

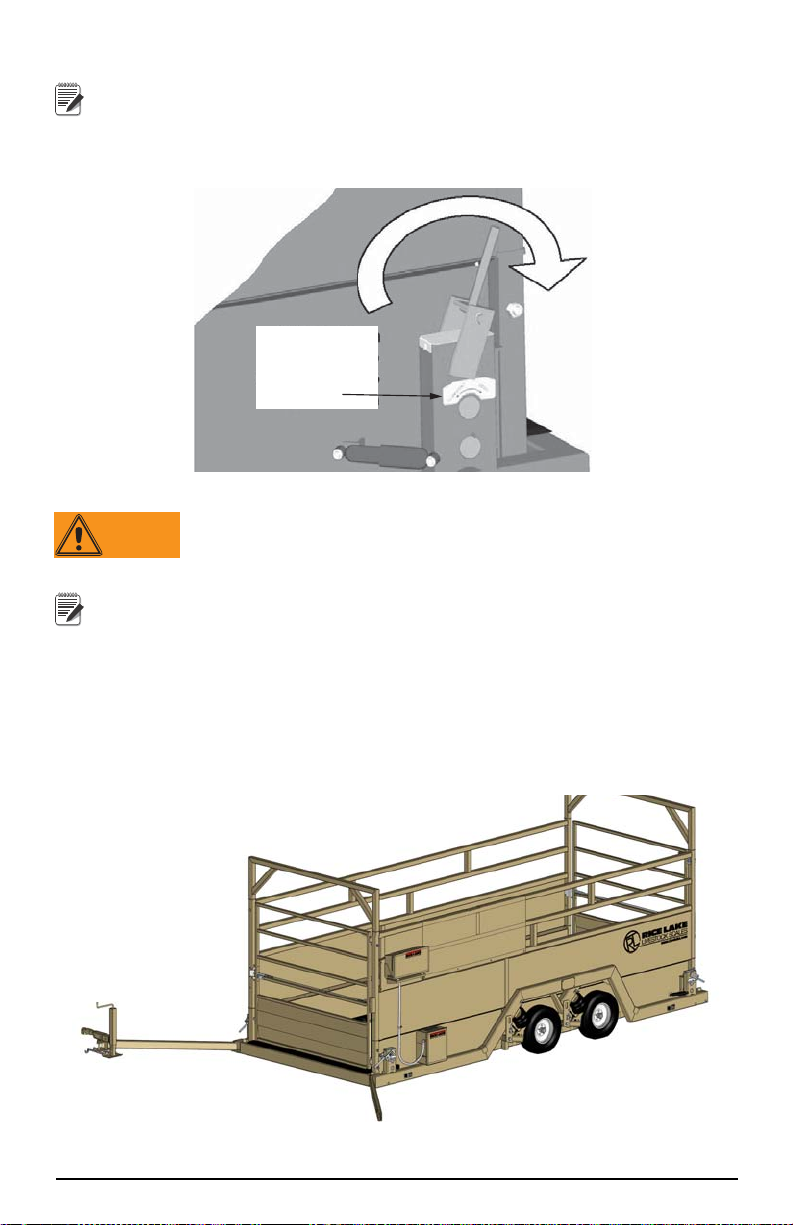

The MAS-M is an agricultural implement consisting of a scale with air ride suspension

and swing out hitch, sheeted animal cage suspended by four S-type load cells through

a cam style On-Board scale system, and weigh center. In transport mode the scale

system is locked down, protecting the load cells from damage during transport. To

convert to weigh mode the entire scale is lowered to the ground, the hitch is spl it and

swung outward and the scale is raised to the weigh mode using a lever and cam

system. The weigh center contains the digital indicator and ticket printer. To convert

back to transport mode the process is reversed (lower the scale, swing hitch inward

and lock and raise the suspension using the integral air pump).

The MAS-M can be used on any firm surface up to 7% grade (4-degree slope) and has

a low deck height (6”) for easy step in.

Figure 1-4. Multiple Animal Scale Mobile

6 MAS-M Operator’s Manual

Page 11

1.3 Lifting Instructions

Lift the scale only in designated locations (see Figure 1-5). The scale may be lifted by

forklift (ensuring the forks reach through both walls) or by 4 straps and a crane or

loader. Ensure the scale is in the transport mode (locked down – see next section)

when loading and transporting the scale.

Figure 1-5. Lift Points

Introduction 7

Page 12

2.0 Assembly

Note

Lifting

Fixture

Nylon Locknut

2.1 Unloading

2.1.1 Install one lifting fixture on each of the four corners.

If lifting fixtures are in place, skip to Section 2.1.2

1. Remove the nylon locknut from the bolt inst alled for shipping.

2. Place the lifting fixture with small hole over the bolt.

3. Reinstall the nut leaving the fixture free to move.

Figure 2-1. Lifting Fixture

2.1.2 Slinging the scale.

The MAS-M can be slung using 4 straps conn ected from the lifting lugs to a single

point in the center. To obtain a lifting point closer to the center of gravity straps

should be 1 to 2 ft longer on the rear of the scale. See Figure 2-2.

• Strap length 8 x 13 = 6 ft minimum

• Strap length 8 x 18 = 9 ft minimum

Figure 2-2. Slinging the Scale

8 MAS-M Operator’s Manual

Page 13

2.1.3 Lift the scale.

Shipping Stub

Note

1. If stacked, monitor the four corners directly below the lifting fixtures.

2. Each corner has a shipping stub inserted, these stubs are not bolted in place,

ensure they remain with the lower scale.

3. Once the upper scale of the stack is removed the stubs can be discarded.

Figure 2-3. Shipping Stub

4. The scale can now be stored as is or placed on a relatively flat location to be

assembled.

2.2 Package Removal

The indicator and tires are shrink wrapped for transportation. Be careful when

removing to avoid damaging the indicator or tires when removing.

1. Remove the tires and indicator, then re-strap the walls if the scale is to be

transported while packaged.

The bolt that holds the walls and the cross members in place during

shipping is not used for assembly.

Please recycle the packaging material.

Place the parts safely and in a location they will not be damaged.

Assembly 9

Page 14

2.2.1 Wheel Assembly and Torque Specification

Note

Note

It is extremely important to apply an d maintain proper wheel mounting torque on the

scale axle. Torque is a measure of the amount of tightening applied to a fastener (nut

or bolt) and is expressed as length times force. For example, a force of 90 pounds

applied at the end of a wrench one-foot long will yield 90 ft-lbs of torque. Torque

wrenches are the best method to assure the proper amount of torque is bein g applied.

Wheel bolts/nuts must be tightened and maintained at the proper torque

levels to prevent loose wheels, broken studs and possible dangerous

separation of wheels from the axle. Be sure to use only the fasteners

matched to the cone angle of the wheel (usually 60° or 90°).

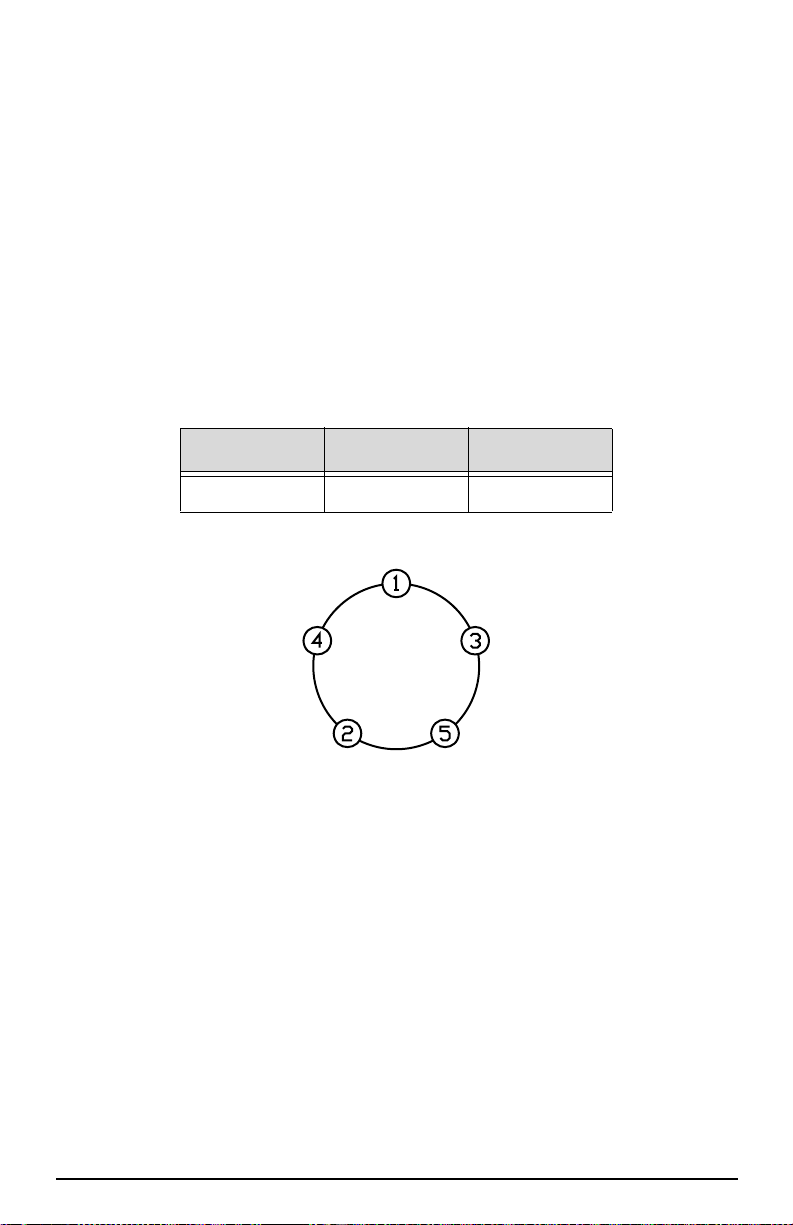

The proper procedure for attaching the wheels is as follows:

1. Start all bolts/nuts by hand to prevent cross threading.

2. Tighten bolts/nuts in the sequence shown in Figure 2-4.

The tightening of the fasteners should be done in stages, following the

recommended sequence, tighten fasteners per torque chart in Table 2-1.

3. Wheel bolts/nuts should be re-torqued after the first 10 miles, 25 miles and

again at 50 miles.

Wheel Torque Sequence (ft-lbs)

1st Stage 2nd Stage 3rd Stage

20-25 50-60 90-120

Table 2-1. Wheel Torque

Figure 2-4. Wheel Torque Pattern

4. Once the wheel nuts have been torqued use a white marker to mark the end of

each stud to show they have been torqued.

10 MAS-M Operator’s Manual

Page 15

2.3 Cage Assembly

Silicone

Wall Insert

WARNING

Note

Note

2.3.1 Apply the silicone bead

Before installing the walls a silicone bead must be added.

1. Clean the upper flange of the floor and the lower wall flange with mineral

spirits.

2. Apply an 1/8” bead of silicone along the upper edge of the floor pane l along the

entire length as shown in Figure 2-5.

Figure 2-5. Silicon Bead

2.3.2 Install walls

Wall installation should be done with 2 people or an overhead

crane.

1. Lift the first wall by using one sling in the center.

The wall with the operator’s instructions is mounted on the left side.

2. Stand the wall vertical and place the inserts from the wall into the tubes of the

cage floor. The more vertical the wall the easier assembly will be.

3. Repeat for the opposite wall.

4. Install the top cross members.

5. Insert the 3/4 x 3 1/2” bolts t hrough the cage wall and inserts on the indicator

side of the cage, head of bolt to the inside.

A come-along from the top of the cross member to bottom of the cage

corner post may be required.

For 18 ft scales a 1/2 x 3” bolt and nylon locknut is installed on the center

post with the nut on the outside.

Assembly 11

Page 16

2.3.3 Install the Gate

Note

Hook Bolt

Spring Pin

Nut and washer

Cage Wall

Gate

Jam nut and washer

Nylon washer

Install Spring Pins

after gate is in

place.

Install the gate with the hinge bolts on the opposite side of the scale.

Hook bolts must be assembled with lock washer on the inside of gate

and the jam nut on the outside.

Figure 2-6. Assemble Gate to Scale

1. Install jam nut and lock washer onto the hook bol ts. Screw the nut on abo ut 2”.

2. Insert one hook bolt into the lower and up per holes of the cage wall with the

hook portion pointing upward.

3. Install nut and washer onto the hook bolts securing them to the cage wall.

4. Place nylon washer onto the hook portion of the upper and lower hook bolts and

install the gate onto the hooks.

5. Insert roll pin through the hook bolts.

6. Repeat steps 2-4 for second gate.

7. Adjust the hinge side gap between the gate and the cage wall to about 3” and

snug hinge bolts.

12 MAS-M Operator’s Manual

Page 17

2.3.4 Complete Cage Assembly

1. Install the 5/16” carriage bolts and serrated nuts with the head of the bolts on the

inside of the cage. Begin by tightening the bolts from the center of the sheet

section working outward.

2. Tighten the 3/4” x 3 1/2” bolts installed in Section 2.3.2.

3. Assemble the latch with 3/8 x 3 1/4” bolts, lock washers, nuts and the latch pin

with the supplied hardware.

Figure 2-7. Latch Assembly

4. Install the 3/4” EVA hose on the latch pin (Mobile units only).

5. Adjust the gates and latches per the adjustment procedure.

Assembly 13

Page 18

2.4 Gate and Latch Adjustment Procedure

Note

The gates shall be assembled following the listed criteria:

• Hook Bolts - Assemble with lock washer on inside of gate and jam

nut on the outside.

• Hinge Side Gap - Approximately 3” between the gate and the

corner post.

• Gate Latch Pin - Install rubber tubing on the latch pin (Mobile units

only).

Adjust gates as follows:

1. Adjust the hook bolts to align the top of the gate on the latch side with the top of

the cage wall.

2. Adjust the hook bolts so the latch side gap is about 1 1/2”.

3. Install and adjust the latch so the gate latch pin does not rub on the top or bottom

of the latch. Adjust the hook bolts only if necessary.

14 MAS-M Operator’s Manual

Page 19

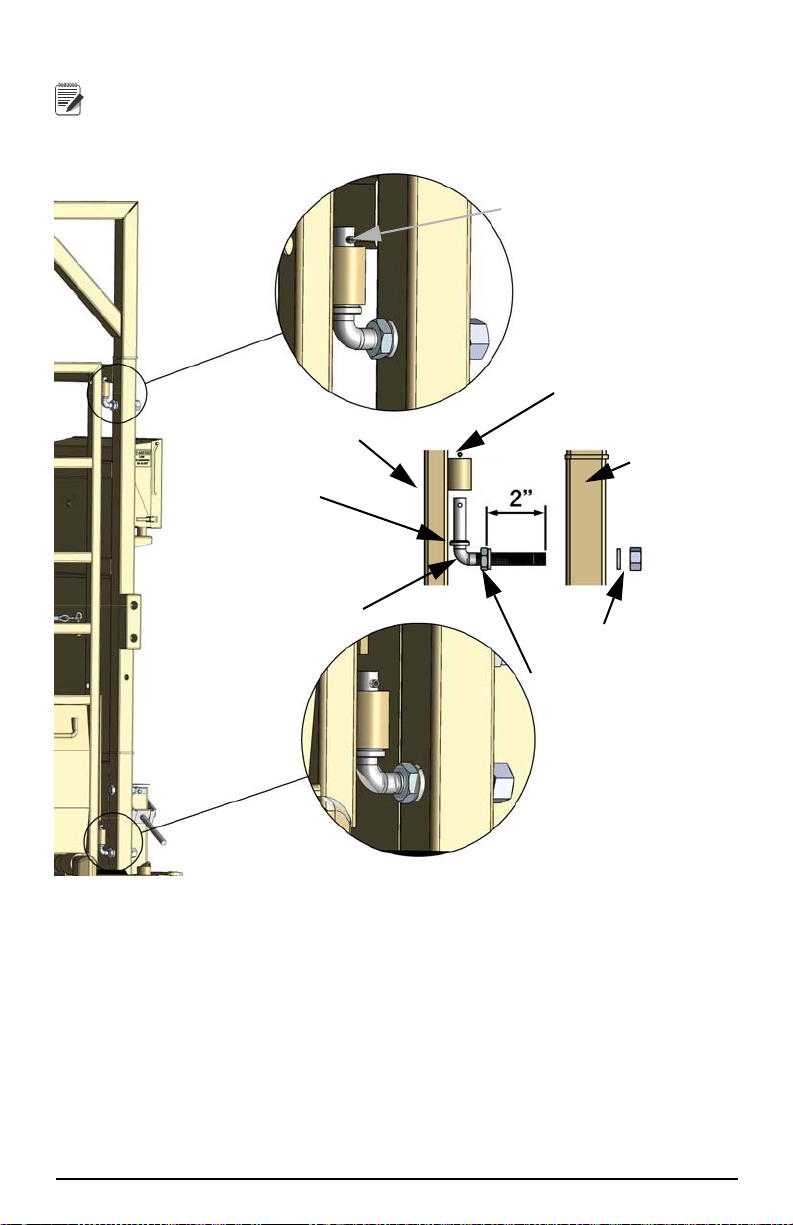

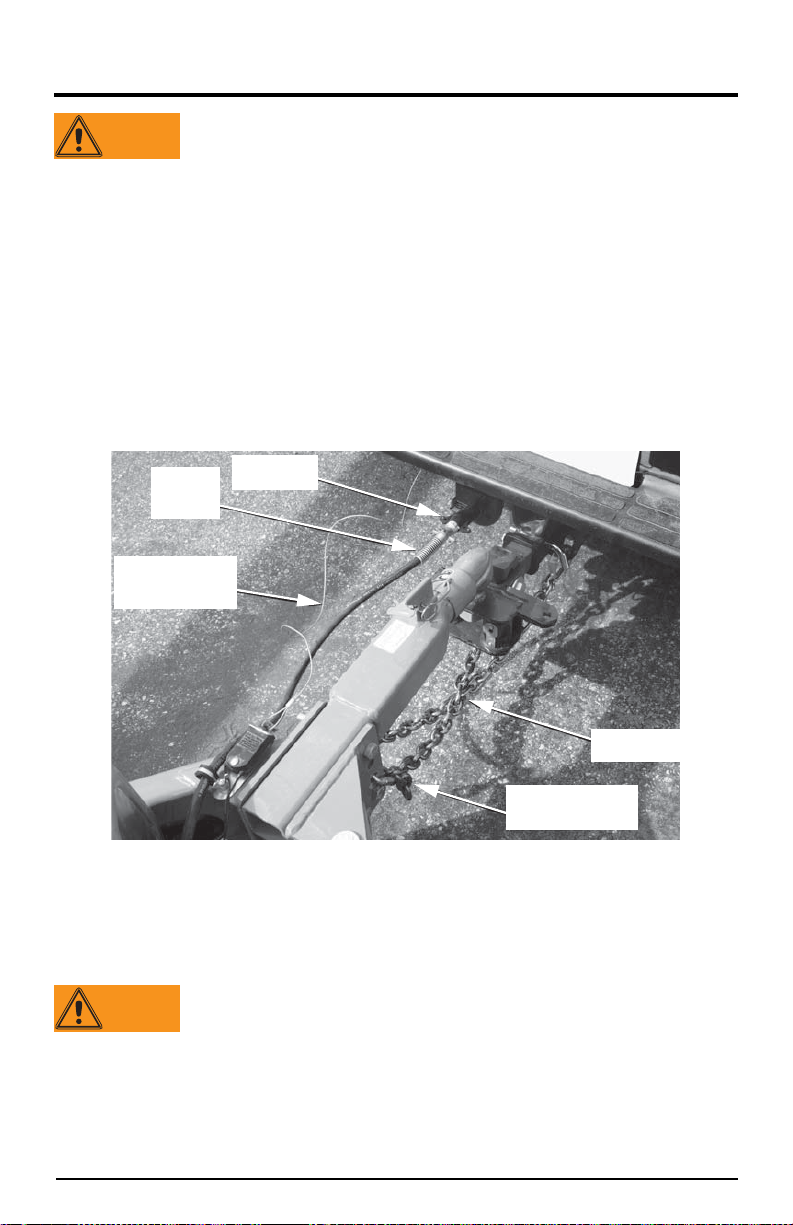

2.4.1 Hitch Assembly

1. If the hitch arm does not come mounted, assemble the right hitch member (wit h

coupler) to the cage using the pin installed in the hole. Ensure the clip pin is

installed on the bottom of the pin.

2. Connect the two halves of the hitch and install the forward pin t hrough bot h left

and right hitch members.

3. Install the safety chains as shown in Figure 2-8.

Figure 2-8. Safety Chain

4. Assemble jack, tighten bolts.

5. Install power cable and connect breakaway switch.

6. Connect the slip hook with the safety latch onto one end of each chain.

7. Install the quick link into the 4th link of the chain on the opposite end of the slip

hook.

8. Insert the quick link into the bottom hole on th e hitch mounting plate.

Assembly 15

Page 20

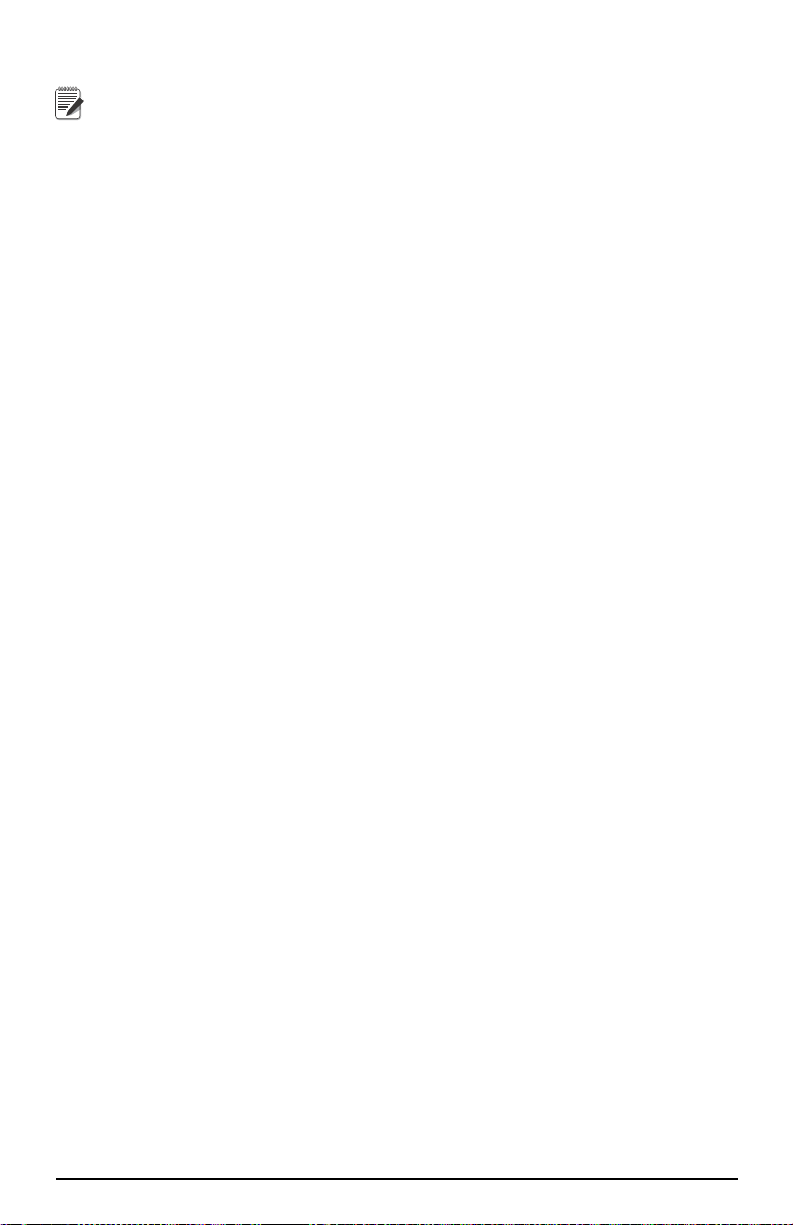

2.5 Optional 920i Weighcenter Mounting

Adhesive

Conduit Clamp 9/32Ø

1. Before installing the bracket a bead of silicone must be added. See Figure 2-9.

(Apply silicone where labeled adhesive)

2. Clean the wall tubes where bracket will mount and the space between the holes

on the mount bracket with mineral spirits.

3. Install the adhesive tape on the mounting bracket between the holes.

4. Place the mounting bracket onto the cage wall by pressing the adhesive tightly

to the cage.

5. Secure with four bolts.

Figure 2-9. Weighcenter Mounting

6. Mount the weighcenter onto the mo unting bracket and route the cable as shown

in Figure 2-9.

7. Install the clamps to secure the conduit.

• Mount the upper conduit clamp using the lower left mounting bracket bolt.

• Secure the lower end of the conduit by drilling a hole through the cage

sheeting and installing the clamp with the bolt provided.

Battery Box Connections

1. Connect the scale cable and secure with a cable tie.

2. Connect the power wires as shown in Figure 2-10.

3. Replace the battery cover.

Figure 2-10. Battery Connections

16 MAS-M Operator’s Manual

Page 21

2.6 T-Belt

Ensure the T-Belt hold down loops are installed and hooked into the corner posts of

the cage.

Figure 2-11. T-Belt

Assembly 17

Page 22

3.0 Towing Instructions

WARNING

Use Adapter

If Required

Cross Chains

Under Hitch

Adjust Safety Chain

Length Here

Hook Up

Electrical

Cable

Attach Breakaway

Switch Cable

To Truck Frame

WARNING

Read these instructions before towing.

This unit is not intended for the transportation of livestock or any

other goods. Any addition of weight to the scale in transport

mode may cause premature component failure and voids the

Rice Lake warranty.

The scale must be in “Transport Mode” to be towed. See Section 3.1.2 on page 22 for

converting to transport mode.

The scale is designed to be towed level (frame parallel to the ground) using a 2” ball.

To achieve the level towing condition, the required hitc h height of the tow ing vehicle

must be approximately 16”. If the hitch of the towing vehicle i s not in this ran ge, use

an adapter to achieve a height in this range. The hitch weight of the scale is

approximately 500lb. An equalizer hitch may be used for towing if desired (such as

the EAZ-LIFT Adjustable Weight Distributing Hitch #1009).

Safety chains must be connected during towing (see Figure 3-1). Connect the safety

chains. Cross the chains under the hitch for proper protection. Safety chain length is

adjustable by inserting the quick link through any link of the chain.

The scale must be connected electrically to the tow vehicle. Ensure that the

wiring of the towing vehicle is compatible with the scale wiring before hooking up.

Figure 3-1. Hitch Connection

See the label on the hitch for the wiring code (or see Figure 5-9 for wiring diagram).

The scale is supplied with a 7-pin connector. It is crucial the wiring is correct so the

battery (which supplies power to the control box) is charged during transport.

Improper wiring can cause brake failure.

If the scale is to be towed at night or if the lights of the tow vehicle are

obstructed by the scale, add on lights are available. These lights plug into a 6-pin

receptacle located on the rear of the battery box and attach magnetically to the

scale frame.

18 MAS-M Operator’s Manual

Page 23

The scale is equipped with electric brakes. The brakes must be synchronized with the

Suspension Stop Right Height Label

Tran s po rt M o d e

Weigh Mode

WARNING

tow vehicle brakes before towing. See Section 5.3.2 on page 32 for procedures. The

breakaway switch for the electric brakes must be connected during towing. This

switch activates the scale brakes in the unlikely event of scale separation from the tow

vehicle. The metal cable must be attached to a point on the tow vehicle other than the

primary connection point.

Figure 3-2. Ride Height

The scale is designed to be towed at a ride height of approximately 8 inches. A ride

height label is attached to every shock absorber to visually confirm the ride height.

After the scale is hooked up to the tow vehicle, check all the ride height labels to

ensure proper air bag inflation. Add or remove air as necessary.

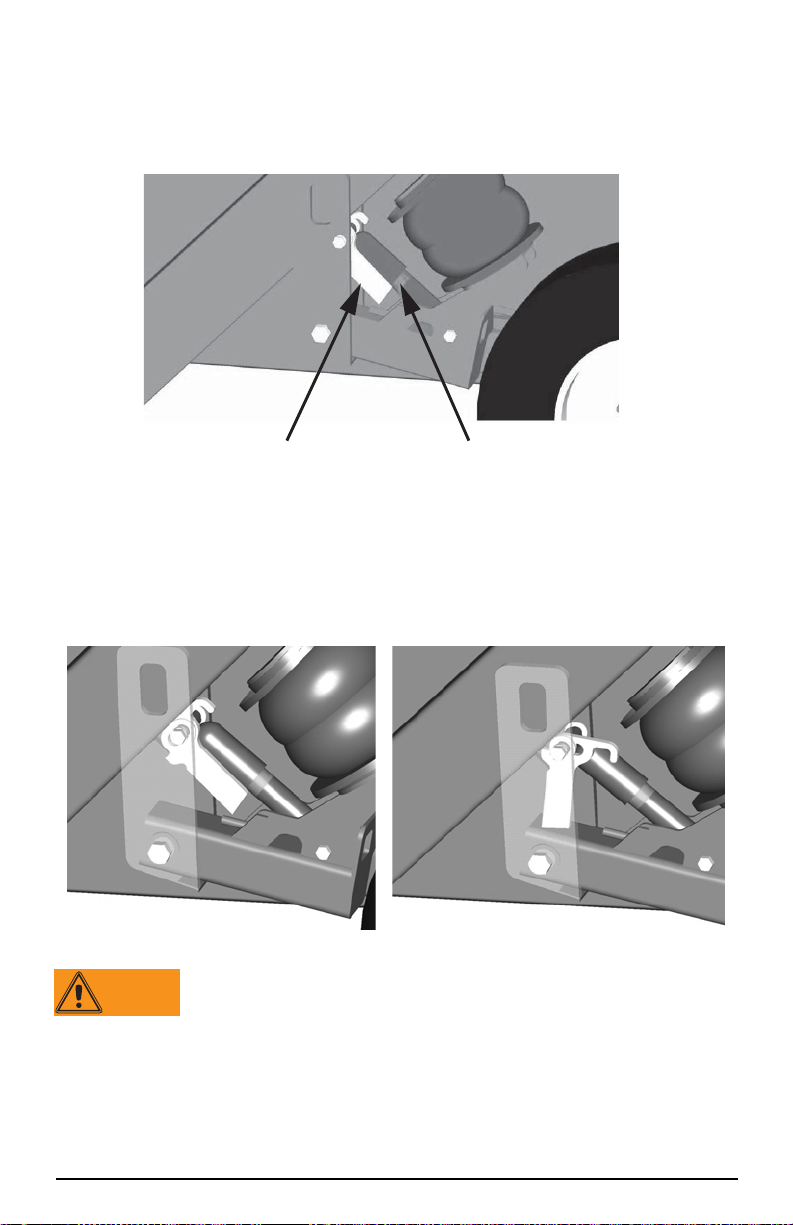

Suspension stops (one on each axle of the scale) are supplied to prevent the scale from

dropping to the ground in the event of an air system failure. These stops must be in

the transport position during towing.

Figure 3-3. Suspension Stop

The Suspension Stops are not to be used as a means of

transporting the scale. It is only to be used to as a safety device,

allowing removal of the scale from the roadway in the event of an

air system failure.

Towing Instructions 19

Page 24

3.1 Switching Between Modes

Note

Note

3.1.1 Converting to Weigh Mode

1. Park the scale in as level a location as possible. Ensure there are no obstructions

under the deck that would affect weighing accuracy.

The scale will weigh properly on a slope up to 4 degrees

(approximately 7%).

2. Turn the power switch located in the weigh center to the ON position.

3. If the scale is not level the indicator will d isplay “

and roll angle below, allowing the scale to be leveled.

4. With the drop leg retracted extend the jack until it begins lifting up on the scale

hitch.

5. Disconnect the scale from the truck hitch and un plug all wiri ng. Move the truck

clear of the scale.

6. Using the hitch jack, lower the scale hitch to the ground.

7. Flip the suspension stops (on each axle of the scale) into the weigh mode (see

Figure 3-3). Scale will not fully lower to ground with stops in transport

position.

8. Ensure the dump valve located on the battery box is cl osed and open all valves

located directly above the air bags.

9. Slowly open the dump valve to empty the air from the scale suspension. The

scale will lower to the ground.

10.Inspect all four corners of the scale. Although the scale will weigh properly up

to four degrees off level, individual corners of the scale should not be allowed to

teeter. If any of the corners are not contacting the ground, either move the scale

to a more level location or do the following:

11.Close the dump valve and turn on the air pump to slightly raise the scal e. Once

the scale frame has lifted sufficiently, turn off the pump.

If the air pump is not functioning, the scale can be raised using the

auxiliary fill directly below the dump valve.

Out Of Level” with the pitch

12.Place shims directly under the base frame, under the load cell stands, to prevent

teetering (see Figure 3-4).

13.Open the dump valves to lower the scale onto the ground and shims.

Figure 3-4. Shimming Locations

20 MAS-M Operator’s Manual

Page 25

14.Unpin the hitch and swing both hitch halves clear.

Note

Rotate Cam To

Raise Scale Into

Weigh Position

(See Decal)

WARNING

Note

The hitch sections can be removed. To remove the hitch, remove the pins

from the scale end of the hitch arms, and pull all wiring through the

driver’s hitch tube.

15.USING BOTH HANDS, raise the platform (rotate cam handle in

direction indicated by decal) to enable the scale (see Figure 3-5).

Figure 3-5. Scale Lift

The lift mechanism is an over center cam style lift and lock. If not

disturbed, the scale will remain “locked” in the up (weigh)

position. Always grip lift handle with two hands when raising and

lowering the scale.

Cam levers point toward each other in weigh mode and away from each

other in transport. See decals for direction of levers in each mode.

16.Ensure the weigh center power switch is in the ON position. Verify the indicator

does not show out of level. If it does, shim the scale as necessary (see steps 1113 above).

17.The weigh indicator should be powered u p. The readout of GROSS weight on

the indicator should be near zero (within four percent of the scale capacity). If it

is not, ensure the scale is fully lifted and that there is no debris on or under the

scale.

Figure 3-6. Scale in Weigh Mode

Towing Instructions 21

Page 26

3.1.2 Converting to Transport Mode

WARNING

Note

Proper Ride Height

Over Inflated

Note

WEIGH

T

R

A

N

S

DO NOT ATTEMPT TO MOVE THE

SCALE UNLESS VALVES ARE IN

TRANSPORT POSITION

1. Turn OFF the power switch located in the weigh center. Close and latch the

weight center cover.

2. USING BOTH HANDS lower the platform (rotate the cam handles in the

direction indicated by decal) to disengage the scale. Ensure the handles are in

the fully locked position.

The lift mechanism is an over center cam style lift and lock. If not

disturbed the scale will remain “locked” in the up (weigh)

position. Always grip lift handle with two hands when raising and

lowering the scale.

Cam levers point toward each other in weigh mode and away from each

other in transport. See decals for direction of levers in each mode.

3. Swing the hitch halves together and pin. Ensure the hitch pins have the safety

pins installed.

4. Add air to the scale suspension so that the frame rises evenly off the ground to

the correct ride height of approximately 8 inches (as indicated by the ride height

labels on the shock absorbers). Use either compressor on scale or a remote

compressor connected to the auxiliary air fill.

Figure 3-7. Scale Suspension

5. Close all the air valves. During scale towing, all valves MUST be closed.

After connecting to the tow vehicle you must operate the valves again.

22 MAS-M Operator’s Manual

Figure 3-8. Air Valve Position

Page 27

6. Flip the suspension stops into th e transport position.

W

E

I

G

H

T

R

A

N

S

.

2

1

Note

WARNING

Figure 3-9. Transport Position

7. Extend the jack so the scale hitch rises off the ground.

8. Position the truck near the scale hitch.

9. Connect the scale to the truck and connect all wiring.

10.CONNECT SAFETY CHAINS.

11.Connect equalizer hitch if desired.

12.Retract the jack.

13.Recheck the ride height of the scale and adjust as indicated on the ride height

labels on the shock absorbers. (See step 4 on page 22)

For Tandem Axle Scales:

Once the scale is connected to the tow vehicle and the ride height has

been set, with the dump valve closed, open the valves on the front and

rear axle to allow the pressure to equalize. Repeat for each side of the

scale. Close the valves before transporting the scale.

Do not move the vehicle until the scale is in the locked transport

position, all air valves are closed, the jack is retracted and the

drop leg pin is installed, the suspension stops are in transport

position, and the safety chains are attached.

Figure 3-10. Scale in Transport Mode

Towing Instructions 23

Page 28

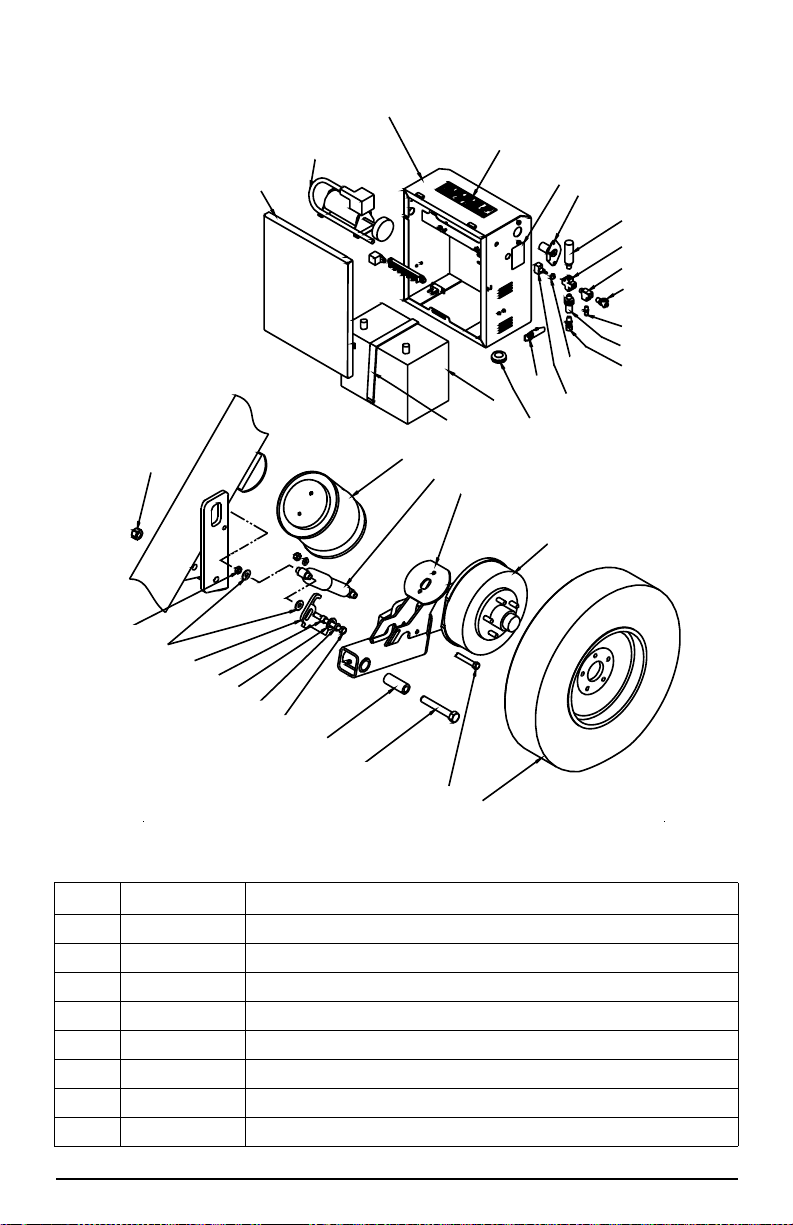

4.0 Repair Parts

13

13

14

26

8

46

40

29

70

1

8

14

51

53

66

67

12 11

55

68

10

27

2330

46

28

52

28 52

28

52

69

7

71

7

47

72

73

**Lift Mechanism

*

Figure 4-1. MAS-M

*See Figure 4-2 Details A-D for gate hardware (item 14).

**See Figure 4-2 Detail E for lift mechanism parts.

24 MAS-M Operator’s Manual

Page 29

Key Part No. Description

131436 Weigh Center w/ Indicator (see Operator’s manual PN 159192)

1

126788 Plug Plastic Round 1-1/8”

7

126787 Scale T-belting (83” width)

8

127740 Cover Plate Scale Frame/J-box

10

126819 Foam Gasket J-box

11

131891 Scale Junction Box 4 Cell SS

12

130931 Cage Cross-member

13

131782 Gate Short Sheeted

14

126951 Bolt Carriage 5/16 x 1/2 Round Head Grade A Zinc

23

131708

26

131946

131708

27

131947

127168 Pin, Hitch Pivot

28

130567 Frame, 13’

29

130773 Frame, 18’

126950 Nut 5/16 Flanged Serrated

30

130022 Operator Shield

40

45728 Screw, Self Drilling 12-24 x 7/8

131707 Cage Floor MAS-M, 13’

46

131934 Cage Floor MAS-M, 18’

15097 Bolt, 3/4-10NC x 3 1/2 Hex Head, Grade 5 Zinc

47

14697 Nut, Lock, 3/4-10NC Hex, Nylon Insert Zinc

127716 Jack w/ Drop Leg and Mount

51

126966 Hair Pin

52

127715 Hitch Coupler Mobile MAS

53

106387 Bumper

55

131896 Hitch Member Right

66

131900 Hitch Member Left

67

132692 Label MAS-M Weigh/Transport Mode

68

127094 Label MAS-M Transport/Weigh Mode

69

127721 Battery Box w/ compressor and wiring

70

127098 Transportation Position Decal

71

131955 Safety Chain

72

130842 Rice Lake Decal

73

127727 Standard Hitch Cable w/Connectors

N/S

127090 Label Basic Operating Instructions

N/S

Cage Wall 13’

Cage Wall 18’ Right

Cage Wall 13’

Cage Wall 18’ Left

Repair Parts 25

Page 30

34

'HWDLO'

'RRU+DUGZDUH/DWFK

45

19

22

42

36

20

'HWDLO%

'RRU+DUGZDUH+LQJH

13 15

33

24

14

'HWDLO$

'RRU+DUGZDUH/DWFK6LGH

18

20

56

19

'HWDLO(

/LIWLQJ0HFKDQLVP

9

17

2

3

6

57

58

59

60

61

16

16

58

65

62

63

64

'HWDLO&

'RRU+DUGZDUH+LQJH6LGH

43

44

35

42

26 MAS-M Operator’s Manual

Figure 4-2. MAS-M Details

Page 31

Key Part No. Description

127184 Upper Notched Load Cell Pin

2

21444 Load Cell S-Type 10K

3

127163 Eyebolt Machined 10K

127668 Lower Load Cell Retainer

6

127200 Load Cell Cam Stand Cover SS

9

127007 Bolt 1/4x1/2

151807 Washer, Plain 3/4in Nylon

13

110950 Pin, Spring 1/4 x 1 1/4

14

151589 Hinge Hanger Bolt Hook

15

127684 Plug Plastic Round 2”

16

127177 Lower Notched Load Cell Pin

17

126926 Pin Spring Slotted 1/4x2-1/4

127033 Cap Screw, 3/8-16 x 3/4

18

15159 Washer, 3/8 Lock

19

132684 Nut, 3/8-16 Grade5

20

131784 Gate Latch

22

127021 Hair Pin 1/8 x 2 9/16

15181 Washer, 3/4

24

132179 Hinge Bracket

31

111074 Nut, 3/4-10NC

33

132217 Jam Nut, 3/4-10NC

34

21939 Washer, 5/16

35

131886 Cable, 1/4” OD x 6 ft

36

71872 Bolt, 3/4-10NC x 4

37

14697 Nut, Lock 3/4-10NC

39

131887 Quick Link 1/4 in

42

131701 Eye Bolt, 5/16-18 x 2 1/2

43

14646 Nut, Lock 5/16-18NC

44

39528 Bolt, 3/8-16NC x 2 1/4

45

132427 Strike Plate

56

131787 Cam with Lockdown

57

127165 Spacer Upper Notched Pin

58

127732 Cam Handle

59

131785 Cam Without Lockdown

60

15167 Lockwasher ½

61

14765 Bolt 1/2 x 4

127561 Scale Cable Female MS Conn 132”

22093 Bolt 3/8 x 2 Grade5

62

15161 Flat washer 3/8 SS SAE

63

126992 Nut 3/8 SS

64

128626 Scale Damper Assembly w/Bushings

65

Repair Parts 27

Page 32

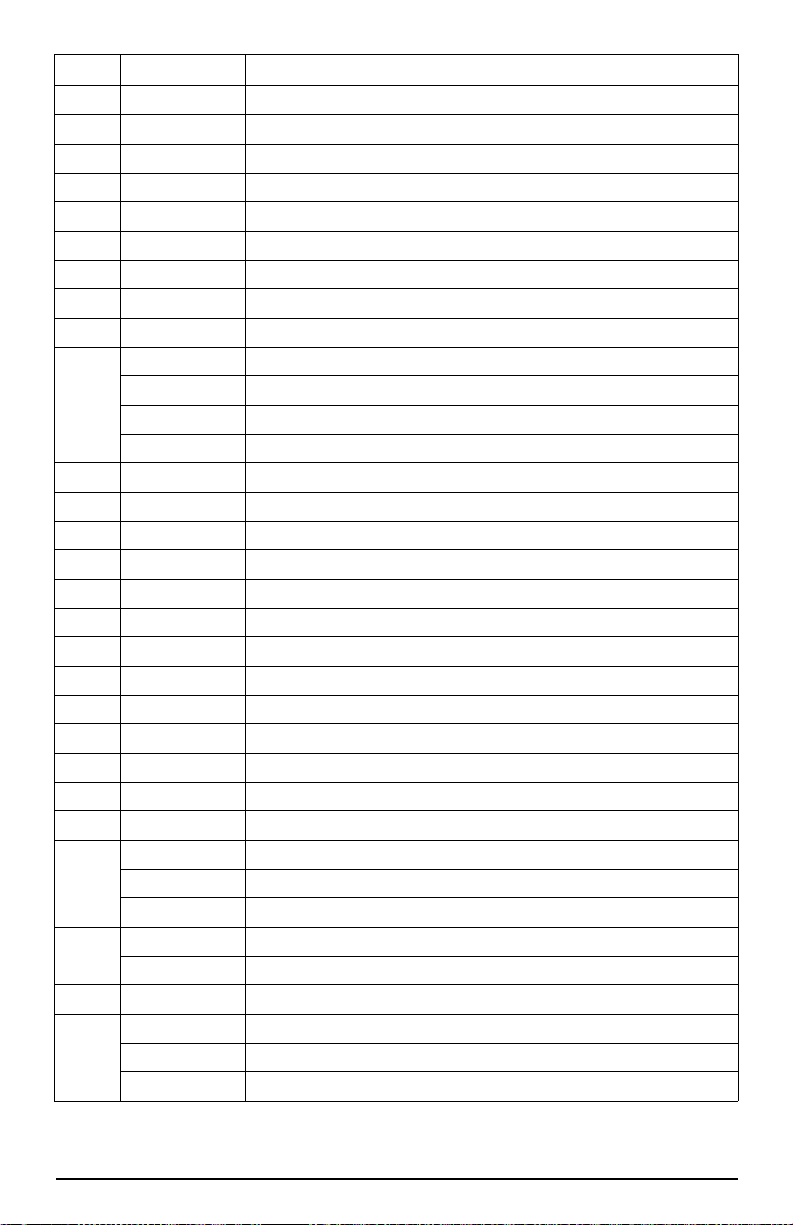

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

Key Part No. Description

47 127171 Door Assembly Battery Box

48 127414 Air Compressor 12V, 1 CFM

49 127170 Battery housing

50 128266 Label “Not for Transportation ….”

51 131015 Label Hitch Plug Wiring

52 127393 6 Way Round Trailer Receptacle

53 127406 Relief Valve Air 150 PSI

54 126900 4FP Brass Cross

28 MAS-M Operator’s Manual

Figure 4-3. Battery Box and Tire/Wheel Parts

Page 33

Key Part No. Description

55 127070 Brass Tee Forger 4FP

56 126891 Valve Brass Drain Cock

57 127399 Valve Air Tank w/ Core and Cap

58 126901 Fitting Brass 4FP Terminal Bolt

59 126902 Fitting Brass 4MP to ¼ Synflex

60 128108 Switch Seal Hex

61 127398 Switch ON/OFF

62 127289 Latch SS Pull Up

63 126944 Grommet 1-3/8 x 1/4

64 127106 Battery Deep Cycle Marine

127402 Terminal Block 6 Pole

127397 Relay Headlight 12v

127076 Circuit Breaker 12V 30 Amp

65 127073 Strap 1” with Clasp

66 14697 Nut Lock Nylon ¾

67 126936 Nut Jam ½

68 127046 Washer 7/16 USS

69 127334 Suspension Stop Arm

70 127178 Bushing Suspension Stop

71 15179 Washer ¾ SAE

72 15167 Lock washer ½

73 14768 Bolt ½ x4-1/2

74 127169 Bushing Pivot Axle

75 14788 Bolt ¾ x 5

76 14757 Bolt ½ x 3

77 127129 Tire and Rim ST175/80R13

78 132389 Hub and Drum, Dexter 3500# Axle w/ 10x2.5 Brakes

132387 Left Dexter 3500# Axle w/ 10x2.5 Brakes

132388 Right Dexter 3500# Axle w/ 10x2.5 Brakes

79 127718 Axle Arm Left

127719 Axle Arm Right

80 127745 Suspension Shock Absorber

81 127405 Air Spring 2B8-550

127069 Ball Valve, Miniature

82133 Nipple, Pipe 1/4NTP x 3

Repair Parts 29

Page 34

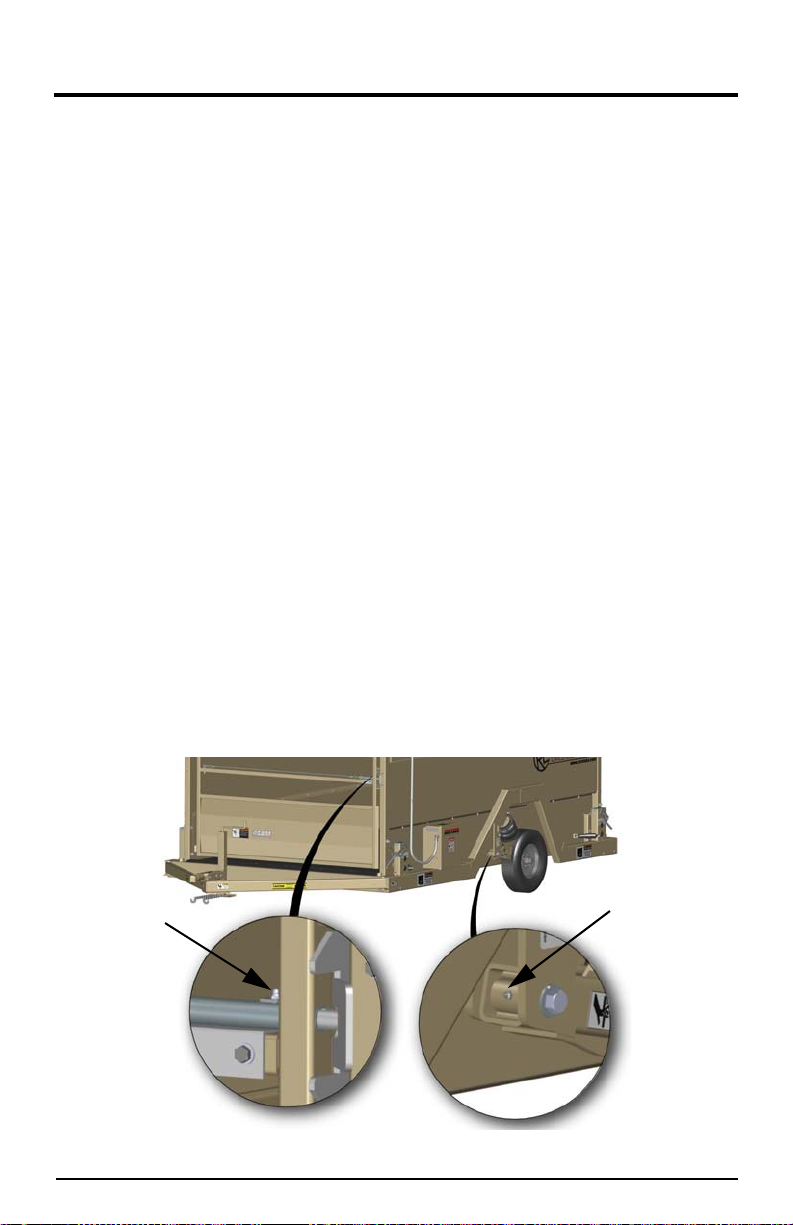

5.0 Maintenance

Grease zerk

on gate

latches

Grease zerk

at axle pivot

5.1 Maintenance Schedule

Before Each Use

1. Grease axle pivot locations, using the provided grease zerks (see Figure 5-1),

using a “Black Moly” type grease.

First Week

1. Check torque on all wheel nuts (see Section 5.3.4 on page 33).

Weekly

1. Check entire scale for buildup of debris. Remove any debris found on, under or

around the scale. Rubber T-belting at both ends of the scale are removable to

make clean out easier. To remove T-belting, unhook the stretch cord that hooks

into the corner tube of the cage.

2. Check for dirt and debris in the load cell stands and clean accordingly.

3. Check all external cables and conduit for damage.

First Month (in addition to weekly maintenance)

1. Check torque on all wheel nuts (see Section 5.3.4 on page 33).

2. Adjust scale brakes.

Monthly (in addition to weekly maintenance)

1. Charge scale battery if necessary.

2. Tire Pressure. 45 psi./40psi. - Single /Tandem Axle

3. Grease gate latch zerks (see Figure 5-1) using a “Black Moly” type grease.

Yearly (in addition to weekly and monthly maintenance)

1. Check and grease wheel bearings (see Section 5.3.5 on page 33).

2. Disassemble each load cell location and grease all pins and eye bolts (see

Section 5.2.2 on page31).

3. Adjust scale brakes (see Section 5.3.3 on page 32).

30 MAS-M Operator’s Manual

Figure 5-1. Grease Zerk Locations

Page 35

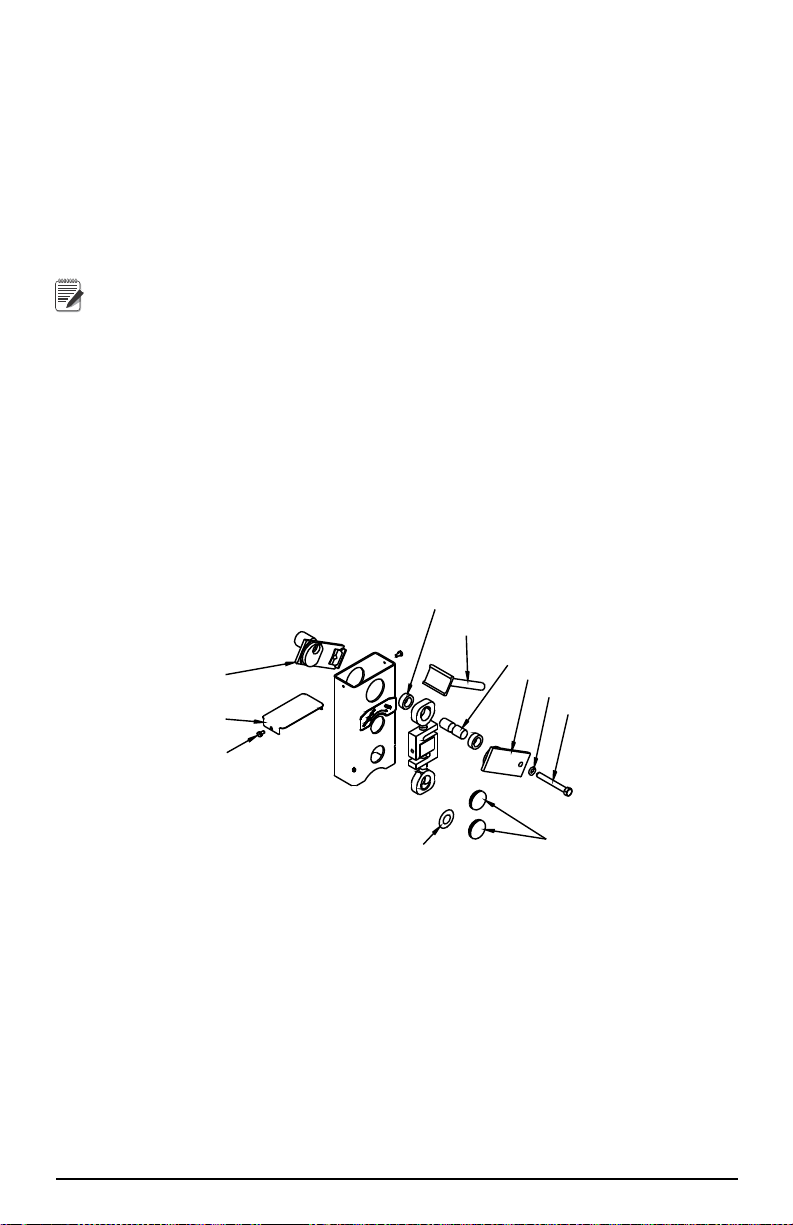

5.2 Scale Maintenance Procedures

Note

26

27

28

35

36

33

37

38

39

40

34

5.2.1 Cleaning Load Cell Stands

It is very important to keep any excess debris from building up in t he load cell stand.

Lift scale and block it up, clean any dirt out of the load cell stands through the drain

holes located at the bottom of the stand.

5.2.2 Disassembly and Greasing

This is very important to ensure the long life of the unit. Use the parts list drawings

for item numbers.

Use quality high-pressure grease.

Avoid bending or twisting the load cell wires.

a. Remove the cell stand cover (27).

b. Remove the plug covers (34)

c. Remove the bolt which holds together items 26, 39, 38.

d. While holding the cam handle (36), remove the outer cam (38).

e. Remove the load cell pin (37) and spacers (35). The load cell assembly will be

free on top and rest against the inside of the cell stand.

f. Remove the inner cam (26).

g. Remove the lower retainer (33)

h. Grease all bearing surfaces except where the eyebolt contacts the pin (upper and

lower pins, cams, upper and lower eyebolts).

i. Reassemble in reverse order as described above.

Figure 5-2. Disassembly and Greasing

Maintenance 31

Page 36

5.3 Scale Maintenance Procedures

WARNING

Note

5.3.1 How to Use The Electric Brakes Properly

The scale brakes are designed to work in synchronization with the tow vehicle brakes.

Never use the tow vehicle or scale brakes alone to stop the combined load.

The brake controller must be set up according to the manufacturer's recommendations

to ensure proper synchronization between the tow vehicle and the scale. Additionally,

you may have to make small adjustments occasionally to accommodate changing

loads and driving conditions.

Proper synchronization of tow vehicle to scale braking can only be accomplished by

road testing. Brake lockup, grabbing, or harshness is quite often due to the lack of

synchronization between the tow vehicle and the scale being towed, too high of a

threshold voltage (over 2 volts), or under adjusted brakes.

The following should only be performed in a safe environment

such as an unpopulated road free of traffic or under controlled

conditions.

Before any synchronization adjustments are made, the scale brakes should be

burnished-in by applying the brakes 20-30 times with approximately a 20 m.p.h.

decrease in speed, e.g. 40 m.p.h. to 20 m.p.h. All ow ample time for brakes to cool

between application. This allows the brake shoes and magnets to slightly "wear-in" to

the drum surfaces.

5.3.2 Synchronizing The Scale Brakes

To ensure safe brake performance and synchronization, read the brake controller

manufacturer's instructions completely before attempting any synchronization

procedure.

Make several hard stops from 20 M.P.H. on a dry paved road free of sand and gravel.

If the scale brakes lock and slide, decrease the gain setting on the controller . If they do

not slide, slightly increase the gain setting. Adjust the controller just to the point of

impending brake lockup and wheel skid.

Not all scale brakes are capable of wheel lockup. Loading conditions,

brake type, wheel and tire size can all affect whether a brake can lock. It

is not generally considered desirable to lock up the brakes and slide the

tires. This can cause unwanted flat spotting of the tires and could also

If the controller is applying the scale brakes before the tow vehicle brakes, then the

controller adjustments should be made so the scale brakes come on in synchronization

with the tow vehicle brakes. For proper braking performance it is recommended that

the controller be adjusted to allow the scale brakes to come on just slightly ahead of

the tow vehicle brakes. When proper synchronization is achieved there will be no

sensation of the scale “jerking” or “pushing” the tow vehicle during braking.

result in a loss of control.

5.3.3 Brake Adjustment

Brakes should be adjusted (1) after the first 200 miles (first month) of operation when

the brake shoes and drums have “seated,” (2) at 3,000 mile intervals (or yearly), (3) or

as use and performance requires. The brakes should be adjusted in the following

manner:

1. Jack or block the axle arm to allow free rotation of the wheel.

2. Remove the adjusting hole cover from the adjusting slo t on the bottom of the

brake backing plate.

32 MAS-M Operator’s Manual

Page 37

3. Rotate the star wheel of the adjuster assembly with a screwdriver or standard

adjusting tool to expand the brake shoes. Adjust the brake shoes out until the

pressure of the linings against the drum makes the wheel very difficult to turn.

4. Then rotate the star wheel in the opposite direction until the wheel turns

freely with a slight lining drag.

5. Replace the adjusting hole cover and lower the wheel to the ground.

6. Repeat the above procedure on all brakes. For best results the brakes

should all be set at the same clearance.

5.3.4 Wheel Assembly and Torque Specification

1. Start all bolts or nuts by hand to prevent cross threading.

2. Tighten bolts or nuts in the sequence shown below.

3. The tightening of the fasteners should be done in st ages, per torque chart below

following the recommended sequence.

4. Wheel nuts/bolts should be torqued before first road use and after each wheel

removal. Check and re-torque after the first 10 miles, 25 miles, and again at 50

miles.

1st Stage 2nd Stage 3rd Stage

20-25 50-60 90-120

Table 5-1. Wheel Torque Sequence (ft-lbs)

Figure 5-3. Wheel Torque Sequence

5.3.5 Bearing Adjustment

In the event the hub is removed follow this procedure for wheel bearing adjustment.

1. After placing the hub, bearings, washers, and spindle nut on the ax le spindle

rotate the hub assembly slowly while tightening the spindle nut to

approximately 50 lbs.-ft.

2. Then loosen the spindle nut to remove the torque. Do not rotate the hub.

3. Finger tighten the spindle nut until just snug.

4. Back the spindle nut out slightly until the first castellation lines up with the

cotter key hole and insert the cotter pin

5. Bend over the cotter pin legs to secure the nut.

6. The nut should be free to move with the only restraint being the cotter pin.

7. Install the dust cover and rotate the wheel to ensure the cotter key does not

contact the dust cover.

Maintenance 33

Page 38

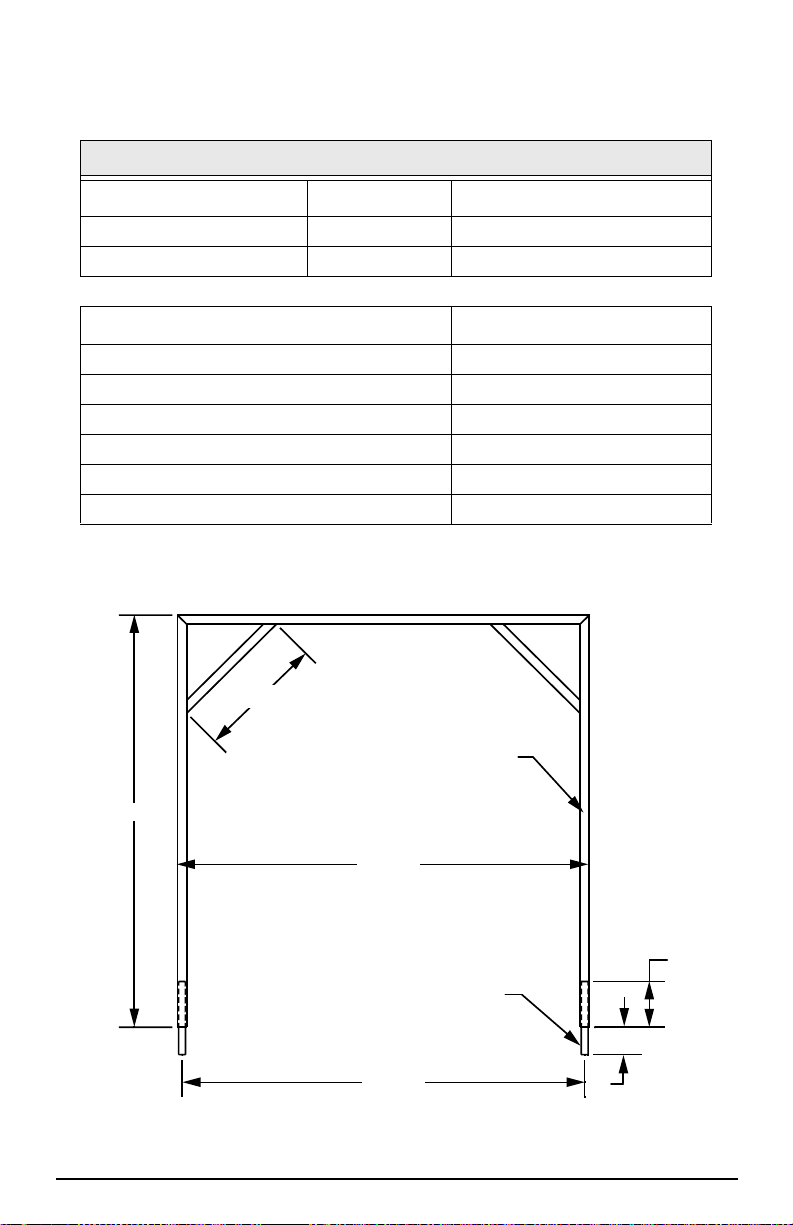

5.3.6 Axle Parts

27 1/2”

90”

89 1/4”

87 1/4”

10

6

1 1/2” OD

2 x 2 TUBING

Axles are Dexter 3500lb, 5-bolt with 10x2-¼” brakes.

Following are replacement parts available from Dexter.

Bearings

Dexter Kit # Industry Part # Cup/Cone

Inner K71-390-00 L68111 / L68149

Outer K71-306-00 L44610 / L44649

Description Dexter Part #

Inner Bearing Seal 010-004-00

Magnet K71-104-00

Brake Shoe and Lining K71-047-00

Brake Assembly LH 023-026-00

Brake Assembly RH 023-027-00

Hub 008-247-05

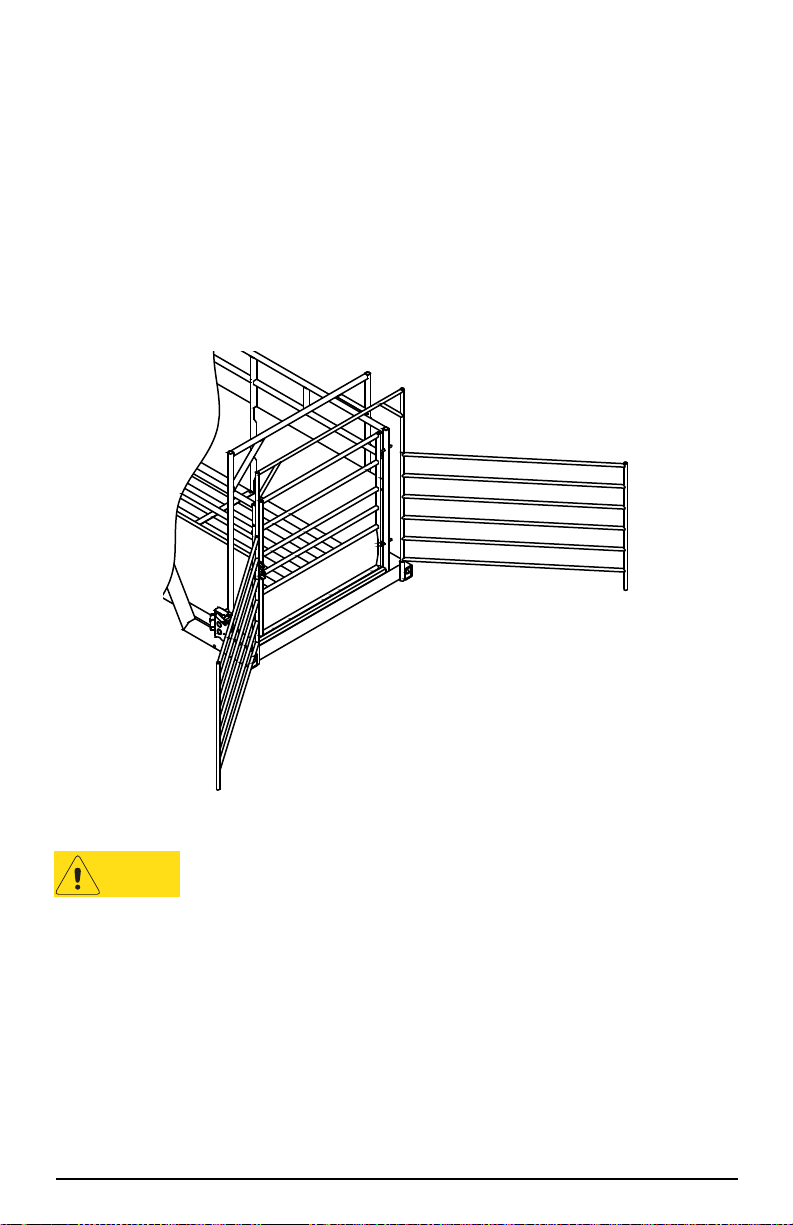

5.4 Gathering Panel Attachment

Suggested Construction

34 MAS-M Operator’s Manual

Figure 5-4. Gathering Panel Frame

Page 39

Building a simple framework that can be set into the provided scale posts can

CAUTION

accommodate mounting of most any panel. In some cases extra support of the

mounting frame may be required.

Figure 5-4 shows the suggested construction of a framework you can build to support

the type of gathering panels you have. Some gathering panels can be set directly into

the corner posts located on the corners of the scale and require only a shortened

version of the drawing above that can be set into the top of the panels. (See Figure 5-

5) However, with the wide variety of panels available we cannot provide a mounting

means for all of them.

However you decide to mount you panels you must ensure the panels or framework

are not attached to the scale cage and must have a clearance of 1" from any live

portion of the scale. Any contact between the panels or framework and the scale can

cause the weight reading to be inaccurate.

Figure 5-5. Gather Panel Attachment

Gathering Panel Warranty Information

Gathering panels or handling attachments must be removed from

the scale during transport. The scale is not intended for the

transportation of goods or livestock.

The design of the scale only allows for 100 pounds to be added to

either end of the scale, for a MAXIMUM addition of 200 pounds,

during transport. All attachments that will remain on the scale

must not exceed the weight limit of 100 pounds on the front and/

or 100 pounds on the rear. If the total of the attachments on either

the front or the rear exceeds 100 pounds the warranty will be

void.

Any additions to the scale may affect the balance and towability

of the scale.

Any attachments to the scale must be secured during transport

and not interfere with any safety device or the operation scale

mechanisms.

Maintenance 35

Page 40

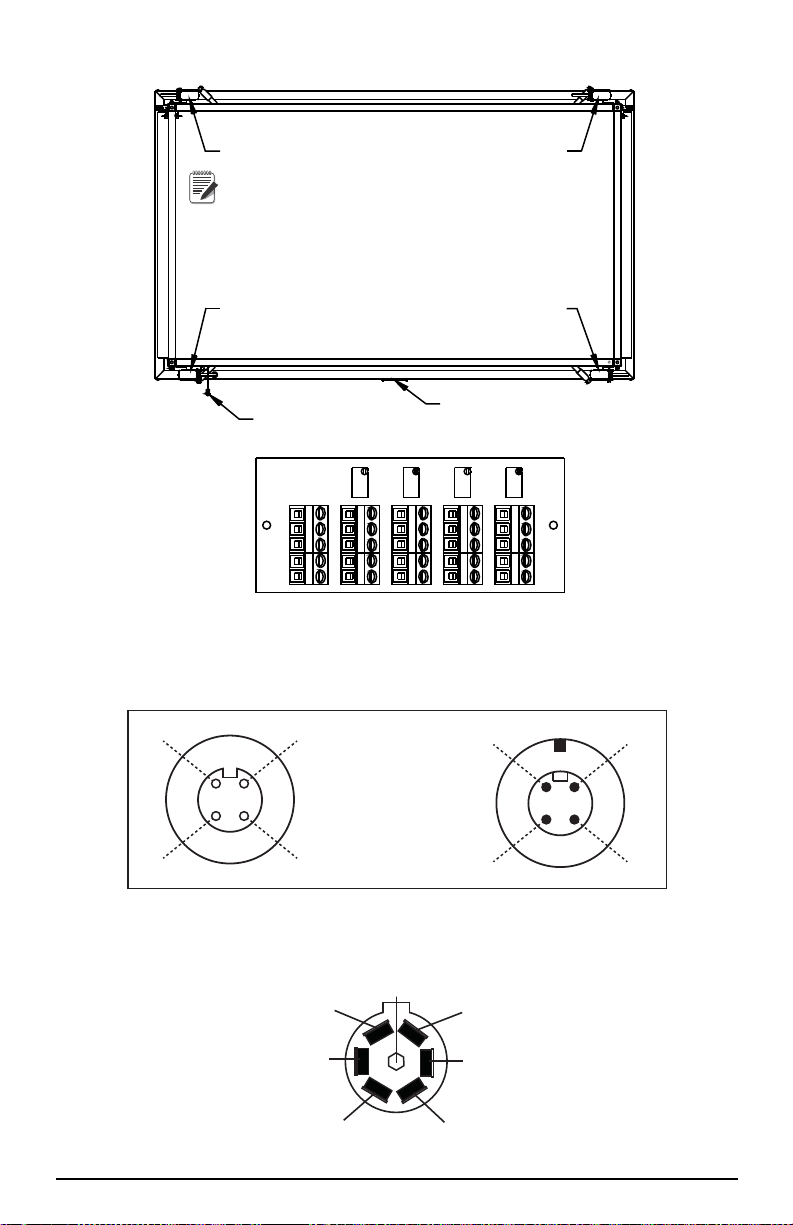

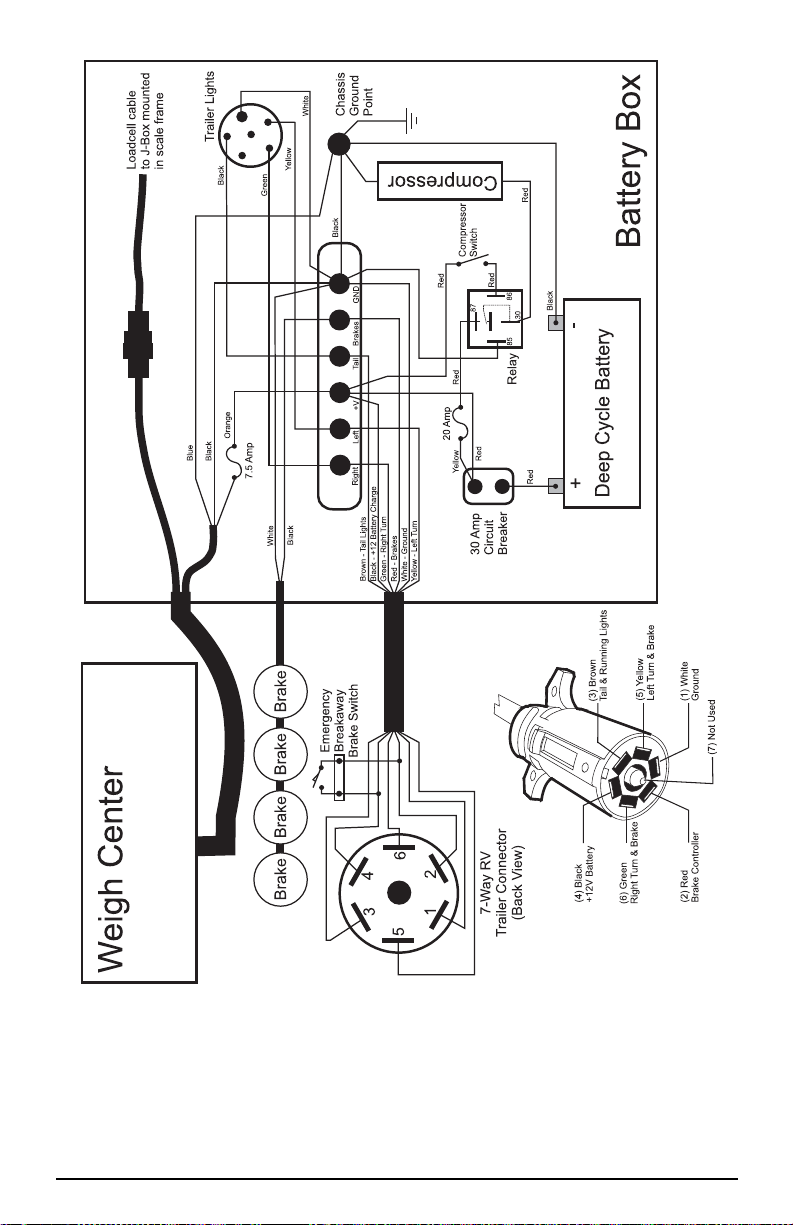

5.5 Wiring Diagrams

Load Cell #1

Load Cell #2

Load Cell #4

Load Cell #3

Scale Cable

Junction Box

Trimmers

Load Cell #4

Load Cell #1

Load Cell #2

Load Cell #3

Indicator

Black

Green

White

Shield

Red

+E

-E

+S

-S

GND

V1 V2 V3 V4

Load cell wiring shown is effective for all

models later than 09/17/2013, models

built prior to that date should rewire the

scale to the updated configuration. For

information on rewire download Technical

Bulletin PN 159193 from www.ricelake.com.

Note

DA

B

Indicator

AD

CB

Scale

A -EXC Black

B +SIG Green

C +EXC Red

D -SIG White

Connector

C

7 WAY TRAILER CONNECTOR

Reverse Lights

12V Battery Power

Right Turn & Brake

Brake Controller Output

Tail & Running Lights

(7) Purple

(

4) Black

(6) Green

(2) Red

(3) Brown

(5) Yellow

Left Turn & Brake

(1) White

Ground

Figure 5-7. Scale/Indicator System Connection

Figure 5-6. Load Cell Wiring Diagram

36 MAS-M Operator’s Manual

Figure 5-8. Electrical Connection

Page 41

Figure 5-9. System Wiring Diagram

Maintenance 37

Page 42

5.6 Specifications

t

N

A

T

I

O

N

A

L

C

O

N

F

E

R

E

N

C

E

t

O

N

W

E

I

G

H

T

S

A

N

D

M

E

A

S

U

R

E

S

Size / Model # ___________________________

Serial # _________________________________

Date Purchased _________________________

Unit ID # _______________________________

MAS8-13 MAS8-18

Length Overall 18’-8” 24’-5”

Length Deck 12’-9” 18’-6”

Width Overall 8’-6” 8’-6”

Width Deck 7’-5” 7’-5”

Deck Height 6” 6”

Height 99” 99”

Deck Covering 5/8” Recycled Molded Rubber Flooring System

Weight 3100 lbs. 4600 lbs.

Capacity 15000 lbs. 20000 lbs.

Section Cap 10000 lbs. 20000 lbs.

Approval Class IIIL (IIIHD) IIIL (IIIHD)

Approvals

Grad Size 5 lb (2 kg) 5 lb (2 kg)

**Paint Powder Coated Galvanized Steel

Tire Pressure 50 PSI 45 PSI

Wheel size 13” 5 on 4.5” 13” 5 on 4.5”

Tire Size ST175/80R13 ST175/80R13

Lug Torque 90-120 ft-lbs 90-120 ft-lbs

Battery 12V Deep Cycle 12V Deep Cycle

**Structural Steel is not galvanized.

38 MAS-M Operator’s Manual

99-091A4

AM4*

Page 43

5.7 Towing Checklist

Each item of checklist to be reviewed and list to be signed by dealer and customer at

delivery.

[ ] Operator Safety section of manual has been reviewed.

[ ]

Scale is not intended for the transport of livestock or any other

goods or materials.

[ ] Ball on towing vehicle must be 2”

[ ]

Hitch height of towing vehicle must be between approximately

16” above the ground such that the scale is in towing level.

[ ] Safety chains must always be connected during towing.

[ ] Towing vehicle must be wired correctly (see label on hitch)

[ ] Magnetic lighting package must be on the scale during towing.

[ ]

Scale is equipped with electric brakes and must be

synchronized. See synchronization procedure in manual.

[ ]

Scale is designed to be towed at a ride height indicated by

labels

outside of the indicated range may result in suspension damage.

[ ] Suspension stops must be in the transport position during towing.

[ ]

Converting the scale from weigh mode to transport mode and

back to weigh mode has been reviewed.

on the suspension shock absorbers. Towing at ride heights

[ ] Safety pins are installed in all the hitch pins.

[ ]

Dexter recommends to re-torque wheel lug nuts at 10, 25 and

50

miles.

Buyer ________________________Date_________________ __

Dealer ________________________

Copy to be retained by dealer

Fax copy to manufacturer: Fax #:

715-234-6967

Maintenance 39

Page 44

Mobile Group Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and

systems properly installed by a Distributor or Original Equipment Manufacturer

(OEM) will operate per written specifications as confirmed by t he Distributor/OEM

and accepted by RLWS. All systems and components are warranted against defects in

materials and workmanship for two years.

RL WS warrants that the equipment sold hereunder will conform to the current written

specifications authorized by RLWS. RLWS warrants the equipment against faulty

workmanship and defective materials. If any equipment fails to conform to these

warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given

prompt written notice with a detailed explanation of the alleged

deficiencies.

• Individual electronic components returned to RLWS for warranty

purposes must be packaged to prevent electrostatic discharge (ESD)

damage in shipment. Packaging requirements are listed in a publication,

Protecting Your Components From Static Damage in Shipment, available

from RLWS Equipment Return Department.

• Examination of such equipment by RLWS confirms that the

nonconformity actually exists, and was not caused by accident, misuse,

neglect, alteration, improper installation, improper repair or improper

testing; RLWS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person

other than RLWS or its duly authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective

equipment. Buyer is responsible for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location

repairs, including assembly or disassembly of equipment, nor will RLWS

be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMITATION W ARRANTIES OF MERCHANTABILITY OR

FITNESS

IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS

HEREUNDER

ACCEPTING

TO

S

TO

N

MODIFY

MADE

BUYER.

FOR A PARTICULAR PURPOSE. NE ITHER RLWS NOR DISTRIBUTOR WILL,

AND BUYER AGREE TH AT RLWS’ SOLE AND EXCLUSIVE LIABILITY

IS LIMITED TO REPA I R OR REPLACEMENT OF SUCH GOODS. IN

THIS WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER CLAIMS

WARRANTY.

HOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY

THE SELLER FOR WARRANTY CLAIMS.

O TERMS, CONDITION S, UNDERSTANDING, OR AGREEMENTS PURPORTING TO

THE TERMS OF THIS WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS

IN WRITING AND SIGNED BY A CORPORATE OFFICER OF RLWS AND THE

© Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET

RICE LAKE, WISCONSIN 54868 • USA

40 MAS-M Operator’s Manual

Page 45

For More Information

Web Site

Frequently Asked Questions (FAQs) at

http://www.ricelake.com/faqs.aspx

Contact Information

Hours of Operation

Knowledgeable customer service representatives are available 6:30 a.m. - 6:30 p.m.

Monday through Friday and 8 a.m. to 12 noon on Saturday. (CST)

Telephone

• Sales/Technical Support 800-472-6703

• Canadian and Mexican Customers 800-321-6703

• International 715-234-9171

Immediate/Emergency Service

For immediate assistance call toll-free 1-800-472-6703 (Canadian and Mexican

customers please call 1-800-321-6703). If you are calling after standard business

hours and have an urgent scale outage or emergency, press 1 to reach on-call

personnel.

Fax

Fax Number 715-234-6967

E-Mail

• US sales and product information at

prodinfo@ricelake.com

• I nternational (non-US) sales and product information at

intlsales@ricelake.com

Mailing Address

Rice Lake Weighing Systems

230 West Coleman Street

Rice Lake, WI 54868 USA

Maintenance 41

Page 46

Notes

42 MAS-M Operator’s Manual

Page 47

Page 48

230 W. Coleman St. • Rice Lake, WI 54868 • USA

U.S. 800-472-6703 • Canada/Mexico 800-321-6703 • International 715-234-9171 • Europe +31 (0) 88 2349171

www.ricelake.com www.ricelake.mx www.ricelake.eu www.ricelake.co.in m.ricelake.com

© Rice Lake Weighing Systems 02/2014 132051 Rev E

Loading...

Loading...