Page 1

™

LoadRunner

OnBoard Weighing System for Dump Trucks

Series

Installation & Service

Manual

162356 Rev A

Page 2

Page 3

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

Contents

1.0 Introduction..................................................................................................................................... 1

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Considerations Before Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Welding Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.0 Load Pin and Transducer Specification ......................................................................................... 3

2.1 Onboard Dump Truck Kit Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Load Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Pressure Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.0 Roll Off Load Pin Installation .......................................................................................................... 5

3.1 Installing the Load Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 Installing the Inclinometer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Power Cable Connection to Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Hydraulic Pressure Transducer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5 Routing Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 Install the Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.6.1 Electrical Wiring and Data Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.7 Final Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.0 Configuration and Calibration ...................................................................................................... 13

4.1 User and Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Initial Setup of the OB-350 Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.2.1 Initial Password Entry and Clock Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.2.2 Configuration of Input Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 Configuration of Count By . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.4 Configuration of Zero Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.5 Configuration of Inclinometer Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.6 Configuration of Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.7 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.7.1 Calculating the SPAN (Net Weight) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4.7.2 Enter Tare Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.7.3 Set Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.7.4 Full Span (Net Load) Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.0 Service and Troubleshooting........................................................................................................ 20

5.1 System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3 Sensor Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.1 Load Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.3.2 Visual Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.4 Cables and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4.1 Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.4.2 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Hardware Warranty Statement ................................................................................................................. 22

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Rice Lake Weighing Systems is an ISO 9001 registered company.

Specifications subject to change without notice.

Version 1.0, May 7, 2014

Contents i

Page 4

ii LoadRunner™ Series Installation & Service Manual

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

Page 5

1.0 Introduction

Important

CAUTION

WARNING

DANGER

WARNING

This manual is intended for use by technicians responsible for installing and servicing LoadRunner Series Onboard

Weighing Systems.

This manual contains instructions for i

systems). For straight trucks, this manual includes rigid under-body mounting instructions in four and six point

configurations, as well as under-body load pin installation instructions for tipping bodies and hoist chassis. Tipping

body installations can be either Lift-to-Weigh or Live-Weigh system types.

Authorized distributors and their employees can view or download this manual from the Rice Lake

Weighing Systems distributor site at

1. 1 S af et y

Safety Symbol Definitions:

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could result in serious injury or death, and

includes hazards that are exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury.

nstalling various types of Onboard Weighing Systems (non Legal-for-Trade

www.ricelake.com.

Indicates information about procedures that, if not observed, could result in damage to equipment or

corruption to and loss of data.

General Safety

Do not operate or work on this equipment unless you have read and understand the instructions and

warnings in this manual. Failure to follow the instructions o

death. Contact any Rice Lake Weighing Systems dealer for replacement manuals.

Proper care is your responsibility.

Failure to heed may result in serious injury or death.

DO NOT allow minors (children) or inexperienced persons to operate this unit.

DO NOT operate without all shields and guards in place.

DO NOT jump on the scale.

DO NOT use for purposes other than weight taking.

DO NOT place fingers into slots or possible pinch points.

DO NOT use any load bearing component that is

DO NOT use this product if any of the

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

Keep hands, feet and loose clothing away from moving parts.

components are cracked.

worn beyond 5% of the original dimension.

r heed the warnings could result in injury or

Introduction 1

Page 6

WARNING

1.2 Considerations Before Installation

Important

WARNING

Failure to observe these recommendations and instructions could result in a hazardous

operating condition.

This manual is intended to provide information for the mounting of Onboard Weighing Systems sensors in a

variety of applications. In applying the installation procedures, which follow, some fundamental precautions and

recommendations must be observed by the installer:

• Rice Lake Weighing Systems’ Onboard Scales are design

ed for applications covering a broad range of

vehicle types. Things to take into consideration are:

- Significant variations in mountings

- Variations in load sensor models

- Specifications

- System configurations

• Installation procedures are similar for both new vehicle mountings

and retro-fit mountings. When doing a

retro-fit mounting, ensure that all vehicle structures are free from cracks, excessive wear, corrosion,

alignment problems, etc. that could affect safety and scale performance.

• Load cells, load cell bearing plates, mounting brackets an

d load cell hardware should be painted upon

installation to help protect the installation from corrosion. Industry appropriate, quality enamel paint is

recommended.

- For environments where high concentrations of sa

lts are used on road surfaces, under-body coating is

recommended (3M™ Underseal™ part number 3M-8883 Universal Rubb erized Undercoating).

- Load cells, bearing plates, brackets and hardware shou

ld be periodically inspected for any evidence of

rust or corrosion. If areas of corrosion are present, they should be cleaned with a wire brush and

re-painted or undercoated.

- Load cell connectors must be connected or capped during painting or undercoating.

• The instructions outlined herein are designed to

ensure that a correct installation will provide maximum

safety, optimum system performance and accuracy, a long operating life, and reasonable installation costs. It

is required that the installer comply with all guidelines and material specifications outlined in this manual,

with special emphasis on detail and inspection of work.

• Installation must comply with appropriate

regulations of the U.S. Department of Transport ation (DOT), state

and local regulations, the recommended standards and practices of the Society of Automotive Engineers

(SAE), standards of the American W elding Society (AWS), and the recommendations of the truck, trailer and

body, hoist and/or suspension manufacturer.

1.2.1 Welding Specifications

Welding, metalworking and assembly shou ld only be performed by qualified personnel experienced in welding on

vehicle body structures and sub frames. Only welding equipment of the highest quality should be used in the

welding of load cell bearing plates. When welding, use procedures that ensure high quality welds. Over-welding

may result in distortion and damage, while under welding may not develop adequate strength.

Rice Lake Weighing Systems recommends removal of load cell after tack welding bearing plates in

position so that final welding is performed without load ce

current, or cable damage.

If welding with load cells in position, the installer must ensure that electrical current cannot flow through the load

cell. All load cell terminals must be shorted together. Attach the ground strap directly to the vehicle frame member

to which the bearing plates will be welded. Never weld directly to a load cell.

Always disconnect battery terminals before performing any welding.

2 LoadRunner™ Series Installation & Service Manual

ll being subjected to excessive heat, weld

Page 7

2.0 Load Pin and Transducer Specification

Note

3

4

1

5

6

7

2

2

8

9

10

11

12

13

15

14

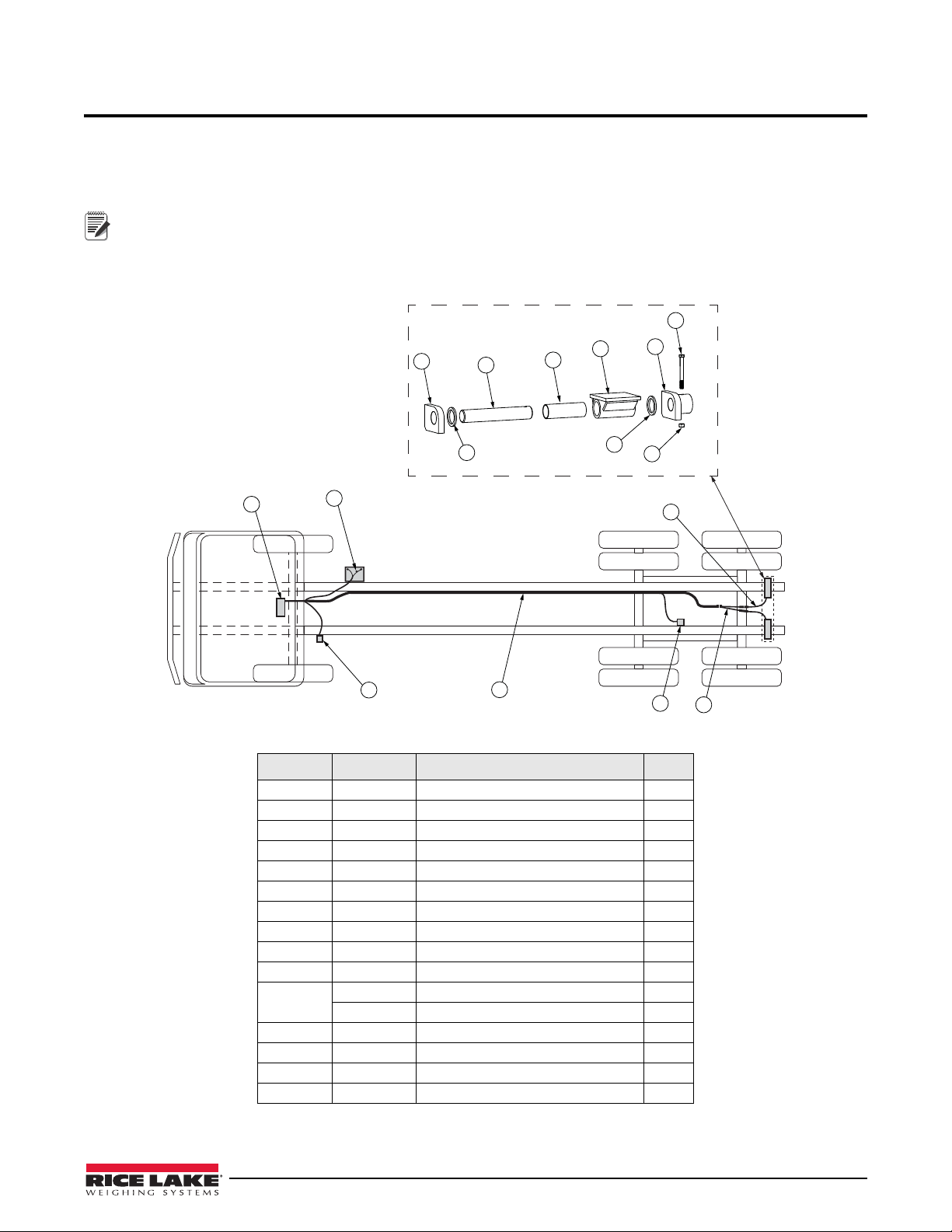

The Rice Lake Roll Off and Dump Truck kits are typically LIFT-TO-WEIGH KITS. This means that with the hoist

in the relaxed state (on the chassis), no weight reading is available. The hoist needs to be elevated to a position

showing the correct angle on the in-cab digital display unit, approximately four degrees, for the weight reading

degrees to be valid and accurate.

This manual provides instructions for the installation of straight frame dump trucks and “pup” dump trailers only.

For information on full frame or frame-less end dump or side du

Precision Loads manual (PN 115094).

2.1 Onboard Dump Truck Kit Parts

mp trailers, please refer to the Rice Lake

Figure 2-1. Onboard System – Dump Truck Kit Illustration

Item No. Part No. Description Qty

1 119966 Support, 1 x 4 x 5.16 1

2 119963 Ring, .25 x 2.25 x 3 4

3 131207 Pin, Load Dump Truck 2

4 119974 Glass Tubing 2

5 119973 Load Cell Mount Weldment 2

6 119969 Weldment, Support Ring 2

7 153117 Screw, Cap 1/2-20NF x 5” 2

8 Nut, Top Locking 2

9 131800 Cable Assembly 6’ 3

10 131226 Splitter, Cable Y-Splitter 1

11 131222 Inclinometer, Onboard 1

158196 Bracket, Onboard Inclinometer 1

12 131228 Cable Assembly 15’ (5M) 1

13 131200 Transducer, Hydraulic 1

14 131219 Indicator, OB3502 Channel 1

15 131221 Cable Assembly Fuse 1

Table 2-1. Onboard System – Dump Truck Kit Parts List

Load Pin and Transducer Specification 3

Page 8

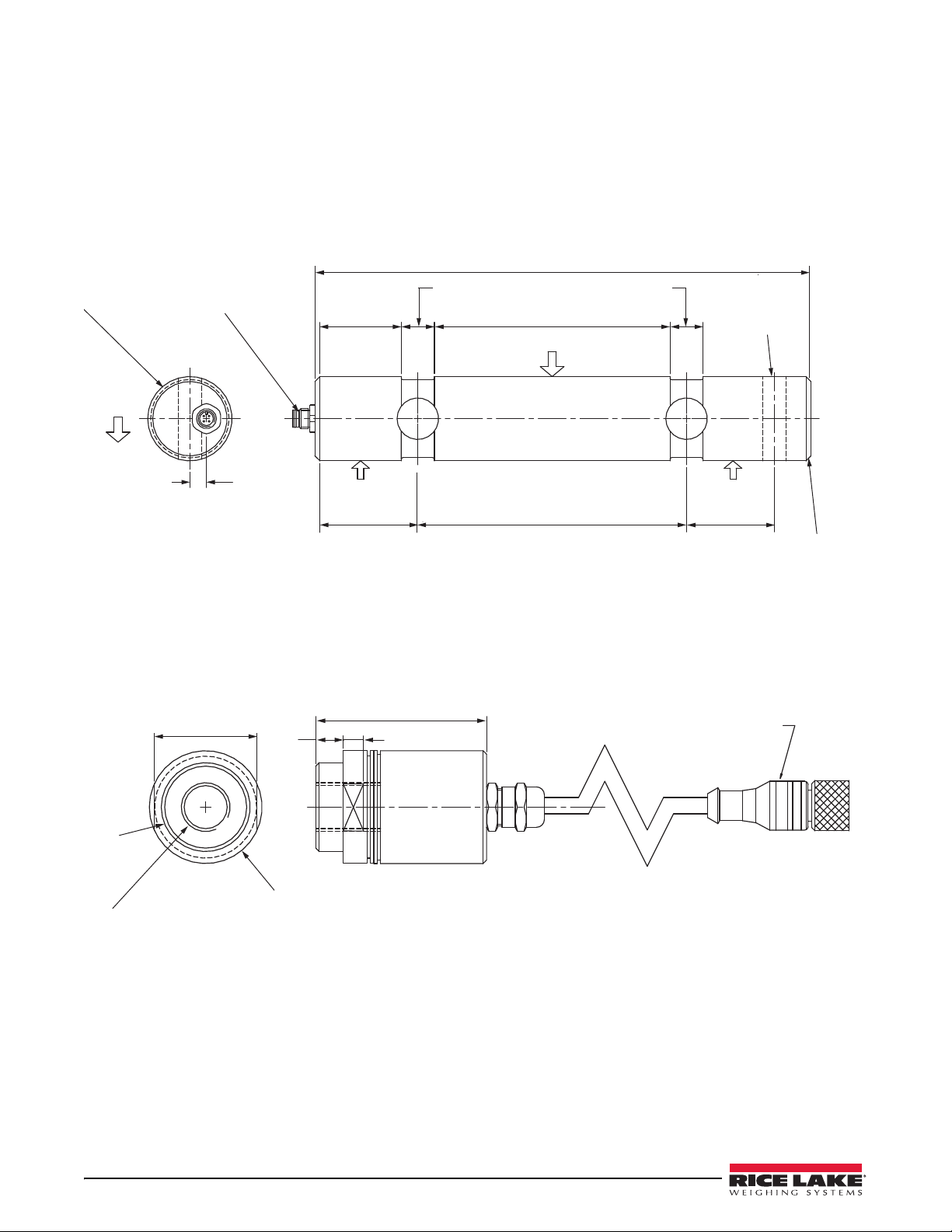

2.2 Load Pins

Electrical

Connector

Double shear load pin

made from heat treated alloy steel

nickel plated for corrosion resistance

fitted with an M12 commercial vehicle class connector

11.8" (300 mm)

2"

(49 mm)

0.79"

(20 mm)

5.5"

(142 mm)

0.79"

(20 mm)

0.5 Ø (14 mm )

Orientation and

Anti-rotation

Reaction

Force

Reaction Force

2.4"

(62 mm)

6.4"

(162 mm)

2"

(53 mm)

Chamfer

0.12"

(3 mm) x 45°

Both Ends

0.4"

(10 mm)

Ø 2" d10 Ø

50.70

50.58

Direction of Load

Direction

of Load

1.2" A/F

(30 mm)

0.25" (6 mm)

0.31"

(8 mm)

2" (50 mm)

1" Ø

(26 mm)

9/16

"-18 SAE

1.2" Ø

(33 mm)

16' (5 M) if four core cable

with a M12 fully moulded male connector

Material: Stainless Steel

Sealing: Fully welded to IP68

Hinge pivot and lift cylinder load pins built by Rice Lake Weighing Systems are available in two sizes:

• 2 inch diame ter (see Figure 2-2) Dump Truck

Full length hinge bars are also available a

Lake Weighing Systems dealer or the factory). All load pins are supplied with collars and bolts with locknuts to

secure pin position. The installer must ensure that all load pin installations can receive required initial and periodic

lubrication.

s direct replacements for tipping bodies with hinge bars (contact a Rice

2.3 Pressure Transducer

Figure 2-2. 2 Inch Diameter Load Pin (PN 131207)

Figure 2-3. Oil Pressure Transducer (PN 13 1211)

4 LoadRunner™ Series Installation & Service Manual

Page 9

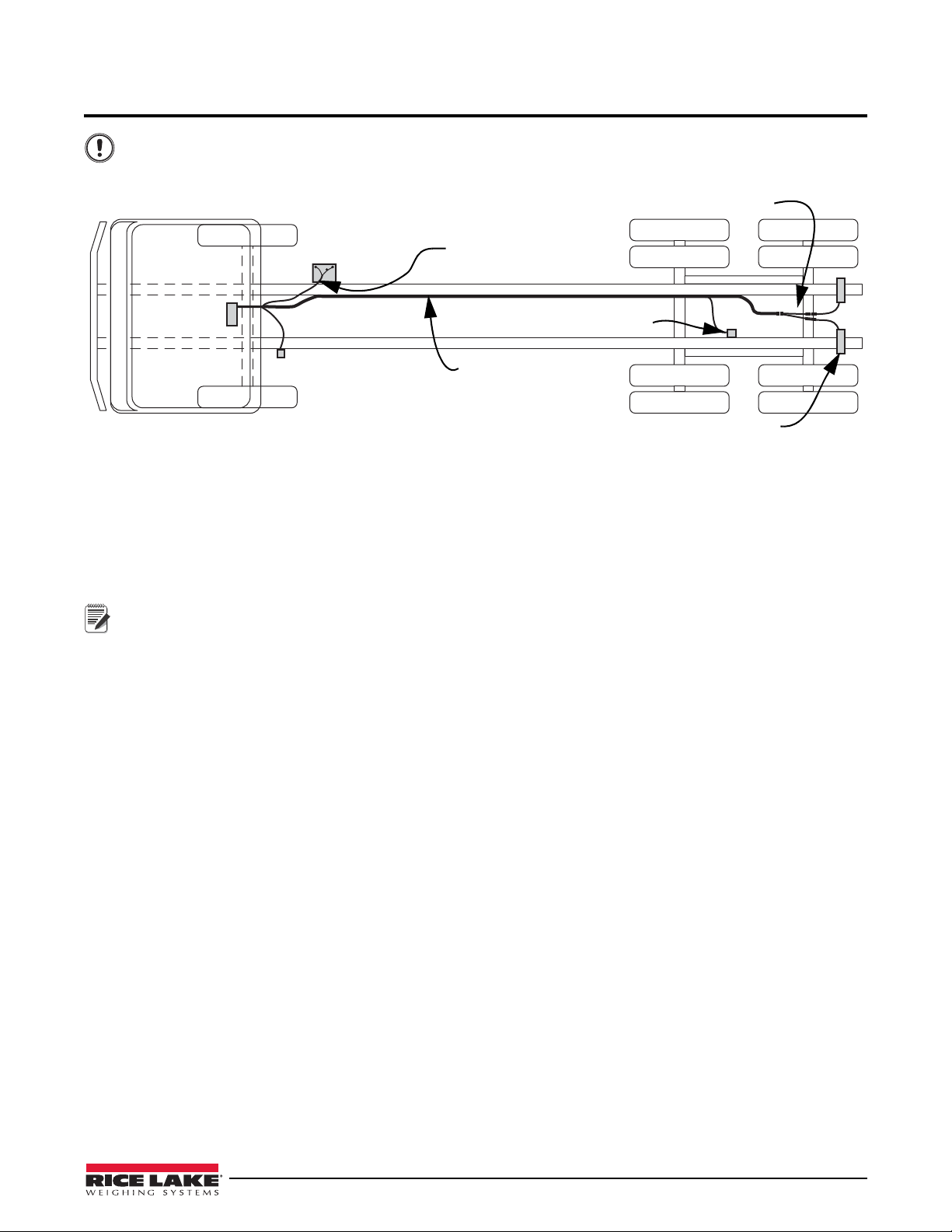

3.0 Roll Off Load Pin Installation

Important

Load Pin Kits

Inclinometer

Y Cable

Battery

Trans du ce r

Indicator

Power Cable

Homerun Cable

Note

All load pin installations require lubrication facilities. Normally lubrication is provided through the central

pivot area.

Lake pivots are furnished with drilled and tapped holes for the insertion of a standard lube zerk which

must be supplied and installed by the system installer.

3.1 Installing the Load Pins

1. Remove the rear fenders from the truck, if required, to gain free and clear access to the pivots.

2. Use jacks or a forklift to support the rear of the dump bucket

pivot pins are being replaced.

3. Remove the bolt and washer from the collar/support on the

Removing pivot pins on some vehicles may be difficult if rust is present or if the hoist chassis pivot and the truck

chassis supports are out of alignment. If rust is an issue,

tapping the pivot pin out. Use a pry bar as a lever to assist with any misalignment problems to remove the

existing pivot pins.

4. Push the pivot pins out of the supports.

5. Mark the frame where the pivot supports are located, in an area

frame smooth. This will assist in the location of the new supports.

6. Remove the supports from t

7. Using a power grinder or a wire brush, clean the area where the supports were

frame. Grind the frame smooth to ensure a clean weld for the support installation.

OEM Roll Off pivots typically have existing lubrication fittings included in their pivots. Rice

Figure 3-1. LoadRunner System Layout

and maintain its position/alignment while the

pivot.

use a penetrating lubricant and appropriate tools for

that will not be affected by grinding the

he frame of the truck.

located, both sides of the

Roll Off Load Pin Installation 5

Page 10

8. Weld supports to frame according to Figure 3-2.

3/8"

Ty p

0.50"

3/8"

Ty p

3/8"

3/8"

??

Support Plate

Support Plate

Support Collar Weldment

Support Collar Weldment

Truck Angle

Figure 3-2. Weld Supports to Frame

6 LoadRunner™ Series Installation & Service Manual

Page 11

9. Install each mount assembly and load pin per Figure 3-3.

Never strike the load cell directly, as it may cause

damage to the load cell. Use a wood block (or similar

material) to cushion the load cell, and tap lightly.

Important

Step 1

Insert neoprene

bushing into the

support opening.

Step 2

Place a collar over the

neoprene bushing and

snug against the support.

Step 3

Place the mount weldment

over the neoprene bushing

between the supports.

Step 4

Press the neoprene

bushing farther in to the

mount weldment to hold it.

Step 5

Place the remaining collar

into the space between the

mount weldment and the

spacer.

Step 6

Press the neoprene

bushing the rest of the

way in to support the

components.

Step 7

Push the load pin through

the neoprene bushing,

aligning the holes in the

load pin and the support.

Step 8

Secure load pin to the

support using a bolt

and nut.

Left Rear - Connector should be toward the cab

Right Rear - Connector should be away from the cab.

Cab of Truck

Step 9

Using grease, lubricate

the neoprene bushing.

Note

Figure 3-3. Install Load Pins Assembly

The load pins have arrows indicating the downward force, or direction of load applied to register a positive

weight value. See Figure 2-2 for load pin specifications and load direction.

Roll Off Load Pin Installation 7

Page 12

3.2 Installing the Inclinometer

Inclinometer Bracket

Hoist Frame

Inclinometer

Important

Note

Inclinometer should be installed on the hoist as close as possible to the load pins. Grind off any paint or rough areas

of the frame.

The inclinometer should be installed on a flat surface that will not interfere with any moving parts on the

frame. It must be installed as level to the frame as possible.

Figure 3-4. Install Inclinometer

Rice Lake Weighing Systems recommends one of the following mounting options, dependant on the type of

truck frame the unit is being mounted to.

Mounting Bracket Option 1

1. Align the mounting bracket to the frame and mark the holes.

2. Set the bracket aside and drill holes

3. Align the bracket with the holes and

Mounting Bracket Option 2

1. Align the mounting bracket to the frame and mark the holes.

2. Weld mounting studs to the frame where marked.

3. Place the bracket on the mounting studs and se

Mounting Bracket Option 3

1. Align the mounting bracket to be level with the frame.

2. Weld around the bracket to secure to frame.

Installing Inclinometer

1. Install the inclinometer to the bracket using the hardware included. The cable connection should be at the

bottom.

in the frame where marked.

secure with bolts, washer and nuts.

cure with washers and nuts.

8 LoadRunner™ Series Installation & Service Manual

Page 13

3.3 Power Cable Connection to Battery

Brown wire to positive

Fuse

Blue wire to negative

Tee Fitting

Reducing Fitting

Transducer

Hydraulic Valve

Important

Note

Figure 3-5. Power Connection to Battery

1. Wire the fuse (5A) to the brown wire.

2. Connect the power cable to the battery.

- Brown wire connects to positive terminal.

- Blue wire connects to ground.

3.4 Hydraulic Pressure Transducer

The hydraulic pressure transducer should be installed at the hydraulic control valve.

Figure 3-6. Install Hydraulic Pressure Transducer

1. Remove the hose where the transducer is to be installed.

2. Install a tee fitting to connect the hose to the hydraulic valve.

3. Insert a reducer if required (

4. Run the cable along the frame to the cable access hole in the cab.

transducer

Allow for slack when fitting and securing hydraulic hose lines as these move during normal operation.

) to the opening in the tee where the transducer is to be installed.

9/1

6” straight thread with O-ring is required to fit the Rice Lake pressure

Wire-tie the cable to the frame.

Plan a transducer cabling route that has little or no risk

Use split loom on all exposed cable to protect in areas where damage could be an issue.

of pinching, stretching or melting the cables.

Roll Off Load Pin Installation 9

Page 14

3.5 Routing Wiring

Important

Note

Load

Pins

Inclinometer

Y Cable

Battery

Trans du ce r

Indicator

Power Cable

15

’ Cable

6’ Cable

Note

Because each truck is different, cable routing will be specific to the truck the system will be installed on.

Plan a route that has little or no risk of pinching, stretching or melting the cables.

Use split loom on all exposed cable to protect in areas where damage could be an issue.

Wire tie any excess cable to the frame.

For cab-over type truck cabs, all scale system cabling must run around the main pivot point of the cab-over

hinge. For conventional cabs, look for cab access grommets

For ease of connection, label the cables used in installation prior to threading through the hole into the cab.

1. Connect 6’ ca

bles to the load pins.

2. Connect the load pin cables to the Y cable.

3. Connect 15’ cable and 3’ cable (if

4. Route the 15’ cable along

frame to the indicator through access hole in the cab.

5. Wire tie the cable to the frame

necessary) to the Y cable.

approximately every 18 inches.

6. Follow the same route with the inclinometer cable.

7. Route the power cable from the battery to the

Connecting wiring to the indicator is shown in Section 3.6.

indicator location.

in the flooring near the driver seat area.

Figure 3-7. Wi ring Diagram

10 LoadRunner™ Series Installation & Service Manual

Page 15

3.6 Install the Indicator

Panel mount

Roof/under dash mount

Dash mount

Optional Radio DIN mount

0.71 in

(18 mm)

4.00 in

(100.5 mm)

2.50 in

(62.5 mm)

5.71 in

(145 mm)

1.73 in

(44 mm)

5.71 in

(145 mm)

4.80 in

(122 mm)

1.57 in

(40 mm)

2.32 in

(59 mm)

3.54 in

(90 mm)

3.54 in

(90 mm)

Ø 0.25 in (6.5 mm)

holes for u-brackets

0.157 in (4 mm) self taper

0.137 in (3.5 mm) deep

Panel mount holes

Important

Figure 3-8. Indicator Mounting Options

If the indicator will be installed in the cab, choose an area that is easily visible to the driver. A mounting bracket is

provided.

When running cable to the indicator, use existing access hole if available, if not, a hole will need to be

drilled in the cab. Insert a grommet to protect wiring.

Do not allow cable jacket to contact bare metal edges.

Figure 3-9. Indicator Dimensions

Roll Off Load Pin Installation 11

Page 16

3.6.1 Electrical Wiring and Data Connections

1

3

2

4

5

6

12B1D4FB

T

The indicator is fitted with one Power and one Input Channel connector as standard. CANbus, Channel 2 and RS-232 are optional.

Full connector options are shown below.

Figure 3-10. Rear Panel Identification and Bulkhead Connectors

1

2

3

4

5

6

Input Channel 1, Max +/-39.0625 milli-Volts (Hydraulic Pressure Transducer)

Input Channel 2, Max +/-39.0625 milli-Volts (Load Pin Connection)

Power Input

CANbus digital input & output (Inclinometer Connection)

RS-232 output for printers and data captur

receive)

e devices (pin 9 = vehicle volts, pin 5 = ground, pin = 2 transmit, pin 3 =

Alpha-numeric unique indicator serial number, also appears on power-on

POWER & ALARM, socket is MALE – CON 1 on PCB

Pin 1

Pin 2

Pin 3

Pin 4

BROWN Vehicle voltage Supply 12V (LCV) or 24V (MCV & HGV)

WHITE Output 1 12V or 24V

BLUE Ground Ground 0 Volts (common)

BLACK Output 2 12V or 24V

3.7 Final Installation

1. Reinstall the fenders.

2. T est the hoist to make sure none of the cables at risk

lowered.

3. Test the hoist to make sure the scale reads positively with applied weight. If positive weight is not

displayed, it is possible

that the load pins or a load pin are not in the correct position and reading

backwards. Pin position can be changed by rotating 180 degrees.

of being pinched, stretched or cut when it is raised and

12 LoadRunner™ Series Installation & Service Manual

Page 17

4.0 Configuration and Calibration

Note

OptionsAlarms

Alarm 1

Alarm 2

Cells

CAN

Diagnostics

Menu

OLED

Info

Display

Split

Input 2

Input 1

Configuration

Span

Zero

Tare

Calibration

Modes

RS-232

PRINTER

Count

1 lb

10 lb

20 lb

50 lb

100 lb

200 lb

INC

ON

OFF

System

PUK

Pin

Clock

Net

Gross

Net & Gross

ON

OFF

Chan

Load

Z/Func

Keyboard

Inhibit

Keyboard

Printer

Printer CSV Data

Printer G PVWS

None

Format 1-4

Scoreboard

Net 4

Gross 4-5

G PVWS

BA4840

4.1 User and Setup Menu

The menu structure has two levels of security: an open user menu for driver operators and a password setup menu

for calibrations and options for making changes to the user menu.

The default password is 0350. Keep this for your records.

Figure 4-1. User and Setup Menu – Electrical Wiri ng and Data Connections

User and Setup Menu

Parameter Choices

Display OLED

Diagnostics Cells

Alarms Alarm 1

Info

CAN

Alarm 2

Table 4-1. User and Setup Menu – Electrical Wiring and Data Connections

Adjust the brightness of the display; High, Med or Low.

Firmware version and serial number display.

To display mV/V for load cells or transducers on separate channels.

To display CANbus diagnostics (not used).

Allows configuration of audible alarms.

Description

Configuration and Calibration 13

Page 18

Symbols

Keys

M

E

N

U

(OK)

Diagnostics

Alarms

Options

Configuration

Calibration

System

A B C D

E

User and Setup Menu

Parameter Choices

Options Modes Select weighing mode to be displayed -

Load/Chan Load function gives the option to accumulate the amount of load (wei

collected from site.

Channel Function - Split screen function is added to the MENU screen.

RS-232 Select or change RS-232 output option.

Count Select count by in kg - 1, 2, 5, 10, 20, 50, 100, 200,

Z/Func Allows operator access to Zero/Tare function on the display.

Inc For use with roll off systems and

inclinometer.

Configuration Input 1(F)

Input 2 (R)

Split

CAN

Calibration Ta re

Zero

Span

System Pin

PUK

Clock

Air/Oil pressure transducer or load cell setting on truck type.

Air/Oil pressure transducer or load cell setting on truck type.

Setting varies depending on input 1/input 2 values.

Not Used

Entry of empty vehicle weight for gross weight calculation.

No load zero calibration.

Entry of load for span calibration.

Enter a password.

Not Used.

Change system time and date.

Description

Net. Gross or Net & Gross. See Section 4.6.

ght) delivered or

dump trucks, turn on to calibrate zero degrees of

Table 4-1. User and Setup Menu – Electrical Wiring and Data Connections

The following configuration and calibration instructions require symbols to make selections. When selecting a

symbol, press the corresponding key below the symbol. See

Figure 4-2.

(OK)

Figure 4-2. Symbol Keys

4.2 Initial Setup of the OB-350 Indicator

The system password allows access modification of the options: Configuration, Calibration and System Setup

menus. When in the configuration and setup menus, the function keys will perform the following functions:

Figure 4-3. Setup Mode

A

B

C

D

E

14 LoadRunner™ Series Installation & Service Manual

Accept or Enter key - enters data

Down arrow key - scrolls down wi

Up arrow key - scrolls up within the menu selection

Carriage Return/Circle - Previous screen or back function

When in a menu function (passwor

Selectable MENU options

thin the menu selection

d) and OK is not visible, use this key as the enter and accept.

Page 19

4.2.1 Initial Password Entry and Clock Setup

1. Press the power button to power on the indicator.

2. Press the Circle key to enter the menu screen.

3. Use

4. Press

5. Press to select Pin.

6. Press (OK) to display PIN input screen.

7. Enter Password or Pin code,

• Press

• Press

8. When PIN is correct, press

9. Press

or to scroll to System.

(OK).

0 3 5 0, using the following:

or to number 0-9.

to move cursor left.

to enter code.

(OK) to accept PIN.

10. Press

11. To Set PIN, select PIN, press

12. Use

13. Press

to back up to MENU.

(OK) and repeat 2 - 6.

or to scroll to Clock.

(OK).

14. Select the edit key to modify time (military) and date (international)

• Press

• Press

15. When complete, press

or to number 0-9.

to move cursor left.

three times to exit and return to system setup

menu

4.2.2 Configuration of Input Channels

1. Scroll to Configuration.

2. Press

3. Press

4. Press

5. Use

6. Press

7. Use

8. Press

9. Use

10. Press

(OK).

(OK) with Input 1 selected.

(OK) again to configure the channel.

or to scroll to Air/Oil Transducer.

.

or to scroll to Input 2.

(OK) again to configure the channel.

or to scroll to load cells.

to return to the system setup menu.

Configuration and Calibration 15

Page 20

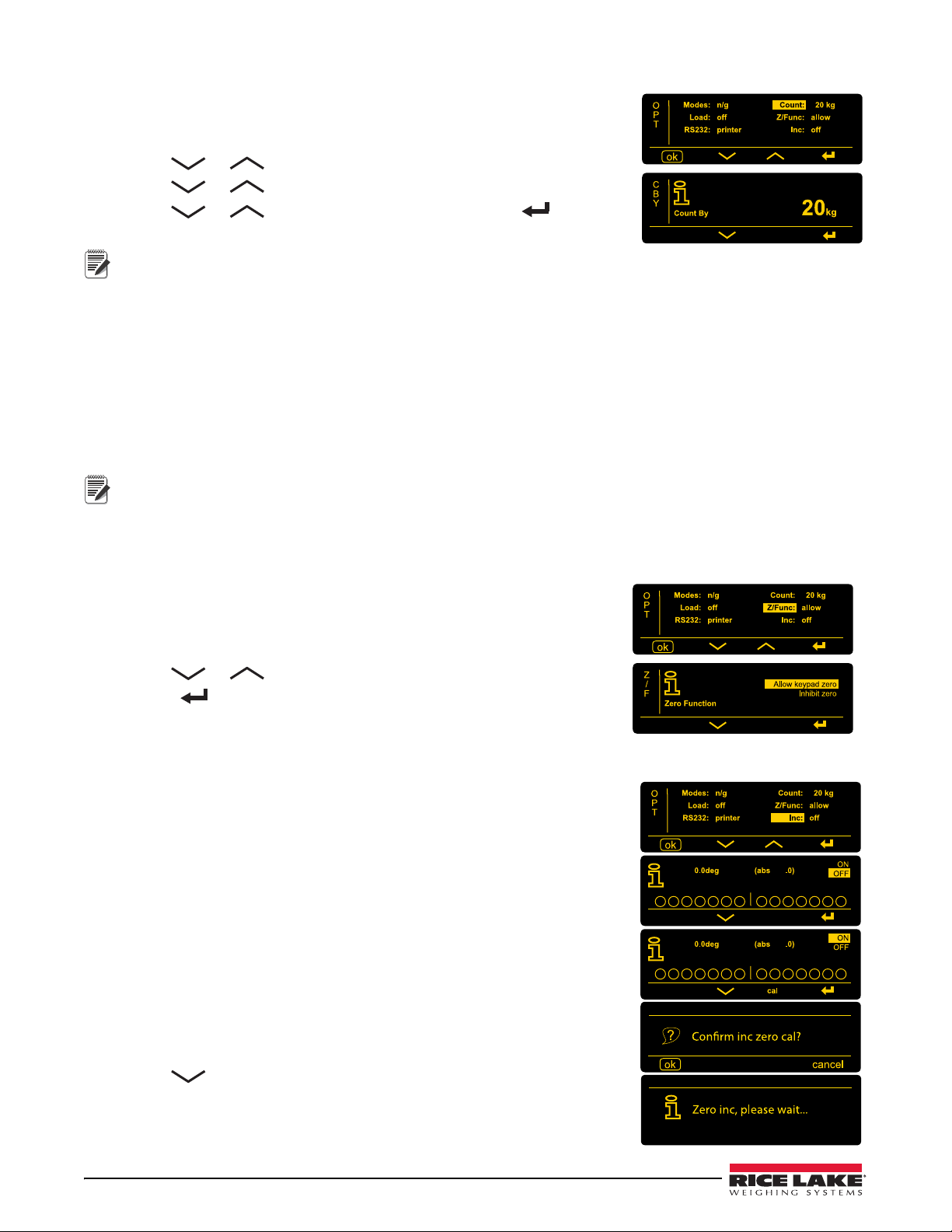

4.3 Configuration of Count By

Note

Note

The count by value in the division size, in lbs, that the scale will increment by

on the display.

1. Use

or to scroll to Option. Press (OK).

2. Use or to scroll to Count. Press (OK).

3. Use or to scroll to the Count By value. Press .

Selectable count by values are 1, 2, 5, 10, 20, 50, 100 and 200 lbs.

Rice Lake Weighing Systems recommends using 20 lb minimum.

Choosing a lower weight value may cause your weight to fluctuate

may be more difficult.

Example: If 50lb is selected, the weight values will increase by a factor of 50lbs: 50, 100, 150, etc.

on the display and returning to zero weight

4. Scroll to Z/Func: and press (OK).

4.4 Configuration of Zero Function

The Zero function setting allows you to turn on and off the zero key when in normal weighing mode.

Selectable zero function settings are:

• Allow Keypad Zero – Activate container tare (Gross Mode) or Zero (Net Mode) button on main menu to

zero load up to 1

When the tare button is pressed in gross mode, the weight will return to the original empty weight tare value.

• Inhibit zero – De-activate operator zero functionality

To set the Zero Function:

100 lbs of weight by the operator.

MENU, select Options.

1. In

2. Press (OK).

3. In OPTIONS menu, select Z/Func.

4. Press

(OK).

5. Use or to scroll to desired option.

6. Press

7. Zero is be added to the

to confirm setting.

MENU screen.

4.5 Configuration of Inclinometer Calibration

On dump truck and roll off applications, the load runner system uses the load

pins and hydraulic pressure transducer to determine a weight value. To achieve

the best accuracy, calibrate the system at the same incline that weight will be

read, with +/- 1-2°.

The Inclinometer setup scree

and absolute angle (abs 0.0). For this application, use the level indicators,

which light up for every degree the body is raised.

The numeric value will indicate a negative value as the body is raised, which is

normal. The level

indicators to the right will light up, 1° per circle.

The inclinometer function allows v

to achieve an accurate weight value consistently.

1. Make sure the truck is on a level surface

position.

2. Scroll to

Option, press (OK).

3. Scroll to Inc, press (OK).

4. Use to scroll to ON.

5. Ensure the body is in the down position and the truck is on a level

surface.

6. Press

CAL to zero the inclinometer.

n shows both the body angle in a numeric value

isual determination of the height of the body

and the body is in the down

16 LoadRunner™ Series Installation & Service Manual

Page 21

4.6 Configuration of Modes

Truck Scale

Note

With the inclinometer option turned on, the inclinometer screen is visible by switching display screens when

pressing the menu button.

The display screen will toggle between the following when configured for:

Gross Mode:

Toggles between gross only weight display, inclinome

Net Mode:

Toggles between net only weight display, inclinom

Net and Gross Mode (factory recommended setting):

Toggles between net only weight display, gross only weight display

menu mode.

To set mode:

1. In

MENU, select Options.

2. Press (OK).

3. In OPTIONS menu, select Modes.

4. Press

(OK).

5. In MODES menu, press to toggle between

NET & GROSS

GROSS

NET

ter standard display and menu mode

eter with net weight display and menu mode

, inclinometer with net weight display and

6. Press to confirm setting.

4.7 Calibration

Calibration requires the use of a truck scale in order to calibrate the system. First determine the empty vehicle

weight or tare weight of the truck. Once the tare and zero calibration are performed, load the vehicle as close to its

legal maximum limit as possible to determine the span or net weight value used for calibration.

4.7.1 Calculating the SPAN (Net Weight)

1. To determine actual TARE weight, drive the empty vehicle onto a truck scale and note the total weight.

Figure 4-4. Vehicle on Truck Scale

2. Load the vehicle as close to its legal maximum as possible.

3. Weigh the loaded vehicle, using the sa

4. Calculate

NET weight using: Gross - Tare = Net.

me truck scale, and record the GROSS vehicle weight.

Prior to calibration, with the display in the Inclinometer/Net Weight or Inclinometer mode raise the body clear of

the chassis (the factory recommendation is three or four de

on span calibration and normal weighing.

grees). Record the bubble indication setting for use

Configuration and Calibration 17

Page 22

4.7.2 Enter Tare Weight

lb

lb

lb

lb

lb

Prior to calibration, with the display in the Inclinometer/Net Weight or

Inclinometer mode raise the body clear of the chassis (the factory

recommendation is three or four degrees). Record the bubble

indication setting for use on span calibration and normal weighing.

Note

lb

lb

Note

1. Ensure vehicle is empty, then weigh and record T ARE (empty vehicle)

weight on an accurate truck scale.

MENU screen, select Calibration and press ok.

2. In

3. Select Tare.

4. Press ok (defaults to 10000).

5. Press

6. Enter vehicle TARE (empty) weight recorded in Section 4.7.1.

edit.

7. Press

8.

Press again to return to MENU screen.

.

4.7.3 Set Zero Calibration

1. Make sure the vehicle is on level ground.

Tippers: raise the body clear of the c

four degrees.

2. In

CAL menu, press to select Zero.

3. Press

4. Press

5. Press

ok.

cal.

ok to Confirm Ch 1 Zero.

hassis, approximately three or

6. Press

The Rice Lake Roll Off and Dump Truck kits are typically LIFT-TO-WEIGH KITS. This means that with the hoist in

the relaxed state (on the chassis), no weight reading is available. The hoist needs to be elevated to a position

showing the corr

degrees to be valid and accurate.

18 LoadRunner™ Series Installation & Service Manual

to return to CAL menu.

ect angle on the in-cab digital display unit, approximately 4 degrees, for the weight reading

Page 23

4.7.4 Full Span (Net Load) Calibration

lb

lb

lb

lb

lb

lb

1. Load vehicle to its legal max, record GROSS weight.

2. Weigh and record the TARE (empty) vehicle.

3. Subtract the T ARE weight from the GROSS weight to give

the SPAN (NET) weight.

31900 -12500 =19400 kg SPAN (NET) PAYLOAD

If the vehicle is a tipper, raise the body clear of the chassis.

4. In

CAL menu, press to Span.

5. Press

6. Press

7. Edit the SPAN (NET) weight, as in steps 1 & 2 above.

ok (defaults to 22680 lb).

edit.

8. Press

9. Press

10. Press

11. Press

when done.

cal.

ok to Confirm Ch 1 Span cal.

twice to return to MENU screen.

Configuration and Calibration 19

Page 24

5.0 Service and Troubleshooting

WARNING

5.1 System Maintenance

This section of the manual is intended to assist the user with techniques for system maintenance and

troubleshooting. Maintenance of the onboard scale can be done quickly and needs to be done at regular intervals.

For service issues make sure you have original

source quickly. Scale meters are built with simple but effective internal system diagnostics programs that isolate

component performance.

With reference to onboar d scale service an

some fundamental precautions and recommendations must be observed by servicing personnel.

Failure to observe these recommendations and instructions could result in a hazardous operating

condition.

• Servicing personnel must ensure that all vehicle structures are free from cracks, excessive wear, corrosion,

alignment problems, etc. that can affect safety and scale performance.

• The instructions outlined herein are designed to ensure

maximum safety, optimum system performance and accuracy, for a long operating life. It is therefore

extremely necessary that the installer comply with all guidelines and material specifications outlined in this

manual, with special emphasis on detail and inspection of work.

• Service and repair work must be in compliance with ap

Transportation (DOT), state and local regulations, the recommended standards and practices of the Society

of Automotive Engineers (SAE), standards of the American Welding Society (AWS), and the

recommendations of the truck, trailer and body, hoist and/or suspension manufacturer.

test numbers to work with, the test numbers help locate a problem

d repair procedures that involve load pins, trunnions and air transducers,

that a properly serviced installation will provide

propriate regulations of the U.S. Department of

5.2 Calibration

System calibration needs to be performed at the time of original scale installation. Rice Lake Weighing Systems

recommends that scale calibration be repeated about one month after original scale installation to adjust for any

mechanical influences that “seat” a new scale.

There is no typical interval for scale ca

comparison data of onboard scale loads as compared to weights obtained from certified platform scales or

pre-measured loads. If this is not possible, six-month re-calibration intervals are recommended. See Section 4.7.

libration that can be universally specified. Instead, operators should keep

5.3 Sensor Maintenance

5.3.1 Load Pins

For hinge load pins, thorough pin lubrication is critical to proper scale performance . Ensure all load pins used in

roll-off and other pin applications are always well-lubricated.

5.3.2 Visual Inspection

At the end of each day, service personnel should perform visual inspections that look for:

• Signs of wear or “polishing”

• Signs of weld cracking or failure

• Evidence of excessive corrosion

• Evidence of potential chassis

• Body runner or support structure cracking or bending

When the load pins were originally installed,

rigid and co-planar surfaces for welding. If these surfaces have become cracked, corroded or out of alignment, then

corrective action must be taken to ensure proper performance and safety of the onboard scale installation.

instructions specified that mounting brackets required clean, flat,

20 LoadRunner™ Series Installation & Service Manual

Page 25

5.4 Cables and Connectors

5.4.1 Cables

Inspect for any loosening of cables that might result in exposure to damage. Repair by adding more cable ties to

tighten up the cable run.

5.4.2 Connections

Rice Lake We ighing Systems uses special connectors which do not corrode and can withstand extremely cold

conditions. When aluminum connectors are present, especially in environments with high humidity or ro ad salts,

the connectors should be periodically cleaned and protected with plumbers tape. If a connector is severely

corroded, contact Rice Lake Weighing Systems for replacement information.

Service and Troubleshooting 21

Page 26

Hardware Warranty Statement

Rice Lake Weighing Systems (RLW S) warrants tha t all RLWS brand equipment and systems properly installed by

a Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by

the Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects in

materials and workmanship for two (2) years, unless otherwise stated.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized by

RLWS. RLWS warrants the equipment against faulty workmanship and defective ma terial s. If any equipment fails

to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the warranty

period subject to the following conditions:

Upon discovery by Buyer of such non-conformity, RLWS will be given prompt written notice with a detailed

explanation of the alleged deficiencies.

Individual electronic components returned to RLWS for warranty purposes must be packaged to prevent

electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a publication, "Protecting

Your Components From Static Damage in Shipment," available from RLWS Equipment Return Department.

Examination of such equipment by RLWS confirms that the non-conformity actually exists, and was not caused by

accident, misuse, neglect, alteration, improper installation, improper repair, or improper testing. RLWS shall be the

sole judge of all alleged non-conformities.

Such equipment has not been modified, altered, or changed by any person other than RLWS or its duly authorized

repair agents.

RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible for shipping

charges both ways

In no event will RLWS be responsible for travel time or on-location repairs, including assembly or disassembly of

equipment. Nor will RLWS be liable for the cost of any repairs made by others.

Installer is completely responsible for the design and fitting of the installation, and any changes which might result

in voidance of the warranty of the manufacturer of equipment to which the products are installed.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMIT ATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. NEITHER RLWS NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BU YER AGREE THAT RLWS' SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS

LIMITED TO REPAIR OR R EPLACEMENT OF SUCH GOODS. IN ACCEPTI NG THIS WA RRANTY,

THE BUYER WAIVES ANY AND ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE

SELLER FOR WARRANTY CLAIMS.

No terms, conditions, understanding, or agreements purporting to modify the terms of this warranty shall have any

legal effect unless made in writing and signed by a corporate officer of RLWS and the Buyer.

© Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

22 LoadRunner™ Series Installation & Service Manual

Page 27

Hardware Warranty Statement 23

Page 28

Page 29

230 W. Coleman St. • Rice Lake, WI 54868 • USA

U.S. 800-472-6703 • Canada/Mexico 800-321-6703 • International 715-234-9171 • Europe +31 (0) 88 2349171

www.ricelake.com www.ricelake.mx www.ricelake.eu www.ricelake.co.in m.ricelake.com

© Rice Lake Weighing Systems 05/14 PN 162356 Rev A

Loading...

Loading...