Page 1

480 Legend Series

Digital Weight Indicator

Version 1.03

Operation Manual

PN 163374 Rev A

Page 2

Page 3

Contents i

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

Contents

1.0 Introduction............................................................................... 1

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Front Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3.1 Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3.2 Annunciator Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.4 Front Panel Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.1 Numeric Keypad - Editing Procedure for Numeric Values . . . . 7

1.5 Indicator Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5.1 Status Lights While in Various Menus. . . . . . . . . . . . . . . . . . . . 8

1.5.2 Zero Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5.3 Toggle Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5.4 Acquire Tare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5.5 Preset Tare (Keyed Tare) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.5.6 Display Tare. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5.7 Print Ticket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5.8 Toggle Gross/Net Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5.9 View Audit Trail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5.10 Enter New Unit ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5.11 Display Accumulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5.12 Display or Change Time and Date . . . . . . . . . . . . . . . . . . . . . 10

1.5.13 Display, Edit and Set Setpoint Value . . . . . . . . . . . . . . . . . . . 11

1.5.14 View Firmware Version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5.15 Enter User Password. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.0 User Menus ............................................................................. 13

3.0 Appendix ................................................................................. 17

3.1 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2 Regulatory Mode Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

480 Limited Warranty.......................................................................... 22

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Rice Lake Weighing Systems is an ISO 9001 registered company.

Version 1.03, June 09, 2015

Page 4

ii 480 Legend Series

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

Page 5

Introduction 1

1.0 Introduction

The 480 is a single-channel digital weight indicator housed in a NEMA Type

4X/IP66-rated stainless steel enclosure. The indicator front panel consists of a

large (.8 in, 20 mm), six-digit, seven-segment LED display and

seven-button keypad.

Features

•Auto switching AC power supply 115 VAC to 230 VAC, 50-60 Hz.

•Drives up to ten 350or twenty 700 load cells.

•Supports four and six wire load cell connections.

•Two communications ports with Demand or Continuous outputs.

• Optional analog output module provides 0–10/2-10 VDC or 0–20/4–20

mA tracking of gross or net weight values.

• Optional digital I/O card, four outputs/two inputs for setpoints and key

functions.

•Unit ID up to six numeric, operator entered.

•Accumulator with report and clear.

•Time and date.

•Audit trail tracking.

Supported Applications

•Custom Ticket Printing: Gross, Net & Setpoint format can be customized

up to 300 characters and print Time and Date, Unit ID, and Consecutive

Ticket Number.

•Basic Weighing: Gross or net mode with operator menu to other functions.

•Accumulation: Weights are totaled, with armed print function.

• Batching: Up to eight batch steps with latched or continuous outputs for

Gross, Net, Delay setpoint. Actions include trip high or low, wait for

standstill, print, accumulate and tare.

•Keyed Tare: Preset tare value can be entered when the gros s weight is at

zero.

•Local/Remote: Remote unit displays weight and transmits key press

commands to the local unit.

Manuals (Including the 480 Legend Series Technical manual (PN

119201) referred to in this manual) can be viewed or downloaded the

Rice Lake Weighing Systems website at

www.ricelake.com

Please leave this manual with the indicator when installation and

configuration are complete.

Page 6

2 480 Legend Series

1. 1 Sa fe ty

Safety Symbol Definitions

Indicates a potentially hazardous situation that, if not avoided,

could result in serious injury or death, and includes hazards that

are exposed when guards are removed.

Indicates information about procedures that, if not observed,

could result in damage to equipment or corruption to and loss of

data.

Safety Precautions

Do not operate this equipment unless you have read and

understand the instructions and warnings in this manual. Failure

to follow the instructions or heed the warnings could result in

injury or death. Contact any Rice Lake Weighing Systems dealer

for replacement manuals. Proper care is your responsibility.

General Safety

Failure to heed may result in serious injury or death.

DO NOT open the indicator, all procedures that require work inside the indicator

enclosure are to be performed by qualified service personnel only.

DO NOT allow minors (children) or inexperienced persons to operate this unit.

DO NOT operate without the enclosure completely assembled.

DO NOT use for purposes other than weight taking.

DO NOT place fingers into slots or possible pinch points.

DO NOT use this product if any of the components are cracked.

DO NOT exceed the rated specification of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

DO NOT submerge.

Before opening the unit, ensure the power cord is disconnected from the outlet.

WARNING

Important

WARNING

Page 7

Introduction 3

1.2 Operating Modes

The 480 has two modes of operation:

Normal (Primary) Weigh Mode

Normal mode is the default mode of the indicator. The indicator displays

gross or net weights as required, using the annunciators described in

Section 1.3.2 on page 5 to indicate scale status and the type of weight

value displayed.

User Menu Setup Mode

The user menu setup mode is used to access the Accumulator Functions,

Audit Trail, display the Tare, Unit ID, Time & Date, Setpoints, Serial

Communications parameters, Print Formats, and view the Firmware

Version.

It is accessible by pressing the

MENU key on the front panel.

1.3 Front Panel Display

Figure 1-1 shows the 480 LED annunciators, keypad and key functions.

The symbols shown by the keys (representing up, down, enter, left, right)

describe the key functions assigned in the operating modes. The keys are used

to navigate through menus, select digits within numeric values, and

increment/decrement values.

Figure 1-1. 480 Front Panel, Showing LED Annunciators and Key Functions

PRELIMINA

The up, down, enter, left and right arrows by the keys

describe the functions assigned in the operating modes.

Keys are also used to navigate through menus, select

digits within numeric values, and increment/decrement

Numeric Keypad – Enter numeric

values.

Page 8

4 480 Legend Series

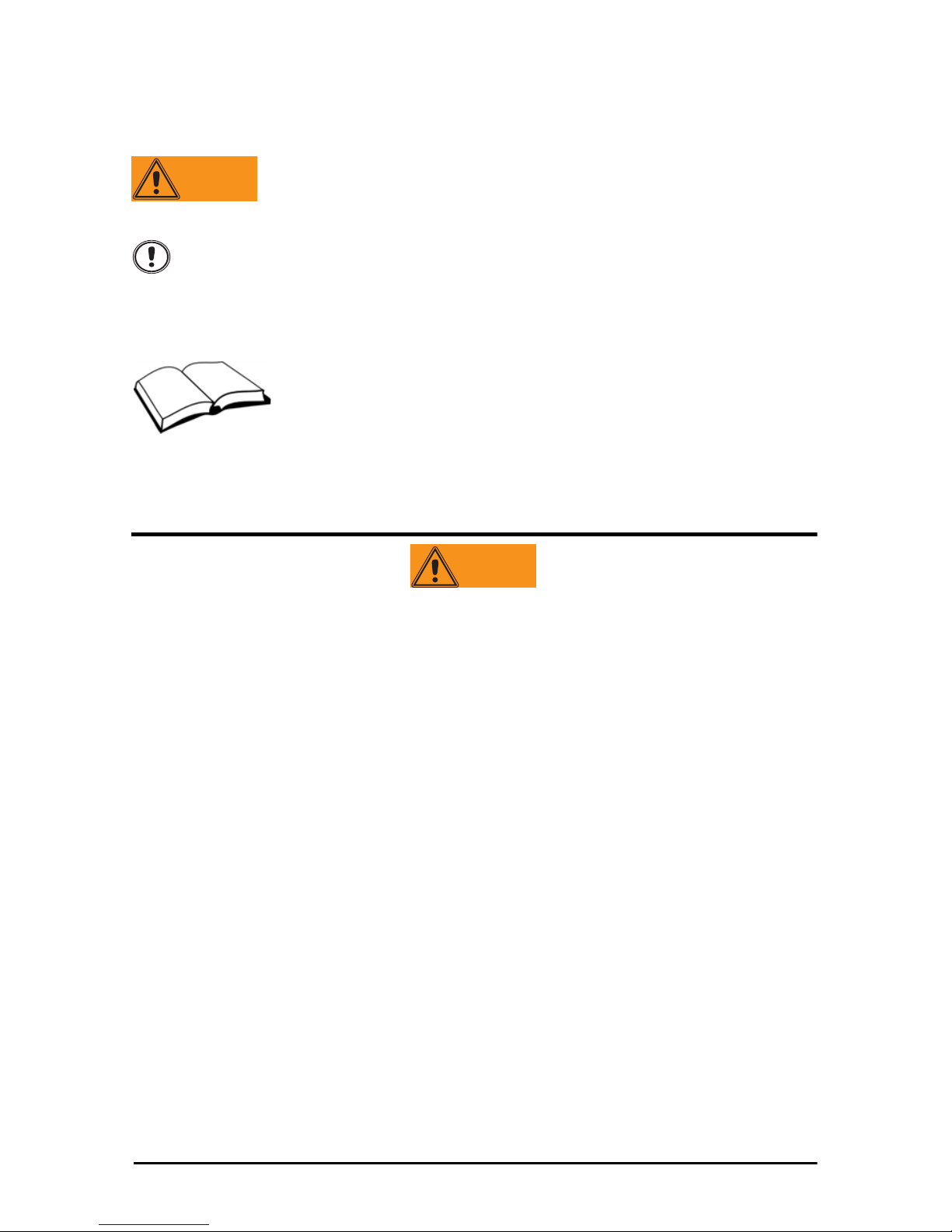

1.3.1 Key Functions

See the 480 Legend Series Technical manual (PN 119201) for more information.

Key Function

Turns the unit on/off.

If power mode is set to manual, the POWER button must be

used to turn the unit on and off. If power mode is set to

auto, the unit will automatically power on when it’s plugged

in and the only way to turn it off is to unplug power.

The MENU key is used to access the User Setup menu.

Sets the current gross weight to zero, provided the amount of weight to

be removed or added is within the specified zero range and the scale is

not in motion. The zero band is defaulted to 2% of full scale, but can be

configured for up to 100% of full scale.

Switches the weight display to an alternate unit.

In numeric entry mode used as a “clear” key.

Sends “on-demand” print format out the serial port, provided the

conditions for standstill are met. PRINT may be displayed while the unit

prints.

Performs one of several predetermined Tare functions dependent on the

mode of operation s. To view a stored tare, see Section 1.5.6.

Also acts as an “enter” key for numeric or parameter entry.

Toggles the display between gross and net. If a tare value has been

entered or acquired, the net value is the gross weight minus the tare.

Gross mode is shown by the Gross/Brutto annunciator; net mode is

shown by the Net annunciator.

During a numeric entry, sets the currently select digit to 0, then selects one

digit to the right.

Table 1-1. Key Functi ons

POWER

Note

MENU

ZERO

UNIT

PRINT

TARE

GROSS

NET

B/N

Note

Page 9

Introduction 5

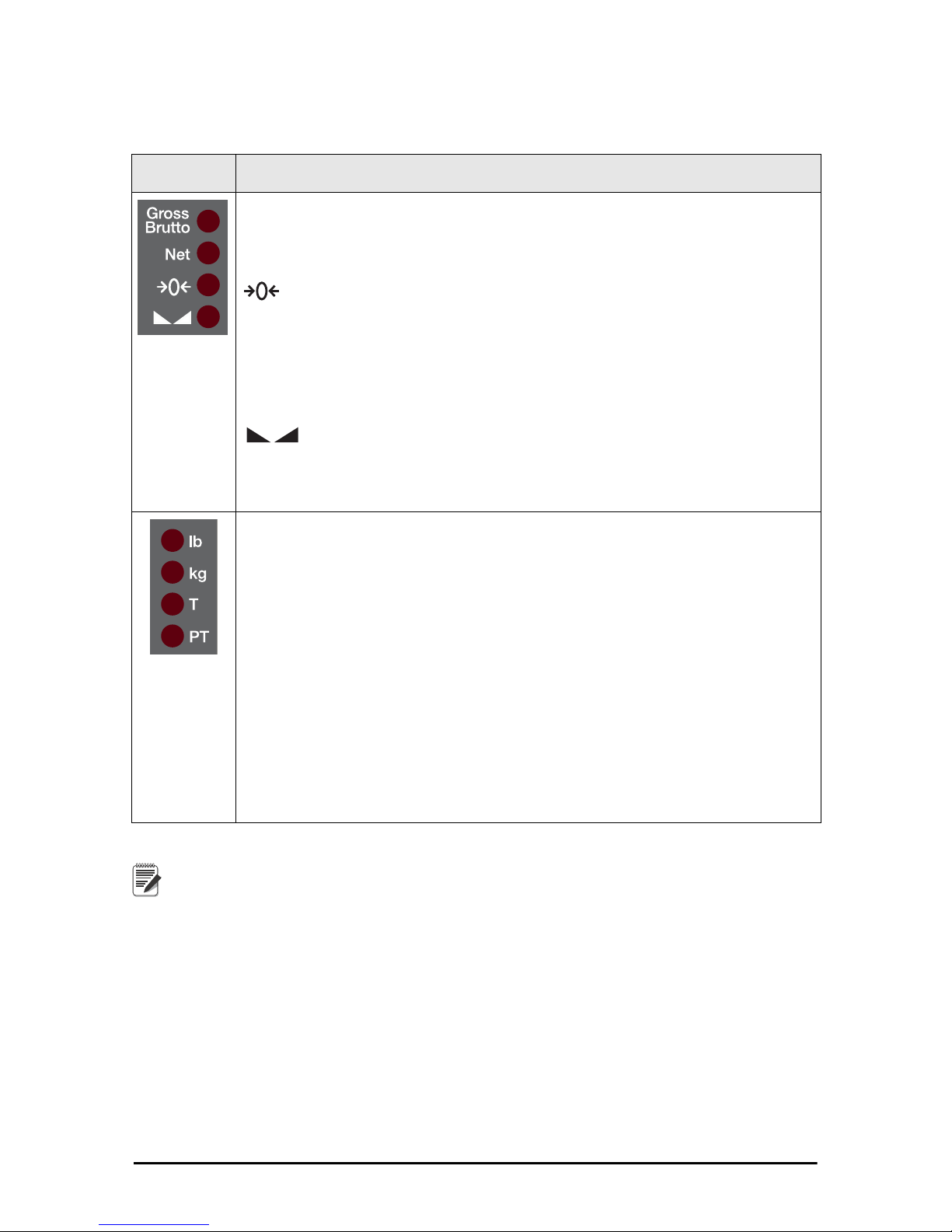

1.3.2 Annunciator Functions

The 480 display uses a set of eight LED annunciators to provide additional

information about the value being displayed.

See the 480 Legend Series Technical manual (PN 119201) for more information.

LED Description

Gross/Brutto LED

Gross weight display mode (or Brutto in OIML mode)

Net LED

Net weight display mode

Zero (Center of Zero) LED

The Center of Zero LED indicates that the current gross weight reading is

within +/- 0.25 display divisions of the acquired zero, or is within the

center of zero band.

A display division is the resolution of the displayed weight value, or the

smallest incremental increase or decrease that can be displayed or

printed.

Standstill LED

Scale is at standstill or within the specified motion band. Some

operations, including Zero, Tare and Printing, can only be done when the

standstill LED is on.

lb/kg LED

Displays which unit of measure is being used.

lb and kg annunciators indicate the units associated with the displayed

value: lb = pounds, kg = kilograms.

The displayed units can also be set to short tons (tn), metric tons (t),

ounces (oz), grams (g), NONE (no units information displayed). The lb and

kg LEDs function as primary and secondary units annunciators. If neither

primary nor secondary units are lb or kg, the lb annunciator is lit for

primary units and kg is lit for secondary units.

T LED

Indicates that a push-button tare weight has been acquired and stored in

memory.

PT LED

Indicates that a preset tare weight has been keyed in or entered and

stored in memory.

Table 1-2. LED Annunciators

Note

Page 10

6 480 Legend Series

1.4 Front Panel Key Functions

Figure 1-2. Front Panel Key Functions

Four front panel keys are used as directional keys to navigate through the

menus (see Figure 1-2).

•

UNIT () and PRINT ( ) scroll left and right on the same menu level.

•

ZERO () and GROSS/NET ( ) move up and down to different menu

levels.

•The

TARE key serves as an Enter key ( ) for selecting parameter

values within the menus.

•The

MENU key allows front panel access to user setup and

configuration mode.

Navigating Through Levels

Figure 1-3. Menu Navigation

To select a parameter, press or to scroll left or right until the desired

menu group appears on the display, then press to move down to the

sub-menu or parameter you want. When moving through the menu

parameters, the present value appears first on the display.

PRINT

MENU

UNIT

POWER

TARE

GROSS

NET

B/N

ZERO

Move UP/Increment Value

Move DOWN/Decrement Value

Move RIGHT/Next

Access User Setup

Move LEFT/Previous

Power ON/OFF

ENTER Value

1st Level

sub-menu

Present Value

Value

When moving through values below the first menu level, press to return to the level

above. Press

to move to the next parameter on the level below.

2nd Level

sub-menu

Value Value

1st Level

sub-menu

2

nd

Level

sub-menu

Page 11

Introduction 7

Edit Parameter Values

To change a parameter value, scroll left or right to view the values for that

parameter. When the desired value appears on the display , press

ENTER (TAR E)

to select the value and move back up one level. To edit numerical values, use

the navigation keys to select the digit and to increment or decrement the

value.

Figure 1-4. Editing Procedure for Numeric Values

1.4.1 Numeric Keypad - Editing Procedure for Numeric Values (480Plus Only)

Figure 1-5. Numeric Keypad for the 480Plus

With the numeric keypad option, the method for editing numeric values relies

on the numbers which are embossed on the keypad in oppose to usin g the

arrows.

1. When editing numeric values, insert the required value using the

numeric keypad.

2. Press to save the value entered and return to the level above.

• Press to set the currently selected digit to 0.

• Press to enter a decimal point.

When editing fractional numeric values, the decimal point must be

positioned in accordance with the primary units formatting, otherwise

the keyed number may be rejected by the software.

0 0 0 0 0 0

When editing numeric values, press or to change the

digit selected. Press or to increment or decrement the

value of the selected digit. Press to save the value entered

and return to the level above.

Note

Page 12

8 480 Legend Series

1.5 Indicator Operations

Basic 480 operations are summarized below.

See the 480 Legend Series Technical manual (PN 119201) for more information.

1.5.1 Status Lights While in Various Menus

Sub-menu levels are indicated by the LEDs as shown below.

First sub-menu level

Second sub-menu level

Third sub-menu level

Fourth sub-menu level

1.5.2 Zero Scale

1. In gross mode, remove all weight from the scale and wait for the

LED to light.

2. Press . The LED lights to indicate the scale is zeroed.

1.5.3 Toggle Units

1. Press to toggle between primary and secondary units. The

current unit LED will be lit.

1.5.4 Acquire Tare

1. Place container on scale and wait for the LED to light.

2. Press to acquire the tare weight of the container. Net weight is

displayed and the

T LED lights to show the tare value was entered.

See Section 3.2 on page 19 for Regulatory Mode Functions.

1.5.5 Preset Tare (Keyed Tare)

1. With the scale empty and display showing zero weight, press .

2. Display will show (000000); the focused digit will flash.

3. Edit the value using the following method; or with the 480PLUS, use

the keypad.

• Press or to select the digit.

• Press or to increment or decrement the value.

4. Press when the value is correct. The display will change to the

Net mode and the

PT LED lights to show the preset tare was entered.

Note

ZERO

UNIT

TARE

TARE

TARE

Page 13

Introduction 9

1.5.6 Display Tare

When a stored Ta re value is displayed, the Gross and Net LEDs will be off

and the will be lit. To display a stored tare:

1. Press .

2. Press to AUDIT.

3. Press to

TARE and press .

4. Press repeatedly to return to weighing mode.

If there is no tare in the system, the value displayed will be zero and the Gross

and Net LED will be turned off.

See Section 3.2 on page 19 for more information.

1.5.7 Print Ticket

1. Press to print either the Gross or Net format.

2. Wait for LED to light.

3. Press to send data to the serial port.

If LED is not lit and the

PRINT key is pressed, the print action will take

place only if the scale comes out of motion within 3 seconds. If the scale stays

in motion for over 3 seconds, the PRINT key press is ignored.

1.5.8 Toggle Gross/Net Mode

1. Press to switch the display mode between gross and net. If a

tare value has been entered or acquired, the net value is the gross weight

minus the tare.

Gross mode —

Gross/Brutto LED is lit.

Net mode —

Net LED is lit.

1.5.9 View Audit Trail

1. Press .

2. Press to AUDIT.

3. Press . The audit trail CALIB is displayed.

4. Press then or to CNT, TIME or DATE.

5. Press to view selected parameter.

6. Press twice to return to CALIB.

7. Press to the audit trail CONFIG and repeat steps 5 and 6 to view

configuration number.

8. Press repeatedly to return to weighing mode.

MENU

PRINT

PRINT

GROSS

NET

B/N

MENU

Page 14

10 480 Legend Series

1.5.10 Enter New Unit ID

1. Press .

2. Press to AUDIT.

3. Press until display reads UNIT ID.

4. Press to view the current value.

5. Edit the value using the following method; or with the 480PLUS, use

the keypad.

• Press or to select the digit.

• Press or to increment or decrement the value.

6. Press when the value is correct.

7. Press repeatedly to return to weighing mode.

1.5.11 Display Accumulator

1. Press .

2. Press to AUDIT.

3. Press until display reads ACCUM.

4. Press to display VIEW.

5. Press or to select desired parameter (VIEW, TIME, DATE, PRINT,

CLR Y).

• For VIEW, TIME or DATE, press to view the value. Press or

to return to selected parameter.

• To PRINT or CLEAR, press , then press to print or clear

the accumulator. Press to return to selected parameter

6. Press repeatedly to return to weighing mode.

If the accumulated value exceeds 999999, display show “EE ACC”. The

value will still be correct and will print correctly up to 1,000,000,000.

1.5.12 Display or Change Time and Date

To set the date and time:

1. Press .

2. Press to AUDIT.

3. Press until display reads TIMDAT (TIME/DATE).

4. Press and select Time or Date with or .

5. Press to view the current setting.

MENU

TARE

MENU

TARE

TARE

Note

MENU

Page 15

Introduction 11

6. To edit the value of the time, in 24 hour or 12 hour format (hh.mm.ss),

use the following method.

• Press or to select hours, minutes, or seconds – the selected value

will be flashing

• Press or to increment or decrement the value.

7. Press when the value is correct.

Use the same procedure to enter the date in the same format configured

for the indicator.

8. Press repeatedly to return to weighing mode.

The time and date are backed up with an internal battery. If the main

power is interrupted, time and date will not be lost.

When in 12 hour format, the PT LED indicates pm setting.

1.5.13 Display, Edit and Set Setpoint Value

1. Press .

2. Press to AUDIT.

3. Press until display reads

SETPNT.

4. Press and navigate across to desired setpoint number (1-8).

5. Press and navigate across to select User.

6. Press and navigate across to select Value or Enable.

7. Press to view and edit the value.

• To edit Value, use the following method; or with the 480PLUS, use

the keypad.

- Press or to select the digit.

- Press or to increment or decrement the value.

- Press when the value is correct.

• To edit

ENABLE:

- Press or to select ON/OFF.

- Press when the value is correct.

8. Press repeatedly to return to weighing mode.

TARE

Note

MENU

TARE

TARE

Page 16

12 480 Legend Series

1.5.14 View Firmware Version

1. Press .

2. Press . AUDIT is displayed.

3. Press until display reads VERS.

4. Press . FIRMW is displayed.

5. Press to view version.

6. Press repeatedly to return to weighing mode.

1.5.15 Enter User Password

1. Remove the setup switch access screw from the back of the enclosure.

2. Insert a non-conductive tool into the access hole and press the

configuration switch. Indicator display changes to show

CONFIG.

3. Press or until PASWRD is displayed.

4. Press . CNFG is displayed.

5. Press to USER.

6. Press . 000000 is displayed.

7. To edit the password, use the following method; or with the 480PLUS,

use the keypad.

• Press or to select the digit.

• Press or to increment or decrement the value.

• Press when the value is correct.

8. Press to return to PASWRD.

9. Press to CONFIG.

10. Press to return to weighing mode.

When entering a user function, the operator will now be required to enter the

password.

Enter 999999 to reset password, this will also reset the

configuration back to default values.

MENU

TARE

Important

Page 17

User Menus 13

2.0 User Menus

Figure 2-1. Menu Key User Menu

Figure 2-2. Setpoint Setup Menu

SETPNT

PFRMAT

MISC

TARE

0

AUDIT

CALIB

CNT

TIME

DATE

CONFIG

CNT

TIME

DATE

UNITID

000000

TIMDAT

TIME

DATE

ACCUM

TIME

DATE

VIEW

PRINT

CLR Y

MENU CONFIG FORMAT CALIBR PROGRM DIG IN ALGOUT PASWRD USBMEM TEST

VERS

SERIAL

ETHNET USB

See

Figure 2-2

See

Figure 2-3

See

Figure 2-4

See

Figure 2-5

See

Figure 2-6

See

Figure 2-8

See

Figure 2-7

TIMDAT

ACCUM

SERIALSETPNT

ETHNET

......

BATCHG SETPT1-8

USER

000000

PREACT

SUPVSR

CONFIG FORMAT CALIBR PROGRM DIG IN ALGOUT PASWRD USBMEMMENU TEST

AUTO

OFF

MANUAL

000000

VALUE

OFF

ON

ENABLE

OFF

ON

PUSHAC

OFF

ON

PUSHPR

OFF

ON

WAITSS

HIGHER

LOWER

TRIPKIND

OFF

GROSS

NET

-GROSS

-NET

DELAY

OFF

ON

PUSHTR

000000

HYSTER

OFF

ON

BATSEQ

NONE

1-8

DIGOUT

Page 18

14 480 Legend Series

Figure 2-3. Serial Menu

COM-1

TIMDAT

ACCUM

SERIALSETPNT

PFRMAT

......

COM-2

STREAM

TRIGER

DEMAND

PRN

NONE

COMAND

BAUD

LOCAL

REMOTE

NONE

STRUR

STRLFT

STRIND

ECHO

OFF

ON

SBITS

1 STOP

2 STOP

TERMIN

CR

CR-LF

EOLDLY

000

BITS

7ODD

7EVEN

8NONE

PRNMSG

OFF

ON

BAUD

4800

2400

1200

19200

38400

9600

BITS

7ODD

7EVEN

8NONE

SBITS

1 STOP

2 STOP

TERMIN

CR

CR-LF

EOLDLY

000

ECHO

OFF

ON

PRNMSG

OFF

ON

TRIGER

STR2

STR3

STR4

NONE

PRN

STR1

STR5

4800

2400

1200

19200

38400

9600

MENU CONFIG FORMAT CALIBR PROGRM DIG IN ALGOUT PASWRD USBMEM TEST

Page 19

User Menus 15

Figure 2-4. Ethernet Menu Layout

Figure 2-5. USB Menu Layout

0 - 65535

0 STR - 1

STR - 2

STR - 5

STR - 4

STR - 3

SERIAL

ETHNET

USB

...

...

IPADRS NETMSK DFTGWY MAC SERVER CLIENT

0.0.0.0

ON

OFF

0.0.0.0 0.0.0.0

00.00.00.00.00.00

DHCP

STRIND

STRLFT

COMAND

DEMAND

TRIGER TIMOUT

TERMIN SFMT

PORT EOLDLY ECHO

CR

CR/LF

0

0 - 255

1 - 65535

10001

ON

OFF

0 - 65535

0 STR - 1

STR - 2

STR - 5

STR - 4

STR - 3

STRIND

STRLFT

COMAND

DEMAND

TRIGER

TERMIN

CR

CR/LF

EOLDLY

0

0 - 255

PORT

1 - 65535

10001

ECHO

ON

OFF

TIMOUT SFMT

RMOTIP

0.0.0.0

MENU CONFIG FORMAT CALIBR PROGRM DIG IN ALGOUT PASWRD USBMEM TEST

ETHNET USB

PFRMAT

...

...

TRIGER

DEVICE

HOSTPC

DRIVE

DEMAND

COMAND

MENU CONFIG FORMAT CALIBR PROGRM DIG IN ALGOUT PASWRD USBMEM TEST

Page 20

16 480 Legend Series

Figure 2-6. Print Format Menu

Figure 2-7. Version User Menu

Figure 2-8. Misc. Menu

TIMDAT

ACCUM

SERIALSETPNT

PFRMAT

......

Display first 6

characters of format

Display and edit

active character and

ASCII value

Delete active

character

Scroll right in format string

Scroll left in format string

Increment ASCII value of active character

Decrement ASCII value of active character

Press to insert a space

before the active character

GFMT

NFMT

ACCFMT

SPFMT

MENU CONFIG FORMAT CALIBR PROGRM DIG IN ALGOUT PASWRD USBMEM TEST

VERSPFRMAT

MISC

......

FIRMW

LR

Legally

Relevant

VERSION VERSION

MENU CONFIG FORMAT CALIBR PROGRM DIG IN ALGOUT PASWRD USBMEM TEST

MISC

POWER

BKLGHT BAT

OFF

ON

AUTO

10 SEC

30 SEC

1 MIN

5 MIN

10 MIN

BAT LEVEL

MANUAL

AUTO

MENU CONFIG FORMAT CALIBR PROGRM DIG IN ALGOUT PASWRD USBMEM TEST

Page 21

Appendix 17

3.0 Appendix

3.1 Error Messages

The 480 provides a number of front panel error messages to assist in problem

diagnosis. Table 3-1 lists these messages and their meanings.

Error

Message

Description Solution

E A/D A/D physical error Call Rice Lake Weighing Systems (RLWS)

Service at 800-472-6703.

EEEROM EEPROM physical error

EVIREE Virgin EEPROM Use TEST menu to perform DEFLT (restore

defaults) procedure, then recalibrate load cells.

EPCKSM Parameter checksum

error

EACKSM A/D calibration

checksum error

A/D converter requires recalibration.

Call RLWS Service.

EFCKSM Printer format checksum

error

Call RLWS Service at 800-472-6703.

ELCKSM Load cell calibration

checksum error

Recalibrate load cells.

EIDATA Internal RAM checksum

error

Call RLWS Service at 800-472-6703.

E REF A/D reference error A/D converter requires recalibration.

Call RLWS Service.

ERROR Internal program error Check configuration.

Call RLWS Service if unable to clear error by

cycling power or if error recurs.

OVERFL Overflow error Weight value too large to be displayed.

- - - - - -

- - - - - -

- - - - - -

Gross > overload limit Gross value exceeds overload limit. Check

configuration or signal input level. Overload can

be caused by input signal > 45 mV or common

mode voltage > 950 mV.

- - - - - -

Gross < 20d behind zero Gross value is more than 20 divisions behind

zero.

RNGERR GRADS > 100,000

WVAL > 100,000

Only shows up in Config mode.

EEPERR EEPROM error Call RLWS for service at 800-472-6703.

HINOFF? High offset Zero load at powerup is more than initial zero

range (INIZR) setting of calibration zero –

remove the extra load.

Table 3-1. 480 Error Messages

Page 22

18 480 Legend Series

Shorting the excitation voltage shuts the excitation voltage off. The only

way to restore excitation voltage is to cycle power.

LINOFF Low offset Zero load at power up is less than initial zero

range (INIZR) setting of calibration zero – add

the missing load.

NOBATT No battery The RTC lost time/date tracking at previous

power off state due to low battery or no battery

condition. The printer, accumulator and

AUDUT functions will fail to get time and date.

EUCKSM Configuration checksum The checksum value of configuration has

changed from that stored in memory.

OIMLER OIML parameter error Parameter set incorrectly for use in the OIML

mode. Example: Primary units set for lb or oz.

EE-ACC Accumulator error Error with the accumulator such as attempting

to display an accumulated value greater than

six digits.

Error

Message

Description Solution

Table 3-1. 480 Error Messages

Note

Page 23

Appendix 19

3.2 Regulatory Mode Functions

At zero weight push-button tare will prompt for keyed tare when tare

function is set to keyed or both.

Regulatory

Parameter

Weight On

Scale

Tare In

System

Front Panel

Key Tare

Front Panel Key

Zero

NTEP Zero No “000000” Zero

Yes Cl e ar tare Zero

Negative No No action Zero

Yes Clea r tare Z ero

Positive No Tare Zero

Yes Tare Zero

Canada Zero No “000000” Zero

Yes Clear tare Clear tare

Negative No No action Zero

Yes Clear tare Clear tare

Positive No Tare Zero

Yes No action Clear tare

OIML Zero No “000000” Zero

Yes Clear tare Zero & Clear tare

Negative No No action Zero

Yes Clear tare Zero & Clear tare

Positive No “000000” Zero

Yes Tare Zero & Clear Tare

None Zero No “000000” Zero

Yes Clear tare Clear tare

Negative No No action Zero

Yes Clear tare Clear tare

Positive No Tare Zero

Yes Clear tare Clear tare

Table 3-2. TARE and ZERO Key Functions for REGULAT Parameter Settings

Note

Page 24

20 480 Legend Series

3.3 Specifications

Model Numbers

United States 480-2A/480Plus-2A (NEMA Type 5-15)

International 480-2A/480Plus-2A (CEE 7/7)

Power – AC

Line Voltages 115 to 230 VAC

Frequency 50 or 60 Hz

Power Consumption 70 mA @ 115 VAC (8W)

35 mA @ 230 VAC (8W)

Fusing 2.5 A 5 x 20 mm fuse

Analog Specifications

Full Scale Input Signal Up to 35 mV

Excitation Voltage 5 ± 0.1VDC

Sense Amplifier Differential amplifier with

4- and 6-wire sensing

Analog Signal

Input Range Up to 7 mV/V

Analog Signal

Sensitivity 0.1 V/graduation minimum

0.5 V/grad recommended

Local Resistance 35-1140

Noise (ref to input) 0.5 V p-p 3

Internal Resolution 523,376 counts

Display Resolution 100,000 dd

Measurement Rate 37 measurements/sec

Input Sensitivity 38 nV per internal count

System Linearity Within 0.01% of full scale

Zero Stability 13 nV/°C

4

Span Stability 13 ppm/°C

5

Calibration Method Software, constants stored in EEPROM

Common Mode

Voltage AGND + 250mV V min

6

Excitation - 250 mV V max

Rejection 120 dB minimum @ 50 or 60 Hz

Normal Mode

Rejection 100 dB minimum @ 50 or 60 Hz

Input Overload -0.3 V to Excitation +0.3 V

7

RFI Protection Signal, excitation, and sense lines protected by capacitor bypass

and ESD suppressors

Analog Output (Optional)

Type Fully isolated, voltage or current output,16-bit resolution.

Voltage output 0 –10 VDC

Voltage load resistance 1K minimum

Current output 0–20 mA or 4–20 mA

Current loop resistance 1200

maximum

Page 25

Appendix 21

Digital Specifications

Microprocessor ARM Cortex M3 STM32F103ZET6

Digital Filters Adaptive Filter and Rolling Averaging Filter; software selectable

Digital I/O (Optional)

Type Fully isolated

Digital Inputs 2 or 4 inputs, Opto isolated, 5 to 24 VDC input, active high

Digital Outputs 4 or 8 dry-contact relays

Up to 30VDC at 2A current

Serial Communications

Port 1 Full duplex RS-232

Port 2 Full duplex RS232, or output only Active 20mA current loop.

Both Ports 1200 to 38400 bps; 7 or 8 data bits; even, odd, or no parity; 1 or

2 stop bits

Operator Interface

Display 6-digit LED display. 7-segment, 0.8 in (20 mm) digits

LED annunciators Gross, net, center of zero, standstill, lb/primary units, kg/

secondary units, T, PT

Keypad 7-key flat membrane panel

Environmental

Operating Temperature –10 to +40°C (legal);

–10 to +50°C (industrial)

Storage Temperature –25 to +70°C

Humidity 0–95% relative humidity

Enclosure

Enclosure Dimensions 9.5 in x 6 in x 2.75 in

24 cm x 15 cm x 7 cm

Weight 6 lb

Rating/Material 4X

Certifications and Approvals

NTEP

CoC Number12-123

Accuracy Class III/IIIL n

max

: 10 000

OIML R76/2006-NL1-12.48

European Test CertificateTC8322

European EC Type-ApprovalT5692

Accuracy ClassIIIn

max

: 10 000

Measurement Canada

Approval AM-5892

Accuracy Class III/IIIHD n

max

: 10 000

•

N

A

T

I

O

N

A

L

C

O

N

F

E

R

E

N

C

E

•

O

N

W

E

I

G

H

T

S

A

N

D

M

E

A

S

U

R

E

S

Ethernet/USB options will be available

in future versions.

Note

Page 26

22 480 Legend Series

480 Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and

systems properly installed by a Distributor or Original Equipment Manufacturer

(OEM) will operate per written specifications as conf irmed by the Distr ibutor/OEM

and accepted by RLWS. All systems and components are warranted against defects in

materials and workmanship for two years.

RLWS warrants that the equipment sold hereunder will conform to the current written

specifications authorized by RLWS. RLWS warrants the equipment against faulty

workmanship and defective materials. If any equipment fails to conform to these

warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given

prompt written notice with a de tailed explanation of the alleged

deficiencies.

• Individual electronic components returned to RLWS for warranty purposes

must be packaged to prevent electrostatic discharge (ESD) damage in

shipment. Packaging requirements are listed in a publication, Protecting

Your Com ponents From Static Damage in Shipment , available from RLWS

Equipment Return Department.

• Exami nation o f such equi pment b y RLWS confirms that the nonconformity

actually exists, and was not caused by accident, misuse, neglect, alteration,

improper installation, improper repair or improper test ing; RLWS shall be

the sole judge of all alleged nonconformities.

• Such equi pment has not been modified, altered, or changed by any person

other than RLWS or its duly authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective

equipment. Buyer is responsible for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs,

including assembly or disassembly of equipment, nor will RLWS be liable

for the cost of any repairs made by others.

T

HESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMITATION WARRANTIES OF MERCHANTABILITY OR

FITNESS

FOR A PARTICULAR PURPOSE. N EITHER RLWS NOR DISTRIBUTOR WILL,

IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS

AND BUYER AGREE TH AT RLWS’ SOLE AND EXCLUSIVE LIABILITY

HEREUNDER

IS LIMITED TO REP AI R OR REPLACEMENT OF SUCH GOODS. IN

ACCEPTING

THIS WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER CLAIMS

TO

WARRANTY.

S

HOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY

TO

THE SELLER FOR WARRANTY CLAIMS.

N

O TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO

MODIFY

THE TERMS OF THIS WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS

MADE

IN WRITING AND SIGNED BY A CORPORATE OFFICER OF RLW S AND THE

BUYER.

© Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET

RICE LAKE, WISCONSIN 54868 • USA

Page 27

Page 28

230 W. Coleman St. • Rice Lake, WI 54868 • USA

U.S. 800-472-6703 • Canada/Mexico 800-321-6703 • International 715-234-9171 • Europe +31 (0)26 472 1319

www.ricelake.com www.ricelake.mx www.ricelake.eu www.ricelake.co.in m.ricelake.com

© Rice Lake Weighing Systems 06/2015 PN 163374 Rev A

Loading...

Loading...