Page 1

™

EtherNet / IP

Interface for 520 and 920i™ Indicators

Installation and

Programming Manual

88537

Page 2

Page 3

Contents

About This Manual ................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 1

2.0 Installation ................................................................................................................................... 2

2.1 Installing the EtherNet/IP Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1.1 Installing EtherNet/IP Option in the 920i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1.2 Installing EtherNet/IP Option in the 520. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 EtherNet/IP Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 LED Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.0 Commands ................................................................................................................................... 6

3.1 Output Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Input Command Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Command Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.0 Appendix .................................................................................................................................... 13

4.1 Configuration Procedure for 920i and PLC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 EDS File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3 EtherNet/IP Interface Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

EtherNet/IP Interface Limited Warranty ................................................................................................ 17

5FDIOJDBMUSBJOJOHTFNJOBSTBSFBWBJMBCMFUISPVHI3JDF-BLF8FJHIJOH4ZTUFNT

$PVSTFEFTDSJQUJPOTBOEEBUFTDBOCFWJFXFEBUXXXSMXTDPNPSPCUBJOFE

CZDBMMJOHBOEBTLJOHGPSUIFUSBJOJOHEFQBSUNFOU

© 2006 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

January 2006

Page 4

ii 520/920i EtherNet/IP Installation and Programming Manual

Page 5

About This Manual

This manual provides information needed to install

and use the Rice Lake Weighing Systems

1

EtherNet/IP

™

Interface. The EtherNet/IP Interface

allows 520 and 920i indicators to communicate with

an EtherNet/IP network.

This manual applies to Version 2.05 or later of the

920i indicator software, Version 1.07 or later of the

520 indicator software. See the 520 or 920i

Installation Manual for additional installation

information and detailed descriptions of indicator

functions.

1. EtherNet/IP™ is a trademark of ControlNet International,

Ltd. under license by Open DeviceNet Vendor Association,

Inc.

1.0 Introduction

EtherNet/IP (“Ethernet industrial protocol”) is an

open industrial networking standard that allows

control applications to make use of widely-available

Ethernet communications components and phys ical

media. EtherNet/IP is based on the IEEE 802.3

Ethernet standard, the TCP/IP protocol suite, and

™

(Common Industrial Protocol), the real-time I/O

CIP

2

and information protocol used by both DeviceNet

3

and ControlNet

™

networks.

™

The EtherNet/IP Interface is installed inside the

indicator enclosure. Installation in NEMA 4X

stainless steel enclosures permits use in washdown

environments.

Some procedures described in this manual

require work inside the indicator enclosure.

These procedures are to be performed by

qualified service personnel only.

Authorized distributors and their

employees can view or download this

manual from the Rice Lake Weighing

Systems distributor site at

www.rlws.com.

The EtherNet/IP Interface returns weight and status

information from a

520 or 920i indicator to the

network and provides limited control of indicator

functions to the programmer. Indicator configuration

and calibration cannot be performed through the

EtherNet/IP Interface.

2. CIP™ and DeviceNet™ are trademarks of the Open DeviceNet Vendor Association.

3. ControlNet™ is a trademark of ControlNet International, Ltd.

Introduction 1

Page 6

2.0 Installation

The EtherNet/IP Interface hardware consists of a

dual-board option card. EtherNet/IP-specific functions

are provided by a EtherNet/IP module, which is

factory-installed onto a bus adapter card. The bus

adapter card plugs into an open option card slot on the

520 or 920i CPU board (or expansion board) and

provides power and access from the indicator bus to

the EtherNet/IP module.

This section describes the procedures used to install

the EtherNet/IP Interface into the

indicators.

2.1 Installing the EtherNet/IP Interface

Use the following procedure to install the EtherNet/IP

Interface into

520 and 920i indicators.

520 and 920i

2.1.1 Installing EtherNet/IP Option in the 920i

Use the following procedure to install the EtherNet/IP

Interface in the

920i indicator:

1. Disconnect indicator from power source.

Disconnect power before removing indicator

backplate.

The 920i has no on/off switch. Before

opening the unit, ensure the power cord is

disconnected from the power outlet.

2. Open indicator enclosure. For indicator models

with backplates, place indicator face-down on

an antistatic work mat. Remove screws that

hold the backplate to the enclosure body.

Use a wrist strap to ground yourself and

protect components from electrostatic

discharge (ESD) when working inside the

indicator enclosure.

3. Carefully align the large connector (J1) on the

bus adapter card with connector J5 or J6 on the

920i CPU board. Press down to seat the bus

adapter card in the CPU board connector.

4. Use the screws and lockwashers provided in

the option kit to secure the other end of the

option card to the threaded standoffs on the

CPU board (see Figures

2-4 and 2-1).

5. Wire the card to the network as described in

Section 2.2 on page 4.

6. Use cable ties to secure loose cables inside the

enclosure.

Figure 2-1. Option Installed on 920i CPU Board

7. For indicator models that include a backplate,

position the backplate over the enclosure and

reinstall the backplate screws. For the 920i

desktop and universal models, use the torque

pattern shown in Figure 2-2 to prevent

distorting the backplate gasket. Torque screws

to 15 in-lb (1.7 N-m).

16 12

14

Torque backplate s crews

to 15 in-lb (1.7 N-m)

5

3

1

17

9

Figure 2-2. 920i Enclosure Backplate

8

7

10

11

18

13

6

2

4

15

8. Ensure no excess cable is left inside the

enclosure and tighten cord grips.

9. Reconnect power to the indicator. The

indicator automatically recognizes all

installed option cards when the unit is

powered on. No hardware-specific

configuration is required to identify the

newly-installed EtherNet/IP Interface to the

system.

2 520/920i EtherNet/IP Installation and Programming Manual

Page 7

J1

LED Array

DIP Switch

EtherNet/IP

Module

TEST

3.3V

GND

Figure 2-4. Option Installed 520 CPU Board

RJ-45

Connector

J2

Figure 2-3. Bus Adapter Card and EtherNet/IP Module

2.1.2 Installing EtherNet/IP Option in the 520

Use the following procedure to install the EtherNet/IP

Interface in the

1. Disconnect indicator from power source.

2. Place indicator on an antistatic work mat.

Remove screws that hold the enclosure cover

to the enclosure body.

3. Carefully align the large option card

connector with connector J2 on the CPU

board (see

option card in the CPU board connector.

4. Use screws provided in the option kit to

secure the other end of the option card to the

threaded standoffs on the CPU board.

5. Install terminal block end of cable assembly

to EtherNet/IP option card.

520 indicator:

Disconnect power before removing

indicator enclosure cover.

The 520 has no on/off switch. Before

opening the unit, ensure the power cord is

disconnected from the power outlet.

Use a wrist strap to ground yourself and

protect components from electrostatic

discharge (ESD) when working inside the

indicator enclosure.

Figure 2-4). Press down to seat the

6. Remove existing cover plate.

7. Re-use kep nuts to secure EtherNet/IP cover

plate to standoffs located on inside of

enclosure backplate (see

Figure 2-5).

8. Once cabling is complete, position the cover

over the enclosure and reinstall the screws.

9. Reconnect power to the indicator.

Figure 2-5. EtherNet/IP 520 Backplate Cable Assembly

10. The indicator automatically recognizes all

installed option cards when the unit is

powered on. No hardware-specific

configuration is required to identify the

newly-installed EtherNet/IP interface to the

system.

Installation 3

Page 8

2.2 EtherNet/IP Network Connections

Feed the EtherNet/IP network cable through the

indicator cord grip. Allow enough cable for routing

along inside of enclosure to connector on the

EtherNet/IP module. Connect network cables to

connector on the EtherNet/IP module (see

Figure 2-3),

then use cable ties to secure network cables to the

cable tie mounts.

2.3 LED Status Indicators

An LED array on the EtherNet/IP module provides

status information for troubleshooting (see

Figure 2-6):

• LED 1 provides status about the link

• LED 2 provides status information about the

EtherNet/IP module

• LED 3 provides network status

• LED 4 can be configured to indicate whenever a

packet is sent or received

The LED array can be configured using the Anybus

IPConfig software (

provide different status information, as described

below.

1

4

LED configuration 1, 2, or 3) to

Link status

Activity

Module status

Network status

2

3

LED 2: Module Status

LED 2 can be set to any of four configuration states,

1–4, as described in the following tables.

configuration 4

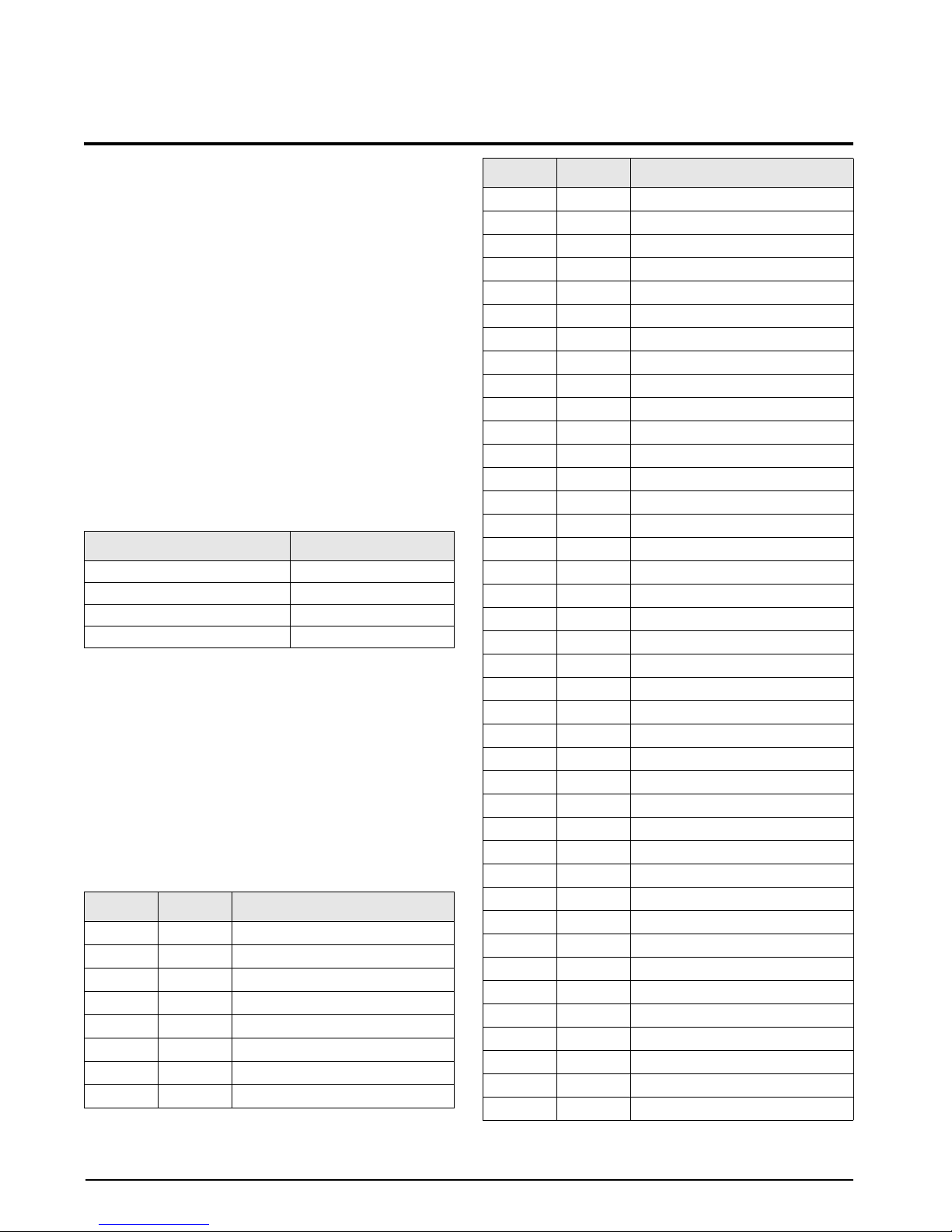

LED 2 Color State Description

Green Flashing

Red Flashing

Table 2-3. LED 2 states, using LED Configuration 1

LED 2 Color State Description

Green On Operating at 100 Mbps

Red 2 flashes on,

Table 2-4. LED 2 states, using LED Configuration 2

deactivates LED 2.

IP address not set using

at 1 Hz

at 1 Hz

Flashing

at 2 Hz

Flashing

at 4 Hz

On Duplicate IP address detected

long off

3 flashes on,

long off

4 flashes on,

long off

5 flashes on,

long off

configuration switch

MAC address not valid

Failed to load Ethernet

configuration from FLASH

Internal error

Off Operating at 10 Mbps

MAC address not valid

Failed to load Ethernet

configuration from FLASH

Internal error

Duplicate IP address

detected

LED

Figure 2-6. EtherNet/IP Status LED Module

LED 1: Link Status

LED 1 Color State Description

Green On Module has a link

Off Link not sensed

Table 2-1. LED 1 states, using LED Configuration 1

LED 1 Color State Description

Green On Module has a link

Off Link not sensed

Flashing Module receiving/transmitting

Table 2-2. LED 1 states, using LED Configuration 2

4 520/920i EtherNet/IP Installation and Programming Manual

LED 2 Color/State Description

Steady off No power to module

Steady green Module operating correctly

Flashing green Module not configured

Flashing red Recoverable fault detected

Steady red Internal error detected

Flashing red/green Performing power-on self-test

Table 2-5. LED 2 states, using LED Configuration 3

Page 9

LED 3: Network Status

LED 3 can be set to configuration states 1–3. In LED

configuration 1

established connections to the module;

configuration 2

, LED 3 flashes the number of

LED

deactivates LED 3.

Watchdog LED

A single bi-color LED on the surface of the

EtherNet/IP module provides diagnostic information

for debugging the module itself.

Table 2-7 lists the

indications provided by the debugging LED.

LED 3 Color/State Description

Steady off No power to module or no IP address

assigned

Steady green At least one EtherNet/IP connection

established

Flashing green No EtherNet/IP connections

Flashing red Connection time-out

Steady red Duplicate IP address detected

Flashing red/green Performing power-on self-test

Table 2-6. LED 3 states, using LED Configuration 3

LED 4: Activity

LED 4 can be set to configuration state 1 or 2. In LED

configuration 1

is transmitted or received.

, LED 4 flashes green each time a packet

LED configuration 2

deactivates LED 4 and provides transmit/receive

indication on LED 1.

Status Description

Off No power

Red, 4Hz DPRAM check fault

Red, 2Hz ASIC and FLASH ROM check fault

Red, 1Hz RAM check fault

Green, 2Hz Module not initialized

Green, 1Hz Module initialized and running

Table 2-7. Debugging LED Indications

Installation 5

Page 10

3.0 Commands

Commands are used by the EtherNet/IP master device

to send and receive data from the EtherNet/IP

Interface as integer or floating-point data. The master

sends eight bytes in the output format (used to write

commands to the indicator) and reads eight bytes in

the input format (used to read data from the indicator).

Decimal Point Handling

Integer commands return no decimal point information

to the master. For example, a value of 750.1 displayed

on the indicator is returned to the master as 7501.

Floating point commands support decimal point

information with no special handling.

3.1 Output Command Format

To perform a command, the master uses the output

command format to send four 16-bit words to the

EtherNet/IP Interface. These four words contain the

command and any parameters necessary to execute it.

The output command format is shown in

Word Description

Word 1 Command number

Word 2 Parameter

Word 3 Value (MSW)

Word 4 Value (LS W)

Table 3-1. Output Command Format

The contents of each output command format word

are described below:

Command number

The number representing the indicator command is

sent in the first word.

Table 3-2 lists the commands

that can be specified for 520 and 920i indicators.

NOTE: A lockout feature that looks for any change in the

output format data is incorporated into the indicator receive

mechanism to prevent inundation by the same command.

Repeated commands must be separated by any other valid

command/parameter/value combination.

Decimal Hex Command

0 0x000

1 0x001

2 0x002

3 0x003

4 0x004

9 0x009

10 0x00A

11 0x00B

Table 3-2. 520 / 920i Remote Commands

Return Status and Weight (integer)

Display Channel

Display Gross Weight

Display Net Weight

Display Count

Gross/Net key press (toggle)

Zero

Display Tare

Table 3-1.

Decimal Hex Command

12 0x00C

13 0x00D

14 0x00E

16 0x010

17 0x011

18 0x012

19 0x013

20 0x014

21 0x015

22 0x016

23 0x017

32 0x020

33 0x021

34 0x022

35 0x023

37 0x025

38 0x026

39 0x027

40 0x028

95 0x05F

96 0x060

97 0x061

98 0x062

99 0x063

112 0x070

113 0x071

114 0x072

115 0x073

116 0x074

253 0x0FD

254 0x0FE

256 0x100

268 0x10C

288 0x120

289 0x121

290 0x122

291 0x123

293 0x125

294 0x126

295 0x127

Enter Tare

Acquire Tare

Clear Tare

Primary Units

Secondary Units

Tertiary Units

Units key press (toggle units)

Print Request

Display Accumulator

Clear Accumulator

Push Weight to Accumulator

Return Gross (integer)

Return Net (integer)

Return Tare (integer)

Return Count

Return Current Display (integer)

Return Accumulator (integer)

Return Rate of Change (integer)

Return Peak (integer)

Set Batching State

Batch Start

Batch Pause

Batch Reset

Batch Status

Lock Indicator Front Panel

Unlock Indicator Front Panel

Set Digital Input ON

Set Digital Input OFF

Read Digital Input Status

No operation

Reset Indicator

Return Status as Weight (float)

Set Tare (float)

Read Gross (float)

Read Net (float)

Read Tare (float)

Read Piece Count (float)

Read Current Display (float)

Read Accumulator (float)

Read Rate of Change (float)

Table 3-2. 520 / 920i Remote Commands (Continued)

6 520/920i EtherNet/IP Installation and Programming Manual

Page 11

Decimal Hex Command

296 0x128

304 0x130

305 0x131

306 0x132

307 0x133

320 0x140

321 0x141

322 0x142

323 0x143

Read Peak (float)

Set Setpoint Value (float)

Set Setpoint Hysteresis (float)

Set Setpoint Bandwidth (float)

Set Setpoint Preact (float)

Read Setpoint Value (float)

Read Setpoint Hysteresis (float)

Read Setpoint Bandwidth (float)

Read Setpoint Preact (float)

Table 3-2. 520 / 920i Remote Commands (Continued)

Parameter value

To allow communication with a multi-scale indicator,

the scale number is sent in the second word of the

output command format. Zero (0) represents the

current scale. Certain commands require a parameter

other than a scale number, such as a slot number,

setpoint number, or other selection parameter. See the

command descriptions in

Section 3.3 on page 8 for

specific command requirements.

Val ue

The third and fourth words of the output format are

used to pass value data on certain commands. Values

entered in these words are treated as unsigned long

integers or floating-point values, depending on the

command.

Status Data

Indicator status data is returned in the second word

Table 3-4). Batch commands return batch status

(see

in place of the low byte (see Table 3-5). Setpoint

commands return batch status in the low byte of the

status word and the setpoint number in the high byte.

Word 2

Bit

00 Error No error

01 Tare not entered Tare entered

02 Not zero Center of zero

03 Weight invalid Weight OK

04 Standstill In motion

05 Primary units Other units

06 Tare not acquired Tare acquired

07 Gross weight Net weight

08 Channel number

09

10

11

12

13

14 Integer data Floating point data

15 Positive weight Negative weight

Table 3-4. Indicator Status Data Format

Indicator Status Data

Val ue =0 Valu e=1

(NOTE: Value 0 represents scale #32)

Not used

3.2 Input Command Format

In response to a command, the EtherNet/IP Interface

returns data and status information to the master as

four 16-bit words. This information is returned in the

input command format shown in

The value type can be set for those commands that do

not specify integer or floating point data by sending a

command 0x000 to specify integer data or command

0x100 for floating-point data. The value type is

returned in the status word (bit 14) of the input format.

Word Description

Word 1 Command number

Word 2 Status

Word 3 Value (MSW)

Word 4 Value (LS W)

Table 3-3. Input Command Format

Command number

The first word echoes the command number. If the

command fails or is not recognized, the negative of

the command number is returned to signal the error.

Table 3-3.

Word 2

Bit

00 Digital input 4 OFF

01 Digital input 3 OFF Digital input 3 ON

02 Digital input 2 OFF Digital input 2 ON

03 Digital input 1 OFF Digital input 1 ON

04 Batch not paused Batch paused

05 Batch not running Batch running

06 Batch not stopped Batch stopped

07 Alarm OFF Alarm ON

Batch Function Status Data

Val ue =0 Valu e=1

Digital input 4 ON

(520) Error

(520) No error

Table 3-5. Batch Function Status Data Format

Value

Weight data is returned to the master in the third and

fourth words of the input command format, depending

on the command and the value type. The weight data

returned is the displayed weight after the command is

executed, unless the command specifies otherwise.

Commands 7

Page 12

3.3 Command Descriptions

NOTE: For all commands that require a scale number, a value

of 0 indicates the current scale. Unless otherwise specified,

the indicator returns weight and status data for the specified

scale.

Return Status and Current Weight as Integer

Command: 0, 0x000

Parameter: Scale number

Command 0 returns the status and weight of the

specified scale in integer format, without changing the

display. This command also causes the

format-independent commands to return a value in the

integer format.

Display Channel

Command: 1, 0x001

Parameter: Scale number

Command 1 causes the weight of the specified scale to

be displayed and returned in its current mode and

format. This command is valid for the

Display Gross Weight

Command: 2, 0x002

Parameter: Scale number

Command 2 causes the gross weight of the specified

scale to be displayed and returned.

Display Net Weight

Command: 3, 0x003

Parameter: Scale number

Command 3 causes the net weight of the specified

scale to be displayed and returned.

Display Piece Count

Command: 4, 0x004

Parameter: Scale number

Command 4 causes the piece count on the specified

scale to be displayed and returned. This command is

valid only for the

520 indicator, and only if count

mode is enabled.

Gross/Net Key Press (toggle mode)

Command: 9, 0x009

Parameter: Scale number

Command 9 toggles between gross and net mode (and

count mode, if enabled). If a scale number other than 0

is specified, the action may not be evident until the

specified scale is displayed.

Zero

Command: 10, 0x00A

Parameter: Scale number

Command 10 performs a zero operation on the current

scale.

Display Tare

Command: 11, 0x00B

Parameter: Scale number

920i only.

Command 11 causes the tare weight on the specified

scale to be displayed. If a scale number other than 0 is

specified, the indicator first causes the specified scale

to be displayed. The tare data continues being

returned even if the display times out and returns to

another mode.

Enter Tare (integer)

Command: 12, 0x00C

Parameter: Scale number

Value: Tare weight

Command 12 enters a tare for the scale selected. Tare

data must be in integer format. The indicator

continues to return weight data in the current mode for

the specified scale.

Acquire Tare (simulate TARE key press)

Command: 13, 0x00D

Parameter: Scale number

Command 13 acquires a tare based on the weight

currently on the specified scale. The indicator

continues to return weight data in the current mode for

the specified scale.

Clear Tare

Command: 14, 0x00E

Parameter: Scale number

Command 14 clears the tare for the specified scale.

The indicator continues to return weight data in the

current mode for the specified scale.

Primary Units

Command: 16, 0x010

Parameter: Scale number

Command 16 switches the current format of the

specified scale to the primary units configured for that

scale.

Secondary Units

Command: 17, 0x011

Parameter: Scale number

Command 17 switches the current format of the

specified scale to the secondary units configured for

that scale.

Tertiary Units

Command: 18, 0x012

Parameter: Scale number

Command 18 switches the current format of the

specified scale to the tertiary units configured for that

scale, if available. This command is valid for the

920i

only.

Units Key Press (toggle units)

Command: 19, 0x013

Parameter: Scale number

Command 19 toggles the current format of the

specified scale to the next units configured for that

scale, as available.

8 520/920i EtherNet/IP Installation and Programming Manual

Page 13

Print Request

Command: 20, 0x014

Parameter: Scale number

Command 20 causes the indicator to execute a print

command for the current scale.

Display Accumulator

Command: 21, 0x015

Parameter: Scale number

Command 21 causes the value of the accumulator for

the specified scale to be displayed and returned. This

command is only valid if the accumulator for the

specified scale is enabled.

Parameter: Scale number

Command 37 returns the weight value for the

specified scale as currently displayed. This may

include gross, net, tare, piece count, or accumulator

values, as enabled. On the

920i, the weight value is

returned in the mode used to display a scale widget.

Return Accumulator as Integer

Command: 38, 0x026

Parameter: Scale number

Command 38 returns the accumulator value for the

specified scale. This command is only valid if the

accumulator for the specified scale is enabled.

Clear Accumulator

Command: 22, 0x016

Parameter: Scale number

Command 22 clears the value of the accumulator for

the specified scale. This command is only valid if the

accumulator for the specified scale is enabled.

Push Weight to Accumulator

Command: 23, 0x017

Parameter: Scale number

Command 23 adds the net weight on the specified

scale to the value of the accumulator for the specified

scale. The scale must return to net zero between

accumulations. The indicator returns the accumulated

weight data for the specified scale. This command is

only valid if the accumulator for the specified scale is

enabled.

Return Gross as Integer

Command: 32, 0x020

Parameter: Scale number

Command 32 returns the gross weight value for the

specified scale as an integer.

Return Net as Integer

Command: 33, 0x021

Parameter: Scale number

Command 33 returns the net weight value for the

specified scale as an integer.

Return Rate of Change as Integer

Command: 39, 0x027

Parameter: Scale number

Command 39 returns the current rate of change value

for the specified scale. This command is valid only for

the

920i.

Return Peak as Integer

Command: 40, 0x028

Parameter: Scale number

Command 40 returns the net peak value for the

specified scale. This command is valid only for the

520 indicator, and only if the peak hold function is

enabled.

Set Batching State

Command: 95, 0x05F

Parameter: State (0 = off; 1 = auto; 2 = manual)

Command 95 sets the batching (BATCHNG)

parameter. Indicator status is returned with the current

weight for the last scale specified.

Return Tare as Integer

Command: 34, 0x022

Parameter: Scale number

Command 34 returns the tare weight value for the

specified scale as an integer.

Return Piece Count

Command: 35, 0x023

Parameter: Scale number

Command 35 returns the piece count value for the

specified scale. This command is valid only for the

520 indicator, and only if count mode is enabled.

Return Current Display as Integer

Command: 37, 0x025

Commands 9

Page 14

Batch Start

Command: 96, 0x060

Parameter: Scale number

Command 96 starts a batch program from the current

step after a stop, pause, or reset. Batch status is

returned with the current weight for the specified

scale.

Batch Pause

Command: 97, 0x061

Parameter: Scale number

Command 97 pauses a batch program at the current

step. Batch status is returned with the current weight

for the specified scale.

Batch Reset

Command: 98, 0x062

Parameter: Scale number

Command 98 stops a batch program and resets it to

the first batch step. Batch status is returned with the

current weight for the specified scale.

Batch Status

Command: 99, 0x063

Parameter: Scale number

Command 99 returns the status of a batch. Batch

status is returned with the current weight for the

specified scale.

Lock Front Panel of Indicator

Command: 112, 0x070

Parameter: Scale number

Command 112 disables all the keys on the front panel

of the indicator. Indicator status is returned with the

current weight for the specified scale.

Unlock Front Panel of Indicator

Command: 113, 0x071

Parameter: Scale number

Command 113 re-enables all the keys on the front

panel of the indicator. Indicator status is returned with

the current weight for the specified scale.

Set Digital Output ON

Command: 114, 0x072

Parameter: Slot number

Val ue : Bit n umber

Command 114 sets the specified digital output ON

(active). Use slot number 0 for onboard digital

outputs. Indicator status is returned with the current

weight for the last scale specified.

Set Digital Output OFF

Command: 115, 0x073

Parameter: Slot number

Value: Bit number

Command 115 sets the specified digital output OFF

(inactive). Use slot number 0 for onboard digital

outputs. Indicator status is returned with the current

weight for the last scale specified.

Read Digital I/O

Command: 116, 0x074

Parameter: Slot number

Command 116 returns the status for all digital I/O in

the specified slot in words 3and 4 (On the

520, status

is returned only for the digital inputs.) Use slot

number 0 for onboard digital I/O. Indicator status is

returned in the status area for the last scale specified.

No Operation

Command: 253, 0x0FD

Parameter: Scale number

Command 253 provides a command to use between

operations, as necessary, without causing the indicator

to perform any action. Indicator status and weight for

the specified scale is returned.

Reset Indicator

Command: 254, 0x0FE

Parameter: None

Command 254 provides a command to remotely reset

the indicator. No data is returned.

Return Status and Current Weight as Float

Command: 256, 0x100

Parameter: Scale number

Command 256 returns the status and weight of the

specified scale in floating-point format, without

changing the display. This command also causes the

format-independent commands to return a value in the

floating-point format.

Set Tare as Float

Command: 268, 0x10C

Parameter: Scale number

Value: Tare weight

Command 268 enters a tare for the scale selected in

floating-point format. The indicator returns the tare

weight as taken, or 0 for no tare.

10 520/920i EtherNet/IP Installation and Programming Manual

Page 15

Read Gross Weight as Float

Command: 288, 0x120

Parameter: Scale number

Command 288 returns the gross weight value for the

specified scale in floating-point format.

Read Net Weight as Float

Command: 289, 0x121

Parameter: Scale number

Command 289 returns the net weight value for the

specified scale in floating-point format.

Read Tare as Float

Command: 290, 0x122

Parameter: Scale number

Command 290 returns the tare weight value for the

specified scale in floating-point format.

Read Piece Count as Float

Command: 291, 0x123

Parameter: Scale number

Command 291 returns the piece count value for the

specified scale in floating-point format. This

command is only valid for the

520, and only if count

mode is enabled.

Read Current Display as Float

Command: 293, 0x125

Parameter: Scale number

Command 293 returns the weight value for the

specified scale as currently displayed in floating-point

format. This may include gross, net, tare, piece count,

rate-of-change, or accumulator values, as enabled. On

920i, the weight value is returned in the mode used

the

to display a scale widget.

Read Accumulator as Float

Command: 294, 0x126

Parameter: Scale number

Command 294 returns the accumulator value for the

specified scale in floating-point format. This

command is only valid if the accumulator for the

specified scale is enabled.

Read Rate of Change as Float

Command: 295, 0x127

Parameter: Scale number

Command 295 returns the current rate of change value

for the specified scale in floating-point format. This

command is only valid for the

Read Peak Value as Float

Command: 296, 0x128

Parameter: Scale number

920i.

Command 296 returns the net peak value for the

specified scale in floating-point format. This

command is only valid for the

520, and only if the

peak hold function is enabled.

Set Setpoint Value as Float

Command: 304, 0x130

Parameter: Setpoint number

Value: Target value

Command 304 sets the target value for the specified

setpoint in floating-point format. This command is

only valid if the setpoint is enabled and requires a

target value.

Set Setpoint Hysteresis as Float

Command: 305, 0x131

Parameter: Setpoint number

Value: Hysteresis value

Command 305 sets the hysteresis value for the

specified setpoint in floating-point format. This

command is only valid if the setpoint is enabled and

requires a hysteresis value.

Set Setpoint Bandwidth as Float

Command: 306, 0x132

Parameter: Setpoint number

Value: Bandwidth value

Command 306 sets the bandwidth value for the

specified setpoint in floating-point format. This

command is only valid if the setpoint is enabled and

requires a bandwidth value.

Set Setpoint Preact as Float

Command: 307, 0x133

Parameter: Setpoint number

Value: Preact value

Command 307 sets the preact value for the specified

setpoint in floating-point format. This command is

only valid if the setpoint is enabled and requires a

preact value.

Read Setpoint Value as Float

Command: 320, 0x140

Parameter: Setpoint number

Command 320 returns the target value for the

specified setpoint in floating-point format. This

command is only valid if the setpoint is enabled and

requires a target value.

Read Setpoint Hysteresis as Float

Command: 321, 0x141

Parameter: Setpoint number

Command 321 returns the hysteresis value for the

specified setpoint in floating-point format. This

command is only valid if the setpoint is enabled and

requires a hysteresis value.

Read Setpoint Bandwidth as Float

Command: 322, 0x142

Parameter: Setpoint number

Commands 11

Page 16

Command 322 returns the bandwidth value for the

specified setpoint in floating-point format. This

command is only valid if the setpoint is enabled and

requires a bandwidth value.

Read Setpoint Preact as Float

Command: 323, 0x143

Parameter: Setpoint number

Command 323 returns the preact value for the

specified setpoint in floating-point format. This

command is only valid if the setpoint is enabled and

requires a preact value.

12 520/920i EtherNet/IP Installation and Programming Manual

Page 17

4.0 Appendix

4.1 Configuration Procedure for 920i and PLC

The following steps describe a typical procedure used to configure EtherNet/IP for a 920i controller and a PLC.

This example uses the CompactLogix L32E controller with RSLogix

Automation®.

1

1. Use iRev to configure the scales and scale capacities for the 920i.

2. Calibrate each scale and load any custom program required.

3. Power down the 920i. Install the EtherNet/IP option card (PN 87803). Write down the MAC address

shown on the back of the card.

4. Connect the EtherNet/IP option card to the network.

5. Use the MAC address on the back of the Anybus card to assign an IP address for the EtherNet/IP card.

The IP address can be assigned using the ARP function in DOS.

6. Use DOS to PING the EtherNet/IP card.

7. If the PING is successful, begin configuring the PLC.

8. Load RSLogix 5000 onto the same PC running iRev.

9. Load RSLinx and configure and DH+™ driver .

10. Use the RS-232 connector to connect the PC to the PLC.

11. Configure the I/O Configuration outlined in the RSLogix manual (1769-UM011E-EN-P, available on the

Rockwell Automation website, www.rockwellautomation.com).

12. Use the Generic Ethernet Module to add the 920i with EtherNet/IP to the I/O configuration; assign a name.

13. Using RSLinx®, configure an Ethernet driver.

14. Attempt a connection to the PLC using RSLogix 5000. (See the manual, ENET-UM001D-EN-P,

available on the Rockwell Automation website, for instructions.)

15. Without a program loaded on the PLC, turn the key to run. Click on the RLWS EtherNet/IP module in

I/O Config window. Another window will open that shows module properties.

the

16. Click on Module Info and verify that Anybus-S EtherNet/IP is shown as the Product Name. If so, the PLC

is communicating with the EtherNet/IP card.

17. Close the Module Info window, then open Controller Tags and verify the three tags assigned for this

module. For example, if the name assigned to the module was RLWS_EthernetIP, listed tags should include

RLWS_EthernetIP:I (input b uffer), RLWS_EthernetIP:O (output buffer), and RLWS_EthernetIP:C (control buffer).

18. Data should begin filling the input buffer from the 920i. Initial data received will not make sense, but

data in Word 4 should change with change made in the weight applied to the scale.

19. Write the ladder or structured language code for the PLC. When data is acquired from the 920i, a SWPB

(swap bits) instruction is required to swap the upper and lower bytes for all four outbound words. Data

received must also use the SWPB instruction to swap inbound words. By using the SWPB instruction,

words can be MOVEd to a destination tag then treated as real values elsewhere in the PLC program. See

Figure 4-1 on page 14.

™

5000 software, both from Rockwell

1. Rockwell Automation®, RSLogix™ 5000, RSLinx®, and DH+™ are all trademarks of Rockwell Automation, Inc

.

Appendix 13

Page 18

Input_1

<Local:1:I.Data.0>

0

Control Bits

B_Bit1

[]

)(

Control Bits

1

Control Bits

2

B_Bit1

[]

B_Bit1

[]

Swap Byte

Source RLWS_EthernetIP:I.Data(0)

8192

Order Mode HIGH/LOW

Dest DevNetIn1

32

SWPB

SWPB

Swap Byte

Source RLWS_EthernetIP:I.Data(1)

3329

Order Mode HIGH/LOW

Dest DevNetIn2

269

SWPB

Swap Byte

Source RLWS_EthernetIP:I.Data(2)

0

Order Mode HIGH/LOW

Dest DevNetIn3

0

SWPB

Swap Byte

Source RLWS_EthernetIP:I.Data(3)

0

Order Mode HIGH/LOW

Dest DevNetIn4

0

Word 1 for the

Device Net Command

SWPB

Swap Byte

Source DevNetCmd1

32

Order Mode HIGH/LOW

Dest RLWS_EthernetIP:O.Data(0)

8192

Word 2 of 4 for the

DevNet Command

Swap Byte

Source DevNetCmd2

1

Order Mode HIGH/LOW

Dest RLWS_EthernetIP:O.Data(1)

256

Swap Byte

Source DevNetCmd3

0

Order Mode HIGH/LOW

Dest RLWS_EthernetIP:O.Data(2)

0

Swap Byte

Source DevNetCmd4

0

Order Mode HIGH/LOW

Dest RLWS_EthernetIP:O.Data(3)

0

SWPB

Word 3 of 4 for the

DevNet Command

SWPB

Word 4 of 4 for the

DevNet Command

SWPB

(End)

14 520/920i EtherNet/IP Installation and Programming Manual

Figure 4-1. Ladder Logic for Bit-swapping

Page 19

4.2 EDS File

The EDS file for the EtherNet/IP adapter, shown below, is included on the CD that comes with the option. The

EDS file must be installed in the host device to enable communication with the indicator.

[File]

DescText = "HMS AnyBus-Communicator EtherNet/IP";

CreateDate = 04-02-2003;

CreateTime = 14:40:00;

ModDate = 07-22-2003;

ModTime = 10:45:00;

Revision = 1.2;

[Device]

VendCode = 90;

VendName = "HMS Networks";

ProdType = 12;

ProdTypeStr = "Communication Adapter";

ProdCode = 1;

MajRev = 1;

MinRev = 17;

ProdName = "Anybus-C EtherNet/IP";

Catalog = "Anybus-C EtherNet/IP";

[Device Classification]

Class1 = EtherNetIP;

[Params]

Param1 =

0, $ first field shall equal 0

,, $ path size,path

0x0000, $ descriptor

0xC7, $ data type : 16-bit Unsigned Integer

2, $ data size in bytes

"Output Size", $ name

"", $ units

"", $ help string

0, 504, 16, $ min, max, default data values

0, 0, 0, 0, $ mult, dev, base, offset scaling not used

0, 0, 0, 0, $ mult, dev, base, offset link not used

0; $ decimal places not used

Param2 =

0, $ first field shall equal 0

,, $ path size,path

0x0000, $ descriptor

0xC7, $ data type : 16-bit Unsigned Integer

2, $ data size in bytes

"Input Size", $ name

"", $ units

"", $ help string

0, 504, 16, $ min, max, default data values

0, 0, 0, 0, $ mult, dev, base, offset scaling not used

0, 0, 0, 0, $ mult, dev, base, offset link not used

0; $ decimal places not used

[Connection Manager]

Connection1 =

0x04010002, $ trigger & transport

$ 0-15 = supported transport classes (class 1)

$ 16 = cyclic (1 = supported)

Appendix 15

Page 20

$ 17 = change of state (0 = not supported)

$ 18 = on demand (0 = not supported)

$ 19-23 = reserved (must be zero)

$ 24-27 = exclusive owner

$ 28-30 = reserved (must be zero)

$ 31 = client 0 (don't care for classes 0 and 1)

0x44240405, $ point/multicast & priority & realtime format

$ 0 = O=>T fixed (1 = supported)

$ 1 = O=>T variable (0 = not supported)

$ 2 = T=>O fixed (1 = supported)

$ 3 = T=>O variable (0 = not supported)

$ 4-7 = reserved (must be zero)

$ 8-10 = O=>T header (4 byte run/idle)

$ 11 = reserved (must be zero)

$ 12-14 = T=>O header

$ 15 = reserved (must be zero)

$ 16-19 = O=>T point-to-point

$ 20-23 = T=>O multicast

$ 24-27 = O=>T scheduled

$ 28-31 = T=>O scheduled

,Param1,, $ O=>T RPI,Size,Format

,Param2,, $ T=>O RPI,Size,Format

,, $ config part 1 (dynamic assemblies)

,, $ config part 2 (module configuration)

"ABC-EIP IO Connection", $ connection name

"", $ Help string

"20 04 24 01 2C 96 2C 64"; $ exclusive output path

4.3 EtherNet/IP Interface Specifications

Power Requirements

Bus Adapter Card with EtherNet/IP Module, DC Power:

Supply voltage: 6 VDC, supplied by 520/920i bus

Typical current draw: 270 mA

Power consumption: 1.62 W

Indicators, Typical AC Load:

520 Power (TRMS): 3.51 W

Current (TRMS): 33.7 mA

920i Power (TRMS): 2.18 W

Current (TRMS): 28.9 mA

Communications Specifications

EtherNet/IP Network Communications:

Twisted-pair cabling at 10 or 100Mbps

Environmental Specifications

Temperature: –10° to +40° C (14° to 104° F)

Conformance

The Anybus-S EtherNet/IP Interface has been tested by

ODVA’s independent test lab and found to comply with the

ODVA composite conformance test, revision 3.

The EtherNet/IP Interface has been found in accordance with

EMC directive 89/336/EEC for European standards EN

50081-2 and EN 61000-6-2.

16 520/920i EtherNet/IP Installation and Programming Manual

Page 21

EtherNet/IP Interface Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by

the Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects in

materials and workmanship for one year.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized

by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment

fails to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to

prevent electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a

publication, “Protecting Your Components From S tatic Damage in Shipment,” availabl e from RLWS

Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was

not caused by accident, misuse, neglect, alteration, improper installation, improper repair or

improper testing; RLWS shall be the sole judge of all alleged non-conformities.

• S uch equipment has not been modified, altered, or changed by any person other than RLWS or its

duly authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible

for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER

RLWS

RLWS AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO

REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND

ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE SELLER FOR

WARRANTY CLAIMS.

NO TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO MODIFY THE TERMS OF THIS

WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN WRITING AND SIGNED BY A CORPORATE

OFFICER OF RLWS AND THE BUYER.

NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

© 2006 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

Appendix 17

Loading...

Loading...