Page 1

EL-304A

Four-Channel Signal T rim Junction Box

Installation Manual

16937

Page 2

Introduction

The EL-304A Junction Box can accommodate up to four load cells. Additional

load cells may be connected to the EL-304A Junction Box by wiring additional

junction boxes to the EXPANSION terminal on the EL-304A. Load cell output can

be trimmed with potentiometers either individually or paired in sections.

When correctly installed, the NEMA 4X fiberglass-reinforced polyester enclosure

will withstand 40 psi water pressure. It is not, however, designed for highpressure washdown applications, exposure to steam, or exposure to hightemperature liquids.

CHANGING CABLE LENGTH

Locate the junction box so load

cell cable length need not be

changed. Load cell output is

temperature-compensated for the

supplied cable length. Altering

that length will alter the cell’s

signal output.

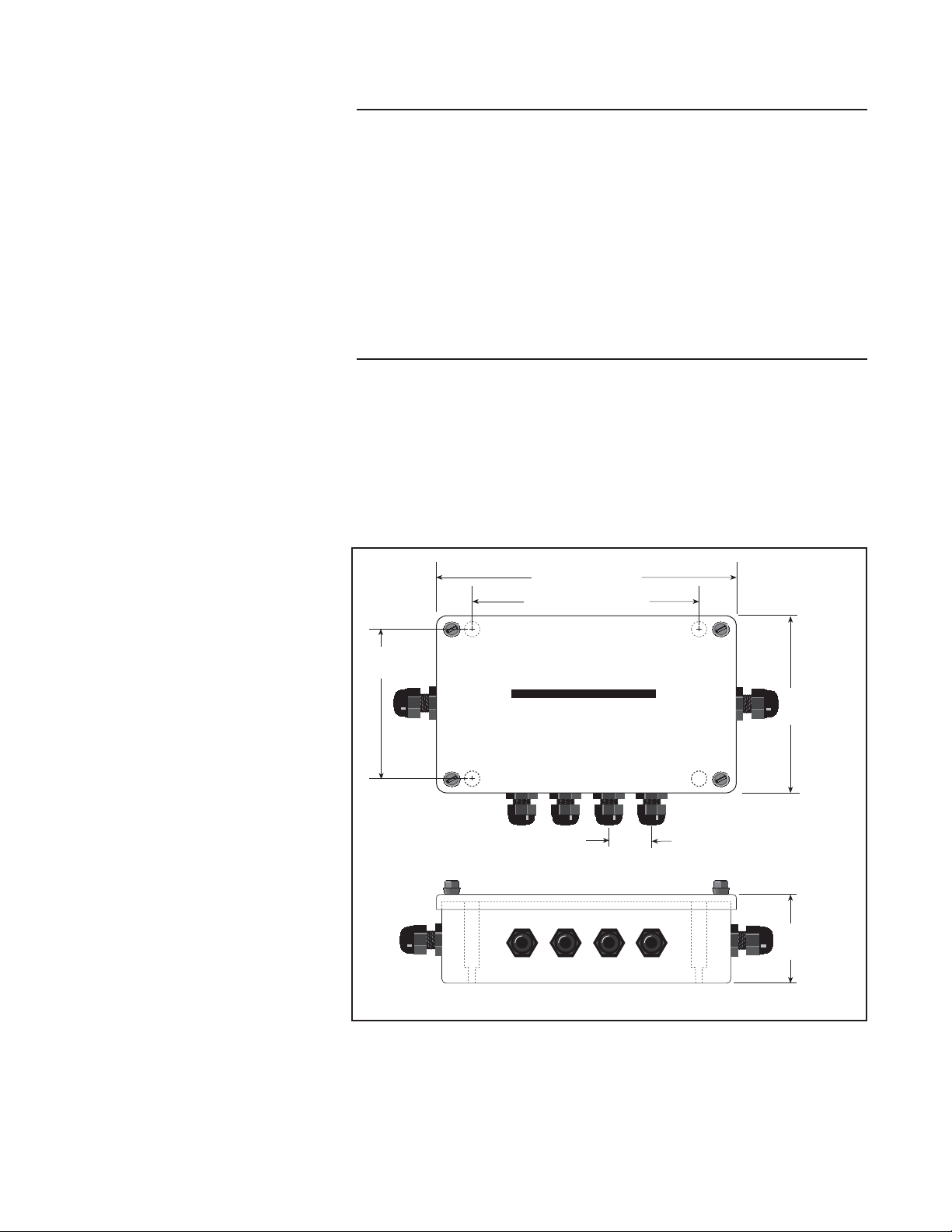

Mounting the Junction Box Enclosure

Mount the enclosure in a location convenient for servicing and away from

standing water. Try to mount the enclosure in a location that will not require

extending the load cell cables.

Depending on the mounting surface, the enclosure is attached using the four panhead screws provided, bolts, or other suitable masonry fasteners. Figure 1 below

shows dimensions for mounting the enclosure.

9.88" (251mm)

7.625" (193.6mm)

5.625"

(142.8mm)

RICE LAKE WEIGHING SYSTEMS

6.62"

(168.1mm)

FIGURE 1: EL-304A ENCLOSURE DIMENSIONS

© 1996 Rice Lake Weighing Systems, Inc., Rice Lake, WI USA. All Rights Reserved

Rice Lake Weighing Systems, Inc., 230 West Coleman Street, Rice Lake, WI 54868

Main Office (715) 234-9171 Service (715) 234-2003 FAX (715) 234-6967

1

1.38" (35.1mm)

3.25"

(82.6mm)

12/96

Page 3

Wiring

WIRING PATTERN

See back cover of Rice Lake

Weighing Systems Load Cell

Product Selection Guide for

wiring color codes.

1 2 3 4

DIP switches 3 & 4 must

be ON to enable trimming.

OFF

The terminal strips are labeled “Cell 1” through “Cell 4” and are used to connect

the individual load cells. Determine the number of load cells to be connected to

the junction box. The EL-304A has been designed to connect and trim four load

cells. However, it is possible to use this box with other combinations. On a track

scale or other system where load cells may be connected together in section

“pairs”, even numbers of cells (four or eight) may be used with the EL-304A. This

is done by paralleling the excitation and signal leads of a load cell pair, and

connecting them to the same input on the J-Box. However, it is recommended

practice when using more than four load cells to “daisy-chain” EL-304A J-Boxes

together using the expansion connectors.

After determining the wiring pattern, route the load cell cables through the nylon

cord grip assemblies. Leave the grips loose until final closure. Before connecting

load cell cables to the terminals, check that all wire ends have been properly

stripped and tinned. Connect the load cell and indicator cables to the appropriate

connectors. DIP switches 3 and 4 must be ON for any cells which you will be

trimming. If using less than four load cells, remove any unused channels from the

circuit by turning dip switches 3 and 4 to OFF on those channels.

SHLD

–SIG

+SIG

+EXC

–EXC

SHLD

–SIG

+SIG

+EXC

–EXC

CABLE DRIP LOOPS

If cables will be exposed to water

or other liquids, bend a short

downward loop in all cables near

the cord grips so any fluids

draining down the cables will drip

off before reaching the junction

box.

SENSE LEADS

Use sense leads to correct small

errors which can cause inaccurate readings and drifting

problems, especially if the

indicator is located far from the

junction box.

EXPANSION

SHLD

+SIG

–SIG

+SEN

+EXC

–SEN

–EXC

EL 304A

REVISION 1

1-90

SECTION #1

CELL #2 CELL #3

1 2 3 4

OFF

SECTION #2

RICE LAKE WEIGHING SYSTEMS

TRIM

SHLD

–SIG

OFF

ON

1 2 3 4

OFF

CELL #1

+SIG

+EXC

–EXC

TRIM

SHLD

–SIG

1 2 3 4

OFF

OFF

ON

1 2 3 4

OFF

CELL #4

+SIG

+EXC

INDICATOR

SHLD

+SIG

–SIG

+SEN

+EXC

–SEN

–EXC

EL304A COMPONENTS REV. 1.0 (1-90)

–EXC

FIGURE 2: EL-304A MAIN BOARD

The INDICATOR terminal strip is used to connect the main cable to the indicator.

Determine the indicator’s load cell input connections from the operating manual.

Run a cable from the indicator to the junction box through the larger cord grip and

make the connections on the INDICATOR terminal.

2

Page 4

Whenever a large amount of trim

seems necessary to equalize

output (more than 7% of normal

output), check for other possible

problems. Always strive for the

least amount of trim.

Trimming Procedure

The EL-304A J-Box is a signal trimming device. Each cell can be set for coarse,

medium, or fine trim with its own 4-pole dip switch. Switches 1 and 2 work in various

combinations to alter the sensitivity of the trimming potentiometers as shown in the

table below. Switches 3 and 4 must be ON for each active cell to enable trimming.

Approximate Trim Ranges - EL-304A Summing Board

tnemtsujdA

1hctiwS 2hctiwS

FFOFFOenoNenoNenoN

FFONOeniF%8.6–%53.%8.21–%7.

NOFFOmuideM%5.21–%53.%3.22–%7.

NONOesraoC%6.71–%53.%9.92–%7.

egnaR

053 Ω slleC 007 Ω slleC

NOTE: On older models of the

EL-304A Junction Box, the

Section Trim pots work in the

opposite direction as the

Individual Cell Trim pots.

To decrease resistance for

maximum signal on these

units, turn Individual pots

counterclockwise and Section

pots clockwise.

Caution

!

When loading the corners with

test weights, do not exceed the

concentrated load capacity

(CLC) specified by the scale

manufacturer.

For example, to enable trimming using the fine adjustment range, set DIP switches

2, 3 and 4 on active channels to ON, and switch 1 to OFF.

1. Turn the four individual cell potentiometers fully counterclockwise to give

maximum signal output from each cell.

To trim cells individually, be sure the Section Trim jumpers

are in the OFF position as shown at right.

2. To trim cells in pairs, set the Section Trim jumpers to the

ON position. If section trimming is chosen, turn the two

section potentiometers fully counterclockwise so both

sections are at maximum signal output.

3. Remove all weight from the scale and zero the indicator. Place calibrated test

weights over each load cell or section in turn. The amount of test weights to

be used will depend on the scale configuration; for specific recommendations,

refer to

Technology (NIST). For a four-cell platform, we recommend using 25% of

scale capacity.

4. Record the value displayed on the indicator after the test weight is placed in

turn on each corner, directly over the load cell, or over each section. Allow the

scale to return to zero each time to check for friction or other mechanical

problems. Select the load cell or section that has the lowest value as your

reference point. This cell or section will not be trimmed.

Handbook 44

, published by the National Institute of Standards and

SECTION #1

OFF

TRIM

ON

Caution

!

To prevent water and other

contaminants from entering the

J-Box, fill any unused cable grips

with post screw plugs (part

number 19538). One plug is

provided.

5. Place the same test load over each cell or section in turn. Using the

corresponding potentiometer, trim each cell or section down to equal the

reference point. As corner corrections are somewhat interactive, check all

cells or sections again for repeatability. If necessary, repeat steps 4 and 5.

6. Tighten the cord grip assemblies with a wrench. To be watertight, each cord

grip must be tightened so the rubber sleeve begins to protrude from the hub.

7. Unused hubs must be plugged to prevent moisture entry. See the

Replacement Parts and Components

8. Insert the enclosed desiccant bag and replace the cover, tightening the cover

screws in an alternating pattern to be certain the gasket is compressed equally

in all locations. If the enclosure is located in a damp or wet area, change the

desiccant (part number 16038) every four to six months.

3

catalog to order extra hole plugs.

Electronic

Loading...

Loading...