Page 1

EL232 XPCD

Explosion Proof Remote Display

Installation Manual

16942

Page 2

Page 3

Contents

About This Manual................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 5

1.1 System Limitations and Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Front Panel Annunciators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.0 Installation and Wiring................................................................................................................ 7

2.1 EL232 XPCD Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.1 Mounting and Mounting Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2 Sealoff Fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3 Cabling and Conduit Runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.1 Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.2 Conduit Runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 AC Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.0 Indicator Setup........................................................................................................................... 12

3.1 Serial Data Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.1 Condec Data Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.2 Electroscale Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1.3 Analogic Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.4 Cardinal Data Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2 Serial Data Input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.1 RS232 C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.2 20 mA Active Current Loop Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.3 20 mA Passive Current Loop Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3.3 Configuration of the EL232 XPCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.3.1 Loss of Signal Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 Serial Data Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.0 EL232 XPCD Operation............................................................................................................... 19

4.1 Lamp Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.2 Software Revision. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.3 Current Baud Rate Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.4 Input Signal Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.5 Indicator Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4.6 Receiving Data for the First Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.0 Appendix.................................................................................................................................... 21

5.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2 Recommended Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.3 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

EL232 XPCD Limited Warranty............................................................................................................... 23

Copyright © 2002 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

March 2002

1

Page 4

2

ES232 XPCD Installation Manual

Page 5

About This Manual

The EL232 XPCD explosion proof remote display represents the latest in state-of-the-art microprocessor

technology specifically applied to the explosion proof weighing marketplace. This EL232 has been modified for

use in a hazardous electrical environment.

This manual provides information on installation of the EL232 XPCD. The installer should be familiar with the

National Electrical Code and RP 12.6 ( Recommended Practice ) requirements for installation of equipment in

hazardous areas (NEC Article 504, Intrinsically Safe Systems ) published through the Instrument Society of

America.

This equipment is intended only for industrial applications.

Warning

Improper specification, installation, or service of this equipment could result in personal injury or property

damage.

Read all of the manual prior to installation. Do not assume that all hazardous area installations are identical.

Do not begin installation until all safety procedures are in place including lockouts, additional ventilation, or

washdowns. Make sure plant safety personnel have checked the area in which you will be working and have

officially declared it safe for work to proceed.

All explosion proof enclosures must remain closed unless being serviced by qualified personnel in an area

which safety inspectors have tested and declared safe. All other openings have sealoff fittings or plugs

provided. Each opening must have a sealoff fitting or plug correctly installed in it. Sealoff installation is

critical. Maximum voltage inside of enclosure must not exceed 250VAC.

The illustrations shown on the following pages represent a basic explosion proof flame control theory

(XPCD).

This instrument and accompanying equipment must be installed and serviced by an

authorized technician in accordance with the instructions provided in this manual.

1

Page 6

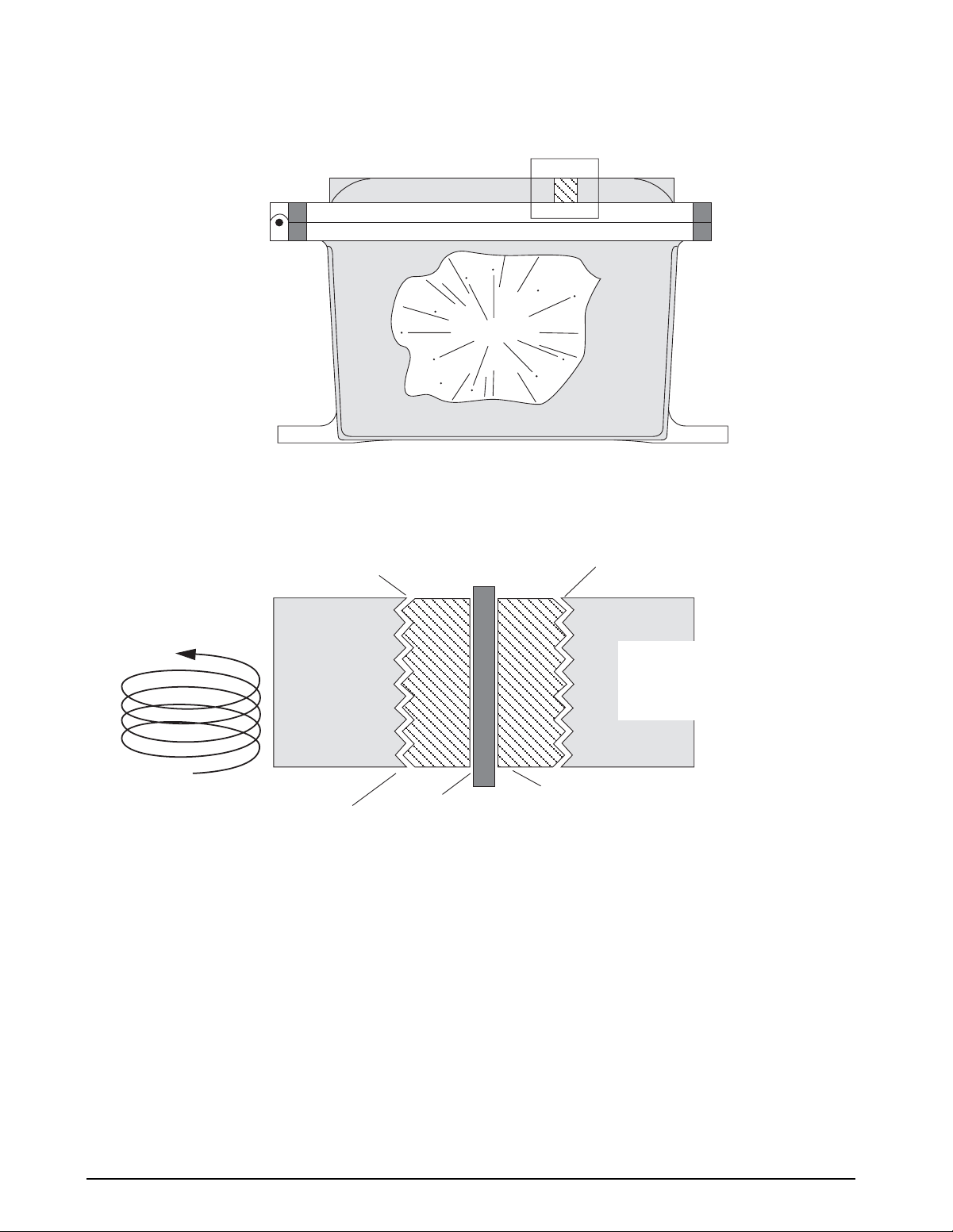

2

Enlarged view

below

Explosion

HAZARDOUS

AREA

Cooling from

conduction of heat

along the threads

There must be a minimum of five full

threads of engagement of a 2–A

2–B fit for a Group C enclosure.

Group B increases this to eight full

threads of engagement.

Cross–section of a

shaft-type threaded

operator

Propagation of gas due to

pressure from an internal

explosion is along the

threads

Lower

temperature

gases

High temperature

gases

Shaft clearance

not to exceed 0.00033”

INSIDE OF

ENCLOSURE

The push buttons, rotary switches and sealing fittings are all attached to the enclosure via drilled and

tapped holes in the enclosure. Just as with the flange, all threaded operators and fittings carefully control

the flame path.

EL232 XPCD Installation Manual

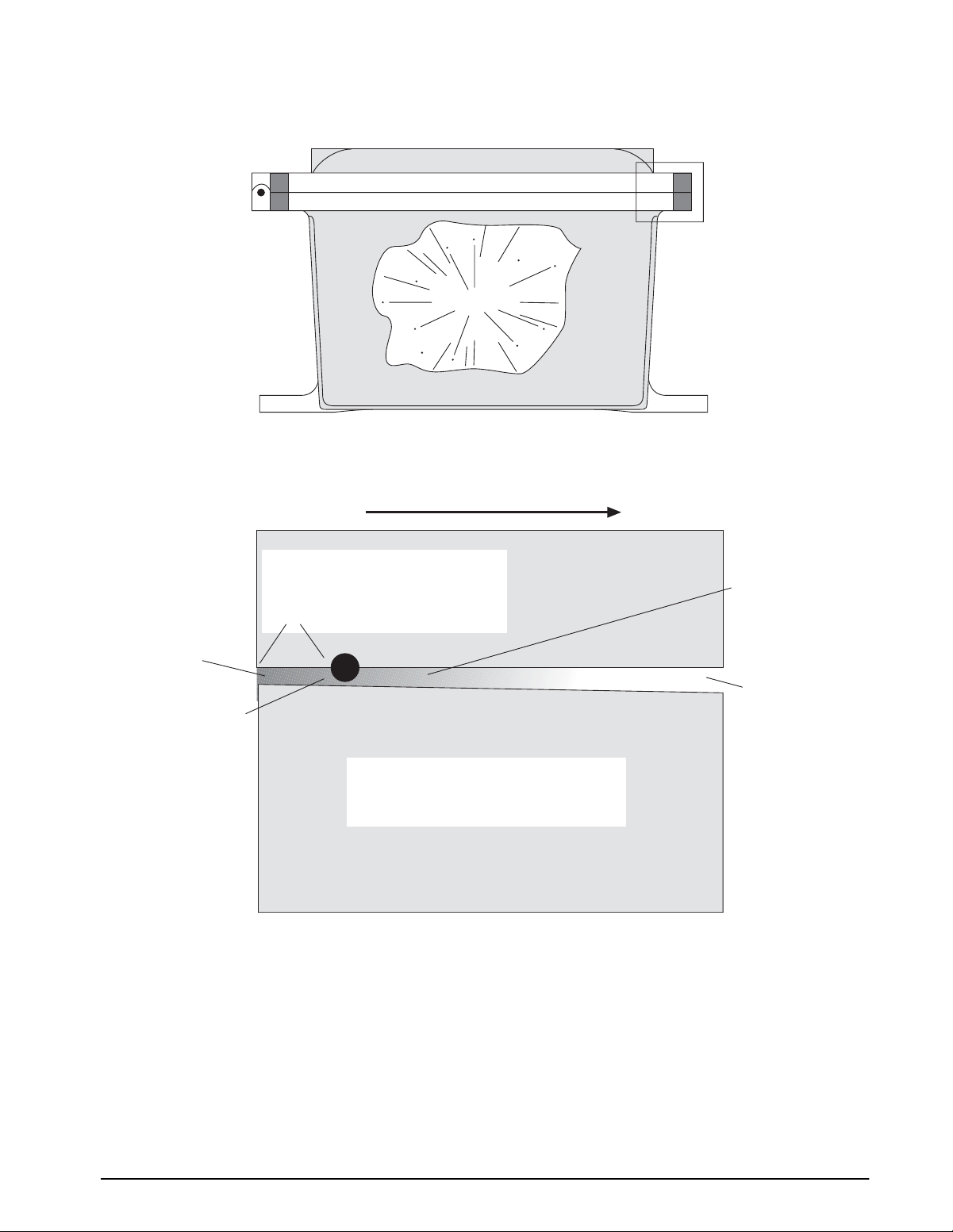

Page 7

Enlarged view

below

Explosion

High temperature

gases

Gasket

INSIDE OF

ENCLOSURE

Propagation of gas due to

pressure from an internal

explosion

The distance from the boundary of

the inside of the enclosure to the

gasket is known as the Flame Path.

This distance must be at least 1" for

Group C throughG.

For clarity, the slope of the flange

faces has been greatly enhanced

(Typically, the slope is .0015"/inch)

Cooling from

expansion of gas

(Boyle’s Gas Law)

Lower

temperature

gases

HAZARDOUS

AREA

The design intent of an explosion proof enclosure is not to contain an explosion, but to control it. The flame

path is carefully controlled at the flanges. This insures that if an explosion occurs, any gases that escape will

be cooled to a temperature below the ignition point of any atmosphere specified within that enclosure’s

rating.

3

Page 8

4

EL232 XPCD Installation Manual

Page 9

1.0 Introduction

The EL232 XPCD is a high performance serial remote data display. It receives serial ASCII data (20 mA current

loop or RS-232), and displays weight data on a 8" LED display. Five LED status indicators are provided for Lbs,

Kg, Gross, Net, and no signal. (see Figure 1-1 on page 6).

The EL232 XPCD supports twelve scale formats which include:

• UMC Series

• General Freedom I and II

• Electroscale 560

•A & D Instruments 4322, 4323, 4316

•Weightronix WI-110 and WI-120

•Toledo indicators with “High speed data format”

• Flex-weigh DWM-4

• Analogic AN5315, AN5316, AN5322

• Masstron M-2500 and M-5000

•Fairbanks 90-164 series

• Streeter Richardson 9000

• Cardinal 738

• Instruments with programmable ASCII output

• Generic smart receiver mode

1.1 System Limitations and Restrictions

The following items represent limitations and restrictions on the use of the EL232 XPCD:

• All wiring, connections, conduit and grounds must comply with the National Electrical Code.

• No modifications can be made in the field.

• It is mandatory to return the EL232 XPCD to Rice Lake Weighing Systems for service.

Introduction

5

Page 10

6

1.2 Front Panel Annunciators

Figure 1-1 illustrates the EL232 XPCD front panel which include six LED display digits and five LED

annunciators.

FROM SUPPLY BEF

ASS'Y TIGHT WHILE

CLASS II

DIVISION 1

GROUP E F & G

CAUTION:

TO PREVENT IGNITION OF

HAZ. ATMOS., DISCONNECT

ORE OPENING. KEEP

CIRCUIT IS ALIVE

CLASS I

DIVISION 2

GROUP C & D

LBS KGS GROSS NET NO SIGNAL

MADE IN U.S.A.

REMOTE WEIGHT DISPLAY

EL232 XPCD Installation Manual

Figure 1-1. EL232 XPCD Front Panel

Page 11

2.0 Installation and Wiring

This section is provided to help the installer and describes the procedures for installing the EL232 XPCD remote

display and enclosure, AC wiring, conduit runs, and internal modifications for the EL232 XPCD.

2.1 EL232 XPCD Enclosure

The following sections describe mounting locations and how to mount the enclosure and sealoff the fittings.

2.1.1 Mounting and Mounting Locations

The mounting and installation of an explosion proof enclosure is more inv olv ed than a general purpose unit and it

is recommended that all outdoor installations have a shelter, roof, enclosure, or covering. The EL232 XPCD

enclosure is cast aluminum and direct sunlight can cause it to heat to a very high temperature which can damage

the electronics inside. (Such damage is not covered by the warranty). Sheltering the unit from sunlight will help

control the internal temperature. In cold climates, it is recommended an indicator heater be installed (optional).

These are small and easily installed on the backplate.

Sunlight and variable temperatures can also cause moisture to condensate inside the enclosure. It is

recommended to shelter the outdoor installation by a shelter, roof, enclosure, or covering. Moist environments

can also be controlled by the use of desiccants. Contact your local dealer for information on desiccants.

Caution

!

The explosion proof enclosure is substantially heavier than a standard enclosure and thus the mounting surface

must be capable of reliably supporting the added weight.

The mounting and installation of the EL232 XPCD must be into Division II or safe electrical area per NEC,

Section 500. The inside of an explosion proof enclosure is classified as a Division II environment.

Do not place desiccants on top of circuit boards. Place them in the bottom of the

enclosure away from electronics and wires.

Glass Face

The glass face on the EL232 XPCD may look indestructible but it is not. If damaged in any way, the entire unit

must be completely turned off at the source until it is replaced. The enclosure must be protected from blows and

scrapes from passing equipment, falling objects, thick glues or resins, certain acids which eat aluminum, and

other hazards which can break or damage the enclosure.

The glass window in the enclosure must be not become scratched, pitted, or damaged in any way. Do not wipe

the glass with dirty gloves or rags as this can cause the glass to become scratched.

Installation and Wiring

7

Page 12

8

2.2 Sealoff Fittings

The utmost care must be taken to completely seal the inside of the remote display off from the outside world. To

do this all wiring into and out of the enclosure must be in conduit using sealoff fittings between the remote

display and the conduit. The sealoff fittings ensure that the hazardous atmosphere does not travel either through

the conduit or through insulation or wiring back to the safe area. The graphic shown belo w illustrates the location

of sealoff fittings.

FROM SUPPLY BEF

ASS'Y TIGHT WHILE

ORE OPENING. KEEP

CIRCUIT IS ALIVE

CLASS II

DIVISION 1

GROUP E F & G

CAUTION:

TO PREVENT IGNITION OF

HAZ. ATMOS., DISCONNECT

CLASS I

DIVISION 2

MAKE SURE THE MOUNTING SUPPORT IS CAPABLE

OF HOLDING CONDUIT TIGHT AGAINST IT. NO

STRAIN MUST BE PLACED ON THE SEALOFF

FITTING ASSEMBLY .

WHEN USING FLEXIBLE CONDUIT, USE

MULTIPLE PIPE STRAPS TO SECURE

RIGID CONDUIT TO THE SUPPORT

STRUCTURE. ATTACH THE FLEXIBLE

CONDUIT TO THE RIGID CONDUIT ONLY

AFTER MULTIPLE STRAPS HAVE BEEN

ATTACHED TO PREVENT ANY STRAIN

FROM REACHING THE SEAL-OFF FITTINGS.

GROUP C & D

LBS KGS GROSS NET NO SIGNAL

REMOTE WEIGHT DISPLAY

MADE IN U.S.A.

SEAL FITTING

18" MAX.

FROM BOX

These fittings, once installed and sealed are very difficult to remove so make sure all the wiring has been double

checked before beginning. If rigid conduit is not being used for connection to the scale base, be sure to install an

approved strain relief fitting to avoid pulling the wires out of the sealoff fittings in an accident. Doing so would

open a flame path to the enclosure and defeat its purpose.

Note:

The inside of an explosion proof enclosure is considered a Division II area when the enclosure has

been properly sealed.

EL232 XCPD Installation Manual

Page 13

2.3 Cabling and Conduit Runs

2.3.1 Cabling

There are two types of cables that pass through a sealoff fitting, single conductor and multi conductor.

Single Conductor Cabling

Single conductor cables are typically redundant ground wires (used with resistive intrinsic safety barrier). Due to

the nature of the method by which insulation is applied to wire, a single conductor wire (single or multi strand)

can be considered gas tight. It is not necessary to strip the insulation back ahead of entry into the safe area. Single

conductor cables will pass through a sealoff fitting as shown below.

Conduit to Indicator or other Safe

Area ( 18" Max. Group C & D)

Single

Conductor

Cable

Sealing Cement

Packing Fiber

Hazardous Area

Airspace

Packing Plug

Safe Area

Airspace

Conduit or Strain Relief

to Hazardous Area

Figure 2-1. Single Conductor Cable

Multi Conductor Cabling

Multi conductor cables may be load cell cables, AC power, serial data inputs or other signals. Because of the

airspace that typically exists within the outer insulation of a multi conductor cable, they cannot be considered gas

tight. Therefore, to insure that the explosion proof enclosure is allowed to vent internal pressure appropriately,

the outer insulation must be removed back to the point ahead of entry into the safe area. Multi conductor cables

will pass through a sealoff fitting as shown below.

Conduit to Indicator or other Safe

Area ( 18" Max. Group C & D)

Multi-Conductor

Cable

Packing Plug

Sealing Cement

Packing Fiber

Safe Area

Airspace

Hazardous Area

Airspace

Conduit or Strain Relief

to Hazardous Area

Figure 2-2. Multi Conductor Cable

A sealing fitting must be installed within 18" of the enclosure for Groups C-G and 6" for Groups A and B.

Using the enclosed packing fiber and sealing cement, follow the directions for sealing the sealoff fittings

carefully. Make sure there are no openings, no matter how small to the outside.

An enclosure without sealoff fittings correctly installed and sealed is not explosion proof

Warning

therefore can pose serious injury or death.

Installation and Wiring

9

Page 14

10

2.3.2 Conduit Runs

Conduit can be run either vertically or horizontally. But either way the conduit must be sealed properly to

maintain the explosion proof integrity of the unit. The following paragraphs explain the proper way to install a

conduit run and the sealing fittings.

Horizontal Conduit Runs

Install the fitting with covered filling opening facing up. Remove the threaded cover and pack Adaco

®

packing

fiber around and between cables at both ends of fitting to block the flow of cement into conduits. Packing fiber

must not project into the main cavity of fitting. The cavity length free of packing fiber must be at least equal to

inside diameter of conduit but not less than 5/8".

Mix the cement per label instructions using the enclosed shipping container. Fill the container with clean cold

water to “water line” (make sure not to exceed required amount of water). Gradually pour cement from the

plastic bag into water and stir thoroughly for proper mixture. Fill the fitting in one continuous pour to the top of

filling opening within five minutes after mixing cement. Tamp with a blunt stick to expel any air bubbles. Install

and tighten filling opening cover.

Fittings requiring more than 16 oz. of cement must be filled from a single mixture of cement and water. Do not

pour in stages.

Caution

!

Vertical Conduit Runs

Water-mix sealing compound should not be poured or installed at temperatures below 35° F. Adaco

no. 1 sealing cement must be used as a part of Adalet UL listed fittings.

Install the fitting with angled fill plug or cap fill plug towards the top. Remov e angled fill plug, large hole plug or

threaded cover. Pack Adaco packing fiber around and between cables at lower end of sealing fitting to block flow

of cement into conduit. Packing fiber must not project into main cavity of fitting. Install and tighten large plug or

threaded cover with fill plug facing up but do not install fill plugs at this time.

Mix the cement per label instructions using the enclosed shipping container. Fill the container with clean cold

water to “water line” (make sure not to exceed required amount of water). Gradually pour cement from the

plastic bag into water and stir thoroughly for proper mixture. Fill the fitting in one continuous pour to the top of

filling opening within five minutes after mixing cement. Tamp with a blunt stick to expel any air bubbles. Install

and tighten fill plug.

EL232 XCPD Installation Manual

Page 15

2.4 AC Power Wiring

K2

Electrical connections made in an explosion proof

installation are made through rigid steel conduit

through threaded openings in the back or sides of the

enclosure and must comply with the National

Electrical Code for installation of equipment in

hazardous areas (NEC Article 504, Intrinsically Safe

Systems ).

Connect the black wire (AC Hot) to terminal strip

J1-#3 on the CPU board located in the bottom of the

enclosure (shown below).

TxD

RxD

PB

PB6

PB5

PB4

2

3

51617

18 19

1

J1

GND

PRINT

K4

K3

Figure 2-3. J1 Location on CPU Board

Connect the neutral wire (white) to terminal J1-#1,

and the ground wire (green) to terminal J1-#2. Use a

#16 AWG or smaller wire and strip approximately

3/16" and insert it beneath the compression plate in

the connector. Tighten the terminal with a screwdriver

and test the connection by pulling gently on the wire.

117 VAC

GND

NEUTRAL

Installation and Wiring

11

Page 16

12

3.0 Indicator Setup

This section is provided to help the installer set up indicators to the EL232 XPCD. You must determine what

indicator will supply the data to the EL232 XPCD. Once this is determined, there are certain setup parameters

which you need to know depending on which indicator is chosen.

The EL232 XPCD supports the following scale formats and are listed in Table 3-1:

• UMC Series

• General Freedom I and II

• Electroscale 560

•A & D Instruments 4322, 4323, and 4316

•Weightronix WI-110 and WI-120

•Toledo indicators with “high speed data format”

• Flex-weigh DWM-4

• Analogic AN5315, AN5316, AN5322

• Masstron M-2500 and M-5000

•Fairbanks 90-164 series

• Streeter Richardson 9000

• Cardinal 738

• Instruments with programmable ASCII output

• Generic smart receiver mode

3.1 Serial Data Inputs

The EL232 XPCD can accept serial ASCII data sent in RS232C, 20 mA active, or 20 mA passive current loop

formats. These formats determine the electrical way that data is transmitted. The EL232 XPCD can read the data

transmission strings sent by 12 of the more popular scale indicator families as shown in Table 3-1. It cannot read

data from indicators not included in this list unless the formatting exactly matches one on the list (or if you have

a custom program).

Set up the EL232 XPCD on the bench with the indicator you intend to use before taking it to the installation site.

Note:

Brand

Condec 1000 - 2000 series Continuous 1200 or 4800 See Figure 3-1

555/600/700 1200 to 9600

General Freedom Series I RS232 1200 to 9600 7 data bits, parity - odd,

Series II RS232

Electroscale 560 Current loop or RS232 in

A & D Instruments 4322, 4321, 4316 Current loop -passive or

Weightronix 110 and 120 Current loop or RS232 1200 to 9600 Toledo - Current loop (active or

Flex-Weigh DWM-4 - Current loop (active or

Analogic AN5315, AN5316,

AN5322

Model Interface Baud Rate Data Format/Notes

1200 See Figure 3-2

continuous mode

2400 -

RS232

4800 -

passive)

1200 to 9600 Data preamble - FF, FF, FF

passive)

Current loop or RS232 in

continuous mode

1200 to 9600 See Figure 3-3

postamble FF FF 0A

EL232 XCPD Installation Manual

Table 3-1. Indicator Setup Parameters

Page 17

Brand Model Interface Baud Rate Data Format/Notes

Masstron M2500, M5000 Continuous 4800 Fairbanks 90-164 Continuous current loop via

port C

Streeter Amet 9000 Current loop 1200, 2400, 9600 Cardinal 738 Curr ent loop or RS232 using

S3=10000100

Generic smart

receiver

N/A RS232 or current loop 1200 to 9600 Can receive serial data in a

1200 -

1200 to 9600 See Figure 3-4

wide variety of intuitive

formats. Use when all else

fails.

Table 3-1. Indicator Setup Parameters (Continued)

Any device that has a programmable ASCII output can be used with the EL232 XPCD. Set the device to emulate

any of the following:

3.1.1 Condec Data Format

Figure 3-1 shows the Condec UMC series continuous output data format.

<STX> <POL> <wwwwwww> <UNIT> <G/N> <S> <TERM>

STX (02h)

Weight: 7 digits, right-justified, dummy

zeroes, decimal point with no leading

zeroes except for leading zero

immediately preceding the decimal point.

Leading zeroes transmitted as spaces.

3.1.2 Electroscale Data Format

Figure 3-2 shows the Electroscale continuous output data format.

Polarity:

<Space> = Positive

< – > = Negative

G = gram

K = kilogram

L = pound

T = ton (short)

<Space> = ton (metric),

grain, ounce or none

Figure 3-1. Condec Continuous Output Data Format

<SOT> <R> <nnnnnnn> <EOT>

SOT (01h) “R” (52h)

Seven bytes of numeric data.

Figure 3-2. Electroscale Continuous Output Data Format

EOT (04h)

G for Gross

N for Net

<CR> or

<LF> or

<CR> <LF>

Status:

<Space> = valid

I = Invalid

M = Motion

O = Over/under range

Indicator Setup

13

Page 18

3.1.3 Analogic Data Format

Figure 3-3 shows the Analogic continuous output data format.

<STX> <nnnnnnnnn> <ttttttttt> <SP> <S> <UNIT> <SP> <TERM>

14

STX (02h)

Net Weight: 9 characters, 7

active weight digits, no leading

zeroes, decimal point, negative

sign precedes first active digit.

Tare Weight: 9 characters, 7

active weight digits, no leading

zeroes, decimal point, negative

sign precedes first active digit.

Space

character

Status <S> is the sum of:

1 = In range

2 = Standstill

4 = Center of Zero

8 = Net mode

For example:

In range = 1

Standstill = 2

Net Mode = 8

<S> = B (hex)

Space

character

0 = kilogram

1 = gram

2 = pound

3 = ton (short/metric)

4 = ounce

5 = none

6 = grain

Figure 3-3. Analogic Continuous Output Data Format

3.1.4 Cardinal Data Format

Figure 3-4 shows the Cardinal continuous output data format.

<CR> <POL> <wwwwwww> <S> <SP> <UNIT> <SP> <G/N> <SP> <SP> <ETX>

Carriage

return

Polarity:

<Space> = Positive

< – > = Negative

Seven digits of weight data, including

decimal point. No leading zero

suppression.

Status:

M = motion

O = out of range

<space> = for none

of the above

Space

character

Space

character

G = gram

K = kilogram

L = pound

T = ton (short)

<Space> = ton (metric),

grain, ounce or none

G for Gross

N for Net

Space character (2)

<CR> or

<LF> or

<CR> <LF>

ETX (03h)

Figure 3-4. Cardinal Continuous Output Data Format

3.2 Serial Data Input

Some weight indicators have multiple outputs. Some can have two or more RS232 outputs or current loop

outputs which can be active or passive. The preferred interface is an active current loop output from the weight

indicator. A passive current loop is second in preference, and RS232 being the least desirable. The transmitted

data must be continuous and demand ports are unusable. Information is explained in further detail in the

following sections.

3.2.1 RS232 C

Data is transmitted as a voltage and alternates between +10 VDC and -11 VDC. Hybrid RS232 signals can swing

between other voltage ranges as long as the positive swing is greater than 4 VDC and the negative is less than - 1

VDC. RS232 is ground referenced and therefore, connects the ground planes of the sending and receiving

instruments. RS232 should never be run more than 50 feet. It may work, but it may not work well or all the time.

Long RS232 data cables can act as a conduit for lightening or other electrical noise to the instrument. If you need

longer cable runs, use a 20 mA current loop.

EL232 XCPD Installation Manual

Page 19

Connect RS232 wiring as shown in Figure 3-5. Strip the wires approximately 3/16" and insert them into the

connectors as shown. Tighten the connectors and test the tightness by gently pulling on the wires.

J2

GND

PRINT

K4

K3

K2

K1

+5V

CL4 IN-

CL4 IN+

CL3 IN-

CL3 IN+

CL2 IN-

CL2 IN+

CL1 IN-

CL1 IN+

CLO OUT-

CLO OUT+

RS232 (+)

GROUND

Figure 3-5. RS232 C Input Hookup

The RS232 receiver in the EL232 XPCD is made from discrete components and requires a lower current than

most integrated circuit RS232 receivers. It is very difficult to damage and holds up under most conditions.

3.2.2 20 mA Active Current Loop Input

Data is transmitted as a current and is passed through an optical isolator. This current causes an LED to emit light

onto a photo transistor, which converts this light into a TTL signal. Current transmission can be made over long

distances and are quite immune from transient voltage or RFI/EMI noise. The distance a current loop can

transmit is limited by the voltage source available to the current loop and the speed of transmission which data is

sent. Normally a current loop should not send data at speeds greater than 4800 baud.

An active current loop means that the instrument which sends the data also supplies the voltage to power the

loop. This voltage can be as small as 5 VDC to as much as 24 VDC. When the loop goes through an optocoupler,

a drop occurs. This drop is about 2 VDC. A current loop can power as many drops as there is v oltage to po wer the

loop. For example, if a current loop is powered by 5 VDC, it can normally drive two drops. If the same loop were

powered by 24 VDC, it could power about 11 remote displays or other devices.

Determine that your indicator has an active current loop and connect it as shown in Figure 3-6. Strip the wires

approximately 3/16" and insert them into the connector as shown. Tighten the connectors and test the tightness

by gently pulling on the wires.

J2

GND

PRINT

K4

K3

K2

K1

+5V

CL4 IN-

CL4 IN+

CL3 IN-

CL3 IN+

CL2 IN-

CLO OUT+

RS-232 (-)

RS-232 (+)

CLO OUT-

CL (+)

CL2 IN+

CL (-)

Figure 3-6. 20 mA Active Current Loop Input Hookup

The 20 mA receiver in the EL232 XPCD is a HP-4200 and requires current swings of less than 4 mA as a mark

and greater than 12 mA for a space. The output of the HP-4200 is a TTL signal which appears at pin #7 of the

chip.

Indicator Setup

15

Page 20

16

3.2.3 20 mA Passive Current Loop Input

In this configuration, an external voltage or current source is connected to a current switch in the sending

instrument. Data is transmitted as a current and is passed through an optical isolator. This current causes an LED

to emit light onto a photo transistor, which converts this light into a TTL signal. Current transmission can be

made over long distances and are quite immune from transient voltage or RFI/EMI noise. The distance a current

loop can transmit is limited by the voltage source available to the current loop and the speed of transmission

which data is sent. Normally a current loop should not send data at speeds great than 4800 baud.

A passive current loop means that the instrument which sends the data does not supply the voltage to power the

loop. The voltage to power the loop must come from an external power supply or receiver. This voltage can be a

small as 5 VDC to as much as 24 VDC. When the loop goes through an optocoupler, a drop occurs. This drop is

about 2 VDC. A current loop can power as many drops as there is voltage to power the loop. For example, if a

current loop is powered by 5 VDC, it can normally only drive two drops. If the same loop were powered by 24

VDC, it could power about 11 remote displays.

The EL232 XPCD can supply power to a passive current loop. This voltage supplies about 8 VDC for use in the

loop.

Determine that your indicator has a passive current loop and connect it as shown in Figure 3-7. Strip the wires

approximately 3/16" and insert them into the connector as shown. Tighten the connectors and test the tightness

by gently pulling on the wires.

J2

GND

PRINT

K4

K3

K2

K1

+5V

CL4 IN-

CL4 IN+

CL3 IN-

CL3 IN+

CL2 IN-

RS-232 (+)

RS-232 (-)

CLO OUT(+)

CLO OUT-

Note:

The serial output is not available when using this input type without board modifications. Consult the factory for

details.

CL2 IN+

CL (-)

CL1 (+)

Install this jumper

Figure 3-7. 20 mA Passive Current Loop Hookup

EL232 XCPD Installation Manual

Page 21

3.3 Configuration of the EL232 XPCD

J2

SW2

OPEN

1

2

3

4

GND

TxD

RxD

PB

PB6

PB5

PB4

RESET SWITCH

To configure the EL232 XPCD, you must know the following:

• Baud rate

• Indicator type

• Data format - RS232 or 20 mA current loop

Once this information is known, it is entered through SW1, the eight-position DIP switch on the upper left hand

corner of the CPU board, shown below:

8

7

6

SW1

OPEN

5

34

2

1

MICROPROCESSOR

+5

+5

MOSI

SCK

PA7/LD

GND

GND

RESET

2345678

1

9

J2

CL3 IN+

CL2 IN-

CL2 IN+

CL1 IN-

CL1 IN+

CLO OUT-

CLO OUT+

RS232 (-)

RS232 (+)

Enter the correct values from Table 3-2.

Baud Rate

Speed SW1-1 SW1-2

1200 On On

2400 Off On

4800 On Off

9600 Off Off

1

2

OPEN

3

4

SW2

111213 1415161718 19

10

K1

+5V

CL4 IN-

CL4 IN+

CL3 IN-

K2

K3

K4

TxD

RxD

PB

PB6

PB5

PB4

PRINT

GND

Figure 3-8. RS232 XPCD CPU Board

The power must be off when these v alues are changed.

If the power is on, press the

board to enter the new values (see Figure 3-9).

J1

2

3

1

117 VAC

GND

NEUTRAL

switch on the CPU

Reset

Table 3-2. Baud Rate Setting

Refer to Table 3-3 on page 18 for specific switch

settings for applicable indicators.

Figure 3-9. Reset Switch Location

Indicator Setup

17

Page 22

Indicator

Indicator Type SW1-3 SW1-4 SW1-5 SW1-6

Condec On On On On

General Freedom Off On On On

Electro 560 On Off On On

A n D Off Off On On

WI-110, WI-120 On On Off On

Toledo Off On Off On

Flexweigh On Off Off On

Analogic Off Off Off On

Masstron On On On Off

Fairbanks Off On On Off

Streeter Richardson On Off On Off

Cardinal 738 Off Off On Off

Generic Off Off Off Off

Table 3-3. Indicator Switch Settings

3.3.1 Loss of Signal Display

Press the Reset switch to enter new values into the

EL232 XPCD, or turn off the power, or wait

approximately 30 seconds and the EL232 XPCD will

reset itself.

The following tables illustrate switch settings for the

loss of signal display.

3.4 Serial Data Output

The EL232 XPCD comes standard with an active 20

mA current loop transmitter which echoes the serial

data received by the EL232 XPCD. This data is

echoed as a 20 mA loop regardless of whether the

input source was RS232 or current loop.

The output is active and supplies current from a

voltage source of approximately 8 VDC. The current

transmitter is an HP-4100 and can transmit data

cleanly at 9600 baud. The HP-4100 supplies mark

currents of >12 mA and space currents of <2 mA.

Certain scale industry remote displays and printers use

darlington type optocouplers as input devices.

Unbiased 4N33 type opto isolators can be turned on

by 2 mA. These are not true current loop receivers. If

a device which the EL232 XPCD is transmitting to

cannot properly receive the data, change the 4N33 to a

4N25 opto isolators and the problem will normally

disappear.

Figure 3-10 illustrates how to connect the current loop

output of the EL232 XPCD.

J2

GND

PRINT

K4

K3

K2

K1

+5V

CL4 IN-

CL4 IN+

CL3 IN-

CL3 IN+

CL2 IN-

CL2 IN+

CL1 IN (+)

RS-232 (-)

RS-232 (+)

CL(+) OUT

CL1 IN (-)

CL(-) OUT

18

Loss of Signal Display

Display SW1-7

Last data Off

- - - - - - On

Table 3-4. Loss of Signal Display

Input Signal Type

Interface SW1-8

RS232 On

20 mA Off

Table 3-5. Input Signal Type

Figure 3-10. 20 mA Active Current Loop Output

You can check the current loop output with a simple

jumper connected between pin J2-3and J2-4. The

LED on the CPU should flash on and off when data is

transmitted.

Note: When using a passive current loop input, the serial

output is not available. Consult the factory for additional

information.

EL232 XCPD Installation Manual

Page 23

4.0 EL232 XPCD Operation

Prior to powering up the EL232 XPCD, double check wiring and setup making sure all wiring is properly

terminated.

Once power is applied, the EL232 XPCD enters the power on clear mode. All status switches are read at this time

and the unit is configured for baud rate, indicator type, and input signal type. The EL232 XPCD display goes

through a power up sequence which can provide valuable information about the operating condition and setup of

the unit.

4.1 Lamp Test

The first display during power on clear is a lamp test.

This test lights all displays, decimal points, and

annunciators. Proper indication is “

8.8.8.8.8.8.” with

five illuminated LEDs above the main display.

Figure 4-1. EL232 XPCD LED Display

4.2 Software Revision

The software revision number which is in the EL232

XPCD is displayed. The display shows rEV 2.6 for

normal revision 2.6 program. This helps identify

specially modified software.

4.3 Current Baud Rate Setting

The EL232 XPCD next shows the current baud rate

setting it had read from switch SW1. The display

shows,

baud,

bAUd12 for 1200 baud, bAUd24 for 2400

bAUd48 for 4800 baud, or bAUd96 for 9600

baud.

4.4 Input Signal Type

The display shows rS232 for RS232 data setting or

C LOOP for current loop input. Refer to Section 3.1

for further information on setting the correct input

data type.

4.5 Indicator Type

Finally, the EL232 XPCD shows the indicator type

which the EL232 XPCD is receiving. This is

displayed as

number from 1 to 12. Refer to Table 4-1 for a

numerical list of indicator types.

Numeric Display Indicator Type

10 Fairbanks

11 Streeter Richardson 9000

12 Cardinal 738

16 Generic Format

From the power on clear sequence, the current status

of the display and the current setup information can be

verified. This can be done at any time by pressing the

reset switch (see Figure 3-9 on page 17) on the CPU

or by removing AC power from the unit.

Ind 1 where the 1 can be an indicator

1 Condec, UMC

2 General Freedom

3 Electroscale 560

4A N D Instruments

5Weightronix 110, 120

6Toledo Hi Speed data format

7 Flex-weigh DWM-4

8 Analogic

9 Masstron

Table 4-1. Numeric Indicator Type

EL232 XPCD Operation 19

Page 24

4.6 Receiving Data for the First Time

After the power up sequence, the EL232 XPCD synchronizes with the incoming serial data line and looks for

data to receive. If no readable data is received within a few seconds, the

display is lit and the display shows, “

- - - - - -”. This LED is also lit if transmission should stop for more than 8-10

seconds during normal operation.

SW1-7 selects the data displayed during a loss of signal state (Section 3.3.1). If SW1-07 is open, the last value

received is displayed continuously. If this switch is closed, the display again shows, “

is again received. This can be used to alert the operator that data on the display may not be valid. When the data

returns to normal, the display updats and the

NO SIG lamp goes out.

When communication is established, the current weight value is displayed. Decimal points are inserted into the

display as indicated by the meter. If the data format from the meter makes LB, Kg, Gross or Net status available,

the EL232 XPCD displays this information with the appropriate LED status lamps. Some formats do not make

this data available. In this case, the LEDs will not be illuminated.

NO SIG LED in the upper right of the

- - - - - -” until readable data

20 EL232 XCPD Installation Manual

Page 25

5.0 Appendix

CL4

4CL3CL3CL2CL2CL1CL1CLOCLO

2RS2

5.1 Troubleshooting

If any of the following conditions are observed:

• Suspect water or leakage in the enclosure

• The glass becomes scratched, cracked, chipped, or pitted.

•A sealing fitting is sheared off or damaged

• The door is hit by a vehicle or object

• If you notice or suspect any damage to the unit

Do the following:

• Clear area of all personnel and notify plant safety

• Shut down all power to the unit at the source and lock out

•When the area has been cleared of the hazard and plant safety has declared the area safe for workers to

enter, call your scale dealer

• Do not attempt to restart the unit until all damaged parts have been replaced and the unit has been tested.

The most common problems are indicator incompatability, mis-wiring, and mis-programming both in the

indicator and in the EL232 XPCD setup. Double check the output of the meter and make sure something is being

transmitted. Use an oscilloscope, printer, logic probe, or voltmeter to verify that the meter is sending continuous

data. Use a logic probe to check the signal on the EL232 XPCD CPU board to see if data is actually being

received. Connect the probe as shown below.

serial data

(TTL levels)

RESET

OPEN

SW2

1

2

3

4

Ground

J2

RS

Figure 5-1. Logic Probe Location

CL

5.2 Recommended Spare Parts

The following table consists of the recommended spare parts for EL232 XPCD, rev. 3.5 board sets.

RLWS Part Number Description Quantity

21036 Display board 1

21035 CPU board 1

16347 Serial transmitter chip 2

16348 Serial receiver chip 2

16445 Fuse .5A Slo-blo 1

22134 Display lens 1

Table 5-1. Recommended Spare Parts List

Appendix 21

Page 26

5.3 Specifications

Display:

High-intensity, red LED, 0.8” (20.3mm) high digits

Input Voltage:

117 VAC, 60 Hz

Amps:

40 mA

Weight:

Approximately 25 lb (11.3 kg)

Baud Rate:

1200, 2400, 4800, and 9600

Interfaces:

20 mA and RS232 standard. The EL232 XPCD

can communicate, as shipped, with twelve of the

most common scale indicator families currently

available. Please consult factory for model

numbers and interface requirements.

Warranty:

One year limited warranty

{(8.38)}

BASEPLATE

{(8.38)}

{(11.50)}

{(10.00)}

{(11.25)}

{(10.25)}

{(13.00)}

22 EL232 XPCD Installation Manual

Page 27

EL232 XPCD Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by

the Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects in

materials and workmanship for one year.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized

by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment

fails to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to

prevent electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a

publication, Protecting Your Components From Static Damage in Shipment, available from RLWS

Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was

not caused by accident, misuse, neglect, alteration, improper installation, improper repair or

improper testing; RLWS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other than RLWS or its

duly authorized repair agents.

•RLWS will have a reasonable time to repair or replace the defectiv e equipment. Buyer is responsible

for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

T

HESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION

RLWS NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS

REPAIR

ALL

OTHER CLAIMS TO WARRANTY.

S

HOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE SELLER FOR

WARRANTY

N

O TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO MODIFY THE TERMS OF THIS

WARRANTY

OFFICER

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER

AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO

OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND

CLAIMS.

SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN WRITING AND SIGNED BY A CORPORATE

OF RLWS AND THE BUYER.

© 2002 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

Appendix 23

Loading...

Loading...