Page 1

DWM-IV

Digital Weightmeter

Operator Manual

113873

Page 2

Page 3

Page 4

Page 5

Page 6

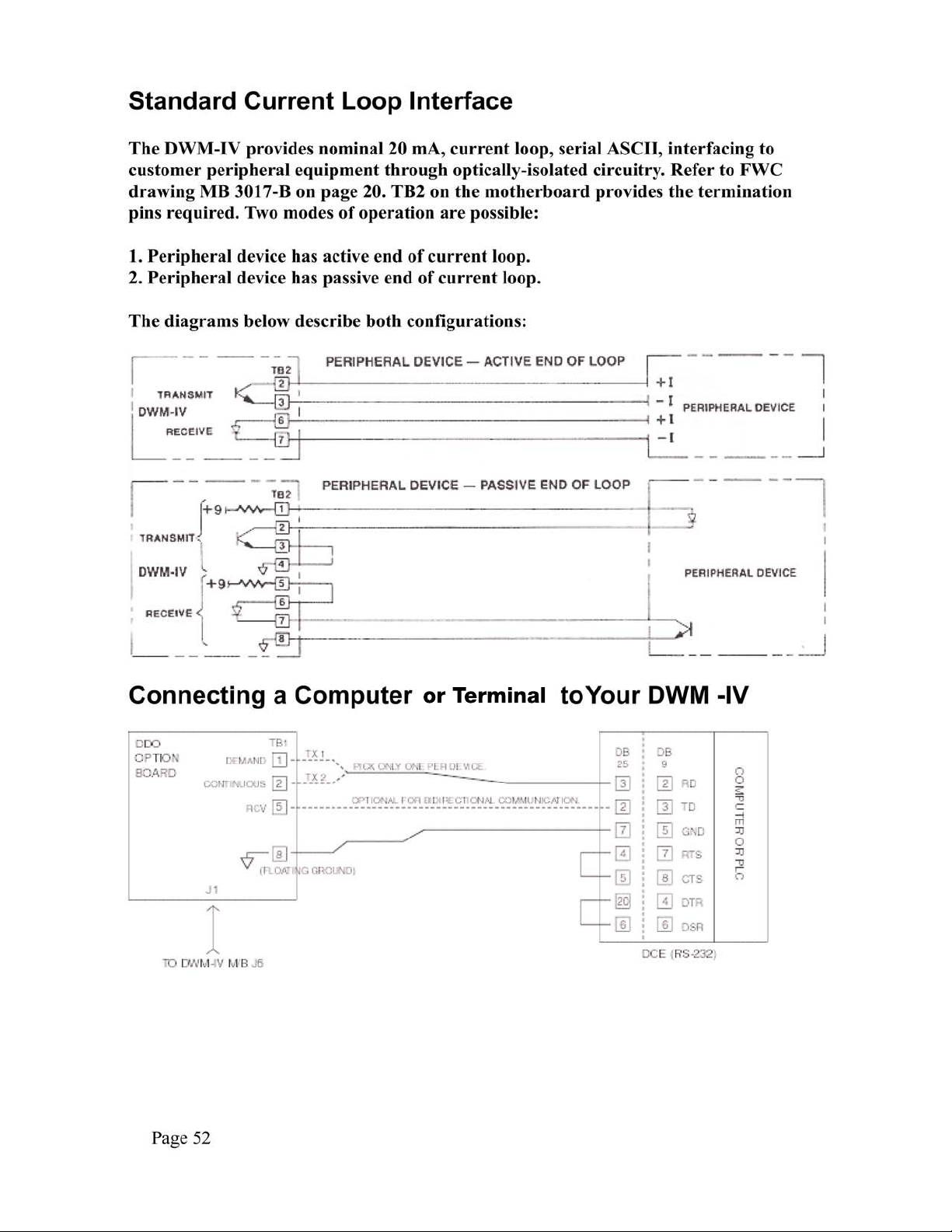

Data Output: Serial ASCII 20 mA current loop with selectable baud rates (15019.2K),

selectable auto or manual print, continuous data out, or bi-directional communication.

Remote Control Inputs: Zero, Tare, Net/Gross, Print. Requires voltage-free contacts.

Enclosure: NEMA-12 wall mount/dust-tight.

Options:

Outputs: Dual port serial RS-232, RS-422, RS-485, and/or 20mA current loop; Parallel

BCD; Analog 4-20mA or 0-5 VDC.

Time and Date: Battery backed up time and date with selectable 12 or 24 hour mode.

Setpoints: Up to six (6) single speed or three (3) two speed setpoints with Zero

Interlock and Fill Complete output.

Table Stand: Provides 60 degree angle mount stand for wall mount enclosure.

N4S Enclosure: NEMA-4 Stainless Steel watertight wall mount enclosure.

Custom Systems: Flex-Weigh offers full engineering support for customized systems.

Contact your local dealer for further details.

Specifications:

Keyboard: Sealed keyboard with tactile keys.

Display: 6 digits and (-) sign. Seven (7) segment, 0.5" high blue vacuum fluorescent

type, with annunciators for: function select, center zero, tare, net, pieces, F1, and F2.

Internal Raw Count: 100,000 counts maximum.

Display Resolution: 1 part in 10,000 maximum Legal for Trade, 1 part in 24,000

extended, 1 part in 100,000 maximum in high resolution mode.

Display Increments: x1, x2, x5, x10, x20, x50, x100.

Decimal Point Location: Selectable 14 places to the left.

A/D Conversion Rate: 15 updates per second.

Response Time: Zero (0) to full scale capacity, selectable to 0.5 to 4 seconds.

Display Rate: Selectable 0.25, 0.5, 1, 2, 5, 10, or 20 updates per second.

Page 4

Page 7

Over Capacity: Displays OLOADat 102% of Full Scale Capacity.

Center Zero: Light indication when scale is within +/-0.25 digit of center of zero (0).

Load Cell Excitation: 15 VDC, powers up to twelve (12) 350 ohm load cells.

Input Sensitivity: 0.6 to 12 microvolts per digit.

Accuracy: 0.01% of full scale or +/- one digit, whichever is greater.

Data Output: Serial ASCII 20 mA current loop with selectable baud rates (15019.2K),

selectable auto or manual print, continuous data out, or bi-directional communication.

Operating Temperature: -10 degrees C to +40 degrees C (+14°F to +104°F).

Humidity: Maximum: 95% RH non-condensing.

Power: 120 or 240 VAC, 5060 Hz, 25 watts.

Fuse: 1/4A @ 120 VAC, 1/8A @ 240 VAC.

Dimensions: 12" (30.48 cm) H x 10" (25.4 cm) W x 5" (12.7 cm) D.

Weight: 16 lb (7.25 kg).

Page 5

Page 8

Page 9

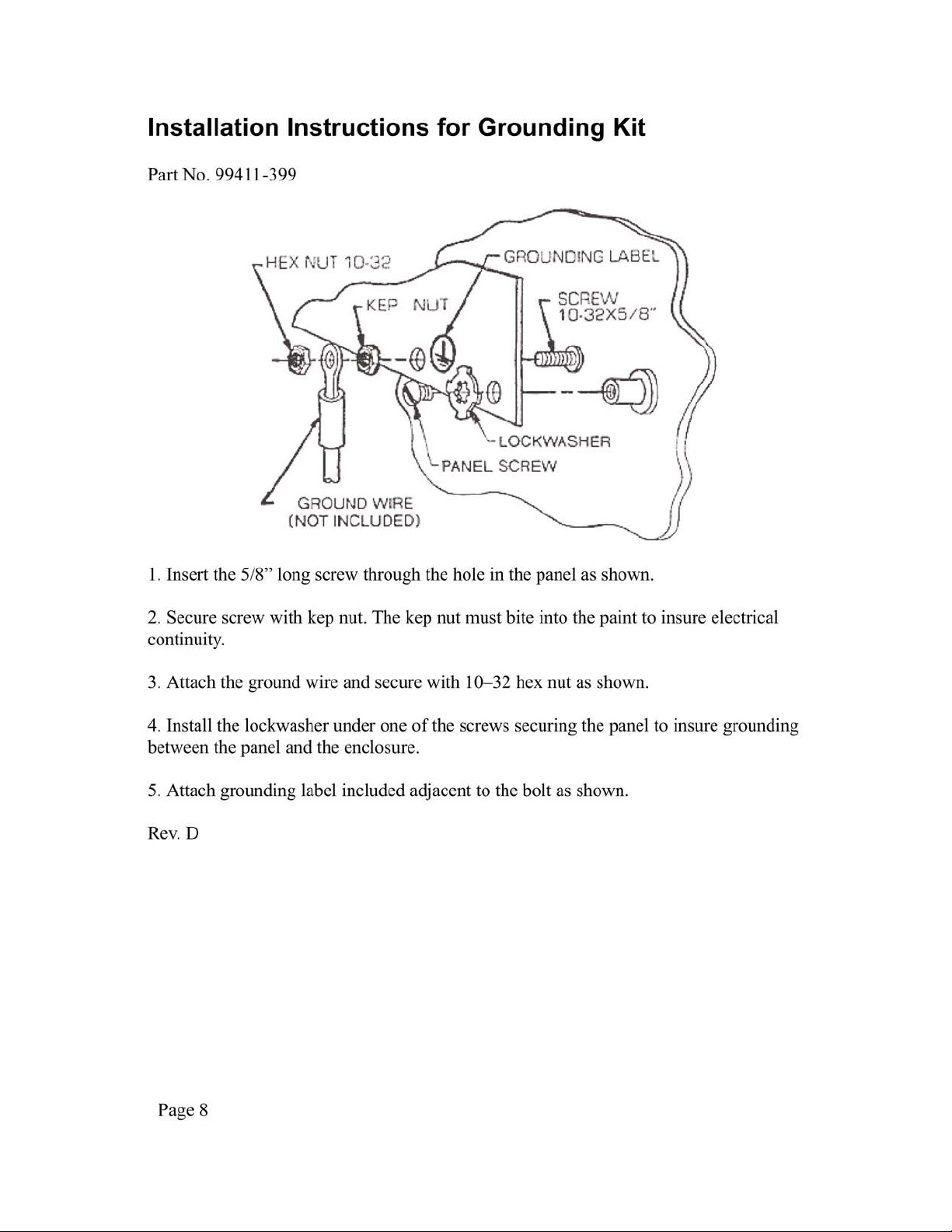

Installation Requirements

Maximum performance is guaranteed only when installation of the scale system is

performed by a qualified scale technician. For best performance, the AC mains supplying

the scale system must be an isolated circuit free from other loads and not in close

proximity to inductive or SCR controls.

WARNING: THIS SCALE MUST BE OPERATED FROM AN AC POWER SOURCE

THAT PROVIDES AN EARTH GROUND FOR THE SCALE CHASSIS TO ENSURE

SAFE OPERATION AND PROPER PERFORMANCE. THE POWER CORD IS THE

POWER DISCONNECT DEVICE. CARE SHOULD BE TAKEN NOT TO BLOCK

ACCESS TO THE OUTLET IN CASE OF AN EMERGENCY.

Unpacking and Inspection

Remove the weightmeter display from its shipping container. Discard the protective

materials. Do not plug the meter into an AC voltage source until completing the

inspection of the instrument. With a proper screw driver, loosen the screws holding the

lid clasps in place. Open the lid and visually inspect to make sure there are not signs of

shipping damage such as broken wires, loose components, or fractured printed circuit

boards. This visual inspection is necessary if a shipping claim needs to be processed.

Every care has been taken to minimize potential damage that could occur if rough

handling is experienced in transit.

Handbook 44 Requirements

The following applies to Model DWM-IV weightmeters used on Handbook 44

applications.

1) Wire seal provision is required on access lid.

2) Piece count feature must be disabled (Step F5.0 of SET-UP procedure).

3) RFI (Radio Frequency Interference) protection kit option is required in areas where

RFI is present.

Page 7

Page 10

Page 11

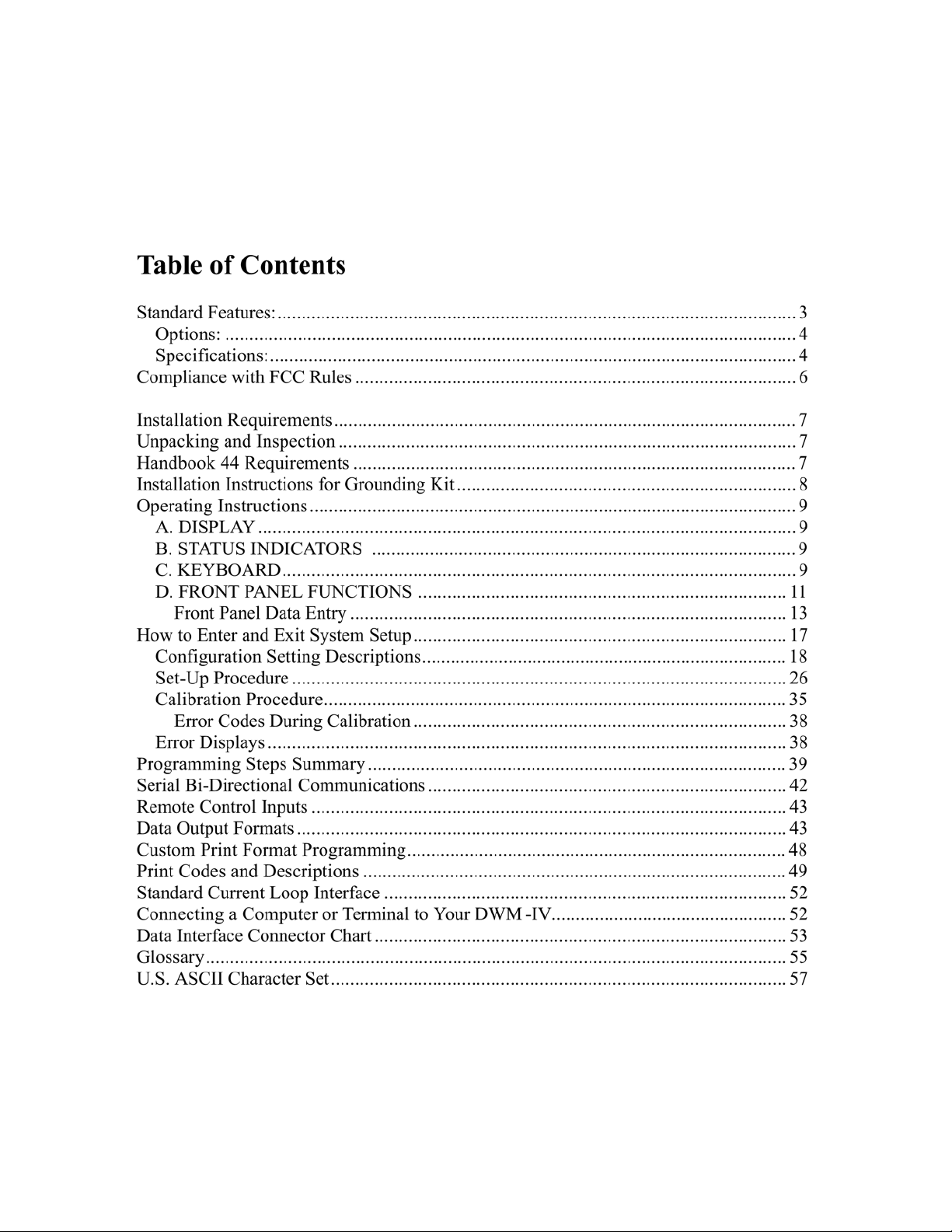

Operating Instructions

A. DISPLAY

The display indicates the arithmetic result of the analog signal derived from the scale

base. The display indicates: OLOAD at 102% of capacity and above.

B. STATUS INDICATORS

The DWM-IV illuminates a triangular arrow above the proper legend for current status of

the display. The status indicators are:

1. SEL - illuminated while accessing the front panel options.

2. ZERO - illuminated when the scale base is within +/- 0.25 increment of zero

3. TARE - when lit, indicates that a tare value is being displayed.

4. NET - when lit, indicates that a non-zero tare value is currently being used.

5. PIECES - illuminated when in the piece count mode to indicate that the display is

showing pieces instead of weight.

6. F1 - Future option. (not labeled on standard units)

7. F2 - Future option. (not labeled on standard units)

C. KEYBOARD

1. [Zero] Button: This button allows re-zeroing of the scale over a +/- 2% range of scale

capacity or full scale capacity (programmable). During set-up, the automatic zero tacking

may be disabled if desired. This button must be pressed for approximately two seconds to

capture zero.

2. [Tare] Button: This button is used to remove the container weight value from the

weight indication. When pressed with weight on the scale no motion present, this tare

value will be stored and subtracted from the gross weight to indicate a net weight display

of zero. Pressing the [TARE] button places the system in net weighing mode.

Page 9

Page 12

3. [Gross/Net] Button: If a tare has been entered, this button will alternately select

between the gross and net weight modes. If the tare has been cleared to zero, the DWMIV will automatically select the gross weight mode. This button will be inactive while the

tare value remains equal to zero.

4. [Print] Button: This button initiates a print cycle to an external peripheral device such

as a ticket printer or computer. The output format may be programmed during the set-up

procedure.

5. [Recall] Tare: The instrument is equipped with a key board to provide a means of

entering a known tare weight. Up to six (6) digits of digital tare may be entered up to the

full capacity. Entries greater than full capacity will be cleared to zero. The least

significant digit (LSD) is automatically rounded to conform to the pre-programmed

instrument LSD. Press the [RECALL TARE] button then a numeric button corresponding

to the tare register desired (if ten (10) tare look-up feature is enabled) and the [ENTER]

button. The previously displayed data will be shown. Enter the required value and press

[ENTER]. This value is then stored in memory. A non-zero value places the system in net

weighing mode.

6. [Select]: This button is used to access the pre-programmed front panel functions as

indicated on the corresponding buttons zero through nine.

7. [Clear]: Used to clear a mistaken entry while in one of the data entry modes.

8. [Enter]: This button is used to store data into memory and also to sequence through the

data entry procedure.

Page 10

Page 13

D. FRONT PANEL FUNCTIONS

TEST Allows the operator to test the integrity of the weight display by sequentially

lighting each segment of all digits, all segments, and each arrow indicator. These results

show that all drivers and displays operate in both the on and the off conditions.

PRESET The DWM-IV provides up to eight (8) outputs which may be used to control

solid state relays. The system may be configured for three (3) two-speed or six (6) singlespeed, cascaded setpoints. In addition, zero interlock and FILL COMPLETE outputs are

provided which, when used with additional, external hardware, may be used to simplify

batching operations. Enter the weight value desired for each preset starting with number

zero through to number three (3) or six (6). The zero interlock preset is number zero. If it

is desired to merely view the presets already in memory, simply press [ENTER] without

pressing any numeric buttons or [CLEAR]. The weight values will be displayed from

zero (0) to three (3) or six (6) then return to normal weight display mode.

DRIBBLE The value entered as the dribble amount is subtracted from the final

setpoint (PRESET-PREACT) and this amount is the fast feed cut-off setpoint. It

represents the amount of material desired to be filled at the slow rate. The values are

entered in the manner as described for PRESET above where number one (1) corresponds

to PRESET number one (1) above, etc. This function is only active if the two-speed

configuration has been selected.

PREACT Enter the value of weight that is to be subtracted from the preset value in

computing the final cut-off value for the output. This value represents the amount of inflight material.

T/D This function allows the operator to enter the current time and date for print-out

purposes. The time and date option must be installed and enabled for this feature to be

operative.

Page 11

Page 14

SUBTOTAL The DWM-IV contains ten (10) registers for weight accumulation. The

subtotal of all previously recorded weights or pieces may be recalled and/or printed using

this button. The totals registers remain intact after use.

TOTAL The totals may be viewed/printed as described in SUBTOTAL above with the

exception that after printing, the current total register is cleared to zero along with the

consecutive numbering register. The current register used for totalizing is selected by this

function.

ID The ID function allows the operator to enter up to seven (7) digits of numeric ID.

The current value of ID is displayed and may be changed by use of the numeric and

[ENTER] buttons.

CN The consecutive number may be viewed or changed using this button. The CN is

automatically cleared to zero by totalizing but may be initialized to any value by use of

the numeric buttons. The CN increments before a print cycle begins, as initiated by the

[PRINT] button.

PC WT This function allows the instrument to be used for piece counting by entering

the known weight per piece. This mode is automatically selected if the current piece

weight register is OTHER than zero. The front panel indicator for PIECES will illuminate

while in the pieces mode. Any of nine (9) different registers may be selected with

different piece weight factors.

Page 12

Page 15

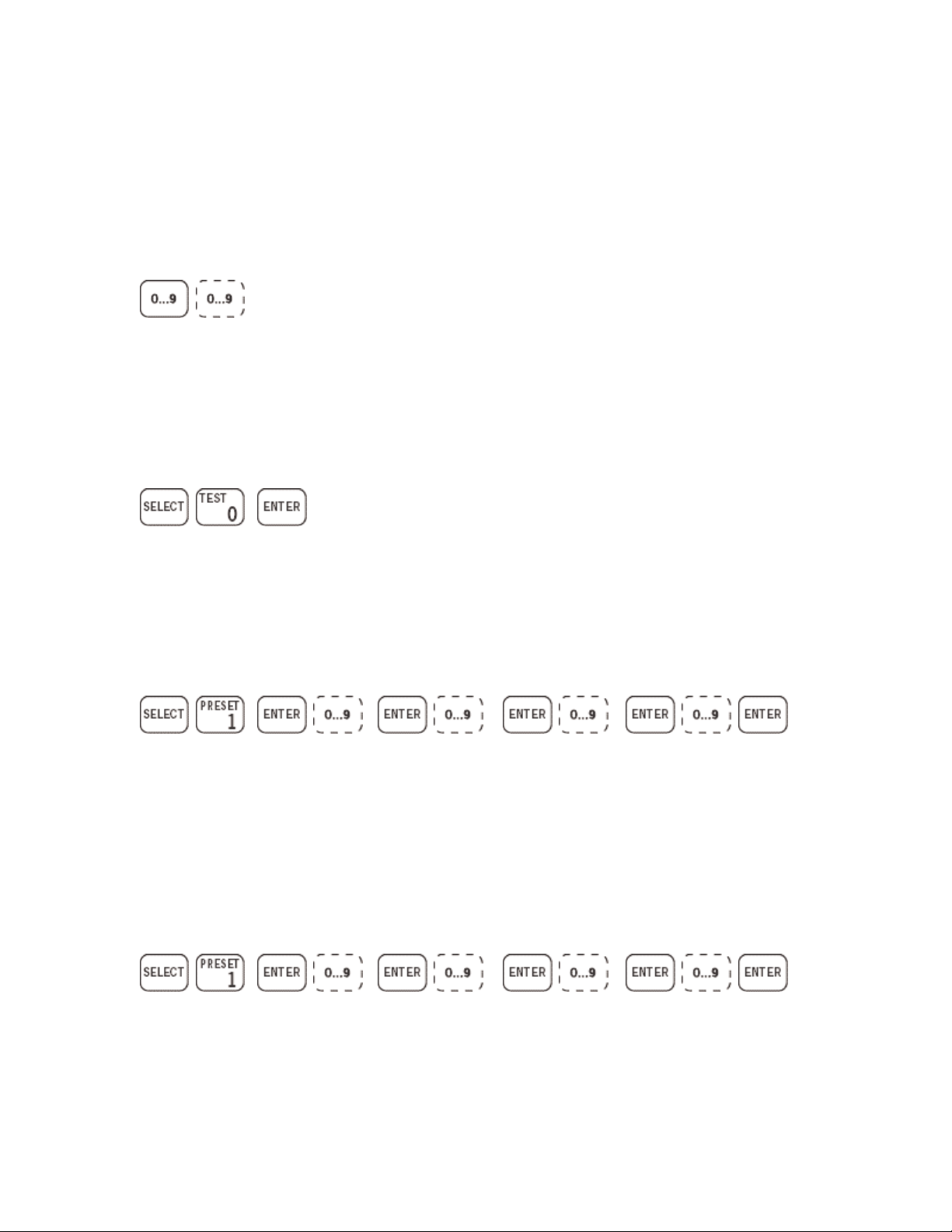

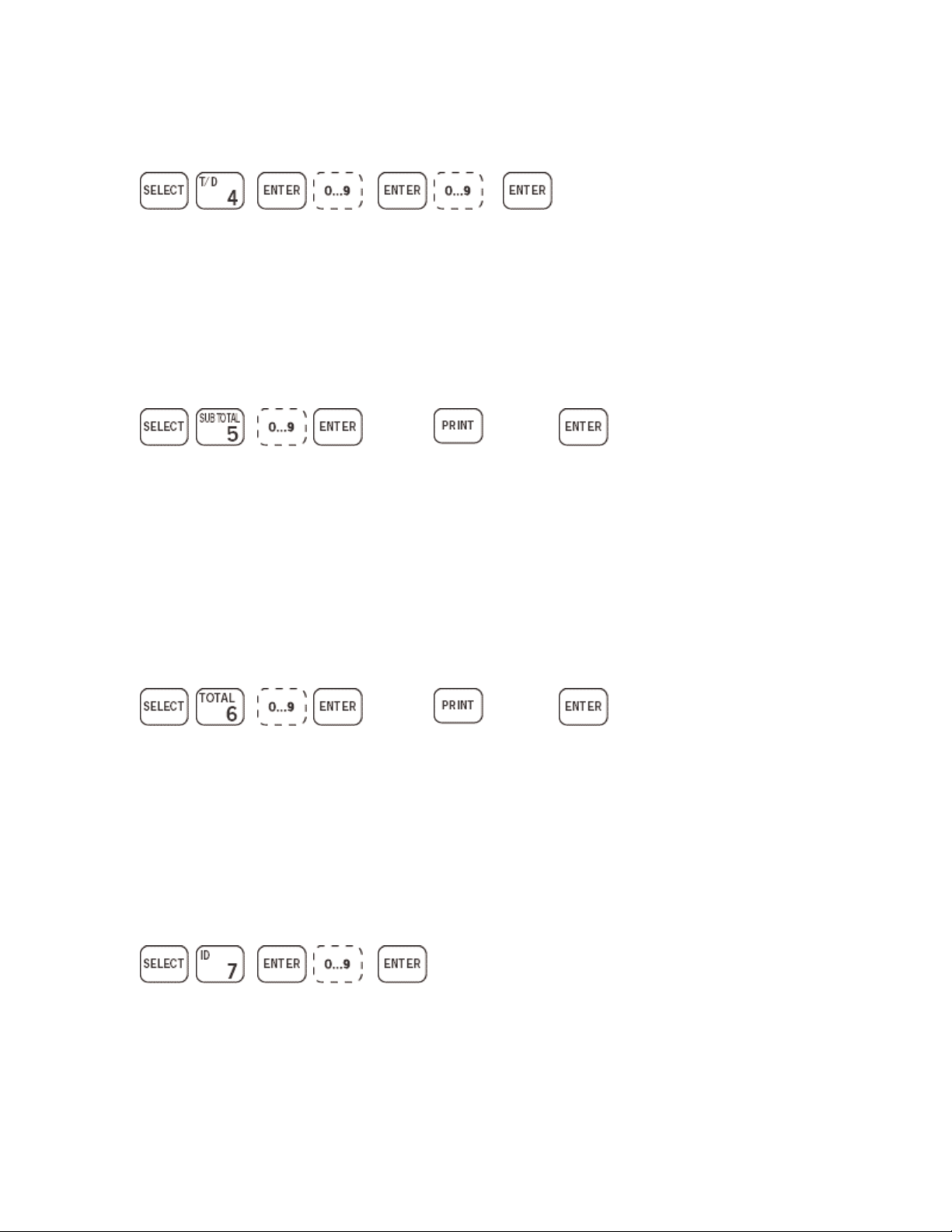

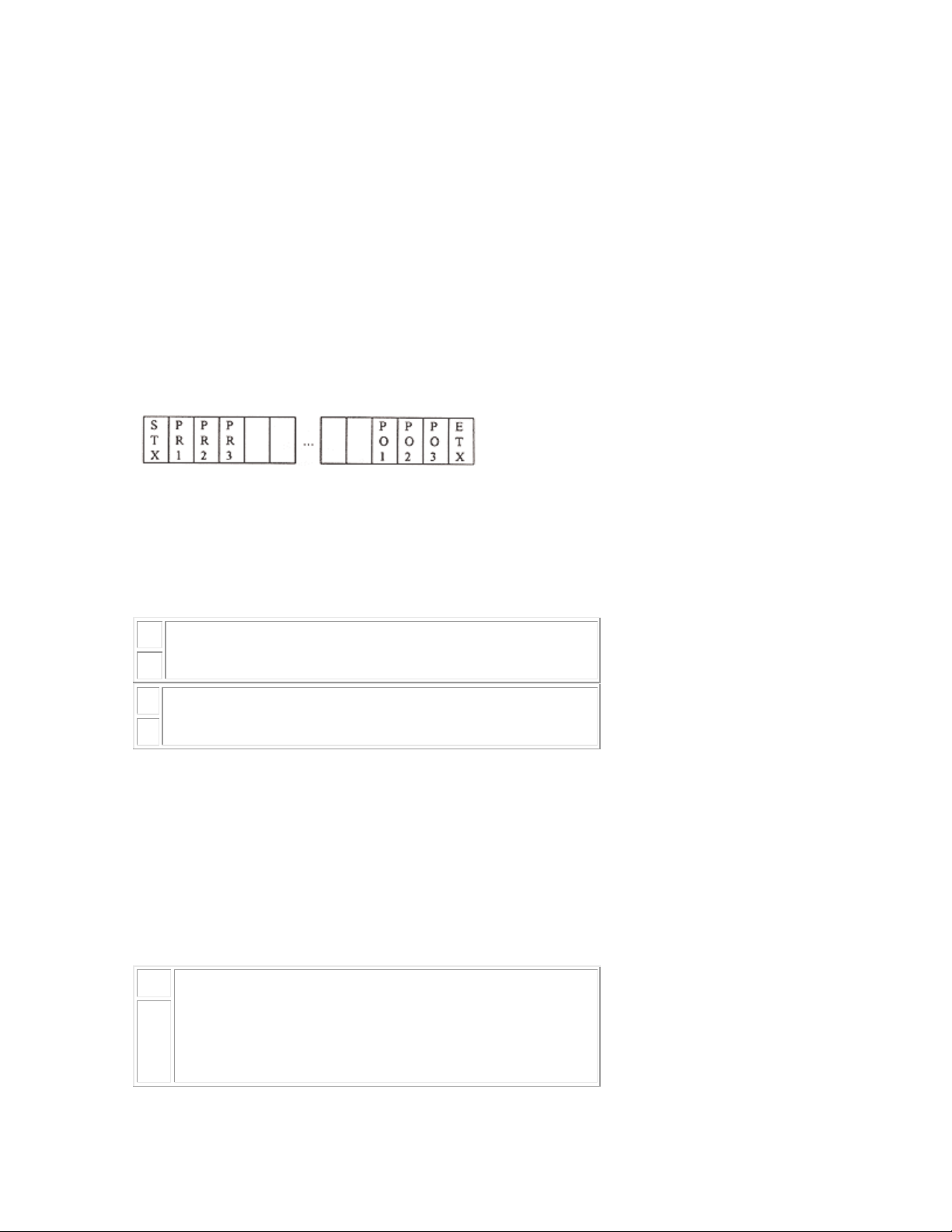

Front Panel Data Entry

Select the desired function from the examples given below. Then press

the buttons in the order shown from left to right. The following

symbols are used to indicate numeric button entry which may be

comprised of multiple numeric entries.

The dotted line symbol indicates that numeric entry at this point in the

sequence is not required unless the data are to be changed.

FUNCTION 0: TEST all display segments.

FUNCTION 1: PRESET entry of weight values. Two speed feed

enabled.

Preset

0

FUNCTION 1: PRESET entry of weight values. Single speed feed

enabled.

Preset

0

Preset 1 Preset 2

Preset 1

Preset

2-5

Preset

3

Preset

6

Page 13

Page 16

FUNCTION 2: DRIBBLE entry of weight values.

Dribble

1

FUNCTION 3: PREACT entry of weight values. Two speed feed

enabled.

Preact

1

FUNCTION 3: PREACT entry of weight values. Single speed feed

enabled.

Dribble

2

Preact 2

Dribble

3

Preact

3

Preact

1

FUNCTION 4: T/D Time and Date Entry - 12 Hour Mode.

Date Time

Page 14

Preact

2-5

Preact

AM-

6

PM

Page 17

FUNCTION 4: T/D Time and Date Entry - 24 Hour Mode.

Date Time

FUNCTION 5: SUBTOTAL Subtotal viewing or printing of selected

register.

or

Reg #

FUNCTION 6: TOTAL Total viewing or printing of selected register.

Also selects the current register.

Reg #

Prints

Subtotal

or

Prints

Total

Exits.

No

Printing

Exits.

No

Printing

FUNCTION 7: ID Numeric ID entry of up to seven digits.

ID

Page 15

Page 18

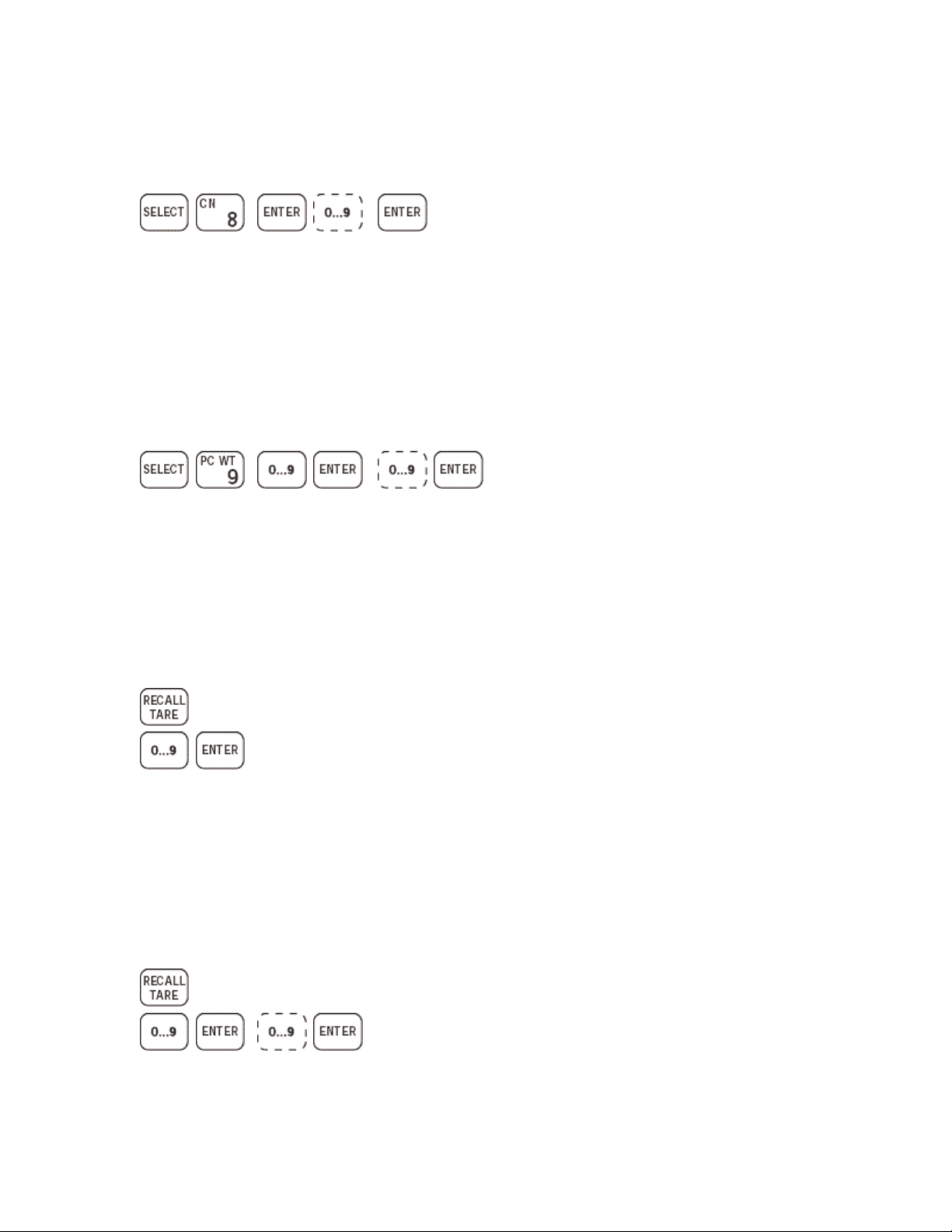

FUNCTION 8: CONSECUTIVE NUMBERING CN viewing or

changing.

CN

FUNCTION 9: PIECE WEIGHT Weight per Piece Entry and Piece

Mode Selection. Note: Selecting Register 0 will disable the piece

counting mode and return the display to the weight mode.

Pc Wt

Reg #

RECALL TARE: Keyboard Tare Entry of Known Tare Value.

Tare

Weight

RECALL TARE: Keyboard Tare Entry (Ten Tare Look -up)

Pc Wt

Page 16

Tare

Reg

Tare

Weight

Page 19

How to Enter and Exit System Setup

Locate the small dip switch block in the lower right corner of the mother board. Turn on

S1, the display should then show FSE F1.

From the FSE Fn display you may scroll forwards and backwards using the [TARE] and

[ZERO] buttons. When the page you want is displayed, press [PRINT] to accept and view

the first step in that page.

Example: If the setup switch S1 is turned on, the display will show FSE F1. Press

[ZERO] button. The display will show FSE F6, press [PRINT], display will show F6.0 n.

You may now change the current setting for F6.0 by pressing [TARE], accept the setting

by pressing [PRINT], or backup to F5.9 by pressing [ZERO].

You may also go directly to the page you wish to change by pressing the pa ge number

minus 1 on the keypad, after S1 is turned on. (Example: Operate S1. Display shows FSE

F1. Press 3. Display shows FSE F4.)

Upon completion of your changes you may exit and save without having to go all the way

to the end of the setup steps by pressing the [F1] button (on most units this will be an

unlabeled button under [RECALL/TARE], second down from the top, on the right hand

side). The display will go to FCd0. Press [PRINT] to save changes or press [TARE] to

change option to 1 or 2. Option 1 will discard all changes you have made (you can also

do this by turning off S1 at any time before the display shows FILEd. Option 2 (not

available on earlier software) is used to reset the factory defaults into the EEPROM

where all of the setup data is stored (U14 under the A/D board.).

Once you have selected which FCd option to use (usually 0 which is how it comes up

automatically) save your selection by pressing [PRINT] after about a second the display

should read FILEd, at this time you may turn off the setup switch S1 and return to the

weighing mode.

Function Select Enable Descriptions:

F1 Contains settings that control the overall operation of the scale, such as averaging,

update rate, motion detection, zero tracking, etc.

F2 Tare functions, setpoint options & powerup options are set here.

F3 Serial port parameters, enabling of print fields, and custom formatting.

F4 Serial data output formats, modes.

F5 Enables individual right hand keyboard functions.

Page 17

Page 20

F6 Calibration, capacity and increment size selection.

F7 Only available on custom systems.

Configuration Setting Descriptions

F1.0 Raw Counts Display

Enable Raw counts mode is used for diagnostic purposes and is also useful for

precalculating calibration settings. Once enabled, it will display the internal counts from

the A/D (analog/digital) converter which should fall between 250-100,000 counts on

standard software. If your display is showing top or bottom dashes it is already out of

range and raw counts will show the same indication. Check your wiring and millivolt

output from the load cell(s). This is the only configuration setting that does not have to be

written to permanent memory to take effect, just push [TARE] to set it to E, press

[PRINT] to accept the setting and turn off S1. The display will show all of the

annunciator arrows to show that it is in raw counts mode. To disable raw counts and

return to normal weighing, either repeat the above procedure setting to d, or simply

remove power. When you power the system back up raw counts mode will be disabled.

F1.1 Digital Averaging

Used to increase the stability of the weight readings. Higher settings will make the

display more stable in a noisy environment (wind, vibration, etc.), but will slow down the

display response. Lower settings will speed up the response but may cause excessive

motion and jitter in the display.

F1.2 Display Update Rate

This setting controls how often new readings are sent to the display. Higher settings will

make the display more responsive and give more of a scrolling number effect. Lower

settings will cause readings to appear to change all at once and may mask some

instabilities.

F1.3 Motion Detection

This controls how much the readings have to change to cause motion to be detected.

Motion detection is used to prevent printing, taring and zeroing of the scale when the

weight is unstable.

F1.4 Auto Zero Tracking Enable

F1.5 Auto Zero Tracking Width

Page 18

Page 21

Used to control the automatic ZEROING of the scale. It will automatically track small

drifts in weight such as caused by small amounts of debris, rain, or thermal drift.

Tracking width sets how much drift can be automatically zeroed out. Example, if you

have a truck scale with 20 lb increments and your tracking width is set to 3, anything that

weighs 60 lb or less will be zeroed out. This may not be desirable if you are using your

system for filling/batching and have a very slow fill rate or if you are trying to weigh

very small items (which is not recommended) as the tracking may happen faster than you

are filling and will cause it to appear that the scale is not working.

F1.6 - 2% Zero Range

Will prevent the scale from being Zeroed if the reading is more than 2% of the capacity

set in F6. Useful to prevent accidental re-zeroing and subsequent restarting of batch

systems when a batch is already being processed.

F1.7 Right Hand Keyboard Enable

Turns on/off the right hand side of the keyboard. Has no effect on the four (4) function

buttons under the display.

F1.8 Output Options

Controls the function of the J4 connector on the mother board. Should be disabled if not

used as it will slow down the system.

F1.9 High Resolution Mode

Allows you to bypass the normal four (4) raw counts per digit requirement that would

limit you to about 24,000 display units. You should not use this unless necessary as

neither the internal circuitry of the A/D board nor the load cells connected to it were

designed for such extremes.

F2.0 Tare Enable

Controls whether or not the front panel [TARE] button will operate. The tare function

should be used to remove an empty container weight without having to zero the scale.

When the [TARE] button is pushed the scale will enter the tare weight automatically and

switch to the net mode. You can switch between the gross mode and net mode using the

[GROSS/NET] button.

F2.1 Tare Interlock

Prevents the tare from being cleared if the scale is not at zero. Used mostly to prevent the

accidental clearing of the tare value while it is still in use.

Page 19

Page 22

F2.2 Auto Clear Tare

Causes the tare value to be cleared automatically when the scale returns to zero. Use this

to force entry of a new tare weight for each container being used (such as in a recycle

center application, where you have multiple bins).

F2.3 Ten Tare Look -up

Enables the storage of up to ten (10) tare values. You can use this to store the tare values

for several containers and retrieve them by register number as needed.

F2.4 Battery Back-up Enable

Prevents values in the random access memory from being cleared by a power-up

sequence. This consists of ID numbers, Consecutive Numbers, tare values, preset,

dribble, preact, totals, etc. Revision D and higher mother boards have a 24-hour back-

up circuit built-in. This can be extended to approximately ten (10) years on all mother

boards with an addition of a time/date module.

F2.5 Stand-by Mode on Power-up

Will cause the display annunciator arrows to light upon power-up. The display will be

disabled until either the [ZERO] or [TARE] buttons are pressed. Required by Weights

and Measures in some areas to show that a power failure has occurred.

F2.6 External Gross/Net Enable

When enabled the front panel [GROSS/NET] button will not operate. The system will

instead take an input (contact closure) from TB1-3 of the mother board. Unlike the front

panel switch this input is closed for net and open for gross.

F2.7 Two-Speed Feed

Part of the preset function, enables the [DRIBBLE] button on the front panel. The value

in the dribble will be subtracted from the preset, and used to operate the two speed relay

function. If enabled there are three (3) presets, disabled there are six (6).

F2.8 Sequential Feed

Controls how the output relays (connected to J7) operate during two-speed feed

operation. When disabled, both the slow and fast feed relays are energized initially. The

fast feed relay is de-energized when the weight reaches the preset minus the dribble

value. The slow feed relay is de-energized when the preset weight minus the preact is

reached.

Page 20

Page 23

When this setting is enabled, only the fast feed relay is initially energized. The fast feed

relay is de-energized and the slow feed relay is simultaneously energized when the

weight reaches the preset minus the dribble value. The slow feed relay is de-energized

when the preset weight minus the preact is reached.

F2.9 Invert Relays

If enabled the On/Off function of the output relays (J7) is reversed. The relays will be off

below the presets and turn on as they are reached. Exception: relays K7 and K8 (fill

complete and zero interlock) are not affected by this setting.

F2.A Parallel Feed

Allows presets to operate independently of each other. In this mode presets can be set to

any value. It is not necessary for each preset to be of a higher value than the one before it.

Each output will operate as if it were the only one. If disabled the outputs operate

sequentially. First preset one (1) and then preset two (2), then preset three (3), etc. The

value of each preset must be higher than the one before it for the system to operate

properly.

F3.0 Baud Rate

Used to set the baud rate (speed) of all serial ports. Serial data is available at TB2 and J6

on the mother board. This must be set the same as the device to which it is connected.

F3.1 Parity

The checksum bit used in serial communication. It can be even, odd or none. This is also

where you would set the number of data bits (7 or 8). This must be set the same as device

to which it is connected.

F3.2 Checksum

This checksum is for an entire data stream (one line of print, etc.) as opposed to parity

which is for one character. It is used during communications to verify that the received

data contains no errors.

F3.3 Delay After Carriage Return/Line Feed

Used to cause the system to pause after a carriage return. Needed with some devices to

allow the data which was just sent to be processed (such as some older printers without

buffering). If not needed set to 0 as it slows down the system.

Page 21

Page 24

F3.4 Consecutive Number Print

F3.5 ID Print

Controls whether or not these items will be included in the data sent out of the serial port

(such as to a printer).

F3.6 Negative Print Enable

Allows printing of negative weight readings. This is not allowed in Legal for Trade

applications.

F3.7 - 24-Hour Clock

If enabled and you have a time/date module, all times will be in Military Time (24

hour). If disabled, times are 12 hour AM/PM.

F3.8 Preamble/Postamble/Custom Formatting

Note: When this step is entered, F3.8 is not displayed. The display advances

immediately to the preamble entry field, FF FF FF.

This is used with the serial ports. It allows you to add characters to the beginning and

ending of the data stream. For example, this can be used to cause a printer to reset or

change the print size at the beginning of a print, and reset, cut-off or paper release at the

end of a print. Only three (3) preamble and three (3) postamble characters are allowed.

All preamble and postamble values are in hexadecimal (base 16, 0-9, A-F). If not used

they should be set to FF. Note, that if custom print formatting has been enabled in

F4.7 or F4.8 custom print formatting will begin after the postamble has been entered.

All custom print formatting is done in decimal (base 10, 0-9). Custom print formatting

consists of two (2) pages. The first is used for normal print output (F4.7) and is ended by

the first 255. The second is used for totals printing (F4.8) and is ended by the second

255.

F4.0 Print Mode

Controls how prints are initiated. 1 is the normal setting and will latch the request for

print from any input (front panel [PRINT] button, contact closure TB1-1, print command

from bi-directional interface) and print when stable weight data is available as per F1.3.

2 will only print if the weight data is stable as per F1.3 at the time the request is made.

3 is autoprint and will print based on F1.3, F4.2 and F4.3 without an external request.

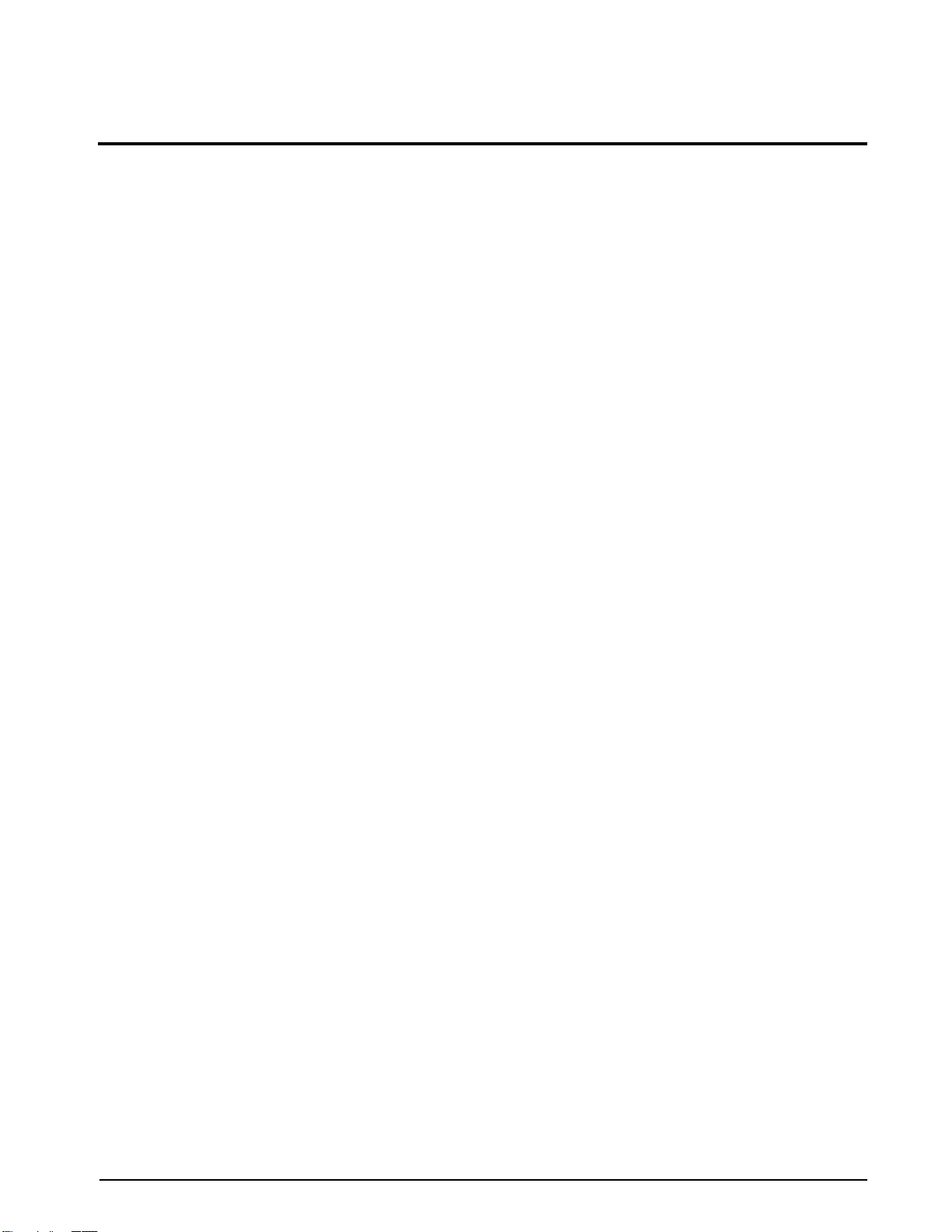

Print data is available on TB2 of the mother board or from channel 1 (demand) of DDO

(dual-data output) option board which, if installed, is connected to J6.

Page 22

Page 25

F4.1 Continuous Data Format

Selects the data format used for continuous data output. Normally used for remote

displays and scoreboards and in some computer applications. This data is available from

TB2 of the mother board and from channel 2 (continuous) of the DDO (dual-data

output) option board which, if installed, is connected to J6. Note, that if both demand and

continuous data are used the data on TB2 will contain both data streams and may cause

errors. Therefore, if both demand and continuous data are to be used it is recommended

that they both be connected to the DDO board. If this function is not used, disable it as

it will slow down the system.

F4.2 Weight Change Percentage

Used with the auto-print function in F4.0. Specifies the percentage of change based on

full capacity (as set in the calibration procedure (F6)) necessary to rearm the auto-print.

For example, if your scale has a capacity of 100,000 lb and F4.2 is set to 15%, a weight

change of 15,000 lb would be required to rearm the auto-print.

F4.3 Minimum Print

Used with the auto-print function in F4.0. Sets the number of increments (as set in F6.1

and F6.2) above zero required before the auto-print is allowed to function. For example,

if F6.1 is set to 20 and F6.2 is set to 0 and F4.3 is set to 30 then the auto-print will

not operate until the weight on the scale exceeds 600 lb. This would be useful on a truck

scale to prevent prints occurring when people walk across the scale.

F4.4 Bi-Directional Communications

Any function that can be performed from the keyboard can be performed through the bidirectional interface. Connection to this interface is provided on TB2 on the mother board

(in current loop) If a current loop device is not available and RS232 is needed then a

DDO option board must be installed and connected to J6 on the mother board and the

built in current loop input port must be disabled by cutting JP1 located just below J3 and

to the left of J6 on the mother board. The response rate on this function is very low. Send

the data as slowly as possible to avoid errors. Disable this function if not used, as it may

pick up random noise.

F4.5 Weight Data Format

Controls the way weight data is sent out to the serial ports. Setting 0 {Displayed weight

only} will send whatever weight is currently displayed whether it be gross or net. Setting

1 {Single line gross/tare/net} will send a gross/tare/net string with only one (1) CR/LF

at the end. If the display is in the net mode, this will put all three (3) items on one (1) line

(if there is room. See printer for more information). Setting 2 {Multiple line

gross/tare/net} will send a gross/tare/net string with a CR/LF after each item. If the

display is in the net mode, this will put each item on its own line. Setting 3 {Status

Page 23

Page 26

weight and tare} should be used when communicating with a computer. It contains

information on the current modes and status of the system sufficient to compute the

gross, tare and net and whether the scale is in gross or net mode.

F4.6 Time and Date Format

Controls the order in which time and date is printed.

F4.7 Print Format

Controls the order print data items are sent out to the port.

F4.8 Total Format

Controls the order totals items are sent out to the port.

F4.9 Weight Accumulation

Causes a running total based on displayed weight to be maintained. There are a total of

ten (10) registers that can be used to store totals. To view a current total without clearing

it or to select a new accumulation register use the sub-total function. To view and clear

totals use the total function. Note: You dont have to use the same total and sub-total

registers, you can total one while accumulating to another.

F5.0 Piece Weight Enable

Enables the front panel [PC WT] button. This function is used for counting. You are

given nine (9) registers in which you store weight values for single items. When a register

is selected the weight on the scale is divided by the value in the register and the number

of items is displayed. To turn this function off and return to the normal weighing mode,

set the register to 0. Note, that this counting function is limited to display resolution

and will not be as accurate as a dedicated counting scale it is provided for convenience

only. This mode must be disabled in Legal for Trade applications.

F5.1 Consecutive Number

Enables the front panel [CN] button. This allows you to view and set a consecutive

number which may be printed. It will automatically be incremented by one each time a

print is performed.

F5.2 ID Number

Enables the front panel [ID] button. This allows you to view and enter ID values, used

only for printing.

Page 24

Page 27

F5.3 Total/SubTotal

Enables the front panel [TOTAL] and [SUBTOTAL] buttons. This allows you to view

and clear totals data.

F5.4 Time and Date

Enables the front panel [T/D] button. Allows you to set the time and date.

F5.5 Presets

Enables the front panel [PRESET], [PREACT], and [DRIBBLE] (if F2.7 is enabled)

buttons. Allows setting of set points. This includes the zero interlock value which is

displayed as set point 0 (this value should never be set to 0, and should always be less

than the first set point). Any unused set points should be set to 0. Set point outputs are

provided on J7 of the mother board. These outputs are TTL compatible. If other voltage

levels are needed a solid-state opto-coupled relay board is available as an option. Specify

AC or DC output and voltage level when ordering.

F5.6 Recall Tare

Enables the front panel [RECALL TARE] button. This button allows you to view the

current tare value and change it if necessary. If F2.3 is enabled it also allows you to select

the current register being used. This is the button you use to enter keyboard tares. Both

the [TARE] and the [RECALL TARE] buttons store their values in the same register.

F6.0 Weight Units Used for Printing

Controls the weight unit abbreviation used in printing and has no effect on the display.

For example, if the scale display shows 100 and you press [PRINT] you would get 100

lb on your printout if F6.0 is set to 0 and 100 TONNE if F6.0 is set to 4. Note,

that no units conversion takes place; only the unit name is changed.

F6.1 Increment Size

Sets the count-by size used for displaying weights. For example, a setting of 20

would allow a minimum display of 20 and would count by 20. Note, this leaves a dead

zero and if you set a decimal point position the dead zero will remain.

F6.2 Decimal Position

Sets where the decimal point will be. Example, if you want an increment size of .002

set F6.1 to 2 and F6.2 to 3. Note that increasing the decimal position by one will

increase the number of counts displayed by 10 times. Maximum display resolution is

Page 25

Page 28

normally approximately 20,000 counts. To compute the number of counts divide the set

capacity by the increment size.

F6.3 Enter Cal Mode

This is how you calibrate the scale. Enable this and continue on to F6.4. If you do not

enable it you will advance to CAL d (calibration done) and the calibration will be

unchanged and you will exit from set-up mode.

F6.4 Linearity

Allows you to correct for small linearity errors in the middle of the weight range. This is

not allowed in Legal for Trade applications. If not used, this should be set to 0 if set

to -0, linearity will not be affected but you will be required to place full capacity

weight for calibration.

Set-Up Procedure

Place the internal CAL switch (S1-1) to the ON position. The scale must be configured

before operation by programming the needed parameters. Use the following front panel

switches to view and/or change existing data values:

[ZERO] Used to scroll backward through the programming sequence steps.

[TARE] Used to scroll forward through the programming sequence steps when in

function select mode and to sequence through available choices of individual functions.

[PRINT] Used to accept displayed data then to advance one step in the programming

sequence.

[CLEAR] Used to return to the Function Select Enable portion of the SET-UP procedure.

[F1] Used to advance to the end of the SET-UP procedure to save or discard the changes

entered. This button is not labeled and is located below the [RECALL TARE] button.

FSE Function Select Enable Selects the starting function group to be programmed. Use

[ZERO] and [TARE] buttons to move back and forth through this menu. Press print to

enter that section at the first item.

Choices: F1, F2, F3, F4, F5, F6 (F7 on some custom systems)

FSE F1

F1.0 Raw Counts Display Enable

d - Show normal counts on display.

Page 26

Page 29

E - Display the internal raw counts.

F1.1 Digital Averages

Number of A/D conversions which comprise the running average.

Choices: 1, 2, 4, 8, 16, 32

F1.2 Display Update Rate

Number of display updates per second.

Choices: 20, 10, 5, 2, 1, 0.50, 0.25

F1.3 Motion Limit in Digits

Select the width of the motion window by use of the TARE key. A selection of d will

disable the no-motion requirement for use by the zero, tare and print functions.

Choices: 0.5, 1, 2, 3, 4, 5, 6, d

F1.4 Auto zero tracking Enable

d - AZT disabled.

E - AZT enabled.

F1.5 Auto zero tracking width

Number of digits over which zero will track.

Choices: 0.5, 1, 2, 3

F1.6 Two Percent Zero Range Enable

d - Zero active at any weight.

E - Zero active to +/-2% of capacity about zero.

F1.7 Key Functions Enable

d - All right-hand keys disabled.

E - All key functions enabled.

Page 27

Page 30

F1.8 Output Options

d - Neither of the following options installed.

1 - Analog output card installed.

2 - BCD output card installed.

F1.9 High Resolution Enable

d - Minimum four raw counts per digit.

E - Minimum one raw count per digit.

FSE F2

F2.0 Tare Enable

d - Tare disabled.

E - Tare enabled.

F2.1 Tare Interlock

d - Tare may be changed at any weight indication.

E - Weight must be at zero to clear tare.

F2.2 Auto Clear Tare

d - Not Active.

E - Tare will automatically clear when indication returns to less than 10 positive digits of

zero and no motion.

F2.3 Ten Tare Look -Up

d - Provides single tare register.

E - Enables ten register tare look-up.

F2.4 Battery Option Enable

d - Battery backed option not installed.

E - Battery backed option installed.

Page 28

Page 31

F2.5 Enter Stand-By Mode on Power-Up Enable

d - Weight indication appears after display test.

E - Weight display will be disabled and all status indicators will be on until zero or tare

button is pressed.

F2.6 External Gross/Net Enable

d - Front panel gross/net switch active.

E - External gross/net input determines the mode of weight.

F2.7 Two Speed Feed Enable

d - Single speed outputs (six presets).

E - Two speed feed active (three presets).

F2.8 Sequential Feed Enable

d - Relays act in parallel fashion; both fast and slow relays energize below preset.

E - Relays act in sequential fashion; fast relay energizes, then slow relay energizes.

F2.9 Invert Relays Enable

d - RLY1 through RLY6 non-inverted output.

E - RLY1 through RLY6 inverted output. RLY7 (Fill Complete) and RLY8 (Zero

Interlock) remain as before.

F2.A Parallel Feed Enable

d - Relays operate in sequential order.

E - Independent action of relay output.

Page 29

Page 32

FSE F3

F3.0 Baud Rate Selection X100

Select the desired BAUD rate according to the chart. Older DDO boards have a limited

rating on the current loop ports of 1200 BAUD. If Continuous Data output is selected,

BAUD rate should be 2400 or greater.

Choices: 192, 96, 48, 24, 12, 6, 3, 1.5

F3.1 Parity Selection

d - 7 Bits, No Parity.

1 - 7 Bits, Even Parity.

2 - 7 Bits, Odd Parity.

8b - 8 Bits, No Parity.

8be - 8 Bits, Even Parity.

8bo - 8 Bits, Odd Parity.

F3.2 Checksum Transmit Enable

d - No checksum

E - Checksum transmitted, prior to CR-LF, as the 2s compliment of previously sent

characters.

F3.3 Delay After CR-LF

The amount of delay, after a carriage return or line feed is transmitted, in seconds.

Choices: 0, 0.1, 0.2, 0.5, 0.75, 1.0, 1.5

F3.4 Consecutive Number Print Enable

d - Disable the printing of the CN.

E - Enable the printing of the CN.

Page 30

Page 33

F3.5 ID Print Enable

d - Disable the printing of the ID.

E - Enable the printing of the ID.

F3.6 Negative Print Enable

d - Disable printing of negative weights.

E - Enable printing of negative weights (non HB44).

F3.7 24 Hour Clock Enable

d - 24 hour clock disabled (12 hour with AM/PM).

E - 24 hour military time enabled.

F3.8 Preamble Characters

xxxxxx Enables the user to define up to three characters to be sent at the beginning of a

print. The characters are entered in hexadecimal. A value of FF is not transmitted. The

front panel keys are re-defined during this step as follows:

ZERO - Decrements current digit.

TARE - Increments current digit.

GROSS - Selects next digit to the right.

PRINT - Accepts displayed value and advances to next step.

xxxxxx Postamble Characters

Enables the user to define up to three characters to be sent at the end of a print as above

for Preamble.

FSE F4

F4.0 Print Mode

d - Print output disabled.

1 - Print button latches Print Request. Printing will occur when motion ceases and scale

positive.

Page 31

Page 34

2 - Print will occur if not in motion and positive at the time Print button is pressed.

3 - Auto print after motion and positive weight is above value specified in F4.3 below

and change greater than the value specified in F4.2 below has occurred.

F4.1 Continuous Data Format

d - Continuous output disabled.

1 - Status, weight, and tare data sent.

2 - Z660 Scoreboard output.

3 - Remote display, RD-IV, output.

4 - Straight ASCII output only with preamble and postamble sent.

F4.2 Weight Change Percentage

The following values specify the percentage change of Full Scale Capacity before the

auto print latch is re-armed.

Choices: 5, 10, 15, 20, 25%

F4.3 Minimum Print

Digits above zero before auto print is latched.

Choices: 0, 10, 20, 30

F4.4 Bidirectional Communications

d - Bidirectional communications disabled.

1 - Bidirectional communications to customer computer enabled and configured for halfduplex operation. Information sent to the weigh meter is not echoed.

F4.5 Weight Data Format

0 - Displayed weight only.

1 - Single line Gross, Tare, Net.

2 - Multiple line Gross, Tare, Net.

3 - Status, Weight and Tare.

Page 32

Page 35

F4.6 Time/Date Print Format

d - Time/Date printing disabled.

1 - Time then Date printed.

2 - Date then Time printed.

3 - Time only printed.

4 - Date only printed.

F4.7 Weight, Time/Date, ID and CN Print Format

0 - Weight, ID, Time/Date, CN

1 - ID Time/Date Wei ght, CN

2 - ID Time/Date, CN Weight

3 - ID Time/Date CN Weight

4 - Time/Date ID CN Weight

5 - Time/Date ID Weight, CN

6 - ID, Time/Date, CN Weight

7 - ID Time/Date CN, Weight

C - Custom Weight Print Format Enable

F4.8 Total, Time/Date, ID and CN Print Format

0 - Total, ID, Time/Date, CN

1 - ID Time/Date Total, CN

2 - ID Time/Date, CN Total

3 - ID Time/Date CN Total

4 - Time/Date ID Total CN

5 - Time/Date ID Total, CN

Page 33

Page 36

6 - ID, Time/Date, CN Total

7 - ID Time/Date CN, Total

C - Custom Totals Print Format Enable

F4.9 Weight Accumulation Enable

d - Disable weight accumulation and print out.

E - Enable weight accumulation of all previous displayed weights printed.

FSE F5

F5.0 Piece Weight Enable

d - Piece Weight entry disabled.

E - Piece Weight entry enabled.

F5.1 Consecutive Number Enable

d - Consecutive Number function disabled.

E - Consecutive Number function enabled.

F5.2 ID Number Enable

d - ID Number function disabled.

E - ID Number function enabled.

F5.3 Total-Subtotal Enable

d - Total and Subtotal functions disabled.

E - Total and Subtotal functions enabled.

F5.4 Time/Date Enable

d - Time/Date entry function disabled.

E - Time/Date entry function enabled.

Page 34

Page 37

F5.5 Presets Enable

d - Preset, Dribble, and Preact disabled.

E - Preset, Dribble, and Preact enabled.

F5.6 Recall Tare Enable

d - Recall Tare entry disabled.

E - Recall Tare entry enabled.

Calibration Procedure

FSE F6

F6.0 Weight Units used for Printing

d - No weight units printed.

0- Lb

1- kg

2- g

3- Ton

4 - Tonne (metric ton)

5- oz

6 - oz troy

F6.1 Increment Size

Least significant digit increment size.

Choices: 1, 2, 5, 10, 20, 50, 100

F6.2 Decimal Position

Display decimal position from none to four places to the left.

0 - No decimal

Page 35

Page 38

1- .X

2 - .XX

3 - .XXX

4 - .XXXX

F6.3 Enter CAL Mode

d - Continue to last step (CAL d)

E - Enter CAL mode.

F6.4 Linearity Factor

Corrects non-linearity in weigh system. The value required is determined

empirically. Amount of correction depends upon percent usage of the load cell as

well as the system capacity and resolution.

Choices: 7 to -7

E SCALE Empty Scale

Remove all weight from the scale and then press the [PRINT] button.

888888 Full Scale Capacity

888888 indicates the previously entered Full Scale Capacity in even units. Use the

numeric keyboard to enter the Full Scale capacity. Press the [ENTER] button to

advance to the next step.

15 SEC Zero Setting Fifteen Second Delay

Counts down from 15 to zero to capture the zero setting. If the [SELECT] button is

pressed during the time-out period, the meter will immediately terminate the delay

and ignore the motion criterion to capture the weight. Allow at least three (3)

seconds after weight has been applied to the scale before pressing [SELECT] or the

weight captured may be erroneous.

Add Ld Add Load or Add ALL

The weight applied must be at least 5% of the full scale capacity. The message Add

ALL will appear if Linearity Factor is not zero indicating that Full Scale Capacity

must be applied.

Page 36

Page 39

[PRINT] - Advances to next step if span must be set.

[TARE] - Establishes a new zero calibration setting without changing the span

calibration previously set. The display will show CAL d. This feature is disabled if

the Add ALL message is displayed.

888888 Test Weight

Apply known weight to scale. Fractional or decimal weights are not acceptable

only whole numbers. Use the numeric keyboard to enter the applied weight. Press

the [ENTER] button to advance to the next step. If Add ALL was displayed in the

previous step, the system will use the Full Scale Capacity as the test weight value

and automatically proceed to the next step.

15 SEC Span Setting Fifteen Second Delay

Counts down from 15 to zero to capture the span setting. If the [SELECT] button is

pressed during the time-out period, the meter will immediately terminate the delay

and ignore the motion criterion to capture the weight. Allow at least three (3)

seconds after weight has been applied to the scale before pressing [SELECT] or the

weight captured may be erroneous.

CAL d Calibration Done

Indicates that the calibration procedure is complete.

[PRINT] - Advances to next step.

[7] - Decreases span setting.

[9] - Increases span setting.

FCd File Changed Data

Changes will be saved or discarded.

0 - Save the entered values in memory and use again on power up.

1 - Discard present values and restore previously entered values.

2 - Initialize the EEPROM (U14) to the factory settings.

[PRINT] - Advance to the next step.

Page 37

Page 40

FILEd The programmed data will have been saved or discarded after this message

is displayed. Return the CAL switch S1 to the OFF position and the display will

return to the normal mode of operation.

Error Codes During Calibration

The following error messages (CE1 to CE5) are shown on the display if the system

detects an error:

CE1 Insufficient test weight. Value must be greater than or equal to 5% of Full

Scale Capacity.

CE2 Full Scale Capacity will exceed internal A/D counts. Remedy by lowering gain

on A/D circuit board and/or lowering Full Scale Capacity weight (Step Empty

Scale). Deadload may be too high initially. Add a resister (50k500k ohm) between

+EXC (TB1, pin 7) and -SIG (TB1, pin 1) on A/D circuit board.

CE3 Insufficient A/D counts for resolution selected. Remedy by increasing gain on

A/D circuit board or increasing the Increment Size (Step F6.1). Deadload may be

too high initially. Add a resister (50k500k ohm) between +EXC (TB1, pin 7) and SIG (TB1, pin 1) on A/D circuit board.

CE4 Motion detected during delay period. Ensure that the scale base is not bumped

or unstable during calibration.

CE5 The scale has gone into overcapacity, undercapacity, or negative during delay

period. Check load cell connections and polarity of leads. Gain may need to be

lowered as described with CE2 above.

Press the [PRINT] button to continue.

Error Displays

OLOAd -Applied weight has exceeded 102% of Full Scale Capacity.

- - - - - - - Top dashes indicate maximum A/D counts exceeded.

LO CAP -Scale has gone below 200 A/D counts.

_ _ _ _ _ _ -Bottom dashes indicate incoming load cell signal is the wrong polarity.

Check that signal leads are not reversed. If weight indication returns with more

applied weight then deadload is insufficient. Remedy by adding a high-quality

resistor (50k-500k ohm) between +EXC (TB1, pin 7) and +SIG (TB1, pin 2).

bAd CAL -This error indicates that re-calibration and set-up is necessary.

Page 38

Page 41

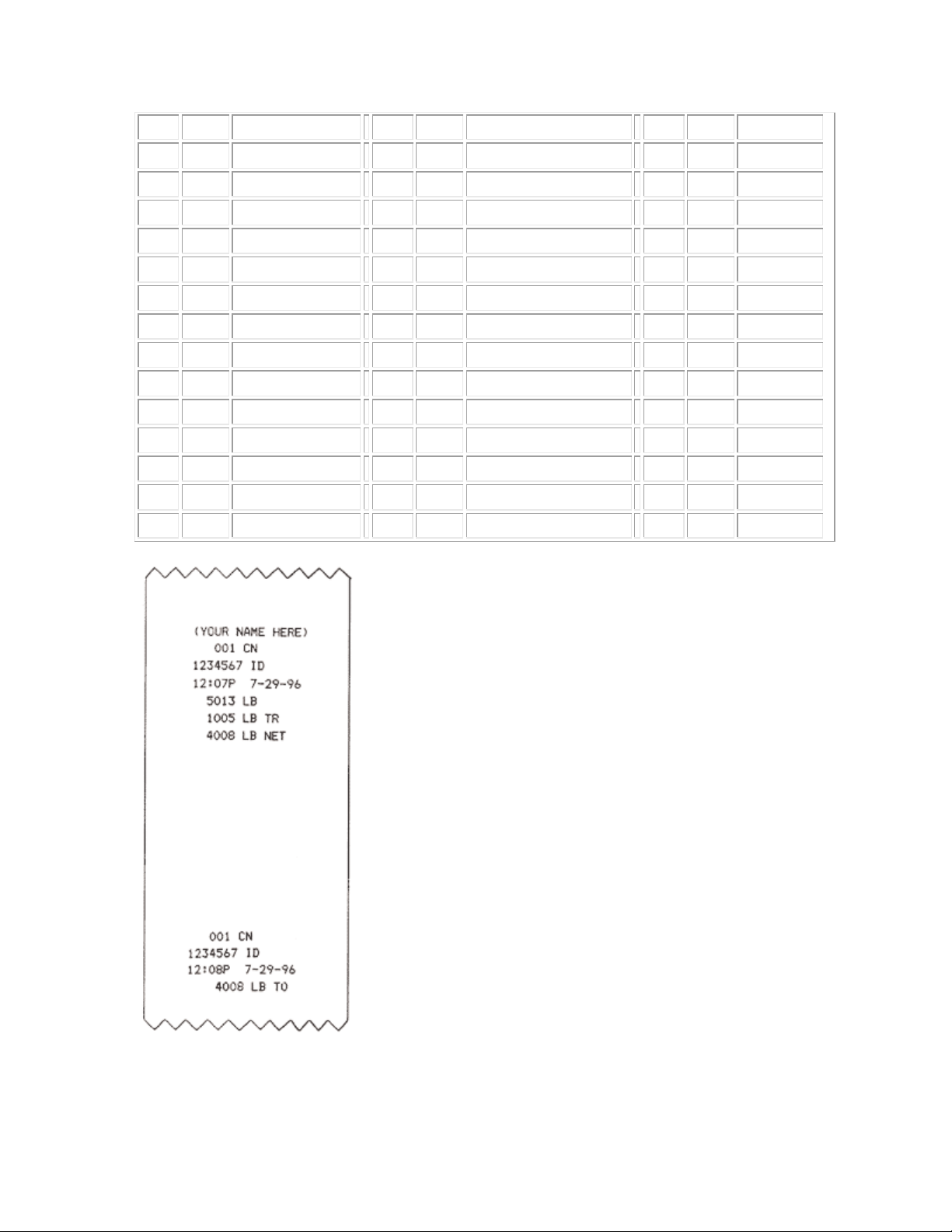

Programming Steps Summary

Record the final settings for each step in the boxes ([ ]) below for future reference.

[ ]F1.0 Raw Counts Display Enable

[ ]F1.1 Digital Averages

[ ]F1.2 Display Update Rate

[ ]F1.3 Motion Limit in Digits

[ ]F1.4 Auto Zero Tracking Enable

[ ]F1.5 Auto Zero Tracking Width

[ ]F1.6 2 % Zero Range Enable

[ ]F1.7 Key Functions Enable

[ ]F1.8 Output Options

[ ]F1.9 High Resolution Enable

*[ ]F1.A

*[ ]F1.B

*[ ]F1.C

*[ ]F1.D

[ ]F2.0 Tare Enable

[ ]F2.1 Tare Interlock

[ ]F2.2 Auto Clear Tare

[ ]F2.3 Ten Tare Look -up

[ ]F2.4 Battery Option Enable

[ ]F2.5 Stand-By Mode Enable

[ ]F2.6 External Gross Net Enable

Page 39

Page 42

[ ]F2.7 Two Speed Feed Enable

[ ]F2.8 Sequential Feed Enable

[ ]F2.9 Invert Relays Enable

[ ]F2.A Parallel Feed Enable

*[ ]F2.B

*[ ]F2.C

*[ ]F2.D

[ ]F3.0 Baud Rate Selection

[ ]F3.1 Parity Selection

[ ]F3.2 Checksum Transit Enable

[ ]F3.3 Delay After CR-LF

[ ]F3.4 CN Print Enable

[ ]F3.5 ID Print Enable

[ ]F3.6 Negative Print Enable

[ ]F3.7 24 Hour Clock Enable

[ ]F3.8 Preamble

[ ],[ ],[ ]

Postamble

[ ],[ ].[ ]

Custom formatting - use chart

[ ]F4.0 Print Mode

[ ]F4.1 Continuous Data Format

[ ]F4.2 Weight Change Percentage

Page 40

Page 43

[ ]F4.3 Minimum Print in Digits

[ ]F4.4 Computer Communications

[ ]F4.5 Weight Data Format

[ ]F4.6 Time/Date Print Format

[ ]F4.7 Weight Print Format

[ ]F4.8 Totals Print Format

[ ]F4.9 Weight Accumulation Enable

[ ]F5.0 Piece Weight Enable

[ ]F5.1 CN Enable

[ ]F5.2 ID Enable

[ ]F5.3 Total-Subtotal Enable

[ ]F5.4 Time and Date Enable

[ ]F5.5 Presets Enable

[ ]F5.6 Recall Tare Enable

*[ ]F5.7

*[ ]F5.8

*[ ]F5.9

*[ ]F5.A

*[ ]F5.B

*[ ]F5.C

*[ ]F5.D

[ ]F6.0 Weight Units for Printing

[ ]F6.1 Increment Size

Page 41

Page 44

[ ]F6.2 Decimal Position

[ ]F6.3 Enter CAL Mode

[ ]F6.4 Linearity Factor

*[ ]F7.0

*[ ]F7.1

*[ ]F7.2

*[ ]F7.3

*[ ]F7.4

*[ ]F7.5

*[ ]F7.6

*[ ]F7.7

*[ ]F7.8

*[ ]F7.9

*[ ]F7.A

*[ ]F7.B

*[ ]F7.C

* only used in custom applications

The following section describes the convention used by the DWM-IV to

communicate with a user-supplied computer or terminal. Data is transmitted as:

one start bit, seven or eight data bits, one even, odd, or no parity bit, and two stop

bits for a total of 11, 12 or 13 bits per character. The BAUD rate, parity and serial

communications enable must be configured while in the SET-UP procedure using

F3.0, F3.1, F4.4.

Serial Bi-Directional Communications

All functions accessible from the front panel may also be accessed using a remote

communication link. The following table describes the ASCII codes to be

transmitted to the DWM-IV which represent the front panel buttons:

Page 42

Page 45

Remote Control Inputs

The functions of ZERO, TARE, GROSS/NET, selection and PRINT may be

performed remotely via voltage-free contacts across the indicated pins on TB1 of the

DWM-IV motherboard and pins 5 or 6. ZERO, TARE, and PRINT inputs should

have a minimum duration of 500 milliseconds while the GROSS/NET input must be

maintained closed for net and open for gross.

Data Output Formats

The DWM-IV data output is selectable using the Set-up procedure using F3.2, F3.4,

F3.5, F3.6, F3.8, F4.1, F4.5, F4.6, F4.7, F4.8, F6.0 as described in the manual. The

information sent can optionally include time/date, consecutive number and ID

number. Additionally, the output can be configured to send the data in any of eight

(8) different formats. The weight data may be configured in any of four (4) formats.

The time/date information may be selected from four (4) formats.

Whenever data is transmitted, the first character sent is always an ASCII STX (02h)

to signify the start of data block. The data previously selected

is sent and is always terminated by an ASCII ETX (03h). The Continuous Output

formats do not adhere to this convention, however. In addition to the characters

Page 43

Page 46

described, the user may program up to three (3) preamble characters that are sent

after the STX character and up to three (3) postamble characters which are

transmitted just before the ETX character. These characters may be used for

special purposes such as releasing the paper clamp on a ticket printer or performing

a double wide print out.

All Weight data fields are six (6) active characters in length. If required by the

programmed capacity, this field will be expanded to seven (7) characters to include

the decimal point (2Eh) justified in the proper position within the weight field. Nonsignificant leading zeroes will be transmitted as spaces but the least significant three

(3) characters are not zero suppressed.

Data Block Format:

Data Block

where PR is preamble and PO is postamble.

In the format descriptions below, the following abbreviations apply:

U

represents the programmed units and may be

from zero to seven characters long.

N

T

represents the tare and may be any of the following

depending on the programmed configuration:

R

1. TR If single register tare is used and tare was entered via pushbutton.

2. TR(K) If single register tare is used and tare was entered via the keyboard.

3. TRx If Ten-Tare Look-up is enabled. x represents the tare register currently

selected. Tare value was entered via the pushbutton.

4. TRx(K) Ten -Tare Look-up as in 3. above but entered via the keyboard.

Represents the checksum data which is the sum of the

CK

data previously sent and is in 2's complement binary

notation. The checksum is comprised of two ASCII

SM

hexadecimal characters. These two characters are only

inserted if the 'Checksum Transmit Enable' is enabled.

Page 44

Page 47

S

ASCII character space (20h).

P

C

ASCII character carriage return (0Dh).

R

L

ASCII character line feed (0Ah).

F

A. Displayed Weight Only

Gross wt Only

Net wt Only

B. Single Line GTN

Note: If tare equals zero or in the gross mode, the format is the same as in Displayed

Weight Only above.

C. Multiple Line GTN

Gross wt

Tare w t

Net wt

Page 45

Page 48

D. Status, Weight and Tare

Status Words Table

Bit STATUS A STATUS B STATUS C

8 7 0 0 Relay 8

4 6 Center Zero Print Key Relay 7

H

2 5 Motion Decimal pos Relay 6

1 4 Gross Decimal pos Relay 5

8 3 Negative Decimal pos Relay 4

4 2 Undercap Zero Incr Size Relay 3

L

2 1 Overcap Incr Size Relay 2

1 0 LB Incr Size Relay 1

Notes:

1. Conditions noted are true if corresponding bit is a logic 1.

2. Increment Size values correspond to the following table:

Bit 2 1 0

0 0 0 By 1's

0 0 1 By 2's

0 1 0 By 5's

0 1 1 By 10's

1 0 0 By 20's

1 0 1 By 50's

1 1 0 By 100's

3. Decimal Position values correspond to the following table:

Bit 5 4 3

0 0 0 No Decimal

0 0 1 Illegal

Page 46

0 1 0 XXXXX.X

Page 49

0 1 1 XXXX.XX

1 0 0 XXX.XXX

1 0 1 XX.XXXX

4. Print Key = 1 if front panel PRINT key is being pressed.

5. Relay = 1 if relay energized.

6. Each Status Word is comprised of two ASCII hex characters (0 - 9, A - F),

representing the two 4-bit patterns that make up each Status Word. Example: 5 1 in

the Status B position would be bit pattern 0101 0001 = count by .2 and print button

pressed.

E) Time/Date Format

12 Hour

Time Date

HH:MMASMM-DD-YYS

PS P

24 Hour

Time Date

HH:MMSMM-DD-YYS

PP

F) Totals Format

Where 'x' represents the totals register number currently selected. If checksum is

enabled, it is inserted before a CR-LF sequence.

G) ID Number

H) Consecutive Number

Page 47

Page 50

I) Z660 Scoreboard

J) ASCII - with Preamble and Postamble (No STX or ETX)

K) RD

Custom Print Format Programming

By selecting the custom print options, it is possible to design a print output to

conform to almost any given requirements.

Custom data sent via the PRINT function (either front panel button, remote input,

or external voltage free contact) is enabled by selecting the C option under F4.7,

Weight Print Format, of the SET-UP procedure. Similarly, custom totals data is

enabled via F4.8, Totals Print Format.

A total of eighty (80) print codes may be entered as a combination of weight print

codes and totals print codes. The codes are each one byte (8 bits) long. Any value

less than 128 is treated as a literal ASCII character and will print as such. Codes

greater than 127 are special print codes and the DWM-IV will interpret them

according to the chart below to perform the described action. The code 150 is in

essence a NO OPERATION code (print zero spaces) and may be used to reserve

space if later it is determined that codes must be inserted . In this way, not all of the

codes need be re-entered. Merely replace the 150 codes with the required ones. A

Page 48

Page 51

total of eighty (80) codes may be entered. It is possible to print out particular

headers or titles by using the ASCII representations for them in decimal.

Entering Print Codes

1. first enable under F4.7 and/or F4.8.

2. Under F3.8 of the SET-UP procedure, enter the preamble and postamble data, if

needed.

3. After the postamble step the weight data codes are entered. The display will show

the following:

xx.yyy

where xx is the code count and yyy is the print code in decimal. to enter a new

code, use the numeric keypad. Press [ENTER] to store the code and advance to the

next one. Press [ENTER] without pressing any numeric buttons to retain the

existing data. Terminate the codes with a value of 255 and [ENTER]. The display

will blink momentarily.

4. Enter the codes for the totals print-out using the same method described above

for the weight codes. Remember to always terminate the codes with value 255. Any

number greater than 255 will be ignored and the previous data will be re-displayed.

Print Codes and Descriptions

For the following table, refer to the Data Output Formats (referred to as D.O.F.)

and SET-UP procedure sections of this manual.

Code Descriptions

128

129

130

131

132

Inserts ASCII STX and up to three (3) bytes of preamble codes, as set in step F3.8

of set-up procedure.

Formats weight data as described in D.O.F. Type is selected in Step F4.5 of SET UP procedure.

Formats time and date data as programmed in Step F4.6 of SET-UP.

Formats the ID number entered using Function 7 from the front panel. Must be

enabled under F3.5.

Formats the consecutive number. Must be enabled under Step F3.4.

133

134

135

Formats the total or subtotal data and register number as described in D.O.F.

Prints the total register number currently selected (zero to nine).

Internal code for carriage return-line feed. Do not use.

Page 49

Page 52

136

Internal code for carriage return-line feed and checksum insertion if enabled. Do

not use.

137

138

139

140

141

142

143

144

145

146

147

148

Inserts the previously entered postamble entered under Step 3.8 of SET-UP

procedure.

Formats net weight data for a GTN-type print-out. If DWM-IV is in gross mode of

operation, this field is padded with spaces in place of the weight data.

Formats tare weight data for a GTN-type print. If in the gross mode, field is padded

with spaces.

Gross weight data for GTN print-out.

Formats according to ÔDisplayed Weight OnlyÕ as described in D.O.F. section of

this manual.

Formats the time data in twelve (12) or twenty-four (24) hour mode as pre-

programmed in Step F3.7.

Formats the Date data as month, day, and year.

Inserts the checksum data described in D.O.F.

Delay.

Store Preamble.

Format Tare.

Continuous Format.

149

150-

239

240-

254

Job: Date:

Step Code Comment Step Code Comment Step Code Comment

1 150 No Operation 24 10 47

2 40 ( 25 13 48

3 89 Y 26 130 Formats/Date 49

4 79 O 27 10 50

5 85 U 28 13 51

6 82 R 29 129 Formats Weigh Data 52

7 32 Space 30 10 53

8 78 N 31 13 54

End Buffer (NO ETX).

Specifies multiple spaces ;150=0 spaces ,151=1 space, 160=10 spaces etc.

Specifies multiple carriage returns as above.

Sample DWM-IV Custom Print Codes

Page 50

Page 53

9 65 A 32 255 Ends Print Field 55

10 77 M 33 132 56

11 69 E 34 10 57

12 32 35 13 58

13 72 H 36 131 59

14 69 E 37 10 60

15 82 R 38 13 61

16 69 E 39 130 62

17 41 ) 40 10 63

18 10 Line Feed 41 13 64

19 13 Carriage Return 42 133 Formats Totals 65

20 132 Formats CN 43 10 66

21 10 44 13 67

22 13 45 255 Ends Total Field 68

23 131 Formats ID 46 69

Page 51

Page 54

Page 55

Page 53

Page 56

Page 54

Page 57

Page 55

Page 58

Page 59

Page 60

VT 11 00001011 013 0B K 75 01001011 113 4B TA11

FF 12 00001100 014 0C L 76 01001100 114 4C TA12

CR 13 00001101 015 0D M 77 01001101 115 4D TA13

SO 14 00001110 016 0E N 78 01001110 116 4E TA14

SI 15 00001111 017 0F O 79 01001111 117 4F TA15

DLE 16 00010000 020 10 P 80 01010000 120 50 TA16

DC1 17 00010001 021 11 LLO Q 81 01010001 121 51 TA17

DC2 18 00010010 022 12 R 82 01010010 122 52 TA18

DC3 19 00010011 023 13 S 83 01010011 123 53 TA19

DC4 20 00010100 024 14 DCL T 84 01010100 124 54 TA20

NAK 21 00010101 025 15 PPU U 85 01010101 125 55 TA21

SYNC 22 00010110 026 16 V 86 01010110 126 56 TA22

ETB 23 00010111 027 17 W 87 01010111 127 57 TA23

CAN 24 00011000 030 18 SPE X 88 01011000 130 58 TA24

EM 25 00011001 031 19 SPD Y 89 01011001 131 59 TA25

SUB 26 00011010 032 1A Z 90 01011010 132 5A TA26

ESC 27 00011011 033 1B [ 91 01011011 133 5B TA27

FS 28 00011100 034 1C \ 92 01011100 134 5C TA28

GS 29 00011101 035 1D ] 93 01011101 135 5D TA29

RS 30 00011110 036 1E ^ 94 01011110 136 5E TA30

US 31 00011111 037 1F _ 95 0101111 1 137 5F UNT

space 32 00100000 040 20 LA0 ` 96 01100000 140 60 SC0

! 33 00100001 041 21 LA1 a 97 01100001 141 61 SC1

" 34 00100010 042 22 LA2 b 98 01100010 142 62 SC2

# 35 00100011 043 23 LA3 c 99 01100011 143 63 SC3

$ 36 00100100 044 24 LA4 d 100 01100100 144 64 SC4

% 37 00100101 045 25 LA5 e 101 01100101 145 65 SC5

& 38 00100110 046 26 LA6 f 102 01100110 146 66 SC6

' 39 00100111 047 27 LA7 g 103 01100111 147 67 SC7

( 40 00101000 050 28 LA8 h 104 01101000 150 68 SC8

) 41 00101001 051 29 LA9 i 105 01101001 151 69 SC9

* 42 00101010 052 2A LA10 j 106 01101010 152 6A SC10

+ 43 00101011 053 2B LA11 k 107 01101011 153 6B SC11

, 44 00101100 054 2C LA12 l 108 01101100 154 6C SC12

- 45 00101101 055 2D LA13 m 109 01101101 155 6D SC13

Page 58

Page 61

. 46 00101110 056 2E LA14 n 110 01101110 156 6E SC14

/ 47 00101111 057 2F LA15 o 111 01101111 157 6F SC15

0 48 00110000 060 30 LA16 p 112 01110000 160 70 SC16

1 49 00110001 061 31 LA17 q 113 01110001 161 71 SC17

2 50 00110010 062 32 LA18 r 114 01110010 162 72 SC18

3 51 00110011 063 33 LA19 s 115 01110011 163 73 SC19

4 52 00110100 064 34 LA20 t 116 01110100 164 74 SC20

5 53 00110101 065 35 LA21 u 117 01110101 165 75 SC21

6 54 00110110 066 36 LA22 v 118 01110111 166 76 SC22

7 55 00110111 067 37 LA23 w 119 01110000 167 77 SC23

8 56 00111000 070 38 LA24 x 120 01111000 170 78 SC24

9 57 00111001 071 39 LA25 y 121 01111001 171 79 SC25

: 58 00111010 072 3A LA26 z 122 01111010 172 7A SC26

; 59 00111011 073 3B LA27 { 123 01111011 173 7B SC27

< 60 00111100 074 3C LA28 | 124 01111100 174 7C SC28

= 61 00111101 075 3D LA29 } 125 01111101 175 7D SC29

> 62 00111110 076 3E LA30 ~ 126 01111110 176 7E SC30

? 63 00111111 077 3F UNL DEL 127 01111111 177 7F SC31

Page 59

Page 62

DWM-IV Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by

the Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects in

materials and workmanship for one (1) year.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized

by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment

fails to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to

prevent electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a

publication, Protecting Your Components From Static Damage in Shipment, available from RLWS

Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was

not caused by accident, misuse, neglect, alteration, improper installation, improper repair or

improper testing; RLWS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other than RLWS or its

duly authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible

for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER

RLWS

RLWS AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO

REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND

ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE SELLER FOR

WARRANTY CLAIMS.

NO TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO MODIFY THE TERMS OF THIS

WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN WRITING AND SIGNED BY A CORPORATE

OFFICER OF RLWS AND THE BUYER.

NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

© 2009 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

Loading...

Loading...