Page 1

DC-788

Counting Scale

Counting Scale

Operation Manual

Version 1.09

91685

Page 2

Page 3

Contents

1.0 Introduction.................................................................................................................................. 1

1.1 Capacities and Resolutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Description of Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Keyboard and Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.1 Display Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.2 Indicator Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3.3 Key Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.0 Installation ................................................................................................................................... 6

2.1 Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Repacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Setting Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Powering Up the DC-788 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.1 AC Power Source . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.2 DC Battery Pack Replacement/Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4.3 Battery Charging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.4 Start-Up Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.5 Setting the Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.6 Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.7 Block Diagram of Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.8 Physical Layout of Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.0 Configuration Settings ............................................................................................................... 12

3.1 Configuring Specification 141 and 142 Settings from the Scale Keyboard . . . . . . . . . . . . . . . . 12

3.1.1 Customer Specification (141 Settings). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.1.2 Weight and Measurement Specifications (142 Settings). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.0 Calibration ................................................................................................................................. 19

5.0 Scale Operations........................................................................................................................ 21

5.1 Counting Scale Accuracy and the TEP (Teraoka Error Prediction) Mode . . . . . . . . . . . . . . . . . . 21

5.2 Weight Unit Switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.3 Toggling Between Scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4 Setting Tare Weights in Weighing Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4.1 One Touch Tare (When the Tare Weight is Unknown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4.2 Digital Tare (When Tare Weight is Known in Advance) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4.3 Tare Addition or Subtraction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.4.4 Tare Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5 Entering Unit Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5.1 Unit Weight Operation by Sampling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.5.2 Unit Weight Operation by Key Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.6 Setting a Lot Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.7 Setting a Sequence Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.8 Operations Without Recalling an Item Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.8.1 A Single Counting Operation - Without Recalling an Item Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.8.2 Part Accumulation or Subtraction and Negative Counting - Without Recalling an Item Code . . . . . . . . 25

5.8.3 Setting a Temporary Lot Number, Part Number or Part Name - Without Recalling an Item Code. . . . . 27

5.9 Using Item Codes in Weighing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.9.1 Recalling Item Codes using Item Code Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.9.2 View Item Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.9.3 Adding Parts To and Subtracting Parts From Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.9.4 Tare Override . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.9.5 Delete Item Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Page 4

6.0 Scale Programming................................................................................................................... 31

6.1 Checking Memory Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.2 Review the Item Code Numbers Programmed in Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.3 Program Item Code, Tare Weight, Unit Weight, Inventory, Part Number, Part Name, Lot Number,

Setpoint 1 and Setpoint 2 32

6.4 View Item Code Programming in Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.5 Program a General Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.6 Resetting the Sequence Number to Zero. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.7 Programming a Temporary Lot Number, Part Number or Part Name . . . . . . . . . . . . . . . . . . . . 35

6.7.1 Change the Lot Number Temporarily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.7.2 Change the Part Number Temporarily. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.7.3 Change the Part Name Temporarily . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.8 Delete Item Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.8.1 Delete All Item Codes in Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.8.2 Delete a Specific Item Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.8.3 Delete All Inventory Values from Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.8.4 Delete All Unit Weight Values from Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.8.5 Delete All Tare Weight Values From Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.8.6 Delete all Part Numbers From Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.8.7 Delete All Setpoint Data in Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.8.8 Delete All Part Names in Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.0 External Devices: Printers, PCs and Scales.............................................................................. 41

7.1 Printer Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.1.1 Zebra LP2844. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.1.2 DIGI GP460R . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7.1.3 Epson TM-U210 and TM-U290, Star SP2320 and SP298 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2 Printer Label Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2.1 No Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2.2 DIGI GP460R Label Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2.3 ZEBRA LP2844 Barcode Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

7.2.4 Epson TMU200 or Star SP2320 Tape Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2.5 Epson TM-U295 or Star SP298 Ticket Printers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.2.6 DIGI TVP1000 Barcode Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.3 Connecting to a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3.1 Setting the Scale Specifications for Communication to a PC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3.2 Communication Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

7.3.3 Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.3.4 Characters That Can Be Transmitted by RS-232C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7.3.5 RS-232C Data Transmission Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7.4 Remote Scale Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7.4.1 Setting the Specifications for Scale 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7.4.2 Remote Platforms Available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.0 Appendix .................................................................................................................................... 54

8.1 DC-788 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.2 DC-788 Error Message List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.3 ASCII Code Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.0 DC-788 Limited Warranty........................................................................................................... 57

5FDIOJDBMUSBJOJOHTFNJOBSTBSFBWBJMBCMFUISPVHI3JDF-BLF8FJHIJOH4ZTUFNT

$PVSTFEFTDSJQUJPOTBOEEBUFTDBOCFWJFXFEBUXXXSJDFMBLFDPNPSPCUBJOFE

CZDBMMJOHBOEBTLJOHGPSUIFUSBJOJOHEFQBSUNFOU

© 2007 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Version 1.09, July 2007

Page 5

About This Manual

This manual contains operating procedures for the DC-788 counting scale and provides the user with all the

information necessary for setup and operation. It is organized based on the procedures you will likely follow

when setting up and using your counting scale. This manual applies to Version 1.09 of the DC-788 counting scale

series.

Some procedures described in this manual require work inside the scale base. These procedures are to

#AUTION

be performed by qualified service personnel only.

Authorized distributors and their employees can view or download this manual from the

DIGI distributor site at www.DigiScales.com.

1.0 Introduction

The DC-788 is a low cost counting scale that offers practical solutions for a full range of counting applications.

Its counting resolution of 1/1,000,000 gives you maximum counting precision and accu racy. Its high-visibility

red LCD display enables operators to easily see weights and quantities. With the ability to store an item code,

part number, part name, lot number, tare weigh t, unit weight, inventory quantity and setpoint value for 100 of

your pieces, parts, or items, the DC-788 is a self-contained inventory system. The RS-232 output allows you to

connect to a printer or PC, while the remote scale channel lets you add another weighing platform. When

portability is required, choose the battery operation option of the DC-788 for over 24 hours of continuous use in

mobile workstations, outdoor applications, and rental fleets. It’s waterproof keyboard and splash-proof housing

make the DC-788 rugged enough to operate reliably in many environments and withstand transport from one

area of the plant to another or from one business to the next.

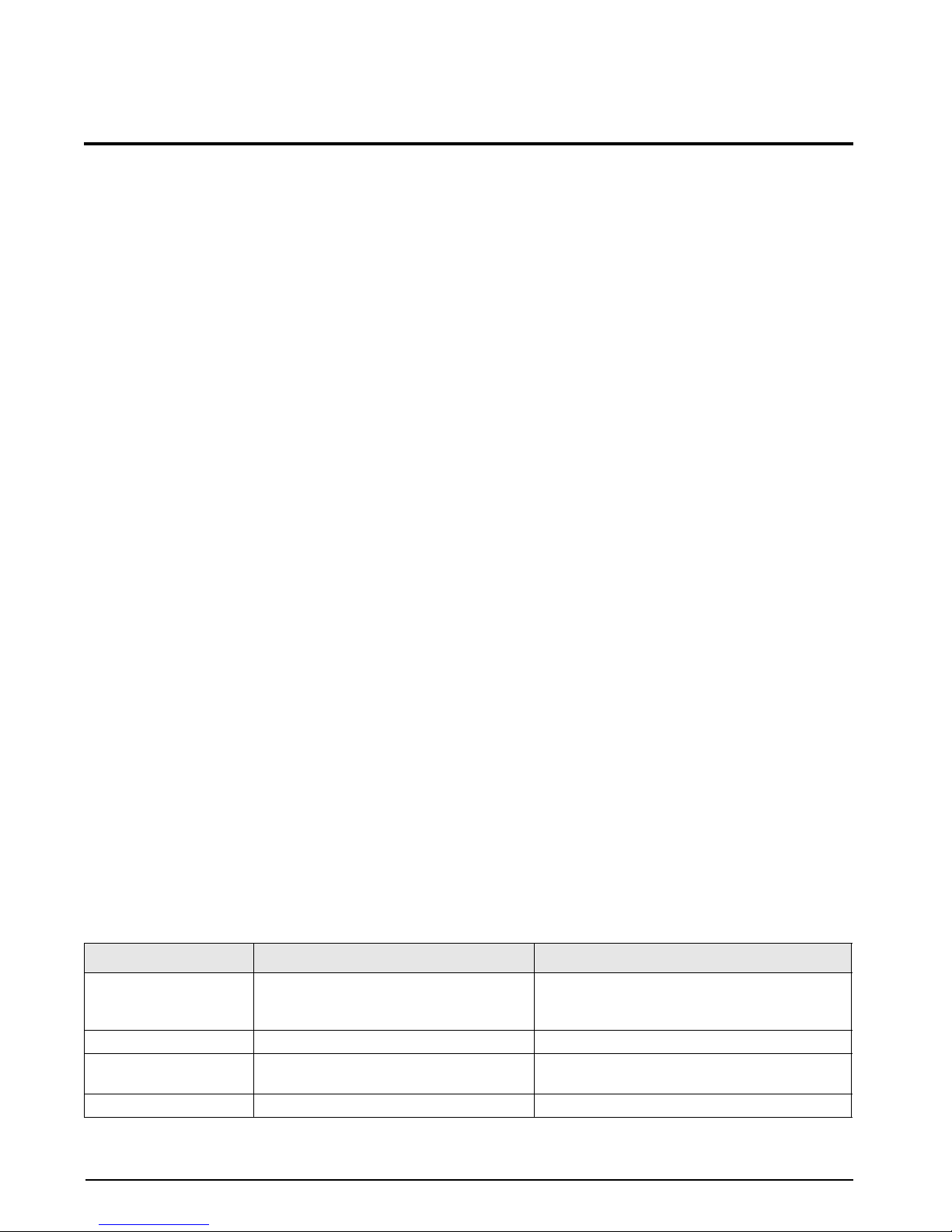

1.1 Capacities and Resolutions

Table 1-1 lists the scale capacities, minimum graduations, and tare ranges for all models of the DC-788 counting

scales. The display resolution is 1/10,000 with an internal or counting resolution of 1/1,000,000. Units are

selectable from lb to kg from the keyboard.

DC-788 Single Scale

DC-788 Capacity Minimum Graduation Ta r e R an g e

500 g 0.1 g (1e = 200IR) 0-249.9 g

1 kg 0.2 g (1e = 200IR) 0 - 0.4998 kg

2.5 kg 0.5 g (1e = 200IR) 0 - 0.9995 kg

5 kg 1 g (1e = 200IR) 0 - 2.499 kg

10 kg 2 g (1e = 200IR 0 - 9.998 kg

25 kg 5 g (1e = 200IR 0 - 9.995 kg

1 lb 0.0001 lb (1e = 100IR) 0 - 0.9998 lb

2 lb 0.0002 lb (1e = 100IR) 0 - 0.0095 lb

5 lb 0.0005 lb (1e = 100IR) 0 - 9.995 lb

10 lb 0.001 lb (1e = 100IR) 0 - 9.999 lb

20 lb 0.002 lb (1e = 100IR) 0 - 9.998 lb

50 lb 0.005 lb (1e = 100IR) 0 - 9.995 lb

Table 1-1. DC-788 Capacities, Minimum Graduations and Tar e Ranges

Introduction 1

Page 6

1.2 Modes of Operation

1.2.1 Description of Modes of Operation

The DC-788 has three modes of operation:

• Weighing Mode – where all weighing, counting and printing operations take place.

• Programming Mode – where item and inventory data can be programmed into the memory of the scale.

The display will show ProG to indicate that you are the Programming Mode.

• Maintenance Mode - where your DIGI dealer can set specifications, perform scale calibration and

other maintenance functions.

1.3 Keyboard and Display

Figure 1-1 shows the DC-788 console with its indicator lamps, the function keyboard and the numeric keypad.

Annunciators are described in Section 1.3.2. Section 1.3.3 describes the DC-788 keyboard and keypad.

Figure 1-1. DC-788 Display

1.3.1 Display Specifications

Tare weight display 5 digits

Weight display 5 digits

Unit weight display 5 digits

Quantity display 7 digits

Table 1-2. DC-788 Display Specifications

1.3.2 Indicator Lamps

Table 1-3 shows a list of the indicator lamps that the DC-788 uses to provide additional information about the

value being displayed. The indicator lamps are illuminated when the specific function is being performed.

Indicator Lamp Function or Meaning

0

NET

KG

LB

RECOMP

INSUFF

On when the gross weight is zero and is stable

On when the display shows net weight (when a tare weight is entered or recalled)

On when the item is being weighed in kg units with [kg/lb] key pressed

On when the item is being weighed in lb units with [kg/lb] key pressed

On when unit weight recomputing is possible

On when the net weight is below the specified percentage of scale capacity

Table 1-3. DC-788 Indicator Lamps and Function

2 DC-788 Operation Manual

Page 7

Indicator Lamp Function or Meaning

scale 1

scale 2

prog

wt/1000

apw

∑

out

in

batt

charge

On when scale 1 is in use (the built-in platform)

On when scale 2 is in use (an external platform)

On when the scale is in Programming Mode

On when the unit weight is being displayed per 1000 pcs.

On when the unit weight is displayed per one piece (average piece weight).

Quantity is accumulating

Item out of item inventory (subtracting from inventory)

Item in to item inventory (adding to inventory)

Battery warning when weak and needs charging (only for rechargeable battery type)

Battery charging (only for rechargeable battery type)

Table 1-3. DC-788 Indicator Lamps and Function

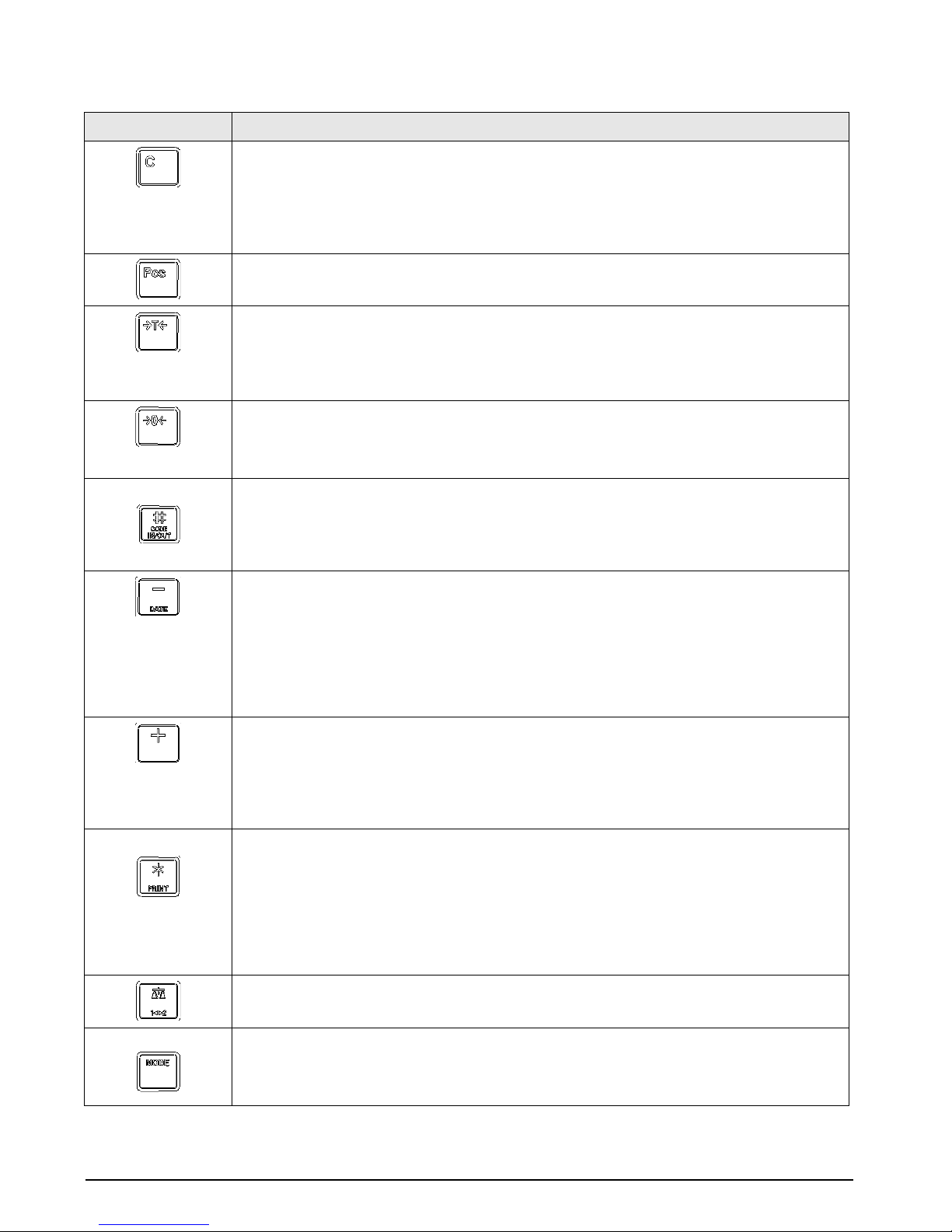

1.3.3 Key Functions

The DC-788 features many functions for managing inventory information and scale operation. Figure 1-2 shows

the two key-sheet layouts and Table 1-4 lists the keys and key functions of the DC-788 keyboard and keypad.

Some keys have different functions depending on what mode or function you are in.

Key Description

ON/OFF - Turns the scale display on or off

to

Numeric keys - Used to enter numeric values. When using the scale, first enter a numeric

DECIMAL key - Used to set the decimal point.

Figure 1-2. Key Sheet Layout

value, then press the appropriate function key.

Table 1-4. DC-788 Key Functions

Introduction 3

Page 8

Key Description

CLEAR key.

Weighing Mode - Used to clear the Unit Weight. Used to return to the weighing display when

doing accumulation.

Programming Mode - Used to delete an Item Code or associated value when programming item

codes. Used to Cancel input in programming SPC codes. Used to Reset

Sequence Number to zero when programming Sequence Codes.

PCS key - Used for computing unit weight by sampling.

TARE key.

Weighing Mode - Used to set or clear the tare value.

Programming Mode - Used to store SPC changes and escape to the Weighing Mode when

programming specifications.

Maintenance Mode - Used to escape to the Weighing Mode from the Maintenance Mode.

REZERO key.

Weighing Mode - Used to reset the weight display to zero.

Maintenance Mode - Used to enter different parts of the Maintenance Mode when combined with

numeric codes.

CODE/IN-OUT key.

Weighing Mode - Used to recall Item Codes from memory and to determine inventory IN/OUT

status.

- (Minus) key.

Weighing Mode - Used to delete a character entered during operations. Used to subtract a

quantity during accumulation. Also prompts printing of a label if an external

printer is connected.

Programming Mode - Used to navigate to the previous specification when programming SPC

codes. Used to move between item codes when reviewing already

programmed item codes. Used to display the current date and time when

programming the date and time.

+ (Plus) key.

Weighing Mode - Used to accumulate data. Also prompts printing of a label if an external

printer is connected.

Programming Mode - Used to navigate to the next specification when programming SPC codes.

Used to move between item codes when reviewing already programmed

item codes. Used to store set point data when programming item codes.

* PRINT key - Print/Data setting key.

Weighing Mode - Used to print a label when an external printer is connected. Used to clear

TOTAL data when doing accumulation.

Programming Mode - Used to temporarily store changes to specification data when programming

SPCs. Used to store data to Item Code memory when programming Item

Codes. Used to store changes to item codes when editing Item Code

information. Used to store the date and time when programming Date and

Time.

SCALE key. Used to select between Scale 1 and Scale 2 if an external scale is

connected.

MODE key - Used to enter the programming mode from the weighing mode. Used to

4 DC-788 Operation Manual

enter the command mode when using numeric commands.

Table 1-4. DC-788 Key Functions

Page 9

Key Description

KG/LB/INVENT key- Used to convert the weighing units between kg and lb. Also used to toggle

on and off whether inventory stored in memory is being affected by the

current transaction.

UNIT WEIGHT key - Used to set the unit weight and display all digits of the unit weight.

Table 1-4. DC-788 Key Functions

Introduction 5

Page 10

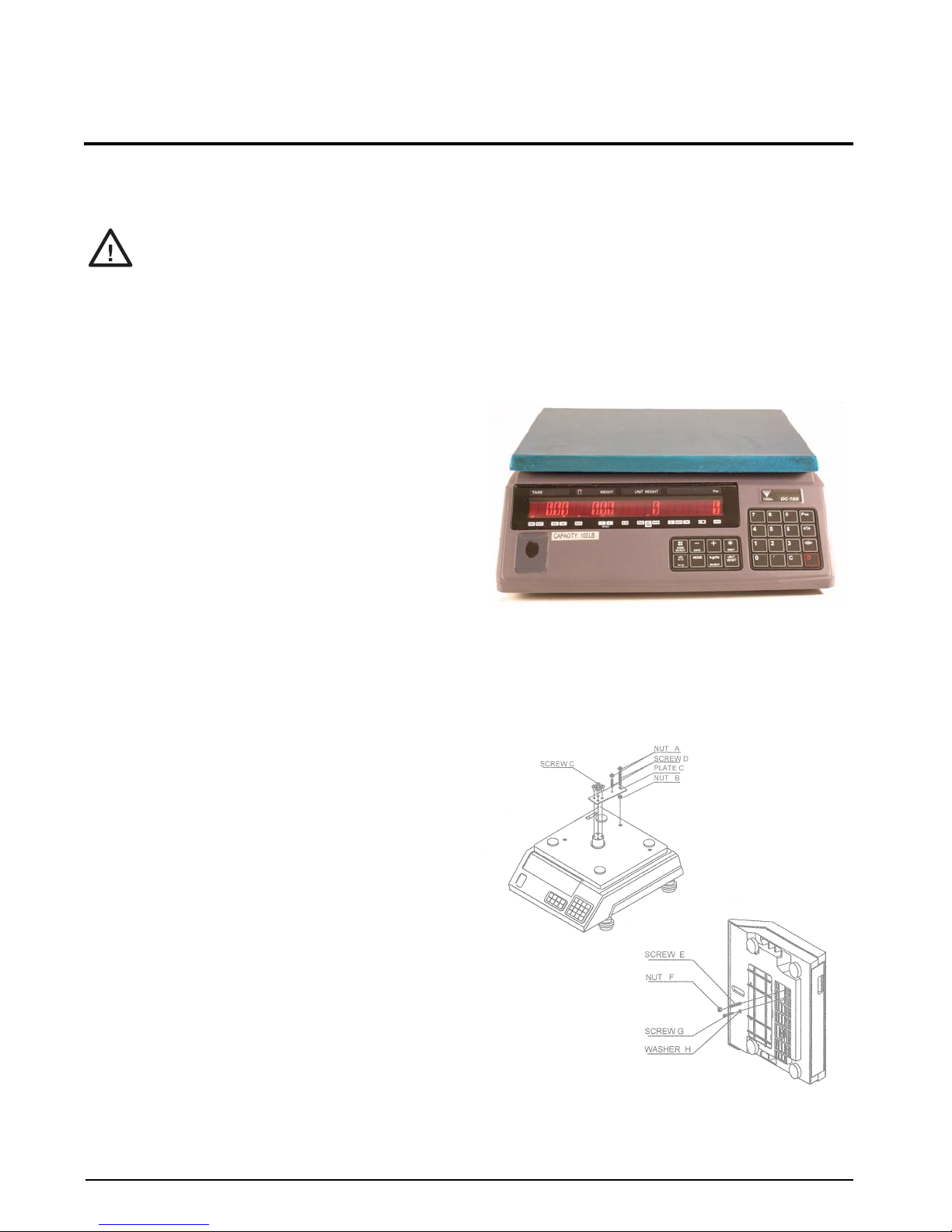

2.0 Installation

This section describes the procedure for the installation and setup of the DC-788 counting scale.

2.1 Unpacking

Do not turn scale upside down. Always work with scale on its side! Damage to the load cell can occur if

#AUTION

1. Immediately after unpacking, visually inspect the DC-788 counting scale to ensure all components are

included and undamaged. If any were damaged in shipment, notify Rice Lake Weighing Systems and the

shipper immediately.

2. The DC-788 counting scale is carefully packed for protection during shipping. After openin g the box,

remove all the components. Check the insides of the box carefully to make sure you have all of the

pieces. The package should include the following:

• DC-788 counting scale

• Stainless steel platter

• AC power cord

• Operation Manual

the scale is turned upside down.

3. Remove the bag protecting the scale and the protective film covering the front panel and platter.

4. Seat the stainless steel platter on the platter supports, with the four corner pins inserted into the corner

rubber stops. For DC-788 scales with a 2 lb. capacity, the scale must first be unlocked using the

following procedure.

• Take off the two Nuts A and Screw C.

Then remove Screws D, Plate C and Nut

B. Then turn the scale on its side to

complete removal of the locking screw.

REMINDER: Do not turn the scale upside

down as this can damage the load cells.

• Remove Nut F and then Screw E. Then

take off Screw G and Washer H.

5. After ensuring that all parts are present, store the DC-788 scale box for possible future use.

6 DC-788 Operation Manual

Page 11

2.2 Repacking

If the DC-788 counting scale must be returned for modification, calibration or repair, it must be properly packed

with sufficient cushioning materials. Whenever possible, use the original carton when shipping the DC-788.

Damage caused by improper packaging is not covered by the warranty.

2.3 Setting Up

Place the scale on a solid, level surface away from fans, breezes, and sources of electrical interference.

Level the scale by turning the four adjustable legs located on the bottom of the scale while referencing the bubble

level located on the front of the scale (see

NOTE: To ensure a higher degree of scale stability, turn in all four adjustable legs before leveling. Turn out adjustable legs to

level as needed.

Figure 2-1).

Figure 2-1. Leveling Bubble

2.4 Powering Up the DC-788

The DC-788 can be operated either from an AC power source or with a rechargeable battery pack (DC power).

The DC power allows the unit to be completely portable. Instructions for DC operation are contained in

Section 2.4.2.

2.4.1 AC Power Source

To power up the DC-788 using the AC power cord:

1. Connect the AC power cord under the scale base as shown in Figure 2-2.

Figure 2-2. AC Plug-in Location on Underside of DC-788

2. Plug the AC power cord into a grounded 115 VAC receptacle.

3. Press the ON/OFF key located on the front of the scale. The scale will run through a check of the LCD

Installation 7

Page 12

display’s segments. How thorough the segment check is depends on the setting of SPC 20, Bit 2. The

default is 1: Normal (For further instructions on how to set the scale’s specifications, see

Section 3.1.2):

• If SPC 20, Bit 2 is set to 0: Fast, the scale display’s 888’s for 1.5 seconds, then blanks for 1.5

seconds. It then displays 888’s again followed by a blank display for another 1.5 seconds before

going into the normal weighing mode.

• If SPC 20, Bit 2 is set to 1: Normal, the scale’s display will test the LCD segments for each numeral

from 0 to 9, asterisks, decimal points and annunciators before going into the normal weighing mode.

4. Once the scale is on, the time interval before the scale will automatically power itself off, if there no key

is pressed and no weight is placed on the platter, is determined by SPC 00- Auto Power-Off Function.

The default is 0000: Disabled. (For further instructions on how to set the scale’s specifications, see

Section 3.1.1)

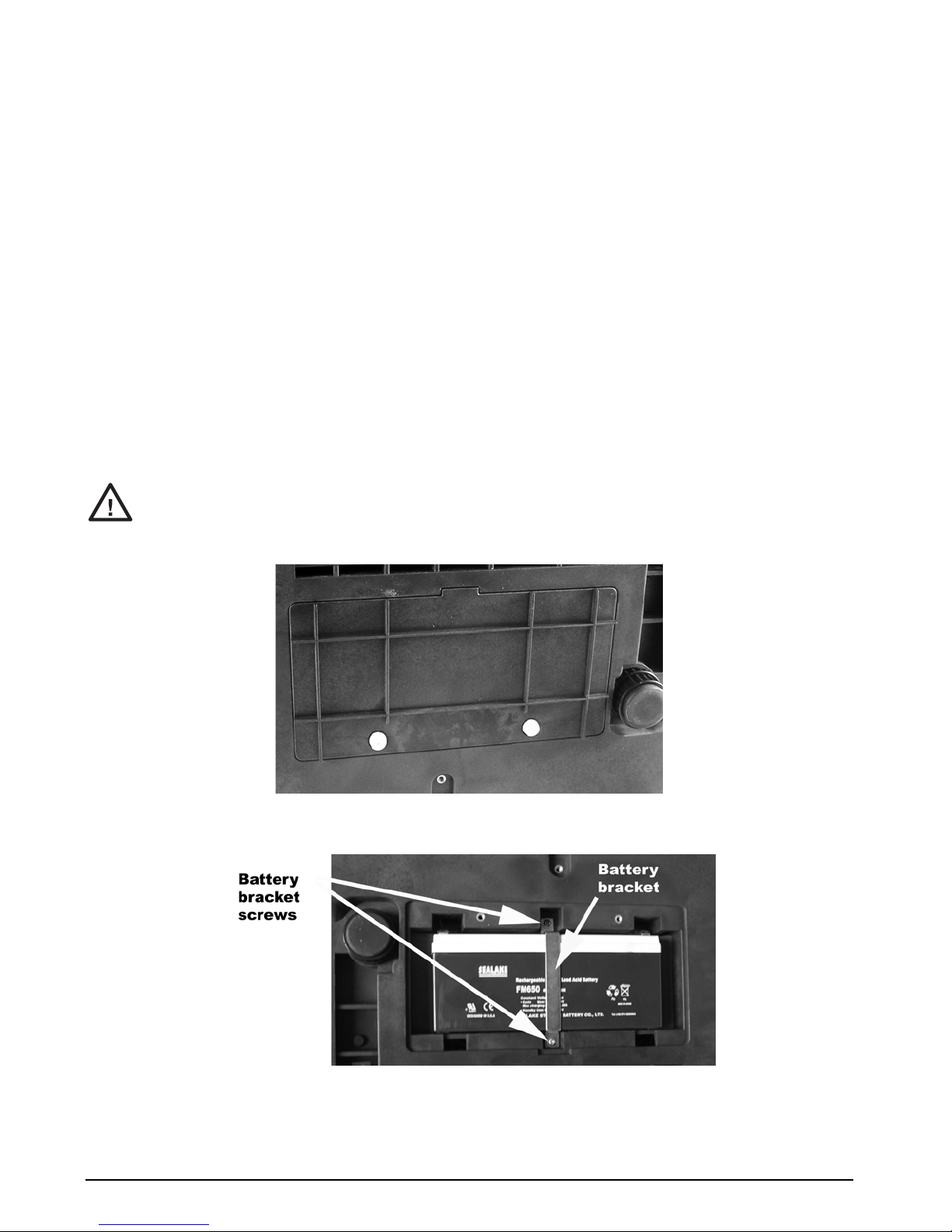

2.4.2 DC Battery Pack Replacement/Installation

An optional DC battery pack (PN 88933) for the DC-788 is available and can be purchased from RLWS to ship

with the scale or retrofit in the field. The rechargeable 6V 5.0 AH battery pack allows for up to 24 hours of scale

use without an AC power supply. It is located in the bottom of the scale base. Use the following procedure to

install or replace the battery pack.

1. Unplug the scale from power source.

2. Place scale its left side.

Do not turn the scale upside down. Always work with the scale on its side. Damage to the load cell can

#AUTION

occur if the scale is turned upside down.

3. Unscrew the two thumb screws holding the battery compartment door closed.

Figure 2-3. Thumb Screws for Battery Compartment

4. Unscrew the two screws holding on the battery holding bracket and remove the bracket.

5. Remove the battery from its compartment, then disconnect the black (-) and red (+) electrical leads from

the battery .

8 DC-788 Operation Manual

Figure 2-4. Removing Battery Bracket.

Page 13

6. Attach the red lead to the positive (+) terminal of the new DC battery pack, and the black lead to the

negative (-) terminal. Place new DC battery pack in battery compartment.

7. Replace the battery holding bracket and fasten it with its two screws.

8. Replace the battery compartment door and fasten it with its two thumb screws.

9. Put the scale back upright on its feet.

10. Press the ON/OFF key located on the front of the scale. The scale will run through a check of the LCD

display’s segments. How thorough the segment check is depends on the setting of SPC 20, Bit 2. The

default is 1: Normal (For further instructions on how to set the scale’s specifications, see

Section 3.1.2):

• If SPC 20, Bit 2 is set to 0: Fast, the scale display’s 888’s for 1.5 seconds, then blanks for 1.5

seconds. It then displays 888’s again followed by a blank display for another 1.5 seconds before

going into the normal weighing mode.

• If SPC 20, Bit 2 is set to 1: Normal, the scale’s display will test the LCD segments for each numeral

from 0 to 9, asterisks, decimal points and annunciators before going into the normal weighing mode.

2.4.3 Battery Charging

A fully charged battery allows for approximately 24 hours of continuous use. When the battery is low the battery

indicator light will light up. It will take approximately 8-10 hours to fully recharge a battery that has been

completely dissipated. To charge the battery, plug in the AC power cord.

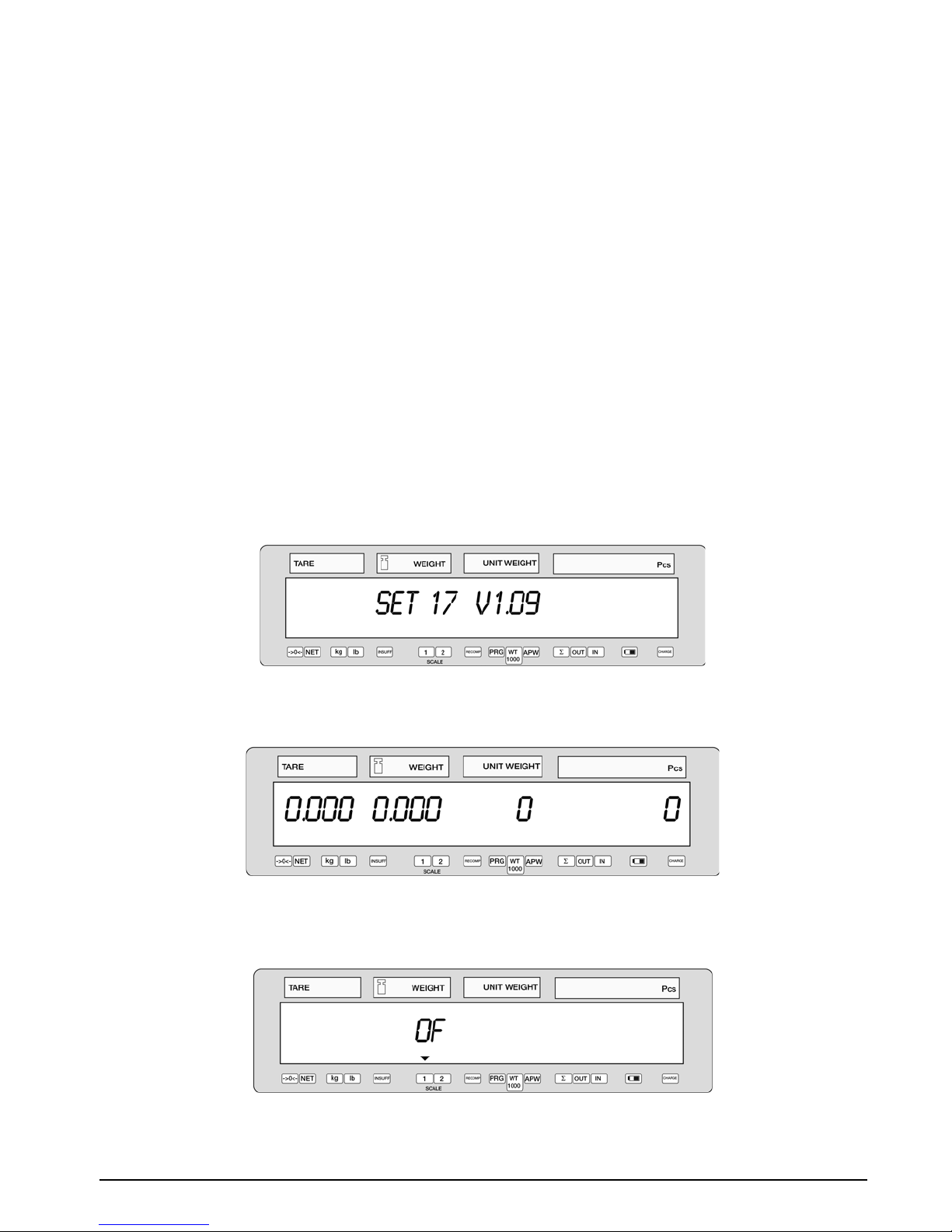

2.4.4 Start-Up Screens

1. If SPC 20, Bit 3 - Version Display When Power On is set to 0: Allow, the scale will display the current

version of the firmware it is using as it powers up (For further instructions on how to set the

specifications, see

Section 3.1.2).

2. After a test of the different elements of the display, the scale takes you to the stand-by screen in the

Weighing Mode. SPC 20, Bit 2 - Selection of Segment-Check Style controls whether the startup test of

the segments is Fast or Standard. At the stand-by screen the

TARE, WEIGHT, UNIT WEIGHT and PCS

displays show zeroes.

From this stand-by screen all of the basic weighing, counting and inventory operations can be performed

3. If there is anything on the platform(s) and it exceeds the scale start range, the display will show the error

message OF indicating “weight overflow”.

Note: The Initial Start Range settings are controlled by SPC 20, Bit 1. The default setting is 0: ± 10% OF FULL SCALE.

If this error appears, remove the weight from the platform and the scale will continue its startup

sequence.

Installation 9

Page 14

2.5 Setting the Date

Without a power supply, the DC-788 will reset the time and date. For units that do have battery power, the time

and date can be supported for up to 20 days in the OFF status without any AC power supply. After 20 days the

unit will reset itself.

The procedure below can also be used to adjust the time when moving from Standard to Daylight Savings Time

or when the scale is moved to a new facility in a different time zone.

NOTE: SPC 04, Bits 3 and 2 - ORDER OF MONTH, DATE AND YEAR allows you to set the format for the date that you prefer

the scale to display. The default is 00: Month/Date/Year. To change these specifications, see

Section 3.1.2).

1. Press the MODE key twice until the display shows ProG.

2. Press the – (Minus) key to display the current time and date.

3. Press the – (Minus) key again.

4. Using the keyboard, enter the desired date i.e.: [0] [6] [0] [9] [0] [5] for June 9th, 2005.

5. Press the * PRINT key to store the date setting.

6. Using the keyboard, enter the time, i.e.: [1] [5] [0] [5]

7. Press the * PRINT key to store the time setting

8. Press the MODE key to exit the weighing mode.

2.6 Replacement Parts

The following list contains the part numbers and descriptions of replacement parts available for the DC-788

counting scale.

RLWS Part Number Description

88933 Battery Pack, 6 V, 5.0AH lead acid

89994 Keysheet, 16 keys, DC-788

89997 Keysheet, 8 keys, DC-788

89999 Keyboard

90152 Mainboard for DC-788

90153 Loadcell, 2 lb

90154 Loadcell, 10 lbs

90155 Loadcell, 20 lbs

90156 Loadcell, 50 lbs

90157 Loadcell, 100 lbs

90188 Top c o v e r

90160 Support platter

90171 Platter cover, 10 lb to 100 lb

65956 Platter cover, 2 lb

10 DC-788 Operation Manual

Table 2-1. DC-788 Replacement Parts

Page 15

2.7 Block Diagram of Electrical Connections

The following block diagram illustrates the electrical connections.

7"%

3FDIBSHBCMF

#BUUFSZ7PIN

&FQSPN$

5SBOTGPSNFS

$IBSHF$POUSPMMFS

,FZQBE

1PXFS4FMFDUPS

.JDSPDPOUSPMMFS

)4FSJFT

"%$POWFSUPS

3FHVMBUPS

2.8 Physical Layout of Electrical Connections

The following diagram illustrates the actual layout of electrical connections.

1JO'FNBMF"NQIFOPM

GPS&YUFSOBM-PBEDFMM

7

-$%.PEVMF

34$

*OUFSGBDF

-PBEDFMM

-PBEDFMM

"$3FDFQUBDMF

34

*OUFSGBDF

$/

1

$/

1

%$.BJO#PBSE45#

"%#PBSE

45#

$/

1

0QFSBUPS-$%

-PBEDFMM

3FDIBSHBCMF#BUUFSZ

70IN

4$8%

5SBOTGPSNFS

'VTF

"7

$/

1 1

,FZCPBSE

45#

185

$/

1

$/

Installation 11

Page 16

3.0 Configuration Settings

This section presents the setup and configuration of the DC-788 counting scale to be used specifically by

distributors and service technicians. Configuring these specifications allow you to tailor the DC-788 to your

specific applications.

Setting the specifications allows you to modify the functionality of the DC-788. Use the tables in this section to

view the options you can modify.

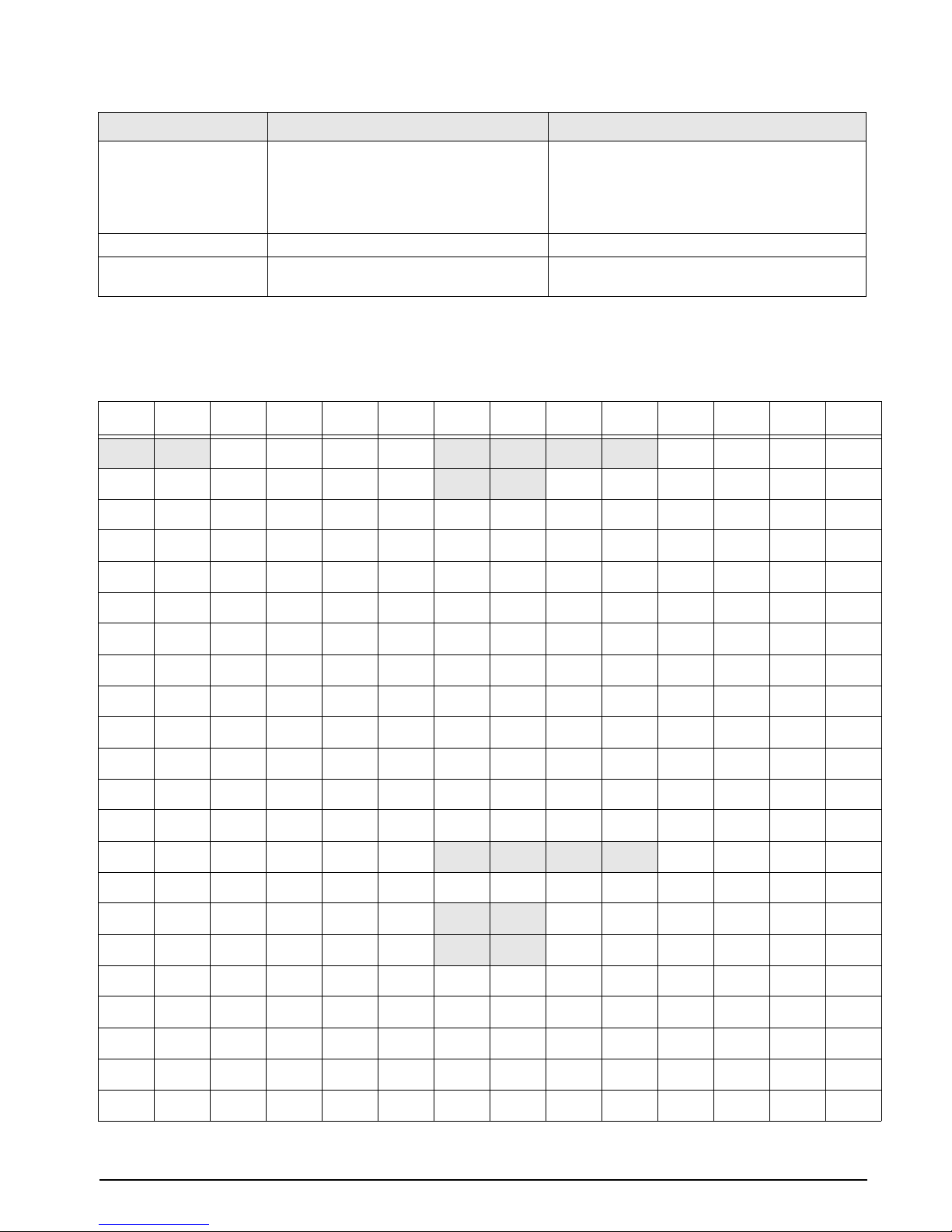

3.1 Configuring Specification 141 and 142 Settings from the Scale Keyboard

The following tables list the DC-788 specifications, their corresponding default values, and the other possible

values to which they can be programmed. The default values are set at the factory when the scale is shipped.

SPC 0 through SPC 19 (

through SPC 35 (Table 3-2) are weight and measurement specifications, and use the 142 access code

In programming specifications, the + (Plus) and – (Minus) keys allow you to move to the next or previous

specification. The CLEAR key cancels any input you have made. The * PRINT key temporarily stores to

memory any changes you have made. The TAR E

you to the weighing mode. Note also th at when programming specifications, only th e 0 and 1 keys on the

numeric keypad are enabled, since those are the only valid entries.

3.1.1 Customer Specification (141 Settings)

1. To configure customer specifications, press and hold the REZERO key and enter 141 using the numeric

keypad. The first SPC code is displayed.

Table 3-1 ) are customer specifications and use the 141 access code, while SPC 20

key saves to memory the changes you have made and returns

The Weight display shows what specification you are in (in this case, SPC00). The Unit Weight display

shows how this specification is currently programmed (Bit 3 = 0; Bit 2 = 0; Bit 1 = 0, and Bit 0 = 1 in this

example, while the PCS display will show any changes you enter.

If this is the SPC that you want to modify, enter the new setting from the numeric keypad and press the *

PRINT key to enter the change into temporary memory and move to the next SPC code.

2. Use the + (plus) and – (minus) keys to scroll through the specifications until you find the one you want.

Then make your changes per the instructions in Step 1.

3. To change another SPC code before exiting, repeat Steps 1 and 2.

4. To save all the changed SPC settings currently in temporary memory and exit to the Weighing Mode,

press the TARE key.

12 DC-788 Operation Manual

Page 17

SPEC No. Bit 3 Bit 2 Bit 1 Bit 0

00 Auto Power-off Function (for no key operation and weighing operation)

0000: Auto power-off disable when scale is not in use (DEFAULT)

0001: 3 minutes

0010: 10 minutes

0011: 30 minutes

1011: 1 hour

0101: 3 hours

0110 ~ 1111 - not used

(SP1_OFFT)

01 0: Not used

02 Buzzer

Error Alarm

Set Point Alarm

Not Used

0: On (DEFAULT)

1: Off

(SP1_BUZZ)

03 Unit weight base per

1000PCS or 1 PCS

0: On (DEFAULT)

1: Off

(SP1_ALARM)

Sampling time for unit

weight calculation

display

0: 1000PCS (DEFAULT)

1: 1PCS

(SP1_UWID)

0: 10 times

1: 5 times (DEFAULT)

(SP1_STFUWC)

Note: When SPEC 27 Gross Mode is set to 0:

Allow, the scale remains in

UW/1000, regardless of

how this SPEC 3 is set.

See note under SPEC 27.

04 Order of month, date and year

00: MM/DD/YY (DEFAULT)

01: DD/MM/YY

10: YY/MM/DD

11: Not used

(SP1_DATEO)

05 Function of RS-232 Interface

00: PC

01: Printer (DEFAULT)

10: Not used

11: Not used

(SP1_RS232IF)

06 RTS/CTS Handshaking of

Baud Rate of RS-232C

RS-232C

0: On (DEFAULT)

0: (DEFAULT)

1: Off

(SP1_PALARM)

Negative Counting

0: Allow (DEFAULT)

1: Inhibit

(SP1_NCOUNT)

Re-zero Function

0: Allow (DEFAULT)

1: Inhibit

(SP_RZF)

Set Point Type

00: % quantity (DEFAULT)

01: % weight

10: Quantity

11: Weight

(SP1_SPT)

Extrent of insufficient samples

00: 0.1% (DEFAULT)

01: 0.2%

10: 0.0%

11: Not used

(SP1_INSUFFRG)

0: On

1: Off (DEFAULT)

(SP1_RTS)

07 Stop bit of RS-232C

0: 1 bit (DEFAULT)

1: 2 bit

(SP1_STOP)

000: 1200 bps 100: 19200 bps

001: 2400 bps 101: Not used

010: 4800 bps 110: Not used

011: 9600 bps (DEFAULT) 111: Not used

(SP1_BAUD)

Data length of RS-232C

0: 7 bit

1: 8 bit (DEFAULT)

(SP1_DLEN)

Parity of RS-232C

00: None (DEFAULT) 10: Even

01: Odd 11: Not used

(SP1_PAR)

Tab le 3-1. DC-788 (141) Settings

Configuration Settings 13

Page 18

SPEC No. Bit 3 Bit 2 Bit 1 Bit 0

08 RS-232C PC Protocol

0000: Inhibit data transfer (DEFAULT)

0001: Standard stream type (continuous output

0010: Standard manual type

0011: Stand command type

0100~ 1111: Not used

(SP1MODE)

09 External Printer Type

0000: No Printer (DEFAULT)

0001: DIGI GP460R Label Printer

0010: Zebra LP2844 Bar Code Printer

0011: Epson TMU200 or Star SP2320 Tape Printers

0100: Epson TM295 or Star SP298 Ticket Printers

0101: TVP1000 Bar Code Printer

(SP1PRINTER)

10 Interval of Time Out Error of RS-232

Transmission Condition

of RS-232

Additional Parity Code in

Te x t o f R S -2 3 2

00: 1 Second

01: 3 Seconds (DEFAULT)

10: 5 Seconds

11: 10 Seconds

(SP1TIME)

11 Tare Weight in Text of

RS-232

0: No

1: Yes (DEFAULT)

(SP1_TW)

12 Date & Time in Text of

RS-232

0: No

1: Yes (DEFAULT)

(SP1_DTIME)

13 Print When Pressing the +

or - Key

0: No (DEFAULT)

1: Yes

(SP1_PRTK) (*V1.09)

Unit Weight in Text of

RS-232

0: No

1: Yes (DEFAULT)

(SP1_UW)

Parts Information in Text

of RS-232:

0: Include Parts Information

1: Include Only ID Code

(Output like DC-180.

Requires a setpoint value to

be entered to work)

External Printer Print Format

000: Default Format (DEFAULT)

001: Customer Format 1

010: Customer Format 2

~

111: Customer Format 7

(SP1PRINTER)

0: Weight Stable (DEFAULT)

1: Unconditional

(SP1_COND)

Gross Weight in Text of

RS-232

0: No

1: Yes (DEFAULT)

(SP1_GW)

Header Code in Text of

RS-232

0: No

1: Yes (DEFAULT)

(SP1_HEAD)

0: No (DEFAULT)

1: Yes

(SP1_APAR)

Quantity in Text of

RS-232

0: No

1: Yes (DEFAULT)

(SP1_TP)

Weight Range of Data

Output

0: Always (DEFAULT)

1: Over 20e

(SP1_MINWTL)

14 DC-788 Operation Manual

Tab le 3-1. DC-788 (141) Settings

Page 19

SPEC No. Bit 3 Bit 2 Bit 1 Bit 0

14 Clear Unit Weight When

Swap Scale

Rezero When Swap Scale

Auto Scale Switching

Zero Display

0: No (DEFAULT)

1: Yes

(SP1_UC) (*V1.06)

15 Display “MEM EXIST”

message reminding you

that there is an

accumulation in memory

0: No

1: Yes (DEFAULT)

(SP1_MEXIST) (V1.10)

16 - 19 Not Used

0: No (DEFAULT)

1: Yes

(SP1_RZ) (*V.106)

Clear TARE Weight When

Swapping Scales

0: No (DEFAULT)

1: Yes

0: No (DEFAULT)

1: Yes

(SP1_ASS) (*V1.07)

Scale Number in Text of

RS-232

0: No

1: Yes (DEFAULT)

0: Display 0 With ‘/’

1: Display 0 Without ‘/’

(DEFAULT)

(SP1_DIS0) (*V1.10)

Number of Setpoints

0: 2 Setpoints (Default)

1: 3 Setpoints

(SP1_SPN) (v1.10)

Tab le 3-1. DC-788 (141) Settings

3.1.2 Weight and Measurement Specifications (142 Settings)

To make changes to the Weight and Measurement Specifications, the span switch must be on. (For instructions

on how to turn the span switch on, see

Section 4.0.)

1. To configure customer specifications, press and hold the REZERO key and enter 142 using the numeric

keypad. The first SPC code is displayed.

The Weight display shows what specification you are in (in this case, SPC20). The Unit Weight display

shows how this specification is currently programmed (Bit 3 = 1; Bit 2 = 0; Bit 1 = 0, and Bit 0 = 0),

while the PCS display will show any changes you enter.

If this is the SPC that you want to modify, enter the new setting from the numeric keypad and press the *

PRINT key to enter the change into temporary memory and move to the next SPC code.

2. Use the + (Plus) and – (Minus) keys to scroll through the specifications until you find the one you want.

Then make your changes per the instructions in Step 1.

3. To change another SPC code before exiting, repeat Steps 1 and 2.

4. To save all the changed SPC settings currently in temporary memory and exit to the Weighing Mode,

press the TARE key.

Configuration Settings 15

Page 20

SPEC No. Bit 3 Bit 2 Bit 1 Bit 0

20 Version Display When

Power On

Selection of

Segment-Check Style

Start Range

0: Allow (DEFAULT)

1: Inhibit

0: Fast (DEFAULT)

1: Standard

(SP_VER)

(SP_SEGCK)

21 Minimum Display (Scale 1)

00: 1

01: 2 (DEFAULT)

10: 5

11: 10

(SPMINID)

22 Selection of Resolution (Scale 1)

0000: 1/2500

0001: 1/5000 (NTEP Setting)

0010: 1/10000 (DEFAULT)

0011: 1/15000

0100: 1/20000

0101: 1/25000

0110: 1/30000

0111: 1/12500

(SPRES)

23 Not Used

0: (DEFAULT)

Weight Decimal Point Position (Scale 1)

000: No Decimal Point

001: 1st Digit (0000.0)

010: 2nd Digit (000.00)

011: 3rd Digit (00.000)

100: 4th Digit (0.0000)

(SPWPT)

24 Selection of Resolution (Scale 2)

00: ±10% of Full Scale (DEFAULT)

01: ± 5% of Full Scale

10: ± 3% of Full Scale

11: ± 2% of Full Scale

(SPSRANGE)

Minimum Display (Scale 2)

00: 1

01: 2

10: 5 (DEFAULT)

11: 10

SPMINID1)

0000: 1/2500

0001: 1/5000 (NTEP Setting)

0010: 1/10000 (DEFAULT)

0011: 1/15000

0100: 1/20000

0101: 1/25000

0110: 1/30000

0111: 1/12500

(SPRES1)

25 Not Used

0: (DEFAULT)

Tabl e 3-2. DC-788 Weight and Measurement Specifications

16 DC-788 Operation Manual

Weight Decimal Point Position (Scale 2)

000: No Decimal Point

001: 1st Digit (0000.0) (DEFAULT)

010: 2nd Digit (000.00)

011: 3rd Digit (00.000)

100: 4th Digit (0.0000)

(SPWPT1)

Page 21

SPEC No. Bit 3 Bit 2 Bit 1 Bit 0

26 Weight Stability Conditions

2nd Scale

Please note that the scale

IR Mode Protected by

Span Switch

switch is not activated until

the 2nd scale has been

calibrated.

00: Loose

01: Normal (DEFAULT)

10: Tight

11: Stringent

(S PWTATA BC)

27 Weight Unit Base

0: kg

1: lb (DEFAULT)

(SPBASE)

28 Manual Tare

Cancellation

0: Allow (DEFAULT)

1: Inhibit

(SP_MTC)

29 Digital Tare

Type of Decimal Point

0: .(Standard) (DEFAULT)

1: ,(Europe)

(SP_DPF)

Ta r e S ub t r a c t i o n

0: Allow (DEFAULT)

1: Inhibit

(SP_TS)

Accumulation When

Ta r e

0: Inhibit (DEFAULT)

1: Enable

(SP_SCALET)

Negative Weight

Display Mask

0: Minus Gross > 9e

1: Minus Gross Weight

(DEFAULT)

(SP_NMASK)

Ta r e A cc u mu l a t i o n

0: Allow (DEFAULT)

1: Inhbit

(SP_TA)

Zero Tracking When

Ta r e

0: No (DEFAULT)

1: Yes

(SP_SPSW)

Gross Mode

0: Allow

1: Inhibit (DEFAULT)

(SP_GROSSM)

Note: When the Gross

Mode is enabled, it disables

the ability to switch

between lb/kg or to switch

to APW because the lb/kg

key is used for the gross

mode. When Gross Mode

is enabled, the scale stays

in UW/1000 regardless of

how SPEC 3 is set.

Auto Tare Clear When

Rezero

0: Allow

1: Inhibit (DEFAULT)

(SP_AUTOT)

Weight Reset When

Tare

0: Allow

1: Inhibit (DEFAULT)

(SP_DT)

30 Ta r e A u t o Cl e a r

0: Allow

1: Inhibit (DEFAULT)

(SP_TAUTO)

31 Accumulation

0: 0: Allow (DEFAULT)

1: Inhibit

(SP_ACC)

Tabl e 3-2. DC-788 Weight and Measurement Specifications

0: Allow

1: Inhibit (DEFAULT)

(SP_ACCT)

Unit Weight Auto Clear

0: Allow

1: Inhibit (DEFAULT)

(SP_UAUTO)

Accumulation Number

Display

0: Allow (DEFAULT)

1: Inhibit

(SP_ANO)

0: Allow (DEFAULT)

1: Inhibit

(SP_ZTT)

Auto Clear Condition

0: >=Gross 21e & >=Net 5e

1: >=Net 1e & Quantity Not

0 (DEFAULT)

(SP_AUTOCC)

WT Data

Synchronization (+ key

only)

0: Allow (DEFAULT)

1: Inhibit

(SP_WDS)

Configuration Settings 17

0: Allow (DEFAULT)

1: Inhibit

(SP_WR)

Not Used

0: (DEFAULT)

Accumulation Display

Style

0: “Total” (DEFAULT)

1: “Add”

(SP_ADS)

Page 22

SPEC No. Bit 3 Bit 2 Bit 1 Bit 0

32 Exit From Accumulation

Mode After 15 Second

Time Out

Exit From Acculumation

Mode When Weight

Change

Quantity Accumulation

Without Removing

Weight

Quantity Accumulation

Without Changing

Weight (for >= ±10e)

0: Allow (DEFAULT)

1: Inhibit

(SP_EA15)

0: Allow (DEFAULT)

1: Inhibit

(SP_EAWC)

33 Loadcell Sensitivity Selection mV/V (1st Scale)

0000: 0.95 ~ 1.09 (Default) 0100: 1,69 ~ 1.95 1000: 0.40 ~ 0.46 1100: 0.71 ~ 0.82

0001: 1.09 ~ 1.27 0101: 1.95 ~ 2.25 1001: 0.46 ~ 0.53 1101: 0.82 ~ 0.95

0010: 1.27 ~ 1.46 0110: 2.25 ~ 2.59 1010: 0.53 ~ 0.61

0011: 1.46 ~ 1.69 0111: 2.59 ~ 3.00 1011: 0.61 ~ 0.71

(SPSST)

34 Loadcell Sensitivity Selection mV/V (2nd Scale)

RLWS recommends a setting of 0000 for bench scales and 0011 for floor scales connected as a second scale.

0000: 0.95 ~ 1.09 0100: 1,69 ~ 1.95 1000: 0.40 ~ 0.46 1100: 0.71 ~ 0.82

0001: 1.09 ~ 1.27 0101: 1.95 ~ 2.25 1001: 0.46 ~ 0.53 1101: 0.82 ~ 0.95

0010: 1.27 ~ 1.46 0110: 2.25 ~ 2.59 1010: 0.53 ~ 0.61

0011: 1.46 ~ 1.69 (Default) 0111: 2.59 ~ 3.00 1011: 0.61 ~ 0.71

(SPSST1)

35 1st Scale Weight Unit

0: kg (DEFAULT)

1: g

(SP_GBASE1)

NOTE: Units for Scale 1

should be set to be the

same as the units on Scale

2 (See SPEC 35, Bit 2)

2nd Scale Weight Unit

0: kg (DEFAULT)

1: g

(SP_GBASE2)

NOTE: Units for Scale 2

should be set to be the

same as the units on Scale

1 (See SPEC 35, Bit 3)

0: Allow (DEFAULT)

1: Inhibit

(SP_QARW)

Negative Weight

Display Mask Range

0: Minus Gross > 9e

1: Minus Gross >20e

(DEFAULT)

(SP_NMRG)

0: Allow (DEFAULT)

1: Inhibit

(SP_QACW)

Not Used

0: (DEFAULT)

Tabl e 3-2. DC-788 Weight and Measurement Specifications

18 DC-788 Operation Manual

Page 23

4.0 Calibration

The DC-788 counting scale is a high-precision instrument. Although the scale needs very little maintenance, you

may want to check the calibration after every month or so of normal usage. To do this you will need to have a test

weight of approximately the total capacity of the scale (i.e. a 10 lb weight if you have a 10 lb capacity scale).

After the scale is initially installed, put the weight on the platform and record the weight displayed. Then every

month or so put the same weight on the scale and verify that it still reads the same.

Many facilities have a technician come in and check their units with certified test weights four times a year. If

you are ISO certified, you will want to check to see if your certification specifies more stringent requirements in

order to stay in compliance. Your DIGI scale dealer has the calibrated test weights, expertise and experience to

perform this task for you as well as to check other operating parameters of your scale and help you effectively

integrate scales into your operations. If you do not know who your local DIGI dealer is, call us at

1-715-736-0002 and we will help you find someone who can provide you with on-site support.

Follow the instructions below to calibrate your DC-788 scale to ensure its continued accuracy.

NOTE: You can exit the Maintenance Mode and return to the Weighing Mode at any time by pressing the TARE key. If you

have a remote scale attached to the DC-788, you must first set the SPECs for that remote scale before beginning the calibration

process.

1. Turn the scale on, then press the span switch to reset it. (See Figure 4-1 below.)

2. The scale will display the model number, firmware version number and the message S ON indicating that

the Span Switch is currently on.

3. While pressing the REZERO key, enter 8715 from the numeric keypad to enter the calibration mode.

Figure 4-1. Location of Span Switch

Calibration 19

Page 24

4. The scale display will confirm that you are in the Calibration Mode.

5. You can select which scale you are calibrating, Scale 1 or Scale 2, by pressing the SCALE key. (If a 2nd

scale is not installed and set in the specifications, pressing the SCALE key has no effect.) If you have

not yet set up the remote scale in the specifications, press the TAR E key to exit the calibration process

and and set the specifications. Then power down the scale to commit the changes to the scale’s memory

before returning to calibration. (For information on setting specifications, see

“Configuration Settings”

on page 12.)

6. Make sure that there is no weight on the platform of the scale you are calibrating and press the * PRINT

key. The scale will flash briefly as it searches for the zero point and then will display it.

7. Place a reference weight on the platform. It is preferable to calibrate the scale using a weight equal to the

full capacity of the scale (i.e. a 5 lb weight for 5 lb capacity scale, etc.) If the reference weight is not

equal to the full capacity of the scale, it must at least be greater than 10% of the full scale capacity.

If the reference weight is equal to the full capacity of the scale, press the * PRINT key. If the reference

weight is less than the full capacity of the scale, enter the value of the weight placed on the platter using

the numeric keys before pressing the * PRINT key. The weight you enter will appear in the Weight

display.

8. The display will flash briefly again as the span settings for calibration of the scale are being temporarily

saved. Then the display will return to the weighing mode with the calibrated weight showing in the

Weight window..

9. To exit the Maintenance Mode and save your calibration, power down your DC-788 s cale. To exit the

Maintenance Mode and return to the Weighing Mode without saving your calibration, press the TARE

key.

20 DC-788 Operation Manual

Page 25

5.0 Scale Operations

The following sections contain detailed operator instructions for the DC-530 counting scale (see Figure 5-1).

Included are instructions on how to switch between scale platforms, how to enter tare weights, how to enter unit

weights, and how to perform counting operations both in the regular Counting Mode and th e TEP (Teraoka Error

Prediction) Mode.

Figure 5-1. DC-788 Counting Scale

5.1 Counting Scale Accuracy and the TEP (Teraoka Error Prediction) Mode

Counting scale accuracy is primarily determined by the following factors:

• S ample size (number of pieces)

• Total sample size as a percentage of full scale capacity

• P iece-to-piece weight variation

As a general rule when determining sample size of fairly uniform pieces, the larger the sa mple size the grea ter the

total sample weight, therefore, the better the counting accuracy. Selecting the smallest capacity scale that can

obtain the highest counting resolution should be considered, but should not sacrifice the capacity required for the

heaviest container of parts. For this kind of application, a scale like the DC-530 with an extra scale channel is

often the best selection.

There is a direct relationship between piece-to-piece weight variation (non-uniformity) and counting accuracy.

Therefore, elimination of the piece-to-piece weight variations can be accomplished by:

1. Isolating the sample used to calculate the unit weight and use the same sample to re-check the scale.

2. Recalculating the unit weight from lot-to-lot of parts. Parts manufactured on one machine may vary

slightly from another machine relative to weight.

3. Tightening the manufacturing tolerances on the parts reduces piece weight variations and increases count

accuracy.

Parts can vary greatly in their value. With parts of lesser value per piece, the extra sampling and time involved in

trying to achieve 100% accuracy as opposed to 99.5% may not be cost-effective. However, with high value

items 100% accuracy is vital. To address this need, the DC-530 provides you with two counting modes: Regular

Counting Mode and TEP (Teraoka Error Prediction) Mode. Regular Counting Mode offers you the same

ultra-high-precision that all DIGI products are noted for. When you have high-value items, TEP Mode walks you

through a more extensive sampling process from which the scale calculates and displays the number of parts that

can be counted at a time with no counting error.

Scale Operations 21

Page 26

5.2 Weight Unit Switching

The weight units displayed can be changed between Kg and Lb during weighing operations by pressing the kg/lb

key. The appropriate annunicator will light. SPC27 - Base Weight Units sets the default weight unit to Kgs or

Lbs. If you are using more than one scale, SPC35 sets the weighing units for the 1st and 2nd scales. (For further

instructions on how to set the specifications, see

Section 3.1.2)

5.3 Toggling Between Scales

To toggle between Scales 1 and 2, press the SCALE key. The indicator lamp for the appropriate scale lights on

the display.

NOTE: This function is available only when SPC26 - 2nd Scale is enabled. (For further instructions on how to set the

specifications, see

Section 3.1.2)

5.4 Setting Tare Weights in Weighing Mode

This section will describe the different tare-related operations you can perform from the weighing mode. Tare

weight can be set by one touch tare using the TARE key or, if the value is known ahead of time, can be entered

digitally using the digital tare function. Tare addition and subtraction can also be done digitally or by using the

TARE key. Finally, an existing tare stored with an Item Code can be overridden temporarily in the Weighing

Mode if needed.

Note: The following SPC codes must be set properly to allow these operations before continuing: SPC 28, Bit 1 - MANUAL

TARE CANCELLATION sets whether or not the tare weight can be cancelled from the keyboard. SPC 28 also controls whether

TARE SUBTRACTION (Bit 2) and TARE ACCUMULATION (Bit 1) are allowed or inhibited and whether AUTO TARE CLEAR WHEN

REZERO (Bit 0) takes place or not. SPC 29 controls whether the scale allows DIGITAL TARE entry (Bit 3), whether the scale can

do ACCUMULATION WHEN TARE (Bit 2), if there will be ZERO TRACKING WHEN TARE (Bit 1) and WEIGHT RESET WHEN

TARE (Bit 0). SPC 30 sets whether or not TARE AUTO CLEAR is activated (Bit 3). (For further instructions on how to set the

specifications, see

Section 3.1.2)

5.4.1 One Touch Tare (When the Tare Weight is Unknown)

1. While in the weighing mode, place a bin, box or other weight to be tared out on the platform.

2. Press the TAR E key to subtract the tare weight. The Net annuciator will light up, the Weight display

should now show 0 and the tare weight will show in the Tare display.

3. If you remove the tare weig ht from the platform, the tare weight will show as a negative weight in the

weight window and the Net annunciator will remain lit.

Note: This tare weight will be overridden by the weight stored with an Item Code when you call up an Item Code.

4. To clear this tare weight and return to the Weighing Mode, press the TA RE key again. The net

annunciator will not longer be lit.

5.4.2 Digital Tare (When Tare Weight is Known in Advance)

1. While at the stand-by screen, enter the known tare weight by using the numeric keypad.

2. Press the TAR E key to subtract the tare weight. The Net annunciator will light up and the tare weight

will be displayed in the weight display.

Note: This tare weight will be overridden by the weight stored with an Item Code when you call up an Item Code.

3. To clear this tare weight and return to the Weighing Mode, press the TA RE key again. The net

annunciator will no longer be lit.

Note: For digital tare entry, the decimal must be in the appropriate place as it would be displayed in the weight display. For

example,.250 would be entered as 0.250, not.250. The weight display shows weight entered with a negative sign indicating that

it is a tare weight.

5.4.3 Tare Addition or Subtraction

Two tares can be accumulated or subtracted using the TAR E key as well. Tare weights cannot be accumulated or

subtracted by digital entry.

Note: SPC 28, Bits 2 and 1 must be set to 00 to enable Tare Accumulation and Tare Subtraction. (For further

instructions on how to set the specifications, see

1. Place the container, box or item to be tared on the platform and press the TARE key. The weight display

should show 0, the Net annunicator will illuminate and the tare weight will appear in the Tare display.

Section 3.1.2)

22 DC-788 Operation Manual

Page 27

2. Place another tare weight on the platform and press the TAR E key again. This will add the two tare

weights together (Tare Addition).

3. Tare weights can be subtracted individually by removing one from the platform and pressing the TARE

key again. T o clear all the tare weights and return to the Weighing Mode, remove all the tare weights and

press the TARE key. The Net annunicator will no longer be lit.

5.4.4 Tare Override

For instructions on how to temporarily override a tare that is called up with an Item Code, please see

Section 5.9.4.

5.5 Entering Unit Weights

Entering unit weights can be done either by sampling, as presented in Section 5.5.1, or by key entry as described

in Section 5.5.2.

NOTES: SPC 05 - EXTENT OF INSUFFICIENT SAMPLES controls unit weight sampling. The default setting for the SPC is 00:

0.1 percent.

SPC 14, Bit 3 - CLEAR UNIT WEIGHT WHEN SWAP SCALE sets whether the unit weight determined by sampling is

automatically transferred from Scale 1 to Scale 2 or is cleared when you transfer scales. SPC 14, Bit 1 - AUTO SCALE

SWITCHING, sets . When you have a procedure that involves sampling an item’s unit weight on the DC-788’s built-in

platform and then want to go immediately to weighing and counting boxes or bins on a floor scale or other external

scale, set SPC 14 to 1: YES. If the external Scale 2 is not necessarily going to be used for weighing the same item as is

being sampled on Scale 1, set SPC 14 to 0: NO.

SPC 03 - UNIT WEIGHT BASE PER 1000PCS OR 1PCS controls whether the unit weight is displayed per 1000 pieces

or per 1 piece. The default settings for this SPC is 0: 1000 pieces.

(For further instructions on how to set the specifications, see Section 3.1.1)

Unit Weight per 1000 Pieces vs. Unit Weight per 1 Piece

The scale’s internal microprocessor calculates unit weights to 7 or 8 decimal places. However, the scale display

generally can only show Unit Weight to 5 characters. If this Unit Weight is recorded from the scale display and

entered by key entry, this can introduce errors in the Unit Weight and consequently in the counts. This error

increases as the Unit Weight of the parts being counted decreases.

Example: A sample of 10 zener diodes is placed on the scale. The Unit Weight is computed by the scale to be

0.0006536 lbs. However, the scale has a 5 character display for Unit Weight so the scale can only display.0065 as

the Unit Weight. If this Unit Weight were recorded and keyboard entered in future counting operations, the

resulting error would be: 00065 =.55%

.0006536

On the other hand, with entry of the Unit Weight as “weight per 1000 pieces” the decimal place is, in effect,

moved three places to the right, allowing 3 more decimal places of accuracy. In this example, the entry would be

made as 0.6536 per 1000 pieces, eliminating the error.

As a practical note, entering unit weights per 1000 pieces also lessens the chances of entering the wrong number

of zeros when keying in weights with many leading zeros. Misentry of unit weights is a common cause of

inaccurate counting.

When might you want to use unit weight per 1 piece? Generally in one of two cases:

1. If you are working with other existing systems or procedures that are already set up to record unit weight

per piece (inventory systems, labeling requirements, etc).

2. If the unit weight or your pieces is more than 100 lbs, as in the case of some castings, engine parts and

the like. When the unit weight is over 100 lbs, the number of digits in the scale’s Quantity display will

not be able to fully display counts of more than 100 pieces.

5.5.1 Unit Weight Operation by Sampling

Unit weight operation by sampling is accomplished by placing a 10 piece sample on the scale and then pressing

the PCS key. The scale calculates a unit weight based on the capacity of the scale compared to the weight of the

sample. If you wish to use a sample of more than 10 pieces, place the sample on the scale, then input the sample

size before pressing the PCS key.

Scale Operations 23

Page 28

If the sample size is insufficient to give an accurate unit weight, no unit weight will be displayed, the INSUFF

lamp will be illuminated and you have the following options:

• You can add pieces to the sample (keeping track of how many you add) until the INSUFF lamp goes

out Key in the new total sample quantity and press the PCS key. The scale will compute and

display the unit weight.

• The scale will prompt you to add enough pieces to bring the sample up a weight that allows

calculation of a more accurate unit weight The weight will appear in the Weight display, the word

ADD in the Unit Weight display and the number of pieces to be added in the PCS display

• Add exactly the number of pieces requested (the PCS display will go down to 0) and press the PCS

key. The scale will compute and display the unit weight and the INSUFF lamp will go out.

You can ignore or override the INSUFF indicator by pressing the PCS key again without adding more pieces to

the sample. However, it may affect counting accuracy to use a Unit Weight calculated on the basis of an

insufficient sample. If you do press the PCS key again, the scale will compute and display the unit weight based

on the original sample you gave it.

If the RECOMP indicator is lit, the accuracy of the unit weight computation can be improved by adding

approximately double the number of pieces currently on the scale and pressing the

flash as it recomputes the unit weight, after which it will display the new Unit Weight.

PCS key again. The scale will

.

5.5.2 Unit Weight Operation by Key Entry

Unit weight operation by key entry is accomplished by using the numeric keypad to enter the known value of the

unit weight and then pressing the UNIT WEIGHT key. An example of unit weight operation by key entry is

shown below:

1. With the display in the weighing mode, enter the known unit weight using the keyboard, for example,

200.00.

2. Press UNIT WEIGHT key to enter the unit weight.

3. Place a 2 lb. weight on the scale. The scale displays the quantity for the weight placed on the scale, for

example, the weight display reads 2.000, the unit weight display reads 200.00, and the quantity display

reads 10).

4. Press the CLEAR key to clear the Unit Weight.

5.6 Setting a Lot Number

Lot numbers can be attached to Item Codes when programming item codes into memory. For instructions on

how to set a lot number, see

A Lot Number which is not associated with a specific item code can also be set temporarily in the Weighing

Mode. If the DC-788 is connected to an external printer or PC, this Lot Number will appear on labels an d

receipts or be output to the PC as part of the data string. For instructions on how to set a temporary Lot Number

not associated with an Item Code, see

Section 6.3.

Section 5.8.3.7 below.

5.7 Setting a Sequence Number

The scale can maintain and print a sequence number to aid in transaction tracking and auditing. If the sequence

number is set to “0”, no sequence number will be incremented or tracked. Otherwise the sequence number will

automatically increment by 1 each time a label is printed by pressing the + (Plus), - (Minus), or * PRINT keys.

24 DC-788 Operation Manual

Page 29

1. At the stand-by screen, press the MODE key twice to enter the Programming Mode.

2. Press and hold the REZERO key while entering [.] [.] [7]. The scale will go to the Sequence Number

Reset screen.

3. To save the new sequence number and exit, press the * PRINT key. To exit without saving the new

sequence number, press the CLEAR key twice.

5.8 Operations Without Recalling an Item Code

The following sections describe ways to carry out operations without having to recall the Item codes.

5.8.1 A Single Counting Operation - Without Recalling an Item Code

At times you may want to perform a weighing and counting operation without recalling an Item Code from

memory. This can be done from the keyboard in the Weighing Mode.

1. Place a 10 piece sample on the scale and press the PIECES key or enter the unit weight from the

numeric keypad and press the UNIT WEIGHT key. The display will flash briefly, then return to normal.

2. To set a tare value, enter the tare from the numeric keypad and press the TAR E key or place the container

to be tared on the platter and press the TARE key.

3. Place the product to be weighed and counted on the platter. The total weight and pieces count will be

displayed. If a printer is connected to the DC-788, you can print a label with the data by pressing the *

PRINT key .

4. To perform another weighing and counting operation, remove the product from the scale platter and

press the CLEAR key.

5.8.2 Part Accumulation or Subtraction and Negative Counting - Without Recalling an Item Code

The DC-788 has the capability to acquire the total number of parts using the accumulation or reduction function

of the scale (similar to the add/subtract functions of a calculator).

5.8.2.2 Part Accumulation or Subtraction

To find the total accumulated quantity of similar containers filled with parts, use the accumulation procedure

detailed below . This does not af fect the inventory quantity for this item in the scale’s memory. To add or subtract

from inventory, see

Section 5.9.3.

1. Enter the unit weight of the pieces (if known) or conduct a sampling process (Section 5.5.1) to determine

the unit weight of the pieces. Press the PCS key.

2. Enter the known tare weight, or place an empty container on the scale to perform tare function

Section 5.4). Press the TAR E key.

(

NOTE: If SPC 3, Bit 1 - Negative Counting is set to 0: Allow, a quantity of pieces may be displayed if a tare is entered with no

weight on the scale. (For more information on how to set customer specifications, see

Section 3.1.1.)

3. Place container 1 (full of parts) on the scale.

4. Press the + (Plus) key to store the total in container 1. The Memory annunicator ∑ is now illuminated.

The weight display briefly shows totAL 1 and the quantity display shows the total pieces in the first

container.

Note: If the DC-788 is connected to a printer or PC, the data will be printed or outputted each time the + (plus), - (minus) or *

PRINT keys are pressed. If SPC 32, Bit 3 - Exit From Accumulation Mode After 15 Sec Time Out is set to 0: Allow, the display will

return to the weighing mode automatically after 15 seconds. If it is set to 1: Inhibit, you must press the CLEAR key to return to the

weight display. (For more information on how to set the Weight and Measurement specifications, see

Section 3.1.2.)

Scale Operations 25

Page 30

5. Remove container 1 and place container 2 (full of parts) on the scale.

6. Press the + (Plus) key (Total 2 is equal to container 1 plus container 2) The Memory indicator ∑ will be

illuminated.

7. Continue with the remainder of the containers to be counted. The total number of parts stored in all the

containers will be stored in the accumulation register.

8. To subtract pieces from the accumulation, place the container to be subtracted on the platform and press

the - (Minus) key. The display will show CORR and the number of pieces being subtracted. The

Memory indicator ∑ will continue to be illuminated.

Wait for the Total screen to clear and return to the Weighing Mode or press the CLEAR key.

9. When done with accumulation and subtraction, remove all products from the platter and press the

CLEAR key to clear the Unit Weight. (Note: If you try to press the CLEAR key while there is data in the

accumulation register, you will get an error message which says MEM EXIST. You must press the *

PRINT key to clear the accumulation register before the CLEAR key can be used to clear any unit

weight data on the display.

10. Press the + (Plus) key to display the accumulated total when the Unit Weight is zero. Wait for the Total

screen to clear and return to the Weighing Mode or press the CLEAR key.

11. Press the TARE key to clear the Tare Weight.

12. Press the + (Plus) key to display the total accumulation data. Wait for the Total screen to clear and

return to the Weighing Mode or press the CLEAR key.

13. Enter [3] [6] from the keyboard and press the - (Minus) key to subtract the data. Wait for the Total

screen to clear and return to the Weighing Mode or press the CLEAR key.

14. Press the * PRINT key to clear the accumulation register. The Memory indicator ∑ will no longer be lit.

If the DC-788 is connected to a printer or a PC, the total accumulation data will be printed or output.

5.8.2.3 Negative Counting

Just as you can count by adding parts to the scale, you can also count by removing parts from the scale. This is

called “negative counting” because a negative weight is displayed while counting. Contrary to what may seem

intuitively logical, you do not use the (-) key to do negative counting. The (-) key is only used to delete an entry

in accumulation mode that you want to erase. This procedure does not affect the inventory quantity for this item

stored in the scale. To reduce inventory, see

NOTE: To utilize the negative counting feature, SPC 3, Bit 1 - Negative Counting must be set to “0: ALLOW”. (For information

on setting Customer specifications, see

Section 3.1.1.)

Section 5.9.3.

There are two ways to do this depending on whether at the end you want to see the total amount remaining in the

container or the total amount removed from the container.

26 DC-788 Operation Manual

Page 31

5.8.2.4 Counting Out of a Full Container - See Total Amount Remaining in the Container

To carry out this operation you must know the tare weight ahead of time.

1. Place the full container on the scale. Press the TAR E key.

2. Remove a 10 piece sample to the container and press the PIECES key. After the unit weight has been

calculated, return the 10 piece sample to the container.

3. Remove a number of parts from the container. The QUANTITY window of the scale display will show

the number of pieces you have removed. This process can be repeated as many times as desired.

4. If at the end of the procedure, if you want to see how many remain in the bin or container, you first have

to know the tare weight of the bin or container. After removing the parts you want to take out of the bin,

simply digitally enter the tare weight of the bin and press the TARE key. The scale will display how

many parts were left in the bin.

If a printer or PC is connected to the DC-788, pressing the * PRINT key will print a label to put on the

bin showing the new, lower, total quantity or output the data to the PC.

5.8.2.5 Negative Counting - Total Removed Displayed at the End

With this procedure you can count accurately out of a full container for kiting, shipping, etc.without having to

know the tare weight of the container.

1. Place a full container on the scale and press TAR E.

2. Remove a 10 piece sample from the container and press PIECES. After the unit weight has been

calculated, return the 10 piece sample to the container.

3. Remove the number of pieces you need for kiting, shipping, etc. The amount removed will be displayed

in the QUANTITY window. If you need a label for each kit or container and an external printer is

connected to the DC-788, press the + (Plus) key after removing each batch of pieces. The Memory

indicator

∑ will be illuminated and the scale displays the accumulated total of pieces removed so far.

Then press the TARE key.

4. After removing each batch of pieces, press the + (Plus) key, then the TA RE key.

5. When you have removed the last batch of pieces, press the * PRINT key to show the total number of

pieces you have counted out of the full container. If a printer or PC is connected to the DC-788, pressing

the * PRINT key will print a label to put on the bin showing the number of pieces removed or output the