Page 1

CB-2

Automated Concrete Batching System

Version 2.0

Installation/Operation Manual

93603

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

About This Manual ....................................................................................................................................1

Safety ........................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 2

1.1 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Indicator Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0 Installation ................................................................................................................................... 5

2.1 Important Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.1 Two Power Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.2 I/O Power and Manual Panel Same Phase Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1.3 Unused Inputs Must be Jumpered to 120V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 CB-2 Main Junction Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Load Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.3.1 Serial Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.4 Digital I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.5 Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.6 Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.6.1 Option Cards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.7 Installing an Optional PS-2 Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.0 Configuration of Scale Parameters ........................................................................................... 18

3.1 Configuration Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.1.1 iRev Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.1.2 Front Panel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2 Menu Structures and Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2.1 SCALES Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.0 Configuration of User Parameters ............................................................................................. 22

4.1 Application Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.0 Calibration ................................................................................................................................. 40

5.1 Gravity Compensation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2 Front Panel Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3 Serial Command Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.4 iRev Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.0 Utilities....................................................................................................................................... 44

6.1 Material Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6.1.1 Usage Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.1.2 Adjust Inventory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.1.3 Clear Day Totals through Yearly Totals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.2 Tune Plant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.2.1 Min. Drop Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.2.2 Tune Jogs Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.3 Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.3.1 Print Mix Designs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.3.2 Print Application Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6.3.3 Print Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice. Rice Lake Weighing Systems is an ISO 9001 registered company.

Version 2.0 November 2013

Page 4

6.4 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

6.4.1 Test Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

6.4.2 Test Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.4.3 Test Ticket Printer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.4.4 Test Report Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.4.5 Test Serial Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.4.6 Print Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.4.7 Clear Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

7.0 EZ Change Criticals ................................................................................................................... 55

8.0 Batching ..................................................................................................................................... 56

9.0 Front Panel................................................................................................................................. 58

9.1 Front Panel Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.1.1 Power Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.1.2 Auxiliary Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.1.3 Aggregate Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.1.4 Cement Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.1.5 Mixer Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.1.6 Plant Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.1.7 Water Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.1.8 Admixture Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

10.0 Appendix .................................................................................................................................... 60

10.1 Configuration Parameters for the CB-2 Weighed Materials Discharged Using an Inch Gate . 60

10.2 Configuration Parameters for CB-2 Weighed Materials Discharged Using an Open Close Gate.

61

10.3 Weighing Material Preact Configuration Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.3.1 Preacts - Hopper Scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.3.2 Preacts - Decumulative Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.3.3 EZ Change Criticals - Material Preacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.3.4 Preact Value Level When Used in Lose in Weight (LIW). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.4 Entering a Mix Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

10.4.1 To Add a Mix Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

10.5 CB-2 Moisture Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

10.6 Changing the Location of a Material. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

10.7 Dual Speed and Dual Concurrent Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

10.8 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

10.9 CB-2 Loss In Weight Inching Gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10.10 CB-2 Loss In Weight Open/Close . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

10.11 MNDot Conversion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

10.12 Moisture Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.12.1 Cement/Water/Aggregate Mix Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.12.2 Oven Dry vs. Saturated Surface Dry Mix Designs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

10.12.3 Example of Weight Adjustments Based on a Saturated Surface Dry Mix Design . . . . . . . . . . . . . . . . . 77

10.12.4 Calculating Aggregate Moisture Content. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.12.5 Specifying Moisture Content and Absorption Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.12.6 Calibrating a Moisture Probe. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.13 Reservoir Metered Water. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.14 Tuning Inching Gates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.15 Setting up Time & Date Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10.16 CB-2 Administrative Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10.17 Adding Counter and Position Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

2 CB-2 Installation Manual

Page 5

About This Manual

WARNING

WARNING

WARNING

Important

CAUTION

WARNING

This manual is intended for use by service technicians responsible for installing and servicing the CB-2 and the

end user who will be operating the CB-2 automated concrete batching system.

In this manual, you will see many references to the CB-2 and

panel that includes Rice Lake’s 920i

®

HMI digital weight indicator. The 920i is the heart and brain of the CB-2

the 920i. To clarify, the CB-2 is a stand-alone batch

and is responsible for weight/scale data as well as running the CB-2 batching program. The CB-2 also contains

additional hardware that is interfaced to the 920i. The majority of the additional hardware is for controlling the

batch plant through digital I/O and then through solid-state 120V/240V relay modules.

Some procedures described in this

manual require work inside the

losure. These procedures are to be

enc

performed by qualified service

personnel only.

Authorized distributors and their employees

can view or download this manual from the

Rice Lake Weighing Systems distributor site

at www.ricelake.com.

Safety

Safety Symbol Definitions

Indicates a potentially hazardous situation that, if not avoided, could result in serious injury or death,

and includes hazards that are exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided may result in minor or moderate injury.

Indicates information about procedures that, if not observed, could result in damage to equipment or

corruption to and loss of data.

Safety Precautions

Do not operate or work on this equipment unless you have read and understand the instructions and

warnings in this manual. Failure to follow the instructions or heed the warnings could result in injur

or death. Contact any Rice Lake Weighing Systems dealer for replacement manuals. Proper care is

your responsibility.

Some procedures described in this manual require work inside the indicator enclosure. These

procedures are to be performed by qualified service personnel only.

General Safety

Failure to heed may result in serious injury or death.

DO NOT allow minors (children) or inexper

DO NOT use for purposes other than weight taking.

DO NOT place fingers into slots or possible pinch points.

DO NOT use any load-bearing component that is wo

DO NOT use this product if any of the

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

DO NOT use near water.

Before opening the unit, ensure the power cord

Keep hands, feet and loose clothing

ienced persons to operate this unit.

rn beyond 5% of the original dimension.

components are cracked.

is disconnected from the outlet.

away from moving parts.

y

Installation/Operation Manual - Safety 1

Page 6

1.0 Introduction

The CB-2 is a versatile, efficient concrete batching control system ideal for ready-mix, central mix, and block

plants. The CB-2 makes it easy and affordable to streamline your plant. From weighing raw material to automatic

printing of tickets and reports, the entire operation can be cost-effectively controlled from this one controller.

iRev provides functions for installing the new software into the CB-2.

Standard Features - Hardware

Standard hardware features of the CB-2 include:

• Panel type 920i HMI digital indicator that can

control up to three scales

• Six totalizing counters for units with admix

metering

• One addition totalizing counter for units with

metered water

• Twenty switch board assemblies with their

associated switches and appropriate

annunicators which are mounted on the front

panel of the CB-2 enclosure

• 920i expansion card with 1MB of memory

• Four digital I/O boards

• 4 - 24 channel relay boards

• Standard manual override controls

Standard Features - Software

Standard software features of the CB-2 include the

following:

• One aggregate and one cement scale sampling

60 times per second

• Batch/Load report

• Automatic aeration control for cement silos

and weigh hoppers

• Multiple free fall values per material with

automatic “learning” abilities

• Split batching for loads larger than plant

capacity with pre-weighing next batch for

maximum throughput

• Automatic dust collection outputs

• Precision control of inching gates for

aggregate and cement discharge

• Passcode protection

• U.S. or metric units

• Order loading with customer, job site, directions,

and special instructions

2 Installation/Operation Manual

Page 7

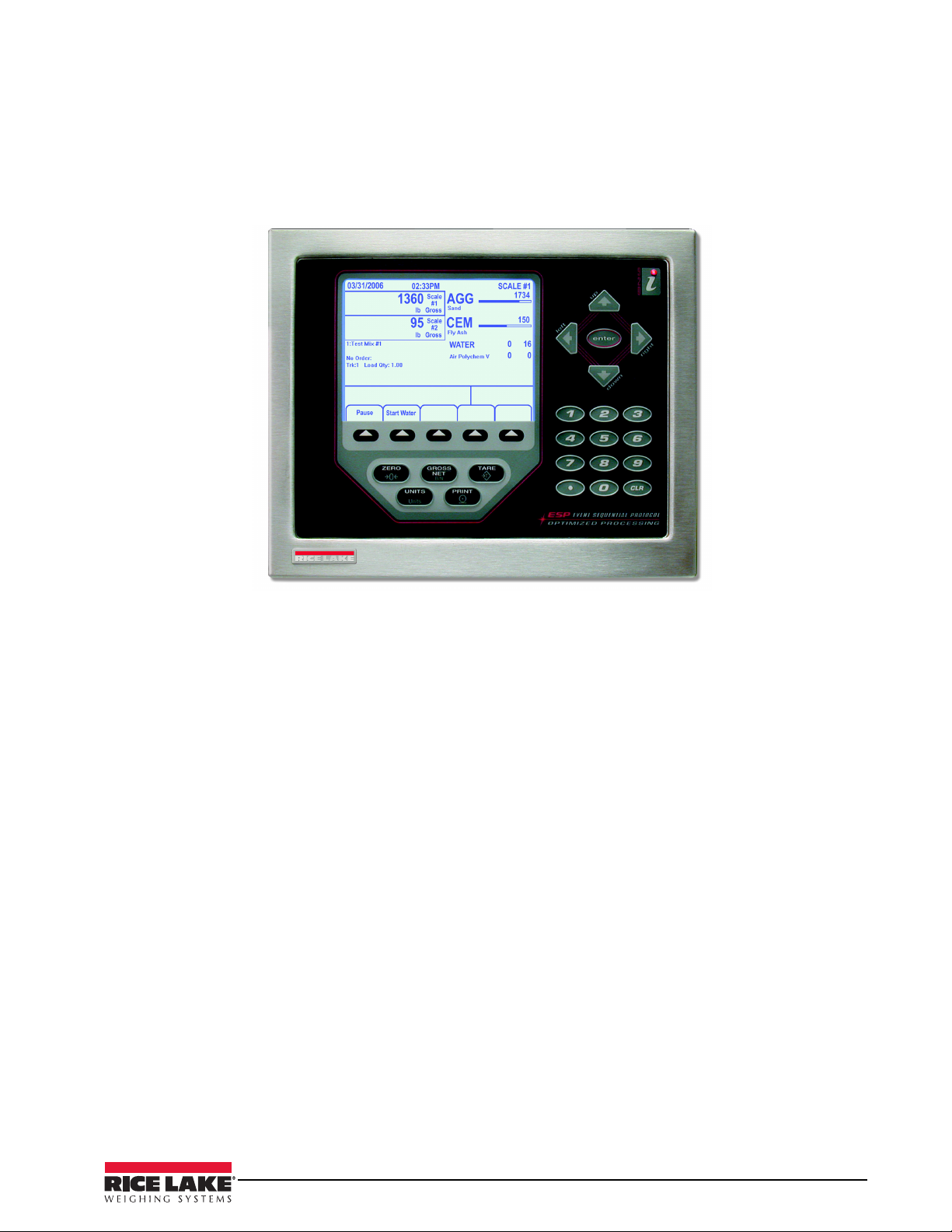

Front Panel

The 920i front panel, shown in Figure 1-1, consists of a 27-button keypad with a large backlit LCD display. The

keys are grouped as five configurable softk

eys, five primary scale function keys, four navigation keys, and

numeric entry keys.

Two scale widgets can be displayed in standard metered water

applications. Status areas on the display are used

for operator prompts and entering data. Display contrast can be adjusted with the LCD contrast potentiometer.

Figure 1-1. 920i Front Panel

1.1 Operating Modes

The 920i in the CB-2 automated concrete batching

system has two basic modes of operation:

Normal mode

Normal mode is the weighing mode of the

indicator. The CB-2 “program” only executes in

Normal Mode. The weight is only displayed in

Normal Mode. Once configuration is complete

and a legal seal is affixed to the large fillister-head

screw on the indicator enclosure, this is the only

mode in which the

When in Normal Mode, the

always show softkeys. The operator’s interaction

will be driven by softkey selections. As softkeys

are collectively named in the Main Menu. On the

far right of the main menu is the “Admin Menu”

softkey. The Admin Menu may be passcode

protected. The Admin Menu is where all

configuration and database entry takes place. A

large portion of this manual is dedicated to

explaining the categories and individual settings

in the Admin Menu.

920i can operate.

CB-2 program will

nfiguration Mode) is entered by pressing the

Co

setup switch. Setup Mode will be used during the

initial installation of the CB-2. Calibration of the

scales, configuration of filtering and motion band,

and upgrading the CB-2 software are some of the

important tasks that require the indicator to be in

Setup Mode. Once the CB-2 has been installed

and calibrated, there will probably be only three

reasons to ever enter Setup Mode again;

• Annual service calibration of scales

• Adding a PS/2 keyboard

• Upgrading the CB-2 software

Section 3 of this manual explains the Scale

configurati

on and calibration while in Setup

Mode.

To enter setup mode, remove the l

arge fillister

head screw from the enclosure. Insert a

screwdriver or a similar tool into the access hole

and press the setup switch once. The indicator

display changes to show scale configuration

menus.

Setup mode

A few of the procedures described in this manual

require the indicator to be in setup mode,

including configuration and calibration.

Setup Mode (sometimes referred to as

Installation/Operation Manual - Introduction 3

Page 8

1.2 Indicator Operations

The CB-2 does not allow the 920i to execute any of its standard operations like Gross/Net, Units, Print, Tare, and

Zero because they are not applicable to this application. In other words, the Gross/Net, Tare, Units, and Print

keys are disabled all the time. The Zero key is allowed at times during the loading process and while no load is

batching.

Zero Scale Process

Because the CB-2 always has two or more scales, the zeroing of the scale is a three-step process. Only the scale

that is selected can be zeroed. There are two ways to tell which scale is selected. First, the top weight widget will

show Scale #1 and display the current weight in/on scale #1 when scale # 1 is selected. It will show Scale #2 if

cement scale is selected and so on. Also, the selected scale # is displayed in the upper right hand corner of the

display.

Remember that the scale assignments will always be:

Aggregate Scale 1

Cement Scale 2

Water Scale 3

Example: To zero the cement scale;

1. Press the Zero key. If zeroing is not allowed at this time, you will be informed. If zeroing is allowed, the

message “Up/Down nav keys are enabled” is displayed.

2. Press the down arrow key until scale 2 (the cement scale) is shown in the top weight widget and in the

upper righthand corner of the display.

3. Press the zero key again. If the 920i allows the zero command, then the selected scale (scale 2, the

cement scale), should now read zero. The CB-2 automatically puts the aggregate scale (scale #1) back in

the top widget and redraws the text AGG, CEM, next to the appropriate weight widgets.

4 Installation/Operation Manual

Page 9

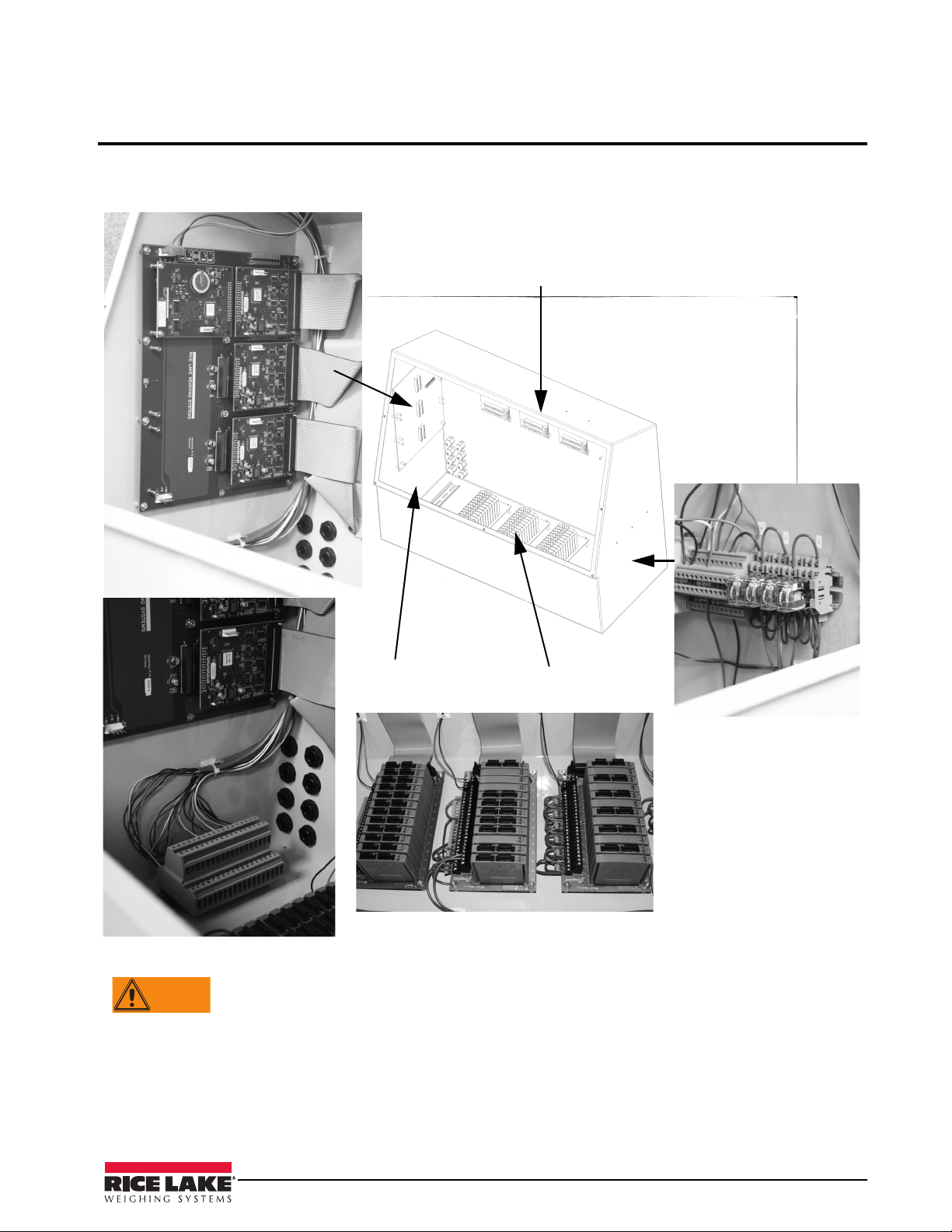

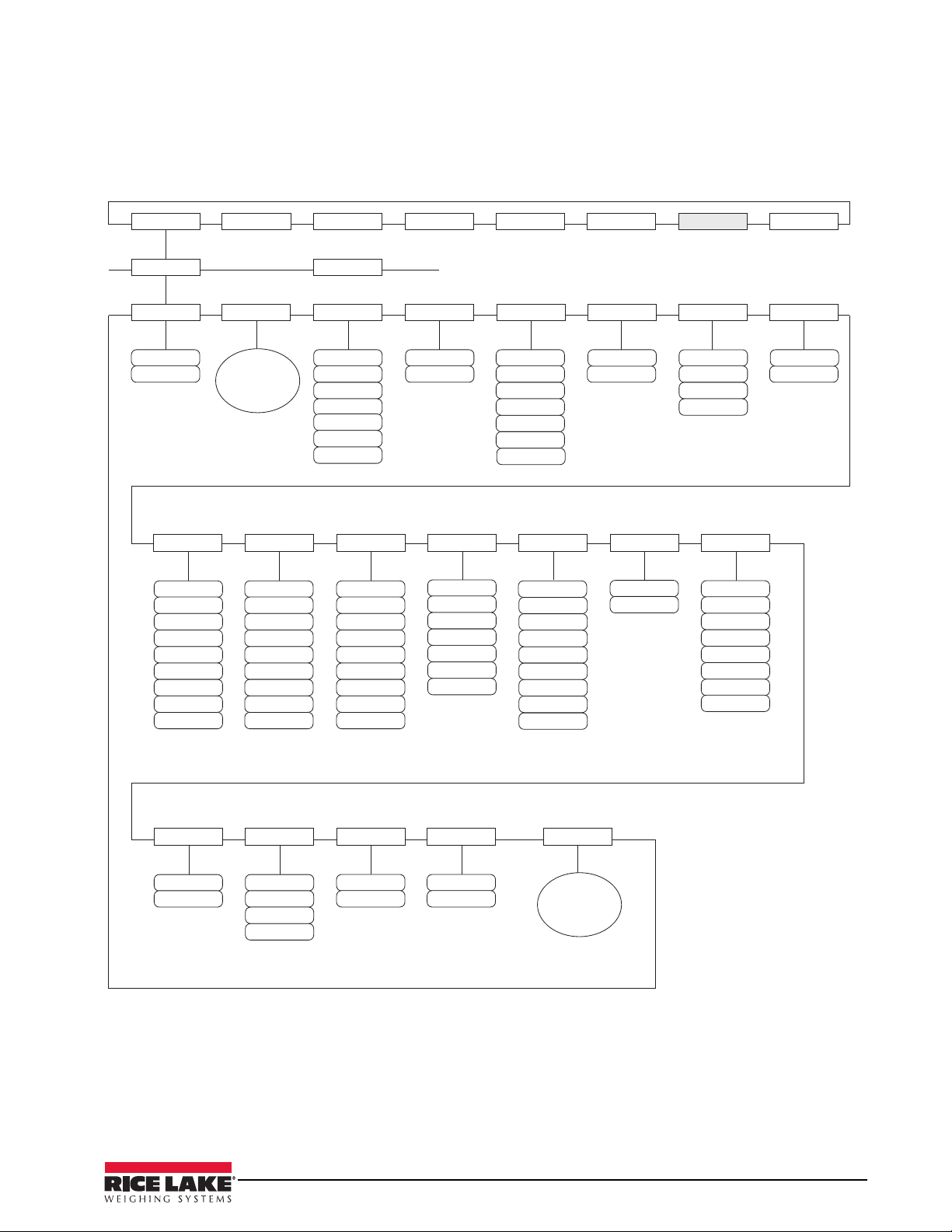

2.0 Installation

Expansion Board

Breakout Boards

Terminal Blocks

Relay Racks

Agg Conveyor and Air

Compressor Latching

Relay Circuits

WARNING

This section explains the main junction box, load cell, digital I/O, and serial communications connections located

inside of the CB-2. The 920i HMI indicator is housed inside the CB-2 enclosure which is shown below in

Figure 2-1 along with examples of several oth

er key component parts.

Figure 2-1. CB-2 Enclosure

• Use a wrist strap to ground yourself and protect components from electrostatic discharge (ESD) when

working inside the indicator enclosure.

• This unit uses double pole/neutral fusing which could create

an electric shock hazard. Procedures

requiring work inside the indicator must be performed by qualified service personnel only.

• The supply cord serves as the power disconnect

for the 920i. The power outlet supplying the indicator

must be installed near the unit and be easily accessible.

Installation/Operation Manual - Installation 5

Page 10

2.1 Important Notes

2.1.1 Two Power Sources

The CB-2 requires two separate power sources to run. The power cord that came wired to your CB-2 ONLY

powers the electronics. This power should come from a quality UPS with power conditioning. This clean power

must be separated as far as possible (distance in the electrical circuit) from the power source used to power the

motion control on the batch plant.

Another power source must be brought into the CB-2 to power the I/O (output relays), that control the plant. No

power cord is supplied because this power must be brought directly from its own circuit or fed from another

manual panel.

2.1.2 I/O Power and Manual Panel Same Phase Power

The CB-2 and manual panel will both be wired to the same I/O points for most plant controls (exceptions are air

compressors or other equipment the CB-2 doesn’t control in automatic mode). Because of this, it is critical that

the 120V “hot” that is used for the CB-2 I/O power, is the same “hot” phase used by the manual panel.

2.1.3 Unused Inputs Must be Jumpered to 120V

The CB-2 uses 120V input signals from various sensors for positive and negative feedback. At a minimum, the

CB-2 requires the following signals:

• Cement discharge gate closed (Terminal 4-13 - Rack 2, Point 7)

• Aggregate discharge gate closed (Terminal 4-15 - Rack 2, Point 8)

• Aggregate conveyor running (Terminal 4-9 - Rack 2, Point 5)

• E-Stop not pressed. This is fed 120VAC from inside the CB-2 automatic panel if 120V I/O power is

supplied.

If your plant is not equipped with any of these sensors, you must get 120VAC to these inputs to satisfy the CB-2

interlocks. The best place to get 120VAC is to jumper from terminals 6, 7, 8 on the top row of the main junction

block.

6 Installation/Operation Manual

Page 11

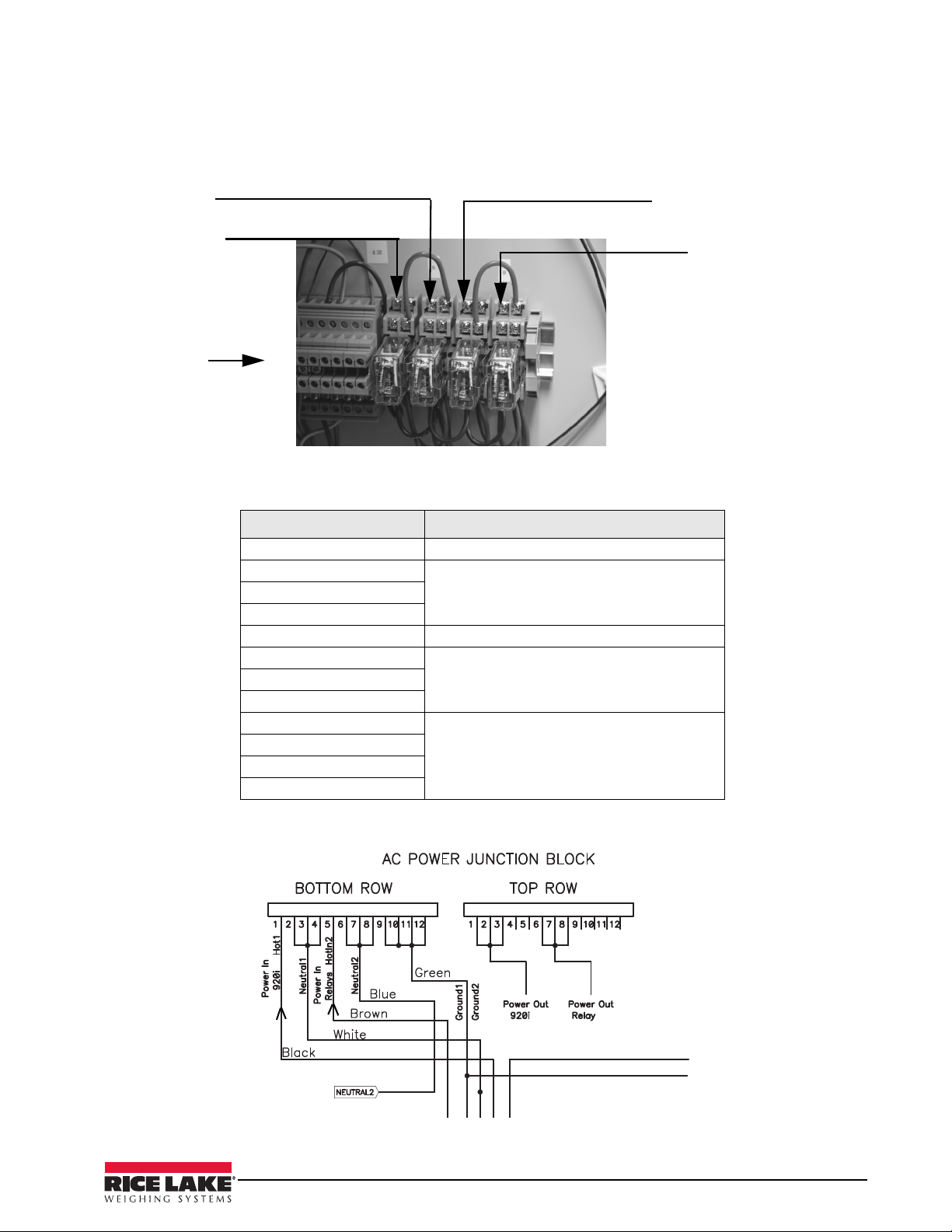

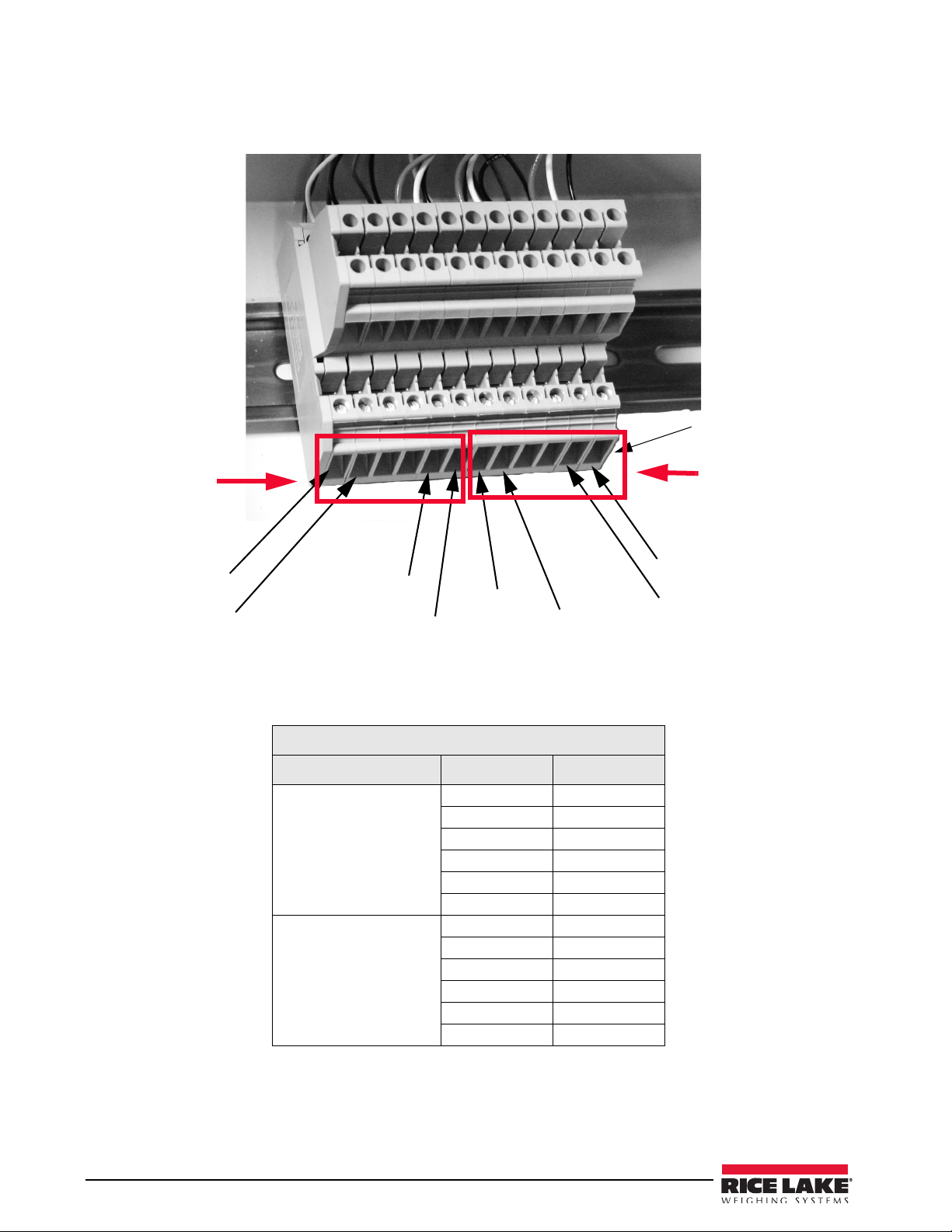

2.2 CB-2 Main Junction Block

Relay 1

Relay 2 Agg.

conveyor start

Relay 3

Relay 4 Air

Compressor

start

12 pin

connector w/

pin 1 starting at

left and shown

in greater detail

in Figure 2-3

below.

The CB-2 main junction box provides access for outside power to be brought into the enclosure using two sets of

customer supplied 110V power - one for the 920i indicator and the other for the relays/plant control.

Figure 2-2 illustrates the 12 pin connector used plus the relays.

Figure 2-2. CB-2 AC Power Junction Block

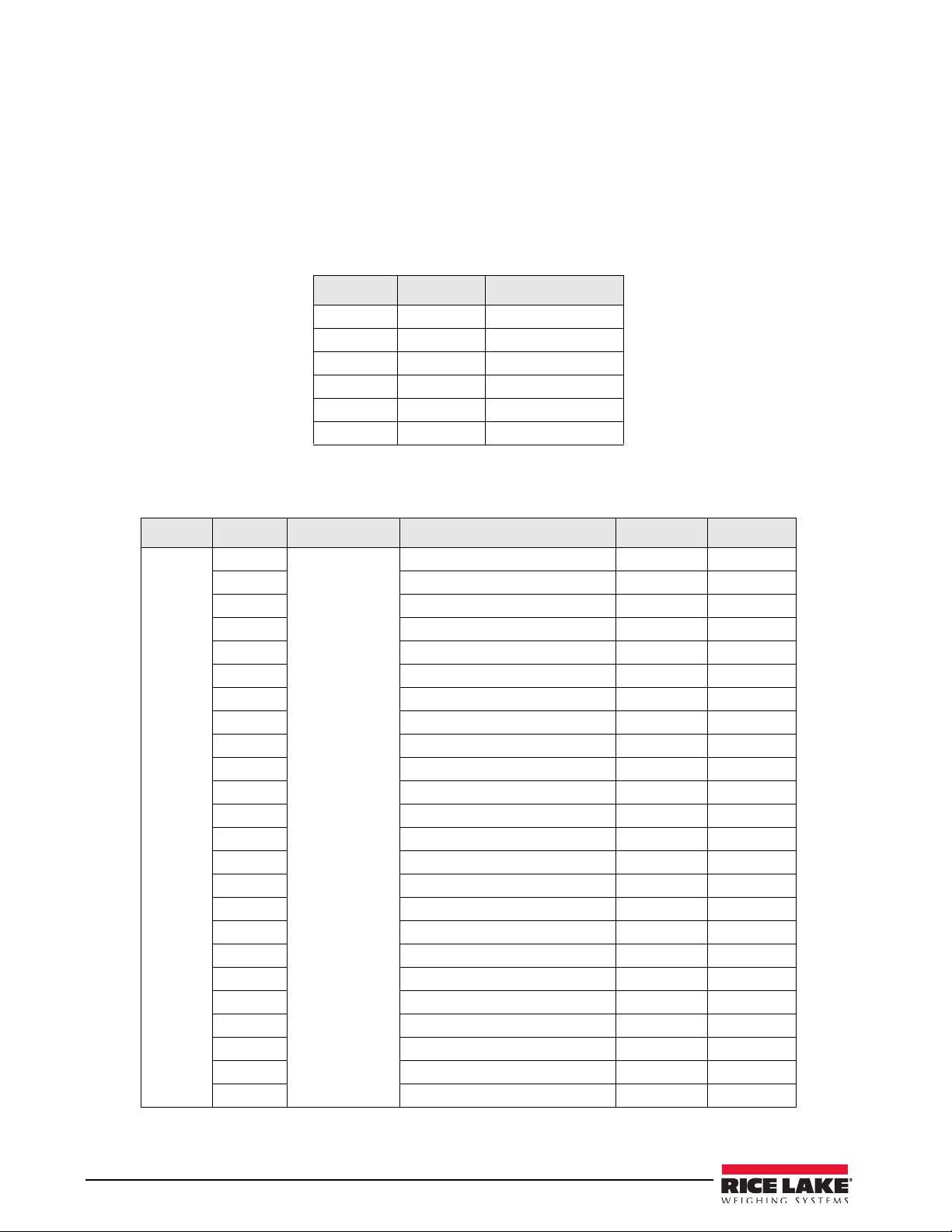

Table 2-1 lists the pin connections located on the BOTTOM ROW of the terminal strip for power to the CB-2.

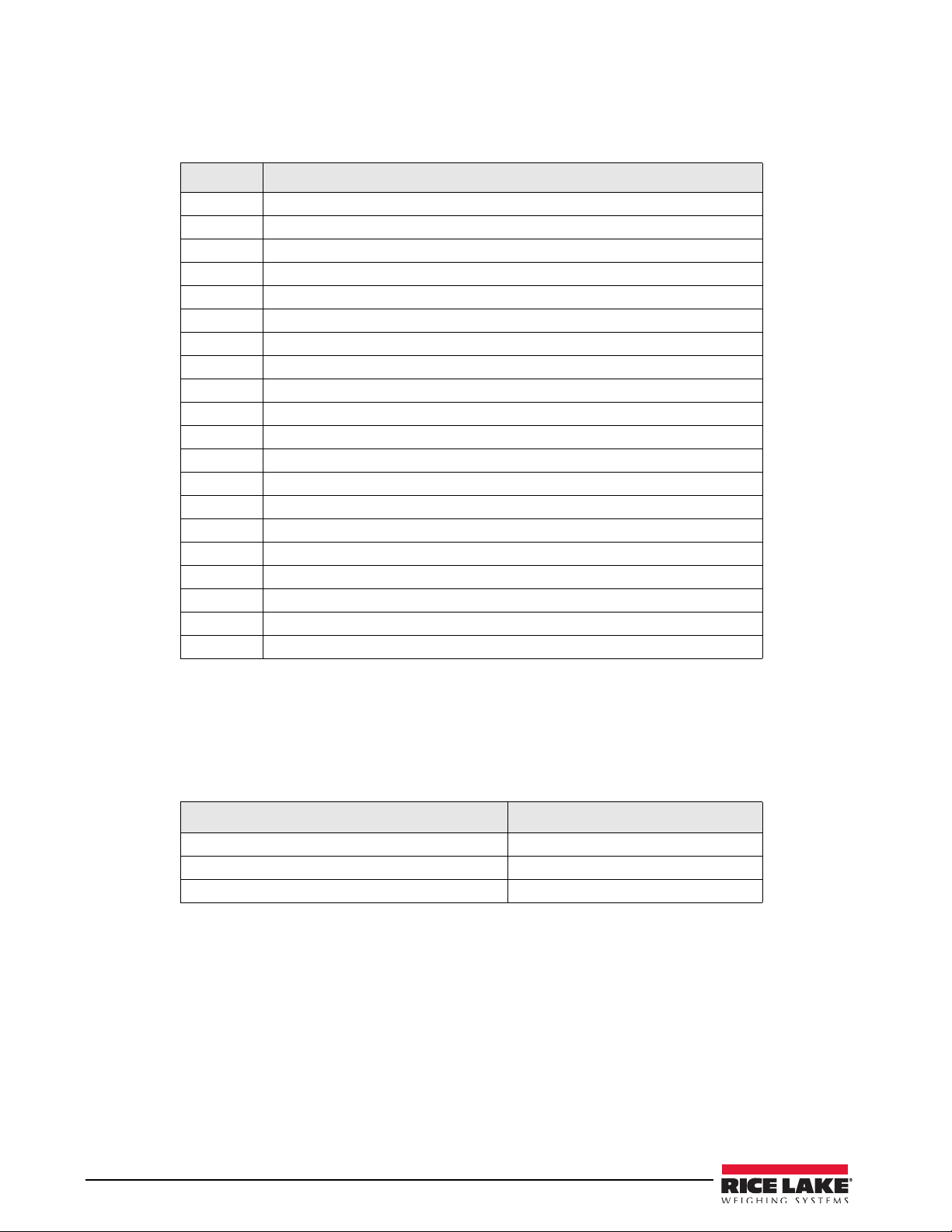

Bottom Row Pin Number Function

1 Line 1, provides power to 920i

2 Neutral

3

4

5 Line 2, pr

6 Neutral

7

8

9 Ground

10

11

12

Table 2-1. CB-2 AC Power Junction Block Power Connections Into the Enclosure

ovides power to relays

Figure 2-3. AC Power 12 Pin Connector as Shown in Detail from Figure 2-2 (above)

Installation/Operation Manual - Installation 7

Page 12

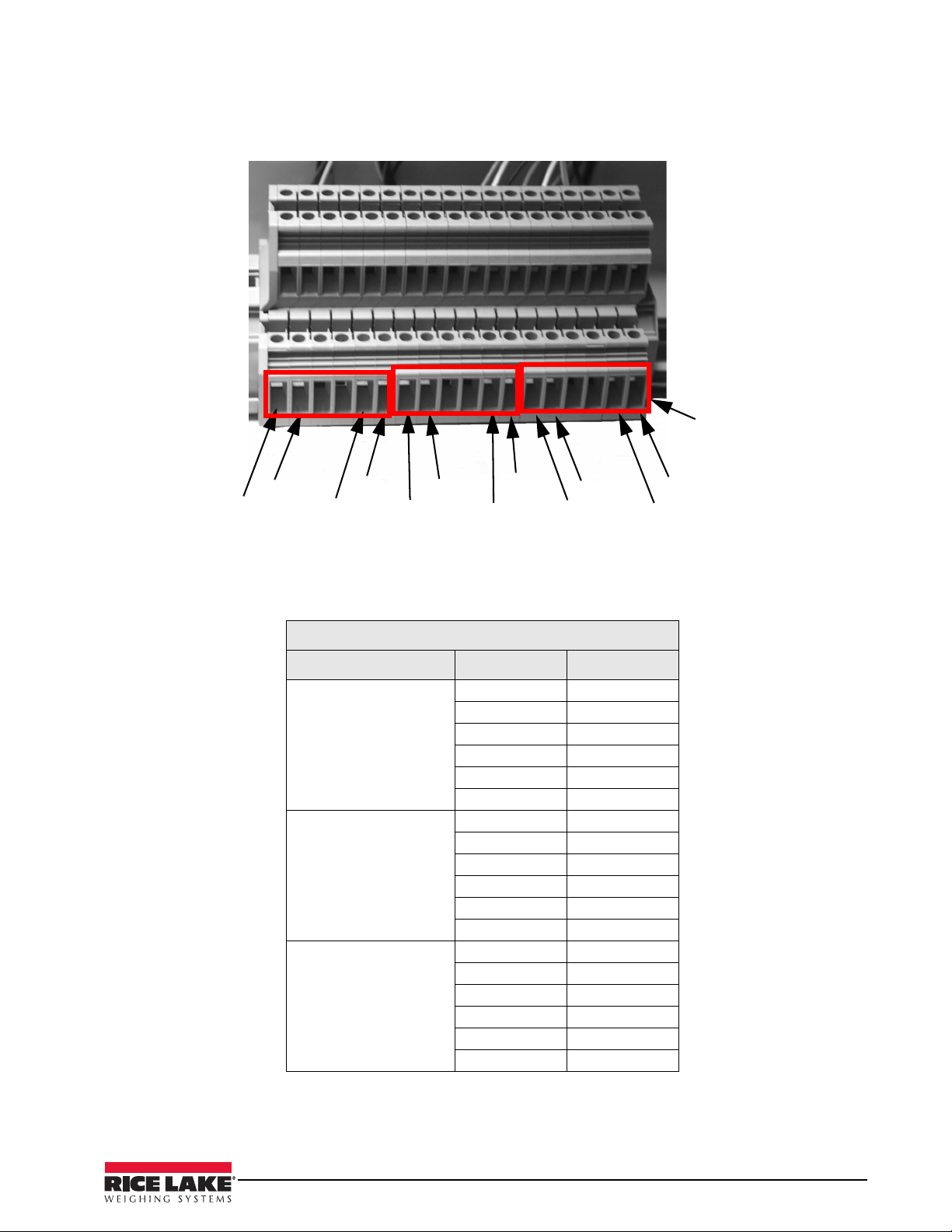

2.3 Load Cells

Pin 1

+ SIG

- SIG

+ EXC

- EXC

+ SIG

- SIG

+ EXC

- EXC

Aggregate

Side

Cement Side

The CB-2 comes pre-wired at the factory. Figure 2-4 shows the loadcell connections on the lower row.

Table 2-2 lists the load cell connections for a CB-2 automated concrete batching system that contains two load

cells.

Figure 2-4. Terminal Blocks Load Cell Connection (Metered Water)

Bottom Connector - Load Cells

Load Cell Connector Pin Number Signal

Load Cell 1

Aggregates

Load Cell 2

Cement

Table 2-2. Load Cell Connectors for Units with Two Load Cells (Metered Water)

1 - EXE

2 + EXE

3 - SEN

4 + SEN

5 - SIG

6 + SIG

7 - EXE

8 + EXE

9 - SEN

10 + SEN

11 - SIG

12 + SIG

8 Installation/Operation Manual

Page 13

For units containing three load cells, the following table and diagram illustrate the load cell connectors used.

+SIG

- SIG

+EXC

-EXC

+SIG

-SIG

+EXC

-EXC

+SIG

-SIG

+EXC

-EXC

Pin 1

Aggregate

Side

Water Side

Cement Side

(Middle)

Figure 2-5. Terminal Blocks Load Cell Connection (Weighed Water Option)

The following table lists the load cell connections for a CB-2 automated concrete batching system that contains

three load cells.

Bottom Connector - Load Cells

Load Cell Connector Pin Number Signal

Load Cell 1

Aggregates

Load Cell 2

Cement

Load Cell 3

Water

Table 2-3. Load Cell Connectors for Units with Three Load Cells (Weighed Water)

1 - EXE

2 + EXE

3 - SEN

4 + SEN

5 - SIG

6 + SIG

7 - EXE

8 + EXE

9 - SEN

10 + SEN

11 - SIG

12 + SIG

13 - EXE

14 + EXE

15 - SEN

16 + SEN

17 - SIG

18 + SIG

Installation/Operation Manual - Installation 9

Page 14

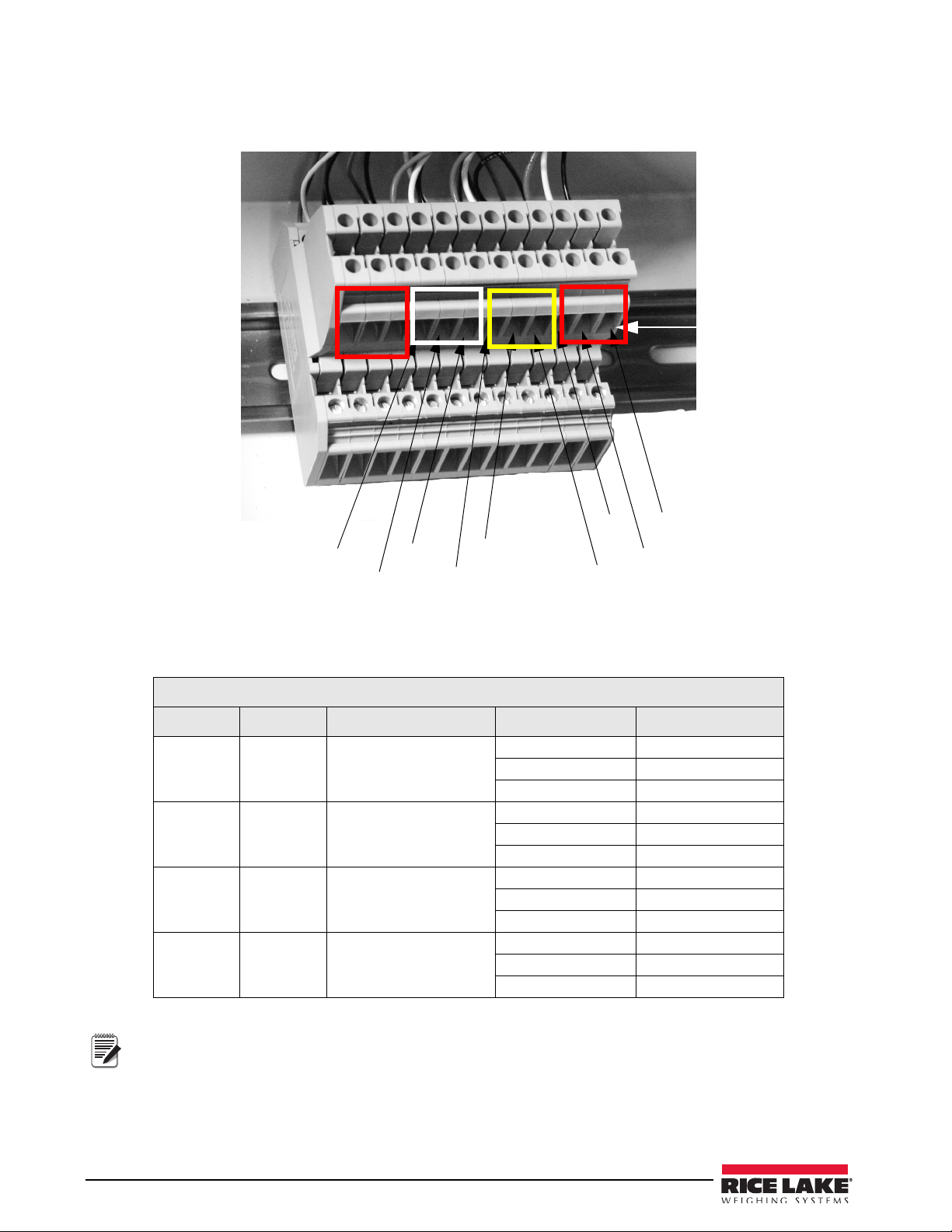

2.3.1 Serial Communications

TX

RX

GND

TX

RX

GND

TX

RX

GND

Pin 1

1

2

3

4

5

6

7

8

9

11

12

10

Note

The CB-2 supports RS-232 communications and their connections are shown in Figure 2-6, below.

Figure 2-6. Terminal Block RS-232 Connections

Serial ports are configured using the SERIAL menu which is shown in Tab le 2-4.

Top Connector - Serial Communications

Description Port # Port Connector Pin Number Signal

PC Port 1 J11

Ticket and

Report

Printer

Preprinted

Ticket Printer

iRev or

Keyboard

Port 4 J10

Port 3 J9

Port 2 _

Table 2-4. Serial Communications Connections

For CB-2 units with the weighed water option, serial connections remain the same using the same 9 pins

as is shown in Figure 2-5.

1 GND

2 RXD

3 TXD

4 GND

5 RXD

6 TXD

7 GND

8 RXD

9 TXD

10 Not Used

11 Not Used

12 Not Used

10 Installation/Operation Manual

Page 15

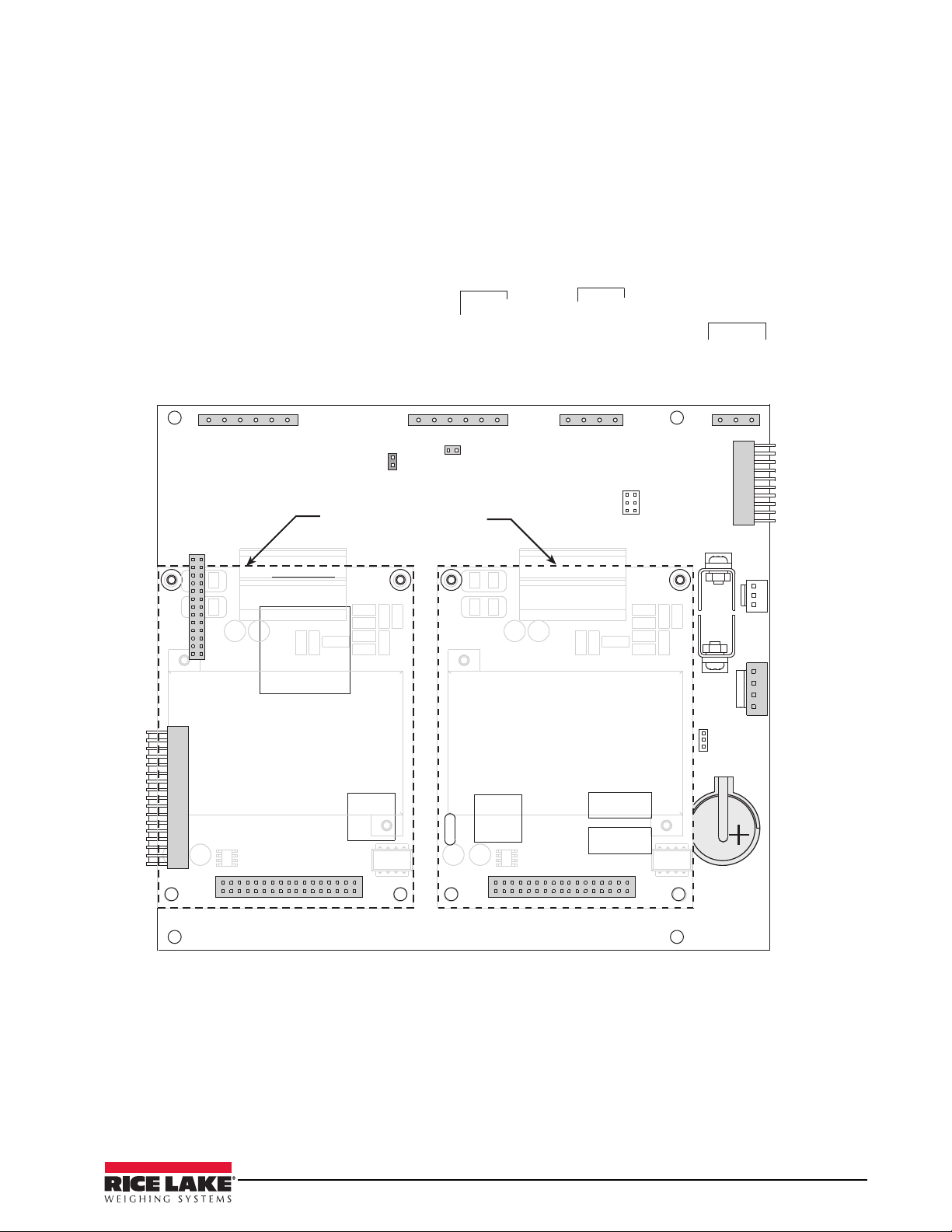

+

1035

+

1035

+

1035

+

1*&;0

#6;;&3

015*0/

+

o7%$

(/%

(/%

7%$

&91"/4*0/#64

(/%

343Y%

345Y%

(/%oN"065

343Y%

345Y%

N"065

343Y%

345Y%

N"065

345Y%

345Y%¦

7%$

(/%

&.&3(&/$:4501%*0

."/6"-.0%&%*0

3&.05&45"35%*0

3&.05&1"64&%*0

*/5&3'"$&

#0"3%

$0//&$5*0/

108&3

4611-:

48

+1

+

+

+

%*(*5"-*0

+

1035

015*0/$"3%

$0//&$503

015*0/$"3%

$0//&$503

015*0/$"3%-0$"5*0/4

+

#"55&3:

+

48

#005

.0%&

4-05

4-05

(/%N"065

3&.05&

4&561

48*5$)

5*$,&5"/%

3&103513*/5&3

4*/(-&

015*0/"-5*$,&5

13*/5&313*/5&3

015*0/

1$

Figure 2-7. CB-2 CPU Board, Showing Option Card Locations

Installation/Operation Manual - Installation 11

Page 16

2.4 Digital I/O

Digital inputs can be set to provide many batching functions on the CB-2. Digital inputs are active low (0 VDC),

inactive high (5 VDC).

Digital outputs are typically used to co

rather than source, switching current. Each output is a normally open collector circuit, capable of sinking 24 mA

when active. Digital outputs are wired to switch relays when the digital output is active (low, 0 VDC) with

reference to a 5 VDC supply.

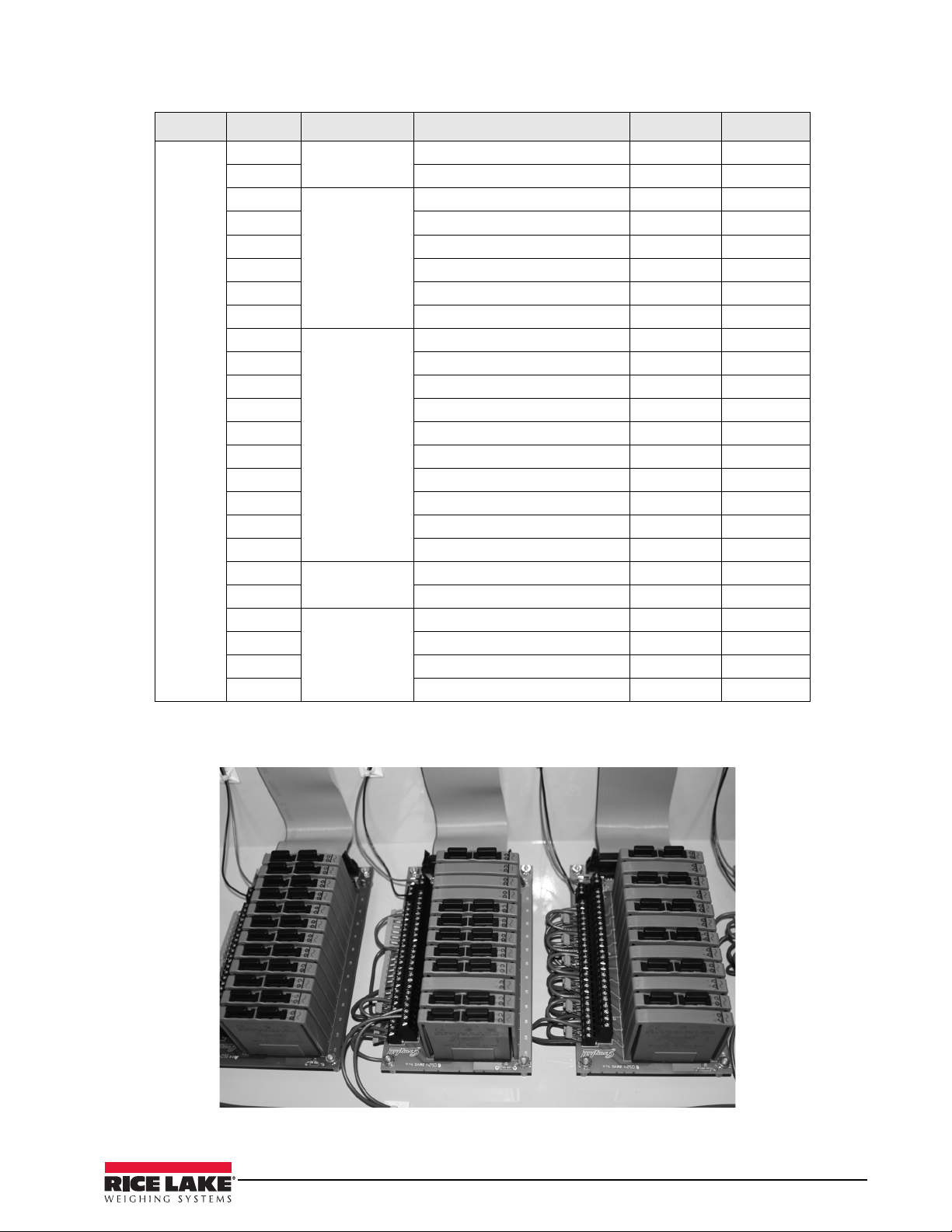

Table 2-5 shows the pin assignments for connector J2 which

Table 2-5. J2 Pin Assignments (Digital I/O) on CB-2 Main Board

Digital inputs and outputs are configured using the DIG I/O menu. See Section 3.1 on page 18 for configuration

information.Table 2-6 through 2-9 lists the digital I/O channels and their pre-defined functions for the CB-2.

ntrol relays that drive other equipment. Outputs are designed to sink,

is located on the CB-2 CPU board.

J2 Pin J2 Signal Function

1 +5 VDC

2 GND

3 DIO 1 Emergency Stop

4 DIO 2 Manual Mode

5 DIO 3 Remote Start

6 DIO 4 Remote Pause

Digital I/O

Slot 3 Bit 1 Digital Output Aggregate 1 Batch 3-1 SP1

Location Ty pe Description Ter m i n a l # Setpoint

2 Aggregate 2 Batch 3-3 SP2

3 Aggregate 3 Batch 3-5 SP3

4 Aggregate 4 Batch 3-7 SP4

5 Aggregate 5 Batch - Option 3-9 SP5

6 Aggregate 6 Batch - Option 3-11 SP6

7 Aggregate 7 Batch - Otion 3-13 SP7

8 Aggregate 8 Batch - Option 3-15 SP8

9 Aggregate Discharge Open 3-17

10 Aggregate Discharge Closed 3-19

11 Aggregate Vibrator 3-21

12 Sand Bin Vibrator 3-23

13 Cement 1 Batch 3-25 SP9

14 Cement 2 Batch 3-27 SP10

15 Cement 3 Batch 3-29 SP11

16 Cement 4 Batch 3-31 SP12

17 Dust Collection 3-33

18 Alarm/Horn 3-35

19 Aggregate Conveyor Start 3-37

20 Aggregate Conveyor Stop 3-39

21 Cement Discharge Open 3-41

22 Cement Discharge Closed 3-43

23 Cement Vibrator 3-45

24 Weigh Hopper Aeration 3-47

12 Installation/Operation Manual

Table 2-6. Digital I/O Pin Assignments for Slot 3

Page 17

Digital I/O

Slot 4 Bit 1 Digital Output Reservoir Discharge 4-1 67

Location Ty pe Description Ter m i n a l # Setpoint

2 Tailwater Discharge 4-3

3 Digital Input Reservoir Gate Closed 4-5

4 Water Reservoir Empty 4-7

5 Aggregate Conveyor is Running 4-9

6 Air Pressure OK 4-11

7 Cement Gate is Closed 4-13

8 Aggregate Gate is Closed 4-15

9 Digital Output Out of Tolerance Signal 4-17

10 Load Complete 4-19

11 Reset Water Counters 4-21

12 Reset Admixtures Counters 4-23

13 Cement 1 Aeration 4-25

14 Cement 2 Aeration 4-27

15 Cement 3 Aeration 4-29

16 Cement 4 Aeration 4-31

17 Cold Water 4-33 SP17

18 Hot Water 4-35 SP18/68

19 Digital Input Not Presently Used 4-37

20 Water Meter Pulse Input 4-39

21 Digital Output Air Compressor Start 4-41

22 Air Compressor Stop 4-43

23 Lower Boot 4-45

24 Raise Boot 4-47

Table 2-7. Digital I/O Pin Assignments for Slot 4

SLOT 3

SLOT 4

SLOT 5

Figure 2-7. Digital I/O Relay Racks for the CB-2 Automated Concrete Batching System

Installation/Operation Manual - Installation 13

Page 18

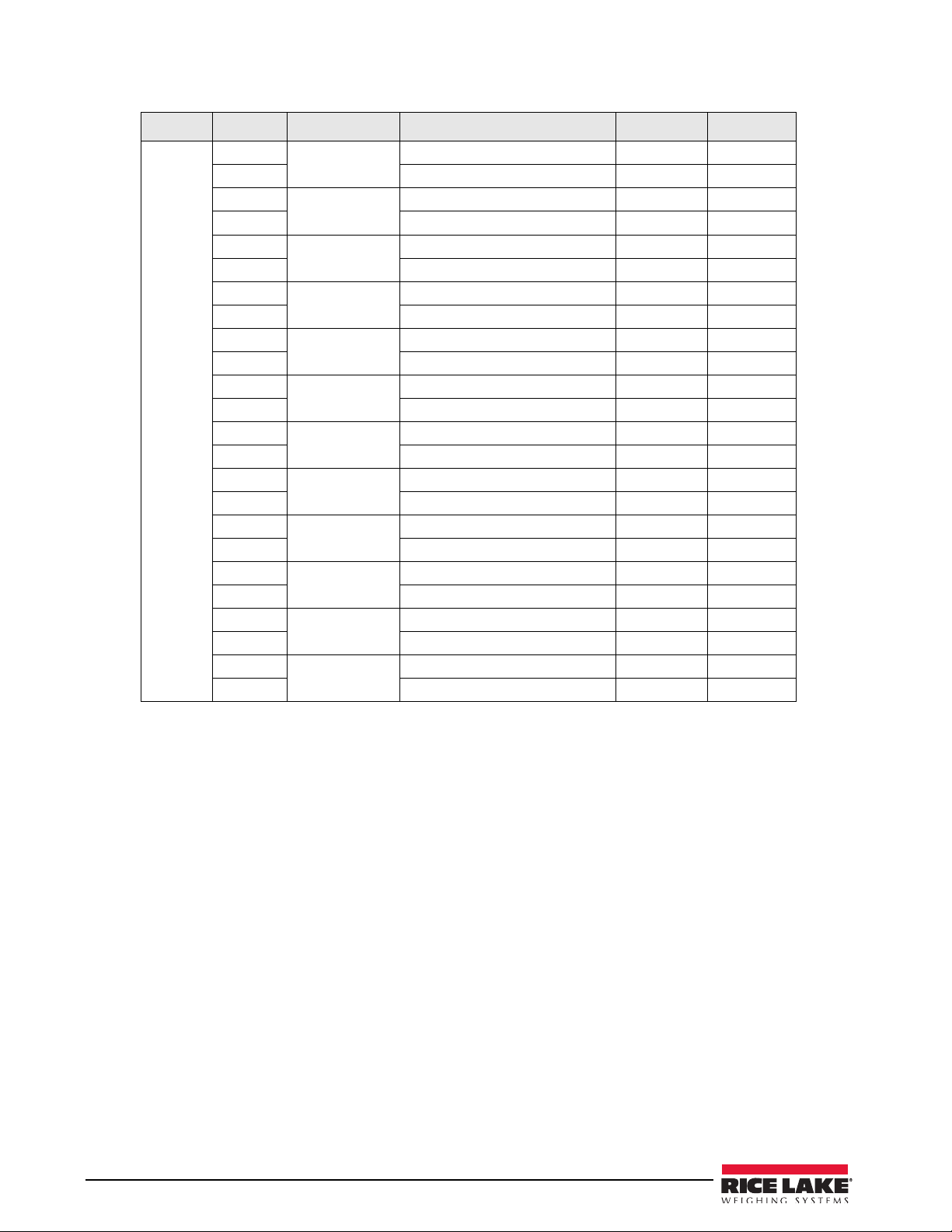

Digital I/O

Slot 5 Bit 1 Digital Output Admixture 1 Fill/Feed 5-1 SP19

Location Ty pe Description Ter m i n a l # Setpoint

2 Admixture 1 Discharge 5-3

3 Digital Input Admixture 1 Bottle Empty Light 5-5

4 Admixture 1 Pulse Light/Counter 5-7

5 Digital Output Admixture 2 Fill/Feed 5-9 SP20

6 Admixture 2 Discharge 5-11

7 Digital Input Admixture 2 Bottle Empty Light 5-13

8 Admixture 2 Pulse Light/Counter 5-15

9 Digital Output Admixture 3 Fill/Feed 5-17 SP21

10 Admixture 3 Discharge 5-19

11 Digital Input Admixture 3 Bottle Empty Light 5-21

12 Admixture 3 Pulse Light/Counter 5-23

13 Digital Output Admixture 4 Fill/Feed 5-25 SP22

14 Admixture 4 Discharge 5-27

15 Digital Input Admixture 4 Bottle Empty Light 5-29

16 Admixture 4 Pulse Light/Counter 5-31

17 Digital Output Admixture 5 Fill/Feed 5-33 SP23

18 Admixture 5 Discharge 5-35

19 Digital Input Admixture 5 Bottle Empty Light 5-37

20 Admixture 5 Pulse Light/Counter 5-39

21 Digital Output Admixture 6 Fill/Feed 5-41 SP24

22 Admixture 6 Discharge 5-43

23 Digital Input Admixture 6 Bottle Empty Light 5-45

24 Admixture 6 Pulse Light/Counter 5-47

Table 2-8. Digital I/O Pin Assignments for Slot 5

14 Installation/Operation Manual

Page 19

Note

WARNING

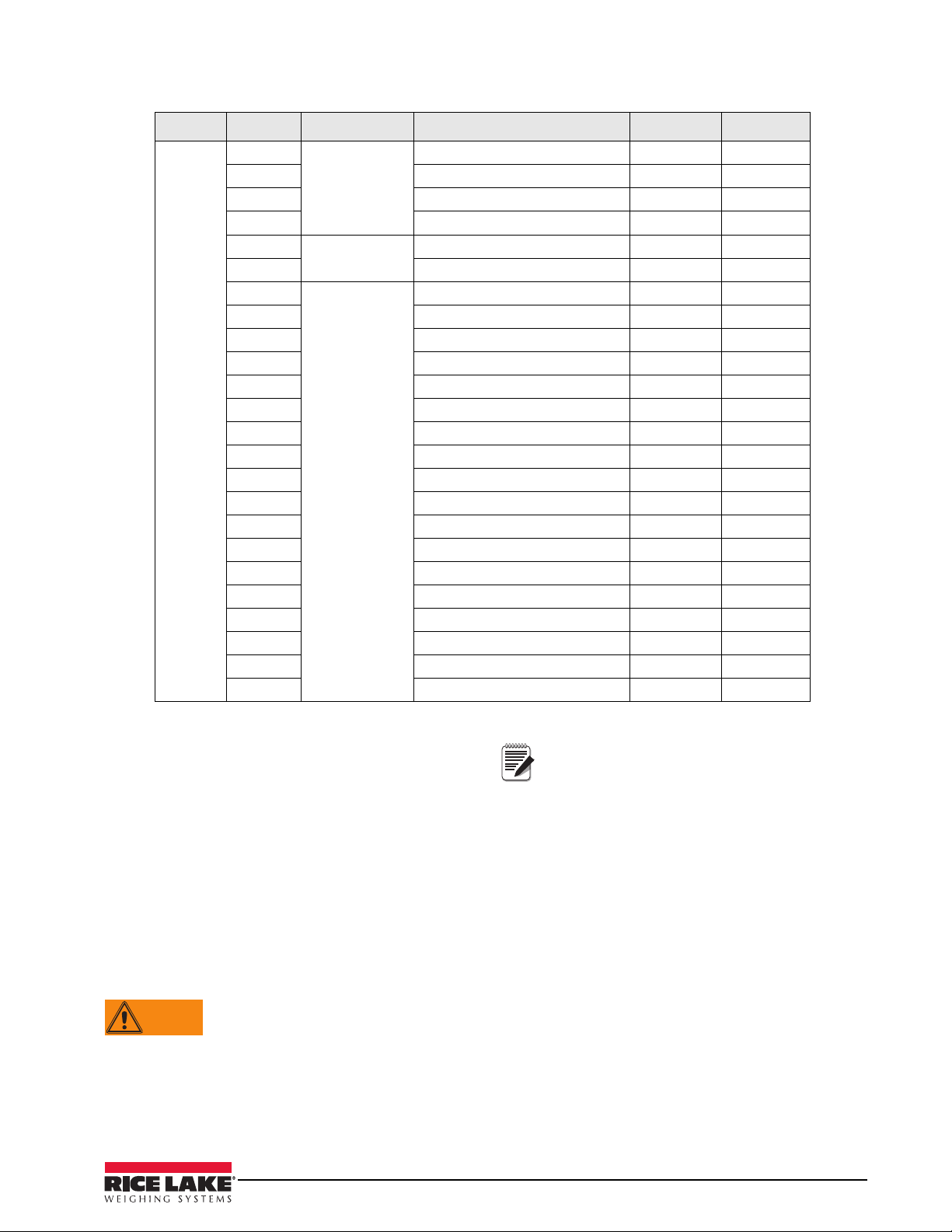

Digital I/O

Slot 8 Bit 1 Digital Output Mixer Start 8-1

Location Ty pe Description Ter m i n a l # Setpoint

2 Mixer Stop 8-3

3 Mixer Discharge Gate Open 8-5

4 Mixer Discharge Gate Closed 8-7

5 Digital Input Mixer Gate is Closed 8-9

6 Truck/Mixer in Position 8-11

7 Digital Output Watchdog Pat 8-13

8 Not Used 8-15

9 Cement 5 8-17 13/59

10 Cement 6 8-19 14/60

11 Cement 7 8-21 15/61

12 Cement 8 8-23 16/62

13 Aux Output #1 8-25 51

14 Aux Output #2 8-27 52

15 Aux Output #3 8-29 53

16 Aux Output #4 8-31 54

17 Aux Output #5 8-33 55

18 Aux Output #6 8-35 56

19 Aux Output #7 8-37 57

20 Aux Output #8 8-39 58

21 Aux Output #9 8-41

22 Aux Output #10 8-43

23 Aux Output #11 8-45

24 Aux Output #12 8-47

Table 2-9. Digital I/O Pin Assignments for Slot 6

2.5 Battery Replacement

The 3V, coin type lithium battery (PN 69290) on the

CPU board maintains the real-time clock and protects

data stored in the system RAM when the indicator is

not connected to AC power.

Data protected by the CPU board

time and date, truck and tare memory, onboard

database information, and setpoint configuration.

iRev to store a copy of the indicator configuration

Use

on a PC before attempting battery replacement. If any

data is lost, the indicator configuration can be restored

from the PC.

Risk of explosion if battery is replaced with incorrect type. Dispose of batteries per manufacturer

instruction.

battery includes

Memory option card data is also protected

by a lithium battery. All database

inf

ormation stored on a memory card is lost

if the memory card battery fails.

Watch for the low battery warning on the LCD display

and periodically check the battery voltage on both the

CPU board and on any installed memory option cards.

Batteries should be replaced when the indicator low

battery warning comes on, or when battery voltage

falls to 2.2 VDC. Life expectancy of the battery is ten

years.

See Figure 2-7 on page 11 for CPU board battery

location and orientation (positive side up).

Installation/Operation Manual - Installation 15

Page 20

2.6 Replacement Parts

Table 2-3 lists replacement parts for the CB-2 automated concrete batching system.

PN Description

88792 Power supply, 12V (1)

67609 Memory module 1MB (1)

67612 Board assembly, CPU for 920i (1)

93536 Totalizing counters (7)

42467 Relays, 120V models

96008 Relays, 220V models

89198 CB-2 switch board assembly (4)

93540 CB-2 switch board assembly (2)

67608 Expansion board, digital I/O (1)

71462 Fuse, 3.15amp

52315 Relay mounting board (1)

67614 LCD, fluorescent display (1)

67869 920i interface board (1)

52318 Relay, input module, 12V

52319 Relay, Input module, 220V model

52316 Relay, output module, 12V

52317 Relay, output module, 220V model

89199 Breakout board assembly

69781 iRev CD

67612 920i Main Board for the CB-2

Table 2-11. Part Numbers for 920i Option Cards

2.6.1 Option Cards

Table 2-11 lists the available option 920i option cards that are used in the CB-2 automated concrete batching

system. Any of the listed option cards can be installed in Slot 1 or Slot 2 of the CPU board or in any available slot

of an attached expansion board.

Option Card Rice Lake Part Number

Single Channel A/D Card 68532

Dual Channel A/D Card 67611

1 MB NV RAM Memory Expansion Card 67609

Table 2-11. Part Numbers for 920i Option Cards

16 Installation/Operation Manual

Page 21

2.7 Installing an Optional PS-2 Keyboard

To increase the speed and ease of entering alpha-numeric data, a standard PS/2 keyboard can be connected. Use

the following steps to install a PS/2 keyboard.

1. Place the 920i into Setup Mode by pressing the setup switch. See Section 1.1 (setup mode) for finding

and pressing the setup switch. This may involve breaking an inspectors lead seal.

2. When the 920i enters into Setup Mode, Scales is selected. Press the right arrow key on the keypad, so

Serial is selected.

3. Press the down arrow key once. Port 1 is selected.

4. Press the right arrow key once to select Port 2.

5. Press the down arrow key one. CMD will be selected.

6. Press the right arrow key once to select KEYBRD.

7. Press the Up arrow key twice. SERIAL should be selected and there should be a Save and Exit softkey in

the lower right-hand side of the display.

8. Press the Save and Exit softkey.

9. Power down the CB-2 with the key switch.

10. Bring the end of the PS/2 keyboard cable into the CB-2 through one of the cord grips on the back of the

enclosure. Plug in the PS/2 keyboard into the PS/2 connector (located between the display contrast

potentiometer and the DB-9 serial port) about 2” away from the setup switch. Your CB-2 may be

equipped with an optional keyboard connector extension. If this is the case, there will be a cable running

out of the back of the CB-2 enclosure with a female PS/2 connector on the end of it.

11. Power up the CB-2 with the key switch.

12. Test the keyboard. F1 to F5 on the keyboard should map to the softkeys from left to right, respectively.

Installation/Operation Manual - Installation 17

Page 22

3.0 Configuration of Scale Parameters

Note

The CB-2 is designed as a universal controller for all types of automated concrete production. There are many

settings and features that are only used by special applications. The factory default settings assume a two-scale

transit mix application and most of the default values will not need to be changed for this type of application. In

addition, system software has been pre-loaded along with a default database.

However, for the CB-2 to batch accurately, certain critical paramet

tuned (see tune plant section). As part of the default configuration, a minimum number of materials, physical

locations, and mix designs have been added. The mapping of the actual physical plant controls to the I/O points

in the software is also setup in the initial configuration.

To set up a standard configuration the

920i indicator, the indicator must be placed in setup mode. The setup

switch is accessed by removing the large fillister head screw on the back of the enclosure. Switch position is

changed by inserting a screwdriver into the access hole and pressing the switch.

When the indicator is placed in setup mode, a series of menus is shown

the words

Scale Configuration. The SCALES menu is highlighted as the first used to configure the indicator.

Detailed descriptions of these menus are provided in Section 3.2.

When configuration is complete, press the

Exit or Save and Exit softkey to exit setup mode, then replace the setup

switch access screw.

•The

Exit softkey exits setup mode without saving parameter changes to NV RAM. Changes made to the

configuration remain in the system until indicator power is cycled.

Save and Exit writes all parameter changes to NV RAM before returning to normal mode.

•

3.1 Configuration Methods

The 920i indicator can be configured by using the front panel keys to navigate through a series of configuration

menus or by sending commands or configuration data to an indicator serial port. Configuration using the menus

is described in Section 3.1.2.

Configuration using the serial port can be accomplished using e

configuration utility.

Some configuration parameters, such as those used to configure the 920i display and widgets, cannot

be accessed through the configuration menus. iRev provides the most complete and efficient

configuration interface for the 920i.

ers must be determined and the plant must be

across the top of the display, along with

ither the serial command set described in the iRev

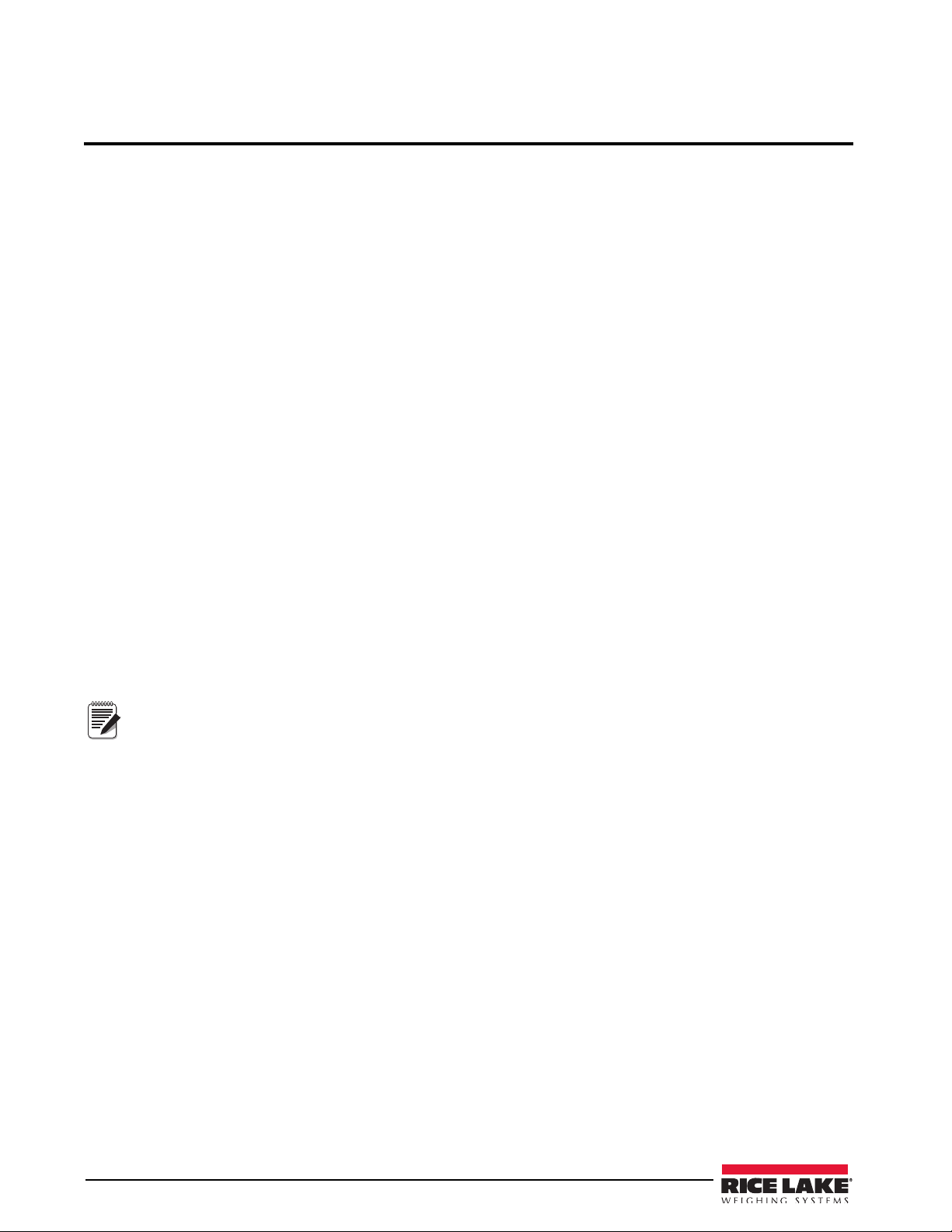

3.1.1 iRev Configuration

The iRev configuration utility provides the preferred method for configuring the 920i indicator. iRev runs on a

personal computer to set configuration parameters for the indicator. When

configuration data is downloaded to the

iRev supports both uploading and downloading of indicator configuration data. This capability allows

920i indicator.

iRev configuration is complete,

configuration data to be retrieved from one indicator, edited, then downloaded to another indicator with an

identical hardware configuration.

18 Installation/Operation Manual

Page 23

Figure 3-1. iRev Hardware Configuration Display

To use iRev, do the following:

1. Install

iRev on an IBM-compatible personal computer. See XX for detailed hardware and software

requirements.

2. With both indicator and PC powered off, connect the PC

serial port to the RS-232 pins on the indicator

serial port.

3. Power up the PC and the indicator. Use the setup sw

4. Start the

iRev provides online help for each of its configuration displays. Parameter descriptions provided in this manual for

iRev program.

front panel configuration can also be used when configuring the indicator using

itch to place the indicator in setup mode.

iRev: The interface is different, but

the parameters set are the same.

See the 9

920i.

20i Installation and Operation Manual, PN 67887 for more information about using iRev to configure the

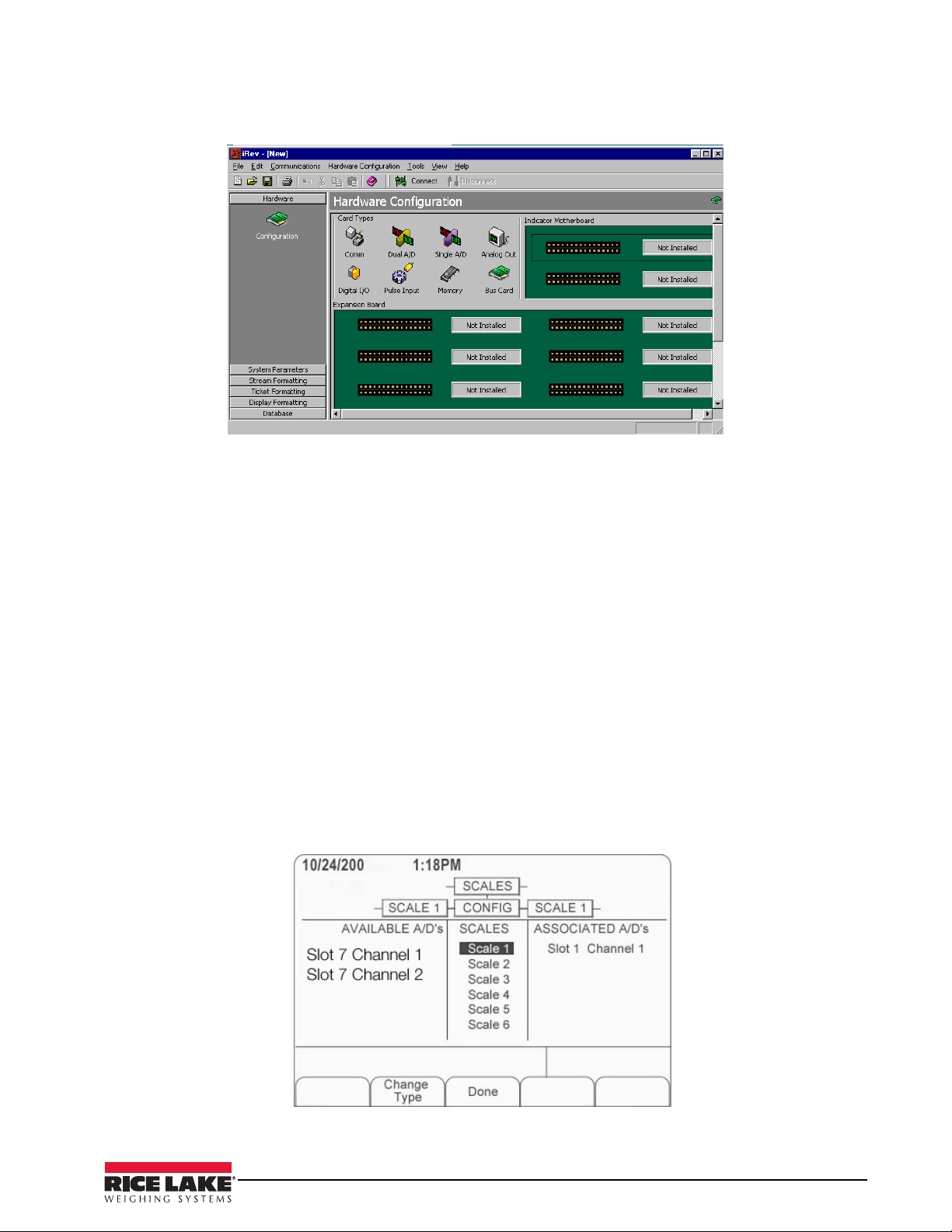

3.1.2 Front Panel Configuration

Use the CONFIG submenu under the SCALES menu to configure A/D scales. For example, in an indicator with

a single-channel A/D card installed in Slot 1, the Scale Configuration display will show the A/D listed (

Channel 1

softkey,

AVAILABLE A/D’s column, the center softkey changes to Done, as shown in Figure 3-2. Press Done to exit the Scale

) under the AVAILABLE A/D’s column. Use the left navigation key to select the A/D, then press the center

Add. The A/D is then moved to the Associated A/D’s column. If no other A/D’s are listed in the

Slot 1

Configuration display.

Figure 3-2. Scale Configuration Display

Installation/Operation Manual - Configuration of Scale Parameters 19

Page 24

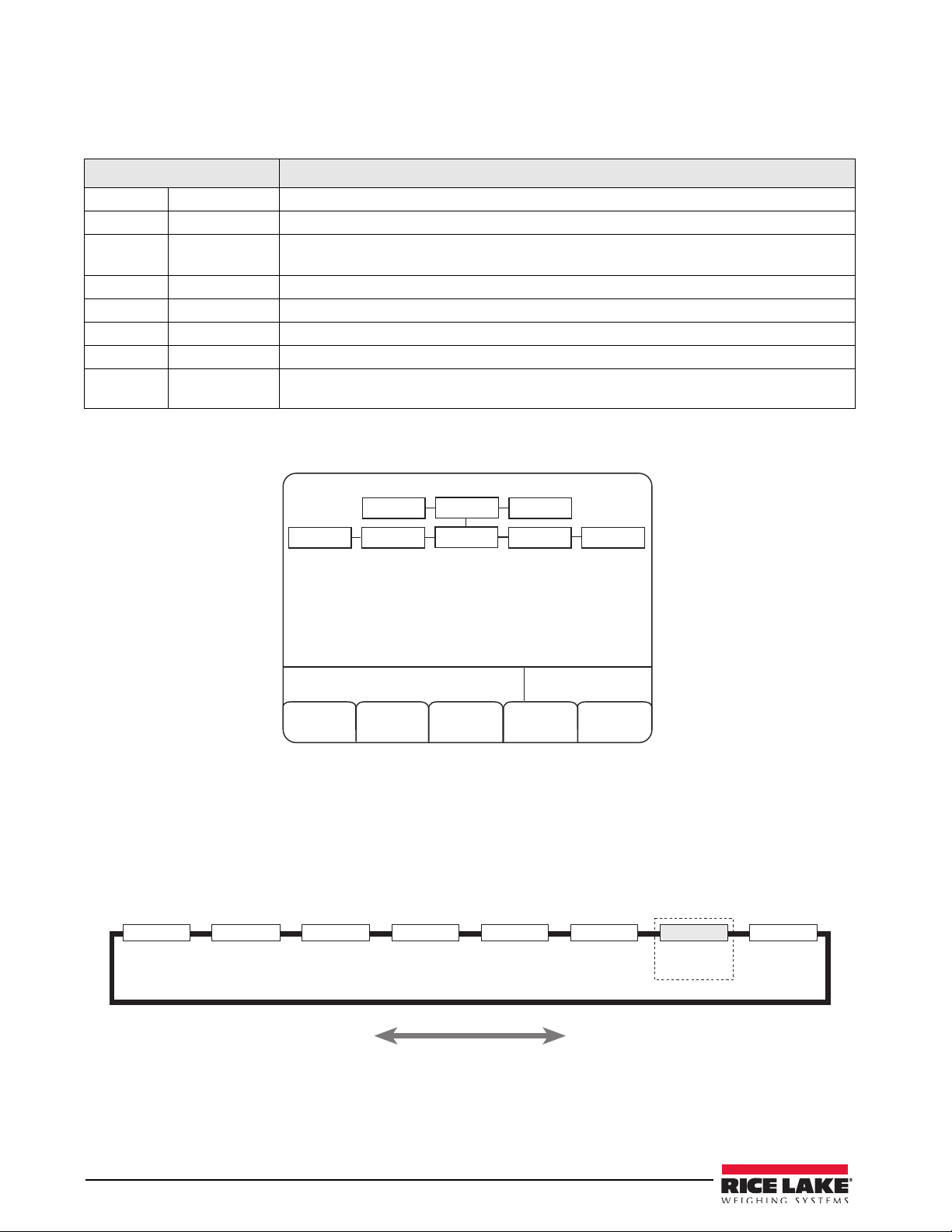

The 920i indicator can be configured using a series of menus accessed through the indicator front panel when the

05/30/2013

08:13AM

Exit

Scale 1 Configuration

Save

and Exit

SERIAL

SCALES

VERS

SCALE 2

SCALE 1

CONFIG SCALE 2 CONFIG

4$"-&4 4&3*"- '&"563& 1'03.5 4&5154 %*(*0 "-(065 7&34

4IPXOPOMZJG

"OBMPH0VUQVU

DBSEJTJOTUBMMFE

indicator is in setup mode. Table 3-1 summarizes the functions of each of the main menus.

Menu Menu Function

SCALES Configuration Configure and calibrate scales.

SERIAL Serial Configure communications ports.

FEATURE Feature Set date and time formats,

initial consecutive number value, define softkeys and setpoint prompts.

PFORMT Print Format Set print format used for header, g

SETPTS Setpoints Configure setpoints and batching mode.

DIG I/O Digital I/O Assign digital input/output functions.

ALGOUT Analog Output Configure analog output module. Used only if an

VERSION Ver sion Display installed software version number. The Re

be used to restore all configuration parameters to their default values.

Table 3-1. 920i Menu Summary

truck mode, passwords, keyboard locks, regulatory mode, and

ross, net, truck in/out, setpoint, and auxiliary ticket formats.

alog output option is installed.

set Config softkey on the Version menu can

Figure 3-3. Scale 1 Configuration

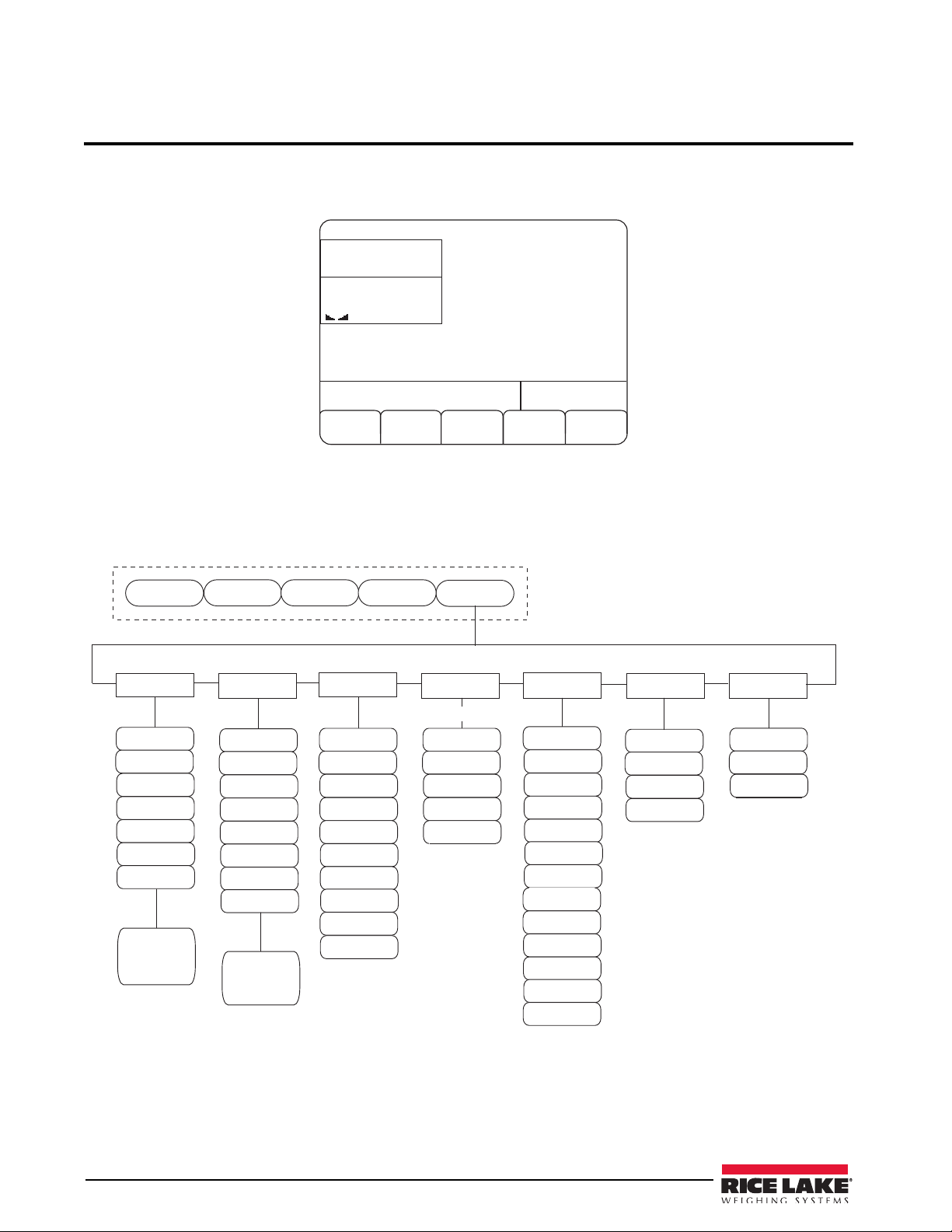

3.2 Menu Structures and Parameter Descriptions

The following sections provide graphic representations of the 920i menu structures and tables describing the

menu parameters. Default values are shown in bold type; numeric ranges and string values are shown in italic

type. Parameters shown surrounded by a dotted-line box only appear under the special circumstances explained

under each box.

Figure 3-4. Configuration Menu Flow

20 Installation/Operation Manual

Page 25

3.2.1 SCALES Menu

4$"-&4 4&3*"- '&"563& 1'03.5 4&5154 %*(*0 "-(065 7&34

4$"-&Y

(3"%4

;3"/(& .05#"/%

073-0"%

445*.&

%*('-5 %*('-5

OVNCFS

;53,#/%

0''

%

%

%

%

%

%

%

%

%

'4

'4%

'4%

'4

OVNCFS

%'4&/4 3"553"1

%'5)3)

4.13"5

18361.% 5"3&'/

065

065

065

065

065

065

065

%

%

%

%

%

%

%

/0/&

%

0''

0/

);

);

);

);

);

);

);

);

(0

%&-":

#05)

1#5"3&

/05"3&

,&:&%

4FF

'03."5

4VCNFOV

0''

%

%

%

%*('-5

$0/'*(

"$$6.

$"-*#3

0''

0/

7*4*#-&

0/

0''

'03."5

4FF

$"-*#3

4VCNFOV

8.55)3)

OVNCFS

The SCALES menu is shown in Figure 3-5. Parameters shown in each diagram are described in the table

following that diagram.

Figure 3-5. SCALES Menu

Please refer to PN 67887, 920i Installation Manual, for additional information on scale parameters and

their descriptions.

Installation/Operation Manual - Configuration of Scale Parameters 21

Page 26

4.0 Configuration of User Parameters

05/30/2013 08:13AM

Admin Menu

CB-2 2 Scale

Prepare

Load

Utilities

SCALE 1

EZ-Change

Criticals

AGG

CEM

Scale

Scale

#1

#2

lb Gross

lb Gross

00

0

1SFQBSF

-PBE

6UJMJUJFT

"ENJO

.FOV

&;$IBOHF

$SJUJDBMT

*OUFSWBMT

5JNFST

4FSJBM1PSUT%BUBCBTFT

"QQMJDBUJPO

1BSBNFUFST

4JNVMBUJPO

.PEF4FUVQ

$MPDL 1BTTXPSE

#BUDIJOH

1SFGFSFODFT

#BUDIJOH-JNJUT

1$1PSU

4FF"EEJUJPOBM

4VC1BSBNFUFST

BOEEFTDSJQUJPOT

MPDBUFEJO

5BCMF

8BUFS4ZTUFN

"ENJY4ZTUFN

.JYJOH4ZTUFN

#BUDIJOH-JNJUT

5JDLFUT3FQPSUT

4FUVQ

*%T

.BUFSJBMT

#BUDIJOH-JNJUT

4DBMFT

.JYFT

-PBET

-PDBUJPOT

0SEFST

$VTUPNFST

5SVDLT

4FF"EEJUJPOBM

4VC1BSBNFUFST

BOEEFTDSJQUJPOT

MPDBUFE

JO5BCMF

.BY5JNF

#FUXFFO1VMTFT

#BUDIJOH-JNJUT

"HH$POWFZPS

3VOPVU5JNF

1SJOU-JOF%FMBZ

#FFQ%VSBUJPO

4UBSU$POWFZPS

8BSOJOH5JNF

%JTQMBZ5JNF

%BUB&OUSZ

5JNFPVU

$POmHVSBUJPO

&YJU5JNFPVU

1BTTXPSE

5JNFPVU

#BUDIJOH-JNJUT

%FCVH1SPDFTT

1PSU

5JDLFU1SJOUFS

1PSU

%FCVH-PHJD

1PSU

3FQPSU1SJOUFS

1PSU

#BUDIJOH-JNJUT

*HOPSF"MM*OQVUT

*HOPSF.JYFS(BUF

-JNJU4XJUDI

8BJUGPS5PM

"DDFQU

%JTBCMF0VUQVUT

"VUP4FRVFODF

%FMBZ

+PH5JNF

$PSSFDUJPO

4DBMF

3BNQ6Q

4DBMF

3BNQ6Q

4DBMF

3BNQ6Q

4DBMF

3BNQ6Q

4DBMF

3BNQ%PXO

4DBMF

3BNQ%PXO

4DBMF

3BNQ%PXO

4DBMF

3BNQ%PXO

5JNF

#BUDIJOH-JNJUT

%BUF

%BUF'PSNBU

5JNF'PSNBU

,FZJO/FX

1BTTXPSE

#BUDIJOH-JNJUT

3FLFZ/FX1BTT

XPSEUP7FSJGZ

/FX1BTTXPSE

"DDFQUFE

,EVEL0ARAMETERS

,EVEL0ARAMETERS

,EVEL0ARAMETERS

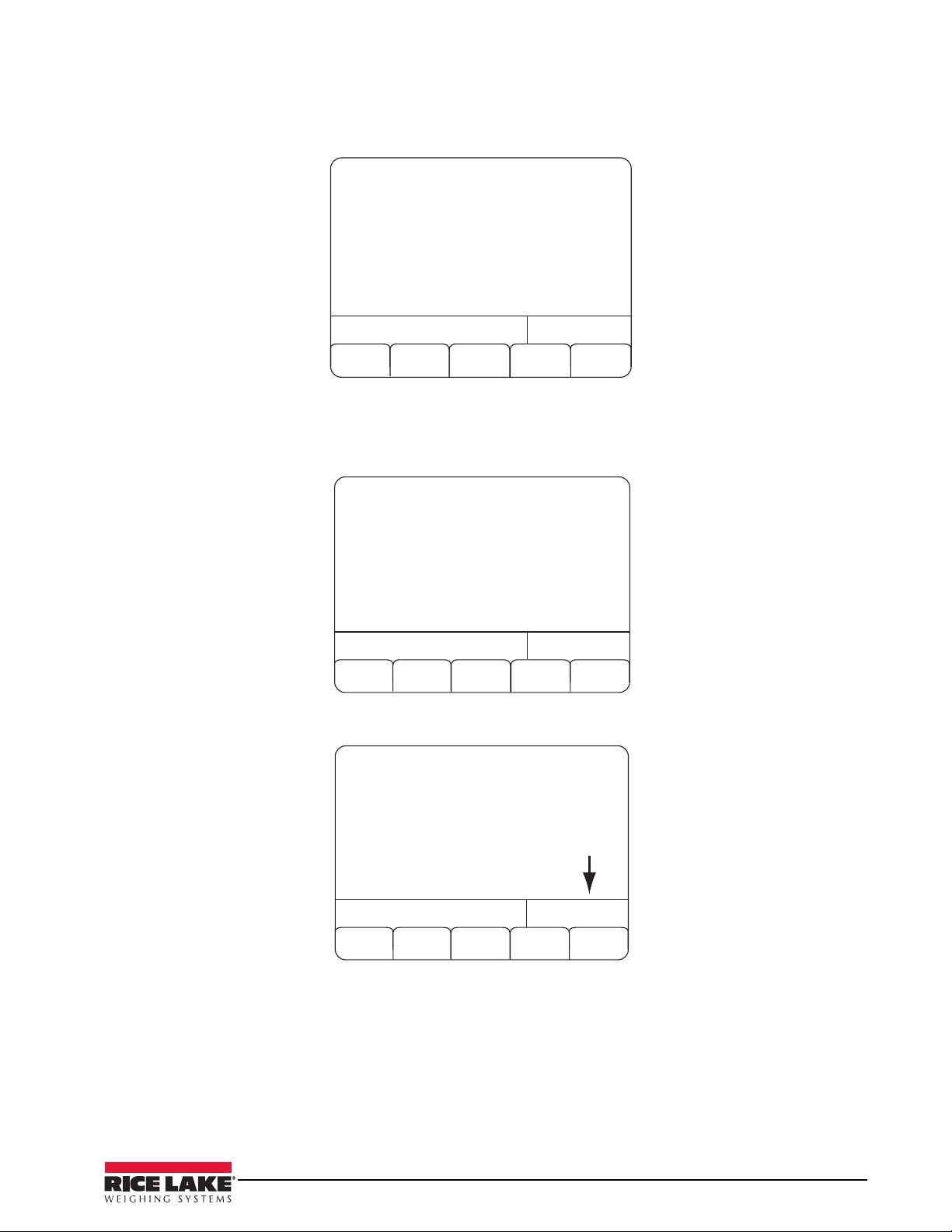

The CB-2 has many parameters that must be configured in order for the unit to batch properly. Use the

configuration parameters mode to set values for parameters controlling system operation. Press the

softkey to access those configuration parameters which are listed in Figure 4-2.

Figure 4-1. Admin Menu Softkey Location

All of the Admin Menu parameters are listed below in the following flow chart to better help illustrate all of the

different parameter levels that must be set to ensure proper operation. To access each sub-parameter use the

down arrows on the 920i to scroll up or down through the various menu choices.

Admin Menu

up or

22 Installation/Operation Manual

Figure 4-2. Admin Menu Flowchart

Page 27

4.1 Application Parameters

05/30/2013 08:13AM

Exit

Application Parameters

SCALE 1

Application Parameters : ==>

Databases : ==>

Intervals and Timers : ==>

Serial Ports : ==>

Simulation Mode Setup : ==>

Clock : ==>

Password : ==>

Select Category

05/30/2013

08:13AM

Exit

Batching Preferences

SCALE 1

Batching Preferences : ==>

Batching Limits : ==>

Water System : ==>

Admix System : ==>

Mixing System : ==>

Tickets/Reports Setup : ==>

IDS : ==>

Application Parameters

05/30/2013

08:13AM

Exit

Order Based Loading

SCALE 1

Order Based Loading : Yes

Metric (S.I.) System : No

State Regulatory Mode : Standard

Prompt for Truck ID : Yes

NET Mode Batching : No

Split Batching Allowed : Yes

Split Batch Even 1/4 : Yes

Batching Preferences

‘Discharge’ Keypress Required : FirstBatch

Aggregate Conveyor Control : Manual

Maintain Conveyor Power : No

No

Yes

The Application Parameter menu category is the first item displayed under the Admin Menu softkey.

Figure 4-3. Application Parameters Screen

If there is a right arrow displayed on the 920i screen, that means that there are more menu choices to choose

from. Press the

Again, press the

right arrow key on the 920i to access additional menu choices. A list of sub menus are displayed.

right arrow to access the additional sub-parameters as shown below.

Figure 4-4.

Batching Preferences

Figure 4-5. Order Based Loading

Each menu item is set up similarly by navigating through the various menu structures and entering parameter

values for each.

The following tables describe the sub-parameters for

each parameter listed.

Installation/Operation Manual - Configuration of User Parameters 23

Page 28

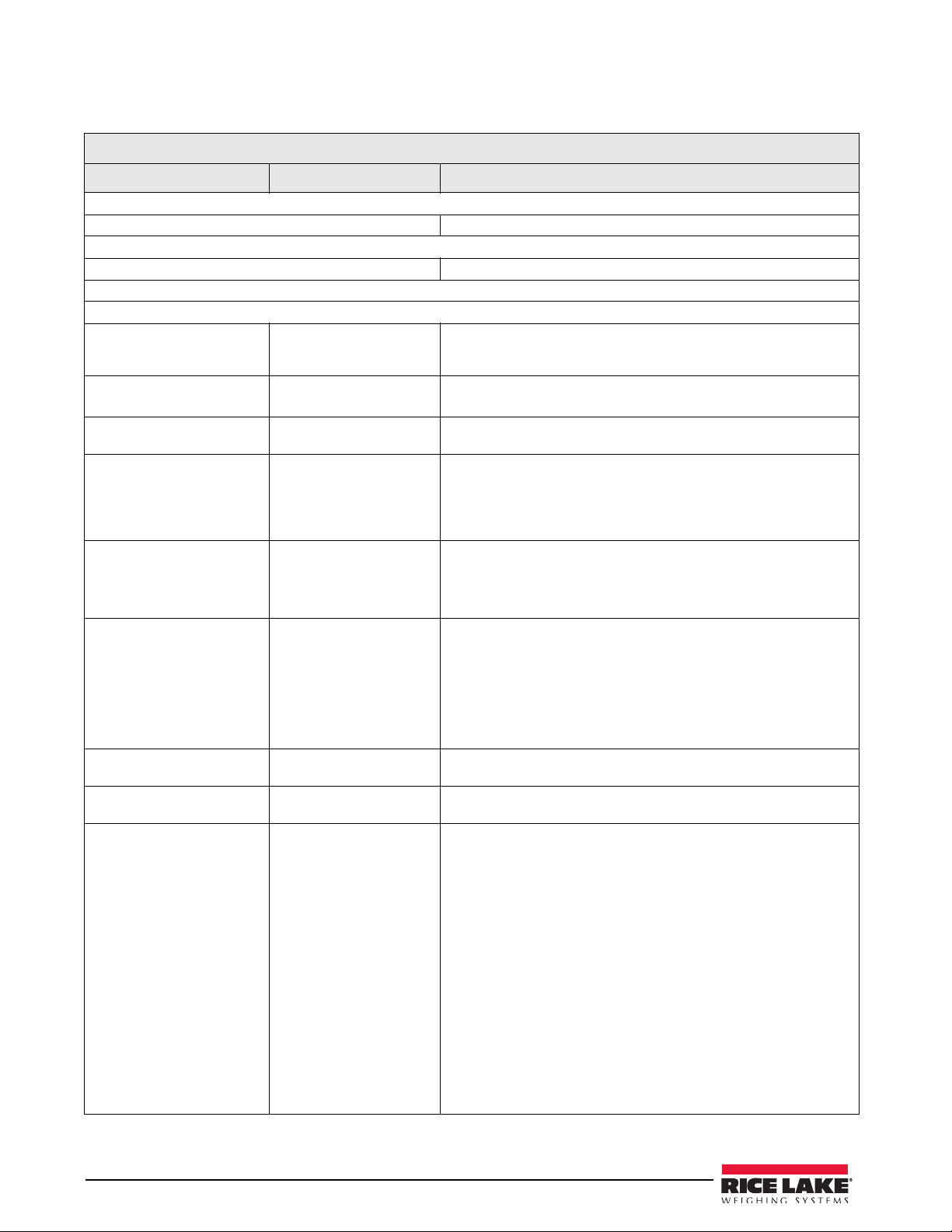

Application Parameters

ADMIN Menu

Parameter Choices Description

Level 2 Sub-menu

APPLICATION PARAMETERS

Level 3 Sub-menu

Batching Preferences

Level 4 Sub-menu ADMIN MENU/APPLICATION PARAMETERS/BATCHING PREFERENCES

Bolded items indicate the softkey default settings

Order Based Loading Load Only

Order Only

Mixed

Keyed Order ID

Metric (S.I.) System No

State Regulatory Mode Standard

Mix Design Weights

No

Yes

Yes

MnDot

CAL TRAN

NYSDOT

Other

SSD

OD

Select the Load Only softkey if all loads will be entered individually. Order Only

if all loads will be done through orders, and Mixed if some will be orders and

some individual loads.

Select Yes if you wish to enter your own order IDs.

Select Yes if operating using metric measurements.

Selects the desired state regulatory mode to operate in.

(Only Standard and MnDOT are currently supported)

See Truck Formatting information in Section xx on page dd for more

information on MnDot regulatory mode.

Indicate whether aggregate weights in the mix designs will be in Saturated

Surface Dry or Oven Dry weights.

Batching Mode

Split Batching Allowed No

Split Batch Even No

Continuous Batching

Tar ge t

Design

Yes

Yes

No

Yes

Count

Partial

(Note: MnDOT installations are always OD - oven dry.)

Target mode batching (default) will adjust the amount of each ingredient on a

scale based on the amount of the ones previously dispensed to come as

close as possible to the target number of yards/cubic meters.

Design mode batching will attempt to batch the design amount of a material

to come as close as possible to the mix design material proportions. Design

mode batching is currently unsupported.

Select Yes if trucks may be loaded that exceed the plant capacity. Trucks with

up to five times plant capacity may be loaded.

Select Yes to split the batches equally. Otherwise, all but the final batch will

be at plant capacity.

In an order based system, selecting Yes will cause the multiple loads of a

multi-load order to be run automatically one after the other until the order is

filled.

In a load based system, the same load will be run continuously until the Last

Batch softkey is pressed.

Count will prompt for a number of batches to run continuously.

Partial will prompt for a number of single batch units to run. The number can

include partial amounts and no batch will exceed a single unit. For instance, if

a mix design is specified that generates one yard and the operator keys in

1.6, the CB-2 will generate 1.6 yards of product in two 0.8 yard batches.

Likewise, if a mix design is specified that would generate two yards of material

and the operator enters 2.5 at the prompt, the CB-2 will determine that three

batches are required and generate five yards of product in three 1 2/3 yard

batches.

24 Installation/Operation Manual

Table 4-1. Application Parameters Sub-menu List

Page 29

ADMIN Menu

Parameter Choices Description

Prompt for Truck ID No

Yes

‘Discharge’ Keypress Required Never

First Batch

Always

Aggregate Conveyor Control Manual

Auto

Maintain Conveyor Power No

Yes

Boot Control Manual

Auto

Pipe Line/Preweigh Next Batch No

Yes

Weigh-up Dust Collecting No

Yes

Wait for Tol. Accept No

Yes

Scale Inspect Mode No

Yes

ESTOP is Fatal No

Yes

Air Pressure Sensor No

Yes

Auto Correct Preact Weights No

Yes

Auto Correct Jog Weights No

Yes

Jog Correction 50 % of difference used to adjust.

Auto Correct Burst Times No

Yes

Zero Tolerance Override Required No

Yes

Auto Advance Jog Tuning No

Yes

Prompt for a 1 to 6 character truck ID when preparing to batch a load.

Select to require a softkey be pressed before starting the discharge cycle.

Select First Batch to require the Discharge keypress only on the first batch

while split batching.

(Note that this does not apply to water added during weigh-up.)

Manual control of the aggregate conveyor indicates that the operator will

manually start the conveyor.

Auto indicates that the CB-2 will start and stop the conveyor. Note that if Auto

is selected it is critical that an audible alarm and light be wired to the system

alarm output to warn before the conveyor is started.

Yes indicates that the Aggregate Conveyor Start output must remain on to

keep the conveyor operating. No indicates the output is to be pulsed to latch

the conveyor on.

Manual control is selected if either the discharge boot is manually controlled

or if there is none.

In auto mode, the Lower Boot output is pulsed on for two seconds at the

beginning of the discharge cycle, and the Raise Boot output is pulsed on for

two seconds when the discharge is completed.

With split batching, pipe lining allows a scale to be used to weigh ingredients

for the next batch for a multi-batch load as soon as the discharge for the

scale is complete for the current batch

If Yes, the Dust Collection output will be set on while cement is being

dispensed into the cement hopper scale. (Dust collection is not supported for

a loss in weight cement scale.)

Set to No to bypass any operator intevention required to bypass tolerance

exceptions.

In scale inspection mode, the system will pause when the tolerance check is

done if the scale is in tolerance to allow the inspector to force an out of

tolerance condition

If the Yes softkey is selected, pressing the ESTOP button will automatically

cancel the current batch.

Yes indicates that the Air Pressure OK digital input must be on before the

weigh-up or discharge cycle may begin.

Yes will automatically correct the preact weight levels based on actual results.

Yes will automatically correct the jog weight levels based on actual results.

Yes will automatically correct inching gate burst times based on actual results.

Yes will require a softkey press to continue if the scale is outside the zero

tolerance band at the start of weigh-up.

No indicates that no action will be required if a scale is outside the zero

tolerance band at the start of weigh-up.

No zero tolerance checking is done on loss in weight scales.

This feature is currently unsupported.

.

.

Table 4-1. Application Parameters Sub-menu List

Installation/Operation Manual - Configuration of User Parameters 25

Page 30

ADMIN Menu

Parameter Choices Description

Start Allowed in ‘Manual’ mode No

Yes

Jog and Correct Last Batch Only No

Yes

Batcher Air After Weigh-up No

Yes

Delete Load Rec After Load No

Yes

Batching Limits

Level 4 Sub-menu ADMIN MENU/APPLICATION PARAMETERS/BATCHING LIMITS

Maximum Plant Capacity 10.0 Maximum plant capacity in yard/cubic meters.

Minimum Plant Capacity 0.25 Smallest allowable quantity. Must not be greater than 1/2 of the maximum

To t a l Ya r d s ( D a i ly ) These four values are accumulators maintained by the CB-2. The time frames

Total Yards (Weekly)

Total Yards(Monthly)

Total Yards (Yearly)

Water System

Level 4 Sub-menu ADMIN MENU/APPLICATION PARAMETERS/WATER SYSTEM

Weighed Water No

Yes

Water Reservoir No

Yes

Start Water with Weigh-up No

Yes

Water to Truck/Mixer First No

Yes

Start Water With Discharge

Manual

Cement Discharge

Aggregate Discharge

Skiphoist Discharge

Weighup

Material 1

Material n

Suspend Water During Cement No

Yes

Percent Tailwater 20 Percent of total water to be added after all other materials have been added

Minimum Tailwater Amount 20 gal/160 lb Minimum amount of tailwater.

Truck Washout Amount 300 gal/2500 lb Amount of water to be used to do a truck washout (code 9274).

Select Yes to allow a batch to be started while in Manual mode.

If Yes is selected, jogging will only be done on the final batch of a split batch

load.

Select Yes to have the cement weigh hopper aeration start just after the last

ingredient is weighed on the cement scale.

If no is selected the load record will be retained after the load has been

processed.

plant capacity.

(daily, weekly, etc) are arbitrary. Each value contains the amount batched

since the last time it was set to zero.

No for metered water, Yes for weighed. The default for a two scale system is

No and for a three scale system is Yes.

Yes if water is to be metered into a reservoir, No if water is weighed or directly

metered into the truck or mixer.

Yes if water can be dispensed into the truck or mixer while the other materials

are being weighed.

Yes to discharge all head water (excluding tail water) into truck/mixer before

aggregates and cement are added.

Discharge will automatically start the front water discharge at the beginning of

the discharge cycle.

Manual will display a Start Water softkey during weigh-up to allow the

operator to begin dispensing water before the other materials have been

weighed. (If the water discharge has not begun before the discharge cycle

begins, the water is added at that point.)

Cement Discharge will start the front water discharge when the cement

discharge begins.

Aggregate Discharge will start the front water discharge when the aggregate

discharge begins.

Skiphoist Discharge will start the front water discharge when the aggregate

skiphoist discharge begins.

Weighup will start the water discharge while the other materials are being

weighed.

Select a material to start adding the water when the weigh up of that material

begins.

Yes will suspend water and admixture discharge while cement is being

discharged.

to the truck or mixer.

26 Installation/Operation Manual

Table 4-1. Application Parameters Sub-menu List

Page 31

ADMIN Menu

Parameter Choices Description

Water Adjust per Batch No

Yes

Admix System

Level 4 Sub-menu ADMIN MENU/APPLICATION PARAMETERS/ADMIX SYSTEM

Suspend Admixture Addition No

Yes

Single Empty Signal No

Yes

Mixing System

Level 4 Sub-menu ADMIN MENU/APPLICATION PARAMETERS/MIXING SYSTEM

Enable Mixer Controls No

Yes

Auto Start/Stop Mixer No

Yes

Mixer Start is Latched No

Yes

Auto Discharge Mixer No

Yes

Power Discharge Gate to Close No

Yes

Discharge Gate Close Time 3.0 Time in seconds for the mixer discharge gate to open/close. If Power

Mixer Discharge Time 8.0 Maximum time in seconds for the mixer to discharge.

Gate Closed Limit Switch No

Yes

Gate Open Limit Switch No

Yes

Ticket/Reports Setup

Level 4 Sub-menu ADMIN MENU/APPLICATION PARAMETERS/TICKETS & REPORTS SETUP

Print Custom Batch Ticket No

Yes

Print Ticket Number No

Yes

# Line Feeds Number of initial lines to space to reach correct starting location.

DOT Header “Certificate of Compliance” This string will be printed at the head of any ticket printed for an order that has

Source Length 6 Maximum printable material source length.

Yes if the water adjustment amounts are to be per batch, No if they are to be

per yard/cubic meter.

Set this to Yes to inhibit the adding of all admixtures without changing the mix

designs

.

Yes if Admixture 1 Bottle Empty on indicates all bottles are empty.

Set to Yes if a mixer is part of your system and you wish to have the CB-2

control it.

If Yes, the CB-2 will control the running of the mixer.

If Yes, the CB-2 will pulse the Mixer Start output on for two seconds to start

the mixer and pulse the Mixer Stop output to stop the mixer.

Otherwise, the Mixer Start output is set on and held on to run the mixer.

If Yes the CB-2 will control the discharge of the mixer.

If Yes, CB-2 will set the Mixer Gate Close output on to close the mixer

discharge gate.

Discharge Gate to Close was set to Yes, this is the amount of time the Mixer

Gate Close output will be held on. If Gate Open Limit Switch is set to No and

Power Discharge Gate to Close to Yes, this is the amount the Mixer Gate

Open output will remain on to open the gate.

If Yes, CB-2 will use the Mixer Gate is Closed input to recognize that the gate

is closed.

If Yes, CB-2 will use the Mixer Gate is Open input to recognize that the gate is

open.

Print Custom Batch Ticket (requires special software)

Select Yes to print the batch ticket number on the batch ticket.

it’s DOT parameter defined as other than None.

Table 4-1. Application Parameters Sub-menu List

Installation/Operation Manual - Configuration of User Parameters 27

Page 32

ADMIN Menu

Parameter Choices Description

Header Text Lines Header Line 1 Left

Print Plant Number No

Print Customer & Job Site No

Print Instructions /Notes No

Print Driver Name No

Print Price No

Print Slump No

Print Job IDs No

Body Text Lines

Batch Weights on Ticket None

Print Water/Cement Ratio No

Print Time Loaded No

Print Water Adjustment No

Flag Out-of-Tolerance No

Header Line 1 Right

Header Line 2 Left

Header Line 2 Right

Header Line 3 Left

Header Line 3 Right

Header Line 4 Left

Header Line 4 Right

Header Line 5 Left

Header Line 5 Right

Header Line 6 Left

Header Line 6 Right

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Body Line 1 Left

Body Line 1 Right

Body Line 2 Left

Body Line 2 Right

Body Line 3 Left

Body Line 3 Right

Body Line 4 Left

Body Line 4 Right

Body Line 5 Left

Body Line 5 Right

Body Line 6 Left

Body Line 6 Right

Load Totals

Individual Batches

Yes

Yes

Yes

Yes

Allows the user a total of 6 header lines to place at the top of the batch ticket

(maximum 510 characters per line, 255 per section).

To change, press the [Change] softkey and enter the new data.

Select Yes to print the plant number on the batch ticket.

Select Yes to print the customer name and delivery address on the batch

ticket.

Select Yes to print the order instructions and notes on the batch ticket

Select Yes to print the driver’s name on the batch ticket.

Select Yes to print the unit and total price on the batch ticket.

Select Yes to print the requested slump value on the batch ticket

Select Yes to print the job IDs on the batch ticket.

Allows the user a total of six body lines to place in the middle of the batch

ticket (maximum 510 characters per line, 255 per section).

To change, press the [Change] softkey and enter the new data.

Select Individual Batches to print the batch data individually for each batch in

a split batch load. Load Totals prints the load data with split batch data

totaled. None suppresses printing of batch.

Select Yes to print the water to cement ratio for a load.

Select Yes to print the load time on the printed ticket.

Select Yes to print the water adjustment on the printed ticket.

Select Yes if you want the out of tolerance ingredients to be flagged with an

asterisk.

28 Installation/Operation Manual

Table 4-1. Application Parameters Sub-menu List

Page 33

ADMIN Menu

Parameter Choices Description

Trailer Text Lines

Form Feed No

IDs

Level 4 Sub-menu ADMIN MENU/APPLICATION PARAMETERS/IDS

Order Number 1000000 Enter the numeric order number. (1000000 - 1999999)

Load Number 2000000 Enter the numeric load number. (2000000 - 2999999)

Batch Number 3000000 Enter the numeric batch number. (3000000 - 3999999)

Ticket Number 1 Enter the new numeric ticket number.

Plant Number 1 Enter the new numeric plant number.

TAXES AND MISCELLANEOUS CHARGES

Level 4 Sub-menu

State Sales Tax Rate % Unsupported

County/Local Tax Rate % Unsupported

Trailer Line 1 Left

Trailer Line 1 Right

Trailer Line 2 Left

Trailer Line 2 Right

Trailer Line 3 Left

Trailer Line 3 Right

Trailer Line 4 Left

Trailer Line 4 Right

Trailer Line 5 Left

Trailer Line 5 Right

Trailer Line 6 Left

Trailer Line 6 Rightt

Yes

Allows the user a total of six trailer lines to place at the end of the batch ticket

(maximum 510 characters per line, 255 per section).

To change, press the [Change] softkey and enter the new data.

Select Yes if you want a form feed command sent to the printer at the end of

the ticket.

Table 4-1. Application Parameters Sub-menu List

Installation/Operation Manual - Configuration of User Parameters 29

Page 34

Database Parameters

ADMIN Menu

Parameter Choices Description

Level 2 Sub-menu

DATABASES

Level 3 Sub-menu

Materials Select or enter the material ID You have the ability to Add, Copy, Change, Delete or Exit

Level 4 Sub-menu ADMIN MENU/APPLICATION PARAMETERS/DATABASES/MATERIALS

Material ID ID used to reference this material

Name Material name

Source Material source

Material Type Weighed

Metered

Material Class Aggregate

Cement

Primary Water

Admix

Auxiliary Water

Under Tolerance % 2% Enter the percentage under the target at which the material dispense is

Over Tolerance % 2% Enter the percentage over the target at which the material dispense is

Daily Material Used 0.0 Daily dispensed accumulator

Weekly Material Used 0.00 Weekely dispensed accumulator

Monthly Material Used 0.00 Monthy dispensed accumulator

Yearly Material Used 0.00 Yearly dispensed accumulator

Material On Hand 0.00 Material on hand

Material Type = Weighed

Scale Settle Time 1.00 Minimum settle time

Slow Fill Weight 0 Weight to be dispensed at slow rate.

Minimum Drop Weight 500 Minimum dispense weight. Mixes calling for less than this aount will jog to the

Preacts Select to set up preacts.

Jogs Select to set up jogs

Material Class = Aggregate

Absorbed moisture 0.0 Material absorption factor

Material Type = Metered

Conversion Factor 1 Volume units per pulse

Blow out time 0.0 Blowout time in seconds for bottled material.

Coast pulses 1 Pulse counting setpoint number

Coast time 5 Maximum coast time in seconds

Discharge delay 0.00 Delay time in seconds after the selected discharge point before discharge is

Input is ON when empty No

Yes

Material Class = Admix

Select the method used to dispense this material.

Select one the five options for materials.

considered under tolerance.

considered over tolerance.

target.

actually started.

Emply signal polarity for bottled/reservoired materials.

30 Installation/Operation Manual

Page 35

ADMIN Menu

Parameter Choices Description

Add With

Dosage by 100 weight

Water weight 0.0 For water based admixtures, water weight per admix volume unit.

Preact

Front Water

Tail Water

Discharge

Cement Discharge

Aggregate Discharge

Skiphoist Discharge

Last

Weighup

Material 1

.

.

Material n

No

Yes

Preact is used to account for material still in suspension after the filling is stopped. The amount in suspension

will depend on the distance from the source to the top of the material already on the scale and that, in turn, is

inversely proportional to the amount of weight on the scale – the more weight the less distance.

Front Water will add the admixture with the front water,

Tail Water will add the admixture with the tail water,

Discharge will add the admixture when the materials are added to the truck

or mixer.

Cement Discharge will start the admixture discharge when the cement

discharge begins.

Aggregate Discharge will start the admixture discharge when the aggregate

discharge begins.

Skiphoist Discharge will start the admixture discharge when the aggregate

skiphoist discharge begins.

Last will add the admixture after all other materials (except tailwater) have

been added.

Weighup will start the admixture discharge while the other materials are being

weighed.

Select a material to start adding the admixture when the weighup of that

material begins

Dosage by yard of concrete or by 100 weight of cement.

The preact levels are used to adjust the amount of preact depending on how much material will be in the

weigh hopper when the dispensing for the material is complete - the more material on the scale, the less

material that will remain in suspension

Learn Preact Off

On

Adjustment Precent 50 Percent by which preact adjustment is made for preact in Learn mode