Page 1

®

BenchMark Series

Single Point Bench Scales

Technical Manual

22125 Rev D

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

1.0 Introduction..................................................................................................................................... 1

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 10" x 10" and 12" x 12" SL Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 12", 18" and 24" Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 12" x 18" Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.5 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5.1 10" x 10" and 12" x 12" SL Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5.2 12" x 18" Stainless Steel Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.5.3 12", 18" and 24" Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0 Installation ...................................................................................................................................... 5

2.1 Leveling Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Connecting the Load Cell Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.3 Grounding the Scale Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.0 Calibration ...................................................................................................................................... 6

4.0 Troubleshooting Guide.................................................................................................................... 7

5.0 Load Cell Replacement................................................................................................................... 8

5.1 10"x10" and 12"x12" SL Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.2 12", 18", and 24" Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.3 Installing Protective Clamshells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.0 Replacement Parts ....................................................................................................................... 11

6.1 10" x 10" and 12" x 12" SL and SL/HE Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2 12" x 12" and 12" x 18" Models, Mild Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.3 12" x 18" Model, Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.4 18" x 18", 18" x 24" and 24" x 24" Models, Mild and Stainless Steel . . . . . . . . . . . . . . . . . . . . . . . . . 17

BenchMark Series Limited Warranty ....................................................................................................... 19

For More Information ................................................................................................................................ 20

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Rice Lake Weighing Systems

is an ISO 9001 registered company.

October 23, 2014

Contents i

Page 4

ii Benchmark Series Single Point Bench Scales

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

Page 5

1.0 Introduction

Important

WARNING

WARNING

Congratulations on choosing a scale from the BenchMark™ series, the highest-quality single-point benchtop scale

available. The following types of NTEP-approved BenchMark scales are available:

Authorized distributors and their employees can view or download this manual from the Rice Lake Weighing

Systems distributor site at: www.ricelake.com

• The light-capacity SL series featuring stainless steel construction in 10"x10" and 12"x12" platforms with

capacities from 5 lb to 100 lb.

• A mid-range model with a 12"x18" platform and a cover and

This model is available in capacities from 50 lb to 100 lb.

• The medium-capacity series is construc

ted with stainless steel covers, and mild steel—or optional stainless

steel—frame construction. This series is available in sizes from 12" x 12" up to 24" x 24" in capacities

from 30 lb to 1,000 lb. This manual covers each scale series.

One exciting feature of the BenchMark series is its ability to be converted into a checkweigher

and head from a CW-80 CheckWeigher to your BenchMark scale, the features of a checkweigher are available to

you. Contact your Rice Lake Weighing Systems distributor for more information.

1. 1 S af et y

Safety Symbol Definitions:

Indicates a potentially hazardous situation that, if not avoided could result in death or serious injury, and

includes hazards that are exposed when guards are removed.

Indicates information about procedures that, if not observed, could result in damage to equipment or

corruption to and loss of data.

frame that are constructed of stainless steel.

. By adding the neck

General Safety

Do not operate or work on this equipment unless you have read and understand the instructions and

warnings in this manual. Failure to follow the instructions or heed the warnings could result in injury or

death. Contact any Rice Lake Weighing Systems dealer for replacement manuals. Proper care is your

responsibility.

Failure to heed may result in serious injury of death.

DO NOT allow minors (children) or inexperi

DO NOT operate without all shields and guards i

DO NOT jump on the scale.

DO NOT use for purposes other then weight taking.

DO NOT place fingers into slots or possible pinch points.

DO NOT use any load bearing component that i

DO NOT use this product if any of the components are cracked.

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

Before opening the unit, ensure the power cord is disconnected from the outl

Keep hands, feet and loose clothing

enced persons to operate this unit.

n place.

s worn beyond 5% of the original dimension.

away from moving parts.

et.

Introduction 1

Page 6

1.2 10" x 10" and 12" x 12" SL Models

Overload Protection Springs

Lift up Protection Screw

Overload Protection Screw

All seven models of the 10" x 10" and 12"x12" SL series have stainless steel covers and frame systems. All models

use a single point load cell. The 10, 20, 30, 50, and 100 lb models come standard with a potted single point load cell

that offers extra protection against water infiltration but is not designed for washdown use. The 30, 50, and 100 lb

models can also be supplied with an RL1140 stainless steel load cell. Extra load cell protection is also available in

optional stainless steel “clamshells” which enclose the load cell. See Section 5.0 for information about clamshell

installation. All load cells come with

The SL series scales use a sensitive 4-point, spring-plate suspension to minimize shock and overload damage

susceptible of light-capacity scales. The system uses a bolt and an overload protection spring at each of four

loading points beneath the top cover (see Figure 1-1). Each spring is set for a specific tension so that it will

compress to prevent overload damage. If a potentia

at that corner compresses. When the spring compresses, the load is taken off the load cell. This eliminates the

possibility of overloading the load cell. Likewise, if a load more than 150% of total capacity is placed anywhere on

the deck, the springs will compress and remove the load from the load cell.

In addition to the overload protection spring, the SL models inc

beneath the load cell to help prevent overload damage.

To protect the load cell from being acciden

spider, a lift up protection screw is incorporated into the design (see Figure 1-2).

10 feet of cable.

Figure 1-1. Overload Springs

lly damaging load is placed on a corner of the scale, the spring

orporate a load cell overload protection screw

tally forced upward and damaged by improperly lifting the scale by the

2 Benchmark Series Single Point Bench Scales

Figure 1-2. Lift up Protection Screw

Page 7

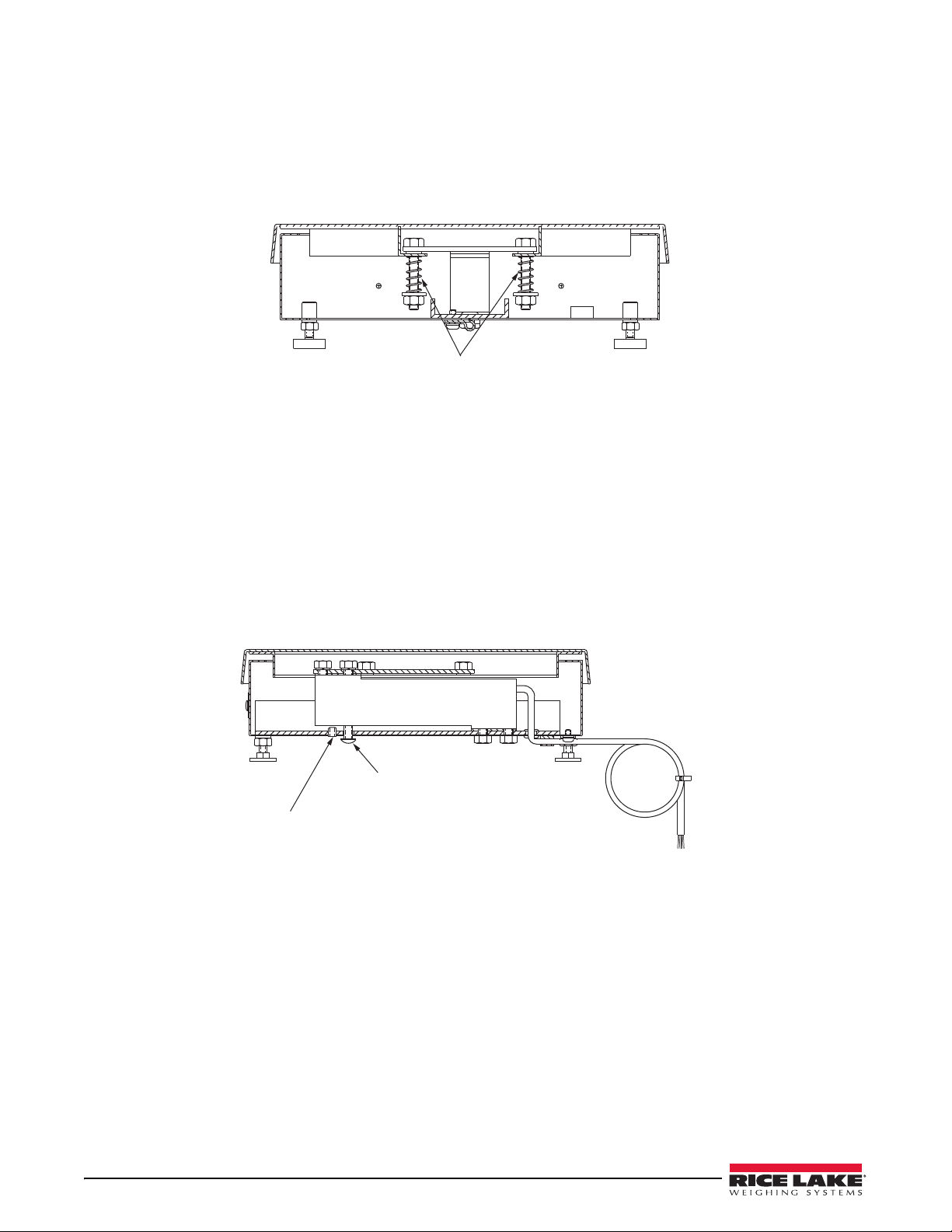

1.3 12", 18" and 24" Models

Top Frame

Overload Protection Screw

Overload Stops

Larger models in the series use mild steel frames and stainless steel deck covers for light washdown with a damp

sponge. All models are available with mild steel or optional stainless steel underbody frame construction. The

standard load cell is a single point load cell. Options include a stainless steel RL1140 load cell for 12" x 12" and

12" x 18" models and protective stainless steel clamshells for all models using a single point load cell. All load

cells come with 10 feet of cabling.

Figure 1-3. 12" x 12" With Overloads

These medium-capacity bench scales provide overload protection for the load cell by positive stops located beneath

each corner of the top frame (see Figure 1-3). These stops are set at the factory for 100% of scale capacity

Additional overload protection is provided by

damage.

an overload screw beneath the load cell to help prevent shock

.

1.4 12" x 18" Stainless Steel

The 12" x 18" model has a stainless steel cover and underbody frame to meet USDA requirements and make it

ideal for washdown use. The 12" x 18: comes standard with a single point load cell; a stainless steel load cell is

optional for both the 50 lb and 100 lb models. Extra load cell protection is available with the optional stainless steel

“clamshell” that encloses the load cell. See Section 5.0 for information about clamshell installati

come with 10 feet of cabling.

These medium capacity bench scales provide overload protec

of the top frame. These stops are set at the factory for 100% of scale capacity. Additional overload protection is

provided by an overload screw beneath the load cell to help prevent shock damage.

tion with positive stops located beneath each corner

on. All load cells

Introduction 3

Page 8

1.5 Specifications

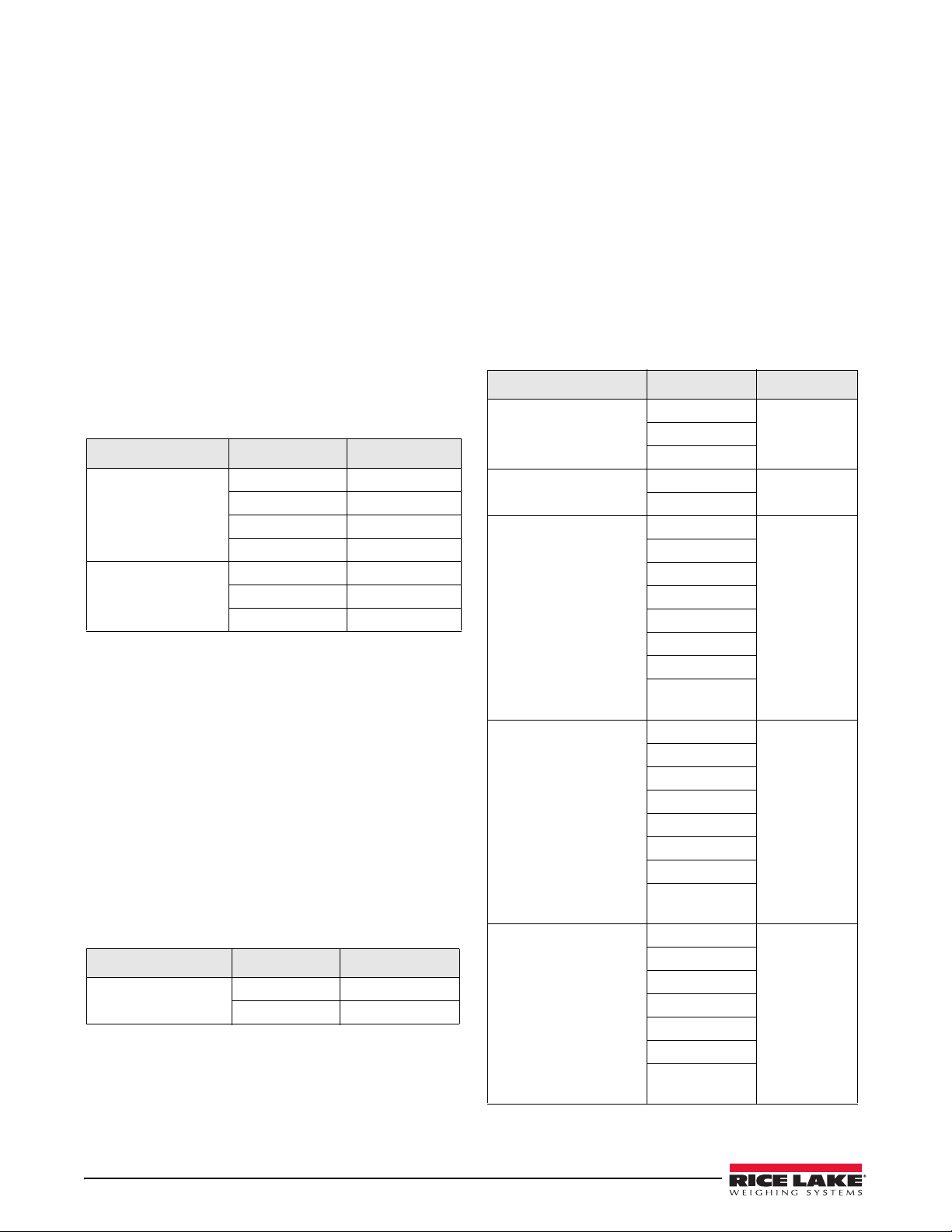

1.5.1 10" x 10" and 12" x 12" SL Models

Load Cell: Potted single point

(5 lb is not potted)

Potted single point, stainless steel load

cell

cell optional on 30, 50, and 100 lb

models

Rated Output: 0.91 mV/V

Maximum Overload: 200%

Overload Protection: Spring loaded spider

Cable Length: 10 ft. (3 m) – 6 wire shielded

Output Impedance (ohms): 350

Compensated

Temperature Range: -10°C/14°F to +50°C/122°F

Safe Temperature Range:-30°C/-22°F to +70°C/158°F

Dimensions/Capacities:

1.5.2 12" x 18" Stainless Steel Model

Load Cell: Potted single point

Potted single point, stainless steel load

cell

optional on 50 lb and 100 lb models

Rated Output: 0.91 mV/V

Maximum Overload: 200%

Overload Protection: 5 point, independently adjusted

Cable Length: 10 ft. (3 m) – 6 wire shielded

Output Impedance (ohms): 350

Compensated

Temperature Range: -10°C/14°F to +50°C/122°F

Safe Temperature Range:-30°C/-22°F to +70°C/158°F

Dimensions/Capacities:

1.5.3 12", 18" and 24" Models

Load Cell: 12"x12" and 12"x18":

Potted single-point

18"x18", 18"x24" and 24"x24":

Overload Protection: 5 point, independently adjusted

Cable Length: 10 ft. (3 m) – 6 wire shielded

Rated Output: 0.91 mV/V

Output Impedance: 350

Maximum Overload: 200%

Compensated

Temperature Range: -10°C/14°F to +50°C/122°F

Safe Temperature Range:-30°C/-22°F to +70°C/158°F

Dimensions/Capacities:

Size Capacity Height

10" x 10"/

254mm x 254mm

5 lb / 2.3 kg 3.15" / 80 mm

10 lb / 4.5 kg 3.15" / 80 mm

20 lb / 9.1 kg 3.15" / 80 mm

30 lb / 13.6 kg 3.15" / 80 mm

12" x 12"/

305mm x 305mm

30 lb / 15 kg 3.25" / 92 mm

50 lb / 25 kg 3.25" / 92 mm

100 lb / 50 kg 3.25" / 92 mm

Table 1-1. 10" x 10" and 12" x 12" SL Model Sizes

Size Capacity Height

12" x 18" /

305mm x 457mm

50 lb / 25 kg 4.00" / 102mm

100 lb / 50 kg 4.00" / 102mm

Table 1-2. 12" x 18" Stainless Steel Model Sizes

Size Capacity Height

12" x 12" /

305mm x 305mm

30 lb / 13.6 kg 3.62" / 92mm

50 lb / 25 kg

100 lb / 50 kg

12" x 18" /

305mm x 457mm

50 lb / 25 kg 3.62" / 92mm

100 lb / 50 kg

18" x 18" /

457mm x 457mm

50 lb / 25 kg 5.25" /

133mm

100 lb / 50 kg

150 lb / 75 kg

200 lb / 100 kg

250 lb / 125 kg

300 lb / 150 kg

500 lb / 250 kg

1000 lb / 500

kg

18" x 24" /

457mm x 610mm

50 lb / 25 kg 5.25" /

133mm

100 lb / 50 kg

150 lb / 75 kg

200 lb / 100 kg

250 lb / 125 kg

300 lb / 150 kg

500 lb / 250 kg

1000 lb / 500

kg

24" x 24" /

610mm x 610mm

100 lb / 50 kg 5.25" /

133mm

150 lb / 75 kg

200 lb / 100 kg

250 lb / 125 kg

300 lb / 150 kg

500 lb / 250 kg

1000 lb / 500

kg

Table 1-3. 12", 18, and 24" Model Sizes

4 Benchmark Series Single Point Bench Scales

Page 9

2.0 Installation

Important

For 6-wire operation: For 4-wire operation:

6-Wire Color Code Function

Red +Signal

White - Signal

Green + Excitation

Black - Excitation

Blue + Sense

Brown - Sense

Yellow or Bare Shield

Table 2-1. Load Cell Wiring - 6 Wire

4-Wire Color Code Function

Red + Signal

White - Signal

Green and Blue* + Excitation

Black and Brown* - Excitation

Yellow or Bare Shield

* Connect Sense and Excitation wires together

if using 4-wire system without sense leads.

Table 2-2. Load Cell Wiring - 4 Wire

2.1 Leveling Scale

Remove the scale from the shipping container and place it in the desired location. Lift off the deck cover and locate

the bubble level. Adjust the four corner feet until the scale is level and all feet contact the support surface so the

scale does not rock. Lock the jam nuts on the feet when the final level is correct.

2.2 Connecting the Load Cell Cable

All models come with 10 feet of color-coded load cell cable.

Do not cut this cable. The load cell is temperature-compensated for an exact cable length of 10 feet.

See your indicator manual to determine the proper load cell cable input connectors. Use the following color codes

to wire the load cell cable.

2.3 Grounding the Scale Base

Bench scales can build up a static electricity charge during weighing operations. If powerful enough, this charge

can travel through the load cell cable to the indicator. To prevent this, all bench scales should be adequately

grounded so that static charges and transient electrical surges can drain directly to ground. Recommended practice

is to connect the scale base to an AC ground circuit using at least #12 wire. All BenchMark scales have either a

grounding screw or a hole for such a grounding screw located on the bottom of the lower frame for this purpose.

Installation 5

Page 10

3.0 Calibration

It is recommended that the scale be “exercised” by loading it to near capacity two or three times before calibration

to be certain that everything is seated. To calibrate your BenchMark:

1. With no load on scale, place the indicator in its calibration mode and perform a zero calibration.

2. Place test weights on platform equal to 70%–100% of scale’s capacity. If several weights are used, they

distribute them evenly around the platform.

3. Perform a span calibration.

4. Remove the test weights and check the zero reading. If necessary, repeat the calibration process.

See the indicator manual for the specific indicator calibration procedure.

6 Benchmark Series Single Point Bench Scales

Page 11

4.0 Troubleshooting Guide

Use the following troubleshooting tips for the Benchmark scale if necessary.

Symptom Probable Cause Remedy

No display Power disconnected Connect power

Cable cut or disconnected Repair cable

Signal leads incorrectly wired at indicator Connect according to the manual

Display starts at zero Incorrect load cell c

Faulty indicator Service indicator

Erratic Weight display Vibration near the scale Remove the source of the vibration, or adjust

Scale not level Level the scale

Water damage to the load cell or cable Replace the load cell

Faulty indicator Service the indicator

Loose load cell screws Tighten to correct torque

Faulty load cell Test and replace if necessary

Consistently low weight Indicator not properly adjusted to zero Zero indicator correctly

Scale deck cover binding Obtain adequate clearance

Overload stops set too high Reset the stops correctly

Indicator not calibrated for scale Calibrate the scale

Faulty load cell Test and replace if necessary

able connections Connect according to the manual

gital averaging of indicator to minimize erratic

di

display

Table 4-1. Benchmark Troubleshooting Table

Troubleshooting Guide 7

Page 12

5.0 Load Cell Replacement

Important

Lift up

Protection

Screw

Overload

Protection

Screw

Load Cell Screw

Load Cell Screw

Top Sub-Assembly

Load Plate / Spider

Top Cover

Scale Model Spring Length "H"

10 x 10 - 5 Lb 1.06

10 x 10 - 10 Lb .94

10 x 10 - 20 Lb .97

10 x 10 - 30 Lb 1.43

12 x 12 - 30 Lb 1.43

12 x 12 - 50 Lb 1.12

12 x 12 - 100 Lb 1.16

Table 5-1. Overload Spring Length

H ±.0 2

Figure 5-2. Spring Height

5.1 10"x10" and 12"x12" SL Models

1. Unplug AC power from indicator and disconnect load cell cable from indicator.

2. Lift off scale top cover.

3. Locate two upper load cell

Do not remove four spring-loaded screws that attach load plate to spider assembly.

4. Lift off load plate/spider assembly as a unit.

5. Remove spacer between load plate and load cell and set it aside.

screws. Use 7/16" wrench to unscrew and remove those two load cell screws.

6. Turn scale over and back off overload protection screw one complete turn. Completely unscrew and

remove lift up protection screw.

7. Use 7/16" wrench to unscrew and remove two lower load ce

removed from scale. Do not lose shim beneath load cell.

8. Thread cable of replacement load cell through rubber grommet. P

two lower load cell screws. Torque to 80 in-lb.

9. Replace lift up protection screw by screwing it in

10. Turn scale right side up. Position spacer on load cell, then place load plate/spider assembly into position.

Screw in

two upper load cell screws. Torque to 80 in-lb.

11. Using an accurate caliper, check compressed spring le

necessary, adjust spring length to specifica

necessary.

12. Connect load cell cable to indicator.

13. Recalibrate scale as described in Section 3.0.

14. Adjust overload protection screw on bottom of scale by

on top cover, centered on platform. Use a hex wrench to screw in overload protection screw until it touches

load cell, then back off 1/6 turn. Recheck calibration.

8 Benchmark Series Single Point Bench Scales

Figure 5-1. Load Cell Mount Diagram

ll screws. The load cell and cable can now be

osition load cell on shim and screw in

until it lightly bottoms, then back it off 1/4 turn.

ngth on four overload springs (Figure 5-2). If

tions shown in Tabl e 5-1. Replace top cover and re-level scale if

loading scale to 125% capacity. Place this weight

Page 13

5.2 12", 18", and 24" Models

Overload Stop

Screws

Overload

Protection Screw

Load Cell Screws

Load Cell

Screws

Load Plate

Top Frame

1. Unplug AC power from indicator and disconnect load cell cable from indicator.

2. Lift off scale top cover.

3. Remove two load cell screws.

4. Lift off top spider.

5. Remove spacer plate and set it aside.

Figure 5-2. 12" x 12" Load Cell Mount

6. Loosen the four overload stop screws and turn each screw in one turn to provide ample clearance for the

new load cell. Turn scale over and back off overload protection screw one complete turn to provide

clearance.

7. Unscrew and remove lower load cell screws. Depending on model of scale, there will be eit

lower load cell screws.

8. Remove bottom shim beneath loa

d cell and set it aside.

9. Remove load cell and cable from scale.

10. Thread cable of replacement load cell through rubber grommet.

11. Position bottom shim directly beneath load cel

l and screw in lower load cell screws. Torque to 80 in-lbs for

12" x 12" and 12" x 18" scales, to 120 in-lb for 18" x 18", 18" x 24", and 24" x 24" scales.

12. Turn scale right side up. Position spacer plate on load cell, then

place top spider into position.

13. Screw in four upper load cell screws. Torque to 80 in-lbs for 12" x 12" and 12" x 18" scales, to 120 in-lb

fo

r 18" x 18", 18" x 24", and 24" x 24" scales.

14. Connect load cell cable to indicator.

15. Recalibrate scale as described in Section 3.0 of this manual.

16. Adjust overload protection screw on bottom of scale by

loading scale to 125% capacity. Place this weight

on top cover, centered on platform. Use a hex wrench to screw in overload protection screw until it touches

the load cell, then back off 1/6 turn. Recheck calibration.

17. To reset corner overload stop screws, load top spider ove

r one corner with approximately 30% of scale

capacity. Adjust screw under that corner to just touch top frame. Place a drop of a non-permanent,

high-strength locking compound such as LOCTITE

®

on the thread. Back screw off slightly so it is not

touching.

her two or four

LOCTITE is a registered trademark of the Loctite Corporation

Load Cell Replacement 9

Page 14

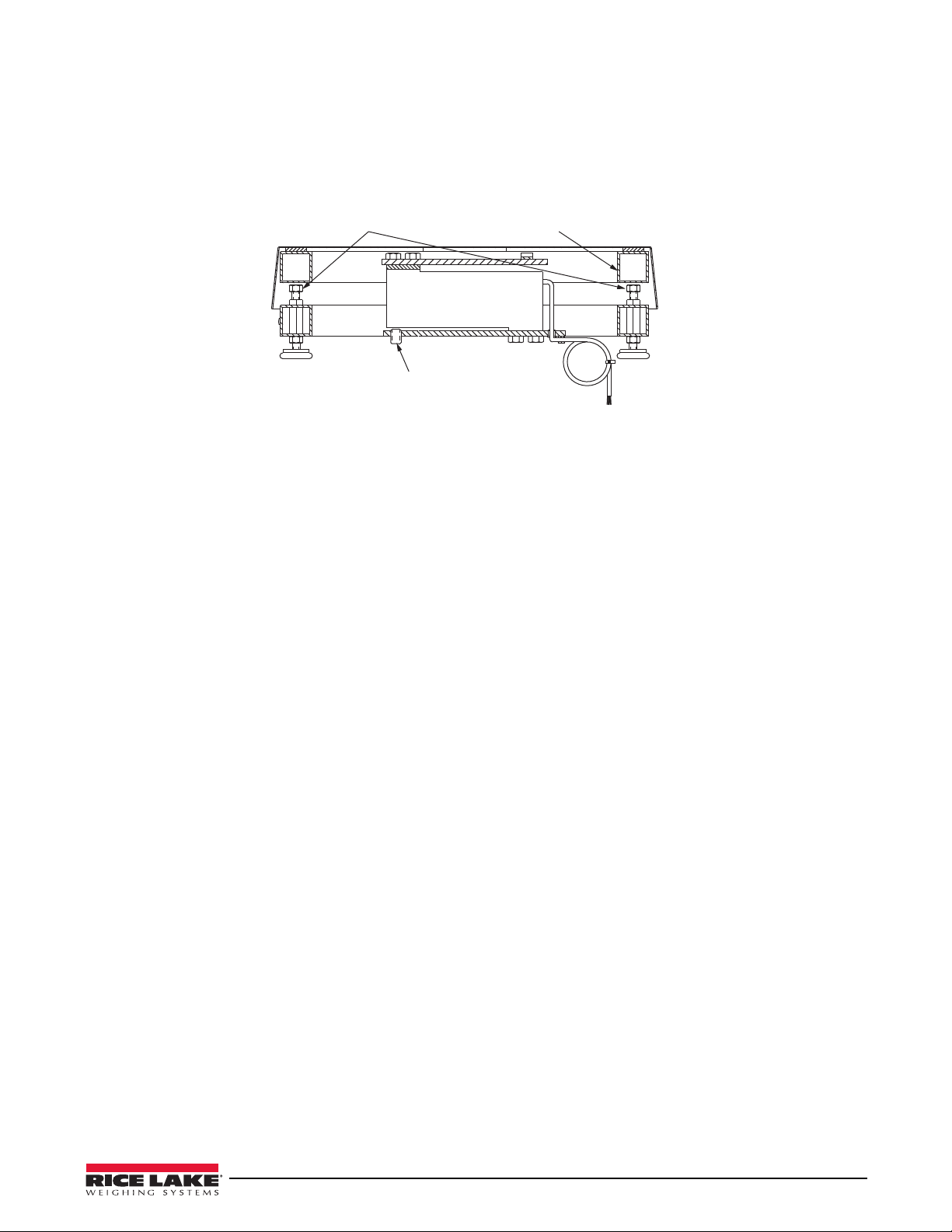

5.3 Installing Protective Clamshells

Important

UPPER

CLAM SHELL

LOWER

CLAM

SHELL

Stainless steel enclosures called clamshells are available to provide extra protection for the load cell of every

BenchMark scale. All clamshells are pre-drilled for load cell screws, overload screws, and cables. Any existing

load cell shims or spacers are installed inside the clamshells.

1. The lower clamshell fits inside the upper cl

part of it touches the load cell, then tighten the lower load cell screws to the specifications given

Section 5.1 or Section 5.2.

When installing the upper clam shell, position it so there is clearance on all sides to prevent any binding

problems with the lower clam shell.

2. Tighten the upper load cell screws to the required torque.

3. When installation is complete

, reset all overload protection screws as described in Section 5.1 or

Section 5.2.

4. Calibrate the scale according to the proce

amshell and is installed first. Position the clamshell so that no

dure described in Section 3.0.

Figure 5-3. Clamshell Enclosure

10 Benchmark Series Single Point Bench Scales

Page 15

6.0 Replacement Parts

Section BB (Enlarged)

Top View of Scale

with cover

18

19

20

21

23

22

26

27

24

25

2

3

4

5

7

8

9

10

11

13

14

15

16

17

A

A

B

B

12

Section AA (Enlarged)

6.1 10" x 10" and 12" x 12" SL and SL/HE Series

Figure 6-1. 10 x 10 and 12 x 12 SL and SL/HE Parts Illustration

Replacement Parts 11

Page 16

Item Part No. Description Qty.

2 14920 Screw, Overload Protection, 8 -32UNC x 1/4, SS 1

3 35128 Foot, 1/4 - 20 NC x 1 3/16 SS 4

4 14645 Jam Nut, Foot 1/4 - 20, SS 4

5 19086 Bottom Subassembly, (2 lb – 30 lb, 10 in x 10 in) 1

35066 Bottom Subassembly, (30 lb – 100 lb, 12 in x 12 in) 1

7 52342 Label, Bench Scale 1

8 19091 Cover, Top, 10 x 10 SS 1

35069 Cover, Top, 12 x 12 SS 1

9 19088 Spider, Top, 10 x 10 1

35068 Spider, Top, 12 x 12 1

10 15148 Lockwasher 1/4 SS 4

11 21948 Screw, Load Cell, 1/4 - 20 x 5/8 SS 4

12 15410 Bubble Level, Plastic, 15 mm 1

13 Load cell 1

14 15132 Lockwasher, #8, SS 1

15 14857 Pan Head Screw, 8 - 32 x 1/4 SS 1

16 15408 Rubber Grommet, 3/16 ID x 1/2 OD 1

17 16141 Cable Tie, 8" 1

18 14984 Cap screw (2 lb-20 lb models) 4

21947 Cap screw (30 lb model) 4

35199 Cap screw (50 lb-100 lb models) 4

19 15412 Spring, overload (2 lb model) 4

21945 Spring, overload (5 lb model) 4

15416 Spring, overload (10 lb model) 4

21946 Spring, overload (20 lb model) 4

21944 Spring, overload (30 lb model) 4

35086 Spring, overload (50 lb model) 4

35200 Spring, overload (100 lb model) 4

20 15149 Flat Washer, 1/4 type A, SS 4

21 14634 Nut, Nylon Insert, 1/4-20, SS 4

22 19089 Load Cell Shim, SS 1

23 15409 Plastic Wire Clamp 1

24 19090 Load Plate, (2 lb – 30 lb, 10 in x 10 in) 1

35067 Load Plate, (30 lb – 100 lb, 12 in x 12 in) 1

25 15150 Washer, Rubber 4

26 15138 Washer, #8, SS 1

27 14862

Screw, 8 - 32 x 3/8 SS 1

Table 6-1. 10 x 10 and 12 x 12 SL and SL/HE Parts List

12 Benchmark Series Single Point Bench Scales

Page 17

6.2 12" x 12" and 12" x 18" Models, Mild Steel

Top View of 12" Scale Series with cover

removed to show location of rubber pads

13

14

12

11

9

10

8

7

6

4

3

2

1

19

10

9

17

16

15

Section AA (Enlarged)

20

AA

Figure 6-2. 12" x 12" and 12" x 18" Mild Steel Parts Illustration

Replacement Parts 13

Page 18

Item Part No. Description Qty.

1 35128 Foot, 1/4-20 NC x 1 3/16 4

2 14645 Jam Nut, Foot 4

3 32993 Frame, Bottom, 12" X

32992 Frame, Bottom, 12" X

4 52342 Label, Bench Scale 1

6 14739 Bolt, Overload, 12" X

7 19092 Cover, Top, 12" X

19093 Cover, Top, 12" X

8 26408 Bumper, Round Self Adhesive 12

9 15147 Washer, Locking, 1/4 4

10 14962 Screw Cap, 12" X

11 19089 Spacer, Load Cell 1

12 15410 Spirit Level Bubble, Plastic 1

13 Load Cell 1

14 19132 Frame, Top, 12" X

19134 Frame, Top, 12" X

15 16141 Cable Tie 1

16 15409 Plastic Wire Clamp 1

17 15418 Rubber Grommet, 3/16 X 1/2 od 1

19 14918 Overload Protection Screw, 8-32 X 1/4 1

20 19139 Square Insert Guide 8

12" 1

18" 1

12" 4

12" 1

18"

18" 4

12" 1

18" 1

Table 6-2. 12" x 12" and 12" x 18" Mild Steel Parts List

14 Benchmark Series Single Point Bench Scales

Page 19

6.3 12" x 18" Model, Stainless Steel

Top View of Scale with

cover removed

4

24

18

15

16

19

21

20

14

11

8

22

3

2

1

17

9

10

12

7

Figure 6-3. 12" x 18" Stainless Steel Parts Illustration

Replacement Parts 15

Page 20

Item Part No. Description Qty.

1 35128 Foot, Bench Scale, 1/4-20 NC 4

2 14645 Nut, Jam, 1/4-20 NC, Hex 4

3 32795 Bottom Sub-assembly 1

4 52342 Label, Bench Scale 1

7 32957 Top C o v e r, 1 2 " X 18" 1

8 Load Cell 1

9 15148 Washer, Lock, 1/4 Regular 4

10 14963 Screw, Cap, 1/4-20 NC X 3/4 4

11 35082 Shim, Load Cell 1

12 15410 Level, Spirit Bubble 1

14 32797 Spider Top, 12" x

15 16141 Cable Tie, 8" Nyl

16 15418 Grommet, Rubber 1

17 14920 Screw, Set, 8-32 NC x 1/4, Hex 1

18 15409 Clamp, Cable, No. 8 Hole 1

19 15138 Washer, Plain, Std No. 8 1

20 15132 Washer, Lock, No. 8, Type A 1

21 14862 Screw, Mach, 8-32 NC x 3/8 1

22 19089 Shim, Load Cell 1

24 26408 Bumper, Self Adhesive 4

18" 1

on 1

Table 6-3. 12" x 18" Stainless Steel Parts List

16 Benchmark Series Single Point Bench Scales

Page 21

6.4 18" x 18", 18" x 24" and 24" x 24" Models, Mild and Stainless Steel

15

16182021241

2

3

4

6

7

8

11 19 12

17

9

10

14

22

25

26

27

8

Figure 6-4. 18" x 18", 18" x 24" and 24" x 24" Models Parts Illustration

Item Part No. Description Qty.

1 19141 Foot, 3/8-16 X .78 4

2 14649 Jam Nut, Foot Ms 4

14653 Jam Nut, Foot Ss 4

3 49766 Frame Bottom, 18" X

49768 Frame Bottom, 18" X

49770 Frame Bottom, 18" X

49772 Frame Bottom, 18" X

49774 Frame Bottom, 24" X

49776 Frame Bottom, 24" X

19108 Frame Bottom, 18" X

19109 Frame Bottom, 18" X

19110 Frame Bottom, 18" X

19111 Frame Bottom, 18" X

19112 Frame Bottom, 24" X

19114 Frame Bottom, 24" X

4 52342 Label Roll, 4" X

6 14742 Bolt, 3/8-16 NC X 1, Hex Head 4

7 19094 Cover, Top, 18" X

19095 Cover, Top, 18" X

19096 Cover, Top, 24" X

18", MS (RL1260/PMW16 Load Cell) 1

18", SS (RL1260/PMW16 Load Cell) 1

24", MS (RL1260/PMW16 Load Cell) 1

24", SS (RL1260/PMW16 Load Cell) 1

24", MS (RL1260/PMW16 Load Cell) 1

24", SS (RL1260/PMW16 Load Cell) 1

18", MS (RL1250 Load Cell) 1

18", SS (RL1250 Load Cell) 1

24", MS (RL1250 Load Cell) 1

24", SS (RL1250 Load Cell) 1

24", MS (RL1250 Load Cell) 1

24", SS (RL1250 Load Cell) 1

1.25" 1

18" 1

24" 1

24" 1

Table 6-4. 18" x 18", 18" x 24" and 24" x 24" Models Parts List

Replacement Parts 17

Page 22

Item Part No. Description Qty.

8 26407 Bumper, Self Adhesive 20

9 15153 Washer, Lock, 5/16 Regular, MS 8

15154 Washer, Lock, 5/16 Regular, SS 8

10 26668 Screw, Cap, 5/16-18 NC x 3/4, Hex, MS 4

26669 Screw, Cap, 5/16-18 NC x 3/4, Hex, SS 4

26667 Screw, Cap, 5/16-18 NC x 1, hex, MS 4

26670 Screw, Cap, 5/16-18 NC x 1, hex, SS 4

11 49785 Plate, Washer, MS (RL1260/RLPMW16 load cell) 1

49786 Plate, Washer, SS (RL1260/RLPMW16 load cell) 1

19102 Plate, Washer, MS (RL1250 load cell) 1

19103 Plate, Washer, SS (RL1250 load cell) 1

12 15410 Level, Spirit Bubble 1

14 19140 Insert, Glide, Square 8

15 49765 Frame, Top, 18" x 18", MS (RL1260/RLPMW16 Load Cell) 1

49767 Frame, Top, 18" x 18", SS (RL1260/RLPMW16 Load Cell) 1

19116 Frame, Top, 18" x 18", MS (RL1250 Load Cell) 1

19117 Frame, Top, 18" x 18", SS (RL1250 Load Cell) 1

19118 Frame, Top, 18" x 24", MS (RL1250 Load Cell) 1

19119 Frame, Top, 18" x 24", SS (RL1250 Load Cell) 1

49769 Frame, Top, 18" x 24", MS (RL1260/RLPMW16 Load Cell) 1

49771 Frame, Top, 18" x 24", SS (RL1260/RLPMW16 Load Cell) 1

49773 Frame, Top, 24" x 24", MS (RL1260/RLPMW16 Load Cell) 1

49775 Frame, Top, 24" x 24", SS (RL1260/RLPMW16 Load Cell) 1

19120 Frame, Top, 24" x 24", MS (RL1250 Load Cell) 1

19121 Frame, Top, 24" x 24", SS (RL1250 Load Cell) 1

16 16141 Cable, Tie, 8" Nylon 1

17 15409 Clamp, Cable, No. 8 Hole 1

18 15418 Grommet, Rubber 1

49788 Screw, Cap, 5/16-18 NC X 1 1/4, Hex, MS (RL1260 Load Cell) 4

49789 Screw, Cap, 5/16-18 NC X 1 1/4, Hex, SS (RL1260 Load Cell) 4

26667 Screw, Cap, 5/16-18 NC X 1, Hex, MS (RL1250 Load Cell) 4

26668 Screw, Cap, 5/16-18 NC X 3/4, Hex, MS (RL1250 Load Cell) 4

26669 Screw, Cap, 5/16-18 NC X 3/4, Hex, SS (RL1250 Load Cell) 4

20 49787 Shim Plate (RL1260/RLPMW16 Load Cell) 1

22264 Shim Plate (RL1250 Load Cell) 1

21 15045 Screw, Set, 1/2-20 NF X 1/2, Hex, MS 1

15047 Screw, Set, 1/2-20 NF X 1/2, Hex, SS 1

22 14858 Screw, Mach, 8-32 NC X 5/16, MS 1

14862 Screw, Mach, 8-32 NC X 3/8, SS 1

24 32849 Load Cell 1

25 35316 Screw, Cap, 1/4-20 NC X 2, Hex, MS 1

35199 Screw, Cap, 1/4-20 NC X 2, Hex, SS 1

26 15145 Washer, Plain, 1/4 Type A, MS 1

15149 Washer, Plain, 1/4 Type A, SS 1

27 14635 Nut, Lock, 1/4-20 NC, Hex, MS 1

14634 Nut, Lock, 1/4-20 NC, Hex, SS 1

Table 6-4. 18" x 18", 18" x 24" and 24" x 24" Models Parts List

18 Benchmark Series Single Point Bench Scales

Page 23

BenchMark Series Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by the

Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects in materials

and workmanship for two years.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized by

RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment fails

to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the warranty

period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to

prevent electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a

publication, “Protecting Your Components From Static Damage in Shipment,” available from RLWS

Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was

not caused by accident, misuse, neglect, alteration, improper installation, improper repair or improper

testing; RLWS shall be the sole judge of all alleged nonconformities.

• Such equipment has not been modified, altered, or changed by any person other than RLWS or its duly

authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible

for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER RLWS

NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO REPAIR

OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER

CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE SELLER FOR

WARRANTY CLAIMS.

No terms, conditions, understanding, or agreements purporting to modify the terms of this warranty shall have any

legal effect unless made in writing and signed by a corporate officer of RLWS and the Buyer.

© Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

Replacement Parts 19

Page 24

For More Information

Web Site

• Frequently Asked Questions (FAQs) at

• http://www.ricelake.com/faqs.aspx

Contact Information

Hours of Operation

Knowledgeable customer service representatives are available 6:30 a.m. - 6:30 p.m. Monday through Friday and 8

a.m. to 12 noon on Saturday. (CST)

Telephone

• Sales/Technical Support 800-472-6703

• Canadian and Mexican Customers 800-321-6703

• International 715-234-9171

Immediate/Emergency Service

For immediate assistance call toll-free 1-800-472-6703 (Canadian and Mexican customers please call

1-800-321-6703). If you are calling after standard business hours and have an urgent scale outage or emergency,

press 1 to reach on-call personnel.

Fax

Fax Number 715-234-6967

E-mail

• U.S. sales and product information at

• prodinfo@ricelake.com

• International (non-U.S.) sales and product information at

• intlsales@ricelake.com

Mailing Address

Rice Lake Weighing Systems

230 West Coleman Street

Rice Lake, WI 54868 USA

20 Benchmark Series Single Point Bench Scales

Page 25

Page 26

230 W. Coleman St. • Rice Lake, WI 54868 • USA

www.ricelake.com www.ricelake.mx www.ricelake.eu www.ricelake.co.in m.ricelake.com

U.S. 800-472-6703 • Canada/Mexico 800-321-6703 • International 715-234-9171 • Europe +31 (0)26 472 1319

© Rice Lake Weighing Systems 10/23/14 PN 22125 Rev D

Loading...

Loading...