Page 1

In-Motion Belt Scale System

To be the best by every measure

#$

Version 2.00

Installation & Operation

Manual

94805

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com or obtained

by calling 715-234-9171 and asking for the training department.

Integrator Hardware Setup ..............................................................................................................................26

1.0 Introduction and Overview........................................................................................................... 1

1.1 Belt Conveyor Scale System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Application Brief . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.4 Selecting a Mounting Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.5 Poor Choices for Belt Scale Installations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 Handbook 44 Requirements for Belt Scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.

2.0 Integrator Hardware Installation ............................................................................................... 14

2.1 Unpacking and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2 Scale Carriage Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Junction Box Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Attaching the Idlers to the Scale Carriage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5 Speed Sensor Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Scale Carriage Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.0 Integrator Hardware Setup ........................................................................................................ 26

3.1 Enclosure Disassembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.2 Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Enclosure Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 CPU Board Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Fuse Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Parts Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 Replacement Parts and Assembly Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

. . . . . . . . . 6

. . . . . . . 7

. . 9

. . . . 14

. . . . 16

. . . 22

. . . . 26

. . . 32

. . . 33

. . . . 33

. . . . 33

. . . . 34

4.0 Supervisor Mode Parameters.................................................................................................... 38

4.1 Admin. Passcode (numeric) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4.2 Scale Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Load Cell MV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Total Load Cell Build . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.5 Rate Unit Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.6 Filter (s). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.7 Filter Threshold (divisions) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.8 Speed Unit Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.9 Fixed Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.10 Unit of Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.11 Unit of Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.12 Rate Count By . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.13 Totalizer Count By . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.14 Load Display Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.15 Load Count By . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.16 Auto Zero Tracking (%) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.17 Auto Zero Tracking Percentage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

18 Dead Band . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.

. . . . . . 40

. . . . . . 40

. . . . 40

. . . . . . 40

. . . . . . . . . 40

. . . . 40

. . . . 40

. . . . . . 40

. . . . 40

. . . . . . 40

. . . . 41

. . . . 41

. . . . 41

. . . . 41

. . . 41

. . . . 41

Page 4

4.19 Cal. Test Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4.20 Cal. Test Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.21 Calibration Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.22 Material Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.23 Zero Error% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.24 Zero Counts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.25 Span Error% . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.26 Idler Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.27 Number of Idlers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.28 Belt Test Revolutions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.29 Pulses per Revolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.30 Belt Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.31 Pulses Per Unit Measure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.32 Test Duration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.33 Tons per Pulse (output) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.34 Pulse Duty Cycle (in seconds) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.35 Alarm - Low Rate Alarm Value (%) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.36 Maximum Speed Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.37 Low Rate Alarm Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.38 High Rate Alarm Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.39 Speed Alarm Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.40 Totalizer Pulse Bit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.41 Fill Output Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.42 Remote Print Input Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.43 Print Output Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.44 Print Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.45 Stream Output Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.46 Stream Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.47 Clear Totalizer with Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.48 Remote Totalizer Reset Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.49 Integrator Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.50 Preact Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.51 Enable Batching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.52 Analog 1 Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.53 Analog 2 Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.54 Setting Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.55 Interfacing a PLC to the Belt Scale System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

. . . . 42

. . . . 42

. . . . . . 42

. . . . . . 42

. . . . . . 42

. . . . 42

. . . . . . 42

. . . . 42

. . . . 42

. . 43

. . . . . . 43

. . 43

. . . . . . 43

. . 43

. 43

. 43

. . 43

. . . . 43

. . . . 43

. . . . . . 43

. . . . . . 43

. . 44

. . . . 44

. . . . . . 44

. . 44

. . . . 44

. . . . 44

. 44

. . . . 44

. . . . 44

. . . . 44

. . . . 45

. . . . 45

. . 45

5.0 Calibration ................................................................................................................................. 46

5.1 Speed Sensor Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.2 Integrator Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.3 Complete System Calibration Test Used In Conjunction with integrator Calibration . . . . . . . . . . . . . 49

. . . . 47

6.0 Run Sequence ............................................................................................................................ 53

6.1 Target Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.3 Reset Totalizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 Start Fill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . 54

. . . . . . 54

. . . . . . . . . 54

7.0 Handbook 44 Requirements for Belt-Conveyor Scales ............................................................. 55

7.1 Reference Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7.2 Conditions of Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 BCi Installation Manual

. . . . 55

Page 5

8.0 Maintenance .............................................................................................................................. 56

8.1 Maintenance Checkpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.2 Belt Scale Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 BCi Integrator Troubleshooting Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

. 58

9.0 Appendix .................................................................................................................................... 60

9.0 BCi Permanent Field Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9.0 BCi integrator Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . 64

Page 6

4 BCi Installation Manual

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

Page 7

About This Manual

Intern et

Warning

This manual is intended for use by service technicians responsible for installing and servicing the BCi In-Motion

Belt Scale System Installation & Operation Manual.

This manual can be viewed and downloaded from the Rice Lake Weighing Systems web

site at

company.

Some procedures described in this manual require work in and around working parts of the

belt scale. These procedures are to be performed by qualified service personnel

www.ricelake.com. Rice Lake Weighing Systems is an ISO 9001 registered

only .

1.0 Introduction and Overview

A belt conveyor scale is a device that continuously measures bulk material as it moves along a conveyor. The

system requires two general parameters to operate:

•It needs to know the weight of the material being moved along the conveyor belt

It needs to know the speed at which it’s moving along the conveyor belt.

•

The weight of the material on the belt is determin

and then subtracting the average weight of the unloaded belt. The speed at which the material is moving is

determined by measuring the speed of an idler or wheel in contact with the conveyor belt. The weight and speed

is combined to give a running total and a rate of flow of the material. The correct operation of the scale system

requires the components to be installed correctly, periodically calibrated, and properly maintained.

Typical applications where a belt conveyor scale can be used are:

• Mining

• Quarries

• Bulk Material Blending

• Truck/Barge/Rail Loading

• Process Control Applications

A belt conveyor scale is also able to compute the tota

of time and while it is in motion.

The BCi In-Motion Belt Scale System is durable and one of the mos

handles capacities up to 10,000 tons per hour with unsurpassed accuracy. It’s innovative integrator fits a wide

variety of applications - from simple inventory reporting to automated load-out.

ed by weighing a section of conveyor belt loaded with material

l mass of the material that is conveyed over a given period

t accurate scales in its class. The BCi easily

1.1 Belt Conveyor Scale System Components

The main components of a basic belt conveyor scale include:

• Scale carriage

• Load cells

• Belt travel pickup speed sensor (not shown)

• Electronic integrator

BCi Installation & Operation Manual - Introduction and Overview 1

Page 8

BCi Electronic Integrator

Load Cells

Scale Carriage

Figure 1-1. Component Parts of the BCi Belt Conveyor Scale System

2 BCi Installation & Operation Manual

Page 9

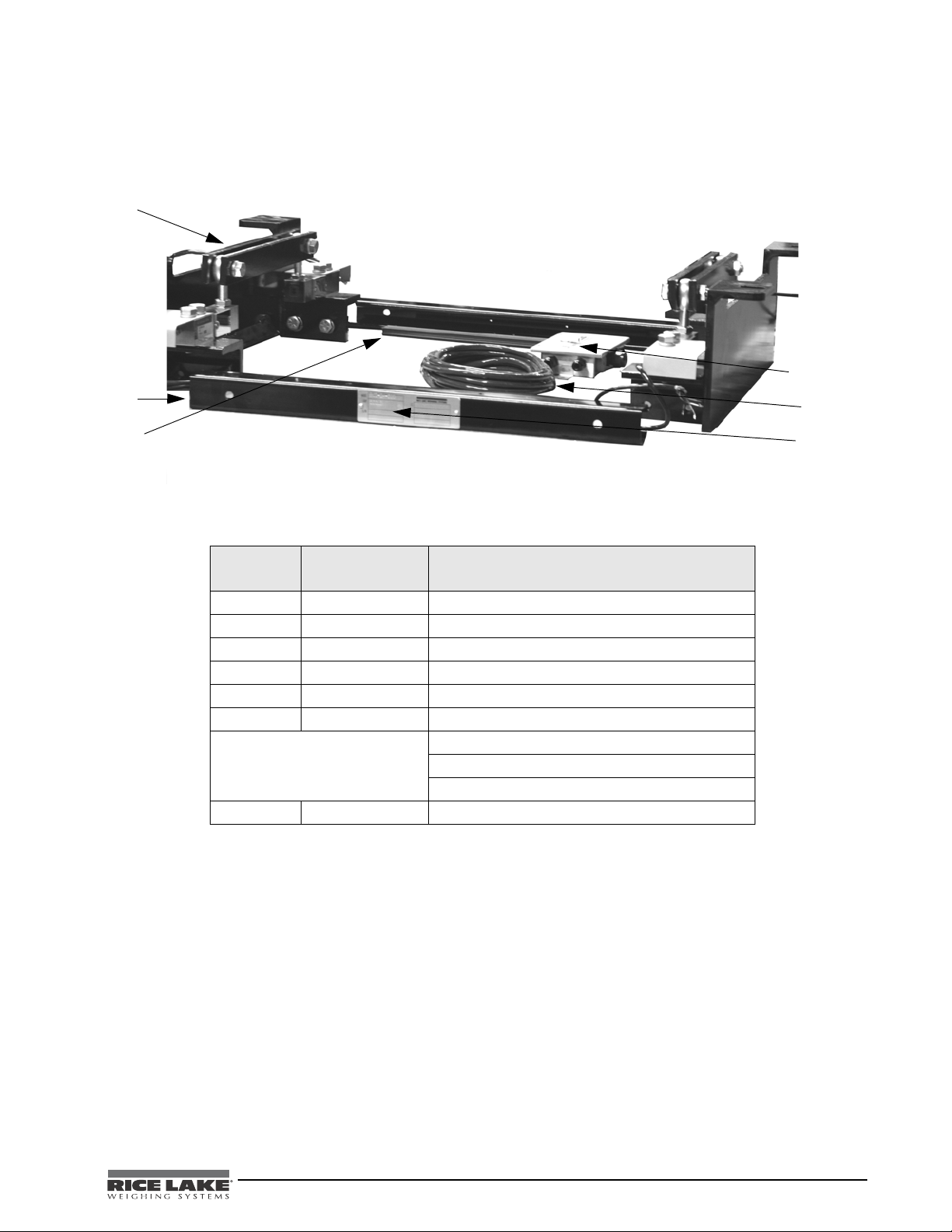

Scale Carriage

1

2

3

4

5

6

The scale carriage is mounted to a conveyor structure and transmits the forces resulting from the belt load and

directs those forces to the load sensor(s). The following picture and table illustrate the component parts shipped

with the scale carriage.

Figure 1-2. Scale Carriage Components

RLWS Part

Number

1 - - - - - End Plate Assembly (2)

2 - - - - - Uni-Strut Middle Bars (2)

3 - - - - - Uni-Strut Closure Strips (2)

4 38557 Home Run Cable (1)

5 88956 Junction Box w/ Grounding Lug (1)

6 16863 Metal Serial Tag (1)

Nuts (2)

Bolts (2)

Lock Washers (2)

97416 Shim Kit

Description (Qty.)

Table 1-1. Scale Carriage Component Part Numbers

BCi Installation & Operation Manual - Introduction and Overview 3

Page 10

Load Cells

There are four strain gauge load cells located on the corners of the weigh idler. These sensors support the weight

of the conveyor belt and the material moving along on the belt. The weight signals from the load cells are

combined and processed by the integrator.

Figure 1-3. Load Cell Location on Scale Carriage

4 BCi Installation & Operation Manual

Page 11

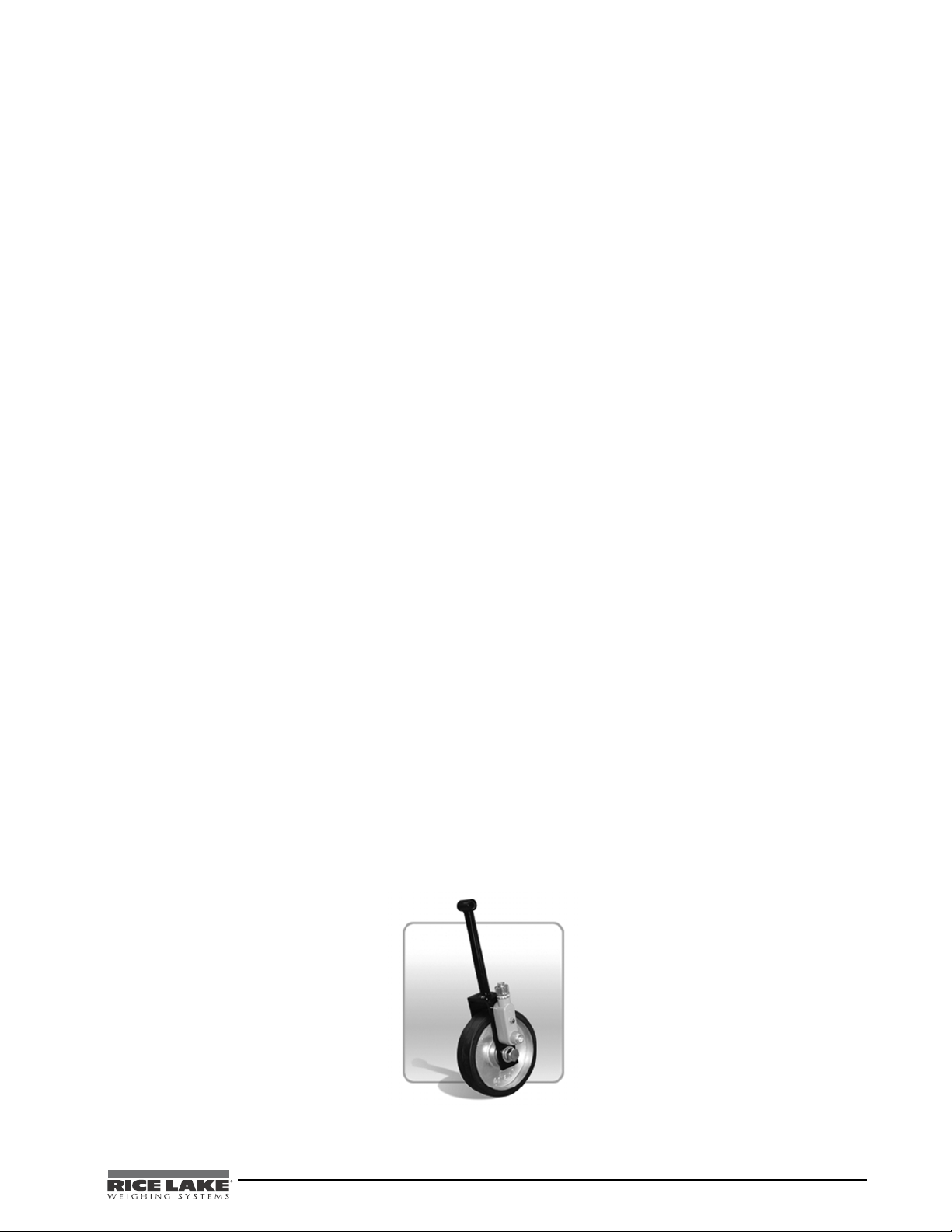

Belt Travel Speed Wheel - Optional

The belt travel speed wheel is located near the weigh frame. Positive contact must be maintained between the roll

and the belt for proper operation. The speed sensor should never come in contact with material that is being

conveyed along the belt nor the belt itself. The signal generated by the speed wheel is converted by the integrator

into a value that represents belt travel distance. Various devices used for sensing belt travel include AC and DC

generators, mechanical belt or chain drives, photo-optical segmented disks, and electromagnetic pulse

generators. Installation procedures for the speed wheel are explained in detail on page 24. The graphic below

illustrates the major component parts of the speed wheel.

Figure 1-4. Speed Wheel

RLWS Part Number Description (Qty)

94969 Complete Speed Wheel Assembly (1)

96543 Speed Wheel (1) (wheel only)

94979 Speed Proximity Sensor (1)

94970 Speed Wheel Bracket Assembly (1) (wheel not included)

Cabling to integrator (1)

94980 U-Bolts (2)

21161 Splice Box (1)

98501 Expansion Cable - 20’

100038 Magnetic Shaft Encoder

Table 1-2. Speed Wheel Assembly Component Part Numbers

Magnetic Shaft Encoder - Optional

Another option besides the belt travel speed wheel is a magnetic shaft encoder which can also be used to

determine belt travel distance like the speed wheel. The magnetic shaft encoder should never come in contact

with material that is being conveyed along the belt nor the belt itself. The signal generated by the encoder is

converted by the integrator into a value that represents belt travel distance.

Figure 1-5. Magnetic Shaft Encoder

BCi Installation & Operation Manual - Introduction and Overview 5

Page 12

Electronic Integrator

13*/5

6/*54

40'5,&: 40'5,&:

40'5,&:

40'5,&: 40'5,&:

Outputs from the belt travel speed sensor and from the load cell carriage are combined in the integrator to

produce a running total of material passed over the belt conveyor scale. Using the BCi HMI as a calibrated

electronic integrator allows signals to be converted into values that represent the weight and speed of the material

that is traveling on the conveyor.

1.2 Operation

The BCi front panel, shown below consists of a 27-button keypad with a large backlit LCD display. The keys are

grouped as five configurable softkeys, five primary scale functions keys, four navigational keys, and numeric

entry keys. It should be noted that the scale parameters and calibration values cannot be changed without first

pressing the

settings. Pressing

TARE key and unlocking the parameters. After pressing the TARE key, press enter to unlock the

ZERO when the display is on the main menu will clear the Reset Total.

Figure 1-6. BCi Front Panel

The following sections describe the front panel key operation of the belt scale integrator.

Zero

This parameter will initiate the front panel zero mechanism. Periodic use of the zero parameter is required due to

weather conditions.

This will print the custom ticket if the print port is configured.

Reset Totalizer

Often during this operation of a belt scale, the totalizer will need to be reset. This is known as the reset totalizer.

Press the

operator will press

Diagnostics

Reset Totalizer softkey to access this parameter. The integrat or will prompt the user, “Clear Totalizer?” The

Yes to clear the totalizer, or No to leave the accumulated weight in the totalizer.

This softkey displays the current mV input, PPS (pulses per second from the speed sensor), current analog output

(if installed), current A/D counts, and the master total. This is just informational data that the operator or a

technician can use from troubleshooting purposes.

Supervisor Mode

Use this softkey to enter the Supervisor Mode. If there is no passcode configured the BCi will enter into the

Setup Mode. If a passcode is configured, the operator will need to enter the passcode before the BCi will switch

to the Supervisor Mode. To configure a passcode, see the Supervisor’s Parameters.

6 BCi Installation & Operation Manual

Page 13

1.3 Application Brief

There are four factors used to determine a suitable belt scale application on a given conveyor.

• Load cell size

• Belt speed

•Idler spacing

• Belt splicing

Load Cell Size

The capacity of the belt scale is rated on the maximum continuous load that can be carried across the weigh idler.

The capacity of the conveyor shou ld be known p rior to determining the components of the scale system. The load

cells should be sized to operate across a loading range with a marginal safety factor. The minimum net loading

should be greater than 10% of the rated capacity and the maximum loading should be less than 65%. The load

applied to the loadcell can be calculated with the following formula:

Net load = (conveyor capacity / belt speed) x idler spacing

Gross load = net load + (idler weight + belt weight + mounting hardware)

Examples:

Net load = (50,000 lbs per minute / 400 feet per minute) x 4 foot spacing

Net load = (125 lbs per foot) x 4 foot spacing

Net Load = 500 lbs.

Gross load = 500 lbs + (175 lb idler + 48 lb belt + 24 lbs hardware)

Gross Load = 747 lbs.

Net Load > 10% of total load cell capacity

(4) x 500 lb load cells x 10% = 200 lbs 500 lbs > 200 lbs (500 lb load cells are okay)

(4) x 1000 lb load cells x 10% = 400 lbs 500 lbs > 400 lbs (500 lb

(4) x 2000 lb load cells x 10% = 800 lbs 500 lbs > 800 lbs (2000 lb load cell

Gross Load < 65% of total load cell capacity

load cells are okay)

s are too large)

(4) x 250 lb load cells x 65% = 650 lbs 747 lbs > 650 lbs (250 lb load cells are too small)

(4) x 500 lb load cells x 65% = 1300 lbs 74

(4) x 1000 lb load cells x 65% = 2600 lbs 74

The example listed would require 500 lb or 1000 lb load

Belt Speed

7 lbs < 1300 lbs (500 lb load cells are okay)

7 lbs < 2600 lbs (1000 lb load cells are okay)

cells.

The belt speed is defined as the maximum velocity of the unloaded conveyor belt. The belt speed can be variable,

but for sizing requirements the maximum speed is required.

BCi Installation & Operation Manual - Introduction and Overview 7

Page 14

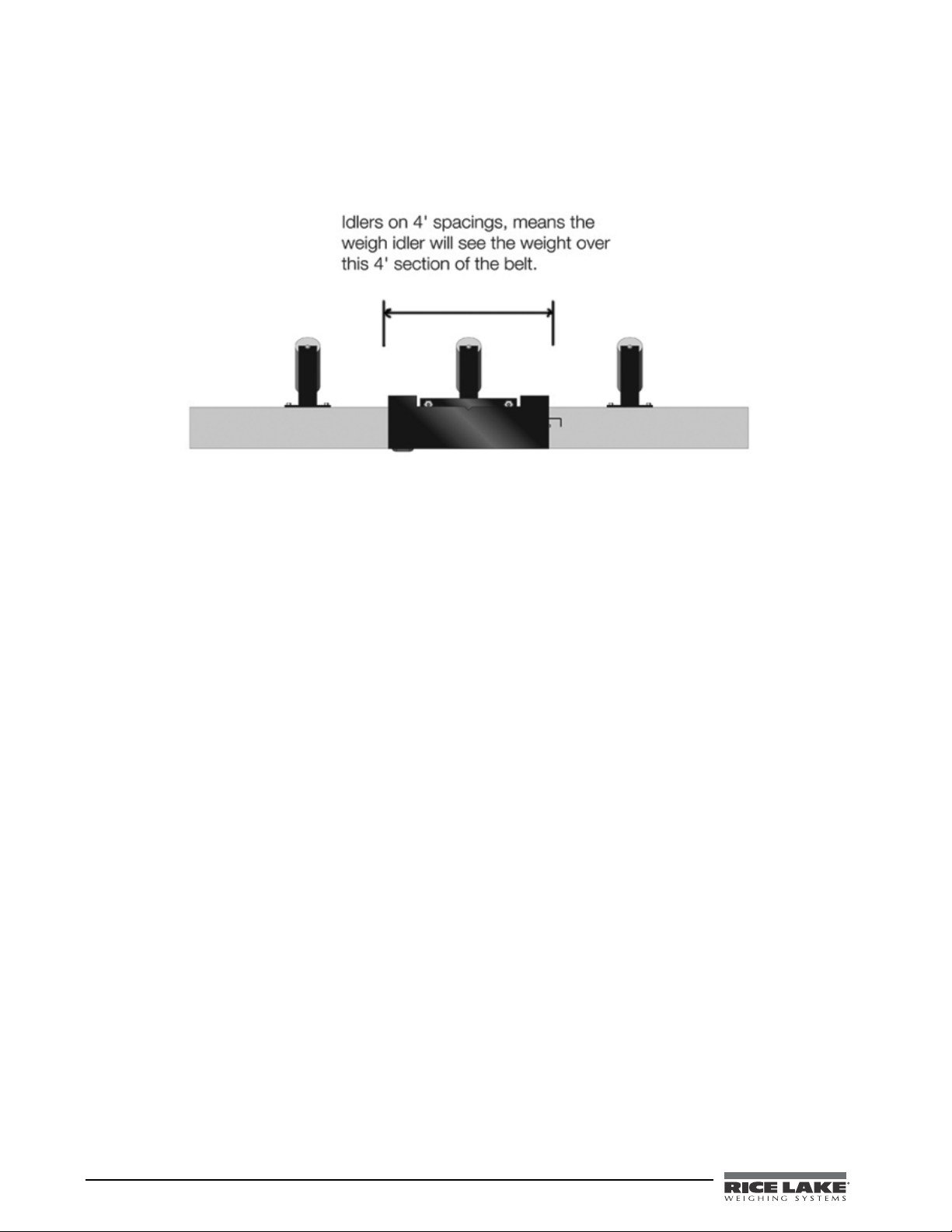

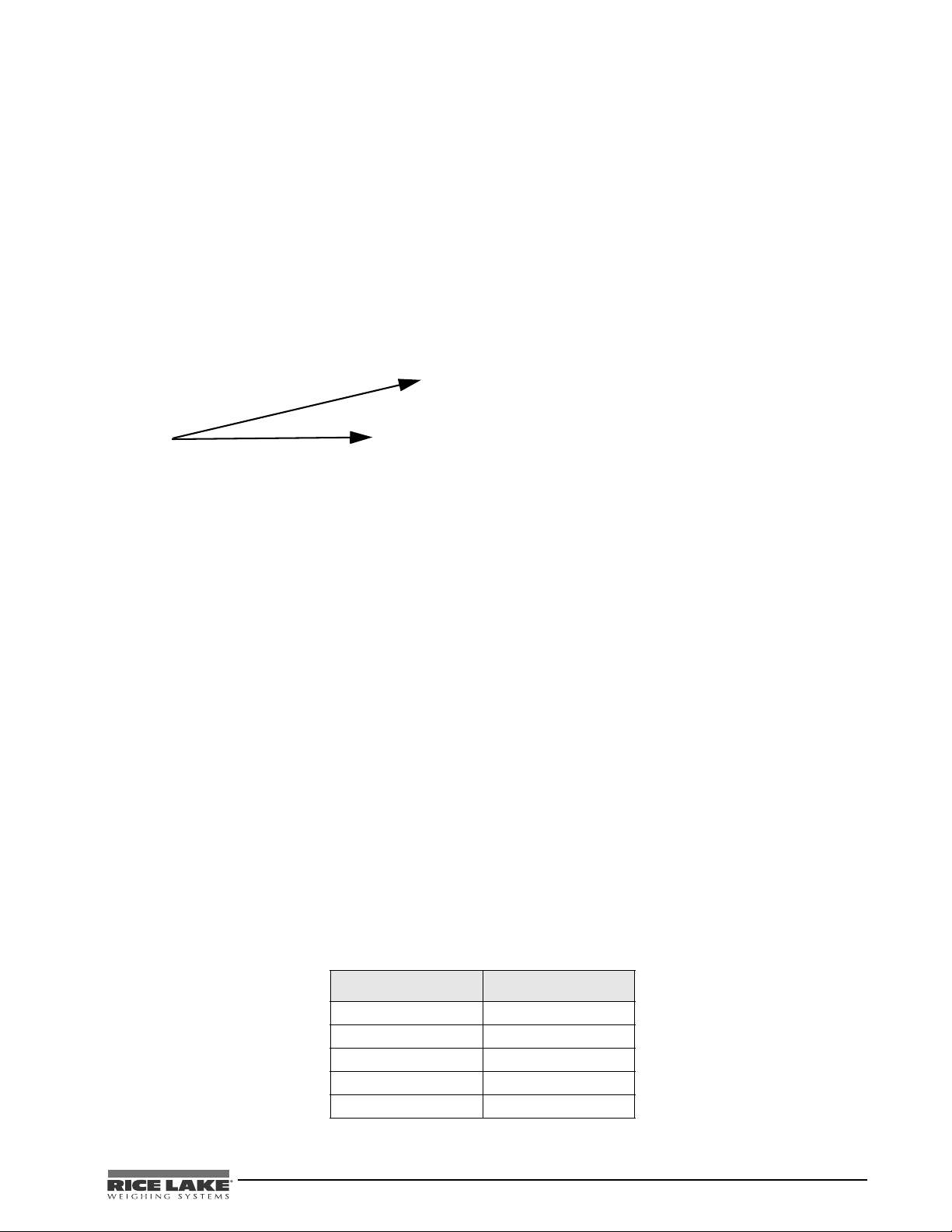

Idler Spacing

The spacing between idlers should conform to the recommendations of the idler manufacturer and the Conveyor

Equipment Manufacturer’s Association specifications. A general rule of thumb is the idler supports the belt half

the distance from the previous idler to half the distance to the following idler as shown in the example below.

Figure 1-7. Idler Spacing Example

The number of weigh idlers required to accurately weigh the material being conveyed is determined by the

velocity of the conveyor belt. The scale born time of the material should be greater than 400 mSec. If the belt

speed multiplied by the idler spacing is less than 400 mSec, the idler spacing must be increased or multiple weigh

idlers must be used. Scale born time can be calculated with the following formula:

Scale Time = (Idler Spacing / Belt Speed)

Example: Scale Ti

me = (4 feet / 8.33 fps) = 480 mSec

Belt Splicing

Belt splices also have a contributing factor in limiting the belt scale’s capacity. Mechanical belt splices can shock

load and damage load cells on high speed conveyors. Vulcanized splices are preferred for proper scale operation.

Figure 1-8. Mechanical Belt Splicing Example

8 BCi Installation & Operation Manual

Page 15

1.4 Selecting a Mounting Location

It is very important to select the right mounting location for the scale carriage along the conveyor structure and

the location of the speed sensor. There are several factors that must be taken into consideration when selecting a

mounting location. Those factors will determine the overall long-term and short-term accuracy you might expect.

Those factors include the following:

• Tension

• Uniform Belt Loading

• Single Load Point on Belt

• Material Slippage

• Convex Curves

• Concave Curves

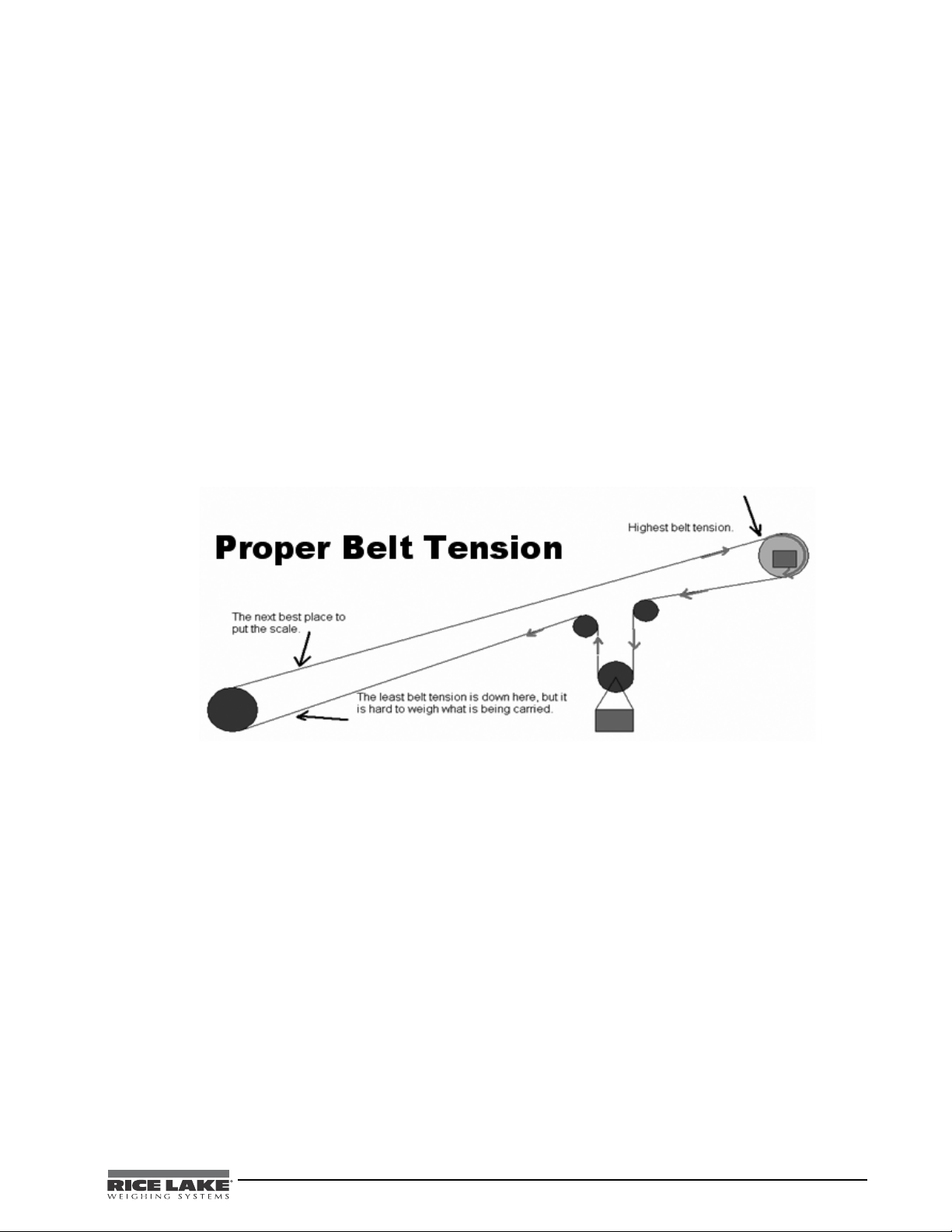

Tension

The transfer of weight along the conveyor belt can be greatly affected by belt tension. By locating the scale

carriage in an area of the conveyor with the least amount of tension, the scale will be more accurate and achieve

better performance. An ideal location to mount the scale carriage is near a tail section of the conveyor, but far

enough forward so as not to be influenced by infeed skirts boards, etc. Figure 1-9 illustrates the proper belt

tension.

•Trippers

• Speed Sensor Mounting Location

• Electronic Wiring Location

• Speed Wheel

• Troughing Angle

Figure 1-9. Proper Belt Tension Example

Uniform Belt Loading

It is desirable that the belt loading be as uniform as possible to prevent unequal shifts in material. To minimize

surges or feed variations, hoppers should be equipped with depth limiting gates or other flow control devices

such as a feeder.

Single Load Point on Belt

On high accuracy installations, the conveyor should be loaded at one and the same point. This assures constant

belt tension at the scale during all loading conditions.

Material Slippage

The belt scale system processes belt loading and belt travel to arrive at an accurate weight. Product speed must be

equal to the belt speed at the scale. So the conveyor speed and slope should not exceed that at which material

slippage occurs. This is typically less than a 20% pitch for most materials.

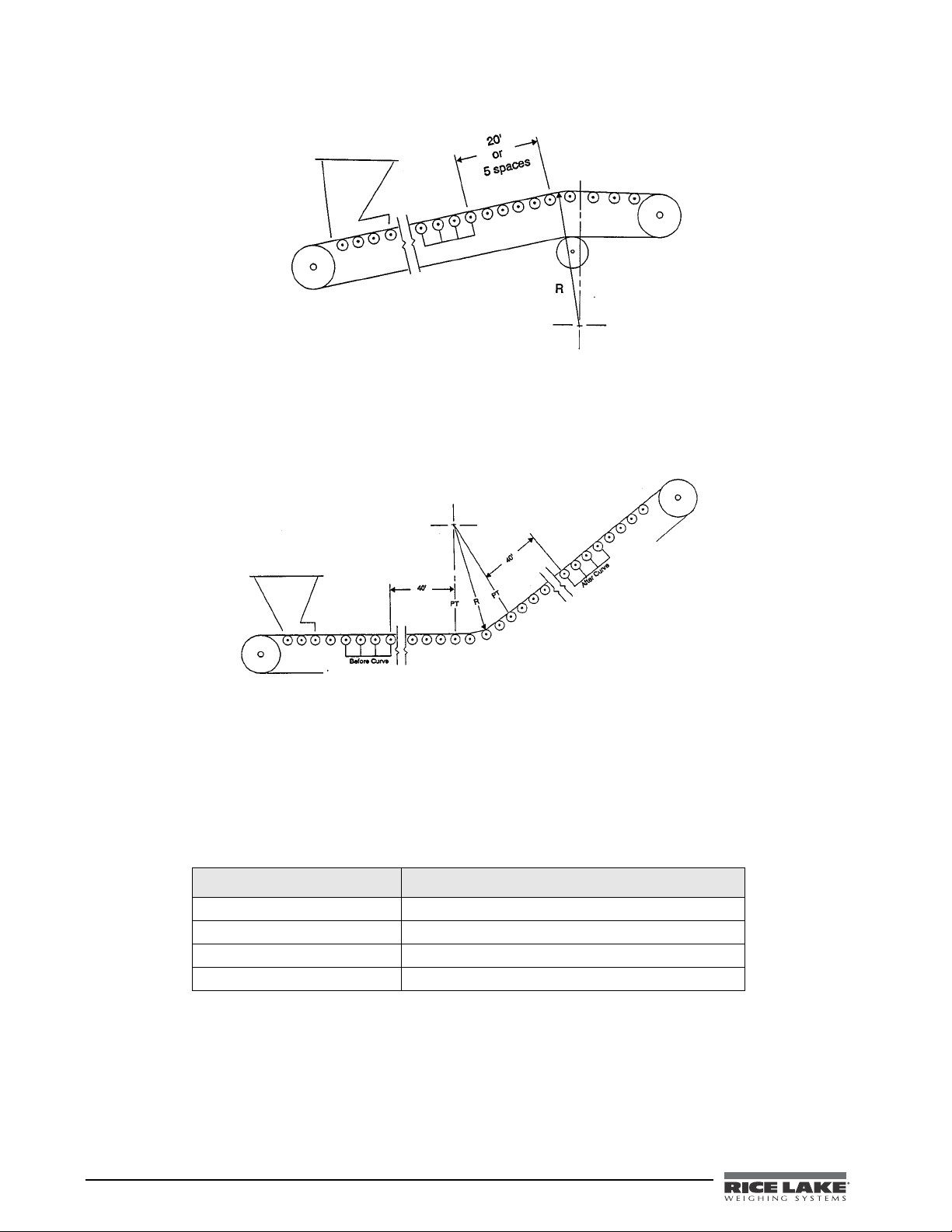

Convex Curves

Conveyors that have convex curves should be avoided or the scale should be located in a section of the conveyor

that is not affected by the curve.

Convex curves are permissible at a distance of 20 feet or a m

inimum of five idler spaces beyond the scale area

idlers.

BCi Installation & Operation Manual - Introduction and Overview 9

Page 16

Figure 1-10. Convex Curved Conveyor

Concave Curves

Conveyors that have concave curves should be avoided or the scale should be located in a section of the conveyor

that is not affected by the curve. If there is a curve, the belt must remain in contact with the idler rollers at all

times for at least 20 feet (6m).

Figure 1-11. Concave Curved Conveyor

Trippers

Tripper belts, mechanical sweep samplers, training idlers, feed points, skirt boards and other device that also

affect belt tension should be located away from the scale carriage.

If the scale must be installed on a conveyor with a tripper, then the same rules apply as for an installation in a

ncave conveyor.

co

nce

The following table offers basic guidelines for minimum dista

s and applies to both horizontal and incline

conveyors.

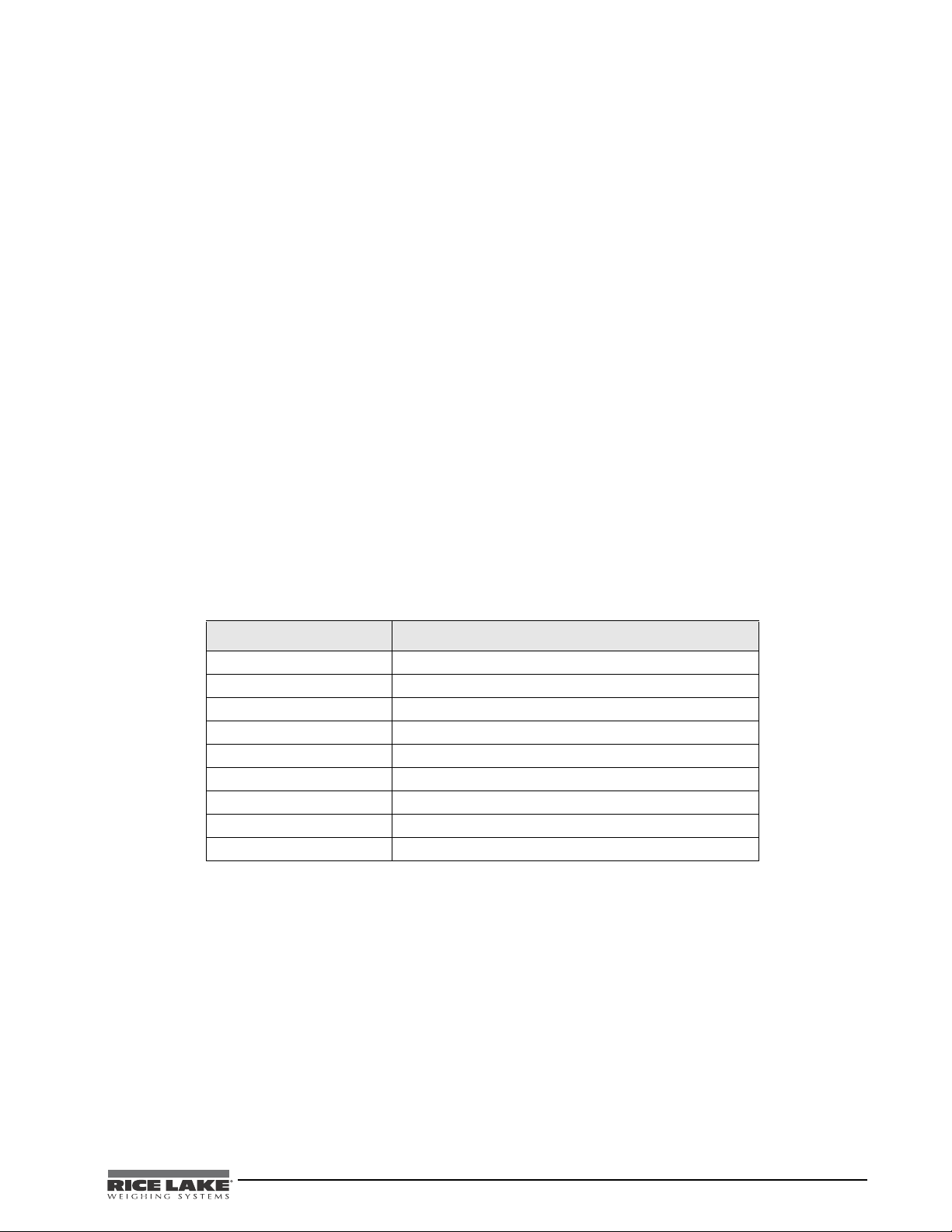

Type of Conveyor Distance from Scale Carriage

End of skirt boards or feed point 15’ or 4 idler spaces whichever is greater

Training idler or sweep sampler 30’ or 8 idler spaces, whichever is greater

Tripper or concave curve 40’ from the first idler affected by the curve

Convex curve or head pulley 20’ or 5 idler spaces

Table 1-3. Distance Points from Conveyor to Scale Carriage

Speed Sensor or Magnetic Shaft Encoder Mounting Location - (Optional items)

The optional speed sensor location is not as critical as scale carriage location, however improper installation of

the speed sensor will significantly affect the performance of the scale system. The speed sensor must give an

accurate representation of the speed of the material and travel of the belt.

10 BCi Installation & Operation Manual

Page 17

The favorable location for the speed sensor is the tail roll of the conveyor, provided that the conveyor is not

driven from the tail, and that the tail roll is accessible.

Figure 1-12. Speed Sensor Pulley

If the tail roll is not accessible then the speed sensor can be mounted on a tailing wheel that rides on the return

side of the belt, or on a live shaft roller . If a trailing wheel is used, the wheel should be located on a section of the

belt in which belt vibration will not add movement to the wheel. The preferable location would be directly

opposite a conveyor return roll.

If a live shaft roller is installed to sense the belt speed, the roller

should have positive contact with the belt. The

preferred location would be between two retu rn idlers with the speed roller being installed on the top side of the

returning belt and the return idlers installed on the bottom side.

Electronic Wiring Location

The location for the electronics to be mounted is determined by accessibility, wire routing, and environment. The

scale electronics require a clean and stable 120 VAC supply. The enclosure for the electronics is rated NEMA

4X. The electronics can be mounted up to 2000’ away from the scale carriage provided the optional load cell

sense wiring is installed. If the electronics are to be installed within 200’ of the scale carriage, the optional sense

wiring is not required. To reduce the effects of signal interference, the scale signals should not be ru n in conduit

or cable trays in conjunction with high voltage cables.

are

The digital input and output signals

compatible with OPTO 22 G4 5VDC relay modules and can be

controlled with AC, DC or dry contact signals. The analog output signal for rate of flow can be wired for 0-10

VDC, 2-10 VDC, 0-20mA current or 4- 20mA current. The printer signal can be RS-232, RS-485, or 20 mA

current loop.

Speed Wheel

If an optional speed wheel is used, the wheel should be located on a section of the belt in which belt vibration

will not add movement to the wheel. The preferable location would be directly opposite a conveyor return roll.

Figure 1-13. Optional Speed Wheel Assembly

BCi Installation & Operation Manual - Introduction and Overview 11

Page 18

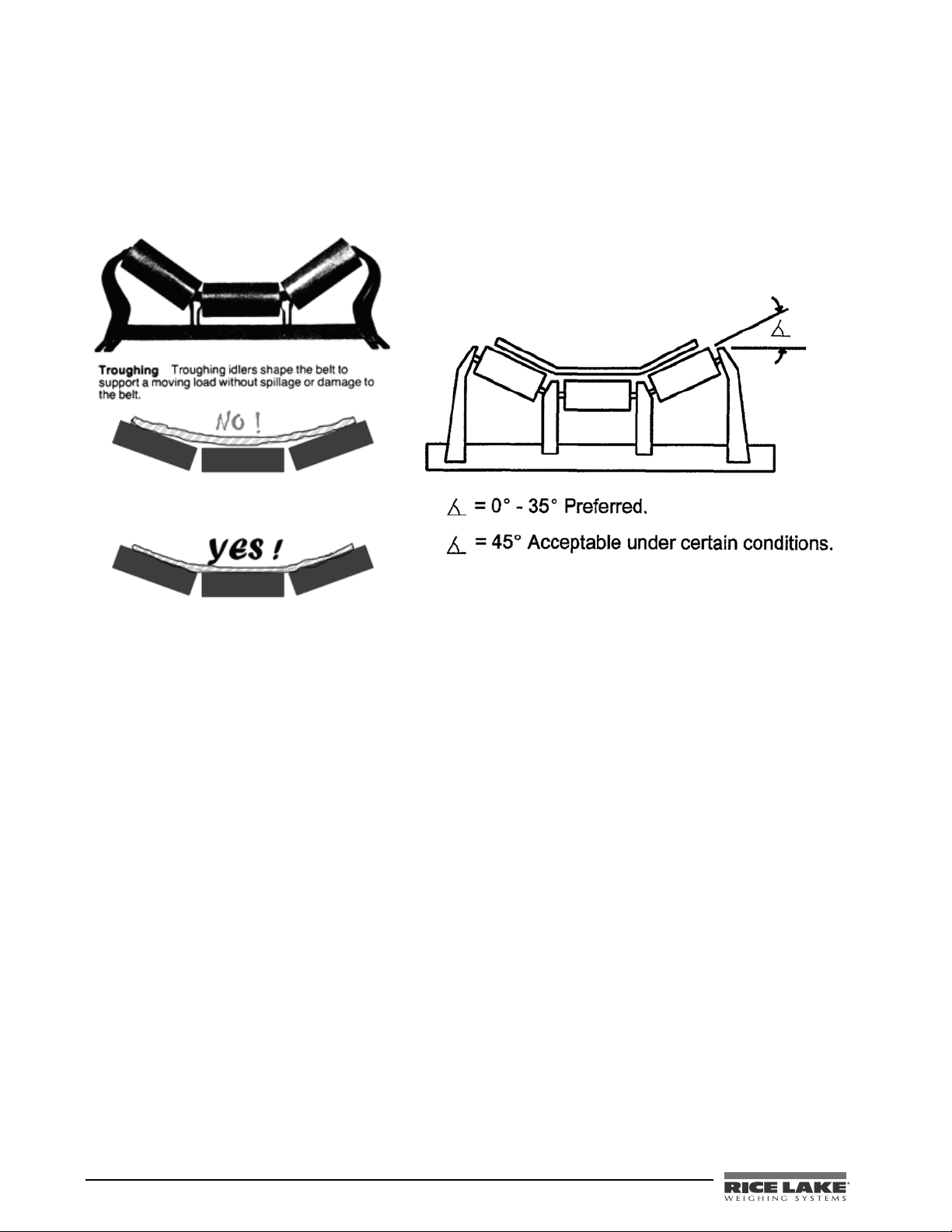

Troughing Angle

The use of idlers with steep troughing angles causes many problems. Not only does the bean or catenary effect of

the belt become more pronounced as the toughing increases, but the effect of idler misalignment is amplified as

well. The graphics below show an example of a correct and an incorrect troughing angles.

Troughing angles of 35 degrees or less are preferred for all h

igh accuracy installations. Troughing angles of 45

degrees are acceptable under certain conditions.

Figure 1-14. Troughing Angle Examples

1.5 Poor Choices for Belt Scale Installations

There are several instances where a belt scale installation would not be the best solution. The following list

points these out.

• Conveyors with multiple loading points

• Conveyors with convex or concave curves

• Conveyors with different stringer members i

• Conveyors that do not receive periodic inspections and housekeeping

• Conveyors where there is no facility to conduct a simulat

• Conveyors that are used in cold weather that are not i

• Tripper convey ors

• Radial stacking conveyors

• Applications where the belt scale results are compared w

• Applications where the belt scale weighment is subject to certific

Handbook 44 requirements.

• Applications where plant personnel are unwilling or unable to perfo

• Conveyors with more than 2-ply belting

• Conveyors that are installed outdoors, but are not equipped with a cover over the c

n troughing rolls

ed test

nstalled in a heated conveyor gallery

ith a marine draft survey

ation but the conveyor does not meet

rm routine conveyor maintenance

arry belt.

12 BCi Installation & Operation Manual

Page 19

1.6 Handbook 44 Requirements for Belt Scales

The following is a listing of various Handbook 44 requirements for belt scales.

• Minimum divisions shall not be greater than 0.1 of the minimum

• On test, the recorder must show the initial totalizer reading; the final tota

measure and the quantity delivered along with the time and date.

• The integrator master totalizer shall not be reset

• In the event of loss of power of up to 24 hours, the accumulated me

totalizer shall be retained in memory during that power loss.

• An audio or visual alarm indication shall be activated when the flow rate

in excess of 98% of the rated capacity.

• The totalizer can only advance when the belt conveyor

on the belt, the totalizer could not register).

• The master totalizer shall not be re-settable without breaking a security seal.

Means shall be provided that the totalizer reading shall be retained

•

event of a power failure.

• The belt scale integrator must factor in belt speed as a function

• Zero is to be limited to +/- 2% without breaking the security sea

• Auto zero mechanism shall be designed to operate only after a whole number of belt r

• An indication shall be provided for when the auto zero adjustment

• Belt speed device shall be designed so that there is no slip.

• An event logger must provide an audit trail of all calibration adjustment with a prin

demand. It shall have the capacity to retain records equal to ten times the number of sealable parameters

in the device, but not more than 1000 records are required, (ie: time and date of change; the parameter

value; the parameter ID).

• A zero circuit should provide for an average of one belt revolution (track +/-).

• Remote outputs record for (digital and analog), the total tons,

• Front panel calibration that is password protected w/ audit trail.

• Ability to enter the belt length and indicate in feet.

•

Ability to accept pulse input for belt speed indication.

the master totalizer without breaking a security seal.

is running (ie: if the belt is shut down with coal

totalized load.

asured quantity on the master

equals or falls below 35% or is

for a minimum of 24 hours in the

of calculating tons per hour weight.

l.

has reached its maximum limit.

rate in% of full cap, and the belt speed.

lizer reading, the unit of

evolutions.

ted copy available on

BCi Installation & Operation Manual - Introduction and Overview 13

Page 20

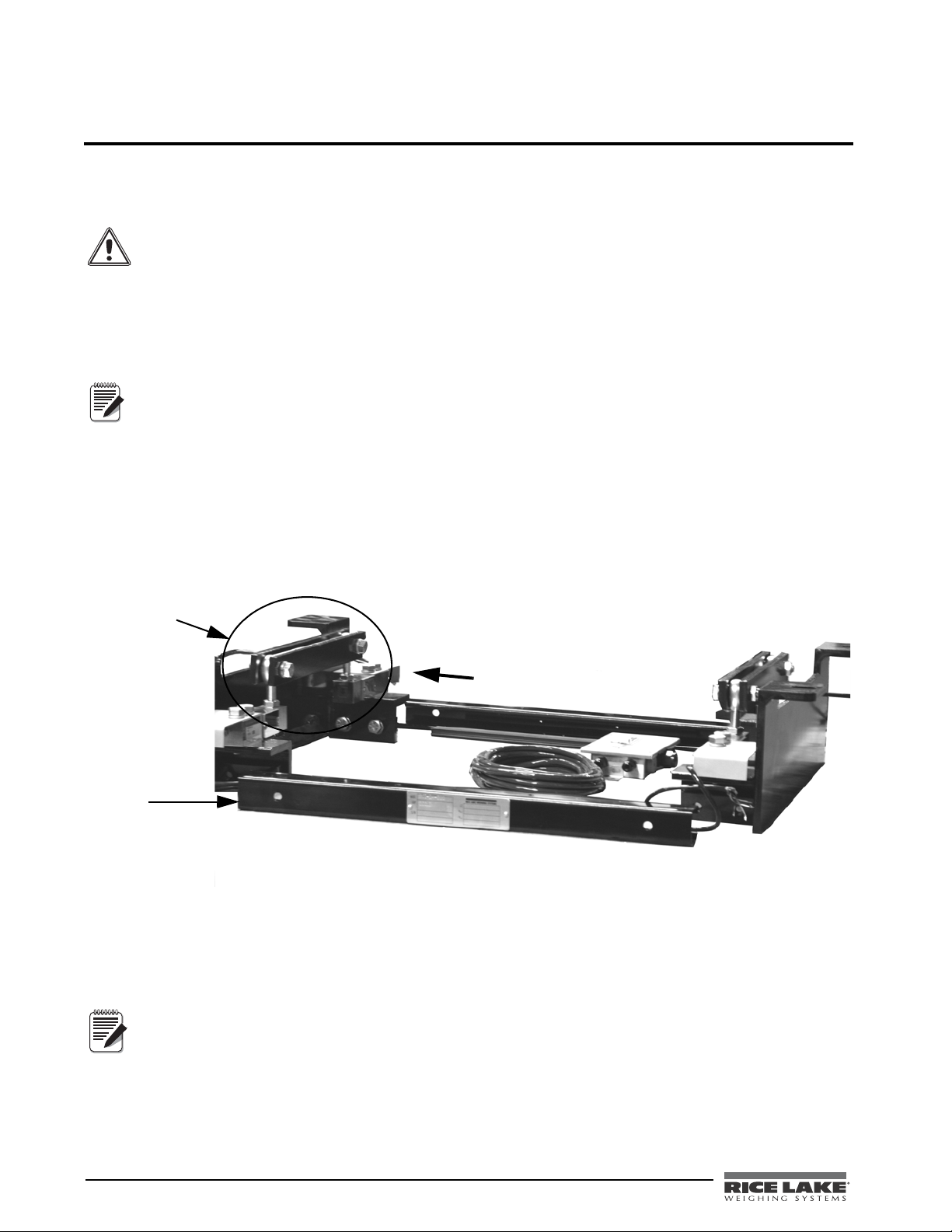

2.0 Integrator Hardware Installation

Warning

Note

End plate

assembly (x2)

Uni-Strut center

bars

Note

This section describes procedures for assembling the scale carriage, adding the idlers to the scale carriage, speed

sensor connections, and any associated wiring.

Installation instructions for the integrator (BCi) are explained starting on page 25.

Take all necessary safety precautions when setting up the BCi In-motion belt scale system, including

wearing safety shoes, protective eye wear and

2.1 Unpacking and Assembly

Upon receipt of the shipping pallet, visually inspect all components to make sure that they are included and

undamaged. The shipping carton should contain the scale carriage, the integrator, this manual, and a parts kit. If

any parts were damaged in shipment, notify Rice Lake Weighing Systems and the shipper immediately.

To ensure that all products received from the manufacturer are in good shape upon arrival, it is

recommended to fully inspect all contents and properl

2.2 Scale Carriage Installation

The proper location must be chosen for installation of the scale carriage prior to installation. Information on page

12 helps choose the correct location for the scale carriage.

Once the correct location for the scale carriage is chosen, use the following steps to assemble the carriage as

there is mini

to work with the junction box. Figure 2-1 shows the component parts for the scale carriage that need to be

assembled.

mal assembly required. Tools required for assembly include a 3/4" wrench and a small screwdriver

using the proper tools.

y complete the bill of lading.

The exact steps for assembling the scale carriage may vary depending on the site location and size of carriage.

14 BCi Installation & Operation Manual

Figure 2-1. Scale Carriage Component Parts

1. Space the two end plate assemblies far enough apart

so that the uni-strut center bars will slide into the

channels on the end plate assembly making sure that the uni-strut center bar is centered equally from

both ends.

There should be roughly a 5/8" gap on each side and the drilled mounting holes (for junction box

placement), should be facing upwards.

Page 21

.

Figure 2-2. Slide the Uni-Strut Center Bars onto the End Plate Assembly

2. Using a 3/4" wrench, tighten the bolts on each end of the uni-strut center bars on both ends of the end

plate assembly.

Figure 2-3. Tighten Bolts

BCi Installation & Operation Manual - Integrator Hardware Installation 15

Page 22

2.3 Junction Box Installation

The BCi In-Motion Belt Scale uses the TuffSeal JB4SS (PN 88956) junction box. It is a four -channel sig nal trim

junction box with an expansion board enclosed. The junction box is a stainless steel NEMA 4X enclosure that

comes with a standard Prevent

or environmental changes.

Use the following steps to install the junction box.

1. Set the junction box onto the uni-strut center bar an

2. Attach the ground lug (shown below).

®

breather vent which inhibits the buildup of pressure cause by sudden temperature

Figure 2-4. TuffSeal Junction Box

d attach to the bar using the enclosed screws.

Figure 2-5. Attach the Ground Lug onto the Junction Box

16 BCi Installation & Operation Manual

Page 23

Wiring the Junction Box

Run load cell

cable

through

scale

carriage

channel

The four channel TuffSeal JB4SS has been designed to connect and trim up to four load cells per board.

However, it is possible to use this junction box with other combinations.

Run the load cell cables from the load cells through the channels

Figure 2-6. Route Load Cell Cable From Load Cell to Junction Box

on the scale carriage over to the junction box.

3. Open the cover to the junction box to expose the interior.

4. Wire the junction box by running the load cell

Figure 2-7. Junction Box Interior

cable inside of the junction box.

Use the following table to wire the load cell cables.

Wire Color Signal

Red +EX

Black -EX

Green +SIG

White -SIG

Silver Braid SHIELD

Table 2-1. Load Cell Wiring

BCi Installation & Operation Manual - Integrator Hardware Installation 17

Page 24

5. Use the expansion port on the main board to connect multiple junction boxes in series to accommodate

+1

15 15

+1

+1

15

&91

15

+1

$&--

$&--

$&--

$&--

*/%

&9

4*

4)%

4*

&9

.

4*

4$

4*

&9

&9

4*

4)%

4*

&9

&9

4*

4)%

4*

&9

4*

4*

&9

4)%

&9

4)%

&9

4&

4&

&91

*/%

4*

4*

&9

4)%

&9

4&

4&

applications that have more than four load cells. Figure 2-8 illustrates the expansion port wiring location.

Figure 2-8. Expansion Port Location

18 BCi Installation & Operation Manual

Page 25

Trimming Procedure

*0

*0

04

04

*0

04

%80

04

*0

#%,,

#%,,

#%,,

#%,,

).$

%8

3)

3($

3)

%8

-

2

.

)

3)

3#

)

!

'

%8

3)

3)

3($

%8

)

3

'

!

,

4

3)

-

3

)

.

,

4

2

%8

%8

3)

3($

3)

%8

3)

%8

3)

3($

%8

3($

3%

3%

%8

0OTENTIOMETERS

*UMPER,OCATIONS

*0AND*0

3HADED

*UMPER,OCATIONS

*0AND*0

3HADED

0OTENTIOMETERS

Insert Uni-strut

closure strip

into uni-strut

center bars

Trimming is a process of equalizing the output from multiple individual load cells. If needed, load cell output can

be individually trimmed with potentiometers.

Whenever a substantial amount of trim (more than 5% of normal output), seems necessary to equalize output,

check for other

possible problems. The best trim is always the least amount of trim. When all errors except cell

mismatch and cable extensions or reductions have been corrected, continue on with the trimming.

Use the following steps to properly trim the JB4SS junction box.

1. Determine the number of load cells needed.

2. Make sure jumpers are in place to enable trimming of the cells corre

Figure 2-9 for the location of jumpers JP1, JP2, JP3 and JP4. Note that you will

sponding to each load cell. See

need to remove jumpers

for any unused cells.

3. Set all potentiometers fully clockwise to give maximum

signal output from each cell (see below for

location of potentiometers).

Figure 2-9. Potentiometer Location

Refer to the TuffSeal Installation manual (PN 91909) for additional information on the junction box.

Once all of the cables are attached and the scale carriage is c

ompletely assembled, take the uni-strut closure strip

and seal up the middle bars.

Figure 2-10. Insert Uni-strut Closure Strip

BCi Installation & Operation Manual - Integrator Hardware Installation 19

Page 26

2.4 Attaching the Idlers to the Scale Carriage

Mount the idlers

to the carriage

using the V-bolts

and bolting them

to the carriage

frame.

Note:

V-bolts can be

purchased

separately from

RLWS.

PN 98806 - fits 3"

angles

PN 99323 - fits 4"

angles

Once the scale carriage is assembled, you can mount the idlers to the carriage.

Figure 2-11. Mount Idlers to Scale Carriage

Mount the idlers to the scale carriage using the large V-bolts and bolting them to the scale carriage frame.

If the scale carriage requires the relocation of cross bracing directly under the sc

should be relocated or replaced as to no t re duce the structural integrity of the conveyor. The minimum clearance

under the scale is 6.50" as measured from the top mounting surface. If the return conveyor belt is less than 6.50"

from the top of the frame, then the scale carriage will require extra shimming or the return idlers will require

relocation. The return side of the conveyor belt must not contact the bottom of the scale when the conveyor is

operating.

20 BCi Installation & Operation Manual

Figure 2-12. Mount Idlers to Scale Carriage Using V-Bolts

ale. Any bracing that is removed

Page 27

Figure 2-13. Scale Carriage Location May Need Cross-Bracing

The idler spacing for the scale has been predetermined, and the three idlers before and after the scale should be

moved to match the same spacing.

Any splices in the conveyor frame work in the scale area

are required to be permanently joined. Additional

bracing may be required under the conveyor frame work to minimize deflection and vibration under the load as

any additional bouncing will decrease the scale’s accuracy.

The 3rd idler before and the 3rd idler after the scale should be

shimmed 1/4" higher than the adjacent

idlers.

These will be the first and last idlers in the scale area.

The first and last scale idlers should be shimmed level across the c

onveyor. If the idlers adjacent to the scale area

are greater than 1/4" lower than the scale area, the adjacent idlers should be shimmed to ramp up to the scale area

in 1/4" increments.

Figure 2-14. Idlers Should be Level

The idler on the scale should be mounted to the scale weigh pads. The existing mounting feet should be removed

and the new feet welded on at the correct spacing for the pads.

Apply alignment string lines across the scale

area idlers, stretching over the 3rd before and the 3rd idler after the

scale carriage.

BCi Installation & Operation Manual - Integrator Hardware Installation 21

Page 28

The scale frame should be shimmed to match the weigh idler to the plane drawn by the alignment strings.

Figure 2-15. Shim Carriage if Needed

Recheck the level of the scale carriage and weigh idler.

The other idlers in the scale area should be shimmed to match the alignment

strings. The finished aligned scale

area idlers should be equally spaced, level, and in a plane 1/4" higher than the adjacent idlers on the conveyor.

2.5 Speed Sensor Installation

The installation of the speed sensor will vary based upon accessibility to the tail roller, belt speed and distance

from the electronic integrator (BCi).

n

There are a variety of scenarios that can be used to i

following steps go through various types of speed sensor installations but individual applications vary for each

job.

Encoder Speed Sensor Located on the Tail Pulley or Live Shaft Roller

1. Drill and tap a 3/8" hole centered on the tail roll shaft.

2. Prepare a mounting stud by removing the head of 3/8" x 1 1/2" bolt.

3. Thread the mounting stud into the tail roll shaft.

4. Install the 3/8" to 10mm encoder coupling to the mounting stud.

5.

Install the encoder to the coupling.

6. Fabricate a mounting bracket to support the encoder.

Proximity Sensor Located on Idler Pulley

1. Measure the diameter of the idler to be used for the speed sensor.

2. Determine the number of targets to give a pulse a minimum of e

3. Install steel targets equal around the idler.

4

. Mount the proximity sensor within 1/4" of the tar

stall the speed sensor depending on accessibility. The

very 4" of travel.

gets.

22 BCi Installation & Operation Manual

Page 29

Proximity Sensor Located on Wheel

Speed Wheel

Sensor

1. The wheel speed sensor should be mounted to ride against the inside of the return conveyor belting.

2. Install the wheel bracket assembly to the tail end side of the s

cale carriage. The belt travel should pull the

wheel away from the scale carriage.

Figure 2-16. Speed Wheel Sensor

3. Mount the wheel arm to the cross brace closest to the tail of the conveyor. The wheel assembly must be

free to move in the vertical direction and must maintain contact with the belt at all times.

BCi Installation & Operation Manual - Integrator Hardware Installation 23

Page 30

2.6 Scale Carriage Replacement Parts

The table below lists replacement parts for the BCi In-Motion Belt Scale System.

Ref Number Part Number Description (quantity)

1

2

3

4

5

6

7

8

9

10

11

12

- - - - - Unistrut spacer bar (2) Consult Factory Consult Factory

- - - - - Unistrut closure strip (2) Consult Factory Consult Factory

94969 Speed wheel assembly (1)

- - - - - End plate assembly (2) 96730 96732

88956 TuffSeal stainless steel junction box (1)

22066 Machine screws, 10-32NF (2)

14878 Machine screws, 10-32 x 1/2 (2)

16863 Label (1)

14905 Drive screws, 4 x 3/8 (2)

31546 Lock washer, 1/4 (2)

43810 Connecting ring terminal, 1/4 inch (1)

- Load cell (2) 17341 17342

Table 2-2. Scale Carriage Replacement Parts

500 Lb

Capacity

1000 Lb

Capacity

Figure 2-17. Belt Scale Assembly, Top View A

24 BCi Installation & Operation Manual

Page 31

Figure 2-18. Belt Scale Assembly, View B

Figure 2-19. Belt Scale Assembly, View C

Figure 2-20. Belt Scale Assembly, View D

BCi Installation & Operation Manual - Integrator Hardware Installation 25

Page 32

3.0 Integrator Hardware Setup

Warning

$PSEHSJQ

*OTVMBUFEDBCMF

'PJMTJMWFSTJEFPVU

(SPVOEJOHDMBNQ

4IJFMEXJSFDVU

-FOHUIPGGPJMCFGPSFGPMEJOH

CBDLPODBCMFJOTVMBUJPO

$VUJOTVMBUJPOIFSF

GPSGPJMTIJFMEFEDBCMFT

#SBJE

$VUJOTVMBUJPOIFSF

GPSCSBJEFEDBCMFT

/05&*OTUBMMMPDLXBTIFST

mSTUBHBJOTUFODMPTVSF

VOEFSHSPVOEJOHDMBNQ

3.1 Enclosure Disassembly

The integrator enclosure must be opened to install option cards and to connect cables for installed option cards.

The BCi integrator has no on/off switch. Before opening the unit, ensure the power cord is

disconnected from the power outlet.

Ensure power to the integrator is disconnected, then place the integrator face-down on an

antistatic work mat. Remove the screws that hold the backplate to the enclosure body, then lift the backplate

away from the enclosure and set it aside.

3.2 Cable Connections

The universal model of the BCi integrator provides six cord grips for cabling into the unit: one for the power

cord, five to accommodate cabling for option cards. Install plugs in all unused cord grips to prevent moisture

from entering the enclosure.

Cable Grounding

Except for the power cord, all cables routed through the cord grips should be grounded against the integra tor

enclosure. Do the following to ground shielded cables:

• Use the lockwashers, clamps, and keep nuts provided in

enclosure studs adjacent to cord grips. Install grounding clamps only for cord grips that will be used; do

not tighten nuts.

• Route cables through cord grips and grounding clamps to determin

connectors. Mark cables to remove insulation and shield as described below:

• For cables with foil shielding, strip insulation and foil from the cable

grounding clamp. Fold the foil shield back on the cable where the cable passes through the clamp.

Ensure silver (conductive) side of foil is turned outward for contact with the grounding clamp.

• For cables with braided shielding, strip cable insulation

grounding clamp. Strip another half inch (15 mm) of insulation only to expose the braid where the cable

passes through the clamp (see figure below).

the parts kit to install grounding clamps on the

e cable lengths required to reach cable

half an inch (15 mm) past the

and braided shield from a point just past the

Figure 3-1. Grounding Clamp Attachment for Foil-Shielded and Braided Cabling

• For load cell cables, cut the shield wire just past the grounding clamp. Shield wire function is provided

by contact between the cable shield and the grounding clamp.

• Route stripped cables through cord grips and clamps.

in the figure above. Tighten grounding clamp nuts.

• Finish installation using cable ties to secure cables inside

26 BCi Installation & Operation Manual

Ensure shields contact grounding clamps as shown

of integrator enclosure.

Page 33

Load Cells

4*(

4*(o

4&/

4&/o

&9$

&9$o

+

+1+1

CHANNEL 2

CHANNEL 1

SIG+

SIG–

SEN+

SEN–

EXC+

EXC–

J2

J1

JP3 JP4

JP2 JP1

CH 2

CH 1

T o attach cable from a load cell or junction box to an installed A/D card, route the cable through the cord grip and

ground the shield wire.

Next, remove connector J1 from the single-channel A/D card. The connector plugs

into a header on the A/D card.

Wire the load cell cable from the load cell or junction box to connector J1 as shown in the table below.

Figure 3-2. Single-Channel and Dual-Channel A/D Cards

If using 6-wire load cell cable (with sense wires), remove jumpers JP1 and JP2 before reinstalling connector J1.

For 4-wire installation, leave jumpers JP1 and JP2 on. For 6-wire load cell connections on dual-channel A/D

cards, remove jumpers JP3 and JP4 for connections to J2.

d

When connections are complete, reinstall loa

cell connector on the A/D card and use two cable ties to secure the

load cell cable to the inside of the enclosure.

A/D Card

Connector Pin Function

1 +SIG

2 –SIG

3 +SENSE

4 –SENSE

5 +EXC

6 –EXC

• For 6-wire load cell connections to connector J1, remove jumpers JP1 and JP2.

tor J2 (dual A/D cards), remove

• For 6-wire load cell connections to conne

jumpers JP3 and JP4. 2.

Table 3-1. A/D Card Pin Assignments

c

BCi Installation & Operation Manual - Integrator Hardware Setup 27

Page 34

Pulse Input Card

Warning

Caution

+

Use the following procedure to install pulse input cards in BCi integrator:

1. Disconnect integrator from power source.

Disconnect power before removing integrator backplate.

2. Place integrator face-down on an antistatic work mat. Remove screws that hold the backplate to the

enclosure body.

Use a wrist strap to ground yourself and protect components from electrostatic discharge (ESD) when

working inside the integrator enclosure.

3. Carefully align the large option card connector with connector J5 or J6 on the 920i CPU board. Press

down to seat the option card in the CPU board connector.

Use the screws and lockwashers provided in the op

tion kit to secure the other end of the option card to the

threaded standoffs on the CPU board.

Figure 3-3. Pulse Input Card

4. Make connections to the option card as required.

Wire Color Function

Brown +12 V

Black Pulse In

Blue Ground

Table 3-2. Speed Wheel Pulse Input Wiring Colors

5. Use cable ties to secure loose cables inside the enclosure. Once cabling is complete, position

backplate over the enclosure and reinstall the backplate screws. Use the torque pattern shown in the

backplate torque graphic on the next page to prevent distorting the backplate gasket. Torque screws to 15

in-lb (1.7 N-m).

6. Ensure no excess cable is left inside the

enclosure and tighten cord grips.

the

28 BCi Installation & Operation Manual

Page 35

Reconnect power to the integrator.

5PSRVFCBDLQMBUFTDSFXT

UPJOMC/N

7

+

(/%

16-4&*/

7

(/%

Figure 3-4. Backplate Torque

The integrator automatically recognizes all installed option cards when the unit is powered on. No

hardware-specific configuration is required to identify the newly-installed card to the system.

Figure 3-5. Pulse Input Board Option Card

Serial Communications

The four communications ports on the BCi CPU board support full duplex RS-232, 20 mA output, or RS-485

communications at up to 115200 bps.

To attach serial communications cables, route the cable through

the cord grip and ground the shield wire as

described on page 26. Remove the serial connector from the CPU board and wire to the connector. Once cables

are attached, plug the connector into the header on the board. Use cable ties to secure serial cables to the inside of

the enclosure.

BCi Installation & Operation Manual - Integrator Hardware Setup 29

Page 36

The serial port pin assignment table shows the pin assignments for Ports 1, 3, and 4. Port 2 provides DIN-8 and

-$%$POUSBTU

%*/$POOFDUPSGPS

143FNPUF,FZCPBSE

%#$POOFDUPS

GPS1PSU+

DB-9 connectors for remote keyboard attachment of PS/2-type personal computer keyboards (see below). The

DB-9 connector pin assignments for Port 2 are shown in the DB-9 Connector table below.

Connector Pin Signal Port

J11

J9

J10

1 GND

2 RS-232 RxD

3 RS-232 TxD

1 GND / –20mA OUT

2 RS-232 RxD

3 RS-232 TxD

4 +20mA OUT

1 GND / –20mA OUT

2 RS-232 RxD

3 RS-232 TxD

4 +20mA OUT

5 RS-485 A

6 RS-485 B

1

3

4

Table 3-3. Serial Port Pin Assignments

Serial ports are configured using the SERIAL menu.

An optional dual-channel serial communications exp

ansion card, PN 67604, is also available. Each serial

expansion card provides two additional serial ports, including one port that supports RS-485 communications.

Both ports on the expansion card can support RS-232 or 20mA connections.

30 BCi Installation & Operation Manual

Figure 3-6. Interface Board Connections

DB-9 Pin Signal

2 TxD

3 RxD

5 GND

7 CTS

8 RTS

Table 3-4. DB-9 Connector Pin Assignments

Page 37

+

1035

+

1035

+

1035

+

1*&;0

#6;;&3

015*0/

+

o7%$

(/%

(/%

7%$

&91"/4*0/#64

(/%

343Y%

345Y%

(/%oN"065

343Y%

345Y%

N"065

343Y%

345Y%

N"065

345Y%

345Y%¦

7%$

(/%

%*0

%*0

%*0

%*0

*/5&3'"$&

#0"3%

$0//&$5*0/

108&3

4611-:

48

48

+1

+

+

+

%*(*5"-*0

+

1035

015*0/$"3%

$0//&$503

015*0/$"3%

$0//&$503

015*0/$"3%-0$"5*0/4

+

#"55&3:

+

#005

.0%&

4-05

4-05

(/%oN"065

3&.05&

4&561

48*5$)

Figure 3-7. BCi CPU Board, Showing Option Card Locations

BCi Installation & Operation Manual - Integrator Hardware Setup 31

Page 38

Digital I/O

Note

5PSRVFCBDLQMBUFTDSFXT

UPJOMC/N

Digital inputs can be set to provide many integrator functions, including all keypad functions. Digital inputs are

active low (0 VDC), inactive high (5 VDC).

Digital outputs are typically used to con

trol relays that drive other equipment. Outputs are designed to sink,

rather than source, switching current. Each output is a normally open collector circuit, capable of sinking 24 mA

when active. Digital outputs are wired to switch relays when the digital output is active (low, 0 VDC) with

reference to a 5 VDC supply.

The table below shows the pin assignments for connector J2.

J2 Pin J2 Signal

1 +5 VDC

2 GND

3 DIO 1

4 DIO 2

5 DIO 3

6 DIO 4

Table 3-5. J2 Pin Assignments (Digital I/O)

using the DIG I/O menu.

Digital inputs and outputs are config

An optional 24-channel digital I/O expansion card, PN 67601, is available for applications requi

ured

ring more digital

I/O channels.

• The maximum number of option board slots is fourtee n: two onboard s lots, plus two six-card exp ansion

board

s.

• The two-card expansion board is always placed at the en

d of the expansion bus. No more than one

two-card expansion board can be used in any system configuration.

• The panel mount enclosure can accommodat

e a single two-card expansion board.

• The wall mount enclosure can accommodate a two-card or a six-card expansion board.

• Systems using two expansion boards are housed in a custom enclosure.

3.3 Enclosure Reassembly

Once cabling is complete, position the backplate over the enclosure and reinstall the backplate screws. Use the

torque pattern shown below to prevent distorting the backplate gasket. Torque screws to 15 in-lb (1.7 N-m).

Figure 3-8. BCi Enclosure Backplate

32 BCi Installation & Operation Manual

Page 39

3.4 CPU Board Removal

Caution

5PSRVFGVTFBOEJOUFSGBDFCPBSEBDDFTTDPWFSTUP

JOMC/N

'VTFT

''

*OUFSGBDF#PBSE

Note

Caution

If you must remove the BCi CPU board, use the following procedure:

1. Disconnect power to the integrator. Remove backplat

2. Unplug connectors J9, J10, and J11 (serial communications), J2 (digital I/O), P1 (power su

e as described on page 29.

pply), and

connectors to any installed option cards.

3. Remove any installed option cards.

4. Remove the five phillips head screws and two kep nuts from

5. Gently lift up the CPU board, then disconne

ct connectors J12 (power to display), J4 (ribbon cable, J3

the CPU board.

(keypad connector), then the cable J8 (Port 2 serial port).

6. Remove CPU board from the enclosure. If necessary, cut cable ties to shift cables out of the way

To replace the CPU board, reverse the above procedure. Be sure to reinstall cable ties to secure all ca

.

bles inside

the integrator enclosure.

3.5 Fuse Replacement

Fuses for the universal and deep enclosure models of the BCi are located under a cover plate on the outside of the

enclosure. Remove the cover plate, replace the fuses, and reinstall the cover plate as described on page 32.

To protect against the risk of fire, replace fuses only with same type and rating fuse.

Interface board and fuse access cover plates must be in pla

ce for use in NEMA 4X/IP66 applications.

Figure 3-9. Interface Board and Fuse Locations, Universal Model

3.6 Battery Replacement

The lithium battery on the CPU board maintains the real-time clock and protects data stored in the system RAM

when the integrator is not connected to AC power.

Data protected by the CPU board battery includes time and date, truck and tare memory, onboard database

informa

Use

any data is lost, the integrator configuration can be restored from the PC.

Watch for the low battery warning on the LCD display and periodically ch eck the battery voltage on both the

CPU board and on any installed memory option cards. Batteries should be repla ced when the integrator low

battery warning comes on, or when battery voltage falls to 2.2 VDC. Life expectancy of the battery is ten years.

See page 31 for CPU board battery location and

tion, and setpoint configuration.

Revolution to store a copy of the integrator configuration on a PC before attempting battery replacement. If

Memory option card data is also protected by a lithium battery. All database information stored on a

memory card is lost if the memory card battery fails.

Risk of explosion if battery is replaced with incorrect type. Dispose of batteries per manufacturer

instruction.

orientation (positive side up).

BCi Installation & Operation Manual - Integrator Hardware Setup 33

Page 40

3.7 Parts Kit Contents

The Parts Kit Content table lists the parts kit contents for the universal model of the BCi.

PN Description

14626 Kep nuts, 8-32NC (4)

14862 Machine screws, 8-32NC x 3/8 (12)

75068 Sealing washers (14)

15133 Lock washers, No. 8, Type A (4)

30623 Machine screws, 8-32NC x 7/16 (2)

15631 Cable ties (4–single A/D, 6–dual A/D)

15665 Reducing glands for 1/2 NPT cord grips (2)

15887 6-position screw terminal f

19538 Cord grip plugs (4–single A/D, 3–dual A/D)

42350 Capacity label (1–single A/D, 2–dual A/D)

53075 Cable shield ground clamps (4)

70599 6-position screw terminals

71126 4-position screw terminal for J9 and opti

71125 3-position screw terminal for

42149 Rubber feet for tilt stand (4)

15144 Nylon washers for tilt stand, 1/4 x 1 x

68403 Wing knobs for tilt stand (2)

or load cell connection (1–single A/D, 2–dual A/D)

or J2 and J10 (2)

f

onal keyboard connection (2)

J11 (1)

1

/16 (2, universal model only)

Table 3-6. Parts Kit Contents

34 BCi Installation & Operation Manual

Page 41

3.8 Replacement Parts and Assembly Drawings

Replacement parts for the BCi universal enclosure mode are listed below.

Ref Number PN Description (Quantity) See Figure

1 67529 Enclosure, universal (1) 3-10

2 68598 Protective lens (1)

3 67614 LCD display (1)

4 68425 Fuse access coverplate (1)

5 68621 Fuse access coverplate gasket (1)

6 67886 Standoffs, short (4)

7 68661 Standoffs, long (2)

8 70912 CPU board (1)

9 14618 Kep nuts, 4-40NC (2)

10 67613 Power supply, ±6VDC, 25W (1)

11 67536 Power supply bracket (1)

12 16861 High voltage warning label (1)

13 14624 Lock nuts, 6-32NC, nylon (2)

14 14822 Machine screws, 4-40NC x 1/4 (11)

15 67530 Interface board connector plate (1)

16 67535 Interface board gasket (1)

17 14862 Machine screws, 8-32NC x 3/8 (4)*

18 75068 Sealing washers (12)*

19 32365 Setup switch access screw, 1/4 x 20NC x 1/4 (1)

20 44676 Sealing washer for setup switch access screw (1)

21 15626 Cord grips, PG9 (3)

22 15627 Lock nuts, PCN9 (3)

23 30375 Nylon seal rings for P

25 15134 Lock washers, No. 8, Type A (3)

26 14626 Kep nuts, 8-32NC (3)*

27 45043 Ground wire, 4 in w/ No. 8 eye connector (1)

28 68424 Enclosure backplate, universal (1) 3-10

29 67532 Backplate gasket, universal (1) 3-10

30 15631 Cable tie, 3-in nylon (1)*

31 67795 Power cord assembly, 115 VAC and 230 VAC North American units (1) 3-10

69998 Power cord assembly, 230 V

32 67796 Power supply cable assembly,

33 68662 Ribbon cable to interface board, universal (1)

34 16892 Ground/Earth label (1)

35 15650 Cable tie mounts, 3/4 in. (4)

40 53308 Model/serial number label (1)

41 68532 Single-channel A/D card (1, can be single- or dual-channel A/D) —

68533 Dual-channel A/D card (1, can be single- or dual-channel A/D)

43 71027 Fuses (115 VAC models), 2 A T

71026 Fuses (230 VAC models), 2 A Ti

G9 cord grips (3)

A

C European units (1) —

to CPU board (1)

me-Lag TR5 (2) 3-10

i

me-Lag TR5 (2)

Table 3-7. Replacement Parts

BCi Installation & Operation Manual - Integrator Hardware Setup 35

Page 42

Ref Number PN Description (Quantity) See Figure

Caution

45 67869 Interface board (1)

46 14832 Machine screws, 4-40NC x 3/8 (2)

47 22086 Machine screws, 6-32NC x 1/4 (8) 3-10

50 15628 Cord grips, 1/2 NPT (2)

52 30376 Nylon seal rings for 1/2 NPT cord grips (2)

53 15630 Lock nuts for 1/2 NPT cord grips (2)

54 70069 3V Lithium coin battery

55 69898 Nylon spacers (4) 3-10

— 66502 Switch panel membrane (1)

* Additional parts included

in parts kit.

To protect against the risk of fire, replace fuses only with same type and rating fuse.

Table 3-7. Replacement Parts (Continued)

36 BCi Installation & Operation Manual

Page 43

9

9-

,

9,

&

9

#308/8*3&

#-6&8*3&

(3&&/:&--088*3&

&

501

9

9

%

"

'

(

$

9#

9&

9

9

9"

9

9

)

9

+

3&%8*3&

9

'30.-$%%*41-":#0"3%

50#0550.0'$16#0"3%

8"3/*/(

)*()70-5"(

&

Figure 3-10. BCi Universal Model Assembly

BCi Installation & Operation Manual - Integrator Hardware Setup 37

Page 44

4.0 Supervisor Mode Parameters

Supervisor

Mode

SCALE #1

Reset

Totalizer

Diagnostics

11/23/2011 08:13AM

Rate

Speed

Load

Totalizer

TN/Hr

Ft/Min

lb/ft

kg

293467.2

43.21

47.5

207467.8

Supervisor Mode

Softkey

Exit=>

SCALE #1

Master

Totalizer

Integrator

Calibration

Time/Date

Belt

Calibration

11/23/2011 08:13AM

Admin. Passcode (numeric)

Scale Capacity (Max Rate)

Load Cell MV

Total LC Build

Rate Unit Time

Filter

Speed Unit Time

Fixed Speed

Unit of Measure

Unit of Rate

500.00

3.00000

600

Hr

10

Min

0.00

Ft

TN

Use up and down arrows

on BCi to scroll through

various parameters.

Various parameters can be set by using the Supervisor Mode softkey from the main menu.

NOTE: All parameters must be entered prior to calibrating the unit.

Figure 4-1. Supervisor Softkey Location

Press the Supervisor Mode softkey to access the following screen.

Figure 4-2. Supervisor Mode Parameters

Use the up and down arrow keys on the BCi to navigate the parameter list. Use the enter key to select the

parameter to edit. If the parameter is a value that can be entered, a user prompt will open. The operator can then

key in the new value and press

enter to accept the new value. If the parameter has a list of available values, the

value will scroll through all available selections.

38 BCi Installation & Operation Manual

Page 45

4.1 Admin. Passcode (numeric)

SCALE #1

Exit =>

11/23/2011

08:13AM

Rate

Speed

Load

Totalizer

Tn/Hr

Ft/Min

lb/ft

kg

19346.2

43.21

47.5

17467.8

Enter Password

Exit=>

SCALE #1

Master

Totalizer

Integrator

Calibration

Time/Date

Belt

Calibration

11/23/2011 08:13AM

Admin. Passcode (numeric)

Scale Capacity (Max Rate)

Load Cell MV

Total LC Build

Rate Unit Time

Filter

Speed Unit Time

Fixed Speed

Unit of Measure

Unit of Rate

500.00

3.00000

600

Hr

10

Min

0.00

Ft

TN

This parameter allows the administration password to be configured. It prevents unauthorized changes to system

parameters and calibration.

Figure 4-3. Enter Password

Once the password is entered into the BCi, the following menu screen appears. There are several parameters that

can be entered and are explained in the following sections.

Figure 4-4. Main Supervisor Screen

Use the up and down arrows on the BCi to scroll through the menu items. The available parameters are displayed

by pressing the

enter key on the BCi.

BCi Installation & Operation Manual - Supervisor Mode Parameters 39

Page 46

There are many parameters in the

Note

Note

Supervisor Mode (shown in the following

sections), but most will not be used for a

must be set prior to calibration include the following:

Calibration Weight (if using static weights to calibrate)

basic installation. The parameters that

• Idler Spacing

• Number of Idlers

• Belt Length

• Load Cell MV

• Total Load Cell Build

The other parameters that are commonly set are the

filtering values but they can be done after setup and

calibration.

The angle of inclination is

Rice Lake Weighing Systems frames due to

terally opposed shearbeams.

la

not required with

4.2 Scale Capacity

This parameter defines the maximum rated capacity

for the belt scale or the maximum amount of weight

that can pass along the belt scale per hour.

The default parameter is measured in tons/hour.

Enter the maximum rate in tons using the numeric

keypad and press

enter key to save that parameter.

the

4.3 Load Cell MV

Enter the average mv/v rating of all the load cells in

the system.

Use the numeric keypad to enter that value which

must be greater tha

n

0. Press the

enter key to save that

parameter.

4.4 Total Load Cell Build

This parameter is the total load cell capacity of the all

the load cells in system. If you have eight load cells

for example and each one has a rated capacity of XX,

take that capacity and times it by 8 to get the total load

cell capacity to be entered into the BCi integrator.

4.5 Rate Unit Time

This parameter defines what unit of time the rate will

be displayed in on the BCi. Available selections are:

• Hr. - hour (default)

• Min - minute

• Sec - seconds

Press the

choices above. The default rate unit time is Hr.

enter key to toggle between the listed

4.6 Filter (s)

This parameter defines the number of seconds

filtering samples to average the scale load. It is

measured in tenths of seconds.

4.7 Filter Threshold (divisions)

This is the number os division the load must maintain

for the filter to be enabled. If the load sees a change in

weight that is greater than this value, the filter is

flushed.

4.8 Speed Unit Time

This parameter defines how the belt speed is displayed

on the BCi. The selections are displayed in the

following units.

• Hr. - hour

• Min - minute (default)

• Sec - seconds

Press the

enter key to toggle between the listed

choices above. The default speed unit time is

displayed in minutes.

4.9 Fixed Speed