Page 1

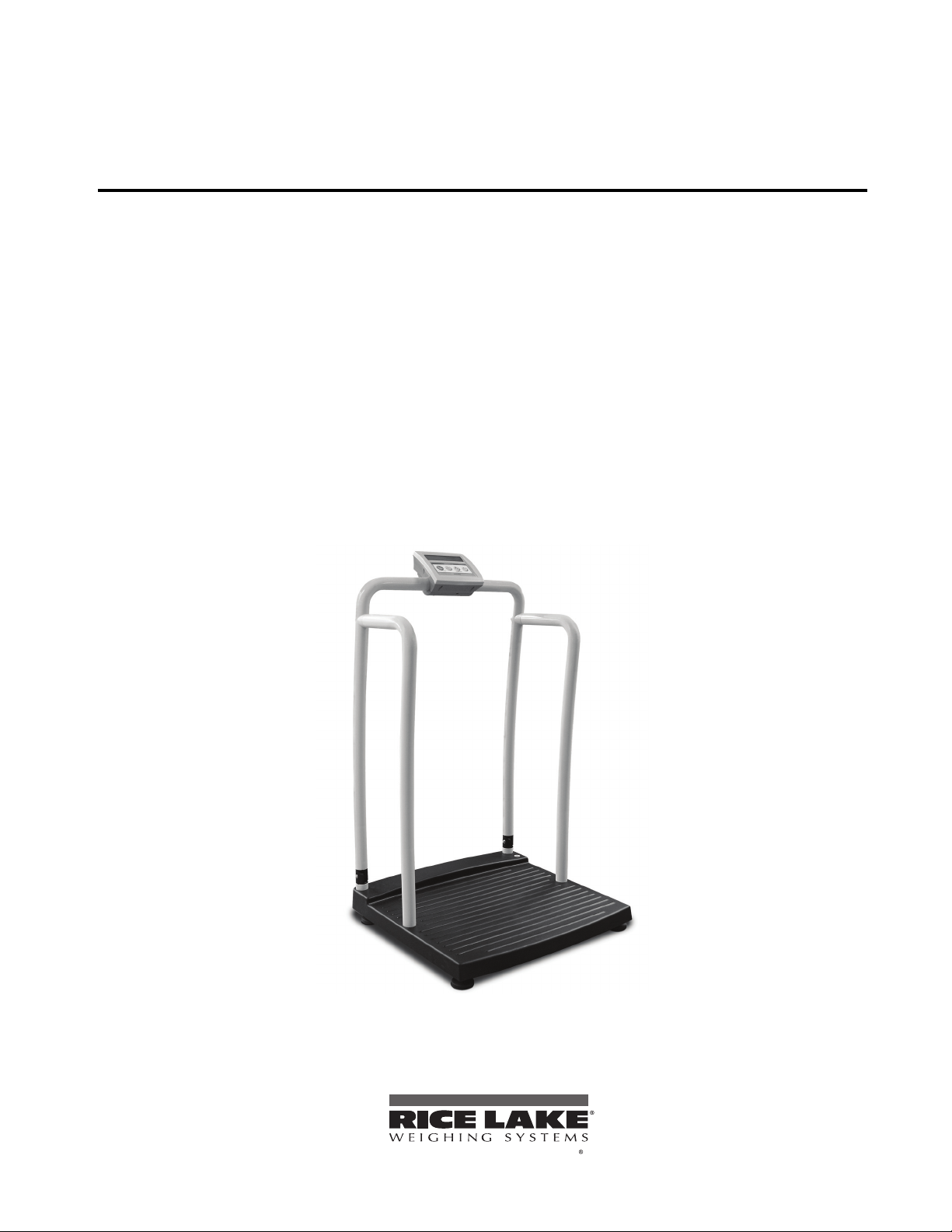

Digital Handrail Scale

To be the best by every measure

240-10 Series

Software Revision 11387

Technical and Operating

Instructions

118594

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com or obtained

by calling 715-234-9171 and asking for the training department

1.0 Introduction.................................................................................................................................. 1

2.0 Scale Assembly ........................................................................................................................... 2

2.1 Unpacking Your Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Repacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Setting Up Your Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Getting Ready to Weigh a Patient . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.0 Scale Operation ........................................................................................................................... 4

3.1 Weighing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Using the Body Mass Index (BMI) Function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.3 Using the Tare Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.0 Scale Configuration ..................................................................................................................... 7

4.1 Enabling Configuration or Calibration Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.3 Numeric Data Entry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.4 Reset To Factory Defaults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.0 Scale Calibration ....................................................................................................................... 13

6.0 RS-232 Communication............................................................................................................. 14

6.1 Pushbutton Keypad Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.2 Standard Remote Protocol (configuration option #9 set to 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.3 ESC Protocol (configuration option #9 set to 0) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.4 Sample and Explanation of ESC Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

. . . . . . . 2

. . . . . 2

. . 3

. . . . . 6

. . . . . 7

. . . . . 8

. . . 12

7.0 Troubleshooting and Testing ..................................................................................................... 20

7.1 Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

8.0 Maintenance .............................................................................................................................. 23

8.1 Basic Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

8.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . 23

Handrail Scale Specifications............................................................................................................... 24

For More Information ............................................................................................................................. 25

Digital Handrail Scale Limited Warranty

............................................................................................... 26

© 2010 Rice Lake Weighing Systems. All rights reserved. Specifications subject to change without notice.

Series 240-10, Software revision 11387

November 2010

Page 4

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

ii Handrail Scale Technical and Operating Instructions

Page 5

1.0 Introduction

The Rice Lake Digital Handrail Scale is designed for weighing bariatrics and ensures sound, accurate weighing

information. A non-skid platform paired with side rails assists persons who need extra support and safety. The

scale is set up to use motion sensing weighing technology, to determine the actual weight of a moving patient.

The weights is displayed on the indicator and can be displayed in pounds or kilograms.

This manual can be viewed and downloaded from the Rice Lake Weighing Systems web site at

www.ricelake.com/health. Rice Lake W

eighing Systems is an ISO 9001 registered company.

Figure 1-1. Digital Handrail Scale

1

Page 6

2.0 Scale Assembly

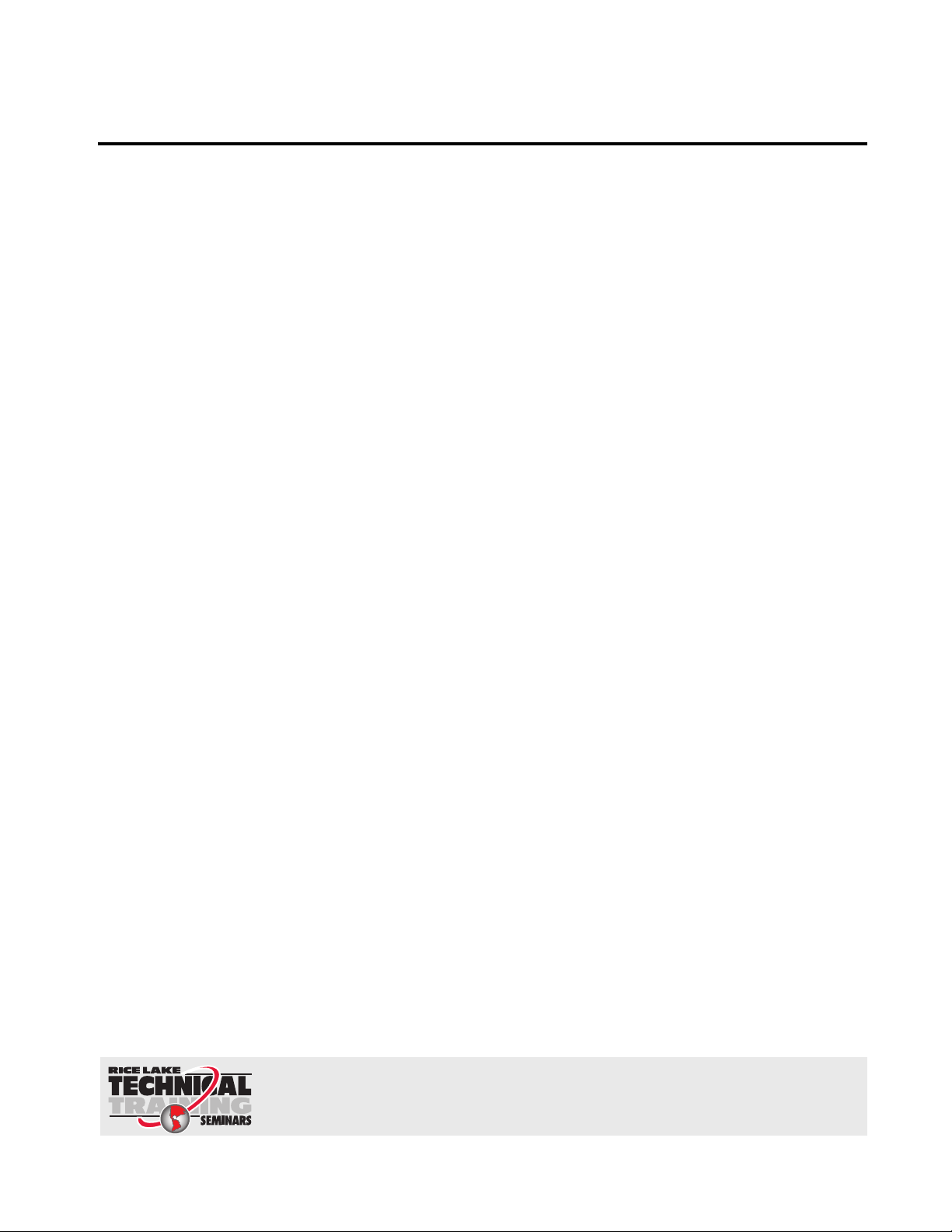

Unfold handles

and set upright

2.1 Unpacking Your Scale

Place the unopened box in an open area that has ample room for unpacking the scale.

Parts contained in the shipping box include:

• The scale

• This manual

• Small box containing AC adaptor and RS-232 cable

• 6 mm Allen Key

2.2 Repacking

If the Digital Handrail Scale must be returned for modification, calibration or repair, it must be properly packed

with sufficient packing materials. Whenever possible, use the original carton when shipping the scale back.

NOTE: Damage caused by improper packaging is not covered by the warranty.

2.3 Setting Up Your Scale

Use the following steps to set up the Digital Handrail Scale.

1. Locate the operation manual from inside the box and set aside as i

proper set up.

2. Using two people, remove the scale out of the packaging material that

of the box by the scale base.

NOTE: DO NOT lift the scale out of the box by its handle as this can cause the hinges to break.

3. Move the scale into the area where the weighing process will occur. It’s recommended to place the scale

on a hard, level surface for the most accurate weighments. Thin carpeting is fine but not recommended.

4. Gently set the scale platform down to the floor

5. Loosen the handles using the Allen key and unfold handles and set upright.

.

t will provide instructions on the

it came in by lifting the scale out

Figure 2-1. Set Up Sides to a Vertical Position

6. Adjust the feet to ensure that the base of the scale base is not touching the floor.

7. Screw in all four legs

8. Attach the wrap around rails.

9. Tighten the hex screw head using the enclosed 6 mm Allen key to stabilize the sca

2 Handrail Scale Technical and Operating Instructions

le.

Page 7

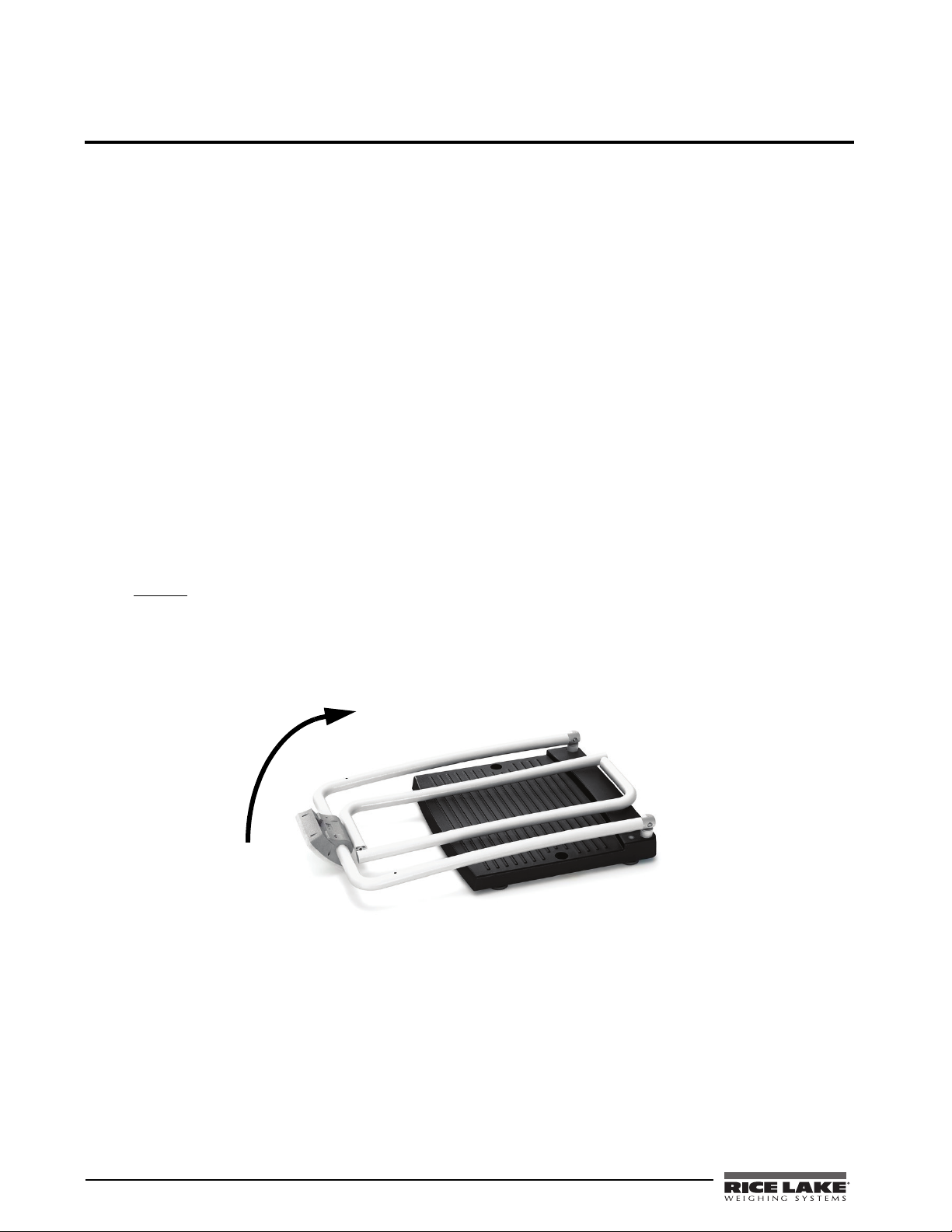

AC Power Connections

Connect the AC power

source here

LED indicator light

illuminates from red to

green when charged

Store the 120 VAC

adaptor here when

not in use

RS-232 port

connection

Store the 230 VAC

adaptor here when

not in use

Back cover to

indicator

Retaining Screw

The Digital Wheelchair Scale has a 120 VAC adaptor or 230 VAC adaptor to use when power is readily available.

The AC power adaptor plugs into the back of the indicator as shown in Figure 2-2.

Figure 2-2. LED Light Location

.

The AC adaptor, when not in use, plugs into the back housing of the indicator for storage. Figure 2-2 shows that

location.

The Digital Wheelchair Scale is capable of running its internal sealed lead-acid rechargeable battery if no

additional power source i

s available. Battery life is approximately 75 hours. If the

LO Bat indicator is showing on

the display, recharge the battery or connect the scale to an AC power source as soon as possible for accurate

weighing.

Battery Charging

When the AC adaptor is connected to a power source, the rechargeable battery goes into recharge mode.

NOTE: To maintain battery longevity we recommend you charge it on a regular basis rather than waiting until it is fully

discharged.

The LED indicator light on the back of the scale housing will illuminate red during the charging period, and

change over to green when the battery becomes fully charged.

Connect the load cell into the load cell connection point. You will he

Put the back on the indicator and secure with the four back cover screws that were previously set aside.

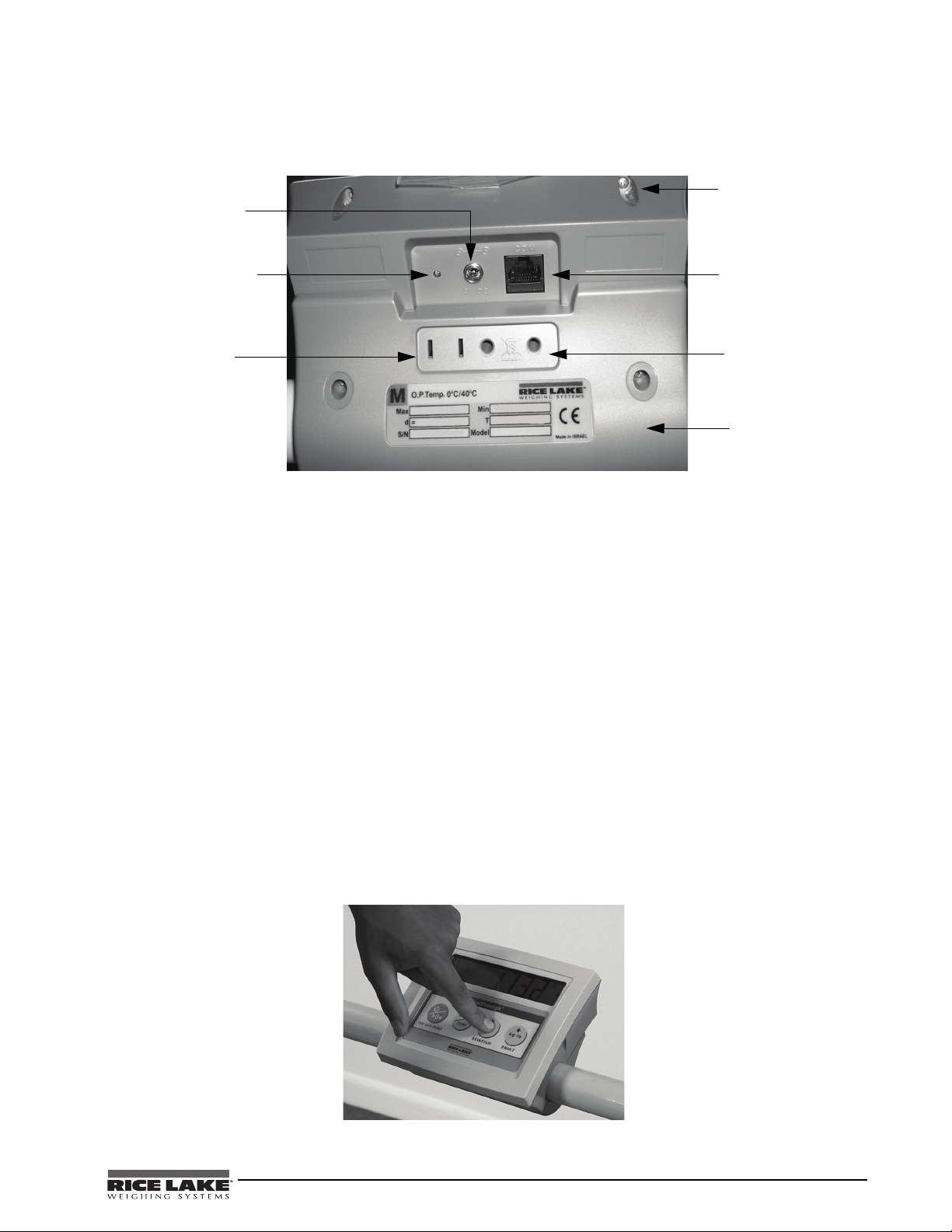

2.4 Getting Ready to Weigh a Patient

Once the scale is properly unpacked and set up, and prior to weighing a patient, step on the scale to check the

scale that all functions are working correctly. The scale is calibrated from the factory so simply turn on the scale

and step on the scale to get a weight reading. Press the

ar a "click" affirming a secure connection.

REWEIGH key again to verify that weight.

Figure 2-3. Press the Reweigh Key to Verify Weight

Handrail Scale Technical and Operating Instructions - Scale Assembly 3

Page 8

3.0 Scale Operation

#AUTION

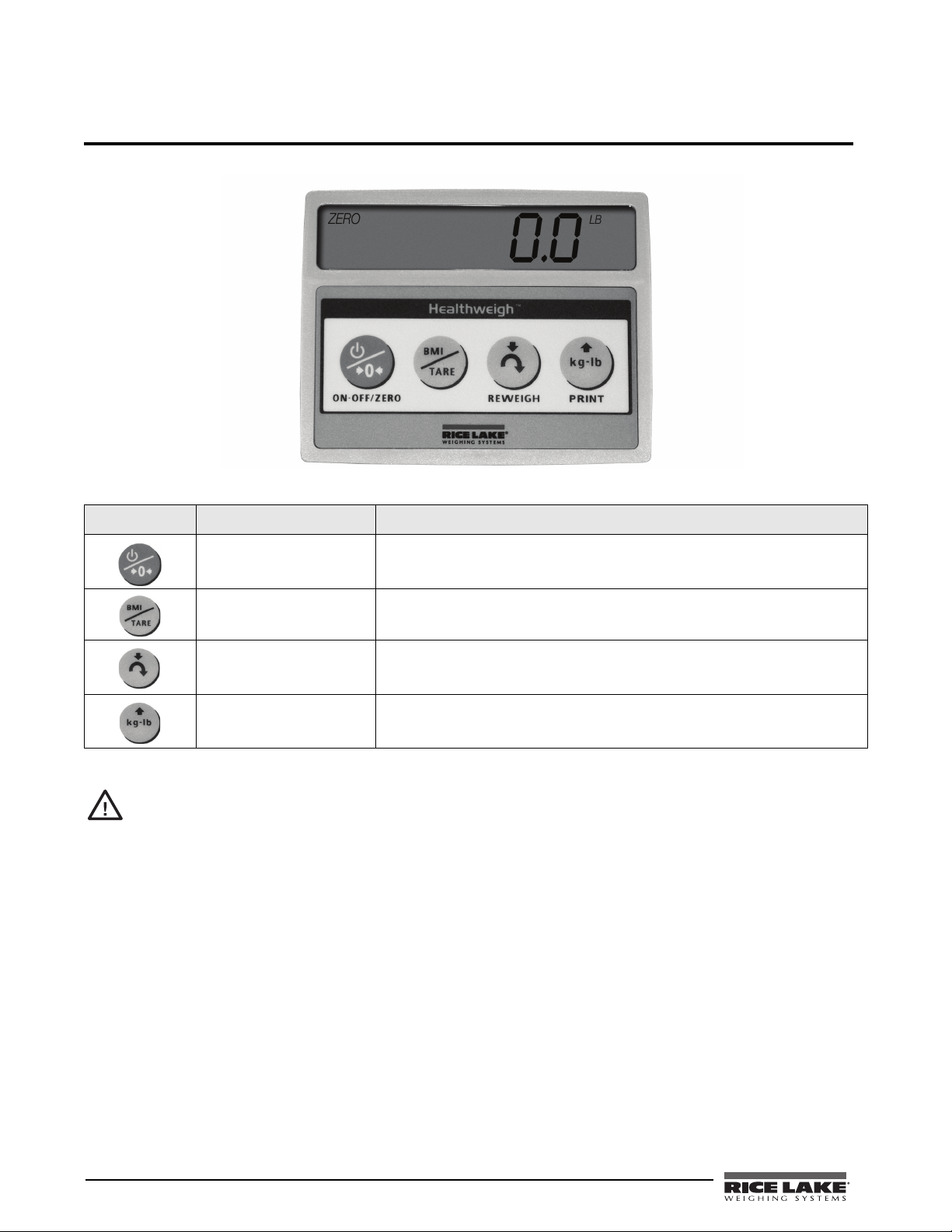

The display has various front panel keys. They are shown below.

Figure 3-1. Front Panel Display Keys

Key Name Function

ON-OFF/ZERO ON-OFF - Switches the scale on or off

ZERO - Clears weight off the scale and returns it back to zero.

BMI/TARE BMI - Enables the user to access the BMI (Body Max Index) function.

TARE - Used to subtract a weight off the scale ie: wheelchair

REWEIGH Allows you to reweigh a patient without having them leave the scale.

Kg-Lb/PRINT Allows the user to toggle between kilograms and pounds.

Press this key to print a weight if connected to a printer.

Table 3-1. Key Functions

The keys on the front panel display are very sensitive so only a gentle pushing motion is required to

obtain results.

The scales have the capability of performing different operations beyond just calculating

weight. The various operating instructions are described below.

3.1 Weighing

Use the following steps to weigh a person.

1. Press the

2. Ask the patient or person to step onto the scale. The

beeps to indicate the end of the weighing process.

3. To reweigh, press the

4. To change the display from Kg to Lb and vice

5. If the display hold feature is on (OP6=1), the weight will remain on the display

steps off the scale. To clear the weight, press the

6. To turn off the scale, press and hold the

On-Off/Zero key to turn on the scale and 0.0 will appear on the display.

display shows WEIGH, then the person’s weight, and

REWEIGH key.

-versa, press the Kg-Lb key.

On-Off/Zero key.

On-Off/Zero key until OFF appears on the display.

even after the patient

4 Handrail Scale Technical and Operating Instructions

Page 9

3.2 Using the Body Mass Index (BMI) Function

Body mass index (BMI) is the relationship between weight and height associated with body fat and health risk. It

is a reliable indicator of body fatness for people and even though BMI does not measure body fat directly,

research has shown the BMI correlates to direct measures of body fat. BMI is an inexpensive and

easy-to-perform method of screening for weight categories that may lead to health problems for adults.

Calculating BMI is one of the best methods for population assess

calculation requires only height and weight, it is inexpensive and easy to use for clinicians and for the general

public. The calculation is based on the following formulas:

Calculate BMI by dividing weight in pounds (lbs) by height in inches (in) squared and multiplying by a

conversion factor of 703.

Ex

ample: weight = 150 lbs, height = 5’5 (65")

2

Calculation: [150

÷ (65)

] x 703 = 24.96

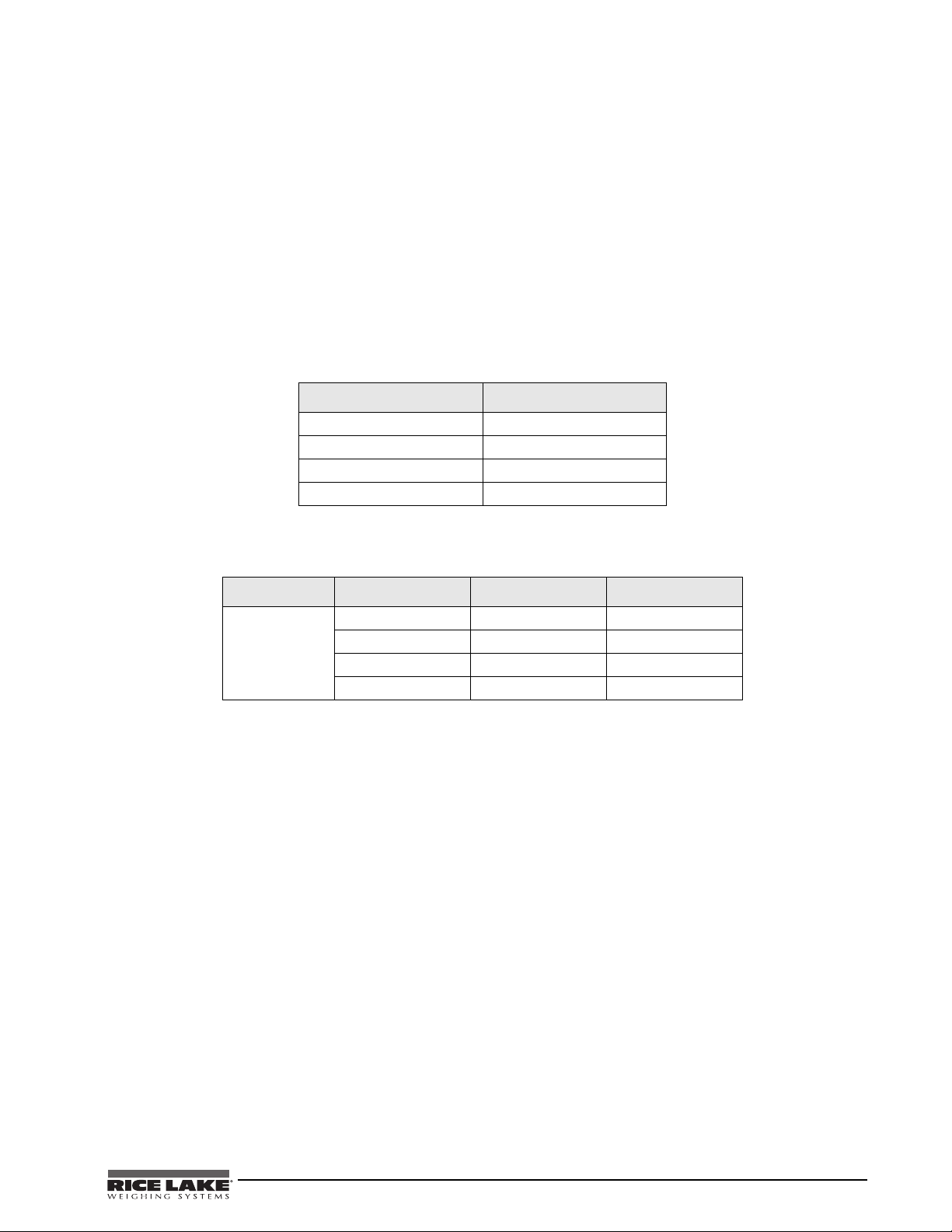

The standard weight status categories associated with BMI ranges for adults a

BMI Weight Status

Below 18.5 Underweight

18.5 - 24.9 Normal

25.0 - 29.9 Overweight

30.0 and Above Obese

Table 3-2. Standard Weight Status

The following examples show weight ranges, the corresponding BMI ranges and the weight status categories for

a sample height.

ment of overweight and obesity. Because

re shown in the following table.

Height Weight Range BMI Weight Status

5’9” 124 lbs or less Below 18.5 Underweight

125 lbs to 168 lbs 18.5 to 24.9 Normal

169 lbs to 202 lbs 25.0 to 29.9 Overweight

203 lbs or more 30 or higher Obese

Table 3-3. BMI Ranges and Weight Status Example

Use the following steps in determining the BMI.

1. To use the BMI function, weigh the patient as described under Weighing (above)3.1 and then press the

BMI key. If weighing in Lbs, the default height of (5 feet) appears on the display. Use the up or down

arrows to increase the feet height by one foot increments). Press the

BMI key again to display inches

(default is 7.0 inches) Again, use the up or down arrows to increase or decrease the inches height by 0.5"

increments. Press the

BMI key again to accept the inches value. The final height value will be displayed

ie: 5-07.5 = 5’ 7.5".

2. If you are weighing in Kgs, the default will be 170.0 cm. Use the up or down arrows to increase

decrease by 0.5 cm increments.

3. To see the patient’s calculated BMI, press the

4. To cancel the BMI display, press the

BMI key.

BMI key again. The BMI appears.

or

Handrail Scale Technical and Operating Instructions - Scale Operation 5

Page 10

3.3 Using the Tare Function

You can use the tare function for deducting an extra weight (such as a wheelchair, or medical equipment attached

to the patient) in a weighing operation.

Use the following steps to use the

1.

With the scale set to

of the load.

2. Press and hold the

appears on the left side of the display.

3. Remove the load from the scale. The weight of the load appears with

4. Ask the patient to step onto the scale with the load. The displa

the weight of the load.

5. The weight of the load remains sto

carrying the same tare weight. For example, when using the same wheelchair for weighing more than

one patient.

6. To cancel the tare weight, press and hold the

weight is also cancelled when the scale is turned off.

Use the following steps to enter a tare without

you’ve got a patient in a wheelchair and the wheelchair has a known weight (has been tagged) you can enter that

weight manually.

1. With the scale set to

alternate between a value and the word TARE .

2. To change the value, press and hold the

value you want. Example: If you want 103.5, hold the key until the display is

3. To advance to the next digit, press the

the right most digit will again be 0. Again, hold the Kg/Lb key until the right most digit is equal to the

next digit in the numbers you want.

4. Continue as in Step 3 until you are displaying the value you want, then press the

5. You can now accurately weigh the patient.

6. To cancel the tare weight, press and hold the

weight is also cancelled when the scale is turned off.

tare function.

0.0, place the extra load on the scale. The display shows WEIGH and then the weight

TAR E key until TARE appears on the display. The display returns to 0.0 and TARE

a negative symbol to the left of it.

y then shows the patient’s weight without

red in memory, so you can continue to weigh patients who are

TAR E key until TARE disappears from the display. The tare

placing that item on the scale. An example of this would be if

0.0 Lbs (there must be no weight on the scale), press the TAR E key. The display will

Kg/Lb key until the right most digit is equal to the first digit of the

0.1.

Kg/Lb key twice quickly. The digit you changed will move left and

TARE key.

TAR E key until TARE disappears from the display. The tare

6 Handrail Scale Technical and Operating Instructions

Page 11

4.0 Scale Configuration

Remove retaining screws x 4 (only 2 shown)

Remove jumper to gain access to configuration

and calibration modes

Options and parameter setup are done through the scale configuration section and is used for setting values and

various parameters and options that are essential for the functioning of the system. Entry into this mode is

possible only when the scale is turned off.

4.1 Enabling Configuration or Calibration Modes

Before the scale will enter either the Configuration or Calibration mode, the configuration enable jumper must be

removed.

ator.

Access to that jumper is gained by removing the back cover of the indic

retaining screws as shown on the left side of Figure 4-1. With the cover removed, the jumper can

through the hole in the rear ho

using (shown in Figure 4-1 - right side). Remove that jumper to gain access to the

configuration and calibration modes.

Remove the four back cover

be seen sticking

Figure 4-1. Gain Access to the Configuration/Calibration Enable Jumper on the Back of the Indicator

After configuration or calibration is done, the jumper must be replaced for normal scale operation.

NOTE: A display of Con En indicates that the jumper is not in place. Put jumper on both pins to return the scale to

normal weigh mode.

4.2 Configuration Mode

To get into the configuration mode, turn the scale off and remove the configuration jumper as shown in

Figure 4-1. Turn the scale on. While

display.

To change from one parameter to the next, press the

To change the value of the parameter, use the

From the

seconds followed by

SAVE phase: to save the configuration data, press the REWEIGH key. DONE appears for one or two

Start and the display enter into weighing mode and is ready to start the weighing process. To

exit with saving changes, press the

Start is displayed, press and hold the Kg-Lb key until IDENT appears on the

REWEIGH key once.

Kg-Lb key.

Lb/Kg key.

Handrail Scale Technical and Operating Instructions - Scale Configuration 7

Page 12

Various parameters can be set up while in configuration mode.

Power Off

Power On-Off

START Kg-Lb Key

0.000

Software Version

Round xx

Full xxx

At

Press and

hold

OP1=X

SAVE

T-OFFX

DONE

OP2=X

OP4=X

OP3=X

OP5=X

OP7=X

OP6=X

OP8=X

Press and

hold the

Kg-Lb key

to advance

to option

2 through

option 8.

= DEF =

A TOLXX

Drange

A LEN X

MESS

A TImE XX

BAUD XX

Software ID

SET=X

OP9=X

OP10=X

GRAV x.xxxx

Figure 4-2. Configuration Mode Menu Structure

4.3 Numeric Data Entry

Use the Kg-Lb key to change the numeric data entry while setting up the various configuration parameters and

while in calibration mode.

Use the following steps:

1. Press and hold the

2. Release the

3. A double click on the

4. Repeat steps 1-3 until the desired number is reached.

Kg-Lb key, the rightmost digit on the display will begin to increment.

Kg-Lb key to stop the increments.

Kg-Lb key will cause the right hand digit to move one place to the left.

8 Handrail Scale Technical and Operating Instructions

Page 13

The following table lists the various display messages and sequence when setting up the scale.

NOTE: <-> means the display toggles between the two values.

Step Function Display Available Parameters

1 With the scale turned

off, r

emove the

confiiguration jumper

as shown in

Figure 4-1.

2 With the scale turned

off,

simultaneously

press the On-Off/

Zero an

3 Indentifies the

4 Identifies software

5 Allows selection of

6 This indicates the

7 This limit defines the

8 Display divisions rOUnd<->XXXX

9 Double ranges limit drAnGe <-> 0 This parameter is preset from the

10 Weight algorithm initial

11 Weight algorithm initial

12 Weight algorithm

d Kg-Lb key.

Enters into

programming m

e

softwar

version

point setting

decimal

mum

maxi

weight. Any weight

above this value will

cause StOP to appear

e displa

on th

the weighing mode.

start of the weighing

threshold to

compensate for a key

press during the Tare

function.

leran

ce

to

expone

nt

maximal expone

ode

ID

allowed

y while in

nt

StArt Scale automatically advances to Step

IdEnt<->11007 Press the REWEIGH key to advance

Id<->11387 Press the REWEIGH key to advance

dOt<->000.0

Default = 0.0

FULL<->XX.XXX

Default= 6

No

dependent on the model you

have. Refer to the serial

number label on your scale

and set appropriately.

Limit <->0.0 Use the numeric data entry (See

Default = 0.2 Lb

A tOL <-> 10 This parameter is preset from the

A LEn <-> 8 This parameter is preset from the

A t INE <-> 10 This parameter is preset from the

00 Lb

te: This value is

Allows the scale to enter into either

configuration or calibration mode.

3.

to the next step.

th

e next step.

to

To change the position of the decimal

point, press the Kg-Lb key to toggle

through the various options. To

advance to the next step, press the

REWEIGH key.

Use the numeric data entry (See

“Numeric Data Entry” on page 8.) to

change the value. T

next step, press the REWEIGH key.

“Numeric Data Entry” on page 8.) to

see optimum weight value of 5 lbs. To

advance to the next step, press the

REWEIGH key.

To change the display divisions, press

e Kg

-Lb key to toggle through the

th

ous options.

vari

0.2, 0.5, 1.0, 2.0, 5.0, 1

To advance to the next step, press the

REWEIGH key.

ctory

. To advance to the next step,

fa

press the REWEIGH key.

factory. To advance to the next step,

press the REWEIGH key.

factory. To advance to the next step,

press the REWEIGH key.

factory. To advance to the next step,

press the REWEIGH key.

o advance to the

0.0, 20.0.

Table 4-1. Configuration Mode Menu

Handrail Scale Technical and Operating Instructions - Scale Configuration 9

Page 14

Step Function Display Available Parameters

13 Message style on

weight algorithm

14 This allows for setting

e baud rate of the

th

RS-232 connection

15 Optional features

Option 1 allows the

ction of unit of

sele

measure (UOM) in

calibration and

programming.

Option 2 allows the

e to work onl

scal

Kg.

Option 3 allows the

scale to work onl

Lb.

Option 4, the scale

be stable to

must

show a Kg or Lb

weight reading. You

can enable or disable

this.

MESS <-> WEIGH This displays the message that will

show on the indicator display. To

change the message, press the Kg-Lb

.

key

WEIGH,

LIVE,

- - - - - To advance to the next step, press the

REWEIGH key.

BAUd <->

Default - 9600

OP1 = 1 Hold the Kg-Lb key for browsing

OP2 = 0 Hold the Kg-Lb key for browsing

y in

OP3 = 0 Hold the Kg-Lb key for browsing

y in

OP4 = 0 Hold the Kg-Lb key for browsing

To change the baud rate, use the

numeric data entry (See “Numeric Data

Entry” on page 8.)

To advance to the next step, press the

REWEIGH key.

r

ough the options. Double click on

th

the Kg-Lb key to change the options

value or

to advance to the next step, press the

REWEIGH key.

OP1 = Unit of measure (UOM) in

calibration and pro

0=Kg

1=Lb

through the options. Double click on

the Kg-Lb key to change the options

value or

to advance to the next step, press the

REWEIGH key.

0=Disable

1= Enable

This option works only if Option 3 is

a

bled

dis

through the options. Double click on

the Kg-Lb key to change the options

value or

to advance to the next step, press the

REWEIGH key.

0=Disable

1=Enable

through the options. Double click on

the Kg-Lb key to change the options

value or

to advance to the next step, press the

REWEIGH key.

0=Disable

1=Enable

Note: won’t show lb or kg until the

scale is at a standstill.

gramming.

Table 4-1. Configuration Mode Menu

10 Handrail Scale Technical and Operating Instructions

Page 15

Step Function Display Available Parameters

Option 5 allows for live

or dynamic weighing

Option 6 allows you to

either enabl

disable the hold

function on the scale

Option 7 allows you to

either enabl

disable the baby scale

function.

Option

choose between 9

lts and 6 volts

vo

Option

select the

communi

protocol.

Option 10 allows you

to ena

menu.

e or

e or

8 allows you to

9 allows you to

cations

ble the user

OP5 = 0 Hold the Kg-Lb key for browsing

through the options. Double click on

the Kg-Lb key to change the options

value or

to advance to the next step, press the

REWEIGH key.

0=Disable

1=Enable

OP6 = 1 Hold the Kg-Lb key for browsing

through the options. Double click on

the Kg-Lb key to change the options

value or

to advance to the next step, press the

REWEIGH key.

0=Disable

1=Enable

OP7=0 Hold the Kg-Lb key for browsing

through the options. Double click on

the Kg-Lb key to change the options

value or

to advance to the next step, press the

REWEIGH key.

0=Disable

1=Enable

Note: L

OP8 = 1 Hold the Kg-Lb key for browsing

through the options. Double click on

the Kg-Lb key to change the options

value or

to advance to the next step, press the

REWEIGH key.

0=9 volts

1=6 volts

Note: L

OP9 = 1 Hold the Kg-Lb key for browsing

through the options. Double click on

the Kg-Lb key to change the options

value or

to advance to the next step, press the

REWEIGH key.

0= escape

1= standard protocol

OP10 = 1 Hold the Kg-Lb key for browsing

through the options. Double click on

the Kg-Lb key to change the options

value or

to advance to the next step, press the

REWEIGH key.

0= enable

1= disable

eave set to 0

eave set to 1

Table 4-1. Configuration Mode Menu

Handrail Scale Technical and Operating Instructions - Scale Configuration 11

Page 16

Step Function Display Available Parameters

16 Set Option defaults Set < - > 1 To change, press the Kg-Lb key.

0 - default

Options = (OPx)

1 = US default (US defaults

OP1-1, OP2-0, OP3-0, OP4-0, OP5-0,

OP6-1, OP-7-0, OP8-1, OP9-1,

OP10-1).

2 = European 1 default

3 = European 2 default

9 = Used if OP1 through OP10 have

chan

been

the factory default settings.

Note: Always se

indicators. To advance to the next

step, press the REWEIGH key.

17 Determines the

automati

time when the scale is

not in use. Options are

between one and 20

minutes.

This is used when the

un

operated.

18 StArt or SAvE If no changes were made in the

19 Con En

c shut off

it is battery

t-OFF <-> 5 Press and hold the Kg-Lb key to scroll

thr

the display (0-9). If you want a value

from 10 to 19, with the display sitting

at 1, double press the Kg-Lb key and

10 appears. Press and hold the Kg

key

want a value of 20, with the display

sitting at 2, double press the Kg-Lb

key and 20 will appea

To advance to the next step, press the

REWEIGH key.

para

automatically show StArt and then

returns to normal weighing mode.

If a parameter was changed, the

disp

changes made, press the REWEIGH

key.

saving changes, press the Kg-Lb key.

Replace the configuration jumper.

ged to something other than

t to 1 or 9 for US

ough the furthest right hand digit on

to begin scrolling 10-19. If you

meters the

lay will show SAvE. To s a v e

To return to weigh mode without

display will

are

r.

-Lb

Table 4-1. Configuration Mode Menu

4.4 Reset To Factory Defaults

The configuration parameters may be reset to factory defaults while in the configuration mode. To do so, enter

the configuration mode. Press the

11305). Press and hold the

function, press the

REWEIGH key and the scale will show DONE, then it will restart. If you do not want to perform

BMI key until =DEF= is displayed. At this point, if you wish to perform the default

the default function, press the

After performing the default function, the scale will require

up to a capacity of 600 lbs. The capacity varies by model - refer to the serial label on your scale and

reconfigure the capacity (FULL) and display divisions (rOUnd) as necessary in the configuration menu.

12 Handrail Scale Technical and Operating Instructions

REWEIGH key once to advance to displaying the software version (ID <->

ON/OFF key.

re-calibration. In addition, the scale will be set

Page 17

5.0 Scale Calibration

Before you can calibrate the scale, verify and set all scale parameters which are noted in “Scale Configuration”

on page 7.

Remove the configuration/calibration jumper (see page 7).

hold both the

Kg-Lb key and the REWEIGH keys until CAL is displayed.

To do a calibration on the scale, the scale must be turned off.

NOTE: The calibration weight must be no less than 60 lb (28 kg) and no more than 300 lb (135 kg).

The following chart illustrates the calibration procedure.

Step Function Display Available Parameters

Turn the scale on. While StArt is displayed, press and

1 Turn the scale on.

While START is

displayed, press and

hold t

he Kg-Lb and

REWEIGH keys until

CAL is displayed.

2 Cal mode entered CAL To advance to the next step, press the

3 Sets the value of the

4 CLEAr Clear the platform and be sure of the

5 Calibrate Zero - - - - -

6 Calibrate Span CAL

7 SAvE To save the new calibration, press the

8 dONE The scale displays that it has saved that

9 StArt The scale reboots.

10 Con En Replace the configuration jumper.

Enters into calibration

mode

bra

tion weight

cali

you are going to use

for calibrating the

span value of the

scale.

StArt The scale automatically advances to

Step 2.

REWE

IGH key.

LOAd <-> XXX.X Use the numeric data entry (explained in

“Numeric Data Entry” on page 8) to set a

calibration weight.

To advance to the next step, press the

REWEIGH key.

e’s stability.

scal

To advance to the next step, press the

REWEIGH key.

Place the requested weight on the scale.

will di

PUT<->XXXX

FAC tOr <-> X.XXX

This

To advance to the next step, press the

REWEIGH key.

This will be displayed for a few seconds

and shows

To advance to the next step, press the

REWEIGH key.

REWEIGH key.

To exit without saving the calibration

ess the ZER

pr

ibration va

cal

advances to the last step.

splay for a few seconds.

the cu

rrent calibration factor.

O key.

lue and automatically

Table 5-1. Calibration Menu

Handrail Scale Technical and Operating Instructions - Scale Calibration 13

Page 18

6.0 RS-232 Communication

The scale comes with an RS-232 port which enables weight data to be transmitted to other equipment, such as a

computer or printer. The RS-232 cable with DB-9 connector (PN 100719) is available from Rice Lake Weighing

System. Figure 2-2on page 2 shows where the RS-232 connection is.

The RS-232 parameters are 9600 baud (selecta

and no handshaking.

There are three methods of communication:

• Pushbutton keypad print

• Standard remote protocol

• Escape protocol

6.1 Pushbutton Keypad Print

With a stable, in-range weight, press and hold the Kg-Lb/Print key for at least three seconds, or until the scale

emits two quick beeps. Note that if the scale does not beep after five seconds, then release the button as the

weight was either in motion, or out of range.

• If displaying weight and not BMI, the scale will send

xxxxxxxxx<SP>uu<SP>mmmm

Where:

xxxxxxxxx is the weight with decimal point and " - " si

mmmmm is the mode (gross or net)

Examples:

-10 Lb net = <SP><SP><SP><SP>-10.0<SP>lb<SP><SP>Net<SP><SP><SP><CR><LF>

10 Lb gross = <SP><SP><SP><SP><SP>-10.0<SP>lb<SP>Gross<SP><CR><LF>

m<SP><CR><LF>

ble in the programming mode), 8 data bits, 1 stop bit, no parity

out the following 21 character string:

gn, if negative uu is the unit (lb or kg).

• In BMI mode (displaying the BMI value), the scale will send out the following data:

GROSS WEIGHT 215.0 LB

TARE WEIGHT 0.0 LB

NET WEIGHT 215.0 LB

PATIENT HEIGHT 6-01.0 FT

PATIENT BMI 28.4

6.2 Standard Remote Protocol (configuration option #9 set to 1)

When connected to a computer, there are five commands that can be used in the standard remote protocol to

communicate with the scale. They are:

• t - tare the scale. If in gross mode, will tare and go to ne

return to gross mode.

• w - the scale sends the actual weight to the computer.

• i - the scale sends the software ID of the scale.

• z - the scale will be set to zero (0.0) if possible.

• p - the scale sends the same data as a pushbutton keypad print.

The format of the returned data will be the same as noted un

p commands will not return a value if the scale is in motion, or displaying an invalid weight.

t mode. If in net mode, will remove tare and

der the pushbutton keypad print. Note that the w and

14 Handrail Scale Technical and Operating Instructions

Page 19

6.3 ESC Protocol (configuration option #9 set to 0)

The ESC Protocol differs from the standard protocol and enables weight and unit of measure data to be

transmitted for full integration into electronic medical records or for diagnostic testing of the battery life, load

cells, etc. The scale will only transmit data upon receiving the proper command set.

You can test the command set and review the scales’ response using either PROCOMM Plus or the Dietary/

Fitness files found on our web

set up "hot" keys for the commands. Refer to Table 6-1 for a listing of those commands.

An Escape Protocol is where the escape <ESC> is used to indicate that there is a c

data.

Table 6-1 lists a complete list of ESC commands that are used with the scale

site, www.ricelake.com/health. If using PROCOMM Plus, we recommend you

ommand following and not just

.

Command/

Response ESC Character

Reading R R This value tells the PC that the scale is sendin

Weight W Wnnn.n This is the patient’s weight (ie: W0200.5

Units N Nc This indicates in which unit the values have been taken (m=metric,

Packet

End of

OP

)

(E

Diagnostics

est)

(requ

Diagnostics

onse)

(resp

Control (set a

)

value

E E This indicates that the end of the command/data packet has been

A Accc This is the request for a diagnostic test on certain parts of the scale

Z Zccc This will be the response to the diagnostics done on the scale. Values

C Cccc=c This is to set the value of the scale’s global settings

ESC value with

Parameters

Description

g a reading. Immediately

following this will be the value that is sent

Example: <ESC>R<ESC>E

<ESC>R<ESC>W0200.5<ESC>Nm<ESC>E

means 200.5 lb). If t

overloaded, the scale will return the value of 999.9.

c=constitutional

reached

such as the battery life, loadcells, etc.

• AD value (ADC) = E06=AD is too high, E07=AD is too low

• Overload (OVL) = E10

• Battery (BAT) = E4U= (Bat ok) or E4L (Bat Low, but still usable - 1

bar le

ft on the indicator

• Calibration information OK (CAL) = E11=Calibration was not okay

an

d the user needs to recalibrate.

will include any error codes to indicate what is wrong with the scale, or

all zeros (Z000) to indicate that all is well.

<ESC>CUOM=m<ESC>E will set the unit of measurment to KG

• Unit of measurement (metric or constitutional) (UOM) = c (m or c)

he scale is

Table 6-1. RS-232 Communication Parameters

If you’re using the Rice Lake files, please follow the instructions below.

1. Go to www.ricelake.com/health and download

the Rswin.exe and Inbar.ini files located in the downloads

section of the web site and download them to your computer.

2. Ensure that the scale is connected to the computer via RS-232 cable.

Handrail Scale Technical and Operating Instructions - RS-232 Communication 15

Page 20

3. Double click on the Rswin.exe file and the following screen appears.

Click on FILES

and in dropdown

menu, select

LOAD

CONFIGURATION

as noted in Step 4

Figure 6-1. Rswin Screen

4. Click on FILES and in the dropdown menu, select LOAD CONFIGURATION. At this time double click on the

file, Inbar.ini.

5. Click on

STRINGS and the following screen appears.

6. Click on

16 Handrail Scale Technical and Operating Instructions

Figure 6-2. Strings to be Used in the RS-232 Transmission

This screen is showing that the function keys are already pre-programmed with command sets. For

example, pressing the

DISPLAY and in the drop down menu, select either HEX or ASCII.

F1 key is the same as sending <ESC>R<ESC>E.

Page 21

Examples of what you would see in the HEX screen are shown in Figure 6-3.

Figure 6-3. HEX Screen Example

Examples of what you would see in the ASCII screen are shown in Figure 6-4.

Figure 6-4. ASCII Screen Example

6.4 Sample and Explanation of ESC Protocol

When the scale measures weight and sends this over the communications line to the PC, the string will look like

this.

<SCALE> --------<PC>

Handrail Scale Technical and Operating Instructions - RS-232 Communication 17

Page 22

&4$3&4$&

3FBEJOH

SFRVFTU

&01

3#!,%0#

&01

6OJUPG.FBTVSF.FUSJD

&4$3&4$8&4$/N&4$&

3FBEJOH

$PNNBOE

8FJHIU

3#!,%0#

DIRECTIONOFCOMMUNICATION

When the user wants to diagnose any problems with the scale, the operator will have to ask the scale to send the

&4$"#"5&4$&

%JBHOPTFCBUUFSZ

&01

3#!,%0#

DIRECTIONOFCOMMUNICATION

&4$;&6&4$&

#BUUFSZJTPLBZ

OPFSSPST

&01

3#!,%0#

DIRECTIONOFCOMMUNICATION

error data (if any exists). This is done with the Diagnostics (request) command and will look like this:

If the battery is okay, the scale will reply with the following value:

18 Handrail Scale Technical and Operating Instructions

Page 23

If the battery is critically low, it will reply with:

&4$;&-&4$&

#BUUFSZJTWFSZMPX

6OTUBCMF

&01

Handrail Scale Technical and Operating Instructions - RS-232 Communication 19

Page 24

7.0 Troubleshooting and Testing

Refer to the following instructions to check and correct any failure before contacting service personnel.

Symptom Possible Cause Corrective Action

Scale does not turn on Dead battery Connect the scale to a power source.

Faulty electrical outlet Use a different electrical outlet.

Bad power supply Replace adaptor.

Questionable weight or the scale

ot zero

es n

do

Weighing is performed but the display

shows WEIGH and REWEIGH every

seconds; the weighing process

few

takes too long and no weight is

displayed

The display shows a STOP message The load on the scale exceeds the

The display shows LO Bat message The battery is low Recharge the battery.

The display shows Err messag

detailed in the table

Err 2 Low saturation state (low A/D) The load cell is not connected properly. Check

Err 3 High saturation state (high A/D) See Err 2

Err 6 Unstable weight. Cannot calibrate Check the load cells’ mechanica

Err 7 Mathematical error; division by zero.

Calibration or configuration settings

are messed up

The display shows a Con En message The configuration jumper is not in

below

e as

External object is interfering with the

scale

Display did not show 0.0 before

ng

weighi

Scale is not placed on a level floor Ensure the scale is level and begin the weighing

Scale is out of calibration Check the weight with a known weight value.

Improper tare Place the tare item on the scale. Press

The patient is not sitting still Ask the patient to be still.

apacity of the scale

c

Cannot ca

Pushed the wrong

place.

lculate cali

bration factor.

keys Reset to factory defaults. See Page 9 for

Remove the interfering object from the scale.

Help the patient off the scale, zero the scale and

begin the weighing process again.

oce

ss again.

pr

REWEIGH. Once the weight of the item is

displayed, pr

the scale.

Remove the excess weight and use the scale

according to manufacture’s specs.

the cables and mec

problem persists, replace the set of load cells.

and see that nothing touches them and that the

cables are properly welded.

This error will show when trying to calibrate the

unit with no calibration weight on the unit.

instructions.

stall the configuration jumper on both pins. (see

In

page 4 for more information).

ess TAR

Press the REWEIGH button again.

E. Place the patient back on

hanical connections. If the

l surroundings

Table 7-1. Troubleshooting Table for the Rice Lake Scale Line

20 Handrail Scale Technical and Operating Instructions

Page 25

7.1 Test Mode

Power On-Off

START REWEIGH Key

TEST

Version

BAT

A-D

FACTOR

At

Press and

hold

Power Off

Remove Config/

Calibr. Jumper

The test mode menu is a special mode used for checking four very important parameters which are useful in

knowing the system’s state and for troubleshooting. Entry into this mode is possible only when the scale is turned

off. Turn the scale on. While Start is displayed, press and hold the REWEIGH key until both the middle arrows

appear on the display.

The test mode has four parameters. They are:

•Weighing

• Internal count

• Battery indication

• Calibration factor

Alternating between the parameters is performed by pressing the

Press the

Press the

Kg-Lb key to zero the scale in test mode.

Kg-Lb + REWEIGH to exit weighing mode.

REWEIGH key.

Figure 7-1. Test Mode Menu Structure

Table 7-2 lists the various display messages when testing the scale.

NOTE: <-> means the display toggles between the two values.

Step Function Display Available Parameters

1

Turn the scale on.

While StArt is

displayed, pr

hold the REWEIGH

key.

2

3

4

ess and

This enters int

the test mode of

the sc

ale.

Identifies the

software ID

Shows the current

weight value

Shows the current

A/D count

o

StArt The scale automatically advances to Step

2.

IdEnt <-> 11007 Press the REWEIGH key to advance to

the next step.

tESt <-> 0.0 To zero the display, press the Kg-Lb key.

To advance to the next step, press the

REWEIGH key.

A-d <-> XXXX To advance to the next step, press the

REWEIGH key.

Table 7-2. Test Mode Menu

Handrail Scale Technical and Operating Instructions - Troubleshooting and Testing 21

Page 26

Step Function Display Available Parameters

5

Checks for current

battery level

bAt <-> XXX or nO bAt If the nO bAt is displayed, there are not

batteries in the unit, or the unit is

operating on its external AC adaptor.

To advance to the next step, press the

REWEIGH key.

6

This shows the

calibration factor.

FACtOr <-> XXXXX Press the REWEIGH key to return to the

top of the test menu.

To exit test mode, press the REWEIGH

and Kg-Lb

key simultaneously, or turn off

the indicator.

Table 7-2. Test Mode Menu

22 Handrail Scale Technical and Operating Instructions

Page 27

8.0 Maintenance

The following section provides instructions for maintaining and cleaning the Rice Lake line of scales.

Maintenance operations other than those described in this section should be performed by qualified service

personnel.

8.1 Basic Maintenance

Before the first use of the scale and after periods of non-use, check the scale for proper operation and function. If

the scale does not operate correctly, contact qualified service personnel.

p

Go through the following ste

1. Check the overall appearance of the entire scale for an

2. Inspect the condition of the AC adaptor for cord cracking or

8.2 Cleaning

Proper care and cleaning is essential to ensure a long life of accurate and effective operation. Before beginning

the cleaning process, disconnect the scale from the AC power source.

1. Clean all external surfaces with a clean, damp cloth or tissue. Mild soap and water solution

Dry with a clean soft cloth.

2. Do not immerse the scale into cleaning or other liquid soluti

3. Do not use Isopropyl alcohol or other solutions to c

s for basic maintenance.

y obvious signs of damage, abuse, etc.

fraying or for broken or bent prongs.

may be used.

ons.

lean the display surface.

Handrail Scale Technical and Operating Instructions - Maintenance 23

Page 28

Handrail Scale Specifications

Power

120 VAC-9VDC-50Hz / 230 VAC-9VDC-50Hz

Battery Type

Sealed lead acid battery

Battery Use

75 hours

Automatic power-off can be configured from 0 - 20 minutes

Data Communications

RS-232 with RJ-45 jack

Selectable baud rate, default - 9600

8 bits

No parity

1 stop bit

No handshaking

Environmental

Operating Temperature

50 to +104°F (14 to 40°C)

Storage Temperature

32 to 158°F (0 to 70°C)

Humidity

85% relative humidity

Capacity and Graduation

700lb (310kg) 0.2lb (0.1kg)

Certifications and Approvals

RoHS Compliant

Dimensions

Platform Dimensions

25 in W x 20 in L x 3 in H

24 Handrail Scale Technical and Operating Instructions

Page 29

For More Information

System Manuals

• Rice Lake Digital Handrail Scale Operation Instructions, PN 113809

Literature

• Medical Scales, Handrail Scale, 4 Color, PN 106426

Web Site

• http://www.ricelake.com/health

Contact Information

Hours of Operation

Knowledgeable customer service representatives are available 6:30 a.m. - 6:30 p.m. Monday through Friday and

8 a.m. to 12 noon on Saturday. (CST)

Telephone

• Sales/Technical Support 800-472-6703

• Canadian and Mexican Customers 800-321-6703

• International 715-234-9171

Immediate/Emergency Service

For immediate assistance call toll-free 1-800-472-6703 (Canadian and Mexican customers please call

1-800-321-6703). If you are calling after standard business hours and have an urgent scale outage or emergency,

press 1 to reach on-call personnel.

Fax

Fax Number 715-234-6967

Email

• US sales and product information at prodinfo@ricelake.com

• International (non-US) sales and product information at intlsales@ricelake.com

Mailing Address

Rice Lake Weighing Systems

230 West Coleman Street

Rice Lake, WI 54868 USA

Handrail Scale Technical and Operating Instructions - Maintenance 25

Page 30

Digital Handrail Scale Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by

the Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects in

materials and workmanship for two years.

RLWS warrants that the equipment sold hereunder will conform

to the current

by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment

fails to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RL

WS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purpose

prevent electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a

publication, Protecting Your Components From Static Damage in Shipment, available from RLWS

Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually

not caused by accident, misuse, neglect, alteration, improper installation, improper repair or

improper testing; RLWS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed

by any person other than RLWS or its

duly authorized repair agents.

• RLWS will have a reasonable time to repair or replace the

defective equipment. Buyer is responsible

for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location re

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

T

HESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER

RLWS

RLWS

REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND

ALL OTHER CLAIMS TO WARRANTY.

S

WARRANTY CLAIMS.

N

WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN WRITING AND SIGNED BY A CORPORATE

OFFICER OF RLWS AND THE BUYER.

NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO

HOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE SELLER FOR

O TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO MODIFY THE TERMS OF THIS

written specifications authorized

s must be packaged to

exists, and was

pairs, including assembly or

© 2010 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

26 Handrail Scale Technical and Operating Instructions

Page 31

Page 32

PN 118594 11/10

Loading...

Loading...