Page 1

IB Series

Precision Balance

Operation Manual

42193

Page 2

Contents

About This Manual ...................................................................................................................................1

1.0 Introduction ..................................................................................................................................1

1.1 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.2 Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.3 Unlocking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.4 Repacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.5 Site Location and Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.6 Weighing Pan Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1.7 Leveling the Scale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.8 Main Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1.9 Front Panel Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1.10 Start-up Self Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2.0 Calibration ....................................................................................................................................6

3.0 Measuring Weight ........................................................................................................................7

4.0 Count Weighing ............................................................................................................................8

4.1 Count Mode Setting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4.2 Self Counting System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

5.0 Calculation Factor Mode ............................................................................................................11

5.1 Method of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

6.0 Percentage Mode .......................................................................................................................13

6.1 Setting Actual Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

6.2 Setting Numerical Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

7.0 Functions ....................................................................................................................................15

7.1 Selecting Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

7.2 Function List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

7.2.1 Comparator Function Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

7.2.2 Interface Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.2.3 Measurement Conditions and Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

8.0 Comparator Function .................................................................................................................22

8.1 Upper and Lower Limit Setting Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

8.2 Setting Confirmation and Input Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

8.3 Upper/Lower Limit Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

8.3.1 Actual Weight Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

8.3.2 Numeric Input Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

9.0 Accumulation Function ..............................................................................................................27

9.1 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

10.0 Specifications ............................................................................................................................28

10.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10.1.1 Common Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10.1.2 Model Specific Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

10.2 Options and Standard Attachments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

10.3 Model Capacity/Readability Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

11.0 Troubleshooting .........................................................................................................................31

IB Series Limited Warranty ....................................................................................................................32

Copyright © 2001 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Version 2.1, November 2001

Page 3

About This Manual

This manual is intended for use by service technicians

responsible for installing and servicing the IB Series

electronic tuning fork scale.

Configuration and calibration of the scale can be

accomplished using the IB Series front panel keys.

1.0 Introduction

The IB Series is an advanced precision weighing

instrument utilizing a high-precision electronic tuning

fork sensor which provides stable measurement over

years of usage. It provides ultra-fast response time and

greatly improved resistance to external vibrations.

Features include:

•Measures weight in thirteen units (mg, g, kg,

ct, oz, lb, ozt, dwt, gr, HK tael, SIN tael, TW

tael and mommes)

•Switchable for straightweighing, piece count,

or over/under checkweighing mode

•Built-in automatic zero tracking

•Die-cast aluminum housing, making it

resistant to chemicals and electromagnetic

interference

•Counting mode, checkweighing mode,

calculation factor mode, and percentage mode

capabilities

• Large .5 " (12.5mm) liquid crystal display

(LCD)

•Optional glass breeze shield available for all

round pan models

•Available in 115 VAC adapter. 230 VAC

adapter (optional)

1.1 Operating Modes

The IB Series has four weighing modes:

Normal (weighing) mode

Normal mode is the “production” mode of the

scale. The IB Series displays gross or net weights

as required, using the LCD annunciators

described in Table 1-1 on page 4 to indicate scale

status and the type of weight value displayed.

A checkweighing function can be used with the

normal weighing mode. It is convenient for

classifying weighing items according to whether

they fall within a pre-determined weight range.

The limit setting procedure is described in Section

4.1 on page 7.

Authorized distributors and their employees

can view or download this manual from the

Rice Lake Weighing Systems distributor site

at

www.rlws.com

Counting mode

The IB Series is capable of parts counting.

Sampling is done by placing the sample on the

scale and designating the number of pieces in the

sample. Four preset sample quanitities are

available.

Entering the counting mode is done through the

front panel keypad, and is explained in detail in

Section 4.0 on page 8.

Calculation Factor mode

In calculation factor mode, the desired index is

memorized, the index for the weight of the item

placed on the scale is calculated and the

calculated value is displayed. This is a convenient

function that allows conversion into various units,

and is explained in detail in Section 5.0 on

page 11.

Percentage mode

In percentage mode, the weight of the sample

selected as the reference is memorized as 100%.

The ratio between the item being measured and

the reference is displayed as a percentage. The

percentage mode is explained in detail in

Section 6.0 on page 13.

.

1.2 Unpacking and Inspection

Each component of the IB Series system is packed in a

specially designed carton. Remove each component

from its carton, separate the component from its

polystyrene shell assembly, and set the assembly

aside. Inspect the carton interior and inner panels to be

sure that all accessories have been removed. Items

included in this carton include:

• IB Series precision balance scale

•Weighing pan and pan base

•AC adaptor

•Operation manual

•Dust cover

Be sure to replace all packing materials within the

carton set. Store the carton set in a secure area so it is

available whenever shipment of the scale is required.

Introduction 1

Page 4

2

SLEEP

T

LOW-BATT

RICE LAKE

IB

P

F

S

LEEP

T

L

O

W

-B

A

TT

RICE LAKE

IB

P

F

Immediately after unpacking, a visual inspection of

the instrument should be conducted. Keep the scale in

an upright position. The shipper and Rice Lake

Weighing Systems should be notified immediately if

any damage occurred during transportation.

Instructions for assessment of damage and further

procedures will then be determined.

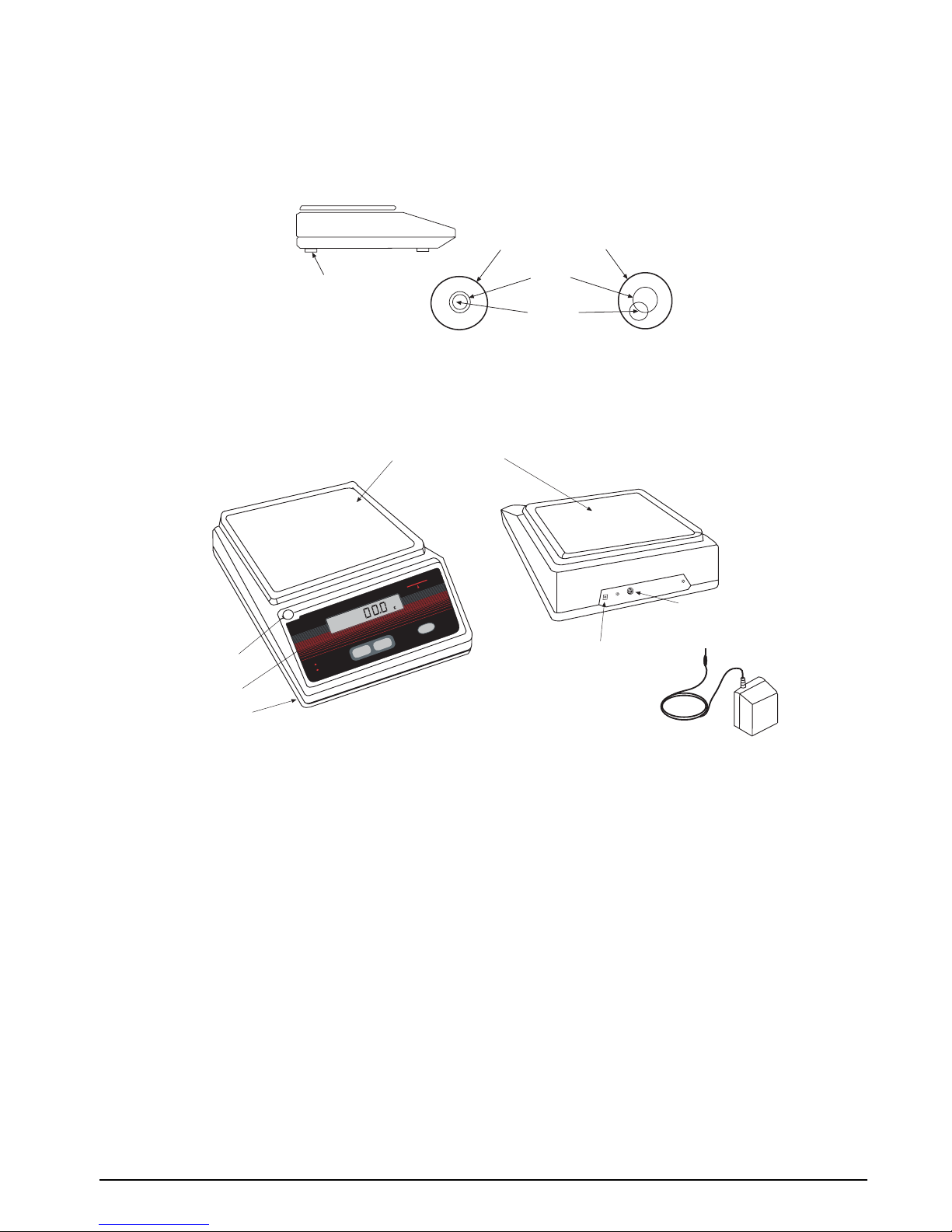

1.3 Unlocking

Locate a black rubber cap at the top of the scale.

Remove the cap to find a lock lever in it. Turn the

lever to the center of the scale to unlock.

Note: Before relocation or transportation, turn the lever to

the edge of the scale for locking mechanism.

Pan base

fitting screw

For installation

For transportation

Figure 1-1. Unlocking Scale

The IB Series is a precision instrument and requires

careful handling. Certain precautions must be taken to

ensure weighing accuracy.

•Weighing accuracy may be affected by

installation or extended usage. To ensure

accurate measurement, perform calibration

(as described in Section 2.0).

•Always remove objects from the weigh pan

gently. Shock, especially applied to the sides

of the scale, may result in loss of accuracy.

• If the capacity of the scale is exceeded, an

error message is displayed. Do not

[o-Err]

leave an over-capacity load on the pan.

1.6 Weighing Pan Attachment

Use the following steps to properly attach the IB

Series weigh pan.

1. Attach the pan base onto the center of the

main base.

2. Fix the position of the pan base by tightening

the attachment screw (as shown in Fig 1-1)

using a screwdriver or coin.

Attachment

Screw

1.4 Repacking

If the IB Series counting scale must be returned for

modification or repair, be sure that it is properly

packed with the original packing material and original

carton assembly if possible. Any damage caused by

improper packaging will not be covered by the

warranty.

1.5 Site Location and Precautions

Try to select a good, clean environment for installing

the scale. The following environmental factors may

cause the scale to give inaccurate measurements:

• Installation on a weak surface that may flex

when objects are put on it or put on the scale.

•Greatly varying temperature and humidity.

•Vibration or an unstable surface for

installation of the scale.

•Air flow from heaters or air conditioning

units.

•Corrosive gases or large amounts of dust.

•Direct, intense sunlight.

Figure 1-2. Weighing Pan Attachment

3. Place the weighing pan on the pan base.

(weighing pan comes in both retangular and

round types).

IB Series Operation Manual

Figure 1-3. Weighing Pan

Page 5

S

L

E

E

P

T

L

O

W

-

B

A

T

T

RICE LAKE

IB

P

F

1.7 Leveling the Scale

The scale must be level for proper operation. Use the four level adjusters located at the four corners of the scales

main unit to adjust the horizontal position of the scale until the bubble of the level indicator lies within the red

circle. Ensure that the scale sits solidly and does not wobble due to uneven adjustment.

LEVEL INDICATOR

ADJUSTERS

1.8 Main Components

The main parts of the IB Series balance are:

Level Indicator

Display

Level Adjusters

BLUE

CIRCLE

BUBBLE

Figure 1-4. Bubble Adjustment

Weighing Pan

Adaptor

Connector

Output Connectors

for Optional Equipment

AC Adaptor

Figure 1-5. Main Component Parts of the IB Series

Introduction 3

Page 6

4

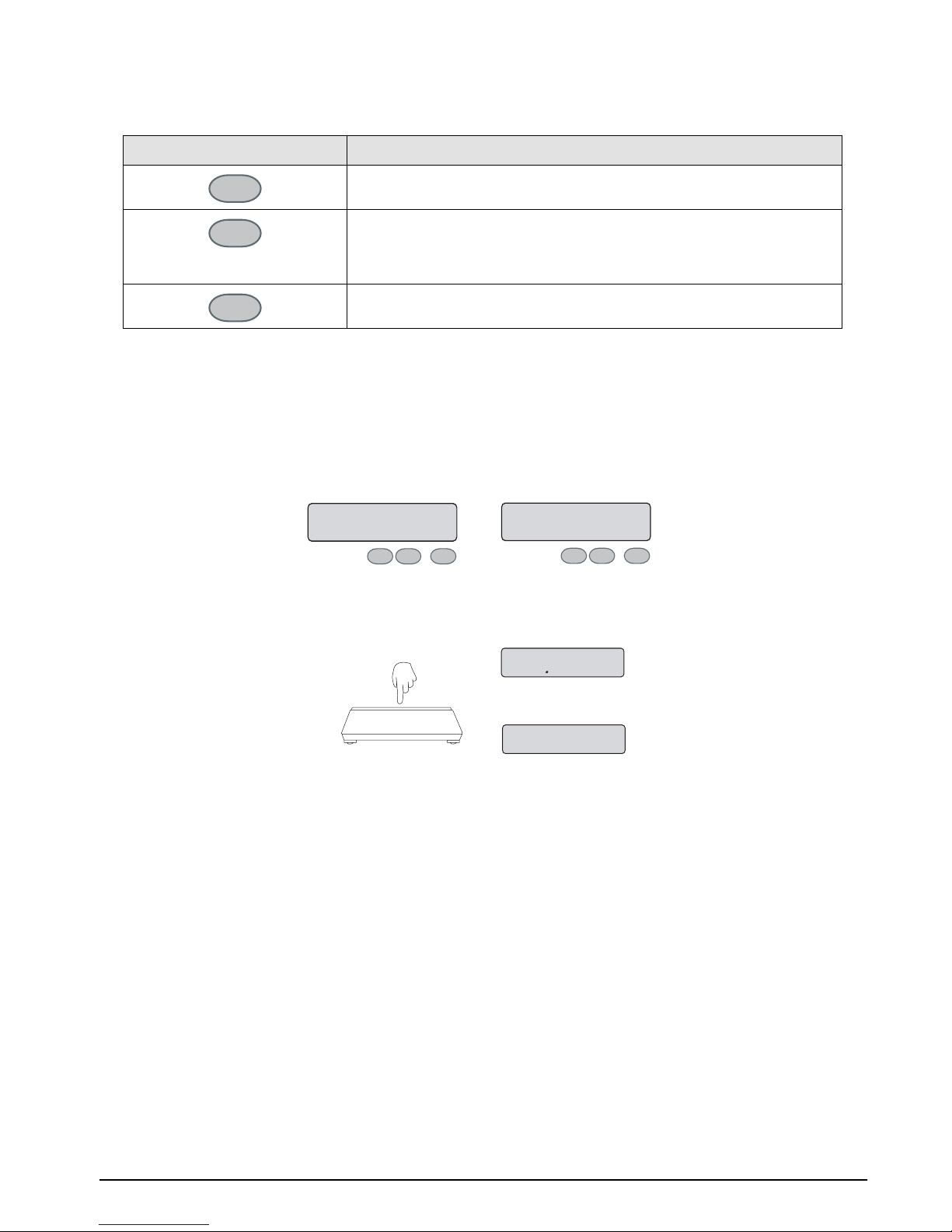

1.9 Front Panel Keypad

Table 1-1 on page 4 shows the IB Series LED annunciators, keypad, and normal mode key functions.

SLEEP

LOW-BATT

P

Figure 1-6. Front Panel Keypad

F

RICE LAKE

T

IB

The LCD annunciators shown on the IB Series front panel describe the indicator functions assigned in setup

mode. In setup and calibration mode, the keys are used to navigate through menus, select digits within numeric

values, and increment/decrement values. The key symbols shown in the LCD display describe the functions

assigned in setup mode.

Indicator Symbols Meaning

g Unit display for weighing mode

PCS Unit display for counting mode

% Unit display for percentage scale

# Unit display for index scale

∑

M Indicates value setting in progress for limit or sampling functions.

"

Display during total mode (displayed in conjunction with each scale mode’s unit

display).

Scale stability display (scale is unstable when not displayed).

Display indicates automatic memory update in index mode (simplified SCS method).

Indicates the measurement range and remaining weight. In Comparator Mode, the bar

graph performs judgments.

Table 1-1. LCD Annunciator Functions

IB Series Operation Manual

Page 7

The front panel operation key symbols describe the functions assigned to the scale.

Operation Key

P

F

T

Sets limit function or cancels functions

• Sets and memorizes data in the count mode and when the limit function is

operating.

• Calls up and selects functions and items.

• Selects row during numerical setting (limit function).

• Selects operation zero and tare subtraction.

• Selects input numeral during numerical setting (limit function).

Table 1-2. Front Panel Key Functions

Function

1.10 Start-up Self Test

A self test must be performed prior to using the scale. To perform a self test, do the following:

1. Connect the AC power adapter to the IB Series scale and insert into a 115V service outlet.

2. Press the

characters are lit. After a few moments, the display reads

ON/OFF

key. All segments and characters light for a self test. Confirm that all segments and

[0.00g]

:

Display Character Check

M

▲▲

–

0.0.0.0

▼

▲

Figure 1-7. Display Character Check

Pcs

➩

Kg.

T

FP

0.00

T

FP

g

3. Verify that the display changes by touching the pan slightly. It should return immediately to

release. A flashing

[g]

annunciator means that the scale has not yet stabilized.

123.4

g

➩

g

0.0

Figure 1-8. Verifying Scale Weight

[0.00g]

upon

Introduction 5

Page 8

6

2.0 Calibration

This section describes procedures for calibrating the IB Series scale. Follow the steps in Table 2-1 to calibrate the

IB Series scale.

.

Step

1

2

3

4

5

6 When calibration is complete, the scale automatically returns to the weighing mode.

Hold down the

Hold down the

The display will show

contents of the parameters are the same as at function

Note: Unit will not appear in setting at

advance to on 0. In this case, use a reference weight of the weight unit selected in function

appears. The scale will automatically be set to the zero point. Verify that nothing is placed on the

[on 0]

weighing pan.

After the IB performs the zero adjustment,

calibration weight on the center weigh pan (see Table 2-2 below for designated calibration weights).

F

key until

key, then press the

T

[Func]

Select weight unit from parameters “1” to “d”, by pressing the

[unit].

[CAL]

➙

key, then release both keys.

F

[on FS]

Action

appear in sequence, then release the key.

[71 uA]

. After setting the parameter , pr ess the

[1 SEt 1]

and

[73 ub 0]

automatically appears. Gently place the designated

at the same time. The display will

key. The

T

F

key.

[71 uA]

Table 2-1. Calibration Steps for the IB Series Scale

Notes:

• Press the P key to cancel calibration procedures and return to the weight display.

appears on the display, the weight exceeds the scale capacity.

[o-Err]

• If

• Standard calibration weight is 1/2 capacity. However, when possible, calibrate using a full capacity weight. See

Table 2-2 below for the unit system capacities.

[1-Err]

• If

• If

(1%) is exceeded.

appears on the display, the calibration weight is less than 50% of the standard.

[2-Err]

appears on the display, an object other than the calibration weight is on the pan, or the display tolerance

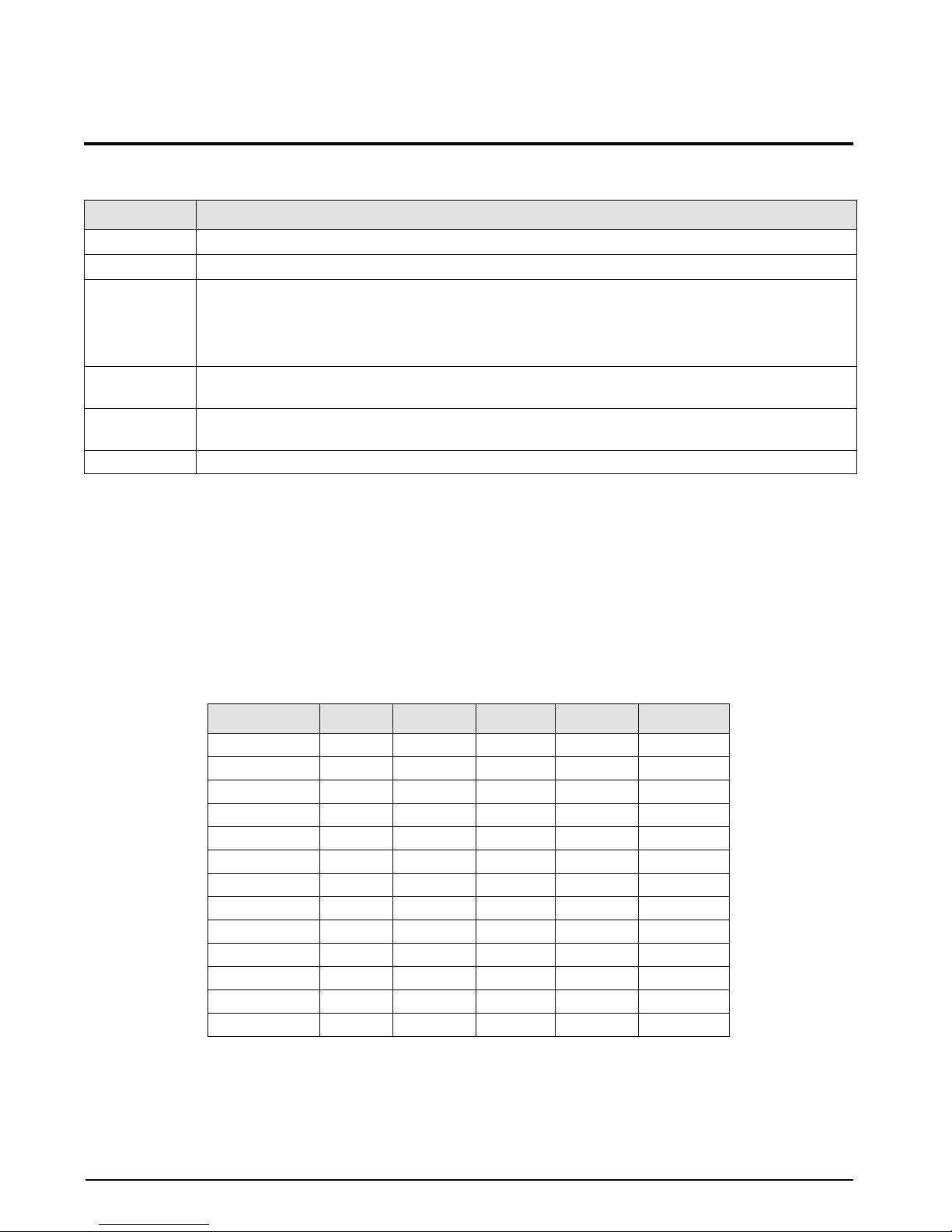

Unit No. (mark)

1 (mg) 100,000 2,000,000 5,000,000 10,000,000 15,000,000

2 (g) 1000 2000 5000 10,000 1,500

3 (kg) 1 2 5 10 15

4 (ct) 5,000 10,000 25,000 50,000 75,000

5 (oz) 35 70 170 350 520

6 (lb) 2.2 4.4 11 22 33

7 (ozt) 32 64 160 320 480

8 (dwt) 640 1200 32000 6400 9600

9 (gr) 15,000 30,000 77,000 150,000 230,000

A (tl) 26 53 130 260 400

b (tl) 26 52 130 260 390

c (tl) 26 53 130 260 400

d (mom) 260 530 1,300 2,600 4,000

IB-1000 IB-2000 IB-5000 IB-10K IB-15K

Table 2-2. Unit System Capacities

IB Series Operation Manual

Page 9

3.0 Measuring Weight

0.0

g

Tare Subtraction

1234.5

g

Net Weighing

0.0

g

Zero Point Setting

678.9

g

Additional Weighing

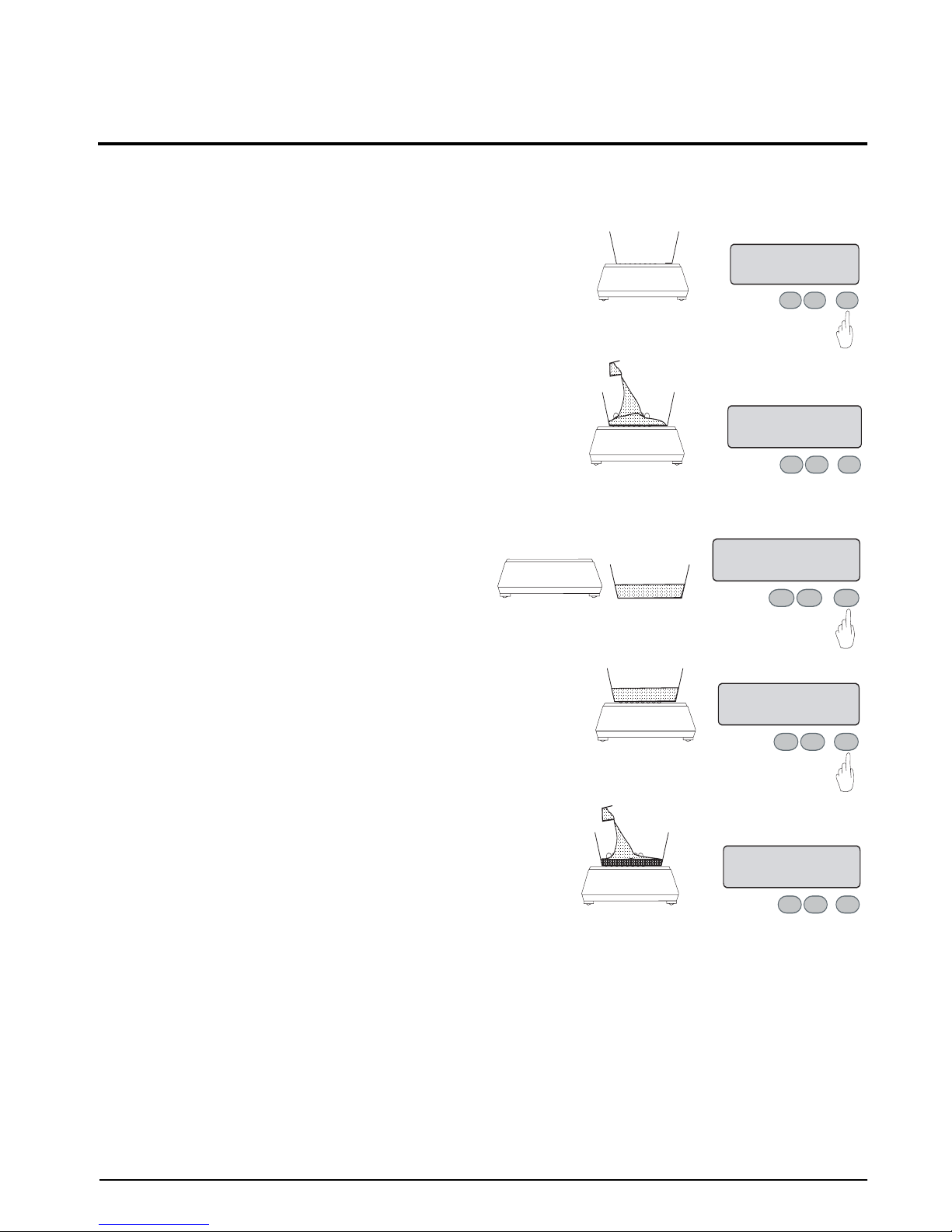

This section describes procedures for tare subtraction and weighing on the IB Series scale. Follow the steps

below for tare subtracting and weighing on the IB Series scale.

1. Place a container on the weigh pan, press the

T

key. The zero

display appears.

2. Place the product in the container. The net weight is displayed.

3. If you wish to remove the product or to return

the display to zero, press the

4. Without removing the product, press the

T

key.

T

key.

T

FP

P

Zero Point Setting

P

F

0.0

F

T

g

T

5. Add the next product quantity. Only the additional amount is

displayed.

Notes:

• Tare subtraction procedure is the same for weighing or count modes.

• When tare weighing is performed, product weighing range is reduced by the amount of the tare weight.

weighing range = capacity - tare weight

• A flashing

If weighing is performed in an unstabilized condition, accurate weigh results will not be returned.

[0-ERR] appears if the load exceeds roughly 101% of the scale capacity. The net weighing range will be reduced by

•

the tare container from the capacity of the scale.

[g] indicator means the scale has not stabilized; when the indicator remains lit, the scale has stabilized.

P

Measuring Weight

T

F

T

FP

7

Page 10

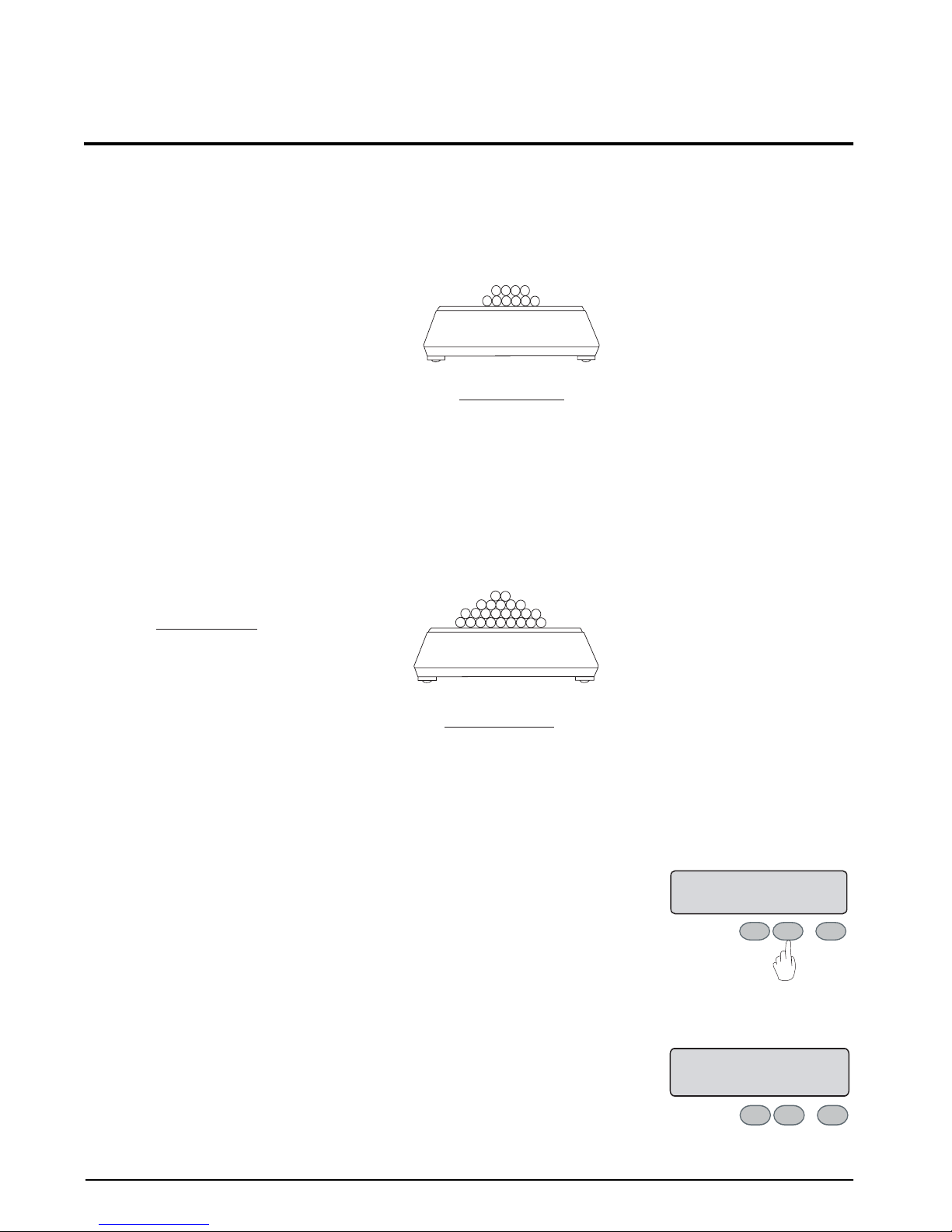

4.0 Count Weighing

Count weighing is used to determine piece count rather than weight. In order for the scale to perform this

function it must know the average piece weight. By loading a specified number of pieces on the pan and entering

that count, the scale calculates and stores in memory the piece weight for that product. This process is referred to

as “sampling. ” F or e xample, ten pieces are placed on the scale. When “10” is entered, the unit piece weight is set.

Sampling

Average Unit Weight = Piece Weight

Total Wt. 10 g

Piece Count 10

Next, the product to be weighed is placed on the scale. The scale calculates the piece count by dividing the total

weight by the piece weight.

= Piece Weight = 1g

10 pieces are placed

on the scale

Total Weight = 10g

Calculating Piece Count

Total Weight

Piece Weight

= Piece Count

Total Wt. 250 g

Piece Weight 1 g

= Piece Count = 250pcs

A load of product is

placed on the scale

Total Weight = 250g

4.1 Count Mode Setting Procedure

1. Hold down the F key for about four seconds. Release

when the [Func] display appears.

2. The first item of the function display appears: mode

type.

8 IB Series Operation Manual

Function Access

FUNC

F

P

Mode Type

T

1.SET 1

T

FP

Page 11

3. If the weighing mode display appears, press the T

0

Exit Mode Settings

pcs.

0.0

pcs

Zero Scale

U. SET

Sample Quantity Setting

key to enter the count mode.

Weighing Mode

Count Mode

4. To exit the function setting display and enter the

count mode press the

P key.

1.SET 1

T

FP

➩

1.SET 2

T

FP

T

FP

4.2 Self Counting System

Self Counting System (SCS) allows the user to start with any sample quantity selected. The concept of SCS

keeps the user within built-in parameters. If the user adds more than three times the pieces previously on the

scale, a message will display indicating pieces must be removed to get back within the built-in parameters. If the

user stays within the parameters, the count display continues to flash, advising that SCS is active.

1. Place the tare vessel on the weighing pan and then

press the

display does not indicate zero.

T key. Also perform this operation if the

2. Continuously press the

is displayed.

3. The display flashes, indicating that a value must be

entered. Set the desired quantity of the sample by

pressing the

incremented by one according to the pattern

indicated below each time the T key is

pressed

T key. The displayed quantity will be

5

F key until [U SEt] message

10

30

100

FP

TFP

Set Sample Quantity

ON 10

pcs.

TFP

T

Count Weighing 9

Page 12

4. Place the selected number of items in the tare vessel

and then press the F key. The display will

temporarily go blank and a tone will be emitted,

indicating the quantity has been memorized. The

[" ] flashes, indicating that memory is being

updated.

5. If additional items are placed in the tare vessel

(maximum of three times the displayed quantity),

the new quantity will be memorized. A tone will

then be emitted indicating the new quantity has been

memorized.

6. Place additional items in the tare vessel. Memory is

updated automatically.

Sample Quantity Memorized

10

pcs.

P

T

F

Automatic Memory Update

30

pcs.

T

FP

Automatic Memory Update

85

pcs.

T

FP

7. When satisfied that enough sample quantity has

been placed on the scale to achieve a good average

piece weight, press the

F key to save it to memory.

The display stops flashing and the average piece

weight remains in memory until it is changed by

starting a new SCS process, beginning at step one

above.

NOTE: Once the F key has been pressed to memorize the

average piece weight, repeated pressing of the

F key allows display of the current weight and count.

End Sample Memorization

85

pcs.

T

FP

10 IB Series Operation Manual

Page 13

5.0 Calculation Factor Mode

In calculation factor mode, the desired index is memorized, the index for the weight of the item placed on the

scale is calculated and the calculated value is displayed. This allows conversion into various units.

5.1 Method of Operation

1. Hold down the F key until [C Set] appears. The [M]

symbol and the display begins flashing. If a

reference value has already been set, that value

displays.

2. Press the

and the bar graph underneath flashes. The desired

value can now be set.

3. If the

will be incremented according to the pattern below.

Press the T key repeatedly until the desired value is

displayed.

0

T key until the [0] displays to the right side

T key is pressed again, the displayed value

Minus mark

_

1

2

3

~

9

Decimal point

.

C. SET

T

FP

➩

➩

Input Setting Value

Select Setting Value

Setting Index Value

0.00

#

0.0

T

FP

#

1.0

T

FP

4. Press the F key to set the value pre viously set in step

three and shift its display to the left side. Set the

next digit by repeating steps three and four. Repeat

this process until the desired value has been

completely entered.

5. After the reference value has been completely set,

press the

the reference value setting has been completed and

the scale returns to calculation factor mode.

P key. A long tone emits, indicating that

Setting Second Digit

10

FP

End Reference Value

123

FP

Calculation Factor Mode 11

#

T

#

T

Page 14

6. When an item is placed on the scale, the index of its

weight is calculated and the calculated value

displays. This display is equal to the index (1.23)

times the weight of the item (100 g).

Measurement of Index

123.00

FP

#

T

12 IB Series Operation Manual

Page 15

6.0 Percentage Mode

0 %

Zero Scale

The weight of the sample selected as the reference is memorized as 100%. The ratio between the item being

measured and the reference is displayed as a percentage.

6.1 Setting Actual Weight

1. Press the T key to zero the scale. This operation is

also performed if the tare vessel is used.

T

FP

2. Continuously press the

The [M] symbol and the display flash. If a reference

value has been previously set, that value displays.

3. Next, place the reference sample on the weighing

pan (tare vessel) and press the

temporarily goes blank and a long tone emits. The

reference value is memorized and the scale returns

to measurement mode.

4. Place the item to be measured on the weighing pan

(tare vessel) and the ratio to the reference value is

F key until [P SEt] displays.

F key. The display

P. SET

P

F

➩

➩

T

Reference Value Memorized

Setting Index Value

0.00 %

100.00 %

T

FP

Ratio to Reference Value

displayed in percent (%).

130.00 %

T

FP

Note: The percentage resolution will automatically RANGE, depending on the percent of scale capacity used for the

reference weight.

IB 1000 IB 2000 IB 5000 IB 10K IB 15K % Scale capacity Display resolution

Less than .5g 1g 2.5g 5g 7.5g .05% L-ERR

Less than 5g 10g 25g 50g 75g .5% 1%

Less than 50g 10g 250g 500g 750g 5% 0.1%

Less than 500g 1000g 2500g 5000g 7500g 50% 0.01%

More than 500g 1000g 2500g 5000g 7500g Over 50% 0.01%

Example: IB 1000

Reference Weight: 487g

In the IB 1000 column from the table above, 487g is more than 50g, but less than 500g. The display resolution

will be in increments of 0.01%.

Table 6-1. Break Points for the IB Series Scale.

Percentage Mode 13

Page 16

6.2 Setting Numerical Value

1. Press the F key until the [P SEt] message is

displayed. The [M] symbol and the setting value

flashes on the display. If the reference value has

been previously set, that value is dislayed.

2. Press the

and the bar graph underneath flashes. The desired

value can now be set.

3. If the

incremented according to the pattern below. Press

the T key repeatedly until the desired value is

displayed.

0

T key until the [0] displays to the right side

T key is pressed again, the displayed value is

Minus mark

_

1

2

3

~

9

Decimal point

.

P. SET

FP

➩

➩

T

Setting Index Value

0.00 %

Start Numeric Input

0.0 %

FP

T

Select Setting Value

3.0 %

T

FP

4. Press the F key to set the value pre viously set in step

three and shift its display to the left side. Set the

next digit by repeating steps three and four. Repeat

this process until the desired value has been

completely entered.

5. After the reference value has been completely set,

press the

the reference value setting has been completed and

the scale returns to calculation factor mode.

Note: The percentage display will automatically set in the range of 1 to 0.001% as with memorization of an actual

reference weight.

P key. A long tone emits, indicating that

Setting Second Digit

30 %

T

FP

End Reference Value

321 %

TFP

14 IB Series Operation Manual

Page 17

7.0 Functions

The following sections describe the functionality of the IB Series scale.

7.1 Selecting Functions

1. Hold down the F key for about four seconds.

Release when the [Func] display appears.

2. The first item of the function display appears: mode

type.

Each time the

F key is pressed, the function item displays appear in sequence.

Mode Type

1.SET 1

P

F

➩

T

Simple Weighing Function

2.SEL 1

Function Access

FUNC

T

FP

Mode Type

1.SET 1

T

FP

Comparator Contents

➩

P

T

F

21.CO.2

FP

T

Response Speed

5 R.E. 3

P

F

➩

Weighing Unit

7. UN.

P

F

➩

Auto Power OFF

Auto Zero

➩➩

4 A.P. 1

T

T

P

T

F

3. A.O 1

P

F

Functions 15

T

Page 18

3. To alter the setting, press the T key with the

desired function display showing. (See Table 7-1

on page 17).

5. RE. 1

T

FP

➩

➩

5. RE. 5

T

FP

4. After confirming the change, press the

function setting is complete and the display returns

to the operational mode.

P key. The

5. RE. 1

T

FP

➩

➩

0.0

g

T

FP

16 IB Series Operation Manual

Page 19

7.2 Function List

Display Function Description

1.SEt *

2.SEL *

3. A0

*

4. AS

*

5.rE

1 Mode Type Weighing Mode (weighing only)

2 Counting Mode + weighing

3 Percentage Mode + weighing

4Weight conversion + weighing

1 Additional Functions Simple Weighing Function Only when setting value

2 Accumulation Function On

3 Comparator Function On

4 Accumulation Function +

Comparator Function

0 Auto Zero No adjustment of zero point

1 Automatic adjustment of zero point

0 Auto Power Off With Battery

1 Auto shut off after three

0 Response

Speed

1Average

2

*

3

Fast

Slow

Option

When minute amounts of liquids or powders are to be measured.

Display

Update

Continuous ON

minutes of non-usage

Short

[34] is selected. Proceed

to type 21 function.

Ambient

Environment

Good

6. S.d

*

8. i.F *

4

5

1 Stabilization

Judgement

2

3

4

0 Ouput Control Output is not effective

1 Constant serial output (old format, 6-digit)

2 Constant serial output (old format, 7-digit)

Judgement

Accuracy

Flexible

Severe

Long

Stabilization

Time

Table 7-1. Function List

Poor

Short

Long

Functions 17

Page 20

Display Function Description

71 uA

72 dA

1Weighing

Unit

2g

3kg

4ct

5oz

6lb

7 ozt

8 dwt

9gr

A tl (Hong Kong)

B tl (Singapore, Malaysia)

C tl (Taiwan)

D mon

1 Least

Readability

2

3

4

5

Group “A” mg

Fine Ex. IB-2000 0.001g

0.02g

0.05g

0.1g

0.2g

Coarse

Table 7-1. Function List (Continued)

18 IB Series Operation Manual

Page 21

Display Function Description

73 uA

74 dA

0Weighing

Unit

1mg

2g

3kg

4ct

5oz

6lb

7 ozt

8 dwt

9gr

A tl (Hong Kong)

B tl (Singapore, Malaysia)

C tl (Taiwan)

D mon

1 Least

Readability

2

3

4

5

Group “B” No unit displayed

Fine Ex. IB-2000 0.001g

0.02g

0.05g

0.1g

0.2g

Coarse

Table 7-1. Function List (Continued)

* = indicates default setting at time of factory shipment.

Notes:

• If activate comparator function is selected, the comparator function data shown in Figure 7.2.1 will supersede the

auto zero display.

• If activate interface function is selected, the interface function data shown on page 21 will supersede the Auto Zero

display. If this display is shown, the display will return to the normal operational mode.

• The auto power off function is available only when the battery option is used.

Functions 19

Page 22

7.2.1 Comparator Function Data

Display Contents Description

21.Co *

22.Li *

23.Pn

24.Bu *

1 Judgment Condition Judgment even when scale unstable

2 Judgment only when scale is stable

0 Judgment Range No judgment around zero point

1Total range includes zero point

1 Number of Setting Points Setting point no. 1 The message “25 LG 2” is

2 Setting point no. 2

3 Setting point no. 3

4 Setting point no. 4

0 Buzzer Operation

(*1: Option)

1 Active Under The buzzer position is

2 Active Accept

3 Active Over

4 Active Under & Accept

5 Active Accept & Over

6 Active Under & Over

Off (buzzer suppressed)

["] mark ON when buzzer deactivated

displayed only during

setting of two points, it is

not valid when setting 1,

3 or 4 points.

shown by the

flashing next to UNDER/

ACCEPT/OVER. This

facilitates monitoring

judgment results.

["] mark

25.LG *

1 Judgment Display Ranking Display

2Two-point bar graph (effective only when 2 points set)

Table 7-2. Comparator Function Data

*1: Buzzer sounds only when buzzer is attached. Option relay output is also common when buzzer output.

20 IB Series Operation Manual

Page 23

7.2.2 Interface Data

Display Item Status

81 oc *

82 bL. *

Note:

• * denotes default setting at time of factory shipment.

• Weight units other than “g”, “kg” and “lb” are indicated by a

attached over this mark.

0 Output Control Output disabled

1 Normal operation, continuous output

2 Continued output when stable (stop if unstable)

3

4 Automatic output X 1 after load stabilized

5 Stable = output X 1; unstable = no output

6 Stable = output X 1; unstable = continue output

7

1 Baud Rate 1200 BPS

2 2400 BPS

3 4800 BPS

Press the

Press the

P key X 1 to ouput (manual) printer X 1

P key once to output X 1

Table 7-3. Interface Data

[# ] mark. A decal with the unit printed on it can be

7.2.3 Measurement Conditions and Results

Integration Time Stabilization Speed Results

Conditions

Good

↓

Normal

↓

Worse

Measurement

Precise

↓

Normal

↓

Coarse

Table 7-4. Measurement Conditions and Results

SrE 1

↓

SrE 3

↓

SrE4

SrE 4

↓

SrE 3

↓

SrE1

65d 4

↓

65d 3

↓

65d 1

65d 4

↓

65d 3

↓

65d 1

Accurate

↓

Less Accurate

Slow

↓

Quick

Functions 21

Page 24

8.0 Comparator Function

The comparator function is convenient for classifying weighing items according to pre-determined weight

ranges. The upper and lower limits of this range are stored in the scale’s memory, and when an item is placed on

the weighing pan it is judged as either acceptable or unacceptable. This function can only be used in weighing

mode.

8.1 Upper and Lower Limit Setting Procedure

To set the upper and lower limits, follow this procedure while referring to Section 8.3 on page 24.

1. Hold down the

[Func] display appears.

2. The first item of the function display appears: mode type.

3. If the count mode display appears, press the T

key to enter the weighing mode.

4. Press the

appears.

F key for about four seconds. Release when the

F key. The limit function display

Count Mode

1.SET 2

T

FP

Function Access

FUNC

1.SET 1

➩

T

FP

Mode Type

T

FP

Weighing Mode

1.SET 1

FP

Limit Function

T

5. Press the

appears.

22 IB Series Operation Manual

T key. The function on display

2.SEL 1

FP

Function OFF Function ON

2.SEL 1

T

FP

➩

2.SEL 2

T

T

FP

Page 25

6. Press the F key. The first limit function

display appears. Press the F key repeatedly

to call up the limit function displays in

sequence.

LIMIT

FUNCTION

DISPLAYS:

Limit Function Data

21.CO.2

T

FP

➩

7. To change the setting parameters, press the

T key with the desired limit function

display showing.

8. After each parameter is set, press the

to return to weighing mode.

P key

Buzzer ON

23.BU.0

T

FP

All Status Judgement

21,CO. 1

T

FP

End Setting

21,CO. 2

T

FP

➩

➩

➩

22.LI.1

Judgement When Stable

21.CO. 2

➩

P

Weighing Mode

00.0

➩

FP

F

FP

Range

T

T

T

Notes:

• To confirm function setting status, press the

display function settings in sequence.

• To end setting sequence at any time, press the P key to return to weighing mode.

F key with the function item display showing (in step two above)

8.2 Setting Confirmation and Input Procedure

1. Hold the P key down for two to three

seconds. Release when the display shows

L.SEt (lower limit set). The ["] indicator

next to UNDER flashes and the lower limit

value is displayed.

Setting Start

L. SET

FP

T

➩

Lower Limit Value

123.4

g

T

FP

Comparator Function 23

Page 26

2. Press the P key to display H.SEt (high [upper]

limit set). The

["] indicator next to OVER

flashes and the lower limit value is displayed.

Setting Start

H. SET

FP

Upper Limit Value

➩

567.8

T

g

T

FP

3. Press the

return to weighing mode.

Note: If the L.SEt display does not appear, the scale is not in function setting mode, or the count mode is in effect (pcs

displayed as unit indicator).

P key to end setting sequence and

End Setting

g.

0.0

T

FP

8.3 Upper/Lower Limit Input

There are two methods of entering upper and lower limit values. Both methods can be used interchangeably.

1. Actual weight input procedure: samples of upper and lower limit weight are placed on the weighing pan.

2. Numeric input procedure: the

limits into the scale’s memory.

The judgement results are shown by the position of the lit

H (high) Measured weight is over the upper limit ...... upper limit weight

C (good) Measured weight is within acceptable range....... upper limit weight lower limit

L (low) Measured weight is under the lower limit ....... lower limit weight

F and P keys are used with numeric key entry to record upper and lower

["] indicator next to OVER/ACCEPT or UNDER.

Note: In the case where lower limit upper limit, the flashing ["] appears next to all OVER/ACCEPT/UNDER indicators

to alert operator to error data.

8.3.1 Actual Weight Input

1. Hold the P key down for two to three seconds.

Release when the display shows L.SEt (lower

limit set). The indicator next to UNDER will

flash.

24 IB Series Operation Manual

Setting Start

L. SET

FP

Flashing Numerals

➩

0.0

g

T

T

FP

Page 27

2. Place a sample of the actual lower limit weight

on the weigh pan and press the F key. The

display goes blank for a moment while the

lower limit value is memorized.

Place Low Sample

Memorize Upper Limit

123.4

FP

g

T

3. Press the

P key to change to the upper limit

setting display. The indicator next to OVER

flashes.

4. Place a sample of the actual upper limit weight

on the weigh pan and press the

F key. The

display is blank for a moment while the upper

limit value is memorized.

5. Press the

P key to end the setting sequence and

return to the weighing mode.

Upper Limit Setting

H. SET

T

FP

Place High Sample

➩

Flashing Numerals

0.0

g

T

FP

Memorize Upper Limit

567.8

End Setting

0.0

P

F

FP

g

T

g.

T

Notes:

• The actual weight setting can be revised as many times as needed by repeating steps two and four.

• When using the

the QB-12K. Also, the next highest place M flashing indicates a (+ -) symbol should be selected.

• A flashing triangle

may be caused by mis-entry or lower limit upper limit setting value. Check the relevant settings if this occurs.

8.3.2 Numeric Input Procedure

F key to advance the digit during numeric setting, the highest place (10.000) can only be entered to

["] appearing next to all OVER/ ACCEPT/ UNDER indicators alerts operators to error data. It

1. Hold the P key down for two to three seconds.

Release when the display shows L.SEt (lower

limit set). The indicator next to UNDER

flashes.

Setting Start

L. SET

FP

Flashing Numerals

➩

0.0

g

T

T

Comparator Function 25

FP

Page 28

2. Press the T key to commence value setting.

All digits are displayed and only the lowest

digit flashes to indicate that input can be

made to that position.

Start Numeric Input

0000.0

g

3. Press the

Each time the key is pressed, a new numeral is

advanced.

0

4. If the

flashes, and the input position shifts

accordingly . Enter numeral as in the third step

above.

T key again to select a numeral.

.......

1

2

F key is pressed, the next digit position

3

4

Move Input Digit

0000.4

g

T

FP

➩

FP

0000.4

Numeral Input

0003.4

T

Enter Digit

g

T

FP

g

T

FP

5. Continue entering the required numerals as

above. When all numerals have been entered,

press the

memory.

P key to record lower limit value in

Lower Limit Setting

123.4

F

P

g

T

26 IB Series Operation Manual

Page 29

9.0 Accumulation Function

100

pcs.

Accumulation

The accumulation function of the IB Series offers summing-up and display of measured data repeatedly. Useful

in mixing or filling applications.

9.1 Operation

1. Load an object on the scale. When the display

shows , press the

display value. The total value and ∑ is displayed

for a moment.

2. Unload the object and allow the balance to

stabilize and re-zero. Display will show .

Once stabilized, load next object and press

the

P key to accumulate the value as in step

1 above.

P key to accumulate the

T

FP

Accumulation

250

pcs.

T

FP

3. Press the

F key to display the total amount.

To clear the accumulated total to zero, press the T

key.

Notes:

• Pressing the

• Accumulation is not effective if weighing in Mode “B” in simple weighing mode.

• To avoid duplication without unloading first object, press the

Display will show

• In counting mode, renewal of unit weight will automatically clear the total.

S key before stabilization may cause inaccurate accumulation reading.

T key after step 1 above to continue the accumulation.

[0], and next object can then be added on top of previous object remaining on scale. Useful for mixing.

Total Amount

550

pcs.

FP

T

Accumulation Function 27

Page 30

10.0 Specifications

This section contains charts for specifications and model data for the IB Series scale.

10.1 Specifications

Refer to the tables below for common specifications and model specific data.

10.1.1 Common Specifications

Item Specification

Measurement method Tuning fork type

Tare subtraction Full capacity, one-touch adjustment (measurable range = capacity - tare weight)

Zero adjustment

Display Maximum 6 column liquid crystal display

Weight correction Semi-automatic span adjustment

Over-scale display

Ambient temperature/humidity

Power Specialized AC adapter (AC 110V DC9V, 400 mA)

Auto zero (can be set to

OFF)

[0-Err] message. (If weight = capacity + 9 digits)

ο

C, 80% relative humidity or less

0~40

Table 10-1. Common Specifications

10.1.2 Model Specific Data

Model Capacity Minimum Graduations Resolution Pan Dimensions

IB-1000 1000g 0.005g 1/200,000 170mm

IB-2000 2000g 0.01g 1/200,000

IB-5000 5000g 0.01g 1/500,000 220mm X 180mm

IB-10K 10kg 0.05g 1/20,000

IB-15K 15Kg 0.1g 1/150,000

* In counting mode, the minimum unit is equal to the minimum graduation value.

28 IB Series Operation Manual

Table 10-2. Model Specific Data

Page 31

10.2 Options and Standard Attachments

Options

• IJ output: for connecting peripherals (printer, comparator, etc.)

•Buzzer output: judgment result alert buzzer function + IJ output.

• Limit output: judgment result alert buzzer connection output + specialized printer output.

•RS-232C output: for two-way communication with peripheral or external units.

•Battery drive: 48-hour charge (when not using output) for use where no service outlet is available.

Standard Attachments

•AC Adaptor

•Dust cover

10.3 Model Capacity/Readability Tables

IB-1000 IB-2000

Set C Unit Mark Capacity Readability

1mgmg1,000,000 10

2g g 1,000 0.01

3kgkg1.0 0.00001

4ctct5,000 0.05

5oz

6lb

7 ozt

8 dwt

9gr

A HK tael

B SIN tael

C TW tael

D mom

#

#

#

#

#

#

#

#

#

35 0.0005

2.2 0.00002

32 0.0005

640 .01

15,000 0.2

26 0.0002

26 0.0002

26 0.0002

260 0.002

Set C Unit Mark Capacity Readability

1mgmg2,000,000 10

2g g 2,000 0.01

3kgkg2 0.00001

4ctct10,000 0.05

5oz

6lb

7 ozt

8 dwt

9gr

A HK tael

B SIN tael

C TW tael

D mom

#

#

#

#

#

#

#

#

#

70 0.0005

4.4 0.00002

64 0.0005

1,200 0.005

30,000 0.2

53 0.0002

52 0.0002

53 0.0002

530 0.002

Specifications 29

Page 32

IB-5000 IB-10K

Set C Unit Mark Capacity Readability

1mgmg5,000,000 100

2g g 5,000 .01

3kgkg5 .0001

4ctct25,000 .5

5oz

6lb

7 ozt

8 dwt

9gr

A HK tael

B SIN tael

C TW tael

D mom

#

#

#

#

#

#

#

#

#

170 0.002

11 0.0002

160 0.002

3,200 0.05

77,000 2

130 .002

130 .002

130 .002

1,300 0.02

Set C Unit Mark Capacity Readability

1mgmg10,000,000 50

2g g 10,000 .05

3kgkg10 0.00005

4ctct50,000 0.2

5oz

6lb

7 ozt

8 dwt

9gr

A HK tael

B SIN tael

C TW tael

D mom

#

#

#

#

#

#

#

#

#

350 0.002

22 0.0001

320 0.002

6,400 0.05

150.000 1

260 0.001

260 0.001

260 0.001

2,600 0.01

IB-15K

Set C Unit Mark Capacity Readability

1mgmg15,000,000 100

2g g 15,000 0.1

3kgkg15 0.0001

4ctct75,000 0.5

5oz

6lb

7 ozt

8 dwt

9gr

A HK tael

B SIN tael

C TW tael

#

#

#

#

#

#

#

#

520 0.005

33 0.0002

480 0.005

9600 0.05

230,000 2

400 0.002

390 0.002

400 0.002

30 IB Series Operation Manual

D mom

#

4,000 0.02

Page 33

11.0 Troubleshooting

The following section contains a troubleshooting chart for the IB Series scale. Refer to this chart to locate causes

and countermeasures to various conditions.

Condition Cause Countermeasure

Limit function data

cannot be set

• Scale is not set to Limit Function mode

• Upper and lower limits have not been

set, or lower limit upper limit setting

has been entered

[#] mark will flash at OVER/ACCEPT/

UNDER positions.

Display will not

stabilize

Displayed value is in

error. Weight value

deviating

Linearity

error

Display is blank • Adapter is not connected

Scale will not weigh

up to rated capacity

•Wind or vibration is affecting scale • Set up scale elsewhere

• Scale is set on unstable surface • Set scale level

• Extended usage or moving scale has

affected span value

• Mis-performed tare subtraction • Reset tare subtraction

• Scale is not set level • Set scale level

• Extended usage or moving scale has

affected span value

• Mechanical adjustment has changed

due to some modification in scale

characteristics, etc

• Battery needs recharging

• Auto Power

•Tare + sample weight exceeds capacity

•(Weight range = maximum capacity tare weight)

OFF is activated

• Check that limit function settings are

correct: See page 27

• Perform span adjustment

• Perform span adjustment

• Consult your local Rice Lake Weighing

Systems Service distributor

• Recharge battery

•Press the

• Recheck tare weight

ON/OFF

The LOW-BATT lamp

is lit

The SLEEP lamp is lit • If the battery option is employed, the

b - ERR

0 - ERR

U - ERR

• If the battery option is employed, the

voltage of the internal batteries has

dropped

displayed value has not been used for

more than three minutes

• Electronic malfunction due to static

electricity electromagnetic interference

• Capacity is exceeded

•Tare is overweight

(Weighing value = sample weight + tare weight)

• Something contacting and holding up pan or pan base

• Recharge batteries or connect the AC

adapter

•Press a key or weigh an item

• Consult your local Rice Lake Weighing

Systems distributor

Table 11-1. Troubleshooting Chart

Troubleshooting 31

Page 34

IB Series Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems manufactured and sold by

RLWS and properly installed by an authorized RLWS Distributor or Original Equipment Manufacturer (OEM)

will operate per written specifications as confirmed by the Distributor/OEM and accepted by rlws. All systems

and components are warranted against defects in materials and workmanship for five years.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized

by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment

fails to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

•Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to

prevent electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a

publication, Protecting Your Components From Static Damage in Shipment, available from RLWS

Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was

not caused by accident, misuse, neglect, alteration, improper installation, improper repair or

improper testing; RLWS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other than RLWS or its

duly authorized repair agents.

•RLWS will have a reasonable time to repair or replace the defectiv e equipment. Buyer is responsible

for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE. NEITHER RLWS NOR DISTRIBUTOR WILL, IN ANY EVENT, BE

LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’ SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS

LIMITED TO REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY,

THE BUYER W AIVES ANY AND ALL OTHER CLAIMS TO W ARRANTY .

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE

SELLER FOR WARRANTY CLAIMS.

NO TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO MODIFY

THE TERMS OF THIS WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN

WRITING AND SIGNED BY A CORPORATE OFFICER OF RLWS AND THE BUYER.

© 2001 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

Loading...

Loading...