Page 1

880 Performance Series

Panel Mount Controller/Indicator

Version 1.01

Operation Manual

152240 - Rev C

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

About This Manual ................................................................................ 1

1.0 Introduction............................................................................... 1

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Front Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Indicator Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.1 Toggle Gross/Net Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.2 Toggle Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.3 Zero Scale. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.4 Acquire Tare . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.5 Remove Stored Tare Value . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.6 Preset Tare (Keyed Tare) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.7 Print Ticket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.8 Front Panel Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.9 Displaying Audit Trail Information . . . . . . . . . . . . . . . . . . . . . . . 7

1.4.10 Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.4.11 Set Time and Date. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.12 Display Accumulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.4.13 Clear the Accumulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.4.14 Display Tare. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.0 Configuration .......................................................................... 11

2.1 Configuration Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.1 Revolution® Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1.2 EDP Command Configuration . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1.3 Front Panel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.1.4 Alphanumeric Entry Procedure . . . . . . . . . . . . . . . . . . . . . . . 14

2.2 Menu Structures and Parameter Descriptions . . . . . . . . . . . . . . 14

2.2.1 Audit Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.2 Setup Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.3 Scale Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2.4 Feature Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2.5 Ports Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.2.6 Ethernet Communications Menu . . . . . . . . . . . . . . . . . . . . . . 22

2.2.7 USB Host . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2.2.8 Print Format Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.2.9 Setpoint Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.2.10 Digital Input/Output Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Rice Lake Weighing Systems is an ISO 9001 registered company.

i 880 Operator’s Manual

Specifications subject to change without notice.

Version 1.01, June 20, 2014

Page 4

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

2.2.11 Analog Output Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.2.12 Version Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.0 Appendix ................................................................................. 27

3.1 Displayed Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.2 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

880 Limited Warranty.......................................................................... 30

Contents ii

Page 5

About This Manual

This manual is intended for use the operator of the 880 digital weight indicators and

applies to indicators using Version 1.01 of the 880 software.

The Technical/Service manual (PN 158387) that is referred to throughout this manual

and is available online.

Manuals can be viewed or downloaded the Rice Lake Weighing Systems

website at

www.ricelake.com/manuals.

Please leave this manual with the indicator when installation and configuration are

complete.

1.0 Introduction

The 880 is a single-channel digital weight indicator housed in a panel mount

enclosure. The front panel bezel can be sealed to a NEMA 4X/IP65 rating. The front

panel consists of a 6-button keypad; a large, seven-digit, 14-segment, vacuum

fluorescent display; two-character dot-matrix annunciator field; and 16-character dotmatrix prompt field. Features include:

• Drives up to 8 350

• Supports four and six wire load cell connections

• Four configurable digital inputs or outputs

• Full duplex RS-232 or half duplex RS-485 communications up to 115200 bps

• Ethernet TCP/IP interface for 10Base-T/100Base-TX network communications

• USB interface for host (type A connection) or device

• Expansion slot for one option card

• Optional DeviceNet

Bradley

®

controllers

• Optional Ethernet/IP interface for Allen-Bradley PLC and other Ethernet/IP

master devices

• Optional Profibus® DP interface

• Optional Modbus TCP interface

• Optional Profinet Interface

• Optional analog output module provides 0–10 VDC, 0-20mA or 4–20 mA

tracking of gross or net weight values

• Optional four channel relay module, dry connect 3A @ 115VAC, 3A @ 30VDC

• Available in 115 VAC and 230 VAC versions

or 16 700 load cells

™

interface for communications network with Allen-

1

3

2

1. DeviceNet™ is a trademark of the Open DeviceNet Vendor Association.

2. Profibus

3. EtherNet/IP

1 880 Operator’s Manual

®

is a registered trademark of Profibus International.

™

is a trademark of the Open DeviceNet Vendor Association.

Page 6

1. 1 S af et y

WARNING

CAUTION

Important

WARNING

WARNING

Safety Symbol Definitions

Indicates a potentially hazardous situation that, if not avoided,

could result in serious injury or death, and includes hazards that

are exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided,

may result in minor or moderate injury.

Indicates information about procedures that, if not observed,

could result in damage to equipment or corruption to and loss of

data.

Safety Precautions

Do not operate or work on this equipment unless you have read

and understand the instructions and warnings in this manual.

Failure to follow the instructions or heed the warnings could

result in injury or death. Contact any Rice Lake Weighing

Systems dealer for replacement manuals. Proper care is your

responsibility.

Some procedures described in this manual require work inside

the indicator enclosure. These procedures are to be performed by

qualified service personnel only.

General Safety

Failure to heed may result in serious injury or death.

DO NOT allow minors (children) or inexperienced persons to operate this unit.

DO NOT operate without all shields and guards in place.

DO NOT step on the unit.

DO NOT jump on the scale.

DO NOT use for purposes other than weight taking.

DO NOT place fingers into slots or possible pinch points.

DO NOT use any load-bearing component that is worn beyond 5% of the original

dimension.

DO NOT use this product if any of the components are cracked.

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

DO NOT use near water.

Before opening the unit, ensure the power cord is disconnected from the outlet.

Keep hands, feet and loose clothing away from moving parts.

Introduction 2

Page 7

1.2 Operating Modes

Gross

Brutto

Net

lb

kg

PT

T

MENU

ZERO

PRINT

GROSS

NET

B/N

TAR E

UNITS

R1 R2 R3

The 880 has three modes of operation:

Normal mode

Normal mode is the weighing mode of the indicator. The indicator

displays gross or net weights as required, and annunciators to indicate

scale status and the type of weight value displayed.

User Setup Mode

User setup mode (accessed by pressing MENU) is used to:

• View the audit trail

• Set the time and date

• View or clear the accumulator value

• Change setpoint values

• View the current tare value

• Enter setup mode (if audit trail is enabled)

See Section 1.4.8 for more information.

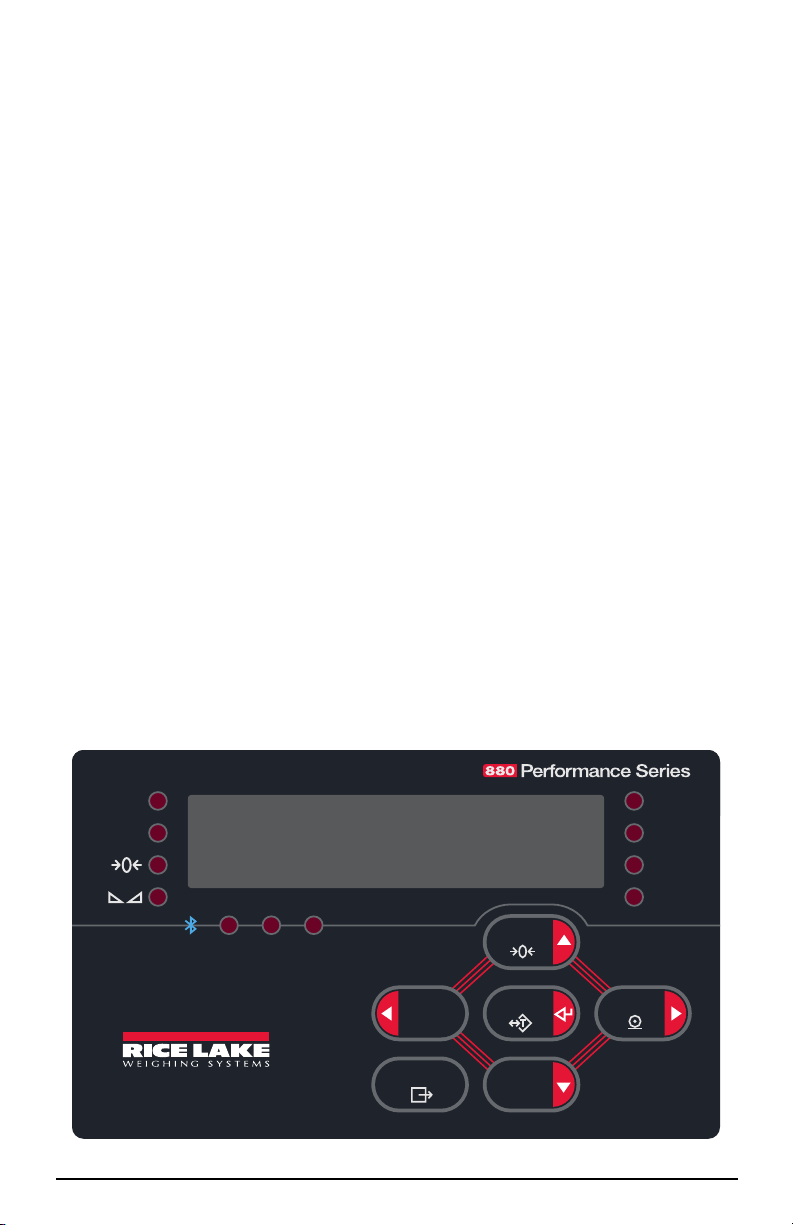

1.3 Front Panel Display

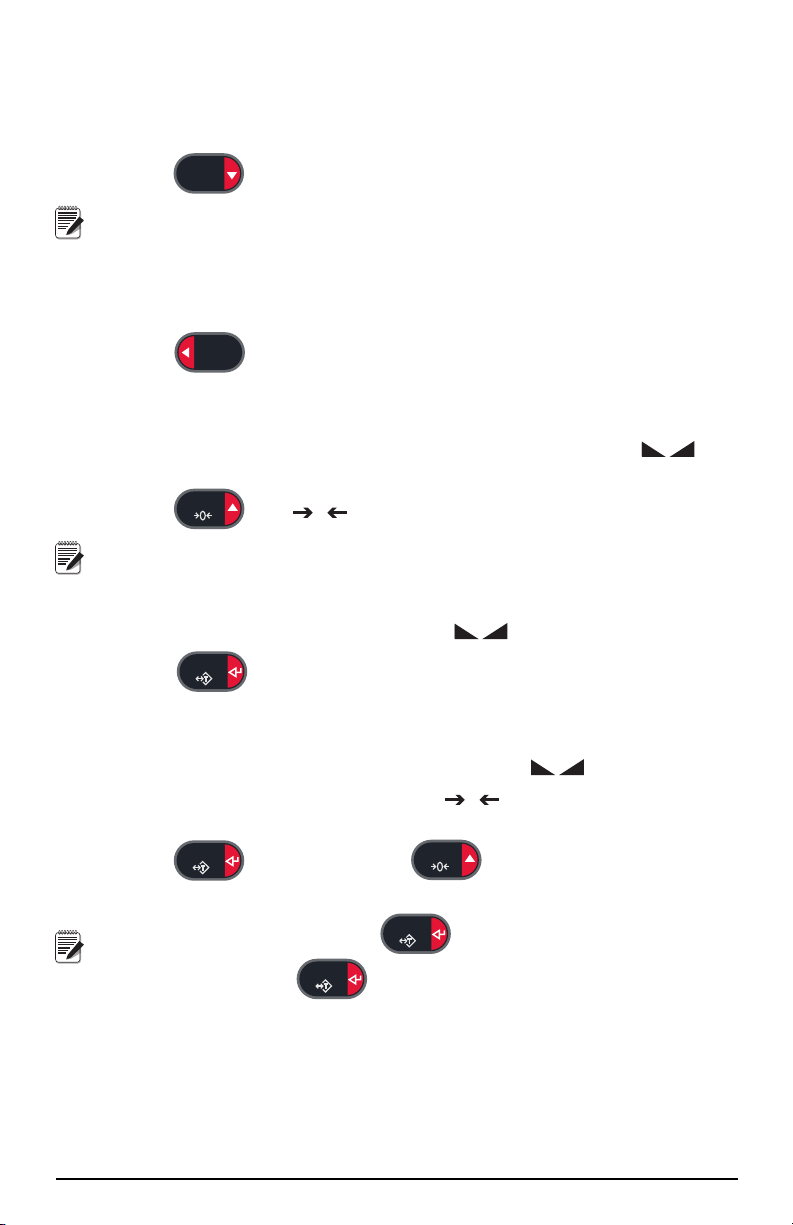

Figure 1-1 shows the 880 front panel keys and the key functions assigned in normal

mode.

The numeric display consists of six large, 14-segment LED digits. If a negative

number is displayed the first LED is used to display “-”, reducing the number of

available digits to five.

The symbols on the keys in Figure 1-1 (representing up, down, enter, left, right)

describe the key functions assigned in setup mode. The keys are used to navigate

through menus, select digits within numeric values, and increment/decrement values.

See Section 2.1.3 for information about using the front panel keys in setup mode.

3 880 Operator’s Manual

Page 8

Figure 1-1. 880 Front Panel Display

ZERO

PRINT

GROSS

NET

B/N

MENU

UNITS

TAR E

Gross

Brutto

Net

0

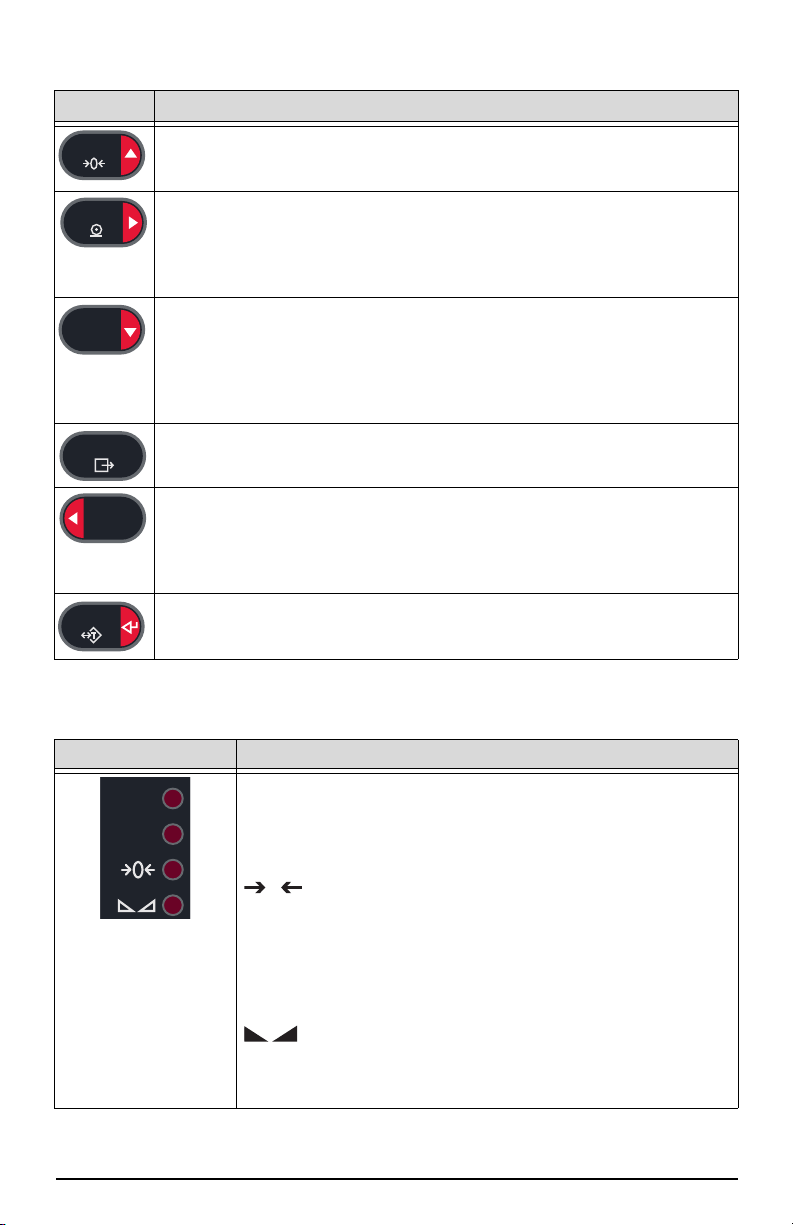

Key Function

Sets the current gross weight to zero.

Also used to navigate to different menu levels or used to increment a

number when editing a value.

Sends “on-demand” print format out the serial port, provided the

conditions for standstill are met. PRINT may be displayed while the unit

prints.

Also used to navigate to different menus or to toggle to another digit when

editing a value.

Toggles between gross and net. If a tare value has been entered or

acquired, the net value is the gross weight minus the tare.

Gross mode is shown by the Gross/Brutto annunciator; net mode is

shown by the Net annunciator.

Also used to navigate to different menu levels or to decrement a number

when editing a value.

The MENU key is used to access the setup menu.

Also acts as the cancel key when editing parameter values.

Switches the weight display to an alternate unit, defined in the Format

menu, see Technical/Service manual for more information.

Units Available: lb, kg, oz, metric ton, ton, gram.

Also used to navigate to different menus or to toggle to another digit when

editing a value.

Performs one of several predetermined Tare functions dependent on the

mode of operation selected in the TAREFN parameter.

Also acts as enter for numeric or parameter entry.

Table 1-1. Key Functions

Key Function

Gross/Brutto LED

Gross weight mode (or Brutto in OIML mode)

Net LED

Net weight mode.

Center of Zero LED

Indicates that the current gross weight reading is within +/-

0.25 display divisions of the acquired zero, or is within the

center of zero band.

A display division is the resolution of the displayed weight

value, or the smallest incremental increase or decrease that

can be displayed or printed.

Standstill LED

Scale is at standstill or within the specified motion band. Some

operations, including Zero, Tare and Printing, can only be done

when the standstill LED is on.

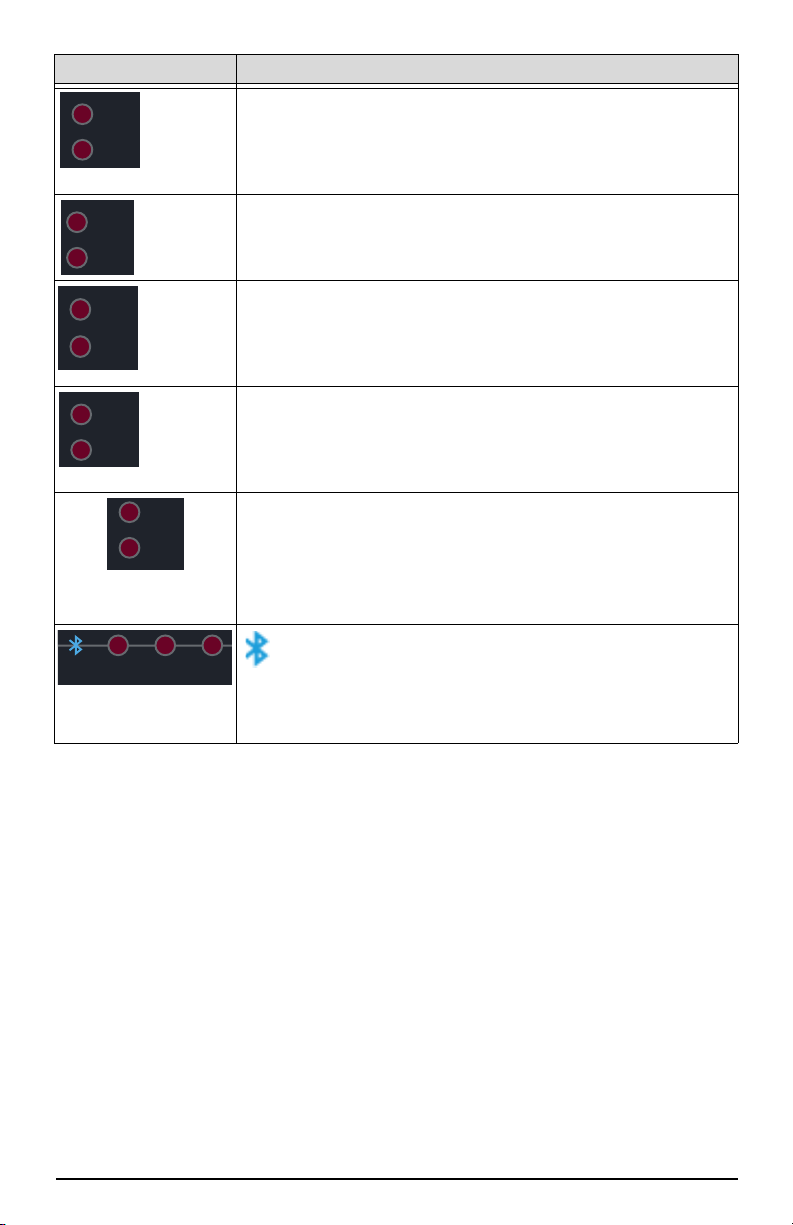

Table 1-2. Annunciator Functions

Introduction 4

Page 9

Key Function

lb

kg

kg

lb

lb

kg

primary

secondary

lb

kg

tn, t, oz,

lb

g or none

lb

kg

tn, T, oz,

kg

g or none

PT

T

R1 R2 R3

lb/kg LED

Displays which unit of measure is being used.

The lb and kg annunciators indicate the units associated with

the displayed value. If the displayed value is pounds, lb will be

lit. If the displayed value is kilograms, kg will be lit.

primary/secondary LED

If the other units value is neither lb or kg, then lb will be lit for

the units assigned as primary, and kg will be lit for the units

assigned as secondary.

lb/tn,t,oz,g,none LED

Alternate units that can be displayed include short tons (tn),

metric tons (t), ounces (oz), grams (g), or NONE (no units). If the

displayed units is one of these alternate units, and the other

unit value is lb, then lb will be lit.

tn,t,oz,g,none /kg LED

Alternate units that can be displayed include short tons (tn),

metric tons (t), ounces (oz), grams (g), or NONE (no units). If the

displayed units is one of these alternate units, and the other

unit value is kg, then kg will be lit.

T LED

Indicates that a tare has been acquired and stored by the

system.

PT LED

Indicates that a preset tare weight has been keyed in or

entered via the EDP serial port.

5 880 Operator’s Manual

Bluetooth

Bluetooth communications enabled

R1, R2 and R3

Range settings for multi interval or multi range

Table 1-2. Annunciator Functions

Page 10

1.4 Indicator Operations

GROSS

NET

B/N

Note

UNITS

ZERO

0

Note

TAR E

TAR E

ZERO

Note

TAR E

TAR E

Basic 880 operations are summarized below:

1.4.1 Toggle Gross/Net Mode

1. Press to toggle the display mode between gross and net.

Net mode is available when a tare value has been entered or acquired,

(NET = GROSS minus TARE). If tare has not been entered or acquired, the

display remains in gross mode. LEDs next to Gross or Net indicates the

current mode.

1.4.2 Toggle Units

1. Press to switch between primary and secondary units. The current

units LED will be lit.

1.4.3 Zero Scale

1. In gross mode, remove all weight from the scale and wait for the LED

to light.

2. Press . The LED lights to indicate the scale is zeroed.

The scale must be stable and within the configured zero range, for the

scale to be zeroed. If the scale cannot be zeroed, NOZERO will display.

1.4.4 Acquire Tare

1. Place container on scale and wait for the LED to light.

2. Press to acquire the tare weight of the container. Net weight is

displayed and the T LED lights to show the tare value was entered.

1.4.5 Remove Stored Tare Value

1. Remove all weight from the scale and wait for the LED to light.

2. The display should read zero and the LED should be lit, zero the

scale if needed.

3. Press (or, in OIML mode ). Display shifts to gross weight

and the Gross LED is lit.

If keyed tare is allowed, press to open the keyed tare prompt. To

clear the tare press again.

0

Introduction 6

Page 11

1.4.6 Preset Tare (Keyed Tare)

Note

TAR E

TAR E

TAR E

Note

PRINT

MENU

MENU

MENU

Tare mode must be set to keyed or both for preset tare to function.

1. With the scale empty and zero weight on the display, press .

2. Display will show (000000); the focused digit will flash.

3. To edit the value:

• Press or to select the digit.

• Press or to increment or decrement the value.

• Press to move to the decimal point entry.

• Press or to adjust the decimal point placement.

• Press when the value is correct.

4. The display will change to the Net mode and the

PT LED lights to show the

preset tare was entered.

Entering a keyed tare of zero will remove the stored tare value.

1.4.7 Print Ticket

1. Wait for the ( ) LED to light.

2. Press to send data to a communications port.

1.4.8 Front Panel Setup

1. Press to enter user setup mode. Use user setup to:

• View audit trail information

• Enter setup mode if audit trail is enabled

• View or set time and date

• View or clear the accumulator

• Change setpoint values and enable/disable setpoints

• View the current tare value

1.4.9 Displaying Audit Trail Information

The Audit Trail Configuration and Calibration counters can be viewed through the

User Menu.

1. Press ,

2. Press to display the Legally Relevant Firmware version.

3. Press to display

4. Press to view the Calibration Counter.

5. Press to return to

6. Press to display

7. Press to view the Configuration Counter.

7 880 Operator’s Manual

AUDIT is displayed.

CALIB.

CALIB.

CFG.

Page 12

8. Press to return to CFG.

MENU

MENU

MENU

Note

MENU

TAR E

TAR E

MENU

Note

9. Press to return to the weigh mode.

1.4.10 Setpoints

Setpoints must be enabled in the setup mode to be accessible in the user setup mode.

To enter the setup mode:

1. Remove the large fillister head screw from the back of the enclosure.

2. Insert a nonconductive tool into the access hole and press the setup switch.

Indicator display changes to show

3. Press or until

4. Press ,

SP CFG is displayed.

SETPTS is displayed.

5. Press , press or to desired setpoint number.

6. Press to enter setpoint settings.

7. Select the type by pressing or to desired setting, then press to set the

value. For complete list of options see Section 3.2.13.

8. When all settings have been made, press to return to weighing

mode.

Setpoints are now accessible from the front panel menu.

Display or Edit Setpoint Value

1. Press . AUDIT is displayed.

2. Press or until

3. Press and the first available setpoint number is displayed.

4. Press or to toggle through each setpoint that is operator accessible.

5. Press , is displayed.

6. Press again to display or edit the value. To edit the value:

• Press or to increment or decrement the value of the flashing digit.

• Press or to select the digit to edit.

SETPTS is displayed.

SCALE.

• Press to move to the decimal point entry.

• Press or to adjust the decimal point placement.

7. Press to accept the displayed value.

8. Repeat the above steps to set

PREACT, if enabled

9. When all settings have been made, press to return to weighing

mode.

Setpoint Value and Preact Value may be accessible from the front panel

in weigh mode.

Some indicator configurations may not allow setpoint values to be

changed through the front panel or may require a password to display or

change the setpoint value.

Introduction 8

Page 13

Turn Setpoint On or Off

MENU

TAR E

MENU

Note

MENU

TAR E

TAR E

MENU

MENU

To turn a setpoint off at the front panel:

1. Press . AUDIT is displayed.

2. Press or until SETPTS is displayed.

3. Press and the first available setpoint number is displayed.

4. Press or to toggle through each setpoint that is operator accessible.

5. Press , then press or to

6. Press , then press or to turn setpoint

ENABLE/DISABLE.

ON/OFF.

7. Press to accept the setting.

8. Press to return to weighing mode.

Some indicator configurations may not allow setpoints to be turned off

through the front panel or may require a password to turn the setpoint on

and off.

1.4.11 Set Time and Date

1. Press , AUDIT is displayed.

2. Press or until

3. Press ,

TIME is displayed.

4. Press , to enter time.

5. To edit the value ( 24 hour format):

• Press or to select the digit.

• Press or to increment or decrement the value.

T&D is displayed.

6. Press when the value is correct.

DATE is displayed.

7. Press , to enter time.

8. To edit the value in specified format (MMDDYY, DDMMYY, or YYMMDD):

• Press or to select the digit.

• Press or to increment or decrement the value.

9. Press when the value is correct.

TIME is displayed.

10. Press to return to weighing mode.

1.4.12 Display Accumulator

Enable accumulator before use in either normal mode or setpoint operations. Once

enabled, weight (net weight if a tare is in the system) is accumulated whenever a print

operation is performed using the

operation or KPRINT serial command. The scale must return to below the threshold

value (except for the setpoint

1. Press to enter the user setup mode, AUDIT is displayed.

2. Press or until ACCUM is displayed.

9 880 Operator’s Manual

PRINT key, digital input, setpoint PSHACC

PSHACC operation) before the next accumulation.

Page 14

ACCUM

Note

PRINT

Note

MENU

TAR E

MENU

Note

MENU

MENU

is only displayed if the accumulator is enabled.

3. Press , VIEW is displayed.

4. Press to view the current accumulator value.

5. While the accumulator value is displayed, press to print the value.

The format of the print ouput can be configured using accumulator print

format. See Section 7.0.

1.4.13 Clear the Accumulator

1. Press to enter the user setup mode, AUDIT is displayed.

2. Press or until

3. Press , then press or until

ACCUM is displayed.

CLR Y is displayed.

4. Press to clear the accumulator,

display returns to

CLR Y.

CLEAR will display briefly and

5. Press to return to the weigh mode.

The PRINT key only performs one accumulation. Weight must return to

zero below the configured threshold value before another accumulation

is allowed.

Threshold is configured in the setup menu, see Section 3.2.3.

1.4.14 Display Tare

When a stored Tare value is displayed, the Gross and Net LEDs will be off and the

will be lit. To display a stored tare:

1. Press .

2. Press to

3. Press twice to return to weighing mode.

If there is no tare in the system, the value displayed will be zero and the Gross and

Net LED will be turned off.

See the Technical Service Manual (PN 158387) for more information pertaining to

the regulatory mode of operation.

TAR E and press to view the current tare value.

Introduction 10

Page 15

2.0 Configuration

Important

Note

MENU

J1 J2 J3 J4 J5 J6

Setup

Switch

Access

MENU

Note

To configure the 880 indicator, the indicator must be placed in setup mode. The setup

switch is accessed through a small hole on the enclosure backplate, insert a nonconductive tool into the access hole and press the configuration switch. Indicator

display changes to show

Use caution when inserting the non-conductive tool into the

backplate, press the tool in about 3/4 inch, using the board as a

guide, until the switch is engaged. Do not use excessive force, the

switch may be damaged.

CONFIG.

If audit trail is enabled, press

Press or until SETUP is displayed, then press to SCALE.

to access setup mode.

.

Figure 2-1. Back View – Setup Switch Access

When the indicator is placed in setup mode, the word

CONFIG is shown on the

display. The CONFIG menu is the first of ten top-level menus used for configuring

the indicator. Detailed descriptions of these menus are given in Section 2.2. When

configuration is complete, return to the CONFIG menu and press the (

ZERO) key

to exit setup mode.

When configuration is complete, press to return to the weigh mode.

2.1 Configuration Methods

The 880 indicator can be configured by using the front panel keys to navigate through

a series of configuration menus or by sending commands or configuration data to the

EDP port. Configuration using the menus is described in Section 2.1.3.

Configuration using the EDP port can be accomplished using either the EDP

command set described in the Technical Service manual or Version 3.0 or later of the

Revolution

®

configuration utility.

2.1.1 Revolution® Configuration

The Revolution configuration utility provides the preferred method for configuring

the 880 indicator. Revolution runs on a personal computer to set configuration

parameters for the indicator. When Revolution configuration is complete,

configuration data is downloaded to the indicator.

See Section 5.0 of the Technical/Service manual (PN 158387) for more

information on Revolution.

11 880 Operator’s Manual

Page 16

2.1.2 EDP Command Configuration

000000

000000

ACCUM

Displayed only

if turned on in

Scale Menu

AUDIT

TARE

SETPTST & D ACCUMSETUP

000000

DATE

TIME

No Access

unless the

jumper is

installed

VIEW CLR Y?

000000

See

Figure 2-7

See

Figure 2-6

See

Figure 2-18

The EDP command set can be used to configure the 880 indicator using either a

personal computer or terminal. Like Revolution, EDP command configuration sends

commands to the indicator EDP port; unlike Revolution, EDP commands can be sent

using any external device capable of sending ASCII characters over a serial

connection.

EDP commands duplicate the functions available using the indicator front panel and

provide some functions not otherwise available. EDP commands can be used to

simulate pressing front panel keys, to configure the indicator, or to dump lists of

parameter settings. See the Technical Service manual for more information about

using the EDP command set.

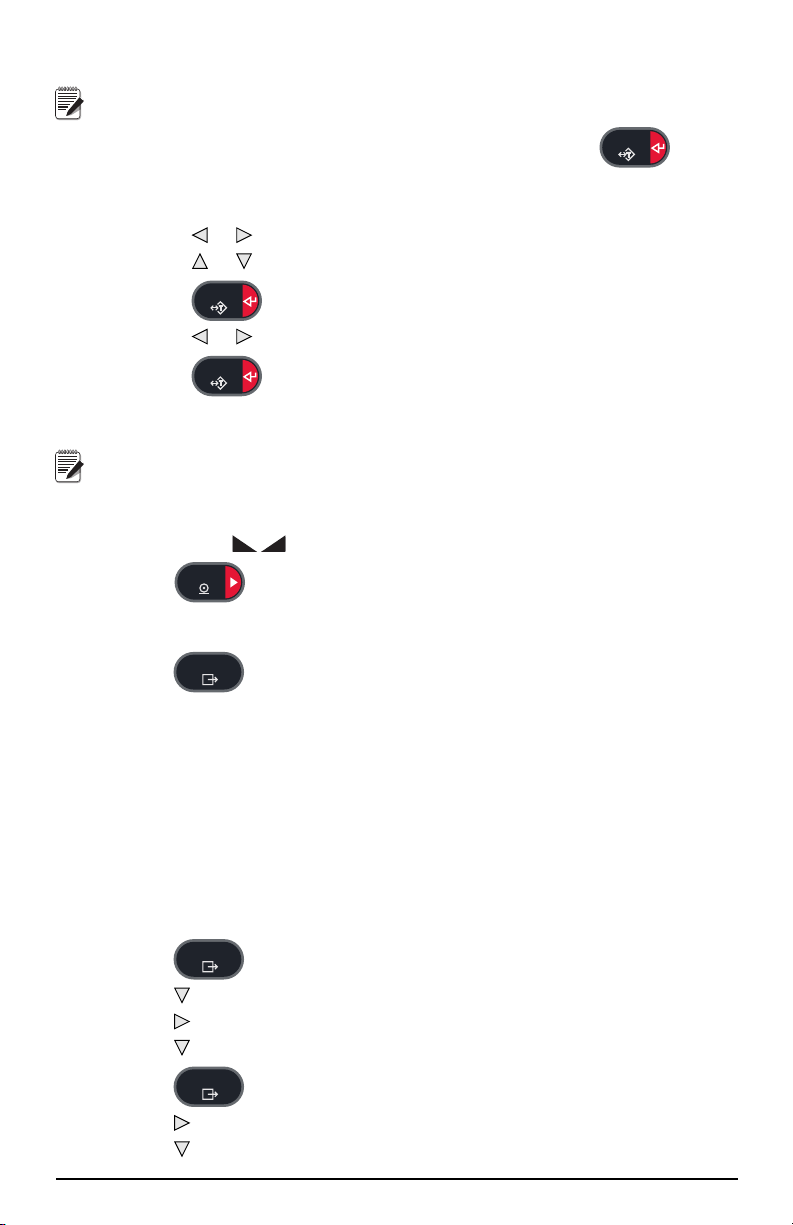

2.1.3 Front Panel Configuration

The 880 indicator can be configured using a series of menus accessed through the

indicator front panel when the indicator is in setup mode. Table 2-1 summarizes the

functions of each of the main menus.

Figure 2-2. 880 Menu Layout

Menu Menu Function

AUDIT Audit Trail Displays the legally relevant (LR) firmware version,

SETUP Setup

T&D Time and Date View and change time and date.

ACCUM Accumulator Displays the current accumulator value.

SETPTS Setpoints Configure setpoints.

TA R E Ta re Ta re f u n c t i o n . E n a b l e s or disables push-button and

configuration count and calibration count.

keyed tare

Table 2-1. 880 Menu Summary

Configuration 12

Page 17

Figure 2-3. Five-Key Keypad Functions in Setup Mode

T

MENU

ZERO

PRINT

GROSS

NET

B/N

TA RE

UNITS

Level 1

Parameter

Current value

Level 2

Parameter

Value Value Value

Level 1

Parameter

Level 2

Parameter

When moving through values below the first menu level, press to return to the level

above.

0 0 0 0 0 0

When editing numeric values, press or to change the selected digit.

Press or to increment or decrement the value of the selected digit.

After the number desired is displayed, press ENTER. The decimal point

will begin flashing if a decimal value is allowed. To move the decimal,

use or to move the decimal position. Press ENTER when done.

Four front panel keys are used as directional keys to navigate through the menus in

setup mode (see Figure 2-3). The

(horizontally) on the same menu level;

down (vertically) to different menu levels. The

UNITS ( ) and PRINT ( ) keys scroll left and right

ZERO () and GROSS/NET ( ) move up and

TARE key ( ) serves as an Enter key

for selecting parameter values within the menus.

Figure 2-4. Setup Mode Menu Navigation

To select a parameter, press or to scroll left or right until the desired menu group

appears on the display, then press to move down to the submenu or parameter you

want. When moving through the menu parameters, the default or previously selected

value appears first on the display.

To change a parameter value, scroll left or right to view the values for that parameter.

When the desired value appears on the display, press to select the value and move

back up one level. To edit numerical values, use the navigation keys to select the digit

and to increment or decrement the value.

13 880 Operator’s Manual

Figure 2-5. Editing Procedure for Numeric Values

Page 18

2.1.4 Alphanumeric Entry Procedure

Display first 6

characters of format

Display and edit

active character and

ASCII value

Delete active

character

Scroll right in format string

Scroll left in format string

Increment ASCII value of active character

Decrement ASCII value of active character

Press to insert a space

before the active character

Press to accept the changes

and return to the level above.

Level 2

Parameter

Level 1

Parameter

Level 2

Parameter

Level 1

Parameter

Press to accept the changes

and return to the level above.

LRV 1.00

number

AUDIT

TARE

SETPTST & D

ACCUMSETUP

CALIB CFG

number

Because of its limited keypad, the 880 will use the following scheme for

alphanumeric entry.

Table 2-2. Editing Procedure for Numeric Values

2.2 Menu Structures and Parameter Descriptions

The following sections provide graphic representations of the 880 menu structures. In

the actual menu structure, the settings you choose under each parameter are arranged

horizontally. To save page space, menu choices are shown in vertical columns. The

factory default setting appears at the top of each column and is bolded. Parameters

shown surrounded by a dotted-line box only appear under the special circumstances

explained under each box.

Most menu diagrams are accompanied by one or more tables that describe all

parameters and parameter values associated with that menu option. Default parameter

values are shown in bold type.

2.2.1 Audit Menu

AUDIT Menu

Parameter Choices Description

LRV --- Legally relevant firmware version

CALIB 000000 Displays total calibration events.

CFG 000000 Displays total configuration events.

Figure 2-6. Audit Menu Structure

Table 2-3. Audit Menu Parameters

Configuration 14

Page 19

2.2.2 Setup Menu

SCALE FEATUR PORTS

PFORMT

SETPTS DIGIO ALGOUT VERS

AUDIT TARESETPTST & D ACCUMSETUP

10000

1-100000

....

30HZ

7.5HZ

15HZ

60HZ

120HZ

240HZ

480HZ

960HZ

LIGHT

MEDIUM

HEAVY

SETUP

........

SCALE

GRADS

OFF

2RNG

3RNG

2INTVL

3INTVL

SPLIT MOTBAN

0-1000-100

ZRANGEZTRKBNFORMAT

0-100

DSPRAT

1-80

FS+2%

FS+ 1D

FS+ 9D

FS

OVRLOA SSTIME

1-65536

SMPRAT DFTHRHDFSENS TAREFN

1-99999

BOTH

NOTARE

PBTARE

KEYED

THRESH CALIBRPWRUPM ACCUM

GO

DELAY

OFF

ON

0-999999

See

Figure 2-9

See

Figure 2-10

2.2.3 Scale Menu

Figure 2-7. Setup Menu Structure

15 880 Operator’s Manual

Figure 2-8. Scale Menu Structure

Page 20

Format Menu

........

SCALE

....

FORMAT

PRI

1D

2D

5D

DSPDIV

DECPNT

888888

888880

8.88888

88.8888

888.888

8888.88

88888.8

SETUP

........

UNITS

LB

KG

OZ

TN

T

G

NONE

SEC

5D

1D

2D

DSPDIV

DECPNT

88888.8

888888

888888

8.88888

88.8888

888.888

8888.88

UNITS

LB

KG

OZ

TN

T

G

NONE

........

SCALE

....

FORMAT

1D

2D

5D

DDIV1DECPT1

888888

888880

8.88888

88.8888

888.888

8888.88

88888.8

SETUP

....

....

MAX1

2000

weight

5D

1D

2D

DDIV2

DECPT2

88888.8

888888

888880

8.88888

88.8888

888.888

8888.88

5D

1D

2D

DDIV3DECPT3

88888.8

888888

888880

8.88888

88.8888

888.888

8888.88

UNITS

LB

KG

OZ

TN

T

G

NONE

MAX2

5000

weight

MAX3

10000

weight

Only available if

SPLIT = 3RNG or 3INTVL

If SPLIT = OFF

If SPLIT = 2RNG, 3RNG, 2INTVL, or 3INTVL

Figure 2-9. Format Menu Structure

Configuration 16

Page 21

Calibration Menu

SCALE

....

....

....

CALIBR

SETUP

....

....

Display and edit

test weight value

WVAL WLIN

POINT1

Same as POINT 1

REZERO

Calibrating, please wait

Press Enter to

compensate for

zero offset

WGT 1

WZERO

Calibrating, please wait

Press Enter

to calibrate zero

Press Menu

to cancel

Previous A/D raw

counts are shown

CAL1

POINT2 POINT3 POINT4 POINT5

WSPAN

Calibrating, please wait

Press Enter

to calibrate span

Press Menu

to cancel

Previous A/D raw

counts are shown

LAST

Calibrating, please wait

Press enter to recall

the last established

pushbutton zero value

to allow calibration

without removing test

weights from the scale.

TEMP

Calibrating, please wait

Press enter to

temporarily zero the

displayed weight of a

non-empty scale.

After span calibration

the previously

calibrated zero value

is used as the offset.

Calibrating, please wait

Press Enter

to calibrate span

Press Menu

to cancel

Previous A/D raw

counts are shown

Display and edit

test weight value

Figure 2-10. Calibration Menu Structure

17 880 Operator’s Manual

Page 22

2.2.4 Feature Menu

CONFIG

....

SETUP

........

REGION

000000

UID

KEYLCK

ZERO

UNLOCK

LOCK

UNITS

UNLOCK

LOCK

PRINT

UNLOCK

LOCK

TARE

UNLOCK

LOCK

MENU

UNLOCK

LOCK

GRSNET

UNLOCK

LOCK

0

RESVAL

LOCALE

OFF

ON

0

CURVAL

CONSC#

PASSWD

USER

0

SETUP

0

FEATUR

LATUDE

0-90

ELEVAT

-9999 to +9999

Shown if LOCALE is ON

See

Figure 2-12

Figure 2-11. Feature Menu Structure

Configuration 18

Page 23

Region Menu

SETUP

........

TFORMT T SEP SET

DFORMT D SEP SET

REGION

REGULA

REGWOR DECFMT

TIME DATE

NTEP

CANADA

INDUST

GROSS

BRUTTO

DOT

COMMA

NONE

OIML

24 HOUR

COLON

COMMA

XX.XXAM

000000

MMDDY4

DDMMY4

Y4MMDD

Y4DDMM

SLASH

DASH

SEMI

MMDDY2

DDMMY2

Y2MMDD

Y2DDMM

12 HOUR

....

FEATUR

SNPSHT

DISPLY

SCALE

ZTARE

NO

YES

KTARE

MTARE

REMOVE

REPLAC

NOTHIN

YES

NO

PRTMOT

NO

YES

PRTPT

NO

YES

CALIB

SCALE

NTEP

NONE

OIML

CANADA

NO

YES

NTARE

NO

YES

OVRBAS

CTARE

See INDUST

submenu below

AUDAG

Figure 2-12. Region Menu Structure

19 880 Operator’s Manual

Page 24

2.2.5 Ports Menu

SETUP

........

COM

SWAP

FLDBUS

USBCOM

....

PORTS

....

BYTE

BOTH

NONE

DVCNET

PRFBUS

Address Address

number number

USB

MEM

ETHNET

LOAD SAVE?

ALL ?

CFG ?

CAL ?

See

Figure 2-14

See

Figure 2-15

Figure 2-13. Ports Menu Structure

Configuration 20

Page 25

Com and USBCOM Menu

SETUP

.......

COM

....

PORTS

TRIGGE

STRIND

COMAND

STRLFT

REMOTE

STOP B

1

2

TERMIN

CR

CR/LF

ECHO

ON

OFF

EOLDLY

0-255

PRNMSG

OFF

ON

BAUD

1200

2400

4800

9600

19200

28800

38400

57600

115200

RESPNS

ON

OFF

TRIGGE

REMOTE

BITS

7ODD

7EVEN

8NONE

STOP B

1

2

BAUD

1200

2400

4800

9600

19200

28800

38400

57600

115200

PRNMSG

OFF

ON

SFMT

format

Menu Structure if TRIGGE is set to REMOTE.

BITS

7EVEN

8NONE

7ODD

USBCOM

TYPE

232

485

ADDRES

0-255

Only Available

if TYPE is

set to 485

Not available in USBCOM

Not available in USBCOM

SFMT

format

Menu Structure if

TRIGGE is set to

STRIND or STRLFT.

21 880 Operator’s Manual

Figure 2-14. Com Menu Structure

Page 26

2.2.6 Ethernet Communications Menu

SETUP

........

....

PORTS

ETHNET

DHCP

ON

OFF

IPADRS

xxx.xxx.xxx.xxx

NETMSK

xxx.xxx.xxx.xxx

DFTGWY

xxx.xxx.xxx.xxx

DNSPRI

xxx.xxx.xxx.xxx

DNSSEC

xxx.xxx.xxx.xxx

MACSERVER

PORT

number

TRIGGE

STRLFT

COMAND

STRIND

TERMIN

CR/LF

CR

EOLDLY

number

TIMOUT

number

SFMT

ECHO

OFF

ON

ON

OFF

RESPNS

RMOTIP TRIGGE

STRLFT

COMAND

STRIND

TERMIN

CR/LF

CR

EOLDLY

number

TIMOUT

number

ECHO

OFF

ON

ON

OFF

RESPNS

RMOTPT

number

SFMT

ALPHA/NUM

ALPHA/NUM

xxx.xxx.xxx.xxx

xx.xx.xx.xx.xx.xx

CLIENT

USB

MEM

LOAD SAVE?

ALL ?

CFG ?

CAL ?

2.2.7 USB Host

Figure 2-15. Ethernet Communications Menu Structure

......

Figure 2-16. USB Host Menu Structure

Configuration 22

Page 27

2.2.8 Print Format Menu

PFORMT

....

....

SETUP

....

....

GFMT

FMT

COM

ETH-S

USBCOM

PORT

format

NFMT SPFMTACCFMT HDRFMT

format

USBMEM

ETH-C

OFF

Note

SETUP

.....

SP CFG

....

SETPTS

SETPT1

BATCHG

SETPT2-20

OFF

AUTO

MANUAL

Same as

SETPT1

OFF

GROSS

NET

-GROSS

-NET

%REL

PAUSE

DELAY

WAITSS

COUNTR

AUTJOG

TIMER

CONCUR

See Figure 2-19

Menu Layout A

See Figure 2-20

Menu Layout B

See Figure 2-21

Menu Layout C

Figure 2-17. Print Format Menu Structure

See Technical/Service Manual (158387) for port choice descriptions.

2.2.9 Setpoint Menu

23 880 Operator’s Manual

Figure 2-18. Setpoint Menu Structure

Page 28

Setpoint Menu – Layout A

A

GROSS, NET, -GROSS, -NET, %REL

%RELSP Only

If PREACT is LEARN

number

VALUE

HIGHER

LOWER

INBAND

OUTBAN

TRIP

If TRIP=

HIGHER or

LOWER

number

HYSTER

OFF

ON

LEARN

PREACT

If TRIP=

INBAND or

OUTBAND

number

BANDVAL

RELNUM

1–20

PREVAL

If PREACT is

ON or LEARN

number

PREADJ

number

PRESTA

number

PCOUNT

number

BATSEQ

OFF

ON

CLRACM

OFF

ON

CLRTAR

OFF

ON

PSHPRT

OFF

ON

WAITSS

PSHTAR

OFF

ON

ACCESS

ON

OFF

DIGOUT

BIT1-4

PSHACM

OFF

ON

ONQUIE

NAME

6ALPHA

SENSE

NORMAL

INVERT

BRANCH

0

1-20

Based on which

DIGIO are config

as OUTPUT

If BATSEQ is ON

NONE

SLOT

SLOT 0

SLOT 1

SLOT 0 - if any DIGIO are configured as OUTPUT.

SLOT 1 - if RELAY option board is installed.

Figure 2-19. Setpoint Menu Structure – Layout A

Configuration 24

Page 29

Setpoint Menu – Layout B

B

PAUSE, DELAY, WAITSS, COUNTR, AUTJOG

SLOT

number

VALUE

CLRACM

OFF

ON

CLRTAR

OFF

ON

PSHPRT

OFF

ON

WAITSS

PSHTAR

OFF

ON

ACCESS

OFF

ON

PSHACM

OFF

ON

ONQUIE

NAME

6ALPHA

SENSE

NORMAL

INVERT

DIGOUT

BIT 1-4

Based on which DIGIO

are config as OUTPUT

BRANCH

0

1-20

COUNTR setpoint

only, if BATSEQ is ON

DELAY, WAITSS and AUTJOG setpoints only.

NONE

SLOT 0

SLOT 1

SLOT 0 - if any DIGIO are configured as OUTPUT.

SLOT 1 - if RELAY option board is installed.

C

TIMER and CONCUR

number

VALUE

ACCESS

OFF

ON

NAME

6ALPHA

SENSE

NORMAL

INVERT

DIGOUT

BIT 1-4

Based on which DIGIO

are config as OUTPUT

START

1

1-20

END

1

1-20

NONE

SLOT

SLOT 0

SLOT 1

SLOT 0 - if any DIGIO are configured as OUTPUT.

SLOT 1 - if RELAY option board is installed.

Figure 2-20. Setpoint Menu Structure – Layout B

Setpoint Menu – Layout C

25 880 Operator’s Manual

Figure 2-21. Setpoint Menu Structure – Layout C

Page 30

2.2.10 Digital Input/Output Menu

SETUP

BIT 1

BIT 2-4

....

DIGIO

....

OFF

PRINT

ZERO

TARE

UNITS

CLEAR

DSPACC

DSPTAR

NT/GRS

CLRCN

BATRUN

BATSTR

BATPAS

BATRST

BATSTP

OUTPUT

SLOT 0

Same as

SLOT 0

BIT 1

SETUP

.....

....

ALGOUT

number

TWSPAN

OFF

ON

MAXNEGMINNEG

OFF

ON

ERRACT

FULLSC

ZEROSC

HOLD

OUTPUT

0-10V

0-20MA

4-20MA

MODE

GROSS

NET

MAX

10000

number

TWZERO

number

MIN

number

0

SETUP

........

....

VERS

....

DEFALT

NO

YES

REG

LRV X.XX

SOFTWR

VX.XX.XX

........

Figure 2-22. Digital Input/Output Menu Structure

2.2.11 Analog Output Menu

The ALGOUT menu is used only if the analog output option is installed. If the analog

output option is installed, configure all other indicator functions and calibrate the

indicator before configuring the analog output. See Technical/Service Manual for

analog output calibration procedures.

2.2.12 Version Menu

Figure 2-23. Analog Output Menu Structure

Figure 2-24. Version Menu Structure

Configuration 26

Page 31

3.0 Appendix

3.1 Displayed Error Messages

The 880 provides a number of front panel error messages to assist in problem

diagnosis. Table 3-1 lists these messages and their meanings.

Error

Message

¯ ¯ ¯ ¯

Over range Check for improper load cell

¯ ¯

_ _ _ _

Under range

_ _

A/D out of range

(center

Or if using local/remote (serial scale) loss of serial scale data.

dashes)

CFGERR Configuration error on power up if there

was an error loading configuration

ERROR Internal program error Check configuration.

HWFERR Hardware failure error

• on failure to write to the EEPROM

• any error (except for a battery error or

an accumulation over range error)

when exiting the menu

LOBATT The low battery error flashes every 30

seconds when the battery is low.

NOTARE Tare is prevented because of

regulatory mode settings, the

configuration of the TAREFN

parameter, motion on the scale, etc.

RANGE A numeric value entered in

configuration is out of the acceptable

range. The error is displayed

momentarily – then parameter being

edited is displayed so the value can be

corrected.

NO ZERO Zero is prevented (due to regulatory

mode settings, motion on the scale,

zero range settings)

Description Solution

wiring, configuration,

calibration, scale hardware

problems.

Press the Enter key to reboot

the indicator.

Press the Enter key to reboot

the indicator.

Replace the battery.

Change regulatory mode

settings or the TAREFN

parameter.

Re-enter a value that is in

range for the parameter being

edited.

Check zero settings and for

motion.

Table 3-1. 880 Error Messages

27 880 Operator’s Manual

Page 32

3.2 Specifications

Power

Line Voltages Input Voltage – 100-240VAC, 9-36VDC

Input Frequency – 47-63Hz

Power Consumption AC: 15 watts

DC: 20 watts

Analog Specifications

Full Scale Input Signal -45 mV to +45 mV

Excitation Voltage 10 VDC ±,

Sense Amplifier Differential amplifier with

Analog Signal Input Range -45 mV to 45mV

Analog Signal Sensitivity:

A/D Sample Rate: 7.5 – 960Hz, software selectable

Input Impedance 200 M, typical

Noise (Usable Minimum

LSB) 0.3 V p-p

Internal Resolution 8 000 000 counts @ 23 usable bits, approximate

Display Resolution 100 000 dd

Input Sensitivity 10 nV per internal count

System Linearity ±0.01% of full scale

Temperature

Zero ±150 nV/°C, maximum

Span ±3.5 ppm/°C, maximum

Calibration Method Software, constants stored in EEPROM

Common Mode Voltage ±0.8V in unbalanced condition

Common Mode Rejection120 dB minimum @ 50 or 60 Hz

Input Overload ± 12 V continuous, static discharge protected

EMI/RFI Protection Signal, excitation, and sense lines protected by capacitor bypass

Optional Analog

Output Fully isolated, voltage or current output

Digital I/O

I/O Channels Up to 4, 5V/TTL, Active Low (0V), each software configurable as

Relay Supply Voltage 5 VDC, 500mA maximum

Input Voltage 0–5.5V maximum

Digital Outputs Active low, sink up to 24mA per output.

8 x 350 or 16 x 700 load cells

4- and 6-wire sensing

0.3 μV/graduation minimum @ 7.5 Hz

1.0 μV/graduation typical @ 120 Hz

4.0 μV/graduation typical @ 960 Hz

and filtering elements

Voltage output: 0 –10 VDC

Load resistance:1k minimum

Current output: 0-20 mA or 4–20 mA

External loop resistance: 500 maximum

input or output

Appendix 28

Page 33

Optional Four channel relay module, dry connect 3A @ 115VAC, 3A @

t

N

A

T

I

O

N

A

L

C

O

N

F

E

R

E

N

C

E

t

O

N

W

E

I

G

H

T

S

A

N

D

M

E

A

S

U

R

E

S

30VDC

Serial Communications

RS-232 Full Duplex

RS-485 Half Duplex

USB USB Type A Connector 2.0

USB Micro A/B Connector 2.0

EtherNet EtherNet TCP/IP

Operator Interface

Display LED, Six 0.56 inch (14 mm),

14 Segment with Decimal or Comma

Keyboard 6-key membrane panel

Environmental

Operating Temperature14°F to 104°F (–10 to +40°C) (legal-for-trade applications);

14°F to 122°F (–10 to +50°C)

(industrial applications)

Storage Temperature –25 to +70°C

Humidity 0–95% relative humidity

Enclosure

Enclosure Dimensions 6.0 in x 4.0 in x 4.95 in

(152 mm x 102 mm x 126 mm)

Weight 2.5 lb (1.2 kg)

Rating/Material Display Bezel NEMA 4X, IP69K

Certifications and Approvals

NTEP

CoC Number: 13-080

Accuracy Class III/IIIL n

max

: 10 000

Measurement Canada

Approval: AM-5931C

Accuracy Class III/IIIHD n

: 10 000

max

File Number: Pending

File Number: Pending

The 880 DC indicator must be connected to a class 2 power source in accordance with

the NEC (National Electrical Code) and local regulations. See equipment data plate for

power requirements.

29 880 Operator’s Manual

Page 34

880 Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and

systems properly installed by a Distributor or Original Equipment Manufacturer

(OEM) will operate per written specifications as confirmed by the Distributor/OEM

and accepted by RLWS. All systems and components are warranted against defects in

materials and workmanship for two years.

RLWS warrants that the equipment sold hereunder will conform to the current written

specifications authorized by RLWS. RLWS warrants the equipment against faulty

workmanship and defective materials. If any equipment fails to conform to these

warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given

prompt written notice with a detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes

must be packaged to prevent electrostatic discharge (ESD) damage in

shipment. Packaging requirements are listed in a publication, Protecting

Your Components From Static Damage in Shipment, available from RLWS

Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity

actually exists, and was not caused by accident, misuse, neglect, alteration,

improper installation, improper repair or improper testing; RLWS shall be

the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person

other than RLWS or its duly authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective

equipment. Buyer is responsible for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs,

including assembly or disassembly of equipment, nor will RLWS be liable

for the cost of any repairs made by others.

These warranties exclude all other warranties, expressed or implied, including

without limitation warranties of merchantability or fitness for a particular purpose.

Neither RLWS nor distributor will, in any event, be liable for incidental or

consequential damages.

RLWS and buyer agree that RLWS’s sole and exclusive liability hereunder is limited

to repair or replacement of such goods. In accepting this warranty, the buyer waives

any and all other claims to warranty.

Should the seller be other than RLWS, the buyer agrees to look only to the seller for

warranty claims.

No terms, conditions, understanding, or agreements purporting to modify the terms of

this warranty shall have any legal effect unless made in writing and signed by a

corporate officer of RLWS and the Buyer.

© Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET

RICE LAKE, WISCONSIN 54868 • USA

Appendix 30

Page 35

Page 36

230 W. Coleman St. • Rice Lake, WI 54868 • USA

U.S. 800-472-6703 • Canada/Mexico 800-321-6703 • International 715-234-9171 • Europe +31 (0) 88 2349171

www.ricelake.com www.ricelake.mx www.ricelake.eu www.ricelake.co.in m.ricelake.com

© Rice Lake Weighing Systems 06/2014 PN 152240 - Rev B

Loading...

Loading...