Page 1

INSTALLATION INSTRUCTIONS

ISO 9001:2008

Seasonal Energy Efficiency Ratio (SEER)

Annual Fuel Utilization Efficiency -

AFUE

HIGHMID

13.0 14.0 16.0

80.0%

RRNL RRPL RRRL

THIS MODEL

10.6

—

Uses least energy

➞

16.05

78% 82% 88% 97%

PACKAGE GAS ELECTRIC

FEATURING EARTH-FRIENDLY R-410A REFRIGERANT

RRNL-B/C 13 SEER (2-5 TONS)

RRPL-B 14 SEER (2-5 TONS)

RRRL-C UP TO 16 SEER (2-5 TONS)

(14 SEER &

ABOVE)

U.L. recognized fuel gas and CO (carbon monoxide) detectors are recommended in all

applications, and their installation should be in accordance with the manufacturer’s

recommendations and/or local laws, rules, regulations, or customs.

SUPERSEDES 92-21916-30-08

92-21916-30-09

Page 2

TABLE OF CONTENTS

I. Safety Information .................................................................................................3

II. Introduction............................................................................................................6

III. Checking Product Received..................................................................................6

IV. Specifications ........................................................................................................6

A. General .............................................................................................................6

B. Major Components............................................................................................6

C.R-410A Refrigerant...........................................................................................6

D.Comfort Alert System........................................................................................7

1. Comfort Alert.................................................................................................7

2. High Pressure Control...................................................................................8

3. Low Pressure Control....................................................................................8

4. Comfort Alert With Active Protection.............................................................8

V. Unit Dimensions ..................................................................................................11

VI. Installation ...........................................................................................................13

A. General ...........................................................................................................13

1. Pre-Installation Check................................................................................13

2. Location Considerations.............................................................................13

B. Outside Installation..........................................................................................13

C.Attaching Exhaust and Combustion Air Inlet Hoods .......................................14

D.Cover Panel Installation/Conversion Procedure .............................................15

1. Horizontal to Downflow ...............................................................................15

2. Downflow to Horizontal ...............................................................................15

E. Clearances......................................................................................................15

F. Rooftop Installation .........................................................................................17

G.Ductwork .........................................................................................................17

H.Return Air........................................................................................................19

I. Filters...............................................................................................................20

VII. Gas Supply, Condensate Drain and Piping.........................................................22

A. Gas Connection ..............................................................................................22

B. LP Conversion Single Stage Gas Heat...........................................................23

C.LP Conversion Two Stage Gas Heat..............................................................24

D.NOx Models ....................................................................................................24

E. Adjusting or Checking Furnace Input..............................................................24

F. Condensate Drain...........................................................................................25

VIII. Wiring ..................................................................................................................25

A. Power Supply..................................................................................................25

B. Hook Up ..........................................................................................................27

C.Internal Wiring.................................................................................................27

D.Thermostat......................................................................................................27

IX. Furnace Section Controls and Ignition System ...................................................28

A. Normal Furnace Operating Sequence Single Stage Gas Heat.......................28

B. Normal Furnace Operating Sequence Two Stage Gas Heat..........................28

C.Operating Instructions.....................................................................................30

D.Burners............................................................................................................31

E. Manual Reset Overtemperature Control .........................................................31

D.Pressure Switch..............................................................................................31

G.Limit Control....................................................................................................31

X. System Operating Information.............................................................................31

A. Advise the Customer.......................................................................................31

B. Furnace Section Maintenance ........................................................................31

C.Lubrication.......................................................................................................32

D.Cooling Section Maintenance .........................................................................32

E. Replacement Parts..........................................................................................33

F. Charging..........................................................................................................33

G.Blower Motor Speed Adjustments...................................................................33

XI. Units with ECM Blower Motors (RRRL-B Models Only)......................................36

A. ECM Motor Interface Control and Settings (RRRL Units Only).......................36

B. Transformer Protection ...................................................................................37

C.Using the Onboard LED to Determine Blower CFM........................................37

D.Unit Operation with Two-Stage Cooling..........................................................38

E. Cooling Airflow Adjustments ...........................................................................38

F. Heating Airflow Adjustments...........................................................................41

G.Cooling Delay Profiles.....................................................................................41

H.Cooling Mode Dehumidification ......................................................................42

I. On Demand Dehumidification Airflow Adjustment ..........................................42

XII. General Data..................................................................................................44-66

XIII. Miscellaneous.................................................................................................67-71

XIV. Airflow Performance Data ..............................................................................72-76

XV. Wiring Diagrams.............................................................................................77-87

XVI. Charge Charts..............................................................................................88-103

XVII. Troubleshooting..........................................................................................104-105

XVIII. Comfort Alert Diagnostic Chart...................................................................106-107

2

Page 3

I. SAFETY INFORMATION

WARNING

!

PROPOSITION 65: THIS FURNACE CONTAINS FIBERGLASS INSULATION.

RESPIRABLE PARTICLES OF FIBERGLASS ARE KNOWN TO THE STATE OF

CALIFORNIA TO CAUSE CANCER. EXHAUST GAS FROM THIS FURNACE

CONTAINS CHEMICALS, INCLUDING CARBON MONOXIDE, KNOWN TO THE

STATE OF CALIFORNIA TO CAUSE BIRTH DEFECTS OR OTHER REPRODUCTIVE HARM.

WARNING

!

THE MANUFACTURER’S WARRANTY DOES NOT COVER ANY DAMAGE OR

DEFECT TO THE AIR CONDITIONER CAUSED BY THE ATTACHMENT OR USE

OF ANY COMPONENTS, ACCESSORIES OR DEVICES (OTHER THAN THOSE

AUTHORIZED BY THE MANUFACTURER) INTO, ONTO OR IN CONJUNCTION

WITH THE AIR CONDITIONER. YOU SHOULD BE AWARE THAT THE USE OF

UNAUTHORIZED COMPONENTS, ACCESSORIES OR DEVICES MAY

ADVERSELY AFFECT THE OPERATION OF THE AIR CONDITIONER AND MAY

ALSO ENDANGER LIFE AND PROPERTY. THE MANUFACTURER DISCLAIMS

ANY RESPONSIBILITY FOR SUCH LOSS OR INJURY RESULTING FROM THE

USE OF SUCH UNAUTHORIZED COMPONENTS, ACCESSORIES OR DEVICES.

WARNING

!

UNITS ARE NOT DESIGN CERTIFIED TO BE INSTALLED INSIDE THE STRUCTURE. DOING SO CAN CAUSE INADEQUATE UNIT PERFORMANCE AS WELL

AS PROPERTY DAMAGE AND CARBON MONOXIDE POISONING RESULTING

IN PERSONAL INJURY OR DEATH.

WARNING

!

DISCONNECT ALL POWER TO UNIT BEFORE STARTING MAINTENANCE.

FAILURE TO DO SO CAN CAUSE ELECTRICAL SHOCK RESULTING IN PERSONAL INJURY OR DEATH.

WARNING

!

THESE UNITS ARE DESIGNED CERTIFIED FOR OUTDOOR INSTALLATION

ONLY. INSTALLATION INSIDE ANY PART OF A STRUCTURE CAN RESULT IN

INADEQUATE UNIT PERFORMANCE AS WELL AS PROPERTY DAMAGE.

INSTALLATION INSIDE CAN ALSO CAUSE RECIRCULATION OF FLUE PRODUCTS INTO THE CONDITIONED SPACE RESULTING IN PERSONAL INJURY

OR DEATH.

WARNING

!

THIS UNIT MUST NOT BE INSTALLED DIRECTLY ON WOOD FLOORING, CLASS

A, CLASS B OR CLASS C ROOF COVERING MATERIALS, OR ANY OTHER COMBUSTIBLE STRUCTURE EXCEPT AS SPECIFIED IN FIGURE 16. FAILURE TO

ADHERE TO THIS WARNING CAN CAUSE A FIRE OR EXPLOSION RESULTING

IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT RETURN DUCTWORK TO

ANY OTHER HEAT PRODUCING DEVICE SUCH AS FIREPLACE INSERT,

STOVE, ETC. UNAUTHORIZED USE OF SUCH DEVICES MAY RESULT IN FIRE,

CARBON MONOXIDE POISONING, EXPLOSION, PERSONAL INJURY, OR

PROPERTY DAMAGE.

3

Page 4

WARNING

!

NEVER ALLOW PRODUCTS OF COMBUSTION OR THE FLUE PRODUCTS TO

ENTER THE RETURN AIR DUCTWORK, OR THE CIRCULATING AIR SUPPLY.

ALL RETURN DUCTWORK MUST BE ADEQUATELY SEALED AND SECURED

TO THE FURNACE WITH SHEET METAL SCREWS, AND JOINTS TAPED. ALL

OTHER DUCT JOINTS MUST BE SECURED WITH APPROVED CONNECTIONS

AND SEALED AIRTIGHT.

FAILURE TO PREVENT PRODUCTS OF COMBUSTION FROM BEING CIRCULATED INTO THE LIVING SPACE CAN CREATE POTENTIALLY HAZARDOUS

CONDITIONS, INCLUDING CAROBON MONOXIDE POISONING THAT COULD

RESULT IN PERSONAL INJURY OR DEATH.

WARNING

!

DO NOT USE AN OPEN FLAME TO CHECK FOR LEAKS. THE USE OF AN OPEN

FLAME CAN RESULT IN FIRE, EXPLOSION, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

WARNING

!

THIS UNIT IS EQUIPPED AT THE FACTORY FOR USE ON NATURAL GAS ONLY.

CONVERSION TO LP GAS REQUIRES A SPECIAL KIT SUPPLIED BY THE DISTRIBUTOR OR MANUFACTURER. MAILING ADDRESSES ARE LISTED ON THE

FURNACE RATING PLATE, PARTS LIST AND WARRANTY. FAILURE TO USE

THE PROPER CONVERSION KIT CAN CAUSE FIRE, CARBON MONOXIDE POISONING, EXPLOSION, PERSONAL INJURY, PROPERTY DAMAGE OR DEATH.

WARNING

!

TURN OFF THE MAIN ELECTRICAL POWER AT THE BRANCH CIRCUIT DISCONNECT CLOSEST TO THE UNIT BEFORE ATTEMPTING ANY WIRING. FAILURE

TO DO SO CAN CAUSE ELECTRICAL SHOCK RESULTING IN PERSONAL

INJURY OR DEATH.

WARNING

!

DO NOT ATTEMPT TO MANUALLY LIGHT THIS FURNACE WITH A MATCH OR

ANY OPEN FLAME. ATTEMPTING TO DO SO CAN CAUSE AN EXPLOSION OR

FIRE RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR

EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL

INJURY OR LOSS OF LIFE.

WARNING

!

THE SPARK IGNITOR AND IGNITION LEAD FROM THE IGNITION CONTROL

ARE HIGH VOLTAGE. KEEP HANDS OR TOOLS AWAY TO PREVENT ELECTRICAL SHOCK. SHUT OFF ELECTRICAL POWER BEFORE SERVICING ANY

OF THE CONTROLS. FAILURE TO ADHERE TO THIS WARNING CAN RESULT

IN PERSONAL INJURY OR DEATH.

WARNING

!

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL TO SHUT OFF,

SHUT OFF THE MANUAL GAS VALVE TO THE APPLIANCE BEFORE SHUTTING OFF THE ELECTRICAL SUPPLY. FAILURE TO DO SO CAN RESULT IN

AN EXPLOSION OR FIRE CAUSING PROPERTY DAMAGE, SEVERE PERSONAL INJURY OR DEATH!

4

Page 5

WARNING

!

DO NOT JUMPER THIS DEVICE! DO NOT reset the overtemperature control

without taking corrective action to assure that an adequate supply of combustion air is maintained under all conditions of operation. Failure to do so can

result in carbon monoxide poisoning or death. Replace this control only with

the identical replacement part.

WARNING

!

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS. WIRING ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION RESULTING IN FIRE, ELECTRICAL SHOCK, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

HOLES IN THE EXHAUST TRANSITION OR HEAT EXCHANGER CAN CAUSE

TOXIC FUMES TO ENTER THE HOME. THE EXHAUST TRANSITION OR HEAT

EXCHANGER MUST BE REPLACED IF THEY HAVE HOLES OR CRACKS IN

THEM. FAILURE TO DO SO CAN CAUSE CARBON MONOXIDE POISONING

RESULTING IN PERSONAL NJURY OR DEATH.

WARNING

!

DISCONNECT MAIN ELECTRICAL POWER TO THE UNIT BEFORE ATTEMPTING MAINTENANCE. FAILURE TO DO SO MAY RESULT IN ELECTRICAL

SHOCK OR SEVERE PERSONAL INJURY OR DEATH.

WARNING

!

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING THE UNIT.

WIRING ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION

RESULTING IN FIRE, ELECTRICAL SHOCK, PROPERTY DAMAGE, SEVERE

PERSONAL INJURY OR DEATH.

WARNING

!

DISCONNECT MAIN ELECTRICAL POWER TO THE UNIT BEFORE ATTEMPTING TO CHANGE BLOWER SPEEDS. FAILURE TO DO SO MAY RESULT IN

ELECTRICAL SHOCK OR SEVERE PERSONAL INJURY OR DEATH.

WARNING

!

DISCONNECT ALL POWER TO UNIT BEFORE SERVICING. CONTACTOR MAY

BREAK ONLY ONE SIDE. FAILURE TO SHUT OFF POWER CAN CAUSE ELECTRICAL SHOCK RESULTING IN PERSONAL INJURY OR DEATH.

!

CAUTION

R-410A systems operate at higher pressures than R-22 systems. Do not use

R-22 service equipment or components on R-410A equipment.

5

Page 6

WARNING

!

IMPORTANT: ALL MANUFACTURER PRODUCTS MEET CURRENT

FEDERAL OSHA GUIDELINES FOR

SAFETY. CALIFORNIA

PROPOSITION 65 WARNINGS ARE

REQUIRED FOR CERTAIN PRODUCTS, WHICH ARE NOT COVERED

BY THE OSHA STANDARDS.

CALIFORNIA'S PROPOSITION 65

REQUIRES WARNINGS FOR PRODUCTS SOLD IN CALIFORNIA THAT

CONTAIN, OR PRODUCE, ANY OF

OVER 600 LISTED CHEMICALS

KNOWN TO THE STATE OF

CALIFORNIA TO CAUSE CANCER

OR BIRTH DEFECTS SUCH AS

FIBERGLASS INSULATION, LEAD

IN BRASS, AND COMBUSTION

PRODUCTS FROM NATURAL GAS.

ALL “NEW EQUIPMENT” SHIPPED

FOR SALE IN CALIFORNIA WILL

HAVE LABELS STATING THAT THE

PRODUCT CONTAINS AND/OR

PRODUCES PROPOSITION 65

CHEMICALS. ALTHOUGH WE HAVE

NOT CHANGED OUR PROCESSES,

HAVING THE SAME LABEL ON ALL

OUR PRODUCTS FACILITATES

MANUFACTURING AND SHIPPING.

WE CANNOT ALWAYS KNOW

“WHEN, OR IF” PRODUCTS WILL

BE SOLD IN THE CALIFORNIA

MARKET.

YOU MAY RECEIVE INQUIRIES

FROM CUSTOMERS ABOUT CHEMICALS FOUND IN, OR PRODUCED

BY, SOME OF OUR HEATING AND

AIR-CONDITIONING EQUIPMENT,

OR FOUND IN NATURAL GAS USED

WITH SOME OF OUR PRODUCTS.

LISTED BELOW ARE THOSE CHEMICALS AND SUBSTANCES COMMONLY ASSOCIATED WITH SIMILAR EQUIPMENT IN OUR INDUSTRY AND OTHER MANUFACTURERS.

• GLASS WOOL (FIBERGLASS)

INSULATION

• CARBON MONOXIDE (CO)

• FORMALDEHYDE

• BENZENE

MORE DETAILS ARE AVAILABLE

AT THE WEBSITES FOR OSHA

(OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION), AT

WWW.OSHA.GOV

OF CALIFORNIA'S OEHHA (OFFICE

OF ENVIRONMENTAL HEALTH

HAZARD ASSESSMENT), AT

WWW.OEHHA.ORG.

EDUCATION IS IMPORTANT SINCE

THE CHEMICALS AND SUBSTANCES ON THE LIST ARE

FOUND IN OUR DAILY LIVES. MOST

CONSUMERS ARE AWARE THAT

PRODUCTS PRESENT SAFETY AND

HEALTH RISKS, WHEN IMPROPERLY USED, HANDLED AND MAINTAINED.

AND THE STATE

CONSUMER

II. INTRODUCTION

This booklet contains the installation and operating instructions for your combination gas

heating/electric cooling unit. There are some precautions that should be taken to derive

maximum satisfaction from it. Improper installation can result in unsatisfactory operation

or dangerous conditions.

Read this booklet and any instructions packaged with separate equipment required to

make up the system prior to installation. Give this booklet to the owner and explain its

provisions. The owner should retain this booklet for future reference.

III. CHECKING PRODUCT RECEIVED

Upon receiving the unit, inspect it for any damage from shipment. Claims for damage,

either shipping or concealed, should be filed immediately with the shipping company.

IMPORTANT: Check the unit model number, heating size, electrical characteristics, and

accessories to determine if they are correct.

IV. SPECIFICATIONS

A. GENERAL

The Combination Gas Heating/Electric Cooling Rooftop is available in 40,60, 80 and 100

BTU/Hr. heating inputs and cooling capacities of 2, 2

cooling. Units are convertible from end supply and return to bottom supply and return by

relocation of supply and return air access panels. See cover installation detail.

The units are weatherized for mounting outside of the building.

WARNING

!

UNITS ARE NOT DESIGN CERTIFIED TO BE INSTALLED INSIDE THE STRUCTURE. DOING SO CAN CAUSE INADEQUATE UNIT PERFORMANCE AS WELL

AS PROPERTY DAMAGE AND CARBON MONOXIDE POISONING RESULTING

IN PERSONAL INJURY OR DEATH.

The information on the rating plate is in compliance with the FTC and DOE rating for single phase units. The following information is for three phase units which are not covered

under the DOE certification program.

1. The energy consumption of the ignition system used with this unit is 9 watts.

2. The efficiency rating of this unit is a product thermal efficiency rating determined

under continuous operating conditions independent of any installed system.

B. MAJOR COMPONENTS

The unit includes a hermetically-sealed refrigerating system (consisting of a compressor,

condenser coil, evaporator coil with thermostatic expansion valve), a circulation air blower, a condenser fan, a heat exchanger assembly, gas burner and control assembly,

combustion air motor and fan, and all necessary internal electrical wiring. The cooling

system of these units is factory-evacuated, charged with R-410A refrigerant and performance tested. Refrigerant amount is indicated on rating plate.

C. R410A REFRIGERANT

All units are factory charged with R-410A refrigerant.

1. Specification of R-410A:

Application: R-410A is not a drop-in replacement for R-22; equipment designs must

accommodate its higher pressures. It cannot be retrofitted into R-22 units.

Pressure: The pressure of R-410A is approximately 60% (1.6 times) greater than R-

22. Recovery and recycle equipment, pumps, hoses and the like need to have design

pressure ratings appropriate for R-410A. Manifold sets need to range up to 800 psig

high-side and 250 psig low-side with a 550 psig low-side retard. Hoses need to have a

service pressure rating of 800 psig. Recovery cylinders need to have a 400 psig service

pressure rating. DOT 4BA400 or DOT BW400.

Combustibility: At pressures above 1 atmosphere, mixture of R-410A and air can

become combustible. R-410A and air should never be mixed in tanks or supply

lines, or be allowed to accumulate in storage tanks. Leak checking should never

be done with a mixture of R-410A and air. Leak checking can be performed safely

with nitrogen or a mixture of R-410A and nitrogen.

1

⁄2, 3, 31⁄2 , 4 and 5 nominal tons of

6

Page 7

2. Quick Reference Guide For R-410A

• R-410A refrigerant operates at approximately 60% higher pressure (1.6 times) than R-

22. Ensure that servicing equipment is designed to operate with R-410A.

• R-410A refrigerant cylinders are pink.

• R-410A, as with other HFC’s is only compatible with POE oils.

• Vacuum pumps will not remove moisture from POE oil.

• R-410A systems are to be charged with liquid refrigerants. Prior to March 1999, R410A refrigerant cylinders had a dip tube. These cylinders should be kept upright for

equipment charging. Post March 1999 cylinders do not have a dip tube and should

be inverted to ensure liquid charging of the equipment.

• Do not install a suction line filter drier in the liquid line.

• A liquid line filter drier is standard on every unit.

• Desiccant (drying agent) must be compatible for POE oils and R-410A

3. Evaporator Coil / TXV

The thermostatic expansion valve is specifically designed to operate with R-410A. DO

NOT use an R-22 TXV. The existing evaporator must be replaced with the factory

specified TXV evaporator specifically designed for R-410A.

4. Tools Required For Installing & Servicing R-410A Models

Manifold Sets:

-Up to 800 PSIG High side

-Up to 250 PSIG Low Side

-550 PSIG Low Side Retard

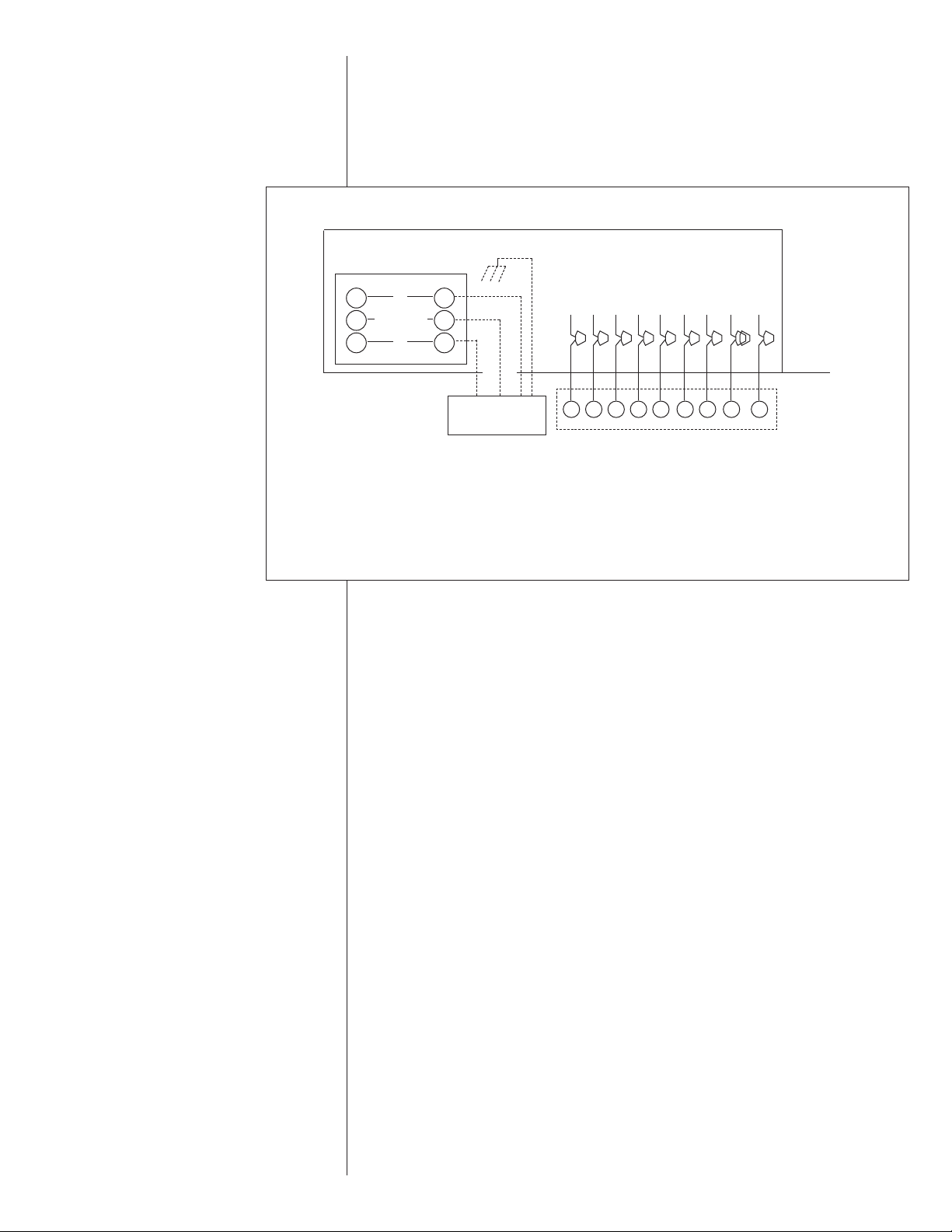

FIGURE 1

LED DESCRIPTION

Manifold Hoses:

-Service Pressure Rating of 800 PSIG

Recovery Cylinders:

-400 PSIG Pressure Rating

-Dept. of Transportation 4BA400 or BW400

!

CAUTION

R-410A systems operate at higher pressures than R-22 systems. Do not use

R-22 service equipment or components on R-410A equipment.

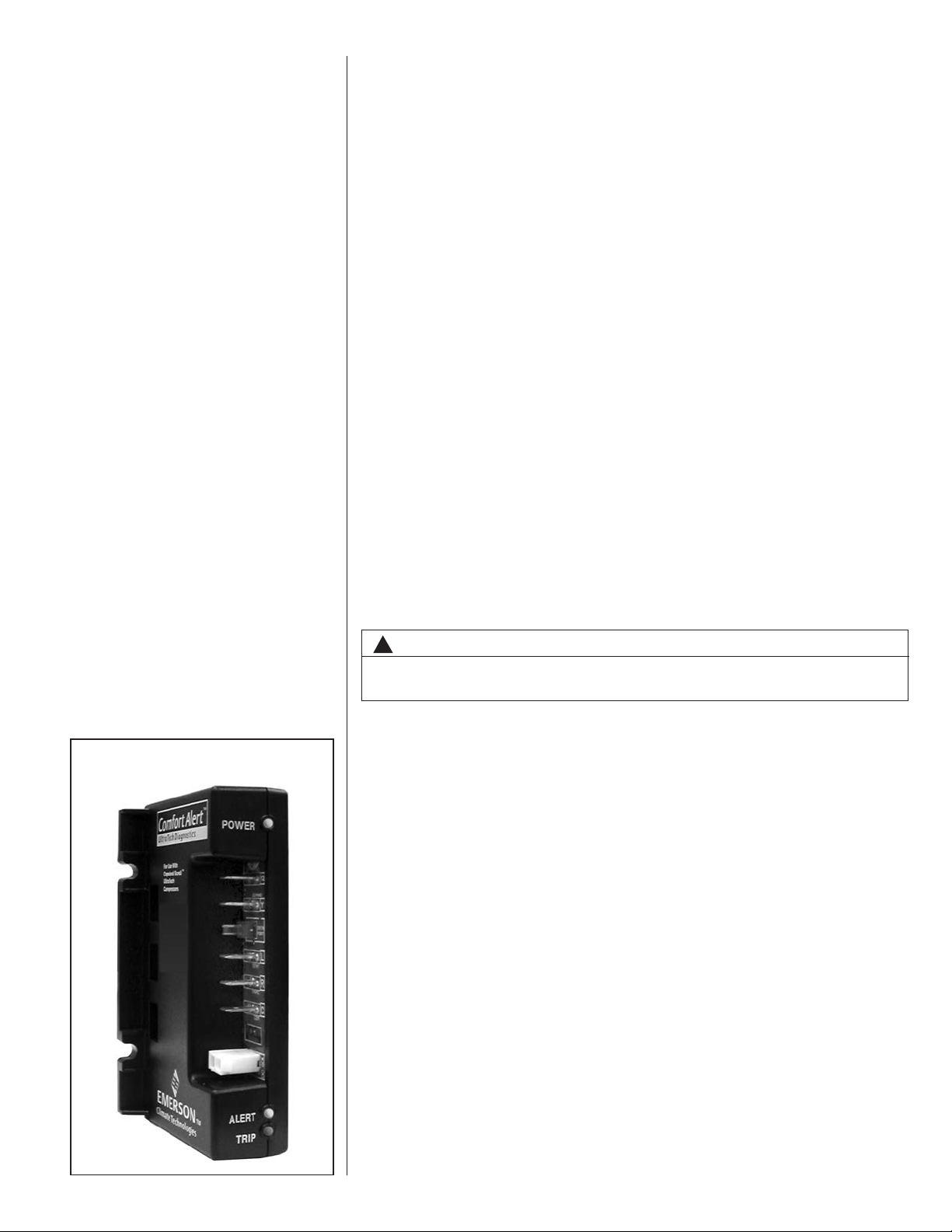

D. COMFORT ALERT™ SYSTEM (2-STAGE MODELS ONLY)

1. Comfort Alert™

The Comfort Alert™ diagnostics module is for troubleshooting air conditioning system failures. By monitoring and analyzing data from the compressor and the thermostat demand, the module can accurately detect the cause of electrical and system-related failures without any external sensors. A flashing LED indicator communicates the ALERT code and guides the service technician more quickly and accurately to the root cause of a problem.

POWER LED (Green): indicates voltage is present at the power connection of the

module.

ALERT LED (Yellow): communicates an abnormal system condition through a

unique flash code. The ALERT LED will flash a number of times consecutively,

pause and then repeat the process. The number of consecutive flashes, defined

as the Flash Code, correlates to a particular abnormal condition. Detailed

descriptions of specific ALERT Flash Codes are shown in the Comfort Alert

Diagnosis Chart in this manual.

TRIP LED (Red): indicates there is a demand signal from the thermostat but no

current to the compressor is detected by the module. The TRIP LED typically

indicates the compressor internal overload protector is open or may indicate

missing high voltage supply power to the compressor.

When an abnormal system condition occurs, the Comfort Alert module displays the

appropriate ALERT and/or TRIP LED. The yellow ALERT LED will flash a number

7

Page 8

of times consecutively, pause and then repeat the process. To identify a Flash

Code number, count the number of consecutive flashes.

IMPORTANT: Every time the module powers up, the last ALERT Flash Code that

occurred prior to shut down is displayed for one minute. The module will continue to

display the flash code until the condition returns to normal or if 24VAC power is

removed from the module.

The control box cover allows access to the Comfort Alert™ status LEDs. An abbreviated Comfort Alert™ diagnostic chart is provided on the control box cover.

2. High Pressure Control (HPC)

The high pressure control (HPC) keeps the compressor from operating in pressure

ranges, which can cause damage to the compressor. This is an auto-reset control that

opens near 610 PSIG and closes once the system pressure drops below 420 PSIG.

The high pressure control is wired in the 24VAC side of the control circuitry.

3. Low Pressure Control (LPC)

The low pressure control (LPC) keeps the compressor from operating in pressure

ranges that can cause damage to the compressor. This is an auto-reset control that

opens near 90 PSIG and closes once the system pressure rises above 135 PSIG.

The low pressure control is wired in the common side of the control circuitry.

4. Comfort Alert With Active Protection

A two-stage cooling thermostat is required for proper unit operation.

Manufacturer recommends the use of thermostats that provide active compressor pro-

tection via the L terminal when the Comfort-Alert module on the unit is connected to the

L terminal on the thermostat.

FIGURE 3

FIGURE 2

WHITE-RODGERS 90-SERIES THERMOSTAT

8

Page 9

The Comfort Alert diagnostics module diagnoses system and electrical problems in

the air conditioning system. Abnormal conditions are indicated by flashing

ALERT codes on the yellow LED on the Comfort Alert module. The flash codes are

transmitted to the thermostat when the L terminal on the Comfort Alert Module is

connected to the L terminal on the thermostat. The White-Rodgers 1F95-CA397

thermostat displays a CHECK SYSTEM icon that flashes at the same rate as the yellow

ALERT LED on the Comfort Alert module. Turn this feature ON to achieve

protection, enabling the thermostat to identify certain fault codes when compressor damage is possible and react to those codes by turning the compressor off.

NOTE: The Comfort Alert™ module does not provide safety protection! It does not disconnect power from the unit.

Comfort Alert™ Flash Codes

1 – Long Run Time

2 – System Pressure Trip

3 – Short Cycling

4 – Locked Rotor

5 – Open Circuit

6 – Open Start Circuit

7 – Open Run Circuit

8 – Welded Contactor

9 – Low Voltage

See Figures 61 and 62 (Comfort Alert Diagnostic Charts) for more troubleshooting information.

Active protection occurs under the following conditions:

1) Flash Code 2 - System Pressure Trip

Condition: Four consecutive compressor protector trips occur where the

average run time until trip is between 1 minute and 15 minutes

Possible causes:

Active Thermostat Reaction:

2) Flash Code 3 - Short Cycling

Condition: A pattern of short cycling emerges where the run time for the

previous four cycles is less than three minutes each.

Possible causes:

Active Thermostat Reaction:

Low suction pressure

• Low pressure switch is open

• Low system charge

Blocked condenser coil

Restricted condenser air flow

The thermostat will cycle the system ON for 5 minutes and OFF for

five minutes to verify system fault. If this ON/OFF cycling repeats for

30 ten-minute cycles, the thermostat concludes there is a system

problem and implements a hard lockout.

High head pressure

• High pressure switch is open

• System overcharged

• Non-condensables in system

Faulty thermostat

Intermittent contactor

The thermostat will cycle the system ON for 5 minutes and OFF for

five minutes to verify the system fault. If this ON/OFF cycling repeats for

30 ten-minute cycles, the thermostat concludes there is a system

problem and implements a hard lockout.

9

Page 10

3) Flash Code 4 - Locked Rotor

Condition: The compressor internal overload trips where the average run

time is less than 15 seconds.

Possible causes:

Active Thermostat Reaction:

4) Flash Code 6 - Open Start Circuit

Condition: Current is detected in the run circuit but not in the start circuit.

Possible causes:

Bad run capacitor

Low line voltage

Excessive liquid refrigerant in compressor

Compressor bearings are seized

Faulty hard start components

The thermostat implements a hard lockout once this error is sensed.

Bad run capacitor

Open circuit in compressor start wiring or connections.

Compressor start winding is damaged

Active thermostat reaction:

5) Flash Code 7 - Open Run Circuit

Condition: Open circuit in compressor run wiring or connections.

Compressor run winding is damaged.

Active Thermostat Reaction:

Resetting the White-Rodgers Thermostat After a Hard Lockout

The White-Rodgers thermostat will automatically reset after a hard lockout once the

Comfort Alert trouble code has been cleared.

The thermostat implements a hard lockout after 3 hours.

The thermostat implements a hard lockout after 3 hours.

10

Page 11

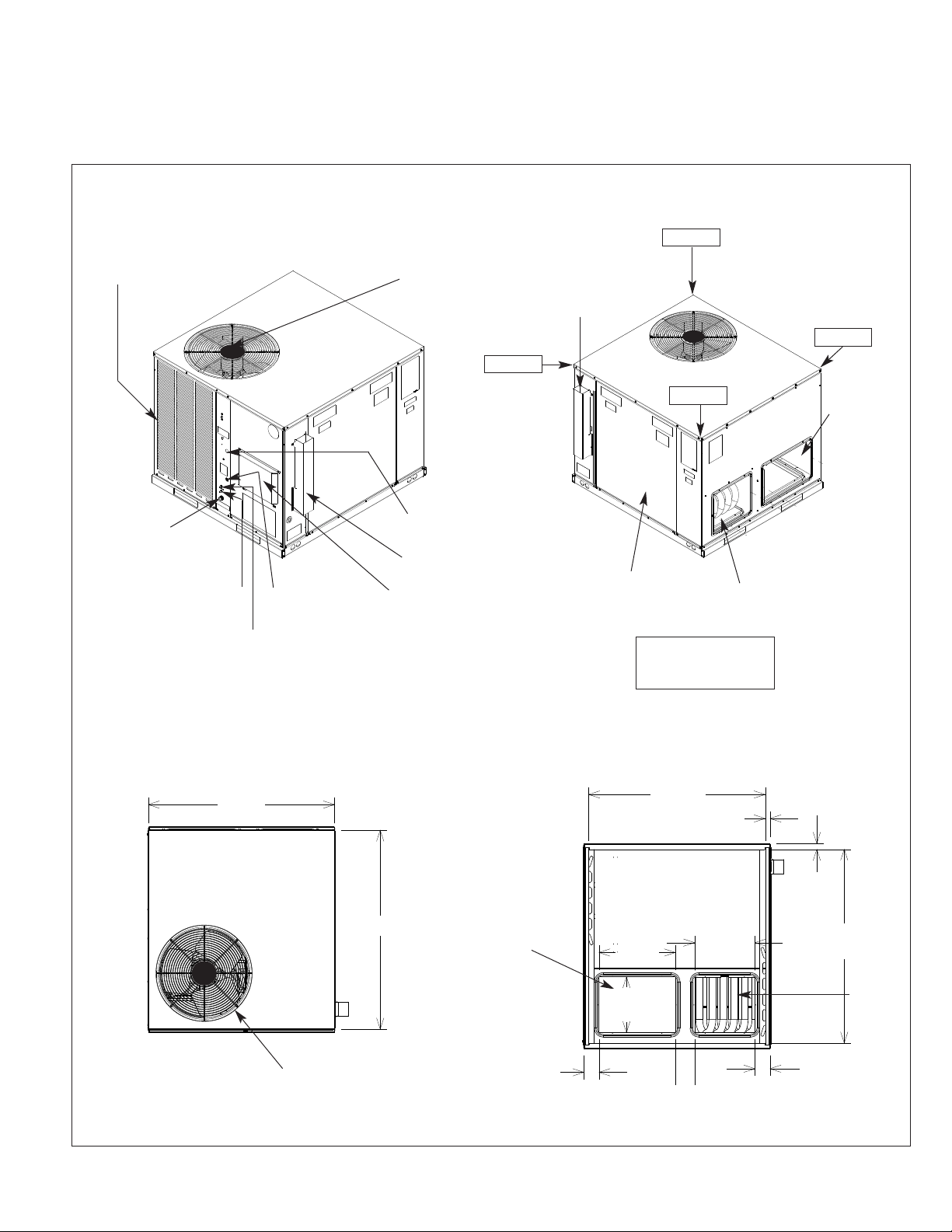

V. UNIT DIMENSIONS

FOR CLEARANCES

SEE FIGURE 4.

FIGURE 4

OUTDOOR COIL

PROTECTIVE GRILLE

OUTDOOR FAN GRILLE

AND COMPRESSOR ACCESS

29% ± 2%

FLUE

EXHAUST

30% ± 2%

20% ± 2%

21% ± 2%

SIDE

RETURN

DUCT

OPENING

THREADED

PVC CONDENSATE

DRAIN CONNECTION

(3/4 NPT)

SUCTION PRESSURE

SERVICE PORT

LIQUID PRESSURE

SERVICE PORT

TOP VIEW

479⁄16”

FIELD CONTROL

WIRE ENTRANCE

FIELD POWER

WIRE ENTRANCE

FLUE EXHAUST

HOOD

COMBUSTION AIR

INLET HOOD

5013⁄16”

BOTTOM

RETURN

DUCT

OPENING

BLOWER/EVAPORATOR

ACCESS PANEL

CORNER WEIGHTS

% OF TOTAL UNIT

BOTTOM VIEW

451⁄16”

INSIDE

191⁄2”

141⁄4”

TYP.

SIDE SUPPLY DUCT

OPENING

WEIGHT

13⁄16”

TYP.

153⁄8”

11⁄2”

TYP.

497⁄16”

INSIDE

BOTTOM

SUPPLY

DUCT

OPENING

OUTDOOR FAN

GRILLE & COMPRESSOR

ACCESS

313⁄16”

33⁄16”

49⁄10”

11

Page 12

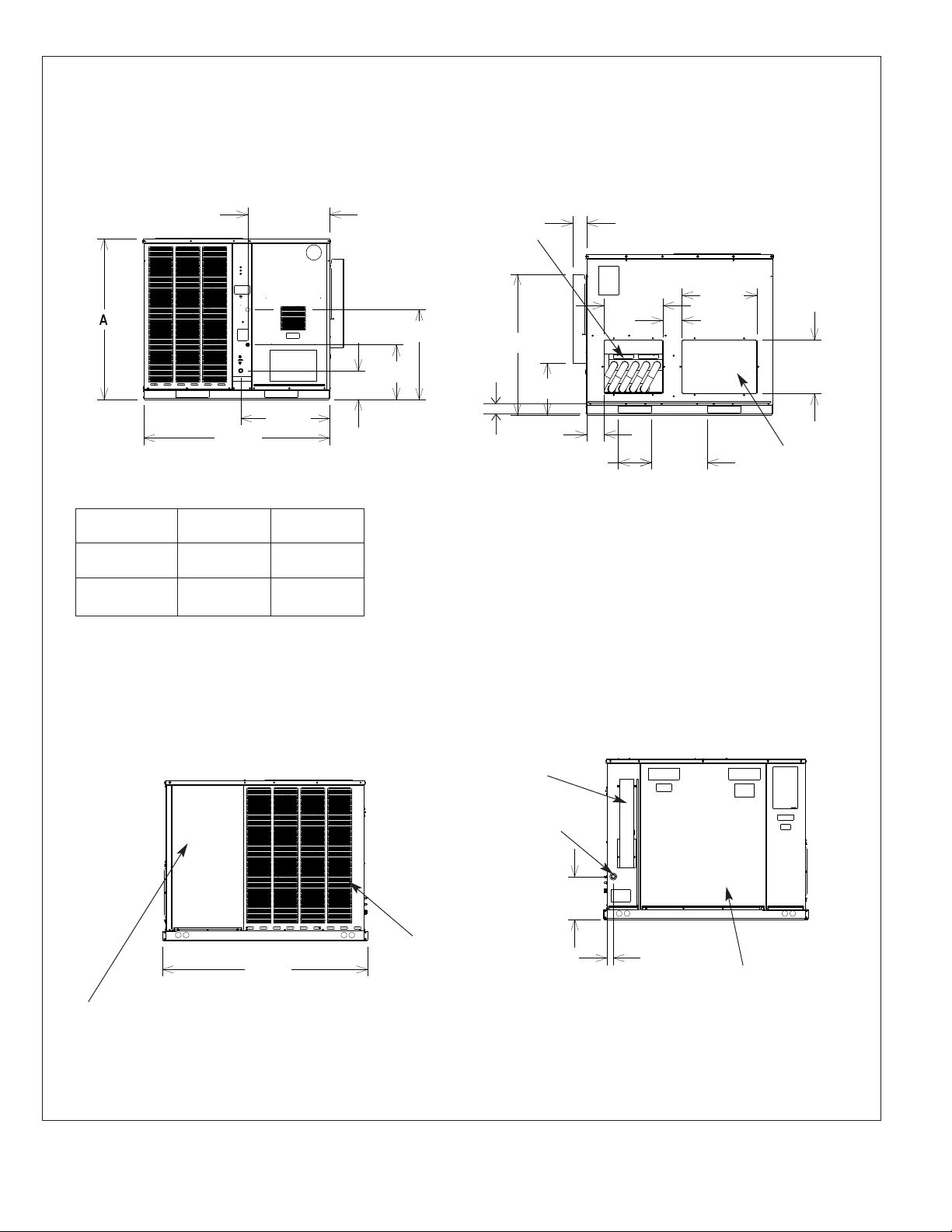

FIGURE 4 (CONTINUED)

MODELS

RRNL & RRPL

B024, B030,

B036

B042, B048,

B060, C060

FRONT VIEW

471⁄2”

MODEL

RRRL

B024

B036, B048,

B060

207⁄8”

2211⁄16”

HEIGHT

“A”

3515⁄16”

41

75⁄16”

227⁄8”

1315⁄16”

21⁄2”

SIDE

SUPPLY

DUCT

OPENING

3515⁄16”

BACK VIEW

39⁄16”

15”

191⁄8”

47⁄8”

131⁄4”

47⁄16”

81⁄2”

TYP.

SHOWN WITH DUCT COVERS REMOVED.

143⁄16”

TYP.

133⁄4”

TYP.

SIDE

RETURN

DUCT

OPENING

FILTER ACCESS PANEL

(FOR UNIT MOUNTED FILTER

ACCESSORY)

SIDE VIEW

527⁄16”

OUTDOOR

COIL PROTECTIVE

GRILLE

SIDE VIEW

FLUE

EXHAUST

HOOD

GAS

SUPPLY

ENTRANCE

1015⁄16”

111⁄16”

BLOWER/

EVAPORATOR

ACCESS PANEL

12

Page 13

VI. INSTALLATION

A. GENERAL

1. PRE-INSTALLATION CHECK-POINTS — Before attempting any installation, carefully consider the following points:

Structural strength of supporting members

(Rooftop Installation)

Clearances and provision for servicing

Power supply and wiring

Gas supply and piping

Air duct connections and sizing

Drain facilities and connections

Location for minimum noise and vibration

2. LOCATION CONSIDERATIONS (CORROSIVE ENVIRONMENT)

The metal parts of this unit may be subject to rust or deterioration if exposed to a

corrosive environment. This oxidation could shorten the equipment’s useful life.

Corrosive elements include, but are not limited to, salt spray, fog or mist in seacoast

areas, sulphur or chlorine from lawn watering systems, and various chemical contaminants from industries such as paper mills and petroleum refineries.

If the unit is to be installed in an area where contaminants are likely to be a

problem, give special attention to the equipment location and exposure.

1. Avoid having lawn sprinkler heads spray directly on the unit cabinet.

2. In coastal areas locate the unit on the side of the building away from the waterfront.

3. Shielding by a fence or shrubs may give some protection.

WARNING

!

DISCONNECT ALL POWER TO UNIT BEFORE STARTING MAINTENANCE.

FAILURE TO DO SO CAN CAUSE ELECTRICAL SHOCK RESULTING IN PERSONAL INJURY OR DEATH.

1. Frequent washing of the cabinet, fan blade and coil with fresh water will remove

most of the salt or other contaminants that build up on the unit.

2. Regular cleaning and waxing of the cabinet with a good automobile polish will provide some protection.

3. Use a good liquid cleaner several times a year to remove matter that will not wash

off with water.

Several different types of protective coatings are offered in some areas. These coatings

may provide some benefit, but the effectiveness of such coating materials cannot be verified by the equipment manufacturer.

The best protection is frequent cleaning, maintenance and minimal exposure to

contaminants.

B. OUTSIDE INSTALLATION

WARNING

!

THESE UNITS ARE DESIGNED CERTIFIED FOR OUTDOOR INSTALLATION

ONLY. INSTALLATION INSIDE ANY PART OF A STRUCTURE CAN RESULT IN

INADEQUATE UNIT PERFORMANCE AS WELL AS PROPERTY DAMAGE.

INSTALLATION INSIDE CAN ALSO CAUSE RECIRCULATION OF FLUE PRODUCTS INTO THE CONDITIONED SPACE RESULTING IN PERSONAL INJURY

OR DEATH.

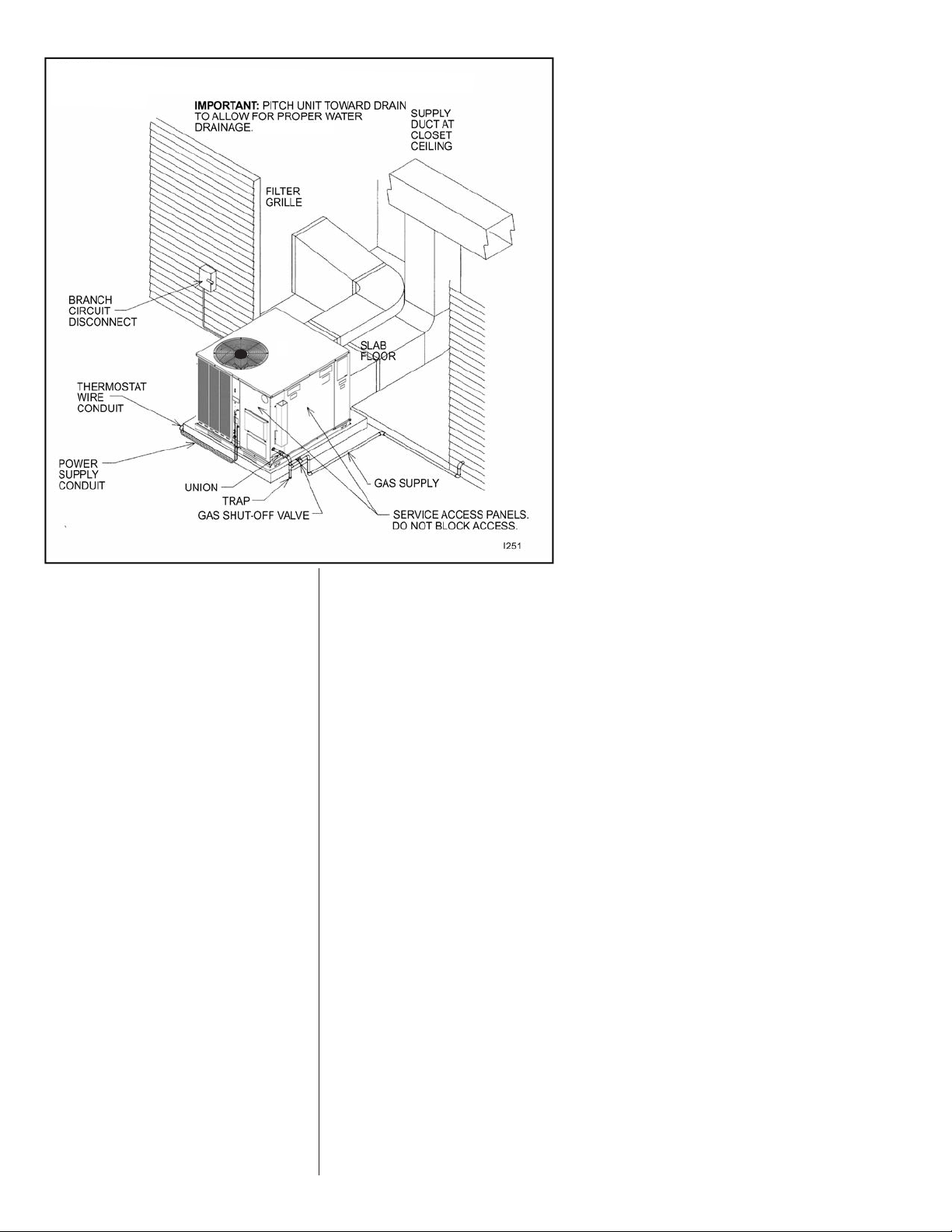

(Typical outdoor slab installation is shown in Figure 5.)

1. Select a location where external water drainage cannot collect around unit.

13

Page 14

FIGURE 5

OUTSIDE SLAB INSTALLATION. CLOSET DISTRIBUTION SYSTEM. SLAB FLOOR

CONSTRUCTION

2. Provide a slab sufficiently high enough above grade to prevent surface water from

entering the unit. Where snowfall is anticipated, mount the unit above the anticipated maximum snow depth for your area. Do not locate unit in an area where excessive snow drifting may block combustion air inlet.

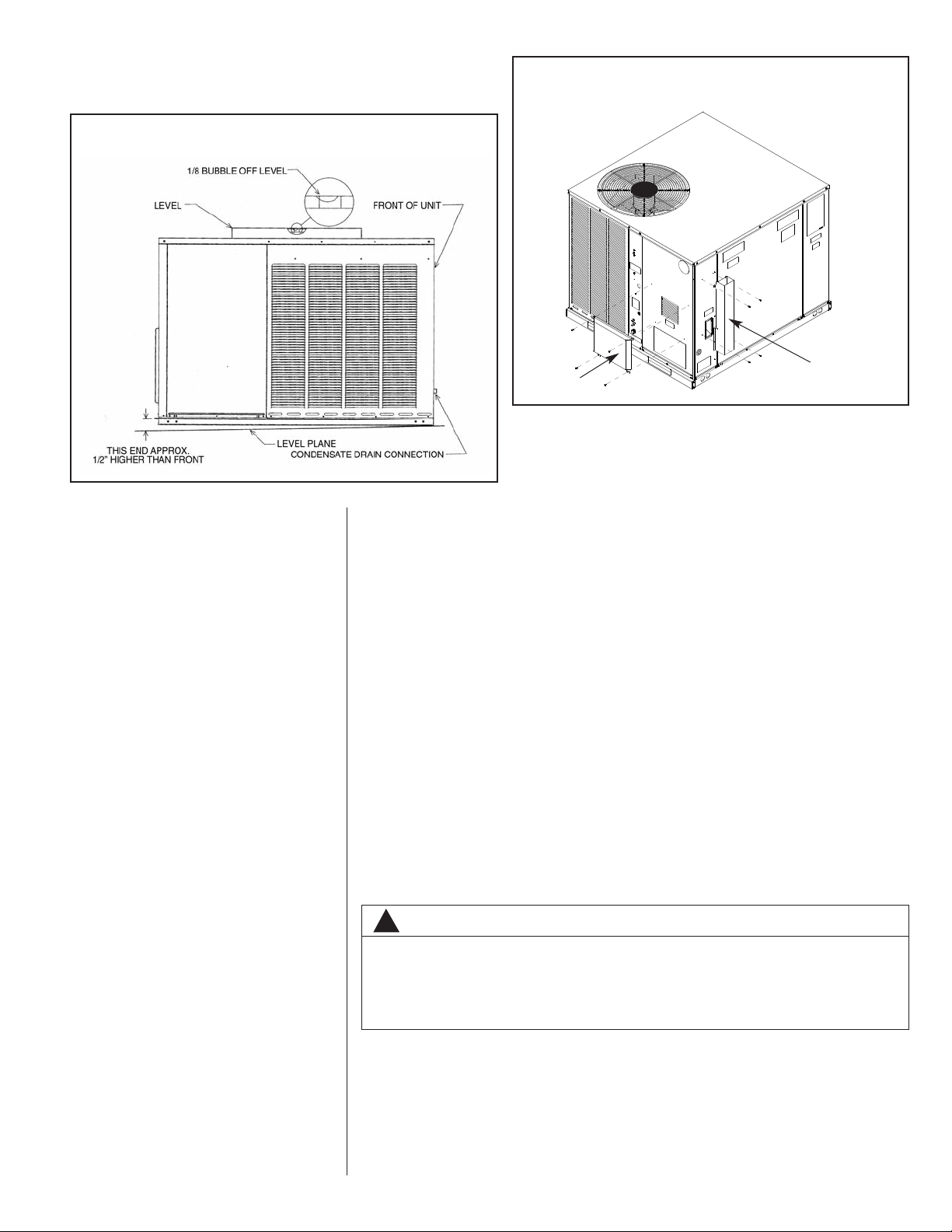

3. Pitch the slab approximately

1

⁄2” so that the unit will be pitched toward the drain. See

Figure 6.

4. The location of the unit should be such as to provide proper access for inspection

and servicing as shown in Figure 12.

5. Locate unit where operating sounds will not disturb owner or neighbors. The slab

should be isolated from the foundation wall.

6. Locate unit so roof runoff water does not pour directly on the unit. Provide gutter or

other shielding at roof level.

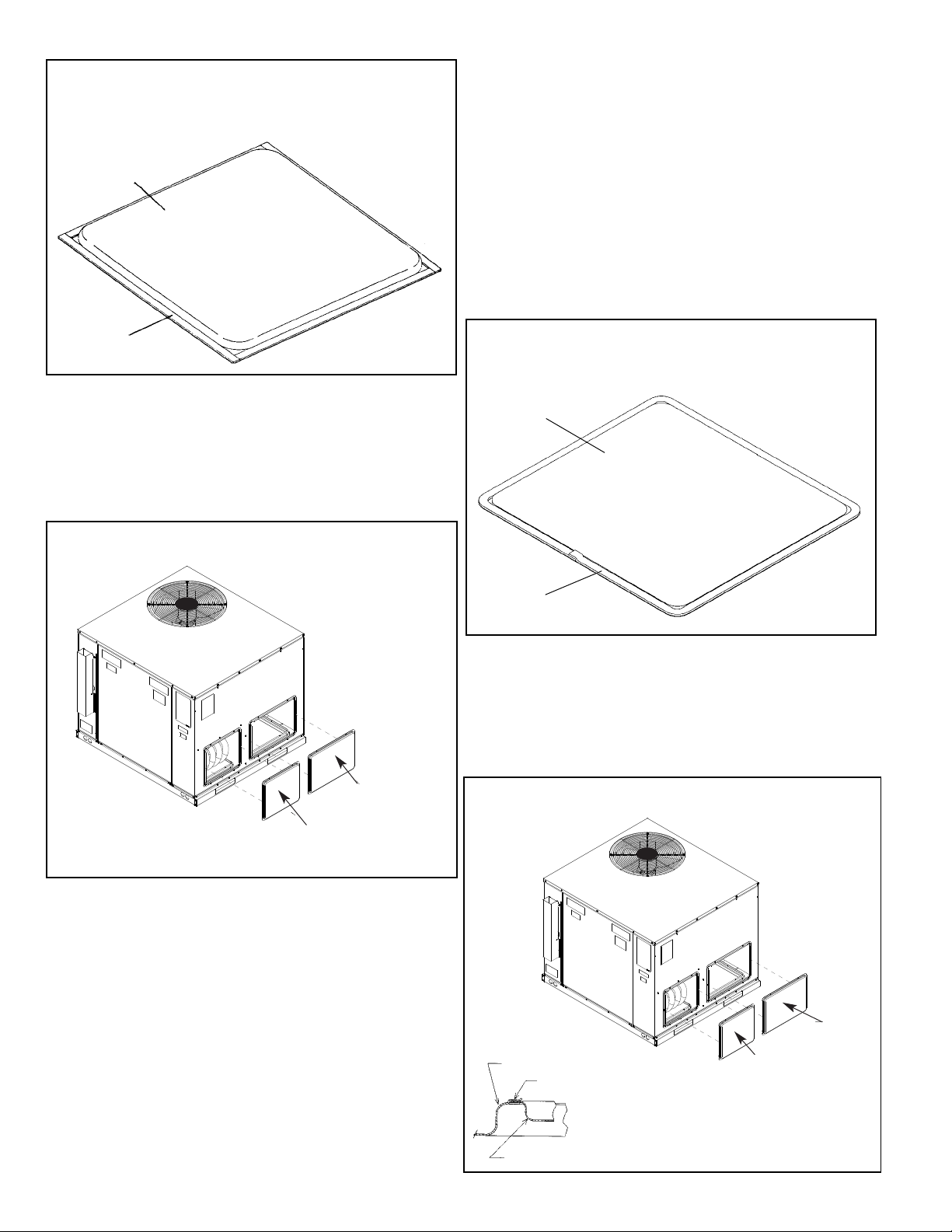

C. ATTACHING EXHAUST AND COMBUSTION AIR INLET HOODS

IMPORTANT: Do not operate this unit without the exhaust and combustion air inlet

hood properly installed. These hoods are shipped in a carton in the return air compartment inside the unit and must be attached when the unit is installed. See Figure 7.

To attach exhaust and combustion air inlet hood:

1. Remove 3 screws securing filter access panel and remove filter access panel. For location of filter access panel, see Figure 4.

2. Remove both exhaust and combustion air inlet hoods from their carton, located inside

the return air compartment.

3. Attach filter access panel.

4. Attach the combustion air inlet hood and the exhaust hood each with 4 screws as shown

in Figure 7. Screws are in parts bag shipped in the burner compartment.

5. Vent the unit using the flue exhaust hood, as supplied from the factory, without alteration

or addition. The only exception is with factory approved additions. Consult your local utility or other authority having jurisdiction for accepted venting techniques.

14

Page 15

FIGURE 6

PITCHING UNIT TO INSURE PROPER CONDENSATE DRAINAGE.

FIGURE 7

COMBUSTION AIR INLET HOOD & EXHAUST HOOD

INSTALLATION

EXHAUST

HOOD W/(4)

SCREWS

I655

COMBUSTION

AIR INLET

HOOD W/(4)

SCREWS

D. COVER PANEL INSTALLATION/CONVERSION PROCEDURE

1. HORIZONTAL TO DOWNFLOW

a. Remove screws and covers from the supply and return bottom sections. NOTE:

Rotate the supply cover 90° and remove.

b. Install gasket (supplied with parts bag) around perimeter of cover on the insulated

side. See Figure 9.

c. Secure covers to the side of the unit using existing screws and those supplied in

the parts bag.

2. DOWNFLOW TO HORIZONTAL

a. Remove screws and covers from the supply and return bottom sections.

b. Install gasket (supplied with parts bag) around perimeter of cover as illustrated in

Figure 8.

c. Install covers in the unit bottom with the insulated side up. NOTE: Supply cover

must be inserted through supply opening with narrow side toward unit. Once

cover is through opening, rotate 90° and slip back flange of cover under tab at the

back of bottom duct opening. See Figure 11.

d. Secure supply cover to base of unit with 2 screws, engaging prepunched holes in

raised duct opening flange.

e. Secure return covers to base of unit with screws engaging prepunched holes in

raised duct opening flange.

WARNING

!

THIS UNIT MUST NOT BE INSTALLED DIRECTLY ON WOOD FLOORING, CLASS

A, CLASS B OR CLASS C ROOF COVERING MATERIALS, OR ANY OTHER COMBUSTIBLE STRUCTURE EXCEPT AS SPECIFIED IN FIGURE 16. FAILURE TO

ADHERE TO THIS WARNING CAN CAUSE A FIRE OR EXPLOSION RESULTING

IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

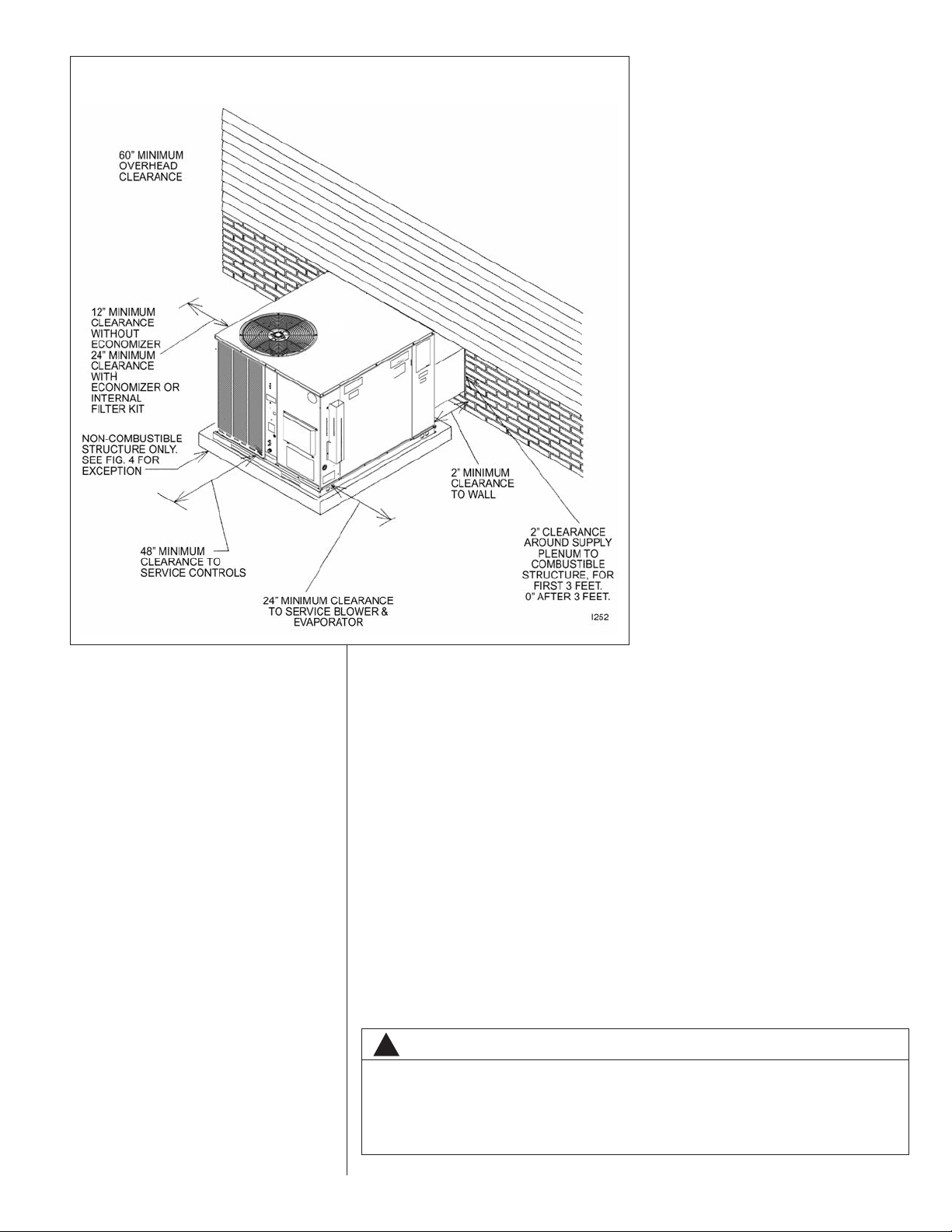

E.CLEARANCES

The following minimum clearances must be observed for proper unit performance and

serviceability. See Figure 12.

1. Provide 48” minimum clearance at front of the unit. Provide 24” minimum clearance

on right side of unit. If economizer is used, a 24” minimum clearance is required on

15

Page 16

FIGURE 5

COVER GASKET DETAILFOR UNITS SHIPPED FOR DOWNFLOW

APPLICATION BEING CONVERTED TO SIDE DISCHARGE

TAPE

AROUND FLANGE

SUPPLY/RETURN

AIR COVER

FIGURE 6

COVER GASKET DETAILFOR UNITS SHIPPED FOR SIDE DISCHARGE

APPLICATION BEING CONVERTED TO DOWNFLOW

TAPE

AROUND FLANGE

SUPPLY/RETURN

AIR COVER

I654

FIGURE 7

DUCT COVER INSTALLATION SIDE MOUNTING

I264

RETURN

DUCT COVER

(ATTACH WITH 6 SCREWS)

SUPPLY

DUCT COVER

(ATTACH WITH 6 SCREWS)

I

FIGURE 8

DUCT COVER INSTALLATION BASE PAN MOUNTING

I265

BASE PAN

SUPPLYDUCT

COVER

*

(INSULATION

SIDE UP),

ATTACH WITH

TWO SCREWS.

RETURN

DUCT

COVER

(INSULATION

SIDE UP ,

ATTACH

WITH 4

SCREWS)

SUPPLYDUCT

COVER

*

ROTATE SUPPLY COVER 90° AFTER IT IS INSERTED

THROUGH OPENING. SLIP FLANGE OF COVER

UNDER LANCE AT BACK OF BOTTOM SUPPLY DUCT

OPENING. SEE DETAILAT LEFT. THEN SECURE

COVER BY INSTALLING 2 SCREWS USING HOLE

NEAREST THE OUTSIDE OF UNIT.

LANCE AT BACK OF BOTTOM

SUPPLYDUCT OPENING

FIGURE 8

COVER GASKET DETAIL FOR UNITS SHIPPED FOR DOWNFLOW

APPLICATION BEING CONVERTED TO SIDE DISCHARGE

FIGURE 9

COVER GASKET DETAIL FOR UNITS SHIPPED FOR SIDE DISCHARGE

APPLICATION BEING CONVERTED TO DOWNFLOW

FIGURE 10

DUCT COVER INSTALLATION SIDE MOUNTING

FIGURE 11

DUCT COVER INSTALLATION BASE PAN MOUNTING

16

Page 17

FIGURE 12

CLEARANCES

left side of unit. (See Figure 12.) If no economizer is required, then a 12” clearance

is required on left side of unit.

2. Provide 60” minimum clearance between top of unit and maximum 3 foot overhang.

3. Unit is design certified for 2” minimum clearance between supply duct and a combustible structure for the first 3 feet of duct. 0” clearance is allowed after 3 feet.

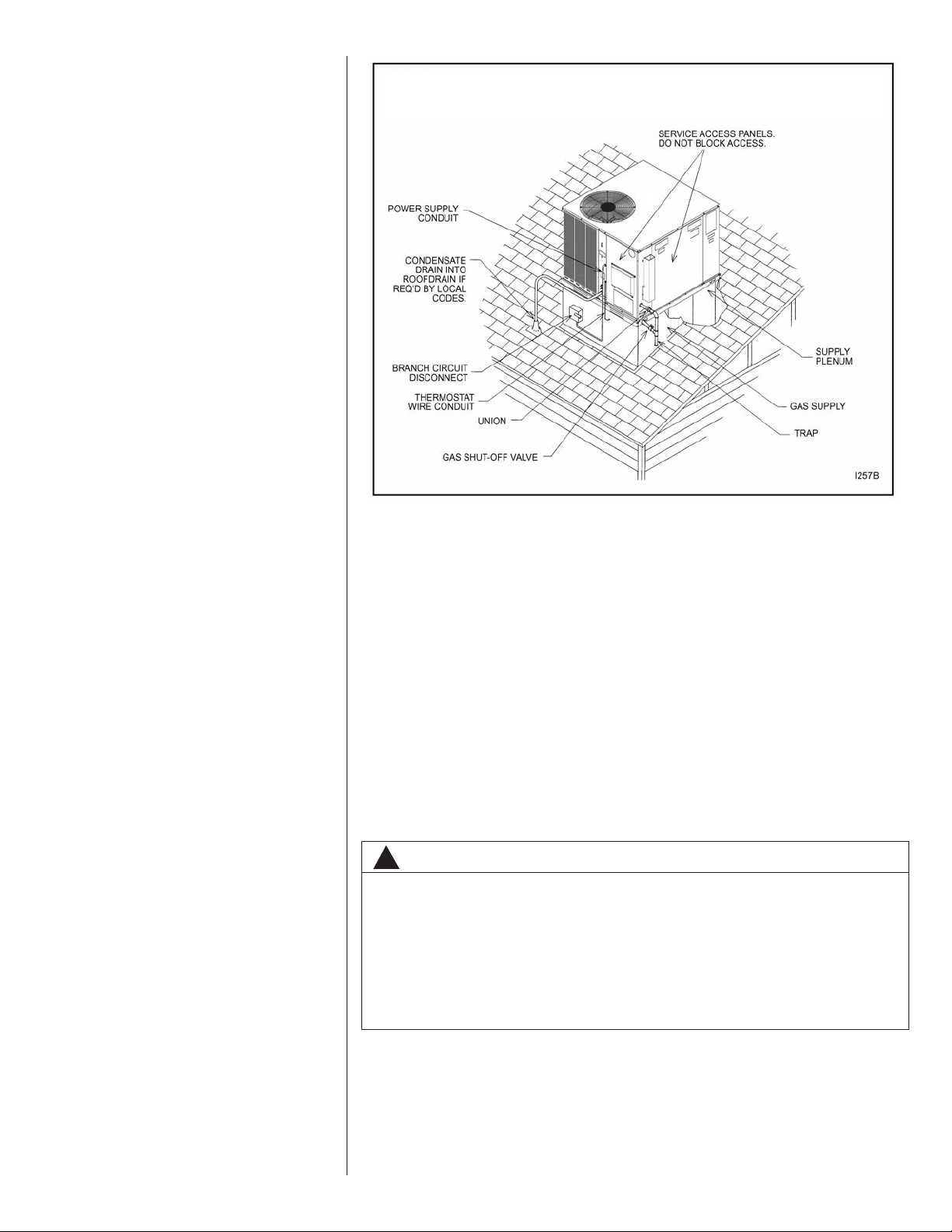

F. ROOFTOP INSTALLATION

1. Before locating the unit on the roof, make sure that the roof structure is adequate to

support the weight involved. (See electrical & physical tables in this book for weight

of unit.) THIS IS VERY IMPORTANT AND THE INSTALLER’S RESPONSIBILITY.

2. For rigging and roofcurb details, see Figures 17, 18, and 19.

3. The location of the unit on the roof should be such as to provide proper access for

inspection and servicing.

IMPORTANT: If unit will not be put into service immediately, block off supply and return

air openings to prevent excessive condensation.

G. DUCTWORK

The installing contractor should fabricate ductwork in accordance with local codes. Use

industry manuals as a guide when sizing and designing the duct system. Contact Air

Conditioning Contractors of America, 1513 16th St. N.W., Washington, D.C. 20036.

WARNING

!

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT RETURN DUCTWORK TO

ANY OTHER HEAT PRODUCING DEVICE SUCH AS FIREPLACE INSERT,

STOVE, ETC. UNAUTHORIZED USE OF SUCH DEVICES MAY RESULT IN FIRE,

CARBON MONOXIDE POISONING, EXPLOSION, PERSONAL INJURY, OR

PROPERTY DAMAGE.

17

Page 18

FIGURE 10

EXCEPTION TO NON-COMBUSTIBLE FLOORING REQUIREMENT

I458

BOTH ENDS

MUST BE

OPEN FOR

DOWNFLOW

OR SIDEFLOW

DUCTWORK

TO PROVIDE

VENTILATION

COMBUSTIBLE

STRUCTURE

1” MIN.

NOMINAL

4 x 4 TIMBER

(SIDES ONLY)

SIDEFLOW

SUPPLY

PLENUM

CONNECTION

SUPPLY

PLENUM

(DOWNFLOW)

RETURN PLENUM

(DOWNFLOW)

SIDEFLOW

RETURN PLENUM

CONNECTION

3-1/2” MIN.

FIGURE 13

EXCEPTION TO NON-COMBUSTIBLE FLOORING REQUIREMENT

FIGURE 14

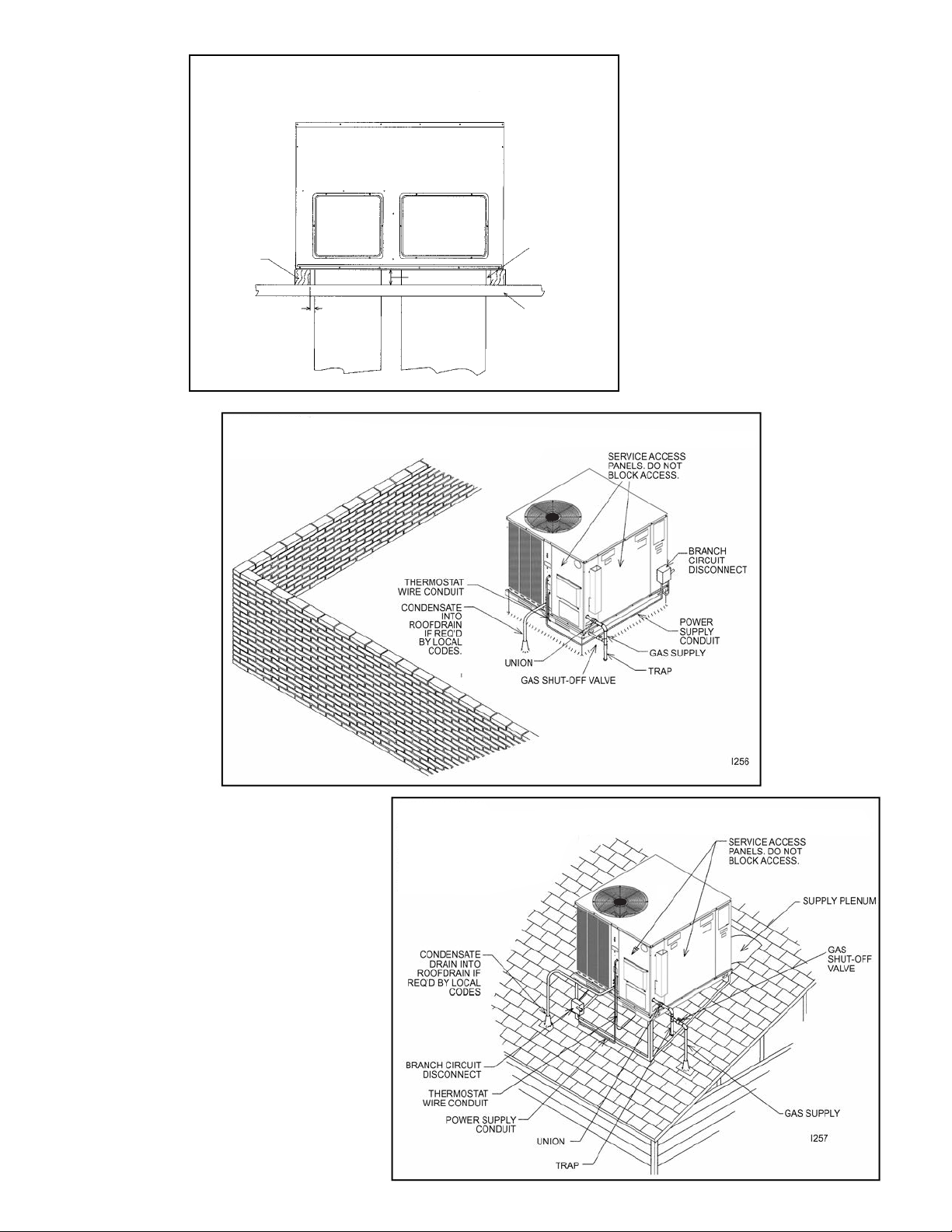

FLAT ROOFTOP INSTALLATION, ATTIC OR DROP CEILING DISTRIBUTING SYSTEM. MOUNTED ON

ROOFCURB, PITCH UNIT TOWARD DRAIN.

18

FIGURE 15

PITCHED ROOFTOP INSTALLATION, ON ANGLE-IRON STAND, SIDE FLOW DUCTWORK,

ATTIC OR DROP CEILING

DISTRIBUTING SYSTEM.

PITCH UNIT TOWARD DRAIN.

Page 19

FIGURE 16

PITCHED ROOFTOP INSTALLATION, ON ROOFJACK, DOWNFLOW DUCTWORK, ATTIC OR

DROP CEILING DISTRIBUTING SYSTEM. PITCH UNIT TOWARD DRAIN.

Place the unit as close to the conditioned space as possible allowing clearances as indicated. Run ducts as directly as possible to supply and return outlets. Use of non-flammable weatherproof flexible connectors on both supply and return connections at unit to

reduce noise transmission is recommended.

On ductwork exposed to outside temperature and humidity, use a minimum of 2” of

insulation and a vapor barrier. Distribution system in attic, furred space or crawl space

should be insulated with at least 2” of insulation.

cient for ductwork inside the air conditioned space.

Provide balancing dampers for each branch duct in the supply system. Properly support

ductwork from the structure.

IMPORTANT: In the event that the return air ducts must be run through an “unconfined”

space containing other fuel burning equipment, it is imperative that the user/homeowner

must be informed against future changes in construction which might change this to a

“confined space.” Also, caution the user/homeowner against any future installation of

additional equipment (such as power ventilators, clothes dryers, etc., within the existing

unconfined and/or confined space which might create a negative pressure within the

vicinity of other solid, liquid, or gas fueled appliances.

1

⁄2” to 1” thick insulation is usually suffi-

H. RETURN AIR

WARNING

!

NEVER ALLOW PRODUCTS OF COMBUSTION OR THE FLUE PRODUCTS TO

ENTER THE RETURN AIR DUCTWORK, OR THE CIRCULATING AIR SUPPLY.

ALL RETURN DUCTWORK MUST BE ADEQUATELY SEALED AND SECURED

TO THE FURNACE WITH SHEET METAL SCREWS, AND JOINTS TAPED. ALL

OTHER DUCT JOINTS MUST BE SECURED WITH APPROVED CONNECTIONS

AND SEALED AIRTIGHT.

FAILURE TO PREVENT PRODUCTS OF COMBUSTION FROM BEING CIRCULATED INTO THE LIVING SPACE CAN CREATE POTENTIALLY HAZARDOUS

CONDITIONS, INCLUDING CAROBON MONOXIDE POISONING THAT COULD

RESULT IN PERSONAL INJURY OR DEATH.

19

Page 20

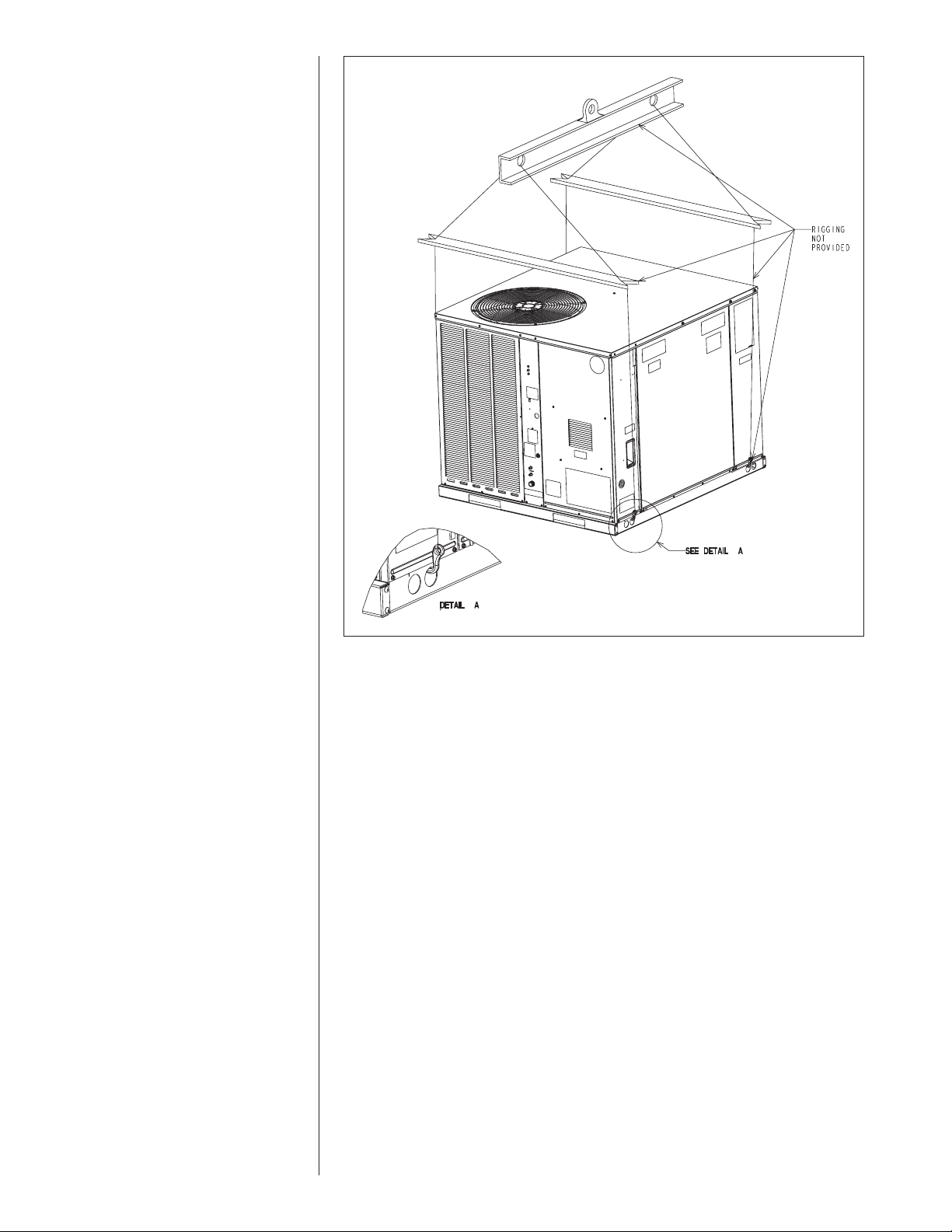

FIGURE 17

LIFTING DETAIL.

I

. FILTERS

The installer must install field supplied filters in the return air duct. A field installed filter

grille is recommended for easy and convenient access to the filters for periodic inspection and cleaning. Filters must have adequate face area for the rated air quantity of the

unit. See air delivery tables for recommended filter size. A field installed internal filter kit

RXRY-B01 is available.

20

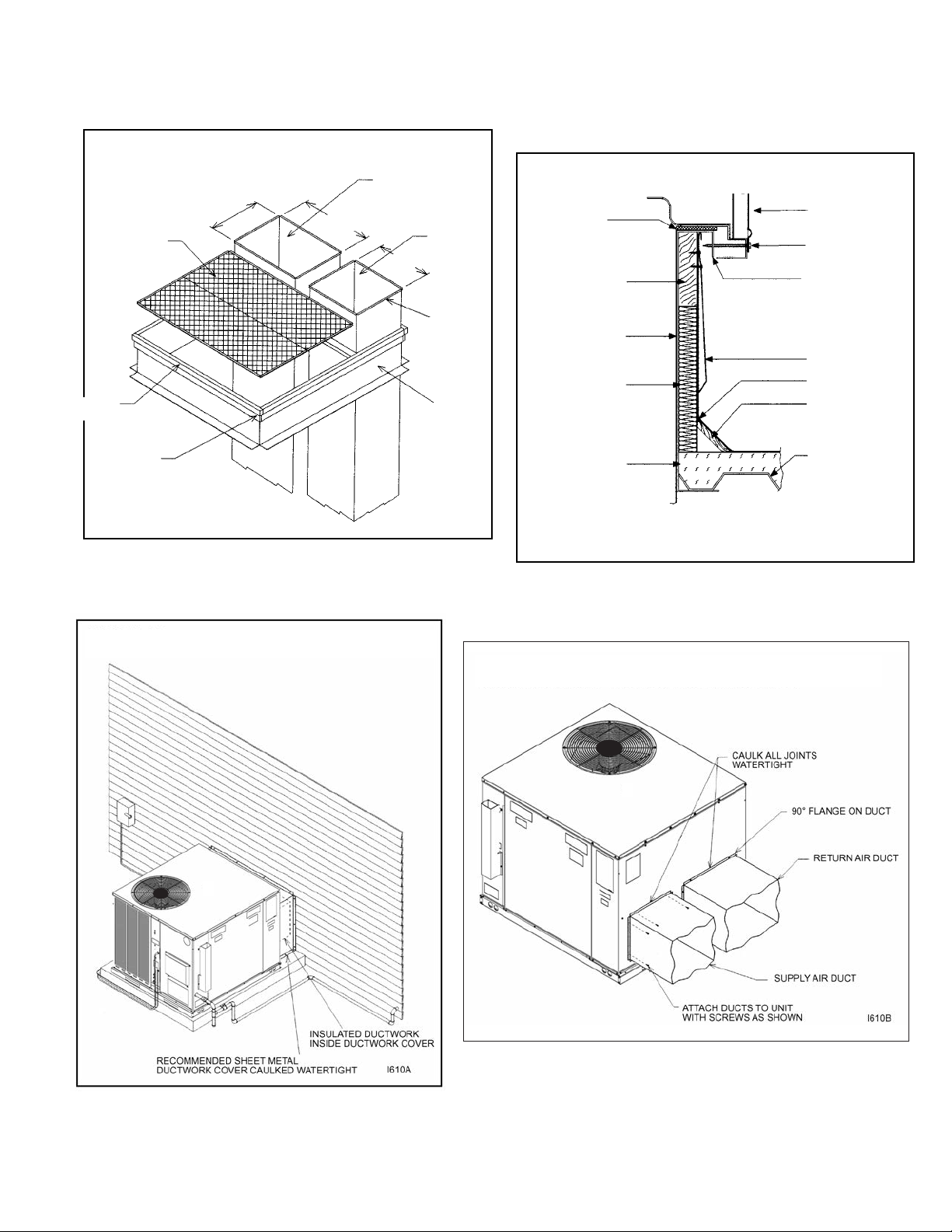

Page 21

I342

RETURN PLENUM

16

1

/2

MAX.

20

1

/2 MAX.

16

3

/8 MAX.

INSULATION

PANELS

NAILING

STRIP

CAULK ALL

JOINTS

WATERTIGHT

SUPPLY

PLENUM

DUCT

FLANGE

(NOT TO

EXCEED 1()

ROOFCURB

FIGURE 15

ROOFCURB

I255

**BY CONTRACTOR

**FOR INSTALLATION OF DUCT AS SHOWN, USE RECOMMENDED

DUCT SIZES FROM ROOFCURB INSTALLATION INSTRUCTIONS. FOR

DUCT FLANGE ATTACHMENT TO UNIT, SEE UNIT INSTALLATION

INSTRUCTIONS (FIGURE 1) FOR SIZE OF DUCT OPENINGS.

ROOFTOP UNIT

TIE DOWN SCREW *

ROOFCURB

ROOF FLASHING

*

ROOFING *

CANT STRIP *

ROOF DECK *

GASKET

NAILING STRIP

INSULATION

*

INSULATION *

** DUCT *

FIGURE 16

ROOFCURB

FIGURE 18

ROOFCURB

FIGURE 19

ROOFCURB

FIGURE 20

DUCTWORK COVER INSTALLATION DETAIL

FIGURE 21

RESIDENTIAL ROOFTOP DUCTWORK INSTALLATION DETAIL.

21

Page 22

VII.GAS SUPPLY, CONDENSATE DRAIN AND

FIGURE 19

SUGGESTED GAS PIPING

FROM GAS

METER

*

Factory supplied grommet must be utilized.

MANUAL GAS

SHUT-OFF

VALVE

UNIT GAS SUPPLY

CONNECTION

*

ROOF OR GROUND LEVEL INSTALLATION

Nominal

Iron Pipe

Size,

Inches

Equivalent Length of Pipe, Feet

10 20 30 40 50 60 70 80

1

/2 132 92 73 63 56 50 46 43

3

/4 278 190 152 130 115 105 96 90

1520350285245215195180170

11/4 1,050 730 590 500 440 400 370 350

11/2 1,600 1,100 890 760 670 610 560 530

TABLE 1

GAS PIPE CAPACITYTABLE (CU. FT./HR.)

VII.PIPING

A. GAS CONNECTION

IMPORTANT: Connect this unit only to gas supplied by a commercial utility.

1. Install gas piping in accordance with local codes and regulations of the local utility

company. In the absence of local codes, the installation must conform to the specifications of the National Fuel Gas Code, ANSI Z223.1 - latest edition.

NOTE: The use of flexible gas connectors is not permitted.

NOTE: The Commonwealth of Massachusetts requires the gas shut-off valve to be

a T-handle gas cock.

2. Connect the gas line to the gas pipe inlet opening provided into the 1/2” inlet valve.

See Figure 5 for typical piping.

3. Size the gas line to the furnace adequate enough to prevent undue pressure drop

and never less than 1/2”.

4. Install a drip leg or sediment trap in the gas supply line as close to the unit as possible.

5. Install an outside ground joint union to connect the gas supply to the control assembly at the burner tray.

6. Gas valves have been factory installed. Install a manual gas valve where local codes

specify a shut-off valve outside the unit casing. (See Figure 22.)

7. Make sure piping is tight. A pipe compound resistant to the action of liquefied

petroleum gases must be used at all threaded pipe connections.

8. IMPORTANT: Any additions, changes or conversions required for the furnace to satisfactorily meet the application should be made by a qualified installer, service

agency or the gas supplier, using factory-specified or approved parts. In the commonwealth of Massachusetts, installation must be performed by a licensed plumber

or gas fitter for appropriate fuel.

IMPORTANT: Disconnect the furnace and its individual shutoff valve from the gas supply piping during any pressure testing of that system at test pressures in excess of 1/2

psig or isolate the system from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of this gas supply system at pressures

equal to or less than 1/2 PSIG.

FIGURE 22

SUGGESTED GAS PIPING

22

Page 23

WARNING

!

DO NOT USE AN OPEN FLAME TO CHECK FOR LEAKS. THE USE OF AN OPEN

FLAME CAN RESULT IN FIRE, EXPLOSION, PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

TO CHECK FOR GAS LEAKS, USE A SOAP AND WATER SOLUTION OR OTHER

APPROVED METHOD. DO NOT USE AN OPEN FLAME.

IMPORTANT: Check the rating plate to make certain the appliance is equipped to burn

the type of gas supplied. Care should be taken after installation of this equipment that

the gas control valve not be subjected to high gas supply line pressure.

In making gas connections, avoid strains as they may cause noise and damage the controls. A backup wrench is required to be used on the valve to avoid damage.

The capacities of gas pipe of different diameters and lengths in cu. ft. per hr. with pressure drop of 0.5 in. and specific gravity of 0.60 (natural gas) are shown in Table 2.

After determining the pipe length, select the pipe size which will provide the minimum

cubic feet per hour re quired for the gas input rating of the furnace. By formula:

Gas Input of Furnace

Cu. Ft. Per Hr. Required =

The gas input of the furnace is marked on the furnace rating plate. The heating value of

the gas (BTU/FT

L.P. gas supplier.

(BTU/HR)

Heating Value of Gas

3

(BTU/FT

3

) may be determined by consulting the local natural gas utility or the

)

B. LP CONVERSION SINGLE STAGE GAS HEAT

WARNING

!

THIS UNIT IS EQUIPPED AT THE FACTORY FOR USE ON NATURAL GAS ONLY.

CONVERSION TO LP GAS REQUIRES A SPECIAL KIT SUPPLIED BY THE DISTRIBUTOR OR MANUFACTURER. MAILING ADDRESSES ARE LISTED ON THE

FURNACE RATING PLATE, PARTS LIST AND WARRANTY. FAILURE TO USE

THE PROPER CONVERSION KIT CAN CAUSE FIRE, CARBON MONOXIDE POISONING, EXPLOSION, PERSONAL INJURY, PROPERTY DAMAGE OR DEATH.

Convert the valve to use liquefied petroleum (LP) gas by replacing the pressure regulator

spring with the conversion kit spring. This LP kit spring allows the regulator to maintain the

proper manifold pressure for LP gas. The correct burner LP orifices are included in the kit.

See Figure 23.

NOTE: Order the correct LP conversion kit from the furnace manufacturer. See

Conversion Kit Index shipped with unit for proper LP kit number. Furnace conversion to LP gas must be performed by a qualified technician.

FIGURE 23

23

Page 24

C. LP CONVERSION TWO STAGE GAS HEAT

Maximum capacity of pipe in thousands of BTU per hour of undiluted liquefied petroleum

gases (at 11 inches water column inlet pressure).

(Based on a Pressure Drop of 0.5 Inch Water Column)

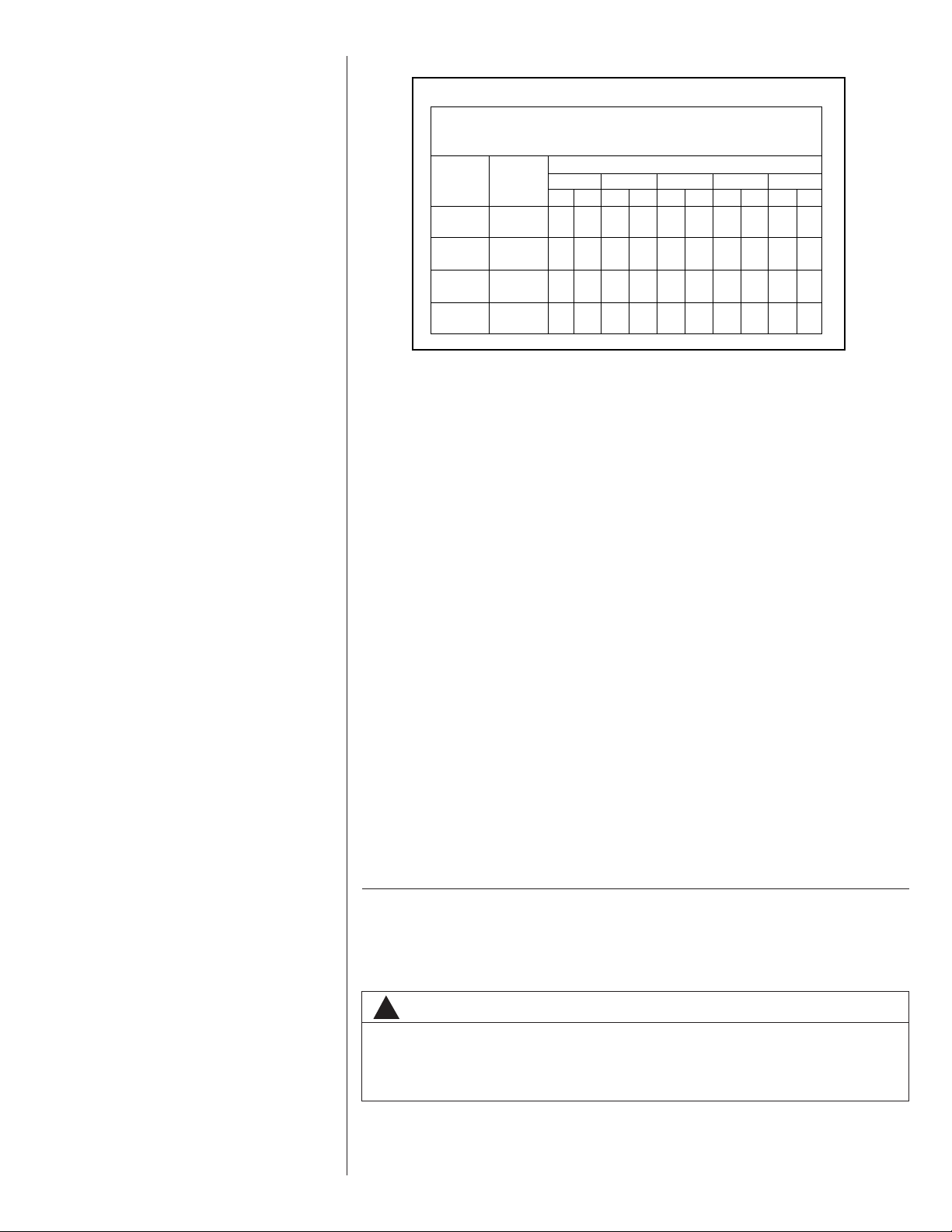

TABLE 2

LP GAS PIPE CAPACITY TABLE (CU. FT./HR.)

Nominal

Iron Pipe

Size, Inches

10 20 30 40 50 60 70 80 90 100 125 150

275 189 152 129 114 103 96 89 83 78 69 63

567 393 315 267 237 217 196 182 173 162 146 132

1,071 732 590 504 448 409 378 346 322 307 275 252

2,205 1,496 1,212 1,039 913 834 771 724 677 630 567 511

3,307 2,299 1,858 1,559 1,417 1,275 1,181 1,086 1,023 976 866 787

6,221 4,331 3,465 2,992 2,646 2,394 2,205 2,047 1,921 1,811 1,606 1,496

1/2

3/4

1

1-1/4

1-1/2

2

Length of Pipe, Feet

Example (LP): Input BTU requirement of unit, 150,000

Equivalent length of pipe, 60 ft. = 3/4” IPS required.

WARNING

!

THIS UNIT IS EQUIPPED AT THE FACTORY FOR USE ON NATURAL GAS ONLY.

CONVERSION TO LP GAS REQUIRES A SPECIAL KIT SUPPLIED BY THE DISTRIBUTOR OR MANUFACTURER. MAILING ADDRESSES ARE LISTED ON THE

FURNACE RATING PLATE, PARTS LIST AND WARRANTY. FAILURE TO USE

THE PROPER CONVERSION KIT CAN CAUSE FIRE, CARBON MONOXIDE POISONING, EXPLOSION, PERSONAL INJURY, PROPERTY DAMAGE OR DEATH.

Convert the valve to use liquefied petroleum (LP) gas by replacing with the gas valve supplied in the conversion kit. The LP gas valve maintains the proper manifold pressure for LP

gas. The correct burner LP orifices are included in the kit.

IMPORTANT: To remove the natural gas valve, remove the four screws securing the manifold pipe to the burner tray. Remove the manifold pipe with gas valve attached.

NOTE: Order the correct LP conversion kit from the furnace manufacturer. See

Conversion Kit Index shipped with unit for proper LP kit number. Furnace conversion to LP gas must be performed by a qualified technician.

D. NOx MODELS

When converting units equipped with NOx inserts to LP gas, the stainless steel mesh

inserts in the entrance of the tubular exchangers are not required to meet SCAQMD NOx

emission levels. Carefully remove these inserts before firing this furnace on LP gas. This

furnace is not designed to operate on LP gas with the NOx inserts in place.

Step by step instructions on removing the NOx inserts and retaining rod are included in the

Conversion Kit Installation Instructions.

E. ADJUSTING OR CHECKING FURNACE INPUT

– Natural Gas Line Pressure 5” - 10.5” W.C.

– LP Gas Line Pressure 11” - 13” W.C.

– Natural Gas Manifold Pressure 3.5” W.C

– LP Gas Manifold Pressure - 10” W.C.

Supply and manifold pressure taps are located on the gas valve body 1/8” N.P.T.

Use a properly calibrated manometer gauge for accurate gas pressure readings.

Only small variations in the gas flow should be made by means of the pressure regulator

adjustment. Furnaces functioning on LP gas must be set by means of the tank or branch

supply regulators. The furnace manifold pressure should be set at 10” W.C. at the gas control valve.

To adjust the pressure regulator, remove the regulator cap and turn the adjustment screw

clockwise to increase pressure or counterclockwise to decrease pressure. Then replace

the regulator cap securely.

24

Any necessary major changes in the gas flow rate should be made by changing the size of

the burner orifices. To change orifice spuds, shut off the manual main gas valve and

remove the gas manifold.

For elevations up to 2,000 feet, rating plate input ratings apply. For high altitudes (elevations

over 2,000 ft.), see conversion kit index 92-21519-47 for derating and orifice spud sizes.

Check of input is important to prevent over-firing of the furnace beyond its designrated input. NEVER SET INPUT ABOVE THAT SHOWN ON THE RATING PLATE. Use

the following table or formula to determine input rate.

Cu. Ft. Per Hr. Required =

Heating Value of Gas

(BTU/Cu. Ft.) x 3600

Time in Seconds

(for 1 Cu. Ft.) of Gas

Page 25

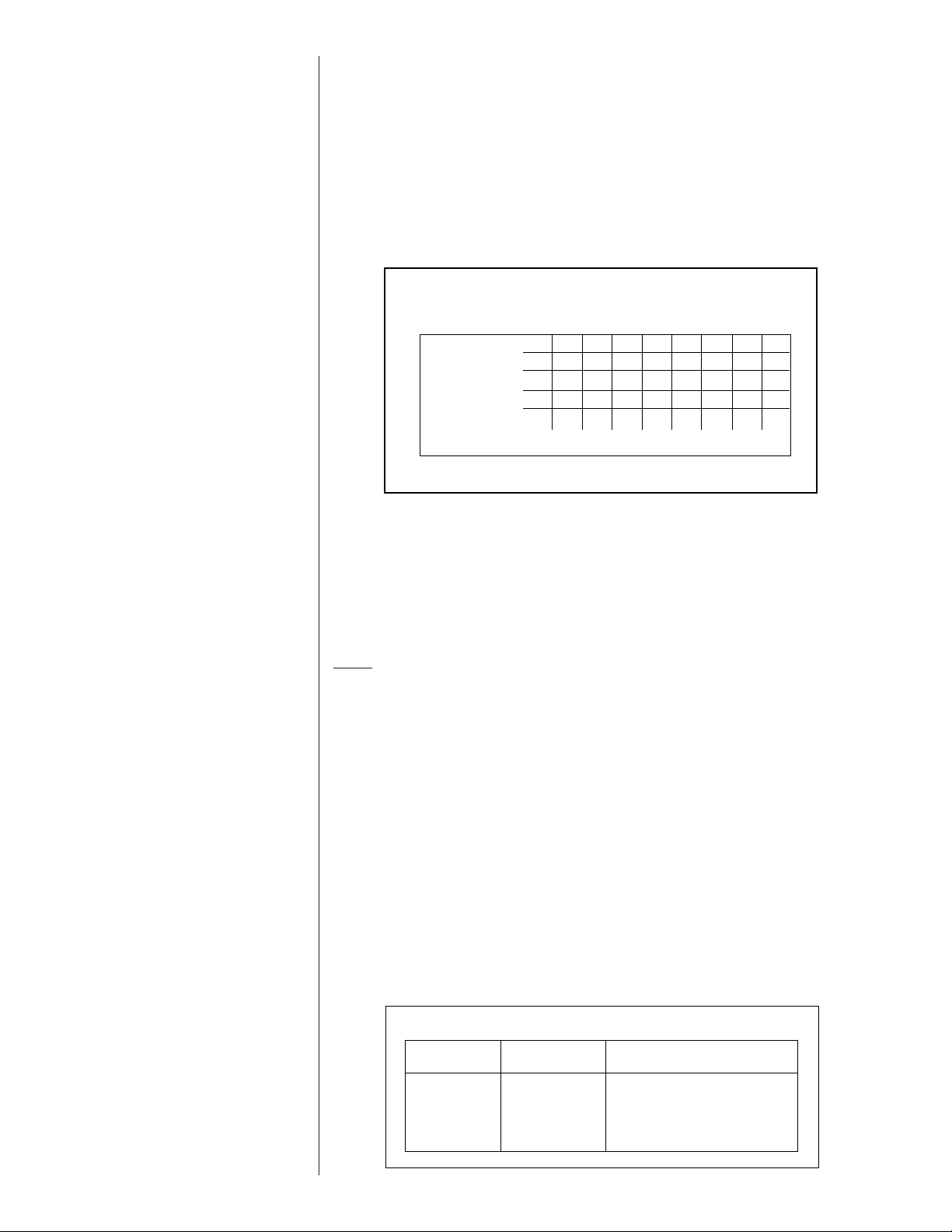

Start the furnace and measure the time required to burn one cubic foot of gas. Prior to

ONE 1 21 1 30 1 34 1 39 3 45

40,000

TEN 13 30 15 0 15 36 16 30 37 30

ONE 0 54 1 0 1 3 1 6 2 30

60,000

TEN 9 0 10 0 10 24 11 0 25 0

ONE 0 41 0 45 0 47 0 50 1 53

80,000

TEN 6 45 7 30 7 48 8 15 18 45

ONE 0 33 0 36 0 38 0 40 1 30

100,000

TEN 5 24 6 0 6 15 6 36 15 0

METER TIME IN MINUTES AND SECONDS FOR NORMAL

INPUT RATING OF FURNACES EQUIPPED FOR NATURAL

OR LP GAS

INPUT

BTU/HR

METER

SIZE

CU. FT.

HEATING VALUE OF GAS BTU PER CU. FT.

900 1000 1040 1100 2500

MIN. SEC. MIN. SEC. MIN. SEC. MIN. SEC. MIN. SEC.

TABLE 3

checking the furnace input, make certain that all other gas appliances are shut off, with

the exception of pilot burners. Time the meter with only the furnace in operation.

IMPORTANT NOTE FOR ALTITUDES ABOVE 2,000 FEET (610 METERS): The main

burner orifices in your furnace and in these kits are sized for the nameplate input and

intended for installations at elevations up to 2,000 feet in the USA or Canada, or for elevations of 2,000 - 4,500 feet (610 -1,373 meters) in Canada if the unit has been derated

at the factory. For elevations above 2,000 feet (610 meters) IN THE USA ONLY (see

ANSI-Z223.1), the burner orifices must be sized to reduce the input 4% for each 1,000

feet (305 meters) above sea level.

NOTICE: DERATING OF THE HEATING INPUT FOR HIGH ALTITUDE IN THE FIELD

IS UNLAWFUL IN CANADA (REFER TO CAN/CGA 2.17). UNITS INSTALLED IN

ALTITUDES GREATER THAN 2,000 FEET (610 METERS) MUST BE SHIPPED FROM

THE FACTORY OR FROM A FACTORY AUTHORIZED CONVERSION STATION

WITH THE HEATING INPUT DERATED BY 10% SO AS TO OPERATE PROPERLY IN

ALTITUDES FROM 2,000 - 4,500 FEET (610 - 1,373 METERS).

F. CONDENSATE DRAIN

The evaporator coil condensate drain ends with a threaded 3/4” nominal PVC stub. A

trap is built in for proper condensate drainage and to prevent debris from being drawn

into the unit. Do not connect the drain to a closed sewer line. Connection to a vented

sewer line is allowed. It is recommended that a PVC cement not be used so that the

drain line can be easily cleaned in the future.

IMPORTANT: DO NOT INSTALL AN EXTERNAL TRAP. DOING SO CAN CAUSE

IMPROPER DRAINAGE OF THE CONDENSATE AND RESULT IN FLOODING WITHIN THE UNIT.

VIII.WIRING

A. POWER SUPPLY

WARNING

!

TURN OFF THE MAIN ELECTRICAL POWER AT THE BRANCH CIRCUIT DISCONNECT CLOSEST TO THE UNIT BEFORE ATTEMPTING ANY WIRING. FAILURE

TO DO SO CAN CAUSE ELECTRICAL SHOCK RESULTING IN PERSONAL

INJURY OR DEATH.

25

Page 26

1. All wiring should be made in accordance with the National Electrical Code.

200 6 4 4 4 3 3 2 2

150 8 6 6 4 4 4 3 3

100 10 8 8 6 6 6 4 4

50 14 12 10 10 8 8 6 6

15 20 25 30 35 40 45 50

TABLE 4

BRANCH CIRCUIT COPPER WIRE SIZE

(BASED ON 1% VOLTAGE DROP)*

SUPPLY WIRE

LENGTH-FEET

*Taken from National Electric Code

BRANCH CIRCUIT AMPACITY

AWG Copper AWG Aluminum Connector Type and Size

Wire Size Wire Size (or equivalent)

#12 #10 T & B Wire Nut PT2

#10 # 8 T & B Wire Nut PT3

# 8 # 6 Sherman Split Bolt TSP6

# 6 # 4 Sherman Split Bolt TSP4

# 4 # 2 Sherman Split Bolt TSP2

TABLE 5

Consult the local power company to determine the availability of sufficient power to

operate the unit. Check the voltage at power supply to make sure it corresponds to

the unit’s RATED VOLTAGE REQUIREMENT. Install a branch circuit disconnect

near the rooftop, in accordance with the N.E.C., C.E.C. or local codes.

2. It is important that proper electrical power is available at the unit. Voltage should not

vary more than 10% from that stamped on the unit nameplate. On three phase units,

phases must be balanced within 3%.

3. For branch circuit wiring (main power supply to unit disconnect), the minimum wire size

for the length of run can be determined from Table 4 using the circuit ampacity found on

the unit rating plate. Use the smallest wire size allowable in Table 4 from the unit disconnect to unit. The disconnect must be in sight and readily accessible of the unit.

NOTES:

1. Wire size based on 60°C rated wire insulation and 30°C Ambient Temp. (86°F).

2. For more than 3 conductors in a raceway or cable, see the N.E.C. for derating the

ampacity of each conductor.

When installed, the unit must be electrically grounded in accordance with local

codes or, in the absence of local codes, with the National Electrical Code,

ANSI/NFPA 70, if an external electrical source is utilized.

IMPORTANT: THIS UNIT IS AP PROVED FOR USE WITH COPPER CONDUCTORS

CONNECTED TO UNIT CONTACTOR.

ONLY

WARRANTY MAY BE JEOPARDIZED IF ALUMINUM WIRE IS CONNECTED TO

UNIT CONTACTOR.

Special instructions apply for power wiring with aluminum conductors: Warranty

is void if connections are not made per instructions.

Attach a length (6” or more) of recommended size copper wire to the unit contactor terminals L1 and L3 for single phase, L1, L2 and L3 for three phase.

Select the equivalent aluminum wire size from the tabulation below:

Splice copper wire pigtails to aluminum wire with U.L. recognized connectors for copper-

aluminum splices. Please exercise the following instructions very carefully to obtain a

positive and lasting connection:

1. Strip insulation from aluminum conductor.

2. Coat the stripped end of the aluminum wire with the recommended inhibitor, and

wire brush the aluminum surface through inhibitor. INHIBITORS: Brundy-Pentex “A”;

Alcoa-No. 2EJC; T & B-KPOR Shield.

3. Clean and recoat aluminum conductor with inhibitor.

4. Make the splice using the above listed wire nuts or split bolt connectors.

5. Coat the entire connection with inhibitor and wrap with electrical insulating tape.

26

Page 27

B. HOOK-UP

To wire unit, refer to the following hook-up diagram (see Figure 24).

Refer to Figure 4 for location of wiring entrances.

Wiring to be done in the field between the unit and devices not attached to the unit, or

between separate devices which are field installed and located, shall conform with the

temperature limitation for Type T wire [63°F rise (35°C)] when installed in accordance

with the manufacturer’s instructions.

FIGURE 24

WIRE HOOK-UP DIAGRAM

FOR INTERNAL WIRING SEE WIRING LABEL ATTACHED TO UNIT

CHASSIS GROUND

T1

CONTACTOR

T2

T3

(2

STAGE

ODD

GAS

HEAT

ONLY)

LOW VOLTAGE

WIRE LEADS

L1

*

L2

L3

Y GRWCY2 L

*L2 connection 3Phase only

HIGH VOLTAGE

DISCONNECT

SWITCH

YGRWC Y2 L

THERMOSTAT

Y - COOLING (LOW STAGE IN 2 STAGE SYSTEMS)

G - FAN ONLY

R - 24V

W - HEATING (LOW HEAT 2 STAGE GAS HEAT)

C - COMMON

Y2 - HIGH STAGE COOLING (TWO STAGE ONLY)

L - ALERT CODES (OPTIONAL WITH COMFORT ALERT

L - AND COMPATIBLE THERMOSTAT)

ODD - ON-DEMAND DEHUMIDIFICATION

W2 - HEATING (HIGH HEAT 2 STAGE GAS)

ODDW2W2

C. INTERNAL WIRING

IMPORTANT: Some single phase units are equipped with a single pole contactor.

Caution must be exercised when servicing as only one leg of the power supply is broken

with the contactor.

A diagram of the internal wiring of this unit is located under the electrical box cover and

in this manual. If any of the original wire as supplied with the appliance must be

replaced, the wire gauge and insulation must be same as original wiring.

Transformer is factory wired for 230 volts on 208/230 volt models and must be changed

for 208 volt applications. See unit wiring diagram for 208 volt wiring.

D. THERMOSTAT

The room thermostat must be compatible with the spark ignition control on the unit.

Generally, all thermostats that are not of the “current robbing” type are compatible with

the integrated furnace control. Two stage units (5 ton) require use of a thermostat capable of 2 stages of cooling. (See Section IV.) See chart below for recommendations. The

low voltage wiring should be sized as shown in Table 6.

Install the room thermostat in accordance with the instruction sheet packed in the box

with the thermostat. Never install the thermostat on an outside wall or where it will be

influenced by drafts, concealed hot or cold water pipes or ducts, lighting fixtures, radiation from fireplace, sun rays, lamps, televisions, radios or air streams from registers.

Refer to instructions packed with the thermostat for “heater” selection or adjustment.

Refer to the RRNL-/RRPL-/RRRL- Specification Sheets for a list of recommended thermostats.

27

Page 28

IX. FURNACE SECTION CONTROLS AND

FIELD WIRE SIZE FOR 24 VOLT THERMOSTAT CIRCUITS

SOLID COPPER WIRE - AWG.

3.0 16 14 12 10 10 10

2.5 16 14 12 12 12 10

2.0 18 16 14 12 12 10

50 100 150 200 250 300

Length of Run – Feet (1)

Thermostat Load - Amps

TABLE 6

(1) The total wire length is the distance from the furnace to the

thermostat and back to the furnace.

NOTE: DO NOT USE CONTROL WIRING SMALLER THAN NO. 18

AWG.

IGNITION SYSTEM

A. NORMAL FURNACE OPERATING SEQUENCE (SINGLE STAGE GAS HEAT)

This unit is equipped with an integrated direct spark ignition control.

1. The thermostat calls for heat.

2. The control board will run a self check to verify that the limit control and manual reset

overtemperature control are closed and that the pressure switch is open. If so, the

induced draft blower (inducer) begins a prepurge cycle.

3. The air proving negative pressure switch closes.

4. 15 seconds after the pressure switch closes, the gas valve opens and the spark is

initiated for a 7 second trial for ignition.

5. Burners ignite and flame sensor proves all burners have lit.

6. The circulating air blower is energized after 30 seconds.

7. The control board enters a normal operation loop in which all safety controls are monitored continuously.

8. Thermostat is satisfied and opens.

9. The gas valve is de-energized and closes, shutting down the burner flame.

10. The control board will de-energize the inducer after a five second post purge.

11. The circulating air blower is de-energized after 90 seconds.

• The integrated control board has a three ignition system.

• After a total of three trials for ignition without sensing main burner flame, the system

goes into a 100% lockout mode.

• After one hour, the ignition control repeats the prepurge and ignition cycles for 3 tries

and then goes into 100% lockout mode again.

• It continues this sequence of cycles and lockout each hour until ignition is successful or

power is interrupted.

• During the lockout mode, neither the spark ignition control or gas valve will be energized

until the system is reset by turning the thermostat to the “OFF” position or interrupting

the electrical power to the unit for 3 seconds or longer.

• The induced draft blower and main burner will shut off when the thermostat is satisfied.

• The circulating air blower will start and run on the heating speed if the thermostat fan

switch is in the “ON” position.

The integrated furnace control is equipped with diagnostic LED. The LED is lit continuously

when there is power to the control, with or without a call for heat. If the LED is not lit, there

is either no power to the control or there is an internal component failure within the control,

and the control should be replaced.

If the control detects the following failures, the LED will flash on for approximately 1/4 sec-

28

ond, then off for 3/4 second for designated failure detections.

1 Flash: Failed to detect flame within the three tries for ignition.

2 Flash: Pressure switch or induced draft blower problem detected.

3 Flash: High limit or auxiliary limit open.

4 Flash: Flame sensed and gas valve not energized or flame sensed with no “W” signal.

5 Flash: Overtemperature switch open.

B. NORMAL FURNACE OPERATING SEQUENCE (TWO STAGE GAS HEAT

FOR RRRL-C)

This unit is equipped with a two stage integrated direct spark ignition control.

TABLE 6

Page 29

NORMAL HEAT MODE

A. Call For First Stage (low fire) Only:

1. Zone thermostat contacts close, a call for first stage (low fire) heat is initiated.

2. Control runs self check.

3. Control checks the high-limit switch for normally closed contacts, each pressure switch

for normally open contacts, and all flame rollout switches for continuity.

4. Control energizes high inducer speed.

5. Control checks pressure switches for closure.

6. If pressure switches are closed, the control starts a 30 second prepurge.

7. After prepurge timeout, control initiates spark for 2 seconds minimum, 7 second maximum ignition trial, initiates 30 second, second stage (high fire) warm up timing.

8. Control detects flame, de-energizes spark and initiates 30 second delay on blower timing.

9. After a fixed 30 seconds indoor blower delay on, the control energizes the indoor blower.

10. After the 30 second second stage warmup period control checks thermostat input. If

only W1 is called for, W2 is de-energized and the control starts a 5 second off delay on

the W2 inducer speed.

11. After fixed 5 seconds the gas valve shifts to low and the W2 inducer speed is de-energized.

12. Control enters normal operating loop where all inputs are continuously checked.

B. Call For Second Stage, After First

Stage Established; Starting from A.11:

1. If a call for second stage (high fire) is initiated after a call for first stage heat is established, the control energizes the W2 inducer speed assures the high-fire pressure

switch is closed and energizes the second stage of the gas valve.

2. Control enters normal operating loop where all inputs are continuously checked.

C. Second Stage Satisfied; First Stage

Still Called For; Starting From B.2:

1. Once the call for second stage is satisfied, the control starts a 30 second off delay on

W2 inducer and reduces the gas valve to first stage.

2. Control enters normal operating loop where all inputs are continuously checked.

D. First Stage Satisfied:

1. Zone thermostat is satisfied.

2. Control de-energizes gas valve.

3. Control senses loss of flame.

4. Control initiates 5 second inducer postpurge and 90 second indoor blower delay off.

5. Control de-energizes inducer blower.

6. Control de-energizes indoor blower.

7. Control in the stand by mode with solid red LED.

E. First Stage and Second Stage

Removed Simultaneously:

1. Upon a loss of W1 and W2 the gas valve is de-energized.

2. Upon a loss of flame, the inducer will complete a 5 second postpurge and the indoor

blower will complete a 90 second delay off.

3. Control in the stand by mode with solid red LED.

The integrated control is a four-ignition system.

After a total of four cycles without sensing main burner flame, the system goes into a 100%

lockout mode. After one hour, the ignition control repeats the prepurge and ignition cycles

for 4 tries and then go into 100% lockout mode again. It continues this sequence of cycles

and lockout each hour until ignition is successful or power is interrupted. During the lockout

mode, neither the ignitor or gas valve will be energized until the system is reset by turning

the thermostat to the “OFF” position or interrupting the electrical power to the unit for 3

seconds or longer. The induced draft blower and main burner will shut off when the thermostat is satisfied.

The circulating air blower will start and run on the heating speed if the thermostat fan

switch is in the “ON” position.

The integrated furnace control is equipped with diagnostic LED. The LED is lit continuously

when there is power to the control, with or without a call for heat. If the LED is not lit, there

is either no power to the control or there is an internal component failure within the control,

and the control should be replaced.

If the control detects the following failures, the LED will flash on for approximately 1/4 second, then off for 3/4 second for designated failure detections.

1 Flash: Failed to detect flame within the four tries for ignition.

2 Flash: Pressure switch or induced draft blower problem detected.

3 Flash: High limit or auxiliary limit open.

4 Flash: Flame sensed and gas valve not energized or flame sensed with no “W” signal.

5 Flash: Overtemperature switch open.

29

Page 30

C. OPERATING INSTRUCTIONS

This appliance is equipped with a direct spark intermittent ignition device. This device

lights the main burners each time the room thermostat (closes) calls for heat. See operating instructions on the back of the furnace/controls access panel.

WARNING

!

DO NOT ATTEMPT TO MANUALLY LIGHT THIS FURNACE WITH A MATCH OR

ANY OPEN FLAME. ATTEMPTING TO DO SO CAN CAUSE AN EXPLOSION OR

FIRE RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

TO START THE FURNACE

1. STOP! Read the safety information on the Operating Instructions Label located on this

appliance.

WARNING

!

IF YOU DO NOT FOLLOW THESE INSTRUCTIONS EXACTLY, A FIRE OR

EXPLOSION MAY RESULT CAUSING PROPERTY DAMAGE, PERSONAL

INJURY OR LOSS OF LIFE.

2. Set the thermostat to its lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance does not have a pilot. It is equipped with an ignition device which automatically lights the burner. Do NOT

5. Remove control door/access panel.

6. Move switch to the “OFF” position.

7. Wait five (5) minutes to clear out any gas. Then smell for gas, including near the floor.

If you smell gas, STOP!

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any phone in your building.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

• instructions.

• If you cannot reach your gas supplier, call the fire department.

If you don’t smell gas, go to the next step.

8. Move the switch from “OFF” position to “ON” position.

9. Replace the control door.

10. Turn on all electric power to the appliance.

11. Set the thermostat to the desired setting.

12. If the appliance will not operate, follow the instructions below on how to shut down the

furnace.

try to light the burner by hand.

30

WARNING

!

THE SPARK IGNITOR AND IGNITION LEAD FROM THE IGNITION CONTROL

ARE HIGH VOLTAGE. KEEP HANDS OR TOOLS AWAY TO PREVENT ELECTRICAL SHOCK. SHUT OFF ELECTRICAL POWER BEFORE SERVICING ANY

OF THE CONTROLS. FAILURE TO ADHERE TO THIS WARNING CAN RESULT

IN PERSONAL INJURY OR DEATH.

The initial start-up on a new installation may require the control system to be energized for

some time until any air has bled through the system and fuel gas is available at the burners.

TO SHUT DOWN FURNACE

1. Set the thermostat to the lowest setting.

2. Turn off all electric power to the appliance if service is to be performed.

3. Remove control door.

4. Move switch to the “OFF” position.

5. Replace control door.

Page 31

WARNING

!

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL TO SHUT OFF,

SHUT OFF THE MANUAL GAS VALVE TO THE APPLIANCE BEFORE SHUTTING OFF THE ELECTRICAL SUPPLY. FAILURE TO DO SO CAN RESULT IN

AN EXPLOSION OR FIRE CAUSING PROPERTY DAMAGE, SEVERE PERSONAL INJURY OR DEATH!

D. BURNERS

Burners for these units have been designed so that field adjustment is not required.

Burners are tray-mounted and accessible for easy cleaning when required.

E. MANUAL RESET OVERTEMPERATURE CONTROL