Page 1

RRKA-A

Parts List

28-July-2017

This parts list is current as of the above revision date.

See http://www.rheempartslists.net/92-42800-RRKA-A.pdf for the current revision.

Package Gas-Electric

Page 2

Table of Contents

Model Explanation.... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . ... Page 3

Parts Numbers

Panels - Miscellaneous 018-030 . ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... .. Page 4

Panels - Miscellaneous 036-060 . ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... .. Page 5

Electrical Group . ..... ..... ..... ..... ..... .... . .... . .... ..... ..... ..... ..... ..... .... . .... . .... ..... ..... ..... ... Page 6

Fan Group... ..... ..... ..... ..... ..... .... . .... . .... ..... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... .. Page 7

Blower Group... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... ..... .... . .... . .... ..... ..... ..... .... Page 7

Coil Parts .. ..... ..... ..... ..... ..... .... . .... . .... ..... ..... ..... ..... ..... .... . .... . .... ..... ..... ..... ..... ... Page 8

Compressor Group ... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ... Page 9

Heat Exchanger-Burner Group.... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... ..... .... . .... . .... ..... Page 10

Gas Controls ... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ... Page 10

Accessories ... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... .... Page11

Orifice Selection Chart.... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... ..... .... . .... . .... ..... ..... ... Page 12

Drawings/Photographs

Exploded View .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... Page 13

Control Box Assembly ... ..... ..... ..... ..... .... . .... . .... ..... ..... ..... ..... ..... .... . .... . .... . .... ..... .... Page14

Blower Assembly ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... ..... .... . .... . .... ..... ..... ..... .. Page 15

Evaporator Coil Assembly..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... .... Page16

Condenser Coil Group.. ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... Page 17

Heat Exchanger Assembly.... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... ..... .... . .... . .... ..... .... Page 18

Burner Assembly ... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... .... Page19

Notes/Disclaimer . ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... .... . .... . .... . .... ..... ..... ..... ..... ..... .... . .... . . Page 20

Page 2 of 20

28-July-2017

92-42800-RRKA-A

Page 3

MODEL NUMBER EXPLANATION

* R K A - A 0 3 6 J K 1 0 E A J A

1 2 3 4 5 6 7 8 9 10 11

(1) TRADENAME IDENTIFICATION (7) ELECTRICAL DESIGNATION

J = 208/230V -1 PH - 60 HZ.

(2) PRODUCT CLASSIFICATION C = 208/230V -3 PH - 60 HZ.

R = ROOFTOP

(8) DRIVE PACKAGE

(3) EFFICIENCY DESIGNATION K = DIRECT DRIVE

(4) DESIGN SERIES (9) HEATING CAPACITY - (MBH)

A = FIRST DESIGN 04 = 40,000

06 = 60,000

(5) TECHNICAL VARIATIONS 08 = 80,000

10 = 100,000

(6) COOLING CAPACITY (BTU/HR)

018 = 18,000 042 = 42,000 (10) IGNITION SYSTEM

024 = 24,000 048 = 48,000 E = ELECTRIC

030 = 30,000 060 = 60,000 X = ELECTRIC NOX

036 = 36,000

(11) OPTION CODES

SERIAL NUMBER EXPLANATION

1 R A 1 2 3 4 A D A A F 2 6 9 5 0 0 0 1

1 2 3 4 5 6 7 8 9 10 9

(1) GAS CODE (7) TECHNOLOGYVARIATIONS

(2) BLOWER CONTROL BOARD (8) PLANT:

F = FORT SMITH, AR

(3) COMPRESSOR IDENTIFICATION NUMBER

(9) WEEK

(4) IGNITION DEVICE

(10) YEAR

(5) INDUCER BLOWER

(11) PRODUCTION NUMBER

(6) HEAT EXCHANGER

Page 3 of 20

28-July-2017

92-42800-RRKA-A

Page 4

No. Notes

1 Front Base Pan - Before F3405 AS-58628-01 AS-58628-01 AS-58628-01

1 Front Base Pan - After F3405 AS-58628-07 AS-58628-07 AS-58628-07

2 Base Rail (2) - Before F3605 AE-58562-02 AE-58562-02 AE-58562-02

2 Base Rail (2) - After F3605 AE-58562-03 AE-58562-03 AE-58562-03

3 Back Base Pan- Before F3605 AS-58607-10 AS-58607-10 AS-58607-10

3 Back Base Pan- After F3605 AS-58607-64 AS-58607-64 AS-58607-64

4 Blower Shelf AS-58630-01 AS-58630-01 AS-58630-01

5 Blower ShelfTransition AS-58607-19 AS-58607-19 AS-58607-19

6 Divider Panel AS-58607-03 AS-58607-03 AS-58607-03

7 Bulkhead Assembly AS-58607-01 AS-58607-01 AS-58607-01

8 Exhaust Hood AS-58629-01 AS-58629-01 AS-58629-01

Combustion Air Inlet Hood AE-58599-01 AE-58599-01 AE-58599-01

9 Corner Post AS-58607-40 AS-58607-40 AS-58607-40

10 Blower Access Panel AS-58607-09 AS-58607-09 AS-58607-09

11 End Panel AS-58607-04 AS-58607-04 AS-58607-04

12 Supply Cover - Pictured AS-58607-06 AS-58607-06 AS-58607-06

12 Supply Cover - Side Option AS-58607-35 AS-58607-35 AS-58607-35

13 Return Cover - Pictured AS-58607-05 AS-58607-05 AS-58607-05

13 Return Cover - Side Option AS-58607-34 AS-58607-34 AS-58607-34

14 Top Panel AS-58607-07 AS-58607-07 AS-58607-07

15 Grille AS-58634-01 AS-58634-01 AS-58634-01

16 Fan Motor See FanGroup

17 Fan Blade See FanGroup

18 Venturi AE-58585-01 AE-58585-01 AE-58585-01

19 Filter Access Panel AS-58607-08 AS-58607-08 AS-58607-08

20 Condenser Louver Panel AS-58607-37 AS-58607-37 AS-58607-37

21 Center Post AE-58569-01 AE-58569-01 AE-58569-01

22 Control Access Panel AS-58607-20 AS-58607-20 AS-58607-20

23 Compressor See Compressor Group

24 Heat Exchanger See Heat Exchanger Group

24d Collector Box See Heat Exchanger Group

25 Induced Draft Blower w/Gasket See Electrical Group

26 Control Box (w/o components) AE-58597-01 AE-58597-01 AE-58597-01

27 Control Box Cover AE-58598-01 AE-58598-01 AE-58598-01

28 Furnace Shelf AS-58607-11 AS-58607-11 AS-58607-11

29 Burner Floor AE-58594-01 AE-58594-01 AE-58594-01

30 Exhaust Transition AS-58607-36 AS-58607-36 AS-58607-36

Burner Assembly See Burner Group

Bulkhead Valve (2) 61-22369-04 61-22369-04 61-22369-04

Bulkhead Valve Locknut (2) 63-22368-01 63-22368-01 63-22368-01

Heat Exchanger Tube Support AE-58590-01 AE-58590-01 AE-58590-01

Bulkhead Valve Cap (2) 83-100635-01 83-100635-01 83-100635-01

Grommet - Gas Supply Piping 56-22114-01 56-22114-01 56-22114-01

MODEL

TECHNICALVARIATION

COOLING CAPACITY

PANELS, MISCELLANEOUS PARTS

RRKA-

A

018

RRKA-

A

024

RRKA-

A

030

Page 4 of 20

28-July-2017

92-42800-RRKA-A

Page 5

No. Notes

1 Front Base Pan - Before F3405 AS-58628-01 AS-58628-01 AS-58628-01 AS-58628-01

1 Front Base Pan - On or After F3405 AS-58628-07 AS-58628-07 AS-58628-07 AS-58628-07

2 Base Rail (2) - Before F3605 AE-58562-02 AE-58562-02 AE-58562-02 AE-58562-02

2 Base Rail (2) - On or After F3605 AE-58562-03 AE-58562-03 AE-58562-03 AE-58562-03

3 Back Base Pan- Before F3605 AS-58607-10 AS-58607-10 AS-58607-10 AS-58607-10

3 Back Base Pan- On or After F3605 AS-58607-64 AS-58607-64 AS-58607-64 AS-58607-64

4 Blower Shelf AS-58630-01 AS-58630-01 AS-58630-01 AS-58630-01

5 Blower ShelfTransition AS-58607-19 AS-58607-19 AS-58607-19 AS-58607-19

6 Divider Panel AS-58607-03 AS-58607-03 AS-58607-03 AS-58607-03

7 Bulkhead Assembly AS-58607-01 AS-58607-01 AS-58607-01 AS-58607-41

8 Exhaust Hood AS-58629-01 AS-58629-01 AS-58629-01 AS-58629-01

Combustion Air Inlet Hood AE-58599-01 AE-58599-01 AE-58599-01 AE-58599-01

9 Corner Post - Before F4704 AS-58607-40 AS-58607-40 AS-58607-40 AS-58607-40

9 Corner Post - On or After F4704 AS-58607-40 AS-58607-40 AS-58607-40 AS-58607-46

10 Blower Access Panel - Before F4704 AS-58607-09 AS-58607-09 AS-58607-09 AS-58607-09

10 Blower Access Panel - On or After F4704 AS-58607-09 AS-58607-09 AS-58607-09 AS-58607-47

11 End Panel - BeforeF4704 AS-58607-04 AS-58607-04 AS-58607-04 AS-58607-04

11 End Panel - On or After F4704 AS-58607-04 AS-58607-04 AS-58607-04 AS-58607-48

12 Supply Cover - Pictured AS-58607-06 AS-58607-06 AS-58607-06 AS-58607-06

12 Supply Cover - Side Option AS-58607-35 AS-58607-35 AS-58607-35 AS-58607-35

13 Return Cover - Pictured AS-58607-05 AS-58607-05 AS-58607-05 AS-58607-05

13 Return Cover - Side Option AS-58607-34 AS-58607-34 AS-58607-34 AS-58607-34

14 Top Panel AS-58607-07 AS-58607-07 AS-58607-07 AS-58607-07

15 Grille AS-58634-01 AS-58634-01 AS-58634-01 AS-58634-01

16 Fan Motor See FanGroup

17 Fan Blade See FanGroup

18 Venturi AE-58585-01 AE-58585-01 AE-58585-01 AE-58585-01

19 Filter Access Panel AS-58607-08 AS-58607-08 AS-58607-08 AS-58607-08

20 Condenser Louver Panel - Before F4704 AS-58607-38 AS-58607-38 AS-58607-38 AS-58607-38

20 Condenser Louver Panel - On or After F4704 AS-58607-38 AS-58607-38 AS-58607-38 AS-58607-52

21 Center Post - BeforeF4704 AE-58569-01 AE-58569-01 AE-58569-01 AE-58569-01

21 Center Post - On or After F4704 AE-58569-01 AE-58569-01 AE-58569-01 AE-58569-03

22 Control Access Panel - BeforeF4704 AS-58607-20 AS-58607-20 AS-58607-20 AS-58607-20

22 Control Access Panel - On or After F4704 AS-58607-20 AS-58607-20 AS-58607-20 AS-58607-50

A Panel Extension (Condenser) - Before F4704 N/A N/A N/A AS-58607-43

B Panel Extension (Burner and Electrical) - Before F4704 N/A N/A N/A AS-59437-03

C Panel Extension (Blower)- Before F4704 N/A N/A N/A AS-58607-44

D Panel Extension (Duct Opening) - Before F4704 N/A N/A N/A AS-58607-45

E Venturi Extension N/A N/A N/A AE-59432-01

F Heat Exchanger Extension N/A N/A N/A AE-59433-01

23 Compressor See Compressor Group

24 Heat Exchanger See Heat Exchanger Group

24d Collector Box See Heat Exchanger Group

25 Induced Draft Blower w/Gasket See Electrical Group

26 Control Box (w/o components) AE-58597-01 AE-58597-01 AE-58597-01 AE-58597-01

27 Control Box Cover AE-58598-01 AE-58598-01 AE-58598-01 AE-58598-01

28 Furnace Shelf AS-58607-11 AS-58607-11 AS-58607-11 AS-58607-11

29 Burner Floor AE-58594-01 AE-58594-01 AE-58594-01 AE-58594-01

30 Exhaust Transition AS-58607-36 AS-58607-36 AS-58607-36 AS-58607-36

Burner Assembly See Burner Group

Bulkhead Valve (2) 61-22369-04 61-22369-04 61-22369-04 61-22369-04

Bulkhead Valve Locknut (2) 63-22368-01 63-22368-01 63-22368-01 63-22368-01

Heat Exchanger Tube Support AE-58590-01 AE-58590-01 AE-58590-01 AE-58590-01

Bulkhead Valve Cap (2) 83-100635-01 83-100635-01 83-100635-01 83-100635-01

Grommet - Gas Supply Piping 56-22114-01 56-22114-01 56-22114-01 56-22114-01

MODEL

TECHNICALVARIATION

COOLING CAPACITY

PANELS, MISCELLANEOUS PARTS

RRKA-

A

036

RRKA-

A

042

RRKA-

A

048

RRKA-

A

060

Page 5 of 20

28-July-2017

92-42800-RRKA-A

Page 6

MODEL

No. Notes

25 Stk Induced Draft Blower w/Gasket 70-23641-01 70-23641-01 70-23641-01 70-23641-01 70-23641-01 70-23641-01 70-23641-01

Gasket - Induced Draft Blower 68-23643-01 68-23643-01 68-23643-01 68-23643-01 68-23643-01 68-23643-01 68-23643-01

Limit Control (On Blower Shelf) See the Heat Exchanger/Burner Group

32 Stk Contactor 42-20044-02 42-20044-02 42-20044-02 42-20044-02 42-20044-02 42-102851-03 42-102851-03

33 Stk Pressure Switch 42-23564-03 42-23564-03 42-23564-03 42-23564-03 42-23564-03 42-23564-03 42-23564-03

34 Integrated Furnace Control Board (IFC) See Gas Controls

35 Stk Transformer 46-18788-07 46-18788-07 46-18788-07 46-18788-07 46-18788-07 46-18788-07 46-18788-07

36 Capacitor - Blower Motor See Blower Group

37 Capacitor - Compressor/Fan See Compressor Group

51 Limit Control - Flame Roll-Out See the Heat Exchanger/Burner Group

Stk Compressor Time Delay Control 42-22756-02 42-22756-02 42-22756-02 42-22756-02 42-22756-02 42-22756-02 42-22756-02

Wiring Harness - 9 pin to 9 terminals AS-102393-02 AS-102393-02 AS-102393-02 AS-102393-02 AS-102393-02 AS-102393-02 AS-102393-02

No. Notes

25 Stk Induced Draft Blower w/Gasket 70-23641-01 70-23641-01 70-23641-01 70-23641-01

Gasket - Induced Draft Blower 68-23643-01 68-23643-01 68-23643-01 68-23643-01

Limit Control (On Blower Shelf) See the Heat Exchanger/Burner Group

32 Stk Contactor 42-22464-01 42-22464-01 42-22464-01 42-22464-01

33 Stk Pressure Switch 42-23564-03 42-23564-03 42-23564-03 42-23564-03

34 Integrated Furnace Control Board (IFC) See Gas Controls

35 Stk Transformer 46-18788-07 46-18788-07 46-18788-07 46-18788-07

36 Capacitor - Blower Motor See Blower Group

37 Capacitor - Compressor/Fan See Compressor Group

51 Limit Control - Flame Roll-Out See the Heat Exchanger/Burner Group

Stk Compressor Time Delay Control 42-22756-02 42-22756-02 42-22756-02 42-22756-02

Wiring Harness - 9 pin to 9 terminals AS-102393-02 AS-102393-02 AS-102393-02 AS-102393-02

TECHNICALVARIATION

COOLING CAPACITY

ELECTRICAL DESIGNATION

Wiring Harness - 9 pin to 6 pin and 4 flag

terminals (6 pin to Fan Board)

Leadwire - from Flame Sensor to 9 pin

Wiring Harness Plug

Capacitor Adaptor Plate (2 in. round

capacitor)

Capacitor Adaptor Plate (2 in. X 1-1/4 in.

oval capacitor)

MODEL

TECHNICALVARIATION

COOLING CAPACITY

ELECTRICAL DESIGNATION

Wiring Harness - 9 pin to 6 pin and 4 flag

terminals (6 pin to Fan Board)

Leadwire - from Flame Sensor to 9 pin

Wiring Harness Plug

Capacitor Adaptor Plate (2 in. round

capacitor)

Capacitor Adaptor Plate (2 in. X 1-1/4 in.

oval capacitor)

RRKA-

A

018

J

AS-58696-01 AS-58696-01 AS-58696-01 AS-58696-01 AS-58696-01 AS-58696-01 AS-58696-01

45-25323-02 45-25323-02 45-25323-02 45-25323-02 45-25323-02 45-25323-02 45-25323-02

AE-54609-01 AE-54609-01 AE-54609-01 AE-54609-01 AE-54609-01 AE-54609-01 AE-54609-01

AE-54609-02 AE-54609-02 AE-54609-02 AE-54609-02 AE-54609-02 AE-54609-02 AE-54609-02

RRKA-

A

036

C

AS-58696-01 AS-58696-01 AS-58696-01 AS-58696-01

45-25323-02 45-25323-02 45-25323-02 45-25323-02

AE-54609-01 AE-54609-01 AE-54609-01 AE-54609-01

AE-54609-02 AE-54609-02 AE-54609-02 AE-54609-02

RRKA-

A

024

J

ELECTRICAL GROUP

RRKA-

A

042

C

ELECTRICAL GROUP

RRKA-

RRKA-

A

030

J

A

048

C

RRKA-

A

036

J

RRKA-

A

060

C

RRKA-

A

042

J

RRKA-

A

048

J

RRKA-

A

060

J

Page 6 of 20

28-July-2017

92-42800-RRKA-A

Page 7

MODEL

No. Notes

16 Stk Fan Motor 51-21856-06 51-21856-06 51-21854-02 51-21854-02 51-21854-02 51-21854-10 51-21853-21

17 Stk Fan Blade 70-20607-05 70-20607-05 70-21848-05 70-21848-05 70-21848-05 70-21848-07 70-21848-07

37 Capacitor - Compressor/Fan See Compressor Group

No. Notes

16 Stk Fan Motor 51-21854-02 51-21854-02 51-21854-10 51-21853-21

17 Stk Fan Blade 70-21848-05 70-21848-05 70-21848-07 70-21848-07

37 Stk Capacitor - FanMotor 43-100496-02 43-100496-02 43-100496-04 43-100496-04

No. Notes

Stk Blower Assembly(Includes items 36-41) AS-58662-01 AS-58662-01 AS-58662-02 AS-58662-02 AS-58662-02 AS-58662-06 AS-58662-06

36 Stk Capacitor - Blower Motor 43-100496-04 43-100496-04 43-100496-12 43-100496-12 43-100496-12 43-100496-45 43-100496-45

38a Housing AS-58619-01 AS-58619-01 AS-58619-02 AS-58619-02 AS-58619-02 AS-58619-02 AS-58619-02

38b Cut-Off AE-64401-10 AE-64401-10 AE-64401-06 AE-64401-06 AE-64401-06 AE-64401-06 AE-64401-06

39 Stk Blower Motor 51-23608-03 51-23608-03 51-23609-02 51-23609-02 51-23609-02 51-23650-01 51-23650-01

40a Motor Arm Assembly (3) 70-19929-02 70-19929-02 70-19929-02 70-19929-02 70-19929-02 70-19929-02 70-19929-02

40b Motor Band 70-19927-01 70-19927-01 70-19927-01 70-19927-01 70-19927-01 70-19927-01 70-19927-01

41 Stk Blower Wheel 70-18631-01 70-18631-01 70-18625-01 70-18625-01 70-18625-01 70-18625-01 70-18625-01

TECHNICALVARIATION

COOLING CAPACITY

ELECTRICAL DESIGNATION

MODEL

TECHNICALVARIATION

COOLING CAPACITY

ELECTRICAL DESIGNATION

MODEL

TECHNICALVARIATION

COOLING CAPACITY

Motor Mounting BracketAssembly

(includes items 40a, 40b)

RRKA-

A

018

J

RRKA-

A

036

C

RRKA-

A

018

AS-53148-03 AS-53148-03 AS-53148-04 AS-53148-04 AS-53148-04 AS-53148-04 AS-53148-04

RRKA-

A

024

J

FANGROUP

RRKA-

A

042

C

FANGROUP

RRKA-

A

024

BLOWER GROUP

RRKA-

A

030

J

RRKA-

A

048

C

RRKA-

A

030

RRKA-

A

036

J

RRKA-

A

060

C

RRKA-

A

036

RRKA-

A

042

J

RRKA-

A

042

RRKA-

A

048

J

RRKA-

A

048

RRKA-

A

060

J

RRKA-

A

060

Page 7 of 20

28-July-2017

92-42800-RRKA-A

Page 8

No. Notes

CONDENSER COIL:

52 Stk Condenser Coil AS-58677-02 AS-58677-02 AS-58677-03 AS-58677-04 AS-58677-05 AS-58677-05 AS-58677-01

Distributor - 1/2 in. to 3/8 in. twoway N/A N/A 83-19988-01 83-19988-01 83-19988-01 83-19988-01 N/A

Distributor - 5/8 in. to 3/8 in. four way N/A N/A N/A N/A N/A N/A 83-17467-31

Access ValveBody (2) 61-18542-01 61-18542-01 61-18542-01 61-18542-01 61-18542-01 61-18542-01 61-18542-01

Access ValveCore (2) 61-18551-01 61-18551-01 61-18551-01 61-18551-01 61-18551-01 61-18551-01 61-18551-01

Access ValveCap (2) 83-100635-01 83-100635-01 83-100635-01 83-100635-01 83-100635-01 83-100635-01 83-100635-01

EVAPORATOR COIL:

53 Drain Trap (Attached to Drain Pan) 68-23603-01 68-23603-01 68-23603-01 68-23603-01 68-23603-01 68-23603-01 68-23603-01

54 Stk Evaporator Coil AS-58627-71 AS-58627-91 AS-58627-52 AS-58627-62 AS-58627-43 AS-58627-83 AS-58627-05

55 Drain Pan Grommet 56-23601-01 56-23601-01 56-23601-01 56-23601-01 56-23601-01 56-23601-01 56-23601-01

56 Stk Drain Pan AS-58607-32 AS-58607-32 AS-58607-32 AS-58607-32 AS-58607-32 AS-58607-32 AS-58607-32

57 Auxiliary Drain Pipe AE-58611-01 AE-58611-01 AE-58611-01 AE-58611-01 AE-58611-01 AE-58611-01 AE-58611-01

59 Distributor Without Piston N/A N/A N/A N/A N/A 61-23413-08 61-23413-10

60 Stk Flowcheck Piston Kit N/A N/A N/A N/A N/A 61-25414-15 61-25414-17

61 Stk TXV N/A N/A N/A N/A N/A 61-21922-50 61-21922-51

62 Cap Tube Assembly AS-21821-43 AS-21821-44 AS-21821-03 AS-21821-29 AS-21821-15 N/A N/A

Condensate Barrier AE-100544-01 AE-100544-01 AE-100544-01 AE-100544-01 AE-100544-01 AE-100544-01 AE-100544-01

MODEL

TECHNICALVARIATION

COOLING CAPACITY

RRKA-

A

018

RRKA-

A

024

COIL GROUP

RRKA-

A

030

RRKA-

A

036

RRKA-

A

042

RRKA-

A

048

RRKA-

A

060

Page 8 of 20

28-July-2017

92-42800-RRKA-A

Page 9

MODEL

No. Notes

Compressor ID: 6228 6301 5538 5539 5540 6020 6670

23 Stk Compressor 55-23140-03S 55-23140-10S 55-23139-50S 55-23139-62S 55-23139-41S 55-23140-50 55-23140-46S

37 Stk Capacitor - Compressor/Fan 43-23204-03 43-23204-28 43-23204-34 43-23204-32 43-23204-31 43-23204-13 43-23204-43

Compressor ID: 5168 5169 5170 5171 5172 6820

23 Stk Compressor 55-21737-10S 55-21737-70 55-21737-50 55-21737-62 55-21737-41 55-23140-77

37 Stk Capacitor - Compressor/Fan 43-26261-02 43-26261-05 43-23204-34 43-23204-32 43-23204-31 43-26261-10

No. Notes

Compressor ID: 5813 5814 6021 6671

23 Stk Compressor 55-23139-63S 55-23139-71S 55-23140-51 55-23140-47S

37 Capacitor - Fan Motor See FanGroup

Compressor ID: 5873 5874 6819

23 Stk Compressor 55-21737-63S 55-21737-71 55-23140-74

37 Capacitor - Fan Motor See FanGroup

TECHNICALVARIATION

COOLING CAPACITY

ELECTRICAL DESIGNATION

MODEL

TECHNICALVARIATION

COOLING CAPACITY

ELECTRICAL DESIGNATION

RRKA-

A

018

J

RRKA-

A

036

C

RRKA-

A

024

J

COMPRESSOR GROUP

RRKA-

A

042

C

COMPRESSOR GROUP

RRKA-

030

RRKA-

048

A

J

A

C

RRKA-

A

036

J

RRKA-

A

060

C

RRKA-

A

042

J

RRKA-

A

048

J

RRKA-

A

060

J

Page 9 of 20

28-July-2017

92-42800-RRKA-A

Page 10

No. Notes

24 Stk Heat Exchanger - Includes Center Panel and Turbulators AS-58632-01 AS-58632-02 AS-58632-03 AS-58632-04

24a Turbulators

24b NOX Insert Assembly

24c Lower Burner Assembly (NOX models) AE-59148-01 AE-59148-01 AE-59148-01 AE-59148-01

Collector Box Gasket 68-23644-01 68-23644-01 68-23644-01 68-23644-01

24d Collector Box AE-58588-01 AE-58588-01 AE-58588-01 AE-58588-01

Stk Limit Control (On Blower Shelf) - Cooling Capacity 018/024 47-23610-11 47-23610-05 47-23610-03 47-23610-01

Stk Limit Control (On Blower Shelf) - Cooling Capacity 030-060 47-23610-11 47-23610-03 47-23610-03 47-23610-01

29 Burner Floor See Panels Group

42 Radiation Shield AE-58595-01 AE-58595-01 AE-58595-01 AE-58595-01

43 Stk Burner Tube w/Shield

Stk,3 One-piece Burner Retrofit Kit - See Note 3 AS-60993-82 AS-60993-83 AS-60993-84 AS-60993-85

44 Burner Support Bracket (2) AE-61588-01 AE-61588-01 AE-61588-01 AE-61588-01

45 Stk Manifold (w/o Orifices) 81-23604-01 81-23604-01 81-23604-01 81-23604-01

Square Head Plug - (Used on Manifold to plug extra holes)

47 Burner Orifice - Natural Gas See Orifice Selection Chart

47 Burner Orifice - LP See Orifice Selection Chart

47 Number of Orifices (2) (3) (4) (5)

48 Stk Flame Sensor 62-23543-02 62-23543-02 62-23543-02 62-23543-02

49 Stk Ignitor w/Cable 62-23556-01 62-23556-01 62-23556-01 62-23556-01

50 Burner Support - (Holds Burners between the Burner Support Brackets) AE-58592-01 AE-58592-01 AE-58592-01 AE-58592-01

51 Stk,1 Limit - Manual Reset (Burner Compartment) - Before F2501 (See Note1) 47-22861-01 47-22861-01 47-22861-01 47-22861-01

51 Stk,1 Limit - Manual Reset (Burner Compartment) - After F2501 (See Note1) 47-100241-01 47-100241-01 47-100241-01 47-100241-01

No. Notes

Stk Furnace Control Board 62-23554-02 62-23584-01 62-23554-02 62-23584-01

Stk Fan Board 47-23619-03 47-23619-03 47-23619-03 47-23619-03

46 Stk Gas Valve - Natural Gas 60-105055-01 60-105055-01 60-23490-03 60-23490-03

46 Stk,2 Gas Valve - LP See Note 2 See Note 2 SeeNote 2 See Note 2

Stk LP Conversion Kit EP-85H EP-85H EP-84W EP-84W

No. Notes

Stk Furnace Control Board 62-23554-02

Stk Fan Board 47-23619-03

46 Stk Gas Valve - Natural Gas 60-23490-01

46 Stk,2 Gas Valve - LP See Note 2

Stk LP Conversion Kit EP-84W

No. Notes

34 Stk Integrated Furnace Control Board (IFC) 62-23599-01 62-23599-01 62-23599-01 62-23599-01

46 Stk Gas Valve - Natural Gas 60-105055-01 60-23490-03 60-23490-01 60-24290-01

46 Stk,2 Gas Valve - LP See Note 2 See Note 2 SeeNote 2 See Note 2

Stk LP Conversion Kit EP-85H EP-84W EP-84W EP-84W

No. Notes

34 Stk Integrated Furnace Control Board (IFC) 62-23599-04

46 Stk Gas Valve - Natural Gas 60-105055-01

46 Stk,2 Gas Valve - LP See Note 2

Stk LP Conversion Kit EP-85H

MODEL

TECHNICALVARIATION

HEATING CAPACITY

HEAT EXCHANGER, BURNER / MANIFOLD

MODEL

TECHNICALVARIATION

GAS CODE

GAS CONTROLS

MODEL

TECHNICALVARIATION

GAS CODE

GAS CONTROLS

MODEL

TECHNICALVARIATION

GAS CODE

GAS CONTROLS

MODEL

TECHNICALVARIATION

GAS CODE

GAS CONTROLS

RRKA-

A

04

AE-58591-02

(2)

75-23684-01

(2)

75-22840-01

(2)

81-23593-01

(3)

RRKA-

A

1A

RRKA-

A

1TF

RRKA-

A

1R

RRKA-

A

2G

RRKA-

A

06

AE-58591-02

(3)

75-23684-01

(3)

75-22840-01

(3)

81-23593-01

(2)

RRKA-

A

1C

RRKA-

A

1S

RRKA-

A

08

AE-58591-02

(4)

75-23684-01

(4)

75-22840-01

(4)

81-23593-01

(1)

RRKA-

A

1D

RRKA-

A

1X

RRKA-

A

10

AE-58591-02

(5)

75-23684-01

(5)

75-22840-01

(5)

N/A

RRKA-

A

1F

RRKA-

A

2A

Page 10 of 20

28-July-2017

92-42800-RRKA-A

Page 11

No. Notes

Economizer - 3 Position RXRE-CAA30

Economizer - Modulating RXRD-CAM10

Fresh Air Damper - 3 Position RXRF-FAB1

Fresh Air Damper - Fixed 35% RXRF-FAA1

Low Ambient Control RXRZ-A18

High Pressure Control RXAB-A02

Low Pressure Control RXAC-A02

MODEL

TECHNICALVARIATION

COOLING CAPACITY

OPTIONS AND ACCESORIES

RRKA-

A

ALL

Page 11 of 20

28-July-2017

92-42800-RRKA-A

Page 12

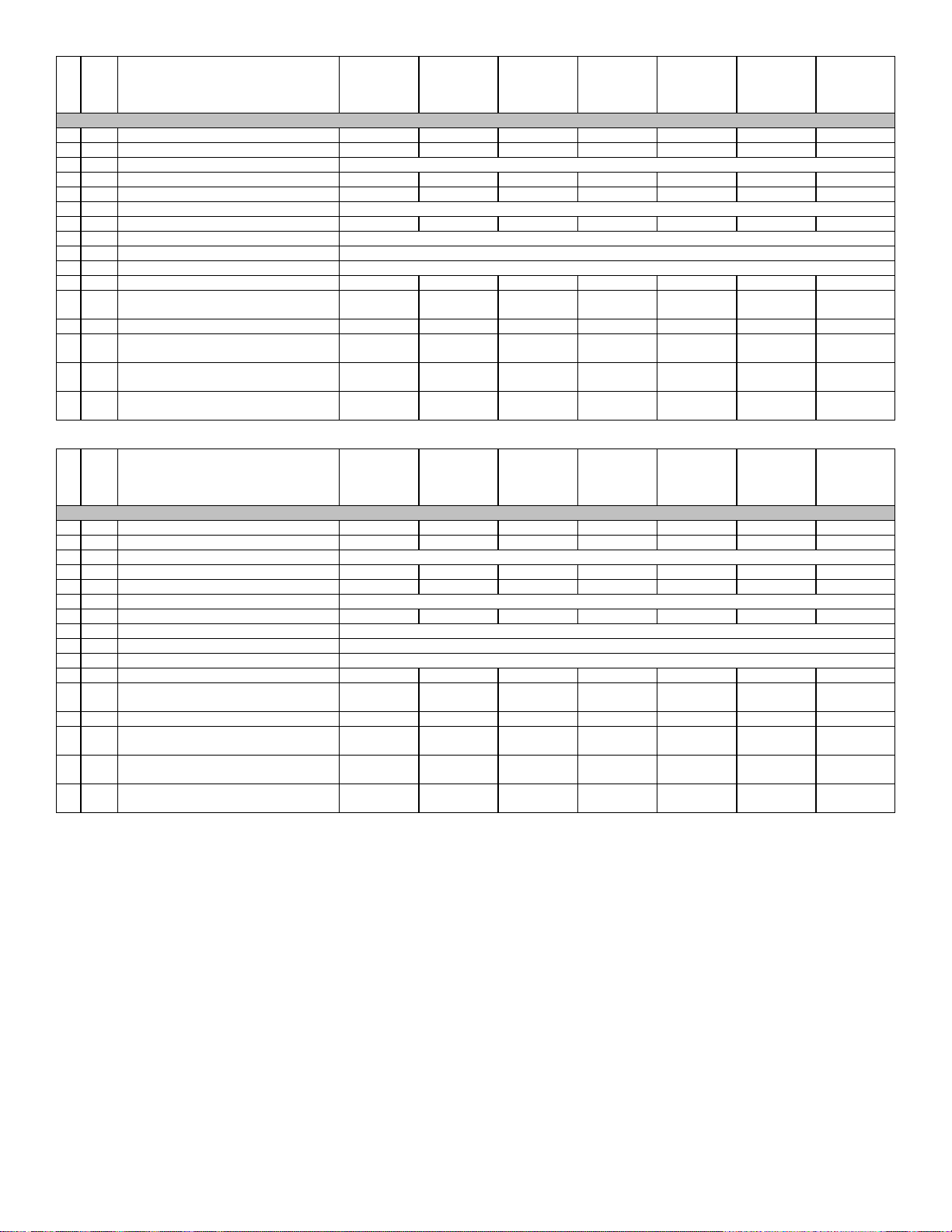

CAUTION: Selection of the correct Natural Gas Orifice requires the following information for the specific installation:

1) Furnace Input Rating (BTU/HR)

2) Number of Burners

2) Altitude (ft.)

For detailed information and instructions for Orifice selection, see the Gas Furnace LP Conversion Kit Index 92-21519-47 and the latest edition of the

National Fuel Gas Code Handbook, or the National Standard of Canada, Natural Gas and Propane Installation Code, CAN B149.1.

CAUTION:This information is provided for replacement purposes only. Conversion for operation at High Altitude must be done using the kit specified

on the product specification sheet for the unit.

NOTE:This Orifice sizing chart is based on a Natural Gas heating value of 1075 BTU/cu. ft and a pressure setting of 3.5 in. water column.

NOTE: Factory installed orifices are calculated and sized based on a Natural Gas heating value of 1075 BTU/cu. ft. and an elevation of 0 - 2000 ft.

Furnace

Input

Rating (BTU/HR)

40,000 36,000 2 62-22175-45 62-22175-47 62-22175-48 62-22175-49 62-22175-45 62-22175-15

60,000 54,000 3 62-22175-45 62-22175-47 62-22175-48 62-22175-49 62-22175-45 62-22175-15

72,000 N/A 4 62-22175-15 62-22175-49 62-22175-50 62-22175-51 62-22175-15 N/A

80,000 72,000 4 62-22175-45 62-22175-47 62-22175-48 62-22175-49 62-22175-45 62-22175-15

90,000 N/A 5 62-22175-15 62-22175-49 62-22175-50 62-22175-51 62-22175-15 N/A

100,000 90,000 5 62-22175-45 62-22175-47 62-22175-48 62-22175-49 62-22175-45 62-22175-15

120,000 108,000 6 62-22175-45 62-22175-47 62-22175-48 62-22175-49 62-22175-45 62-22175-15

135,000 121,500 6 62-22175-44 62-22175-45 62-22175-47 62-22175-48 62-22175-44 62-22175-45

150,000 135,000 6 62-22175-42 62-22175-43 62-22175-44 62-22175-45 62-22175-42 62-22175-44

180,000 N/A 9 62-22175-45 62-22175-47 62-22175-48 62-22175-49 62-22175-45 N/A

210,000 N/A 9 62-22175-43 62-22175-44 62-22175-45 62-22175-47 62-22175-43 N/A

210,000 N/A 10 62-22175-45 62-22175-47 62-22175-48 62-22175-49 62-22175-45 N/A

225,000 202,500 9 62-22175-42 62-22175-43 62-22175-44 62-22175-45 62-22175-42 62-22175-44

250,000 225,000 10 62-22175-42 62-22175-43 62-22175-44 62-22175-45 62-22175-42 62-22175-44

252,000 225,000 9 62-22175-40 62-22175-42 62-22175-43 62-22175-44 62-22175-40 62-22175-42

252,000 N/A 12 62-22175-45 62-22175-47 62-22175-48 62-22175-49 62-22175-45 N/A

290,000 N/A 14 62-22175-45 62-22175-47 62-22175-48 62-22175-49 62-22175-45 N/A

300,000 270,000 12 62-22175-42 62-22175-43 62-22175-44 62-22175-45 62-22175-42 62-22175-44

330,000 N/A 14 62-22175-43 62-22175-44 62-22175-45 62-22175-47 62-22175-43 N/A

350,000 315,000 14 62-22175-42 62-22175-43 62-22175-44 62-22175-45 62-22175-42 62-22175-44

400,000 360,000 14 62-22175-40 62-22175-42 62-22175-43 62-22175-44 62-22175-40 62-22175-42

CAUTION: Selection of the correct LP Orifice requires the following information for the specific installation:

1) Furnace Input Rating (BTU/HR)

2) Number of Burners

2) Altitude (ft.)

For detailed information and instructions for Orifice selection, see the Gas Furnace LP Conversion Kit Index 92-21519-47 and the latest edition of the

National Fuel Gas Code Handbook, or the National Standard of Canada, Natural Gas and Propane Installation Code, CAN B149.1.

CAUTION:This information is provided for replacement purposes only. Conversion to LP or for operation at High Altitude should be done using the

kit(s) specified on the product specification sheet for the unit.

NOTE:This Orifice sizing chart is developed using the specified pressure setting of 10 in. water column instead of the 11.0 in watercolumn used by the NFG and

CANB149.1.

NOTE: Orifices supplied in the LP Conversion Kit are calculated and sized based on a heating value of 2500 BTU/cu. ft. and an elevation of 0 - 2000 ft.

Furnace

Input

Rating (BTU/HR)

40,000 36,000 2 62-22175-55 62-22175-55 62-22175-56 62-22175-56 62-22175-55 62-22175-13

60,000 54,000 3 62-22175-55 62-22175-55 62-22175-56 62-22175-56 62-22175-55 62-22175-13

72,000 N/A 4 62-22175-13 62-22175-57 62-22175-57 62-22175-59 62-22175-13 N/A

80,000 72,000 4 62-22175-55 62-22175-55 62-22175-56 62-22175-56 62-22175-55 62-22175-13

90,000 N/A 5 62-22175-13 62-22175-57 62-22175-57 62-22175-59 62-22175-13 N/A

100,000 90,000 5 62-22175-55 62-22175-55 62-22175-56 62-22175-56 62-22175-55 62-22175-13

120,000 108,000 6 62-22175-55 62-22175-55 62-22175-56 62-22175-56 62-22175-55 62-22175-13

135,000 121,500 6 62-22175-54 62-22175-55 62-22175-55 62-22175-56 62-22175-54 62-22175-55

150,000 135,000 6 62-22175-54 62-22175-55 62-22175-55 62-22175-56 62-22175-54 62-22175-54

180,000 N/A 9 62-22175-55 62-22175-55 62-22175-56 62-22175-56 62-22175-55 N/A

210,000 N/A 9 62-22175-54 62-22175-55 62-22175-55 62-22175-56 62-22175-54 N/A

210,000 N/A 10 62-22175-55 62-22175-55 62-22175-56 62-22175-56 62-22175-55 N/A

225,000 202,500 9 62-22175-54 62-22175-55 62-22175-55 62-22175-56 62-22175-54 62-22175-54

250,000 225,000 10 62-22175-54 62-22175-55 62-22175-55 62-22175-56 62-22175-54 62-22175-54

252,000 225,000 9 62-22175-53 62-22175-54 62-22175-54 62-22175-55 62-22175-53 62-22175-54

252,000 N/A 12 62-22175-55 62-22175-55 62-22175-56 62-22175-56 62-22175-55 N/A

290,000 N/A 14 62-22175-55 62-22175-55 62-22175-56 62-22175-56 62-22175-55 N/A

300,000 270,000 12 62-22175-54 62-22175-55 62-22175-55 62-22175-56 62-22175-54 62-22175-54

330,000 N/A 14 62-22175-54 62-22175-55 62-22175-55 62-22175-56 62-22175-54 N/A

350,000 315,000 14 62-22175-54 62-22175-55 62-22175-55 62-22175-56 62-22175-54 62-22175-54

400,000 360,000 14 62-22175-53 62-22175-54 62-22175-54 62-22175-55 62-22175-53 62-22175-54

Canadian High

Altitude Derated

Input

(BTU/HR)

Canadian High

Altitude Derated

Input

(BTU/HR)

PACKAGE EQUIPMENT - ORIFICE SELECTION CHART - NATURAL GAS

Number

of

Burners

PACKAGE EQUIPMENT - ORIFICE SELECTION CHART - LP

Number

of

Burners

0 - 2000

U.S.

0 - 2000

U.S.

2001 - 4000

U.S.

2001 - 4000

U.S.

Elevation (ft.)

4001 - 6000

U.S.

Elevation (ft.)

4001 - 6000

U.S.

Country

8000+

U.S.

Country

8000+

U.S.

0 - 2000

Canada

0 - 2000

Canada

2001 - 4500

Canada

2001 - 4500

Canada

28-July-2017

92-42800-RRKA-A

Page 12 of 20

Page 13

Exploded View

Page 13 of 20

28-July-2017

92-42800-RRKA-A

Page 14

Control Box Assembly

Page 14 of 20

28-July-2017

92-42800-RRKA-A

Page 15

Blower Assembly

Page 15 of 20

28-July-2017

92-42800-RRKA-A

Page 16

Evaporator Coil Assembly

Page 16 of 20

28-July-2017

92-42800-RRKA-A

Page 17

Condenser Coil Group

Page 17 of 20

28-July-2017

92-42800-RRKA-A

Page 18

Heat Exchanger Assembly

Page 18 of 20

28-July-2017

92-42800-RRKA-A

Page 19

Burner Assembly

Page 19 of 20

28-July-2017

92-42800-RRKA-A

Page 20

NOTES

Stk It is recommended that stock be maintained for this part.

N/A Not Applicable

1 The Flame Roll-Out Limit Control on these models was changed on the date code shown to a higher-rated switch. This change wasmade in order to

reduce nuisance tripping. It is recommended that the higher-rated switch be used for replacement.

2 Order GasValve forNatural Gas along with LP Conversion Kit.

3 This kit includes all necessary items to retrofit units using individual burner tubes with the later one-piece burner design.

DISCLAIMER: This document is intended to provide general replacement parts information to aid qualified

service personnel in the repair of these models. The complete Model and Serial Number of the unit under repair

should be specified when selecting and ordering replacement parts. Specifications and illustrations are subject

to change without notice. Document 92-42800-RRKA-A supersedes all previous parts lists for these models. See

http://www.rheempartslists.net/92-42800-RRKA-A for the latest revision of this document. The manufacturer

assumes no obligation for errors or omissions. Service personnel must verify the proper and safe operation of

equipment after the replacement of any original components.

P.O. Box 17010

Fort Smith, AR 72917-7010

Loading...

Loading...