Rheem RQRM Installation Manual

INSTALLATION INSTRUCTIONS

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORT TION!

!

DO NOT DESTROY THIS MANUAL

PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE BY A SERVICEMAN

WARNING

!

ANT SAFETY INFORMA

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO

QUALIFIED, LICENSED SERVICE PERSONNEL FOR PROPER

INSTALLAT I ON, ADJUSTMENT AND OPERATION OF THIS

UNIT. READ THESE INSTRUCTIONS THOROUGHLY BEFORE

AT TEMPTING INSTALLATION OR OPERATION. FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN IMPROPER

INSTALLAT I ON, ADJUSTMENT, SERVICE OR MAINTENANCE

POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK,

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

ISO 9001:2008

PACKAGE HEAT PUMPS FEATURING

INDUSTRY STANDARD R-410A

REFRIGERANT

RQRM 15/16 SEER SERIES – (2 - 5 TONS)

RQPM 14 SEER SERIES – (2 - 5 TONS)

RQNM 13 SEER SERIES – (2 - 5 TONS)

[ ] INDICATES METRIC CONVERSION

SUPERSEDES 92-20522-47-08

92-20522-47-09

TABLE OF CONTENTS

I. Safety Information .................................................................................................3

II. Introduction............................................................................................................4

Unit Dimensions.................................................................................................5-6

III. Checking Product Received ..................................................................................7

IV. Equipment Protection ............................................................................................7

V. Specifications ........................................................................................................7

VI. Installation .............................................................................................................7

A. General .............................................................................................................7

1. Pre-Installation Check Points........................................................................7

2. Location.........................................................................................................7

B. Outside Slab Installation ...................................................................................8

C.Clearances........................................................................................................8

D.Rooftop Installation ...........................................................................................9

VII. Ductwork................................................................................................................9

VIII. Filters.....................................................................................................................9

IX. Condensate Drain, Indoor Coil ..............................................................................9

X. Condensate Drain, Outdoor Coil .........................................................................10

XI. Electrical Wiring...................................................................................................10

A. Power Wiring...................................................................................................10

B. Electric Heater Kit Instructions........................................................................10

C.Control Wiring .................................................................................................11

D.Internal Wiring.................................................................................................11

E. Grounding .......................................................................................................11

F. Thermostat......................................................................................................12

XII. Indoor Air Flow Data............................................................................................12

XIII. Pre-Start Check...................................................................................................12

XIV. Startup.................................................................................................................12

XV. Operation.............................................................................................................13

XVI. Auxiliary Heat ......................................................................................................13

XVII. Demand Defrost Control......................................................................................14

XVIII. General Data..................................................................................................16-24

XIX. Miscellaneous

Electrical and Physical Data...........................................................................25-27

Airflow Performance.......................................................................................28-33

Electric Heater Kit...........................................................................................34-38

Wiring Diagram...............................................................................................39-45

Charge Charts................................................................................................46-58

Installation instructions are updated on a regular basis. This is done as product

changes occur or if new information becomes available. In this publication, an arrow ()

denotes changes from the previous edition or additional new material.

2

I. SAFETY INFORMATION

WARNING

!

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED, LICENSED

SERVICE PERSONNEL FOR PROPER INSTALLATION, ADJUSTMENT AND

OPERATION OF THIS UNIT. READ THESE INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO FOLLOW

THESE INSTRUCTIONS MAY RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SERIVICE OR MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

PROPOSITION 65: THIS APPLIANCE CONTAINS FIBERGLASS INSULATION.

RESPIRABLE PARTICLES OF FIBERGLASS ARE KNOWN TO THE STATE OF

CALIFORNIA TO CAUSE CANCER.

WARNING

!

THE MANUFACTURER’S WARRANTY DOES NOT COVER ANY DAMAGE OR

DEFECT TO THE HEAT PUMP CAUSED BY THE ATTACHMENT OR USE OF ANY

COMPONENTS, ACCESSORIES OR DEVICES (OTHER THAN THOSE AUTHORIZED BY THE MANUFACTURER) INTO, ONTO OR IN CONJUNCTION WITH THE

HEAT PUMP. YOU SHOULD BE AWARE THAT THE USE OF UNAUTHORIZED

COMPONENTS, ACCESSORIES OR DEVICES MAY ADVERSELY AFFECT THE

OPERATION OF THE HEAT PUMP AND MAY ALSO ENDANGER LIFE AND

PROPERTY. THE MANUFACTURER DISCLAIMS ANY RESPONSIBILITY FOR

SUCH LOSS OR INJURY RESULTING FROM THE USE OF SUCH UNAUTHORIZED COMPONENTS,ACCESSORIESOR DEVICES.

WARNING

!

DISCONNECT ALL POWER TO THE UNIT BEFORE STARTING MAINTENANCE. FAILURE TO DO SO CAN RESULT IN SEVERE ELECTRICAL SHOCK

OR DEATH.

WARNING

!

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT RETURN DUCTWORK TO

ANY OTHER HEAT PRODUCING DEVICE SUCH AS A FIREPLACE INSERT,

STOVE, ETC. UNAUTHORIZED USE OF SUCH DEVICES MAY RESULT IN FIRE,

CARBON MONOXIDE POISONING, EXPLOSION, PROPERTY DAMAGE,

SEVERE PERSONAL INJURY OR DEATH.

WARNING

!

TURN OFF ELECTRIC POWER AT THE FUSE BOXOR SERVICEPANEL BEFORE

MAKING ANY ELECTRICAL CONNECTIONS.

ALSO, THE GROUND CONNECTION MUST BE COMPLETED BEFORE MAKING

LINE VOLTAGE CONNECTIONS. FAILURE TO DO SO CAN RESULT IN ELECTRICAL SHOCK, SEVERE PERSONAL INJURY OR DEATH.

WARNING

!

THE UNIT MUST BE PERMANENTLY GROUNDED. A GROUNDING LUG IS

PROVIDED. FAILURE TO GROUND THIS UNIT CAN RESULT IN FIRE OR ELECTRICAL SHOCK CAUSING PROPERTY DAMAGE, SEVERE PERSONAL INJURY

OR DEATH.

WARNING

!

ONLY ELECTRIC HEATER KITS SUPPLIED BY THIS MANUFACTURER AS

DESCRIBED IN THIS PUBLICATION HAVE BEEN DESIGNED, TESTED, AND

EVALUATED BY A NATIONALLY RECOGNIZED SAFETY TESTING AGENCY

FOR USE WITH THIS UNIT. USE OF ANY OTHER MANUFACTURED ELECTRIC

HEATERS INSTALLED WITHIN THIS UNIT MAY CAUSE HAZARDOUS CONDITIONS RESULTING IN PROPERTY DAMAGE, FIRE, BODILY INJURY OR

DEATH.

3

WARNING

!

PROPOSITION 65: THIS APPLIANCE

CONTAINS FIBERGLASS INSULATION. RESPIRABLE PARTICLES OF

FIBERGLASS ARE KNOWN TO THE

STATE OF CALIFORNIA TO CAUSE

CANCER.

II. INTRODUCTION

This booklet contains the installation and operating instructions for your package heat

pump. There are a few precautions that should be taken to derive maximum satisfaction

from it. Improperinstallation can result in unsatisfactory operation ordangerous conditions.

Read this booklet and any instructions packaged with separate equipment required to

make up the system prior to installation. Give this booklet to the owner and explain its

provisions. The owner should retain this booklet for future reference.

NOTE: A load calculation must be performed to properly determine the required

heating and cooling for the structure. Also, the duct must be properly designed and

installed for proper airflow. Existiing ductwork must be inspected for proper size and

sealed system. Proper airflow is necessary for both user comfort and equipment

performance.

IMPORTANT: Proper application, installation and maintenance of this equipment is

a must if consumers are to receive the full benefit for which they have paid.

A. R-410A REFRIGERANT

All units are factory charged with R-410A refrigerant.

WARNING

!

THE MANUFACTURER’S WARRANTY DOES NOT COVER ANY DAMAGE OR DEFECT TO THE HEAT

PUMP CAUSED BY THE ATTACHMENT OR USE OF ANY COMPONENTS, ACCESSORIES OR

DEVICES (OTHER THAN THOSE

AUTHORIZED BY THE MANUFACTURER) INTO, ONTO OR IN CONJUNCTION WITH THE HEAT PUMP.

YOU SHOULD BE AWARE THAT

THE USE OF UNAUTHORIZED COMPONENTS, ACCESSORIES OR

DEVICES MAY ADVERSELY

AFFECT THE OPERATION OF THE

HEAT PUMP AND MAY ALSO

ENDANGER LIFE AND PROPERTY.

THE MANUFACTURER DISCLAIMS

ANY RESPONSIBILITY FOR SUCH

LOSS OR INJURY RESULTING

FROM THE USE OF SUCH UNAUTHORIZED COMPONENTS, ACCESSORIES OR DEVICES.

1. Specification of R-410A:

Application: R-410A is not a drop-in replacement for R-22; equipment designs must

accommodate its higher pressures. It cannot be retrofitted into R-22 units.

Pressure: The pressure of R-410A is approximately 60% (1.6 times) greater than

R-22. Recovery and recycle equipment, pumps, hoses and the like need to have design

pressure ratings appropriate for R-410A. Manifold sets need to range up to 800 psig

high-side and 250 psig low-side with a 550 psig low-side retard. Hoses need to have a

service pressure rating of 800 psig. Recovery cylinders need to have a 400 psig service

pressure rating. DOT 4BA400 or DOT BW400.

Combustibility: At pressures above 1 atmosphere, mixture of R-410A and air can

become combustible. R-410A and air should never be mixed in tanks or supply

lines, or be allowed to accumulate in storage tanks. Leak checking should never

be done with a mixture of R-410A and air. Leak checking can be performed safely

with nitrogen or a mixture of R-410A and nitrogen.

2. Quick Reference Guide For R-410A

• R-410A refrigerant operates at approximately 60% higher pressure (1.6 times) than R-

22. Ensure that servicing equipment is designed to operate with R-410A.

• R-410A refrigerant cylinders are pink.

• R-410A, as with other HFC’s is only compatible with POE oils.

• Vacuum pumps will not remove moisture from POE oil.

• R-410A systems are to be charged with liquid refrigerants. Prior to March 1999, R410A refrigerant cylinders had a dip tube. These cylinders should be kept upright for

equipment charging. Post March 1999 cylinders do not have a dip tube and should be

inverted to ensure liquid charging of the equipment.

• Do not install a suction line filter drier in the liquid line.

• A liquid line filter drier is standard on every unit.

• Desiccant (drying agent) must be compatible for POE oils and R-410A.

3. Evaporator Coil / TXV

The thermostatic expansion valve is specifically designed to operate with R-410A. DO

NOT use an R-22 TXV. The existing evaporator must be replaced with the factory

specified TXV evaporator specifically designed for R-410A.

4. Tools Required For Installing & Servicing R-410A Models

Manifold Sets:

-Up to 800 PSIG High side

-Up to 250 PSIG Low Side

-550 PSIG Low Side Retard

Manifold Hoses:

-Service Pressure Rating of 800 PSIG

Recovery Cylinders:

-400 PSIG Pressure Rating

-Dept. of Transportation 4BA400 or BW400

!

CAUTION

R-410A systems operate at higher pressures than R-22 systems. Do not use

R-22 service equipment or components on R-410A equipment.

4

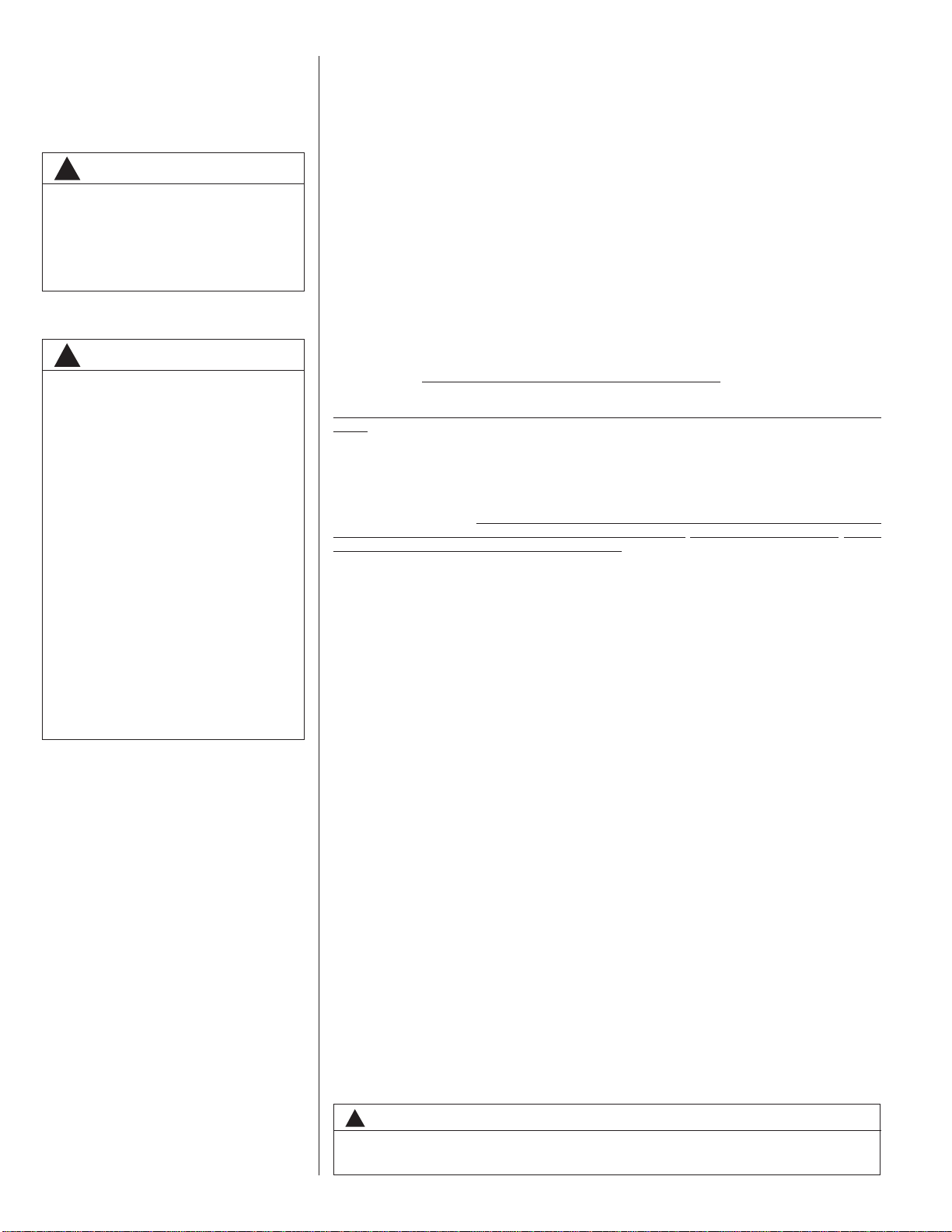

FIGURE 1

211/16"

[266.7 mm]

59"

[1498.6 mm]

53

1

/2"

[1358.9 mm]

3

1

/16"

[77.7 mm]

A

CONTROL

BOX ACCESS

211/16"

[266.7 mm]

CONDENSATE

DRAIN

PAN

ACCESS

PRIMARY

HIGH VOLTAGE

ENTRANCE

1

23

/32" [43.7 mm]

4

13

/32"

[111.8 mm]

5

9

/64"

[130.5 mm]

19

7

/8"

[505 mm]

57/8"

[149.5 mm]

3

1

/2"

[88.9 mm]

3

3

/4"

[95.3 mm]

721/32"

[194.3 mm]

313/64"

[81.2 mm]

AUXILIARY

HIGH VOLTAGE

ENTRANCE

1

23

/32" [43.7 mm]

LOW VOLTAGE

ENTRANCE

7

/8" [22.2 mm]

RECOMMENDED UNIT

DISCONNECT LOCATION

UNIT DIMENSIONS AND ACCESS LOCATIONS

Model Height “A”

FRONT VIEW

RQNM, RQPM: 024, 030 036

RQRM: 024

RQNM, RQPM: 042, 048, 060

RQRM: 030, 036, 042, 048, 060

29 1/8”

37 1/8”

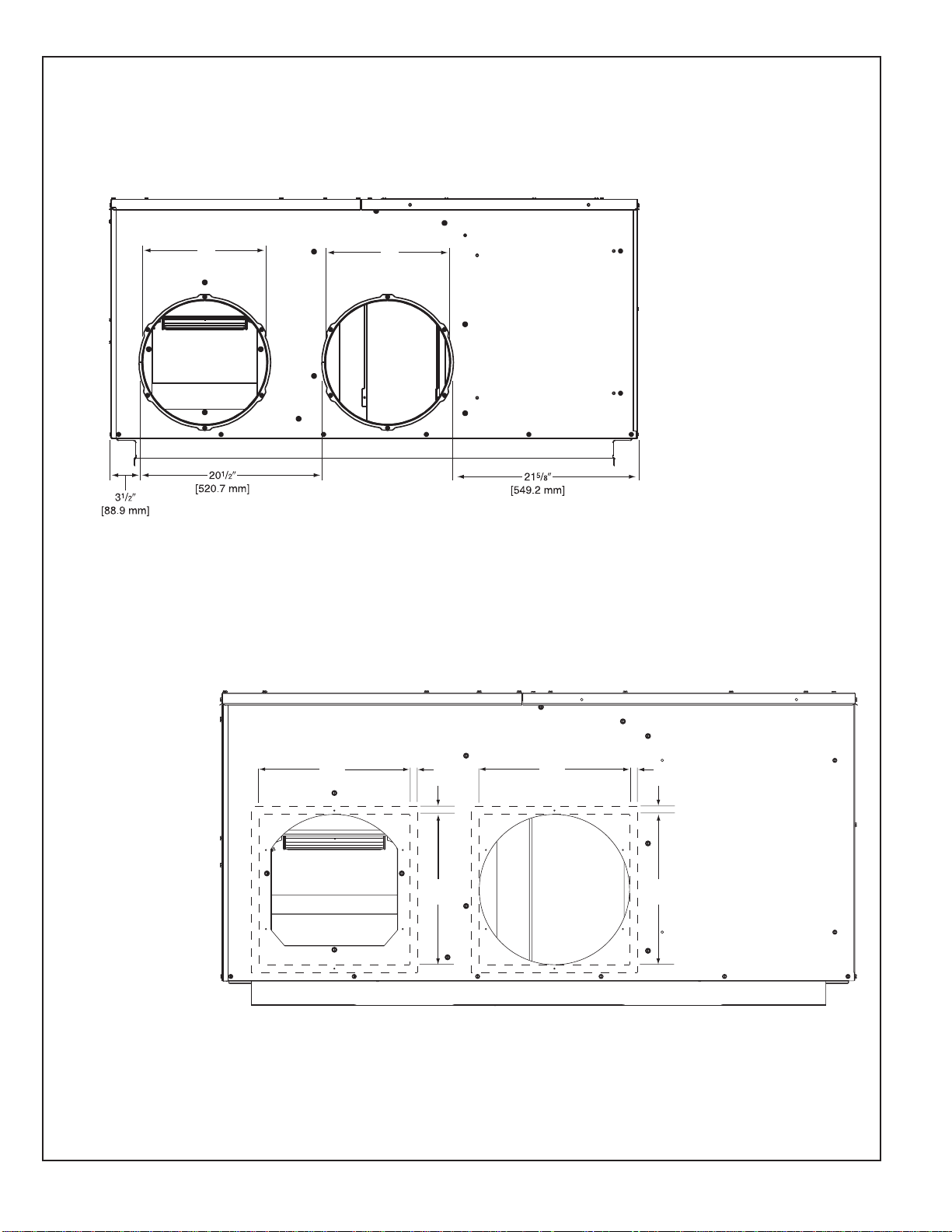

BOTTOM VIEW

ELECTRICAL CONNECTIONS

5

DUCT CONNECTIONS

14.00"

[355.6 mm]

14.00"

[355.6 mm]

[19.05 mm]

"

3

4

/

14.00"

[355.6 mm]

14.00"

[355.6 mm]

[19.05 mm]

"

3

4

/

IMPORTANT: DO NOT SCREW OR DRILL OUTSIDE THE DESIGNATED AREAS.

14"

[355.6 mm]

14"

[355.6 mm]

ROUND DUCT CONNECTIONS

IN THIS AREA

DO NOT DRILL OR INSTALL SCREWS

SQUARE DUCT CONNECTIONS

6

III. CHECKING PRODUCT RECEIVED

Upon receiving the unit, inspect it for any damage from shipment. Claims for damage,

either shipping or concealed, should be filed immediately with the shipping company.

Check the unit model number, heating size, electrical characteristics, and accessories to

determine if they are correct.

IV. EQUIPMENT PROTECTION FROM THE

ENVIRONMENT

The metal parts of this unit may be subject to rust or deterioration in adverse environmental conditions. This oxidation could shorten the equipment’s useful life. Salt spray, fog or

mist in seacoast areas, sulphur or chlorine from lawn watering systems, and various chemical contaminants from industries such as paper mills and petroleum refineries are especiallycorrosive.

If the unit is to be installed in an area where contaminants are likely to be a problem,

specialattentionshould be given to the equipmentlocation and exposure.

1. Avoidhaving lawnsprinklerheads spraydirectionon the unit cabinet.

2. In coastal areas, locate theunit on theside of the buildingaway fromthe waterfront.

3. Shielding provided bya fence orshrubs maygive someprotection.

4. Elevating the unit off its slab or base enough to allow air circulation will help avoid

holdingwater against thebasepan.

Regular maintenance will reduce the buildup of contaminents and help to protect

the unit’s finish.

WARNING

!

DISCONNECT ALL POWER TO THE UNIT BEFORE STARTING MAINTENANCE. FAILURE TO DO SO CAN RESULT IN SEVERE ELECTRICAL SHOCK

OR DEATH.

1. Frequent washing of the cabinet, fan blade and coil with fresh water will remove most

of thesalt or other contaminants that build up on the unit.

2. Regular cleaning and waxing of the cabinet with an automobile polish will provide

some protection.

3. A liquid cleaner may be used several times a year to remove matter that will not wash

off with water.

Several different types of protective coatings are offered in some areas. These coatings

may provide some benefit, but the effectiveness of such coating materials cannot be verified by the equipment manufacturer.

The best protection is frequent cleaning, maintenance and minimal exposure to

contaminants.

V. SPECIFICATIONS

Suitable for use in mobile homes, manufactured housing, and conventionally constructed

residential andcommercialbuildingswhere horizontally-ductedsystems arepreferred.

VI. INSTALLATION

A. GENERAL

1. PRE-INSTALLATION CHECK-POINTS

Before attempting any installation, the following points should be carefully considered:

a. Structural strength of supporting members.

(rooftop installation)

b. Clearances and provision for servicing.

c. Power supply and wiring.

d. Air duct connections.

e. Drain facilities and connections.

f. Location for minimum noise.

2. LOCATION

These units are designed for outdoor installations. They can be mounted on a

slab or rooftop. They are not to be installed within any part of a structure such as

an attic, crawl space, closet, or any other place where condenser air flow is

restricted or other than outdoor ambient conditions prevail. Since the application

of the units is of the outdoor type, it is important to consult your local code authorities at the time the first installation is made.

7

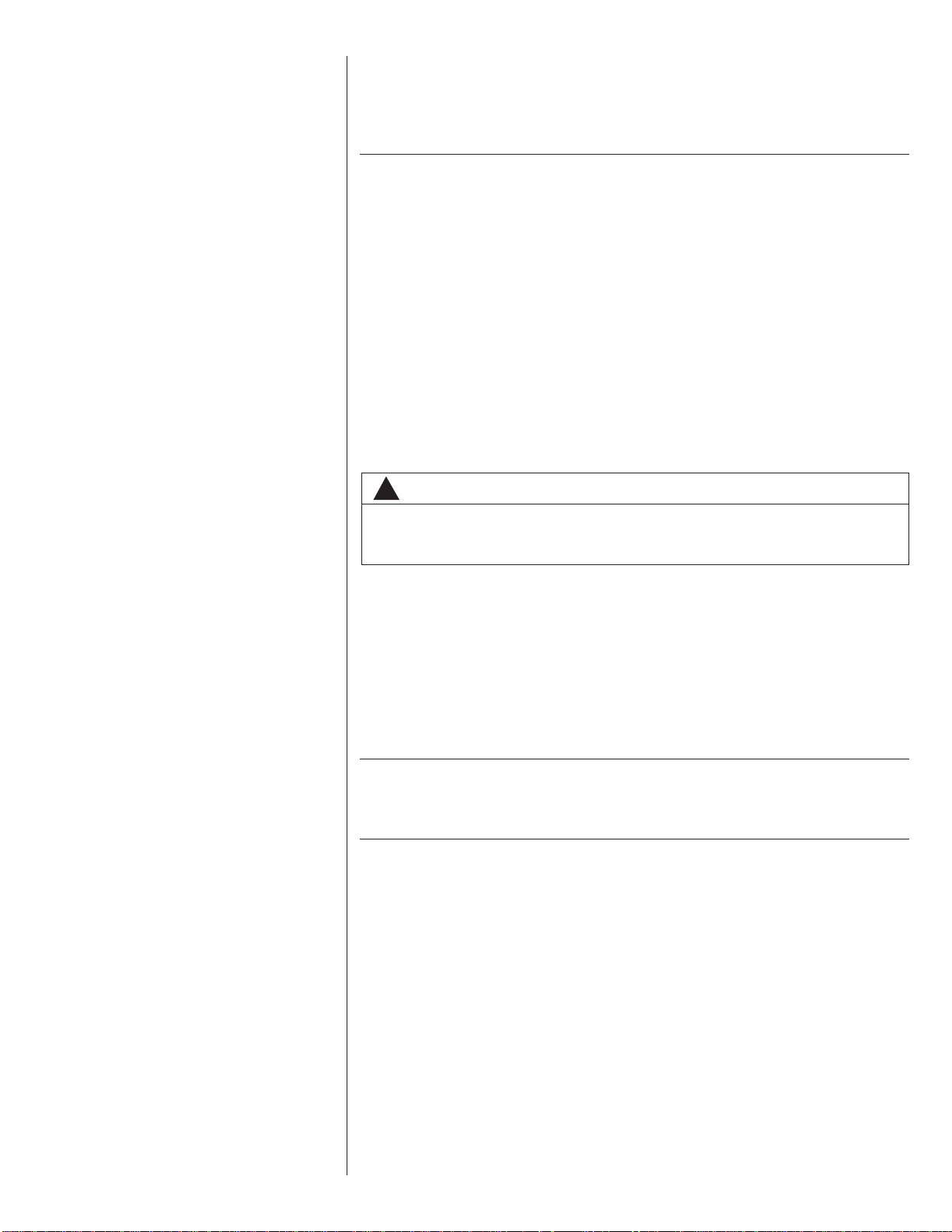

FIGURE 2

PACKAGED HEAT PUMP

OUTSIDE SLAB INSTALLATION, BASEMENT OR

CRAWL SPACE DISTRIBUTION SYSTEM

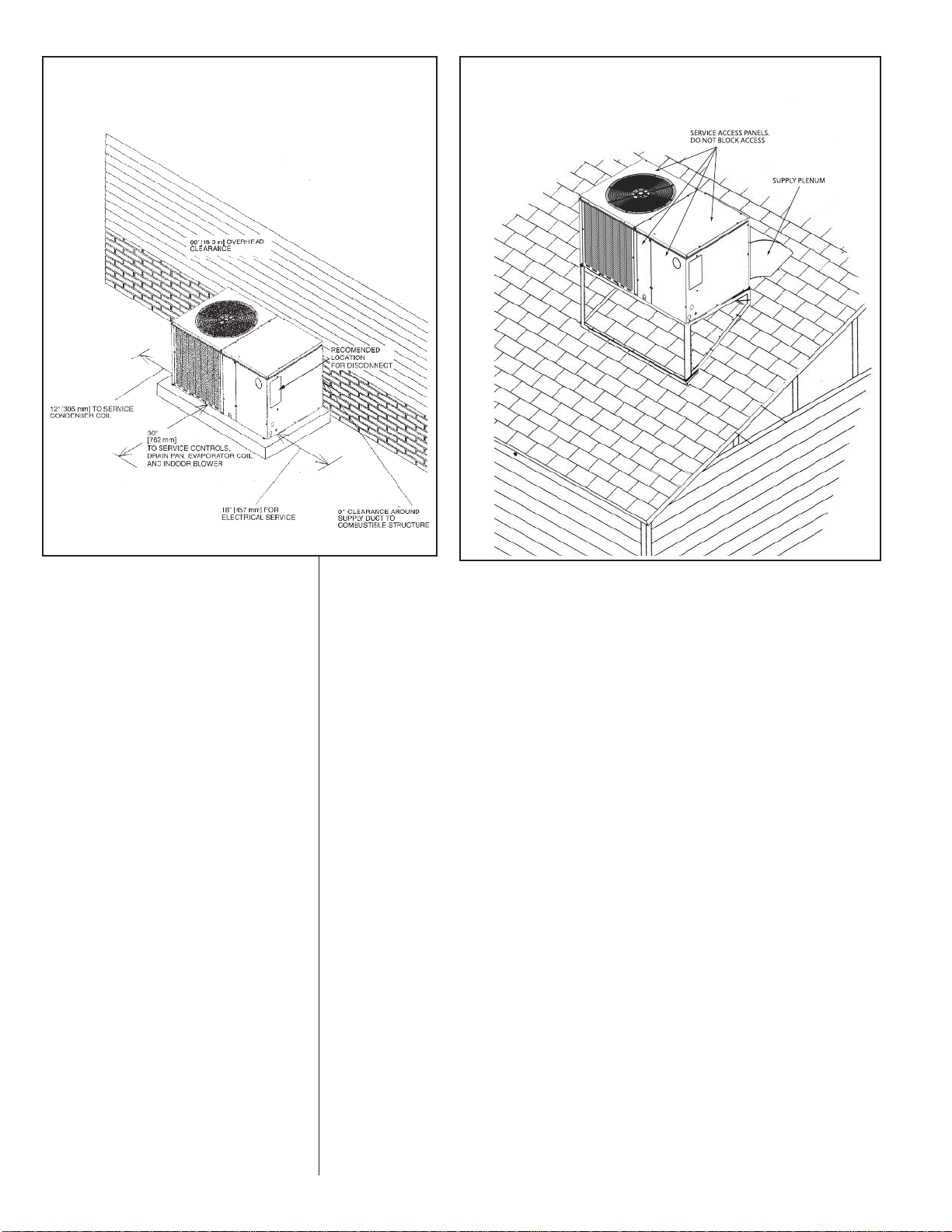

FIGURE 3

PACKAGED HEAT PUMP

PITCHED ROOFTOP INSTALLATION, ATTIC

OR DROP CEILING DISTRIBUTING SYSTEM.

MUST BE MOUNTED LEVEL.

B. OUTSIDE SLAB INSTALLATION

(Typical outdoor slab installations are shown in Figure 2.)

1. Select a location where external water drainage cannot collect around the unit.

2. Provide a level concrete slab extending 3" beyond all four sides of the unit. The

slab should be sufficient above grade to prevent ground water from entering the

unit.

IMPORTANT: To prevent transmission of noise or vibration, slab should not be

connected to building structure.

3. The location of the unit should be such as to provide proper access for inspection

and servicing.

4. Locate unit where operating sounds will not disturb owner or neighbors.

5. Locate unit so roof runoff water does not pour directly on the unit. Provide gutter

or other shielding at roof level. Do not locate unit in an area where excessive

snow drifting may occur or accumulate.

6. It is essential that the unit be elevated above the base pad to allow for condensate drainage and possible refreezing of condensation. Provide a base pad which

is slightly pitched away from the structure. Route condensate off base pad to an

area which will not become slippery and result in personal injury.

IMPORTANT: Avoid blocking openings in bottom of unit.

7. Where snowfall is anticipated, the height of the unit above the ground level must

be considered. Mount unit high enough to be above average area snowfall and to

allow for proper condensate drainage.

IMPORTANT: Avoid blocking openings in bottom of unit.

C. CLEARANCES

The following minimum clearances must be observed for proper unit performance

and serviceability.

1. Provide 30" minimum clearance at the front and 18" on the right side of the unit

for service access. Provide 12" minimum clearance on the left side of the unit for

air inlet.

2. Provide 60" minimum clearance from top of unit.

8

3. Unit is design certified for application on combustible flooring with 0" minimum

clearance.

4. See Figure 2 for illustration of minimum installation-service clearances.

D. ROOFTOP INSTALLATION

1. Before locating the unit on the roof, make sure that the strength of the roof and

beams is adequate at that point to support the weight involved. (See specification

sheet for weight of unit.) This is very important and user’s responsibility.

2. The unit should be placed on a solid and level platform of adequate strength.

IMPORTANT: Avoid blocking openings in bottom of unit. (See Figure 3).

Provision for disposal of outdoor coil defrost water runoff must be provided.

3. The location of the unit on the roof should be such as to provide proper access for

inspection and servicing.

IMPORTANT: If unit will not be put into service immediately, cover supply and return

openings to prevent excessive condensation.

VII. DUCTWORK

Ductwork should be fabricated by the installing contractor in accordance with local codes

and NFPA90A. Industry manuals may be used as a guide when sizing and designing the

duct system - contact Air Conditioning Contractors of America, 1513 16th St. N.W.,

Washington, D.C. 20036.

WARNING

!

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT RETURN DUCTWORK TO

ANY OTHER HEAT PRODUCING DEVICE SUCH AS A FIREPLACE INSERT,

STOVE, ETC. UNAUTHORIZED USE OF SUCH DEVICES MAY RESULT IN FIRE,

CARBON MONOXIDE POISONING, EXPLOSION, PROPERTY DAMAGE,

SEVERE PERSONAL INJURY OR DEATH.

Place the unit as close to the space to be air conditioned as possible allowing clearance

dimensions as indicated. Run ducts as directly as possible to supply and return outlets.

Use of non-flammable waterproof flexible connectors on both supply and return connections at the unit to reduce noise transmission is recommended.

It is preferable to install the unit on the roof of the structure if the registers or diffusers

are located on the wall or in the ceiling. Consider a slab installation when the registers

are low on a wall or in the floor.

On ductwork exposed to outside air conditions of temperature and humidity, use a minimum of 2" of insulation and a vapor barrier. Distribution system in attic, furred space or

crawl space should be insulated with at least 2" of insulation with vapor barrier. One-half

to 1" thickness of insulation is usually sufficient for ductwork inside the air conditioned

space.

Provide balancing dampers for each branch duct in the supply system. Properly support

the ductwork from the structure.

VIII.FILTERS

Filters are not provided with this unit. They must be supplied and installed in the return

air duct by the installer. A field installed filter grille is recommended for easy and convenient access to the filters for periodic inspection and cleaning. Filters must have adequate face area for the rated air quantity of the unit. See General Database for recommended filter size.

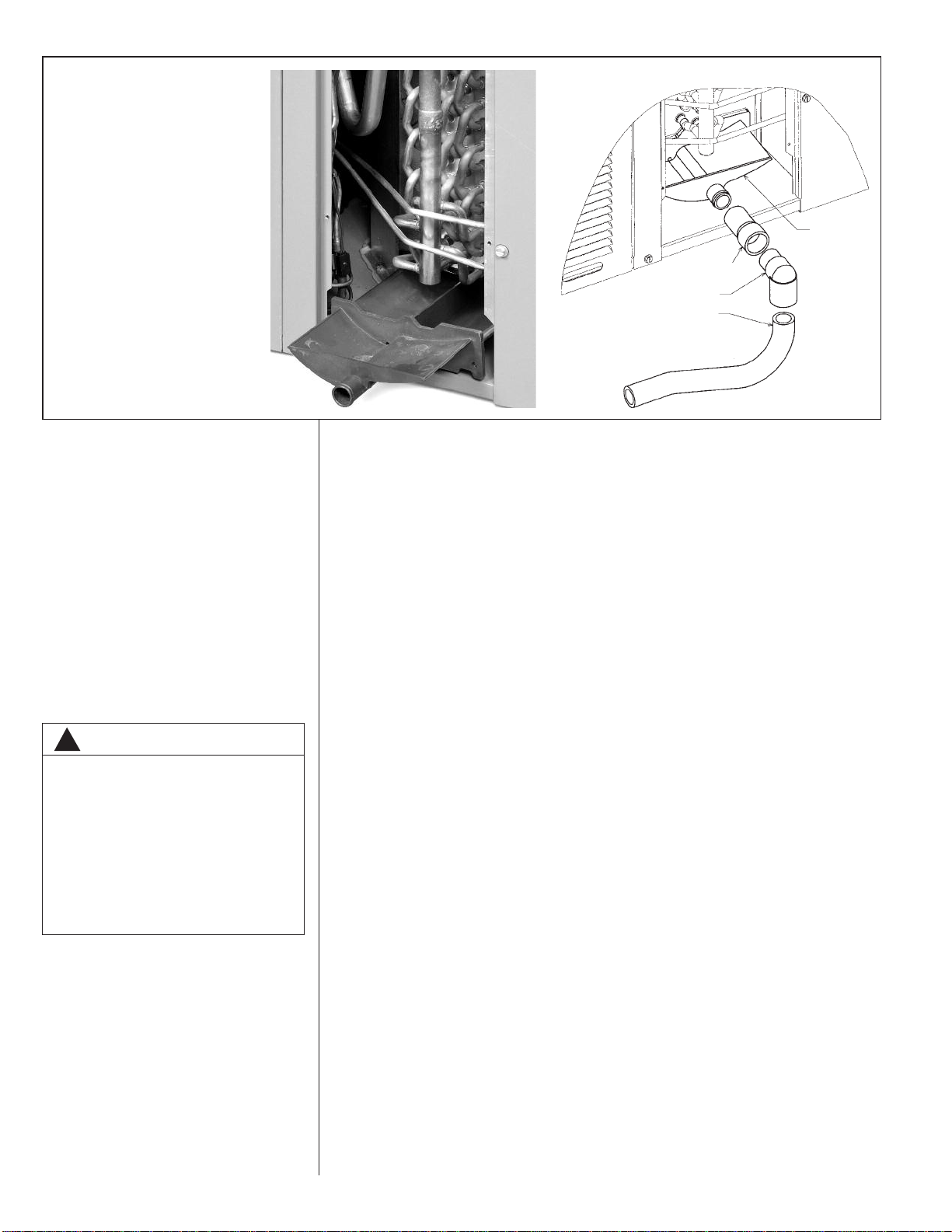

IX. CONDENSATE DRAIN

The indoor coil condensate drain ends with a PVC stub. A trap is provided in for proper

condensate drainage and to prevent debris from being drawn into the unit. Do not connect drain to closed sewer line. It is not recommended that a PVC cement or other permanent installation be used so that the drain line and/or drain pan can be easily cleaned

in the future. The drain trap is located in the control box during shipping. To install, slide

clear plastic tube over drain pan connection. The white PVC trap can be oriented as

required by installation.

9

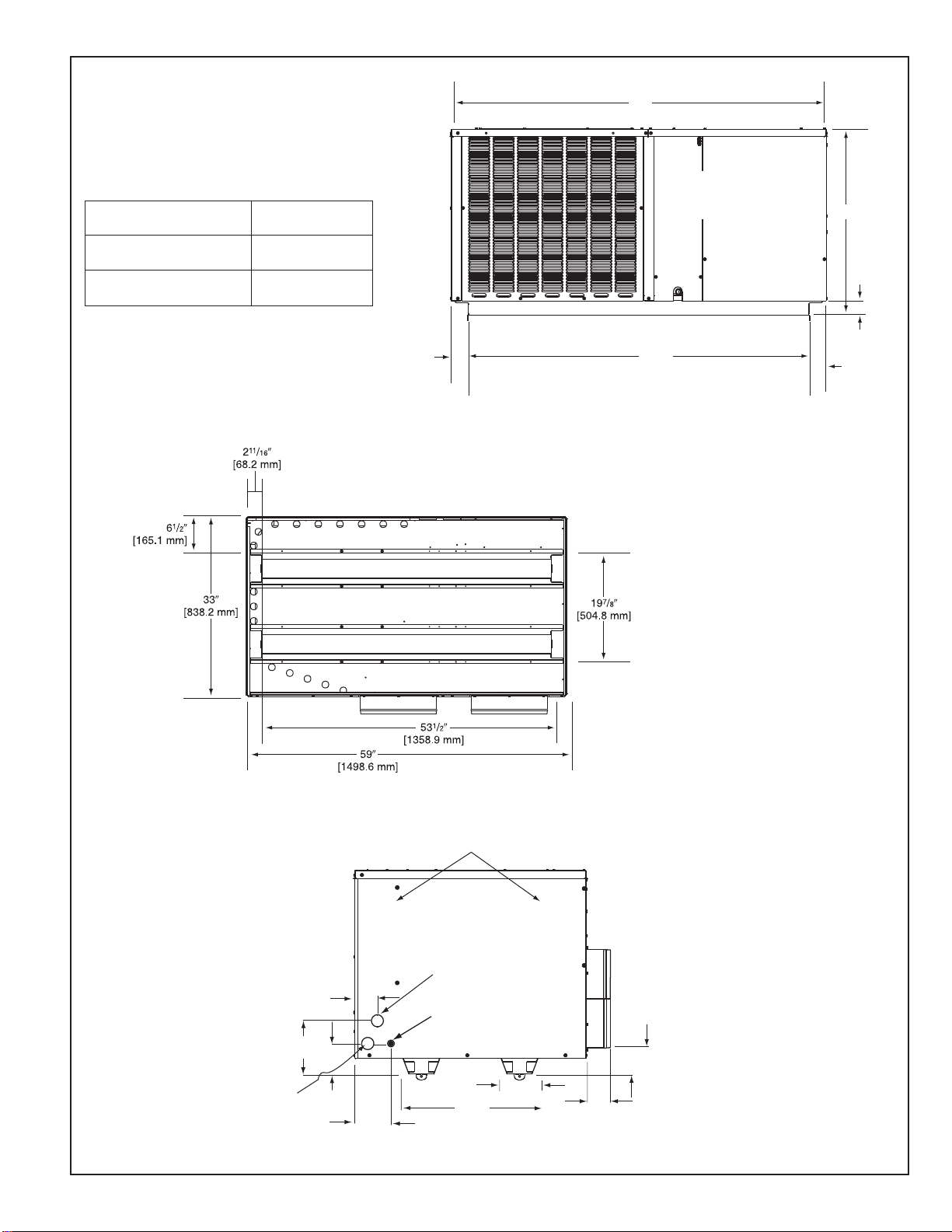

FIGURE 4

REMOVABLE CONDENSATE

DRAIN PAN AND REMOVAL

PROCEDURE

A small side panel grants

access to a removable, sloped

drain pan (A), which helps to

ensure indoor air quality (IAQ)

throughout the life of the unit. A

drain trap (B) assembly

is provided for

convenience.

CLEAR PVC

CONNECTOR TUBE

PVC ELBOW

PVC TRAP

DRAINPAN

“Patent 7,430,877”

WARNING

!

TURN OFF ELECTRIC POWER AT

THE FUSE BOX OR SERVICE

PANEL BEFORE MAKING ANY

ELECTRICAL CONNECTIONS.

ALSO, THE GROUND CONNECTION

MUST BE COMPLETED BEFORE

MAKING LINE VOLTAGE CONNECTIONS. FAILURE TO DO SO CAN

RESULT IN ELECTRICAL SHOCK,

SEVERE PERSONAL INJURY OR

DEATH.

A

B

X. CONDENSATE DRAIN, OUTDOOR COIL

The outdoor coil during heating operation will sweat or run water off. The outdoor coil will

also run water off during the defrost cycle. See Section V, Installation, for mounting precautions.

XI. ELECTRICAL WIRING

Field wiring must comply with the National Electrical Code* and applicable local codes.

*C.E.C. in Canada

A. POWER WIRING

1. It is important that proper electrical power is available at the unit. Voltage should

not vary more than 10% from that stamped on the unit rating plate. On three

phase units, phases must be balanced within 3%.

2. Install a branch circuit disconnect within sight of the unit and of adequate size to

handle the starting current. (See Heater Kit Tables.)

3. For branch circuit wiring (main power supply to unit disconnect), the minimum

wire size can be determined from the National Electrical Code or Canadian

Electrical Code or nameplate or from Heater Kit Tables.

4. This unit supports both single and dual point electrical connection for unit and

electric heat accessory.

5. Power wiring must be run in grounded rain-tight conduit.

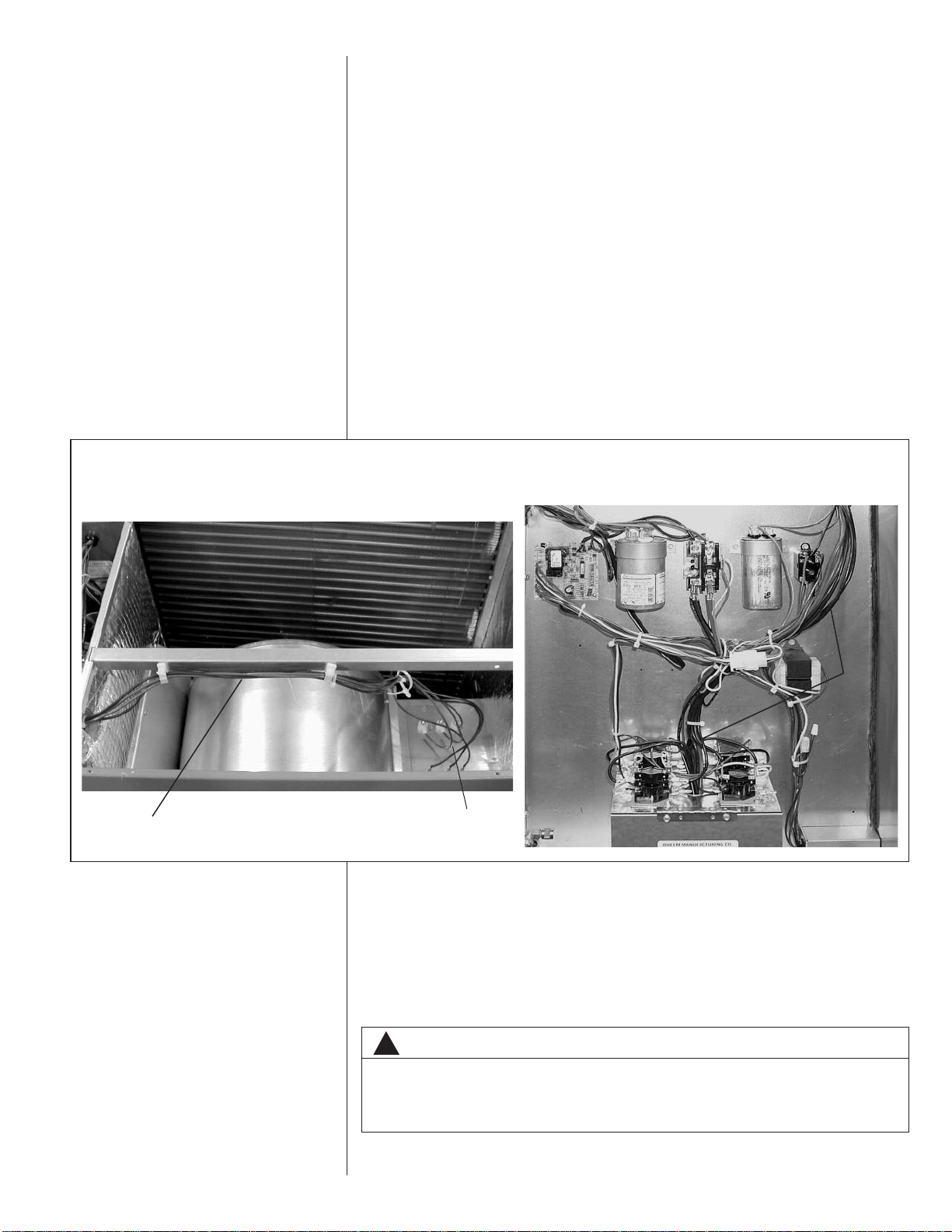

B. POWER WIRING AND ELECTRIC HEATER KIT INSTRUCTIONS

1. Turn off power to unit.

2. Remove control box access panel.

3. Remove unit indoor section top cover.

4. Remove wire notch cover from control bulkhead and discard. Retain screw.

5. Remove heater element cover plate from blower outlet opening and discard. Retain

screws.

6. Mount heater fuse block assembly in location indicated with the three included

screws.

7. Route wire harness assembly through wire notch in control bulkhead and mount element assembly in blower outlet opening with screws previously retained.

8. Center wire routing plate over notch in blower bulkhead and secure with screw previously retained.

9. Route and tie wiring as shown in Figure 5. Wiring must not contact moving parts or

uninsulated electrical connections.

10. Replace unit indoor top cover.

11. Connect power and control wiring as indicated below:

a. Single-point wiring: Connect high voltage field power leads to heater kit fuse

block and connect included unit power pigtails from heater kit fuse block to unit

10

FIGURE 5

HEATER KIT INSTALLATION

contactor L1 and L3 connections. Connect ground lead to ground lug on heater kit

fuse block.

b. Dual-circuit wiring: Remove unit power pigtails from heater kit fuse block and

discard. Connect one set of high voltage field power circuit leads to the heater kit

fuse block and connect ground lead to ground lug on heater kit fuse block.

Connect the second set of high voltage field power leads to L1 and L3 on the unit

contactor. Connect ground lead to ground lug on control box bulkhead.

c. Connect heater kit control plug to receptacle in control box.

12. Replace control box access panel.

13. Restore power to unit and verify proper unit and heater kit operation.

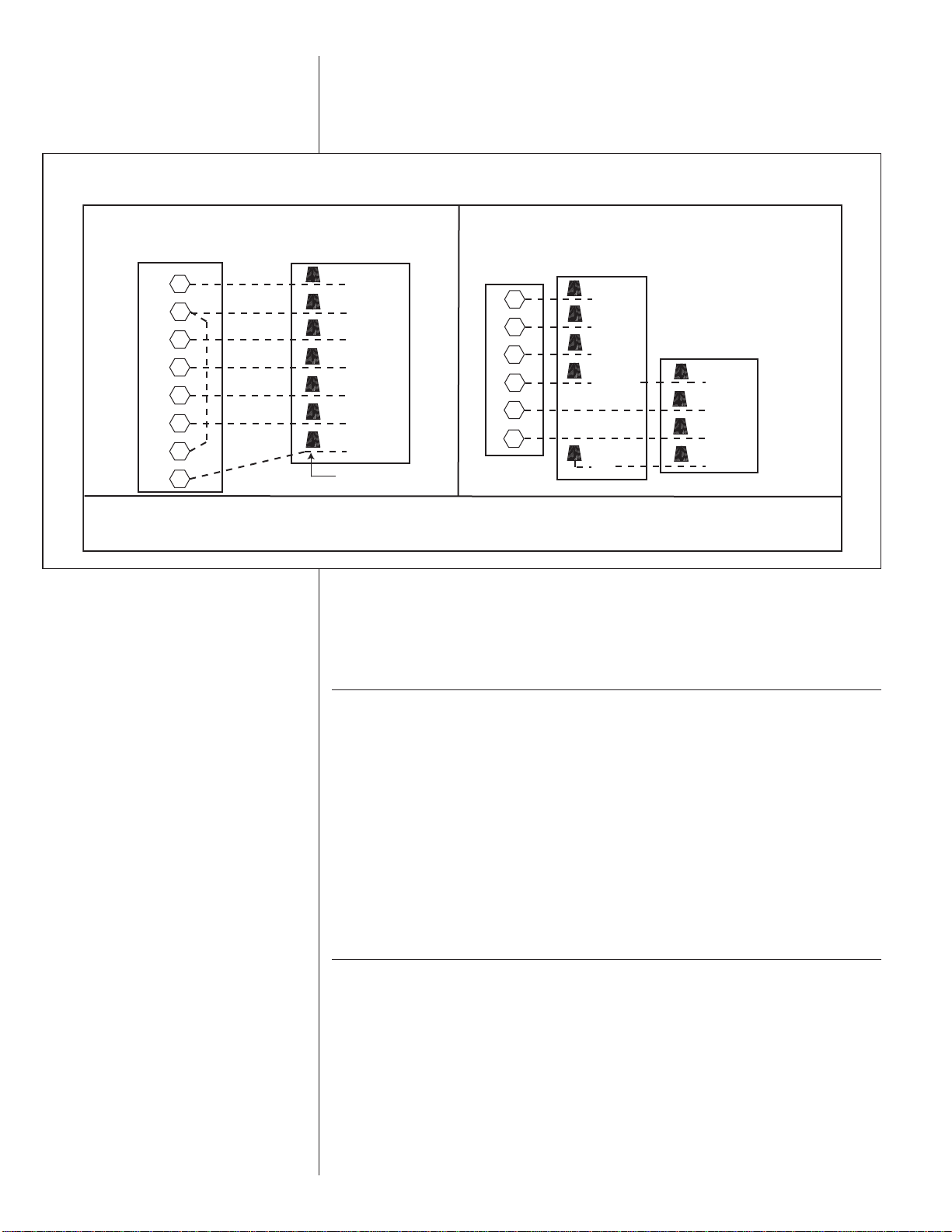

C. CONTROL WIRING (Class II)

1. Do not run low voltage wiring in conduit with power wiring.

2. Control wiring is routed through the 7/8" hole corner adjacent to the control box.

See Electrical Connections, Figure 1. Use a minimum #18 AWG thermostat wire.

For wire lengths exceeding 50', use #16 AWG thermostat wire. The low voltage

wires are connected to the unit pigtails which are supplied with the unit in the low

voltage connection box located within the unit control box. See Figure 5.

3. It is necessary that only heat pump thermostats be used.

4. Figure 6 shows representative low voltage connection diagrams. Read your thermostat installation instructions for any special requirements for your specific thermostat.

RECOMMENDED

WIRING

HEATER

KIT

WIRING

HEATER

ELEMENTS

NOTE — Units installed in Canada require that an outdoor thermostat (30,000

min. cycles of endurance) be installed and be wired with C.E.C. Class I wiring.

D. INTERNAL WIRING

1. A diagram of the internal wiring of this unit is located on the electrical control box

cover. If any of the original wire as supplied with the appliance must be replaced,

the wire gauge and insulation must be the same as original wiring.

E. GROUNDING

WARNING

!

THE UNIT MUST BE PERMANENTLY GROUNDED. A GROUNDING LUG IS

PROVIDED. FAILURE TO GROUND THIS UNIT CAN RESULT IN FIRE OR ELECTRICAL SHOCK CAUSING PROPERTY DAMAGE, SEVERE PERSONAL INJURY

OR DEATH.

11

FIGURE 6

STANDARD

WITH ONE OUTDOOR THERMOSTAT W/EMERGENCY

HEAT RELAY

IF EMERGENCY HEAT RELAY AND OUTDOOR THERMOSTATS ARE NOT USED, A JUMPER BETWEEN “W2” AND “E” CAN BE

INSTALLED TO TRANSFER CONTROL OF HEATING TO THE FIRST STAGE WHEN THE SYSTEM SWITCH IS IN THE

EMERGENCY HEAT POSITION.

THERMOSTAT

SUB-BASE

UNIT CONTROL

WIRE PIGTAILS

OUTDOOR

THERMOSTAT

W/EMERGENCY

HEAT RELAY

THERMOSTAT

SUB-BASE

UNIT CONTROL

WIRE PIGTAILS

RED

PR

BROWN

BLUE

YELLOW

BK/Gr

Y/BL

RED

BK/GR

BLUE

BROWN

PU

BROWN

RED

WH

BL

G

E

Y

B

X

W2

R

Y2

R

G

B

X

E

W2

2 STAGE SYSTEM ONLY

VOLTAGE CONNECTIONS DIAGRAM

F. THERMOSTAT

Mount the thermostat on an inside wall about five feet above the floor in a location

where it will not be affected by unconditioned air, sun, or drafts from open doors or

other sources. READ installation instructions in heat pump thermostat package

CAREFULLY because each has some different wiring requirements.

XII. INDOOR AIR FLOW DATA

All 208/230 volt units are equipped with multi-speed indoor blower motors. Each unit is

shipped factory wired for the proper speed at a normal external static. See Airflow

Performance Table for blower performance.

XIII. PRE-START CHECK

1. Is unit properly located and level?

2. Is ductwork insulated, weatherproofed, with proper spacing to combustible materials?

3. Is air free to travel to and from outdoor coil? (See Figure 1.)

4. Is the wiring correct, tight, and according to unit wiring diagram?

5. Is unit grounded?

6. Are field supplied air filters in place and clean?

7. Do the outdoor fan and indoor blower turn freely without rubbing, and are they tight

on the motor shafts?

8. Is unit elevated to allow for outdoor coil condensate drainage during heating opera-

XIV.STARTUP

1. Turn thermostat to “OFF,” turn “on” power supply at disconnect switch.

2. Turn temperature setting as high as it will go.

3. Turn fan switch to “ON.”

4. Indoor blower should run. Be sure it is running in the right direction.

5. Turn fan switch to “AUTO.” Turn system switch to “COOL” and turn temperature set-

6. Is outdoor fan operating correctly in the right direction?

tion and defrost?

ting below room temperature. Unit should run in cooling mode.

12

7. Is compressor running correctly.

8. Turn thermostat system switch to “HEAT.” Unit should stop. Wait 5 minutes, then

raise temperature setting to above room temperature. Unit should run in heating

mode and after about 30 to 50 seconds auxiliary heaters, if installed, should come

on.

9. Check the refrigerant charge using the instructions located on control box cover.

Replace service port caps. Service port cores are for system access only and will

leak if not tightly capped.

Turn thermostat system switch to proper mode “HEAT” or “COOL” and set thermostat

10

to proper temperature setting. Record the following after the unit has run some time.

A. Operating Mode _______________________________

B. Discharge Pressure (High)___________________PSIG

C.Vapor Pressure at Compressor (Low) __________PSIG

D.Vapor Line Temperature at Compressor __________°F.

E. Indoor Dry Bulb______________________________°F.

F. Indoor Wet Bulb _____________________________°F.

G.Outdoor Dry Bulb ____________________________°F.

H.Outdoor Wet Bulb____________________________°F.

I. Voltage at Contactor ________________________Volts

J. Current at Contactor _______________________Amps

K. Model Number_________________________________

L. Serial Number _________________________________

M.Location______________________________________

N.Owner _______________________________________

O.Date_________________________________________

11. Adjust discharge air grilles and balance system.

12. Check ducts for condensation and air leaks.

13. Check unit for tubing and sheet metal rattles.

14. Instruct the owner on operation and maintenance.

15. Leave “USE AND CARE” instructions with owner.

XV. OPERATION

Most single phase units are not equipped with start relay or start capacitor. It is important that such systems be off for a minimum of 5 minutes before restarting to allow

equalization of pressures. Do not move the thermostat to cycle unit without waiting five

minutes. To do so may cause the compressor to stop on an automatic open overload

device or blow a fuse. Poor electrical service can cause nuisance tripping in overloads

or blow fuses.

IMPORTANT: The compressor has an internal overload protector. Under some conditions, it can take up to 2 hours for this overload to reset. Make sure overload has had

time to reset before condemning the compressor.

These units may be equipped with a time delay control (TDC1). The control allows the

blower to operate for 45 to 90 seconds after the thermostat is satisfied.

XVI. AUXILIARY HEAT

The amount of auxiliary heat required depends on the heat loss of the structure to be

heated and the capacity of the heat pump. It is good practice to install strip heat to maintain at least 60°F indoor temperatures in case of compressor failure. The auxiliary heat

is energized by the first stage of the thermostat. The amount of electric heat that is

allowed to come on, as determined by the output of the heat pump, may be controlled by

an outdoor thermostat.

WARNING

!

ONLY ELECTRIC HEATER KITS SUPPLIED BY THIS MANUFACTURER AS

DESCRIBED IN THIS PUBLICATION HAVE BEEN DESIGNED, TESTED, AND

EVALUATED BY A NATIONALLY RECOGNIZED SAFETY TESTING AGENCY

FOR USE WITH THIS UNIT. USE OF ANY OTHER MANUFACTURED ELECTRIC

HEATERS INSTALLED WITHIN THIS UNIT MAY CAUSE HAZARDOUS CONDITIONS RESULTING IN PROPERTY DAMAGE, FIRE, BODILY INJURY OR

DEATH.

A. CONTROL SYSTEM OPERATION

1. In the cooling mode, the thermostat will, on a call for cooling, energize the com-

pressor contactor and the indoor blower relay. The indoor blower can be operated

continuously by setting the thermostat fan switch at the “ON” position.

13

2. In the heating mode, the first heat stage of the thermostat will energize one or

more supplementary resistance heaters. If required or considered desirable, the

resistance heat may also be controlled by outdoor thermostats. In the heating

mode, the thermostat will, on a call for heating, energize the indoor blower relay.

XVII. DEMAND DEFROST CONTROL AND

HIGH/LOW PRESSURE CONTROLS

The demand defrost control is a printed circuit board assembly consisting of solid

state control devices with electro-mechanical outputs. The demand defrost control

monitors the outdoor ambient temperature, outdoor coil temperature, and the compressor run-time to determine when a defrost cycle is required.

Enhanced Feature Demand Defrost Control: Has high and low pressure control

inputs with unique pressure switch logic built into the microprocessor to provide

compressor and system protection without nuisance lock-outs. Cycles the compressor off for 30 seconds at the beginning and end of the defrost cycle to eliminate the

increased compressor noise caused by rapidly changing system pressures when

the reversing valve switches. See the end of this section for diagnostic flash codes

for the two diagnostic LED’s provided on the control.

DEFROST INITIATION

A defrost will be initiated when the three conditions below are satisfied:

1) The outdoor coil temperature is below 35°F.

2) The compressor has operated for at least 34 minutes with the outdoor coil temperature below 35°F.

3) The measured difference between the ambient temperature and the outdoor

coil temperature is greater than the calculated delta T.

Additionally, a defrost will be initiated if six hours of accumulated compressor runtime has elapsed without a defrost with the outdoor coil temperature below 35°F.

DEFROST TERMINATION

Once a defrost is initiated, the defrost will continue until fourteen minutes has

elapsed or the coil temperature has reached the terminate temperature. The terminate temperature is factory set at 70°F, although the temperature can be changed

to 50°F, 60°F, 70°F or 80°F by relocating a jumper on the board.

TEMPERATURE SENSORS

The coil sensor is clipped to the outdoor coil. The air sensor is located in the outdoor coil compartment.

If the ambient sensor fails the defrost control will initiate a defrost every 34 minutes

with the coil temperature below 35°F.

If the coil sensor fails the defrost control will not initiate a defrost.

TEST MODE

The test mode is initiated by shorting the TEST pins. In this mode of operation, the

enable temperature is ignored and all timers are sped up by a factor of 240. To initiate a manual defrost, short the TEST pins. Remove the short when the system

switches to defrost mode. The defrost will terminate on time (14 minutes) or when

the termination temperature has been achieved. Short TEST pins again to terminate the defrost immediately.

TROUBLE SHOOTING DEMAND DEFROST

Set the indoor thermostat select switch to heat and initiate a call for heat.

Jumper the “test pins” to put the unit into defrost. If the unit goes into defrost and

comes back out of defrost, the indication is that the control is working properly.

If the unit did not go into defrost using the test pins, check to ensure that 24V is

being supplied to the control board. If 24V is present then replace the control.

14

HIGH/LOW PRESSURE CONTROL MONITORING - ENHANCED

DEFROST CONTROL

Status of high and low pressure controls is monitored by the enhanced feature

demand defrost control and the following actions are taken.

High Pressure Control – Provides active protection in both cooling and heating

modes at all outdoor ambient temperatures. The high pressure control is an automatic reset type and opens at approximately 610 psig and closes at approximately

420 psig. The compressor and fan motor will stop when the high pressure control

opens and will start again if the high side pressure drops to approximately 420 psig

when the automatic reset high pressure control resets. If the high pressure control

opens 3 times within a particular call for heating or cooling operation, the defrost

control will lock out compressor and outdoor fan operation.

Low Pressure Control – Provides active protection in both heating and cooling

modes at all outdoor ambient temperatures. The low pressure control is an automatic reset type and opens at approximately 15 psig and closes at approximately

40 psig. Operation is slightly different between cooling and heating modes.

Cooling Mode: The compressor and fan motor will stop when the low pressure

control opens and will start again when the low side pressure rises to approximately 40 psig when the low pressure control automatically resets. If the low

pressure switch opens 3 times within a particular call for cooling operation, the

defrost control will lock out compressor and outdoor fan operation.

Heating Mode: The compressor and fan motor will stop when the low pressure

control opens and will start again when the low side pressure rises to approximately 40 psig when the low pressure control automatically resets. If the low

pressure switch trips 3 times within 120 minutes of operation during a particular

call for heating operation, the defrost control will lock out compressor and outdoor fan operation. If the lock-out due to low pressure occurs at an outdoor

ambient temperature below 5°F, the defrost control will automatically exit the

lock-out mode when the outdoor ambient temperature rises to 5°F. This feature

is necessary since the low pressure control could possibly have opened due to

the outdoor ambient being very low rather than an actual system fault.

Exiting Lock-Out Mode: To exit the lock-out mode, remove 24 volts to the defrost

control by removing power to indoor air-handler/furnace or by shorting the two

defrost control test pins together.

ENHANCED FEATURE DEFROST CONTROL DIAGNOSTIC CODES

LED 1 LED 2 Control Board Status

OFF OFF No Power

ON ON Coil Sensor Failure

OFF ON Ambient Sensor Failure

FLASH FLASH Normal

OFF FLASH Low Pressure Lockout (short test pins to reset)

FLASH OFF High Pressure Lockout (short test pins to reset)

ON FLASH Low Pressure Control Open

FLASH ON High Pressure Control Open

Alternate Flashing 5 Minute Time Delay

15

XVIII. GENERAL DATA - RQRM

NOMINAL SIZES 2.5-4 TONS [8.7-13.6 kW]

Model RQRM- Series A024JK A030JK A036JK A042JK

Cooling Performance

Gross Cooling Capacity Btu [kW] 24,400 [7.15] 29,600 [8.67] 35,000 [10.25] 43,000 [12.6]

EER, SEER

Nominal CFM/AHRI Rated CFM [L/s] 800/900 [378/425] 1000/1000 [472/472] 1200/1200 [566/566] 1400/1425 [661/672]

AHRI Net Cooling Capacity Btu [kW] 24,000 [7.03] 29,200 [8.56] 34,400 [10.08] 42,000 [12.31]

Net Sensible Capacity Btu [kW] 20,000 [5.86] 23,050 [6.75] 27,000 [7.91] 32,200 [9.43]

Net Latent Capacity Btu [kW] 4,000 [1.17] 6,150 [1.8] 7,400 [2.17] 9,800 [2.87]

Net System Power kW 1.85 2.13 2.58 3.14

Heating Performance [Heat Pumps]

High Temp. Btuh [kW] Rating 23,800 [6.97] 28,800 [8.44] 33,200 [9.73] 39,500 [11.57]

System Power KW / COP 1.79/3.9 2.11/4 2.63/3.7 2.89/4

Low Temp. Btuh [kW] Rating 11,700 [3.43] 16,000 [4.69] 18,600 [5.45] 22,400 [6.56]

System Power KW / COP 1.65/2.08 1.95/2.4 2.37/2.3 2.75/2.4

HSPF (Btu/Watts-hr) 8888.5

Compressor

No/Type 1/Scroll 1/Scroll 1/Scroll 1/Scroll

Outdoor Sound Rating (dB)

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 12.12 [1.13] 16.54 [1.54] 16.54 [1.54] 16.54 [1.54]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 4.33 [0.4] 5.78 [0.54] 5.78 [0.54] 5.78 [0.54]

Rows / FPI [FPcm] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5] 4 / 13 [5]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 3200 [1510]] 3200 [1510] 3200 [1510] 4200 [1982]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 825 825 825 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/10x9 [254x229] 1/10x9 [254x229] 1/10x9 [254x229] 1/11x9 [279x229]

Drive Type/No. Speeds Direct/2 Direct/2 Direct/2 Direct/2

No. Motors 1111

Motor HP 1/2 1/2 1/2 3/4

Motor RPM 1050 1050 1050 1050

Motor Frame Size 48 48 48 48

Filter - Type Field Supplied Field Supplied Field Supplied Field Supplied

Furnished No No No No

(NO.) Size Recommended in. [mm x mm x mm] (1)1x20x16 [25x508x406] (1)1x20x20 [25x508x508] (1)1x24x24 [25x610x610] (1)1x24x24 [25x610x610]

Refrigerant Charge Oz. [g] 176 [4990] 203 [5755] 194 [5500] 206 [5840]

Weights

Net Weight lbs. [kg] 385 [175] 429 [195] 429 [195] 479 [217]

Ship Weight lbs. [kg] 409 [186] 455 [206] 455 [206] 505 [229]

1

2

5

13/16 13/16 13/16 13/16

76 76 76 78

Continued ->

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. AHRI capacity is net and includes the effect of fan motor heat. Units are suitable for operation in CFM range shown in airflow tables. Units are certified in accordance with the Unitary

Air Conditioner Equipment certification program, which is based on AHRI Standard 210/240 or 360.

2. EER and/or SEER are rated at AHRI conditions and in accordance with DOE test procedures.

3. Heating Performance is rated at 47° F ambient, 70° F entering dry bulb for High Temp rating and 17° F ambient, 70° F entering dry bulb for Low Temp rating. Performance

ratings do include the effect of fan motor heat.

4. Outdoor Sound Rating shown is tested in accordance with AHRI Standard 270.

16

GENERAL DATA - RQRM

NOMINAL SIZES 2.5-4 TONS [8.7-13.6 kW]

Model RQRM- Series A048JK A060JK

Cooling Performance

Gross Cooling Capacity Btu [kW] 46,500 [13.62] 57,500 [16.85]

EER, SEER

Nominal CFM/AHRI Rated CFM [L/s] 1600/1525 [755/720] 2000/1900 [944/897]

AHRI Net Cooling Capacity Btu [kW] 45,500 [13.33] 56,000 [16.41]

Net Sensible Capacity Btu [kW] 34,700 [10.17] 41,450 [12.14]

Net Latent Capacity Btu [kW] 10,800 [3.16] 14,550 [4.26]

Net System Power kW 3.45 4.63

Heating Performance [Heat Pumps]

High Temp. Btuh [kW] Rating 43,500 [12.75] 54,800 [16.06]

System Power KW / COP 3.19/4 4.2/3.82

Low Temp. Btuh [kW] Rating 23,800 [6.97] 31,600 [9.26]

System Power KW / COP 2.79/2.5 3.65/2.54

HSPF (Btu/Watts-hr) 8.5 8.5

Compressor

No/Type 1/Scroll1/Scroll 1/Scroll

Outdoor Sound Rating (dB)

Outdoor Coil - Fin Type Louvered Louvered

Tube Type Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 16.54 [1.54] 16.54 [1.54]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered

Tube Type Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 5.78 [0.54] 5.78 [0.54]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan - Type Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1

CFM [L/s] 4200 [1982] 4200 [1982]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/11x9 [279x229] 1/11x9 [279x229]

Drive Type/No. Speeds Direct/2 Direct/2

No. Motors 11

Motor HP 3/4 1

Motor RPM 1050 1050

Motor Frame Size 48 48

Filter - Type Field Supplied Field Supplied

Furnished No No

(NO.) Size Recommended in. [mm x mm x mm] (1)1x24x24 [25x610x610] (1)1x24x24 [25x610x610]

Refrigerant Charge Oz. [g] 216 [6124] 202 [5727]

Weights

Net Weight lbs. [kg] 481 [218] 482 [219]

Ship Weight lbs. [kg] 507 [230] 508 [230]

1

2

5

13/16 12/15

78 78

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. AHRI capacity is net and includes the effect of fan motor heat. Units are suitable for operation in CFM range shown in airflow tables. Units are certified in accordance with the Unitary

Air Conditioner Equipment certification program, which is based on AHRI Standard 210/240 or 360.

2. EER and/or SEER are rated at AHRI conditions and in accordance with DOE test procedures.

3. Heating Performance is rated at 47° F ambient, 70° F entering dry bulb for High Temp rating and 17° F ambient, 70° F entering dry bulb for Low Temp rating. Performance

ratings do include the effect of fan motor heat.

4. Outdoor Sound Rating shown is tested in accordance with AHRI Standard 270.

17

GENERAL DATA - RQPM

NOMINAL SIZES 2-5 TONS [7-17.6 kW]

Model RQPM- Series A024JK A030JK A036CK A036JK

Cooling Performance

Gross Cooling Capacity Btu [kW] 24,000 [7.03] 29,400 [8.61] 36,000 [10.55] 36,000 [10.55]

EER, SEER

Nominal CFM/AHRI Rated CFM [L/s] 800/800 [378/378] 1000/1000 [472/472] 1200/1200 [566/566] 1200/1200 [566/566]

AHRI Net Cooling Capacity Btu [kW] 23,600 [6.91] 29,000 [8.5] 35,400 [10.37] 35,400 [10.37]

Net Sensible Capacity Btu [kW] 18,400 [5.39] 23,000 [6.74] 27,600 [8.09] 27,600 [8.09]

Net Latent Capacity Btu [kW] 5,200 [1.52] 6,000 [1.76] 7,800 [2.29] 7,800 [2.29]

Net System Power kW 2 2.41 3.05 3.05

Heating Performance [Heat Pumps]

High Temp. Btuh [kW] Rating 23,200 [6.8] 28,000 [8.2] 34,200 [10.02] 34,200 [10.02]

System Power KW / COP 1.93/3.5 2.27/3.62 2.78/3.6 2.78/3.6

Low Temp. Btuh [kW] Rating 13,200 [3.87] 15,200 [4.45] 19,000 [5.57] 19,000 [5.57]

System Power KW / COP 1.71/2.26 2.01/2.22 2.48/2.24 2.48/2.24

HSPF (Btu/Watts-hr) 8888

Compressor

No/Type 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll

Outdoor Sound Rating (dB)

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 10.44 [0.97] 12.65 [1.18] 12.65 [1.18] 12.65 [1.18]

Rows / FPI [FPcm] 1 / 20 [8] 1 / 20 [8] 1 / 20 [8] 1 / 20 [8]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5 0.375 [9.5]

Face Area sq. ft. [sq. m] 4.33 [0.4] 4.33 [0.4] 4.33 [0.4] 4.33 [0.4]

Rows / FPI [FPcm] 2 / 15 [6] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 3200 [1510] 3200 [1510] 3200 [1510] 3200 [1510]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 825 825 825 825

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/10x9 [254x229] 1/10x9 [254x229] 1/10x9 [254x229] 1/10x9 [254x229]

Drive Type/No. Speeds Direct/2 Direct/2 Direct/2 Direct/2

No. Motors 1111

Motor HP 1/2 1/2 1/2 1/2

Motor RPM 1050 1050 1050 1050

Motor Frame Size 48 48 48 48

Filter - Type Field Supplied Field Supplied Field Supplied Field Supplied

Furnished No No No No

(NO.) Size Recommended in. [mm x mm x mm] (1)1x20x16 [25x508x406] (1)1x20x20 [25x508x508] (1)1x24x24 [25x610x610] (1)1x24x24 [25x610x610]

Refrigerant Charge Oz. [g] 90 [2552] 93 [2637] 93 [2637] 93 [2637]

Weights

Net Weight lbs. [kg] 308 [140[ 331 [150] 356 [161] 356 [161]

Ship Weight lbs. [kg] 332 [151] 355 [161] 380 [172] 380 [172]

1

2

5

12/14 12.05/14 11.6/14 11.6/14

76 76 76 76

Continued ->

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. AHRI capacity is net and includes the effect of fan motor heat. Units are suitable for operation in CFM range shown in airflow tables. Units are certified in accordance with the Unitary

Air Conditioner Equipment certification program, which is based on AHRI Standard 210/240 or 360.

2. EER and/or SEER are rated at AHRI conditions and in accordance with DOE test procedures.

3. Heating Performance is rated at 47° F ambient, 70° F entering dry bulb for High Temp rating and 17° F ambient, 70° F entering dry bulb for Low Temp rating. Performance

ratings do include the effect of fan motor heat.

4. Outdoor Sound Rating shown is tested in accordance with AHRI Standard 270.

18

Loading...

Loading...