Rheem RQMP-A030JK, RQMP-A024JK, RQMP-A036CK, RQMP-A036JK, RQMP-A042CK Installation Instructions Manual

...Page 1

INSTALLATION INSTRUCTIONS

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORT TION!

!

DO NOT DESTROY THIS MANUAL

PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE BY A SERVICEMAN

WARNING

!

ANT SAFETY INFORMA

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO

QUALIFIED, LICENSED SERVICE PERSONNEL FOR PROPER

INSTALLAT I ON, ADJUSTMENT AND OPERATION OF THIS

UNIT. READ THESE INSTRUCTIONS THOROUGHLY BEFORE

AT TEMPTING INSTALLATION OR OPERATION. FAI LURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN IMPROPER

INSTALLAT I ON, ADJUSTMENT, SERVICE OR MAINTENANCE

POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK,

PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

PACKAGE HEAT PUMPS FEATURING EARTHFRIENDLY R-410A REFRIGERANT

RQPM 14 SEER SERIES – (2 - 5 TONS)

RQNM 13 SEER SERIES – (2 - 5 TONS)

[ ] INDICATES METRIC CONVERSION

(14 SEER

MODELS ONLY)

SUPERSEDES 92-20522-47-03

92-20522-47-04

Page 2

TABLE OF CONTENTS

I. Safety Information .................................................................................................3

I. Introduction............................................................................................................4

I

III. Checking Product Received ..................................................................................7

IV. Equipment Protection ............................................................................................7

V. Specifications ........................................................................................................7

VI. Installation .............................................................................................................7

A. General .............................................................................................................7

1. Pre-Installation Check Points ........................................................................7

2. Location.........................................................................................................7

B. Outside Slab Installation ...................................................................................8

. Clearances ........................................................................................................8

C

D. Rooftop Installation ...........................................................................................9

VII. Ductwork................................................................................................................9

VIII. Filters.....................................................................................................................9

IX. Condensate Drain, Indoor Coil ..............................................................................9

X. Condensate Drain, Outdoor Coil .........................................................................10

XI. Electrical Wiring...................................................................................................10

A. Power Wiring ...................................................................................................10

B. Electric Heater Kit Instructions ........................................................................10

C. Control Wiring .................................................................................................11

D. Internal Wiring .................................................................................................11

E. Grounding .......................................................................................................11

F. Thermostat ......................................................................................................12

XII. Indoor Air Flow Data............................................................................................12

XIII. Pre-Start Check ...................................................................................................12

XIV. Startup .................................................................................................................12

XV. Operation.............................................................................................................13

XVI. Auxiliary Heat ......................................................................................................13

XVII. Demand Defrost Control......................................................................................14

XVIII. General Data ..................................................................................................15-20

XIX. Miscellaneous

Electrical and Physical Data...........................................................................21-22

Airflow Performance .......................................................................................23-26

Electric Heater Kit...........................................................................................27-30

Wiring Diagram...............................................................................................31-34

Charge Charts ................................................................................................35-40

Installation instructions are updated on a regular basis. This is done as product

changes occur or if new information becomes available. In this publication, an arrow ()

denotes changes from the previous edition or additional new material.

2

Page 3

I. SAFETY INFORMATION

WARNING

!

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED, LICENSED

SERVICE PERSONNEL FOR PROPER INSTALLATION, ADJUSTMENT AND

OPERATION OF THIS UNIT. READ THESE INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO FOLLOW

THESE INSTRUCTIONS MAY RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SERIVICE OR MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

PROPOSITION 65: THIS APPLIANCE CONTAINS FIBERGLASS INSULATION.

RESPIRABLE PARTICLES OF FIBERGLASS ARE KNOWN TO THE STATE OF

CALIFORNIA TO CAUSE CANCER.

WARNING

!

THE MANUFACTURER’S WARRANTY DOES NOT COVER ANY DAMAGE OR

DEFECT TO THE HEAT PUMP CAUSED BY THE ATTACHMENT OR USE OF ANY

COMPONENTS, ACCESSORIES OR DEVICES (OTHER THAN THOSE AUTHORIZED BY THE MANUFACTURER) INTO, ONTO OR IN CONJUNCTION WITH THE

HEAT PUMP. YOU SHOULD BE AWARE THAT THE USE OF UNAUTHORIZED

COMPONENTS, ACCESSORIES OR DEVICES MAY ADVERSELY AFFECT THE

OPERATION OF THE HEAT PUMP AND MAY ALSO ENDANGER LIFE AND

PROPERTY. THE MANUFACTURER DISCLAIMS ANY RESPONSIBILITY FOR

SUCH LOSS OR INJURY RESULTING FROM THE USE OF SUCH UNAUTHORIZED COMPONENTS, ACCESSORIES OR DEVICES.

WARNING

!

DISCO NNE CT ALL POWER TO THE UNIT BEFORE STAR TIN G M AINTENANCE. FAILURE TO DO SO CAN RESULT IN SEVERE ELECTRICAL SHOCK

OR DEATH.

WARNING

!

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT RETURN DUCTWORK TO

ANY OTHER HEAT PRODUCING DEVICE SUCH AS A FIREPLACE INSERT,

STOVE, ETC. UNAUTHORIZED USE OF SUCH DEVICES MAY RESULT IN FIRE,

CA R BON M ONOXID E POI S ONING, EXPL O SION, PROP E R TY D AMAGE,

SEVERE PERSONAL INJURY OR DEATH.

WARNING

!

TURN OFF ELECTRIC POWER AT THE FUSE BOX OR SERVICE PANEL BEFORE

MAKING ANY ELECTRICAL CONNECTIONS.

ALSO, THE GROUND CONNECTION MUST BE COMPLETED BEFORE MAKING

LINE VOLTAGE CONNECTIONS. FAILURE TO DO SO CAN RESULT IN ELECTRICAL SHOCK, SEVERE PERSONAL INJURY OR DEATH.

WARNING

!

THE UNIT MUST BE PERMANENTLY GROUNDED. A GROUNDING LUG IS

PROVIDED. FAILURE TO GROUND THIS UNIT CAN RESULT IN FIRE OR ELECTRICAL SHOCK CAUSING PROPERTY DAMAGE, SEVERE PERSONAL INJURY

OR DEATH.

WARNING

!

ONLY ELECTRIC HEATER KITS SUPPLIED BY THIS MANUFACTURER AS

DESCRIBED IN THIS PUBLICATION HAVE BEEN DESIGNED, TESTED, AND

EVALUATED BY A NATIONALLY RECOGNIZED SAFETY TESTING AGENCY

FOR USE WITH THIS UNIT. USE OF ANY OTHER MANUFACTURED ELECTRIC

HEATERS INSTALLED WITHIN THIS UNIT MAY CAUSE HAZARDOUS CONDITIONS R ESU LTI NG IN PR OPE RTY DAMAGE, FIRE, BODILY INJURY OR

DEATH.

3

Page 4

WARNING

!

PROPOSITION 65: THIS APPLIANCE

CONTAINS FIBERGLASS INSULA-

ION. RESPIRABLE PARTICLES OF

T

FIBERGLASS ARE KNOWN TO THE

STATE OF CALIFORNIA TO CAUSE

CANCER.

II. INTRODUCTION

This booklet contains the installation and operating instructions for your package heat

pump. There are a few precautions that should be taken to derive maximum satisfaction

from it. Improper installation can result in unsatisfactory operation or dangerous conditions.

Read this booklet and any instructions packaged with separate equipment required to

make up the system prior to installation. Give this booklet to the owner and explain its

provisions. The owner should retain this booklet for future reference.

NOTE: A load calculation must be performed to properly determine the required

heating and cooling for the structure. Also, the duct must be properly designed and

installed for proper airflow. Existiing ductwork must be inspected for proper size and

sealed system. Proper airflow is necessary for both user comfort and equipment

performance.

IMPORTANT: Proper application, installation and maintenance of this equipment is

a must if consumers are to receive the full benefit for which they have paid.

A. R-410A REFRIGERANT

All units are factory charged with R-410A refrigerant.

WARNING

!

THE MANUFACTURER’S WARRANTY DOES NOT COVER ANY DAMAG E OR D E FECT TO THE HEAT

PUMP CAUSED BY THE ATTACHMENT OR US E OF ANY COMP ONE N T S, AC C E SSORIES OR

DE V ICES (OTHE R TH AN THOSE

AUTHORIZED BY THE MANUFACTURER) INTO, ONTO OR IN CONJUNCTION WITH THE HEAT PUMP.

YO U S H OULD BE AWAR E T H AT

THE USE OF UNAUTHORIZED COMPO N E NTS, AC C E SSORIES O R

DE V I CES MA Y ADVERS E L Y

AFFECT THE OPERATION OF THE

HE A T PU M P AN D MAY ALSO

ENDANGER LIFE AND PROPERTY.

THE MANUFACTURER DISCLAIMS

ANY RESPONSIBILITY FOR SUCH

LO S S OR INJU R Y RE S ULTING

FROM THE USE OF SUCH UNAUTHORIZED COMPONENTS, ACCESSORIES OR DEVICES.

1. Specification of R-410A:

Application: R-410A is not a drop-in replacement for R-22; equipment designs must

accommodate its higher pressures. It cannot be retrofitted into R-22 units.

Pressure: The pressure of R-410A is approximately 60% (1.6 times) greater than

R-22. Recovery and recycle equipment, pumps, hoses and the like need to have design

pressure ratings appropriate for R-410A. Manifold sets need to range up to 800 psig

high-side and 250 psig low-side with a 550 psig low-side retard. Hoses need to have a

service pressure rating of 800 psig. Recovery cylinders need to have a 400 psig service

pressure rating. DOT 4BA400 or DOT BW400.

Combustibility: At pressures above 1 atmosphere, mixture of R-410A and air can

become combustible. R-410A and air should never be mixed in tanks or supply

lines, or be allowed to accumulate in storage tanks. Leak checking should never

be done with a mixture of R-410A and air. Leak checking can be performed safely

with nitrogen or a mixture of R-410A and nitrogen.

2. Quick Reference Guide For R-410A

• R-410A refrigerant operates at approximately 60% higher pressure (1.6 times) than R-

22. Ensure that servicing equipment is designed to operate with R-410A.

• R-410A refrigerant cylinders are pink.

• R-410A, as with other HFC’s is only compatible with POE oils.

• Vacuum pumps will not remove moisture from POE oil.

• R-410A systems are to be charged with liquid refrigerants. Prior to March 1999, R410A refrigerant cylinders had a dip tube. These cylinders should be kept upright for

equipment charging. Post March 1999 cylinders do not have a dip tube and should be

inverted to ensure liquid charging of the equipment.

• Do not install a suction line filter drier in the liquid line.

• A liquid line filter drier is standard on every unit.

• Desiccant (drying agent) must be compatible for POE oils and R-410A.

3. Evaporator Coil / TXV

The thermostatic expansion valve is specifically designed to operate with R-410A. DO

NOT use an R-22 TXV. The existing evaporator must be replaced with the factory

specified TXV evaporator specifically designed for R-410A.

4. Tools Required For Installing & Servicing R-410A Models

Manifold Sets:

-Up to 800 PSIG High side

-Up to 250 PSIG Low Side

-550 PSIG Low Side Retard

Manifold Hoses:

-Service Pressure Rating of 800 PSIG

Recovery Cylinders:

-400 PSIG Pressure Rating

-Dept. of Transportation 4BA400 or BW400

!

CAUTION

R-410A systems operate at higher pressures than R-22 systems. Do not use

R-22 service equipment or components on R-410A equipment.

4

Page 5

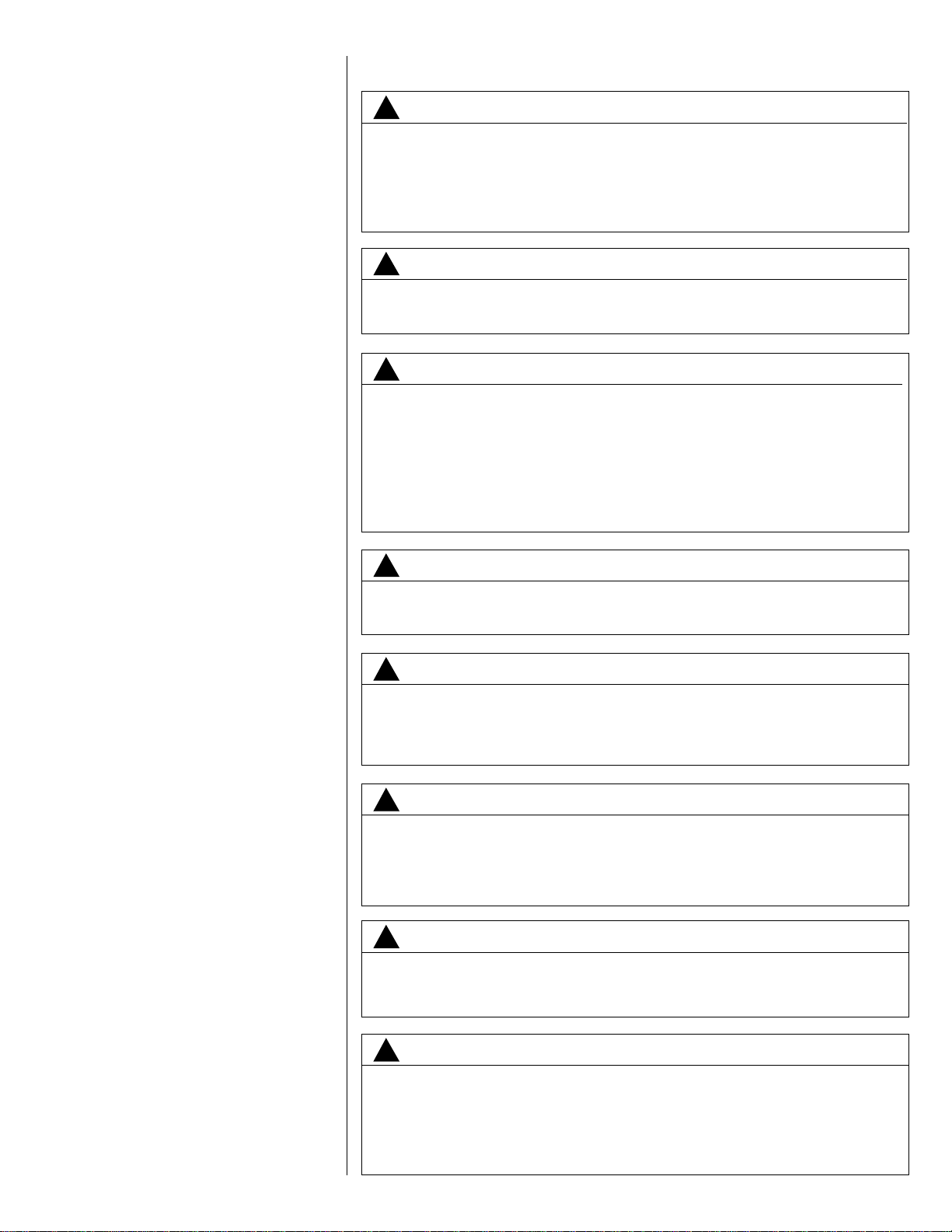

IGURE 1

Model

0

24, 030, 036

0

42, 048, 060

Height “A”

2

9 1/8"

3

7 1/8"

211/16"

[266.7 mm]

59"

[1498.6 mm]

53

1

/2"

[1358.9 mm]

3

1

/16"

[77.7 mm]

A

CONTROL

BOX ACCESS

211/16"

[266.7 mm]

CONDENSATE

DRAIN

PAN

ACCESS

PRIMARY

HIGH VOLTAGE

ENTRANCE

1

23

/32" [43.7 mm]

4

13

/32"

[111.8 mm]

5

9

/64"

[130.5 mm]

19

7

/8"

[505 mm]

57/8"

[149.5 mm]

3

1

/2"

[88.9 mm]

3

3

/4"

[95.3 mm]

7

21

/32"

[194.3 mm]

313/64"

[81.2 mm]

AUXILIARY

HIGH VOLTAGE

ENTRANCE

1

23

/32" [43.7 mm]

LOW VOLTAGE

ENTRANCE

7

/8" [22.2 mm]

RECOMMENDED UNIT

DISCONNECT LOCATION

F

UNIT DIMENSIONS AND ACCESS LOCATIONS

FRONT VIEW

BOTTOM VIEW

ELECTRICAL CONNECTIONS

5

Page 6

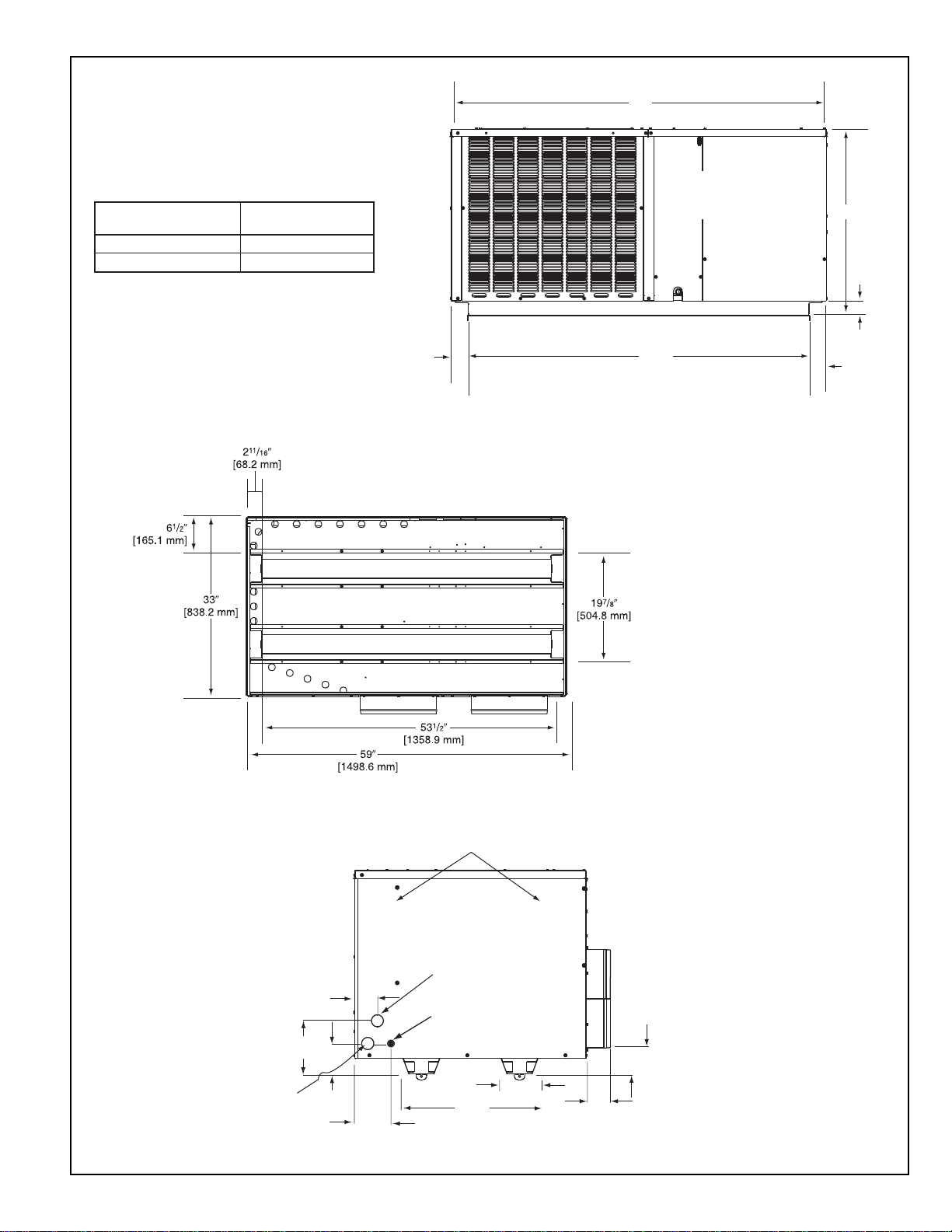

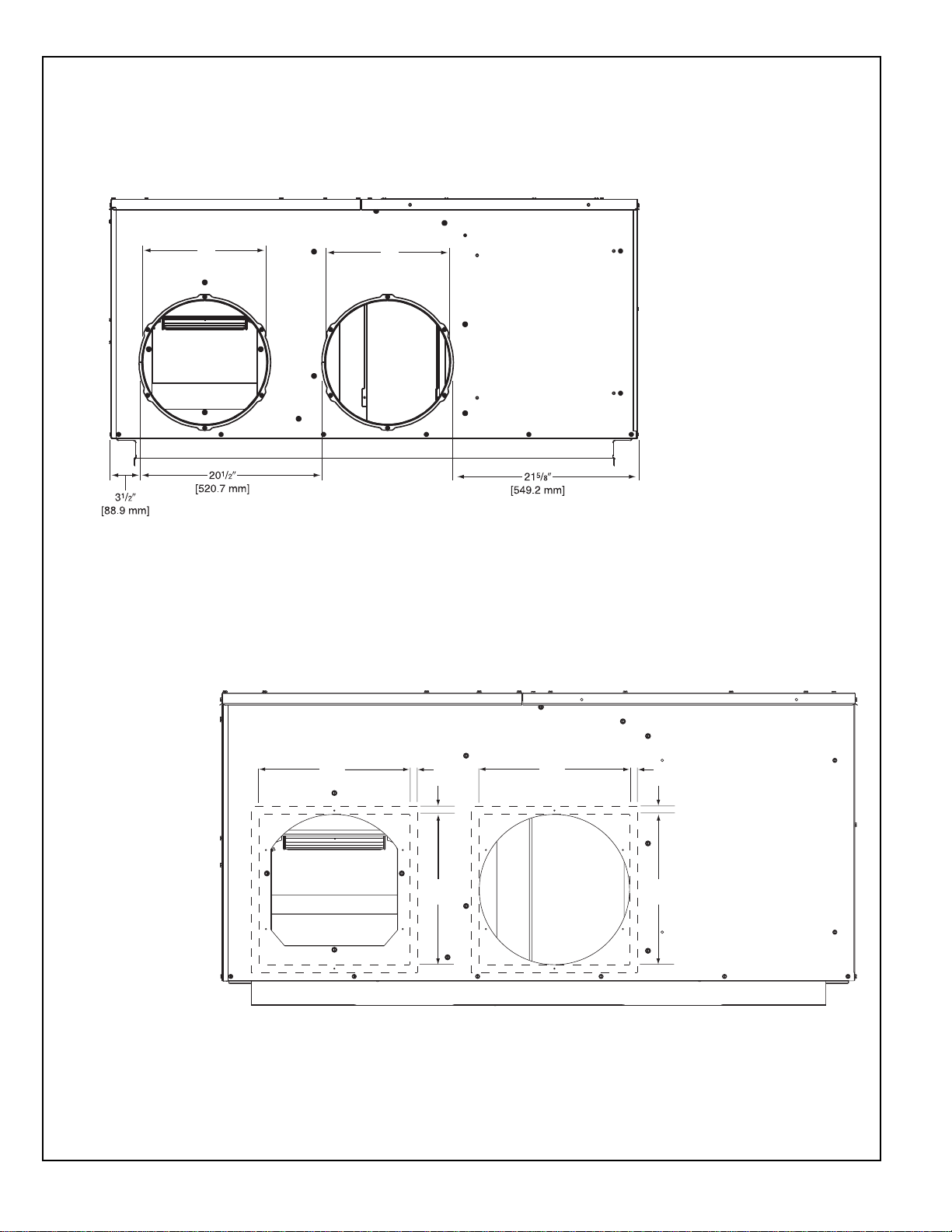

UCT CONNECTIONS

14.00"

[355.6 mm]

14.00"

[355.6 mm]

[19.05 mm]

"

3

4

/

14.00"

[355.6 mm]

14.00"

[355.6 mm]

[19.05 mm]

"

3

4

/

IMPORTANT: DO NOT SCREW OR DRILL OUTSIDE THE DESIGNATED AREAS.

1

4"

[355.6 mm]

14"

[

355.6 mm]

D

OUND DUCT CONNECTIONS

R

IN THIS AREA

DO NOT DRILL OR INSTALL SCREWS

SQUARE DUCT CONNECTIONS

6

Page 7

III. CHECKING PRODUCT RECEIVED

Upon receiving the unit, inspect it for any damage from shipment. Claims for damage,

either shipping or concealed, should be filed immediately with the shipping company.

Check the unit model number, heating size, electrical characteristics, and accessories to

determine if they are correct.

IV. EQUIPMENT PROTECTION FROM THE

ENVIRONMENT

The metal parts of this unit may be subject to rust or deterioration in adverse environmental conditions. This oxidation could shorten the equipment’s useful life. Salt spray, fog or

mist in seacoast areas, sulphur or chlorine from lawn watering systems, and various chemical contaminants from industries such as paper mills and petroleum refineries are especially corrosive.

If the unit is to be installed in an area where contaminants are likely to be a problem,

special attention should be given to the equipment location and exposure.

1. Avoid having lawn sprinkler heads spray direction on the unit cabinet.

2. In coastal areas, locate the unit on the side of the building away from the waterfront.

3. Shielding provided by a fence or shrubs may give some protection.

4. Elevating the unit off its slab or base enough to allow air circulation will help avoid

holding water against the basepan.

Regular maintenance will reduce the buildup of contaminents and help to protect

the unit’s finish.

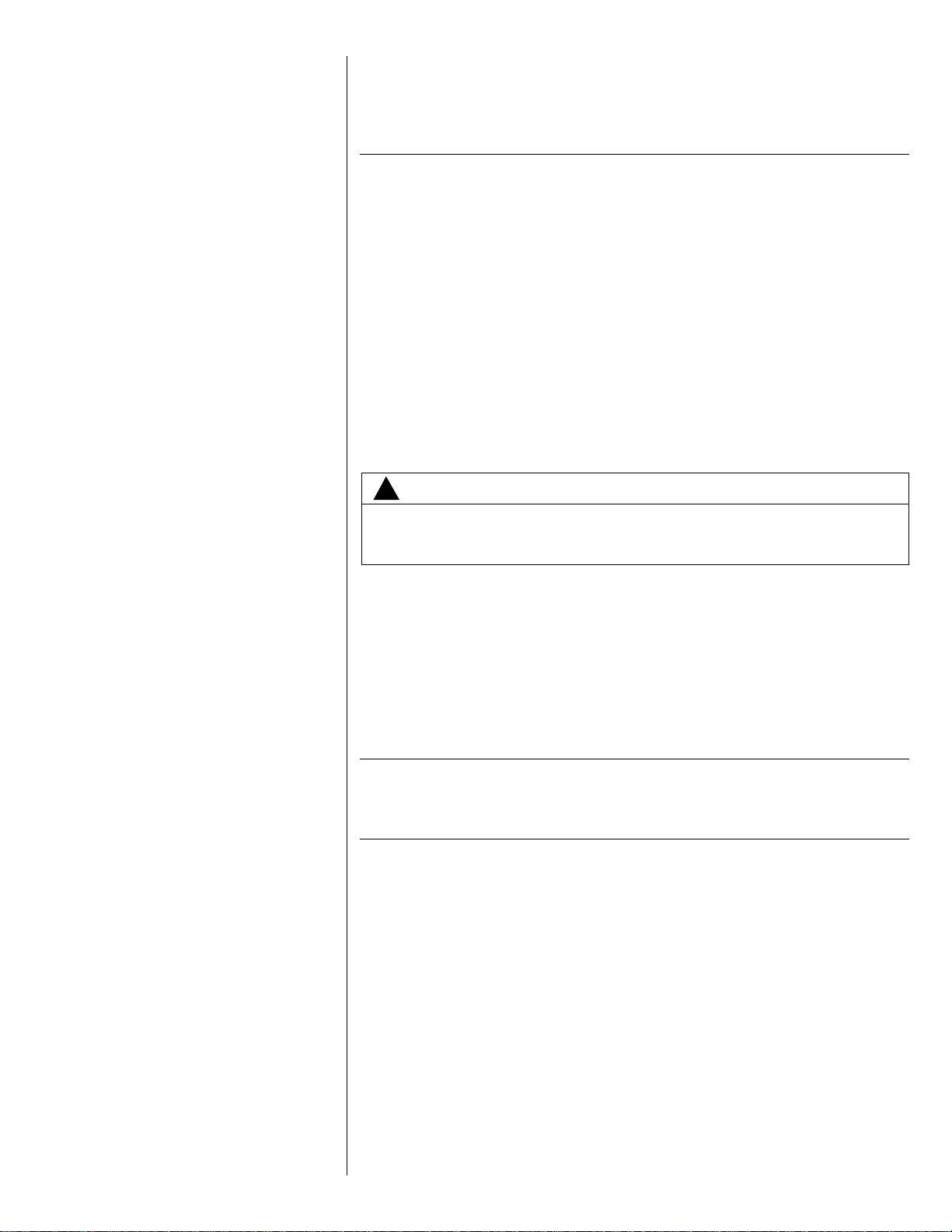

WARNING

!

DISCONNE CT ALL POWER TO THE UNIT BEFORE STARTI NG MAI NTENANCE. FAILURE TO DO SO CAN RESULT IN SEVERE ELECTRICAL SHOCK

OR DEATH.

1. Frequent washing of the cabinet, fan blade and coil with fresh water will remove most

of the salt or other contaminants that build up on the unit.

2. Regular cleaning and waxing of the cabinet with an automobile polish will provide

some protection.

3. A liquid cleaner may be used several times a year to remove matter that will not wash

off with water.

Several different types of protective coatings are offered in some areas. These coatings

may provide some benefit, but the effectiveness of such coating materials cannot be verified by the equipment manufacturer.

The best protection is frequent cleaning, maintenance and minimal exposure to

contaminants.

V. SPECIFICATIONS

Suitable for use in mobile homes, manufactured housing, and conventionally constructed

residential and commercial buildings where horizontally-ducted systems are preferred.

VI. INSTALLATION

A. GENERAL

1. PRE-INSTALLATION CHECK-POINTS

Before attempting any installation, the following points should be carefully considered:

a. Structural strength of supporting members.

(rooftop installation)

b. Clearances and provision for servicing.

c. Power supply and wiring.

d. Air duct connections.

e. Drain facilities and connections.

f. Location for minimum noise.

2. LOCATION

These units are designed for outdoor installations. They can be mounted on a

slab or rooftop. They are not to be installed within any part of a structure such as

an attic, crawl space, closet, or any other place where condenser air flow is

restricted or other than outdoor ambient conditions prevail. Since the application

of the units is of the outdoor type, it is important to consult your local code authorities at the time the first installation is made.

7

Page 8

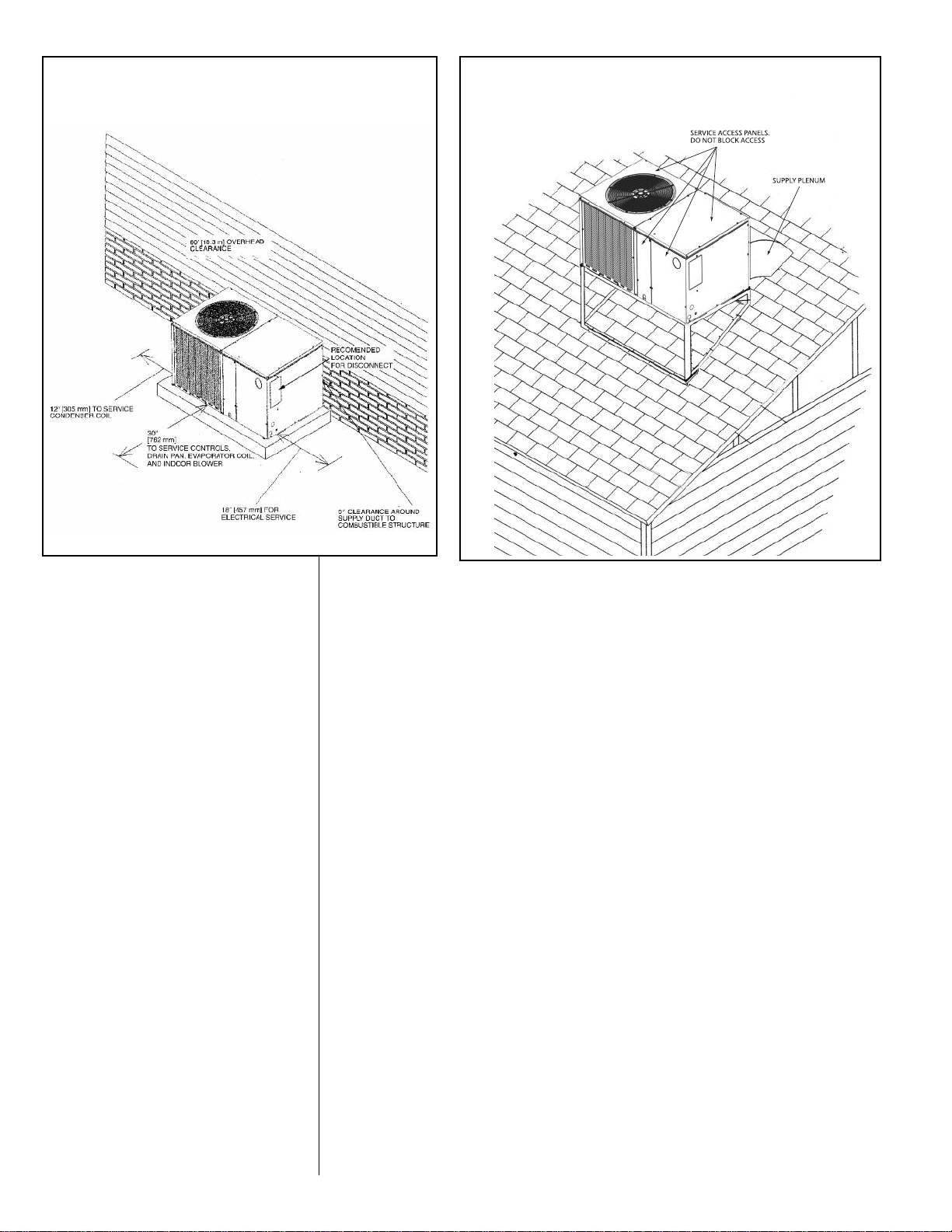

FIGURE 2

PACKAGED HEAT PUMP

UTSIDE SLAB INSTALLATION, BASEMENT OR

O

CRAWL SPACE DISTRIBUTION SYSTEM

FIGURE 3

ACKAGED HEAT PUMP

P

PITCHED ROOFTOP INSTALLATION, ATTIC

R DROP CEILING DISTRIBUTING SYSTEM.

O

MUST BE MOUNTED LEVEL.

B. OUTSIDE SLAB INSTALLATION

(Typical outdoor slab installations are shown in Figure 2.)

1. Select a location where external water drainage cannot collect around the unit.

2. Provide a level concrete slab extending 3" beyond all four sides of the unit. The

slab should be sufficient above grade to prevent ground water from entering the

unit.

IMPORTANT: To prevent transmission of noise or vibration, slab should not be

connected to building structure.

3. The location of the unit should be such as to provide proper access for inspection

and servicing.

4. Locate unit where operating sounds will not disturb owner or neighbors.

5. Locate unit so roof runoff water does not pour directly on the unit. Provide gutter

or other shielding at roof level. Do not locate unit in an area where excessive

snow drifting may occur or accumulate.

6. It is essential that the unit be elevated above the base pad to allow for condensate drainage and possible refreezing of condensation. Provide a base pad which

is slightly pitched away from the structure. Route condensate off base pad to an

area which will not become slippery and result in personal injury.

IMPORTANT: Avoid blocking openings in bottom of unit.

7. Where snowfall is anticipated, the height of the unit above the ground level must

be considered. Mount unit high enough to be above average area snowfall and to

allow for proper condensate drainage.

IMPORTANT: Avoid blocking openings in bottom of unit.

C. CLEARANCES

The following minimum clearances must be observed for proper unit performance

and serviceability.

1. Provide 30" minimum clearance at the front and 18" on the right side of the unit

for service access. Provide 12" minimum clearance on the left side of the unit for

air inlet.

2. Provide 60" minimum clearance from top of unit.

8

Page 9

3. Unit is design certified for application on combustible flooring with 0" minimum

clearance.

4. See Figure 2 for illustration of minimum installation-service clearances.

D. ROOFTOP INSTALLATION

1. Before locating the unit on the roof, make sure that the strength of the roof and

beams is adequate at that point to support the weight involved. (See specification

sheet for weight of unit.) This is very important and user’s responsibility.

2. The unit should be placed on a solid and level platform of adequate strength.

IM PO RTA NT: A void blocking ope nings in bottom of uni t. (See Figure 3).

rovision for disposal of outdoor coil defrost water runoff must be provided.

P

3. The location of the unit on the roof should be such as to provide proper access for

inspection and servicing.

IMPORTANT: If unit will not be put into service immediately, cover supply and return

openings to prevent excessive condensation.

VII. DUCTWORK

Ductwork should be fabricated by the installing contractor in accordance with local codes

and NFPA90A. Industry manuals may be used as a guide when sizing and designing the

duct system - contact Air Conditioning Contractors of America, 1513 16th St. N.W.,

Washington, D.C. 20036.

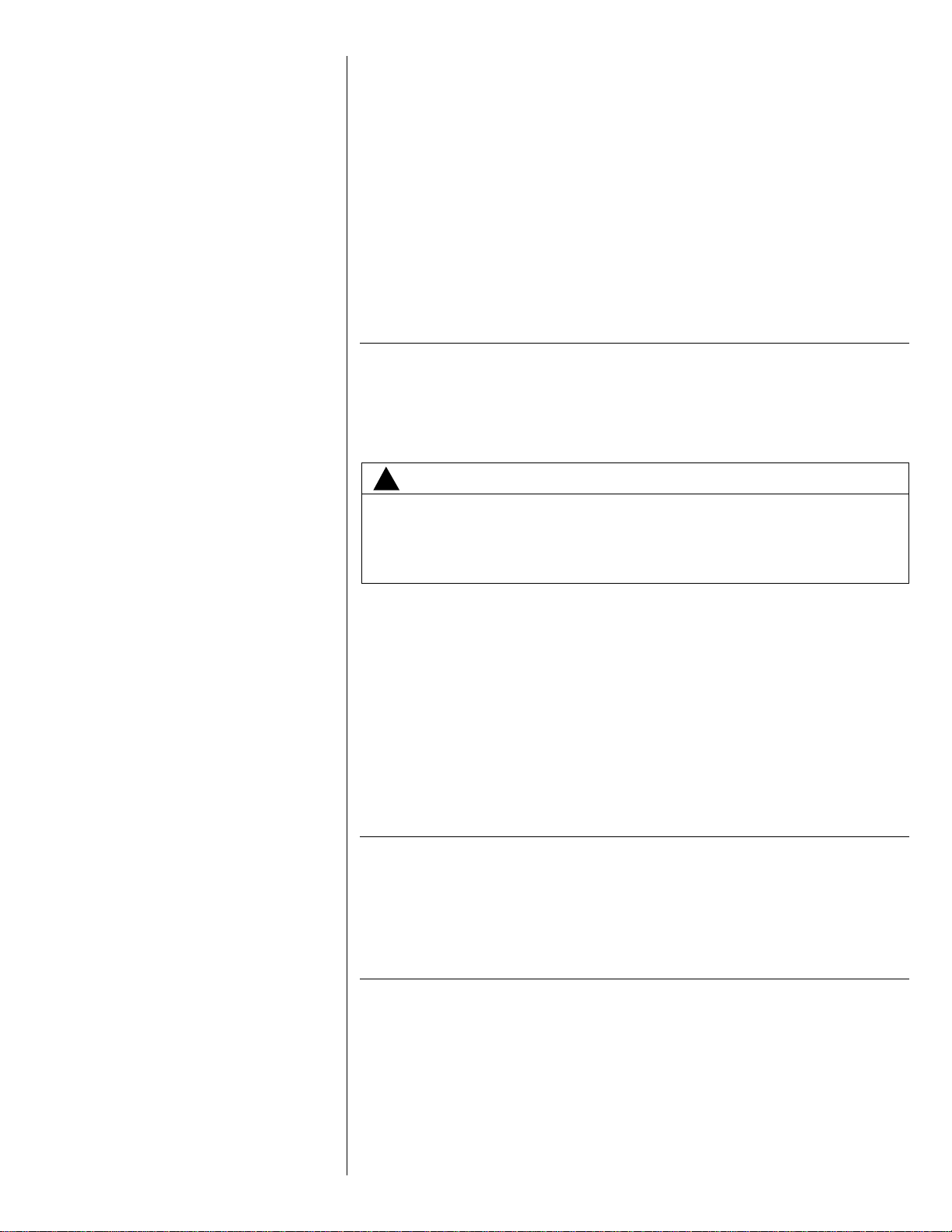

WARNING

!

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT RETURN DUCTWORK TO

ANY OTHER HEAT PRODUCING DEVICE SUCH AS A FIREPLACE INSERT,

STOVE, ETC. UNAUTHORIZED USE OF SUCH DEVICES MAY RESULT IN FIRE,

CA R BON M ONOXID E POI S ONING, EXPL O SION, PROP E R TY D AMAGE,

SEVERE PERSONAL INJURY OR DEATH.

Place the unit as close to the space to be air conditioned as possible allowing clearance

dimensions as indicated. Run ducts as directly as possible to supply and return outlets.

Use of non-flammable waterproof flexible connectors on both supply and return connections at the unit to reduce noise transmission is recommended.

It is preferable to install the unit on the roof of the structure if the registers or diffusers

are located on the wall or in the ceiling. Consider a slab installation when the registers

are low on a wall or in the floor.

On ductwork exposed to outside air conditions of temperature and humidity, use a minimum of 2" of insulation and a vapor barrier. Distribution system in attic, furred space or

crawl space should be insulated with at least 2" of insulation with vapor barrier. One-half

to 1" thickness of insulation is usually sufficient for ductwork inside the air conditioned

space.

Provide balancing dampers for each branch duct in the supply system. Properly support

the ductwork from the structure.

VIII.FILTERS

Filters are not provided with this unit. They must be supplied and installed in the return

air duct by the installer. A field installed filter grille is recommended for easy and convenient access to the filters for periodic inspection and cleaning. Filters must have adequate face area for the rated air quantity of the unit. See General Database for recommended filter size.

IX. CONDENSATE DRAIN

The indoor coil condensate drain ends with a PVC stub. A trap is provided in for proper

condensate drainage and to prevent debris from being drawn into the unit. Do not connect drain to closed sewer line. It is not recommended that a PVC cement or other permanent installation be used so that the drain line and/or drain pan can be easily cleaned

in the future. The drain trap is located in the control box during shipping. To install, slide

clear plastic tube over drain pan connection. The white PVC trap can be oriented as

required by installation.

9

Page 10

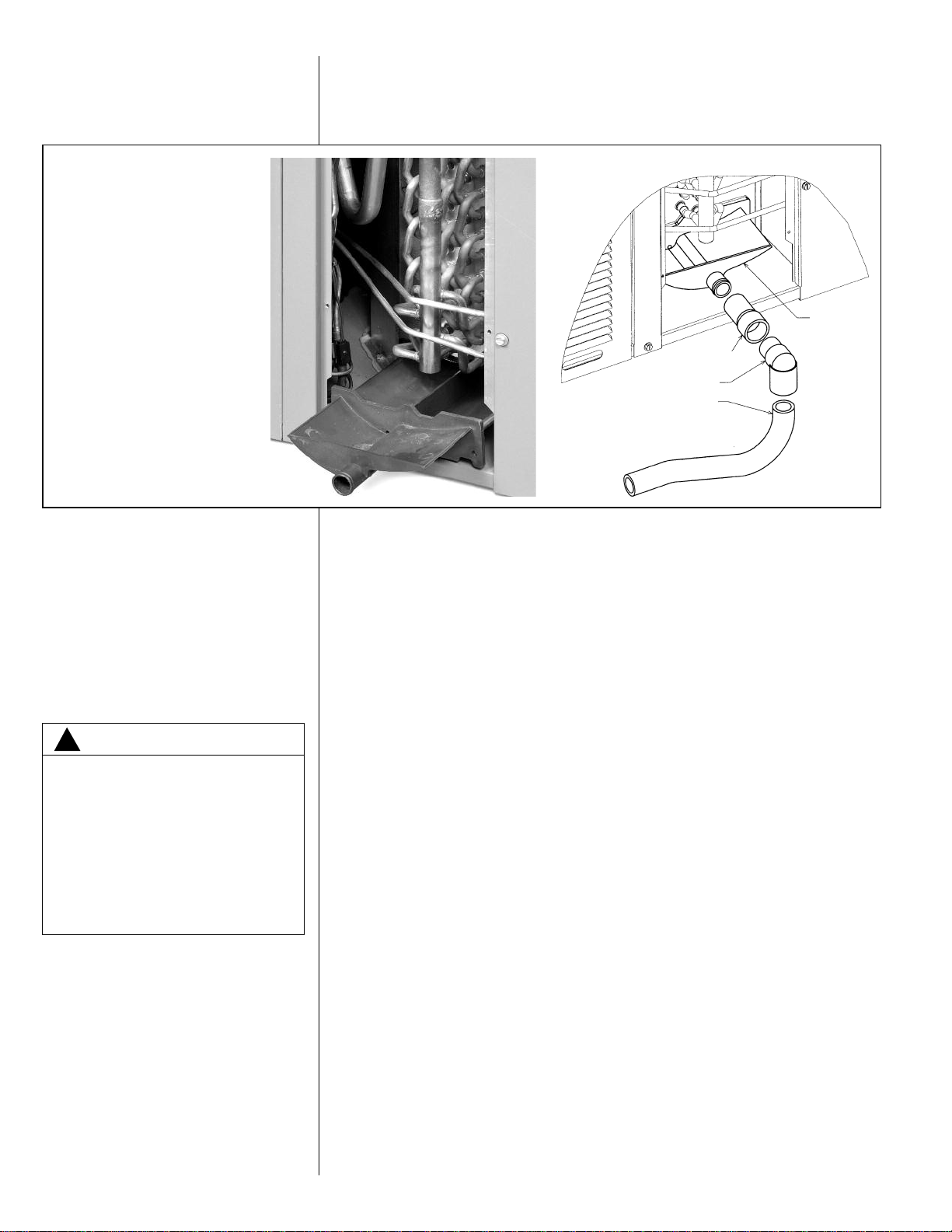

FIGURE 4

EMOVABLE CONDENSATE

R

DRAIN PAN AND REMOVAL

ROCEDURE

P

A small side panel grants

ccess to a removable, sloped

a

drain pan (A), which helps to

ensure indoor air quality (IAQ)

throughout the life of the unit. A

drain trap (B) assembly

is provided for

convenience.

X. CONDENSATE DRAIN, OUTDOOR COIL

The outdoor coil during heating operation will sweat or run water off. The outdoor coil will

also run water off during the defrost cycle. See Section V, Installation, for mounting pre-

autions.

c

RAINPAN

D

LEAR PVC

C

ONNECTOR TUBE

C

VC ELBOW

P

PVC TRAP

WARNING

!

TURN OFF ELECTRIC POWER AT

TH E FUS E BO X OR SERVICE

PA N E L BE F O RE MA KING ANY

ELECTRICAL CONNECTIONS.

ALSO, THE GROUND CONNECTION

MU ST BE COMPLETE D BEFOR E

MAKING LINE VOLTAGE CONNECTIONS. FAILURE TO DO SO CAN

RESULT IN ELECTRICAL SHOCK,

SEVERE PERSONAL INJURY OR

DEATH.

A

B

XI. ELECTRICAL WIRING

Field wiring must comply with the National Electrical Code* and applicable local codes.

*C.E.C. in Canada

A. POWER WIRING

1. It is important that proper electrical power is available at the unit. Voltage should

not vary more than 10% from that stamped on the unit rating plate. On three

phase units, phases must be balanced within 3%.

2. Install a branch circuit disconnect within sight of the unit and of adequate size to

handle the starting current. (See Heater Kit Tables.)

3. For branch circuit wiring (main power supply to unit disconnect), the minimum

wire size can be determined from the National Electrical Code or Canadian

Electrical Code or nameplate or from Heater Kit Tables.

4. This unit supports both single and dual point electrical connection for unit and

electric heat accessory.

5. Power wiring must be run in grounded rain-tight conduit.

B. POWER WIRING AND ELECTRIC HEATER KIT INSTRUCTIONS

1. Turn off power to unit.

2. Remove control box access panel.

3. Remove unit indoor section top cover.

4. Remove wire notch cover from control bulkhead and discard. Retain screw.

5. Remove heater element cover plate from blower outlet opening and discard. Retain

screws.

6. Mount heater fuse block assembly in location indicated with the three included

screws.

7. Route wire harness assembly through wire notch in control bulkhead and mount element assembly in blower outlet opening with screws previously retained.

8. Center wire routing plate over notch in blower bulkhead and secure with screw previously retained.

9. Route and tie wiring as shown in Figure 5. Wiring must not contact moving parts or

uninsulated electrical connections.

10. Replace unit indoor top cover.

11. Connect power and control wiring as indicated below:

a. Single-point wiring: Connect high voltage field power leads to heater kit fuse

block and connect included unit power pigtails from heater kit fuse block to unit

10

Page 11

FIGURE 5

EATER KIT INSTALLATION

H

contactor L1 and L3 connections. Connect ground lead to ground lug on heater kit

fuse block.

b. Dual-circuit wiring: Remove unit power pigtails from heater kit fuse block and

iscard. Connect one set of high voltage field power circuit leads to the heater kit

d

fuse block and connect ground lead to ground lug on heater kit fuse block.

Connect the second set of high voltage field power leads to L1 and L3 on the unit

contactor. Connect ground lead to ground lug on control box bulkhead.

c. Connect heater kit control plug to receptacle in control box.

12. Replace control box access panel.

3. Restore power to unit and verify proper unit and heater kit operation.

1

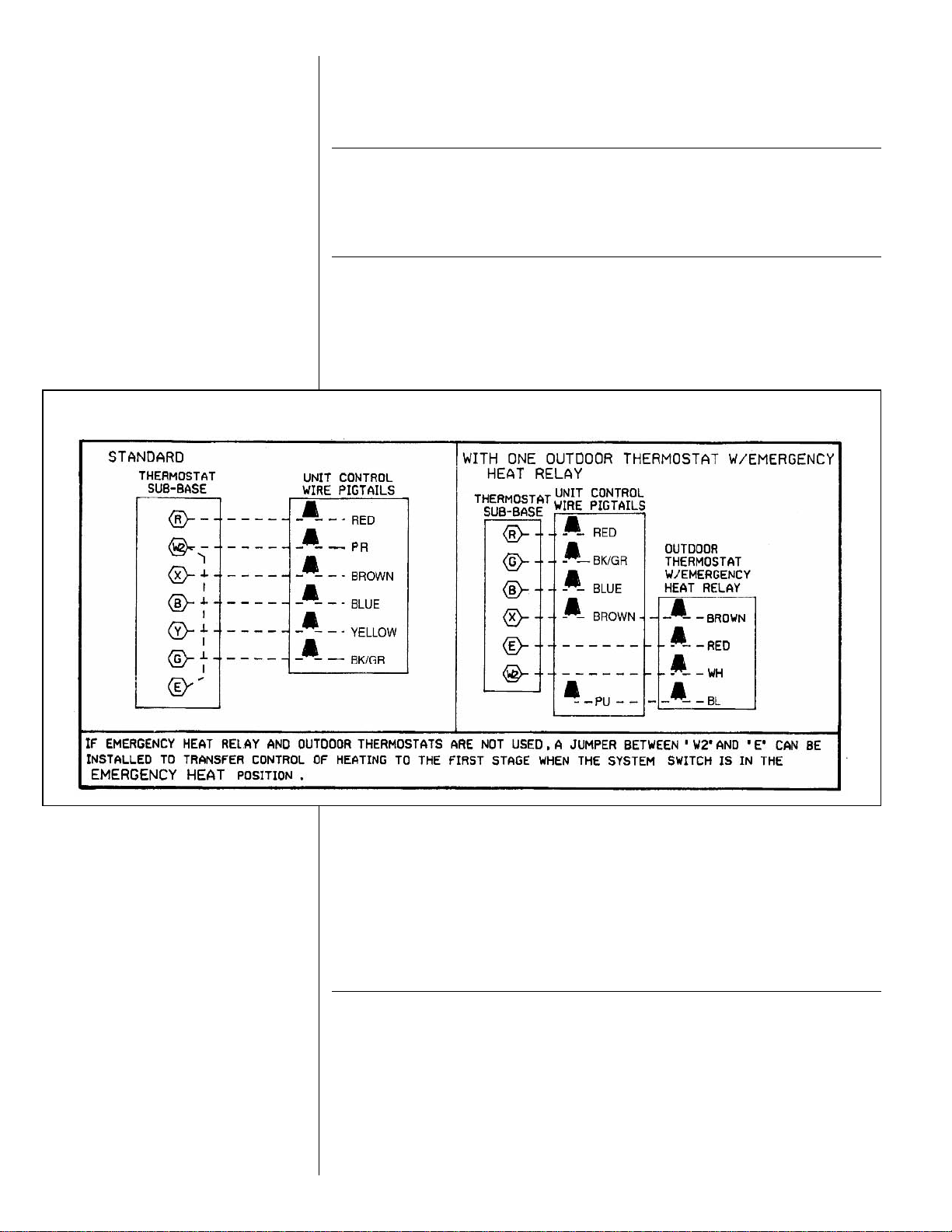

C. CONTROL WIRING (Class II)

1. Do not run low voltage wiring in conduit with power wiring.

2. Control wiring is routed through the 7/8" hole corner adjacent to the control box.

See Electrical Connections, Figure 1. Use a minimum #18 AWG thermostat wire.

For wire lengths exceeding 50', use #16 AWG thermostat wire. The low voltage

wires are connected to the unit pigtails which are supplied with the unit in the low

voltage connection box located within the unit control box. See Figure 5.

3. It is necessary that only heat pump thermostats be used.

4. Figure 6 shows representative low voltage connection diagrams. Read your thermostat installation instructions for any special requirements for your specific thermostat.

RECOMMENDED

WIRING

HEATER

KIT

WIRING

HEATER

ELEMENTS

NOTE — Units installed in Canada require that an outdoor thermostat (30,000

min. cycles of endurance) be installed and be wired with C.E.C. Class I wiring.

D. INTERNAL WIRING

1. A diagram of the internal wiring of this unit is located on the electrical control box

cover. If any of the original wire as supplied with the appliance must be replaced,

the wire gauge and insulation must be the same as original wiring.

E. GROUNDING

WARNING

!

THE UNIT MUST BE PERMANENTLY GROUNDED. A GROUNDING LUG IS

PROVIDED. FAILURE TO GROUND THIS UNIT CAN RESULT IN FIRE OR ELECTRICAL SHOCK CAUSING PROPERTY DAMAGE, SEVERE PERSONAL INJURY

OR DEATH.

11

Page 12

FIGURE 6

VOLTAGE CONNECTIONS DIAGRAM

F. THERMOSTAT

ount the thermostat on an inside wall about five feet above the floor in a location

M

where it will not be affected by unconditioned air, sun, or drafts from open doors or

other sources. READ installation instructions in heat pump thermostat package

CAREFULLY because each has some different wiring requirements.

XII. INDOOR AIR FLOW DATA

All 208/230 volt units are equipped with multi-speed indoor blower motors. Each unit is

shipped factory wired for the proper speed at a normal external static. See Airflow

Performance Table for blower performance.

XIII. PRE-START CHECK

1. Is unit properly located and level?

2. Is ductwork insulated, weatherproofed, with proper spacing to combustible materials?

3. Is air free to travel to and from outdoor coil? (See Figure 1.)

12

4. Is the wiring correct, tight, and according to unit wiring diagram?

5. Is unit grounded?

6. Are field supplied air filters in place and clean?

7. Do the outdoor fan and indoor blower turn freely without rubbing, and are they tight

on the motor shafts?

8. Has crankcase heat been on for at least 12 hours?

9. Is unit elevated to allow for outdoor coil condensate drainage during heating operation and defrost?

XIV.STARTUP

1. Turn thermostat to “OFF,” turn “on” power supply at disconnect switch.

2. Turn temperature setting as high as it will go.

3. Turn fan switch to “ON.”

4. Indoor blower should run. Be sure it is running in the right direction.

5. Turn fan switch to “AUTO.” Turn system switch to “COOL” and turn temperature setting below room temperature. Unit should run in cooling mode.

6. Is outdoor fan operating correctly in the right direction?

Page 13

7. Is compressor running correctly.

8. Turn thermostat system switch to “HEAT.” Unit should stop. Wait 5 minutes, then

raise temperature setting to above room temperature. Unit should run in heating

ode and after about 30 to 50 seconds auxiliary heaters, if installed, should come

m

on.

9. Check the refrigerant charge using the instructions located on control box cover.

Replace service port caps. Service port cores are for system access only and will

leak if not tightly capped.

urn thermostat system switch to proper mode “HEAT” or “COOL” and set thermostat

T

0

1

to proper temperature setting. Record the following after the unit has run some time.

A. Operating Mode _______________________________

B. Discharge Pressure (High) ___________________PSIG

C. Vapor Pressure at Compressor (Low) __________PSIG

. Vapor Line Temperature at Compressor __________°F.

D

E. Indoor Dry Bulb______________________________°F.

F. Indoor Wet Bulb _____________________________°F.

G. Outdoor Dry Bulb ____________________________°F.

H. Outdoor Wet Bulb ____________________________°F.

I. Voltage at Contactor ________________________Volts

J. Current at Contactor _______________________Amps

K. Model Number_________________________________

L. Serial Number _________________________________

M.Location______________________________________

N. Owner _______________________________________

O. Date_________________________________________

11. Adjust discharge air grilles and balance system.

12. Check ducts for condensation and air leaks.

13. Check unit for tubing and sheet metal rattles.

14. Instruct the owner on operation and maintenance.

15. Leave “USE AND CARE” instructions with owner.

XV. OPERATION

Most single phase units are not equipped with start relay or start capacitor. It is important that such systems be off for a minimum of 5

equalization of pressures. Do not move the thermostat to cycle unit without waiting five

minutes. To do so may cause the compressor to stop on an automatic open overload

device or blow a fuse. Poor electrical service can cause nuisance tripping in overloads

or blow fuses.

IMPORTANT: The compressor has an internal overload protector. Under some conditions, it can take up to 2 hours for this overload to reset. Make sure overload has had

time to reset before condemning the compressor.

These units are equipped with a time delay control (TDC1). The control allows the blower to operate for 45 to 90 seconds after the thermostat is satisfied.

minutes before restarting to allow

XVI. AUXILIARY HEAT

The amount of auxiliary heat required depends on the heat loss of the structure to be

heated and the capacity of the heat pump. It is good practice to install strip heat to maintain at least 60°F indoor temperatures in case of compressor failure. The auxiliary heat

is energized by the first stage of the thermostat. The amount of electric heat that is

allowed to come on, as determined by the output of the heat pump, may be controlled by

an outdoor thermostat.

WARNING

!

ONLY ELECTRIC HEATER KITS SUPPLIED BY THIS MANUFACTURER AS

DESCRIBED IN THIS PUBLICATION HAVE BEEN DESIGNED, TESTED, AND

EVALUATED BY A NATIONALLY RECOGNIZED SAFETY TESTING AGENCY

FOR USE WITH THIS UNIT. USE OF ANY OTHER MANUFACTURED ELECTRIC

HEATERS INSTALLED WITHIN THIS UNIT MAY CAUSE HAZARDOUS CONDITIONS R ESU LTI NG IN PR OPE RTY DAMAGE, FIRE, BODILY INJURY OR

DEATH.

A. CONTROL SYSTEM OPERATION

1. In the cooling mode, the thermostat will, on a call for cooling, energize the com-

pressor contactor and the indoor blower relay. The indoor blower can be operated

continuously by setting the thermostat fan switch at the “ON” position.

13

Page 14

2. In the heating mode, the first heat stage of the thermostat will energize one or

more supplementary resistance heaters. If required or considered desirable, the

resistance heat may also be controlled by outdoor thermostats. In the heating

mode, the thermostat will, on a call for heating, energize the indoor blower relay.

XVII. DEMAND DEFROST CONTROL

The demand defrost control is a printed circuit board assembly consisting of solid state

control devices with electro-mechanical outputs. The demand defrost control monitors

the outdoor ambient temperature, outdoor coil temperature, and the compressor runtime to determine when a defrost cycle is required.

DEFROST INITIATION

A defrost will be initiated when the three conditions below are satisfied:

1) The outdoor coil temperature is below 35°F.

2) The compressor has operated for at least 34 minutes with the outdoor coil temperature below 35°F.

3) The measured difference between the ambient temperature and the outdoor coil

temperature is greater than the calculated delta T.

Additionally, a defrost will be initiated if six hours of accumulated compressor run-time

has elapsed without a defrost with the outdoor coil temperature below 35°F.

DEFROST TERMINATION

Once a defrost is initiated, the defrost will continue until fourteen minutes has elapsed or

the coil temperature has reached the terminate temperature. The terminate temperature

is factory set at 70°F, although the temperature can be changed to 50°F, 60°F, 70°F or

80°F by relocating a jumper on the board.

TEMPERATURE SENSORS

The coil sensor is clipped to the top tube on the outdoor coil at the point fed by the distribution tubes from the expansion device (short 3/8" dia. tube). The air sensor is located

behind the compressor access panel.

If the ambient sensor fails the defrost control will initiate a defrost every 34 minutes with

the coil temperature below 35°F.

If the coil sensor fails the defrost control will not initiate a defrost.

TEST MODE

The test mode is initiated by shorting the TEST pins. In this mode of operation, the

enable temperature is ignored and all timers are sped up by a factor of 240. To initiate a

manual defrost, short the TEST pins. Remove the short when the system switches to

defrost mode. The defrost will terminate on time (14 minutes) or when the termination

temperature has been achieved. Short TEST pins again to terminate the defrost immedi-

ately.

TROUBLE SHOOTING DEMAND DEFROST

Set the indoor thermostat select switch to heat and thermostat lever to a call for heat.

Jumper the “test pins” to put the unit into defrost. If the unit goes into defrost and comes

back out of defrost, the indication is that the control is working properly.

If the unit did not go into defrost using the test pins, check to ensure that 24V is being

supplied to the control board. If 24V is present then replace the control.

14

Page 15

Model RQPM- Series A024J

K

A030J

K

A036C

K

A036J

K

Cooling Performance

1

Continued ->

Gross Cooling Capacity Btu [kW] 24,000 [7.03] 29,400 [8.61] 36,000 [10.55] 36,000 [10.55]

EER/SEER

2

12/14 12.05/14 11.6/14 11.6/14

Nominal CFM/ARI Rated CFM [L/s] 800/800 [378/378] 1000/1000 [472/472] 1200/1200 [566/566] 1200/1200 [566/566]

ARI Net Cooling Capacity Btu [kW] 23,600 [6.91] 29,000 [8.5] 35,400 [10.37] 35,400 [10.37]

Net Sensible Capacity Btu [kW] 18,400 [5.39] 23,000 [6.74] 27,600 [8.09] 27,600 [8.09]

Net Latent Capacity Btu [kW] 5,200 [1.52] 6,000 [1.76] 7,800 [2.29] 7,800 [2.29]

Net System Power kW 2 2.41 3.05 3.05

High Temp. Btuh [kW] Rating 23,200 [6.8] 28,000 [8.2] 34,200 [10.02] 34,200 [10.02]

System Power KW / COP 1.93/3.5 2.27/3.62 2.78/3.6 2.78/3.6

Low Temp. Btuh [kW] Rating 13,200 [3.87] 15,200 [4.45] 19,000 [5.57] 19,000 [5.57]

System Power KW / COP 1.71/2.26 2.01/2.22 2.48/2.24 2.48/2.24

HSPF (Btu/Watts-hr) 8 8 8 8

Compresso

r

No./Type 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll

Outdoor Sound Rating (dB)

76 76 76 76

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 10.44 [0.97] 12.65 [1.18] 12.65 [1.18] 12.65 [1.18]

Rows / FPI [FPcm] 1 / 20 [8] 1 / 20 [8] 1 / 20 [8] 1 / 20 [8]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 4.33 [0.4] 4.33 [0.4] 4.33 [0.4] 4.33 [0.4]

Rows / FPI [FPcm] 2 / 15 [6] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 3200 [1510] 3200 [1510] 3200 [1510] 3200 [1510]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 825 825 825 825

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/10x9 [254x228.6] 1/10x9 [254x228.6] 1/10x9 [254x228.6] 1/10x9 [254x228.6]

Drive Type/No. Speeds Direct/2 Direct/2 Direct/2 Direct/2

No. Motors 1 1 1 1

Motor HP 1/2 1/2 1/2 1/2

Motor RPM 1050 1050 1050 1050

Motor Frame Size 48 48 48 48

Filter - Type Field Supplied Field Supplied Field Supplied Field Supplied

Furnished No No No No

(NO.) Size Recommended in. [mm x mm x mm] (1)1x20x16 [25x508x406] (1)1x20x20 [25x508x508] (1)1x24x24 [25x610x610] (1)1x24x24 [25x610x610]

Refrigerant Charge Oz. [g] 90 [2552] 93 [2637] 93 [2637] 93 [2637]

Weights

Net Weight lbs. [kg] 308 [140] 331 [150] 356 [161] 356 [161]

Ship Weight lbs. [kg] 332 [151] 355 [161] 380 [172] 380 [172]

Heating Performance (Heat Pumps)

3

4

XVIII. GENERAL DATA - RQPM

NOMINAL SIZES 2-5 TONS [7-17.6 kW]

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. ARI capacity

is net and includes the effect of fan motor heat. Units are suitable for operation in CFM range shown in airflow tables. Units are certified in accordance with the Unitary Air

Conditioner Equipment certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Heating Performance is rated at 47° F ambient, 70° F entering dry bulb for High Temp rating and 17° F ambient, 70° F entering dry bulb for Low Temp rating. Performance

ratings do include the effect of fan motor heat.

4. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.

15

Page 16

Model RQPM- Series A042C

K

A042J

K

A048C

K

A048J

K

Cooling Performance

1

Continued ->

Gross Cooling Capacity Btu [kW] 44,000 [12.89] 44,000 [12.89] 49,000 [14.36] 49,000 [14.36]

EER/SEER

2

11.85/14 11.85/14 11.8/14 11.8/14

Nominal CFM/ARI Rated CFM [L/s] 1400/1450 [661/684] 1400/1450 [661/684] 1600/1550 [755/731] 1600/1550 [755/731]

ARI Net Cooling Capacity Btu [kW] 43,000 [12.6] 43,000 [12.6] 48,000 [14.06] 48,000 [14.06]

Net Sensible Capacity Btu [kW] 31,800 [9.32] 31,800 [9.32] 36,800 [10.78] 36,800 [10.78]

Net Latent Capacity Btu [kW] 11,200 [3.28] 11,200 [3.28] 11,200 [3.28] 11,200 [3.28]

Net System Power kW 3.63 3.63 4.1 4.1

Heating Performance (Heat Pumps)

High Temp. Btuh [kW] Rating 38,500 [11.28] 38,500 [11.28] 4 ,000 [1 ] 4 ,000 [1 ]

System Power KW / COP 3.31/3.4 3.31/3.4 3.59/3.66 3.59/3.66

Low Temp. Btuh [kW] Rating 21,800 [6.39] 21,800 [6.39] 25,400 [7.44] 25,400 [7.44]

System Power KW / COP 3/2.06 3/2.06 3.22/2.3 3.22/2.3

HSPF (Btu/Watts-hr) 8 8 8 8

Compresso

r

No./Type 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll

Outdoor Sound Rating (dB)

78 78 78 78

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 16.54 [1.54] 16.54 [1.54] 16.54 [1.54] 16.54 [1.54]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 5.78 [0.54] 5.78 [0.54] 5.78 [0.54] 5.78 [0.54]

Rows / FPI [FPcm] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 4200 [1982] 4200 [1982] 4200 [1982] 4200 [1982]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/11x9 [279.4x228.6] 1/11x9 [279.4x228.6] 1/11x9 [279.4x228.6] 1/11x9 [279.4x228.6]

Drive Type/No. Speeds Direct/2 Direct/2 Direct/2 Direct/2

No. Motors 1 1 1 1

Motor HP 3/4 3/4 3/4 3/4

Motor RPM 1050 1050 1050 1050

Motor Frame Size 48 48 48 48

Filter - Type Field Supplied Field Supplied Field Supplied Field Supplied

Furnished No No No No

(NO.) Size Recommended in. [mm x mm x mm] (1)1x24x24 [25x610x610] (1)1x24x24 [25x610x610] (1)1x24x24 [25x610x610] (1)1x24x24 [25x610x610]

Refrigerant Charge Oz. [g] 128 [3629] 128 [3629] 120 [3402] 120 [3402]

Weights

Net Weight lbs. [kg] 408 [185] 408 [185] 429 [195] 429 [195]

Ship Weight lbs. [kg] 434 [197] 434 [197] 455 [206] 455 [206]

3

4

2 2.31 2 2.31

GENERAL DATA - RQPM

NOMINAL SIZES 2-5 TONS [7-17.6 kW]

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. ARI capacity

is net and includes the effect of fan motor heat. Units are suitable for operation in CFM range shown in airflow tables. Units are certified in accordance with the Unitary Air

Conditioner Equipment certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Heating Performance is rated at 47° F ambient, 70° F entering dry bulb for High Temp rating and 17° F ambient, 70° F entering dry bulb for Low Temp rating. Performance

ratings do include the effect of fan motor heat.

4. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.

16

Page 17

Model RQPM- Series A060C

K

A060J

K

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 61,000 [17.87] 61,000 [17.87]

EER/SEER

2

11.9/14 11.9/14

Nominal CFM/ARI Rated CFM [L/s] 2000/1900 [944/897] 2000/1900 [944/897]

ARI Net Cooling Capacity Btu [kW] 59,500 [17.43] 59,500 [17.43]

Net Sensible Capacity Btu [kW] 45,300 [13.27] 45,300 [13.27]

Net Latent Capacity Btu [kW] 14,200 [4.16] 14,200 [4.16]

Net System Power kW 5 5

Heating Performance (Heat Pumps)

High Temp. Btuh [kW] Rating 59,500 [17.43] 59,500 [17.43]

System Power KW / COP 4.74/3.72 4.74/3.72

Low Temp. Btuh [kW] Rating 36,600 [10.72] 36,600 [10.72]

System Power KW / COP 4.26/2.54 4.26/2.54

HSPF (Btu/Watts-hr) 8 8

Compresso

r

No./Type 1/Copeland Scroll 1/Copeland Scroll

Outdoor Sound Rating (dB)

78 78

Outdoor Coil - Fin Type Louvered Louvered

Tube Type Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 16.54 [1.54] 16.54 [1.54]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered

Tube Type Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 5.78 [0.54] 5.78 [0.54]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan - Type Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1

CFM [L/s] 4000 [1888] 4000 [1888]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/11x9 [279.4x228.6] 1/11x9 [279.4x228.6]

Drive Type/No. Speeds Direct/2 Direct/2

No. Motors 1 1

Motor HP 1 1

Motor RPM 1050 1050

Motor Frame Size 48 48

Filter - Type Field Supplied Field Supplied

Furnished No No

(NO.) Size Recommended in. [mm x mm x mm] (1)1x24x24 [25x610x610] (1)1x24x24 [25x610x610]

Refrigerant Charge Oz. [g] 193 [5472] 193 [5472]

Weights

Net Weight lbs. [kg] 481 [218] 481 [218]

Ship Weight lbs. [kg] 507 [230] 507 [230]

3

4

GENERAL DATA - RQPM

NOMINAL SIZES 2-5 TONS [7-17.6 kW]

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. ARI capacity

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Heating Performance is rated at 47° F ambient, 70° F entering dry bulb for High Temp rating and 17° F ambient, 70° F entering dry bulb for Low Temp rating. Performance

4. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.

is net and includes the effect of fan motor heat. Units are suitable for operation in CFM range shown in airflow tables. Units are certified in accordance with the Unitary Air

Conditioner Equipment certification program, which is based on ARI Standard 210/240 or 360.

ratings do include the effect of fan motor heat.

17

Page 18

Model RQNM- Series A024J

K

A030J

K

A036C

K

A036J

K

Cooling Performance

1

Continued ->

Gross Cooling Capacity Btu [kW] 24,600 [7.21] 29,800 [8.73] 36,600 [10.72] 36,600 [10.72]

EER/SEER

2

11/13 11.15/13 11/13 11/13

Nominal CFM/ARI Rated CFM [L/s] 800/800 [378/378] 1000/1000 [472/472] 1200/1200 [566/566] 1200/1200 [566/566]

ARI Net Cooling Capacity Btu [kW] 23,600 [6.91] 28,800 [8.44] 35,200 [10.31] 35,200 [10.31]

Net Sensible Capacity Btu [kW] 18,200 [5.33] 22,400 [6.56] 27,000 [7.91] 27,000 [7.91]

Net Latent Capacity Btu [kW] 5,400 [1.58] 6,400 [1.88] 8,200 [2.4] 8,200 [2.4]

Net System Power kW 2.14 2.58 3.2 3.2

Heating Performance (Heat Pumps)

High Temp. Btuh [kW] Rating 23,400 [6.86] 28,800 [8.44] 35,000 [10.26] 35,000 [10.26]

System Power KW / COP 2.07/3.34 2.45/3.44 2.95/3.48 2.95/3.48

Low Temp. Btuh [kW] Rating 13,800 [4.04] 16,200 [4.75] 19,200 [5.63] 19,200 [5.63]

System Power KW / COP 1.91/2.12 2.22/2.14 2.65/2.1 2.65/2.1

HSPF (Btu/Watts-hr) 7.7 7.7 7.7 7.7

Compresso

r

No./Type 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll

Outdoor Sound Rating (dB)

76 76 76 76

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 10.44 [0.97] 12.65 [1.18] 12.65 [1.18] 12.65 [1.18]

Rows / FPI [FPcm] 1 / 20 [8] 1 / 20 [8] 1 / 20 [8] 1 / 20 [8]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 4.33 [0.4] 4.33 [0.4] 4.33 [0.4] 4.33 [0.4]

Rows / FPI [FPcm] 3 / 13 [5] 3 / 13 [5]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 3200 [1510] 3200 [1510] 3200 [1510] 3200 [1510]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 825 825 825 825

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/10x9 [254x228.6] 1/10x9 [254x228.6] 1/10x9 [254x228.6] 1/10x9 [254x228.6]

Drive Type/No. Speeds Direct/2 Direct/2 Direct/2 Direct/2

No. Motors 1 1 1 1

Motor HP 1/4 1/3 1/2 1/2

Motor RPM 1033 1080 1050 1050

Motor Frame Size 48 48 48 48

Filter - Type Field Supplied Field Supplied Field Supplied Field Supplied

Furnished No No No No

(NO.) Size Recommended in. [mm x mm x mm] (1)1x20x16 [25x508x406] (1)1x20x20 [25x508x508] (1)1x24x24 [25x610x610] (1)1x24x24 [25x610x610]

Refrigerant Charge Oz. [g] 90 [2552] 93 [2637] 93 [2637] 93 [2637]

Weights

Net Weight lbs. [kg] 308 [140] 331 [150] 356 [161] 356 [161]

Ship Weight lbs. [kg] 332 [151] 355 [161] 380 [172] 380 [172]

3

4

2 / 15 [5] 3 / 13 [6]

GENERAL DATA - RQNM

NOMINAL SIZES 2-5 TONS [7-17.6 kW]

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. ARI capacity

is net and includes the effect of fan motor heat. Units are suitable for operation in CFM range shown in airflow tables. Units are certified in accordance with the Unitary Air

Conditioner Equipment certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Heating Performance is rated at 47° F ambient, 70° F entering dry bulb for High Temp rating and 17° F ambient, 70° F entering dry bulb for Low Temp rating. Performance

ratings do include the effect of fan motor heat.

4. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.

18

Page 19

Model RQNM- Series A042C

K

A042J

K

A048C

K

A048J

K

Cooling Performance

1

Continued ->

Gross Cooling Capacity Btu [kW] 43,500 [12.75] 43,500 [12.75] 49,500 [14.5] 49,500 [14.5]

EER/SEER

2

11/13 11/13 11/13 11/13

Nominal CFM/ARI Rated CFM [L/s] 1400/1450 [661/684] 1400/1450 [661/684] 1600/1550 [755/731] 1600/1550 [755/731]

ARI Net Cooling Capacity Btu [kW] 42,000 [12.31] 42,000 [12.31] 47,500 [13.92] 47,500 [13.92]

Net Sensible Capacity Btu [kW] 30,000 [8.79] 30,000 [8.79] 35,900 [10.52] 35,900 [10.52]

Net Latent Capacity Btu [kW] 12,000 [3.52] 12,000 [3.52] 11,600 [3.4] 11,600 [3.4]

Net System Power kW 3.82 3.82 4.32 4.32

Heating Performance (Heat Pumps)

High Temp. Btuh [kW] Rating 39,500 [11.57] 39,500 [11.57] 43,000 [12.6] 43,000 [12.6]

System Power KW / COP 3.56/3.24 3.56/3.24 3.92/3.44 3.92/3.44

Low Temp. Btuh [kW] Rating 22,800 [6.68] 22,800 [6.68] 25,600 [7.5] 25,600 [7.5]

System Power KW / COP 3.25/2.06 3.25/2.06 3.56/2.14 3.56/2.14

HSPF (Btu/Watts-hr) 7.7 7.7 7.7 7.7

Compresso

r

No./Type 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll

Outdoor Sound Rating (dB)

78 78 78 78

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 16.54 [1.54] 16.54 [1.54] 16.54 [1.54] 16.54 [1.54]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 5.78 [0.54] 5.78 [0.54] 5.78 [0.54] 5.78 [0.54]

Rows / FPI [FPcm] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 4200 [1982] 4200 [1982] 4200 [1982] 4200 [1982]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/11x9 [279.4x228.6] 1/11x9 [279.4x228.6] 1/11x9 [279.4x228.6] 1/11x9 [279.4x228.6]

Drive Type/No. Speeds Direct/2 Direct/2 Direct/2 Direct/2

No. Motors 1 1 1 1

Motor HP 1/2 1/2 3/4 3/4

Motor RPM 1075 1075 1075 1075

Motor Frame Size 48 48 48 48

Filter - Type Field Supplied Field Supplied Field Supplied Field Supplied

Furnished No No No No

(NO.) Size Recommended in. [mm x mm x mm] (1)1x24x24 [25x610x610] (1)1x24x24 [25x610x610] (1)1x24x24 [25x610x610] (1)1x24x24 [25x610x610]

Refrigerant Charge Oz. [g] 128 [3629] 128 [3629] 120 [3402] 120 [3402]

Weights

Net Weight lbs. [kg] 408 [185] 408 [185] 429 [195] 429 [195]

Ship Weight lbs. [kg] 434 [197] 434 [197] 455 [206] 455 [206]

3

4

GENERAL DATA - RQNM

NOMINAL SIZES 2-5 TONS [7-17.6 kW]

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. ARI capacity

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Heating Performance is rated at 47° F ambient, 70° F entering dry bulb for High Temp rating and 17° F ambient, 70° F entering dry bulb for Low Temp rating. Performance

4. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.

is net and includes the effect of fan motor heat. Units are suitable for operation in CFM range shown in airflow tables. Units are certified in accordance with the Unitary Air

Conditioner Equipment certification program, which is based on ARI Standard 210/240 or 360.

ratings do include the effect of fan motor heat.

19

Page 20

Model RQNM- Series A060C

K

A060J

K

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 62,000 [18.17] 62,000 [18.17]

EER/SEER

2

11/13 11/13

Nominal CFM/ARI Rated CFM [L/s] 2000/1900 [944/897] 2000/1900 [944/897]

ARI Net Cooling Capacity Btu [kW] 59,000 [17.29] 59,000 [17.29]

Net Sensible Capacity Btu [kW] 44,500 [13.04] 44,500 [13.04]

Net Latent Capacity Btu [kW] 14,500 [4.25] 14,500 [4.25]

Net System Power kW 5.36 5.36

Heating Performance (Heat Pumps)

High Temp. Btuh [kW] Rating 61,000 [17.87] 61,000 [17.87]

System Power KW / COP 5.15/3.52 5.15/3.52

Low Temp. Btuh [kW] Rating 34,400 [10.08] 34,400 [10.08]

System Power KW / COP 4.64/2.18 4.64/2.18

HSPF (Btu/Watts-hr) 7.7 7.7

Compresso

r

No./Type 1/Copeland Scroll 1/Copeland Scroll

Outdoor Sound Rating (dB)

78 78

Outdoor Coil - Fin Type Louvered Louvered

Tube Type Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 16.54 [1.54] 16.54 [1.54]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered

Tube Type Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 5.78 [0.54] 5.78 [0.54]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan - Type Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1

CFM [L/s] 4000 [1888] 4000 [1888]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/11x9 [279.4x228.6] 1/11x9 [279.4x228.6]

Drive Type/No. Speeds Direct/2 Direct/2

No. Motors 1 1

Motor HP 3/4 3/4

Motor RPM 1075 1075

Motor Frame Size 48 48

Filter - Type Field Supplied Field Supplied

Furnished No No

(NO.) Size Recommended in. [mm x mm x mm] (1)1x24x24 [25x610x610] (1)1x24x24 [25x610x610]

Refrigerant Charge Oz. [g] 193 [5472] 193 [5472]

Weights

Net Weight lbs. [kg] 481 [218] 481 [218]

Ship Weight lbs. [kg] 507 [230] 507 [230]

3

4

GENERAL DATA - RQNM

NOMINAL SIZES 2-5 TONS [7-17.6 kW]

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. ARI capacity

is net and includes the effect of fan motor heat. Units are suitable for operation in CFM range shown in airflow tables. Units are certified in accordance with the Unitary Air

Conditioner Equipment certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Heating Performance is rated at 47° F ambient, 70° F entering dry bulb for High Temp rating and 17° F ambient, 70° F entering dry bulb for Low Temp rating. Performance

ratings do include the effect of fan motor heat.

4. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.

20

Page 21

XIX. MISCELLANEOUS

-A024JK -A030JK -A036CK -A036JK -A042CK -A042JK -A048CK -A048JK -A060CK -A060JK

Unit Operating

Voltage Range

187-253 187-253 187-253 187-253 187-253 187-253 187-253 187-253 187-253 187-253

Minimum Circuit

Ampacity

23/23 21/21 19/19 27/27 26/26 36/36 26/26 36/36 32/32 43/43

Minimum Overcurrent

Protection Device Size

3

0/30 30/30 25/25 35/35 30/30 45/45 30/30 45/45 40/40 50/50

Maximum Overcurrent

P

rotection Device Size

35/35 35/35 25/25 40/40 35/35 50/50 35/35 50/50 45/45 60/60

N

o. 1111111111

Volts 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230

P

hase 1131313131

HP 2 2.5 3 3 3.5 3.5 4 4 4.5 4.5

RPM 3450 3450 3450 3450 3450 3450 3450 3450 3450 3450

Amps (RLA) 13.5/13.5 14.1/14.1 10.4/10.4 16.7/16.7 14.1/14.1 21.8/21.8 13.7/13.7 21.8/21.8 17.9/17.9 26.4/26.4

Amps (LRA) 58.3/58.3 73/73 88/88 79/79 95/95 112/112 110/110 117/117 120/120 150/150

No. 1111111111

Volts 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230

Phase 1111111111

HP 1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/3

Amps (FLA) 1.5 1.5 1.5 1.5 1.9 1.9 1.9 1.9 1.9 1.9

Amps (LRA) 3 3 3 3 4 4 4 4 4 4

No. 1111111111

Volts 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230

Phase 1111111111

HP 1/2 1/2 1/2 1/2 3/4 3/4 3/4 3/4 1 1

Amps (FLA) 4.1 4.1 4.1 4.1 6 6 6 6 7.6 7.6

Evaporator Fan

ELECTRICAL DATA - RQPM SERIES

Unit InformationCompressor MotorCondenser Motor

ELECTRICAL AND PHYSICAL DATA

21

Page 22

-A024JK -A030JK -A036CK -A036JK -A042CK -A042JK -A048CK -A048JK -A060CK -A060JK

Unit Operating

Voltage Range

187-253 187-253 187-253 187-253 187-253 187-253 187-253 187-253 187-253 187-253

Minimum Circuit

Ampacity

2

0/20 21/21 17/17 25/25 23/23 33/33 23/23 33/33 31/31 41/41

Minimum Overcurrent

Protection Device Size

25/25 25/25 20/20 30/30 30/30 40/40 30/30 40/40 35/35 50/50

Maximum Overcurrent

Protection Device Size

3

0/30 35/35 25/25 40/40 35/35 50/50 35/35 50/50 45/45 60/60

No. 1111111111

Volts 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230

Phase 1131313131

HP 2 2.5 3 3 3.5 3.5 4 4 4.5 4.5

RPM 3450 3450 3450 3450 3450 3450 3450 3450 3450 3450

Amps (RLA) 13.5/13.5 14.1/14.1 10.4/10.4 16.7/16.7 14.1/14.1 21.8/21.8 13.7/13.7 21.8/21.8 17.9/17.9 26.4/26.4

Amps (LRA) 58.3/58.3 73/73 88/88 79/79 95/95 112/112 83.1/83.1 117/117 120/120 150/150

No. 1111111111

Volts 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230

Phase 1111111111

HP 1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/3 1/3

Amps (FLA) 1.5 1.5 1.5 1.5

Amps (LRA) 3 3 3 3 4 4 4 4 4 4

No. 1111111111

Volts 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230 208/230

Phase 1111111111

HP 1/4 1/3 1/2 1/2 1/2 1/2 3/4 3/4 3/4 3/4

Amps (FLA) 1.5 1.7 2.5 2.5 2.7 2.7 3.2 3.2 5.8 5.8

Amps (LRA) 2.6 2.6 5 5 4.6 4.6 4.4 4.4 11.3 11.3

ELECTRICAL DATA - RQNM SERIES

Unit InformationCompressor MotorCondenser MotorEvaporator Fan

1.9 1.

9

1.9 1.9 1.9 1.9

ELECTRICAL AND PHYSICAL DATA

22

Page 23

INDOOR AIRFLOW PERFORMANCE FOR 2-5 TON PACKAGE HEAT PUMPS – 230V

CFM Air Delivery/RPM/Watts-230 Volts

External Static Pressure-Inches W.C.

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00

CFM 939 877 816 754 693 631 570 508 447

10x9 RPM 585 601 655 744 809 860 915 1001 1043

1/4 Watts 131 116 97 110 121 126 136 149 152

2 Speed CFM 1240 1184 1127 1071 1014 958 901 845 788 732

(X-13 Motor) RPM 607 634 698 761 815 880 946 989 1038 1091

Watts 161 145 159 173 182 196 210 220 231 237

CFM 1169 1109 1049 988 928 868 807 747 687 626

10x9 RPM 603 619 693 756 809 893 942 989 1034 1076

1/3 Watts 144 130 138 151 159 174 185 195 199 209

2 Speed CFM 1365 1316 1266 1217 1168 1119 1069 1020 971 922

(X-13 Motor) RPM 631 677 732 784 843 894 942 1035 1077 1118

Watts 177 190 204 218 234 247 256 279 289 294

CFM 1328 1280 1231 1183 1135 1086 1038 990 941 893

10x9 RPM 648 697 752 807 857 903 989 1036 1077 1114

1/2 Watts 178 191 206 220 233 246 265 277 286 291

2 Speed CFM 1510 1464 1418 1373 1327 1281 1235 1190 1144 1098

(X-13 Motor) RPM 707 743 792 841 890 5021 981 1031 1114 1151

Watts 248 261 277 292 307 322 334 348 366 358

CFM 1542 1490 1438 1386 1335 1283 1231 1180 1128 1076

11x9 RPM 598 617 662 714 758 800 849 876 913 951

1/2 Watts 244 231 237 254 270 285 304 313 326 340

2 Speed CFM 1740 1695 1649 1604 1558 1513 1467 1422 1376 1331

(X-13 Motor) RPM 632 665 709 749 797 833 879 917 951 981

Watts 295 311 331 350 371 386 409 426 440 454

CFM 1701 1655 1609 1563 1517 1471 1425 1379 1333 1287

11x9 RPM 624 648 696 743 787 826 863 895 934 970

3/4 Watts 280 287 309 328 347 363 380 392 410 426

2 Speed CFM 1921 1878 1835 1792 1749 1706 1663 1620 1577 1534

(X-13 Motor) RPM 678 706 738 776 816 865 899 932 967 994

Watts 385 400 416 439 458 484 501 517 537 550

CFM 1986 1945 1905 1864 1823 1782 1741 1700 1659 1618

11x9 RPM 731 759 792 832 871 909 943 979 1014 1055

3/4 Watts 446 458 477 499 521 543 562 582 600 621

2 Speed CFM 2229 2190 2152 2114 2075 2037 1999 1960 1922 1884

(X-13 Motor) RPM 795 824 851 882 919 952 983 1013 1045 1077

Watts 619 638 658 680 703 724 745 764 784 804

Nominal

Cooling

Capacity

Tons

Motor Speed

From Factor

y

Blower Size/

Motor HP #

of S

p

eeds

Motor

S

p

eed

Manufacturer

Recommended Air

-

Flow Range

(

Min / Max

)

CFM

2.0

2.5

3.0

3.5

4.0

5.0 Low (Tap 2)

Low (Tap 2)

Low (Tap 2)

Low (Tap 2)

Low (Tap 2)

Low (Tap 2) 700 / 900

875 / 1125

1050 / 1350

1225 / 1575

1400 / 1800

1750 / 2250

Low

(Tap 2)

High

(Tap 1)

Low

(Tap 2)

High

(Tap 1)

Low

(Tap 2)

High

(Tap 1)

Low

(Tap 2)

High

(Tap 1)

Low

(Tap 2)

High

(Tap 1)

Low

(Tap 2)

High

(Tap 1)

RQPM SERIES

23

Page 24

INDOOR AIRFLOW PERFORMANCE FOR 2-5 TON PACKAGE HEAT PUMPS – 208V

CFM Air Delivery/RPM/Watts-208 Volts

External Static Pressure-Inches W.C.

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00

CFM 959 892 825 758 691 624 557 491

10x9 RPM 582 606 655 723 808 851 906 996

1/4 Watts 132 110 96 106 119 123 132 144

2 Speed CFM 1229 1170 1112 1054 996 938 879 821 763 705

(X-13 Motor) RPM 607 634 698 761 815 880 946 989 1038 1091

Watts 161 145 159 173 182 196 210 220 231 237

CFM 1162 1099 1035 972 908 844 781 717 654 590

10x9 RPM 603 626 690 752 815 906 941 984 1027 1096

1/3 Watts 143 124 136 148 157 175 180 188 192 202

2 Speed CFM 1306 1253 1200 1147 1095 1042 989 937 884 831

(X-13 Motor) RPM 632 679 733 787 841 883 941 1035 1067 1099

Watts 174 187 201 215 227 235 248 266 273 277

CFM 1328 1276 1223 1171 1118 1066 1013 961

10x9 RPM 642 693 747 803 852 903 988 1031

1/2 Watts 173 187 200 214 226 238 254 263

2 Speed CFM 1508 1459 1409 1359 1310 1260 1210 1160 1111 1061

(X-13 Motor) RPM 698 738 789 839 888 933 983 1035 1103 1137

Watts 243 255 271 285 299 310 322 332 343 343

CFM 1531 1477 1423 1370 1316 1262 1208 1154 1101 1047

11x9 RPM 602 619 668 715 757 801 844 878 918 954

1/2 Watts 238 227 236 251 266 281 296 307 320 333

2 Speed CFM 1724 1678 1632 1586 1540 1495 1449 1403 1357 1311

(X-13 Motor) RPM 639 671 715 759 794 834 875 911 948 977

Watts 295 309 330 348 363 380 397 414 429 440

CFM 1708 1658 1609 1559 1510 1460 1410 1361 1311 1262

11x9 RPM 619 651 686 741 783 822 859 894 937 971

3/4 Watts 280 284 298 323 339 355 370 385 402 415

2 Speed CFM 1917 1872 1827 1782 1736 1691 1646 1601 1556 1510

(X-13 Motor) RPM 673 702 736 769 818 860 898 928 960 989

Watts 377 392 409 426 451 473 490 504 518 531

CFM 1954 1914 1874 1833 1793 1753 1713 1673 1632 1592

11x9 RPM 719 747 779 818 857 894 928 963 998 1038

3/4 Watts 439 451 469 491 512 534 553 573 590 611

2 Speed CFM 2173 2136 2098 2061 2024 1986 1949 1911 1874 1837

(X-13 Motor) RPM 775 803 830 860 896 928 959 988 1019 1050

Watts 604 622 642 663 686 706 727 745 765 784

Nominal

Cooling

Capacity

Tons

Motor Speed

From Factor

y

Blower Size/

Motor HP #

of S

p

eeds

Motor

S

p

eed

Manufacturer

Recommended Air

-

Flow Range

(

Min / Max

)

CFM

2.0 Low (Tap 2) 700 / 900

Low

(Tap 2)

High

(Tap 1)

2.5 Low (Tap 2) 875 / 1125

Low

(Tap 2)

High

(Tap 1)

3.0 Low (Tap 2) 1050 / 1350

Low

(Tap 2)

High

(Tap 1)

3.5 Low (Tap 2) 1225 / 1575

Low

(Tap 2)

High

(Tap 1)

4.0 Low (Tap 2) 1400 / 1800

Low

(Tap 2)

High

(Tap 1)

5.0 Low (Tap 2) 1750 / 2250

Low

(Tap 2)

High

(Tap 1)

RQPM SERIES

24

Page 25

INDOOR AIRFLOW PERFORMANCE FOR 2-5 TON PACKAGE HEAT PUMPS – 230V

CFM Air Delivery/RPM/Watts-230 Volts

External Static Pressure-Inches W.C.

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00

CFM 827 811 782 740 684 614 531 435

10x9 Low RPM 450 533 626 742 799 894 932 985

2.0 Low 700 / 900 1/4 Watts 278 273 269 254 244 227 216 198

2 Speed CFM 1230 1223 1216 1211 1187 1125 1020 874 696 504

(PSC Motor) High RPM 575 643 703 767 819 877 976 1001 1072 1092

Watts 479 468 455 448 431 416 357 341 279 259

CFM 1032 1030 1014 979 923 843 735 596 423

10x9 Low RPM 533 570 659 746 795 863 934 1019 1050

2.5 Low 875 / 1125 1/3 Watts 336 331 326 314 303 280 271 227 210

2 Speed CFM 1312 1301 1292 1276 1246 1196 1117 1003 845

(PSC Motor) High RPM 592 646 712 768 824 883 933 1012 1035

Watts 482 473 466 454 433 421 401 349 329

CFM 1261 1253 1225 1177 1110 1023 915 788 641

10x9 Low RPM 648 705 754 802 854 896 985 1008 1041

3.0 Low 1050 / 1350 1/2 Watts 398 395 387 391 370 361 323 310 300

2 Speed CFM 2068 2008 1957 1905 1841 1753 1629 1458 1228 929

(PSC Motor) High RPM 850 883 917 946 972 999 1028 1049 1091 1108

Watts 826 806 784 762 734 702 658 626 546 512

CFM 1431 1394 1348 1302 1258 1208 1140 1030 849 557

11x9 Low RPM 540 579 633 686 724 776 831 868 1035 1076

3.5 Low 1225 / 1575 1/2 Watts 482 479 477 470 459 453 437 423 335 292

2 Speed CFM 1960 1936 1903 1859 1806 1742 1669 1585 1491 1387

(PSC Motor) High RPM 703 727 750 780 809 846 877 910 940 975

Watts 783 782 776 759 750 729 712 686 656 625

CFM 1674 1638 1595 1547 1492 1432 1365 1293 1214 1129.1

11x9 Low RPM 576 618 668 708 753 789 832 874 915 954

4.0 Low 1400 / 1800 3/4 Watts 575 563 556 549 544 532 522 503 483 465

2 Speed CFM 1996 1976 1947 1909 1863 1808 1744 1671 1590 1500

(PSC Motor) High RPM 680 722 752 781 807 833 867 912 936 973

Watts 799 787 784 760 753 749 730 699 693 652

CFM 2044 2017 1983 1941 1892 1836 1773 1702 1623 1537

11x9 Low RPM 689 723 756 798 822 855 889 924 951 988

5.0 Low 1750 / 2250 3/4 Watts 886 870 865 849 831 817 799 782 755 726

2 Speed CFM 2693 2654 2606 2549 2483 2408 2323 2230 2127 2015

(PSC Motor) High RPM 876 897 915 938 956 975 996 1009 1025 1044

Watts 1438 1427 1399 1368 1340 1312 1274 1228 1192 1146

Nominal

Cooling

Capacity

Tons

Motor Speed

From Factor

y

Blower Size/

Motor HP #

of S

p

eeds

Motor

S

p

eed

Manufacturer

Recommended Air-

Flow Range

(

Min / Max

)

CFM

RQNM SERIES

25

Page 26

INDOOR AIRFLOW PERFORMANCE FOR 2-5 TON PACKAGE HEAT PUMPS – 208V

CFM Air Delivery/RPM/Watts-208 Volts

External Static Pressure-Inches W.C.

0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.00

CFM 723 692 654 609 556 496 428

10x9 Low RPM 443 528 651 710 819 863 914

2.0 Low 700 / 900 1/4 Watts 230 222 219 214 202 196 184

2 Speed CFM 1062 1062 1058 1043 1013 962 884 774 627 437

(PSC Motor) High RPM 528 618 674 735 812 895 936 985 1055 1080

Watts 396 393 384 376 361 335 318 297 244 223

CFM 923 904 874 832 774 698 602 483

10x9 Low RPM 498 543 648 728 806 853 947 989

2.5 Low 875 / 1125 1/3 Watts 280 278 268 259 252 243 219 201

2 Speed CFM 1164 1154 1143 1124 1090 1034 948 826 660 445

(PSC Motor) High RPM 526 596 670 744 803 864 945 971 1051 1078

Watts 401 398 388 379 371 350 322 310 259 235

CFM 1145 1142 1118 1073 1006 918

10x9 Low RPM 556 645 703 769 828 909

3.0 Low 1050 / 1350 1/2 Watts 346 340 335 326 321 298

2 Speed CFM 1884 1850 1815 1772 1712 1630 1516 1363 1164 910

(PSC Motor) High RPM 791 834 871 912 946 975 1004 1032 1083 1097

Watts 704 694 675 655 638 606 581 548 464 440

CFM 1279 1237 1196 1151 1098 1032 950 846 717.13 557.65

11x9 Low RPM 490 539 598 653 709 772 811 887 928 978

3.5 Low 1225 / 1575 1/2 Watts 401 400 393 391 381 373 364 343 329 305

2 Speed CFM 1751 1729 1698 1658 1608 1549 1481 1404 1317 1221

(PSC Motor) High RPM 640 668 706 734 781 813 851 888 937 968

Watts 660 658 651 644 628 617 603 581 557 524

CFM 1400 1393 1373 1337 1288 1225 1147 1055 949 828.48

11x9 Low RPM 536 578 623 677 718 782 830 863 902 976

4.0 Low 1400 / 1800 3/4 Watts 471 466 458 455 453 442 429 420 403 374

2 Speed CFM 1786 1764 1734 1695 1649 1595 1532 1462 1384 1297

(PSC Motor) High RPM 618 643 684 726 757 805 841 883 924 955

Watts 665 660 651 646 638 626 612 596 573 555

CFM 1848 1821 1785 1742 1690 1630 1562 1486 1402 1309

11x9 Low RPM 660 685 722 755 795 836 867 904 940 975

5.0 Low 1750 / 2250 3/4 Watts 731 725 720 707 698 680 665 651 623 596

2 Speed CFM 2444 2420 2384 2337 2278 2208 2127 2034 1930 1814

(PSC Motor) High RPM 829 838 863 885 914 936 958 983 1003 1029

Watts 1225 1218 1197 1191 1160 1135 1105 1068 1035 980

Nominal

Cooling

Capacity

Tons

Motor Speed

From Factor

y

Blower Size/

Motor HP #

of S

p

eeds

Motor

S

p

eed