Rheem RQNL, RQPL Installation Manual

INSTALLATION INSTRUCTIONS

!

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO

QUALIFIED, LICENSED SERVICE PERSONNEL FOR

PROPER INSTALLATION, ADJUSTMENT AND OPERATION

OF THIS UNIT. READ THESE INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING INSTALLATION OR OPERATION.

FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT

IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR

MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRICAL

SHOCK, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

ISO 9001:2008

PACKAGE HEAT PUMPS FEATURING

INDUSTRY STANDARD R-410A REFRIGERANT

RQNL- 13 SEER SERIES (2-4 TONS)

RQPL- 14 SEER SERIES (2-4 TONS)

14 SEER ONLY

SUPERSEDES 92-20522-42-07

92-20522-42-08

TABLE OF CONTENTS

I. Safety Information.................................................................................................3

II. Introduction ...........................................................................................................5

A. R-410A Refrigerant...........................................................................................5

1. Specification of R-410A.................................................................................5

2. Quick Reference for R-410A.........................................................................5

3. Evaporator Coil/TXV .....................................................................................5

4. Tools Required for Installing and Servicing R-410A Models.........................5

III. Checking Product Received..................................................................................8

IV. Equipment Protection............................................................................................8

V. Installation.............................................................................................................8

A. General .............................................................................................................8

1. Pre-Installation Check Points........................................................................8

2. Location.........................................................................................................8

B. Outside Slab Installation..................................................................................10

C.Clearances ......................................................................................................10

D.Rooftop Installation..........................................................................................10

VI. Ductwork.............................................................................................................11

VII. Filters ..................................................................................................................12

VIII. Conversion Procedure ........................................................................................13

IX. Condensate Drain...............................................................................................13

X. Condensate Drain, Outdoor Coil.........................................................................14

XI. Electrical Wiring ..................................................................................................14

A. Power Wiring...................................................................................................14

B. Control Wiring .................................................................................................14

C.Internal Wiring.................................................................................................14

D.Grounding .......................................................................................................14

E. Thermostat......................................................................................................15

XII. Indoor Air Flow Data ...........................................................................................16

XIII. Crankcase Heat ..................................................................................................16

XIV. Pre-Start Check...................................................................................................16

XV. Startup.................................................................................................................16

XVI. Operation ............................................................................................................17

XVII. Auxiliary Heat......................................................................................................17

XVIII. Demand Defrost Control and High/Low Pressure Controls.................................18

XIX. General Data..................................................................................................20-24

XX. Miscellaneous

Electrical Data ................................................................................................25-26

Airflow Performance.......................................................................................27-30

Heater Kit Characteristics...............................................................................31-32

Wiring Diagrams.............................................................................................33-37

Charge Charts................................................................................................38-42

Trouble Shooting .................................................................................................43

2

I. SAFETY INFORMATION

WARNING

!

IMPORTANT: ALL MANUFACTURER PRODUCTS MEET CURRENT FEDERAL

OSHA GUIDELINES FOR SAFETY. CALIFORNIA PROPOSITION 65 WARNINGS

ARE REQUIRED FOR CERTAIN PRODUCTS, WHICH ARE NOT COVERED BY

THE OSHA STANDARDS.

CALIFORNIA'S PROPOSITION 65 REQUIRES WARNINGS FOR PRODUCTS

SOLD IN CALIFORNIA THAT CONTAIN, OR PRODUCE, ANY OF OVER 600 LISTED CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER

OR BIRTH DEFECTS SUCH AS FIBERGLASS INSULATION, LEAD IN BRASS,

AND COMBUSTION PRODUCTS FROM NATURAL GAS.

ALL “NEW EQUIPMENT” SHIPPED FOR SALE IN CALIFORNIA WILL HAVE

LABELS STATING THAT THE PRODUCT CONTAINS AND/OR PRODUCES

PROPOSITION 65 CHEMICALS. ALTHOUGH WE HAVE NOT CHANGED OUR

PROCESSES, HAVING THE SAME LABEL ON ALL OUR PRODUCTS FACILITATES MANUFACTURING AND SHIPPING. WE CANNOT ALWAYS KNOW

“WHEN, OR IF” PRODUCTS WILL BE SOLD IN THE CALIFORNIA MARKET.

YOU MAY RECEIVE INQUIRIES FROM CUSTOMERS ABOUT CHEMICALS

FOUND IN, OR PRODUCED BY, SOME OF OUR HEATING AND AIR-CONDITIONING EQUIPMENT, OR FOUND IN NATURAL GAS USED WITH SOME OF OUR

PRODUCTS. LISTED BELOW ARE THOSE CHEMICALS AND SUBSTANCES

COMMONLY ASSOCIATED WITH SIMILAR EQUIPMENT IN OUR INDUSTRY AND

OTHER MANUFACTURERS.

• GLASS WOOL (FIBERGLASS) INSULATION

• CARBON MONOXIDE (CO)

• FORMALDEHYDE

• BENZENE

MORE DETAILS ARE AVAILABLE AT THE WEBSITES FOR OSHA

(OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION), AT

WWW.OSHA.GOV

ENVIRONMENTAL HEALTH HAZARD ASSESSMENT), AT WWW.OEHHA.ORG.

CONSUMER EDUCATION IS IMPORTANT SINCE THE CHEMICALS AND SUBSTANCES ON THE LIST ARE FOUND IN OUR DAILY LIVES. MOST CONSUMERS ARE AWARE THAT PRODUCTS PRESENT SAFETY AND HEALTH

RISKS, WHEN IMPROPERLY USED, HANDLED AND MAINTAINED.

AND THE STATE OF CALIFORNIA'S OEHHA (OFFICE OF

WARNING

!

THE MANUFACTURER’S WARRANTY DOES NOT COVER ANY DAMAGE OR

DEFECT TO THE HEAT PUMP CAUSED BY THE ATTACHMENT OR USE OF ANY

COMPONENTS, ACCESSORIES OR DEVICES (OTHER THAN THOSE AUTHORIZED BY THE MANUFACTURER) INTO, ONTO OR IN CONJUNCTION WITH

THE HEAT PUMP. YOU SHOULD BE AWARE THAT THE USE OF UNAUTHORIZED COMPONENTS, ACCESSORIES OR DEVICES MAY ADVERSELY AFFECT

THE OPERATION OF THE HEAT PUMP AND MAY ALSO ENDANGER LIFE AND

PROPERTY. THE MANUFACTURER DISCLAIMS ANY RESPONSIBILITY FOR

SUCH LOSS OR INJURY RESULTING FROM THE USE OF SUCH UNAUTHORIZED COMPONENTS, ACCESSORIES OR DEVICES.

WARNING

!

DISCONNECT ALL POWER TO THE UNIT BEFORE STARTING MAINTENANCE.

FAILURE TO DO SO CAN RESULT IN SEVERE ELECTRICAL SHOCK OR DEATH.

WARNING

!

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT RETURN DUCTWORK

TO ANY OTHER HEAT PRODUCING DEVICE SUCH AS A FIREPLACE INSERT,

STOVE, ETC. UNAUTHORIZED USE OF SUCH DEVICES MAY RESULT IN FIRE,

CA RB ON MONOXIDE P OISONING, EX PL OSION, PRO PE RT Y DAMAGE,

3

WARNING

!

THE UNIT MUST BE PERMANENTLY GROUNDED. A GROUNDING LUG IS

PROVIDED IN THE ELECTRIC HEAT KIT FOR A GROUND WIRE. (SEE FIGURE

10.) FAILURE TO GROUND THIS UNIT CAN RESULT IN FIRE OR ELECTRICAL

SHOCK CAUSING PROPERTY DAMAGE, SEVERE PERSONAL INJURY OR

WARNING

!

ONLY ELECTRIC HEATER KITS SUPPLIED BY THIS MANUFACTURER AS

DESCRIBED IN THIS PUBLICATION HAVE BEEN DESIGNED, TESTED, AND

EVALUATED BY A NATIONALLY RECOGNIZED SAFETY TESTING AGENCY

FOR USE WITH THIS UNIT. USE OF ANY OTHER MANUFACTURED ELECTRIC

HEATERS INSTALLED WITHIN THIS UNIT MAY CAUSE HAZARDOUS CONDITIONS RES ULTING IN PROPER TY D AMAGE, FIRE, BODILY INJURY OR

DEATH.

4

Recognize this symbol as an indica-

!

tion of Important Safety Information!

WARNING

!

IMPORTANT: ALL MANUFACTURER PRODUCTS MEET CURRENT

FEDERAL OSHA GUIDELINES FOR

SAFETY. CALIFORNIA

PROPOSITION 65 WARNINGS ARE

REQUIRED FOR CERTAIN PRODUCTS, WHICH ARE NOT COVERED

BY THE OSHA STANDARDS.

CALIFORNIA'S PROPOSITION 65

REQUIRES WARNINGS FOR PRODUCTS SOLD IN CALIFORNIA THAT

CONTAIN, OR PRODUCE, ANY OF

OVER 600 LISTED CHEMICALS

KNOWN TO THE STATE OF

CALIFORNIA TO CAUSE CANCER

OR BIRTH DEFECTS SUCH AS

FIBERGLASS INSULATION, LEAD

IN BRASS, AND COMBUSTION

PRODUCTS FROM NATURAL GAS.

ALL “NEW EQUIPMENT” SHIPPED

FOR SALE IN CALIFORNIA WILL

HAVE LABELS STATING THAT THE

PRODUCT CONTAINS AND/OR

PRODUCES PROPOSITION 65

CHEMICALS. ALTHOUGH WE HAVE

NOT CHANGED OUR PROCESSES,

HAVING THE SAME LABEL ON ALL

OUR PRODUCTS FACILITATES

MANUFACTURING AND SHIPPING.

WE CANNOT ALWAYS KNOW

“WHEN, OR IF” PRODUCTS WILL

BE SOLD IN THE CALIFORNIA

MARKET.

YOU MAY RECEIVE INQUIRIES

FROM CUSTOMERS ABOUT CHEMICALS FOUND IN, OR PRODUCED

BY, SOME OF OUR HEATING AND

AIR-CONDITIONING EQUIPMENT,

OR FOUND IN NATURAL GAS USED

WITH SOME OF OUR PRODUCTS.

LISTED BELOW ARE THOSE CHEMICALS AND SUBSTANCES COMMONLY ASSOCIATED WITH SIMILAR EQUIPMENT IN OUR INDUSTRY AND OTHER MANUFACTURERS.

• GLASS WOOL (FIBERGLASS)

INSULATION

• CARBON MONOXIDE (CO)

• FORMALDEHYDE

• BENZENE

MORE DETAILS ARE AVAILABLE

AT THE WEBSITES FOR OSHA

(OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION), AT

WWW.OSHA.GOV

OF CALIFORNIA'S OEHHA (OFFICE

OF ENVIRONMENTAL HEALTH

HAZARD ASSESSMENT), AT

WWW.OEHHA.ORG. CONSUMER

EDUCATION IS IMPORTANT SINCE

THE CHEMICALS AND SUBSTANCES ON THE LIST ARE

FOUND IN OUR DAILY LIVES. MOST

CONSUMERS ARE AWARE THAT

PRODUCTS PRESENT SAFETY AND

HEALTH RISKS, WHEN IMPROPERLY USED, HANDLED AND MAINTAINED.

AND THE STATE

II. INTRODUCTION

This booklet contains the installation and operating instructions for your package heat

pump. There are a few precautions that should be taken to derive maximum satisfaction

from it. Improper installation can result in unsatisfactory operation or dangerous conditions.

Read this booklet and any instructions packaged with separate equipment required to

make up the system prior to installation. Give this booklet to the owner and explain its provisions. The owner should retain this booklet for future reference.

NOTE: A load calculation must be performed to properly determine the required heating

and cooling for the structure. Also, the duct must be properly designed and installed for

proper airflow. Existing ductwork must be inspected for proper size and sealed system.

Proper airflow is necessary for both user comfort and equipment performance.

IMPORTANT: Proper application, installation and maintenance of this equipment is a must

if consumers are to receive the full benefit for which they have paid.

A. R-410A REFRIGERANT

All units are factory charged with R-410A refrigerant.

1. Specification of R-410A:

Application: R-410A is not a drop-in replacement for R-22; equipment designs must

accommodate its higher pressures. It cannot be retrofitted into R-22 units.

Pressure: The pressure of R-410A is approximately 60% (1.6 times) greater than R-

22. Recovery and recycle equipment, pumps, hoses and the like need to have design

pressure ratings appropriate for R-410A. Manifold sets need to range up to 800 psig

high-side and 250 psig low-side with a 550 psig low-side retard. Hoses need to have a

service pressure rating of 800 psig. Recovery cylinders need to have a 400 psig service

pressure rating. DOT 4BA400 or DOT BW400.

Combustibility: At pressures above 1 atmosphere, mixture of R-410A and air can

become combustible. R-410A and air should never be mixed in tanks or supply

lines, or be allowed to accumulate in storage tanks. Leak checking should never

be done with a mixture of R-410A and air. Leak checking can be performed safely

with nitrogen or a mixture of R-410A and nitrogen.

2. Quick Reference Guide For R-410A

• R-410A refrigerant operates at approximately 60% higher pressure (1.6 times) than R-

22. Ensure that servicing equipment is designed to operate with R-410A.

• R-410A refrigerant cylinders are pink.

• R-410A, as with other HFC’s is only compatible with POE oils.

• Vacuum pumps will not remove moisture from POE oil.

• R-410A systems are to be charged with liquid refrigerants. Prior to March 1999, R410A refrigerant cylinders had a dip tube. These cylinders should be kept upright for

equipment charging. Post March 1999 cylinders do not have a dip tube and should

be inverted to ensure liquid charging of the equipment.

• Do not install a suction line filter drier in the liquid line.

• A liquid line filter drier is standard on every unit.

• Desiccant (drying agent) must be compatible for POE oils and R-410A

3. Evaporator Coil / TXV

The thermostatic expansion valve is specifically designed to operate with R-410A. DO

NOT use an R-22 TXV. The existing evaporator must be replaced with the factory

specified TXV evaporator specifically designed for R-410A.

4. Tools Required For Installing & Servicing R-410A Models

Manifold Sets:

-Up to 800 PSIG High side

-Up to 250 PSIG Low Side

-550 PSIG Low Side Retard

Manifold Hoses:

-Service Pressure Rating of 800 PSIG

Recovery Cylinders:

-400 PSIG Pressure Rating

-Dept. of Transportation 4BA400 or BW400

!

CAUTION

R-410A systems operate at higher pressures than R-22 systems. Do not use

R-22 service equipment or components on R-410A equipment.

5

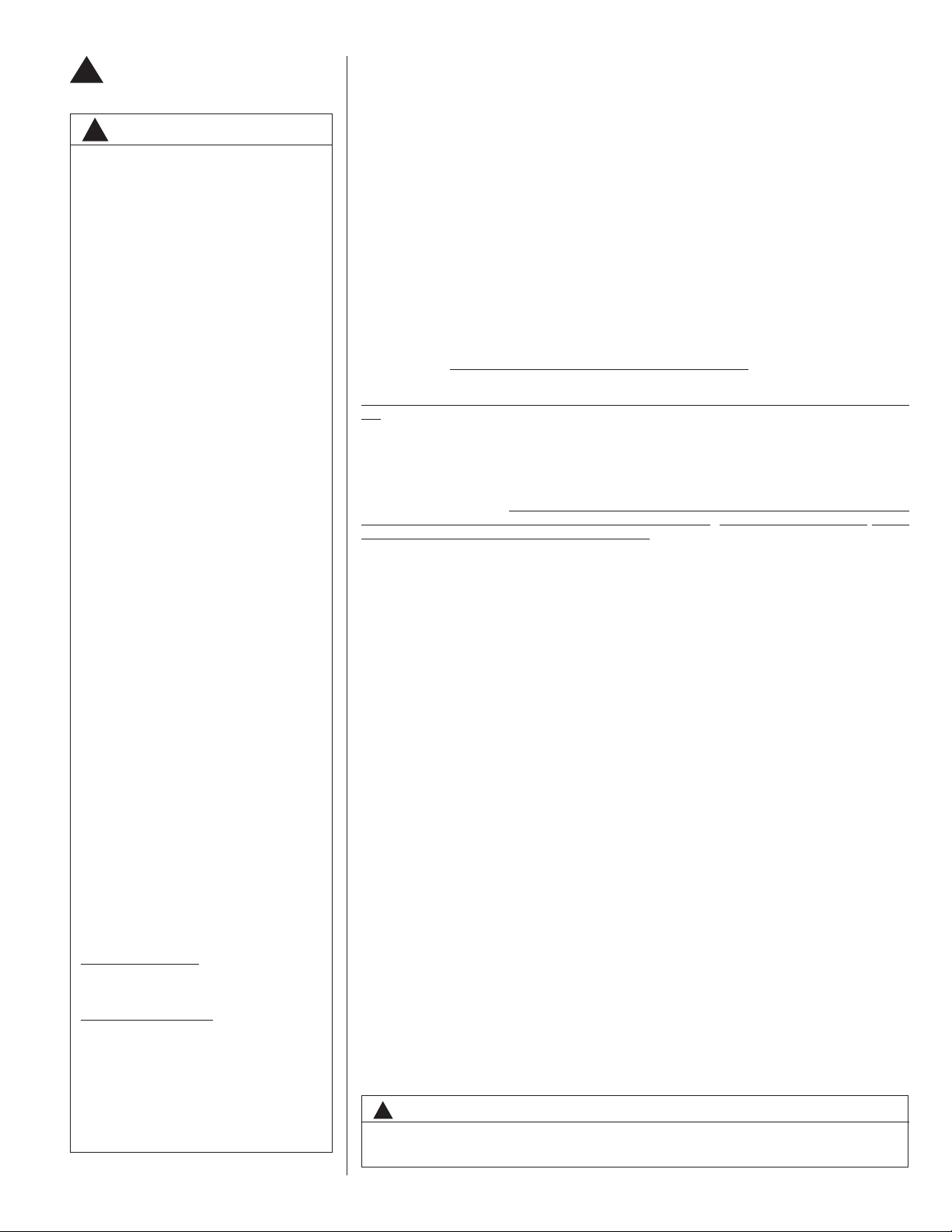

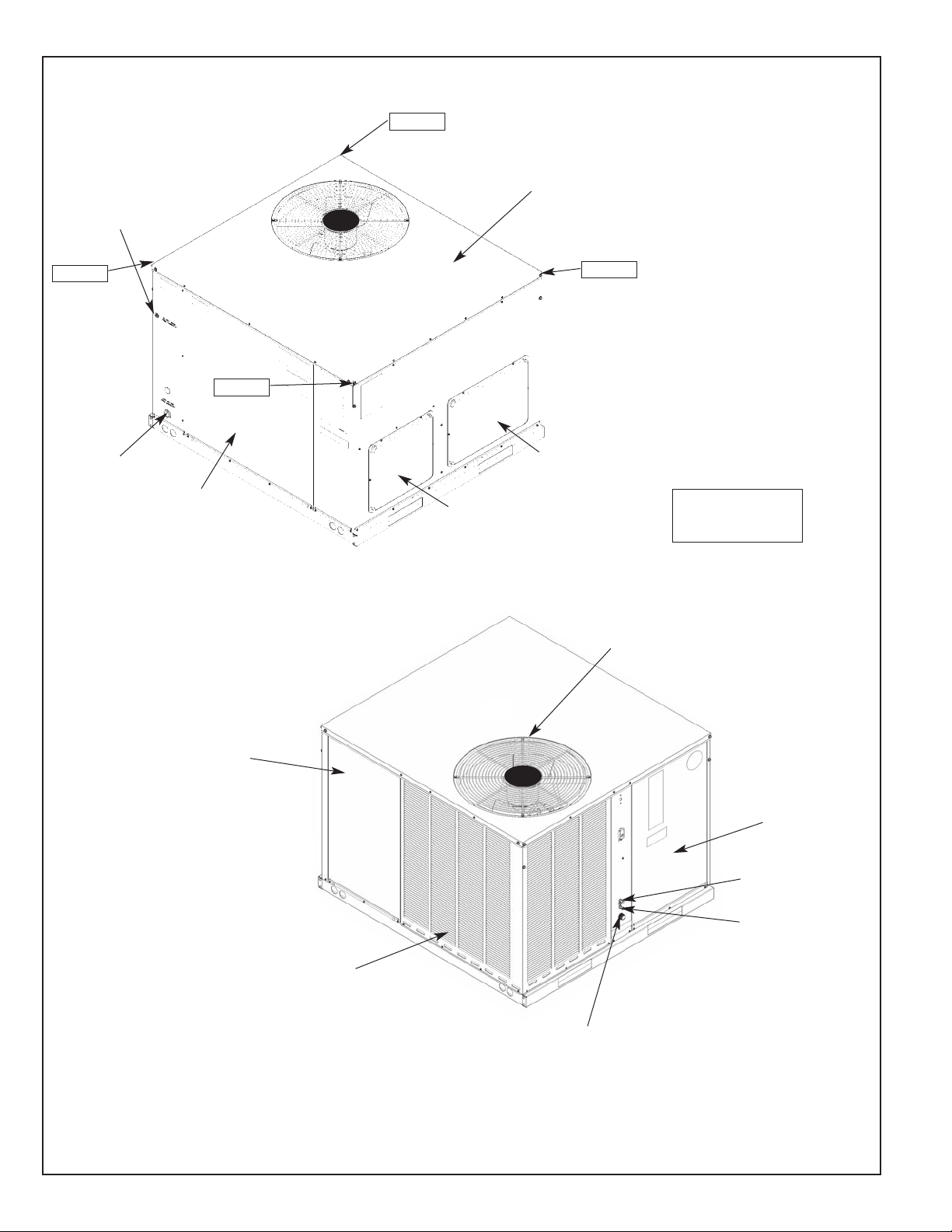

FIGURE 1

THERMOSTAT

WIRE

ENTRANCE

29% ± 2%

30% ± 2%

TOP COVER

21% ± 2%

20% ± 2%

ELECTRICAL

POWER

ENTRANCE

BLOWER/

EVAPORATOR

ACCESS PANEL

FILTER ACCESS

PANEL (FOR

UNIT MOUNTED

FILTER ACCESSORY)

SIDE SUPPLY

DUCT OPENING

SIDE RETURN

DUCT OPENING

CORNER WEIGHTS %

OF TOTAL UNIT

WEIGHT

OUTDOOR FAN GRILLE

AND COMPRESSOR ACCESS

LIQUID PRESSURE

SERVICE PORT

CONTROL

ACCESS PANEL

SUCTION PRESSURE

SERVICE PORT

OUTDOOR COIL

PROTECTIVE GRILLE

THREADED PVC CONDENSATE

DRAIN CONNECTION (3/4 N.P.T.)

6

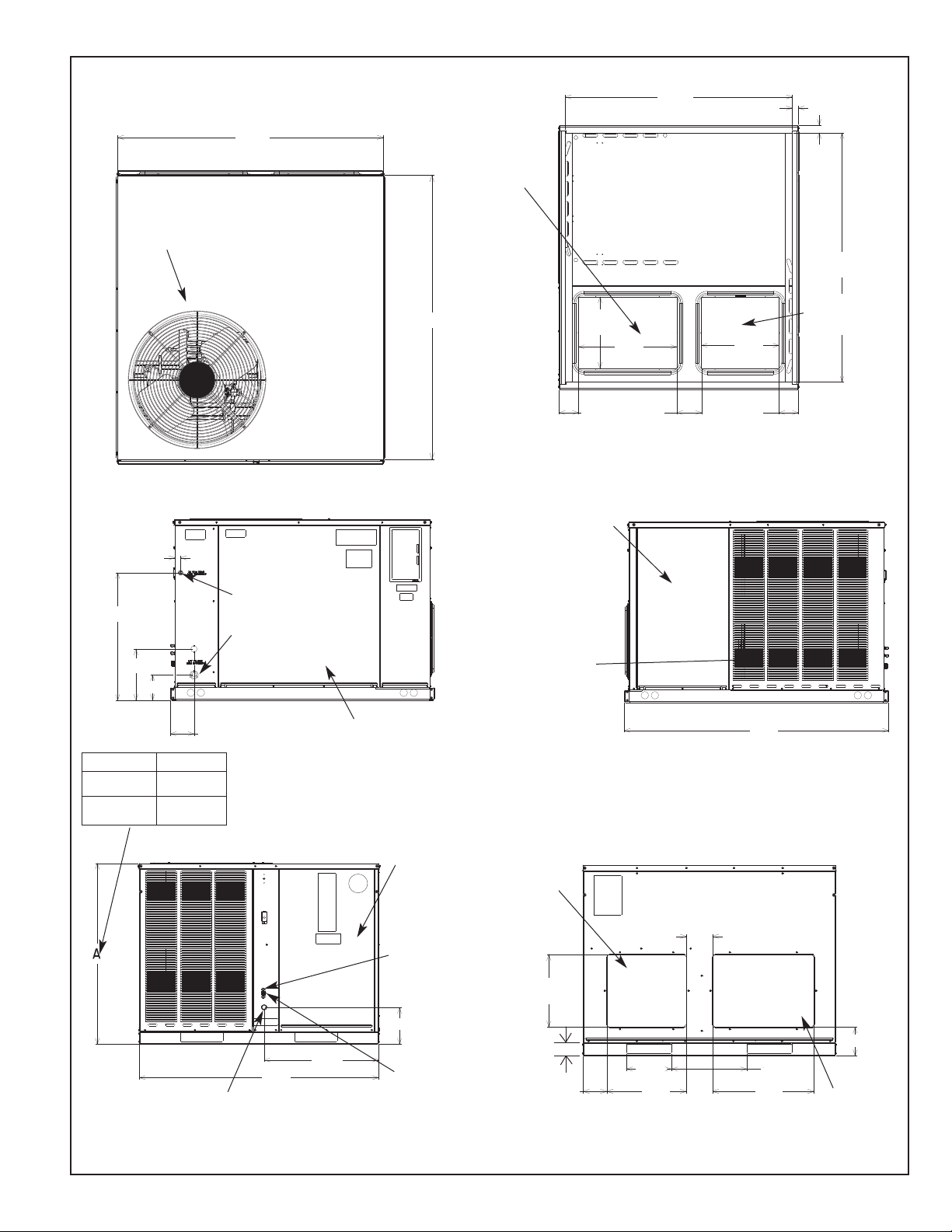

FIGURE 1

OUTDOOR

FAN GRILLE

AND

COMPRESSOR

ACCESS

4719⁄32

ⴖ

451⁄16

INSIDE

ⴖ

BOTTOM

13⁄16

TYP.

ⴖ

ⴖ

11⁄2

TYP.

RETURN

DUCT

OPENING

ⴖ

497⁄16

INSIDE

BOTTOM

5013⁄16

ⴖ

ⴖ

141⁄4

TYP.

199⁄16

ⴖ

ⴖ

153⁄8

SUPPLY DUCT

OPENING

ⴖ

11⁄8

ⴖ

255⁄16

ⴖ

103⁄16

51⁄16ⴖ

Model # Height “A”

B024, B025

B030, B036

B042, B048

35

5

41"

THREADED PVC

CONDENSATED DRAIN

CONNECTION (3/4 N.P.T.)

THERMOSTAT

WIRE

ENTRANCE

ELECTRICAL POWER

ENTRANCE

ⴖ

43⁄4

⁄16"

FRONT VIEW

471⁄2

SIDE VIEW

2211⁄16

ⴖ

BLOWER/

EVAPORATOR

ACCESS

PANEL

PRESSURE

75⁄16

ⴖ

CONTROL

ACCESS

PANEL

LIQUID

SERVICE

PORT

ⴖ

SUCTION

PRESSURE

SERVICE

PORT

ⴖ

313⁄16

FILTER ACCESS

45⁄16

ⴖ

33⁄16

ⴖ

SIDE VIEW

PANEL (FOR

UNIT MOUNTED

FILTER

ACCESSORY)

OUTDOOR

COIL

PROTECTIVE

GRILLE

ⴖ

527⁄16

IMPORTANT:

INSTALLATION MUST NOT INTERFERE WITH DRAINAGE OPENINGS

IN BOTTOM OF UNIT UNDER OUTDOOR COIL.

REAR VIEW

SIDE SUPPLY

DUCT

OPENING

ⴖ

47⁄8

ⴖ

133⁄4

TYP.

21⁄2

ⴖ

ⴖ

47⁄16

SHOWN WITH DUCT COVERS REMOVED.

81⁄2

TYP.

ⴖ

ⴖ

15

191⁄8

143⁄16

TYP.

ⴖ

ⴖ

57⁄16ⴖ

SIDE RETURN

DUCT

OPENING

7

WARNING

!

THE MANUFACTURER’S WARRANTY DOES NOT COVER ANY DAMAGE OR DEFECT TO THE HEAT

PUMP CAUSED BY THE ATTACHMENT OR USE OF ANY COMPONENTS, ACCESSORIES OR

DEVICES (OTHER THAN THOSE

AUTHORIZED BY THE MANUFACTURER) INTO, ONTO OR IN CONJUNCTION WITH THE HEAT PUMP.

YOU SHOULD BE AWARE THAT

THE USE OF UNAUTHORIZED

COMPONENTS, ACCESSORIES OR

DEVICES MAY ADVERSELY

AFFECT THE OPERATION OF THE

HEAT PUMP AND MAY ALSO

ENDANGER LIFE AND PROPERTY.

THE MANUFACTURER DISCLAIMS

ANY RESPONSIBILITY FOR SUCH

LOSS OR INJURY RESULTING

FROM THE USE OF SUCH UNAUTHORIZED COMPONENTS, ACCESSORIES OR DEVICES.

III. CHECKING PRODUCT RECEIVED

Upon receiving the unit, inspect it for any damage from shipment. Claims for damage,

either shipping or concealed, should be filed immediately with the shipping company.

Check the unit model number, heating size, electrical characteristics, and accessories to

determine if they are correct.

IV. EQUIPMENT PROTECTION FROM THE

ENVIRONMENT

The metal parts of this unit may be subject to rust or deterioration in adverse environmental conditions. This oxidation could shorten the equipment’s useful life. Salt spray, fog or

mist in seacoast areas, sulphur or chlorine from lawn watering systems, and various chemical contaminants from industries such as paper mills and petroleum refineries are especially corrosive.

If the unit is to be installed in an area where contaminants are likely to be a problem, special attention should be given to the equipment location and exposure.

1. Avoid having lawn sprinkler heads spray direction on the unit cabinet.

2. In coastal areas, locate the unit on the side of the building away from the waterfront.

3. Shielding provided by a fence or shrubs may give some protection.

4. Elevating the unit off its slab or base enough to allow air circulation will help avoid

holding water against the basepan.

Regular maintenance will reduce the buildup of contaminents and help to protect

the unit’s finish.

WARNING

!

DISCONNECT ALL POWER TO THE UNIT BEFORE STARTING MAINTENANCE.

FAILURE TO DO SO CAN RESULT IN SEVERE ELECTRICAL SHOCK OR DEATH.

1. Frequent washing of the cabinet, fan blade and coil with fresh water will remove most

of the salt or other contaminants that build up on the unit.

2. Regular cleaning and waxing of the cabinet with an automobile polish will provide

some protection.

3. A liquid cleaner may be used several times a year to remove matter that will not wash

off with water.

Several different types of protective coatings are offered in some areas. These coatings

may provide some benefit, but the effectiveness of such coating materials cannot be verified by the equipment manufacturer.

The best protection is frequent cleaning, maintenance and minimal exposure to

contaminants.

V. INSTALLATION

A. GENERAL

1. PRE-INSTALLATION CHECK-POINTS

Before attempting any installation, the following points should be carefully considered:

a. Structural strength of supporting members.

(rooftop installation)

b. Clearances and provision for servicing.

c. Power supply and wiring.

d. Air duct connections.

e. Drain facilities and connections.

f. Location for minimum noise.

2. LOCATION

These units are designed for outdoor installations. They can be mounted on a

slab or rooftop. They are not to be installed within any part of a structure such as

an attic, crawl space, closet, or any other place where condenser air flow is

restricted or other than outdoor ambient conditions prevail. Since the application

8

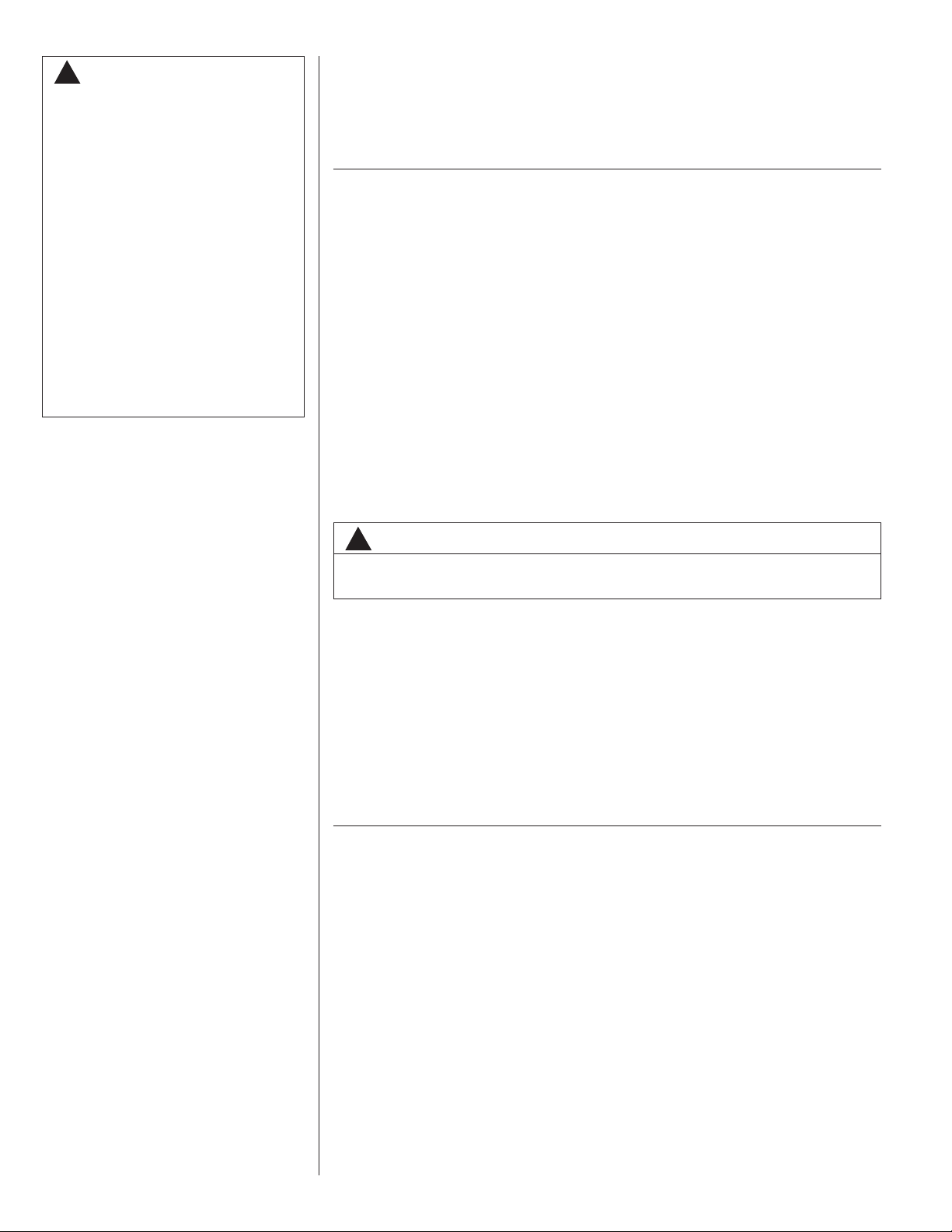

FIGURE 2

PACKAGE HEAT PUMP

OUTSIDE SLAB INSTALLATION, BASEMENT OR

CRAWL SPACE DISTRIBUTION SYSTEM

60ⴖ OVERHEAD

CLEARANCE

12ⴖ CLEARANCE

WITHOUT

ECONOMIZER

24ⴖ CLEARANCE

WITH

ECONOMIZER

FIGURE 3

PACKAGE HEAT PUMP

OUTSIDE SLAB INSTALLATION, CLOSET DISTRIBUTION

FILTER

GRILL

BRANCH

CIRCUIT

DISCONNECT

SERVICE

ACCESS PANELS

DO NOT BLOCK

ACCESS

SUPPLY DUCT AT

CLOSET CEILING

SLAB

FLOOR

36ⴖ

24ⴖ TO SERVICE

BLOWER & EVAPORATOR

0ⴖ MIN.

CLEARANCE

0 ⴖ CLEARANCE AROUND

SUPPLY DUCT TO

COMBUSTIBLE STRUCTURE

FIGURE 4

PACKAGE HEAT PUMP

RIGGING FOR LIFTING

I268

IMPORTANT: UNIT MUST BE LEVEL

TO PREVENT WATER MIGRATION

RIGGING

NOT

PROVIDED

POWER

SUPPLY

CONDUIT

THERMOSTAT

WIRE CONDUIT

I267

DETAIL A

SEE DETAIL A

ST-A1100-01

9

of the units is of the outdoor type, it is important to consult your local code authorities at the time the first installation is made.

B. OUTSIDE SLAB INSTALLATION (Typical outdoor slab installations are shown

in Figures 2 and 3.)

1. Select a location where external water drainage cannot collect around the unit.

2. Provide a level concrete slab extending a minimum 3" beyond all four sides of the

unit. The slab should be sufficient above grade to prevent ground water from

entering the unit. IMPORTANT: To prevent transmission of noise or vibration,

slab should not be connected to building structure.

3. The location of the unit should be such as to provide proper access for inspection

and servicing.

4. Locate unit where operating sounds will not disturb owner or neighbors.

5. Locate unit so roof runoff water does not pour directly on the unit. Provide gutter

or other shielding at roof level. Do not locate unit in an area where excessive

snow drifting may occur or accumulate.

6. It is essential that the unit be elevated above the base pad to allow for condensate drainage and possible refreezing of condensation. Provide a base pad which

is slightly pitched away from the structure. Route condensate off base pad to an

area which will not become slippery and result in personal injury. IMPORTANT:

Do not interfere with openings in bottom of unit.

7. Where snowfall is anticipated, the height of the unit above the ground level must

be considered. Mount unit high enough to be above average area snowfall and to

allow for proper condensate drainage. IMPORTANT: Do not interfere with open-

ings in bottom of unit.

C. CLEARANCES

The following minimum clearances must be observed for proper unit performance

and serviceability.

1. Provide 36" minimum clearance at the front and right side of the unit for service

access. Provide 12" minimum clearance on the left side of the unit for air inlet.

2. Provide 60" minimum clearance between top of unit and maximum 3 foot overhang.

3. Unit is design certified for application on combustible flooring with 0" minimum

clearance.

4. See Figure 2 for illustration of minimum installation-service clearances.

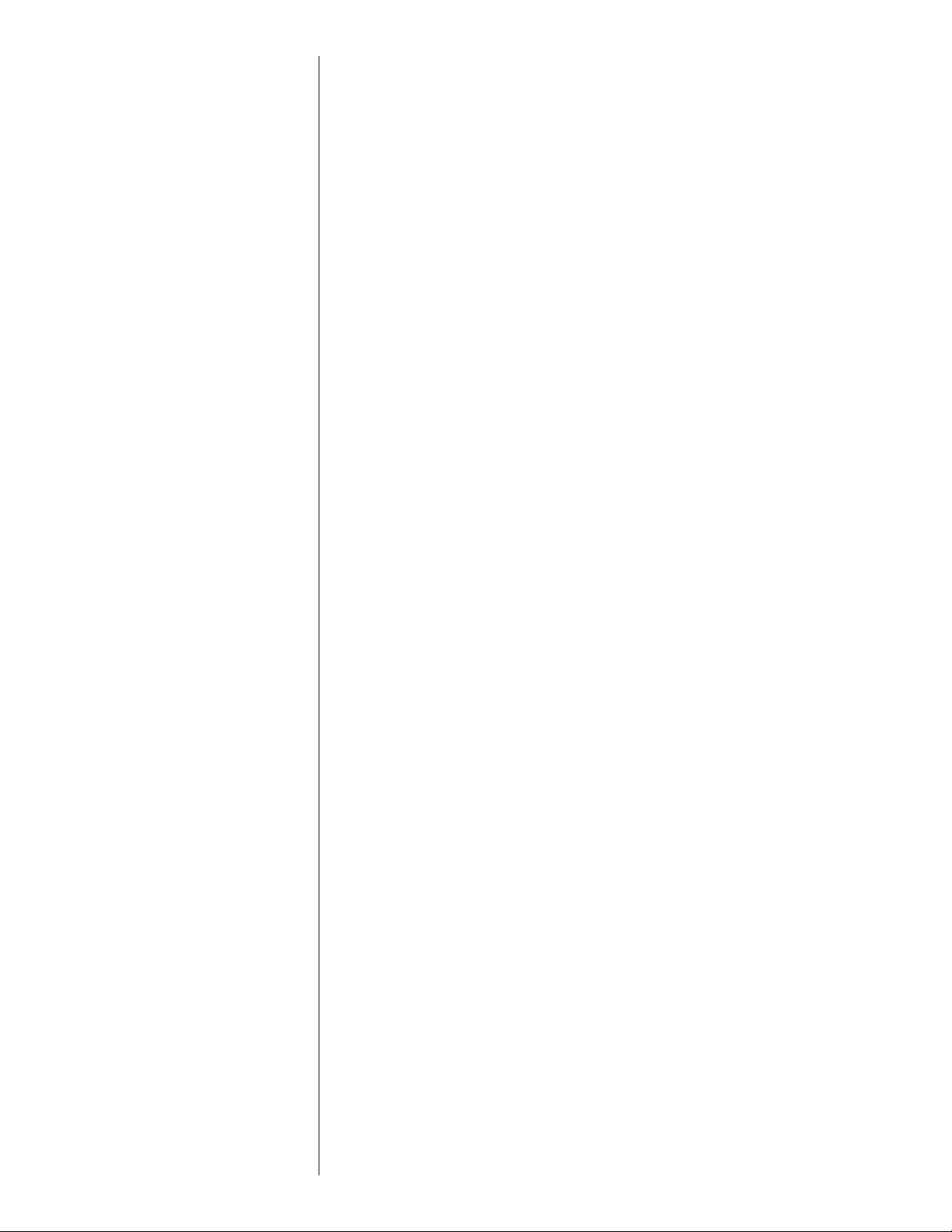

D. ROOFTOP INSTALLATION

1. Before locating the unit on the roof, make sure that the strength of the roof and

beams is adequate at that point to support the weight involved. (See specification

sheet for weight of unit.) This is very important and user’s responsibility.

2. For rigging and roofcurb details, see Figures 4 and 5. Use accessory lift brackets

and field-furnished spreaders.

3. For roofcurb assembly, see Roofcurb Installation Instructions.

4. If the roofcurb is not used, provisions for disposing of condensate water runoff

during defrosting must be provided.

5. The unit should be placed on a solid and level roofcurb or platform of adequate

strength. IMPORTANT: Do not interfere with opening in bottom of unit. (See

Figures 6 and 7.)

6. The location of the unit on the roof should be such as to provide proper access for

inspection and servicing.

IMPORTANT: If unit will not be put into service immediately, cover supply and return

openings to prevent excessive condensation.

10

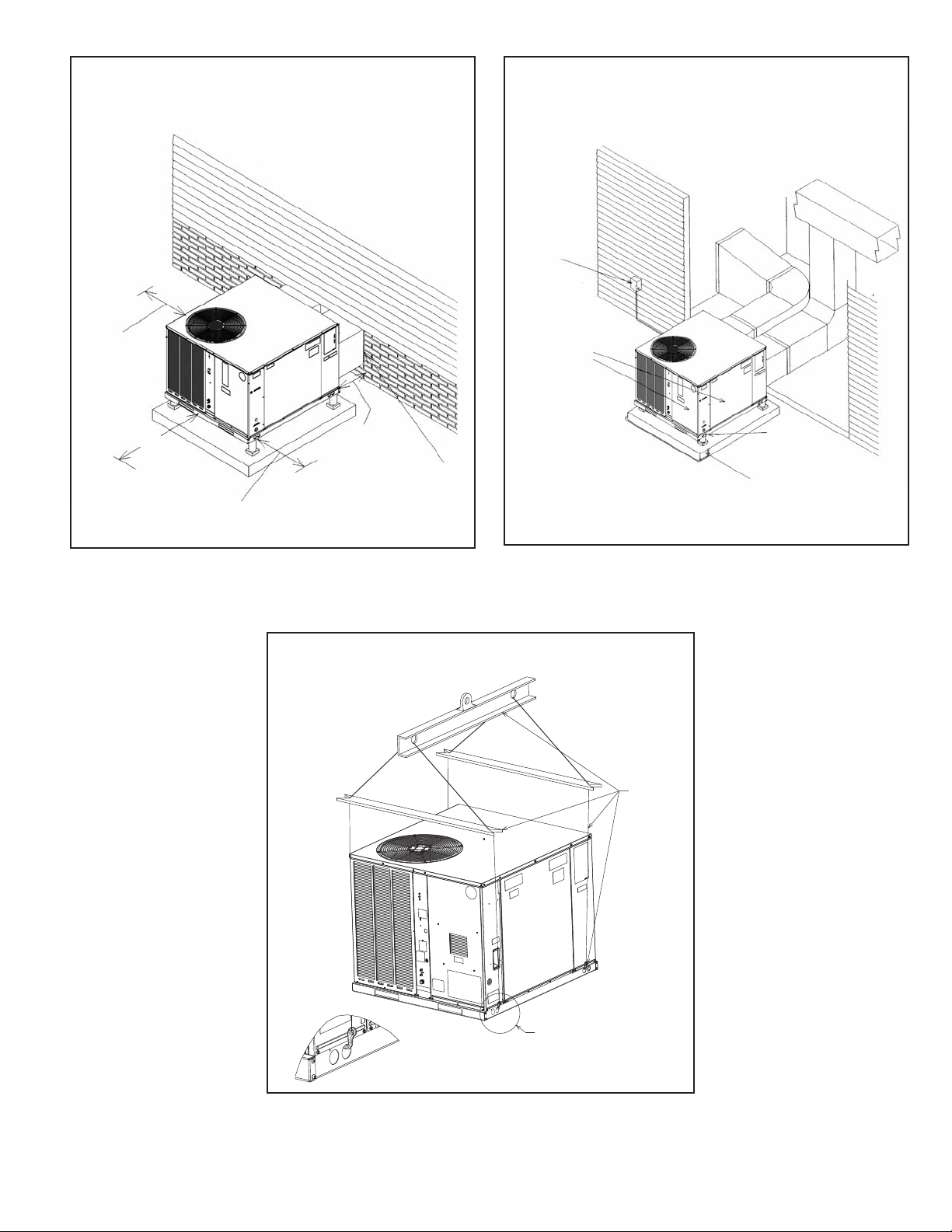

FIGURE 5

PACKAGE HEAT PUMP

ROOFCURB INSTALLATION

I270 I271

VI. DUCTWORK

Ductwork should be fabricated by the installing contractor in accordance with local

codes, state codes and NFPA90A. Industry manuals may be used as a guide when sizing and designing the duct system - contact Air Conditioning Contractors of America,

1513 16th St. N.W., Washington, D.C. 20036.

WARNING

!

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT RETURN DUCTWORK

TO ANY OTHER HEAT PRODUCING DEVICE SUCH AS A FIREPLACE INSERT,

STOVE, ETC. UNAUTHORIZED USE OF SUCH DEVICES MAY RESULT IN FIRE,

CA RB ON MONOXIDE P OISONING, EX PL OSION, PRO PE RT Y DAMAGE,

Place the unit as close to the space to be air conditioned as possible allowing clearance

dimensions as indicated. Run ducts as directly as possible to supply and return outlets.

Use of non-flammable waterproof flexible connectors on both supply and return connections at the unit to reduce noise transmission is recommended.

It is preferable to install the unit on the roof of the structure if the registers or diffusers

are located on the wall or in the ceiling. Consider a slab installation when the registers

are low on a wall or in the floor.

On ductwork exposed to outside air conditions of temperature and humidity, use a minimum of 2" of insulation and a vapor barrier. Distribution system in attic, furred space or

crawl space should be insulated with at least 2" of insulation with vapor barrier. One-half

to 1" thickness of insulation is usually sufficient for ductwork inside the air conditioned

space.

Provide balancing dampers for each branch duct in the supply system. Properly support

the ductwork from the structure.

When installing ductwork use noncombustible flexible connectors between ductwork and

unit to reduce noise and vibration transmission into the ductwork.

11

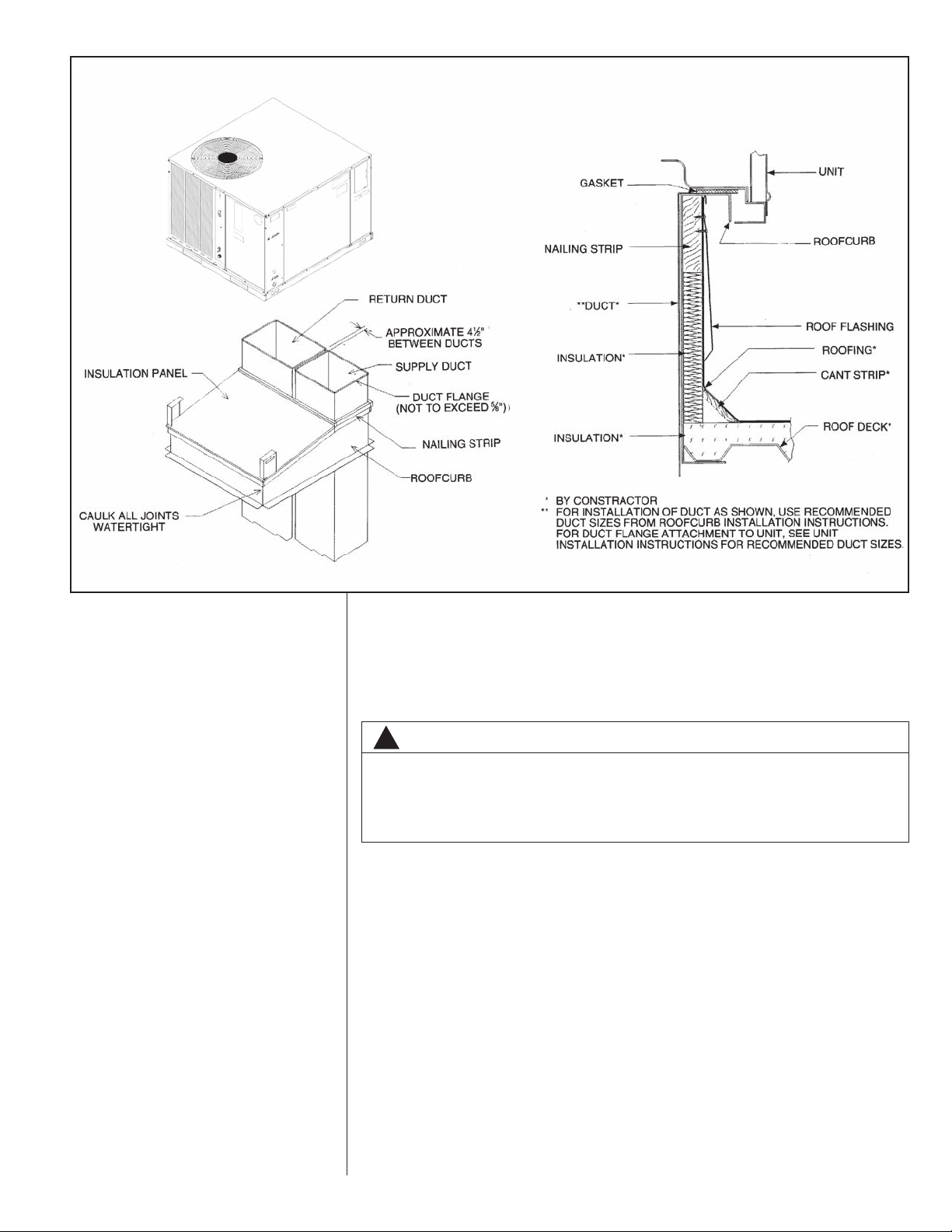

FIGURE 6

PACKAGE HEAT PUMP

FLAT ROOFTOP INSTALLATION, ATTIC OR DROP CEILING

DISTRIBUTION SYSTEM. MOUNTED ON

ROOFCURB. CURB MUST BE LEVEL

SERVICE ACCESS

PANELS. DO NOT

BLOCK ACCESS

CONDENSATE INTO

ROOFDRAIN IF REQ’D

BY LOCAL CODES.

THERMOSTAT WIRE

CONDUIT

BRANCH CIRCUIT

DISCONNECT

POWER

SUPPLY

CONDUIT

I272

VII. FILTERS

Filters are not provided with this unit. They may be supplied and installed in the return

air duct by the installer. A field installed filter grille is recommended for easy and convenient access to the filters for periodic inspection and cleaning. Filters must have adequate face area for the rated air quantity of the unit. See Airflow Performance Table - or

Electrical and Physical Data Table - for recommended filter size.

However, if an internal filter is required, an optional internal filter kit is available which

will work for downflow or horizontal applications. For installation, see Filter Kit

Installation Instruction.

NOTE: Do not operate the system without filters.

12

FIGURE 7

PACKAGE HEAT PUMP

PITCHED ROOFTOP INSTALLATION, ATTIC

OR DROP CEILING DISTRIBUTING SYSTEM.

MUST BE MOUNTED LEVEL.

CONDENSATE

DRAIN INTO

ROOFDRAIN IF

REQ’D BY LOCAL

CODES.

SERVICE ACCESS

PANELS. DO NOT

BLOCK ACCESS

SUPPLY PLENUM

BRANCH

CIRCUIT

DISCONNECT

POWER SUPPLY

CONDUIT

THERMOSTAT

WIRE

CONDUIT

I273

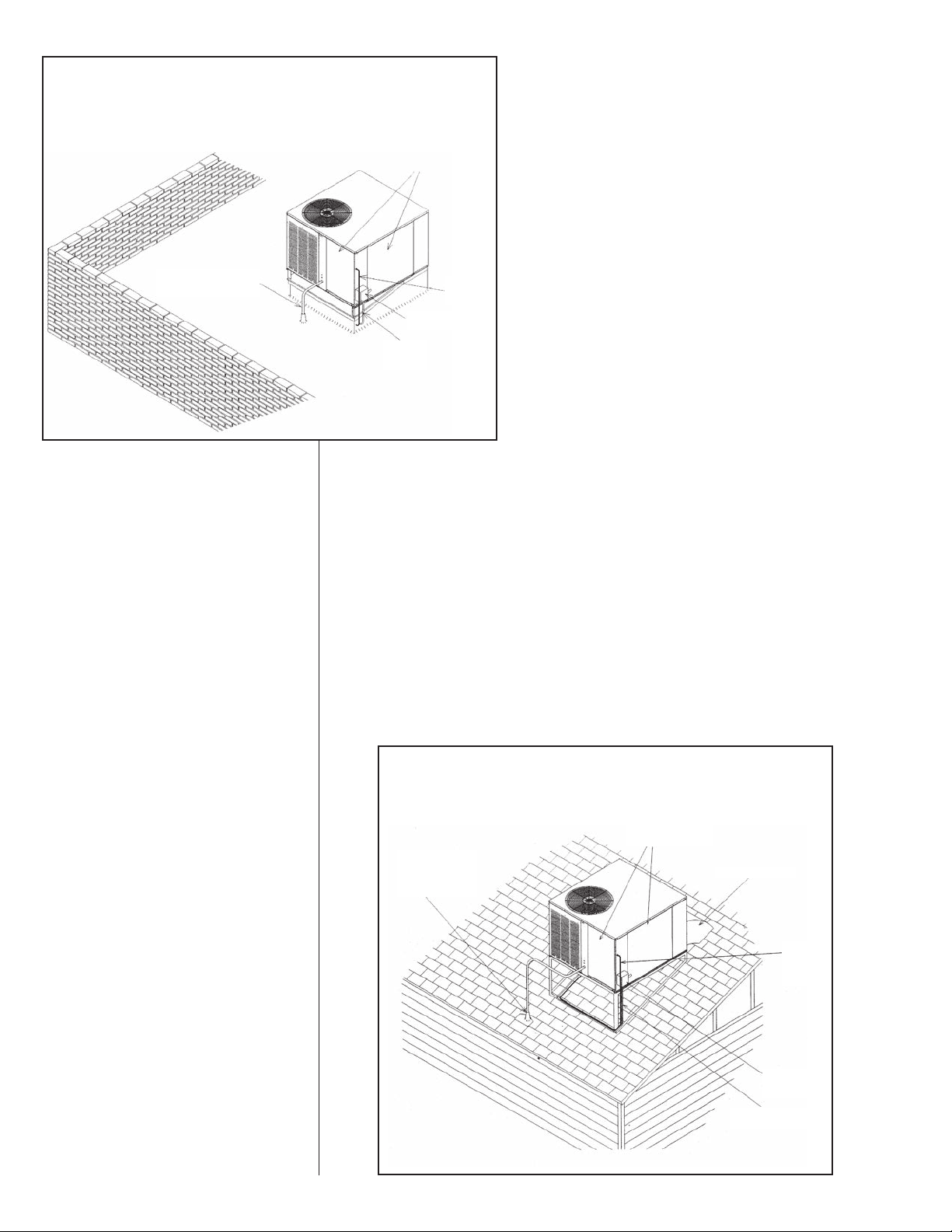

FIGURE 8

COVER GASKET DETAIL

FOR UNITS SHIPPED FOR SIDE DISCHARGE

APPLICATION BEING CONVERTED TO DOWNFLOW

SUPPLY/RETURN

AIR COVER

TAPE

AROUND FLANGE

I654

VIII.CONVERSION PROCEDURE

1. DOWNFLOW TO HORIZONTAL

a. Remove screws and covers from outside of supply and return sections.

b. Install gasket (supplied with parts bag) around perimeter of covers as illustrated in

“Cover Gasket Detail,” Figure 8.

c. Install covers in bottom of unit with insulated side up.

NOTE: Slip back flange of cover under tab on bottom supply duct opening.

d. Secure covers to base of unit with screw engaging prepunched holes in unit base.

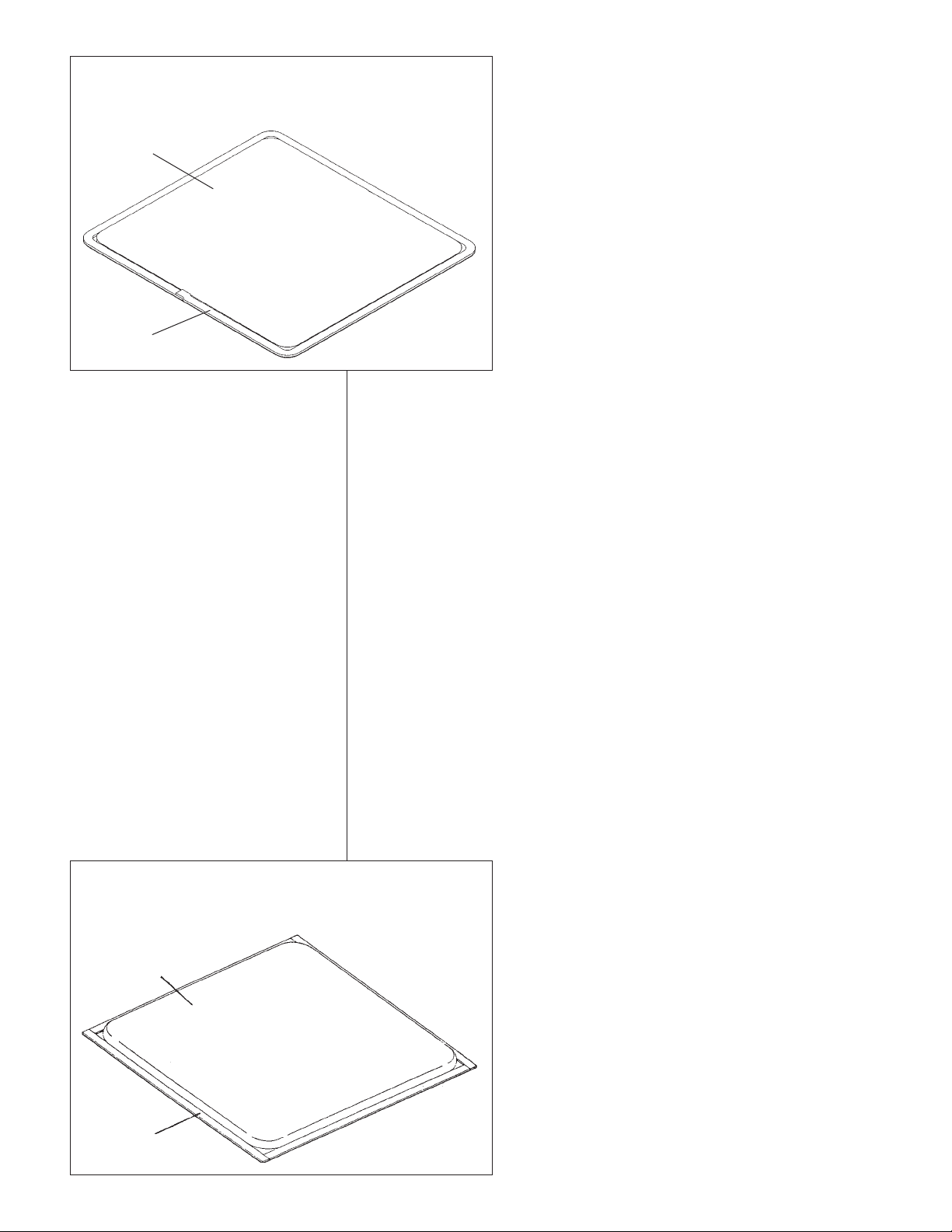

2. HORIZONTAL TO DOWNFLOW

a. Remove screws and covers from the downflow supply and return sections. Both

covers are accessible from the inside of the unit.

NOTE: Supply cover must be rotated 90º before it can be removed.

b. Install gasket (supplied with parts bag) around perimeter of cover on the insulated

side. See Figure 9.

c. Install covers on the outside of the unit over the horizontal supply and return

opening using existing screws.

IX. CONDENSATE DRAIN

The indoor coil condensate drain ends with a threaded (3/4" NPT) PVC stub. A trap is

built in for proper condensate drainage and to prevent debris from being drawn into the

unit. Do not connect drain to closed sewer line. It is recommended that a PVC cement not

be used so that the drain line can be easily cleaned in the future.

NOTE: Do not install an external trap.

FIGURE 9

COVER GASKET DETAIL

FOR UNITS SHIPPED FOR DOWNFLOW APPLICATION

BEING CONVERTED TO SIDE DISCHARGE

SUPPLY/RETURN

AIR COVER

TAPE

AROUND FLANGE

13

X. CONDENSATE DRAIN, OUTDOOR COIL

The outdoor coil during heating operation will sweat or run water off. The outdoor coil will

also run water off during the defrost cycle. See Section V, Installation, for mounting precautions.

XI. ELECTRICAL WIRING

Field wiring must comply with the National Electrical Code* state and local ordinances

that may apply.

*C.E.C. in Canada

A. POWER WIRING

1. It is important that proper electrical power is available at the unit. Voltage should

not vary more than 10% from that stamped on the unit rating plate. On three

phase units, phases must be balanced within 3%.

2. Install a branch circuit disconnect within sight of the unit and of adequate size to

handle the starting current.

3. For branch circuit wiring (main power supply to unit disconnect), the minimum

wire size can be determined from the circuit ampacity found on the unit nameplate

or from Table F and the National Electrical Code or Canadian Electrical Code.

4. This unit incorporates single point electrical connection for unit and electric heat

accessory.

5. Power wiring must be run in grounded rain-tight conduit. Connect the power field

wiring as follows:

a. NO ELECTRIC HEAT - Connect the field wires directly to the contactor in the

unit control box. Connect ground wire to ground lug.

b. WITH ELECTRIC HEAT - Connect the field wires to the terminal block on the

electric heater kit. Connect the ground wire to the ground lug on the heater kit.

NOTE: For installation of the heater kit, follow the instructions provided with the

heater kit.

6. The pigtail wires in the electric heat box are factory wired to the contactor in the

control box and are protected by internal fuses in the hinged fuse box mounted

under the control box. See label on fuse box cover for fuse sizing.

7. DO NOT connect aluminum field wires to electric heat kit power input terminals.

B. CONTROL WIRING (Class II)

1. Do not run low voltage wiring in conduit with power wiring.

2. Control wiring is routed through the 7/8" hole approximately 11" from the unit top

in the corner post adjacent to the control box. Use a minimum #18 AWG thermostat wire. For wire lengths exceeding 50', use #16 AWG thermostat wire. The low

voltage wires are connected to the unit pigtails which are supplied with the unit in

the low voltage connection box located below the unit control box. See Figure 10.

3. It is necessary that only heat pump thermostats be used. Please contact your distributor for part number information.

4. Figure 11 shows representative low voltage connection diagrams. Read your thermostat installation instructions for any special requirements for your specific thermostat. These connection diagrams are wired to minimize the amount of auxiliary

electric heaters to be energized during defrost.

NOTE: Units installed in Canada require that an outdoor thermostat (30,000 min.

cycles of endurance) be installed and be wired with C.E.C. Class I wiring.

C. INTERNAL WIRING

1. A diagram of the internal wiring of this unit is located on the electrical control box

cover. If any of the original wire as supplied with the appliance must be replaced,

the wire gauge and insulation must be the same as original wiring.

D. GROUNDING

14

WARNING

!

THE UNIT MUST BE PERMANENTLY GROUNDED. A GROUNDING LUG IS

PROVIDED IN THE ELECTRIC HEAT KIT FOR A GROUND WIRE. (SEE FIGURE

10.) FAILURE TO GROUND THIS UNIT CAN RESULT IN FIRE OR ELECTRICAL

SHOCK CAUSING PROPERTY DAMAGE, SEVERE PERSONAL INJURY OR

DEATH.

Loading...

Loading...