Page 1

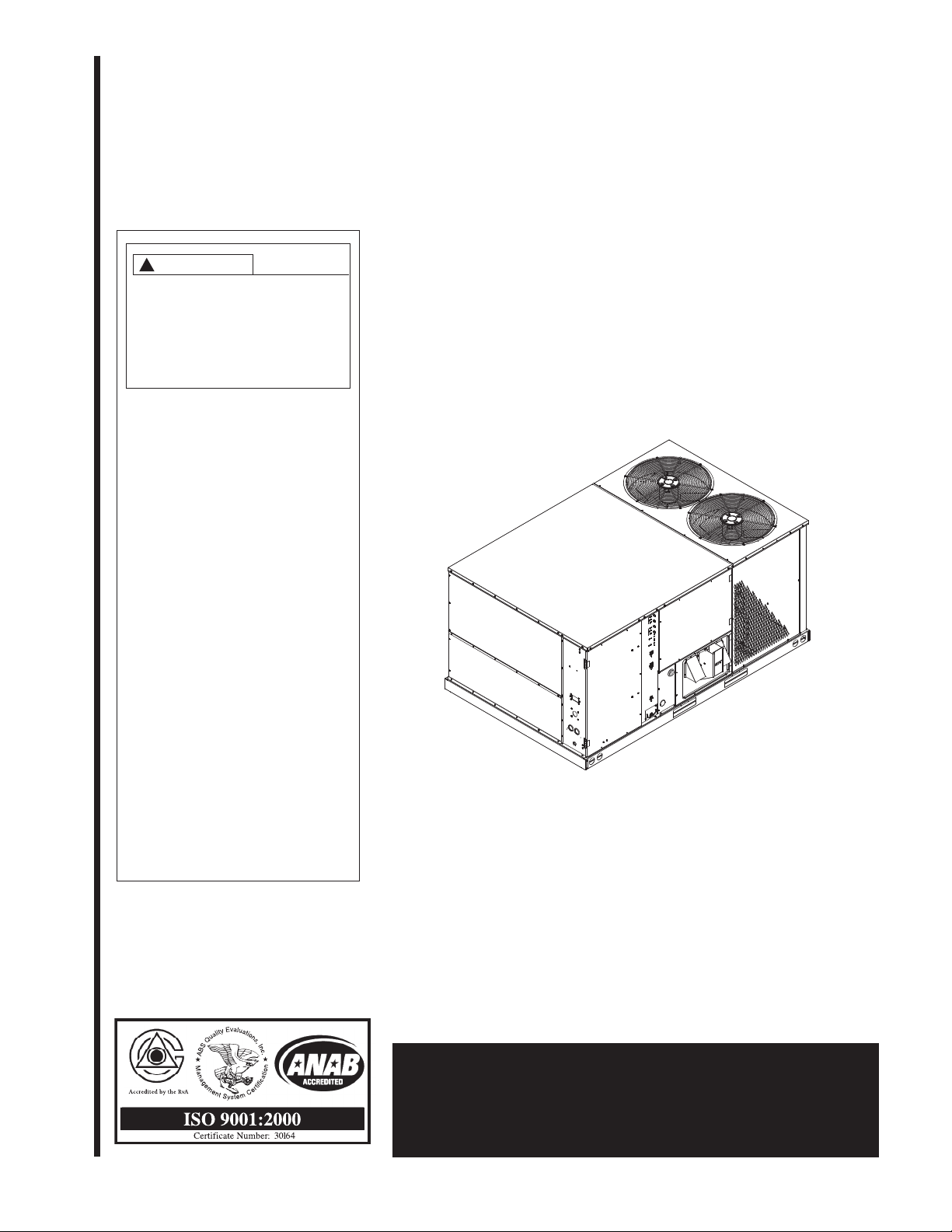

USER’S INFORMATION MANUAL

FOR YOUR COMBINATION GAS HEATING/

ELECTRIC COOLING AIR CONDITIONING UNIT

!

WARNING

FIRE OR EXPLOSION HAZARD

Failure to follow safety warnings

exactly could result in serious

injury, death or property

damage.

— Do not store or use gasoline or

other flammable vapors and

liquids in the vicinity of this or

any other appliance.

— WHAT TO DO IF YOU SMELL

GAS

• Do not try to light any

appliance.

• Do not touch any electrical

switch; do not use any phone

in your building.

• Leave the building

immediately.

• Immediately call your gas

supplier from a neighbor’s

phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas

supplier, call the fire

department.

— INSTALLATION AND SERVICE

MUST BE PERFORMED BY A

QUALIFIED INSTALLER,

SERVICE AGENCY OR THE GAS

SUPPLIER.

71/2 THRU 121/2 TON MODELS

ST-A1111-03

IMPORTANT: READ THESE

INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING TO OPERATE

THIS FURNACE.

DO NOT DESTROY.

PLEASE READ CAREFULLY AND KEEP IN A SAFE PLACE

FOR FUTURE REFERENCE BY A SERVICEMAN OR USER

OF THIS APPLIANCE.

92-20802-102-00

Page 2

INTRODUCTION

Recognize this symbol as an indication of Important Safety Information!

!

This manual contains the operating

instructions for your combination

gas/electric year-round air conditioner.

There are precautions that should be

taken to maximize satisfaction from this

ir conditioner.

a

IMPORTANT: COMPLETELY READ

ALL INSTRUCTIONS PRIOR TO

ATTEMPTING TO OPERATE OR

MAINTAIN THE PRODUCT.

his unit has been designed to give

T

you many years of efficient,

dependable comfort. With regular

maintenance, your unit will operate

satisfactorily year after year. Please

read this manual to familiarize yourself

with operation, maintenance and safety

procedures.

SAFETY

Carefully follow these safety rules:

1. The area around the unit must be

kept clear and free of all

combustible materials including

gasoline and other flammable

vapors and liquids.

2. Do not block the combustion air

inlets or the exhaust air outlet

openings.

3. Do not operate the unit without all

panels and doors securely in place.

!

WARNING

SHOULD OVERHEATING OCCUR OR

THE GAS SUPPLY FAIL TO SHUT

OFF, SHUT OFF THE MANUAL GAS

VALVE TO THE APPLIANCE BEFORE

SHUTTING OFF THE ELECTRICAL

SUPPLY. FAILURE TO DO SO CAN

RESULT IN AN EXPLOSION OR FIRE

CAUSING PROPERTY DAMAGE,

SEVERE PERSONAL INJURY OR

DEATH!

4. Any additions, changes or

conversions required in order for

the unit to satisfactorily meet the

application needs should be made

by a qualified installer, service

gency or the gas supplier, using

a

factory specified or approved parts.

Read your WARRANTY. Contact

the WARRANTOR for conversion

information. The unit was equipped

at the factory for use on NATURAL

GAS ONLY. Conversion to LP GAS

requires a special kit supplied by

the WARRANTOR.

!

WARNING

OBSTRUCTION OF THE AIR VENT

ON AN LP TANK REGULATOR CAN

CAUSE EXPLOSION OR FIRE

RESULTING IN SERIOUS PERSONAL

INJURY, DEATH OR PROPERTY

DAMAGE. PERIODICALLY INSPECT

AND CLEAN THE AIR VENT SCREEN

TO PREVENT ANY OBSTRUCTION.

KEEP PROTECTIVE REGULATOR

COVER IN PLACE, AS EXPOSURE

TO THE ELEMENTS CAN CAUSE ICE

BUILDUP AND REGULATOR

FAILURE.

5. A gas burner needs an adequate

supply of combustion and

ventilation air for proper and safe

operation. Do not block or obstruct

air openings on the unit. Do not

place anything around the unit that

could block the flow of fresh air to

the unit.

6. Do not use this unit if any part has

been under water. Immediately call

a qualified installer, service agency

or the gas supplier to inspect the

unit and to replace any part of the

control system or any gas control

that has been under water.

!

WARNING

O NOT ALLOW DEBRIS SUCH AS

D

LEAVES, GRASS, WEEDS,

SHRUBS, VINES OR SNOW

ACCUMULATE IN THE AREA

SURROUNDING THE UNIT,

PARTICULARLY IN THE VICINITY

OF THE VENT, AIR INTAKE AND

A/C CONDENSER FINS. DOING SO

CAN RESULT IN INADEQUATE

NIT PERFORMANCE OR CREATE

U

A FIRE HAZARD RESULTING IN

PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

7. The combustion air inlet/exhaust

outlet hood and surrounding area

are very hot when operating in

heating mode. Do not allow

children to play on or around

the unit.

SYSTEM OPERATION

INFORMATION

Advice to the Customer

1. Keep the filter clean. Your system

will operate more efficiently and

provide better conditioned air.

2. Arrange your furniture and drapes

so that the supply and return air

registers and grilles are

unobstructed.

3. Close doors and windows. This

will reduce the cooling load on

your system for a more

economical operation.

4. Avoid excessive use of exhaust

fans.

5. Window shades and awnings will

reduce the cooling load.

6. Do not permit the heat generated

by television, lamps or radios to

influence the thermostat

operation.

7. Except for the mounting platform,

keep all combustible articles three

feet from the unit and exhaust

system.

2

Page 3

. Unless you plan to remove panels

8

to service the unit, do not

disconnect the main power to your

unit. This is a safety precaution for

the protection of the compressor.

Otherwise, use the thermostat

switches to shut the system off.

. For extended periods of

9

inoperation, set the thermostat

system switch in the “OFF” position

and fan switch in the “AUTO”

position.

10. Do not allow the unit to become a

play stand for children.

11. IMPORTANT: Replace all blower

doors and compartment cover after

servicing the unit. Do not operate

the unit without all panels and

doors securely in place.

12. Do not allow snow or other debris

to accumulate in the vicinity of the

appliance.

THERMOSTAT

OPERATION

For cooling, position the system switch

to

“Cool” and the fan switch to “Auto.” If

constant fan operation is desired, place

the fan switch in the “On” position.

When heating is desired, position the

system switch to “HEAT” and place the

fan switch in the “Auto” position.

During the heating season, the operation

of the warm air furnace is automatic. Your

installing dealer has provided a wall

mounted thermostat which is sensitive to

the change in the temperature of the air

moving around the thermostat. When the

temperature of the air within the heated

space surrounding the thermostat

decreases, the thermostat switch

functions to initiate the ignition sequence

and open the gas valve.

he spark ignitor located on the main

T

burner tray will safely ignite the gas

(natural or LP) leaving the main burner

ports. After approximately 45 seconds of

burner operation, the blower control will

start the blower. Warm air should now

gently circulate from the supply diffusers

throughout the dwelling and return to the

furnace through return air grille(s).

When the temperature of the circulating

air reaches the temperature setting of the

thermostat, the gas valve will reclose, the

heat exchanger will cool, and the blower

will shut off after 90 seconds.

n the cooling mode, the compressor and

I

circulation air motor are energized upon a

call for cooling. When the thermostat is

satisfied or turned to the “OFF” position,

the compressor is de-energized, but the

circulation air blower continues to operate

for approximately 60 seconds to extract

the residual cooling left in the cooling coil.

We suggest that you experiment with

constant air circulation during the

heating and cooling cycles. To achieve

this style of operation, place the fan

switch on the thermostat subbase to the

“on” position. You may enjoy the comfort

associated with the continuous air

movement, constant air filtration, and the

near even temperature from floor to

ceiling.

With continuous air circulation, some

condensation on the cooling coil can

reevaporate at the end of each cycle and

cause a buildup of humidity prior to the

next cooling cycle.

SELECTION OF ROOM

TEMPERATURE

It is most important to select the

omfort temperature you desire for

c

either heating or cooling by use of the

thermostat temperature selector.

DO NOT PLAY WITH THE

THERMOSTAT. SET IT AND FORGET

IT.

If the temperature selection procedure

is new to you, ask your installing

contractor to familiarize you with the

operation of the thermostat.

3

Page 4

HEATING OPERATION

FOR YOUR SAFETY, READ

BEFORE OPERATING

!

WARNING

IF YOU DO NOT FOLLOW THESE

INSTRUCTIONS EXACTLY, A FIRE OR

EXPLOSION MAY RESULT CAUSING

PROPERTY DAMAGE, PERSONAL

INJURY OR LOSS OF LIFE.

A. This appliance is equipped with an

ignition device which automatically

lights the burners. Do not try to light the

burners by hand.

. BEFORE OPERATING smell all around

B

he appliance area for gas. Be sure to

t

mell next to the ground because some

s

gas is heavier than air and will settle on

the ground.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch, do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s

• If you cannot reach your gas

supplier, call the fire department.

• Do not return to your home until

authorized by the gas supplier for

fire department.

C. Use only your hand to push in or turn

the gas control knob. Never use tools.

If the knob will not push in or turn by

hand, don’t try to repair it, call a

qualified installer, service agency or

the gas supplier. Force or attempted

repair may result in a fire or

explosion.

D. Do not use this appliance if any part

has been under water. Immediately

call a qualified installer, service

agency or the gas supplier to inspect

the appliance and to replace any part

of the control system and any gas

control valve, electrical components,

motors or burners which have been

under water.

NORMAL FURNACE

OPERATING SEQUENCE

This unit is equipped with a two stage

integrated direct spark ignition control.

NORMAL HEAT MODE

A. Call For First Stage (low fire) Only:

1. Zone thermostat contacts close, a

call for first stage (low fire) heat is

initiated.

2. Control runs self check.

3. Control checks the high-limit switch

for normally closed contacts, each

pressure switch for normally open

contacts, and all flame rollout

switches for continuity.

4. Control energizes each inducer.

5. Control checks each pressure switch

for closure.

6. If each pressure switch is closed, the

control starts a 30 second prepurge.

If either pressure switch is still open,

the inducers will continue to be

energized until closure.

4

instructions.

HONEYWELL VR8305Q4351

TWO STAGE GAS VALVE

Used on RKNL- with 225,000 BTUH input and above

7. After prepurge timeout, spark is

initiated and gas valve opens for 2

seconds minimum, 7 second

maximum ignition trial, initiates 45

second, second stage (high fire)

warm up timing.

8. Control detects flame, de-energizes

spark and initiates 45 second delay

on blower timing. Unit is in a high fire

warm up period.

9. After a fixed 45 seconds indoor

blower delay on, the control

energizes the indoor blower.

10. After the 45 second second stage

warmup period control checks

thermostat input. If only W1 is called

for, W2 is de-energized and the

control starts a 5 second off delay on

W2 inducer.

11. After fixed 5 seconds, the W2

inducer is de-energized.

12. Control enters normal operating loop

where all inputs are continuously

checked.

13. Zone thermostat is satisfied.

14. Control de-energizes gas valve.

15. Control senses loss of flame.

16. Control initiates 5 second inducer

postpurge and 90 second indoor

blower delay off.

17. Control de-energizes inducer blower.

18. Control de-energizes indoor blower.

19. Control in the stand by mode with

solid red LED.

B. Call For Second Stage, After First

Stage Established; Starting from

A.11:

1. If a call for second stage (high fire)

is initiated after a call for first stage

heat is established, the control

energizes the W2 inducer and

energizes the second stage of the

gas valve.

2. Control enters normal operating

loop where all inputs are

continuously checked.

C. Second Stage Satisfied; First Stage

Still Called For; Starting From B.2:

1. Once the call for second stage is

satisfied, the control starts a 30

second off delay on W2 inducer

and reduces the gas valve to first

stage.

2. Control enters normal operating

loop where all inputs are

continuously checked.

D. First Stage Satisfied:

1. Zone thermostat is satisfied.

2. Control de-energizes gas valve.

3. Control senses loss of flame.

4. Control initiates 5 second inducer

postpurge and 90 second indoor

blower delay off.

Page 5

HITE RODGERS 36G55-523 TWO STAGE GAS VALVE

W

5. Control de-energizes inducer blower.

6. Control de-energizes indoor blower.

7. Control in the stand by mode with

solid red LED.

E. First Stage and Second Stage Called

Simultaneously:

1. Zone thermostat contacts close, a

call for first stage (low fire) and

second stage (high fire) heat is

initiated.

2. Control runs self check.

3. Control checks the high-limit switch

for normally closed contacts, each

pressure switch for normally open

contacts, and all flame rollout

switches for continuity.

4. Control energizes each inducer.

5. Control checks each pressure switch

for closure.

6. If each pressure switch is closed, the

control starts a 30 second prepurge.

If either switch is still open, the

inducers will continue to be

energized until closure.

Used on (-)KNL-B090, B102, B120, B150 Models

w/150,000 BTUH Input

7. After prepurge timeout, spark is

initiated and gas valve opens for 2

seconds minimum, 7 second

maximum ignition trial, and initiates

45 second stage warm up timing.

8. Control detects flame, de-energizes

spark and starts a 45 second indoor

blower delay on timing. Unit is in a

high fire warm up period.

9. After a fixed 45 seconds indoor

blower delay on, the control

energizes the indoor blower.

10. After the 45 second second stage

warmup period control checks the

thermostat input. If W1 and W2 is

present control enters normal

operating loop where all inputs are

continuously checked.

F. First Stage and Second Stage

Removed Simultaneously:

1. Upon a loss of W1 and W2 the gas

valve is de-energized.

2. Upon a loss of flame, each inducer

will complete a 5 second postpurge

and the indoor blower will complete

a 90 second delay off.

3. Control in the stand by mode with

solid red LED.

The integrated control is a three

ignition system.

After a total of three cycles without

sensing main burner flame, the system

goes into a 100% lockout mode. After

one hour, the ignition control repeats

the prepurge and ignition cycles for 3

tries and then goes into 100% lockout

mode again. It continues this sequence

of cycles and lockout each hour until

ignition is successful or power is

interrupted. During the lockout mode,

neither the ignitor or gas valve will be

energized until the system is reset by

turning the thermostat to the “OFF”

position or interrupting the electrical

5

Page 6

ower to the unit for 3 seconds or longer.

p

The induced draft blower and main

burner will shut off when the thermostat

is satisfied.

The circulating air blower will start and

run on the heating speed if the

hermostat fan switch is in the “ON”

t

position.

The integrated furnace control is

equipped with diagnostic LED. The LED

is lit continuously when there is power to

the control, with or without a call for heat.

f the LED is not lit, there is either no

I

power to the control or there is an

internal component failure within the

control, and the control should be

replaced.

If the control detects the following

failures, the LED will flash on for

approximately 1/4 second, then off for

3/4 second for designated failure

detections.

1 Flash: Failed to detect flame within the

2 Flash: Pressure switch or induced draft

3 Flash: High limit or auxiliary limit open.

4 Flash: Flame sensed and gas valve

5 Flash: Overtemperature switch open.

three tries for ignition.

blower problem detected.

not energized or flame sensed

with no “W” signal.

OPERATING INSTRUCTIONS

This appliance is equipped with

integrated furnace control. This device

lights the main burners each time the

room thermostat (closes) calls for heat.

See operating instructions on the back of

the furnace/controls access panel.

!

WARNING

DO NOT ATTEMPT TO MANUALLY

LIGHT THIS FURNACE WITH A

MATCH OR ANY OPEN FLAME.

ATTEMPTING TO DO SO CAN CAUSE

AN EXPLOSION OR FIRE RESULTING

IN PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

TO START THE FURNACE

1. Set the thermostat to its lowest

setting.

2. Turn off all electric power to the

appliance.

3. This appliance does not have a pilot.

It is equipped with an ignition device

which automatically lights the burner.

Do not

4. Remove control door.

5. Move control knob to the “OFF”

try to light the burner by hand.

position. Turn the knob by hand only,

do not use any kind of tool.

. Wait five (5) minutes to clear out any

6

gas. Then smell for gas, including

near the floor. If you smell gas,

STOP! Follow B in the safety

information on the Operating

Instructions located on the back of

the controls/access panel. If you

don’t smell gas, go to the next step.

7. Move the gas control knob from

“OFF” position to “ON” position.

Operate this appliance with the gas

control knob in the “ON” position

only. Do not use the gas control knob

as a means for throttling the burner

input rate.

. Replace the control door.

8

9. Turn on all electric power to the

appliance.

10. Set the thermostat to the desired

setting.

11. If the appliance will not operate,

follow the instructions below on how

to shut down the furnace.

!

WARNING

THE SPARK IGNITOR AND IGNITION

LEAD FROM THE IGNITION

CONTROL ARE HIGH VOLTAGE. KEEP

HANDS OR TOOLS AWAY TO

PREVENT ELECTRICAL SHOCK.

SHUT OFF ELECTRICAL POWER

BEFORE SERVICING ANY OF THE

CONTROLS. FAILURE TO ADHERE

TO THIS WARNING CAN RESULT IN

PERSONAL INJURY OR DEATH.

The initial start-up on a new installation

may require the control system to be

energized for some time until air has bled

through the system and fuel gas is

available at the burners.

TO SHUT DOWN FURNACE

1. Set the thermostat to the lowest

setting.

2. Turn off all electric power to the

appliance if service is to be

performed.

3. Remove control door.

4. Move control knob to the “OFF”

position.

5. Replace control door.

!

WARNING

SHOULD OVERHEATING OCCUR OR

THE GAS SUPPLY FAIL TO SHUT OFF,

SHUT OFF THE MANUAL GAS VALVE

TO THE APPLIANCE BEFORE

SHUTTING OFF THE ELECTRICAL

SUPPLY. FAILURE TO DO SO CAN

RESULT IN AN EXPLOSION OR FIRE

CAUSING PROPERTY DAMAGE,

SEVERE PERSONAL INJURY OR

DEATH!

MANUAL RESET

OVERTEMPERATURE

CONTROL

Manual reset limit controls are located

on the burner shield. These devices

sense blockage in the heat exchanger

or insufficient combustion air. This

shuts off the main burners if excessive

temperatures occur in the burner

compartment.

Operation of this control indicates an

abnormal condition. Therefore, the unit

should be examined by a qualified

installer, service agency, or the gas

supplier.

!

WARNING

DO NOT ATTEMPT TO DEFEAT

THIS IMPORTANT SAFETY DEVICE.

DO NOT RESET THE

OVERTEMPERATURE CONTROL

WITHOUT TAKING CORRECTIVE

ACTION TO ASSURE THAT AN

ADEQUATE SUPPLY OF

COMBUSTION AIR IS MAINTAINED

UNDER ALL CONDITIONS OF

OPERATION AND THAT NO HEAT

EXCHANGER TUBES ARE

BLOCKED OR PERFORATED.

REPLACE THIS CONTROL ONLY

WITH THE IDENTICAL

REPLACEMENT PART. FAILURE TO

ADHERE TO THIS WARNING CAN

RESULT IN PERSONAL INJURY OR

DEATH.

TROUBLESHOOTING HEATING

PROBLEM

Insufficient heating —

REMEDY

a. Increase temperature setting on

thermostat.

b. Check return air filters and change,

if necessary.

c. Recheck to assure that all supply

registers and diffusers are open.

d. Check closing of all doors and

windows.

e. Check that blower compartment

doors are in place.

f. Call your servicing contractor.

6

Page 7

COOLING OPERATION

To Operate Cooling System

To Start: Set thermostat at desired

setting with system switch on “Cool”

nd fan switch on “Auto” or “On”

a

position.

To Shut Down: Set thermostat to “Off”

position.

SEQUENCE OF OPERATION

- COOLING

1. Thermostat calls for cooling.

2. Compressor, condenser fan motor,

and circulation air blower are

energized.

3. Thermostat is satisfied and opens.

4. Compressor and condenser fan

motor are de-energized.

5. Circulation air blower is deenergized after 60 seconds.

GENERAL INFORMATION COOLING

1. If your outdoor unit is equipped with

an optional external manual high

pressure switch reset button, have

your servicing contractor familiarize

you with its location. Many models

have compressors equipped with

internal pressure relief valves using

an automatic reset feature

eliminating the need for an external

control. This high pressure switch

or the relief valve will open under

excessive high pressures to protect

the compressor. Some models with

internal relief valves will require

power interruption prior to resetting

itself. The high refrigerant pressure

may be due to a temporary

condition, so if your unit is equipped

with a reset button, you may reset it

s required. However, if the

a

problem persists, refer to Item 3,

and/or refer the problem to your

servicing contractor.

2. If the condenser coil is allowed to

become restricted by dirt, lint,

paper, grass clippings, leaves, etc.,

the system efficiency will suffer and

abnormally high refrigerant

operating pressures will result. To

correct this condition, be sure to

first cut off power to the unit and

then clean such material from the

condenser coil and cabinet. Using a

garden hose with a nozzle can be

effective in cleaning the condenser

coil, but the water should be

sprayed from the inside to outside

of the coil in the opposite direction

from the normal airflow. Disconnect

the main power before washing the

coil.

3. If you know or suspect that the

compressor s not working, you

should place the thermostat system

switch on the thermostat subbase

to the “Off” position. This will stop

the operation of the

compressor/condenser unit.

4. If you suspect that a cooling

problem has developed with your

system and before you advise you

servicing contractor, we suggest

you check the following service

hints.

TROUBLESHOOTING COOLING

PROBLEM

No cooling —

EMEDY

R

a. Set thermostat correctly.

b. Reset high pressure switch on

unit.

c. Check fusing or circuit breakers

serving unit.

d. Call servicing contractor.

PROBLEM

Insufficient cooling —

Unit operates continuously

REMEDY

a. Check air filters.

b. Check for blocked return air

system.

c. Check to see if supply registers

have been closed.

d. Check for open doors and

windows.

e. Call your servicing contractor.

Please do not attempt any servicing

operation with which you are not

familiar or experienced unless you

are advised by your servicing

contractor of the proper procedures.

ROUTINE MAINTENANCE

!

WARNING

DISCONNECT MAIN ELECTRICAL

POWER TO THE UNIT BEFORE

ATTEMPTING ANY MAINTENANCE.

FAILURE TO DO SO CAN RESULT IN

SEVERE ELECTRICAL SHOCK OR

DEATH.

Routine maintenance to be provided

by a qualified installer, service

agency or the gas supplier ONLY.

COMBUSTION AREA AND

EXHAUST SYSTEM

1. It is recommended that an annual

inspection of your furnace be done

by a qualified installer, service

agency or the gas supplier.

2. Turn OFF the electrical supply to

the furnace and remove the access

doors.

3. Inspect the gas burners and burner

compartment for dirt, rust, or scale.

!

WARNING

IF DIRT, RUST, SOOT OR SCALE

ACCUMULATIONS ARE PRESENT,

DO NOT OPERATE THIS FURNACE.

INSPECT THE HEAT EXCHANGERS

FOR LEAKS. LEAKS CAN CAUSE

TOXIC FUMES TO ENTER THE

HOME AND CAUSE INJURY OR

DEATH.

4. Inspect the exhaust area inside and

outside the appliance including the

exhaust transition piece and the

exhaust hood. Be sure that the

exhaust transition piece (inside the

appliance) and the hood are in

place and are physically sound,

without holes or excessive

corrosion. If these components

have deteriorated, have a qualified

service professional replace them

using factory specified or

approved replacement parts only.

5. Be sure that the return air duct

connections are physically sound

and are sealed to the unit.

6. Look for obvious signs of

deterioration of the unit.

7. If the unit is free of the above

conditions, replace all access

doors, except furnace access

panel, and restore electrical

power to the unit.

8. Make sure control box cover is in

place. Start the furnace and

observe its operation. Watch the

burner flames to see if they are

bright blue. If a suspected

malfunction is observed, or the

burner flames are not bright blue,

apply appropriate service.

7

Page 8

EXAMINATION OF

INSTALLATION

1. The combustion air inlets and

combustion air outlets must be

clear and free of obstructions.

2. The return and supply duct

onnections should be physically

c

sound and sealed where they

connect to the unit.

3. Check for obvious signs of

deterioration of the unit.

. CONDENSATE DRAIN — Check

4

annually and, if necessary, clean

drain pan and drain line. In winter,

keep drain and trap dry or protect

against freeze-up.

5. The blower compartment and motor

should be inspected and cleaned

periodically by your qualified

installer, service agency or the gas

supplier to prevent the possibility of

overheating due to an accumulation

of dust and dirt on the windings or

on the motor exterior. And, as

suggested elsewhere in these

instructions, the air filters should be

kept clean because dirty filters can

restrict airflow and the motor

depends upon sufficient air flowing

across and through it to keep from

overheating.

6. Perform the examination annually

to insure proper operation.

FILTER MAINTENANCE

Have your qualified installer, service

agency or the gas supplier instruct you

on how to access your filters for regular

maintenance.

!

WARNING

DISCONNECT THE MAIN POWER TO

THE OUTDOOR UNIT BEFORE

ATTEMPTING ANY MAINTENANCE

OPERATION. FAILURE TO DO SO

CAN RESULT IN SEVERE

ELECTRICAL SHOCK OR DEATH.

1. Keep air filters clean. There are

several types of material used in air

filters and there are many possible

locations for air filters. Consult with

your contractor as to the locations

of the filters and type of material in

use.

2. How To Clean:

Glass Fiber (Throwaway) — This

is a disposable type of filter. Inspect

monthly and replace when

ecessary. A new home or building

n

will normally require more frequent

attention to the filters.

Aluminum Mesh — Wash with

detergent and water. Air dry

thoroughly and renew the coating in

compliance with the manufacturer’s

nstructions.

i

Plastic Impregnated Fiber —

Wash with detergent and water or

vacuum clean, then reinstall.

IMPORTANT: Do not operate your

ystem for extended periods

s

without filters, as the dust entrained

in the air may pack into the fin area

of the evaporator coil creating a

condition which could require

extensive repairs.

!

WARNING

A PORTION OF THE DUST

ENTRAINED IN THE AIR MAY

TEMPORARILY LODGE IN THE AIR

DUCT RUNS AND AT THE SUPPLY

REGISTERS. ANY RECIRCULATED

DUST PARTICLES WILL BE HEATED

AND CHARRED BY CONTACT WITH

THE FURNACE HEAT EXCHANGER.

THIS RESIDUE WILL SOIL CEILINGS,

WALLS, DRAPES, CARPETS, AND

OTHER HOUSEHOLD ARTICLES.

LUBRICATION

IMPORTANT: DO NOT attempt to

lubricate the bearings on the blower

motor or the induced draft blower

motor. Addition of lubricants can reduce

the motor life and void the warranty.

The blower motor and induced draft

blower motor are prelubricated by the

manufacturer and do not require further

attention.

The blower motor and induced draft

blower motor must be cleaned

periodically by a qualified installer,

service agency, or the gas supplier to

prevent the possibility of overheating

due to an accumulation of dust and dirt

on the windings or on the motor

exterior. And, as suggested elsewhere

in these instructions, the air filters can

restrict airflow. The motor depends

upon sufficient air flowing across and

through it to keep from overheating.

PROTECTING

EQUIPMENT FROM THE

ENVIRONMENT

The metal parts of this unit may be

subject to rust or deterioration in

adverse environmental conditions.

This oxidation could shorten the

equipment’s useful life. Salt spray,

fog or mist in seacoast areas,

sulphur or chlorine from lawn

watering systems, and various

hemical contaminants from

c

industries such as paper mills and

petroleum refineries are especially

corrosive.

!

WARNING

DISCONNECT ALL POWER TO

UNIT BEFORE STARTING

MAINTENANCE. FAILURE TO DO

SO CAN RESULT IN SEVERE

ELECTRICAL SHOCK OR DEATH.

1. Avoid having lawn sprinkler

heads spray directly on the unit

cabinet.

2. Frequent washing of the cabinet,

fan blade and coil with fresh

water will remove most of the salt

or other contaminants that build

up on the unit.

3. Regular cleaning and waxing of

the cabinet with a good

automobile polish will provide

some protection.

4. A good liquid cleaner may be

used several times a year to

remove matter that will not wash

off with water.

Several different types of protective

coatings are offered in some areas.

These coatings may provide some

benefit, but the effectiveness of such

coating materials cannot be verified

by the equipment manufacturer.

The best protection is frequent

cleaning, maintenance and

minimal exposure to

contaminants.

8

CM 0808

Loading...

Loading...