Rheem RKKB SERIES, RKNB SERIES, RKMB SERIES Owner's Manual

FORM NO. R11-836 REV. 3

Supersedes Form No. R11-836 Rev. 2

RKKB- STANDARD EFFICIENCY SERIES

NOMINAL SIZES 15-25 TONS [52.8-87.9 kW]

ASHRAE 90.1-1989 COMPLIANT MODELS

RKMB- HIGH EFFICIENCY SERIES

NOMINAL SIZES 15 & 20 TONS [52.8 & 70.3 kW]

ASHRAE 90.1-1999 COMPLIANT MODELS

RKNB- SUPER HIGH EFFICIENCY SERIES

NOMINAL SIZE 15 TON [52.8 kW]

ENERGYSTAR COMPLIANT MODEL

PACKAGE

GAS / ELECTRIC ROOFTOP UNITS

2

TABLE OF CONTENTS

Unit Features & Benefits ..............................................................................3-6

Selection Procedure ........................................................................................7

Model Identification Options ..........................................................................8-9

General Data

RKKB- Series ......................................................................................10-18

RKMB- Series ......................................................................................19-24

RKNB- Series ......................................................................................25-27

General Data Notes ..................................................................................28

Performance Data

RKKB- Series ......................................................................................29-30

RKMB- Series............................................................................................31

RKNB- Series ............................................................................................32

Airflow Performance

RKKB- Series ......................................................................................33-34

RKMB- Series ......................................................................................33-34

RKNB- Series ............................................................................................33

Electrical Data

RKKB- Series ......................................................................................35-36

RKMB- Series ......................................................................................37-38

RKNB- Series ......................................................................................39-40

Dimensional Data ....................................................................................41-44

Accessories ............................................................................................45-57

Mechanical Specifications ........................................................................58-59

Typical Wiring ..........................................................................................60-65

Limited Warranty ..........................................................................................68

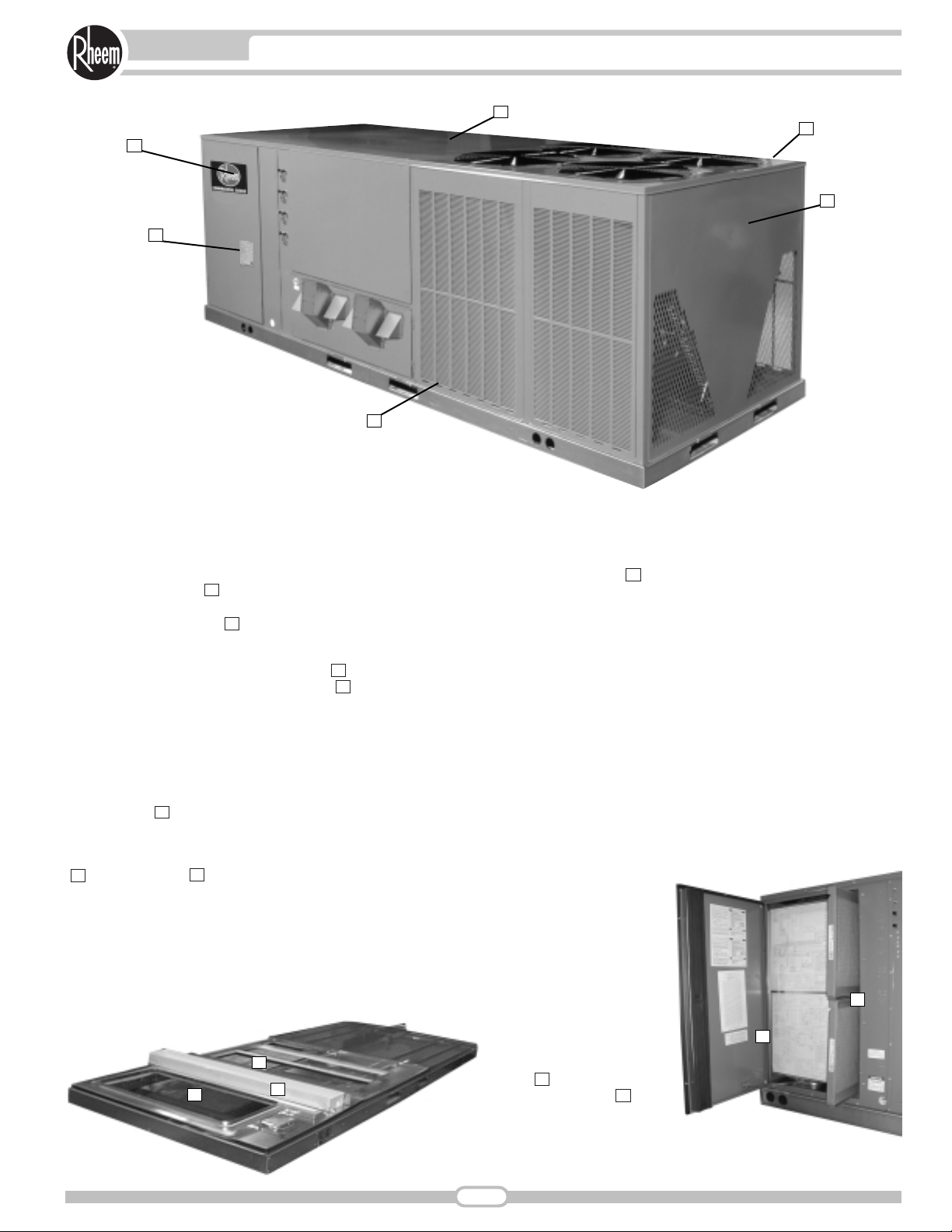

Rheem Package equipment is designed from the ground up with

the latest features and benefits required to compete in today’s

market. The clean design stands alone in the industry and is a

testament to the quality, reliability, ease of installation and serviceability that goes into each unit. Outwardly, the large Rheem Com-

mercial Series

TM

label ( ) identifies the brand to the customer.

The sheet-metal cabinet ( ) uses nothing less than 18-gauge

material for structural components with an underlying coat of

G90. To ensure the leak-proof integrity of these units, the design

utilizes a one-piece top with a 1/8" drip lip ( ), gasket-protected

panels and screws. The Rheem hail guard ( ) is its trademark,

and sets the standard for coil protection in the industry. Every

Rheem package unit uses the toughest finish in the industry,

using electro deposition baked-on enamel tested to withstand a

rigorous 1000-hour salt spray test, per ASTM B117.

Anything built to last must start with the right foundation. In this

case, the foundation is 14-gauge, commercial-grade, full-perimeter base rails ( ), which integrate fork slots and rigging holes to

save set-up time on the job site. The base pan is stamped, which

forms a 1-1/8" flange around the supply and return opening and

has eliminated the worry of water entering the conditioned space

( ). The drainpan ( ) is made of material that resists the

growth of harmful bacteria and is sloped for the latest IAQ benefits. The insulation has been placed on the underside of the

basepan, removing areas that would allow for potential moisture

accumulation, which can facilitate growth of harmful bacteria. All

insulation is secured with both adhesive and mechanical fasteners, and all edges are hidden.

During development, each unit was tested to U.L. 1995, ANSI

21.47, ARI 340-370 and other Rheem-required reliability tests.

Rheem adheres to stringent IS0 9002 quality procedures, and

each unit bears the U.L. and ARI certification labels located on

the unit nameplate ( ). Contractors can rest assured that when

a Rheem package unit arrives at the job, it is ready to go with a

factory charge and quality checks. Each unit also proudly displays the “Made in the USA” designation.

Access to all major compartments is from the front of the unit,

including the filter and electrical compartment, blower compartment, furnace section, and outdoor section. Each panel is permanently embossed with the compartment name (control/filter

access, blower access and furnace access).

Electrical and filter compartment access is through a large, toolless, hinged-access panel. On the outside of the panel is the unit

nameplate, which contains the model and serial number, electrical data and other important unit information.

The unit charging chart is located on the inside of the electrical

and filter compartment door. Electrical wiring diagrams are found

on the control box cover,

which allows contractors

to move them to more

readable locations. To

the right of the control

box the model and serial

number can be found.

Having this information

on the inside will assure

model identification for

the life of the product.

The production line quality test assurance label is

also placed in this location ( ). The two-inch

throwaway filters ( )

are easily removed on a

tracked system for easy

replacement.

10

9

8

7

6

5

4

3

2

1

6

6

7

9

10

2

8

1

4

3

5

3

UNIT FEATURES & BENEFITS—RKKB/RKMB/RKNB- SERIES

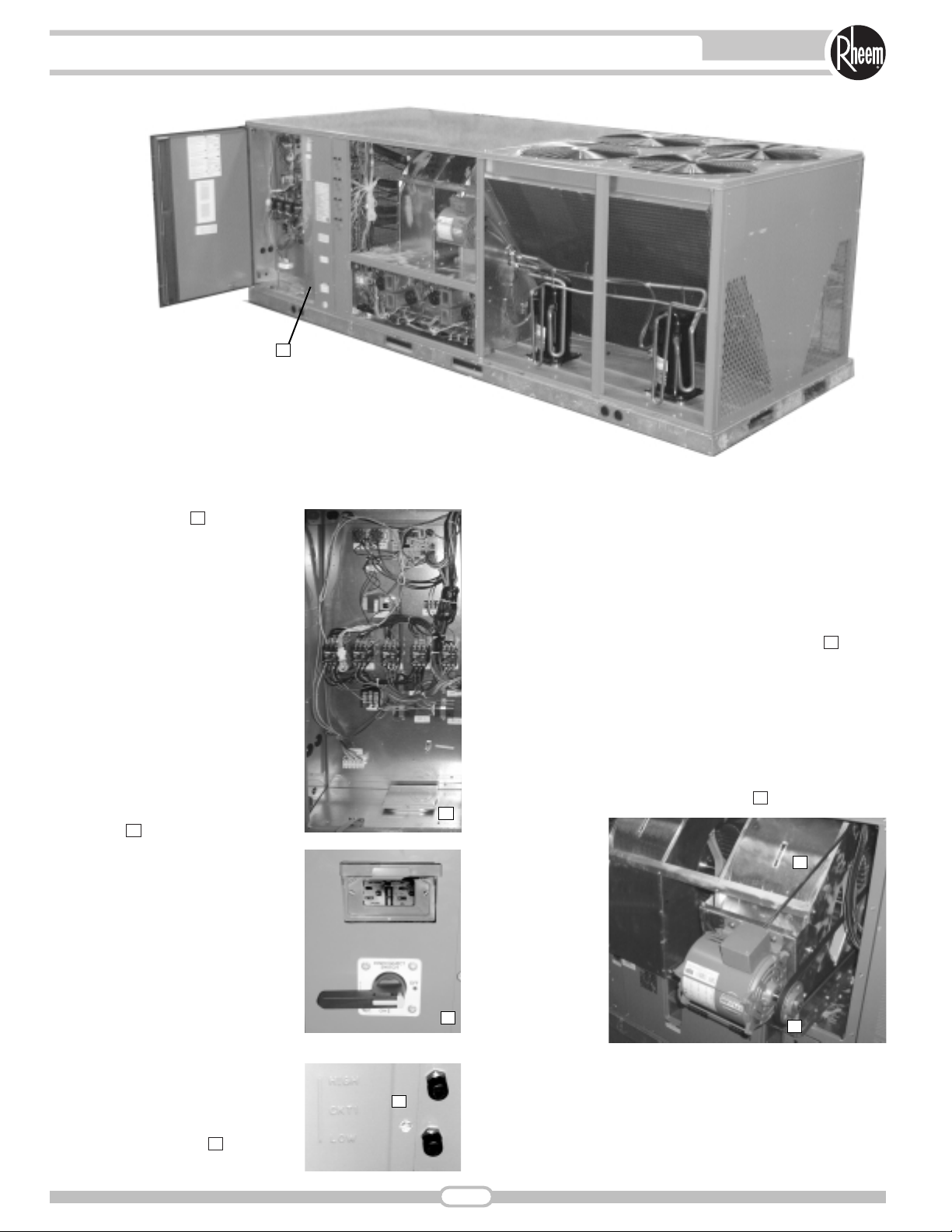

Inside the control box ( ), each electrical component is clearly identified with

a label that matches the component to

the wire diagram for ease of trouble

shooting. All wiring is numbered on

each end of the termination and colorcoded to match the wiring diagram. The

integrated furnace control, used to control furnace operation, incorporates a

flashing LED troubleshooting device.

Flash codes are clearly outlined on the

unit wiring diagram. The control transformer has a low voltage circuit breaker

that trips if a low voltage electrical short

occurs. There is a blower contactor

and compressor contactor for each

compressor.

For added convenience in the field, a

factory-installed convenience outlet and

disconnect ( ) are available. Low and

High voltage can enter either from the

side or through the base. Low-voltage

connections are made through the lowvoltage terminal strip. For ease of

access, the U.L.-required low voltage

barrier can be temporarily removed for

low-voltage termination and then reinstalled. The high-voltage connection is

terminated at the high-voltage terminal

block. The suggested mounting for the

field-installed disconnect is on the exterior side of the electrical control box.

To the right of the electrical and filter

compartment are the externally

mounted gauge ports, which are permanently identified by embossed wording

that clearly identifies the compressor

circuit, high pressure connection and

low pressure connection ( ). With the

gauge ports mounted externally, an

accurate diagnostic of system operation can be performed

quickly and easily.

The blower compartment is to the right of the gauge ports and

can be accessed by removing 5/16" washer-head screws. This

panel is not hinged to assure a water-tight fit with the unit. To

allow easy maintenance of the blower assembly, the entire

assembly easily slides out by removing two 3/8" screws from the

blower retention bracket. The adjustable motor pulley ( ) can

easily be adjusted by loosening the bolts on either side of the

motor mount. Removing the bolts allows for easy removal of the

blower pulley by pushing the blower assembly up to loosen the

belt. Once the belt is removed, the motor sheave can be adjusted

to the desired number of turns, ranging from 0 to 6 turns open.

Where the demands for the job require high static, Rheem has

high-static drives available that deliver nominal airflow up to 2" of

static. By referring to the airflow performance tables listed in the

installation instructions, proper static pressure and CFM requirements can be dialed in. The scroll housing ( ) and blower scroll

provide quiet and

efficient airflow.

The blower

sheave is secured

by an “H” bushing

which firmly

secures the pulley

to the blower shaft

for years of trouble-free operation.

The “H” bushing

allows for easy

removal of the

blower pulley from

the shaft, as

opposed to the

use of a set screw, which can score the shaft, creating burrs that

make blower-pulley removal difficult.

15

14

13

12

11

10

13

11

12

14

15

4

UNIT FEATURES & BENEFITS—RKKB/RKMB/RKNB- SERIES

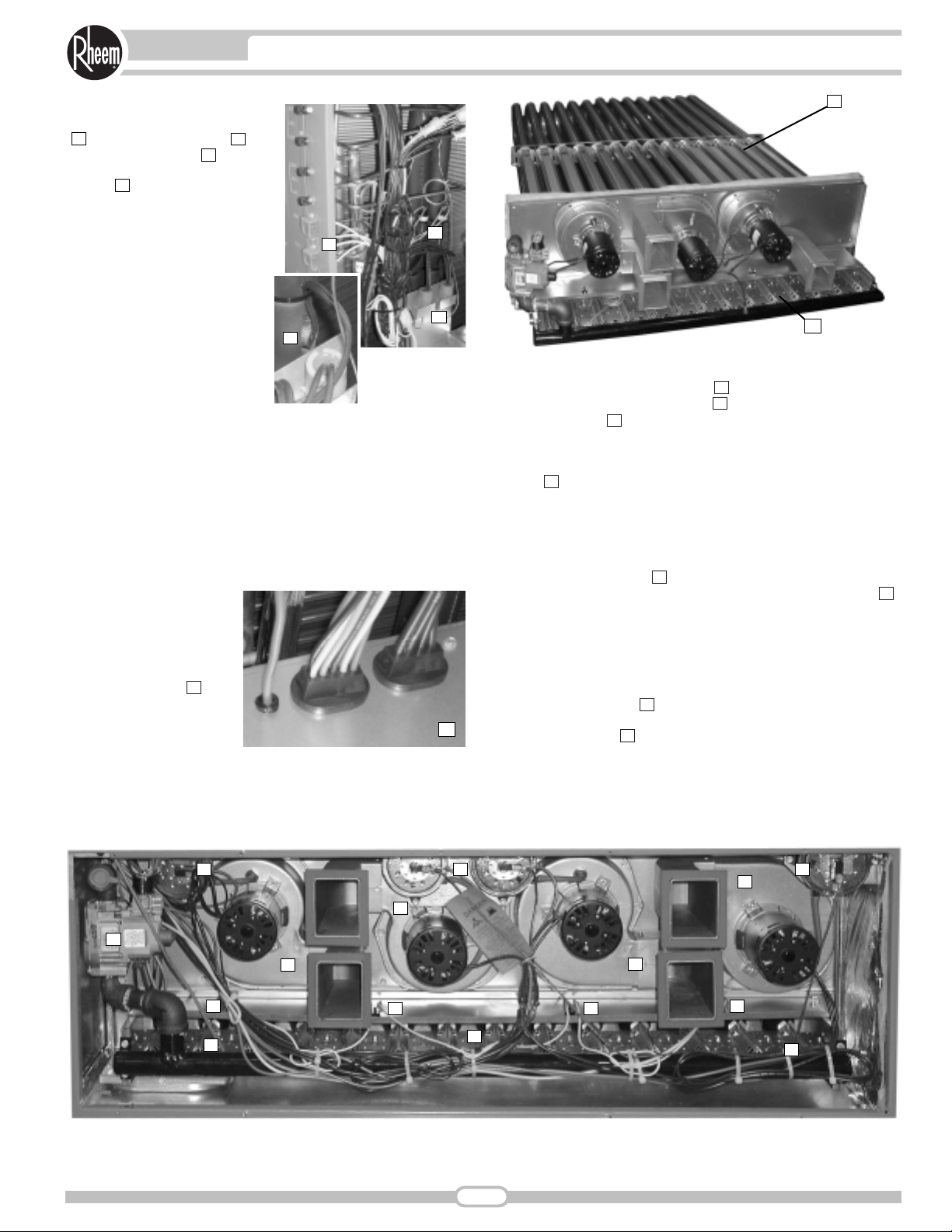

Also inside the blower compartment is the low-ambient control

( ), low-pressure switch ( ),

high-pressure switch ( ) and

freeze stat refrigerant safety

device ( ). The low-ambient

control allows for operation of the

compressor down to 0 degrees

ambient temperature by cycling

the outdoor fans on high pressure.

The high-pressure switch will

shut off the compressors if

pressures exceeds, 450 PSIG

are detected, this may occur if

the outdoor fan motor fails. The

low-pressure switch shuts off

the compressors if low pressure

is detected due to loss of

charge. The freeze stat protects

the compressor if the evaporator coil gets too cold (below

freezing) due to low airflow. Each factory-installed option is

brazed into the appropriate high or low side and wired appropriately. Use of polarized plugs and sharder fittings allow for easy

field installation.

Inside the blower compartment the interlaced evaporator can

also be viewed. The evaporator uses enhanced fin technology for

maximum heat transfer. The cap-tube metering device assures

even distribution of refrigerant throughout the evaporator.

Wiring throughout the unit

is neatly bundled and

routed. Where wire harnesses go through the

condenser bulkhead or

blower deck, a molded wire

harness assembly ( )

provides an air-tight and

water-tight seal, and provides strain relief. Care is

also taken to tuck raw

edges of insulation behind sheet metal to improve indoor air

quality.

The furnace compartment contains the latest furnace technology

on the market. The draft inducers ( ) draw the flame from the

Rheem exclusive in-shot burners ( ) into the aluminized tubular

heat exchanger ( ) for clean, efficient gas heat. Stainless steel

heat exchangers can be factory installed for those applications

that have high fresh-air requirements, or applications in corrosive

environments. Each furnace is equipment with a two-stage gas

valve ( ), which provides two stages of gas heat input. The first

stage operates at 50% of the second stage (full fire). 81% steady

state efficiency is maintained on both first and second stage by

staging the multiple inducers to optimize the combustion airflow

and maintain a near stioceometric burn at each stage.

The direct spark igniter ( ) assures reliable ignition in the most

adverse conditions. This is coupled with remote flame sense ( )

to assure that the flame has carried across the entire length of

the burner assembly. Gas supply can be routed from the side or

up through the base.

Each furnace has the following safety devices to assure consistent and reliable operation after ignition:

• Pressures switches ( ) to assure adequate combustion airflow

before ignition.

• Rollout switches ( ) to assure no obstruction or cracks in the

heat exchanger.

• A limit device that protects the furnace from over-temperature

problems.

28

27

26

25

24

23

22

21

20

19

18

17

16

18

19

24

21

21

26

27 27 27

25

2828

22

23

22

17

16

20

21

21

2828

5

UNIT FEATURES & BENEFITS—RKKB/RKMB/RKNB- SERIES

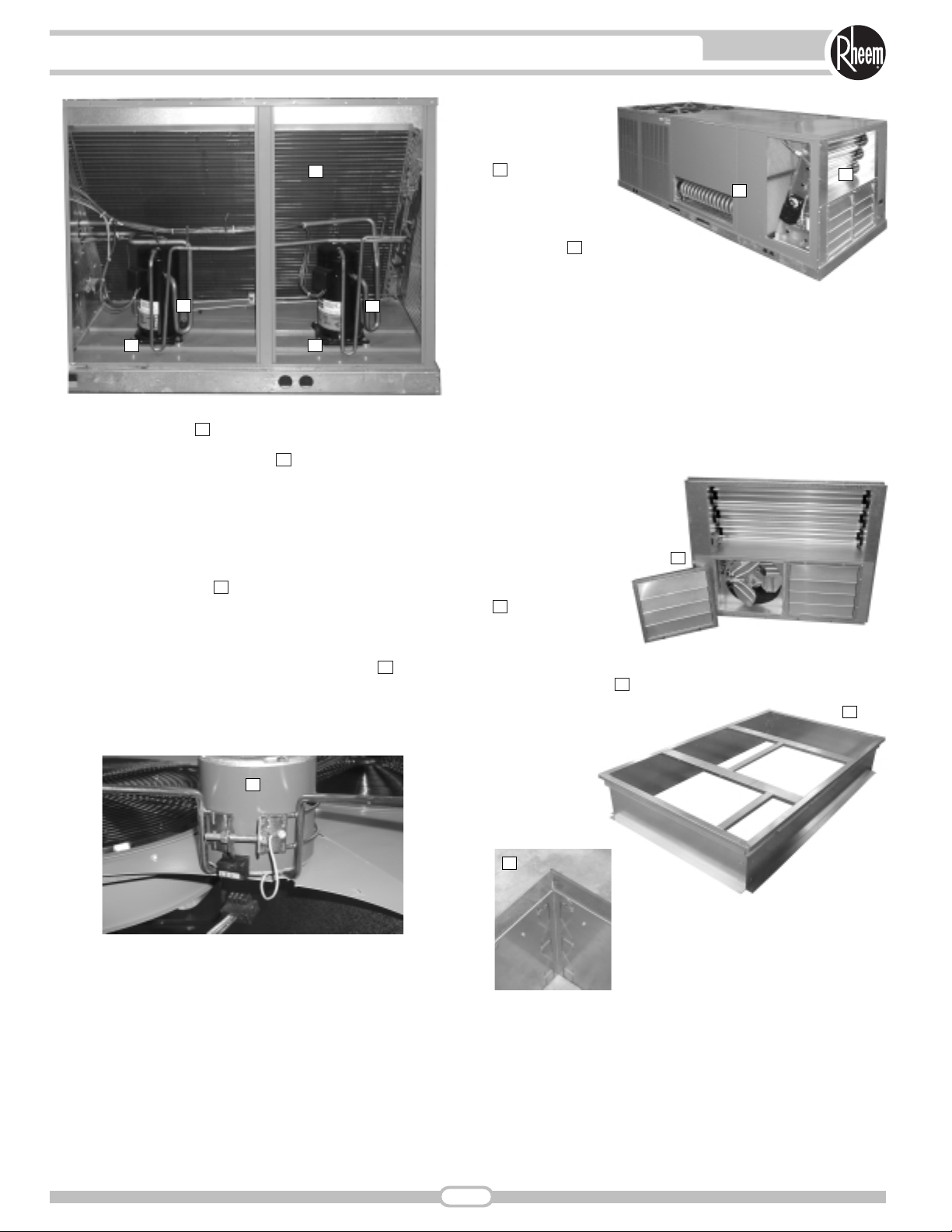

The compressor compartment houses the heartbeat of the unit.

The scroll compressor ( ) is known for its long life, and for

reliable, quiet, and efficient operation. The suction and discharge

lines are designed with shock loops ( ) to absorb the strain and

stress that the starting torque, steady state operation, and shut

down cycle impose on the refrigerant tubing. Each compressor

and circuit is independent for built-in redundancy, and each circuit

is clearly marked throughout the system. Each unit has two

stages of efficient cooling operation, first stage is approximately

50% of second stage.

The condenser fan motor ( ) can easily be accessed and maintained by removing the protective fan grille. The polarized plug

connection allows the motor to be changed quickly and eliminates the need to snake wires through the unit.

The outdoor coil uses the latest enhanced fin design ( ) for the

most effective method of heat transfer. The outdoor coil is protected by louvered panels, which allow unobstructed airflow while

protecting the unit from both Mother Nature and vandalism.

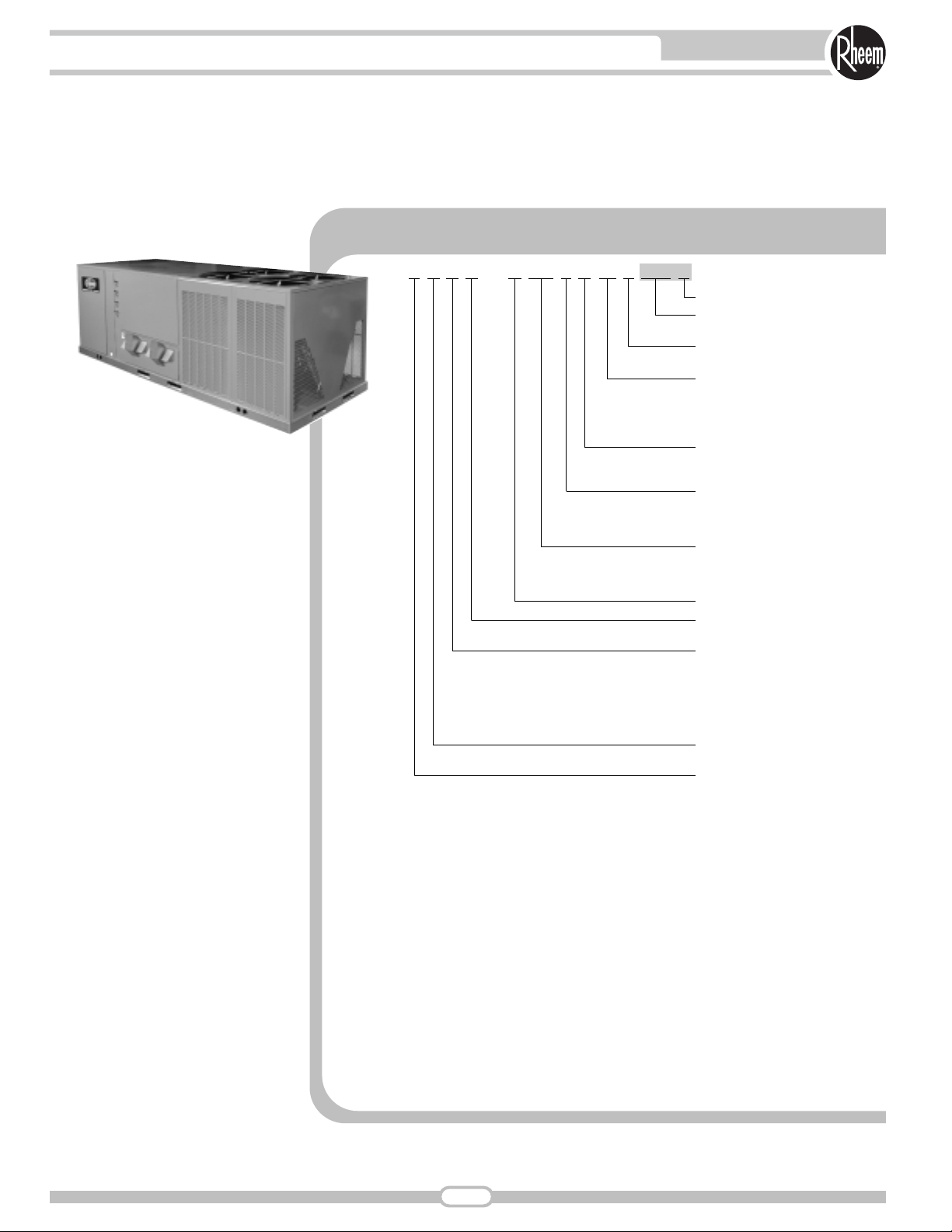

Each unit is

designed for both

downflow or horizontal applications

( ) for job configuration flexibility.

The return air

compartment can

also contain an

economizer ( ). Two

models exits, one for downflow

applications, and one for horizontal

applications. Each unit is pre-wired for the

economizer to allow quick plug-in installation. The

economizer is also available as a factory-installed option. Power

Exhaust is easily field-installed. The economizer, which provides

free cooling when outdoor conditions are suitable and also provides fresh air to meet local requirements, comes standard with

single enthalpy controls. The controls can be upgraded to dual

enthalpy easily in the field. The direct drive actuator combined

with gear drive dampers has eliminated the need for linkage

adjustment in the field. The economizer control has a minimum

position setpoint, an outdoor-air setpoint, a mix-air setpoint, and a

CO

2

setpoint. Barometric

relief is standard on all

economizers. The power

exhaust is housed in the

barometric relief opening

and is easily slipped in with

a plug-in assembly.

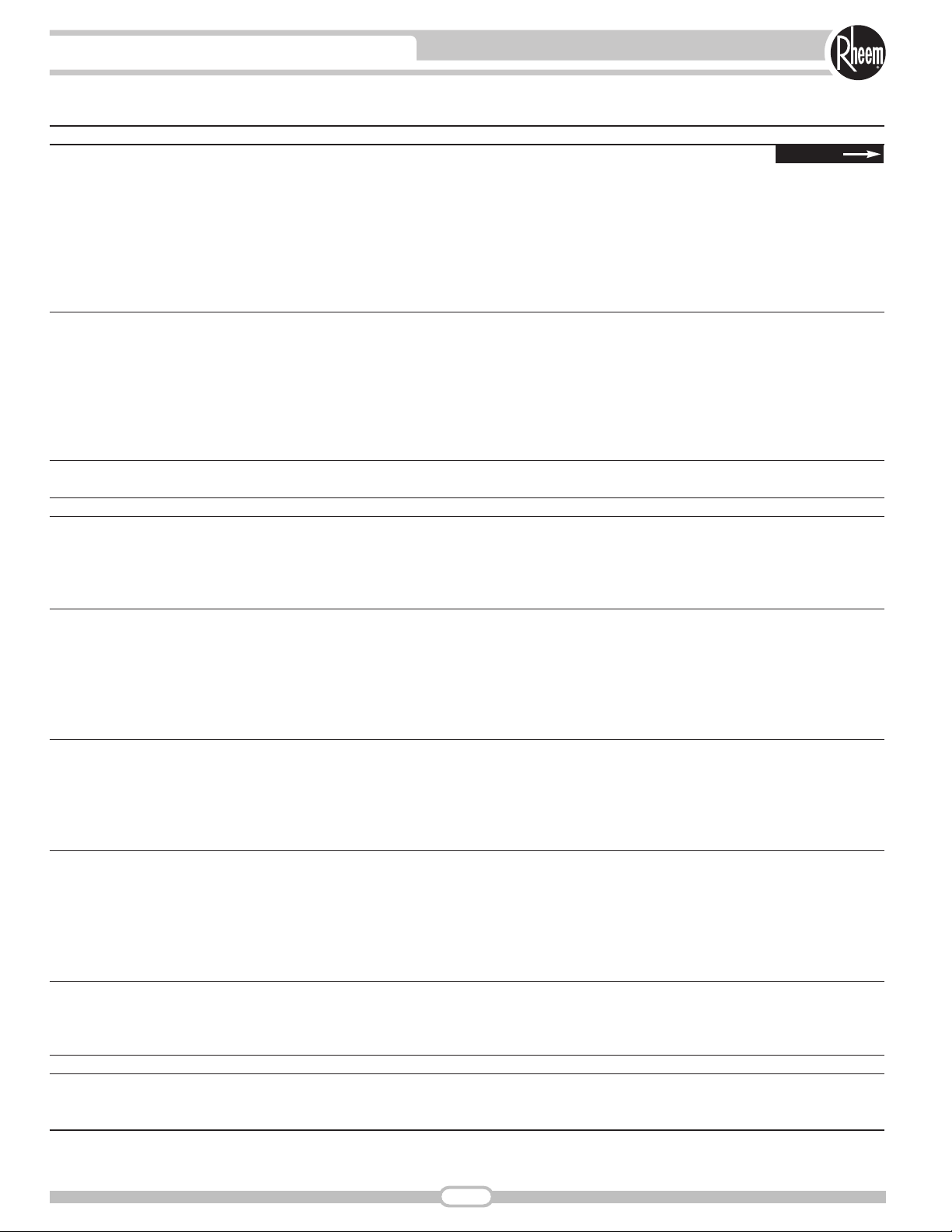

The Rheem roofcurb

( ) is made for

toolless assembly at

the jobsite by sequentially engaging the

corner brackets into the

adjacent curb sides ( ), which makes the

assembly process quick and easy.

36

35

34

33

32

31

30

29

29

32

30

29

35

34

34

33

30

36

31

6

UNIT FEATURES & BENEFITS—RKKB/RKMB/RKNB- SERIES

To select an RKKB- Cooling and Heating unit to meet a job

requirement, follow this procedure, with example, using data

supplied in this specification sheet.

1. DETERMINE COOLING AND HEATING REQUIREMENTS

AND SPECIFIC OPERATING CONDITIONS FROM PLANS

AND SPECS.

Example:

Total cooling capacity— 205,000 BTUH [60.1 kW]

Sensible cooling capacity— 155,000 BTUH [45.4 kW]

Heating capacity— 235,000 BTUH [68.9 kW]

*Condenser Entering Air— 95°F [35°C] DB

*Evaporator Mixed Air Entering—65°F [18°C] WB;

78°F [26°C] DB

*Indoor Air Flow (vertical)— 7200 CFM [3398 L/s]

*External Static Pressure— .70 in. WG

2. SELECT UNIT TO MEET COOLING REQUIREMENTS.

Since total cooling is within the range of a nominal 20 ton

[70.3 kW] unit, enter cooling performance table at 95°F [35°C]

DB condenser inlet air. Interpolate between 63°F [2°C] and

67°F [19°C] to determine total and sensible capacity and

power input for 65°F [18°C] WB evap inlet air at 7400 CFM

[1888 L/s] indoor air flow (table basis):

Total Capacity = 232,700 BTUH [68.2 kW]

Sensible Capacity = 186,500 BTUH [54.66 kW]

Power Input (Compressor and Cond. Fans) = 21,600 watts

Use formula in note ➀ to determine sensible capacity at 78°F

[26°C] DB evaporator entering air:

Sensible Capacity = 172,500 BTUH [50.55 kW]

3. CORRECT CAPACITIES OF STEP 2 FOR ACTUAL

AIR FLOW.

Select factors from airflow correction table at 7200 CFM

[3398 L/s] and apply to data obtained in step 2 to obtain

gross capacity:

Total Capacity, 232,700 x .995 = 231,540 BTUH [67.86 kW]

Sensible Capacity, 172,500 x .987 = 170,260 BTUH [49.90 kW]

Power Input 21,600 x .999 = 21,578 Watts

These are Gross Capacities, not corrected for blower motor

heat or power.

4. DETERMINE BLOWER SPEED AND WATTS TO

MEET SYSTEM DESIGN.

Enter Indoor Blower performance table at 7200 CFM

[3398 L/s]. Total ESP (external static pressure) per the spec of

.70 in. includes the system duct and grilles. Add from the table

“Component Air Resistance,” .15 for wet coil, .05 for downflow

air flow, for a total selection static pressure of .900 (.9) inches

of water, and determine:

RPM = 942

WATTS = 4,717

DRIVE = M (standard 7.5 H.P. motor)

5. CALCULATE INDOOR BLOWER BTUH HEAT EFFECT

FROM MOTOR WATTS, STEP 4.

BTUH = 4,717 x 3.412 = 16,094

6. CALCULATE NET COOLING CAPACITIES, EQUAL TO

GROSS CAPACITY, STEP 3, MINUS INDOOR BLOWER

MOTOR HEAT.

Net Total Capacity = 231,540 – 16,094 =

215,446 BTUH [63.14 kW]

Net Sensible Capacity = 170,260 – 16,094 =

154,166 BTUH [45.18 kW]

7. CALCULATE UNIT INPUT AND JOB EER.

Total Power Input = 21,578 (step 3) + 4,717

(step 4) = 26,295 Watts

EER =

Net Total BTUH [kW] (step 6)=215,446

= 8.19

Power Input, Watts (above) 26,295

8. SELECT UNIT HEATING CAPACITY.

From Physical Data Table read that gas heating output

(input rating x efficiency) is:

Heating Capacity = 243,000 BTUH [71.2 kW]

*NOTE: These operating conditions are typical of a commercial applica-

tion in a 95°F/79°F [35°C/26°C] design area with indoor design

of 76°F [24°C] DB and 50% RH and 10% ventilation air, with

the unit roof mounted and centered on the zone it conditions

by ducts.

[ ] Designates Metric Conversions

7

SELECTION PROCEDURE EXAMPLE—RKKB/RKMB/RKNB- SERIES

RKKB—A180CL25EXXX

Economizer Option (See Next Page)

Factory Installed Options

(See Next Page)

Ignition System

E = Electric

Heating Capacity (MBH)

25 = 250,000 [73.27] 15 Ton

30 = 300,000 [87.92] 20/25 Ton

35 = 350,000 [102.57] 15 Ton

40 = 400,000 [117.23] 20/25 Ton

Drive Package

L = Belt Drive

M = Belt Drive—High Static

Electrical Designation

C = 208-230 V, 3 PH, 60 Hz

D = 460 V, 3 PH, 60 Hz

Y = 575 V, 3 PH, 60 Hz

Cooling Capacity (BTUH) [kW]

180 = 180,000 [52.75]

240 = 240,000 [70.34]

300 = 300,000 [87.92]

Future Technical Variations

Design Series

B = “B Series Cabinet”

Efficiency Designation

K = Standard Efficiency

ASHRAE 90.1-1989 Compliant

M = High Efficiency

ASHRAE 90.1-1999 Compliant

N = Super High Efficiency

EnergyStar Compliant

Product Classification

K = Rooftop—Commercial

Tradebrand

R = Rheem Packaged Gas/Electric

[ ] Designates Metric Conversions

8

MODEL IDENTIFICATION—RKKB/RKMB/RKNB- SERIES

Option Code

Low Ambient

Time Delay

Freeze Stat

Stainless Steel

Heat Exchanger

AA

Unwired Convenience Outlet

AF x

AH x

BN x x

CL x x x

Unfused Services Discount

PB x x

AJ x

No Options

FACTORY INSTALLED OPTION CODES FOR RKKB, RKMB & RKNB

“x” indicates factory installed option.

ECONOMIZER SELECTION FOR RKKB, RKMB & RKNB

Example: RKKB-A240CL40EXXX (where XX is factory installed option)

Example: No Options

RKKB-A240CL40E

Example: No option with factory installed economizer

RKKB-A240CL40EAAB

Example: Options with low ambient, time delay and freeze stat, unwired convenience outlet, unfused service disconnect, and stainless steel heat exchanger with no factory

installed economizer

RKKB-A240CL40ECLA

Example: Options same as above with factory installed economizer

RKKB-A240CL40ECLB

“x” indicates factory installed option.

Instructions for Factory Installed Option(s) Selection

Note: Three characters following the model number will be utilized to designate a factory-installed option or

combination of options. If no factory option(s) is required, nothing follows the model number.

Step 1. After a basic rooftop model is selected, choose a two-character option code from the FACTORY

INSTALLED OPTION SELECTION TABLE.

Proceed to Step 2.

Step 2. The last option code character is utilized for factory-installed economizers. Choose a character from

the FACTORY INSTALLED ECONOMIZER SELECTION TABLE.

9

OPTIONS—RKKB/RKMB/RKNB- SERIES

No Economizer

A x

B x

Single Enthalpy Economizer

With Barometric Relief

Model RKKB- Series A180CL25E A180CL35E A180CM25E A180CM35E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 188,000 [55.1] 188,000 [55.1] 188,000 [55.1] 188,000 [55.1]

EER/SEER

2

9/NA 9/NA 9/NA 9/NA

Nominal CFM/ARI Rated CFM [L/s] 6000/6000 [2831/2831] 6000/6000 [2831/2831] 6000/6000 [2831/2831] 6000/6000 [2831/2831]

ARI Net Cooling Capacity Btu [kW] 180,000 [52.7] 180,000 [52.7] 180,000 [52.7] 180,000 [52.7]

Net Sensible Capacity Btu [kW] 134,000 [39.3] 134,000 [39.3] 134,000 [39.3] 134,000 [39.3]

Net System Power kW 20 20 20 20

Heating Performance (Package Gas/Electric)

4

Heating Input Btu [kW] (1st Stage /2nd Stage) 125,000/250,000 [36.6/73.2]175,000/350,000 [51.3/102.6]125,000/250,000 [36.6/73.2]175,000/350,000 [51.3/102.6]

Temperature Rise Range °F [°C] 15-45 [8.3/25] 30-60 [16.7/33.3] 15-45 [8.3/25] 30-60 [16.7/33.3]

Steady State Efficiency (%) 81 81 81 81

Net Weight lbs. [kg] 1790 [812] 1817 [824] 1820 [826] 1847 [838]

No. Burners 10 14 10 14

(3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610]

No. Stages 2 2 2 2

Integrated Part Load Value

3

9.9 9.9 9.9 9.9

Heating Output Btu [kW] (1st Stage /2nd Stage) 101,500/203,000 [29.7/59.5] 142,000/284,000 [41.6/83.2] 101,500/203,000 [29.7/59.5] 142,000/284,000 [41.6/83.2]

Compressor

No./Type 4/Scroll 4/Scroll 4/Scroll 4/Scroll

Outdoor Sound Rating (dB)

5

91 91 91 91

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 36 [3.34] 36 [3.34] 36 [3.34] 36 [3.34]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Net Latent Capacity Btu [kW] 46,000 [13.5] 46,000 [13.5] 46,000 [13.5] 46,000 [13.5]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46]

Rows / FPI [FPcm] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 16000 [7550] 16000 [7550] 16000 [7550] 16000 [7550]

No. Motors/HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 3 3 5 5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 184 184

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Ye s

(No.) Size Recommended in. [mm] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 82/72 [2325/2041] 82/72 [2325/2041] 82/72 [2325/2041] 82/72 [2325/2041]

Weights

Ship Weight lbs. [kg] 2010 [912] 2037 [924] 2040 [925] 2067 [938]

Gas Connection Pipe Size in. [mm] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05]

CONTINUED

NOM. SIZES 15-25 TONS [52.8-87.9 kW] ASHRAE 90.1-1989 COMPLIANT MODELS

See Page 28 for Notes. [ ] Designates Metric Conversions

10

GENERAL DATA—RKKB- SERIES

GENERAL DATA—RKKB- SERIES

Model RKKB- Series A180DL25E A180DL35E A180DM25E A180DM35E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 188,000 [55.1] 188,000 [55.1] 188,000 [55.1] 188,000 [55.1]

EER/SEER

2

9/NA 9/NA 9/NA 9/NA

Nominal CFM/ARI Rated CFM [L/s] 6000/6000 [2831/2831] 6000/6000 [2831/2831] 6000/6000 [2831/2831] 6000/6000 [2831/2831]

ARI Net Cooling Capacity Btu [kW] 180,000 [52.7] 180,000 [52.7] 180,000 [52.7] 180,000 [52.7]

Net Sensible Capacity Btu [kW] 134,000 [39.3] 134,000 [39.3] 134,000 [39.3] 134,000 [39.3]

Net System Power kW 20 20 20 20

Heating Performance (Package Gas/Electric)

4

Heating Input Btu [kW] (1st Stage /2nd Stage) 125,000/250,000 [36.6/73.2]175,000/350,000 [51.3/102.6]125,000/250,000 [36.6/73.2]175,000/350,000 [51.3/102.6]

Temperature Rise Range °F [°C] 15-45 [8.3/25] 30-60 [16.7/33.3] 15-45 [8.3/25] 30-60 [16.7/33.3]

Steady State Efficiency (%) 81 81 81 81

Net Weight lbs. [kg] 1806 [819] 1841 [835] 1836 [833] 1871 [849]

No. Burners 10 14 10 14

(3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610]

No. Stages 2 2 2 2

Integrated Part Load Value

3

9.9 9.9 9.9 9.9

Heating Output Btu [kW] (1st Stage /2nd Stage) 101,500/203,000 [29.7/59.5] 142,000/284,000 [41.6/83.2] 101,500/203,000 [29.7/59.5] 142,000/284,000 [41.6/83.2]

Compressor

No./Type 4/Scroll 4/Scroll 4/Scroll 4/Scroll

Outdoor Sound Rating (dB)

5

91 91 91 91

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 36 [3.34] 36 [3.34] 36 [3.34] 36 [3.34]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Net Latent Capacity Btu [kW] 46,000 [13.5] 46,000 [13.5] 46,000 [13.5] 46,000 [13.5]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46]

Rows / FPI [FPcm] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 16000 [7550] 16000 [7550] 16000 [7550] 16000 [7550]

No. Motors/HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 3 3 5 5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 184 184

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Ye s

(No.) Size Recommended in. [mm] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 82/72 [2325/2041] 82/72 [2325/2041] 82/72 [2325/2041] 82/72 [2325/2041]

Weights

Ship Weight lbs. [kg] 2026 [919] 2061 [935] 2056 [933] 2091 [948]

Gas Connection Pipe Size in. [mm] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05]

CONTINUED

NOM. SIZES 15-25 TONS [52.8-87.9 kW] ASHRAE 90.1-1989 COMPLIANT MODELS

See Page 28 for Notes. [ ] Designates Metric Conversions

11

12

GENERAL DATA—RKKB- SERIES

Model RKKB- Series A180YL25E A180YL35E A180YM25E A180YM35E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 188,000 [55.1] 188,000 [55.1] 188,000 [55.1] 188,000 [55.1]

EER/SEER

2

9/NA 9/NA 9/NA 9/NA

Nominal CFM/ARI Rated CFM [L/s] 6000/6000 [2831/2831] 6000/6000 [2831/2831] 6000/6000 [2831/2831] 6000/6000 [2831/2831]

ARI Net Cooling Capacity Btu [kW] 180,000 [52.7] 180,000 [52.7] 180,000 [52.7] 180,000 [52.7]

Net Sensible Capacity Btu [kW] 134,000 [39.3] 134,000 [39.3] 134,000 [39.3] 134,000 [39.3]

Net System Power kW 20 20 20 20

Heating Performance (Package Gas/Electric)

4

Heating Input Btu [kW] (1st Stage /2nd Stage) 125,000/250,000 [36.6/73.2]175,000/350,000 [51.3/102.6]125,000/250,000 [36.6/73.2]175,000/350,000 [51.3/102.6]

Temperature Rise Range °F [°C] 15-45 [8.3/25] 30-60 [16.7/33.3] 15-45 [8.3/25] 30-60 [16.7/33.3]

Steady State Efficiency (%) 81 81 81 81

Net Weight lbs. [kg] 1806 [819] 1817 [824] 1836 [833] 1871 [849]

No. Burners 10 14 10 14

(3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610]

No. Stages 2 2 2 2

Integrated Part Load Value

3

9.9 9.9 9.9 9.9

Heating Output Btu [kW] (1st Stage /2nd Stage) 101,500/203,000 [29.7/59.5] 142,000/284,000 [41.6/83.2] 101,500/203,000 [29.7/59.5] 142,000/284,000 [41.6/83.2]

Compressor

No./Type 4/Scroll 4/Scroll 4/Scroll 4/Scroll

Outdoor Sound Rating (dB)

5

91 91 91 91

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 36 [3.34] 36 [3.34] 36 [3.34] 36 [3.34]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Net Latent Capacity Btu [kW] 46,000 [13.5] 46,000 [13.5] 46,000 [13.5] 46,000 [13.5]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 16000 [7550] 16000 [7550] 16000 [7550] 16000 [7550]

No. Motors/HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 3 3 5 5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 184 184

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Ye s

(No.) Size Recommended in. [mm] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 82/72 [2325/2041] 82/72 [2325/2041] 82/72 [2325/2041] 82/72 [2325/2041]

Weights

Ship Weight lbs. [kg] 2026 [919] 2037 [924] 2056 [933] 2091 [948]

Gas Connection Pipe Size in. [mm] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05]

CONTINUED

NOM. SIZES 15-25 TONS [52.8-87.9 kW] ASHRAE 90.1-1989 COMPLIANT MODELS

See Page 28 for Notes. [ ] Designates Metric Conversions

13

GENERAL DATA—RKKB- SERIES

Model RKKB- Series A240CL30E A240CL40E A240CM30E A240CM40E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 242,000 [70.9] 242,000 [70.9] 242,000 [70.9] 242,000 [70.9]

EER/SEER

2

8.7/NA 8.7/NA 8.7/NA 8.7/NA

Nominal CFM/ARI Rated CFM [L/s] 7600/7400 [3586/3492] 7600/7400 [3586/3492] 7600/7400 [3586/3492] 7600/7400 [3586/3492]

ARI Net Cooling Capacity Btu [kW] 228,000 [66.8] 228,000 [66.8] 228,000 [66.8] 228,000 [66.8]

Net Sensible Capacity Btu [kW] 164,000 [48.1] 164,000 [48.1] 164,000 [48.1] 164,000 [48.1]

Net System Power kW 26.2 26.2 26.2 26.2

Heating Performance (Package Gas/Electric)

4

Heating Input Btu [kW] (1st Stage /2nd Stage) 150,000/300,000 [44/87.9] 200,000/400,000 [58.6/117.2] 150,000/300,000 [44/87.9] 200,000/400,000 [58.6/117.2]

Temperature Rise Range °F [°C] 15-45 [8.3/25] 25-55 [13.9/30.6] 15-45 [8.3/25] 25-55 [13.9/30.6]

Steady State Efficiency (%) 81 81 81 81

Net Weight lbs. [kg] 1884 [855] 1900 [862] 1906 [865] 1922 [872]

No. Burners 12 14 12 14

(3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610]

No. Stages 2 2 2 2

Integrated Part Load Value

3

8.8 8.8 8.8 8.8

Heating Output Btu [kW] (1st Stage /2nd Stage) 121,500/243,000 [35.6/71.2] 162,000/324,000 [47.5/94.9] 121,500/243,000 [35.6/71.2] 162,000/324,000 [47.5/94.9]

Compressor

No./Type 4/Scroll 4/Scroll 4/Scroll 4/Scroll

Outdoor Sound Rating (dB)

5

91 91 91 91

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 36 [3.34] 36 [3.34] 36 [3.34] 36 [3.34]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Net Latent Capacity Btu [kW] 64,000 [18.8] 64,000 [18.8] 64,000 [18.8] 64,000 [18.8]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 16000 [7550] 16000 [7550] 16000 [7550] 16000 [7550]

No. Motors/HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 5 5 7.5 7.5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 184 184 213 213

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Ye s

(No.) Size Recommended in. [mm] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 77/72 [2183/2041] 77/72 [2183/2041] 77/72 [2183/2041] 77/72 [2183/2041]

Weights

Ship Weight lbs. [kg] 2104 [954] 2120 [962] 2126 [964] 2142 [972]

Gas Connection Pipe Size in. [mm] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05]

CONTINUED

NOM. SIZES 15-25 TONS [52.8-87.9 kW] ASHRAE 90.1-1989 COMPLIANT MODELS

See Page 28 for Notes. [ ] Designates Metric Conversions

14

GENERAL DATA—RKKB- SERIES

Model RKKB- Series A240DL30E A240DL40E A240DM30E A240DM40E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 242,000 [70.9] 242,000 [70.9] 242,000 [70.9] 242,000 [70.9]

EER/SEER

2

8.7/NA 8.7/NA 8.7/NA 8.7/NA

Nominal CFM/ARI Rated CFM [L/s] 7600/7400 [3586/3492] 7600/7400 [3586/3492] 7600/7400 [3586/3492] 7600/7400 [3586/3492]

ARI Net Cooling Capacity Btu [kW] 228,000 [66.8] 228,000 [66.8] 228,000 [66.8] 228,000 [66.8]

Net Sensible Capacity Btu [kW] 164,000 [48.1] 164,000 [48.1] 164,000 [48.1] 164,000 [48.1]

Net System Power kW 26.2 26.2 26.2 26.2

Heating Performance (Package Gas/Electric)

4

Heating Input Btu [kW] (1st Stage /2nd Stage) 150,000/300,000 [44/87.9] 200,000/400,000 [58.6/117.2] 150,000/300,000 [44/87.9] 200,000/400,000 [58.6/117.2]

Temperature Rise Range °F [°C] 15-45 [8.3/25] 25-55 [13.9/30.6] 15-45 [8.3/25] 25-55 [13.9/30.6]

Steady State Efficiency (%) 81 81 81 81

Net Weight lbs. [kg] 1908 [865] 1932 [876] 1930 [875] 1954 [886]

No. Burners 12 14 12 14

(3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610]

No. Stages 2 2 2 2

Integrated Part Load Value

3

8.8 8.8 8.8 8.8

Heating Output Btu [kW] (1st Stage /2nd Stage) 121,500/243,000 [35.6/71.2] 162,000/324,000 [47.5/94.9] 121,500/243,000 [35.6/71.2] 162,000/324,000 [47.5/94.9]

Compressor

No./Type 4/Scroll 4/Scroll 4/Scroll 4/Scroll

Outdoor Sound Rating (dB)

5

91 91 91 91

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 36 [3.34] 36 [3.34] 36 [3.34] 36 [3.34]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Net Latent Capacity Btu [kW] 64,000 [18.8] 64,000 [18.8] 64,000 [18.8] 64,000 [18.8]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 16000 [7550] 16000 [7550] 16000 [7550] 16000 [7550]

No. Motors/HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 5 5 7.5 7.5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 184 184 213 213

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Ye s

(No.) Size Recommended in. [mm] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 77/72 [2183/2041] 77/72 [2183/2041] 77/72 [2183/2041] 77/72 [2183/2041]

Weights

Ship Weight lbs. [kg] 2128 [965] 2152 [976] 2150 [975] 2174 [986]

Gas Connection Pipe Size in. [mm] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05]

CONTINUED

NOM. SIZES 15-25 TONS [52.8-87.9 kW] ASHRAE 90.1-1989 COMPLIANT MODELS

See Page 28 for Notes. [ ] Designates Metric Conversions

15

GENERAL DATA—RKKB- SERIES

Model RKKB- Series A240YL30E A240YL40E A240YM30E A240YM40E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 242,000 [70.9] 242,000 [70.9] 242,000 [70.9] 242,000 [70.9]

EER/SEER

2

8.7/NA 8.7/NA 8.7/NA 8.7/NA

Nominal CFM/ARI Rated CFM [L/s] 7600/7400 [3586/3492] 7600/7400 [3586/3492] 7600/7400 [3586/3492] 7600/7400 [3586/3492]

ARI Net Cooling Capacity Btu [kW] 228,000 [66.8] 228,000 [66.8] 228,000 [66.8] 228,000 [66.8]

Net Sensible Capacity Btu [kW] 164,000 [48.1] 164,000 [48.1] 164,000 [48.1] 164,000 [48.1]

Net System Power kW 26.2 26.2 26.2 26.2

Heating Performance (Package Gas/Electric)

4

Heating Input Btu [kW] (1st Stage /2nd Stage) 150,000/300,000 [44/87.9] 200,000/400,000 [58.6/117.2] 150,000/300,000 [44/87.9] 200,000/400,000 [58.6/117.2]

Temperature Rise Range °F [°C] 15-45 [8.3/25] 25-55 [13.9/30.6] 15-45 [8.3/25] 25-55 [13.9/30.6]

Steady State Efficiency (%) 81 81 81 81

Net Weight lbs. [kg] 1908 [865] 1932 [876] 1930 [875] 1954 [886]

No. Burners 12 14 12 14

(3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610]

No. Stages 2 2 2 2

Integrated Part Load Value

3

8.8 8.8 8.8 8.8

Heating Output Btu [kW] (1st Stage /2nd Stage) 121,500/243,000 [35.6/71.2] 162,000/324,000 [47.5/94.9] 121,500/243,000 [35.6/71.2] 162,000/324,000 [47.5/94.9]

Compressor

No./Type 4/Scroll 4/Scroll 4/Scroll 4/Scroll

Outdoor Sound Rating (dB)

5

91 91 91 91

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 36 [3.34] 36 [3.34] 36 [3.34] 36 [3.34]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Net Latent Capacity Btu [kW] 64,000 [18.8] 64,000 [18.8] 64,000 [18.8] 64,000 [18.8]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 16000 [7550] 16000 [7550] 16000 [7550] 16000 [7550]

No. Motors/HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 5 5 7.5 7.5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 184 184 213 213

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Ye s

(No.) Size Recommended in. [mm] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 77/72 [2183/2041] 77/72 [2183/2041] 77/72 [2183/2041] 77/72 [2183/2041]

Weights

Ship Weight lbs. [kg] 2128 [965] 2152 [976] 2150 [975] 2174 [986]

Gas Connection Pipe Size in. [mm] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05]

CONTINUED

NOM. SIZES 15-25 TONS [52.8-87.9 kW] ASHRAE 90.1-1989 COMPLIANT MODELS

See Page 28 for Notes. [ ] Designates Metric Conversions

16

GENERAL DATA—RKKB- SERIES

Model RKKB- Series A300CL30E A300CL40E A300CM30E A300CM40E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 300,000 [87.9] 300,000 [87.9] 300,000 [87.9] 300,000 [87.9]

EER/SEER

2

8.9/NA 8.9/NA 8.9/NA 8.9/NA

Nominal CFM/ARI Rated CFM [L/s] 9400/8400 [4436/3964] 9400/8400 [4436/3964] 9400/8400 [4436/3964] 9400/8400 [4436/3964]

ARI Net Cooling Capacity Btu [kW] 282,000 [82.6] 282,000 [82.6] 282,000 [82.6] 282,000 [82.6]

Net Sensible Capacity Btu [kW] 194,000 [56.8] 194,000 [56.8] 194,000 [56.8] 194,000 [56.8]

Net System Power kW 31.7 31.7 31.7 31.7

Heating Performance (Package Gas/Electric)

4

Heating Input Btu [kW] (1st Stage /2nd Stage) 150,000/300,000 [44/87.9] 200,000/400,000 [58.6/117.2] 150,000/300,000 [44/87.9] 200,000/400,000 [58.6/117.2]

Temperature Rise Range °F [°C] 15-45 [8.3/25] 25-55 [13.9/30.6] 15-45 [8.3/25] 25-55 [13.9/30.6]

Steady State Efficiency (%) 81 81 81 81

Net Weight lbs. [kg] 2037 [924] 2053 [931] 2059 [934] 2075 [941]

No. Burners 12 14 12 14

(3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610]

No. Stages 2 2 2 2

Integrated Part Load Value

3

9 9 9 9

Heating Output Btu [kW] (1st Stage /2nd Stage) 121,500/243,000 [35.6/71.2] 162,000/324,000 [47.5/94.9] 121,500/243,000 [35.6/71.2] 162,000/324,000 [47.5/94.9]

Compressor

No./Type 4/Scroll 4/Scroll 4/Scroll 4/Scroll

Outdoor Sound Rating (dB)

5

92 92 92 92

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 36 [3.34] 36 [3.34] 36 [3.34] 36 [3.34]

Rows / FPI [FPcm] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9]

Net Latent Capacity Btu [kW] 88,000 [25.8] 88,000 [25.8] 88,000 [25.8] 88,000 [25.8]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 16000 [7550] 16000 [7550] 16000 [7550] 16000 [7550]

No. Motors/HP 4 at 1/2 HP 4 at 1/2 HP 4 at 1/2 HP 4 at 1/2 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 5 5 7.5 7.5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 184 184 213 213

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Ye s

(No.) Size Recommended in. [mm] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 128/121 [3629/3430] 128/121 [3629/3430] 128/121 [3629/3430] 128/121 [3629/3430]

Weights

Ship Weight lbs. [kg] 2257 [1024] 2273 [1031] 2279 [1034] 2295 [1041]

Gas Connection Pipe Size in. [mm] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05]

CONTINUED

NOM. SIZES 15-25 TONS [52.8-87.9 kW] ASHRAE 90.1-1989 COMPLIANT MODELS

See Page 28 for Notes. [ ] Designates Metric Conversions

17

GENERAL DATA—RKKB- SERIES

Model RKKB- Series A300DL30E A300DL40E A300DM30E A300DM40E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 300,000 [87.9] 300,000 [87.9] 300,000 [87.9] 300,000 [87.9]

EER/SEER

2

8.9/NA 8.9/NA 8.9/NA 8.9/NA

Nominal CFM/ARI Rated CFM [L/s] 9400/8400 [4436/3964] 9400/8400 [4436/3964] 9400/8400 [4436/3964] 9400/8400 [4436/3964]

ARI Net Cooling Capacity Btu [kW] 282,000 [82.6] 282,000 [82.6] 282,000 [82.6] 282,000 [82.6]

Net Sensible Capacity Btu [kW] 194,000 [56.8] 194,000 [56.8] 194,000 [56.8] 194,000 [56.8]

Net System Power kW 31.7 31.7 31.7 31.7

Heating Performance (Package Gas/Electric)

4

Heating Input Btu [kW] (1st Stage /2nd Stage) 150,000/300,000 [44/87.9] 200,000/400,000 [58.6/117.2] 150,000/300,000 [44/87.9] 200,000/400,000 [58.6/117.2]

Temperature Rise Range °F [°C] 15-45 [8.3/25] 25-55 [13.9/30.6] 15-45 [8.3/25] 25-55 [13.9/30.6]

Steady State Efficiency (%) 81 81 81 81

Net Weight lbs. [kg] 2061 [935] 2085 [946] 2083 [945] 2107 [956]

No. Burners 12 14 12 14

(3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610]

No. Stages 2 2 2 2

Integrated Part Load Value

3

9 9 9 9

Heating Output Btu [kW] (1st Stage /2nd Stage) 121,500/243,000 [35.6/71.2] 162,000/324,000 [47.5/94.9] 121,500/243,000 [35.6/71.2] 162,000/324,000 [47.5/94.9]

Compressor

No./Type 4/Scroll 4/Scroll 4/Scroll 4/Scroll

Outdoor Sound Rating (dB)

5

92 92 92 92

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 36 [3.34] 36 [3.34] 36 [3.34] 36 [3.34]

Rows / FPI [FPcm] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9]

Net Latent Capacity Btu [kW] 88,000 [25.8] 88,000 [25.8] 88,000 [25.8] 88,000 [25.8]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 16000 [7550] 16000 [7550] 16000 [7550] 16000 [7550]

No. Motors/HP 4 at 1/2 HP 4 at 1/2 HP 4 at 1/2 HP 4 at 1/2 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 5 5 7.5 7.5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 184 184 213 213

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Ye s

(No.) Size Recommended in. [mm] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 128/121 [3629/3430] 128/121 [3629/3430] 128/121 [3629/3430] 128/121 [3629/3430]

Weights

Ship Weight lbs. [kg] 2281 [1035] 2305 [1046] 2303 [1045] 2327 [1056]

Gas Connection Pipe Size in. [mm] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05]

CONTINUED

NOM. SIZES 15-25 TONS [52.8-87.9 kW] ASHRAE 90.1-1989 COMPLIANT MODELS

See Page 28 for Notes. [ ] Designates Metric Conversions

18

GENERAL DATA—RKKB- SERIES

Model RKKB- Series A300YL30E A300YL40E A300YM30E A300YM40E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 300,000 [87.9] 300,000 [87.9] 300,000 [87.9] 300,000 [87.9]

EER/SEER

2

8.9/NA 8.9/NA 8.9/NA 8.9/NA

Nominal CFM/ARI Rated CFM [L/s] 9400/8400 [4436/3964] 9400/8400 [4436/3964] 9400/8400 [4436/3964] 9400/8400 [4436/3964]

ARI Net Cooling Capacity Btu [kW] 282,000 [82.6] 282,000 [82.6] 282,000 [82.6] 282,000 [82.6]

Net Sensible Capacity Btu [kW] 194,000 [56.8] 194,000 [56.8] 194,000 [56.8] 194,000 [56.8]

Net System Power kW 31.7 31.7 31.7 31.7

Heating Performance (Package Gas/Electric)

4

Heating Input Btu [kW] (1st Stage /2nd Stage) 150,000/300,000 [44/87.9] 200,000/400,000 [58.6/117.2] 150,000/300,000 [44/87.9] 200,000/400,000 [58.6/117.2]

Temperature Rise Range °F [°C] 15-45 [8.3/25] 25-55 [13.9/30.6] 15-45 [8.3/25] 25-55 [13.9/30.6]

Steady State Efficiency (%) 81 81 81 81

Net Weight lbs. [kg] 2061 [935] 2085 [946] 2083 [945] 2107 [956]

No. Burners 12 14 12 14

(3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610]

No. Stages 2 2 2 2

Integrated Part Load Value

3

9 9 9 9

Heating Output Btu [kW] (1st Stage /2nd Stage) 121,500/243,000 [35.6/71.2] 162,000/324,000 [47.5/94.9] 121,500/243,000 [35.6/71.2] 162,000/324,000 [47.5/94.9]

Compressor

No./Type 4/Scroll 4/Scroll 4/Scroll 4/Scroll

Outdoor Sound Rating (dB)

5

92 92 92 92

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 36 [3.34] 36 [3.34] 36 [3.34] 36 [3.34]

Rows / FPI [FPcm] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9]

Net Latent Capacity Btu [kW] 88,000 [25.8] 88,000 [25.8] 88,000 [25.8] 88,000 [25.8]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 16000 [7550] 16000 [7550] 16000 [7550] 16000 [7550]

No. Motors/HP 4 at 1/2 HP 4 at 1/2 HP 4 at 1/2 HP 4 at 1/2 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 5 5 7.5 7.5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 184 184 213 213

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Ye s

(No.) Size Recommended in. [mm] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 128/121 [3629/3430] 128/121 [3629/3430] 128/121 [3629/3430] 128/121 [3629/3430]

Weights

Ship Weight lbs. [kg] 2281 [1035] 2305 [1046] 2303 [1045] 2327 [1056]

Gas Connection Pipe Size in. [mm] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05]

NOM. SIZES 15-25 TONS [52.8-87.9 kW] ASHRAE 90.1-1989 COMPLIANT MODELS

See Page 28 for Notes. [ ] Designates Metric Conversions

19

GENERAL DATA—RKMB- SERIES

NOM. SIZES 15 & 20 TONS [52.8 & 70.3 kW] ASHRAE 90.1-1999 COMPLIANT MODELS

Model RKMB- Series A180CL25E A180CL35E A180CM25E A180CM35E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 188,000 [55.1] 188,000 [55.1] 188,000 [55.1] 188,000 [55.1]

EER/SEER

2

10.2/NA 10.2/NA 10.2/NA 10.2/NA

Nominal CFM/ARI Rated CFM [L/s] 6000/6000 [2831/2831] 6000/6000 [2831/2831] 6000/6000 [2831/2831] 6000/6000 [2831/2831]

ARI Net Cooling Capacity Btu [kW] 180,000 [52.7] 180,000 [52.7] 180,000 [52.7] 180,000 [52.7]

Net Sensible Capacity Btu [kW] 134,000 [39.3] 134,000 [39.3] 134,000 [39.3] 134,000 [39.3]

Net System Power kW 17.6 17.6 17.6 17.6

Heating Performance (Package Gas/Electric)

4

Heating Input Btu [kW] (1st Stage /2nd Stage) 125,000/250,000 [36.6/73.2]175,000/350,000 [51.3/102.6]125,000/250,000 [36.6/73.2]175,000/350,000 [51.3/102.6]

Temperature Rise Range °F [°C] 15-45 [8.3/25] 30-60 [16.7/33.3] 15-45 [8.3/25] 30-60 [16.7/33.3]

Steady State Efficiency (%) 81 81 81 81

Net Weight lbs. [kg] 1790 [812] 1817 [824] 1820 [826] 1847 [838]

No. Burners 10 14 10 14

(3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610]

No. Stages 2 2 2 2

Integrated Part Load Value

3

10.4 10.4 10.4 10.4

Heating Output Btu [kW] (1st Stage /2nd Stage) 101,500/203,000 [29.7/59.5] 142,000/284,000 [41.6/83.2] 101,500/203,000 [29.7/59.5] 142,000/284,000 [41.6/83.2]

Compressor

No./Type 4/Scroll 4/Scroll 4/Scroll 4/Scroll

Outdoor Sound Rating (dB)

5

91 91 91 91

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 36 [3.34] 36 [3.34] 36 [3.34] 36 [3.34]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Net Latent Capacity Btu [kW] 46,000 [13.5] 46,000 [13.5] 46,000 [13.5] 46,000 [13.5]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 16000 [7550] 16000 [7550] 16000 [7550] 16000 [7550]

No. Motors/HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 3 3 5 5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 184 184

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Ye s

(No.) Size Recommended in. [mm] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 82/72 [2325/2041] 82/72 [2325/2041] 82/72 [2325/2041] 82/72 [2325/2041]

Weights

Ship Weight lbs. [kg] 2010 [912] 2037 [924] 2040 [925] 2067 [938]

Gas Connection Pipe Size in. [mm] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05]

CONTINUED

See Page 28 for Notes. [ ] Designates Metric Conversions

See Page 28 for Notes. [ ] Designates Metric Conversions

20

GENERAL DATA—RKMB- SERIES

Model RKMB- Series A180DL25E A180DL35E A180DM25E A180DM35E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 188,000 [55.1] 188,000 [55.1] 188,000 [55.1] 188,000 [55.1]

EER/SEER

2

10.2/NA 10.2/NA 10.2/NA 10.2/NA

Nominal CFM/ARI Rated CFM [L/s] 6000/6000 [2831/2831] 6000/6000 [2831/2831] 6000/6000 [2831/2831] 6000/6000 [2831/2831]

ARI Net Cooling Capacity Btu [kW] 180,000 [52.7] 180,000 [52.7] 180,000 [52.7] 180,000 [52.7]

Net Sensible Capacity Btu [kW] 134,000 [39.3] 134,000 [39.3] 134,000 [39.3] 134,000 [39.3]

Net System Power kW 17.6 17.6 17.6 17.6

Heating Performance (Package Gas/Electric)

4

Heating Input Btu [kW] (1st Stage /2nd Stage) 125,000/250,000 [36.6/73.2]175,000/350,000 [51.3/102.6]125,000/250,000 [36.6/73.2]175,000/350,000 [51.3/102.6]

Temperature Rise Range °F [°C] 15-45 [8.3/25] 30-60 [16.7/33.3] 15-45 [8.3/25] 30-60 [16.7/33.3]

Steady State Efficiency (%) 81 81 81 81

Net Weight lbs. [kg] 1806 [819] 1841 [835] 1836 [833] 1871 [849]

No. Burners 10 14 10 14

(3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610]

No. Stages 2 2 2 2

Integrated Part Load Value

3

10.4 10.4 10.4 10.4

Heating Output Btu [kW] (1st Stage /2nd Stage) 101,500/203,000 [29.7/59.5] 142,000/284,000 [41.6/83.2] 101,500/203,000 [29.7/59.5] 142,000/284,000 [41.6/83.2]

Compressor

No./Type 4/Scroll 4/Scroll 4/Scroll 4/Scroll

Outdoor Sound Rating (dB)

5

91 91 91 91

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 36 [3.34] 36 [3.34] 36 [3.34] 36 [3.34]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Net Latent Capacity Btu [kW] 46,000 [13.5] 46,000 [13.5] 46,000 [13.5] 46,000 [13.5]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 16000 [7550] 16000 [7550] 16000 [7550] 16000 [7550]

No. Motors/HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 3 3 5 5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 184 184

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Ye s

(No.) Size Recommended in. [mm] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 82/72 [2325/2041] 82/72 [2325/2041] 82/72 [2325/2041] 82/72 [2325/2041]

Weights

Ship Weight lbs. [kg] 2026 [919] 2061 [935] 2056 [933] 2091 [948]

Gas Connection Pipe Size in. [mm] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05]

CONTINUED

NOM. SIZES 15 & 20 TONS [52.8 & 70.3 kW] ASHRAE 90.1-1999 COMPLIANT MODELS

21

GENERAL DATA—RKMB- SERIES

Model RKMB- Series A180YL25E A180YL35E A180YM25E A180YM35E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 188,000 [55.1] 188,000 [55.1] 188,000 [55.1] 188,000 [55.1]

EER/SEER

2

10.2/NA 10.2/NA 10.2/NA 10.2/NA

Nominal CFM/ARI Rated CFM [L/s] 6000/6000 [2831/2831] 6000/6000 [2831/2831] 6000/6000 [2831/2831] 6000/6000 [2831/2831]

ARI Net Cooling Capacity Btu [kW] 180,000 [52.7] 180,000 [52.7] 180,000 [52.7] 180,000 [52.7]

Net Sensible Capacity Btu [kW] 134,000 [39.3] 134,000 [39.3] 134,000 [39.3] 134,000 [39.3]

Net System Power kW 17.6 17.6 17.6 17.6

Heating Performance (Package Gas/Electric)

4

Heating Input Btu [kW] (1st Stage /2nd Stage) 125,000/250,000 [36.6/73.2]175,000/350,000 [51.3/102.6]125,000/250,000 [36.6/73.2]175,000/350,000 [51.3/102.6]

Temperature Rise Range °F [°C] 15-45 [8.3/25] 30-60 [16.7/33.3] 15-45 [8.3/25] 30-60 [16.7/33.3]

Steady State Efficiency (%) 81 81 81 81

Net Weight lbs. [kg] 1806 [819] 1841 [835] 1836 [833] 1871 [849]

No. Burners 10 14 10 14

(3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610] (3)2x18x24 [51x457x610]

No. Stages 2 2 2 2

Integrated Part Load Value

3

10.4 10.4 10.4 10.4

Heating Output Btu [kW] (1st Stage /2nd Stage) 101,500/203,000 [29.7/59.5] 142,000/284,000 [41.6/83.2] 101,500/203,000 [29.7/59.5] 142,000/284,000 [41.6/83.2]

Compressor

No./Type 4/Scroll 4/Scroll 4/Scroll 4/Scroll

Outdoor Sound Rating (dB)

5

91 91 91 91

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 36 [3.34] 36 [3.34] 36 [3.34] 36 [3.34]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Net Latent Capacity Btu [kW] 46,000 [13.5] 46,000 [13.5] 46,000 [13.5] 46,000 [13.5]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46] 15.75 [1.46]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6] 4/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 16000 [7550] 16000 [7550] 16000 [7550] 16000 [7550]

No. Motors/HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP 4 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6] 2/18x9 [457.2x228.6]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 3 3 5 5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 184 184

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Ye s

(No.) Size Recommended in. [mm] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457] (3)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 82/72 [2325/2041] 82/72 [2325/2041] 82/72 [2325/2041] 82/72 [2325/2041]

Weights

Ship Weight lbs. [kg] 2026 [919] 2061 [935] 2056 [933] 2091 [948]

Gas Connection Pipe Size in. [mm] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05] 0.75 [19.05]

CONTINUED

NOM. SIZES 15 & 20 TONS [52.8 & 70.3 kW] ASHRAE 90.1-1999 COMPLIANT MODELS

See Page 28 for Notes. [ ] Designates Metric Conversions

Loading...

Loading...