Page 1

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

RHEEM PACKAGE GAS/ELECTRIC

www.rheemac.ca

Rooftop

Heat/Cool

Available in Northern Alberta, Saskatchewan, Manitoba, and

Contact your local ECCO Sales Branch for pricing and

RKKA and RKNA

Models Only

RKKB Models Only

Northwestern Ontario.

for specifications check www.rheemac.ca.

RKKA and RKNA

Models Only

Single Phase

Models Only

ECCO is proud to be a member of:

RKKA Models Only

(RKNA)

RKKA Models Only

RKNB Model Only

Rated in Accordance with

A.R.I. Standard 210 and 360

(RKKB)

ASHRAE

American Society of

Heating, Refrigeration, and

Air Conditioning Engineers, Inc.

www.ashrae.com

HRAI

Heating, Refrigerating

and Air Conditioning

Institute of Canada

www.hrai.ca

HARDI

Heating, Airconditioning &

Refrigeration Distributors

International

www.hardinet.org

SMACNA

Sheet Metal & Air

Conditioning Contractors

National Association Inc.

www.smacna.org

SPIDA

Spiral Duct

Manufacturers

Association

www.spida.org

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 1

Page 2

Heat/Cool

Rooftop

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

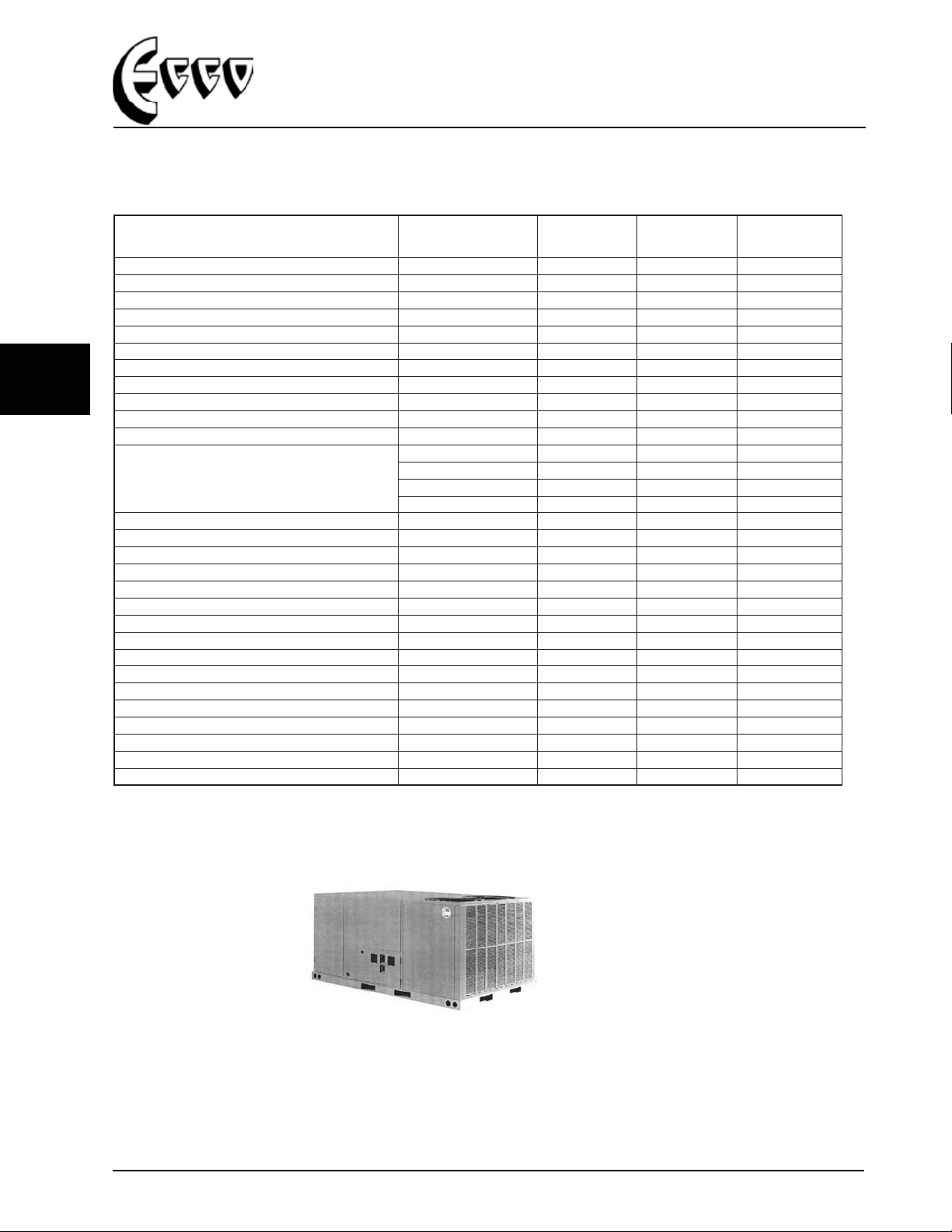

RKKA SERIES — 3 – 7.5 TONS

Engineering Features

• AllmodelsfeatureCopeland®Scroll® compressors offering maximum

reliability, efficiency, and quiet operation. The 6 and 7.5 ton model features

two-stage cooling.

• Aluminizedsteelheatexchangerwithin-shotburnershelpseliminate

corrosion. Stainless steel heat exchangers optional.

• Integratedblower/burnercontrolboardwithbuilt-indiagnosticcapability

permits on-site troubleshooting.

• One-piecetopovertheindoorsectionwithdriplip,drawnpaintedbase

pan,and1"raisedflangesforsupply/returnairconnectionsprovidessuperiorwater

management.

• Convertiblehorizontalandverticalairflowdesignallowsmaximumfieldflexibilityand

minimizesinventoryrequirements.

• Standardfullperimeterforkable14gaugebaserailwithliftingholesforeasier

maneuvering and installations.

• Factoryinstalledone-inchthrowawayfilterwithprovisionsfortwo-inchfilterandtwo-

inch filters for 7.5 ton models.

• Directorbeltdriveoptionstoaccommodateawiderangeofdesignconditionsashigh

as 1.5 inches of external static pressure. 6 and 7.5 ton models available with belt

drive only.

• Easilyremovablefilter,blower,gasheat,andcompressor/controlaccesspanels

permits prompt service.

• Numberandcolorcodedwiringhelpsfacilitateserviceandmaintenance.

• Commoncabinetandcomponentsallowsforinstallationflexibilityandfewerpartsto

inventory.

• Standardfreezestatcontroloffersevaporatorcoilfreezeprotection.(Optionalfor

7.5 ton models).

• Standardhighandlowpressurecontrolsonhighefficiencymodelsandafactoryor

field installed option on standard efficiency models.

• Externallymountedrefrigerantgaugeportsforeasyservicediagnostics.

• Sideandbaseelectricpowerandgasconnectionentryhelpsminimizeroof

penetrations.

• Quickassemblycommonroofcurbshelpssavefieldlaborandmaximizesizeflexibility.

• Easytoinstall,plug-in,slip-in,100%fullymodulatingeconomizers.

• Qualitypowderpaintfinishofferslonglastingprotectionagainstextremeweather

conditions and is able to withstand 1000 HR salt spray test.

RKKA

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

2 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

Page 3

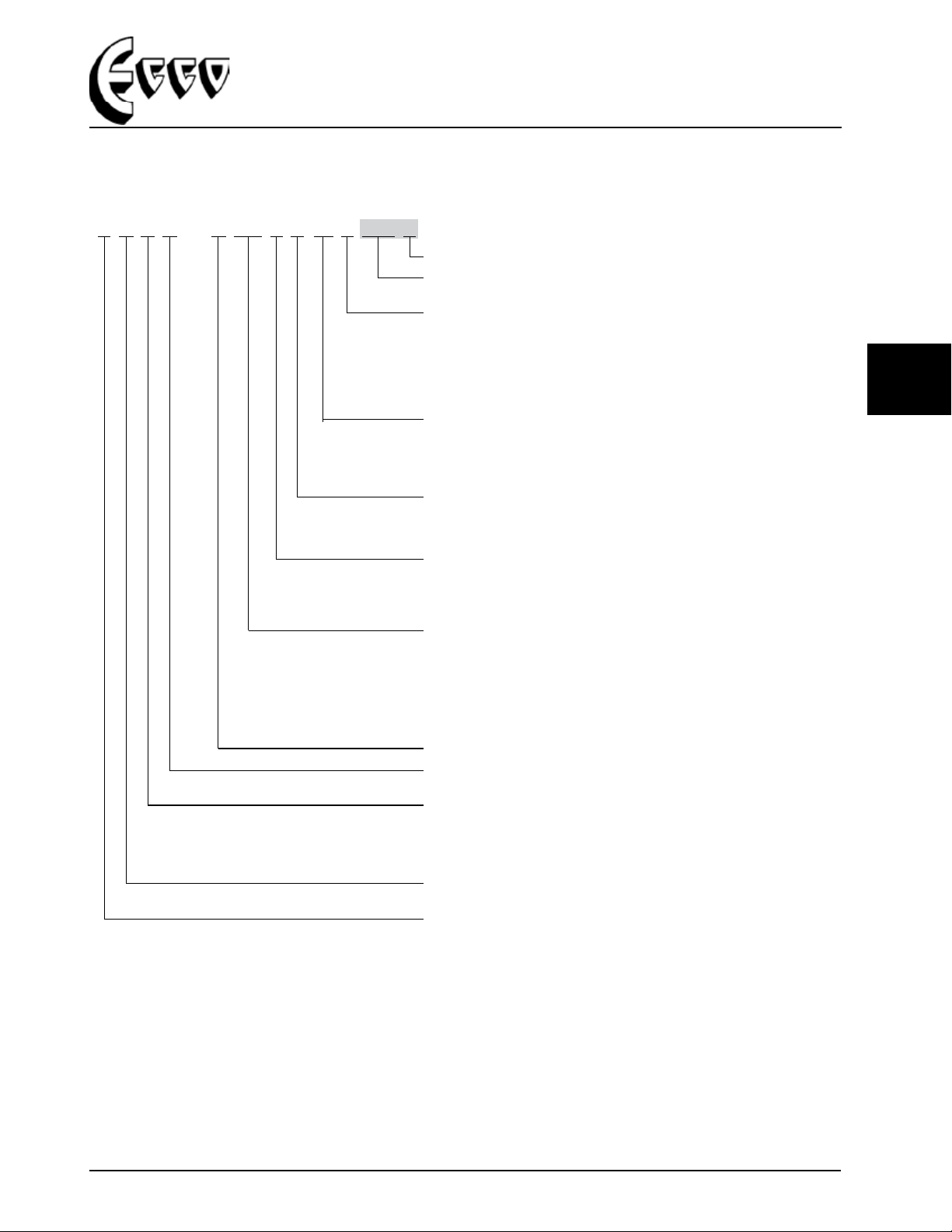

RKKA—A036 C K 08 E XXX

Economizer Option (See Next Page)

Factory Installed Options

(See Next Page)

Ignition System

E = Electric Ignition,

E = 1 Stage Gas Valve, NO

x

X = Electric Ignition,

E = 1 Stage Gas Valve

T = Electric Ignition, Two-Stage

X = Gas Valve (A085 Only)

Heating Capacity (MBH)

08 = 080,000 [23.5]

10 = 100,000 [29.3]

12 = 120,000 [35.2]

13 = 135,000 [39.6]

Drive Package

K = Direct Drive

L = Belt Drive

M = Belt Drive—High Static

Electrical Designation

C = 208-230 V, 3 PH, 60 Hz

D = 460 V, 3 PH, 60 Hz

Y = 575 V, 3 PH, 60 Hz

Cooling Capacity (BTUH) [kW]

036 = 36,000 [10.55]

042 = 42,000 [12.31]

048 = 48,000 [14.07]

060 = 60,000 [17.58]

072 = 72,000 [21.10]

073 = 72,000 [21.10]

085 = 85,000 [24.91]

Future Technical Variations

Design Series

A =1st Design

Efficiency Designation

K = Standard Efficiency (10 SEER)

ASHRAE 90.1-1989 Compliant

M = High Efficiency (12 SEER)

EnergyStar Compliant

Product Classification

K = Rooftop—Commercial

Tradebrand

R = Rheem Package Gas/Electric

[ ] Designates Metric Conversions

RKKA SERIES — 3 – 7.5 TONS (cont’d)

Model Identification

RHEEM PACKAGE GAS/ELECTRIC

Effective Date: December 2006

Rooftop

Heat/Cool

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 3

Page 4

Heat/Cool

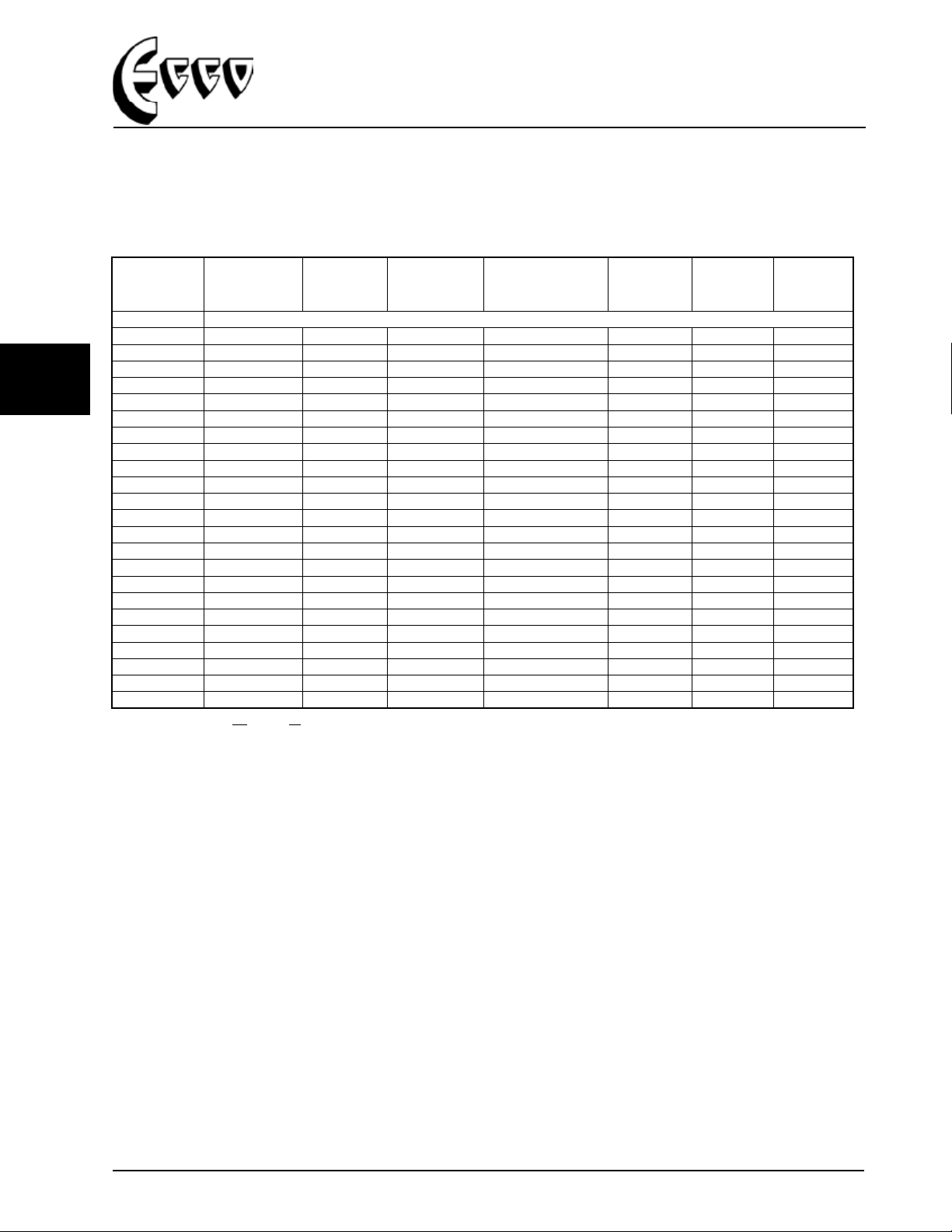

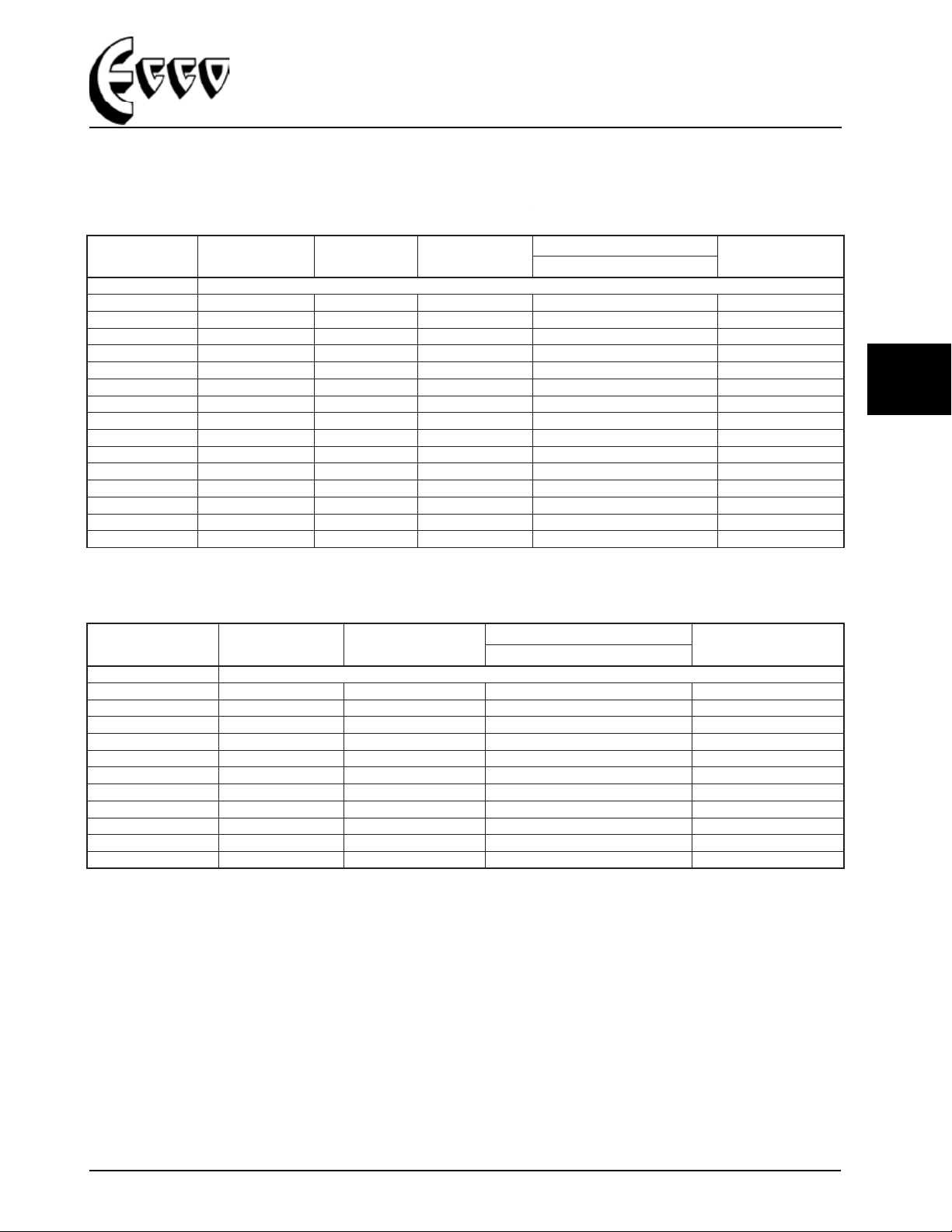

OPTIONS—RKKA- SERIES

Option Code

High and

Low Pressure

Low Ambient

Time Delay

AA No Options

Unwired

Convenience Outlet

Unfused Service

Disconnect

AH x

AK

BB x

Hail Guard

x

xBF

x

x

BU x

CB x x

BH x

x

x

x

BX

CP x

AC x

x

Side Flow

x

Reduced

Height

Baserails

x

x

Stainless

Steel Heat

Exchanger

xxDB x x

x

x

x

xBG

x

BV

x

x

x

x

xAJ

BS

CE x

xx

x

CA x

DA x x x

AE x

AL

BE x x

xxEB x x x

xAD

FACTORY INSTALLED OPTION CODES FOR RKKA

(3-5 TON AND 7.5 TON) [10.6-17.6 kW and 26.4 kW]

(A036, A042, A048, A060, A085)

Example: RKKA-A060CL13EXXX (where XX is factory installed option)

Example: No Options

RKKA-A060CL13E

Example: No option with factory installed economizer

RKKA-A060CL13EAAB

Example: Options with high and low pressure and hailguard, no factory installed economizer

RKKA-A060CL13EBBA

Example: Options same as above with factory installed economizer

RKKA-A060CL13EBBB

[ ] Designates Metric Conversions

Rooftop

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

RKKA SERIES — 3 – 7.5 TONS (cont’d)

Factory Installed Option Codes

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

4 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

Page 5

RHEEM PACKAGE GAS/ELECTRIC

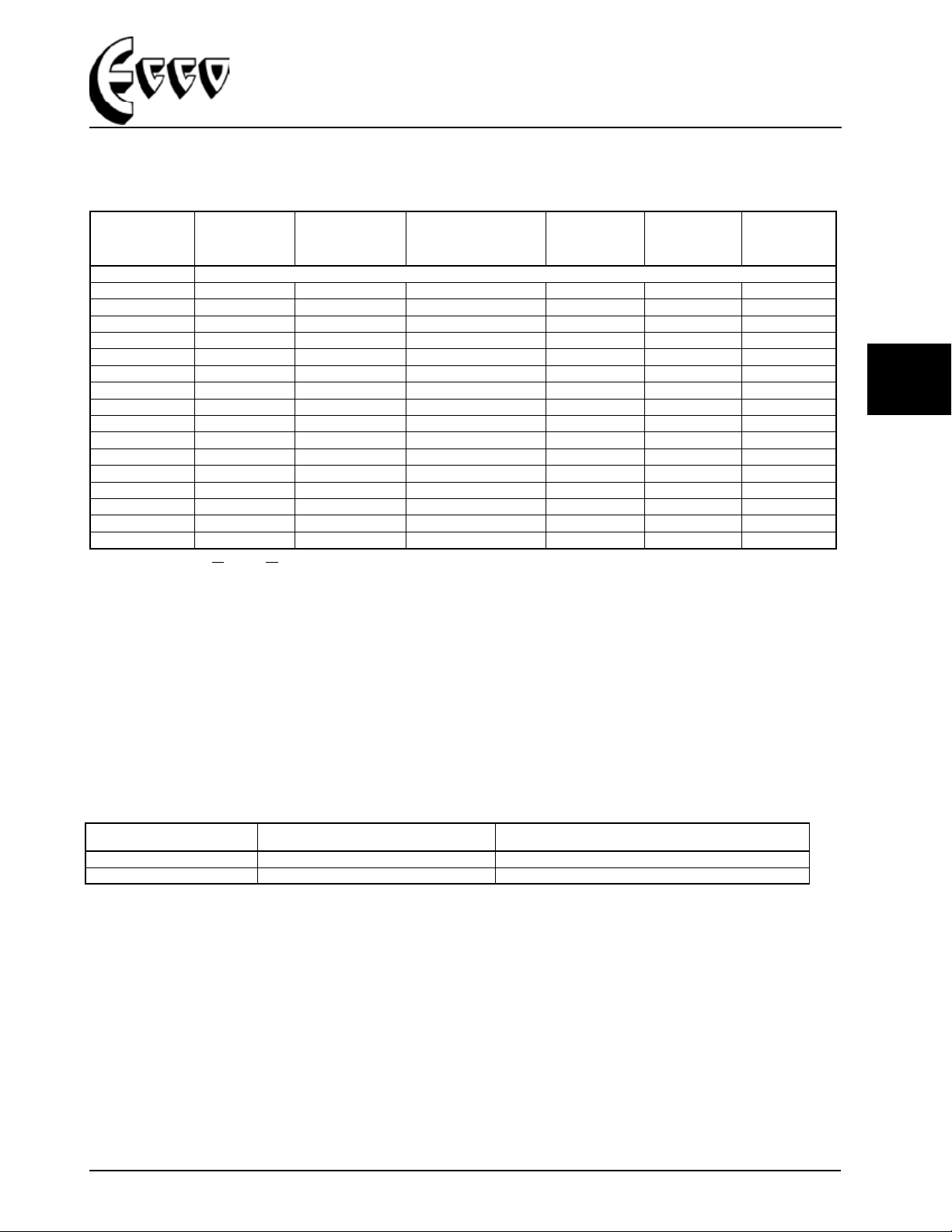

OPTIONS—RKKA- SERIES

Option Code Hail Guard

Unwired

Convenience Outlet

Unfused Service

Disconnect

Low Ambient

Time Delay

Reduced

Height

Baserails

AA No Options

x

xBH x

xCF x x

Stainless

Steel Heat

Exchanger

Side Flow

AJ

BV

x

x

x

x

DC x x x

AD x

x

x

x

BS x

xCG x x

x

xAK

BX x

AL

AH x

BC x

BG x x

AE

BF x x

FACTORY INSTALLED OPTION CODES FOR RKKA (6 TON) [21.1 kW]

(A073)

Example: RKKA-A073CL13EXXX (where XX is factory installed option)

Example: No Options

RKKA-A073CL13E

Example: No option with factory installed economizer

RKKA-A073CL13EAAB

Example: Options with hailguard, low ambient and time delay with no factory installed economizer

RKKA-A073CL13EBCA

Example: Options same as above with factory installed economizer

RKKA-A073CL13EBCB

[ ] Designates Metric Conversions

OPTIONS—RKMA- SERIES

Option Code Hail Guard

Unwired

Convenience Outlet

Unfused Service

Disconnect

Low Ambient

Time Delay

AA No Options

x

BS x

xDC x x x

Stainless

Steel Heat

Exchanger

x

Side Flow

x

AJ

CF

x

x x

AD x

x

x

BV x x

x

xAK

CG x

BC x

x

AH x

BF x x

BH x

AE

BG x x

FACTORY INSTALLED OPTION CODES FOR RKMA (6 TON) [21.1 kW]

(A072)

Example: RKMA-A060CL13EXXX (where XX is factory installed option)

Example: No Options

RKMA-A060CL13E

Example: No option with factory installed economizer

RKMA-A060CL13EAAB

Example: Options with stainless steel heat exchanger and no factory installed economizer

RKMA-A060CL13EAJA

Example: Options same as above with factory installed economizer

RKMA-A060CL13EAJB

No Economizer

Single Enthalpy Economizer

With Barometric Relief

A x

B x

ECONOMIZER SELECTION FOR RKKA & RKMA, RKMB & RKNB

(7.5 TO 15 TON) [26.4 TO 52.8 kW]

“x” indicates factory installed option.

[ ] Designates Metric Conversions

RKKA SERIES — 3 – 7.5 TONS (cont’d)

Factory Installed Option Codes for RKKA (6 Ton) [21.1 kW] (A073)

Economizer Selection

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 5

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

Effective Date: December 2006

Rooftop

Heat/Cool

Page 6

Heat/Cool

Rooftop

RHEEM PACKAGE GAS/ELECTRIC

RKKA SERIES — 3 – 7.5 TONS (cont’d)

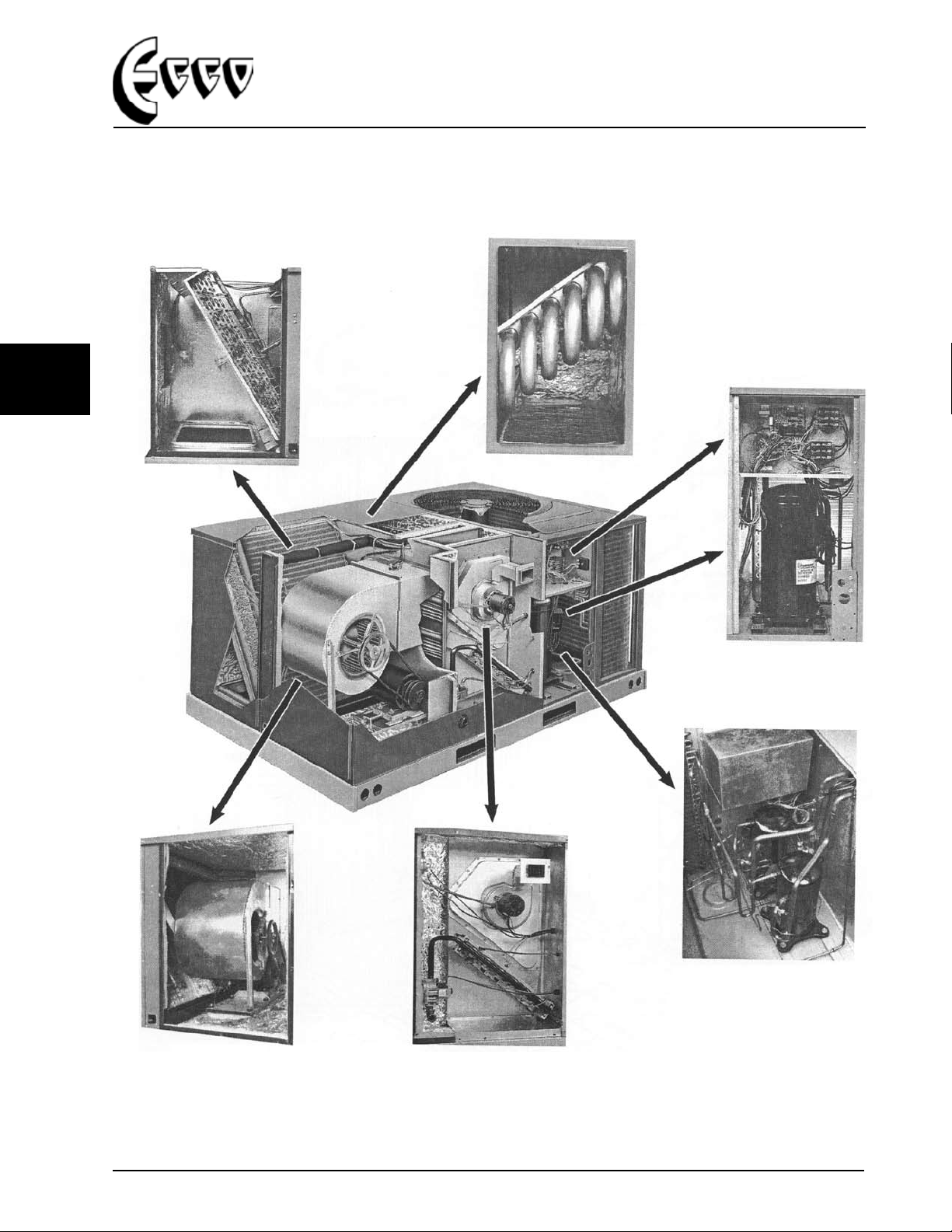

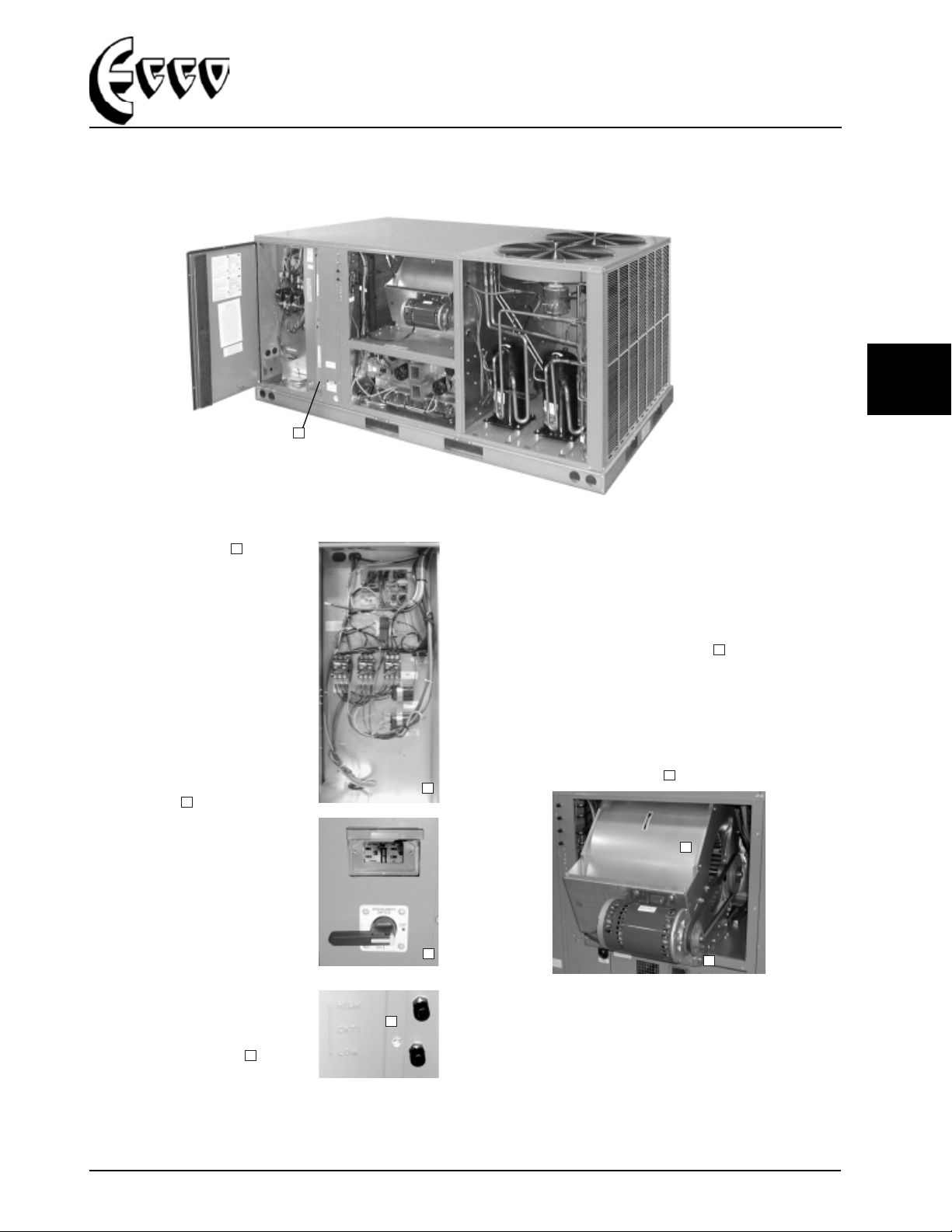

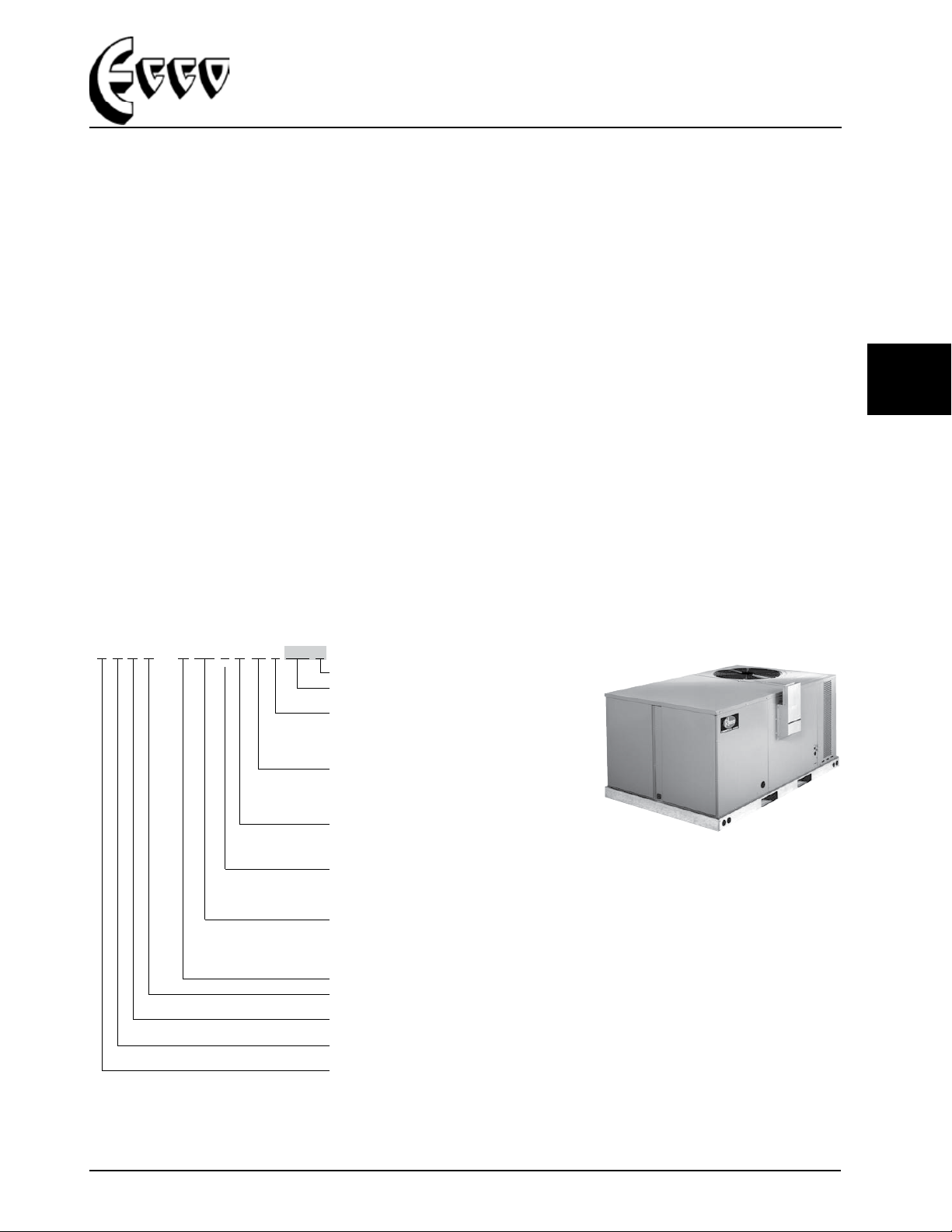

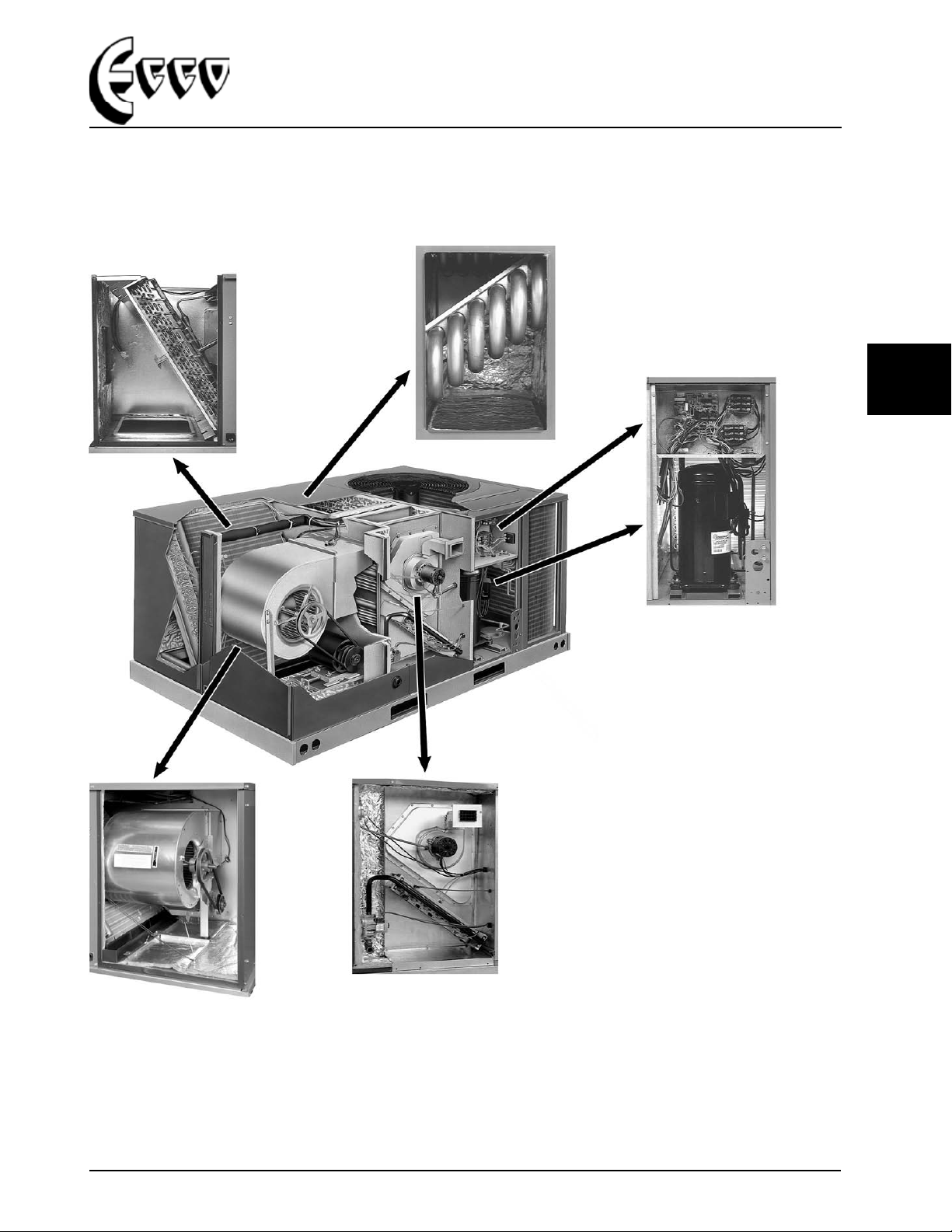

Product Features

Evaporator Coil/Filter Access

• Returnairfilters,normallyprovided,are

removed in this photo.

• Non-corrosiveplastic

condensate pan

Effective Date: December 2006

Tubular Heat Exchanger

• Aluminizedsteel

(viewedfromsupply

air side panel.)

•Stainlesssteelavailable

Control Box Access

Blower Access

• Beltdrivemodelshown

(availableon3-phasemodelsonly.)

Heating Compartment

Access

Compressor Access

(3 to 6 ton Models)

Compressor Access

(7.5 ton Models)

• Dualcompressors

(availablein6and7.5ton

models only) provide

two-stage cooling.

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

6 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

Page 7

RHEEM PACKAGE GAS/ELECTRIC

1. Determine cooling and heating requirements at design conditions.

Example:

Total cooling capacity ........................43,600 BTUH [12.78 kW]

Sensible cooling capacity ..................34,000 BTUH [9.96 kW]

Heating capacity ................................96,000 BTUH [28.13 kW]

Condenser entering air ......................95°F [35°C]

Evaporator entering air ........................63°F [17°C] wb/76°F [24°C] db

Indoor air flow ....................................1600 CFM [755 L/s]

External static pressure......................1.1 in wg

Required efficiency ............................12 SEER

2. Select unit to meet cooling requirements.

Since total cooling is within the range of 4 ton [14.07 kW] unit and

requires 12 SEER efficiency level, enter cooling performance from the

RKKA-A048 at 95°F [35°C] outdoor temperature, 63°F [17°C] wb

entering indoor air, and 1600 CFM [755 L/s]:

Total capacity ....................................46,600 BTUH [13.66 kW]

Power input ........................................4.2 kW

And also, at 76°F [24°C] db indoor entering air, and using the formula

at the bottom of the table:

Sensible capacity ..............................36,646 BTUH [10.74 kW]

3. Select heating capacity of the unit.

In the general data tables, note that the heating capacity of the 4 ton

[14.07 kW] model with the 135,000 input heater can deliver 106,500

BTUH [31.21 kW], which is suitable for this application.

4. Determine blower speed and power to meet the system

requirements.

At the given external static pressure of 1.1 in wg, the belt model must

be selected. Enter the belt drive blower performance data at 1600

CFM [755 L/s] and 1.1 in wg ESP:

RPM ........1195

Watts........755

Drive ........M

5. Calculate indoor blower BTUH heat effect.

BTUH = Watts x 3.413 = 2577

6. Calculate net cooling capacities.

Net total cooling = 46,600 – 2577 = 44,023 BTUH [12.90 kW]

Net sensible cooling = 36,646 – 2577 = 34,069 BTUH [9.98 kW]

[ ] Designates Metric Conversions

SELECTION PROCEDURE EXAMPLE—RKKA/RKMA- SERIES

RKKA SERIES — 3 – 7.5 TONS (cont’d)

Selection Procedure — Example

For more information, please contact your ECCO Sales Representative.

Effective Date: December 2006

Rooftop

Heat/Cool

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 7

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

Page 8

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

RKKA SERIES — 3 – 7.5 TONS (cont’d)

Side and Bottom Discharge — Natural Gas — 1 Phase

FREQUENCY(Hz) INPUT WEIGHT/

STOCK # MODEL COOLING VOLTAGE BTU/HR LBS. PRICE

886112 RKKA-A036JK12E949 3TON 60-208-230 120,000 529 P.O.A.

886116 RKKA-A048JK13E949 4TON 60-208-230 135,000 585 P.O.A.

Heat/Cool

Rooftop

RKKA Series

Note: For Technical Data see end of section.

Side and Bottom Discharge — Natural Gas — 3 Phase

FREQUENCY(Hz) INPUT WEIGHT/

STOCK # MODEL COOLING VOLTAGE BTU/HR LBS. PRICE

886110 RKKA-A036CK12E949 3TON 60-208-230 120,000 529 P.O.A.

886114 RKKA-A048CK13E949 4TON 60-208-230 135,000 585 P.O.A.

886118 RKKA-A060CK13E949 5TON 60-208-230 135,000 585 P.O.A.

886119 RKKA-A060CM13E949* 5TON 60-208-230 135,000 585 P.O.A.

886121 RKKA-A073CM13E949* 6TON 60-208-230 135,000 585 P.O.A.

* Belt Drive – High Static

Note: For Technical Data see end of section.

With Economizer and Stainless Steel Heat Exchanger — 3 Phase

WEIGHT/

STOCK # MODEL TONS VOLTAGE BTU/HR LBS. PRICE

886111 RKKA-A036CM12EAJB* 3 60-208-230 120,000 600 P.O.A.

886102 RKKA-A036YL12EAJB 3 60-575 120,000 600 P.O.A.

886113 RKKA-A048CM13EAJB* 4 60-208-230 135,000 650 P.O.A.

886108 RKKA-A048YM13EAJB* 4 60-575 135,000 650 P.O.A.

886117 RKKA-A060CM13EAJB* 5 60-208-230 135,000 650 P.O.A.

886115 RKKA-A060YM13EAJB* 5 60-575 135,000 650 P.O.A.

886123 RKKA-A073YM13EAJB* 6 60-575 135,000 685 P.O.A.

* Belt Drive – High Static

Note: For Technical Data see end of section.

Accessories

STOCK # MODEL DESCRIPTION PRICE

886144 RXRD-KECM3 EconomizerwithSingleEnthalpy P.O.A.

886150 RXRF-FBA1 ManualOutsideFreshAirDamper P.O.A.

886160 RXRX-AAD01A LouverKit(2sides) P.O.A.

886162 RXRX-AAD01B LouverKit(3sides) P.O.A.

886170 RXAB-A02 HighPressureControlKit P.O.A.

886172 RXAC-A02 LowPressureControlKit P.O.A.

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

8 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

Page 9

RHEEM PACKAGE GAS/ELECTRIC

*Voltage J = 208/230 VAC-1PH-60HZ D = 460 VAC-3PH-60HZ

C = 208/230 VAC-3PH-60HZ Y = 575 VAC-3PH-60HZ

NOTES: If a particular unit is to be converted to operate on LP (propane) for

elevations above 2000 ft. in Canada, the existing Natural Gas to LP

Conversion Kits for the subject models already contain the necessary

orifices and instructions to de-rate the input for 2000-4500 ft.

Canadian applications.

[ ] Designates Metric Conversions

Economizer is designed for downflow or horizontal applications.

Standard on RKKA-A073 and All RKMA- Models.

ACCESSORY EQUIPMENT

Accessory

Description

Model Application

3 to 6 Ton

[10.6 to 21.1 kW]

Accessory

Model No.

3 to 6 Ton

[10.6 to 21.1 kW]

Roofcurb Adapters RKKA-/RKMA-

RXRX-BBCDB21

RXRX-BBCDB22

RXRX-BBCDB23

Economizer with Single Enthalpy

RKKA-/RKMA- RXRD-KECM3

Low Pressure Control RKKA-

RXAC-A02

Time Delay RKKA-/RKMA- RXMD-B01

Low Ambient Control to 0°F [-18°C] RKKA-/RKMA- RXRZ-A18

Fresh Air Damper Manual RKKA-/RKMA- RXRF-FBA1

Fresh Air Damper Motorized RKKA-/RKMA- RXRF-FBB1

Rectangular to Round 18"

Duct Adapters for Concentric Diffuser

RKKA-/RKMA- RXMC-CB03

Rectangular to Round 20"

Duct Adapters for Concentric Diffuser

RKKA-/RKMA- RXMC-CB04

Concentric Diffuser 18" Step RKKA-/RKMA- RXRN-FA60

Concentric Diffuser 18" Flush RKKA-/RKMA- RXRN-FA70

Concentric Diffuser 20" Step RKKA-/RKMA- RXRN-FA65

Concentric Diffuser 20" Flush RKKA-/RKMA- RXRN-FA75

Roofcurb 14" RKKA-/RKMA- RXKG-BAD14

Roofcurb 24" RKKA-/RKMA- RXKG-BAD24

Rectangular to Round 16" Side RKKA-/RKMA- RXMC-BB01

Louver Kit (3 Sides)

RKKA-A048/A060/073

All RKMA- Models

RXRX-AAD01B

High Pressure Control RKKA-

RXAB-A02

Louver Kit (2 Sides) RKKA-A036/A042 RXRX-AAD01A

Factory Installed

3 to 6 Ton

[10.6 to 21.1 kW]

No

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

No

Yes

Yes

Yes

LP Conversion Kits for use with

White Rodgers Gas Valve

RKKA-/RKMA- RXGJ-EP84W

No

LP Conversion Kits for use with

Honeywell Gas Valve

RKKA-/RKMA- RXGJ-EP85H

No

Dual Enthalpy Kit RKKA-/RKMA- RXRX-AV02 No

CO2Sensor Only RKKA-/RKMA- RXRX-AR02 No

Power Exhaust RKKA-/RKMA- RXRX-BFF04C No

Canadian High Altitude Kit

(for Natural Gas Only)

RKKA-/RKMA- RXRX-AH01 No

Accessory

Model No.

6 to 7.5 Ton

[21.1 to 26.4 kW]

RXRX-CCCE50

RXRD-KCCM3

RXAC-A05

RXMD-B04

RXRZ-A85

RXRF-FCA1

RXRF-FCB1

N/A

RXMC-CC04

N/A

N/A

RXRN-FA65

RXRN-FA75

RXKG-BAD14

RXKG-BAD24

N/A

RXRX-AAD01B

RXAB-A05

N/A

RXGJ-EP84W

RXGJ-EP85H

RXRX-AV02

RXRX-AR01

RXRX-BFF03C

RXRX-AH01

Factory Installed

6 to 7.5 Ton

[21.1 to 26.4 kW]

No

Yes

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

No

No

Yes

Yes

No

No

No

No

No

No

No

LP Conversion Kits for use with

Two-Stage Gas Valve

RKKA-A085**13T RXGJ-EP86W

No

RXGJ-EP86W No

ACCESSORIES

RKKA SERIES — 3 – 7.5 TONS (cont’d)

Accessory Equipment

Effective Date: December 2006

Rooftop

Heat/Cool

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 9

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

Page 10

RHEEM PACKAGE GAS/ELECTRIC

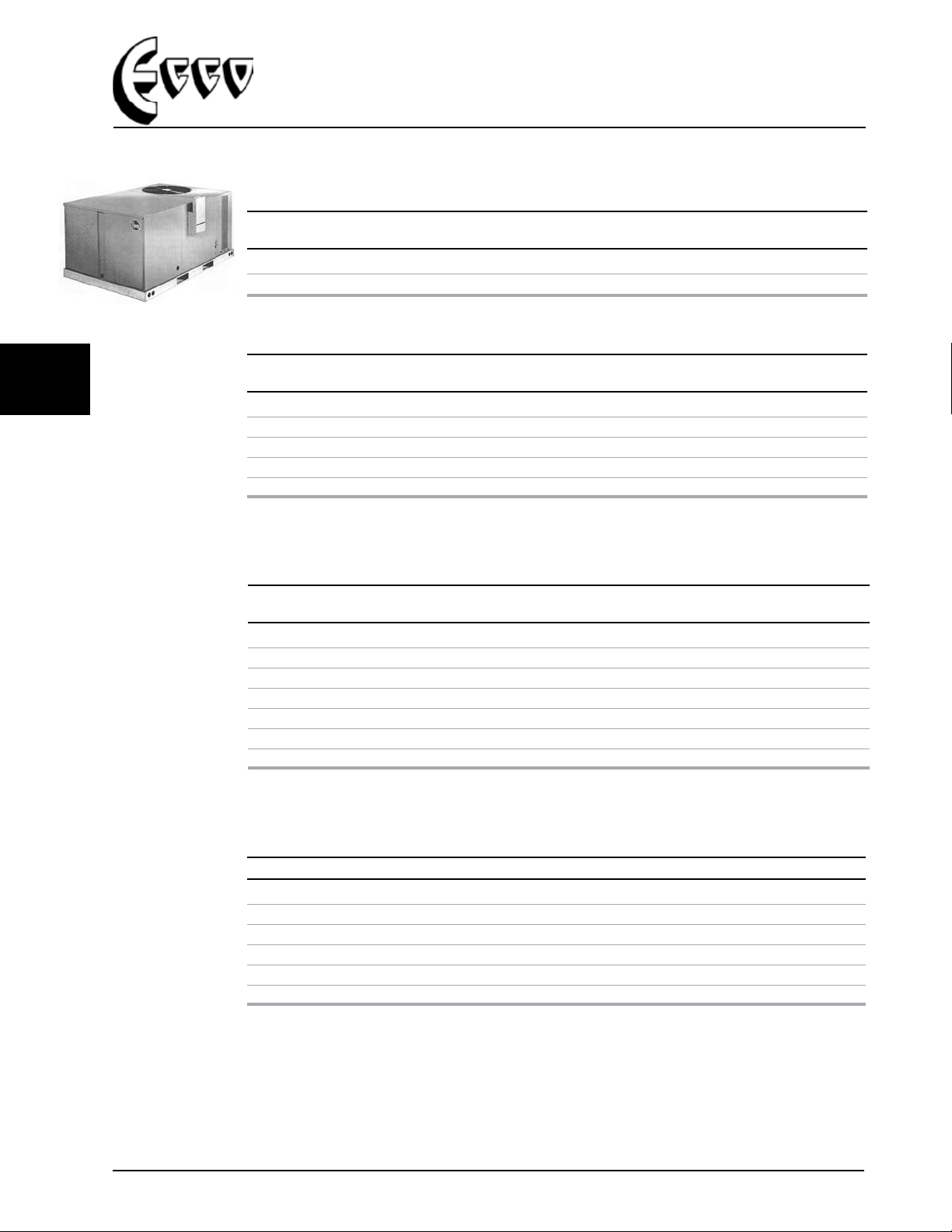

UNIT FEATURES & BENEFITS—RKKB/RKMB/RKNB- SERIES

Rheem Package equipment is designed from the ground up with

the latest features and benefits required to compete in today’s

market. The clean design stands alone in the industry and is a

testament to the quality, reliability, ease of installation and serviceability that goes into each unit. Outwardly, the large Rheem

“B-series” label ( ) identifies the brand to the customer.

The sheet-metal cabinet ( ) uses nothing less than 18-gauge

material for structural components with an underlying coat of

G90. To ensure the leak-proof integrity of these units, the design

utilizes a one-piece top with a 1/8" drip lip ( ), gasket-protected

panels and screws. The Rheem hail guard ( ) is its trademark,

and sets the standard for coil protection in the industry. Every

Rheem package unit uses the toughest finish in the industry,

using electro deposition baked-on enamel tested to withstand a

rigorous 1000-hour salt spray test, per ASTM B117.

Anything built to last must start with the right foundation. In this

case, the foundation is 14-gauge, commercial-grade, full-perimeter base rails ( ), which integrate fork slots and rigging holes to

save set-up time on the job site. The base pan is stamped, which

forms a 1-1/8" flange around the supply and return opening and

has eliminated the worry of water entering the conditioned space

( ). The drainpan ( ) is made of material that resists the

growth of harmful bacteria and is sloped for the latest IAQ benefits. The insulation has been placed on the underside of the

basepan, removing areas that would allow for potential moisture

accumulation, which can facilitate growth of harmful bacteria. All

insulation is secured with both adhesive and mechanical fasteners, and all edges are hidden.

During development, each unit was tested to U.L. 1995, ANSI

21.47, ARI 340-370 and other Rheem-required reliability tests.

Rheem adheres to stringent IS0 9002 quality procedures, and

each unit bears the U.L. and ARI certification labels located on

the unit nameplate ( ). Contractors can rest assured that when

a Rheem package unit arrives at the job, it is ready to go with a

factory charge and quality checks. Each unit also proudly displays the “Made in the USA” designation.

Access to all major compartments is from the front of the unit,

including the filter and electrical compartment, blower compartment, furnace section, and outdoor section. Each panel is permanently embossed with the compartment name (control/filter

access, blower access and furnace access).

Electrical and filter compartment access is through a large, toolless, hinged-access panel. On the outside of the panel is the unit

nameplate, which contains the model and serial number, electrical data and other important unit information.

The unit charging chart is located on the inside of the electrical

and filter compartment door. Electrical wiring diagrams are found

on the control box cover,

which allows contractors

to move them to more

readable locations. To

the right of the control

box the model and serial

number can be found.

Having this information

on the inside will assure

model identification for

the life of the product.

The production line quality test assurance label is

also placed in this location ( ). The two-inch

throwaway filters ( ) are

easily removed on a

tracked system for easy

replacement.

10

9

8

7

6

5

4

3

2

1

6

6

7

9

10

2

8

1

4

3

5

RKKB SERIES — 7.5 – 12.5 TONS

Features

Heat/Cool

Rooftop

Effective Date: December 2006

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

10 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

Page 11

RHEEM PACKAGE GAS/ELECTRIC

UNIT FEATURES & BENEFITS—RKKB/RKMB/RKNB- SERIES

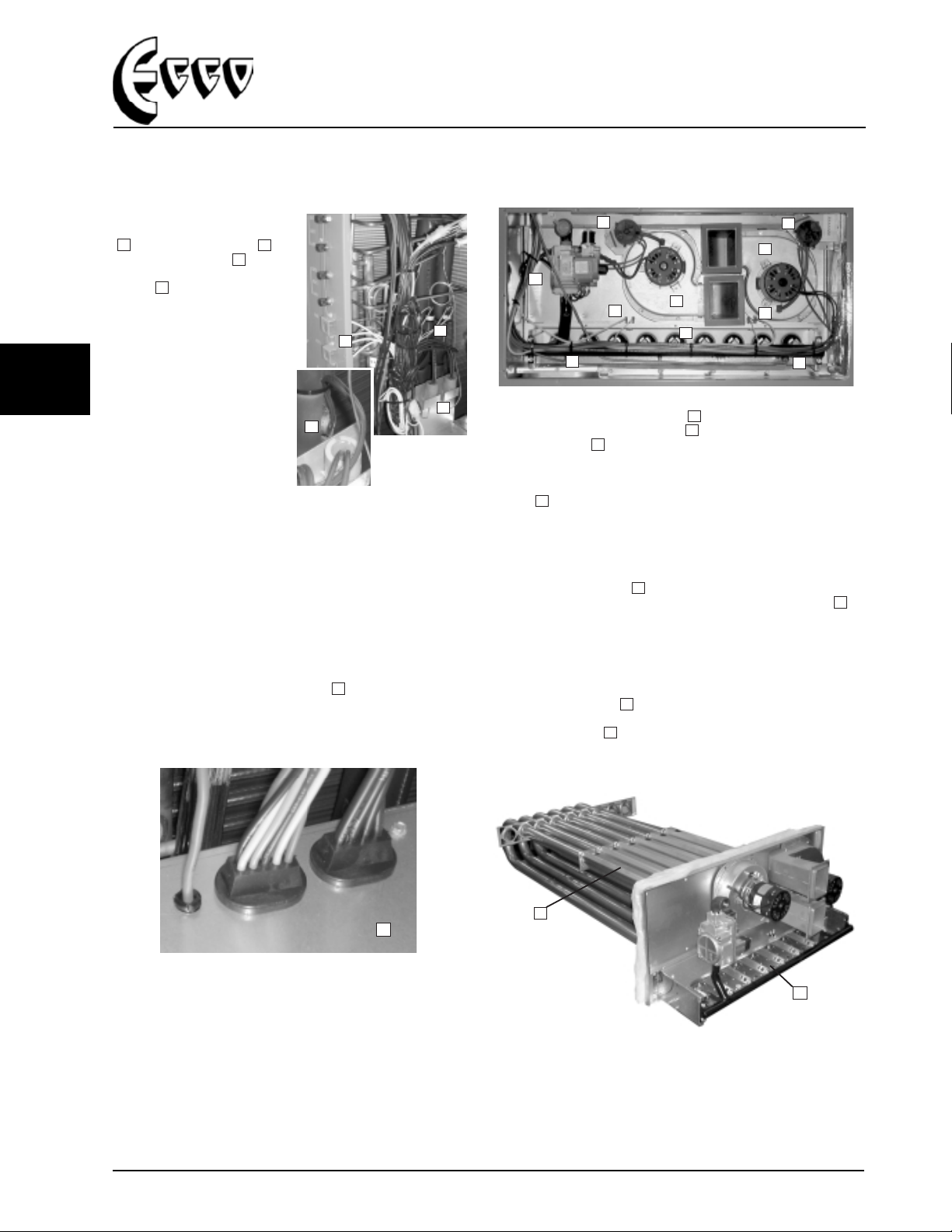

Inside the control box ( ), each electrical component is clearly identified with

a label that matches the component to

the wire diagram for ease of trouble

shooting. All wiring is numbered on

each end of the termination and colorcoded to match the wiring diagram. The

integrated furnace control, used to control furnace operation, incorporates a

flashing LED troubleshooting device.

Flash codes are clearly outlined on the

unit wiring diagram. The control transformer has a low voltage circuit breaker

that trips if a low voltage electrical short

occurs. There is a blower contactor

and compressor contactor for each

compressor.

For added convenience in the field, a

factory-installed convenience outlet and

disconnect ( ) are available. Low and

High voltage can enter either from the

side or through the base. Low-voltage

connections are made through the lowvoltage terminal strip. For ease of

access, the U.L.-required low voltage

barrier can be temporarily removed for

low-voltage termination and then reinstalled. The high-voltage connection is

terminated at the number 1 compressor

contactor. The suggested mounting for

the field-installed disconnect is on the

exterior side of the electrical control box.

To the right of the electrical and filter

compartment are the externally

mounted gauge ports, which are permanently identified by embossed wording

that clearly identifies the compressor

circuit, high pressure connection and

low pressure connection ( ). With the

gauge ports mounted externally, an

accurate diagnostic of system operation can be performed

quickly and easily.

The blower compartment is to the right of the gauge ports and

can be accessed by removing 5/16" washer-head screws. This

panel is not hinged to assure a water-tight fit with the unit. To

allow easy maintenance of the blower assembly, the entire

assembly easily slides out by removing two 3/8" screws from the

blower retention bracket. The adjustable motor pulley ( ) can

easily be adjusted by loosening the bolts on either side of the

motor mount. Removing the bolts allows for easy removal of the

blower pulley by pushing the blower assembly up to loosen the

belt. Once the belt is removed, the motor sheave can be adjusted

to the desired number of turns, ranging from 0 to 6 turns open.

Where the demands for the job require high static, Rheem has

high-static drives available that deliver nominal airflow up to 2" of

static. By referring to the airflow performance tables listed in the

installation instructions, proper static pressure and CFM requirements can be dialed in. The scroll housing ( ) and blower scroll

provide quiet and

efficient airflow.

The blower

sheave is secured

by an “H” bushing

which firmly

secures the pulley

to the blower shaft

for years of trouble-free operation.

The “H” bushing

allows for easy

removal of the

blower pulley from

the shaft, as

opposed to the

use of a set screw, which can score the shaft, creating burrs that

make blower-pulley removal difficult.

15

14

13

12

11

10

13

11

12

14

15

RKKB SERIES — 7.5 – 12.5 TONS (cont’d)

Features (cont’d)

Effective Date: December 2006

Rooftop

Heat/Cool

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 11

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

Page 12

RHEEM PACKAGE GAS/ELECTRIC

UNIT FEATURES & BENEFITS—RKKB/RKMB/RKNB- SERIES

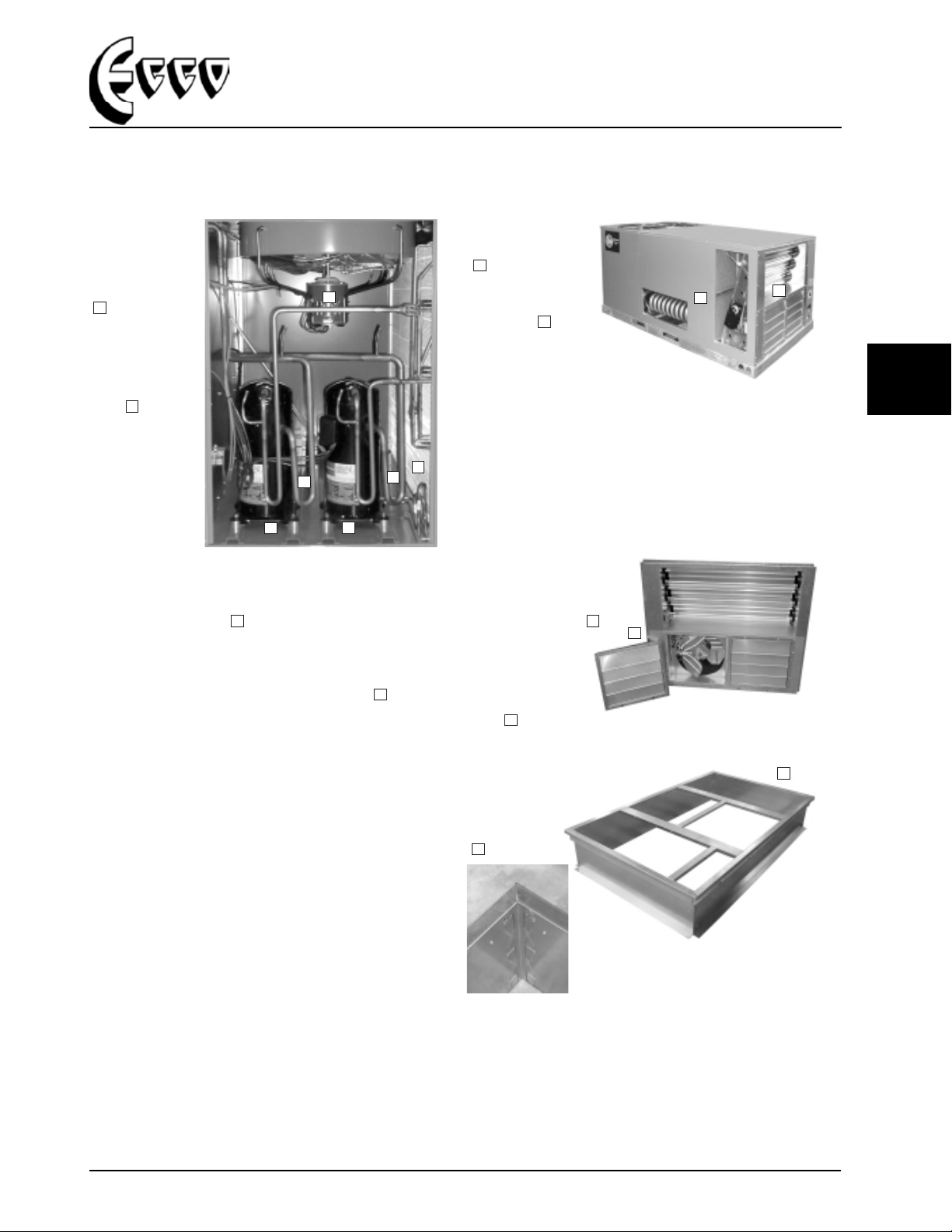

Also inside the blower compartment is the low-ambient control

( ), low-pressure switch ( ),

high-pressure switch ( )

and freeze stat refrigerant safety

device ( ). The low-ambient

control allows for operation of the

compressor down to 0 degrees

ambient temperature by cycling

the outdoor fans on high pressure.

The high-pressure switch will

shut off the compressors if

pressures exceeds, 450 PSIG

are detected, this may occur if

the outdoor fan motor fails. The

low-pressure switch shuts off

the compressors if low pressure

is detected due to loss of

charge. The freeze stat protects

the compressor if the evaporator coil gets too cold (below

freezing) due to low airflow. Each factory-installed option is

brazed into the appropriate high or low side and wired appropriately. Use of polarized plugs and sharder fittings allow for easy

field installation.

Inside the blower compartment the interlaced evaporator can

also be viewed. The evaporator uses enhanced fin technology for

maximum heat transfer. The cap-tube metering device assures

even distribution of refrigerant throughout the evaporator.

Wiring throughout the unit is neatly bundled and routed. Where

wire harnesses go through the condenser bulkhead or blower

deck, a molded wire harness assembly ( ) provides an air-tight

and water-tight seal, and provides strain relief. Care is also taken

to tuck raw edges of insulation behind sheet metal to improve

indoor air quality.

The furnace compartment contains the latest furnace technology

on the market. The draft inducers ( ) draw the flame from the

Rheem exclusive in-shot burners ( ) into the aluminized tubular

heat exchanger ( ) for clean, efficient gas heat. Stainless steel

heat exchangers can be factory installed for those applications

that have high fresh-air requirements, or applications in corrosive

environments. Each furnace is equipment with a two-stage gas

valve ( ), which provides two stages of gas heat input. The first

stage operates at 50% of the second stage (full fire). 81% steady

state efficiency is maintained on both first and second stage by

staging the multiple inducers to optimize the combustion airflow

and maintain a near stioceometric burn at each stage.

The direct spark igniter ( ) assures reliable ignition in the most

adverse conditions. This is coupled with remote flame sense ( )

to assure that the flame has carried across the entire length of

the burner assembly. Gas supply can be routed from the side or

up through the base.

Each furnace has the following safety devices to assure consistent and reliable operation after ignition:

• Pressures switches ( ) to assure adequate combustion airflow

before ignition.

• Rollout switches ( ) to assure no obstruction or cracks in the

heat exchanger.

• A limit device that protects the furnace from over-temperature

problems.

28

27

26

25

24

23

22

21

20

19

18

17

16

18

19

24

21

21

26

27

27

25

28

28

22

23

22

17

16

20

RKKB SERIES — 7.5 – 12.5 TONS (cont’d)

Features (cont’d)

Heat/Cool

Rooftop

Effective Date: December 2006

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

12 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

Page 13

RHEEM PACKAGE GAS/ELECTRIC

UNIT FEATURES & BENEFITS—RKKB/RKMB/RKNB- SERIES

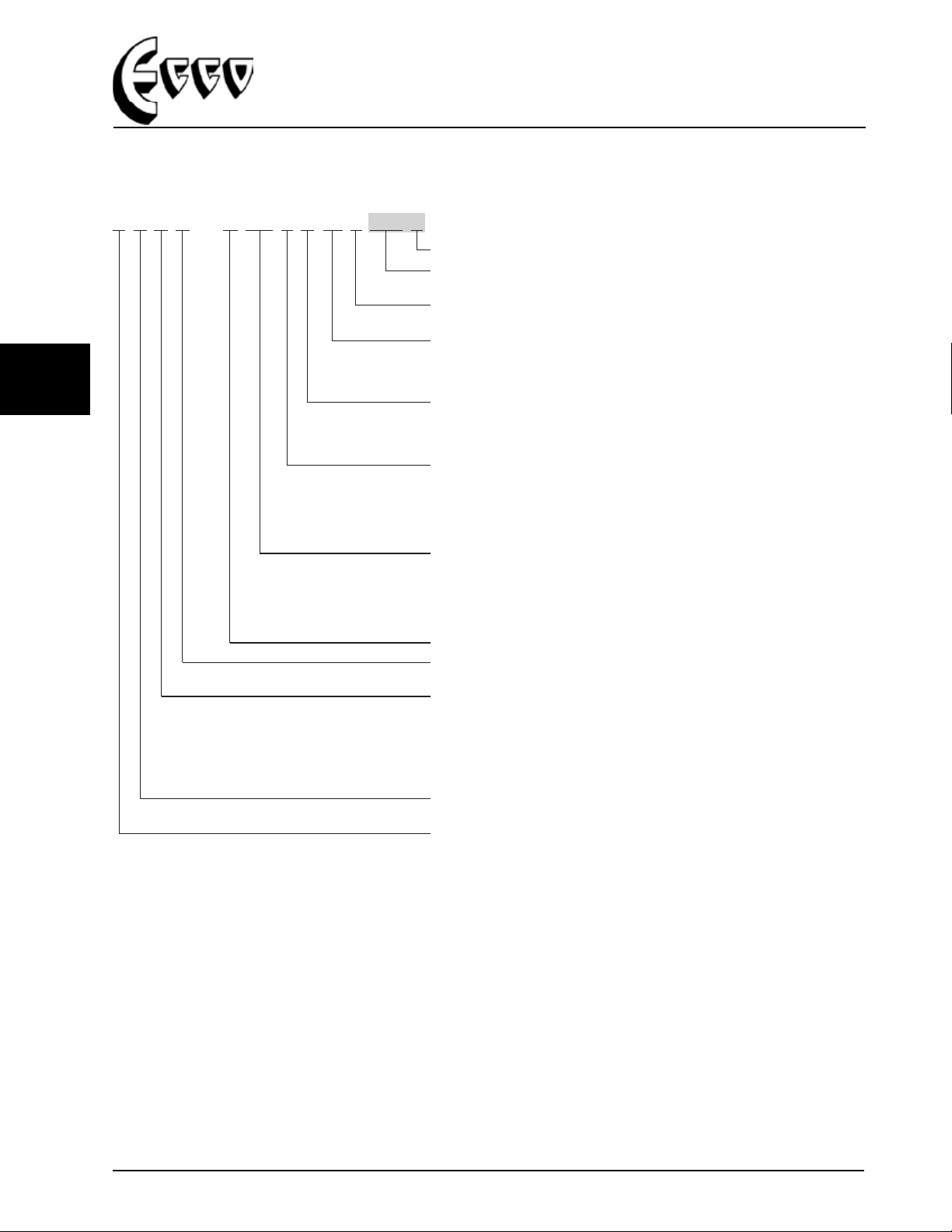

The compressor

compartment

houses the heartbeat of the unit. The

Copeland-compliant

scroll compressor

( ) is known for its

long life, and for

reliable, quiet, and

efficient operation.

The suction and

discharge lines are

designed with shock

loops ( ) to

absorb the strain

and stress that the

starting torque,

steady state operation, and shut down

cycle impose on the

refrigerant tubing.

Each compressor

and circuit is independent for built-in

redundancy, and each circuit is clearly marked throughout the

system. Each unit has two stages of efficient cooling operation,

first stage is approximately 50% of second stage.

The condenser fan motor ( ) can easily be accessed and maintained through the blower compartment. The polarized plug connection allows the motor to be changed quickly and eliminates

the need to snake wires through the unit.

The outdoor coil uses the latest enhanced fin design ( ) for the

most effective method of heat transfer. The outdoor coil is protected by louvered panels, which allow unobstructed airflow while

protecting the unit from both Mother Nature and vandalism.

Each unit is designed

for both downflow or

horizontal applications

( ) for job configuration flexibility. The

return air compartment

can also contain an

economizer ( ). Two

models exits, one for

downflow applications, and one

for horizontal applications. Each unit is

pre-wired for the economizer to allow quick

plug-in installation. The economizer is also available

as a factory-installed option. Power Exhaust is easily fieldinstalled. The economizer, which provides free cooling when

outdoor conditions are suitable and also provides fresh air to

meet local requirements, comes standard with single enthalpy

controls. The controls can be upgraded to dual enthalpy easily in

the field. The direct drive actuator combined with gear drive

dampers has eliminated the need for linkage adjustment in the

field. The economizer control has a minimum position setpoint,

an outdoor-air setpoint, a mix-air setpoint, and a CO

2

setpoint.

Barometric relief is standard on all economizers. The power

exhaust is housed in the

barometric relief opening

and is easily slipped in with

a plug-in assembly.

The Rheem roofcurb ( ) is

made for toolless

assembly at the

jobsite by sequentially engaging the

corner brackets into

the adjacent curb

sides ( ), which

makes the assembly

process quick and easy.

36

35

34

33

32

31

30

29

29

31

32

30

29

35

34

34

33

30

36

RKKB SERIES — 7.5 – 12.5 TONS (cont’d)

Features (cont’d)

Effective Date: December 2006

Rooftop

Heat/Cool

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 13

Page 14

Heat/Cool

RKKB—A090 C L 15 E XXX

Economizer Option (See Next Page)

Factory Installed Options

(See Next Page)

Ignition System

E = Electric

Heating Capacity (MBH)

15 = 150,000 [44.0]

22 = 225,000 [65.9]

25 = 252,000 [73.9]

Drive Package

L = Belt Drive

M = Belt Drive—High Static

N = Belt Drive—RKNB- A090 Only

Electrical Designation

C = 208-230 V, 3 PH, 60 Hz

D = 460 V, 3 PH, 60 Hz

Y = 575 V, 3 PH, 60 Hz

P = 200-220 V, 3 PH, 50 Hz

N = 380-415 V, 3 PH, 50 Hz

Cooling Capacity (BTUH) [kW]

090 = 90,000 [26.38]

102 = 102,000 [29.89]

120 = 120,000 [35.17]

150 = 150,000 [43.96]

181 = 180,000 [52.75]

Future Technical Variations

Design Series

B = “B Series Cabinet”

Efficiency Designation

K = Standard Efficiency

ASHRAE 90.1-1989 Compliant

M = High Efficiency

ASHRAE 90.1-1999 Compliant

N = Super High Efficiency

EnergyStar Compliant

Product Classification

K = Rooftop—Commercial

Tradebrand

R = Rheem Packaged Gas/Electric

[ ] Designates Metric Conversions

Rooftop

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

RKKB SERIES — 7.5 – 12.5 TONS (cont’d)

Model Identification

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

14 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

Page 15

RHEEM PACKAGE GAS/ELECTRIC

OPTIONS—RKKB/RKMB/RKNB- SERIES

Option Code

High and

Low Pressure

Low Ambient

Time Delay

Freeze Stat

Stainless Steel

Heat Exchanger

AA No Options

Unwired Convenience Outlet

AD

AF x

AH x

Hail Guard

x

xBB x

x

x

BG x

BN x x

CD x x

Unfused Services Disconnect

xDH x x x

xEA x x x x

xBF

x

x

x

BK x x

CA x x

DG x x x

AJ x

AC x

FACTORY INSTALLED OPTION CODES FOR KKB, KMB & KNB

(7.5 TO 12.5 TON) [26.4 TO 44.0 kW]

Option Code

Low Ambient

Time Delay

Freeze Stat

Hail Guard

Stainless Steel

Heat Exchanger

No OptionsAA

Unfused Services Disconnect

xBD x

x

x

x

BG x

Unwired Convenience Outlet

CJ x

x

x

AF x

BF

DL x x x

x

x

BN x x

CQ x x

AH x

AJ x

xAD

FACTORY INSTALLED OPTION CODES FOR KKB-A181

“x” indicates factory installed option.

RKKB SERIES — 7.5 – 12.5 TONS (cont’d)

Factory Installed Option Codes

Effective Date: December 2006

Rooftop

Heat/Cool

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 15

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

Page 16

Heat/Cool

OPTIONS—RKKB/RKMB/RKNB- SERIES

No Economizer

Single Enthalpy Economizer

With Barometric Relief

A x

B x

ECONOMIZER SELECTION FOR KKB, KMB & KNB

(7.5 TO 15 TON) [26.4 TO 52.8 kW]

“x” indicates factory installed option.

Instructions for Factory Installed Option(s) Selection

Note: Three characters following the model number will be utilized to designate a factory-installed option or

combination of options. If no factory option(s) is required, nothing follows the model number.

Step 1. After a basic rooftop model is selected, choose a two-character option code from the FACTORY

INSTALLED OPTION SELECTION TABLE.

Proceed to Step 2.

Step 2. The last option code character is utilized for factory-installed economizers. Choose a character from the

FACTORY INSTALLED ECONOMIZER SELECTION TABLE.

Examples:

RKKB-A120CL22E..............................this unit has no factory installed options.

RKKB-A120CL22EBBA ......................this unit is equipped with high and low pressure switches and hail guards.

RKMB-A120CL22EAHA......................this unit is equipped with a convenience outlet and service disconnect.

RKMB-A120CL22EAHB......................this unit is equipped as above and includes an Economizer

with single enthalpy sensor and with barometric relief.

RKMB-A120CL22EAAB ....................this unit is equipped with an Economizer with single enthalpy sensor and

Barometric Relief.

Rooftop

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

RKKB SERIES — 7.5 – 12.5 TONS (cont’d)

Economizer Selection

16 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

Page 17

RHEEM PACKAGE GAS/ELECTRIC

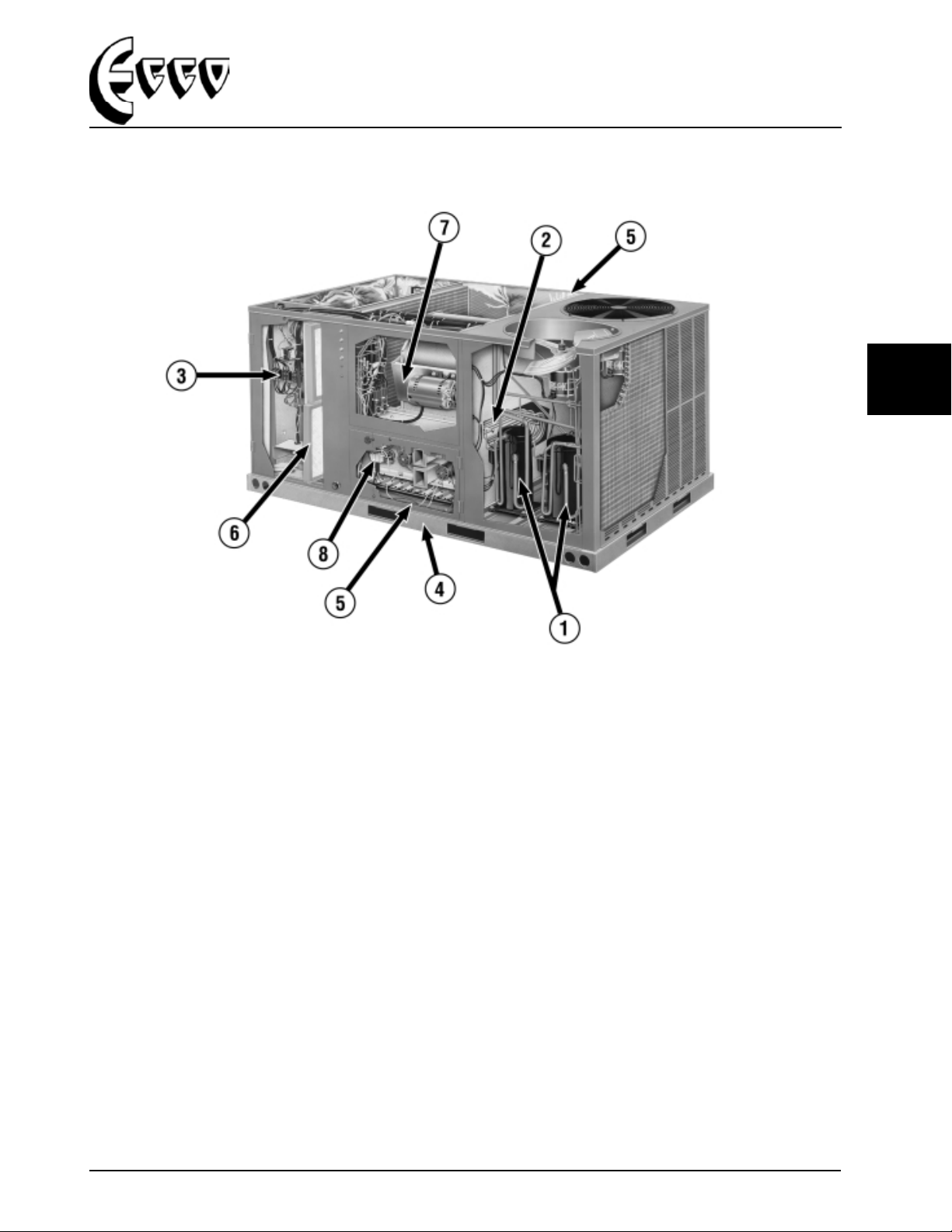

INTRODUCTION

These quality features are included in the Rheem

Gas Heat / Electric Cooling Package Unit

1. Twin Copeland Scroll Compressors for two-stage cooling

2. Tubular heat exchanger for long-life

3. Solid state furnace controls with on-board diagnostics

4. Forkable base rails for easy handling

5. One-piece top, one-piece drawn indoor base pan for superior water management

6. Easy access factory installed filters

7. Slide-out blower assembly for easy maintenance

8. Two-stage gas valve and direct spark ignition for efficiency and reliability

RKKB SERIES — 7.5 – 12.5 TONS (cont’d)

Product Features

Effective Date: December 2006

Rooftop

Heat/Cool

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 17

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

Page 18

RHEEM PACKAGE GAS/ELECTRIC

SELECTION PROCEDURE EXAMPLE—RKKB/RKMB/RKNB- SERIES

To select an RKKB- Cooling and Heating unit to meet a job

requirement, follow this procedure, with example, using data supplied in this specification sheet.

1. DETERMINE COOLING AND HEATING REQUIREMENTS

AND SPECIFIC OPERATING CONDITIONS FROM PLANS

AND SPECS.

Example:

Total cooling capacity— 106,000 BTUH [31.26 kW]

Sensible cooling capacity— 82,000 BTUH [24.03 kW]

Heating capacity— 150,000 BTUH [43.96 kW]

*Condenser Entering Air— 95°F [35°C] DB

*Evaporator Mixed Air Entering—65°F [18°C] WB;

78°F [26°C] DB

*Indoor Air Flow (vertical)— 3600 CFM [1699 L/s]

*External Static Pressure— .40 in. WG

2. SELECT UNIT TO MEET COOLING REQUIREMENTS.

Since total cooling is within the range of a nominal 10 ton

[35.2 kW] unit, enter cooling performance table at 95°F [35°C]

DB condenser inlet air. Interpolate between 63°F [2°C] and

67°F [19°C] to determine total and sensible capacity and

power input for 65°F [18°C] WB evap inlet air at 4000 CFM

[1888 L/s] indoor air flow (table basis):

Total Capacity = 119,500 BTUH [35.02 kW]

Sensible Capacity = 101,200 BTUH [29.66 kW]

Power Input (Compressor and Cond. Fans) = 11,650 watts

Use formula [1.10 x CFM x (1 – DR) x (dbE – 80)] in note to

determine sensible capacity at 80°F [26.7°C] DB evaporator

entering air:

Sensible Capacity = 94,230 BTUH [27.62 kW]

3. CORRECT CAPACITIES OF STEP 2 FOR

ACTUAL AIR FLOW.

Select factors from airflow correction table at 3600 CFM

[1699 L/s] and apply to data obtained in step 2 to obtain

gross capacity:

Total Capacity, 119,500 x .98 = 117,110 BTUH [34.32 kW]

Sensible Capacity, 94,230 x .95 = 89,519 BTUH [26.24 kW]

Power Input 11,650 x .99 = 11,534 Watts

These are Gross Capacities, not corrected for blower motor

heat or power.

4. DETERMINE BLOWER SPEED AND WATTS TO MEET

SYSTEM DESIGN.

Enter Indoor Blower performance table at 3600 CFM [1699 L/s].

Total ESP (external static pressure) per the spec of .40 in.

includes the system duct and grilles. Add from the table “Component Air Resistance,” .076 for wet coil, .13 for vertical air flow,

for a total selection static pressure of .606 (.6) inches of water,

and determine:

RPM = 796

WATTS = 1,650

DRIVE = L (standard 2 H.P. motor)

5. CALCULATE INDOOR BLOWER BTUH HEAT EFFECT

FROM MOTOR WATTS, STEP 4.

BTUH = 1,650 x 3.412 = 5,630

6. CALCULATE NET COOLING CAPACITIES, EQUAL TO

GROSS CAPACITY, STEP 3, MINUS INDOOR BLOWER

MOTOR HEAT.

Net Total Capacity = 117,110 – 5,630 =

111,480 BTUH [32.67 kW]

Net Sensible Capacity = 89,519 – 5,630 =

83,889 BTUH [24.59 kW]

7. CALCULATE UNIT INPUT AND JOB EER.

Total Power Input = 11,534 (step 3) + 1,650

(step 4) = 13,184 Watts

EER =

Net Total BTUH [kW] (step 6) =111,480

= 8.46

Power Input, Watts (above) 13,184

8. SELECT UNIT HEATING CAPACITY.

From Physical Data Table read that gas heating output (input

rating x efficiency) is:

Heating Capacity = 182,300 BTUH [53.43 kW]

*NOTE: These operating conditions are typical of a commercial applica-

tion in a 95°F/79°F [35°C/26°C] design area with indoor design

of 76°F [24°C] DB and 50% RH and 10% ventilation air, with

the unit roof mounted and centered on the zone it conditions

by ducts.

[ ] Designates Metric Conversions

RKKB SERIES — 7.5 – 12.5 TONS (cont’d)

Selection Procedure — Example

Heat/Cool

Rooftop

Effective Date: December 2006

18 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

Page 19

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

RKKB SERIES — 7.5 – 12.5 TONS (cont’d)

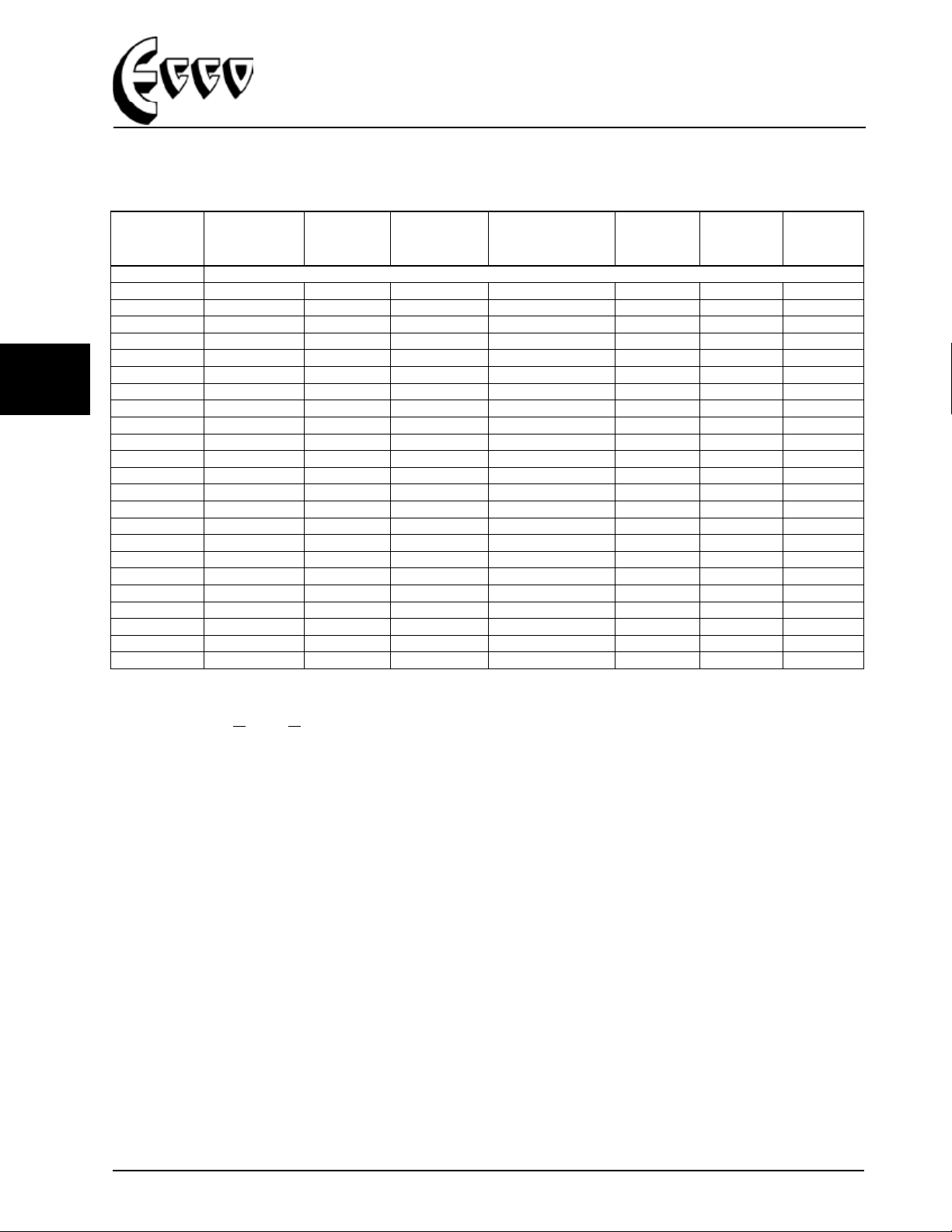

Side and Bottom Discharge — Natural Gas — 3 Phase

FREQUENCY(Hz) INPUT WEIGHT/

STOCK # MODEL COOLING VOLTAGE BTU/HR LBS. PRICE

886122 RKKB-A090CM22E949* 7.5TON 60-208-230 225,000 1098 P.O.A.

886124 RKKB-A120CM22E949* 10TON 60-208-230 225,000 1051 P.O.A.

886130 RKKB-A150CL25E949 12.5TON 60-208-230 252,000 1162 P.O.A.

* Belt Drive — High Static

Note: For Technical Data see end of section.

With Economizer and Stainless Steel Heat Exchanger — 3 Phase

FREQUENCY(Hz) INPUT WEIGHT/

STOCK # MODEL COOLING VOLTAGE BTU/HR LBS. PRICE

886128 RKKB-A090CM22EAJB* 7.5TON 60-208-230 225,000 600 P.O.A.

886129 RKKB-A090YM22EAJB* 7.5TON 60-575 225,000 600 P.O.A.

886125 RKKB-A120CM22EAJB* 10TON 60-208-230 225,000 600 P.O.A.

886127 RKKB-A120YM22EAJB* 10TON 60-575 225,000 600 P.O.A.

* Belt Drive — High Static

Note: For pricing on RKKB Model 12.5 ton units, please contact your local ECCO Sales

Representative.

For Technical Data see end of section.

Accessories

STOCK # MODEL DESCRIPTION PRICE

886180 RXRD-KDCM3 Economizerw/singleenthalpy P.O.A.

FullyModulating(Outdoor)

886164 RXRX-AAD01C OutdoorCoilLouverKit P.O.A.

886174 RXRX-AK01 High/LowPressureSwitchKit P.O.A.

Note: For Technical Data see end of section.

Rooftop

Heat/Cool

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 19

Page 20

Heat/Cool

ACCESSORIES

FIELD INSTALLED ACCESSORY EQUIPMENT

Accessory

Model

Number

Installed

Weight

Lbs. [kg]

Dual Enthalpy Kit

Economizer w/Single Enthalpy RXRD-KDCM3 81 [36.7]

RXRX-AV02 1 [.5]

Horizontal Economizer w/Single Enthalpy RXRD-LDCM3 89 [40.4]

Carbon Dioxide Sensor (Wall Mount) RXRX-AR02 2 [1.0]

Power Exhaust RXRX-BFF02 (C,D,Y) 38 [17.2]

Manual Fresh Air Damper (Horizontal Return Mounted) RXRF-FDA1 21 [9.5]

Shipping

Weight

Lbs. [kg]

90 [40.8]

1 [.5]

94 [42.6]

3 [1.4]

43 [19.5]

26 [11.8]

Factory

Installation

Available?

Yes

No

No

No

No

No

Motorized Fresh Air Damper RXRF-FDB1 43 [19.5] 38 [17.2] No

Roofcurb, 14" RXKG-BAE14 90 [40.8] 85 [38.5] No

Roofcurb, 24" RXKG-BAE24 140 [63.5] 135 [61.2] No

Roofcurb Adapters

(See Chart on Page 78 for Application)

RXRX-CDCE50 300 [136.1] 290 [131.5] No

RXRX-CFCE54 325 [147.4] 315 [142.9] No

RXRX-CFCE56 350 [158.8] 340 [154.2] No

Concentric Diffuser (Step-Down, 20" Round) RXRN-FA65

139 [63.0] 60 [27.2] No

Concentric Diffuser (Step-Down, 18 x 32) RXRN-AA66 247 [112.0] 227 [103.0] No

Concentric Diffuser (Flush, 18 x 28) RXRN-AA71 170 [77.1] 155 [70.3] No

Concentric Diffuser (Flush, 18 x 32) RXRN-AA76 176 [79.8] 161 [73.0] No

Downflow Transition (Rect. to Round)

RXMC-CD04

15 [6.8] 13 [5.9] No

Downflow Transition (Rect. to Rect., 18 x 28)

RXMC-CE05

18 [8.2] 16 [7.3] No

Compressor Time-Delay Relay Kit RXMD-A04 2 [1.0] 1 [.5] Yes

Low-Ambient Control Kit RXRZ-A90 3 [1.4] 2 [1.0] Yes

High/Low Pressure Switch Kit RXRX-AK01 5 [2.3] 4 [1.8] Yes

Freeze-Stat Kit RXRX-AM01 1 [.5] 0.5 [.2] Ye s

Outdoor Coil Louver Kit RXRX-AAD01C 29 [11.3] 26 [11.8] Ye s

Downflow Transition (Rect. to Rect., 18 x 32)

RXMC-CF06

20 [9.1] 18 [8.2] No

RXRX-CGCC12

450 [204.1] 410 [186.0] No

Concentric Diffuser (Step-Down, 18 x 28) RXRN-AA61 200 [90.7] 185 [83.9] No

Concentric Diffuser (Flush, 20" Round) RXRN-FA75 54 [24.4] 42 [19.0] No

38 [17.2] NoManual Fresh Air Damper (Left Panel Mounted) RXRF-GDA1 31 [14.1]

Motor Kit for RXRF-HDA1 RXRX-AT02 35 [15.9] 27 [12.2] No

Unwired Convenience Outlet RXRX-AN01 2 [1.0] 1.5 [.7] Ye s

Unfused Service Disconnect RXRX-AP01 10 [4.5] 9 [4.1] Yes

NOTES: Used with RXRN-AA61 and RXRN-AA71 concentric diffusers.

Used with RXRN-AA66 and RXRN-AA76 concentric diffusers.

Please refer to conversion kit index provided with the unit for LP conversion kit.

[ ] Designates Metric Conversions

Rooftop

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

RKKB SERIES — 7.5 – 12.5 TONS (cont’d)

Accessories — Field Installed

20 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

RKKB Series

Page 21

RHEEM PACKAGE GAS/ELECTRIC

ENGINEERING FEATURES

ENGINEERING FEATURES

RKNA- Series Package Gas Electric Units

1. All models feature Copeland®Scroll®compressors offering maximum reliability, efficiency, and quiet operation.

2. Aluminized steel heat exchanger with in-shot burners helps eliminate corrosion. Stainless steel heat

exchangers optional.

3. Integrated blower/burner control board with built-in diagnostic capability permits on-site trouble shooting.

4. One-piece top over the indoor section with drip lip, drawn painted base pan, and 1" [25.4 mm] raised

flanges for supply/return air connections provides superior water management.

5. Convertible horizontal and vertical airflow design allows maximum field flexibility and minimizes inventory

requirements.

6. Standard full perimeter forkable 14 gauge baserail with lifting holes for easier maneuvering and installations.

7. Factory installed one-inch [25.4 mm] throw away filter with provisions for two-inch [50.8 mm] filter.

8. Direct or belt drive options to accommodate a wide range of design conditions as high as 1.5 inches

[.37 kPa] of external static pressure.

9. Easily removable filter, blower, gas heat, and compressor/control access panels permits prompt service.

10. Number and color coded wiring helps facilitate service and maintenance.

11. Common cabinet and components allows for installation flexibility and fewer parts to inventory.

12. Standard freezestat control offers evaporator coil freeze protection.

13. Factory or field installed high and low pressure controls.

14. Externally mounted refrigerant gauge ports for easy service diagnostics.

15. Side and base electric power and gas connection entry helps minimize roof penetrations.

16. Quick assembly common roof curbs helps save field labor and maximize size flexibility.

17. Easy to install, plug-in, slip-in, 100% fully modulating economizers.

18. Quality powder paint finish offers long lasting protection against extreme weather conditions and is able to

withstand 1000 HR salt spray test.

[ ] Designates Metric Conversions

R K N A—A 036 J K 08 E XXX

Economizer Option (See Next Page)

Factory Installed Options

(See Next Page)

Ignition System

E = Electric Ignition,

E = 1 Stage Gas Valve

X = Electric Ignition,

E = 1 Stage Gas Valve, NO

x

Heating Capacity (MBH)

08 = 080,000 [23.5]

10 = 100,000 [29.3]

12 = 120,000 [35.2]

13 = 135,000 [39.6]

Drive Package

K = Direct Drive

L = Belt Drive

M = Belt Drive—High Static

Electrical Designation

C = 208-230 V, 3 PH, 60 Hz

D = 460 V, 3 PH, 60 Hz

J = 208-230V, 1 PH, 60 Hz

Cooling Capacity (BTUH) [kW]

036 = 36,000 [10.55]

042 = 42,000 [12.31]

048 = 48,000 [14.07]

060 = 60,000 [17.58]

Future Technical Variations

Design Series

A =1st Design

Efficiency Designation

N = Super High Efficiency (13 SEER)

Product Classification

K = Rooftop—Commercial

Tradebrand

R = Rheem Package Gas Electric

[ ] Designates Metric Conversions

RKNA SERIES — 3 – 5 TONS – 13 SEER

Engineering Features

Effective Date: December 2006

Rooftop

Heat/Cool

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 21

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

RKNA SERIES

Page 22

RHEEM PACKAGE GAS/ELECTRIC

OPTIONS—RKNA- SERIES

Option Code

High and

Low Pressure

Low Ambient

Time Delay

AA No Options

Unwired

Convenience Outlet

Unfused Service

Disconnect

AH x

AK

BB x

Hail Guard

x

xBF

x

x

BU x

CB x x

BH x

x

x

x

BX

CP x

AC x

x

Side Flow

x

Reduced

Height

Baserails

x

x

Stainless

Steel Heat

Exchanger

xxDB x x

x

x

x

xBG

x

BV

x

x

x

x

xAJ

BS

CE x

xx

x

CA x

DA x x x

AE x

AL

BE x x

xxEB x x x

xAD

FACTORY INSTALLED OPTION CODES FOR RKNA (3-5 TON) [10.6-17.6 kW]

(A036, A042, A048, A060)

Economizer Codes

A = No Economizer

B = Economizer with Single Enthalpy

Example: RKNA-A060JK13EXX

X (where XX is factory installed option)

Example: No Options

RKNA-A060JK13E

Example: No option with factory installed economizer

RKNA-A060JK13EAAB

Example: Options with stainless steel heat exchanger and no factory installed economizer

RKNA-A060JK13EAJA

Example: Options same as above with factory installed economizer

RKNA-A060JK13EAJB

[ ] Designates Metric Conversions

RKNA SERIES — 3 – 5 TONS – 13 SEER

Factory Installed Option Codes for RKNA (3-5 Ton) [10.6-17.6 kW] (A036, A042, A048, A060)

Heat/Cool

Rooftop

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

22 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

Effective Date: December 2006

Page 23

RHEEM PACKAGE GAS/ELECTRIC

INTRODUCTION

These quality features are included in the

Rheem Package Gas Electric Unit

Evaporator Coil/Filter Access

• Return air filters, normally

provided, are removed in

this photo.

Tubular Heat Exchanger

• Aluminized steel

(viewed from supply

air side panel.)

• Stainless steel available

Heating Compartment Access

Blower Access

• Belt drive model shown.

(Available on 3-phase models only.)

Compressor Access

(3 to 5 Ton [10.6 to 17.6 kW] Models)

Control Box Access

• Non-corrosive plastic

condensate pan

[ ] Designates Metric Conversions

RKNA SERIES — 3 – 5 TONS – 13 SEER (cont’d)

Product Features

Effective Date: December 2006

Rooftop

Heat/Cool

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 23

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

Page 24

Heat/Cool

1. Determine cooling and heating requirements at design conditions.

Example:

Total cooling capacity ........................43,600 BTUH [12.78 kW]

Sensible cooling capacity ..................34,000 BTUH [9.96 kW]

Heating capacity ................................96,000 BTUH [28.13 kW]

Condenser entering air ......................95°F [35°C]

Evaporator entering air ......................63°F [17°C] wb/76°F [24°C] db

Indoor air flow ....................................1600 CFM [755 L/s]

External static pressure......................1.1 in wg

Required efficiency ............................13 SEER

2. Select unit to meet cooling requirements.

Since total cooling is within the range of 4 ton [14.07 kW] unit and

requires 13 SEER efficiency level, enter cooling performance from the

RKNA-A048 at 95°F [35°C] outdoor temperature, 63°F [17°C] wb

entering indoor air, and 1550 CFM [732 L/s]:

Total capacity ....................................47,300 BTUH [732 kW]

Power input ........................................3.5 kW

And also, at 76°F [24°C] db indoor entering air, and using the formula

at the bottom of the table:

Sensible capacity ..............................41,708 BTUH [12.22 kW]

3. Select heating capacity of the unit.

In the general data tables, note that the heating capacity of the 4 ton

[14.07 kW] model with the 135,000 input heater can deliver 106,500

BTUH [31.21 kW], which is suitable for this application.

4. Determine blower speed and power to meet the system

requirements.

At the given external static pressure of 1.1 in wg, the belt model must

be selected. Enter the belt drive blower performance data at 1600

CFM [755 L/s] and 1.1 in wg ESP:

RPM ........1195

Watts........755

Drive ........M

5. Calculate indoor blower BTUH heat effect.

BTUH = Watts x 3.413 = 2577

6. Calculate net cooling capacities.

Net total cooling = 47,300 – 2577 = 44,723 BTUH [13.10 kW]

Net sensible cooling = 41,708 – 2577 = 39,131 BTUH [11.47 kW]

[ ] Designates Metric Conversions

SELECTION PROCEDURE EXAMPLE—RKNA- SERIES

Rooftop

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

RKNA SERIES — 3 – 5 TONS – 13 SEER (cont’d)

Selection Procedure — Example

Side and Bottom Discharge – Natural Gas – 1 Phase

FREQUENCY(Hz) INPUT WEIGHT/

STOCK # MODEL COOLING VOLTAGE BTU/HR LBS. PRICE

886202 RKNA-A036JK12E949 3TON 60-208-230 120,000 550 P.O.A.

886204 RKNA-A048JK13E949 4TON 60-208-230 135,000 592 P.O.A.

886206 RKNA-A060JK13E949 5TON 60-208-230 135,000 604 P.O.A.

Note: For Technical Data see end of section.

24 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

Page 25

RHEEM PACKAGE GAS/ELECTRIC

*Voltage J = 208/230 VAC-1PH-60HZ D = 460 VAC-3PH-60HZ

C = 208/230 VAC-3PH-60HZ

NOTES: If a particular unit is to be converted to operate on LP (propane) for elevations above 2000 ft. in Canada, the existing Natural Gas to LP Conversion Kits for the

subject models already contain the necessary orifices and instructions to de-rate the input for 2000-4500 ft. Canadian applications.

Economizer is designed for downflow or horizontal applications.

[ ] Designates Metric Conversions

ACCESSORY EQUIPMENT

Accessory

Description

Model Application

3 to 5 Ton

[10.6 to 17.6 kW]

Accessory

Model No.

3 to 5 Ton

[10.6 to 17.6 kW]

Roofcurb Adapters RKNA-

RXRX-BBCDB21

RXRX-BBCDB22

RXRX-BBCDB23

Economizer with Single Enthalpy

RKNA- RXRD-KECM3

Time Delay RKNA- RXMD-B01

Low Ambient Control to 0°F [-18°C] RKNA- RXRZ-A18

Fresh Air Damper Manual RKNA- RXRF-FBA1

Fresh Air Damper Motorized RKNA- RXRF-FBB1

Rectangular to Round 18"

Duct Adapters for Concentric Diffuser

RKNA- RXMC-CB03

Rectangular to Round 20"

Duct Adapters for Concentric Diffuser

RKNA- RXMC-CB04

Concentric Diffuser 18" Step RKNA- RXRN-FA60

Concentric Diffuser 18" Flush RKNA- RXRN-FA70

Roofcurb 14" RKNA- RXKG-BAD14

Roofcurb 24" RKNA- RXKG-BAD24

Rectangular to Round 16" Side RKNA- RXMC-BB01

Louver Kit (3 Sides) All RKNA- Models RXRX-AAD01B

Factory Installed

3 to 5 Ton

[10.6 to 17.6 kW]

No

Yes

Yes

Yes

No

No

No

No

No

No

No

No

No

Yes

LP Conversion Kits for use with

White Rodgers Gas Valve

RKNA- RXGJ-EP84W

No

LP Conversion Kits for use with

Honeywell Gas Valve

RKNA- RXGJ-EP85H

No

Dual Enthalpy Kit RKNA- RXRX-AV02 No

CO2Sensor Only RKNA- RXRX-AR02 No

Power Exhaust RKNA- RXRX-BFF04C No

Canadian High Altitude Kit

(for Natural Gas Only)

RKNA- RXRX-AH01 No

High Pressure RKNA- RXAB-A02 Yes

Low Pressure RKNA- RXAC-A02 Ye s

ACCESSORIES

RKNA SERIES — 3 – 5 TONS – 13 SEER (cont’d)

Accessory Equipment

Effective Date: December 2006

Rooftop

Heat/Cool

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 25

Page 26

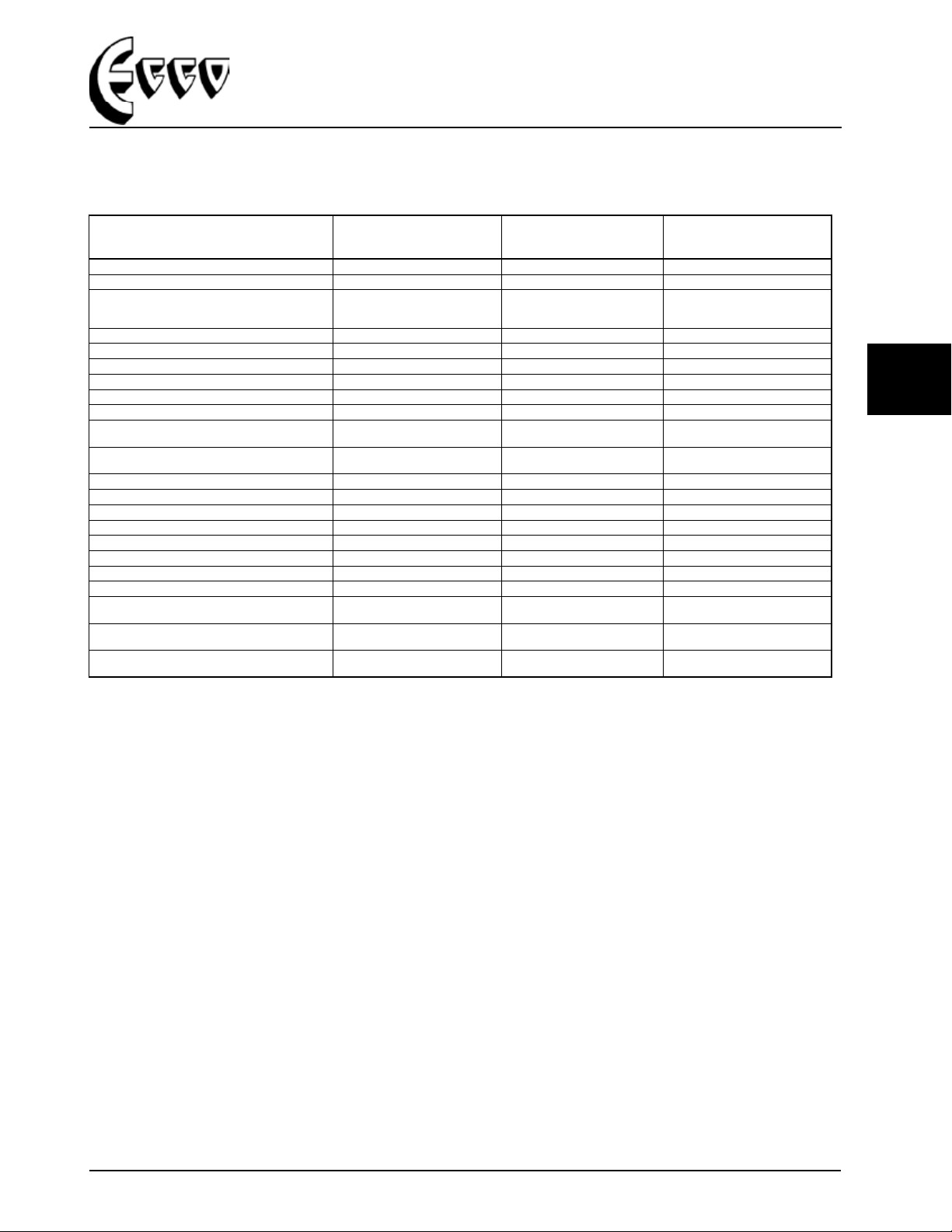

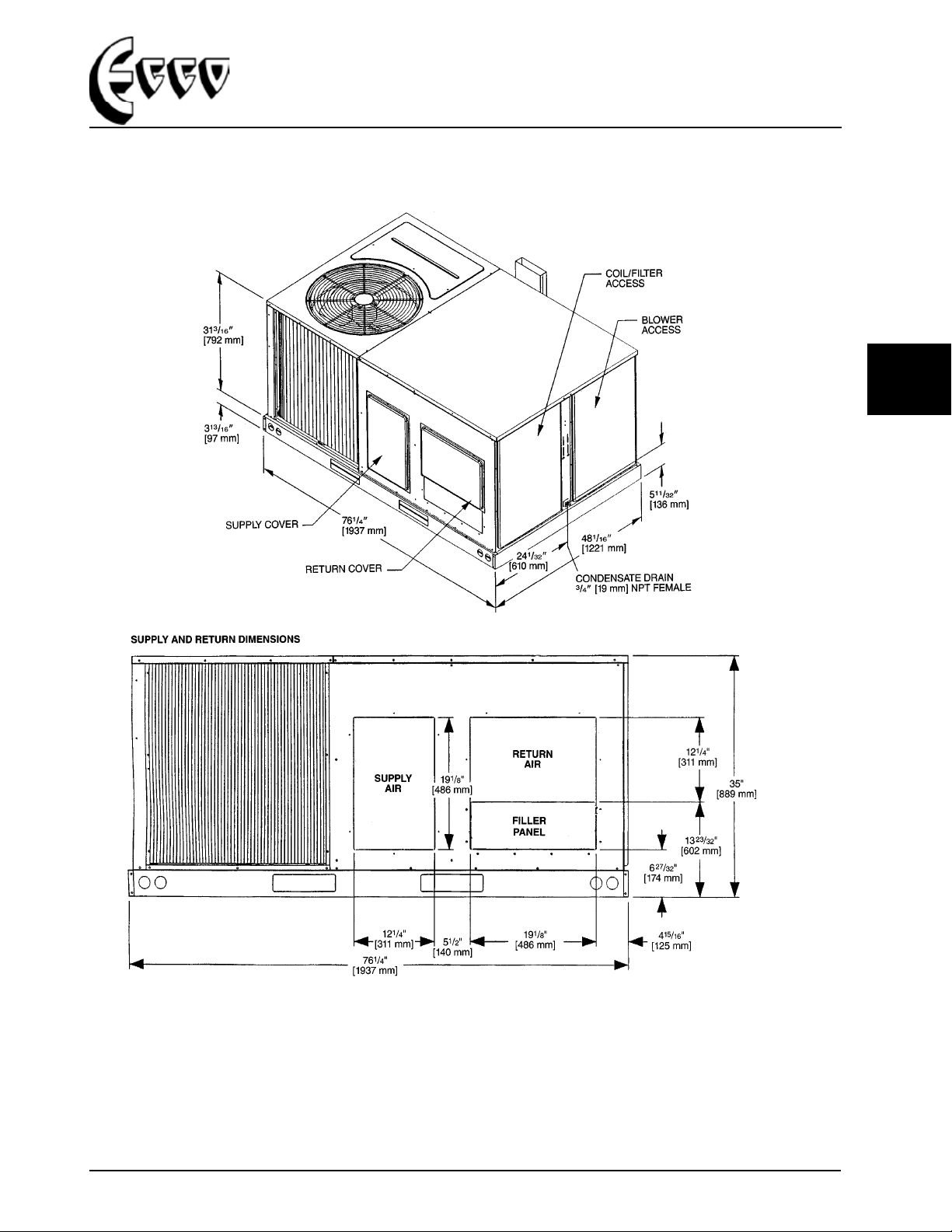

BOTTOM VIEW

[ ] Designates Metric Conversions

UNIT DIMENSIONS—RKKA/RKMA- SERIES

TECHNICAL DATA

RKKA Series — 3 – 6 Tons

Dimensions

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

Heat/Cool

Rooftop

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

26 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

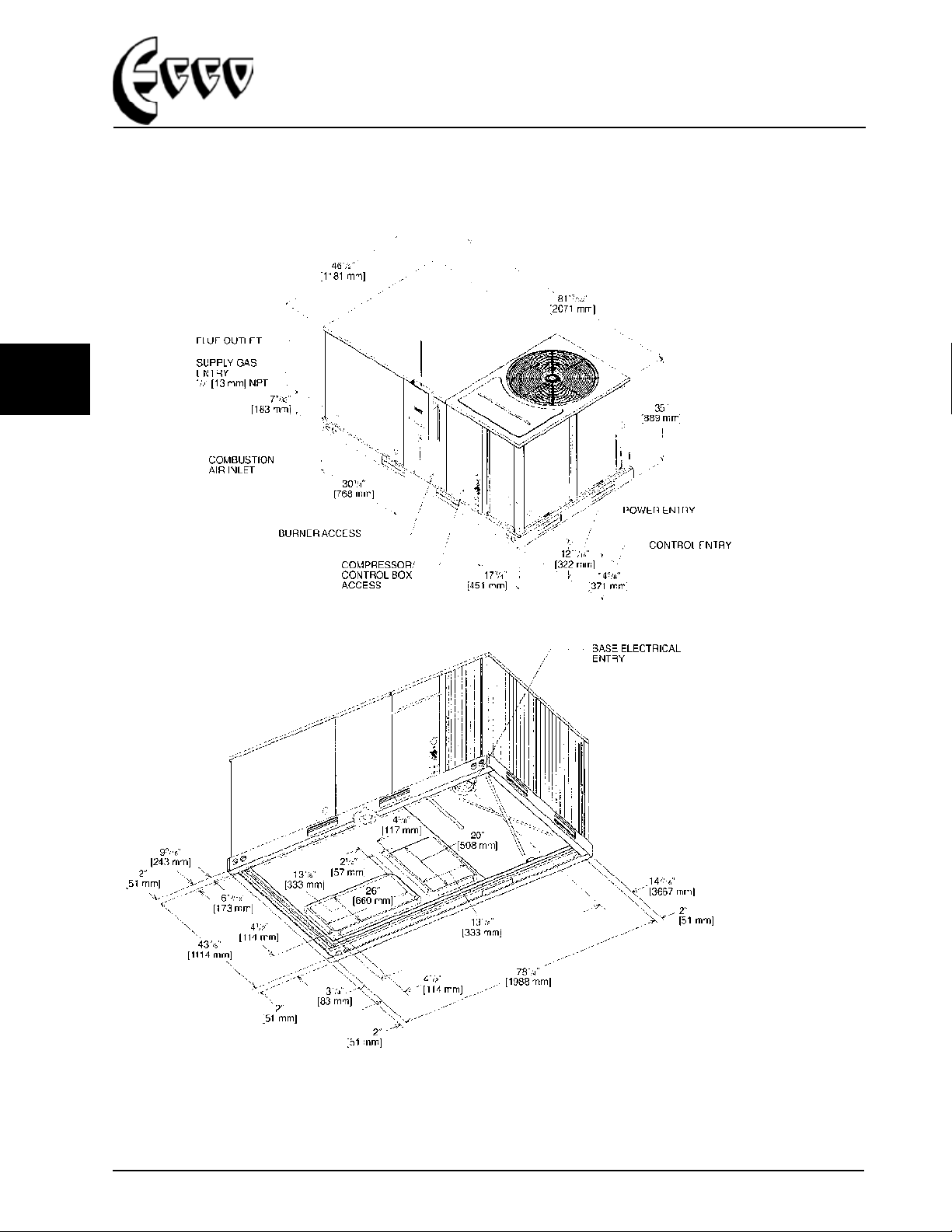

Page 27

[ ] Designates Metric Conversions

UNIT DIMENSIONS—RKKA/RKMA- SERIES

TECHNICAL DATA (cont’d)

RKKA Series — 3 – 6 Tons (cont’d)

Unit Dimensions

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

Rooftop

Heat/Cool

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 27

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

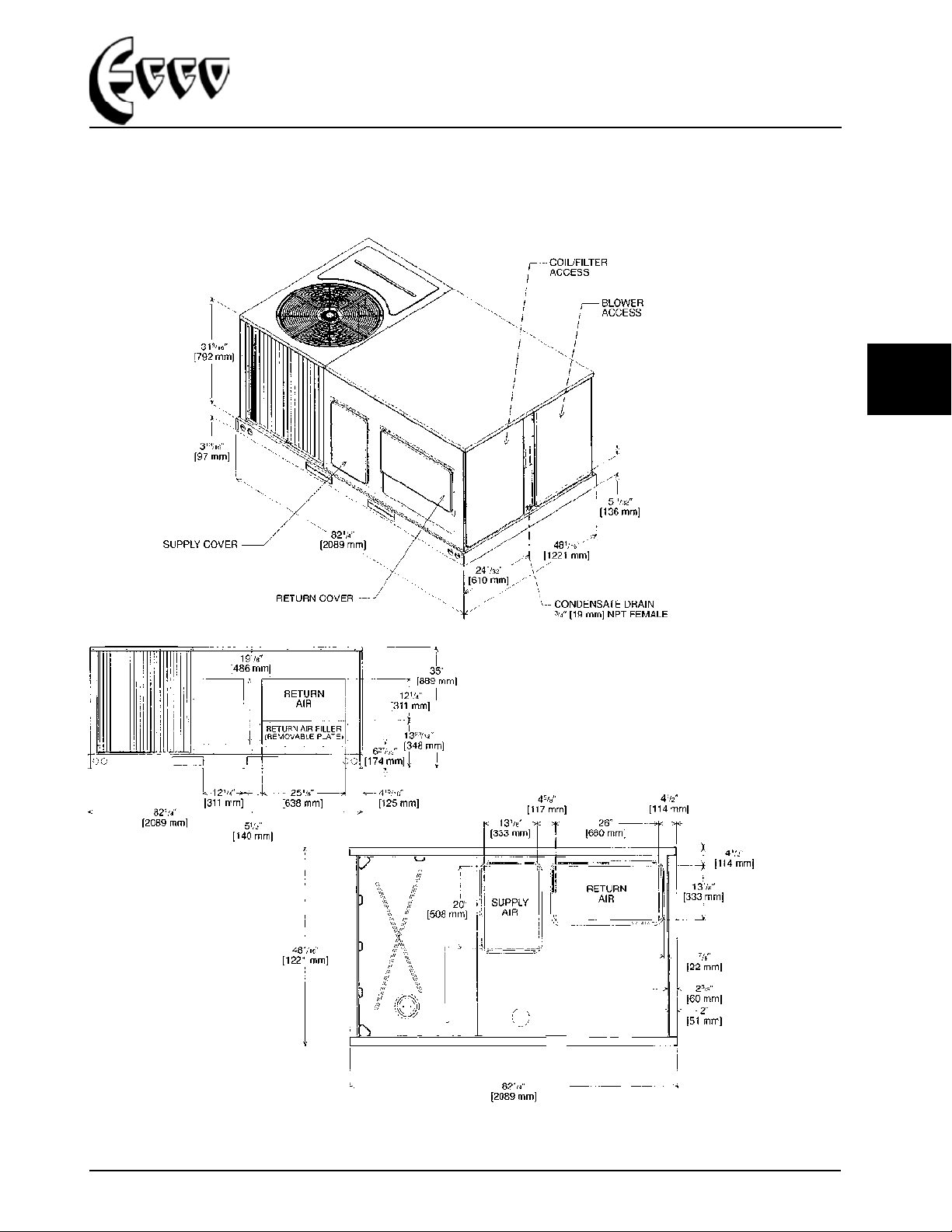

Page 28

Heat/Cool

[ ] Designates Metric Conversions

BOTTOM VIEW

UNIT DIMENSIONS—RKKA/RKMA- SERIES

Rooftop

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

TECHNICAL DATA (cont’d)

RKKA Series — 7.5 Tons

Unit Dimensions

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

28 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

Page 29

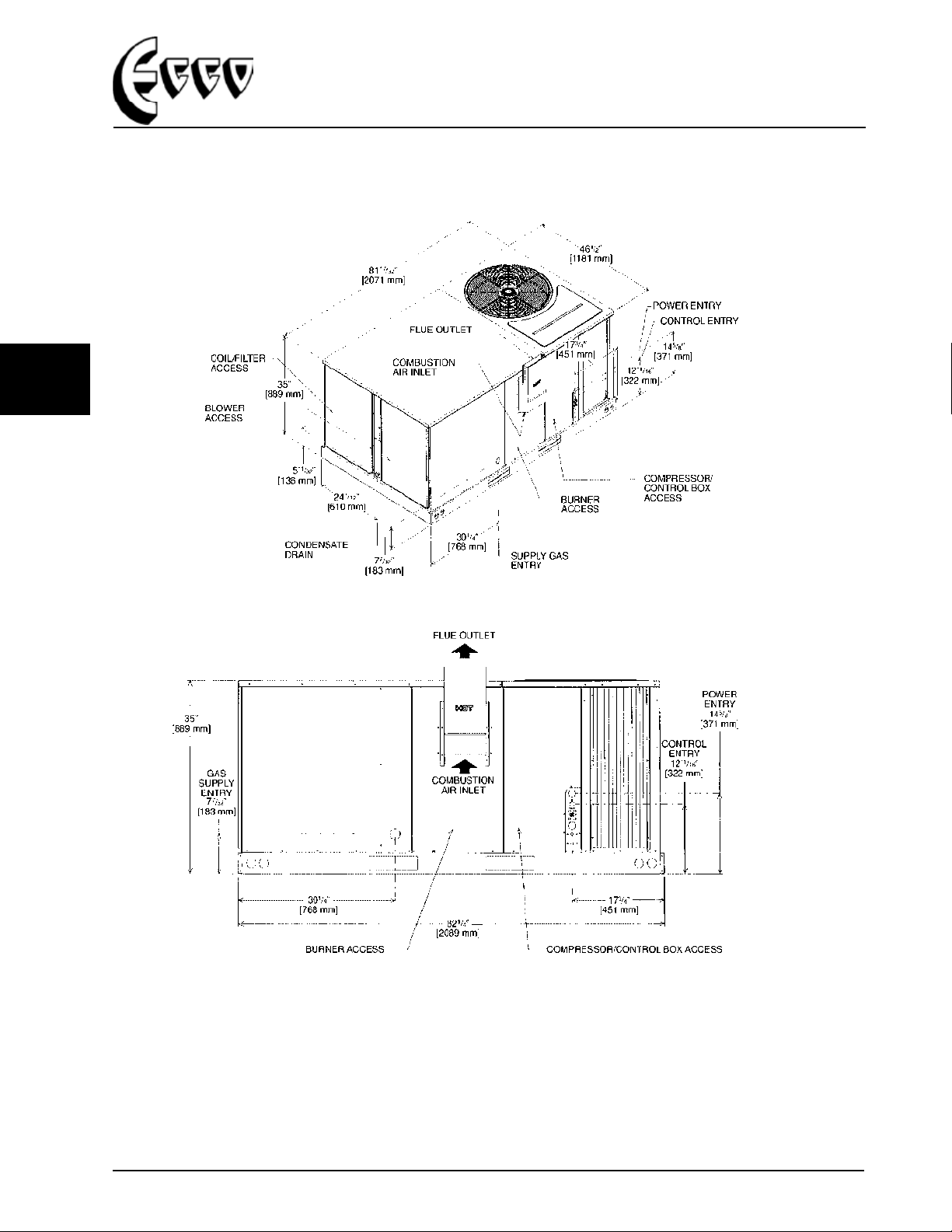

[ ] Designates Metric Conversions

SUPPLY AND RETURN DIMENSIONS

BOTTOM VIEW

UNIT DIMENSIONS—RKKA/RKMA- SERIES

TECHNICAL DATA (cont’d)

RKKA Series — 7.5 Tons (cont’d)

Unit Dimensions

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

Rooftop

Heat/Cool

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 29

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

Page 30

Heat/Cool

[ ] Designates Metric Conversions

UNIT DIMENSIONS—RKKA/RKMA- SERIES

Rooftop

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

TECHNICAL DATA (cont’d)

RKKA Series — 7.5 Tons (cont’d)

Unit Dimensions

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

30 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

Page 31

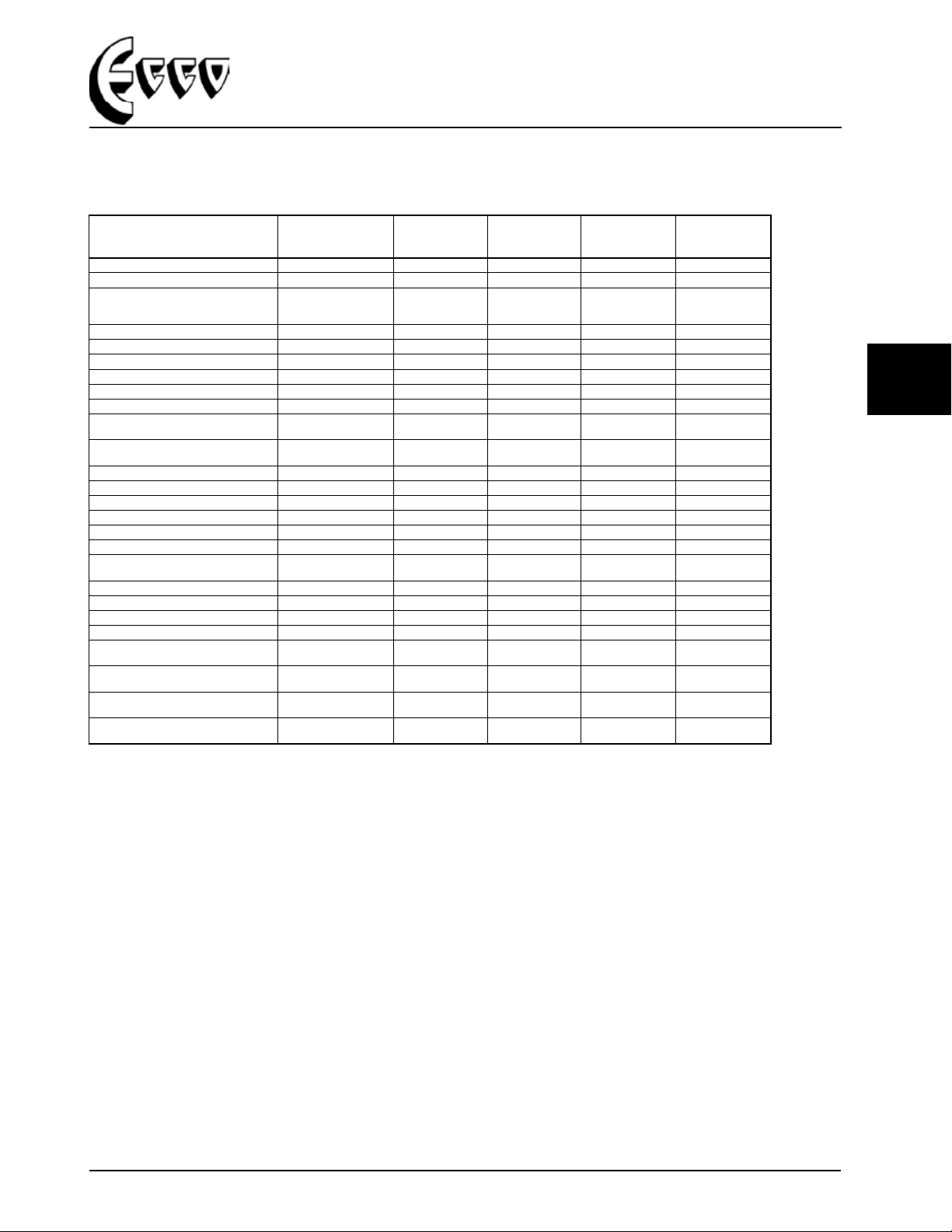

Accessory

3-6 Ton [10.6-21.1 kW]

Economizer with Single Enthalapy 70 [32]

Power Exhaust 19 [9]

Fresh Air Damper (Manual) 11 [5] 9 [4]

16 [7]

60 [27]

Fresh Air Damper (Motorized) 13 [6]

Roof Curb 14" 92 [42] 88 [40]

11 [5]

Roof Curb 24" 108 [49] 104 [47]

Concentric Diffuser 18" Flush 37 [17] 26 [12]

Concentric Diffuser 20" Flush 54 [24] 42 [19]

lbs [kg] lbs [kg]

14 [6]

21 [10]

80 [36]

7.5 Ton [26.4 kW]

92 [42]

37 [17]

16 [7]

108 [49]

54 [24]

lbs [kg]

12 [5]

17 [8]

70 [32]

88 [40]

26 [12]

14 [6]

104 [47]

42 [19]

lbs [kg]

Shipping Operating Operating Operating

Side Discharge Concentric Diffuser RXRN-FA60 35 [16] 20 [9]

Side Discharge Concentric Diffuser RXRN-FA65 55 [25] 40 [18]

—

55 [25]

—

40 [18]

A B C D

22% 27% 23% 28%

23% 29% 21% 27%

Capacity Tons [kW]

7.5 [26.4]

3-6 [10.6-21.1]

Corner Weights by Percentage

381/4[972] 253/4 [654]

39 [991] 261/8 [664]7.5 [26.4]

3-6 [10.6-21.1]

Capacity Tons [kW] A in. [mm] B in. [mm]

WEIGHTS

CENTER OF GRAVITY (C.G.)

CLEARANCES

(3 to 7.5 Ton [10.6 to 26.4 kW] Models)

The following minimum clearances are recommended

for proper unit performance and serviceability.

Recommended

Clearance in. [mm]

Location

48 [1219] A - Front

18 [457] B - Condenser Coil

12 [305] C - Duct Side

36 [914] D - Evaporator End

60 [1524] E - Above

*Without Economizer. 57" [1448 mm] With Economizer

NOTE: Supply duct may be installed

with “0” inch clearance to combustible

materials, provided 1" [25.4 mm]

minimum Fiberglass insulation is

applied either inside or on the outside

of the duct.

[ ] Designates Metric Conversions

UNIT DIMENSIONS—RKKA/RKMA- SERIES

TECHNICAL DATA (cont’d)

RKKA Series — 3 – 7.5 Tons (cont’d)

Weights

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

Rooftop

Heat/Cool

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 31

Page 32

Heat/Cool

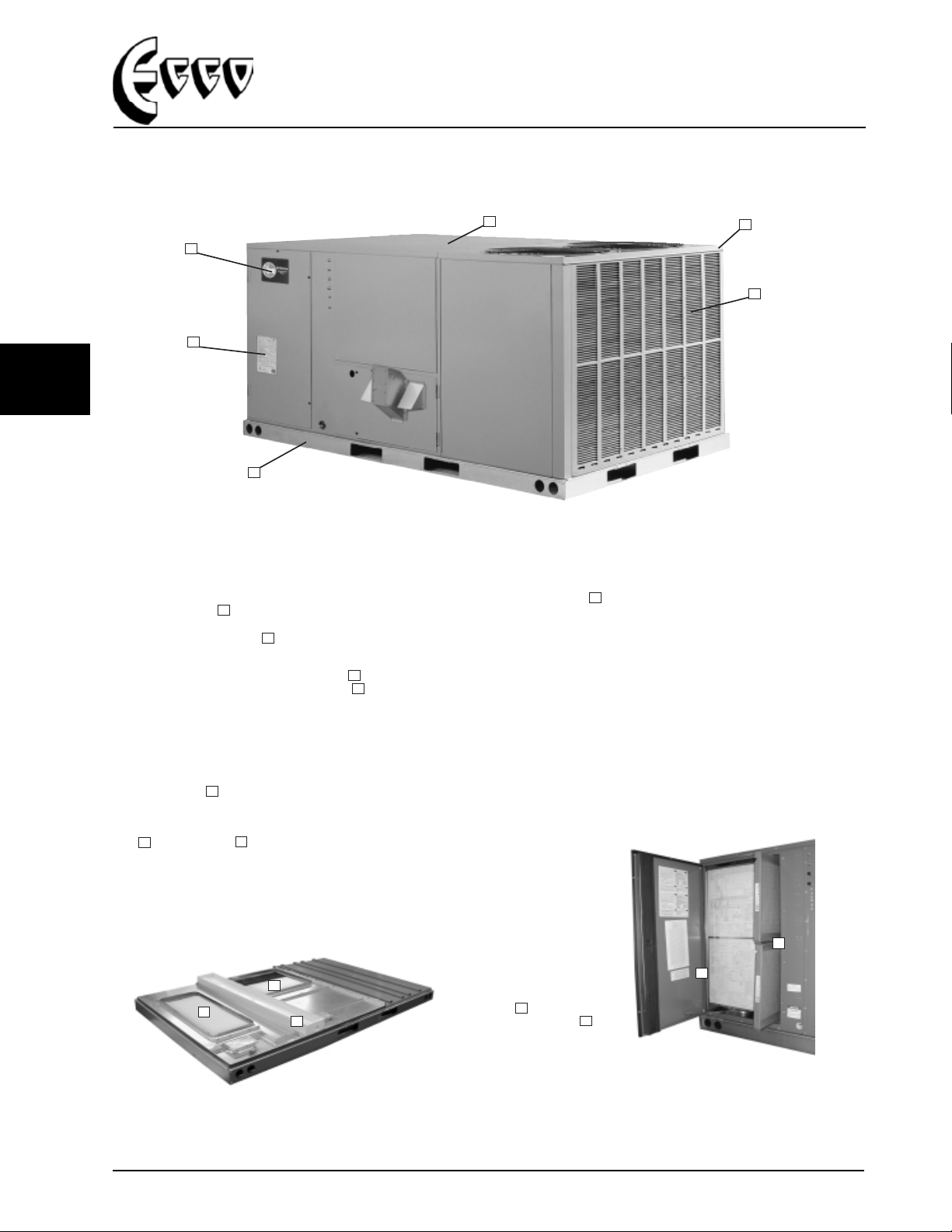

ROOFCURBS (Full Perimeter)

�

Rheem’s new roofcurb design can be utilized on

3 through 7.5 ton [10.6-26.4 kW] models.

�

Two available heights (14" [356 mm] and

24" [610 mm]) for ALL models.

�

Quick assembly corners for simple and fast assembly.

�

Opening provided in bottom pan to match the

“Thru the Curb” electrical connection opening

provided on the unit base pan.

�

2" [51 mm] x 4" [102 mm] Nailer provided.

�

Insulating panels provided.

�

Sealing gasket (28" [711 mm]) provided

with Roofcurb.

�

Packaged for easy field assembly.

[ ] Designates Metric Conversions

TYPICAL INSTALLATION

Roofcurb Model Height of Curb

RXKG-BAD14 14" [356 mm]

RXKG-BAD24 24" [610 mm]

ACCESSORIES

Rooftop

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

TECHNICAL DATA (cont’d)

RKKA Series — 3 – 7.5 Tons (cont’d)

Roofcurbs (Full Perimeter)

TYPICALINSTALLATION

32 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

Page 33

ROOFCURB FOR

RKMA 6 TON [21.1 kW] MODELS

RKKA 7.5 TON [26.4 kW] MODELS

ROOFCURB FOR

RKKA 3-6 TON [10.6-21.1 kW] MODELS

[ ] Designates Metric Conversions

ROOFCURBS (Cont.)

ACCESSORIES

TECHNICAL DATA (cont’d)

RKKA Series — 3 – 7.5 Tons (cont’d)

Roofcurbs (Full Perimeter) (cont’d)

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

Rooftop

Heat/Cool

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 33

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

Page 34

�

Features Honeywell Analog Controls

�

Available factory installed or field accessory

�

Gear Driven Direct Drive Actuator

�

Fully Modulating (0-100%)

�

Low Leakage Dampers

�

Horizontal or Downflow Applications

�

Slip-In Design for Easy Installations

�

Plug-In Polarized 9-pin Electrical Connections

�

Pre-configuring—No Field Adjustments Necessary

�

Standard Barometric Relief Damper Provided

�

Single Enthalpy with Dual Enthalpy upgrade kit

�

CO2Input Sensor Available (field installed)

�

Economizer slips in complete for downflow or

horizontal duct applications

�

Field assembled hood ships with Economizer

�

Optional Remote minimum position

(Honeywell #S963B1128) is available from ProStock.

�

Field installed power exhaust available.

[ ] Designates Metric Conversions

ECONOMIZER

RKMA 6 TON [21.1 kW] Models

RKKA 7.5 TON [26.4 kW] Models

RKKA 3-6 Ton [10.6-21.1 kW] Models

ECONOMIZERS

RXRD-KECM3—RKKA 3-6 Ton [10.6-21.1 kW] Models Single Enthalpy (with Barometric Relief)

RXRD-KCCM3—RKMA 6 Ton [21.1 kW] Models

RKKA 7.5 Ton [26.4 kW] Models

RXRX-AV02—3-7.5 Ton [10.6-26.4 kW] Models Dual Enthalpy Kit

RXRX-AR02—3-7.5 Ton [10.6-26.4 kW] Models Optional CO

2

Sensor

ACCESSORIES

TECHNICAL DATA (cont’d)

RKKA Series — 3 – 7.5 Tons (cont’d)

Economizers

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

Heat/Cool

Rooftop

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

34 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

Page 35

RHEEM PACKAGE GAS/ELECTRIC

[ ] Designates Metric Conversions

Illustration

ST-A0903-01

FRESH AIR DAMPER

RKKA 3-6 Ton [10.6-21.1 kW] Models

RXRF-FBA1 (Manual)

RXRF-FBB1 (Motorized)

RKMA 6 Ton [21.1 kW] Models

RKKA 7.5 Ton [26.4 kW] Models

RXRF-FCA1 (Manual)

RXRF-FCB1 (Motorized)

INTEGRAL POWER EXHAUST FOR ECONOMIZER

(FIELD INSTALLED ONLY)

RXRX-BFF04C—RKKA 3-6 Ton [10.6-21.1 kW] Models

208/230 V, 1 PH and 3 PH, 60 Hz

RXRX-BFF03C—RKMA 6 Ton [21.1 kW] Models

RKKA 7.5 Ton [26.4 kW] Models

208/230 V, 1 PH and 3 PH, 60 Hz

For Honeywell economizer.

Downflow or horizontal applications.

Requires separate 208-230 volt – 1 PH power supply

with disconnect.

Adjustable switch on economizer, factory preset to energize

power exhaust at 95% outside air position.

Polarized plug connects power exhaust relay to economizer.

Model No. No. of Fans Volts Phase Watts (ea.)

High Speed

FLA (ea.) LRA (ea.)

RXRX-BFF03C 1 208-230 1 240 2600 1700 1.06 1.9

RXRX-BFF04C 1 208-230 1 240 2600 1700 1.06 1.9

CFM

RPM

POWER EXHAUST KIT FOR RXRD-KCCM(-), RXRD-KECM(-) ECONOMIZERS

CFM is at 0" W.C. external static pressure.

ACCESSORIES

TECHNICAL DATA (cont’d)

RKKA Series — 3 – 7.5 Tons (cont’d)

Fresh Air Damper

Effective Date: December 2006

Rooftop

Heat/Cool

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

ECCO HEATING PRODUCTS LTD. www.eccohtg.com 35

Page 36

TECHNICAL DATA (cont’d)

Model RKKA- Series A036CK08E A036CK12E A036CL08E A036CL12E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 37,600 [11] 37,600 [11] 37,600 [11] 37,600 [11]

EER/SEER

2

9.4/10.2 9.4/10.2 9.4/10.2 9.4/10.2

Nominal CFM/ARI Rated CFM [L/s] 1200/1200 [566/566] 1200/1200 [566/566] 1200/1200 [566/566] 1200/1200 [566/566]

ARI Net Cooling Capacity Btu [kW] 36,000 [10.5] 36,000 [10.5] 36,000 [10.5] 36,000 [10.5]

Net Sensible Capacity Btu [kW] 26,500 [7.8] 26,500 [7.8] 26,500 [7.8] 26,500 [7.8]

Net System Power kW 3.8 3.8 3.8 3.8

Heating Performance (Package Gas/Electric)

4

Heating Input Btu [kW] (1st Stage / 2nd Stage) 80,000 [23.4] 120,000 [35.2] 80,000 [23.4] 120,000 [35.2]

Heating Output Btu [kW] (1st Stage / 2nd Stage) 64,800 [19] 97,200 [28.5] 64,800 [19] 97,200 [28.5]

Temperature Rise Range ˚F [˚C] 30-60 [16.7/33.3] 50-80 [27.8/44.4] 35-65 [19.4/36.1] 50-80 [27.8/44.4]

Net Weight lbs. [kg] 513 [233] 522 [237] 513 [233] 522 [237]

Steady State Efficiency (%) 81 81 81 81

No. Burners 4 6 4 6

No. Stages 1 1 1 1

Gas Connection Pipe Size in. [mm] 0.5 [12.7] 0.5 [12.7] 0.5 [12.7] 0.5 [12.7]

Compressor

No./Type 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll

Outdoor Sound Rating (dB)

5

78 78 78 78

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Smooth Smooth Smooth Smooth

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 11.04 [1.03] 11.04 [1.03] 11.04 [1.03] 11.04 [1.03]

Rows / FPI [FPcm] 1 / 18 [7] 1 / 18 [7] 1 / 18 [7] 1 / 18 [7]

Net Latent Capacity Btu [kW] 9500 [2.8] 9500 [2.8] 9500 [2.8] 9500 [2.8]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Smooth Smooth Smooth Smooth

Tube Size in. [mm] 0.3125 [7.9] 0.3125 [7.9] 0.3125 [7.9] 0.3125 [7.9]

Face Area sq. ft. [sq. m] 5.17 [0.48] 5.17 [0.48] 5.17 [0.48] 5.17 [0.48]

Rows / FPI [FPcm] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5]

Refrigerant Control Capillary Tubes Capillary Tubes Capillary Tubes Capillary Tubes

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 3600 [1699] 3600 [1699] 3600 [1699] 3600 [1699]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/11x11 [279.4x279.4] 1/11x11 [279.4x279.4] 1/11x11 [279.4x279.4] 1/11x11 [279.4x279.4]

Drive Type/No. Speeds Direct/3 Direct/3 Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 1/2 1/2 1/2 1/2

Motor RPM 1725 1725 1725 1725

Motor Frame Size 48 48 56 56

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Ye s Yes Yes

(No.) Size Recommended in. [mm] (1)1x16x25 [25x406x635] (1)1x16x25 [25x406x635] (1)1x16x25 [25x406x635] (1)1x16x25 [25x406x635]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 72 [2041] 72 [2041] 72 [2041] 72 [2041]

Weights

Ship Weight lbs. [kg] 520 [236] 529 [240] 520 [236] 529 [240]

(1)1x16x25 [25x406x635] (1)1x16x25 [25x406x635] (1)1x16x25 [25x406x635] (1)1x16x25 [25x406x635]

AFUE % 80 80 80 80

CONTINUED

NOM. SIZES 3-7.5 TONS [10.6-26.4 kW] ASHRAE 90.1-1999 COMPLIANT MODELS

[ ] Designates Metric Conversions

GENERAL DATA—RKKA- SERIES

RKKA Series — 3 – 7.5 Tons (cont’d)

Effective Date: December 2006

RHEEM PACKAGE GAS/ELECTRIC

Heat/Cool

Rooftop

– E.&O.E. – May not be in stock at all branches, if so please allow 10 days for delivery.

– All Prices F.O.B. Our Warehouse – Subject to Change Without Notice – All Taxes Extra –

36 www.eccohtg.com ECCO HEATING PRODUCTS LTD.

Page 37

Effective Date: December 2006

Model RKKA- Series A036CM08E A036CM12E A036DK08E A036DK12E

Cooling Performance

1