Rheem RJNL-A036CL, RJNL-A042CK, RJNL-A036CM, RJNL-A036DM, RJNL-A036JK Installation Instructions Manual

...Page 1

INSTALLATION INSTRUCTIONS

RECOGNIZE THIS SYMBOL AS AN INDICATION OF IMPORTANT SAFETY INFORMATION!

!

DO NOT DESTROY THIS MANUAL

PLE ASE READ CARE FUL LY AND KEEP IN A SAFE PLACE FOR FUTURE REFERENCE BY A SERVICEMAN

WARNING

!

THE SE IN STR UCT ION S ARE I NTE NDED AS AI D TO

QUAL I FIE D, LIC E NSE D SE RV I CE PER SON N EL F OR

PROPER INS TA LLAT ION , A D JUS TME N T AN D

OPE RATI ON O F THI S UNI T. R E AD T HES E

INS TRU CTI ONS T HOR OUG H LY B EFO R E ATT EMP T ING

INS TALL ATIO N OR O PER AT ION . FA ILUR E TO FOL L OW

THE SE I N STRUC T ION S MAY RES U LT IN I MPR OPE R

INS TALL ATIO N , A DJU STM E NT, SERVI C E OR

MAI NTE N ANC E PO S SIB LY R E SULT ING I N FI R E,

ELE CTR I CAL SHO C K, PRO PER DAM AG E, PER S ONA L

INJ URY OR D EATH .

ISO 9001:2008

PACKAGE HEAT PUMPS

RJNL 13 SEER SERIES (3-5 TON)

RJNL 11.0 EER SERIES (6 TON)

RJPL 14 SEER SERIES (3-5 TON)

FEATURING INDUSTRY STANDARD R-410A REFRIGERANT

(14 SEER

MODELS ONLY)

SUPERSEDES 92-23577-77-03

92-23577-77-04

Page 2

I.TABLE OF CONTENTS

I. Table of Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

II. Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

III. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

A. R-410A Refrigerant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

IV. Checking Product Received. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

V. Equipment Protection From The Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

VI. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

A

B. Outside Slab Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

C. Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

D. Rooftop Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

VII. Ductwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

VIII. Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

IX. Conversion Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

X. Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

XI. Condensate Drain, Outdoor Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

XII. Electrical Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

A. Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

B. Special Instructions for Power

Wiring with Aluminum Conductors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

C. Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

D. Internal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

E. Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

F. Thermostat. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

XIII. Indoor Air Flow Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

XIV. Crankcase Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

XV. Pre-Start Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

XVI. Startup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

XVII. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

XVIII. Auxiliary Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

A. Control System Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

XIX. Demand Defrost Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

XX. General Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22-37

XXI. Miscellaneous

Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38-47

Indoor Airflow Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48-52

Heater Kits Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53-66

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67-76

Charge Charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77-82

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

2

➤ Installation Instructions are updated on a regular basis. This is done as product

changes occur or if new information becomes available. In this publication, an arrow (➤)

denotes changes from the previous edition or additional new material.

Page 3

II. SAFETY INFORMATION

WARNING

!

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED, LICENSED

SERVICE PERSONNEL FOR PROPER INSTALLATION, ADJUSTMENT AND

OPERATION OF THIS UNIT. READ THESE INSTRUCTIONS THOROUGHLY

BEFORE ATTEMPTING INSTALLATION OPERATION. FAILURE TO FOLLOW

THESE INSTRUCTIONS MAY RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

WARNING

!

IMPORTANT: ALL MANUFACTURER PRODUCTS MEET CURRENT FEDERAL

OSHA GUIDELINES FOR SAFETY. CALIFORNIA PROPOSITION 65 WARNINGS

ARE REQUIRED FOR CERTAIN PRODUCTS, WHICH ARE NOT COVERED BY

THE OSHA STANDARDS.

CALIFORNIA'S PROPOSITION 65 REQUIRES WARNINGS FOR PRODUCTS

SOLD IN CALIFORNIA THAT CONTAIN, OR PRODUCE, ANY OF OVER 600 LISTED CHEMICALS KNOWN TO THE STATE OF CALIFORNIA TO CAUSE CANCER

OR BIRTH DEFECTS SUCH AS FIBERGLASS INSULATION, LEAD IN BRASS,

AND COMBUSTION PRODUCTS FROM NATURAL GAS.

ALL “NEW EQUIPMENT” SHIPPED FOR SALE IN CALIFORNIA WILL HAVE

LABELS STATING THAT THE PRODUCT CONTAINS AND/OR PRODUCES

PROPOSITION 65 CHEMICALS. ALTHOUGH WE HAVE NOT CHANGED OUR

PROCESSES, HAVING THE SAME LABEL ON ALL OUR PRODUCTS FACILITATES MANUFACTURING AND SHIPPING. WE CANNOT ALWAYS KNOW

“WHEN, OR IF” PRODUCTS WILL BE SOLD IN THE CALIFORNIA MARKET.

YOU MAY RECEIVE INQUIRIES FROM CUSTOMERS ABOUT CHEMICALS

FOUND IN, OR PRODUCED BY, SOME OF OUR HEATING AND AIR-CONDITIONING EQUIPMENT, OR FOUND IN NATURAL GAS USED WITH SOME OF OUR

PRODUCTS. LISTED BELOW ARE THOSE CHEMICALS AND SUBSTANCES

COMMONLY ASSOCIATED WITH SIMILAR EQUIPMENT IN OUR INDUSTRY AND

OTHER MANUFACTURERS.

• GLASS WOOL (FIBERGLASS) INSULATION

• CARBON MONOXIDE (CO)

• FORMALDEHYDE

• BENZENE

MORE DETAILS ARE AVAILABLE AT THE WEBSITES FOR OSHA

(OCCUPATIONAL SAFETY AND HEALTH ADMINISTRATION), AT

WWW.OSHA.GOV

ENVIRONMENTAL HEALTH HAZARD ASSESSMENT), AT WWW.OEHHA.ORG.

CONSUMER EDUCATION IS IMPORTANT SINCE THE CHEMICALS AND SUBSTANCES ON THE LIST ARE FOUND IN OUR DAILY LIVES. MOST CONSUMERS ARE AWARE THAT PRODUCTS PRESENT SAFETY AND HEALTH

RISKS, WHEN IMPROPERLY USED, HANDLED AND MAINTAINED.

AND THE STATE OF CALIFORNIA'S OEHHA (OFFICE OF

WARNING

!

THE MANUFACTURER’S WARRANTY DOES NOT COVER ANY DAMAGE OR

DEFECT TO THE AIR CONDITIONER CAUSED BY THE ATTACHMENT OR USE

OF ANY COMPONENTS, ACCESSORIES OR DEVICES (OTHER THAN THOSE

AUTHORIZED BY THE MANUFACTURER) INTO, ONTO OR IN CONJUNCTION

WITH THE AIR CONDITIONER. YOU SHOULD BE AWARE THAT THE USE OF

UNA UTHO RIZE D C OMPO NENT S , ACCE SSOR I ES OR DEV ICES MAY

ADVERSELY AFFECT THE OPERATION OF THE AIR CONDITIONER AND MAY

ALSO ENDANGER LIFE AND PROPERTY. THE MANUFACTURER DISCLAIMS

ANY RESPONSIBILITY FOR SUCH LOSS OR INJURY RESULTING FROM THE

USE OF SUCH UNAUTHORIZED COMPONENTS, ACCESSORIES OR DEVICES.

WARNING

!

DISCONNECT ALL POWER TO THE UNIT BEFORE STARTING MAINTENANCE.

FAILURE TO DO SO CAN RESULT IN SEVERE ELECTRICAL SHOCK OR

DEATH.

3

Page 4

WARNING

!

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT RETURN DUCTWORK TO

ANY OTHER HEAT PRODUCING DEVICE SUCH AS A FIREPLACE INSERT,

STOVE, ETC. UNAUTHORIZED USE OF SUCH DEVICES MAY RESULT IN FIRE,

CA RBO N M ONO XIDE POISON ING , E XPLOSION , P ROP ERT Y D AMAGE ,

SEVERE PERSONAL INJURY OR DEATH.

WARNING

!

THE UNIT MUST BE PERMANENTLY GROUNDED. A GROUNDING LUG IS PROVIDED IN THE ELECTRIC HEAT KIT FOR A GROUND WIRE. (SEE FIGURES 16

AND 17.) FAILURE TO GROUND THIS UNIT CAN RESULT IN FIRE OR ELECTRICAL SHOCK CAUSING PROPERTY DAMAGE, SEVERE PERSONAL INJURY OR

DEATH.

WARNING

!

ONLY ELECTRIC HEATER KITS SUPPLIED BY THIS MANUFACTURER AS

DESCRIBED IN THIS PUBLICATION HAVE BEEN DESIGNED, TESTED, AND

EVALUATED BY A NATIONALLY RECOGNIZED SAFETY TESTING AGENCY

FOR USE WITH THIS UNIT. USE OF ANY OTHER MANUFACTURED ELECTRIC

HEATERS INSTALLED WITHIN THIS UNIT MAY CAUSE HAZARDOUS CONDITIONS RESULTING IN PROPERTY DAMAGE, FIRE , BODILY INJU RY OR

DEATH.

WARNING

!

PROPOSITION 65: THIS APPLIANCE CONTAINS FIBERGLASS INSULATION.

RESPIRABLE PARTICLES OF FIBERGLASS ARE KNOWN TO THE STATE OF

CALIFORNIA TO CAUSE CANCER.

CAUTION

!

R-410A systems operate at higher pressures than R-22 systems. Do not use

R-22 service equipment or components on R-410A equipment.

4

Page 5

Recognize this symbol as an indica-

!

tion of Important Safety Information!

WARNING

!

IMPORTANT: ALL MANUFACTURER PRODUCTS MEET CURRENT

FEDERAL OSHA GUIDELINES FOR

SAFETY. CALIFORNIA

PROPOSITION 65 WARNINGS ARE

REQUIRED FOR CERTAIN PRODUCTS, WHICH ARE NOT COVERED

BY THE OSHA STANDARDS.

CALIFORNIA'S PROPOSITION 65

REQUIRES WARNINGS FOR PRODUCTS SOLD IN CALIFORNIA THAT

CONTAIN, OR PRODUCE, ANY OF

OVER 600 LISTED CHEMICALS

KNOWN TO THE STATE OF

CALIFORNIA TO CAUSE CANCER

OR BIRTH DEFECTS SUCH AS

FIBERGLASS INSULATION, LEAD

IN BRASS, AND COMBUSTION

PRODUCTS FROM NATURAL GAS.

ALL “NEW EQUIPMENT” SHIPPED

FOR SALE IN CALIFORNIA WILL

HAVE LABELS STATING THAT THE

PRODUCT CONTAINS AND/OR

PRODUCES PROPOSITION 65

CHEMICALS. ALTHOUGH WE HAVE

NOT CHANGED OUR PROCESSES,

HAVING THE SAME LABEL ON ALL

OUR PRODUCTS FACILITATES

MANUFACTURING AND SHIPPING.

WE CANNOT ALWAYS KNOW

“WHEN, OR IF” PRODUCTS WILL

BE SOLD IN THE CALIFORNIA

MARKET.

YOU MAY RECEIVE INQUIRIES

FROM CUSTOMERS ABOUT CHEMICALS FOUND IN, OR PRODUCED

BY, SOME OF OUR HEATING AND

AIR-CONDITIONING EQUIPMENT,

OR FOUND IN NATURAL GAS USED

WITH SOME OF OUR PRODUCTS.

LISTED BELOW ARE THOSE CHEMICALS AND SUBSTANCES COMMONLY ASSOCIATED WITH SIMILAR EQUIPMENT IN OUR INDUSTRY AND OTHER MANUFACTURERS.

• GLASS WOOL (FIBERGLASS)

INSULATION

• CARBON MONOXIDE (CO)

• FORMALDEHYDE

• BENZENE

MORE DETAILS ARE AVAILABLE

AT THE WEBSITES FOR OSHA

(OCCUPATIONAL SAFETY AND

HEALTH ADMINISTRATION), AT

WWW.OSHA.GOV

OF CALIFORNIA'S OEHHA (OFFICE

OF ENVIRONMENTAL HEALTH

HAZARD ASSESSMENT), AT

WWW.OEHHA.ORG. CONSUMER

EDUCATION IS IMPORTANT SINCE

THE CHEMICALS AND SUBSTANCES ON THE LIST ARE

FOUND IN OUR DAILY LIVES. MOST

CONSUMERS ARE AWARE THAT

PRODUCTS PRESENT SAFETY AND

HEALTH RISKS, WHEN IMPROPERLY USED, HANDLED AND MAINTAINED.

AND THE STATE

III. INTRODUCTION

This booklet contains the installation and operating instructions for your package heat

pump. There are a few precautions that should be taken to derive maximum satisfaction

from it. Improper installation can result in unsatisfactory operation or dangerous conditions.

Read this booklet and any instructions packaged with separate equipment required to

make up the system prior to installation. Give this booklet to the owner and explain its

provisions. The owner should retain this booklet for future reference.

NOTE: A load calculation must be performed to properly determine the required heating

and cooling for the structure. Also, the duct must be properly designed and installed for

proper airflow. Existing dutwork must be inspected for proper size and sealed system.

Proper airflow is necessary for both user comfort and equipment performance.

IMPORTANT: Proper application, installation and maintenance of this equipment is a

must if consumers are to receiver the full benefit for which they have paid.

A. R-410A REFRIGERANT

All units are factory charged with R-410A refrigerant.

1. Specification of R-410A:

Application: R-410A is not a drop-in replacement for R-22; equipment designs must

accommodate its higher pressures. It cannot be retrofitted into R-22 units.

Pressure: The pressure of R-410A is approximately 60% (1.6 times) greater than R-

22. Recovery and recycle equipment, pumps, hoses and the like need to have design

pressure ratings appropriate for R-410A. Manifold sets need to range up to 800 psig

high-side and 250 psig low-side with a 550 psig low-side retard. Hoses need to have a

service pressure rating of 800 psig. Recovery cylinders need to have a 400 psig service

pressure rating. DOT 4BA400 or DOT BW400.

Combustibility: At pressures above 1 atmosphere, mixture of R-410A and air can

become combustible. R-410A and air should never be mixed in tanks or supply

lines, or be allowed to accumulate in storage tanks. Leak checking should never

be done with a mixture of R-410A and air. Leak checking can be performed safely

with nitrogen or a mixture of R-410A and nitrogen.

2. Quick Reference Guide For R-410A

• R-410A refrigerant operates at approximately 60% higher pressure (1.6 times) than R-

22. Ensure that servicing equipment is designed to operate with R-410A.

• R-410A refrigerant cylinders are pink.

• R-410A, as with other HFC’s is only compatible with POE oils.

• Vacuum pumps will not remove moisture from POE oil.

• R-410A systems are to be charged with liquid refrigerants. Prior to March 1999, R410A refrigerant cylinders had a dip tube. These cylinders should be kept upright for

equipment charging. Post March 1999 cylinders do not have a dip tube and should be

inverted to ensure liquid charging of the equipment.

• Do not install a suction line filter drier in the liquid line.

• A liquid line filter drier is standard on every unit.

• Desiccant (drying agent) must be compatible for POE oils and R-410A.

3. Evaporator Coil / TXV

The thermostatic expansion valve is specifically designed to operate with R-410A. DO

NOT use an R-22 TXV. The existing evaporator must be replaced with the factory

specified TXV evaporator specifically designed for R-410A.

4. Tools Required For Installing & Servicing R-410A Models

Manifold Sets:

-Up to 800 PSIG High side

-Up to 250 PSIG Low Side

-550 PSIG Low Side Retard

Manifold Hoses:

-Service Pressure Rating of 800 PSIG

5

Page 6

Recovery Cylinders:

-400 PSIG Pressure Rating

-Dept. of Transportation 4BA400 or BW400

!

CAUTION

R-410A systems operate at higher pressures than R-22 systems. Do not use

R-22 service equipment or components on R-410A equipment.

IV. CHECKING PRODUCT RECEIVED

Upon receiving the unit, inspect it for any damage from shipment. Claims for damage,

either shipping or concealed, should be filed immediately with the shipping company.

Check the unit model number, heating size, electrical characteristics, and accessories to

determine if they are correct.

V. EQUIPMENT PROTECTION FROM THE

V. ENVIRONMENT

The metal parts of this unit may be subject to rust or deterioration in adverse environmental conditions. This oxidation could shorten the equipment’s useful life. Salt spray,

fog or mist in seacoast areas, sulphur or chlorine from lawn watering systems, and various chemical contaminants from industries such as paper mills and petroleum refineries

are especially corrosive.

If the unit is to be installed in an area where contaminants are likely to be a problem, special attention should be given to the equipment location and exposure.

1. Avoid having lawn sprinkler heads spray direction on the unit cabinet.

2. In coastal areas, locate the unit on the side of the building away from the waterfront.

3. Shielding provided by a fence or shrubs may give some protection.

Regular maintenance will reduce the buildup of contaminents and help to protect

the unit’s finish.

WARNING

!

DISCONNECT ALL POWER TO THE UNIT BEFORE STARTING MAINTENANCE.

FAILURE TO DO SO CAN RESULT IN SE VERE E LECTRICAL SHOCK OR

DEATH.

1. Frequent washing of the cabinet, fan blade and coil with fresh water will remove

most of the salt or other contaminants that build up on the unit.

2. Regular cleaning and waxing of the cabinet with a good automobile polish will provide some protection.

3. A good liquid cleaner may be used several times a year to remove matter that will

not wash off with water.

Several different types of protective coatings are offered in some areas. These coatings

may provide some benefit, but the effectiveness of such coating materials cannot be verified by the equipment manufacturer.

The best protection is frequent cleaning, maintenance and minimal exposure to

contaminants.

VI. INSTALLATION

A. GENERAL

1. PRE-INSTALLATION CHECK-POINTS

Before attempting any installation, the following points should be carefully considered:

a. Structural strength of supporting members.

(rooftop installation)

b. Clearances and provision for servicing.

c. Power supply and wiring.

d. Air duct connections.

6

Page 7

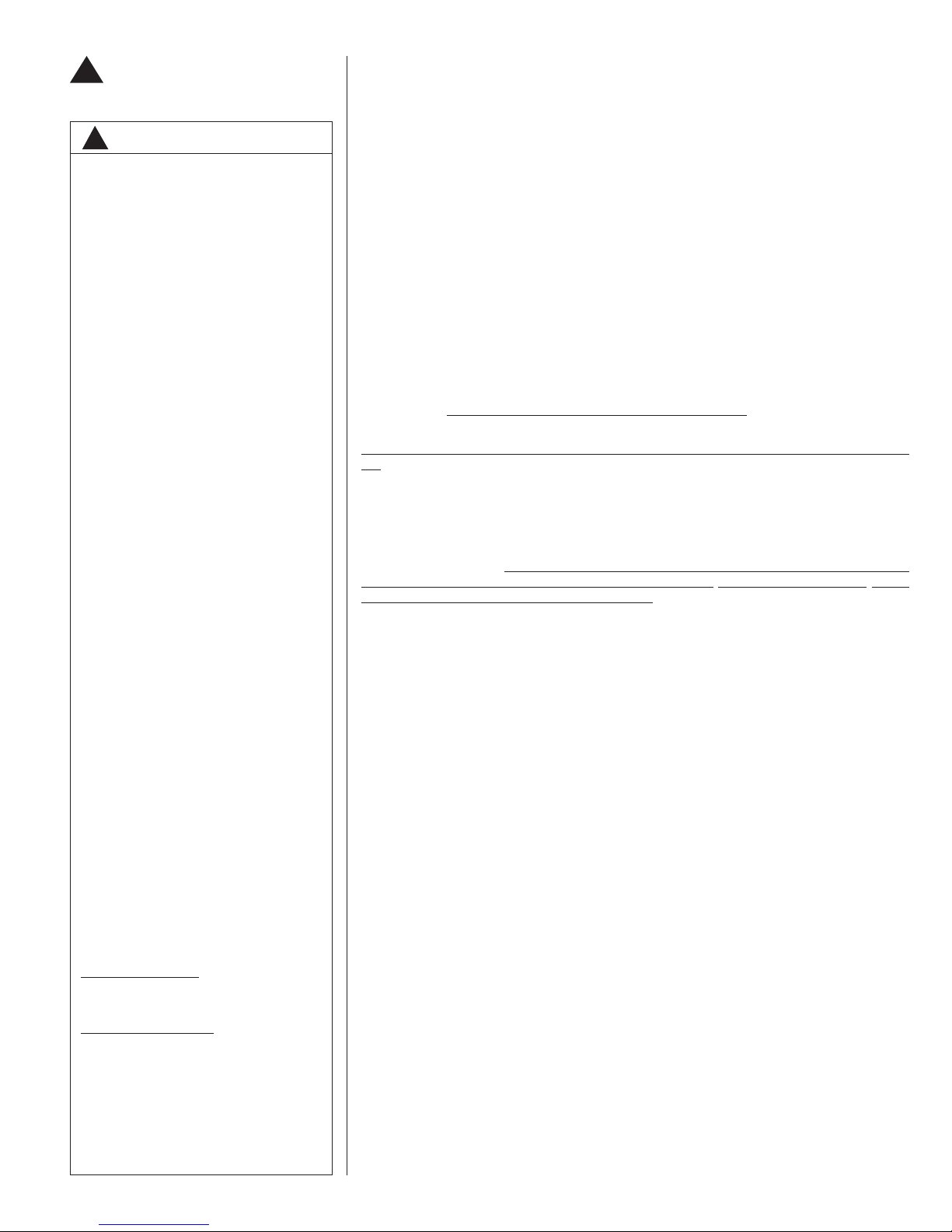

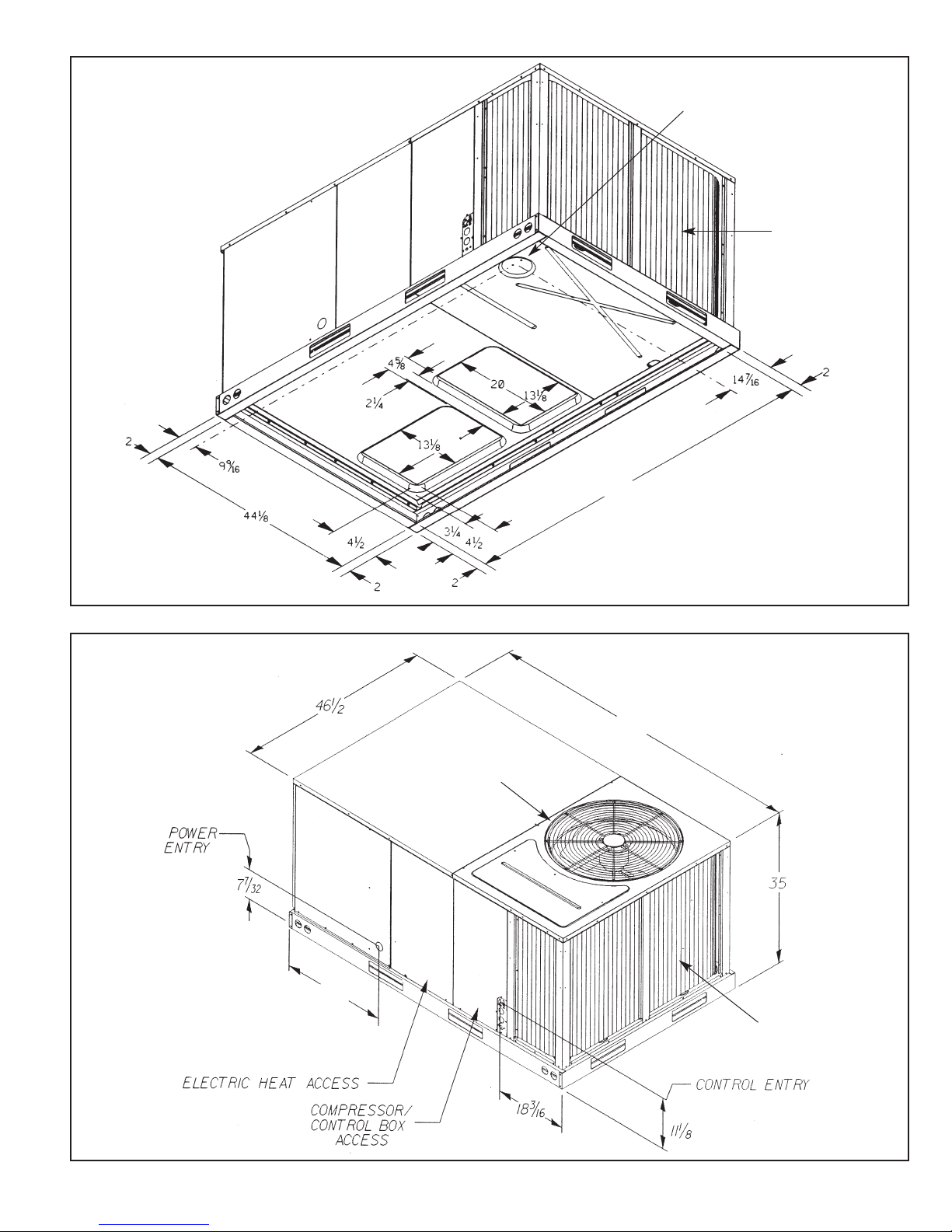

FIGURE 1

UNIT DIMENSIONS

RJNL/RJPL 3-5 TON

FIGURE 2

UNIT DIMENSIONS

RJNL/RJPL 3-5 TON

ILL I316

35

ILL I305

7

Page 8

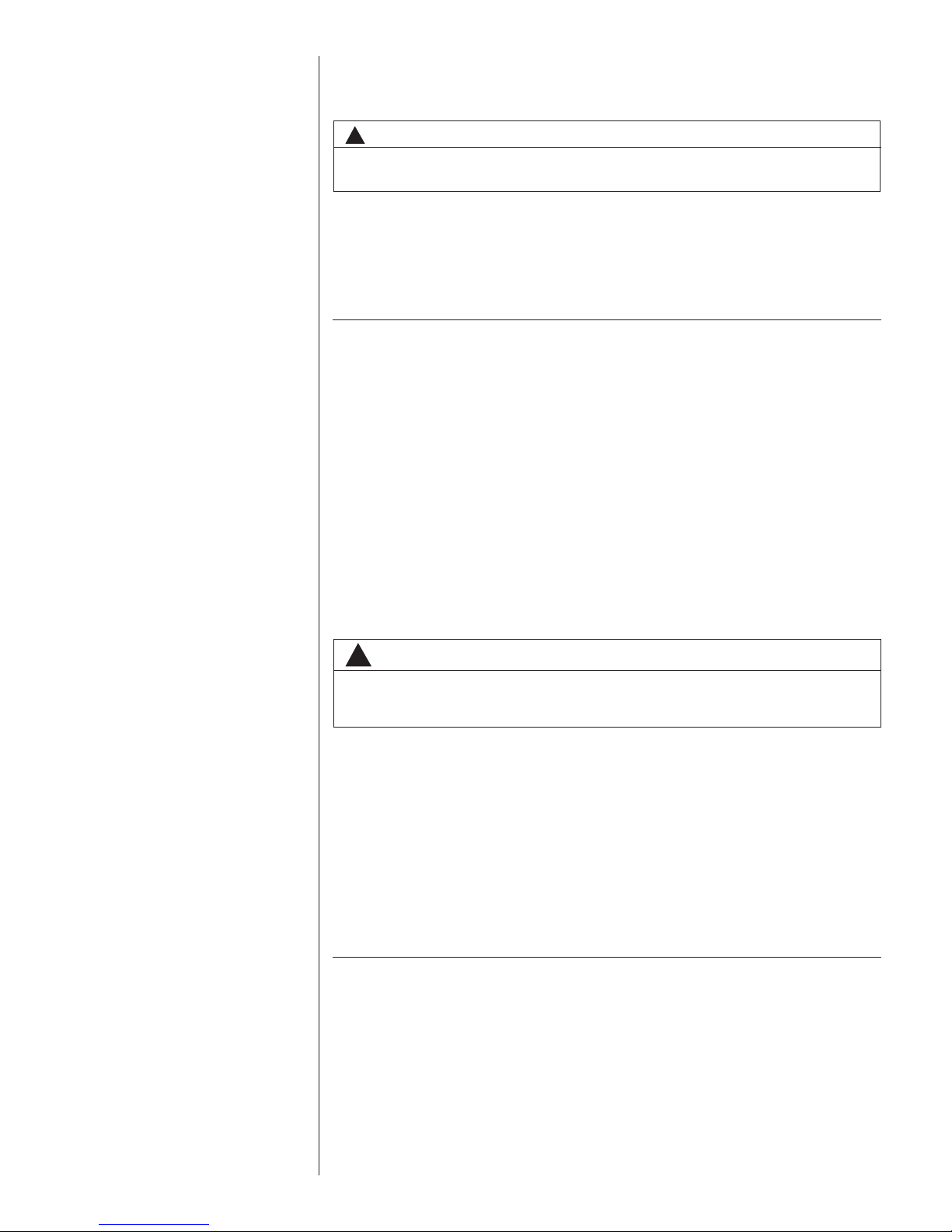

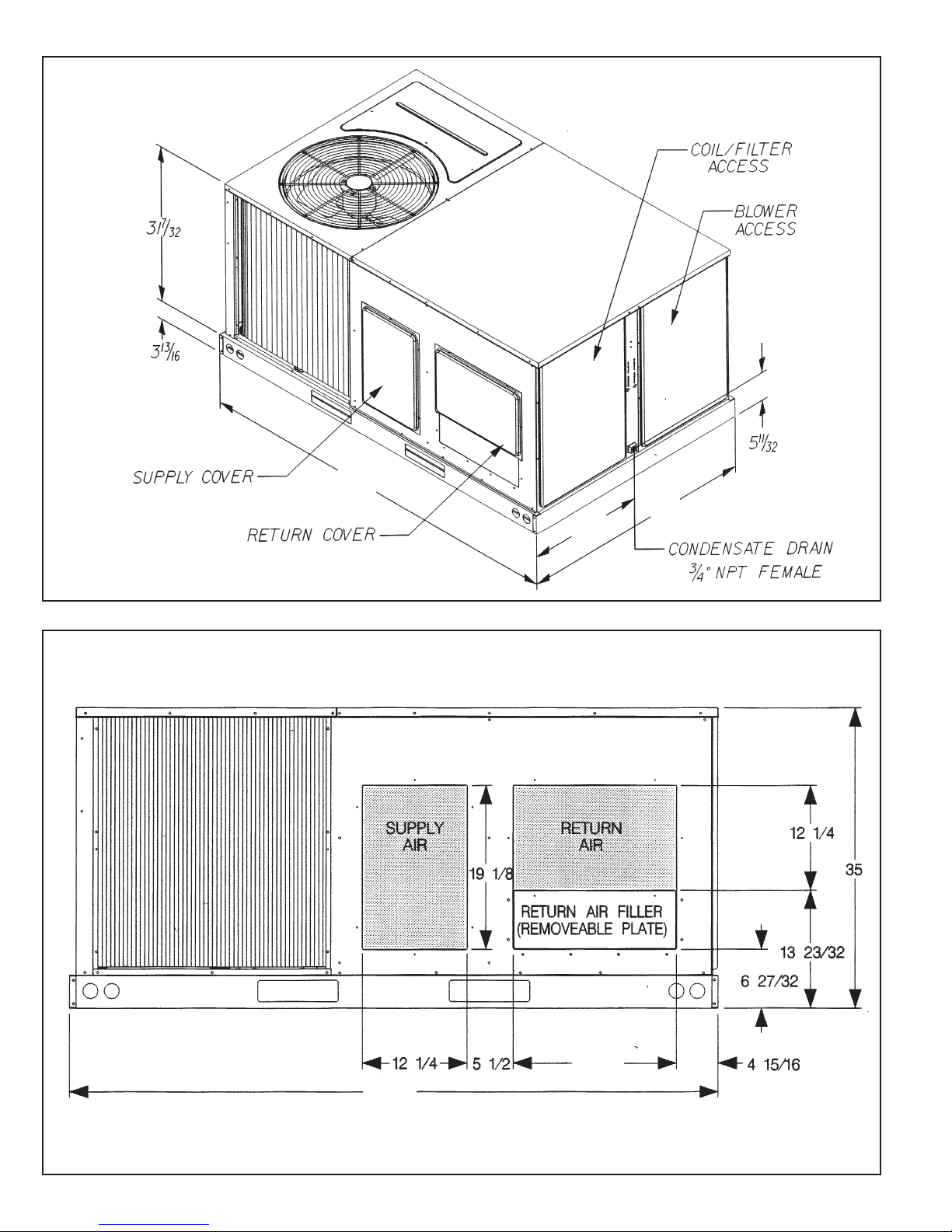

FIGURE 3

NIT DIMENSIONS

U

RJNL/RJPL 3-5 TON

317⁄3

3

2

1

3

⁄16

511⁄32

761⁄4

483⁄32

24

FIGURE 4

UNIT DIMENSIONS

RJNL/RJPL 3 TO 5 TON

RETURN AIR FILTER

(REMOVABLE PLATE)

LL I304

I

8

ILL I288

Page 9

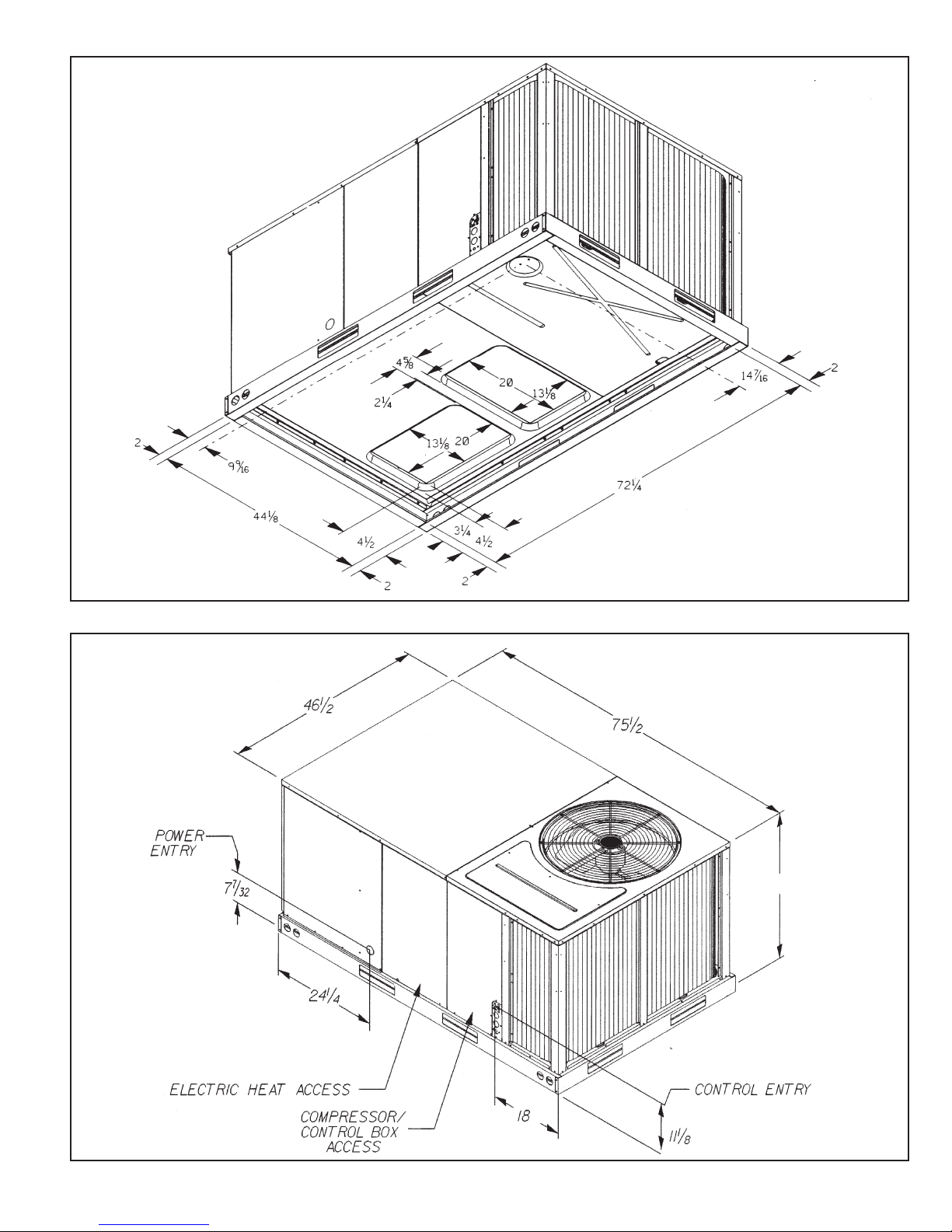

FIGURE 5

UNIT DIMENSIONS

OTTOM VIEW

B

JNL 6 TON

R

BASE ELECTRICAL

ENTRY

CONDENSER

COIL

26

1

8

7

⁄4

FIGURE 6

UNIT DIMENSIONS

RJNL 6 TON

301⁄4

CONDENSER FAN

DISCHARGE GRILLE

8117⁄3

261⁄4

LL 1316

I

2

CONDENSER COIL

ILL1305

9

Page 10

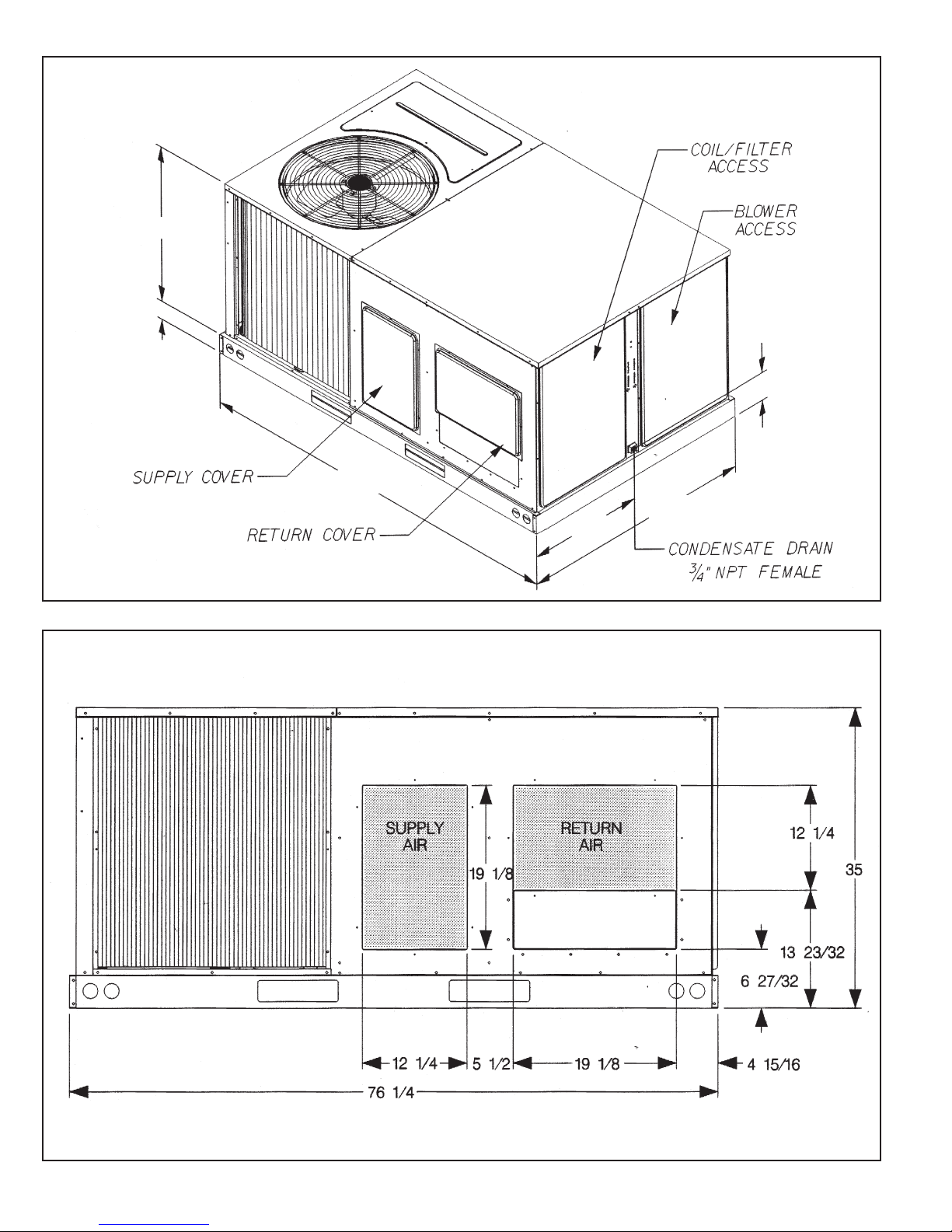

FIGURE 7

NIT DIMENSIONS

U

JNL 6 TON

R

821⁄4

481⁄16

241⁄32

FIGURE 8

UNIT DIMENSIONS

RJNL 6 TON

LL 1304

I

10

25 1/8

82 1/4

ILL 1288

Page 11

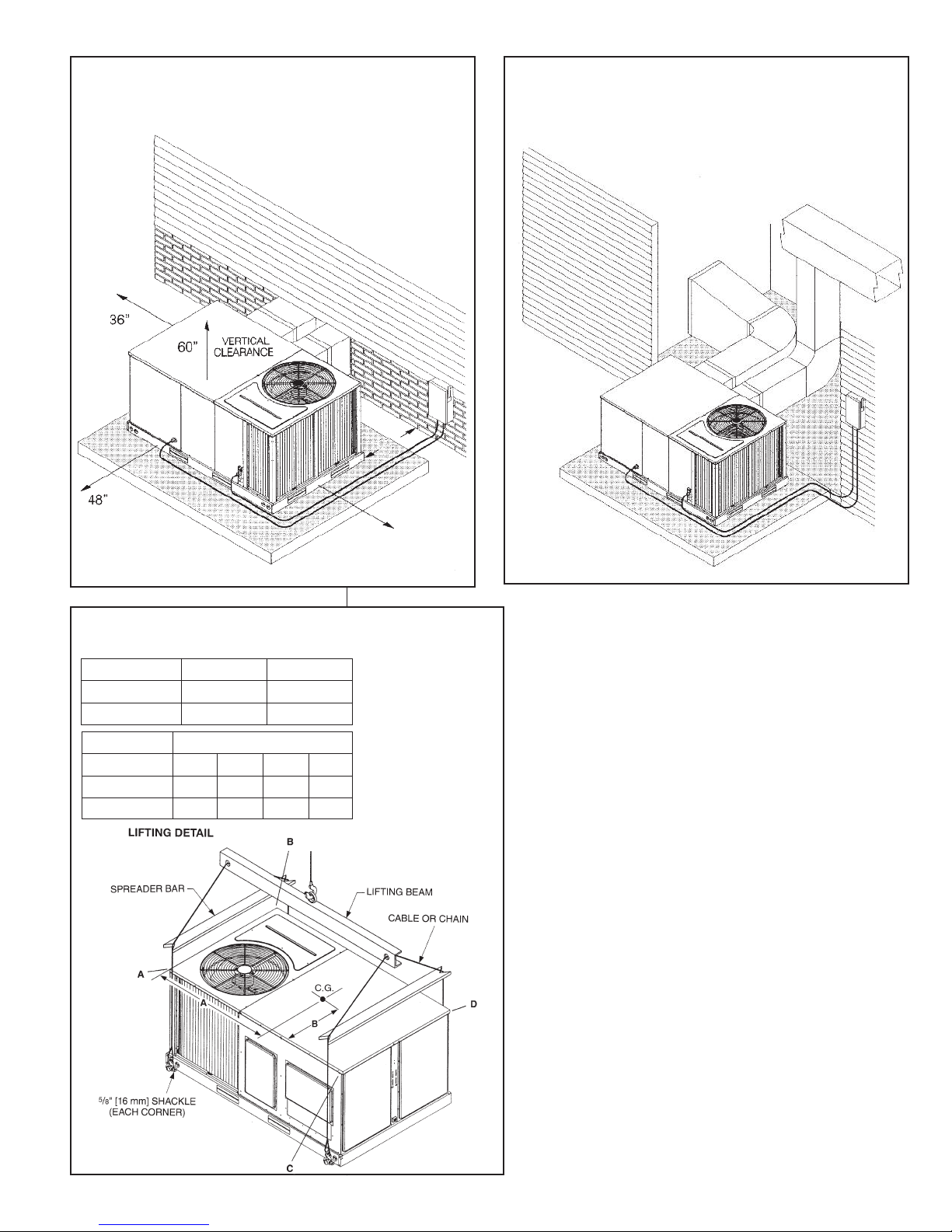

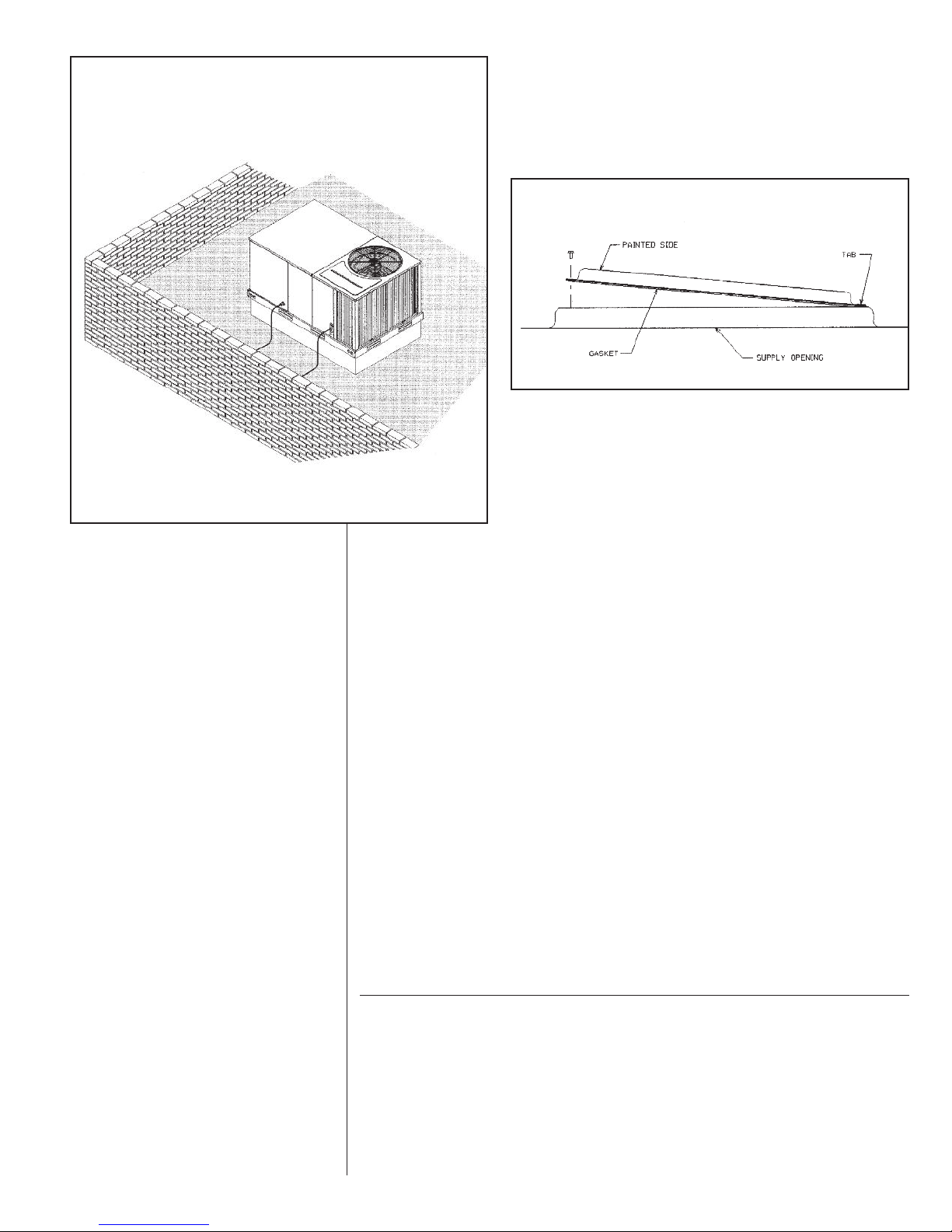

FIGURE 9

ACKAGED HEAT PUMP

P

OUTSIDE SLAB INSTALLATION, BASEMENT OR

RAWL SPACE DISTRIBUTION SYSTEM

C

12”

FIGURE 10

PACKAGED HEAT PUMP

UTSIDE SLAB INSTALLATION, CLOSET DISTRIBUTION

O

SYSTEM. SLAB FLOOR CONSTRUCTION

*

*Allow 57" for economizer

on duct side.

FIGURE 11

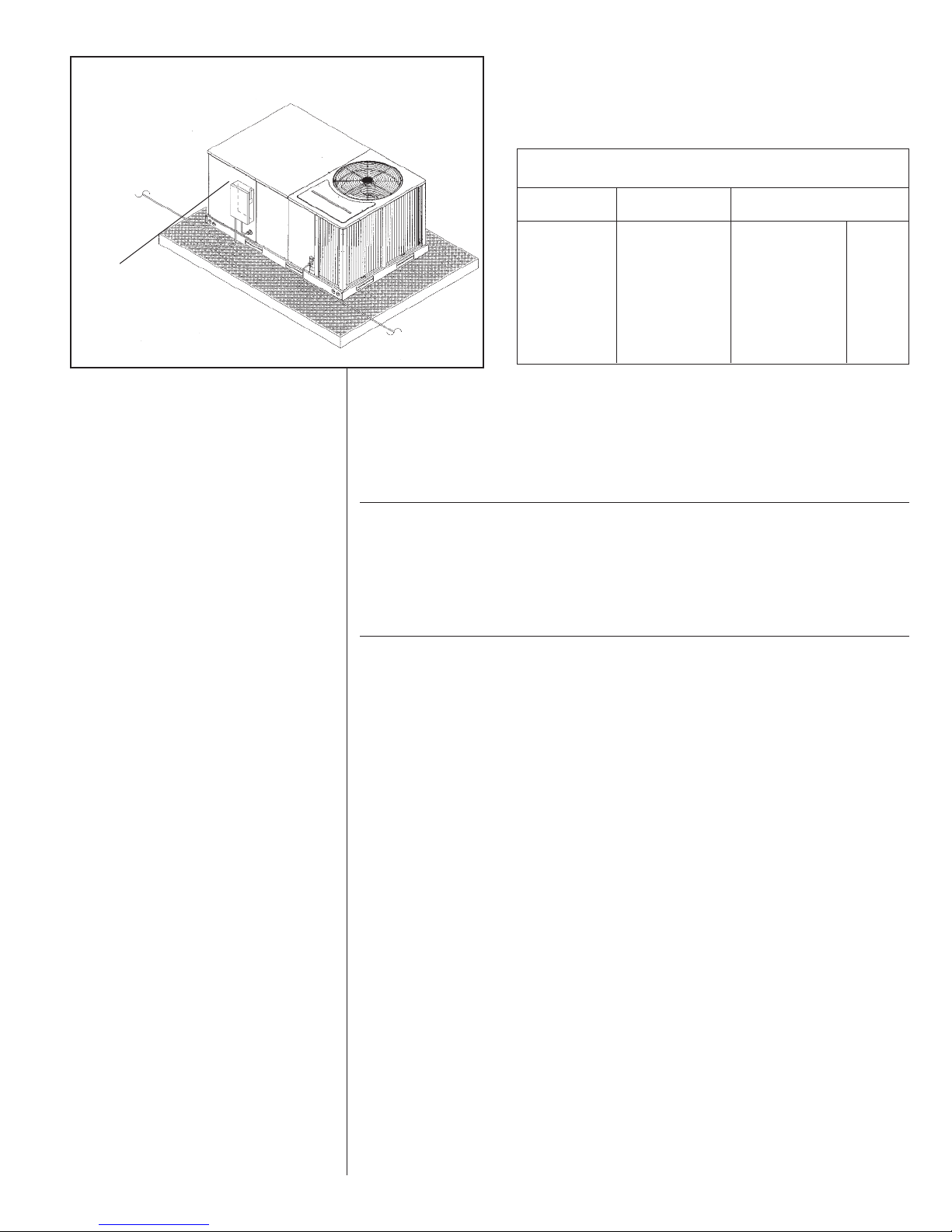

PACKAGED HEAT PUMP

RIGGING FOR LIFTING

Capacity Tons [kW] A in. [mm] B in. [mm]

3.5 [10.6-17.6]

6 [21.1]

Capacity Tons [kW] Corner Weights by Percentage

3.5 [10.6-17.6]

6 [21.1]

1

38

⁄4 [972] 253⁄4 [654]

39 [991]

ABCD

22%

23%

29% 21% 27%

1

26

⁄8 [664]

23% 28%27%

18”

ILL I308

LL I309

I

11

Page 12

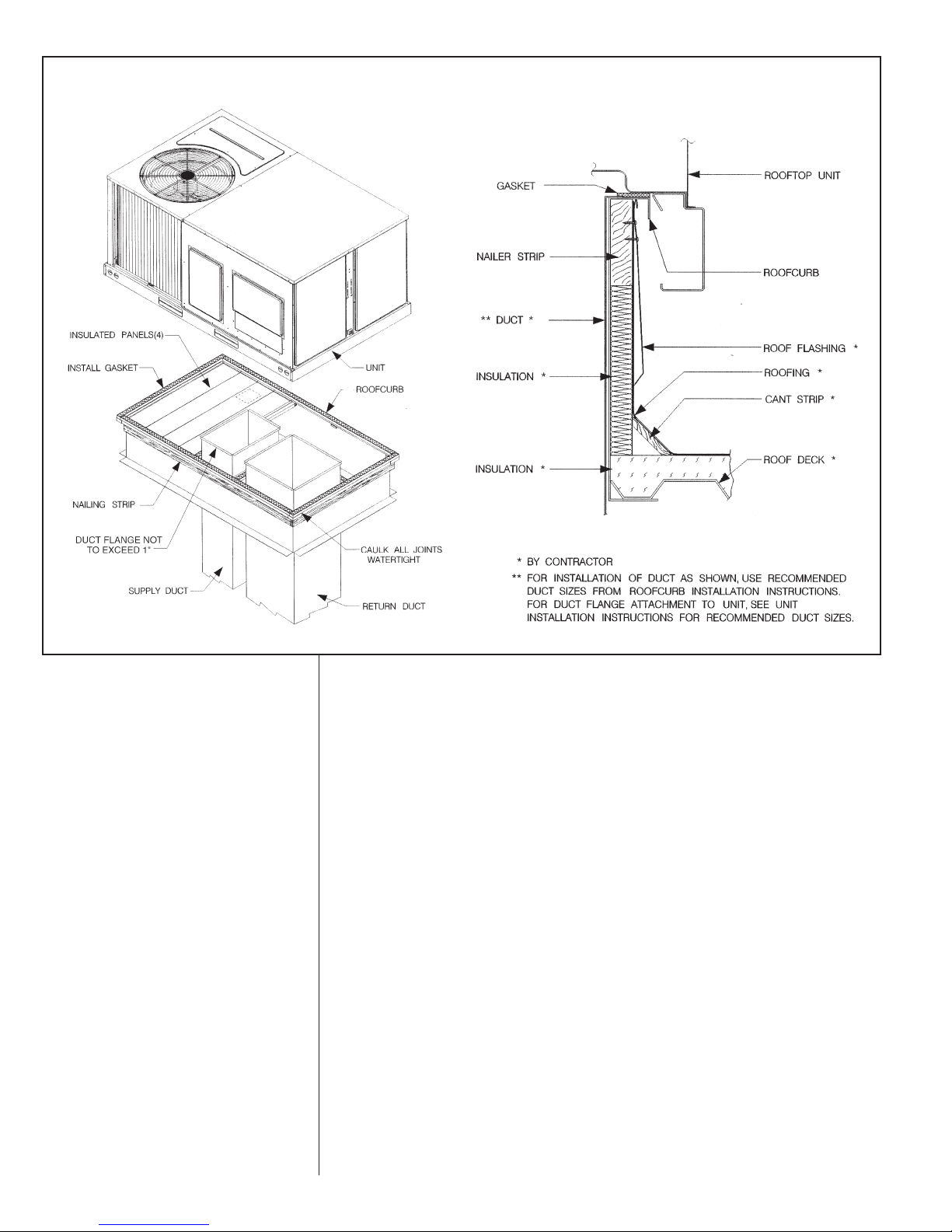

FIGURE 12

PACKAGED HEAT PUMP

OOFCURB INSTALLATION

R

LL I301

I

ILL I300

e. Drain facilities and connections.

f. Location for minimum noise.

2. LOCATION

These units are designed for outdoor installations. They can be mounted on a

slab or rooftop. They are not to be installed within any part of a structure such as

an attic, crawl space, closet, or any other place where condenser air flow is

restricted or other than outdoor ambient conditions prevail. Since the application

of the units is of the outdoor type, it is important to consult your local code authorities at the time the first installation is made.

B. OUTSIDE SLAB INSTALLATION

(Typical outdoor slab installations are shown in Figures 9 and 10.)

1. Select a location where external water drainage cannot collect around the unit.

2. Provide a level concrete slab extending 3" beyond all four sides of the unit. The

slab should be sufficient above grade to prevent ground water from entering the

unit. IMPORTANT: To prevent transmission of noise or vibration, slab should not

be connected to building structure.

3. The location of the unit should be such as to provide proper access for inspection

and servicing.

4. Locate unit where operating sounds will not disturb owner or neighbors.

5. Locate unit so roof runoff water does not pour directly on the unit. Provide gutter

or other shielding at roof level. Do not locate unit in an area where excessive

snow drifting may occur or accumulate.

6. It is essential that the unit be elevated above the base pad to allow for condensate drainage and possible refreezing of condensation. Provide a base pad which

is slightly pitched away from the structure. Route condensate off base pad to an

area which will not become slippery and result in personal injury.

7. Where snowfall is anticipated, the height of the unit above the ground level must

be considered. Mount unit high enough to be above average area snowfall and to

allow for proper condensate drainage.

12

Page 13

FIGURE 13

ACKAGED HEAT PUMP

P

FLAT ROOFTOP INSTALLATION, ATTIC OR DROP CEILING

ISTRIBUTION SYSTEM. MOUNTED ON

D

ROOFCURB. CURB MUST BE LEVEL

LL I310

I

FIGURE 14

OVER GASKET DETAIL

C

ILL I631

C. CLEARANCES

The following minimum clearances must be observed for proper unit performance

and serviceability.

1. Provide 48" minimum clearance at the front of the unit. Provide 36" minimum

clearance at the left and right side of the unit for service access.

2. Provide 60" minimum clearance between top of unit and maximum 3 foot overhang.

3. Unit is design certified for application on combustible flooring with 0" minimum

clearance.

4. See Figure 9 for illustration of minimum installation-service clearances.

D. ROOFTOP INSTALLATION

1. Before locating the unit on the roof, make sure that the strength of the roof and

beams is adequate at that point to support the weight involved. (See specification

sheet for weight of unit.) This is very important and user’s responsibility.

2. For rigging and roofcurb details, see Figures 11 and 12. Use field-furnished

spreaders.

3. For roofcurb assembly, see Roofcurb Installation Instructions.

4. If the roofcurb is not used, provisions for disposing of condensate water runoff

during defrosting must be provided.

5. The unit should be placed on a solid and level roofcurb or platform of adequate

strength. See Figure 13.

6. The location of the unit on the roof should be such as to provide proper access for

inspection and servicing.

IMPORTANT: If unit will not be put into service immediately, cover supply and return

openings to prevent excessive condensation.

VII. DUCTWORK

Ductwork should be fabricated by the installing contractor in accordance with local codes

and NFPA90A. Industry manuals may be used as a guide when sizing and designing the

duct system - contact Air Conditioning Contractors of America, 1513 16th St. N.W.,

Washington, D.C. 20036.

13

Page 14

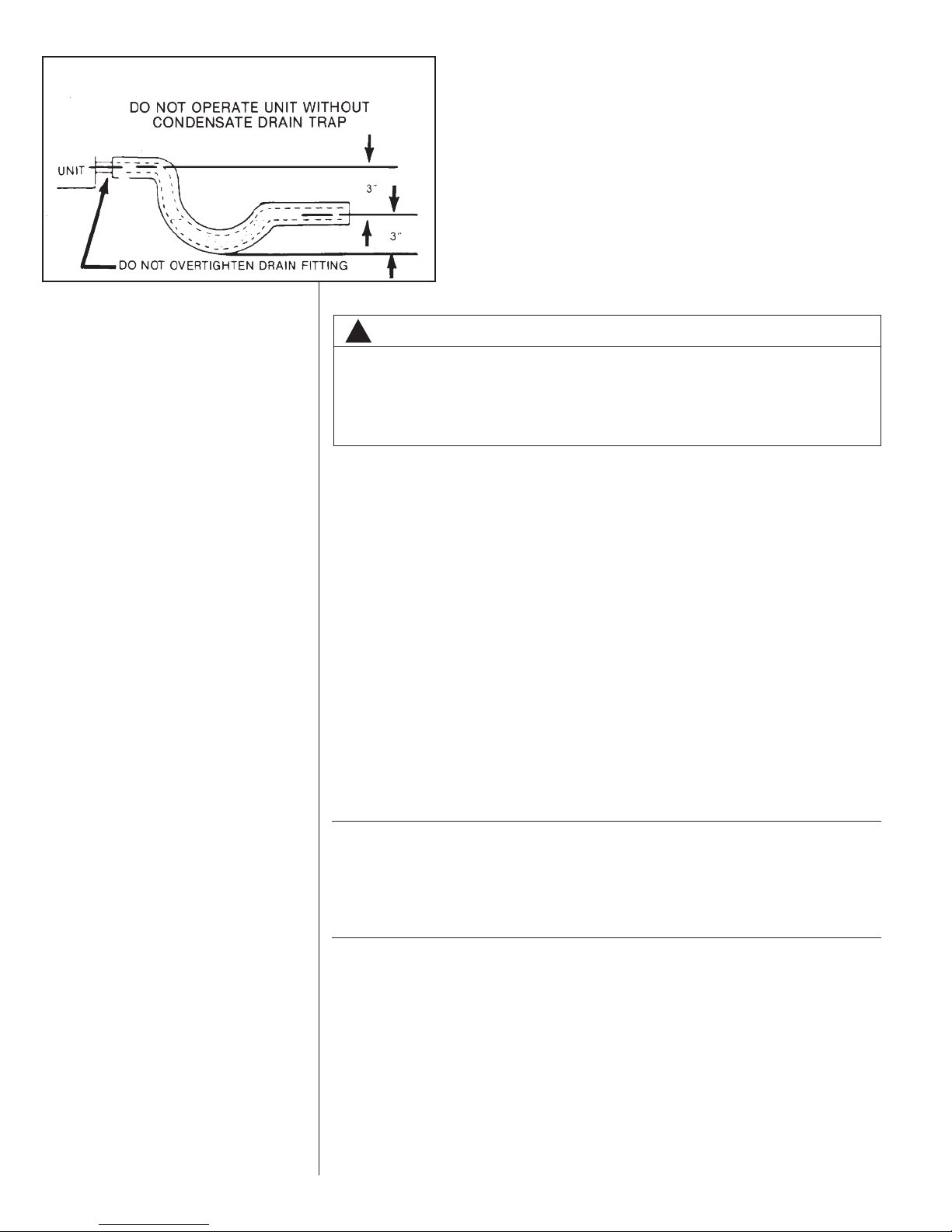

IGURE 15

F

CONDENSATE DRAIN

WARNING

!

DO NOT, UNDER ANY CIRCUMSTANCES, CONNECT RETURN DUCTWORK TO

ANY OTHER HEAT PRODUCING DEVICE SUCH AS A FIREPLACE INSERT,

STOVE, ETC. UNAUTHORIZED USE OF SUCH DEVICES MAY RESULT IN FIRE,

CA RBO N M ONO XIDE POISON ING , E XPLOSION , P ROP ERT Y D AMAGE ,

SEVERE PERSONAL INJURY OR DEATH.

The unit should be placed as close to the space to be air conditioned as possible allowing clearance dimensions as indicated. Ducts should be run as directly as possible to

supply and return outlets. Use of non-flammable waterproof flexible connectors on both

supply and return connections at the unit to reduce noise transmission is recommended.

It is preferable to install the unit on the roof of the structure if the registers or diffusers

are located on the wall or in the ceiling. A slab installation could be considered when the

registers are low on a wall or in the floor.

On ductwork exposed to outside air conditions of temperature and humidity, use a minimum of 2" of insulation and a vapor barrier. Distribution system in attic, furred space or

crawl space should be insulated with at least 2" of insulation with vapor barrier. One-half

to 1" thickness of insulation is usually sufficient for ductwork inside the air conditioned

space.

Balancing dampers should be provided for each branch duct in the supply system.

Ductwork should be properly supported from the structure.

When installing ductwork, consider the following items:

1. Noncombustible flexible connectors should be used between ductwork and unit to

reduce noise and vibration transmission into the ductwork.

2. When auxiliary heaters are installed, use noncombustible flexible connectors and

clearance to combustible material of 0" for the first 3 feet of discharge duct.

Clearance to unit top and side is 0".

14

VIII.FILTERS

This unit is provided with 2 - 25" x 16" x 1" (3-5 ton) 4 - 16" x 16" x 1" (6 ton) disposable

filters. When replacing filters, ensure they are inserted fully to the back to prevent

bypass.

IX. CONVERSION PROCEDURE

DOWNFLOW TO HORIZONTAL

1. Remove the screws and covers from the outside of the supply and return sections.

2. Install the covers in the bottom supply and return openings with the painted side up.

See Figure 15. Use the existing gasket to seal the covers.

3. Secure the supply cover to the base of the unit with 1 screw, engaging prepunched

tab in unit base.

4. Secure the return cover to the base of the unit with screws, engaging prepunched

holes in the unit base.

Page 15

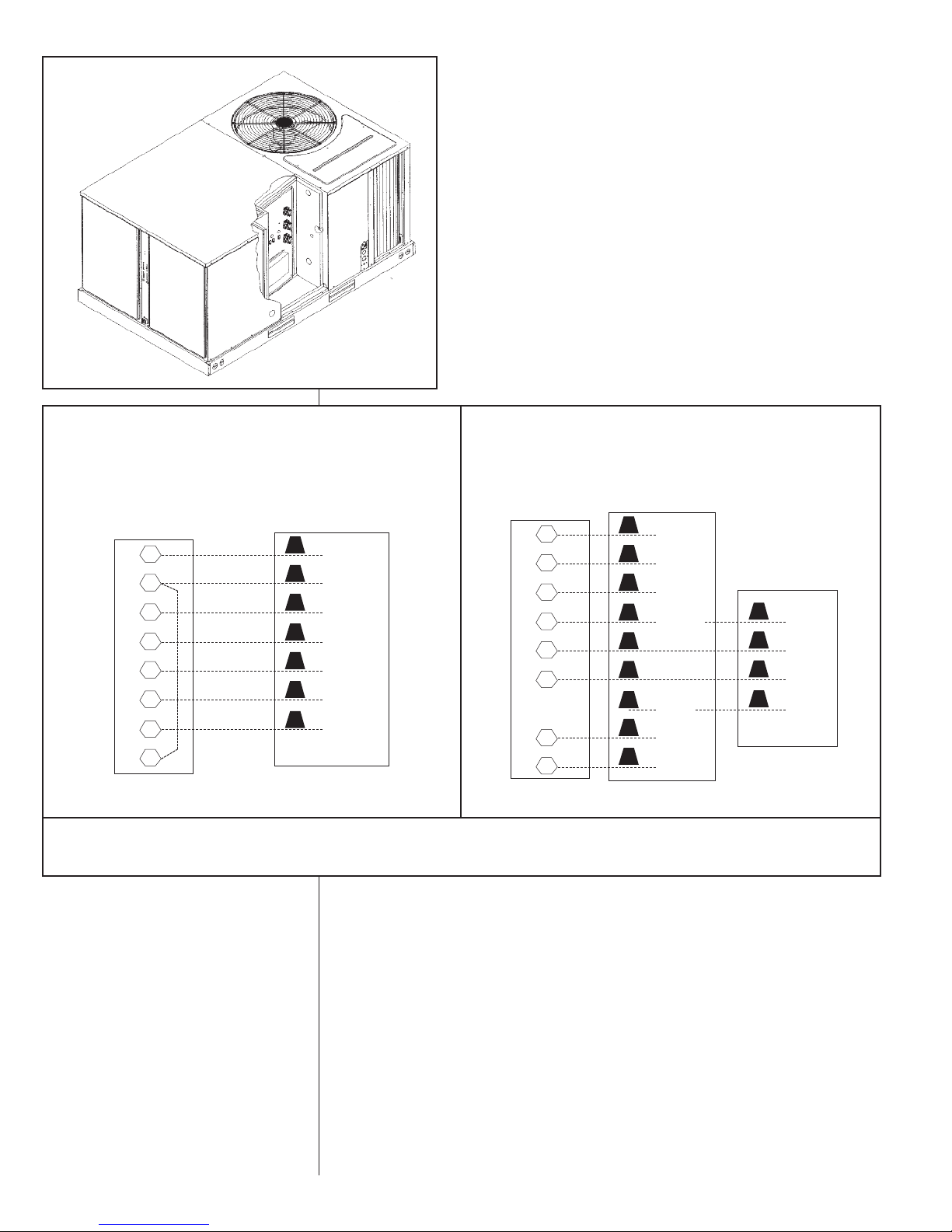

FIGURE 16

BRANCH CIRCUIT DISCONNECT LOCATION

TO POWER

RANCH CIRCUIT

B

ISCONNECT

D

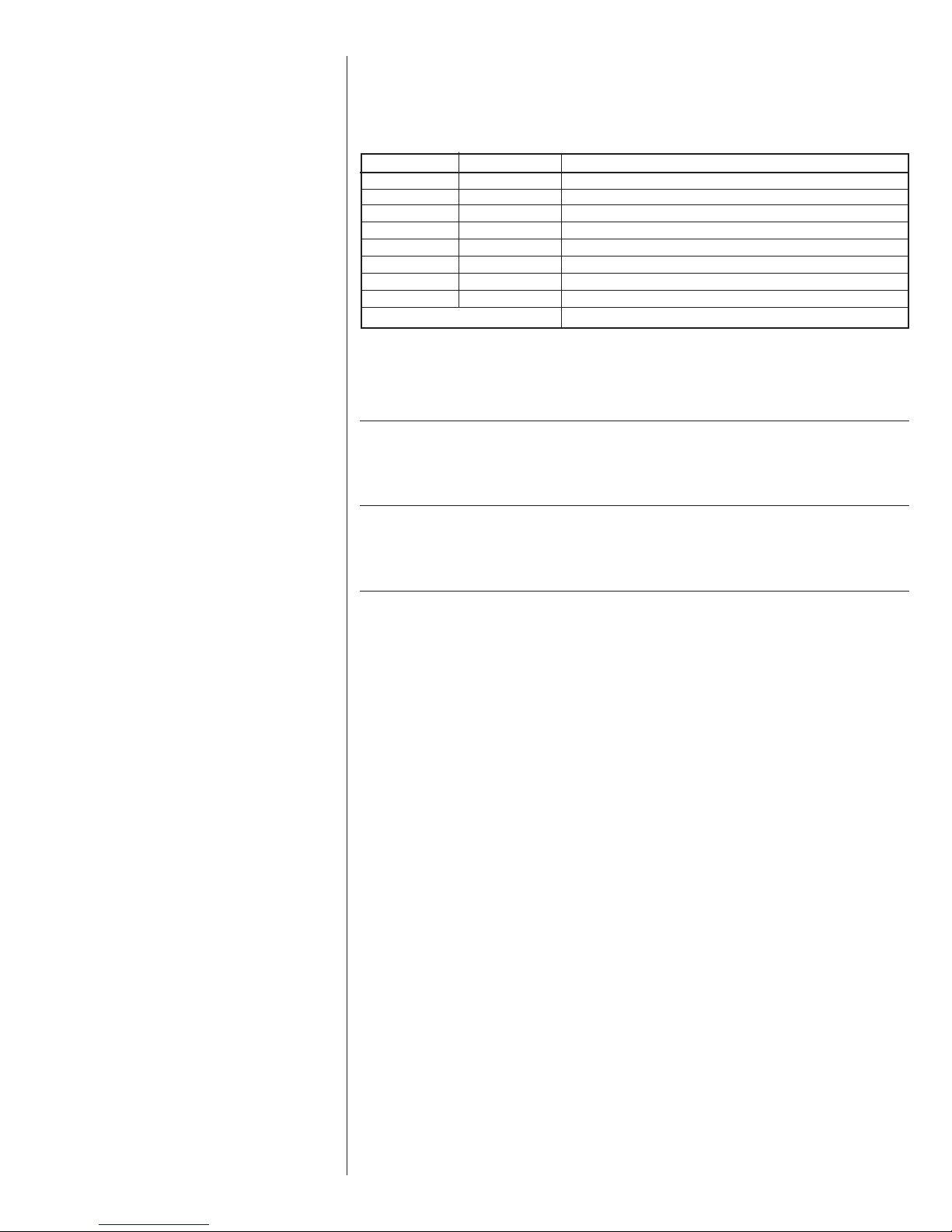

TABLE A

IRE SIZES

W

AWG Copper AWG Aluminum Connector Type and Size

Wire Size Wire Size (or equivalent)

#12 #10 T&B Wire Nut PT2

#10 #8 T&B Wire Nut PT3

#8 #6 Ilsco Split Bolt AK-6

#6 #4 Ilsco Split Bolt AK-4

#4 #2 Ilsco Split Bolt AK-2

#3 #1 Ilsco Split Bolt AK-1/0

#2 #0 Ilsco Split Bolt AK-1/0

O CONTROL

T

#1 #00 Ilsco Split Bolt AK-2/0

#0 #000 Ilsco Split Bolt AK-4/0

X. CONDENSATE DRAIN

The condensate drain connection of the evaporator is 3/4" nominal female pipe thread.

IMPORTANT: Install a condensate trap to ensure proper condensate drainage. See

Figure 15.

XI. CONDENSATE DRAIN, OUTDOOR COIL

The outdoor coil during heating operation will sweat or run water off. The outdoor coil will

also run water off during the defrost cycle. See Section V, Installation, for mounting precautions.

XII. ELECTRICAL WIRING

Field wiring must comply with the National Electrical Code* and local ordinances that may

apply.

*C.E.C. in Canada

A. POWER WIRING

1. It is important that proper electrical power is available at the unit. Voltage should not

vary more than 10% from that stamped on the unit rating plate. On three phase

units, phases must be balanced within 3%.

➤ 2. Install a branch circuit disconnect within sight of the unit and of adequate size to

handle the starting current. A bracket is supplied with the unit for mounting a disconnect to the unit. Refer to Figure 16 for proper location.

3. For branch circuit wiring (main power supply to unit disconnect), the minimum wire

size can be determined from Table C using the circuit ampacity found on the unit

nameplate or from the Electrical Data.

4. This unit incorporates single point electrical connection for unit and electric heat

accessory.

5. Power wiring must be run in grounded rain-tight conduit. Connect the power field

wiring as follows:

a. NO ELECTRIC HEAT - Connect the field wires directly to the contactor pigtails in

the electric heat access area. Connect ground wire to ground lug.

b. WITH ELECTRIC HEAT - Connect the field wires to the terminal block on the

electric heater kit in the electric heat access area. Connect the ground wire to the

ground lug on the heater kit.

NOTE: For field installation of a heater kit, follow the instructions provided with the heater

kit.

15

Page 16

IGURE 17

F

HEATER KIT INSTALLATION

ILL I312

FIGURE 18

OLTAGE CONNECTIONS DIAGRAMS

V

WITH ONE OUTDOOR THERMOSTAT

W/EMERGENCY HEAT RELAY

STANDARD

THERMOSTAT

THERMOSTAT

SUB-BASE

R

W2

X

B

Y1

Y2

G

E

NOTES: IF EMERGENCY HEAT RELAY AND OUTDOOR THERMOSTATS ARE NOT USED, A JUMPER BETWEEN “W2” AND “E” CAN BE INSTALLED TO TRANSFER

CONTROL OF HEATING TO THE FIRST STAGE WHEN THE SYSTEM SWITCH IS IN THE EMERGENCY HEAT POSITION.

Y2 IS ONLY USED WITH OPTIONAL ECONOMIZER.

UNIT CONTROL

WIRE PIGTAILS

RED

BLACK

BROWN

BLUE

YELLOW

ORANGE

GRAY

SUB-BASE

R

G

B

X

E

W2

Y1

Y2

UNIT CONTROL

WIRE PIGTAILS

RED

GRAY

BLUE

BROWN BROWN

BLACK BLACK

YELLOW

ORANGE

OUTDOOR

THERMOSTAT

W/EMERGENCY

HEAT RELAY

RED

WHITE

16

6. The pigtail wires in the electric heat access area are factory wired to the contactor in

the control box.

7. DO NOT connect aluminum field wires to electric heat kit power input terminals.

B. SPECIAL INSTRUCTIONS FOR POWER WIRING WITH ALUMINUM

CONDUCTORS.

1. Select the equivalent aluminum wire size from the tabulation below:

2. Attach a length (6" or more) of recommended size copper wire to the unit terminals

L1 and L3 for single phase, L1, L2, L3 for three phase.

3. Splice copper wire pigtails to aluminum wire with U.L. recognized connectors for

copper-aluminum splices. Follow these instructions very carefully to make a positive

and lasting connection;

a. Strip insulation from aluminum conductor.

b. Coat the stripped end of the aluminum wire with the recommended inhibitor and

wire brush aluminum surface through inhibitor. Inhibitors: Brundy, Pentex “A”;

Alcoa, No. 2EJC; T&B KPOR Shield.

Page 17

TABLE C

COPPER WIRE SIZE – AWG (1% VOLTAGE DROP)

4

3

12

20

2

4

3

4

4

6

6

8

8

10

25

300

4

250

Supply

Wire

Length

Feet

NOTE:

1. Wire size based on 60ºC type copper conductors below 100 ampacity. 2. Wire size based on 75ºC type copper conductors for 100 ampacity and above.

200

150

100

50

6

8

10

14

15

10

30

1

1/0

1/0

2/0

2/0

3/0

3/0

3/0

4/0

4/0

2

3

2

1

1

1/0

1/0

2/0

2/0

2/0

4

3

2

2

1

1

1/0

60

1/0

2

1

3

3

4

4

65

4

4

4

3

3

50

2

4

4

6

6

55

6

6

6

40

4

8

6

45

8

35

1/0

70

3/0

2/0

1

1/0

2

2

4

3

75

4/0

3/0

3/0

2/0

2/0

1/0

1/0

2

3

80

85

Circuit Ampacity

250

250

250

250

300

300

300

300

300

350

4/0

4/0

4/0

4/0

4/0

4/0

250

250

250

250

3/0

3/0

3/0

3/0

3/0

4/0

4/0

1/0

2/0

2/0

2/0

2/0

1

1

3

90

1

1

2

2

95

2

100

1

2

105

1/0

2

110

2/0

1/0

1

115

3/0

1/0

1

120

4/0

3/0

1/0

125

250

4/0

4/0

3/0

3/0

1/0

1

130

1/0

1/0

135

1

350

300

4/0

1/0

1/0

140

350

350

300

4/0

2/0

1/0

145

c. Clean and recoat aluminum conductor with inhibitor.

. Make the splice using the above listed wire nuts or split bolt connectors.

d

e. Coat the entire connection with inhibitor and wrap with electrical insulating tape.

WARRANTY MAY NOT APPLY IF CONNECTIONS ARE NOT MADE PER INSTRUCTIONS

C. CONTROL WIRING (Class II)

1. Low voltage wiring should not be run in conduit with power wiring.

2. Control wiring is routed through the 7/8" hole adjacent to the compressor access

panel. See Figure 2. Use a minimum #18 AWG thermostat wire. For wire lengths

exceeding 50', use #16 AWG thermostat wire. The low voltage wires are connected

to the unit pigtails which are supplied with the unit below the unit control box.

3. It is necessary that only heat pump thermostats be used.

4. Figure 18 shows representative low voltage connection diagrams. Read your thermostat installation instructions for any special requirements for your specific thermostat.

NOTE — Units installed in Canada require that an outdoor thermostat (30,000 min.

cycles of endurance) be installed and be wired with C.E.C. Class I wiring.

350

350

300

4/0

2/0

1/0

150

350

350

300

4/0

2/0

2/0

155

D. INTERNAL WIRING

1. A diagram of the internal wiring of this unit is located on the inside of the compressor access panel. If any of the original wire as supplied with the appliance must be

replaced, the wire gauge and insulation must be the same as original wiring.

IMPORTANT: Some single phase units are equipped with a single pole contactor.

Caution must be exercised when servicing as only one leg of the power supply is broken with the contactor. Some models are equipped with electrically commutated blower motors which are constantly energized unless the main unit disconnect is in the off

position.

E. GROUNDING

WARNING

!

THE UNIT MUST BE PERMANENTLY GROUNDED. A GROUNDING LUG IS PROVIDED IN THE ELECTRIC HEAT ACCESS AREA FOR A GROUND WIRE. FAILURE

TO GROUND THIS UNIT CAN RESULT IN FIRE OR ELECTRICAL SHOCK CAUSING PROPERTY DAMAGE, SEVERE PERSONAL INJURY OR DEATH.

F. THERMOSTAT

The thermostat should be mounted on an inside wall about five feet above the floor in

a location where it will not be affected by unconditioned air, sun, or drafts from open

doors or other sources. READ installation instructions in heat pump thermostat package CAREFULLY because each has some different wiring requirements.

XIII. INDOOR AIR FLOW DATA

Direct-drive blower models are shipped factory wired for the proper speed at a typical

external static. Belt-drive blower models have motor sheaves set for proper CFM at a

typical external static.

17

Page 18

XIV. CRANKCASE HEAT (OPTIONAL)

rankcase heat is not required on scroll type compressors, but may be necessary for

C

difficult starting situations.

XV. PRE-START CHECK

1. Is unit properly located and slightly slanted toward indoor condensate drain?

2. Is ductwork insulated, weatherproofed, with proper spacing to combustible materils?

a

3. Is air free to travel to and from outdoor coil? (See Figure 9.)

4. Is the wiring correct, tight, and according to unit wiring diagram?

5. Is unit grounded?

6. Are field supplied air filters in place and clean?

7. Do the outdoor fan and indoor blower turn freely without rubbing, and are they tight

on the motor shafts?

8. Is unit elevated to allow for outdoor coil condensate drainage during heating opera-

tion and defrost?

XVI. STARTUP

1. Turn thermostat to “OFF,” turn “on” power supply at disconnect switch.

2. Turn temperature setting as high as it will go.

3. Turn fan switch to “ON.”

4. Indoor blower should run. Be sure it is running in the right direction.

5. Turn fan switch to “AUTO.” Turn system switch to “COOL” and turn temperature set-

ting below room temperature. Unit should run in cooling mode.

6. Is outdoor fan operating correctly in the right direction?

7. Is compressor running correctly.

8. Turn thermostat system switch to “HEAT.” Unit should stop. Wait 5 minutes, then

raise temperature setting to above room temperature. Unit should run in heating

mode and after about 30 to 50 seconds auxiliary heaters, if installed, should come

on.

9. Check the refrigerant charge using the instructions located on compressor access

panel cover. Replace service port caps. Service port cores are for system access

only and will leak if not tightly capped.

10. Turn thermostat system switch to proper mode “HEAT” or “COOL” and set thermostat to proper temperature setting. Record the following after the unit has run some

time.

A. Operating Mode _______________________________

B. Discharge Pressure (High) ___________________PSIG

C. Vapor Pressure at Compressor (Low) __________PSIG

D. Vapor Line Temperature at Compressor __________°F.

E. Indoor Dry Bulb______________________________°F.

F. Indoor Wet Bulb _____________________________°F.

G. Outdoor Dry Bulb ____________________________°F.

H. Outdoor Wet Bulb____________________________°F.

I. Voltage at Contactor ________________________Volts

J. Current at Contactor _______________________Amps

K. Model Number_________________________________

L. Serial Number _________________________________

M.Location______________________________________

N. Owner _______________________________________

O. Date_________________________________________

11. Adjust discharge air grilles and balance system.

12. Check ducts for condensation and air leaks.

13. Check unit for tubing and sheet metal rattles.

14. Instruct the owner on operation and maintenance.

15. Leave “INSTALLATION” and ”USE AND CARE“ instructions with owner

18

XVII. OPERATION

Most single phase units are operated PSC (no start relay or start capacitor). It is important that such systems be off for a minimum of 5 minutes before restarting to allow

equalization of pressures. The thermostat should not be moved to cycle unit without

waiting five minutes. To do so may cause the compressor to stop on an automatic open

overload device or blow a fuse. Poor electrical service can cause nuisance tripping in

overloads or blow fuses.

Page 19

IMPORTANT: The compressor has an internal overload protector. Under some condi-

ions, it can take up to 2 hours for this overload to reset. Make sure overload has had

t

time to reset before condemning the compressor.

Some units are equipped with a time delay control (TDC1). The control allows the blower

to operate for up to 90 seconds after the thermostat is satisfied.

XVIII. AUXILIARY HEAT

The amount of auxiliary heat required depends on the heat loss of the structure to be

heated and the capacity of the heat pump. It is good practice to install strip heat to maintain at least 60ºF indoor temperatures in case of compressor failure. The auxiliary heat

s energized by the second stage of the thermostat. The amount of electric heat that is

i

allowed to come on, as determined by the output of the heat pump, may be controlled by

an outdoor thermostat.

WARNING

!

ONLY ELECTRIC HEATER KITS SUPPLIED BY THIS MANUFACTURER AS

DESCRIBED IN THIS PUBLICATION HAVE BEEN DESIGNED, TESTED, AND

EVALUATED BY A NATIONALLY RECOGNIZED SAFETY TESTING AGENCY

FOR USE WITH THIS UNIT. USE OF ANY OTHER MANUFACTURED ELECTRIC

HEATERS INSTALLED WITHIN THIS UNIT MAY CAUSE HAZARDOUS CONDITIONS RESULTING IN PROPERTY DAMAGE, FIRE , BODILY INJU RY OR

DEATH.

A. CONTROL SYSTEM OPERATION

1. In the cooling mode, the thermostat will, on a call for cooling, energize the compressor contactor and the indoor blower relay. The indoor blower can be operated

continuously by setting the thermostat fan switch at the “ON” position. The reversing valve coil is de-energized.

2. In the heating mode, the first heat stage of the thermostat will energize the compressor contactor and the indoor blower relay. The second heat stage will turn on

one or more supplementary resistance heaters. The reversing valve is energized

except in defrost. If required or considered desirable, the resistance heat may

also be controlled by outdoor thermostats.

XIX. DEMAND DEFROST CONTROL AND

HIGH/LOW PRESSURE CONTROLS

The demand defrost control is a printed circuit board assembly consisting of solid

state control devices with electro-mechanical outputs. The demand defrost control

monitors the outdoor ambient temperature, outdoor coil temperature, and the compressor run-time to determine when a defrost cycle is required.

Enhanced Feature Demand Defrost Control: Has high and low pressure control

inputs with unique pressure switch logic built into the microprocessor to provide

compressor and system protection without nuisance lock-outs. Cycles the compressor off for 30 seconds at the beginning and end of the defrost cycle to eliminate the

increased compressor noise caused by rapidly changing system pressures when

the reversing valve switches. See the end of this section for diagnostic flash codes

for the two diagnostic LED’s provided on the control.

DEFROST INITIATION

A defrost will be initiated when the three conditions below are satisfied:

1) The outdoor coil temperature is below 35°F.

2) The compressor has operated for at least 34 minutes with the outdoor coil temperature below 35°F.

3) The measured difference between the ambient temperature and the outdoor

coil temperature is greater than the calculated delta T.

Additionally, a defrost will be initiated if six hours of accumulated compressor runtime has elapsed without a defrost with the outdoor coil temperature below 35°F.

19

Page 20

DEFROST TERMINATION

Once a defrost is initiated, the defrost will continue until fourteen minutes has

elapsed or the coil temperature has reached the terminate temperature. The terminate temperature is factory set at 70°F, although the temperature can be changed

to 50°F, 60°F, 70°F or 80°F by relocating a jumper on the board.

TEMPERATURE SENSORS

The coil sensor is clipped to the outdoor coil. The air sensor is located in the outdoor coil compartment.

If the ambient sensor fails the defrost control will initiate a defrost every 34 minutes

with the coil temperature below 35°F.

If the coil sensor fails the defrost control will not initiate a defrost.

TEST MODE

The test mode is initiated by shorting the TEST pins. In this mode of operation, the

enable temperature is ignored and all timers are sped up by a factor of 240. To initiate a manual defrost, short the TEST pins. Remove the short when the system

switches to defrost mode. The defrost will terminate on time (14 minutes) or when

the termination temperature has been achieved. Short TEST pins again to terminate

the defrost immediately.

TROUBLE SHOOTING DEMAND DEFROST

Set the indoor thermostat select switch to heat and initiate a call for heat.

Jumper the “test pins” to put the unit into defrost. If the unit goes into defrost and

comes back out of defrost, the indication is that the control is working properly.

If the unit did not go into defrost using the test pins, check to ensure that 24V is

being supplied to the control board. If 24V is present then replace the control.

HIGH/LOW PRESSURE CONTROL MONITORING - ENHANCED

DEFROST CONTROL

Status of high and low pressure controls is monitored by the enhanced feature

demand defrost control and the following actions are taken.

High Pressure Control – Provides active protection in both cooling and heating

modes at all outdoor ambient temperatures. The high pressure control is an automatic reset type and opens at approximately 610 psig and closes at approximately

420 psig. The compressor and fan motor will stop when the high pressure control

opens and will start again if the high side pressure drops to approximately 420 psig

when the automatic reset high pressure control resets. If the high pressure control

opens 3 times within a particular call for heating or cooling operation, the defrost

control will lock out compressor and outdoor fan operation.

Low Pressure Control – Provides active protection in both heating and cooling

modes at all outdoor ambient temperatures. The low pressure control is an automatic reset type and opens at approximately 15 psig and closes at approximately

40 psig. Operation is slightly different between cooling and heating modes.

Cooling Mode: The compressor and fan motor will stop when the low pressure

control opens and will start again when the low side pressure rises to approximately 40 psig when the low pressure control automatically resets. If the low

pressure switch opens 3 times within a particular call for cooling operation, the

defrost control will lock out compressor and outdoor fan operation.

Heating Mode: The compressor and fan motor will stop when the low pressure

control opens and will start again when the low side pressure rises to approximately 40 psig when the low pressure control automatically resets. If the low

pressure switch trips 3 times within 120 minutes of operation during a particular

call for heating operation, the defrost control will lock out compressor and outdoor fan operation. If the lock-out due to low pressure occurs at an outdoor

ambient temperature below 5°F, the defrost control will automatically exit the

lock-out mode when the outdoor ambient temperature rises to 5°F. This feature

is necessary since the low pressure control could possibly have opened due to

the outdoor ambient being very low rather than an actual system fault.

20

Page 21

Exiting Lock-Out Mode:

control by removing power to indoor air-handler/furnace or by shorting the two

defrost control test pins together.

To exit the lock-out mode, remove 24 volts to the defrost

ENHANCED FEATURE DEFROST CONTROL DIAGNOSTIC CODES

LED 1 LED 2 Control Board Status

OFF OFF No Power

ON ON Coil Sensor Failure

OFF ON Ambient Sensor Failure

FLASH FLASH Normal

OFF FLASH Low Pressure Lockout (short test pins to reset)

FLASH OFF High Pressure Lockout (short test pins to reset)

ON FLASH Low Pressure Control Open

FLASH ON High Pressure Control Open

Alternate Flashing 5 Minute Time Delay

REPLACEMENT PARTS

Contact your local distributor for a complete parts list.

CHARGE INFORMATION

Refer to the appropriate charge chart included in this manual.

TROUBLESHOOTING

Refer to the troubleshooting chart included in this manual.

WIRING DIAGRAMS

Refer to the appropriate wiring diagram included in this manual.

21

Page 22

XX. GENERAL DATA - RJNL MODELS

Model RJNL- Series A036CK A036CL A036CM A036DK

Cooling Performance

1

Continued ->

Gross Cooling Capacity Btu [kW] 37,800 [11.08] 37,800 [11.08] 37,800 [11.08] 37,800 [11.08]

EER/SEER

2

11.5/13 11.5/13 11.5/13 11.5/13

Nominal CFM/ARI Rated CFM [L/s] 1200/1200 [566/566] 1200/1200 [566/566] 1200/1200 [566/566] 1200/1200 [566/566]

ARI Net Cooling Capacity Btu [kW] 36,200 [10.61] 36,200 [10.61] 36,200 [10.61] 36,200 [10.61]

Net Sensible Capacity Btu [kW] 27,000 [7.91] 27,000 [7.91] 27,000 [7.91] 27,000 [7.91]

Net Latent Capacity Btu [kW] 9,200 [2.7] 9,200 [2.7] 9,200 [2.7] 9,200 [2.7]

Net System Power kW 3.1 3.1 3.1 3.1

Heating Performance (Heat Pumps)

High Temp. Btuh [kW] Rating 34,400 [10.08] 34,400 [10.08] 34,400 [10.08] 34,400 [10.08]

System Power KW / COP 2.94/3.4 2.94/3.4 2.94/3.4 2.94/3.4

Low Temp. Btuh [kW] Rating 19,600 [5.74] 19,600 [5.74] 19,600 [5.74] 19,600 [5.74]

System Power KW / COP 2.72/2.1 2.72/2.1 2.72/2.1 2.72/2.1

HSPF (Btu/Watts-hr) 7.7 7.7 7.7 7.7

Compressor

No./Type 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll

Outdoor Sound Rating (dB)

83 83 83 83

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 16.89 [1.57] 16.89 [1.57] 16.89 [1.57] 16.89 [1.57]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 5.16 [0.48] 5.16 [0.48] 5.16 [0.48] 5.16 [0.48]

Rows / FPI [FPcm] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/0.75 [19.5] 1/0.75 [19.5] 1/0.75 [19.5] 1/0.75 [19.5]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 4000 [1888] 4000 [1888] 4000 [1888] 4000 [1888]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/10x10 [254x254] 1/10x10 [254x254] 1/10x10 [254x254] 1/10x10 [254x254]

Drive Type/No. Speeds Direct/3 Belt/Variable Belt/Variable Direct/3

No. Motors 1 1 1 1

Motor HP 1/2 1/2 3/4 1/2

Motor RPM 1075 1725 1725 1075

Motor Frame Size 48 56 56 48

Filter - Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(NO.) Size Recommended in. [mm x mm x mm] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406]

Refrigerant Charge Oz. [g] 116 [3289] 116 [3289] 116 [3289] 116 [3289]

Weights

Net Weight lbs. [kg] 517 [235] 517 [235] 517 [235] 517 [235]

Ship Weight lbs. [kg] 532 [241] 532 [241] 532 [241] 532 [241]

3

NOMINAL SIZES 3-5 TONS [10.6-17.6 kW]

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. ARI capacity

is net and includes the effect of fan motor heat. Units are suitable for operation to ±20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner

Equipment certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.utdoor Sound Rating shown is tested in accordance with ARI Standard 270.

22

Page 23

GENERAL DATA - RJNL MODELS

Model RJNL- Series A036DL A036DM A036JK A042CK

Cooling Performance

1

Continued ->

Gross Cooling Capacity Btu [kW] 37,800 [11.08] 37,800 [11.08] 37,800 [11.08] 44,000 [12.89]

EER/SEER

2

11.5/13 11.5/13 11.5/13 11.2/13

Nominal CFM/ARI Rated CFM [L/s] 1200/1200 [566/566] 1200/1200 [566/566] 1200/1200 [566/566] 1400/1400 [661/661]

ARI Net Cooling Capacity Btu [kW] 36,200 [10.61] 36,200 [10.61] 36,200 [10.61] 42,000 [12.31]

Net Sensible Capacity Btu [kW] 27,000 [7.91] 27,000 [7.91] 27,000 [7.91] 31,200 [9.14]

Net Latent Capacity Btu [kW] 9,200 [2.7] 9,200 [2.7] 9,200 [2.7] 10,800 [3.16]

Net System Power kW 3.1 3.1 3.1 3.74

Heating Performance (Heat Pumps)

High Temp. Btuh [kW] Rating 34,400 [10.08] 34,400 [10.08] 34,400 [10.08] 41,000 [12.01]

System Power KW / COP 2.94/3.4 2.94/3.4 2.94/3.4 3.38/3.5

Low Temp. Btuh [kW] Rating 19,600 [5.74] 19,600 [5.74] 19,600 [5.74] 24,400 [7.15]

System Power KW / COP 2.72/2.1 2.72/2.1 2.72/2.1 3.12/2.3

HSPF (Btu/Watts-hr) 7.7 7.7 7.7 7.7

Compressor

No./Type 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll

Outdoor Sound Rating (dB)

83 83 83 83

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 16.89 [1.57] 16.89 [1.57] 16.89 [1.57] 16.89 [1.57]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 5.16 [0.48] 5.16 [0.48] 5.16 [0.48] 5.16 [0.48]

Rows / FPI [FPcm] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/0.75 [19.5] 1/0.75 [19.5] 1/0.75 [19.5] 1/0.75 [19.5]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 4000 [1888] 4000 [1888] 4000 [1888] 4000 [1888]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/10x10 [254x254] 1/10x10 [254x254] 1/10x10 [254x254] 1/10x10 [254x254]

Drive Type/No. Speeds Belt/Variable Belt/Variable Direct/3 Direct/3

No. Motors 1 1 1 1

Motor HP 1/2 3/4 1/2 1/2

Motor RPM 1725 1725 1075 1075

Motor Frame Size 56 56 48 48

Filter - Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(NO.) Size Recommended in. [mm x mm x mm] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406]

Refrigerant Charge Oz. [g] 116 [3289] 116 [3289] 116 [3289] 120 [3402]

Weights

Net Weight lbs. [kg] 517 [235] 517 [235] 517 [235] 521 [236]

Ship Weight lbs. [kg] 532 [241] 532 [241] 532 [241] 536 [243]

3

NOMINAL SIZES 3-5 TONS [10.6-17.6 kW]

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. ARI capacity

is net and includes the effect of fan motor heat. Units are suitable for operation to ±20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner

Equipment certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.utdoor Sound Rating shown is tested in accordance with ARI Standard 270.

23

Page 24

GENERAL DATA - RJNL MODELS

Model RJNL- Series A042CL A042CM A042DK A042DL

Cooling Performance

1

Continued ->

Gross Cooling Capacity Btu [kW] 44,000 [12.89] 44,000 [12.89] 44,000 [12.89] 44,000 [12.89]

EER/SEER

2

11.2/13 11.2/13 11.2/13 11.2/13

Nominal CFM/ARI Rated CFM [L/s] 1400/1400 [661/661] 1400/1400 [661/661] 1400/1400 [661/661] 1400/1400 [661/661]

ARI Net Cooling Capacity Btu [kW] 42,000 [12.31] 42,000 [12.31] 42,000 [12.31] 42,000 [12.31]

Net Sensible Capacity Btu [kW] 31,200 [9.14] 31,200 [9.14] 31,200 [9.14] 31,200 [9.14]

Net Latent Capacity Btu [kW] 10,800 [3.16] 10,800 [3.16] 10,800 [3.16] 10,800 [3.16]

Net System Power kW 3.74 3.74 3.74 3.74

Heating Performance (Heat Pumps)

High Temp. Btuh [kW] Rating 41,000 [12.01] 41,000 [12.01] 41,000 [12.01] 41,000 [12.01]

System Power KW / COP 3.38/3.5 3.38/3.5 3.38/3.5 3.38/3.5

Low Temp. Btuh [kW] Rating 24,400 [7.15] 24,400 [7.15] 24,400 [7.15] 24,000 [7.03]

System Power KW / COP 3.12/2.3 3.12/2.3 3.12/2.3 3.12/2.3

HSPF (Btu/Watts-hr) 7.7 7.7 7.7 7.7

Compressor

No./Type 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll

Outdoor Sound Rating (dB)

83 83 83 83

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 16.89 [1.57] 16.89 [1.57] 16.89 [1.57] 16.89 [1.57]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 5.16 [0.48] 5.16 [0.48] 5.16 [0.48] 5.16 [0.48]

Rows / FPI [FPcm] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5] 3 / 13 [5]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/0.75 [19.5] 1/0.75 [19.5] 1/0.75 [19.5] 1/0.75 [19.5]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 4000 [1888] 4000 [1888] 4000 [1888] 4000 [1888]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/10x10 [254x254] 1/10x10 [254x254] 1/10x10 [254x254] 1/10x10 [254x254]

Drive Type/No. Speeds Belt/Variable Belt/Variable Direct/3 Belt/Variable

No. Motors 1 1 1 1

Motor HP 1/2 3/4 1/2 1/2

Motor RPM 1725 1725 1075 1725

Motor Frame Size 56 56 48 56

Filter - Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(NO.) Size Recommended in. [mm x mm x mm] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406]

Refrigerant Charge Oz. [g] 120 [3402] 120 [3402] 120 [3402] 120 [3402]

Weights

Net Weight lbs. [kg] 521 [236] 521 [236] 521 [236] 521 [236]

Ship Weight lbs. [kg] 536 [243] 536 [243] 536 [243] 536 [243]

3

NOMINAL SIZES 3-5 TONS [10.6-17.6 kW]

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. ARI capacity

is net and includes the effect of fan motor heat. Units are suitable for operation to ±20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner

Equipment certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.utdoor Sound Rating shown is tested in accordance with ARI Standard 270.

24

Page 25

GENERAL DATA - RJNL MODELS

Model RJNL- Series A042DM A042JK A048CK A048CL

Cooling Performance

1

Continued ->

Gross Cooling Capacity Btu [kW] 44,000 [12.89] 44,000 [12.89] 50,000 [14.65] 50,000 [14.65]

EER/SEER

2

11.2/13 11.2/13 11.2/13 11.2/13

Nominal CFM/ARI Rated CFM [L/s] 1400/1400 [661/661] 1400/1400 [661/661] 1600/1600 [755/755] 1600/1600 [755/755]

ARI Net Cooling Capacity Btu [kW] 42,000 [12.31] 42,000 [12.31] 47,500 [13.92] 47,500 [13.92]

Net Sensible Capacity Btu [kW] 31,200 [9.14] 31,200 [9.14] 35,700 [10.46] 35,700 [10.46]

Net Latent Capacity Btu [kW] 10,800 [3.16] 10,800 [3.16] 11,800 [3.46] 11,800 [3.46]

Net System Power kW 3.74 3.74 4.22 4.22

Heating Performance (Heat Pumps)

High Temp. Btuh [kW] Rating 41,000 [12.01] 41,000 [12.01] 49,000 [14.36] 49,000 [14.36]

System Power KW / COP 3.38/3.5 3.38/3.5 3.93/3.6 3.93/3.6

Low Temp. Btuh [kW] Rating 24,400 [7.15] 24,400 [7.15] 29,000 [8.5] 29,000 [8.5]

System Power KW / COP 3.12/2.3 3.12/2.3 3.63/2.3 3.63/2.3

HSPF (Btu/Watts-hr) 7.7 7.7 7.7 7.7

Compressor

No./Type 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll

Outdoor Sound Rating (dB)

83 83 83 83

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 16.89 [1.57] 16.89 [1.57] 16.56 [1.54] 16.56 [1.54]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 2 / 22 [9] 2 / 22 [9]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 5.16 [0.48] 5.16 [0.48] 5.16 [0.48] 5.16 [0.48]

Rows / FPI [FPcm] 3 / 13 [5] 3 / 13 [5] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/0.75 [19.5] 1/0.75 [19.5] 1/0.75 [19.5] 1/0.75 [19.5]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 4000 [1888] 4000 [1888] 4000 [1888] 4000 [1888]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/10x10 [254x254] 1/10x10 [254x254] 1/10x10 [254x254] 1/10x10 [254x254]

Drive Type/No. Speeds Belt/Variable Direct/3 Direct/3 Belt/Variable

No. Motors 1 1 1 1

Motor HP 3/4 1/2 1/2 1/2

Motor RPM 1725 1075 1075 1725

Motor Frame Size 56 48 48 56

Filter - Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(NO.) Size Recommended in. [mm x mm x mm] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406]

Refrigerant Charge Oz. [g] 120 [3402] 120 [3402] 187 [5301] 187 [5301]

Weights

Net Weight lbs. [kg] 521 [236] 521 [236] 535 [243] 535 [243]

Ship Weight lbs. [kg] 536 [243] 536 [243] 550 [249] 550 [249]

3

NOMINAL SIZES 3-5 TONS [10.6-17.6 kW]

NOTES:

1. Cooling Performance is rated at 95°F ambient, 80°F entering dry bulb, 67°F entering wet bulb. Gross capacity does not include the effect of fan motor

heat. ARI capacity is net and includes the effect of fan motor heat. Units are suitable for operation to ±20% of nominal cfm. Units are certified in

accordance with the Unitary Air Conditioner Equipment certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Standard 3/4" P-Trap provided.

25

Page 26

GENERAL DATA - RJNL MODELS

Model RJNL- Series A048CM A048DK A048DL A048DM

Cooling Performance

1

Continued ->

Gross Cooling Capacity Btu [kW] 50,000 [14.65] 50,000 [14.65] 50,000 [14.65] 50,000 [14.65]

EER/SEER

2

11.2/13 11.2/13 11.2/13 11.2/13

Nominal CFM/ARI Rated CFM [L/s] 1600/1600 [755/755] 1600/1600 [755/755] 1600/1600 [755/755] 1600/1600 [755/755]

ARI Net Cooling Capacity Btu [kW] 47,500 [13.92] 47,500 [13.92] 47,500 [13.92] 47,500 [13.92]

Net Sensible Capacity Btu [kW] 35,700 [10.46] 35,700 [10.46] 35,700 [10.46] 35,700 [10.46]

Net Latent Capacity Btu [kW] 11,800 [3.46] 11,800 [3.46] 11,800 [3.46] 11,800 [3.46]

Net System Power kW 4.22 4.22 4.22 4.22

H

eating Performance (Heat Pumps)

High Temp. Btuh [kW] Rating 49,000 [14.36] 49,000 [14.36] 49,000 [14.36] 49,000 [14.36]

System Power KW / COP 3.93/3.6 3.93/3.6 3.93/3.6 3.93/3.6

Low Temp. Btuh [kW] Rating 29,000 [8.5] 29,000 [8.5] 29,000 [8.5] 29,000 [8.5]

System Power KW / COP 3.63/2.3 3.63/2.3 3.63/2.3 3.63/2.3

HSPF (Btu/Watts-hr) 7.7 7.7 7.7 7.7

Compressor

No./Type 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll

Outdoor Sound Rating (dB)

83 83 83 83

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 16.56 [1.54] 16.56 [1.54] 16.56 [1.54] 16.56 [1.54]

Rows / FPI [FPcm] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 5.16 [0.48] 5.16 [0.48] 5.16 [0.48] 5.16 [0.48]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/0.75 [19.5] 1/0.75 [19.5] 1/0.75 [19.5] 1/0.75 [19.5]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 4000 [1888] 4000 [1888] 4000 [1888] 4000 [1888]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/10x10 [254x254] 1/10x10 [254x254] 1/10x10 [254x254] 1/10x10 [254x254]

Drive Type/No. Speeds Belt/Variable Direct/3 Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 3/4 1/2 1/2 3/4

Motor RPM 1725 1075 1725 1725

Motor Frame Size 56 48 56 56

Filter - Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(NO.) Size Recommended in. [mm x mm x mm] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406]

Refrigerant Charge Oz. [g] 187 [5301] 187 [5301] 187 [5301] 187 [5301]

Weights

Net Weight lbs. [kg] 535 [243] 535 [243] 535 [243] 535 [243]

Ship Weight lbs. [kg] 550 [249] 550 [249] 550 [249] 550 [249]

3

NOMINAL SIZES 3-5 TONS [10.6-17.6 kW]

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. ARI capacity

is net and includes the effect of fan motor heat. Units are suitable for operation to ±20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner

Equipment certification program, which is based on ARI Standard 210/240 or 360.

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.utdoor Sound Rating shown is tested in accordance with ARI Standard 270.

26

Page 27

GENERAL DATA - RJNL MODELS

Model RJNL- Series A048JK A060CK A060CL A060CM

Cooling Performance

1

Continued ->

Gross Cooling Capacity Btu [kW] 50,000 [14.65] 61,000 [17.87] 61,500 [18.02] 61,500 [18.02]

EER/SEER

2

11.2/13 11.5/13 11.5/13 11.5/13

Nominal CFM/ARI Rated CFM [L/s] 1600/1600 [755/755] 2000/2000 [944/944] 2000/2000 [944/944] 2000/2000 [944/944]

ARI Net Cooling Capacity Btu [kW] 47,500 [13.92] 59,000 [17.29] 59,000 [17.29] 59,000 [17.29]

Net Sensible Capacity Btu [kW] 35,700 [10.46] 44,050 [12.91] 44,050 [12.91] 44,050 [12.91]

Net Latent Capacity Btu [kW] 11,800 [3.46] 14,950 [4.38] 14,950 [4.38] 14,950 [4.38]

Net System Power kW 4.22 5.04 5.04 5.04

Heating Performance (Heat Pumps)

High Temp. Btuh [kW] Rating 49,000 [14.36] 60,000 [17.58] 60,000 [17.58] 60,000 [17.58]

System Power KW / COP 3.93/3.6 4.78/3.6 4.78/3.6 4.78/3.6

Low Temp. Btuh [kW] Rating 29,000 [8.5] 35,800 [10.49] 35,800 [10.49] 35,800 [10.49]

System Power KW / COP 3.63/2.3 4.31/2.4 4.31/2.4 4.31/2.4

HSPF (Btu/Watts-hr) 7.7 7.7 7.7 7.7

Compressor

No./Type 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll

Outdoor Sound Rating (dB)

83 83 83 83

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 16.56 [1.54] 16.56 [1.54] 16.56 [1.54] 16.56 [1.54]

Rows / FPI [FPcm] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Indoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 5.16 [0.48] 5.16 [0.48] 5.16 [0.48] 5.16 [0.48]

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/0.75 [19.5] 1/0.75 [19.5] 1/0.75 [19.5] 1/0.75 [19.5]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 4000 [1888] 4000 [1888] 4000 [1888] 4000 [1888]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/10x10 [254x254] 1/11x9 [279x229] 1/10x10 [254x254] 1/10x10 [254x254]

Drive Type/No. Speeds Direct/3 Direct/2 Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 1/2 1 3/4 1

Motor RPM 1075 1100 1725 1725

Motor Frame Size 48 48 56 56

Filter - Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(NO.) Size Recommended in. [mm x mm x mm] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406] (2)1x25x16 [25x635x406]

Refrigerant Charge Oz. [g] 187 [5301] 195 [5528] 195 [5528] 195 [5528]

Weights

Net Weight lbs. [kg] 535 [243] 565 [256] 565 [256] 565 [256]

Ship Weight lbs. [kg] 550 [249] 580 [263] 580 [263] 580 [263]

0.375 [9.5]

3

NOMINAL SIZES 3-5 TONS [10.6-17.6 kW]

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does not include the effect of fan motor heat. ARI capacity

2. EER and/or SEER are rated at ARI conditions and in accordance with DOE test procedures.

3. Outdoor Sound Rating shown is tested in accordance with ARI Standard 270.utdoor Sound Rating shown is tested in accordance with ARI Standard 270.

is net and includes the effect of fan motor heat. Units are suitable for operation to ±20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner

Equipment certification program, which is based on ARI Standard 210/240 or 360.

27

Page 28

GENERAL DATA - RJNL MODELS

NOMINAL SIZES 3-5 TONS [10.6-17.6 kW]

odel RJNL - Series A060DK A060DL A060DM A060JK

M

ooling performance

C

ross Cooling Capacity Btu [kW] 61,000 [17.87] 61,500 [18.02] 61,500 [18.02] 61,000 [17.87]

G

EER, SEER

Nominal CFM/AHRI Rated CFM [L/s] 2000/2000 [944/944] 2000/2000 [944/944] 2000/2000 [944/944] 2000/2000 [944/944]

AHRI Net Cooling Capacity Btu [kW] 59,000 [17.29] 59,000 [17.29] 59,000 [17.29] 59,000 [17.29]

et Sensible Capacity Btu [kW] 44,050 [12.91] 44,050 [12.91] 44,050 [12.91] 44,050 [12.91]

N

et Latent Capacity Btu [kW] 14,950 [4.38] 14,950 [4.38] 14,950 [4.38] 14,950 [4.38]

N

et System Power kW 5.04 5.04 5.04 5.04

N

Heating Performance (Heat Pumps)

High Temp. Btuh [kW] Rating 60,000 [17.58] 60,000 [17.58] 60,000 [17.58] 60,000 [17.58]

System Power KW / COP 4.78/3.6 4.78/3.6 4.78/3.6 4.78/3.6

ow Temp. Btuh [kW] Rating 35,800 [10.49] 35,800 [10.49] 35,800 [10.49] 35,800 [10.49]

L

ystem Power KW / COP 4.31/2.4 4.31/2.4 4.31/2.4 4.31/2.4

S

HSPF (Btu/Watts-hr) 7.7 7.7 7.7 7.7

Compressor

No/Type 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll 1/Copeland Scroll

utdoor Sound Rating (dB)

O

Outdoor Coil - Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

ube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

T

ace Area sq. ft. [sq. m] 16.56 [1.54] 16.56 [1.54] 16.56 [1.54] 16.56 [1.54]

F

Rows / FPI [FPcm] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

ndoor Coil - Fin Type Louvered Louvered Louvered Louvered

I

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 5.16 5.16 5.16 5.16

Rows / FPI [FPcm] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5] 4 / 13 [5]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/0.75 [19.5] 1/0.75 [19.5] 1/0.75 [19.5] 1/0.75 [19.5]

Outdoor Fan - Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6] 1/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 4000 [1888] 4000 [1888] 4000 [1888] 4000 [1888]

No. Motors/HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP 1 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan - Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/10x10 [254x254] 1/10x10 [254x254] 1/11x9 [279x229] 1/11x9 [279x229]

Drive Type/No. Speeds Belt/Variable Belt/Variable Direct/2 Direct/2

No. Motors 1111

Motor HP 3/4 111