Rheem Prestige Series 80% AFUE 2-Stage ECM Motor Submittal Sheet

PROJECT NAME ______________________________________________________________________________

LOCATION __________________________________________________________________________________

ARCHITECT__________________________________________________________________________________

ENGINEER __________________________________________________________________________________

CONTRACTOR ______________________________________________________________________________

SUBMITTED BY ______________________________ DATE ________________________________________

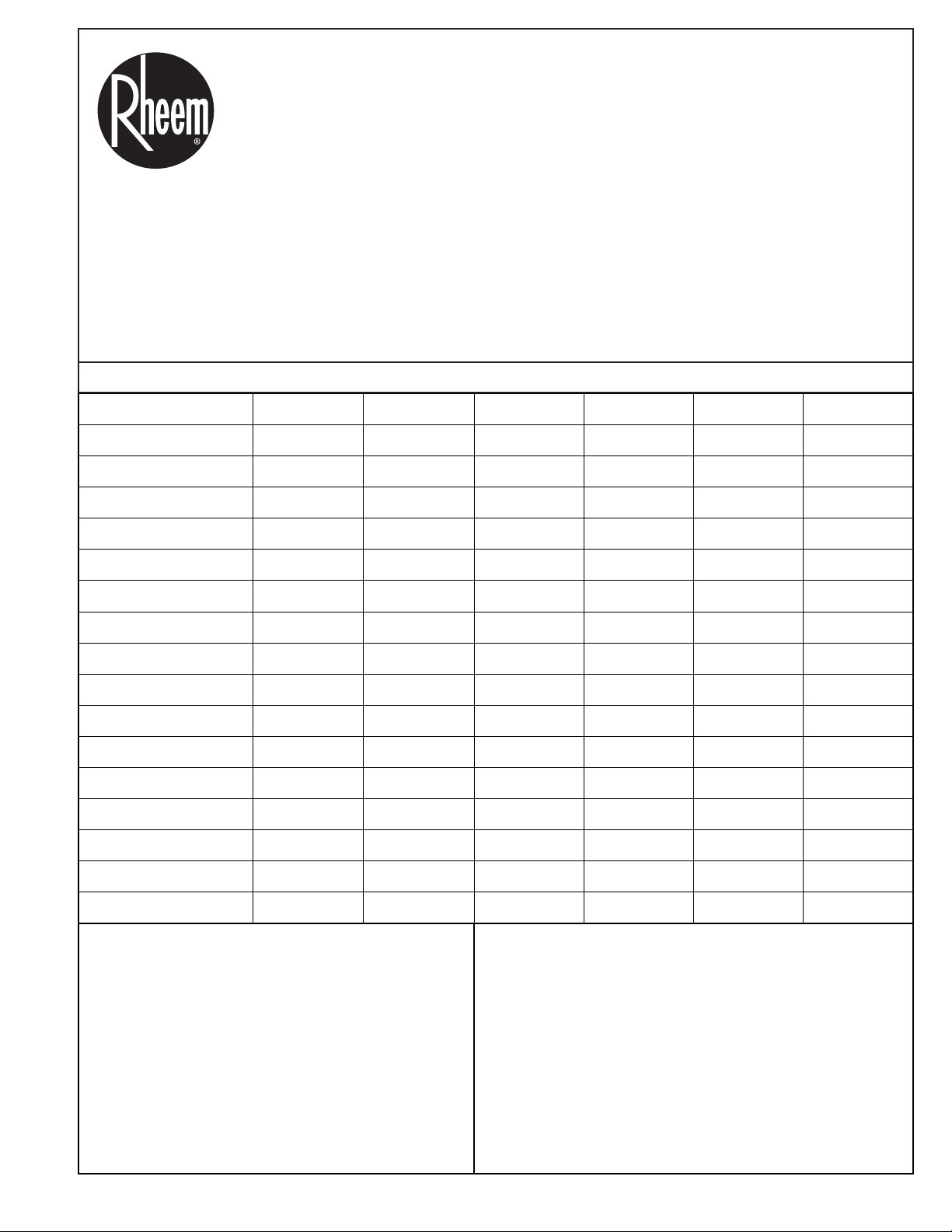

UNIT SUMMARY

SUBMITTAL COVER SHEET

Quantity

Unit Designation

Model No.

Total Cooling

Sensible Cooling

Air Ent. Evaporator

Air Lvg. Evaporator

Heating Input

Heating Output

CFM/ESP

EER/SEER

Electrical

Minimum Ampacity

Min.-Max. Breaker

Net Unit Weight

Accessory

Catalog Form Number

ACCESSORIES: NOTES:

PRINTED IN U.S.A. 10-06 DC FORM NO. X11-1123 REV. 2

Supersedes Form No. X11-1123 Rev. 1

FEATURES FOR RGLE-

■

The Comfort Control2System™ provides over 28 on-board diagnostics and

fault history codes by detecting system and electrical problems. “Call for

Service” alert notification is sent to the thermostat to alert the homeowner of

required service.

■

Serial Communication Enhanced – When installed with a Serial Communicating

Condensing Unit and user interface control ((-)HC-TST550CMMS) 500 Series

thermostat this unit offers 4 or 2 wire installation, auto-configuration, and

diagnostic messaging with full communicating capability.

■

Patented heat exchanger, constructed of both stainless and aluminized steel

for the maximum in corrosion resistance.

■

Low profile “34 inch” [864 mm] design is lighter and easier to handle, and

leaves room for optional equipment.

■

Energy efficient and quiet ECM 2+ communicating motor.

■

Improves cooling efficiency when matched with rated condensing unit and coil.

■

Constant CFM.

■

Seven segment LED for system diagnostics.

■

Diagnostic history for troubleshooting.

■

Dip switch settings for selectable cooling airflow.

■

On-demand dehumidification terminal for improved comfort in cooling mode.

■

Left or right side gas and electric inlet connections.

■

All models feature an integrated board with humidifier and electronic air cleaner

hookups.

■

Insulated blower compartment, a slow-open gas valve, specially designed draft

inducer motor and blower motor make it one of the quietest furnaces on the

market today.

■

Pre-paint galvanized steel cabinet.

■

Easy door removal and replacement.

■

Molded permanent filter.

■

Compatible with single or two-stage thermostat. (For optimal performance, twostage thermostat recommended.)

A variety of cooling coils and plenums designed to use with Super Quiet 80

™

Two

Stage Downflow gas furnaces are available as optional accessories.

✝A.F.U.E. (Annual Fuel Utilization Efficiency) calculated in accordance with Department of Energy test

procedures.

FIELD INSTALLED ACCESSORIES

Fossil Fuel Kit (RXPF-F01 and F02) ................................................................

Filter Rack (RXGF-CCM) ..................................................................................

Combustible Floor Base (RXGC-B17, 21, 24) ..................................................

Supply Air Sensor ..............................................................................................

Chimney Adapter: RXGW-B01 ..........................................................................

Thermostats ......................................................................................................

FORM NO. X33-1304

Supersedes Form No. X33-1304

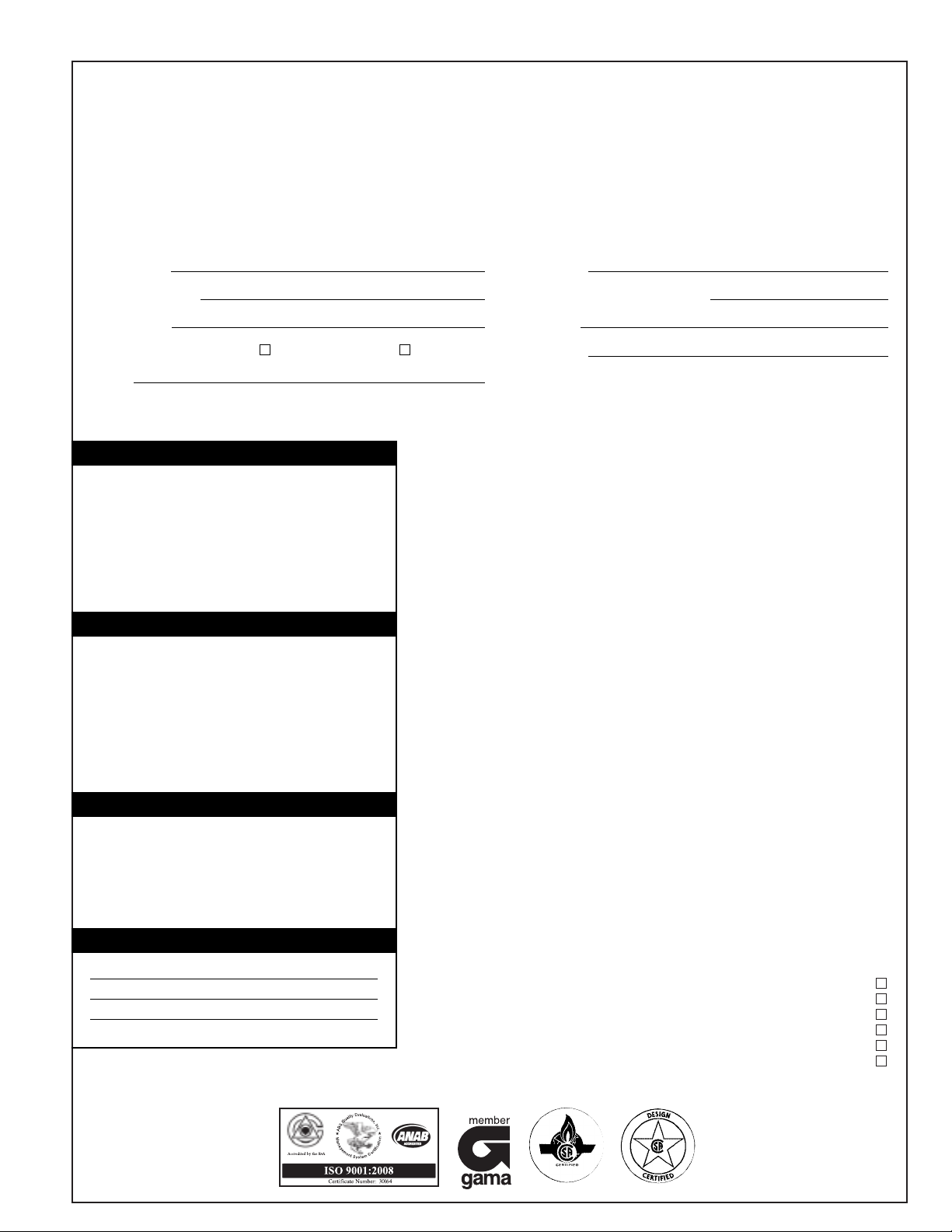

SUBMITTAL SHEET FOR SUPER QUIET 80™TWO STAGE

COMMUNICATING DOWNFLOW GAS FURNACES EQUIPPED

WITH THE COMFORT CONTROL

2

SYSTEM

ECM Equipped Models with Input Rates from 75,000 to 125,000

BTU/HR [22 to 37 kW]

UNIT DATA

HEATING PERFORMANCE

TOTAL CAPACITY INPUT* ......

_______

MBH [kW]

TOTAL CAPACITY OUTPUT* ..

_______

MBH [kW]

DESIGN TEMP. RISE ..............

_______

°F [°C] DB

AFUE ................................................

_______

%

CALIFORNIA SEASONAL

EFFICIENCY ..................................

_______

%

(*uses blower motor heat)

SUPPLY AIR BLOWER PERFORMANCE

TOTAL AIR SUPPLY ................

_______

CFM [L/s]

TOTAL RESISTANCE EXTERNAL

TO UNIT......................................

_______

IWG

BLOWER SPEED ..........................

_______

RPM

POWER OUTPUT REQUIREMENT ..

_______

BHP

MOTOR RATING ........................

_______

HP [W]

POWER INPUT REQUIREMENT ........

_______

kW

ELECTRICAL DATA

POWER SUPPLY........................

___________ Hz

TOTAL UNIT AMPACITY................

_______

AMPS

MINIMUM WIRE SIZE ....................

_______

AWG

MAXIMUM OVERCURRENT DEVICE

FUSES/HACR BREAKER ..........

_______

AMPS

CLEARANCES

FRONT SIDE 3" [76.2 mm]

RIGHT SIDE 3" [76.2 mm]

LEFT SIDE 0" [0 mm]

TOP 1" [25.4 mm]

JOB NAME MODEL NO.

CONTRACTOR OUTDOOR UNIT MODEL NO.

ENGINEER LOCATION

SUBMITTED FOR APPROVAL RECORD ORDER NO.

DATE

Loading...

Loading...